Page 1

G3300 / G3300EZ

848C3593A1 (411)

OWNER’S MANUAL

G

G

B

B

CHAINSAWS

G3300

G3300EZ

GB-1

Page 2

G3300 / G3300EZ

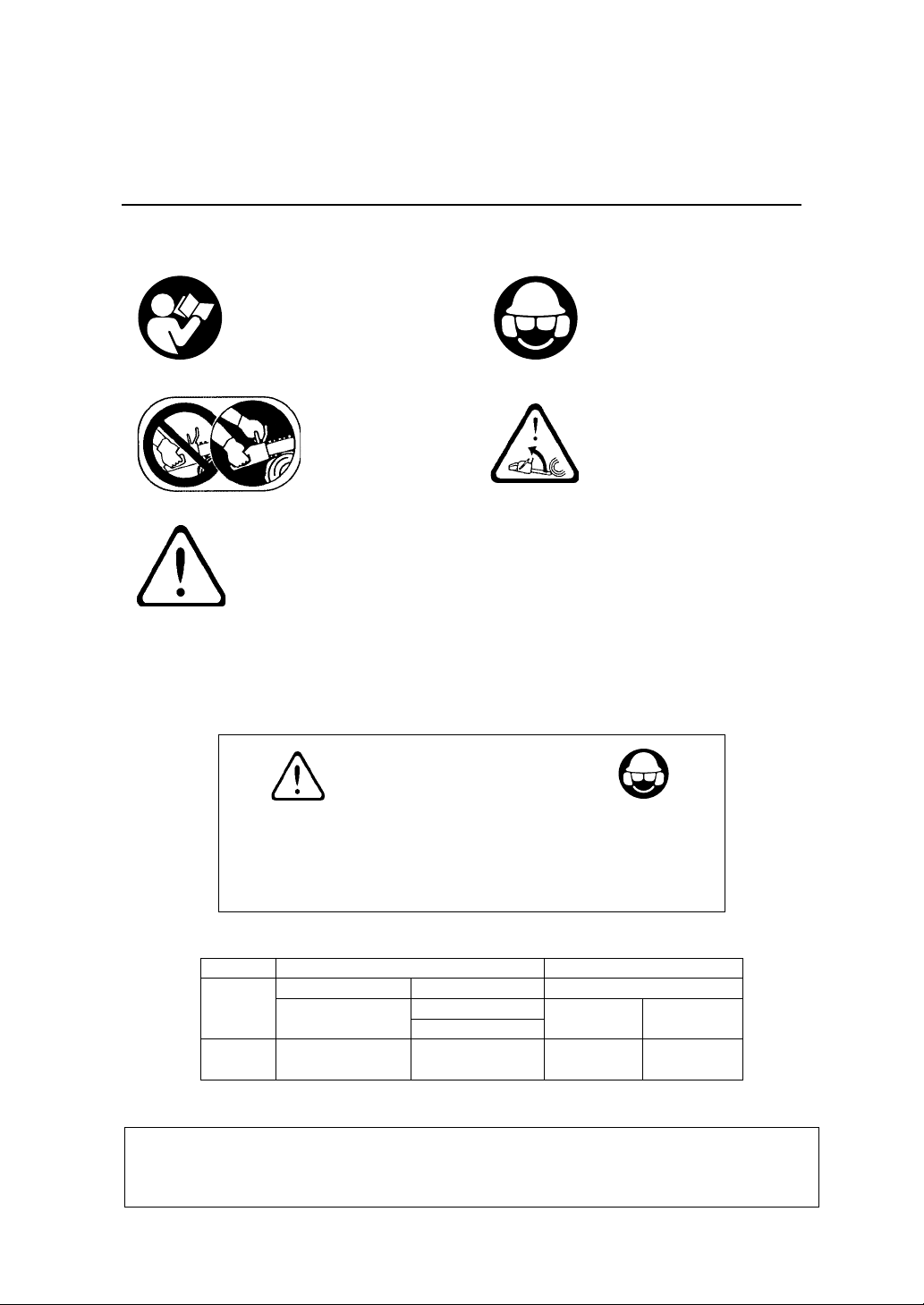

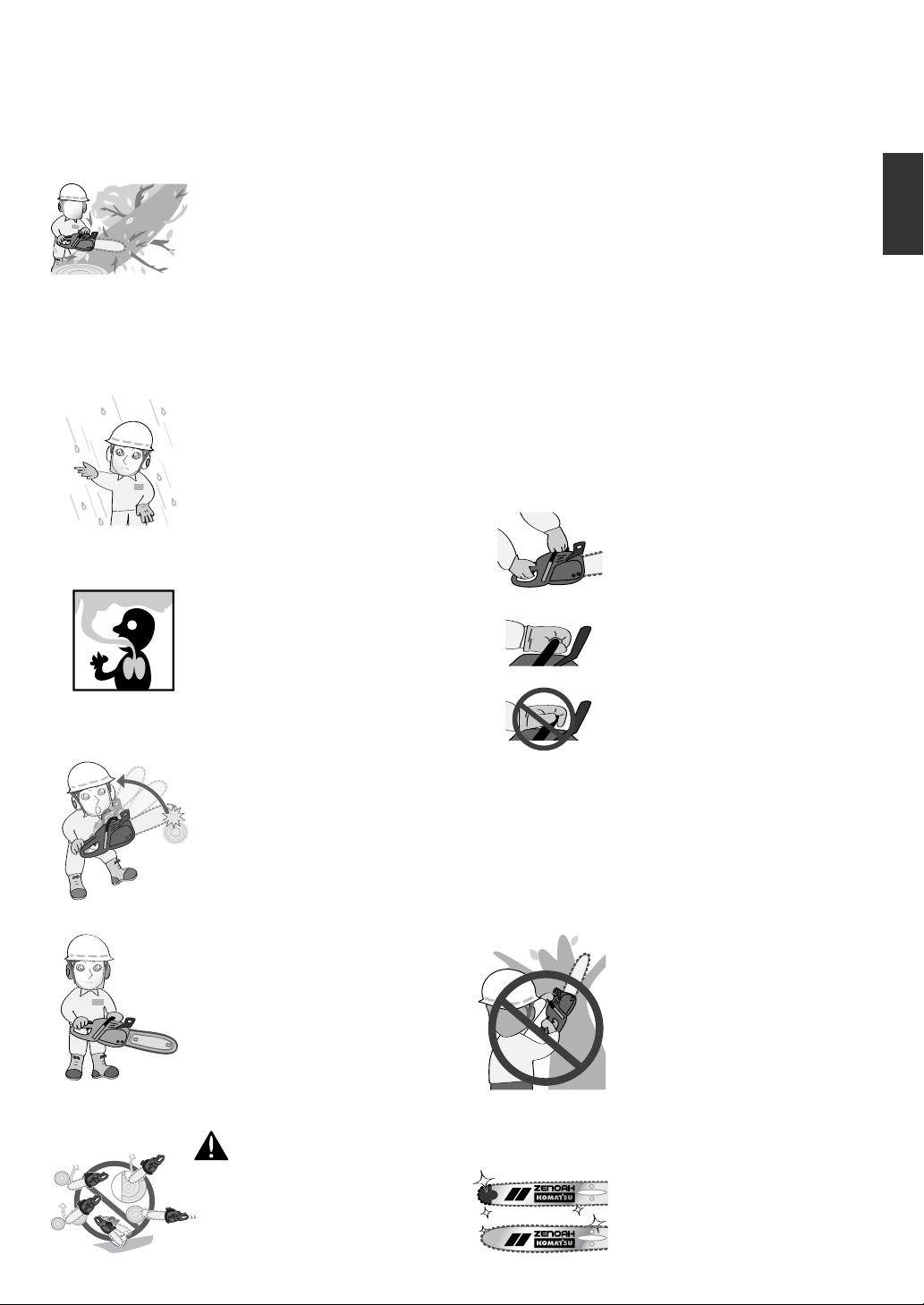

EXPLANATION OF SYMBOLS AND SAFETY WARNINGS

Read operator's instruction

book before operating this

machine.

Use the chain saw

with two hands.

Read, understand and

follow all warnings.

WARNING!!!

RISK OF DAMAGING HEARING

Wear head, eye and ear

protection.

Warning! Danger of

kickback.

GB-2

MAY INVOLVE A DAILY LEVEL OF PERSONAL EXPOSURE TO NOISE

IN NORMAL CONDITIONS OF USE, THIS MACHINE

FOR THE OPERATOR EQUAL TO OR GREATER THAN

85 dB(A)

MODEL

EN 608-ISO 7182

G3300

G3300EZ

APPROVAL NUMBER OF CE EXHAUST EMISSION REGULATION (2002/88/EC)

SOUND LEVEL VIBRATION LEVEL

2000/14/EC

LpA

98.9 dB(A) 112 dB(A)

LwA

