Page 1

SERVICE MANUAL

Product Type: DVD VIDEO PLAYER

Chassis: DP9 (MD)

Manual Series: ZDA-311

Manual Part #: 3829RHN004T

Model Line: D

Product Year: 2005

Summary 1

Cabinet & Main Chassis 2

Electrical 3

Parts List 4

Model Series:

CONTENTS

ZDA-311

....................................................

.............................

....................................................

....................................................

Printed in U.S.A

Copyright © 2005 by Zenith Electronics Corporation

Published March 2005

by Technical Publications

Zenith Electronics Corporation

201 James Record Road

Huntsville, Alabama 35824-1513

Page 2

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ............. 1-3

SERVICING PRECAUTIONS .................................................................................................. 1-4

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS ...................................................................................................................... 1-5

1-2

Page 4

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

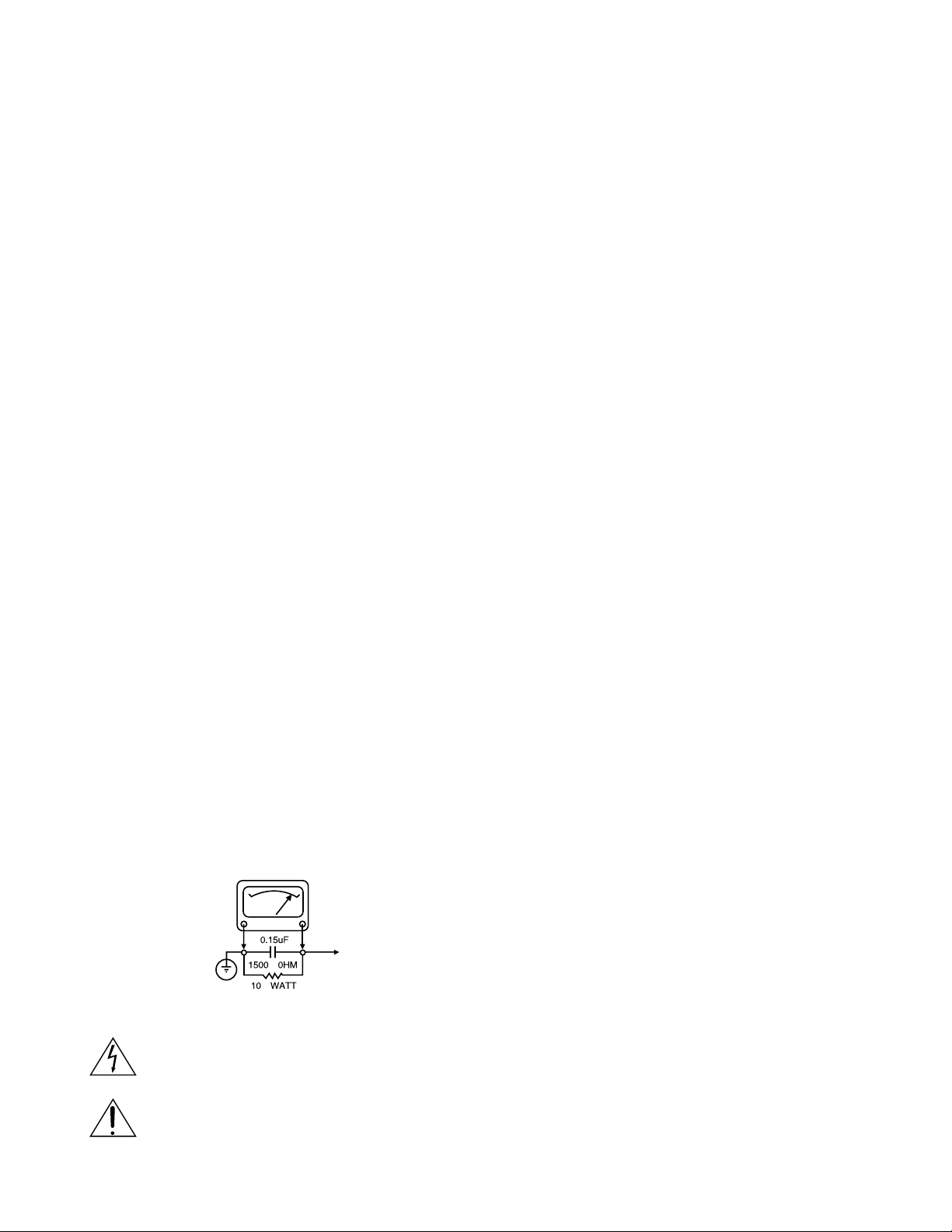

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 5

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this DVD or any of

its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this DVD and/or any of its

electrical assemblies unless all solid-state device heat

sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 6

1-5

SPECIFICATIONS

• GENERAL

Power requirements: AC 120 V , 60 Hz

Power consumption: 8W

Dimensions (Approx.): 360 x 35 x 242 mm (W x H x D) without foot

Weight (Approx.): 1.7 kg

Operating temperature: 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity: 5 % to 90 %

