Page 1

SERVICE MANUAL

Product Type: PLASMA

Chassis: PA-63E

Manual Series:

Manual Part #: 38289S0065E

Model Line:

Product Year: 2007

Z50P3

Model Series:

CONTENTS

Description of Controls .................................................4

Specifications ..............................................................8

Adjustment Instructions ................................................9

Diagrams ...................................................................13

Parts List ...................................................................17

Schematics....................................................................

Published Oct. 2003

by Technical Publications

LG Electronics USA, Inc.

201 James Record Road,

Huntsville, Alabama 35824-1513

Copyright © 2003 by Zenith Electronics Corporation

Printed in Korea

http//www.zenithservice.com

Page 2

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the same specified type.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

SPECIFICATIONS.................................................................4

ADJUSTMENT INSTRUCTIONS ..........................................5

PRINTED CIRCUIT BOARDS.............................................12

BLOCK DIAGRAM...............................................................15

EXPLODED VIEW...............................................................16

EXPLODED VIEW PARTS LIST .........................................17

REPLACEMENT PARTS LIST............................................18

SCHEMATIC DIAGRAM..........................................................

TABLE OF CONTENTS

Page 4

- 4 -

AC100-240V ~ 50/60Hz

NTSC-M, ATSC, 64 & 256 QAM

VHF 2 ~ 13, UHF 14 ~ 69,

CATV 1 ~ 135, CADTV 1 ~ 135, DTV 2 ~ 69

75 Ω

32 ~ 104°F (0 ~ 40°C)

Less than 80%

-4 ~ 140°F (-20 ~ 60°C)

Less than 85%

Z50P3

(50PC3DB-UE)

51.3 x 34.3 x 14.0 inches

1302.6 x 872.0 x 355.8 mm

51.3 x 31.9 x 4.2 inches

1302.6 x 810.0 x 107.7 mm

114.4 pounds / 51.9 kg

95.0 pounds / 43.1 kg

Dimensions

(Width x Height x Depth)

Weight

with stand

without stand

with stand

without stand

Power requirement

Television System

Program Coverage

External Antenna Impedance

Operating Temperature

Operating Humidity

Storage Temperature

Storage Humidity

Environmental

condition

• The specifications shown above may be changed without prior notice for quality improvement.

SPECIFICATIONS

Page 5

- 5 -

ADJUSTMENT INSTRUCTIONS

1. Application Object

These instructions are applied to all of the PDP TV, PA63E.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 110V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

O Preliminary action is applied to the test for afterimage

discharge detection, and 100% FULL WHITE PATTERN

must be operated automatically.

O Test for afterimage discharge detection

1) After pressing Power Only key(only operating by

pressing Power Only key), Full Test Pattern(2 min

30sec) --> Full Black Pattern(30sec) --> After this state,

Full White Pattern is displayed.

(but you must preset the program for Full White State

when you press the Main Power Off/On)

2) Pattern Mode is deselected by pressing CH +/-, Exit Key.

[ Set is activated HEAT-RUN without signal generator in this

mode.

3. MICOM Download(Option)

3-1. Required Test Equipment

(1) JIG-LEVER TYPE for adjusting: 1EA

(2) PC & MONITOR: 2EA

(3) BOARD for INTERFACE: IIC & ISP BOARD: 2EA

(4) 15P D-SUB CABLE: 2EA

(5) Using the 12/15 line of D-SUB 15P

12-SDA/15-SCL

3-2. JIG Connection

3-3. Establishment Program

(1) Establish LGE Monitor Tools v1.1

(2) The program work and it is opened program window as

seen below.

Test Pattern 2min 30sec

Test Pattern 30sec

If you turn on a still screen more than 20 minutes (Especially

Digital pattern(13 CH), Cross Hatch Pattern), an afterimage

may occur in the black level part of the screen.

connection

to PC

connection

to PC

Page 6

- 6 -

ADJUSTMENT INSTRUCTIONS

(3) Click the first icon shown in fig.9. The window seen in

fig.10 should appear.

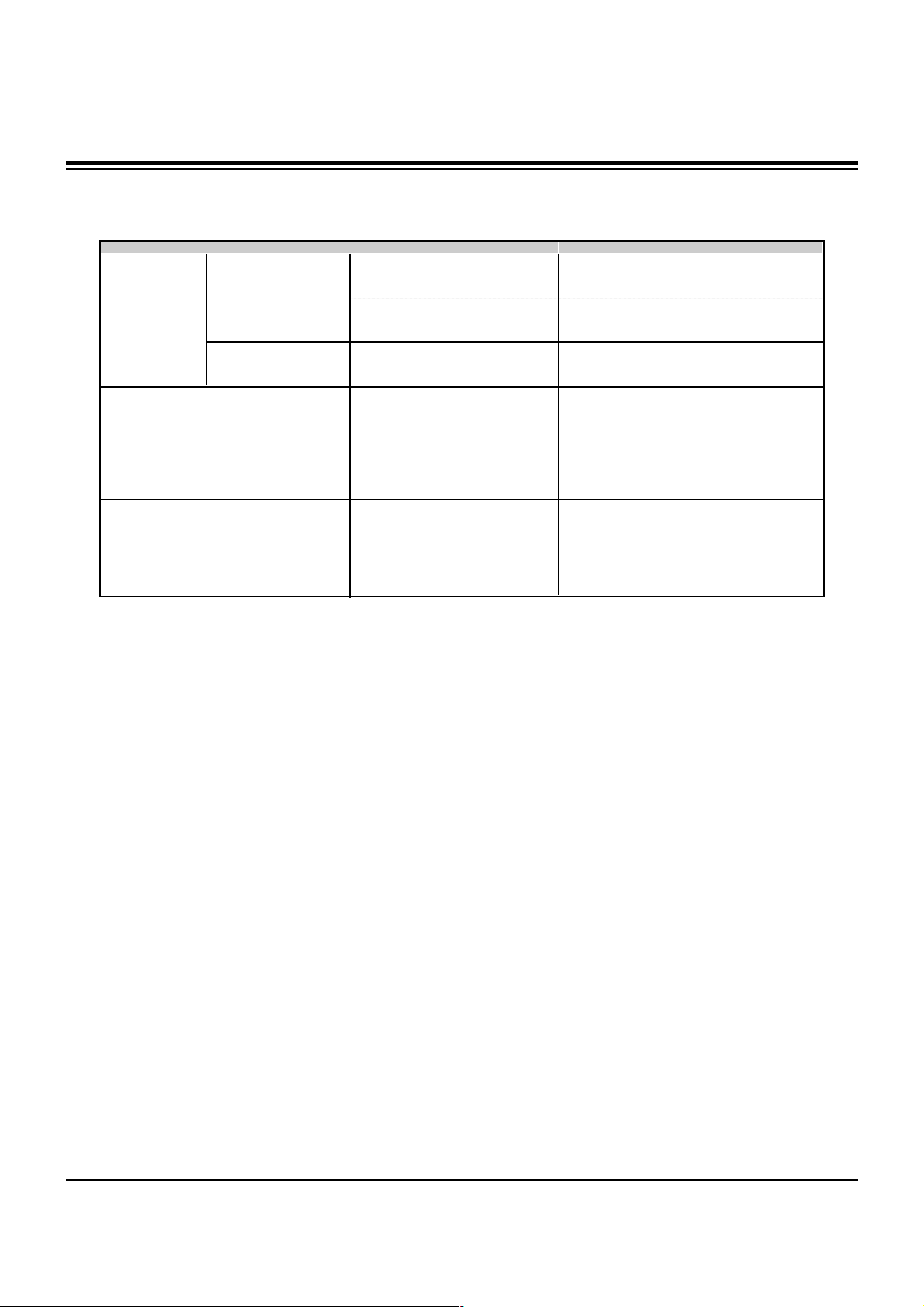

3-4. Set Method

(1) MCU Select: MTV512M64

(2) Option

R/W Option: Auto Write(Verity)

Jig Option: Myson

Transmit Speed: Medium

(3) Check: Just do it with blank micom.

(4) PORT

Chose Parallel Port (normal LPT1)

Attention: You must chose EPP when select Rom BIAS at

LPT

3-5. Download Method

(1) Click the Load File.

(2) Locate and select the correct file from your computer.

(*.hex).

(3) Click the Send.

(4) When you see (ISP COMPLETE) the download is

complete.

Page 7

- 7 -

ADJUSTMENT INSTRUCTIONS

4. ADC-Set Adjustment

4-1. Synopsis

ADC-Set adjustment to set the black level and the Gain to

optimum.

4-2. Test Equipment

Service R/C, 801GF(802V, 802F, 802R) or MSPG925FA

Pattern Generator

(480i/1080i The Horizontal 100% Color Bar Pattern adjust to

within 0.7±0.1Vp-p)

4-3. Adjustment

(1) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 480i Mode

(2) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘2. ADC 480i Comp1’.

Pressing the Enter Key to adjust automatically.

(3) When the adjustment is over, 'MST3361 Component

Success’ is displayed. If the adjustment has errors,

'MST3361 Configuration Error’ is displayed.

(4) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 1080i Mode.

(5) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘3. ADC 1080i Comp1/RGB’.

Pressing the Enter Key to adjust automatically.

(6) When the adjustment is over, 'MST3361 Component

Success’ is displayed. If the adjustment has errors,

'MST3361 Configuration Error’ is displayed.

(7) After the Component MST3361 adjustment is over, convert

the RGB-DTV Mode and display Pattern.

When the adjustment is over, 'MST3361 RGB_DTV

Success’ is displayed.