guaranteed

EN 608-ISO 7505

Front handle Rear handle

2

4.5 m/s

e13*97/68SH2G3*2002/88*0087*00

4.9 m/s

2

Page 3

DECLARATION OF CONFORMITY TO MACHINES DIRECTIVE

(Directive 98/37/EC, 89/336/EEC)

and to the regulations governing transposition

Internal control production

MANUFACTURER :

No. 9, 1-Chome

MINAMIDAI, KAWAGOE City

SAITAMA, JAPAN

DECLARES THAT THE DESIGN OF THE MACHINE DESCRIBED BELOW:

Model : G3300 G3300EZ

Serial no. : 000101 and up

Make : KOMATSU ZENOAH

CONFORMS TO THE REQUIRMENTS OF THE MODIFIED MACHINES DIRECTIVE

(Directive 98/37/EC) AND TO THE NATIONAL REGULATIONS GOVERNING ITS

TRANSPOSITION ABROAD : AND

THAT IT HAS BEEN ISSUED WITH A “CE”CERTIFICATE, NO. M.0303.04.3211

(G3300), M.0303.04.3212 (G3300EZ) BY THE ISTITUTO CERTIFICAZIONE

EUROPEA PALAZZO DEL VESCOVO - V. GARIBALDI, 20 40011 ANZOLA DELL’

