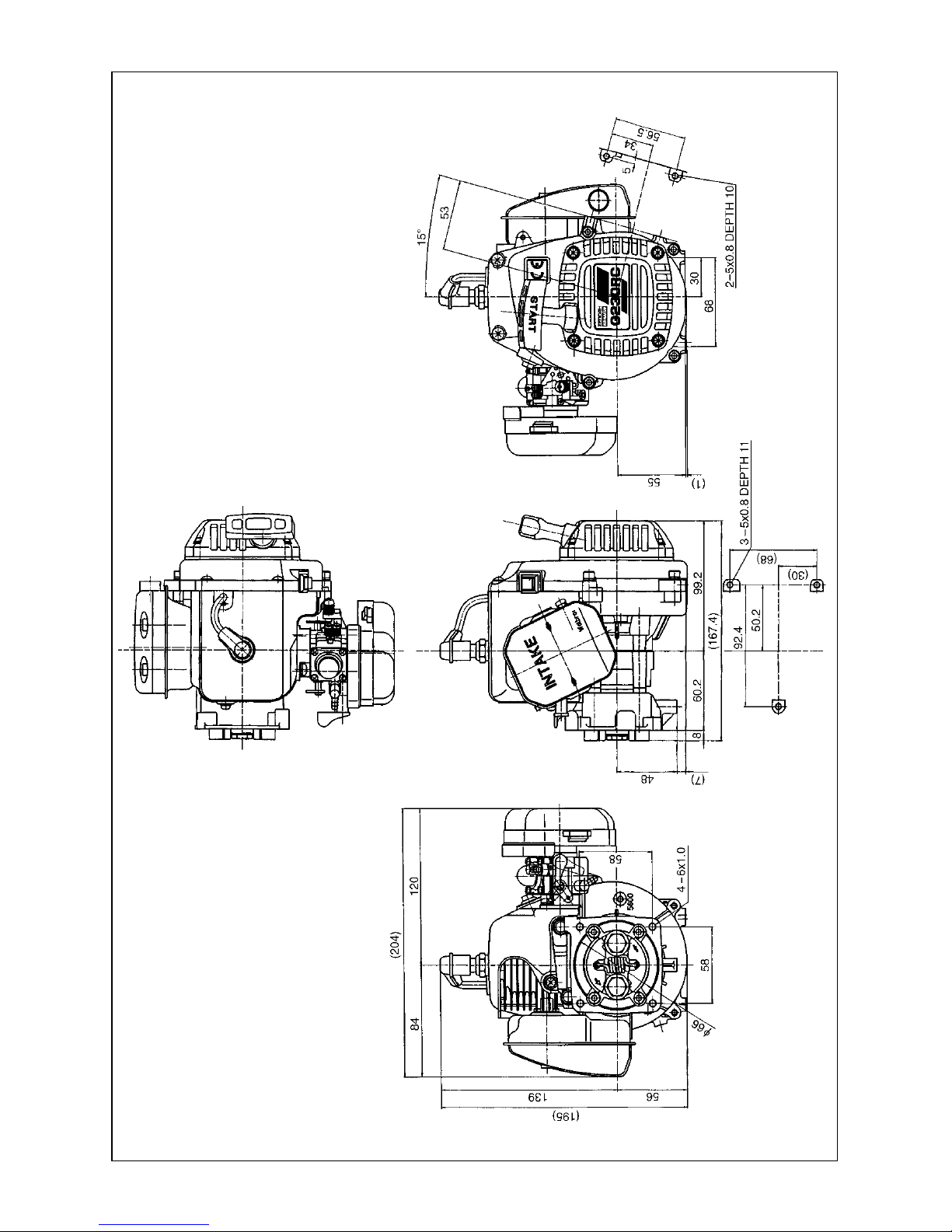

Page 1

G230RC

OWNER’S SERVICE MANUAL

T2070-93110 (205)

• This engine is designed

for the radio controlled

car use. Komatsu Zenoah

assumes that no

responsibility for this

engine that is modified or

used for any other

applications.