(8) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

(9) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

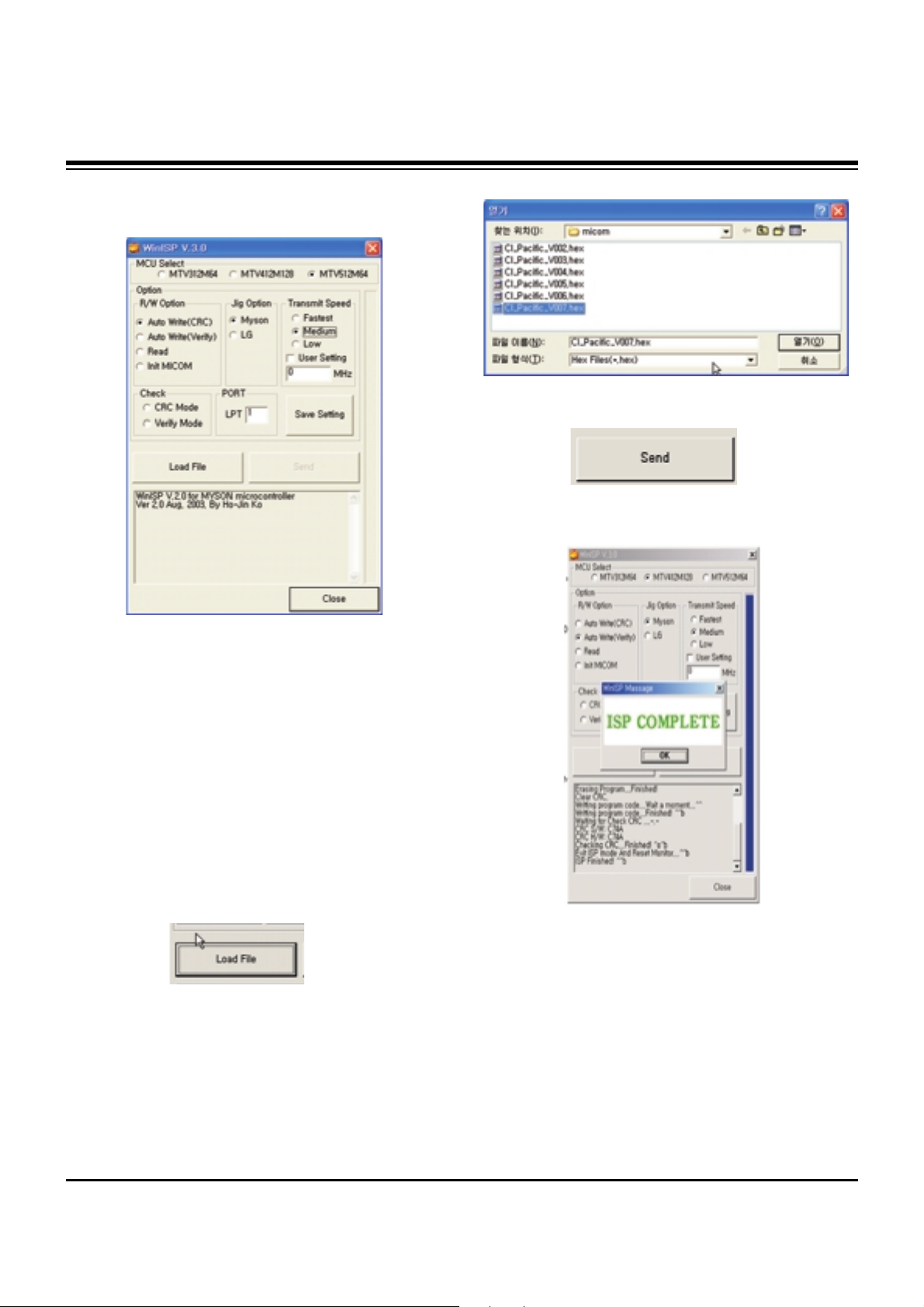

<Adjustment Mode>

<Adjustment Pattern: 480i/1080i 60Hz HozTV31Bar Pattern>

Page 8

- 8 -

ADJUSTMENT INSTRUCTIONS

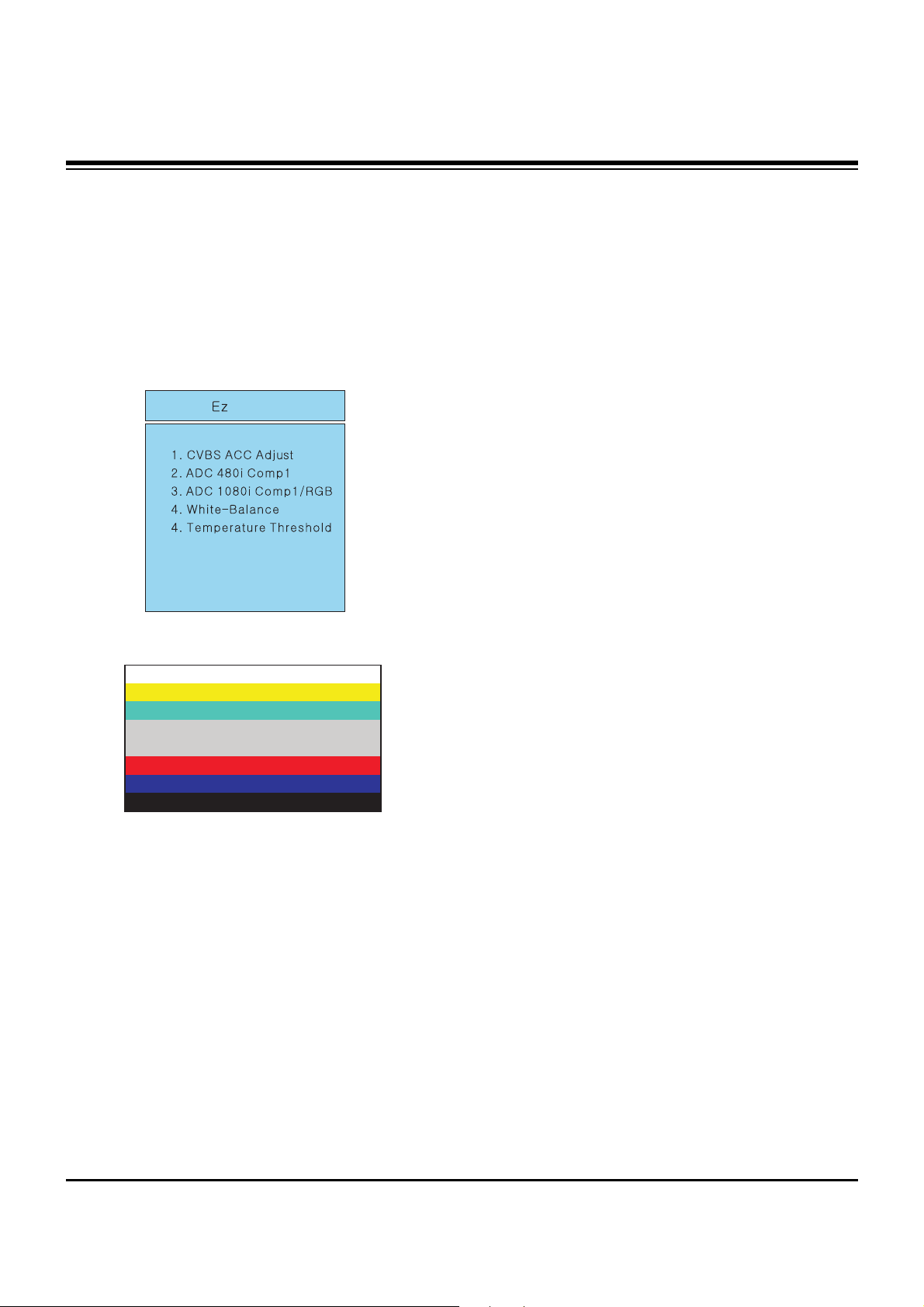

5. POWER PCB Assy Voltage

Adjustment

(Va, Vs Voltage Adjustment)

5-1. Test Equipment : D.M.M 1EA

5-2. Connection Diagram for Measuring

Refer to Fig 1.

5-3. Adjustment

(1) Va Adjustment

1) Connect + terminal of D.M.M to Va pin of P812(50”:

P805) and connect – terminal to GND pin of P812(50”:

P805).

2) Adjust VR901 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P812(50”:

P805) and connect – terminal to GND pin of P812(50”:

P805).

2) Adjust RV401 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

6. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

This is the function that enables “Plug and Play".

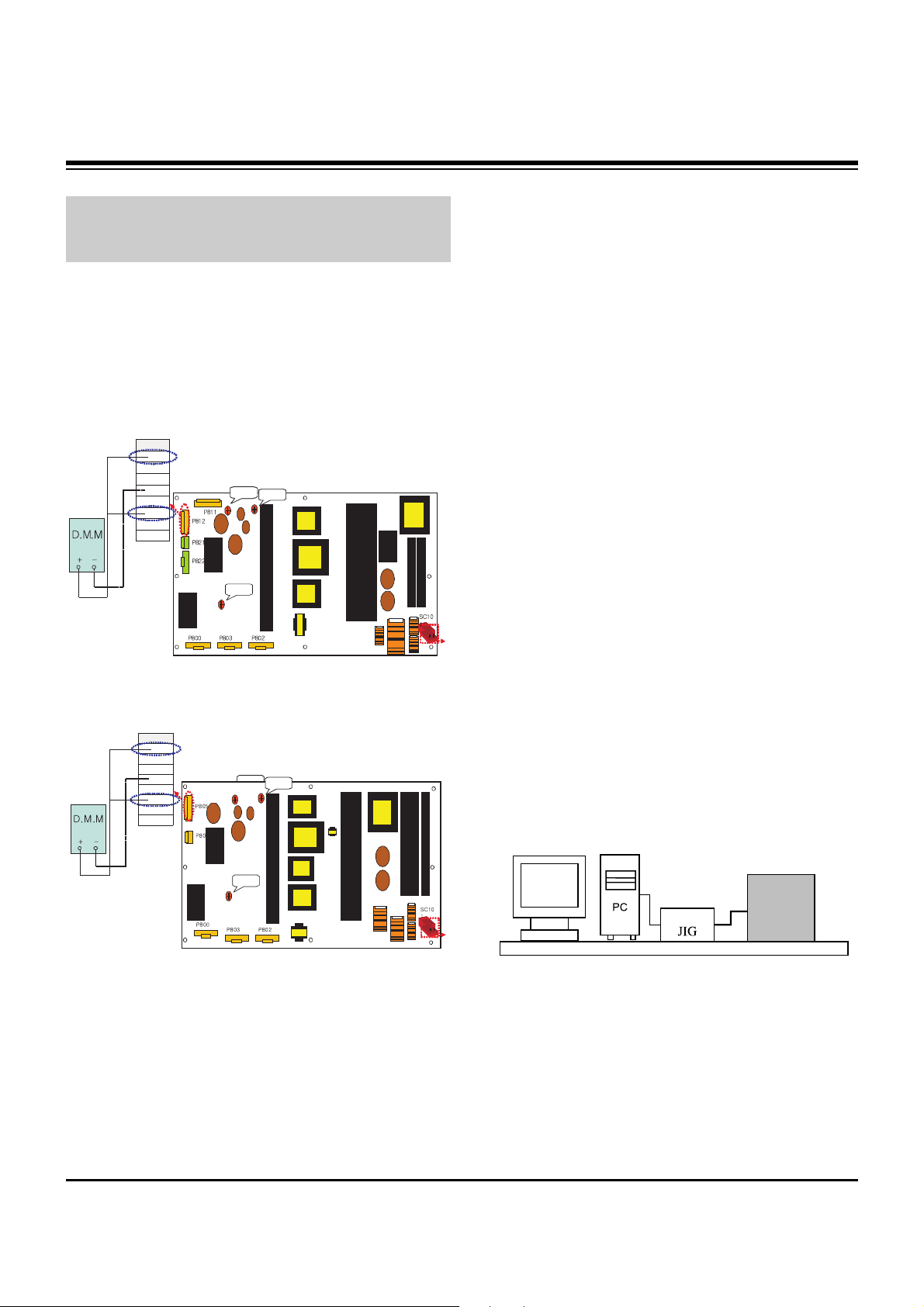

6-1. HDMI EDID Data Input

(1) Required Test Equipment

1) PC, Jig for adjusting DDC. (PC serial to D-sub

Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub cable

4) Jig for HDMI Cable connection

(2) Preparation for Adjustments &

Setting of Device

1) Set devices as below and turn on the PC and JIG.

