Page 1

OWNER'S MANUAL

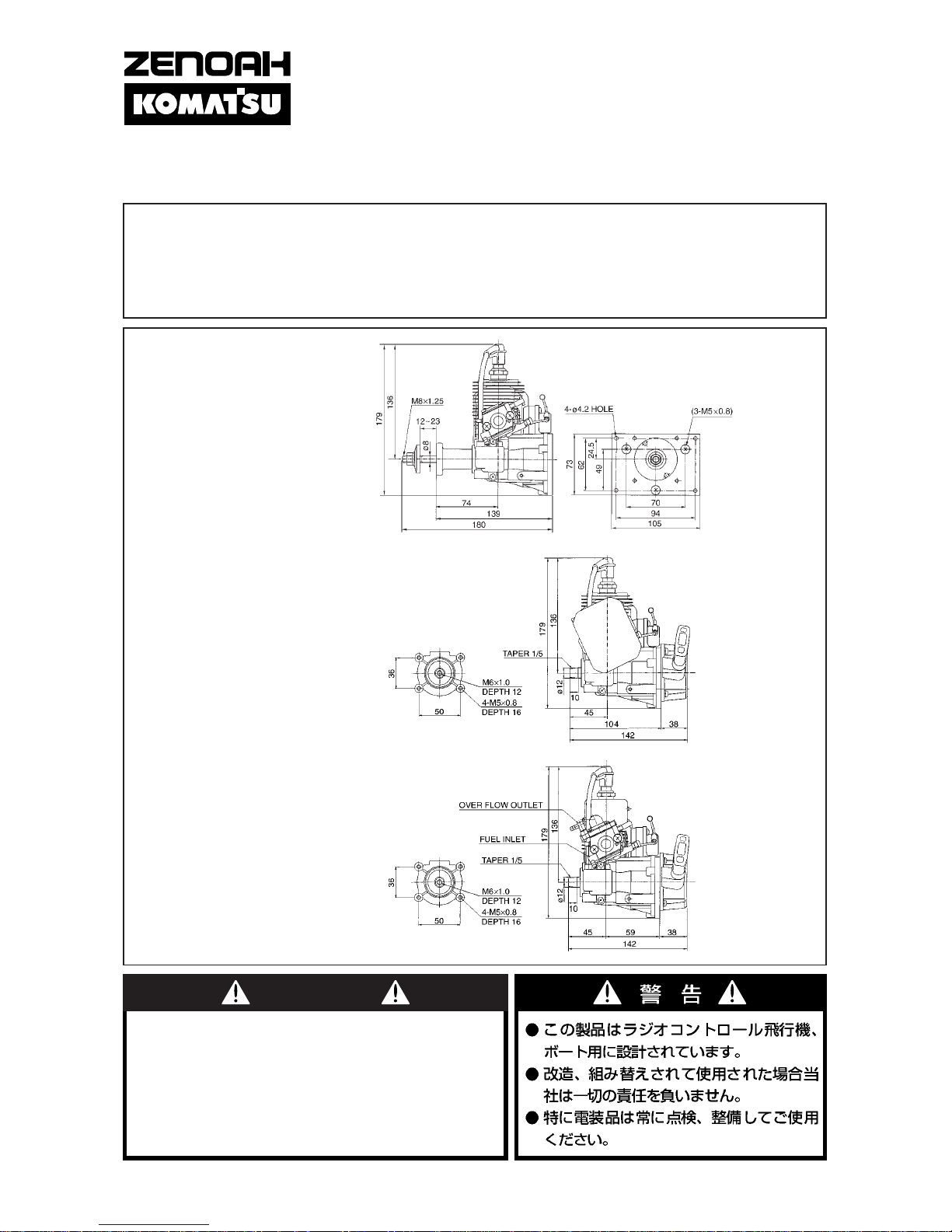

MODEL : G230PU - for Airplane

G230PUH - for Helicopter

G230PUM - for Boat

G230PU

G230PUH

G230PUM

April 2002

1155-93110(204)

• Do not modify any parts of the engine.

• This engine is designed to be used to Radio

controlled products.

• In case any modification by customer, KOMATSU

ZENOAH shall not bear any responsibility from

the damage caused by such modification.

• Keep ignition system well maintained.