EMILIA - ITALY

KOMATSU ZENOAH

G3300 / G3300EZ

G

B

Signed in Saitama, Japan

Isamu NAKAZATO

General Manager, Quality Assurance Department

16 / 2 / 2004

Contents

1. For Safe Operation ................................................................... 4

2. Explanation of Symbols on the Machine .................................. 6

3. Installing Guide Bar and Saw Chain......................................... 6

4. Fuel and Chain Oil .................................................................... 8

5. Operating the Engine ............................................................... 9

6. Sawing .................................................................................... 11

7. Maintenance ........................................................................... 12

8. Maintenance of Saw Chain and Guide Bar ............................ 14

9. Troubleshooting Guide ........................................................... 15

10. Specifications ......................................................................... 16

GB-3

Page 4

G3300 / G3300EZ

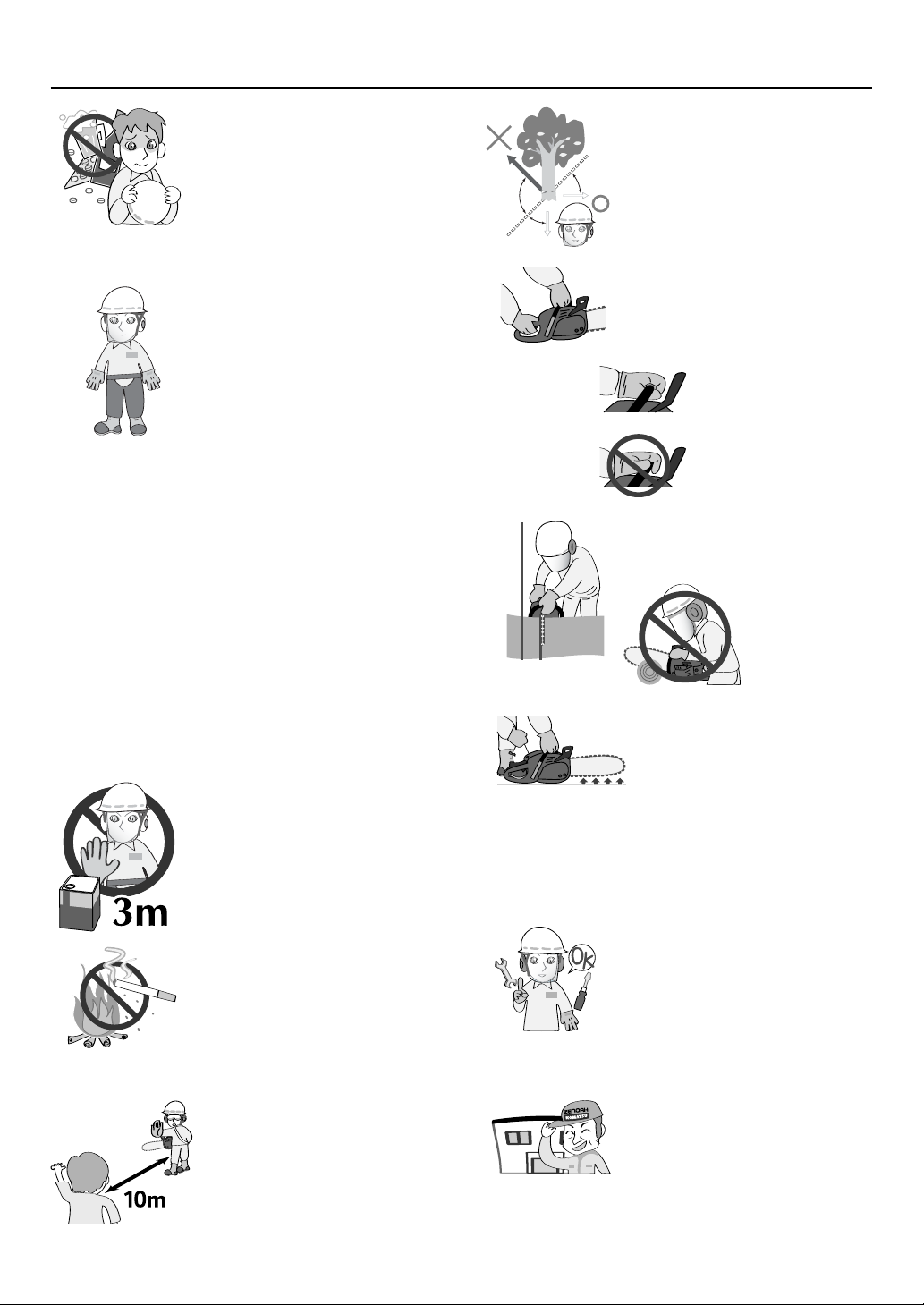

1. For safe operation

1. Never operate a chain saw when

you are fatigued, ill, or upset, or

under the influence of medication that may make you drowsy,

or if you are under the influence

of alcohol or drugs.

2. Use safety footwear, snug fitting

clothing and eye, hearing and

head protection devices.

Use the vibration-proof glove.

3. Keep the saw chain sharp and

the saw, including the A V system,

well maintained. A dull chain will

increase cutting time, and pressing a dull chain through wood will

increase the vibrations transmitted to your hands. A saw with

loose components or with damaged or worn AV buf fers will also

tend to have higher vibration levels.

4. All the above mentioned precautions do not guarantee that you

will not sustain whitefinger disease or carpal tunnel syndrome.

Therefore, continual and regular

users should monitor closely the

condition of their hands and fingers.

If any of the above symptoms appear , seek medical advice immediately.

9. Never start cutting until you have

a clear work area, secure footing, and a planned retreat path

from the falling tree.

10.Always hold the chain saw firmly

with both hands when the engine

is running. Use a firm grip with

thumb and fingers encircling the

chain saw handles.

11.Keep all parts of your body away

from the saw chain when the engine is running.

12.Before you start the engine,

make sure the saw chain is not

contacting anything.

GB-4

5. Always use caution when handling fuel. Wipe up all spills and

then move the chain saw at least

3 m from the fueling point before

starting the engine.

6. Eliminate all sources of sparks or

flame (i.e. smoking, open flames,

or work that can cause sparks)

in the areas where fuel is mixed,

poured, or stored.

7. Do not smoke while handling fuel

or while operating the chain saw.

8. Do not allow other persons to be

near the chain saw when starting or cutting. Keep bystanders

and animals out of the work area.

Children, pets and bystanders

should be a minimum of 10 m

away when you start or operate

the chain saw.

13.Always carry the chain saw with

the engine stopped, the guide

bar and saw chain to the rear,

and the muffler away from your

body.

14.Always inspect the chain saw before each use for worn, Ioose, or

damaged parts. Never operate

a chain saw that is damaged, improperly adjusted, or is not completely and securely assembled.

Be sure that the saw chain stops

moving when the throttle control

trigger is released.

15.All chain saw service, other than

the items listed in the Owner’s

Manual, should be performed by

competent chain saw service

personnel. (E.g., if improper tools

are used to remove the flywheel,

or if an improper tool is used to

hold the flywheel in order to re-

Page 5

G3300 / G3300EZ

move the clutch, structural damage to the flywheel could occur

which could subsequently cause

the flywheel to disintegrate.)

16.Always shut off the engine before setting it down.