• OUTPUTS

VIDEO OUT: 1 Vp-p 75 Ω, sync negative, RCA jack x 1

COMPONENT VIDEO OUT: (Y) 1.0 V (p-p), 75 Ω,negative sync, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

AUDIO OUT: 2.0 Vrms (1 KHz, 0 dB), 600 Ω, RCA jack (L, R) x 1

DIGITAL OUT (COAXIAL): 0.5 V (p-p), 75 Ω, RCA jack x 1

• SYSTEM

Laser: Semiconductor laser, wavelength 650 nm

Signal system: PAL / NTSC

Frequency response: DVD (PCM 96 kHz): 8 Hz to 44 kHz

DVD (PCM 48 kHz): 8 Hz to 22 kHz

CD: 8 Hz to 20 kHz

Signal-to-noise ratio: More than 100 dB (ANALOG OUT connectors only)

Harmonic distortion: Less than 0.02%

Dynamic range: More than 95 dB (DVD/CD)

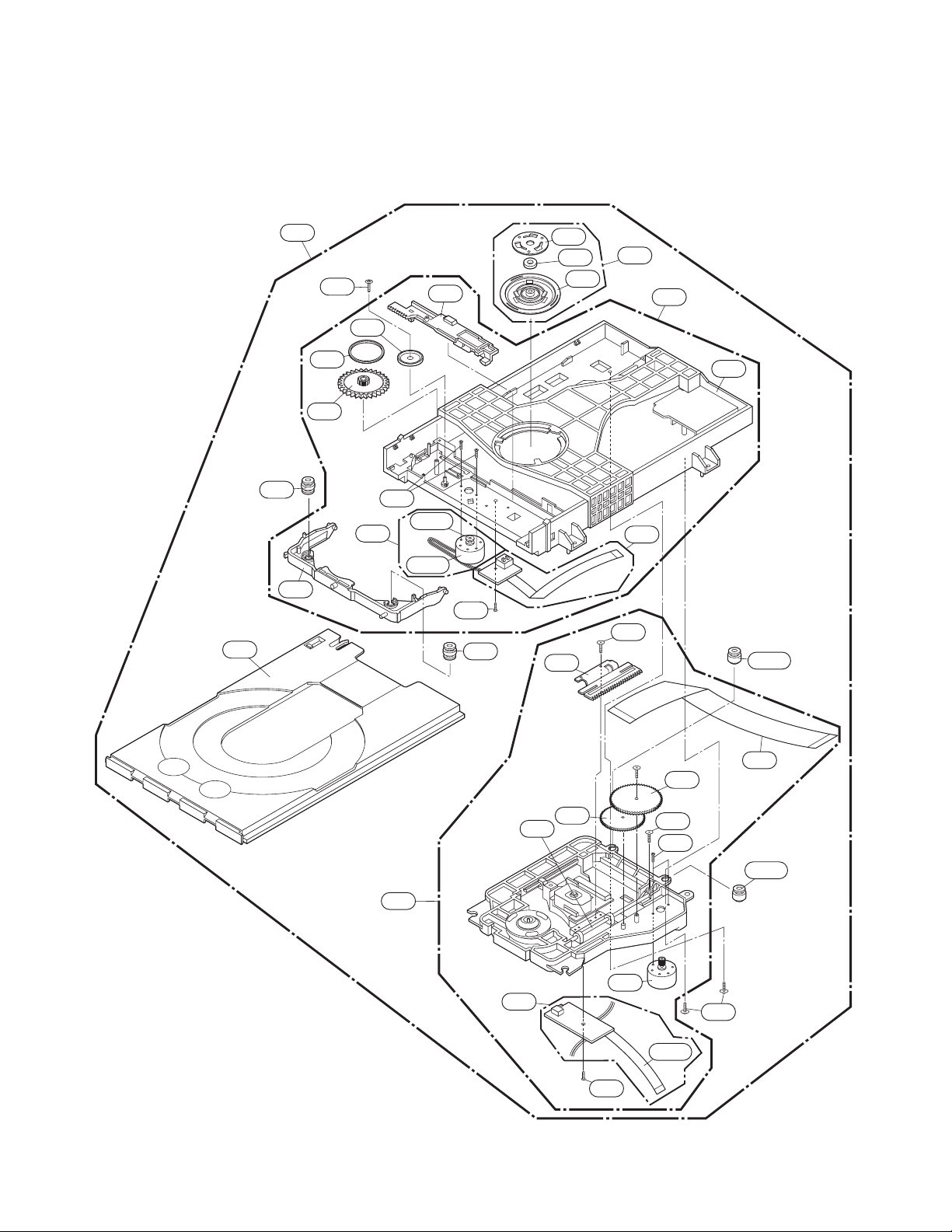

Page 7

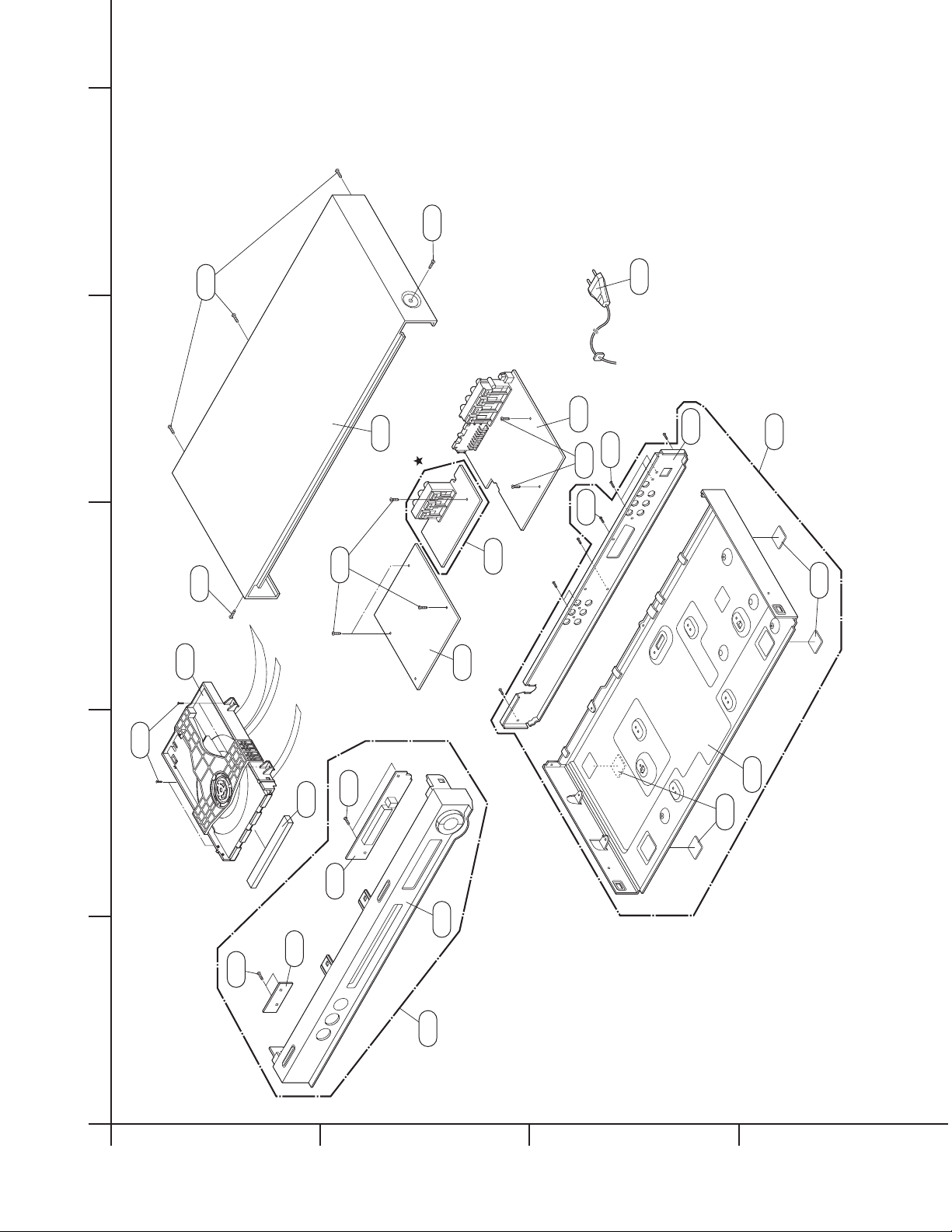

2-1

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

1. Cabinet and Main Frame Section ...........................................................................................2-2