WARNING

Page 2

1.Propeller for airplane

The recommended prop sizes are as shown in the table bellow.

This engine with a standard muffler produces the maximum

output when the engine is running at about 10,000rpm. Be sure

to use a propeller which makes the engine speed

approximately 7,000~9,500rpm while the airplane is flying.

[ NOTE ]

When mounting the spinner, set a pin on the hub with more

than 3mm of diameter, thus preventing slipping.

2. Rotor for helicopter

Adjust the rotor-pitch to obtain 9,000~10,000 rpm of the engine

at full throttle operation.

3. Screw Propeller for boat

The exhaust system (e.g., muffler) is not equipped with as

standard. When you select the exhaust system for the engine,

check how many the engine speed (rpm) is required when the

maximum output is generated by using the muffler you select.

And then decide the appropriate the screw propeller that would

meet such engine speed (rpm) that the muffler required.

In general, standard size of the screw propeller (Surface prop

type) are as follows:

1. SAFETY PRECAUTIONS

2. MOUNTING G230PU

3. PROPELLER, ROTOR & SCREW PROPELLER

4. FUEL

5. OPERATION

Make sure that the G230PU is mounted on the aircraft grade

plywood with more than 6mm of thickness or a mount of

equivalent strength and is firmly fixed with 4 bolts.

[ NOTE ]

1.Be sure to set flat washers or metal plate on the reverse side of

the mount to prevent bolts from sinking into the mount. Before

be sure to check for loose bolts.

2.Since the engine is equipped with a float-less carburetor with a

diaphragm pump, the direction of cylinder and position of fuel

tank can be freely selected .

Hand flip start

Since the G230PU is equipped with the ultra compact C.D.I. type

flywheel magneto ignition system, it should be started according

to the following procedure;