17.Use extreme caution when cutting small size brush and saplings because slender material

may catch the saw chain and be

whipped toward you or pull you

off balance.

18.When cutting a limb that is under tension, be alert for springback so that you will not be

struck when the tension in the

wood fibers is released.

19.Never cut in high wind, bad

weather , when visibility is poor or

in very high or low temperatures.

Always check the tree for dead

branches which could fall during

the felling operation.

20.Keep the handles dry, clean and

free of oil or fuel mixture.

21.Operate the chain saw only in

well ventilated areas. Never start

or run the engine inside a closed

room or building. Exhaust fumes

contain dangerous carbon monoxide.

22.Do not operate the chain saw in

a tree unless specially trained to

do so.

23.Guard against kickback. Kickback is the upward motion of the

guide bar which occurs when the

saw chain at the nose of the

guide bar contacts an object.

Kickback can lead to dangerous

loss of control of the chain saw.

saw chain in the cut. Tip contact

in some cases may cause a lightning fast reverse reaction,kicking

the guide bar up and back towards the operator. Pinching the

saw chain along the top of the

guide bar may push the guide

bar rapidly back towards the operator. Either of these reactions

may cause you to Iose control of

the saw, which could result in

serious personal injury.

• Do not rely exclusively on the

safety devices built into your saw.

As a chain saw user you should

take several steps to keep cutting jobs free from accident or

injury.

(1) With a basic understanding of

kickback you can reduce or

eliminate the element of surprise.

Sudden surprise contributes to

accidents.

(2) Keep a good grip on the saw with

both hands, the right hand on the

rear handle, and the left hand on

the front handle, when the engine

is running. Use a firm grip with

thumbs and fingers encircling

the chain saw handles. A firm

grip will help you reduce kickback and maintain control of the

saw.

(3) Make certain that the area in

which you are cutting is free from

obstructions. Do not let the nose

of the guide bar contact a log,

branch, or any other obstruction

which could be hit while you are

operating the saw.

(4) Cut at high engine speeds.

G

B

24.When transporting your chain

saw, make sure the appropriate

guide bar scabbard is in place.

KICKBACK SAFETY PRECAUTIONS FOR CHAIN SAW USERS

WARNING

• Kickback may occur when the

nose or tip of the guide bar

touches an object, or when the

wood closes in and pinches the

(5) Do not overreach or cut above

shoulder height.

(6) Follow the manufacturer’ s sharp-

ening and maintenance instructions for the saw chain.

(7) Only use replacement bars and

chains specified by the manufacturer or the equivalent.

GB-5

Page 6

G3300 / G3300EZ

2. Explanation of Symbols on the Machine

For safe operation and maintenance, symbols are carved in relief on the machine.

According to these indications, please be careful not to make any mistake.

The port to refuel “MIX GASOLINE”

Position: Fuel cap

The port to top up chain oil

Position: Oil cap

Setting the switch to the “O” position,

the engine stops immediately.

Position: Rear-left of the unit

If you pull out the choke knob, you can

set the choke as a cold start mode.

Position: Upper-right of the aircleaner

cover

The screw under the “H” stamp is The

High-speed adjustment screw.

The screw under the “L” stamp is The

Slow-speed adjustment screw.

The screw at the left of the “T” stamp is

the Idle adjustment screw.

Position: Left side of the rear handle

Shows the directions that the chain

brake is released (white arrow) and activated (black arrow).

Position: Front of the chain cover

If you turn the rod by screwdriver follow

the arrow to the "MAX" position, the chain

oil flow more, and if you turn to the "MIN"

position, less.

Position: Bottom of the power unit

3. Installing Guide Bar and Saw Chain

A standard saw unit package contains the items as illustrated.

(1) Power unit (2) Bar protector

(3) Guide bar (4) Saw chain

(5) Plug wrench

Open the box and install the guide bar and the saw

chain on the power unit as follows:

The saw chain has very sharp edges. Use

thick protective gloves for safety.

[G3300]

1. Pull the guard towards the front handle to check that

the chain brake is not engaged.

2. Loosen the nut and remove the chain cover.

3. Gear the chain to the sprocket and, while fitting the

saw chain around the guide bar, mount the guide

bar to the power unit. Adjust the position of the chain

tensioner.

Pay attention to the correct direction of the

saw chain.

(1)

(1) Moving direction

(2)

(3)

4. Fit the chain cover to the power unit and fasten the

nut to finger tightness.

5. While holding up the tip of the bar, adjust the chain

tension by turning the tensioner screw until the tie

straps just touch the bottom side of the bar rail.

(2) T ensioner nut

(3) Chain cover

GB-6

Page 7

(1) T ensioner screw

(2) Loosen

(3) Tighten

6. Tighten the nut securely with the bar tip held up (12

~ 15 N·m). Then check the chain for smooth rotation

and proper tension while moving it by hand. If necessary, readjust with the chain cover loose.

7. Tighten the tensioner screw.

Note: A new chain will expand its length in the beginning of use.

Check and readjust the tension frequently as a loose chain can

easily derail or cause rapid wear of itseif and the guide bar.

G3300 / G3300EZ

While temporary tightening, you may hear the

“click” sound. But do not stop tightening at

that time. This sound does not mean that the

saw chain and guide bar were assembled.

5. While holding the chain cover , temporary tighten the

nut assembly and fix the bar and chain cover. (You

can fix them even by tightening the lever.)

Check if the saw chain fits on the bar rail. If not,

readjust by loosen the nut assembly.

(3)

(1) Nut assembly

(2) Chain cover

(3) Lever

(1)(2)

(4)

(4)

(4) Proper tension,

No gap

G

B

[G3300EZ]

1. Pull the guard towards the front handle to check that

the chain brake is not engaged.

2. Loosen the nut assembly and dismount the chain

cover.