Purchaser has all

responsibility against any

laws and regulations

existing in the country,

Komatsu Zenoah is

exempt from such law

and regulations.

• Read this OWNER’S

SERVICE MANUAL before

operating this engine.

WARNING

Page 2

Page 3

1. Specifications

2. Fuel

• Mix high-octane (over 95) gasoline and high

grade 2 cycle oil (JASO FC Grade oil or ISO

EGC grade) in the ratio of 25 : 1.

1) Never use any alcohol fuel or alcohol added

fuel, or the rubber parts in the carburetor

and engine will be damaged.

2) Gasoline is very flammable. Avoid smoking,

bringing any fires near fuel.

3) To prevent all possible problem on fueling

system, make sure to use the fuel filter and

fuel pipe packed as accessories.

WARNING

Overall Size (L x W x H) 167 x 204 x 195mm

Weight 2.07kg

Engine Type G230RC

Displacement 22.5cm

3

Clutch Engagement 6000rpm (STD Spring)

Carburetor Type WT-603

Spark Plug NGK CMR7H

Spark Plug Gap 0.65mm

Rotating Direction Counter-Clockwise (View From PTO)

3

Page 4

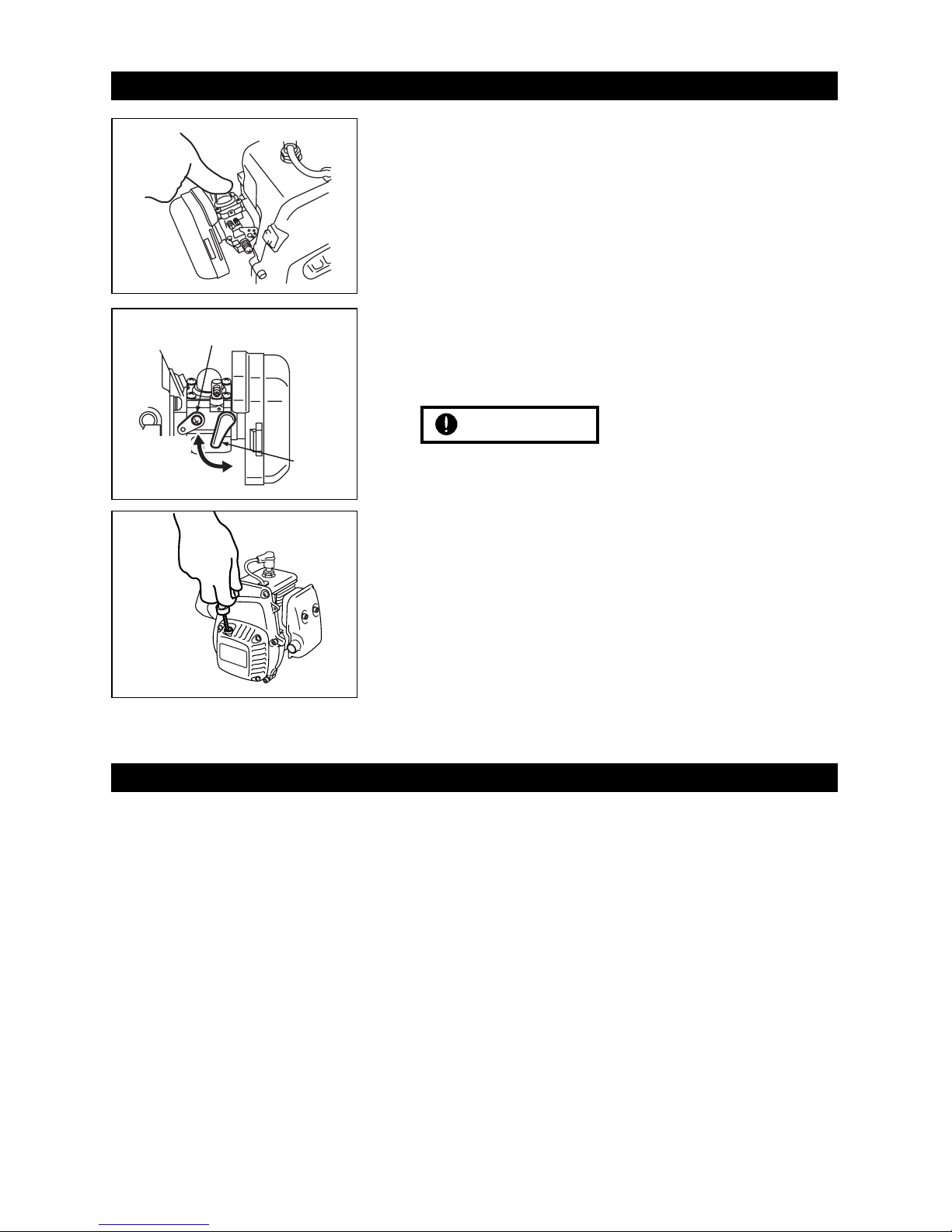

3. Engine Starting

4. Operation

• Push the primer pump several times until

overflown fuel flows out. (Fig.1)

• Close the choke lever(Fig.2), and move the

throttle lever 1/4~1/3 open position.

• Pull the starter(knob) quickly until first firing

noise. (Fig.3)

• Open the choke(Fig.2), throttle idle~1/4 open

• Pull the starter quickly

• Operate engine for a few minutes for the

warming up.

• In case of engine warm condition, choking may

not be necessary.

• Over choking may cause starting difficulty due

to wet spark plug.

In this case change spark plug or dry it, and

remove fuel rest in the cylinder by pulling

starter.

IMPORTANT

• This engine is already tuned up to get high

power and high speed, and needs correct

maintenance to keep such high performance.

• The details for operation may be described in

the separate owners manual to be issued by car

manufacturer.

• Be sure to have the engine cool down for 30

seconds at idle speed after full throttle running.