2) Open S/W for writing DDC (EDID data write & read).

(operated in DOS mode)

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

111

VsAD J

VR951

VaADJ

VR901

3.3VADJ

VR22 1

T8

01

T9

01

T1

12

T5

01

L6

01

5V

GND

Va

GND

GND

NC

Vs

Vs

P811

111

VsAD J

VR951

VsAD J

VR951

VaADJ

VR901

VaADJ

VR901

3.3VADJ

VR22 1

T8

01

T9

01

T1

12

T5

01

L6

01

5V

GND

Va

GND

GND

NC

Vs

Vs

P811

<Fig. 1-1> Connection Diagram of Power Adjustment for

Measuring (Power Board): 42” XGA

VsADJ

VR951

5V

GND

Va

GND

GND

NC

Vs

Vs

P811

111

VaADJ

VR901

3.3VADJ

VR221

T8

01

T9

01

L8

51

T5

01

T1

12

L6

01

VsADJ

VR951

5V

GND

Va

GND

GND

NC

Vs

Vs

P811

111

VaADJ

VR901

VaADJ

VR901

3.3VADJ

VR221

T8

01

T9

01

L8

51

T5

01

T1

12

L6

01

<Fig. 1-2> Connection Diagram of Power Adjustment for

Measuring (Power Board): 50”

LCD TV SET

(or Digital Board)

<Fig. 2>

Page 9

- 9 -

ADJUSTMENT INSTRUCTIONS

6-2. EDID DATA for PA-63E

[42PX3D-UE: Z42PX3D]

: EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 80 5C 34 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 C4 8E 21 00 00 1E 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 00 00 00 FD 00 38

60 | 4B 1F 3C 09 00 0A 20 20 20 20 02 20 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 43 0A 20 01 5F

EDID Block 1 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 02 03 13 F1 44 84 05 03 02 23 15 07 50 65 03 0C

10 | 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28 55 00 C4

20 | 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20 58 2C 25

30 | 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0 2D 10 10

40 | 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D

50 | 10 10 3E 96 00 13 8E 21 00 00 18 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ED

: EDID for RGB-PC

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 68 5C 34 96 0A CF 30 A3 57 4C B0 23

20 | 09 50 4E A1 08 00 01 01 01 01 01 01 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 98 07 32 00 00 18 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 66 21 50 B0 51 00

60 | 1B 30 40 70 36 00 C4 8E 21 00 00 1E 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 20 20 20 00 21

[50PC3D-UE]

: EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 80 5C 34 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 C4 8E 21 00 00 1E 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 00 00 00 FD 00 38

60 | 4B 1F 3C 09 00 0A 20 20 20 20 02 20 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 43 0A 20 01 5F

EDID Block 1 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 02 03 13 F1 44 84 05 03 02 23 15 07 50 65 03 0C

10 | 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28 55 00 C4

20 | 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20 58 2C 25

30 | 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0 2D 10 10

40 | 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D

50 | 10 10 3E 96 00 13 8E 21 00 00 18 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ED

: EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 80 5C 34 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 98 07 32 00 00 18 01 1D 80 18 71 1C 16 20

50 | 58 2C 25 00 C4 8E 21 00 00 9E 00 00 00 FC 00 34

60 | 32 50 58 33 44 2D 55 45 0A 43 0A 20 00 00 00 FD

70 | 00 38 4B 1F 3C 09 00 0A 20 20 20 20 20 20 01 67

EDID Block 1 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 02 03 13 F1 44 84 05 03 02 23 15 07 50 65 03 0C

10 | 00 20 00 8C 0A D0 8A 20 E0 2D 10 10 3E 96 00 C4

20 | 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D 10 10 3E 96

30 | 00 13 8E 21 00 00 18 00 00 00 00 00 00 00 00 00

40 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 7B

: EDID for RGB-PC

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 68 5C 34 96 0A CF 30 A3 57 4C B0 23

20 | 09 50 4E A1 08 00 01 01 01 01 01 01 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 98 07 32 00 00 18 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 66 21 50 B0 51 00

60 | 1B 30 40 70 36 00 C4 8E 21 00 00 1E 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 20 20 20 00 21

Page 10

- 10 -

ADJUSTMENT INSTRUCTIONS

[60PC1D-UE]

: EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 80 5C 34 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 C4 8E 21 00 00 1E 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 00 00 00 FD 00 38

60 | 4B 1F 3C 09 00 0A 20 20 20 20 02 20 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 43 0A 20 01 5F

EDID Block 1 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 02 03 13 F1 44 84 05 03 02 23 15 07 50 65 03 0C

10 | 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28 55 00 C4

20 | 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20 58 2C 25

30 | 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0 2D 10 10

40 | 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D

50 | 10 10 3E 96 00 13 8E 21 00 00 18 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ED

: EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 80 5C 34 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C 2F CE 00 31 40 45 40 61 40 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 98 07 32 00 00 18 01 1D 80 18 71 1C 16 20

50 | 58 2C 25 00 C4 8E 21 00 00 9E 00 00 00 FC 00 34

60 | 32 50 58 33 44 2D 55 45 0A 43 0A 20 00 00 00 FD

70 | 00 38 4B 1F 3C 09 00 0A 20 20 20 20 20 20 01 67

EDID Block 1 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 02 03 13 F1 44 84 05 03 02 23 15 07 50 65 03 0C

10 | 00 20 00 8C 0A D0 8A 20 E0 2D 10 10 3E 96 00 C4

20 | 8E 21 00 00 18 8C 0A D0 8A 20 E0 2D 10 10 3E 96

30 | 00 13 8E 21 00 00 18 00 00 00 00 00 00 00 00 00

40 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 7B

: EDID for RGB-PC

EDID Block 0 table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

___________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 10 01 03 68 5C 34 96 0A CF 30 A3 57 4C B0 23

20 | 09 50 4E A1 08 00 01 01 01 01 01 01 01 01 01 01

30 | 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

40 | 36 00 98 07 32 00 00 18 0E 1F 00 80 51 00 1E 30

50 | 40 80 37 00 C4 8E 21 00 00 1C 66 21 50 B0 51 00

60 | 1B 30 40 70 36 00 C4 8E 21 00 00 1E 00 00 00 FC

70 | 00 34 32 50 58 33 44 2D 55 45 0A 20 20 20 00 21

7. Adjustment of White Balance

7-1. Required Equipment

(1) Color analyzer (CA-100 or similar product)

(2) Automatic adjustor (with automatic adjustment necessity

and the RS-232C communication being possible)

(3) Pattern Generator(MSPG-925FA): DVI Output

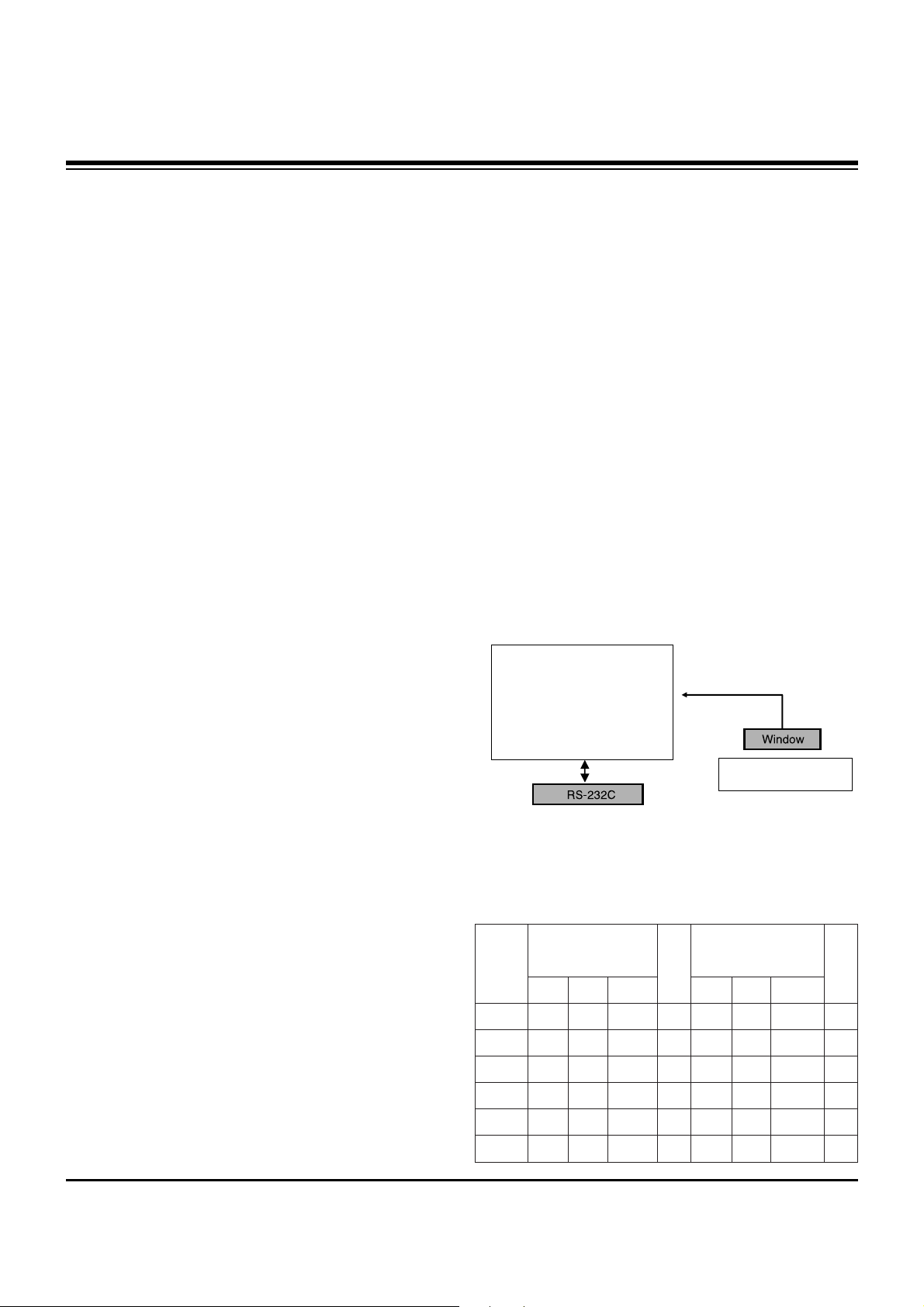

7-2. Connection Diagram of Equipment

for Measuring (Automatic Adjustment)