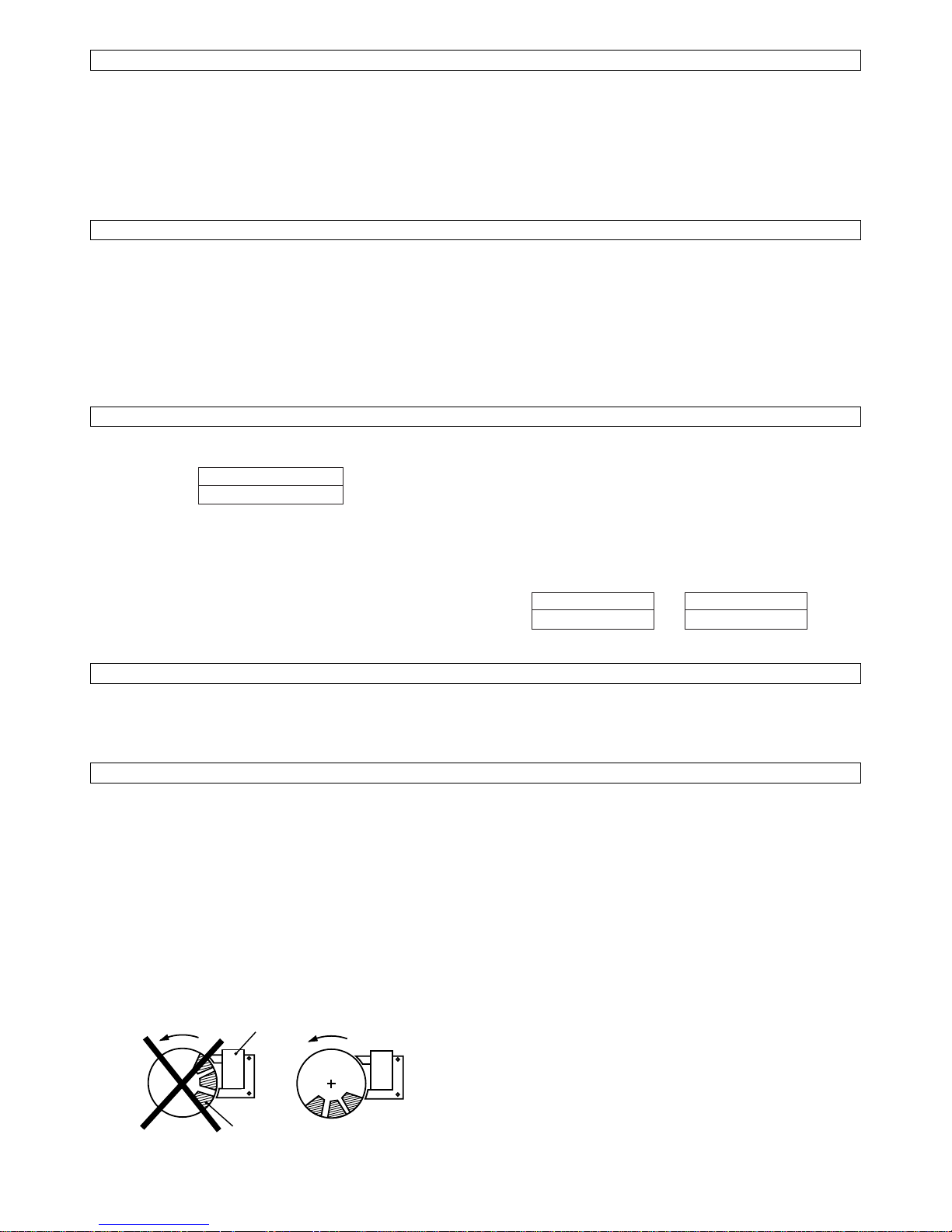

✽ The magneto system of G230PU is designed in such a way

that when the exhaust port is closed by the piston, that is, when

the compression stroke starts (Refer to Fig. 1-A), sparks are

never produced on spark plug no matter how fast the propeller

may be flipped. Be sure to quickly flip the propeller when the

edge of magnet on the rotor is approaching the coil (Fig. 1-B).

It means that the propeller should be quickly flipped about 90

degrees in crank angle before the compression is about to

start.

How to Start the Engine

1.For Airplane

a.FiII the fuel tank with the fuel.

b.Choke the engine and turn the propeller a few times until the

fuel appears at the carburetor.

c. Set the throttle valve at the idle position or at the position

slightly open from the idle position. Quickly flip the propeller

in the counterclockwise direction according to the procedure

described above. Flip the propeller a few times. Then the

engine starts.

2.For Helicopter & Boat

a.Fill the fuel tank with the fuel.

b.Push the priming bulb upper the carburetor until fuel appears

in the priming bulb.(for Helicopter)

c. Choke the engine and open the throttle valve approximately

1/3~1/2 of the full open position.

d. Quickly pull the starter cord when the initial explosion is

heard.

e. When the initial explosion is heard, open the choke, set the

throttle valve at the idle position or at the position slightly

open from the idle position and quickly pull the starter cord a

few more times. Then the engine starts.

[ NOTE ]

• Be sure to open the choke when the initial explosion is heard.

• When the choke is opened, be sure to close the throttle valve

3. If the rubber joint is placed between the engine and the body

for anti-vibration, check if the rubber is too week and select the

proper hardness of the rubber, in order to avoid the unexpected

vibration under operating engine RPM zone.

Note carefully that if the engine is vibrated at idling, then the

idling RPM is likely to get unstable due to overflow at

carburetor by the vibration.

4. Coat the bolts for muffler with anti-looser (e.g., Locktite or

equivalent).when assembling.

• This manual describes the engine. For its mounting and

control, see the instruction manual for the model airplane,

helicopter and boat.

• Each engine is designed for use on each model airplane,

helicopter and boat. If it is used for any other purpose, we

cannot be responsible for its reliability or safety.

• Use genuine parts for replacement.

• Check the propeller, rotor and screw propeller every time.

If it is damaged, replace it with a new one.

• If the propeller (or the rotor or the screw propeller) hit

something while the engine is in operation, immediately

stop the engine and check it.

• Start the engine on a flat surface without pebble stones.

• Never modify the fIywheeI.

• Check the fIywheel. If it is damaged, replace it with a new

one.

• When mixing the fuel, or operating the engine, carry it out

in a well-ventilated place.

Magnet

Coil

Fig.1-A

Fig.1-B

Diameter × Pitch ( in.)

18 × 6, 16 × 8 ~ 10

Diameter ( mm )

65 ~ 75

Pich ratio ( mm )

1.9 ~ 1.4

Mix gasoline and 2-stroke oil at a mixing ratio of 25 ~ 40 :1.