Fig.1

Choke

Lever

Open

Close

Throttle Lever

Fig.2

Fig.3

4

Page 5

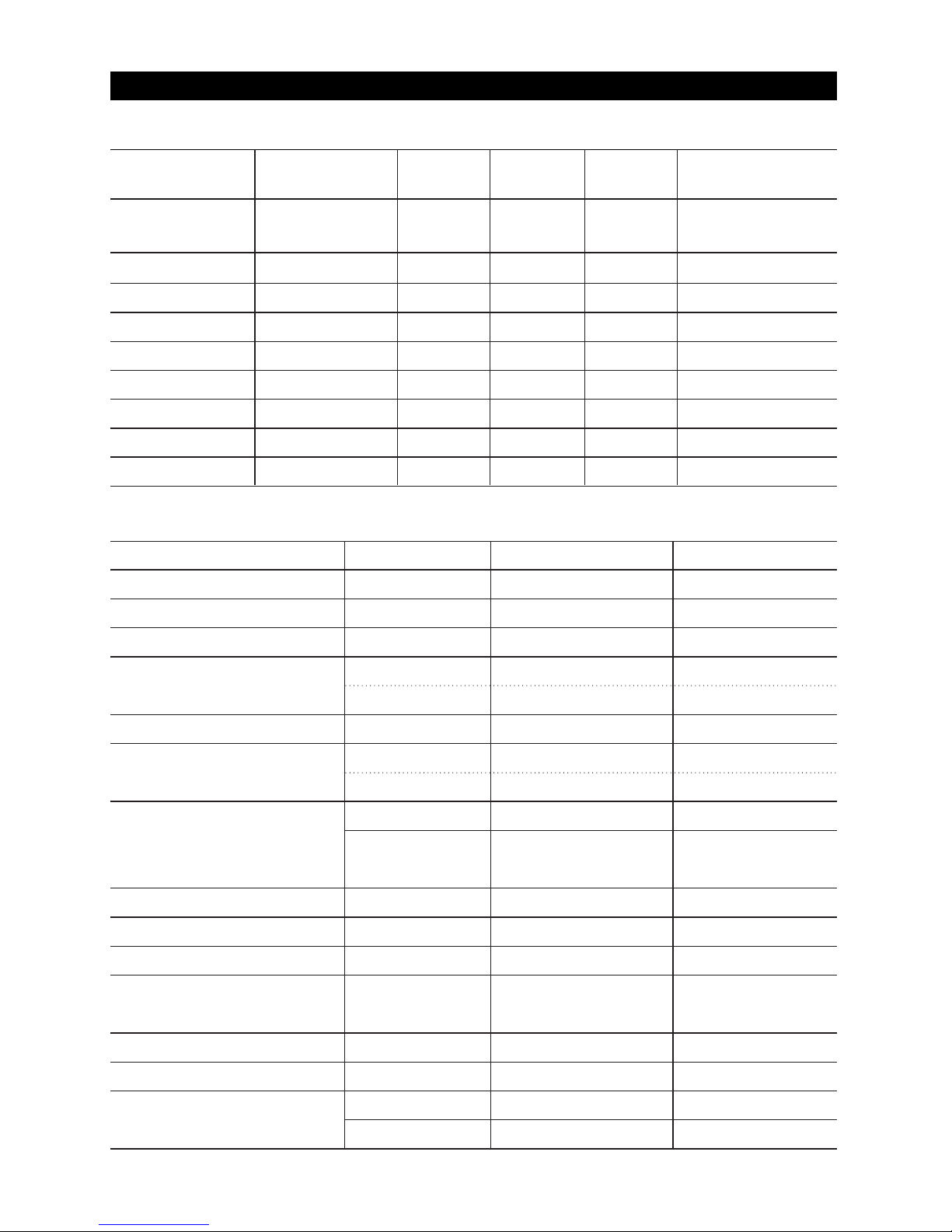

5. Maintenance

1) MAINTENANCE CHART

Before Every Every

Items Action Use 25 hours 100 hours Note

Leakage,

Check ✔

Damage/Crack

Idling Speed Check/Adjust ✔✔✔

Air-cleaner Check/Cleaning ✔✔ Replace if necessary

Spark Plug(gap) Check/Adjust ✔✔ ↑

Cylinder(barrel) Check/Cleaning ✔✔ ↑

Piston, Ring Check/Cleaning ✔✔ ↑

Muffler & Bolt Check/Cleaning ✔✔✔ ↑

Bearings Check/Cleaning ✔✔ ↑

Crank Shaft Check/Alignment ✔ ↑

2) SPECIFICATIONS AND TECHNICAL DATA

Items Unit Specifications Remarks

Bore x Stroke mm 32 x 28

Displacement cm

3

22.5

Effective Compression Ratio 8.8

Type Walbro WT

Carburetor

Venture(mm) ø12.7

Starting Recoil Starter

Type TCI

Ignition

Timing BTC 30°/8000rpm

Standard CMR7H NGK

Spark Plug Option(For Race) CR8HVX NGK

with Terminal Nut

Clutch Engagement Speed rpm 6000

No load max Speed rpm 19500

Idling Speed rpm 4000

Without Air Cleaner

Max. Power kW/rpm 2.10/14000

and Muffler