[

RS-232C Command (Automatic Adjustment)

[42PX3D-UE: Z42PX3D]

Full White Pattern

Digital RGB

PDP MONITOR

COLOR

ANALYZER

TYPE; CA-100

MSPG-925FA

<Fig. 3> Connection Diagram of Automatic Adjustment

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

Jg

Jh

Ji

Cool

Ja

Jb

Jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)(Decimal)

Jd

Je

Jf

00

00

00

ff

ff

ff

7f

7f

7f

Warm

Min

Max

(Deci

mal)

bd

ac

c0

41

40

42

Cool

c0

a9

b1

3f

40

41

Mid

c0

8f

68

40

40

45

Warm

Page 11

- 11 -

ADJUSTMENT INSTRUCTIONS

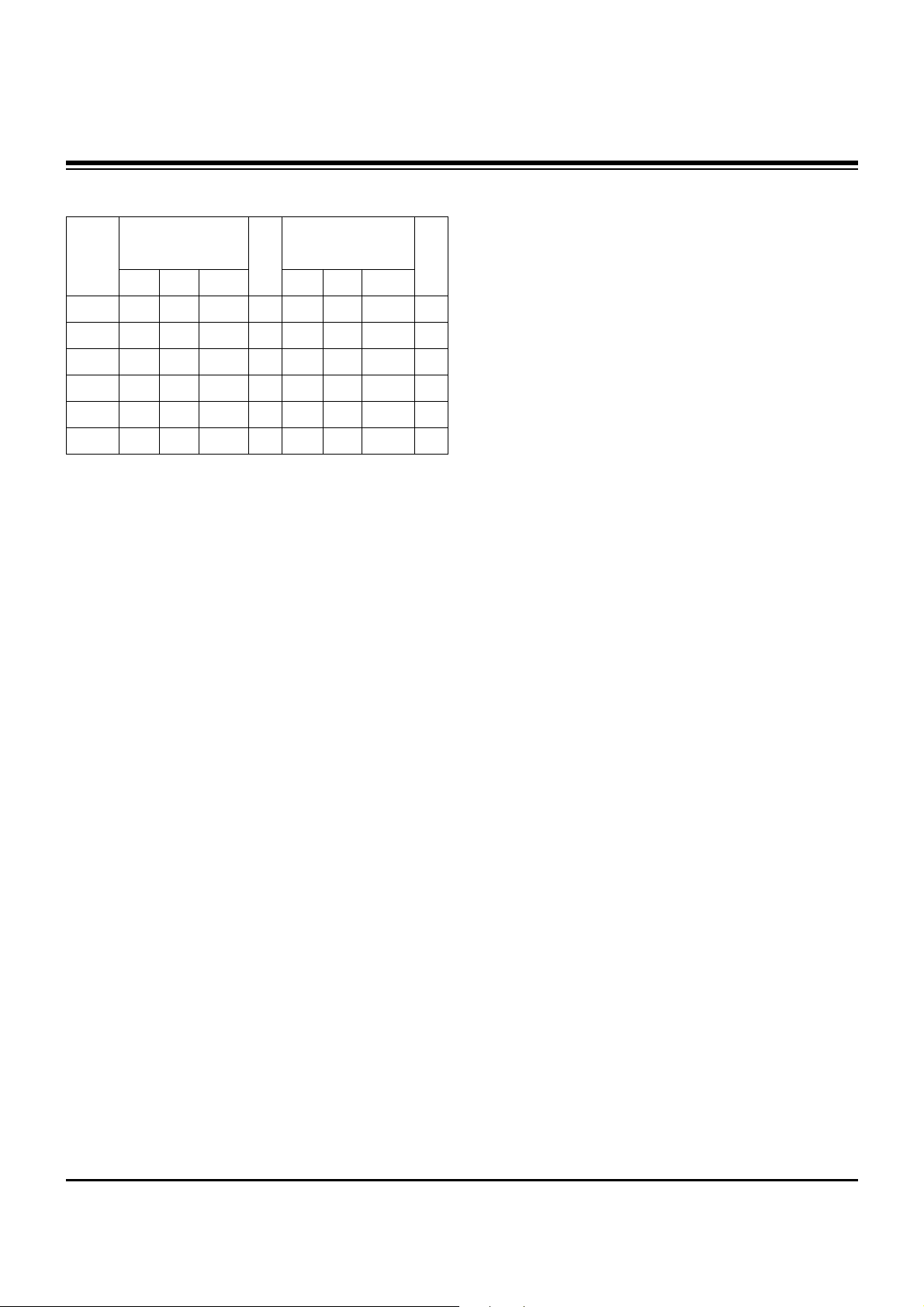

[50PC3D-UE]

7-3. Adjustment of White Balance

O

Calibrate of the CA-100, then attach sensor to PDP module

surface when you adjust.

O

Manual adjustment is also possible by the following sequence.

(1) Enter ‘Ez - Adjust’ by pressing ADJ KEY on the Service

Remote Control.

(2) Select "9. WHITE PATTERN" using CH +/- Key and HEAT

RUN at least 30 minutes by pressing the ENTER Key.

(3) Receive the Window pattern signal from Digital Pattern

Generator.

(AV Input: connect the ‘HDMI’, Digital Pattern Generator input

Pattern => Model: 217, pattern: 6, opt: 106.64.48.1.216)

(4) After attaching sensor to center of screen, select ‘6. White-

Balance’ of ‘Ez - Adjust’ by pressing the ADJ KEY on the

Service R/C. Then enter adjustment mode by pressing the

Right KEY (

G

) .

[42PX3D-UE: Z42PX3D]

1) Adjust the Hight Light using G Gain/R Gain(Cool).

(B Gain: 192, R-Cut/G-Cut/B-Cut: 65/64/66 Fix.)

2) Adjust the Hight Light using G Gain/B Gain(Medium).

(R Gain: 192, R-Cut/G-Cut/B-Cut: 63/64/65 Fix.)

3) Adjust the Hight Light using G Gain/B Gain(Warm).

(R Gain: 192, R-Cut/G-Cut/B-Cut: 64/64/69 Fix.)

[50PC3D-UE]

1) Adjust the Hight Light using G Gain/B Gain(Cool).

(R Gain: 192, R-Cut/G-Cut/B-Cut: 63/61/69 Fix.)

2) Adjust the Hight Light using G Gain/B Gain(Medium).

(R Gain: 192, R-Cut/G-Cut/B-Cut: 64/61/70 Fix.)

3) Adjust the Hight Light using G Gain/B Gain(Warm).

(R Gain: 192, R-Cut/G-Cut/B-Cut: 61/61/70 Fix.)

(6) Adjust using Volume +/- KEY.

(7) After adjustment is complete, exit the adjustment mode by

pressing the ENTER(

V) KEY => ADJ KEY.

High Level: 216gray

[Cool]

X; 0.278±0.002 Y; 0.279±0.002

Color temperature: 11000°K±1500°K

dUV: -3dUV

[Medium]

X; 0.287±0.002 Y; 0.289±0.002

Color temperature: 9300°K±1500°K

dUV: -3dUV

[Warm]

X; 0.315±0.002 Y; 0.316±0.002

Color temperature: 6500°K±1500°K

dUV: -3dUV

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

Jg

Jh

Ji

Cool

Ja

Jb

Jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)(Decimal)

Jd

Je

Jf

00

00

00

ff

ff

ff

7f

7f

7f

Warm

Min

Max

(Deci

mal)

c0

a8

b4

3f

3d

45

Cool

c0

a6

9d

40

3d

46

Mid

c0

85

58

3d

3d

46

Warm

Page 12

- 12 -

PRINTED CIRCUIT BOARDS

MAIN(TOP)

Page 13

- 13 -

PRINTED CIRCUIT BOARDS

MAIN(BOTTOM)

Page 14

- 14 -

PRINTED CIRCUIT BOARDS

CONTROL

SIDE A/V(TOP)

PRE-AMP

SIDE A/V(BOTTOM)

Page 15

- 15 -

BLOCK DIAGRAM

Page 16

- 16 -

EXPLODED VIEW

300

121

560

120

570

305

303

302

301

304

200

580

201

202

203

204

240

400

430

431

250

205

206

208

101

207

600

602

601

590

501

502

520

Page 17

- 17 -

EXPLODED VIEW PARTS LIST

101 5900904001A Fan Module,1.7KRPM DC 12V 250UA 3W 50HZ

120 EAB30829601 Speaker,Woofer g2060102 ND 15W 8OHM 82DB 100HZ 240 X 57 X 49 LUG MACOM

121 EAB30826001 Speaker,Tweeter D013d03k1400 ND 15W 8OHM 85DB 0HZ 88 X 38.3 X 10 LUG

200 EAJ34777301 PDP,Module-XGA PDP50X40000.ADLGB XGA 50INCH 1365X768 16/9 PDP DIVISION

201 6871QCH083A PCB Assembly,CTRL Board CTRL ASS’Y 50 CTRL PDP DIVISION

202 6871QDH115A PCB Assembly,Y DRIVE TOP YDRV ASS’Y 50 X4 PDP DIVISION

203 6871QDH116A PCB Assembly,Y DRIVE BOTTOM YDRV ASS’Y 50 X4 YDRV BTM PDP DIVISION

204 6871QLH063A PCB Assembly,X_LEFT BOARD XRLT ASS’Y 50 X4 PDP DIVISION

205 6871QXH034A PCB Assembly,X_CENTER BOARD XRCT ASS’Y 50 X4 PDP DIVISION

206 6871QRH073A PCB Assembly,X_RIGHT BOARD XRRT ASS’Y 50 X4 PDP DIVISION

207 6871QYH061A PCB Assembly,Y_SUS BOARD YSUS ASS’Y 50 X4 2 LAYER PDP DIVISION

208 6871QZH065A PCB Assembly,Z_SUS BOARD ZSUS ASS’Y 50 X4 2 LAYER PDP DIVISION

240 4980900101C Supporter ASSY,AL SKD

250 4980900102C Supporter ASSY,AL VERTICAL L SKD

300 ACQ30250001 Cover Assembly,50PC3D-UD . 50 LG ERS

301 4980900103B Supporter,FILTER AL 50PC3D-UD.SUSULLJR

302 4980900104B Supporter,FILTER AL 50PC3D-UD.SUSULLJR BOTTOM

303 4980900105B Supporter,FILTER AL 50PC3D-UD.SUSULLJR RIGHT

304 4980900106B Supporter,FILTER AL 50PC3D-UD.SUSULLJR LEFT

305 5230V00025C Filter,PRINTING TOP 50PDP Glass ∏µ® ¿˚øÎ LG CHEMICAL GLASS FILTER (38%)