2. Deck Mechanism Section(DP-9) .............................................................................................2-3

3. Packing Accessory Section ....................................................................................................2-4

Page 8

2-2

EXPLODED VIEWS

1. Cabinet and Main Frame Section

A

5

4

3

2

1

BCD

463

463

300

463

463

250

5.1CH Model

A46

ONLY

A48

463

467

465

320

A44

261

A00

A47

463

452

452

283

A49

280

A42

260

261

A43

Page 9

2. Deck Mechanism Section(DP-9)

2-3

026

012

A00

019

013

017

439

014

015

435

015B

015A

018

440

012

001

030

002

003

A01

A02

020

016

432

012A

A03

035

036

025

010

024

431

435

012A

021

430

035A

438

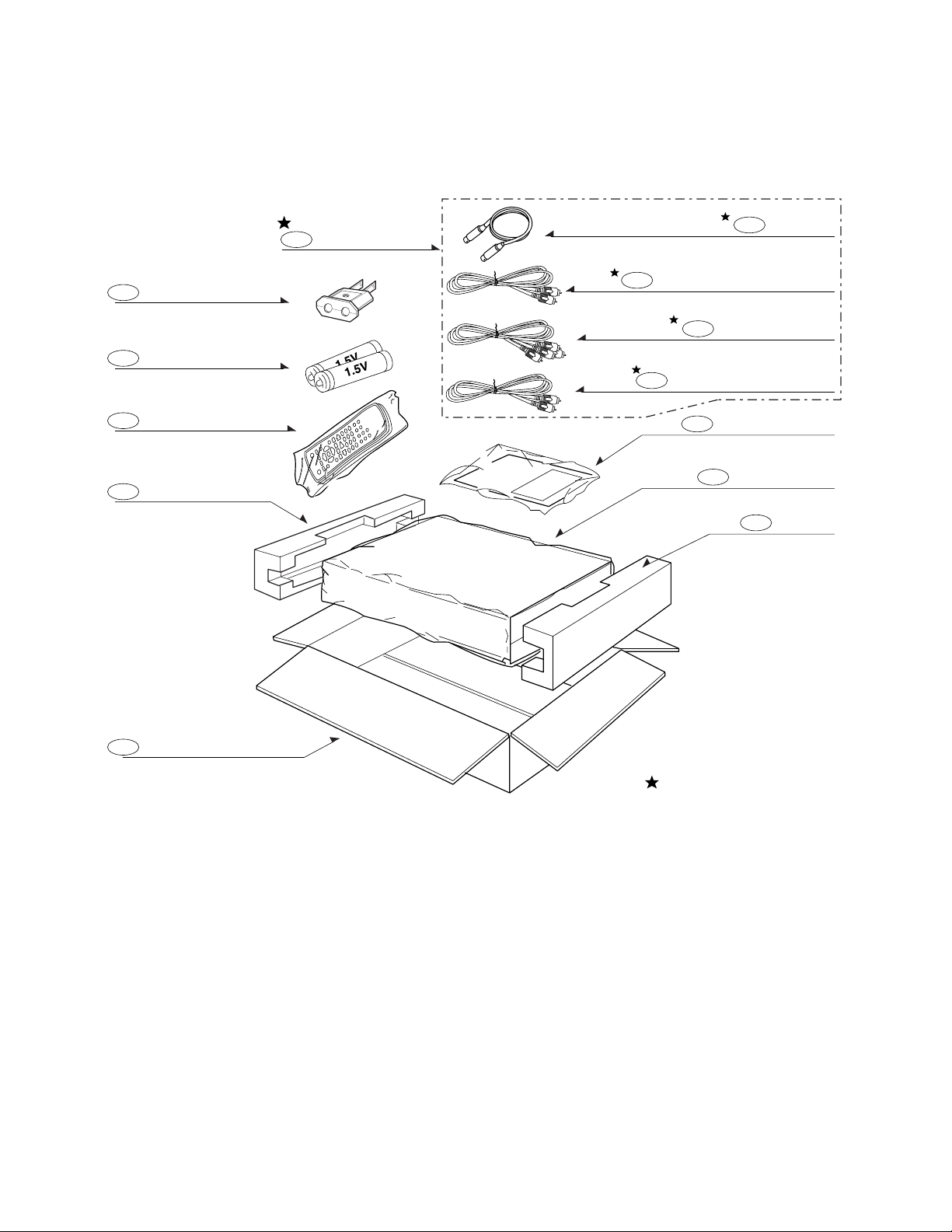

Page 10

2-4

3. Packing Accessory Section

BATTERY

808

AC ADAPTOR

823

PACKING SHEET

804

PACKING

OPTIONAL PARTS

803

806

820

OWNER’S MANUAL

RF CABLE

810

CABLE SET ASS’Y

801

REMOCON

900

BOX CARTON

802

PACKING

803

811

812

PLUG ASS’Y 1WAY(YELLOW)

PLUG ASS’Y 1WAY(BLACK)

PLUG ASS’Y 2WAY

Page 11

3-1

SECTION 3

ELECTRICAL

CONTENTS

ELECTRICAL TROUBLESHOOTING GUIDE......................................................................3-2

1. Power check flow.....................................................................................................................3-2

2. System operation flow ............................................................................................................3-3

3. Test & debug flow ....................................................................................................................3-4

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING ....................3-10

1. SYSTEM 27MHz CLOCK, RESET, FLASH R/W SIGNAL. ....................................................3-10

2. SDRAM CLOCK ......................................................................................................................3-12

3. TRAY OPEN/CLOSE SIGNAL ................................................................................................3-12

4. SLED CONTROL RELATED SIGNAL(NO DISC CONDITION) .............................................3-13

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION) .............................................3-13

6. LASER POWER CONTROL RELATED SIGNAL(NO DISC CONDITION) ............................3-14

7. DISC TYPE JUDGEMENT WAVEFORM ................................................................................3-14

8. FOCUS ON WAVEFORM........................................................................................................3-16

9. SPINDLE CONTROL WAVEFORM(NO DISC CONDITION ...................................................3-17

10. TRACKING CONTROL RELATED SIGNAL(System checking).........................................3-18

11. MT1389D AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF) ..........................................3-19

12. MT1389D VIDEO OUTPUT WAVEFORM .............................................................................3-19

13. AUDIO OUTPUT FROM AUDIO DAC ..................................................................................3-20