Max. Torque N.m/rpm 1.72/10000 ↑

Fuel Consumption g/kW·h 680 (500g/ps·h) ↑

Carburetor H 1 3/8 ± 1/4

Standard setting L 1 1/4 ± 1/4

5

Page 6

5. Maintenance

3) MAINTENANCE SPECIFICATIONS

Items Standard Limit Measuring Device Remarks

Compression (kg/cm2) 8.8 7.3 Compression Gage

Bore (mm) ø32 Plating damaged Eye Checking

Diameter (mm) ø31.97 ø31.87 Micro Meter

Piston Ring

1.01 1.11 Thickness Gauge

Groove width (mm)

Piston Pin Hole (mm) ø8.01 ø8.05 Cylinder Gauge

Clearance between Micro Meter

0.03~0.06 0.15

Piston and Cylinder (mm) Cylinder Gauge

Clearance between

0.02~0.04 0.1 Thickness Gauge

Groove and Piston Ring (mm)

End Gap (mm) 0.05~0.25 0.5 Thickness Gauge

Width (mm) 0.98 0.93 Micro Meter

Piston Pin Diameter (mm) ø8 ø7.98 Micro Meter

Connecting Rod Small end (mm) ø11 ø11.05 Cylinder Gauge

Crankshaft Dia. at Main Bearing (mm) ø12 ø11.98 Micro Meter

Eccentricity (mm) — 0.07 Dial Gauge

Axial Play (mm) — 0.5 Thickness Gauge

Gritty or

Main Bearing — —

Feels Flat Spot

At the skirt end and

the right angle to

the piston pin.