(1)

(1) Nut assembly

(2) Chain cover

(2)

(3)

(3) Loosen

3. Set the guide bar to the power unit, gear the chain

to the sprocket of clutch drum and fit it into the groove

of the bar and the sprocket at the tip of the bar.

• Pay attention to the correct direction of the

saw chain.

• Make sure to fit the chain into the groove

of the bar and the sprocket. If not, you may

fail to tighten the chain.

(2)

(1)

(3)

(1) Moving direction

(4)

(2) Sprocket of the

clutch drum

(3) Guide bar

(4) Sprocket of the bar

4. Move the guide bar back and forth to adjust the position of projection A, B and C to fit in each hole. By

inserting the projections into the bottom of holes,

attach the chain cover securely.

6. After fixing them, attach the bar protector for your

safety.

Pull the lever up and tighten it securely.

Tightening torque:

7.9 ~ 12.8 N·m {80~130kgf-cm}

(3)

(1)

(2)

(1) Lever

(2) Bar protector

(3) Fully tighten

7. If the chain becomes loose while using the unit, attach the bar protector and loosen the nut assembly

around 4 turns.

Dismount the protector and check if the chain fits

on the bar rail. If not, readjust by loosen the nut assembly.

Temporary tighten the nut assembly. The chain is to

be tensioned automatically . After fixing the guide bar,

mount the protector and tighten the lever securely

for fully tightening.

(1)

(1) Loosen (2) Bar protector

(2)

NOTE: A new chain will expand its length in the beginning of use.

Check and readjust the tension frequently as a loose chain can

easily derail or cause rapid wear of itself and the guide bar.

• Replace the guide plate when its file is worn.

(3)

(1)

(2)

(1) Projection A

(2) Projection B

(3) Projection C

GB-7

Page 8

G3300 / G3300EZ

4. Fuel and Chain Oil

■ FUEL

• Gasoline is very flammable. Avoid smoking or

bringing any flame or sparks near fuel. Make sure

to stop the engine and allow it cool before refueling the unit. Select outdoor bare ground for fueling and move at least 3 m (10 ft) away from the

fueling point before starting the engine.

• The Komatsu Zenoah engines are lubricated by oil

specially formulated for air-cooled 2-cycle gasoline

engine use. If Komatsu Zenoah oil is not available,

use an anti-oxidant added quality oil expressly labeled

for air-cooled 2-cycle engine use (JASO FC GRADE

OIL or ISO EGC GRADE).

• Do not use BIA or TCW (2-stroke water -cooling type)

mixed oil.

■ RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

• Exhaust emission are controlled by the fundamental engine parameters and components (eq.,

carburation, ignition timing and port timing) without addition of any major hardware or the introduction of an inert material during combustion.

• These engines are certified to operate on unleaded

gasoline.

• Make sure to use gasoline with a minimum octane

number of 89RON (USA/Canada: 87AL).

• If you use a gasoline of a lower octane value than

prescribed, there is a danger that the engine temperature may rise and an engine problem such as

piston seizing may consequently occur.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health

and the environment.

• Poor quality gasolines or oils may damage sealing

rings, fuel lines or fuel tank of the engine.

■ HOW TO MIX FUEL

4. Pour in the rest of gasoline and agitate again for at

least one minute. As some oils may be difficult to

agitate depending on oil ingredients, sufficient agitation is necessary for the engine to last long. Be

careful that, if the agitation is insufficient, there is an

increased danger of early piston seizing due to abnormally lean mixture.

5. Put a clear indication on the outside of the container

to avoid mixing up with gasoline or other containers.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a

dustless place.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel

spillage around the unit.

1. Select bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point before starting the engine.

3. Stop the engine before refueling the unit. At that time,

be sure to sufficiently agitate the mixed gasoline in

the container.

■ FOR YOUR ENGINE LIFE, AVOID:

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause

severe damage to the internal engine parts very

quickly.

2.

GASOHOL – It can cause deterioration of rubber and/

or plastic parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark

plug fouling, exhaust port blocking, or piston ring

sticking.

4. Mixed fuels which have been left unused for a

period of one month or more may clog the carburetor and result in the engine failing to operate properly.

5. In the case of storing the product for a long period

of time, clean the fuel tank after rendering it empty.

Next, activate the engine and empty the carburetor

of the composite fuel.

6. In the case of scrapping the used mixed oil container, scrap it only at an authorized repository site.

Note: As for details of quality assurance, read the description in

the section Limited Warranty carefully . Moreover, normal wear and

change in product with no functional influence are not covered by

the warranty. Also, be careful that, if the usage in the instruction

manual is not observed as to the mixed gasoline, etc. described

therein, it may not be covered by the warranty.

■ CHAIN OIL

Use motor oil SAE #10W-30 all year round or SAE

#30 ~ #40 in summer and SAE #20 in winter.

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be

mixed.

2. Put some of the gasoline into a clean, approved fuel

container.

3. Pour in all of the oil and agitate well.

GB-8

Note: Do not use wasted or regenerated oil that can cause damage

to the oil pump.

Page 9

5. Operating the Engine

It is very dangerous to run a chainsaw that

mounts broken parts or lacks any parts.

Before starting engine, make sure that all the

parts including bar and chain are installed

properly.

■ ST ARTING THE ENGINE

1. Fill fuel and chain oil tanks respectively, and tighten

the caps securely.

G3300 / G3300EZ

G

B

Do not start the engine while the chain saw

hangs in one hand. The saw chain may touch

your body. This is very dangerous.

(2)

(1)

(1) Fuel

(2) Chain oil

2. Set the switch to “I” position.

(1)

(1) Switch

3. Continuously push the priming bulb until fuel comes

in the bulb.

(1)

(1) Priming bulb

6. When engine has ignited, pull the throttle slightly to

return the choke knob to the original position. If the

engine stops, pull the starter again without pulling

out the choke knob.

7. Allow the engine to warm up with the throttle lever

pulled slightly.