BLOCK DIAGRAMS ..................................................................................................................3-21

1. Overall Block Diagram ..........................................................................................................3-21

2. Power(SMPS) Block Diagram ...............................................................................................3-22

3. SERVO Block Diagram ..........................................................................................................3-23

4. MPEG & MEMORY Block Diagram .......................................................................................3-24

5. VIDEO & AUDIO Block Diagram ...........................................................................................3-25

CIRCUIT DIAGRAMS ................................................................................................................3-26

1. Power(SMPS) Circuit DIAGRAM...........................................................................................3-26

2. AV/JACK Circuit DIAGRAM...................................................................................................3-28

3. SYSTEM Circuit DIAGRAM ...................................................................................................3-30

4. DRIVER Circuit DIAGRAM.....................................................................................................3-32

5. TIMER Circuit DIAGRAM .......................................................................................................3-34

• CIRCUIT VOLTAGE CHART ....................................................................................................3-36

PRINTED CIRCUIT DIAGRAMS ............................................................................................3-38

1. MAIN P.C.BOARD ...................................................................................................................3-38

2. KEY P.C.BOARD .....................................................................................................................3-40

3. TIMER P.C.BOARD .................................................................................................................3-41

4. SMPS P.C.BOARD ..................................................................................................................3-42

Page 12

ELECTRICAL TROUBLESHOOTING GUIDE

1. Power check flow

A. B.

No 5V

No 3.4VA.

Is 3.4VA section working?

YES

Is 5.6V present at collector

of Q126?

YES

Replace Q126.

NO

No 3.4VA

Check FR101

Is there a DC voltage at

Cathode of D105 or D107?

YES

Replace IC101.

NO

Is 3.4VA section working?

YES

NO

Is 3.4V present at emitter

of Q121?

YES

Replace Q121.

YES

NO

Check D105/D106/D107/

D108 and replace.

3-2

Page 13

3-3

2. System operation flow

NO

NO

NO

YES

YES

YES

YES

YES

Power On

1. 8032 initializes SERVO,DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

Tray Closed ?

Tray Close to Closed position

SLED at Inner Side ?

SLED Moves to Inner Position

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Recieve OPEN/CLOSE Key?