400 3809900102M Cover Assembly,50PC3D-UE PA63E 50 BCM CKD

430 3501900004K Base Assembly,STAND 50PC3D-UD PA61A SKD

431 35509K0101F Cover,MOLD HIPS 51SF 50pc1 HIPS 51SF ckd

501 3301900089Q Plate Assembly,AV 50PC3D-UE AF044C(BCM)

3301900089S Plate Assembly,AV 50PC3D-UE SKD BCM

502 3301900094V Plate Assembly,50PC3D-UE AF044C(BCM)

3301900094W Plate Assembly,50PC3D-UE AF044C(BCM)

520 EBR31360004 PCB Assembly,Main PA63E 50PC3D-UE SUSYLJR Broadcom X4

EBR31360005 PCB Assembly,Main PA63E 50PC3D-UE KUSYLMR Broadcom X4

560 68719SM157B PCB Assembly,Sub PA51D 50PC3D-UD SUSLLJR -

68719SM157D PCB Assembly,Sub PA51D 42PC3D-UD KUSLLMR

570 EBR32645102 PCB Assembly,SUB M.I PA63E 50PC3D-UE .SUSLLJR PREAMP+LED

EBR32645103 PCB Assembly,SUB M.I PA63E 50PC3D-UE .KUSLLMR PREAMP+LED

580 6709900020B Power Supply Assembly,50INCH UNIFAICATION PSU PDP LGIT PA61A 530W 50PB2DR

590 6200J000115 Filter,AC Line IJ-N06CESL1 5.3mH 250VAC 6A 0.22uF 1000pF

600 68719SM156A PCB Assembly,Sub PA51D 50PC3D-UD AUSLLAX -

68719SM156B PCB Assembly,Sub PA51D 50PC3D-UD KUSLLMR -

601 4811900021A Bracket Assembly,SIDE AV 42PC3D-UD PA51D NORTH AMERICA

602 48149V0003B Plate,PRESS SPTE T0.3 SIDE AV 50PC1R

No.

Part No.

Description

Page 18

- 18 -

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

Q4005

Q4006

Q4007

Q4008

Q4009

Q4010

Q5004

Q5005

Q5006

Q5007

Q5009

Q5010

Q5011

Q5012

Q5013

Q5014

Q5015

Q5016

Q5017

Q7002

Q7003

Q7005

Q7009

Q7011

Q7012

Q7013

D4001

D4002

D4003

D4005

D4006

D4007

D4008

D5001

D5002

D5015

D7001

D7002

LD101

ZD1001

C100

C1001

C1007

C1008

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIH80002A

0TRIH80002A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TR102009AJ

0TR102009AJ

0TRIY80001A

0TRIY80001A

0TRIY80001A

0TR102009AJ

0TR102009AJ

0DRSE00038A

0DRSE00038A

0DSIH00028A

0DSIH00028A

0DL233309AC

0DR340009AA

0DS226009AA

0DSIH00028A

0DSIH00028A

0DZRM00178A

0DSIH00028A

0DSIH00028A

0DL200000CA

0DZDI00078A

0CH5331K416

0CE107WF6DC

0CK103BH56A

0CK104BF56A

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SA1530A-T112-1R PNP -6V -60

2SA1530A-T112-1R PNP -6V -60

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

KRC102S NPN 30V 0V 50V 100MA

KRC102S NPN 30V 0V 50V 100MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

KRC102S NPN 30V 0V 50V 100MA

KRC102S NPN 30V 0V 50V 100MA

SDC15 1.3V 14.3VTO16.4V 21.2

SDC15 1.3V 14.3VTO16.4V 21.2

MC2838-T112-1 1.2V 75V 300MA

MC2838-T112-1 1.2V 75V 300MA

LED,Chip SAM2333

MBRS340 525MV 40V 4A 0SEC 0F

KDS226 1.2V 85V 300MA 2A 4NS

MC2838-T112-1 1.2V 75V 300MA

MC2838-T112-1 1.2V 75V 300MA

Zener,UDZS5.1B 5.1V

MC2838-T112-1 1.2V 75V 300MA

MC2838-T112-1 1.2V 75V 300MA

LED,DIP SAM5670(DL-2LRG)

Zener,BZT52C3V3S-F

0805N331J500LT 330pF 5% 50V

MVK6.3TP16VC100M 100uF 20% 1

C1005X7R1E103KT- 10nF 10% 25

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

IC1001

IC2002

IC2003

IC3001

IC4001

IC4002

IC4003

IC4004

IC4006

IC4007

IC4008

IC4010

IC4011

IC4012

IC4013

IC4014

IC4016

IC4017

IC5001

IC5002

IC5003

IC5004

IC6003

IC6004

IC6005

IC6006

IC7001

IC7002

IC7004

IC7005

IC7008

IC7010

IC7012

IC7013

IC7015

IC7016

IC7017

Q1001

Q1002

Q101

Q102

Q4001

Q4003

Q4004

0IPRP00702A

0IMMRHY057E

0IMMRHY057E

EAN30267601

0IPRP00009A

0IPRP00538A

0IPMGA0010A

0IKE702900G

0IPRPFA015B

0ISTLPH026A

0IPMGS1006B

0IKE702900G

0IMCRRH001A

0IMCRAL021A

0IMCRSH001A

0IMCRAL006A

0IMCRFA010A

EAN31513601

EAN30744301

EAN30744401

0ISO206900A

0IPRPCI016A

0IMI623200B

0IMCRTH002A

0IPMGKE032A

0IPMGKE032A

0ICB533100A

0ISTL00029A

0IPRP00696A

0IMMRCS012B

0IPH740800H

0IMMRAL014D

0IMMRAL014D

0IMMRAL014D

0IPRP00623A

0IPRP00623A

0IPRP00700A

0TRIY80001A

0TRIY80001A

0TR387500AA

0TR387500AA

0TRIH80002A

0TRIY80001A

0TRIY80001A

BCM3550KPB5G 1.14VTO1.26V

HY5DU561622ETP-D43 256MBIT

HY5DU561622ETP-D43 256MBIT

TPS2052BDRG4 2.7TO5.5 3MSE

ICL3232CBNZ 3VTO5.5V - SSO

FSA1156P6X-NL 1.65TO5.5V 4

AZ1117H-3.3 4.75TO10V 3.3V

KIA7029AF -0.3TO15V 2.9V 5

FMS6400CS1X,LF 4.75VTO5.25

74LVC14APW 1.2TO3.6V 0.01m

SC1566I5M25TRT 2.2V~5.5V 1

KIA7029AF -0.3TO15V 2.9V 5

BA033FP-E2 4.3TO25V 3.3V 1

AT24C512W-10SU-2.7 512KBIT

PQ05DZ1U 6TO16V 5V 8W D2PA

AT24C16AN-10SU-2.7 16KBIT

KA7809R 11.5TO24V 9V 150W

SC4519STRT 2.6V to 16V 0.8

MM1732XVBE 4.5TO9.5 50NSEC

MM1731XVBE 4.0TO9.5 50NSEC

CXA2069Q 8.5TO9.5V - - 1.3

CS4344-CZZR 4.75TO5.25V 3T

M62320FP(SOP) 4.5TO5.5V 0.

THC63LVD103 3VTO3.6V 1W TQ

KIA78R09F 10TO25V 9V 8W DP

KIA78R09F 10TO25V 9V 8W DP

CS5331A-KSR 4.75TO5.25V 48

MC33078DR2G +-5TO+-18V 2mV

MST3361M-LF-110 3.3V_2.5V

CAT24WC08W-T(MST3000) 8KBI

74F08D 4.5TO5.5V 12.9mA AN

AT24C02BN-10SU-1.8 2KBIT 2

AT24C02BN-10SU-1.8 2KBIT 2

AT24C02BN-10SU-1.8 2KBIT 2

CM2021-00TR 1VTO5.5V,0VTO0

CM2021-00TR 1VTO5.5V,0VTO0

TPA3100D2PHPR 10TO26V . .

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

2SC3875S(ALY) NPN 5V 60V 50V

2SC3875S(ALY) NPN 5V 60V 50V

2SA1530A-T112-1R PNP -6V -60

2SC3052 NPN 6V 50V 50V 200MA

2SC3052 NPN 6V 50V 50V 200MA

IC

RUN DATE : 2007.8.17

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit

in the P/No. means as follows;

CC, CX, CK, CN : Ceramic

CQ : Polyestor

CE : Electrolytic

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RF : Fusible

TRANSISTOR

DIODE

CAPACITOR

Page 19

- 19 -

LOCA. NO PART NO DESCRIPTION

C1009

C101

C101

C1010

C1011

C1012

C1016

C1017

C1018

C1019

C102

C1020

C1021

C1022

C1024

C1025

C1027

C1028

C1029

C103

C1030

C1032

C1033

C1034

C1036

C1037

C1038

C1039

C104

C1040

C1041

C1042

C1043

C1044

C1045

C1046

C105

C1050

C1051

C1052

C1053

C1054

C1055

C1056

C1057

C1058

C1059

C1060

C1061

C1062

C1063

0CK104BF56A

0CH5331K416

0CC101CK41A

0CK104BF56A

0CK104BF56A

0CK105CD56A

0CK475CC94A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CC330CK41A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK103BH56A

0CK104BF56A

0CK475CC94A

0CK104BF56A

0CE4763F618

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK475CC94A

0CK103BH56A

0CK103BH56A

0CK103BH56A

0CK104BF56A

0CE4763F618

0CK104BF56A

0CK475CC94A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE4763F618

0CK103BH56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CH2122K516

0CH2122K516

0CH2122K516

0CH2122K516

0CK104BF56A

0CK104BF56A

C1005X7R104KET 100nF 10% 16V

0805N331J500LT 330pF 5% 50V

C1608C0G1H101JT 100pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608X7R1A105KT 1uF 10% 10V

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H330JT 33pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1005X7R104KET 100nF 10% 16V

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

ESF476M016T1A5E05G 47uF 20%

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R1E103KT- 10nF 10% 25

C1005X7R1E103KT- 10nF 10% 25

C1005X7R1E103KT- 10nF 10% 25

C1005X7R104KET 100nF 10% 16V

ESF476M016T1A5E05G 47uF 20%

C1005X7R104KET 100nF 10% 16V

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

ESF476M016T1A5E05G 47uF 20%

C1005X7R1E103KT- 10nF 10% 25

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

0603B103K500CT 10nF 10% 50V

0603B103K500CT 10nF 10% 50V

0603B103K500CT 10nF 10% 50V

0603B103K500CT 10nF 10% 50V

0805B122K500CT 1.2nF 10% 50V

0805B122K500CT 1.2nF 10% 50V

0805B122K500CT 1.2nF 10% 50V

0805B122K500CT 1.2nF 10% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C1064