Keep clear of the saw chain as it will start

rotatIng upon starting of engine.

■ CHECKING THE OIL SUPPLY

Make sure to set up the bar and the chain

when checking the oil supply.

If not, the rotating parts may be exposed. It is

very dangerous.

After starting the engine, run the chain at medium speed

and see if chain oil is scattered off as shown in the figure.

(1) Chain oil

4. Pull out the choke knob completely to close the

choke.

(1)

(1) Choke knob

(2) Close

(2) (3)

(3) Open

NOTE: When restarting immediately after stopping the engine, you

need not to pull out the choke knob.

5. While holding the saw unit securely on the ground,

pull the starter rope vigorously.

The chain oil flow can be changed by inserting a

screwdriver in the hole on bottom of the clutch side.

Adjust according to your work conditions.

(1) Rich

(2) Lean

(3) Chain oil flow adjusting

■ ADJUSTING THE CARBURETOR

(2)

(1) L needle

(2) H needle

(3) Idle adjusting screw

(1)

(3)

GB-9

Page 10

G3300 / G3300EZ

(1)

The carburetor on your unit has been factory adjusted,

but may require fine tuning due to a change in operating conditions.

Before adjusting the carburetor, make sure that the provided air/fuel filters are clean and fresh and the fuel properly mixed.

When adjusting, take the following steps:

Note: Be sure to adjust the carburetor with the bar chain attached.

1. H and L needles are restricted within the number of

turn as shown below.

H needle : -1/4

L needle : -1/4

2. Start the engine and allow it to warm up in low speed

for a few minutes.

3. Turn the idle adjusting screw (T) counterclockwise

so that the saw chain does not turn. If the idling

speed is too slow, turn the screw clockwise.

4. Make a test cut and adjust the H needle for best

cutting power, not for maximum speed.

■ CHAIN BRAKE

This machine is equipped with an automatic brake to

stop saw chain rotation upon occurrence of kickback

during saw cutting. The brake is automatically operated

by inertial force, which acts on the weight fitted inside

the front guard.

This brake can also be operated manually with the front

guard turned down to the guide bar.

To release the brake, pull up the front guard toward the

front handle till a “click” sound is heard.

(3)

In case the brake is not effective, ask our dealer for

inspection and repairs.

If the engine keeps rotating at high speed with the brake

engaged, the clutch will overheat causing trouble.

When the brake engages during operation, immediately

release the throttle lever to stop the engine.

■ STOPPING THE ENGINE

1. Release the throttle lever to allow the engine to idle

for a few minutes.

2. Set the switch to the “O” (STOP) position.

(1) Switch

■ CARBURETOR ANTI-FREEZE MECHANISM

Operating chain saws in temperatures of 0 – 5°C at times

of high humidity may result in ice forming within the carburetor, and this in turn may cause the output power of

the engine to be reduced or for the engine to fail to operate smoothly.

This product has accordingly been designed with a ventilation hatch on the right side of the surface of the insulator cover to allow warm air to be supplied to the engine and to thereby prevent icing from occurring.

Under normal circumstances the product should be

used in the normal operating mode, i.e., in the mode to

which it is set at the time of shipment. However when

the possibility exists that icing may occur , the unit should

be set to operate in the anti-freeze mode before use.

(1) (2)

(1) Release (2) Activate (3) Front guard

[Caution]

Be sure to confirm brake operation during daily inspection.

How to confirm:

1) Turn off the engine.

2) Holding the chain saw horizontally, release your hand

from the front handle, hit the tip of the guide bar to a

stump or a piece of wood, and confirm brake operation. Operating level varies by bar size.

GB-10

Stop the engine, remove the cylinder cover and install

the grommet A to the appropriate position of the mode.

See ■ Maintenance part for how to remove the cylinder

cover.

(1)

(3)

(4)

(5)

(1) Normal operation mode (2) Anti-freeze mode (3) Insulator

(4) Carburetor (5) Grommet A

(2)

(5)

Page 11

6. Sawing

G3300 / G3300EZ

• Before proceeding to your job,

read the section “For Safe

Operation”. It is recommended

to first practice sawing easy

logs. This also helps you get

accustomed to your unit.

• Always follow the safety regulations. The chain saw must

only be used for cutting wood.

It is forbidden to cut other

types of material. Vibrations

and kickback vary with different materials and the requirements of the safety regulations

would not be respected. Do

not use the chain saw as a lever for lifting, moving or splitting objects. Do not lock it over

fixed stands. It is forbidden to

hitch tools or applications to

the PTO other than those

specified by the manufacturer.

• It is not necessary to force the saw into the

cut. Apply only light pressure while running the

engine at full throttle.

• When the saw chain is caught in the cut, do

not attempt to pull it out by force, but use a

wedge or a lever to open the way.

■ GUARD AGAINST KICKBACK

gine at full speed. If the chain is slow

to stop or does not stop, replace the

brake band and clutch drum before

use.

• It is extremely important that the

chain brake be checked for proper

operation before each use and that

the chain be sharp in order to maintain the kickback safety level of this

saw. Removal of the safety devices,

inadequate maintenance, or incorrect replacement of the bar or chain

may increase the risk ot serious personal injury due to kickback.

■ FELLING A TREE

Felling direction

Notch cut

1. Decide the felling direction considering the wind,

lean of the tree, location of heavy branches, ease of

completing the task after felling and other factors.

2. While clearing the area around the tree, arrange a

good foothold and retreat path.

3. Make a notch cut one-third of the way into the tree

on the felling side.

4. Make a felling cut from the opposite side of the notch

and at a level slightly higher than the bottom of the

notch.

When you fell a tree, be sure to warn neighboring workers of the danger.

Felling cut

G

B

• This saw is equipped with a chain

brake that will stop the chain in the

event of kickback if operating properly . You must check the chain brake

operation before each usage by running the saw at full the throttle for I 2 seconds and pushing the front

hand guard forward. The chain

should stop immediately with the en-

Bucking and Limbing

• Always ensure your foothold. Do not stand

on the log.