[ NOTE ]

1.Be sure to use a gasoline-resistant fuel piping. (Do not use any silicon rubber tube).

2.Never use any alcohol fuel or alcohol added fuel, or the rubber part in the carburetor will be damaged.

Page 3

6. CARBURETOR ADJUSTMENT

7. ENGINE BREAK-IN

8. SERVICING

to a position near the idle position before starting the next flipping

(If the engine is started while the throttle is wide open, a great

thrusting force is produced, which is very dangerous).

• Be sure to wear a thick glove when flipping the propeller. Use all

fingers, except thumb, for the flipping operation.

How to Stop the Engine

For stopping the engine, the black lead wire from the coil should be

grounded to the engine body, or the throttle valve should be closed

completely.

The carburetor is provided with 3 adjust screws which are set to

the best (approximately) positions by our company, but they may

need a little adjustment depending on the temperature,

atmospheric pressure (altitude), etc. of the area where the engine

is used. Start the engine without making any adjustments. Make

readjustments only when the engine shows any mal-functioning.

1.Standard opening of each needle as follows;

Low speed needle: 1

1

/8 ±1/4

High speed needle: 13/8 ±1/4

Idle Screw: Turning this screw clockwise increases the idling

R.P.M. Turning it counterclockwise decreases the

idling R.P.M

Low speed needle: This is the fuel adjust screw (not the air

screw). Turning this needle clockwise makes the

mixture gas leaner and turning it counterclockwise

makes it richer.

High speed needle: Turning this needle clockwise makes the

mixture gas leaner and turning it counterclockwise

richer. Set this needle at a position which is 1/4

open from the maximum R.P.M. position while the

airplane is on ground.

[ NOTE ]

1.Do not tighten the High and Low Speed needles too firmly.

2. When the unit has just started and the engine is not warm

enough, there may be insufficient acceleration and the engine

may be stopped. Be sure to perform idling before operation.

No specific break-in is required. The engine is gradually broken-in as it is used and the output is also increased gradually.

The engine can be disassembled or reassembled without any

specific difficulties, but be careful of the following matters;

a.For disassembling, the special tools shown in the parts list are

required in addition to the general tools. Be sure to use a new

gasket when the crankcase and cylinder have been

disassembled.

b.Removing rotor

1.Screw in the stopper (P/N 3350-96220) in place of the spark

plug. Then turn the rotor counterclockwise until the piston

touches the stopper. Take care it can cause damage to the

piston or connecting rod if the stopper is not screwed in to

the bottom.

2.Loosen and remove the rotor securing nut.

3. Remove the rotor by using the puller (P/N 1490-96101). Do

not hit on the crankshaft by a hammer, that can increase the

runout of the shaft.

c.Assembling crankcase

1.Apply grease on the oil seal lips and oil on the bearing.

2.Assemble the crankshaft with a new gasket.

3. When both front and rear crankcases are tightened, the

portion of gasket protruding on the cylinder mounted surface

should be cut off with a knife until the gasket becomes flush

with the cylinder mounted surface.

d.Assembling piston

Before assembling the piston, apply the oil on the small end

bearing and piston, and set the piston ensuring that the arrow

mark on the top of piston is directed toward the direction of

exhaust port.

e.Assembling cylinder

1.Coat the oil on the inner surface of cylinder.

2. The piston is provided with a knock pin which stops the

piston ring from turning. Set the splitted section of piston ring

at the knock pin and assemble the cylinder ensuring not to

break the piston ring.

f. Adjusting air gap of coil.

The air gap of coil should be adjusted to 0.3 mm (0.01").

g.Adjusting ignition time.

This engine with the point-less C.D.I. type requires no

adjustments of ignition time.

Low Speed needle

High Speed needle

Idle Screw

H

L

KILL SWITCH

BLACK LEAD

RED LEAD

ENGINE BODY EARTH

9. SPECIFICATIONS

Specifications are subject to change without notice.