C1065

C2001

C2002

C2003

C2004

C2005

C2006

C2007

C2008

C2009

C2010

C2011

C2012

C2013

C2014

C2015

C2016

C2017

C2018

C2019

C2020

C2021

C2022

C2023

C2024

C2025

C2026

C2027

C2028

C2029

C2030

C2031

C2032

C2033

C2034

C3005

C3007

C3008

C3012

C3013

C3014

C3015

C3016

C3017

C3018

C3019

C3020

C3021

C3022

C3023

0CK103BH56A

0CK475CC94A

0CK104BF56A

0CK104BF56A

0CE107WF6DC

0CE107WF6DC

0CK475CC94A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK103BH56A

0CK104BF56A

0CK103BH56A

0CK473CH56A

0CK473CH56A

0CK104BF56A

0CK104BF56A

0CK272CK46A

0CK272CK46A

0CK102BK56A

0CK102BK56A

0CK102BK56A

0CC471CK41A

0CC471CK41A

0CK103BH56A

0CK102BK56A

0CK102BK56A

0CK104BF56A

0CK105CD56A

0CC471CK41A

0CK105CD56A

0CC471CK41A

0CK105CD56A

0CK105CD56A

0CC471CK41A

0CC471CK41A

0CK475CC94A

0CC080CK11A

0CC080CK11A

0CC150CK41A

0CC150CK41A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK103BH56A

0CK103BH56A

0CE336WD6D8

0CE336WD6D8

0CK106DC67A

0CK106DC67A

C1005X7R1E103KT- 10nF 10% 25

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 1

MVK6.3TP16VC100M 100uF 20% 1

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1608X7R1E473KT 47nF 10% 25V

C1608X7R1E473KT 47nF 10% 25V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

0603B272J500CT 2.7nF 10% 50V

0603B272J500CT 2.7nF 10% 50V

0402B102K500CT 1nF 10% 50V X

0402B102K500CT 1nF 10% 50V X

0402B102K500CT 1nF 10% 50V X

C1608C0G1H471JT 470pF 5% 50V

C1608C0G1H471JT 470pF 5% 50V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1608X7R1A105KT 1uF 10% 10V

C1608C0G1H471JT 470pF 5% 50V

C1608X7R1A105KT 1uF 10% 10V

C1608C0G1H471JT 470pF 5% 50V

C1608X7R1A105KT 1uF 10% 10V

C1608X7R1A105KT 1uF 10% 10V

C1608C0G1H471JT 470pF 5% 50V

C1608C0G1H471JT 470pF 5% 50V

C1608Y5V0J475ZT 4.7uF -20TO+

C1608C0G1H080DT 8pF 0.5PF 50

C1608C0G1H080DT 8pF 0.5PF 50

C1608C0G1H150JT 15pF 5% 50V

C1608C0G1H150JT 15pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1005X7R1E103KT- 10nF 10% 25

RC1A336M05005VR 33uF 20% 10V

RC1A336M05005VR 33uF 20% 10V

JMK212JB106MG-T 10uF 20% 6.3

JMK212JB106MG-T 10uF 20% 6.3

REPLACEMENT PARTS LIST

Page 20

- 20 -

LOCA. NO PART NO DESCRIPTION

C3024

C3025

C3026

C3027

C3028

C3029

C3030

C3031

C3032

C3033

C3034

C3035

C3036

C3037

C3038

C3039

C3040

C3041

C3042

C3043

C3044

C3045

C3046

C3047

C3048

C3049

C3050

C3051

C3052

C3053

C3054

C3055

C3056

C3057

C3058

C3059

C3060

C3061

C3062

C3063

C3064

C3065

C3066

C3067

C3068

C4001

C4002

C4003

C4004

C4005

C4006

0CK104BF56A

0CK102BK56A

0CK103BH56A

0CK475CC94A

0CK104BF56A

0CK103BH56A

0CK103BH56A

0CK102BK56A

0CK475CC94A

0CK104BF56A

0CH8106F691

0CK104BF56A

0CK103BH56A

0CH8106F691

0CK102BK56A

0CK475CC94A

0CK105CD56A

0CK104BF56A

0CK103BH56A

0CK102BK56A

0CK104BF56A

0CK103BH56A

0CK102BK56A

0CK104BF56A

0CK103BH56A

0CK102BK56A

0CK104BF56A

0CK103BH56A

0CK102BK56A

0CK475CC94A

0CK475CC94A

0CK104BF56A

0CE336WD6D8

0CK106DC67A

0CK475CC94A

0CK103BH56A

0CK102BK56A

0CK104BF56A

0CK103BH56A

0CK102BK56A

0CC150CK41A

0CE336WD6D8

0CK106DC67A

0CK104BF56A

0CK475CC94A

0CK334CF56A

0CK104BF56A

0CK334CF56A

0CK473CH56A

0CK334CF56A

0CK104BF56A

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X

C1005X7R1E103KT- 10nF 10% 25

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

MVK4.0TP16VC10M 10uF 20% 16V

0402B102K500CT 1nF 10% 50V X

C1608Y5V0J475ZT 4.7uF -20TO+

C1608X7R1A105KT 1uF 10% 10V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1608Y5V0J475ZT 4.7uF -20TO+

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R104KET 100nF 10% 16V

RC1A336M05005VR 33uF 20% 10V

JMK212JB106MG-T 10uF 20% 6.3

C1608Y5V0J475ZT 4.7uF -20TO+

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

0402B102K500CT 1nF 10% 50V X

C1608C0G1H150JT 15pF 5% 50V

RC1A336M05005VR 33uF 20% 10V

JMK212JB106MG-T 10uF 20% 6.3

C1005X7R104KET 100nF 10% 16V

C1608Y5V0J475ZT 4.7uF -20TO+

C1608X7R1C334KT 330nF 10% 16

C1005X7R104KET 100nF 10% 16V

C1608X7R1C334KT 330nF 10% 16

C1608X7R1E473KT 47nF 10% 25V

C1608X7R1C334KT 330nF 10% 16

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C4007

C4008

C4010

C4011

C4012

C4014

C4015

C4016

C4017

C4018

C4019

C4020

C4021

C4022

C4023

C4024

C4025

C4026

C4027

C4028

C4030

C4032

C4033

C4034

C4035

C4037

C4038

C4039

C4040

C4041

C4043

C4043

C4046

C4047

C4048

C4049

C4050

C4051

C4052

C4053

C4054

C4055

C4056

C4057

C4058

C4060

C4062

C4063

C4064

C4065

C4066

0CK103BH56A

0CC270CK41A

0CK104BF56A

0CC270CK41A

0CE227WF6DC

0CC221CK41A

0CC221CK41A

0CK103BH56A

0CE106WFKDC

0CK102BK56A

0CE476WF6DC

0CK104BF56A

0CH2474F566

0CH2474F566

0CE107WF6DC

0CE106WFKDC

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CE107WF6DC

0CK104BF56A

0CK105CD56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CH8106F691

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30840201

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

EAE30840201

0CE106WFKDC

0CK104BF56A

EAE30840401

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

C1005X7R1E103KT- 10nF 10% 25

C1608C0G1H270JT 27pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H270JT 27pF 5% 50V

MVK8.0TP16VC220M 220uF 20% 1

C1608C0G1H221JT 220pF 5% 50V

C1608C0G1H221JT 220pF 5% 50V

C1005X7R1E103KT- 10nF 10% 25

MVK4.0TP16VC10M 10uF 20% 16V

0402B102K500CT 1nF 10% 50V X

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0805B474K160CT 470nF 10% 16V

0805B474K160CT 470nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 1

MVK4.0TP16VC10M 10uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK6.3TP16VC100M 100uF 20% 1

C1005X7R104KET 100nF 10% 16V

C1608X7R1A105KT 1uF 10% 10V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

4SVPC330M 330uF 20% 4V 2.32A

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

4SVPC330M 330uF 20% 4V 2.32A

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

25SVPD10M 10uF 20% 25V 1.5A

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

REPLACEMENT PARTS LIST

Page 21

- 21 -

LOCA. NO PART NO DESCRIPTION

C4067

C4068

C4070

C4071

C4072

C4073

C4074

C4077

C4078

C4080

C4082

C4083

C4084

C4085

C4086

C4087

C4088

C4089

C4090

C4091

C4094

C4095

C4096

C4097

C4098

C4099

C4100

C4101

C4102

C4103

C4104

C4105

C4106

C4107

C4108

C4109

C5001

C5002

C5003

C5004

C5005

C5006

C5007

C5008

C5009

C5010

C5011

C5012

C5013

C5014

C5015

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CE105WK6DC

0CK104BF56A

0CE476WF6DC

0CE107WF6DC

0CC220CK41A

0CC220CK41A

EAE30840201

0CE106WFKDC

EAE30840301

0CK104BF56A

0CE227WF6DC

0CK104BF56A

0CE107WF6DC

0CK104BF56A

0CE107WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CN475FH67A

0CK224CF56A

0CK153CK51A

0CC561CK41A

0CK476FD67A

0CK104BF56A

0CE336WD6D8

0CE336WD6D8

0CK104BF56A

0CK103BH56A

0CK103BH56A

0CK475CC94A

0CE476WF6DC

0CK103CK56A

0CE476WF6DC

0CK103CK56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

0CK105DH56A

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP50VC1M 1uF 20% 50V 5

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC100M 100uF 20% 1

C1608C0G1H220JT 22pF 5% 50V

C1608C0G1H220JT 22pF 5% 50V

4SVPC330M 330uF 20% 4V 2.32A

MVK4.0TP16VC10M 10uF 20% 16V

10SVPC68M 68uF 20% 10V 1.97A

C1005X7R104KET 100nF 10% 16V

MVK8.0TP16VC220M 220uF 20% 1

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 1

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 1

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

TMK325BJ475MN-T 4.7uF 20% 25

0603B224K160CT 220nF 10% 16V

0603B153K500CT 15nF 10% 50V

C1608C0G1H561JT 560pF 5% 50V

LMK325BJ476MM-T 47uF 20% 10V

C1005X7R104KET 100nF 10% 16V

RC1A336M05005VR 33uF 20% 10V

RC1A336M05005VR 33uF 20% 10V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