1. Execute Pressed Key & IR Key

2. System operation Routine Loop

1. Stop Playback & Open Tray

2. Display tray open message & LOGO

Receive CLOSE Key?

Page 14

3. Test & debug flow

TEST

Check the AC Voltage

Power PCBA(110V or 220V)

YES

Switch on the Power PCBA

YES

Are the DC Voltage outputs OK?

(5V, 3.3V, 12V, 5.6V MOTOR)

YES

Make sure the main PCBA don't short on

VCCs and switch it on.

YES

Are 3.3V and 1.8V DC outputs normal on

main PCBA?

NO

Replace power PCBA or AC transformer.

NO

Repair or Replace Power PCBA

NO

Check the regulators or related diodes.

YES

Connect to PC RS232 Cable and update

the FLASH memory code.

YES

Update FLASH successfully?

YES

A

NO

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal

PRD,RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

3-4

Page 15

3-5

A

Flash Memory operates

properly?

Show LOGO?

Does Tray move inside when

it is not at closed position?

B

NO

NO

YES YES

YES

YES

YES

YES

YES

YES

YES

Check connection lines between

FLASH & MT1389D and the FLASH

access time whether is suitable or not.

NO

SDRAM works properly?

Check connection lines

between SDRAM & MT1389D

and the SDRAM is damaged.

NO

MT1389D VIDEO outputs

properly?

Check the related circuit of

MT1389D.

NO

Have TV signal output?

Check AV cable connection

to TV set.

Normal TROUT &TRIN

signals?

Check the filtering and amp

circuit of TV signal.

NO

Check the load OPEN &

CLOSE switch

NO

Normal TRCLOSE &

TROPEN signal?

Check the Tray control IO

pins on MT1389D & IP9008.

NO

Normal LOAD+ & LOADsignal?

Check the cable connection

between main PCBA and

loader.

Check the Tray control

amplifying circuit on Motor

driver.

NO

Page 16

3-6

B

Does the SLED move to

inner side when it is at outer

position?

YES

Do not put in disc and tray

close.

Optical Lens has movement

for searching Focus?

NO

NO

Motor Driver STBY Pin is

High?

YES

Is FMSO DC Level higher

than 1.4V?

YES

SL+ and SL- output

properly?

YES

Check the cable connection

with MECHA.

Proper FOSO outputs

to motor driver?

NO

NO

NO

NO

Check the connection line of

STBY signal.

Check the related circuit of

FMSO.

Check the amp circuit on

motor driver.

Check FOSO connection on

MT1389D and motor dirver.

C

YES

YES

Proper F+ & F- outputs?

YES

Check cable connect on with

pick-up head.

NO

Check the amp circuit on

motor dirver.

Page 17

3-7

C

LD01 or LD02 output

properly?

Laser turns on when

reading disc?

Put disc in?

Disc ID is correct?

Does spindle rotate?

D

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Check the laser power circuit

on MT1389D and connecting

to power transistor.

NO

Collector voltage of

power transistor is OK?

Check the related circuit on

laser power transistor

NO

Check cable connection

between transistor ouput

and pick-up head.

YES

YES

YES

Check the related circuit on

MT1389D RFL signal.

Check DMSO related

circuit on MT1389D.

NO

NO

Check the spindle control

amp circuit of motor driver.

NO

Laser off

Proper RFL signal on

MT1389D?

Check LDO1 & LDO2 signal

Proper DMSO signal on

MT1389D

SP+ & SP- output properly?

Check the cable connection

between spindle and main

PCBA.

Page 18

3-8

D

Proper signals on A, B, C,

D of MT1389D

Focus ON OK?

Track On OK?

Disc is play ?

E

NO

NO

NO

YES

YES

YES

YES

YES

Check connections between

MT1389D and pick-up head.

NO

Check FEO signal on

MT1389D

YES

Check the FOSO connection on MT1389D and

motor driver.

NO

Check FOSO signal on

MT1389D

YES

YES

Check the TRSO

connection on MT1389D

and motor dirver.

NO

Check the tracking control

amp circuit on motor driver.

NO

Normal TEO Signal on

MT1389D?

NO

Check the related

circuit on MT1389D

Properly TRSO signal on

MT1389D?

T+ & T- output properly?

Check cable connection on

pick-up head.

Check RFO & RFLVL signal

waveform.

Page 19

3-9

E

TEST END

Normal Audio output

when disc playback?

YES

Normal IR.VFD & Front

key functions?

panel

YES

NO

NO

Audio DAC received

correct data stream?

YES

Normal Audio DAC out?