• Be alert to the rolling over of a cut log. Especially when working on a slope, stand

on the uphill side of the log.

• Follow the instructions in “For Safe Operation” to avoid kickback of the saw.

Before starting work, check the direction of bending

force inside the log to be cut. Always finish cutting from

the opposite side of the bending direction to prevent

the guide bar from being caught in the cut.

GB-11

Page 12

G3300 / G3300EZ

A log lying on the ground

Saw down halfway, then roll the log over and cut from

the opposite side.

A log hanging off the ground

In area A, saw up from the bottom one-third and finish

by sawing down from the top. In area B, saw down from

the top one-third and finish by sawing up from the bottom.

Cutting the limbs of Fallen Tree

First check to which side the limb is bent. Then make

the initial cut from the bent side and finish by sawing

from the opposite side.

Be alert to the springing back of a cut limb.

Pruning of Standing Tree

Cut up from the bottom, finish down from the top.

• Do not use an unstable foothold or ladder.

• Do not overreach.

• Do not cut above shoulder height.

• Always use both your hands to hold the

saw.

7. Maintenance

Before cleaning, the inspecting or repairing

the unit, make sure that engine has stopped

and is cool. Disconnect the spark plug to prevent accidental starting.

■ MAINTENANCE AFTER EACH USE

1. Oiling port

Dismount the guide bar and check the oiling port for

clogging.

(1)

(1) Oiling port

2. Guide bar

When the guide bar is dismounted, remove sawdust in

the bar groove and the oiling port.

Grease the nose sprocket from the feeding port on the

tip of the bar.

(1) Oiling port

(2) Grease port

(3) Sprocket

3. Others

Check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and guide

bar mounting. If any defects are found, make sure to

have them repaired before operating the saw again.

GB-12

Page 13

G3300 / G3300EZ

■ PERIODICAL SERVICE POINTS

(Every 25 hours use)

1. Air cleaner

1. Loosen the knob by moving it to the direction A until

it clicks.

2. Pull the cover to the direction B and unfasten the

hooks so that the cover can be detached.

3. When fixing the cylinder cover back into its original

position, align the 3 hooks(3), move the cover in the

opposite direction of removal until it clicks.

A

(1)

(2)

B

(2)

(1)

(1) Knob

(2) Projection

(3)

4. Remove the cleaner element by unfastening the

hooks. Split the element into halves and wash in neutral detergent and warm water. After cleaning, dry

the element completely.

Exchange the element with new one in case it has

been contaminated.

When reinstalling the element to the unit, fit the hook

A and the hole, and then inset the element to the

unit.

NOTE: Make sure that the hook A is correctly fit with the hole to

reduce the chance of damage of the hook A.

(3) Hook

2. Fuel filter

Using a wire hook, take out the filter from the filler port.

Clean away the dirt attached to the filter. Replace with a

new one if needed.

(1)

(1) Fuel filter

Note: Never bend the filter pipe when returning it.

3. Spark plug

Champion

RCJ-7Y

Clean the electrodes with a wire brush and reset the

gap to 0.65 mm as necessary.

4. Cylinder fins

Dust clogging between the cylinder fins will cause overheating of the engine. Periodically check and clean the

cylinder fins after removing the air cleaner and the cylinder cover. When installing the cylinder cover, make

sure that switch wires and grommets are positioned

correctly in place.

G

B

(4)

(3)

(1)

(5)

(2)

(2)

(1) Hooks

(2) Air cleaner element

(3) Hole

(4) Hook A

(5) Hook B

Note: Be sure to block the air intake hole.

5. Sprocket

0.5mm

Check for cracks and for excessive wear interfering with

the chain drive. If the wear is considerable, replace it

with new one. Never fit a new chain on a worn sprocket,

or a worn chain on a new sprocket.

GB-13

Page 14

G3300 / G3300EZ

8. Maintenance of Saw Chain and Guide Bar

■ Saw Chain

It is very important for smooth and safe operation to always keep the cutters sharp.

The cutters need to be sharpened when:

• Sawdust becomes powder-like.

•You need extra force to saw in.

• The cut path does not go straight.

•Vibration increases.

• Fuel consumption increases.

Cutter setting standards:

Be sure to wear safety gloves.

Before filing:

• Make sure the saw chain is held securely.

•Make sure the engine is stopped.

• Use a round file of proper size for the chain.

Chain type: 91VG

File size: 5/32 in (4.0 mm)

Place the file on the cutter and push straight forward.

Keep the file position as illustrated.

Be sure to round off the fr ont edge to reduce

the chance of kickback or tie-strap breakage.

Make sure every cutter has the same length and edge

angles as illustrated.

Cutter length

Filing angle

Side plate angle

Top plate cutting angle

■ Guide Bar

• Reverse the bar occasionally to prevent partial wear .

• The bar rail should always be square. Check for wear

of the bar rail. Apply a ruler to the bar and the out-

After each cutter has been filed, check the depth gauge

and file it to the proper level as illustrated.

Appropriate gauge checker

Make the shoulder round

91VG .025

Depth gauge standard

″″

″ (0.64 mm)

″″

side of a cutter. If a gap is observed between them,

the rail is normal. Otherwise, the bar rail is worn.

Such a bar needs to be corrected or replaced.

Ruler

Gap

No gap

Chain tilts

WARNING:

This saw is equipped with one of the following low

kickback bar/chain combinations:

Komatsu Zenoah Part Number

Saw Model Bar Size Guide Bar Saw Chain

G3300/G3300EZ 14 848CB24G23 2931-52210

GB-14

Page 15

9. Troubleshooting Guide

G3300 / G3300EZ

Case 1. Starting failure

Make sure the icing prevention system is not

working.