C1005X7R1E103KT- 10nF 10% 25

C1608Y5V0J475ZT 4.7uF -20TO+

MVK6.3TP16VC47M 47uF 20% 16V

0603B103K500CT 10nF 10% 50V

MVK6.3TP16VC47M 47uF 20% 16V

0603B103K500CT 10nF 10% 50V

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

LOCA. NO PART NO DESCRIPTION

C5016

C5019

C5020

C5022

C5025

C5026

C5027

C5028

C5029

C5030

C5031

C5032

C5033

C5034

C5035

C5036

C5037

C5038

C5039

C5040

C5041

C5042

C5044

C5045

C5046

C5047

C5048

C5049

C5050

C5051

C5052

C5053

C5054

C5055

C5056

C5057

C5058

C5059

C5060

C5061

C5062

C5063

C5064

C5065

C5066

C5068

C5070

C5071

C5072

C5073

C5074

0CK105DH56A

0CK103CK56A

0CE225WK6DC

0CK104BF56A

0CH2474F566

0CC101CK41A

0CC101CK41A

0CK104BF56A

0CK104BF56A

0CH8226F691

0CH8226F691

0CK104BF56A

0CE476WH6DC

0CK103BH56A

0CH8106F691

0CK104BF56A

0CC101CK41A

0CH8106F691

0CK104BF56A

0CC101CK41A

0CK104BF56A

0CH8106F691

0CE227WF6DC

0CK222CK56A

0CK222CK56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CC101CK41A

0CK104BF56A

0CC101CK41A

0CE225WK6DC

0CK222CK56A

0CE105WK6DC

0CK222CK56A

0CK222CK56A

0CK222CK56A

0CH2474F566

0CH2474F566

0CE225WK6DC

0CK104BF56A

0CH8106F691

0CE105WK6DC

0CK104BF56A

0CH8106F691

0CH8106F691

0CH8106F691

0CK104BF56A

0CH8106F691

C2012X7R105KFT 1uF 10% 25V X

0603B103K500CT 10nF 10% 50V

MVK4.0TP50VC2.2M 2.2uF 20% 5

C1005X7R104KET 100nF 10% 16V

0805B474K160CT 470nF 10% 16V

C1608C0G1H101JT 100pF 5% 50V

C1608C0G1H101JT 100pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK8.0TP25VC47M 47uF 20% 25V

C1005X7R1E103KT- 10nF 10% 25

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H101JT 100pF 5% 50V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H101JT 100pF 5% 50V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK8.0TP16VC220M 220uF 20% 1

0603B222K500CT 2.2nF 10% 50V

0603B222K500CT 2.2nF 10% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H101JT 100pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H101JT 100pF 5% 50V

MVK4.0TP50VC2.2M 2.2uF 20% 5

0603B222K500CT 2.2nF 10% 50V

MVK4.0TP50VC1M 1uF 20% 50V 5

0603B222K500CT 2.2nF 10% 50V

0603B222K500CT 2.2nF 10% 50V

0603B222K500CT 2.2nF 10% 50V

0805B474K160CT 470nF 10% 16V

0805B474K160CT 470nF 10% 16V

MVK4.0TP50VC2.2M 2.2uF 20% 5

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP50VC1M 1uF 20% 50V 5

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

REPLACEMENT PARTS LIST

Page 22

- 22 -

LOCA. NO PART NO DESCRIPTION

C5075

C5076

C5077

C5078

C5079

C5080

C5102

C5103

C5104

C5105

C5106

C5107

C5108

C5109

C6010

C6011

C6012

C6013

C6014

C6015

C6016

C6017

C6018

C6019

C6020

C6021

C6022

C6023

C6024

C6025

C6026

C6027

C6028

C6029

C6030

C6031

C6032

C6033

C6034

C6035

C7001

C7002

C7003

C7007

C7015

C7019

C7020

C7021

C7022

C7023

C7024

0CH8106F691

0CK104BF56A

0CE335WK6D8

0CE335WK6D8

0CH8106F691

0CE335WK6D8

0CC101CK41A

0CC101CK41A

0CE105WK6DC

0CE105WK6DC

0CE225WK6DC

0CK104BF56A

0CH2474F566

0CH2474F566

0CE106WFKDC

0CK104BF56A

0CE226WF6DC

0CE226WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CE476WF6DC

0CE106WFKDC

0CK104BF56A

0CK102BK56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WH6DC

0CE476WF6DC

0CK104BF56A

0CE106WFKDC

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK103BH56A

0CE226WF6DC

0CE226WF6DC

0CC470CK41A

0CK104BF56A

0CK224CF56A

0CK105DH56A

0CK225DK94A

0CK224CF56A

0CK104CK56A

0CK474DK56A

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP50VC3.3M 3.3uF 20% 5

MVK4.0TP50VC3.3M 3.3uF 20% 5

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP50VC3.3M 3.3uF 20% 5

C1608C0G1H101JT 100pF 5% 50V

C1608C0G1H101JT 100pF 5% 50V

MVK4.0TP50VC1M 1uF 20% 50V 5

MVK4.0TP50VC1M 1uF 20% 50V 5

MVK4.0TP50VC2.2M 2.2uF 20% 5

C1005X7R104KET 100nF 10% 16V

0805B474K160CT 470nF 10% 16V

0805B474K160CT 470nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK8.0TP25VC47M 47uF 20% 25V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25

MVK5.0TP16VC22M 22uF 20% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1608C0G1H470JT 47pF 5% 50V

C1005X7R104KET 100nF 10% 16V

0603B224K160CT 220nF 10% 16V

C2012X7R105KFT 1uF 10% 25V X

CL21F225ZBFNNNE 2.2uF -20TO+

0603B224K160CT 220nF 10% 16V

0603B104K500CT 100nF 10% 50V

UMK212BJ474KG-T 470nF 10% 50

LOCA. NO PART NO DESCRIPTION

C7025

C7026

C7027

C7028

C7029

C7030

C7031

C7032

C7033

C7034

C7035

C7036

C7037

C7038

C7039

C7040

C7041

C7042

C7043

C7044

C7045

C7046

C7047

C7048

C7049

C7050

C7051

C7052

C7053

C7054

C7055

C7056

C7057

C7058

C7059

C7060

C7061

C7062

C7063

C7064

C7065

C7066

C7067

C7068

C7069

C7070

C7071

C7072

C7073

C7074

C7075

0CE107WF6DC

0CK104CK56A

0CK104BF56A

0CK104BF56A

0CK105DH56A

0CK105DH56A

0CK104BF56A

0CK105DH56A

0CK105DH56A

0CK104BF56A

0CK103CK56A

0CK103CK56A

0CE107WF6DC

0CC470CK41A

0CK105DH56A

0CK105DH56A

0CK225DK94A

0CK224CF56A

0CK224CF56A

0CE106WH6DC

0CE107WK6DC

0CE226WF6DC

0CK103BH56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CE106WFKDC

0CE106WFKDC

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK473CH56A

0CK473CH56A

0CK473CH56A

MVK6.3TP16VC100M 100uF 20% 1

0603B104K500CT 100nF 10% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C1005X7R104KET 100nF 10% 16V

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

C1005X7R104KET 100nF 10% 16V

0603B103K500CT 10nF 10% 50V

0603B103K500CT 10nF 10% 50V

MVK6.3TP16VC100M 100uF 20% 1

C1608C0G1H470JT 47pF 5% 50V

C2012X7R105KFT 1uF 10% 25V X

C2012X7R105KFT 1uF 10% 25V X

CL21F225ZBFNNNE 2.2uF -20TO+

0603B224K160CT 220nF 10% 16V

0603B224K160CT 220nF 10% 16V

MVK5.0TP25VC10M 10uF 20% 25V

MVK10TP50VC100M 100uF 20% 50

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R1E103KT- 10nF 10% 25

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608X7R1E473KT 47nF 10% 25V

C1608X7R1E473KT 47nF 10% 25V

C1608X7R1E473KT 47nF 10% 25V

REPLACEMENT PARTS LIST

Page 23

- 23 -

LOCA. NO PART NO DESCRIPTION

C7076

C7077

C7078

C7079

C7080

C7081

C7082

C7083

C7084

C7085

C7086

C7087

C7088

C7089

C7090

C7091

C7092

C7095

C7096

C7097

C7098

C7099

C7100

C7108

C7109

C7110

C7141

C7142

C7143

C7144

C7150

C7151

C7152

C7153

C7154

C7155

C7156

C7157

C7158

C7159

C7160

C7161

C1

C10

C11

C12

C13

C2

C3

0CK473CH56A

0CK153CK56A

0CK473CH56A

0CK473CH56A

0CC470CK41A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CC220CK41A

0CC220CK41A

0CK104BF56A

0CE226WF6DC

0CK104BF56A

0CE106WFKDC

0CH5220K416

0CE106WFKDC

0CE106WFKDC

0CH5220K416

0CC150CK41A

0CC150CK41A

0CK104BF56A

0CE476WF6DC

0CK103CK56A

0CK104CK56A

0CK104CK56A

0CK103CK56A

0CK105DH56A

0CK104CK56A

0CK104CK56A

0CK105DH56A

0CK474DK56A

0CK104CK56A

0CK105DH56A

0CE226WF6DC

0CE227WJ6DC

0CE227WJ6DC

0CK104BF56A

0CK104BF56A

6631900010N

6631V39015F

6631V39016E

68509A0004G

6850J00005C

6631900012D

6631900027C

C1608X7R1E473KT 47nF 10% 25V

0603B153K500CT 15nF 10% 50V

C1608X7R1E473KT 47nF 10% 25V

C1608X7R1E473KT 47nF 10% 25V

C1608C0G1H470JT 47pF 5% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608C0G1H220JT 22pF 5% 50V

C1608C0G1H220JT 22pF 5% 50V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

0805N220J500LT 22pF 5% 50V C

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

0805N220J500LT 22pF 5% 50V C

C1608C0G1H150JT 15pF 5% 50V

C1608C0G1H150JT 15pF 5% 50V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

0603B103K500CT 10nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B103K500CT 10nF 10% 50V