When inserted in a

new cylinder.

Piston CylinderPiston Ring

4) CARBURETOR

Items Standard Limit Measuring Device Remarks

Metering Lever set (mm) 1.65 ± 0.16 Vanier

Inlet Valve Opening Pressure (kg/cm2) 1.3~2.3 Leak Tester

Inlet Valve Closing Pressure (kg/cm2) 0.7~1.7 Leak Tester

6

Page 7

5. Maintenance

5) IGNITION SYSTEM

Items Standard Limit Measuring Device Remarks

Spark Plug Air Gap (mm) 0.6~0.7 0.7 Thickness Gauge

Ignition Coil/Flywheel Air Gap (mm) 0.3 0.4 Thickness Gauge

Primary 0.7 — Volt Meter

Secondary 6100 — Volt Meter

Reading between

primary terminal and

iron core.

Reading between

sparking cord end and

iron core.

6) TIGHTENING TORQUE

Items Screw Size Standard (kg·cm) Limit (kg·cm) Remarks

Carburetor M5 (P=0.8) 35 30~40

Insulator M5 (P=0.8) 35 30~40 with Locktight glue

Clutch M6 (P=1.0) 65 50~80

Rotor M8 (P=1.0) 130 100~150

Cylinder M5 (P=0.8) 70 60~80

Crankcase M5 (P=0.8) 65 50~80

Spark Plug M10 (P=1.0) 110 100~120

Muffler M5 (P=0.8) 90 70~100

Fan Cover M5 (P=0.8) 35 30~40

Ignition Coil M4 (P=0.7) 33 25~40

Starter Case M4 (P=0.7) 13 10~15

Tapping Screw TP 4.3 25 20~30

Coil

Resistance

(Ω)

7

Page 8

6. Special Tools

7) SPECIAL TOOLS

Part Name Part No. External Appearance Usage

1 Puller Assy 2890-96100 To remove rotor.

2 Piston Stopper 4810-96220

3 Rod Assy 1101-96220 To remove/install piston pin.

4 Air Gap Gauge 3330-97310 To set ignition coil.

5 Hex Wrench 3304-97611

6 Snap Ring Pliers 5500-96110 To remove snap ring.

To hold crankshaft when

disassembling/assembling

clutch and rotor.

For socket screw of Hex.

3mm, 4mm and 5mm.

8

Page 9

7. Service Guide

1) REMOVING CLUTCH SHOE

1. Remove the housing and plug cap.

2.Remove the spark plug and fit the

stopper(4810-96220) into the plug hole.

3. Remove clutch bolts(14mm Hex.).

2) REMOVING ROTOR (FAN)

4. Remove the rotor nut(12mm Hex.).

5. Remove the rotor using the puller assy (2890-

96100). Apply 8mm puller bolts.

3) ASSEMBLING ROTOR

Insert the gauge(3330-97310) in between the

rotor magnet metal and the coil.Tighten screws

while pressing the coil against the rotor.

Gap Specification 0.3 ~ 0.4mm

Clutch Bolt

(14mm Hex.)

Rotor Nut

17mm Hex.

Puller Bolts

Puller

Rotor

Wrench

Air Gap Gauge

Ignition Coil

9

Page 10

7. Service Guide

4) REMOVING PISTON PIN

1. Remove snap rings from both sides of the

piston pin.

2. Engage the rod assy(1101-96220) to the

piston pin and gently tap with a plastic hammer

to push out the pin while holding piston firmly.

Hard hammering may damage the big end of

the connecting rod.

5) INSTALLING PISTON

1. Make sure to point the arrow mark on the

piston to the exhaust side.