YES

Check Audio

filter,amplify,mute

circuit.

Communications between

IR.VFD Front panel key &

MT1389D is normally?

YES

Check the cable connection

on Front panel.

NO

NO

NO

Check connection between

MT1389D & Audio DAC.

Check the related circuit of

Audio DAC.

Check communication lines

on MT1389D.

Page 20

3-10

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHz CLOCK, RESET, FLASH R/W SIGNAL.

1) MT1389D main clock is at 27MHz(X501)

FIG 1-1

1.0V, 27MHz

2) MT1389D reset is low active.

FIG 1-2

Reset Time

3.3VA

PWR_CTL

RESET

Page 21

3-11

3) RS232 waveform during procedure(Downloading)

FIG 1-3

TXD

RXD

4) Flash R/W enable signal during download(Downloading)

FIG 1-4

PRD

PWR

Page 22

3-12

2. SDRAM CLOCK

FIG 2-1

3. TRAY OPEN/CLOSE SIGNAL

FIG 3-1

DCLK = 128MHz, Vp-p=2.2, Vmax=2.7V

TRIN

TROUT

TRCLOSE

TROPEN

Page 23

3-13

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

FIG 4-1

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 5-1

FOSO(1.5V/1.4V/1.3V)

F+(3.2V/2.7V/2.2V)

F-(3.2V/2.7V/2.2V)

FMSO(1.9V/1.4V/1.1V)

STBY(3.3V)

SL+(4.2V/2.8V/1.2V)

SL-(4.2V/2.8V/1.5V)

Page 24

3-14

6. LASER POWER CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 6-1

7. DISC TYPE JUDGEMENT WAVEFORM

FIG 7-1(DVD)

DCLK = 128MHz, Vp-p=2.2, Vmax=2.7V

F+

FE

RFL

MDI1(0V/180mV)

LD01(3.3V//2.3V)

LD02(3.3V/2.3V)

Page 25

3-15

FIG 7-2 (DVD)

FIG 7-3 (CD)

F+

F+

FE

FE

RFL

RFL

Page 26

3-16

FIG 7-4 (CD)

8. FOCUS ON WAVEFORM

FIG 8-1 (DVD)

FE

FOSO

F+

F-

F+

FE

RFL

Page 27

3-17

FIG 8-2 (CD)

9) SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

FIG 9-1

FOSO

F+

DMSO(1.4V/1.8V)

SP-(3.6V/2.4V)

SP+(3.6V/4.8V)

FE

F-

Page 28

3-18

10. TRACKING CONTROL RELATED SIGNAL(System checking)

FIG 10-1 (DVD)

FIG 10-2 (CD)

TE

TRSO

T+

T-

TE

TRSO

T+

T-

Page 29

3-19

11. MT1389D AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF)

FIG 11-1

12. MT1389D VIDEO OUTPUT WAVEFORM

1) 100%

FIG 12-1

TE

TRSO

T+

T-

Page 30

3-20

2) COMPOSITE VIDEO SIGNAL

FIG 13-2

13. AUDIO OUTPUT FROM AUDIO DAC

FIG 13-1

Page 31

3-21

BLOCK DIAGRAMS

1. Overall Block Diagram

L/R

MIC

DAC_RST

RS232_TXD/MIC_DECT

3V3M/5V

IC301

(6DAC)

CS4360

SER[0:2],DAC_ML1

IC504

AT24C02A

VD33D

IIC/VFD/DAC_TXD

IIC/VFD/DAC_SCK

RS232_RXD

RS232

CN503

MD[00:15]

1M

IC503

VD33D

MA[00:11]

DMCLK

CSJ

BA0

BA1

DQM

WEJ

CASJ

16BIT

SDRAM

RASJ

AMP

IC601

EEPROM

R

L

IC501

CENTER

WOOFER

RL

RR

FL

FR

L/R

IECDAOUT

YC_MIX

27MHz

D2_T[1:3]

SCART_16:9

RGB_SEL

DMUTE

TV_DAC[0:3]

+12V

+12V

IC30[2,3.4]

IR

IC801

BA3308

CENTER

WOOFER

RL

RR

KA5532

OP-AMP

FL

FR

COAXIALSPDI

Y

C

B/Pb

R/PrG/Y

VIDEO BUFFER

CVBS

R/C

RC901

JACK

MTK 1389D

V33A

DISC

IC502

ROMDATA[0:7]

ROMWR

ROMRD

19]