C2012X7R105KFT 1uF 10% 25V X

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

C2012X7R105KFT 1uF 10% 25V X

UMK212BJ474KG-T 470nF 10% 50

0603B104K500CT 100nF 10% 50V

C2012X7R105KFT 1uF 10% 25V X

MVK5.0TP16VC22M 22uF 20% 16V

MVK10TP35VC220M 220uF 20% 35

MVK10TP35VC220M 220uF 20% 35

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

Harness,Single 12P 2.0MM

Harness,Single 3.96MM 4P

Harness,Single 3.96MM 10P

Cable,Assembly RCA R/A TO RCA S/T

Cable,Assembly GT121 HOUSING

Harness,Single 2.50MM 10P

Harness,Single 2.50MM 13P

LOCA. NO PART NO DESCRIPTION

C4

C5

C6

C7

C8

C9

P100

P100

P100

P101

P101

P3002

P4001

P4003

P4004

P4005

P4007

P5002

P6007

P6008

P7004

P7009

P7010

L101

L3002

L4002

L4019

L4020

L4022

L7008

L7020

L7029

L7030

L7031

L7032

R106

R108

J4002

J4003

J4004

J5004

J5005

J5006

J5007

JK100

JK101

P7007

6631900050D

6631900065C

6631900097C

6631900098C

6631900100D

6631T20031J

6602T20009C

6602T20009J

6630V90142A

6602T20009C

6602T20008L

EAG31022001

6630G70017A

6602T25008J

6602T25008M

6602T25008L

6602T20008J

6602T20008L

366-932B

6602T12007D

6630G70016A

6602T25008C

6602T25008B

0LC1032101A

0LC0233002A

0LCML00020B

0LC2000005K

0LC2000005K

6140TBZ047B

0LCML00020B

0LCML00020B

6140VR0008A

6140VR0008A

6140VR0008A

6140VR0008A

0LC0233002A

0LC0233002A

6612J10024A

6612F00099A

6612F00099A

6612J10031A

6612J10031A

6612F00024C

6612J10006K

EAG32151101

6612J10033A

6612B00015B

Harness,Single 2.00MM 10P

Harness,Single 2.50MM 12P

Harness,Single 2.50MM 3P

Harness,Single 2.50MM 4P

Harness,Single 2.50MM 4P

Harness,Single 2.00MM 4P

Conector,Wafer SMAW200-04P

Conector,Wafer SMAW200-10P

Conector,Wafer 6P 2.54MM

Conector,Wafer SMAW200-04P

Conector,Wafer SMW200-12P

Conector,USB UB01123-4HHS-4F

Conector,DSUB 9P 2.77MM

Conector,Wafer SMW250-10P

Conector,Wafer SMW250-13P

Conector,Wafer SMW250-12P

Conector,Wafer SMW200-10P

Conector,Wafer SMW200-12P

Conector,Wafer 3P 2.50MM

Conector,Wafer GT121-31P-TD 31P

Conector,DSUB 15P 2.29MM

Conector,Wafer SMW250-04P

Conector,Wafer SMW250-03P

Inductor,FI-C3216-103KJT 10UH 10%

Inductor,FI-B2012-332KJT 3.3UH 10% - 50M

Inductor,MLI-201209-6R8K 6.8UH 10% 0V 15

Inductor,FI-D2012-223KJT(CE) 22UH 10%

Inductor,FI-D2012-223KJT(CE) 22UH 10%

Inductor,RLF7030T-3R3M4R1 3.3UH 20% 0V

Inductor,MLI-201209-6R8K 6.8UH 10% 0V 15

Inductor,MLI-201209-6R8K 6.8UH 10% 0V 15

Inductor,SLF12575T-330M3R2 33UH 20% Inductor,SLF12575T-330M3R2 33UH 20% Inductor,SLF12575T-330M3R2 33UH 20% Inductor,SLF12575T-330M3R2 33UH 20% Inductor,FI-B2012-332KJT 3.3UH 10% - 50M

Inductor,FI-B2012-332KJT 3.3UH 10% - 50M

Jack,Complex KCN-BT-0-0056 4P N

Jack,Phone PEJ024-01 1P 4P ST

Jack,Phone PEJ024-01 1P 4P ST

Jack,RCA PPJ209-02 14.0MM 1

Jack,RCA PPJ209-02 14.0MM 1

Jack,DIN PSJ014-01 SOCKET 4

Jack,RCA PPJ150-08 14.0MM 2

Jack,Fiber Optic TOX177L(F,T) 3P TX

Jack,Complex PMJ016-13 13P DIN/

Jack,DIN DC1R019WDH SOCKET

REPLACEMENT PARTS LIST

INDUCTOR

CONNECTOR & WAFER

JACK

Page 24

- 24 -

LOCA. NO PART NO DESCRIPTION

P7008

AR2001

AR2002

AR2003

AR2004

AR2005

AR2006

AR2007

AR2008

AR2009

AR2010

AR2011

AR2012

AR2013

AR2014

AR2015

AR2016

AR2017

AR3021

AR6001

AR6002

AR6003

AR6004

AR6005

AR6006

AR6007

AR7001

AR7002

AR7003

AR7004

AR7005

AR7006

R1006

R1008

R101

R101

R101

R1014

R1015

R1016

R1017

R1018

R1019

R102

R102

R102

R1020

R1021

R103

6612B00015B

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ1001C687

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C692

0RJ0222C687

0RJ0222C687

0RJ0222C687

0RJ0222C687

0RJ0222C687

0RJ0222C687

0RJ2000D477

0RJ0102D677

0RJ0000D677

0RJ7501D677

0RJ2002D677

0RJ0511D677

0RJ0182D677

0RJ0182D677

0RJ0182D677

0RJ0562D477

0RJ0562D477

0RJ7501D677

0RJ2002D677

0RJ1200D677

0RJ0000C678

0RJ0562D477

0RJ0000D677

Jack,DIN DC1R019WDH SOCKET

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

RCA86TRJ1K00 1KOHM 5% 1/16W 4

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

MNR04 M0APJ 220 22OHM 5% 1/16W

RCA86TRJ22R0 22OHM 5% 1/16W 4

RCA86TRJ22R0 22OHM 5% 1/16W 4

RCA86TRJ22R0 22OHM 5% 1/16W 4

RCA86TRJ22R0 22OHM 5% 1/16W 4

RCA86TRJ22R0 22OHM 5% 1/16W 4

RCA86TRJ22R0 22OHM 5% 1/16W 4

MCR03EZPF201 200OHM 1% 1/10W 1

MCR03EZPJ100 10OHM 5% 1/10W 16

MCR03EZPJ000 0OHM 5% 1/10W 160

MCR03EZPJ752 7.5KOHM 5% 1/10W

MCR03EZPJ203. 20KOHM 5% 1/10W

MCR03EZPJ5R1 5.1OHM 5% 1/10W 1

MCR03EZPJ180 18OHM 5% 1/10W 16

MCR03EZPJ180 18OHM 5% 1/10W 16

MCR03EZPJ180 18OHM 5% 1/10W 16

MCR03EZPF560 56OHM 1% 1/10W 16

MCR03EZPF560 56OHM 1% 1/10W 16

MCR03EZPJ752 7.5KOHM 5% 1/10W

MCR03EZPJ203. 20KOHM 5% 1/10W

MCR03EZPJ121 120OHM 5% 1/10W 1

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPF560 56OHM 1% 1/10W 16

MCR03EZPJ000 0OHM 5% 1/10W 160

LOCA. NO PART NO DESCRIPTION

R103

R103

R1030

R1032

R1034

R1035

R1036

R1037

R1038

R1039

R104

R104

R104

R1040

R1041

R1042

R1044

R1045

R1046

R1047

R1048

R1049

R105

R105

R105

R1050

R1051

R1054

R1056

R1057

R1058

R1059

R106

R1060

R1061

R1062

R1063

R1064

R1065

R1066

R1067

R1068

R107

R107

R1073

R1074

R1079

R108

R1080

R1081

R1083

0RJ3301D677

0RJ1201D677

0RH1504D622

0RH1504D622

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RJ3301D677

0RJ1201D677

0RJ4700D677

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RH1504D622

0RJ0000C678

0RJ4990D477

0RH1504D622

0RJ0000C678

0RJ0000C678

0RH0000D622

0RJ7501D677

0RJ4700D677

0RJ0000C678

0RJ0000C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0000C678

0RJ0222C678

0RJ2002D677

0RJ0000C678

0RJ0222C678

0RJ0000C678

0RJ0000C678

0RJ0000C678

0RJ4700D677

0RJ4700D677

0RJ4700D677

0RJ4700D677

0RH0000D622

0RJ3301D677

0RJ0000C678

0RJ5600D677

0RJ0000C678

0RJ1201D677

0RJ0000C678

0RJ0000C678

0RJ0000C678

MCR03EZPJ332 3.3KOHM 5% 1/10W

MCR03EZPJ122 1.2KOHM 5% 1/10W

MCR10EZHJ155 1.5MOHM 5% 1/8W 2

MCR10EZHJ155 1.5MOHM 5% 1/8W 2

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPJ332 3.3KOHM 5% 1/10W

MCR03EZPJ122 1.2KOHM 5% 1/10W

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR10EZHJ155 1.5MOHM 5% 1/8W 2

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPF4990 499OHM 1% 1/10W

MCR10EZHJ155 1.5MOHM 5% 1/8W 2

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR10EZHJ000 0OHM 5% 1/8W 2012

MCR03EZPJ752 7.5KOHM 5% 1/10W

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ220 22OHM 5% 1/16W 10

MCR01MZPJ220 22OHM 5% 1/16W 10

MCR01MZPJ220 22OHM 5% 1/16W 10

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ220 22OHM 5% 1/16W 10

MCR03EZPJ203. 20KOHM 5% 1/10W

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ220 22OHM 5% 1/16W 10

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR03EZPJ471 470OHM 5% 1/10W 1

MCR10EZHJ000 0OHM 5% 1/8W 2012

MCR03EZPJ332 3.3KOHM 5% 1/10W

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPJ561 560OHM 5% 1/10W 1

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPJ122 1.2KOHM 5% 1/10W

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR01MZPJ000 0OHM 5% 1/16W 100

REPLACEMENT PARTS LIST

RESISTOR

Page 25

- 25 -

LOCA. NO PART NO DESCRIPTION

R1084

R1085

R1086

R1087

R1088

R109

R110

R1129

R1131

R1132

R1133

R1134

R1135

R1136

R1137

R1139

R1140

R1141

R1142

R1144

R1145

R1157

R1158

R1159

R1160

R1161

R1162

R2002

R2003

R2012

R2013

R2015

R2016

R2017

R2022

R2023

R2024

R2025

R2026

R2027

R2028

R2032

R2033

R2044

R2045

R2046

R2047

R2048

R2049

R2050

R2051

0RJ0000C678

0RJ0271D677

0RJ0271D677

0RJ0271D677

0RJ2701C678

0RH0000D622

0RH0000D622

0RJ2701C678

0RJ2701C678

0RJ0752C678

0RH1504D622

0RJ0000C678

0RJ0000C678

0RJ0392D677

0RJ0392D677

0RH1504D622

0RJ0000C678

0RJ0392D677

0RH1504D622

0RJ2701C678

0RJ2701C678

0RJ3601D677

0RJ3601D677

0RJ3601D677

0RJ3601D677

0RJ1001C678

0RJ1001C678

0RJ0000C678

0RJ1003D677

0RJ0000C678

0RJ4701C678

0RJ0000C678

0RJ0000C678

0RJ4701C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0222C678

0RJ0000C678

0RJ0000C678

0RJ4991D477

0RJ4991D477

0RJ4991D477

0RJ4991D477

0RJ4991D477

0RJ4991D477

0RJ4991D477

0RJ4991D477

MCR01MZPJ000 0OHM 5% 1/16W 100

MCR03EZPJ2R7 2.7OHM 5% 1/10W 1

MCR03EZPJ2R7 2.7OHM 5% 1/10W 1

MCR03EZPJ2R7 2.7OHM 5% 1/10W 1

MCR01MZPJ272 2.7KOHM 5% 1/16W

MCR10EZHJ000 0OHM 5% 1/8W 2012