2. Fit the circlip in the groove so as to face the

end gap below.

Deformed circlip may come off during engine

operation and damage the engine.

6) CARBURETOR ADJUSTMENT

The carburetor comes with a standard setting, it

is for optimum performance under the barometric

pressure and climatic conditions at factory, so it

may be re-adjusted according to load applied.

Idle rpm : 4000 ± 300 rpm (STD Spring)

H needle : 1 3/8 ± 1/4

L needle : 1 1/4 ± 1/4

NOTE

NOTE

Plastic

Hammer

Rod Assy

Piston

Arrow Mark

Circlip

End Gap

Piston

H needle

L needle

Idle Screw

10

Page 11

9. Trouble Shooting

1) ENGINE DOES NOT START

Description Cause Countermeasure

No spark in the spark plug

Spark Plug 1. Wet spark plug electrodes Make them dry

2. Carbon deposited on the electrodes Cleaning

3. Insulation failure by insulator damage Exchange

4. Inproper spark gap Adjust to 0.6~0.7mm

5. Burn out of electrodes Exchange

Magneto 1. Ignition coil inside failure Exchange

2. Damaged cable sheath or disconnected cable Exchange or repair

Switch 1. Switch is OFF ON the switch

2. Switch failure Exchange

3.Primary wiring earthed Repair

Sparks appear in the spark plug

Compression & 1. Over sucking of fuel Drain excess fuel

fueling is normal 2. Too rich fuel Adjust carburetor

3. Overflow Carburetor adjust or exchange

4. Clogging of air cleaner Wash with mixed gasoline

5. Faulty fuel Change with proper fuel

Fueling normal but 1. Worn out cylinder, piston, or piston ring Exchange

poor compression 2. Gas leakage from cylinder and crank case gasket Apply liquid gasket and reassemble.

No fuel supply 1. Choked breather air hole Cleaning

2. Clogged carburetor Cleaning

3. Clogged fuel filter Exchange fuel filter

11

2) LACK OF POWER OR UNSTABLE RUNNING

Description Cause Countermeasure

Compression is normal 1. Air penetration from fuel pipe joints, etc Secure connection

and no misfire 2. Air penetration from intake tube joint or

Change gasket or tightening screws

carburetor joint

3. Water in fuel Change with good fuel

4. Piston start to seizure Replace piston(and cylinder)

5. Muffler choked with carbon Cleaning

Overheating 1. Fuel too lean Adjust carburetor

2. Clogging of cylinder fin with dust Cleaning

3. Poor fuel quality Exchange with proper fuel

4. Carbon deposited in the combustion chamber Cleaning

5. Spark plug electrode red hot Thoroughly clean, adjust spark gap

[ 0.6~0.7(0.023~0.028in) ]