PICK_SEL, VR_CD,VR_DVDIOA

LD01,LD01,V20

ROMAD[0:

VD18A/VD33A

OPU_SEL

LIMIT

TRIN TROUT

OP+,OP-

T[+,-]

F[+,-]

SPE[+,-]

VD18A

STBY

TROPEN ,TRCLOSE,FOSO,TRSO,FMSO,DMSO

1M

8BIT

FLASH ROM

MX29LV800T/B

DVD : A,B,C,D,RF0

CD : A,B,C,D,E,F,RF0

MDI1

UP

PICK

RXD

POWCTL H

M

SL[+,-]

LOAD[+,-]

IC201

IP9008

5.6VA

MOTOR

SPINDLE

SLED

MOTOR

(FEEDING)

MOTOR

LOADING

M

M

IC901

5V

LED DRIVER

LED

DIG901

5V

12V

3.3V

BOARD

POWER

50HZ/60Hz

AC 90V~240V

KEY Input

5.6VA

3.3VA

Page 32

3-22

2. Power(SMPS) Block Diagram

LPF

12V

5V

LPF

WITH

T/ W

5.6V(M)

/ 5.6VA

1389D

WITH 1389C

REG.

8V

LPF

3.2V

3.4VA

PWR CTL

RECTIFIER(14V)

RECTIFIER(5.6V)

TRANS

SWITCHING IC

FILTER

RECTIFIER(9.5V)

RECTIFIER

RECTIFIER(3.4V)

FEED B.

AC100~240V

Page 33

3-23

3. SERVO Block Diagram

FLASH

AD[0:7]

A[0:20]

X501

27MHz

X-TAL

ROM

PRD#, PWR#

PCE#

IC501

MT1389D

EEP

ROM

SCL, SDA

DVDPLAYER

RS232C(MTK)

RXD, TXD

ONE CHIP

MA[0:11]

DQM0 ,DQM1

WE#,CAS#,RAS#

CS#,BA0,BA1

SDCLK

SDCKE

IC503

SDRAM

DQ[0:15]

1M x 16bit

TRCLOSE

ADIN

IC201

IP9008

FOSO,TRSO,FMSO

STBY,V1P4

DMSO,,TROPEN

Motor Driver

ALPC

MDI 1

LD0 1, LDO 2, IOA

V20, PICKSEL

DVD: A,B,C,D, RFO

UP

PICK

CD: A,B,C,D, E, F,RFO

LIMIT,TRIN,TROUT

F+, F-, T+, T-

SP+, SP-

LOAD+, LOAD-

SL+, SL-

M/D

Page 34

3-24

4. MPEG & MEMORY Block Diagram

VIDEO

Interface

IC506

EEPROM

Y2(Y),Y3(Color)

Y4(Y),Y5(Cb),Y6(Cr)

ASPECT(16:9)

SCL,SDA

AUDIO

Interface

AL,AR

AMUTE,DMUTE

ASPDIF

AD[0:7]

A[0:20]

PWR,PCE,PRD

IC502

(8 M )

FLASH MEMORY

IC503

SDRAM

16M

IC508

IC509

A/D Con.

(Karaoke)

OP Amp

CS,DCKE,MA[0:10]

DCLK,WE,CAS,RAS

DQ[0:15]

DQM0,DQM1

MT1389C

IC501 (MPEG + DSP + RF)

AMDAT

ALRCK

ACLK,ABCK

RESET

IC505

RESET IC

X501

27MHz

DOUT

DIN

LED DRIVE IC

BOARD

KARAOKE

Page 35

3-25

5. VIDEO & AUDIO Block Diagram

A/V

JACK

CVBS

COMPONENT (R.G.B) / (Y.Pb.Pr )

SUPER VIDEO (Y/C)

AUDIO 'R'

AUDIO 'L'

IC601 (OP Amp)

LPF&Buffer

REAR 'R'

FRONT 'R'

IC302 (OP Amp)

LPF&Buffer

5.1CH BOARD

REAR 'L'

FRONT 'L'

IC303 (OP Amp)

LPF&Buffer

CENTER

WOOFER

IC304 (OP Amp)

LPF&Buffer

Amp

IC604

VIDEO 6dB

(R.G.B) / (Y.Pb.Pr )

MPEG

(Y/C)

AL

AR

MPEG

DAC RESET

IC301

AUDIO DAC

SCL

ACLK

(5.1CH)

SDA

MPEG

ADATA2

ADATA1

ADATA3

Page 36

Loading...

Loading...