MODEL ZENOAH G230PU ZENOAH G230PUH ZENOAH G230PUM

PURPOSE Airplane Helicopter Boat

TYPE Air cooled Water cooled

DISPLACEMENT 22.5cc

BORE × STROKE 32mm × 28mm

COMPRESSION RATIO 8.6 : 1

MAXIMUM OUTPUT 1.95PS/10500rpm [ 1.80PS/10500rpm ] 2.25PS/11000rpm

OPERATING ENGINE SPEED 2000~10000rpm 3000~11000rpm 3500~15000rpm

IGNITION SYSTEM CDI type Flywheel magneto

CARBURETOR WALBRO WA197A WALBRO WA167A WALBRO WA167A

AIR CLEANER Dry type

STARTING Hand flip Recoil starter

FUEL 2-cycle oil pre-mixed gasoline ( Mix ratio 25~40:1 )

SPARK PLUG NGK BMR7A or CHAMPION RCJ4

DRY WEIGHT [ ✽ with standard muffler ] 1.42Kg [ ✽1.58Kg ] 1.49Kg [ ✽1.65Kg ] 1.45Kg

Page 4

Q' ty per unit

PU PUH PUM

Description

Parts No.

Index

No.

Q' ty per unit

PU PUH PUM

Description

Parts No.

Index

No.

Index Q’ty

No. Parts No. Description /Unit

Index Q’ty

No. Parts No. Description /Unit

Index Q’ty

No. Parts No. Description /Unit

Index Q’ty

No. Parts No. Description /Unit

1 1148-12112 CYLINDER 1 1 0

2 1160-12111 CYLINDER 0 0 1

3 1160-12210 JACKET 0 0 1

4 07851-00515 JOINT 0 0 2

5 07000-03038 O RING 3×38 001

6 1160-12320 O RING 1.5×19.5 0 0 1

7 1160-12330 BOLT M3×8 002

8 1140-13121 GASKET CYL 1 1 1

9 3310-12281 BOLT M5×20 444

10 1140-13151 GASKET INSU 1 1 1

11 1148-13161 INSULATOR 1 1 1

12 3330-14121 GASKET CARB 1 2 1

1155-21101

CRANKCASE COMP

111

13 ✽ CRANKCASE (R) 1 1 1

14 ✽ CRANKCASE (F) 1 1 1

15 2629-21130 PIN 3 3 3

16 1140-21141 GASKET CASE 1 1 1

17 2169-21210 SEAL 12×22×7 111

18 1155-21240 BEARING 2 2 2

19 04065-02812 RING SNAP 1 1 1

20 06034-06001 BEARING 1 1 0

21 1850-21220 SEAL OIL 0 0 1

22 01252-30530 BOLT M5×30 444

23 5600-41111 PISTON 1 1 1

24 1100-41210 RING PISTON 2 2 2

Head Office : 1-9 Minamidai, Kawagoe-city,

Saitama, 350-1192 Japan

Phone: (+81)492-43-1117 Fax: (+81)492-43-7197

Printed in Japan

25 1101-41310 PIN PISTON 1 1 1

26 1260-41320 RING SNAP 2 2 2

27 5500-41410 BEARING 1 1 1

28 1101-41340

WASHER THRUST

222

29 1155-42000 CRANKSHAFT C 1 1 1

30 1155-74110 PLATE MOUNT 1 1 1

31 0262-10516 SCREW CM5×16 333

32 1650-43230 NUT 1 0 0

33 1160-75210 PULLEY 0 1 1

34 1861-75101 RECOlL ASSY 0 1 1

35 0263-30414 SCREW M4×14 044

36 1000-43240 KEY 1 1 1

37 1140-43250 SHIM 0

~20~20~2

38 2629-71210 COIL SO (GRAY) 1 0 0

39 1160-71211 COIL SO (RED) 0 1 1

40 2629-71311 COIL IG 1 1 1

41 0263-30414 SCREW M4×14 222

42 2629-72210

CAP PLUG (BLACK)