Others 1. Dirty air cleaner Wash with mixed gasoline

2. Over loading Reduce load

Page 12

10. Parts list

12

Page 13

Model Name & Cord

Key# Part Number Description Q'ty

GR23101 GR23102 GR23103 GR23104

Remarks

G230RC G230RC1 G230RC2 G230RC3

10. Parts list

13

1 T2070-12110 CYLINDER 1 ●●●●

2 T2070-12210 GASKET 1 ●●●●

3 01252-30522 BOLT 2 ●●●●M5x22L

4 1148-13161 INSULATOR 1 ●●●●

5 1140-13151 GASKET, INSU 1 ●●●●

6 3330-14121 GASKET, CARB 1 ●●●●

7 0263-90520 SCREW 2 ●●●●M5x20L

8 T2070-15110 MUFFLER 1 ●●––

9 01252-30550 BOLT 2 ●●– – M5x50L

10 1140-13141 GASKET, MUFFLER 1 ●●●●

11 1850-32160 SCREW 1 ●●– – M4x12L

12 T2070-21101 CRANKCASE-C 1 ●●●●

13 2629-21130 • PIN 3 ●●●●

14 5500-21141 GASKET, CASE 1 ●●●●

15 1155-21240 BEARING 2 ●●●●

16 2169-21210 SEAL 1 ●●●●

17 1850-21220 SEAL 1 ●●●●

18 04065-02812 RING 1 ●●●●

19 01252-30530 BOLT 4 ●●●●M5x30L

20 T2070-41110 PISTON 1 ●●●●

21 T2070-41210 RING 1 ●●●●

22 1101-41310 PIN 1 ●●●●

23 1260-41320 RING 2 ●●●●

24 5500-41410 BEARING 1 ●●●●

25 1101-41340 WASHER 2 ●●●●

26 T2070-42000 CRANKSHAFT-C 1 ●●●●

27 1650-43230 NUT 1 ●●●●M8x1.0

28 1000-43240 KEY 1 ●●●●

29 1140-43250 SIM 1 ●●●●

30 1140-51111 SHOE 2 ●●●–

31 T2070-51220 SPRING 1 ●●●– (6000rpm IN)

32 1140-51250 SCREW 2 ●●●– M6x22L

33 1140-51230 WASHER 2 ●●●–

34 1140-51242 WASHER 2 ●●●–

35 1140-21162 CASE, CLUTCH 1 ●●●–

36 3350-15250 BOLT 4 ●●●– M5x16L

37 1140-55310 PLATE 1 ●●●–

38 0224-30614 BOLT 1 ●●●– M6x14L

39 T2070-71110 ROTOR 1 ●●●●

40 T2070-71200 COIL-A 1 ●●●●

42 T2070-72210 CAP 1 ●●●●

43 1400-72121 SPRING 1 ●●●●

44 5500-72130 GROMMET 1 ●●●●

45 1260-71261 SPACER 2 ●●●●

46 3350-14150 BOLT 2 ●●●●M4x20L

47 T2070-75101 RECOIL-A 1 ●●●●

48 T2070-75110 • CASE 1 ●●●●

49 5990-75120 • SPRING, SPIRAL 1 ●●●●

50 5990-75131 • REEL 1 ●●●●

51 5990-75141 • RATCHET 1 ●●●●

52 5990-75151 • SPRING, BREAK 1 ●●●●

53 5990-75270 • SCREW 1 ●●●●

54 5990-75160 • RETAINER 1 ●●●●

55 5990-75170 • WASHER 1 ●●●●

56 1861-75180 • ROPE 1 ●●●●

57 1490-75181 • KNOB 1 ●●●●

58 0263-90416 SCREW 4 ●●●●M4x16L

59 T2070-81000 CARBURETOR-A 1 ●●●●WT-603

60 3306-81380 • SCREEN 1 ●●●●

61 3080-81120 • COVER 1 ●●●●

62 3310-81130 • SCREW 1 ●●●●

63 3304-81140 • GASKET 1 ●●●●

64 1172-81150 • DIAPHRAGM 1 ●●●●

65 1751-81470 • GASKET 1 ●●●●

Page 14

10. Parts list

14

Model Name & Cord

Key# Part Number Description Q'ty

GR23101 GR23102 GR23103 GR23104

Remarks

G230RC G230RC1 G230RC2 G230RC3

66 3310-81260 • DIAPHRAGM 1 ●●●●

67 T2070-81210 • BODY-A 1 ●●●●

68 1751-81520 • COVER 1 ●●●●

69 1751-81510 • PUMP 1 ●●●●

70 2867-81270 • SPRING 1 ●●●●

71 3356-81310 • VALVE inlet 1 ●●●●

72 1480-81420 • PLUG welch 1 ●●●●

73 3310-81230 • LEVER 1 ●●●●

74 3310-81240 • SCREW 1 ●●●●

75 3310-81250 • PIN 1 ●●●●

76 2630-81330 • SCREW 1 ●●●●

77 3350-81380 • SPRING 1 ●●●●

78 T2070-81370 • SHAFT throttle 1 ●●●●

79 2670-81410 • SPRING 1 ●●●●

80 2880-81470 • SCREW 2 ●●●●

81 3310-81340 • VALVE throttle 1 ●●●●