Check fuel for water

or substandard mixture.

d

Check for engine

flooding.

Replace with proper

a

fuel.

Remove and dry the

spark plug.

a

Then pull the starter

again with no choke.

d

Check spark ignition.

Case 2. Lack of power/Poor acceleration/

Rough idling

Check fuel for water

or substandard mixture.

Replace with a new

a

plug.

Replace with proper

a

fuel.

d

Check air filter and

fuel filter for clogging.

a

Clean.

Case 3. Oil does not come out

Check oil for substandard quality.

a

Replace.

d

Check oil passage

and ports for clogging.

If the unit seems to need further service, please consult

with an authorized service shop in your area.

a

Clean.

G

B

d

Check carburetor

for inadequate adjustment.

Readjust speed

a

needles.

GB-15

Page 16

G3300 / G3300EZ

10. Specifications

Power unit:

Displacement (cm3): ............................................. 31.8

Fuel: ................ Mixture (Gasoline 50 : Two-cycle oil 1)

Fuel tank capacity (cm3): ....................................... 270

Chain oil: ................................. Motor oil SAE# 10W-30

Oil tank capacity (cm3):.......................................... 200

Carburetor:.....................Diaphragm type (Walbro WT)

lgnition system: ..................................... Pointless (TCl)

Spark plug:......................................Champion RCJ-7Y

Oil feeding system: ............................ Automatic pump

Power ........................................ 1.35/10,000 (kw/min-1)

Max speed ............................................. 12,500 (min-1)

Idle speed ................................................ 2,900 (min-1)

Sprocket (Teeth x Pitch): ................................ 6T x 3/8″

Dimensions (L x W x H) (mm): ................ 380x230x250

Limited warranty

Should any failure occur on the product under normal

operating conditions within the applicable warranty period, the failed part will be replaced or repaired free of

charge by a KOMATSU ZENOAH authorized dealer.

WARRANTY PERIOD: 1 year (6 months if used pr ofessionally, and 30 days if used for rental purpose) from

the date of initial purchase.

THE PURCHASER SHALL BEAR COSTS OF TRANSPORTING THE UNIT TO AND FROM THE KOMATSU

ZENOAH DEALER.

THE PURCHASER SHALL NOT BE CHARGED FOR DIAGNOSTIC LABOR WHICH LEADS TO THE DETERMINATION THAT A WARRANTED PART IS DEFECTIVE, IF

THE DIAGNOSTIC WORK IS PERFORMED AT THE

KOMATSU ZENOAH DEALER.

THE PURCHASER OR OWNER IS RESPONSIBLE FOR

THE PERFORMANCE OF THE REQUIRED MAINTENANCE AS DEFINED BY THE MANUFACTURER IN THE

OWNER/OPERATOR MANUAL.

ANY WARRANTED PART WHICH IS NOT SCHEDULED

FOR REPLACEMENT AS REQUIRED MAINTENANCE,

OR WHICH IS SCHEDULED ONLY FOR REGULAR INSPECTION TO THE EFFECT OF REP AIR OR “REPLACE

AS NECESSARY” SHALL BE WARRANTED FOR THE

WARRANTY PERIOD. ANY W ARRANTED PART WHICH

IS SCHEDULED FOR REPLACEMENT AS REQUIRED

MAINTENANCE SHALL BE WARRANTED FOR THE

PERIOD OF TIME UP TO THE FIRST SCHEDULED

REPLACEMNET POINT FOR THE PART.

ANY REPLACEMENT PART THAT IS EQUIVALENT IN

PERFORMANCE AND DULABILITY MAY BE USED IN

NON-WARRANTY MAINTENANCE OR REPAIRS, AND

Dry weight

Power unit only (kg):

G3300: ............................................................... 3.4

G3300EZ: ........................................................... 3.5

Cutting head:

Guide bar

Type: ................................................ Sprocket nose

Size (in. (mm)):........................................... 14 (350)

Saw chain

Type: ................................................. Oregon 91VG

Pitch (in. (mm)):........................................ 3/8 (9.53)

Gauge (in. (mm)):................................... 0.05 (1.27)

Specifications are subject to change wihout notice.

SHALL NOT REDUCE THE WARRANTY OBLIGATION

OF THE COMPANY.

THE COMP ANY IS LIABLE FOR DAMAGES TO OTHER

ENGINE COMPONENTS CAUSED BY THE FAIRURE OF

A WARRANTED PARTS STILL UNDER WARRANTY.

THE W ARRANTY DOES NOT APPLY T O THOSE UNITS

WHICH HAVE BEEN DAMAGED BY NEGLIGENCE OF

INSTRUCTION LISTED IN THE OWNER/OPERATOR

MANUAL FOR PROPER USE AND MAINTENANCE OF

THE UNITS ACCIDENT MISHANDLING, ALTERATION,

ABUSE, IMPROPER LUBULICATION, USE OF ANY

PARTS OR ACCESSARIES OTHER THAN THOSE

SPECIFIED BY THE COMPANY, OR OTHER CAUSES

BEYOND THE CONP ANY'S CONTROL.

THIS WARRANTY DOES NOT COVER THOSE PARTS

REPLACED BY NORMAL WEAR OR HARMLESS

CHANGES IN THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES INCLUDING THOSE OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE ARE LIMITED TO TWO (2) YEARS OF HOME

USE [ONE (1) YEAR FOR ANY OTHER USE] FROM THE

ORIGINAL DELIVERY DATE.

LIABILITIES FOR INCIDENT AL OR CONSEQUENTIAL

DAMAGE UNDER ANY AND ALL W ARRANTIES ARE

EXCLUDED.

IF YOU NEED TO OBTAIN MORE INFORMATION,

PLEASE CALL YOUR NEAREST SERVICE CENTER, OR

CHECK PLEASE KOMATSU ZENOAH WEB SITE http://

www.zenoah.net

GB-16

Loading...

Loading...