100

43 2850-72110

CAP PLUG (RED) 0 1 1

44 1400-72121 SPRING 1 1 1

45 0260-30422 SCREW M4×22 222

46-1 1148-73120

SPARKPLUG BMR7A

100

46-2 1155-73120

SPARKPLUG RCJ4 0 1 1

47 0263-90550 SCREW M5×50 202

48 0263-30555 SCREW M5×55 020

49 1142-83110 SPACER 5×10×I.6 2 0 2

50 1751-82002 AIRCREANER 0 1 0

51 1145-81002

CARBURETOR 197A

100

52 1148-81002

CARBURETOR 167A

011

53 0263-90520 SCREW M5X20 2 2 2

54 1155-71110 ROTOR 1 1 1

55-1 1155-15110 MUFFLER 1 0 0

55-2 1148-08010 MUFFLER 0 1 0

56 1140-13141 GASKET MUFF 1 2 0

57-1 01252-30550 BOLT M5×50 200

57-2 01252-30560 BOLT M5×60 020

58-1 0263-30408 SCREW M4×8 100

58-2 0263-90416 SCREW M4×16 010

59 1152-43260 HUB 1 0 0

60 1152-43281 STUD 1 0 0

61 1152-43290 WASHER HUB 1 0 0

62 3350-53410 NUT 1 0 0

63 3350-96220 STOPPER (OPT) 1 1 1

64 1490-96101

PULLER ASSY (OPT)

111

65 1110-91320 SOCKET 1 1 1

66 1145-15412 SPACER 0 1 0

67 1158-15420 SPACER 0 1 0

68 1101-96220 ROD-A (OPT) 1 1 1

Q' ty per unit

PU PUH PUM

Description

Parts No.

Index

No.

10. PARTS LIST

PUH, PUMPU

[ NOTE ]

The parts indicated “ ✽ ” in the part number column are supplied as an

assembly. No individual part available.

1 1145-81002 CARBURETOR ASSY

2 3306-81380 • SCREEN 1

3 2630-81120 • PUMP COVER 1

4 3330-81130 • SCREW 1

5 3304-81140 • GASKET, pump 1

6 1172-81150 • DIAPHRAGM, pump 1

7 3310-81311 • VALVE, inlet 1

8 3310-81280 • METERING COVER 1

9 3310-81230 • METERING LEVER 1

10 3310-81250 • PIN 1

11 3310-81240 • SCREW 1

12 2670-81270 • SPRING 1

13 3310-81260 • DIAPHRAGM ASSY 1

14 3310-81290 • GASKET, metering 1

15 1491-81160 • SPRING 1

16 1148-81171 • NEEDLE 1

17 3350-81380 • SPRING 1

18 2630-81330 • SCREW 1

19 1148-81371 • SHAFT ASSY 1

20 2670-81410 • SPRING 1

21 1148-81390 • RING 1

22 3310-81360 • SCREW 1

23 1282-81340 • THROTTLE VALVE 1

24 3310-81351 • SCREW 4

25 3080-81320 • SPRING 1

26 1148-81331 • H NEEDLE 1

27 1480-81420 • PLUG, welch 1

28 1790-81430 • PLUG 1

29 3304-81440 • RING 1

30 3304-81450 • SCREEN 1

31 3304-81910 • GASKET KIT 1

32 3304-81920 • DIAPHRAM KIT 1

1 1148-81002 CARBURETOR ASSY

2 3306-81380 • SCREEN 1

3 2630-81120 • PUMP COVER 1

4 3310-81130 • SCREW 1

5 3304-81140 • GASKET, pump 1

6 1172-81150 • DIAPHRAGM, pump 1

7 3310-81311 • VALVE, inlet 1

8 1751-81520 • METERING COVER 1

9 3310-81230 • METERING LEVER 1

10 3310-81250 • PIN 1

11 3310-81240 • SCREW 1

12 1751-81510 • PRIMER PUMP 1

13 2670-81270 • SPRING 1

14 3310-81260 • DIAPHRAGM ASSY 1

15 1790-81210 • BODY ASSY 1

16 1751-81470 • GASKET, metering 1

17 3350-81380 • SPRING 1

18 2630-81330 • SCREW 1

19 1148-81371 • SHAFT ASSY 1

20 2670-81410 • SPRING 1

21 1148-81390 • RING 1

22 3310-81360 • SCREW 1

23 1282-81340 • THROTTLE VALVE 1

24 1148-81530 • SCREW 4

25 3080-81320 • SPRING 1

26 1148-81331 • H NEEDLE 1

27 1491-81160 • SPRING 1

28 1148-81171 • NEEDLE 1

29 1480-81420 • PLUG, welch 1

30 1790-81430 • PLUG 1

31 3304-81440 • RING 1

32 3304-81450 • SCREEN 1

33 2630-06010 • GASKET KIT 1

34 3304-81920 • DIAPHRAM KIT 1

Loading...

Loading...