82 3310-81360 • SCREW 1 ●●●●

83 1790-81440 • LEVER throttle 1 ●●●●

84 1148-81390 • RING 1 ●●●●

85 T2070-81460 • SHAFT choke 1 ●●●●

86 2670-81450 • VALVE choke 1 ●●●●

87 3350-81350 • SPRING 1 ●●●●

88 3350-81220 • BALL 1 ●●●●

89 1148-81530 • SCREW 4 ●●●●

90 1491-81160 • SPRING 1 ●●●●

91 1148-81171 • NEEDLE low speed 1 ●●●●

92 3080-81320 • SPRING 1 ●●●●

93 T2070-81330 • NEEDLE high speed 1 ●●●●

94 3304-81450 • SCREEN 1 ●●●●

95 3304-81441 • RING 1 ●●●●

96 3360-81440 • PLUG 1 ●●●●

98 T2070-82410 LEVER 1 ●●●●

99 T2070-82510 SPACER 1 ●●●●

100 0263-90560 SCREW 2 ●●– – M5x60L

101 0263-90550 SCREW 2 – – ●●M5x50L

102 T2070-82000 CLEANER-A 1 ●●––

103 5731-82011 • HOUSING 1 ●●––

104 5730-82040 • COVER 1 ●●––

105 1750-82020 • FILTER 1 ●●––

106 5730-82060 • SLEEVE 2 ●●––

107 T2070-31110 COVER, FAN 1 ●●●●

108 3310-12281 BOLT 4 ●●●●M5x20L

109 T2070-32100 COVER-A 1 ●●●●

110 1850-32160 SCREW 1 ●●●●M4x12L

111 1900-31410 SCREW 2 ●●●●TP4.5x18L

112 T1108-73110 SPARKPLUG 1 ●●●●

113 T2070-72200 SWITCH-A 1 ●●●●

114 T2070-75410 LABEL, RECOIL 1 ● – ●●

115 T2071-75410 LABEL, RECOIL 1 – ● ––

116 1726-85004 TANK-A 1 – ● ––

117 5601-85201 • CAP-A 1 – ● ––

118 1726-85601 • PIPE COMP 1 – ● ––

119 5500-85400 • FILTER 1 – ● ––

120 1260-85460 • CLIP 1 – ● ––

121 1799-85400 PIPE COMP 1 ● – ●●

122 5500-85400 FILTER 1 ● – ●●

123 1260-85460 CLIP 1 ● – ●●

124 T3039-91310 SOCKET 1 ●●●●

125 T2070-93110 MANUAL 1 ●●●●

126 2890-96100 PULLER-A 1 ●●●●OP

127 4810-96220 STOPPER 1 ●●●●OP

128 T2070-98100 SPARKPLUG 1 ●●●●OP

(NGK CR8HVX with Terminal Nut)

129 1764-51220 SPRING 1 ●●●– OP (5000rpm IN)

Page 15

11. Warranty

15

1) SCOPE OF APPLICATION

This engine manufactured by Komatsu Zenoah Co. (hereinafter referred as KZ) and

sold to the user directly or through distributor/manufacturer, shall entitle to be covered

by this warranty.

2) LIMIT OF WARRANTY

KZ warrants that ;

1. The quality disclosed in the specifications.

2. The engine which shall be considered defective by KZ, caused by material or

production fault.

3) LIMITS OF COMPENSATION

1. KZ compensates such quality, material and production faults by repairing or

replacing.

2. KZ shall not compensate any other accompanied or benefit losses caused to user

and distributor/manufacturer by such faults and through repairing or replacing.

4) TERMS OF WARRANTY

3 months after purchased by user subject to 12 months from produced month.

5) EXEMPT FROM WARRANTY

KZ shall not warrant this engine even if the fault has been caused during the period of

terms of warranty, in case of that ;

1. Any faults, failures caused from neglect of this OWNER'S SERVICE MANUAL for

proper operation and maintenance.

2. Any modifications not approved by KZ.

3. Normal abrasion and deterioration.

4. Consuming parts.

Page 16

Head Office : 1-9 Minamidai, Kawagoe-city, Saitama, 350-1192 Japan

Phone: (+81)492-43-1117 Fax: (+81)492-43-7197

Loading...

Loading...