Page 1

SERVICE MANUAL

Model Series:

Product Type: Color TV

Chassis: MX474C

Manual Series: CM153

Manual Part #: 923-03459

Model Line: D

Product Year: 2001

General Information ....................................... 1

Servicing ..................................................... 2

Parts ........................................................... 3

Exploded views ............................................. 4

Schematics ................................................... 5

H13A02D

H13A02X

CONTENTS

Printed in U.S.A.

CN DG 5k

Published by Technical Publications

Zenith Electronics Corporation

201 James Record Road - Huntsville, Alabama 35824-1513

Copyright October 2001 by Zenith Electronics Corporation

Page 2

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

A

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from Zenith Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by Zenith Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into

the set is not delayed until the new service literature is printed.

Caution: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage

or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

Graphic symbols

The exclamation point within an equilateral triangle is intended

to alert the service personnel to important safety information in

the service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED

NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on items transported to and from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers,

shields, strain reliefs, power supply cords, and other hardware have been

reinstalled per the original design. Be sure that the safety purpose of the

polarized line plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign

particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a receiving tube or a resistor rated at

1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

6. After re-assembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in

the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by

a .15 mfd 150V AC type capacitor between a known good earth ground

water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part. Voltage

measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp

AC. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.16uF

1600 OHM

10 WATT

Place this probe

on each exposed

metal part.

X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays when

the HV is at the factory-specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may cause a failure of

the picture tube or high-voltage supply and, under certain circumstances

may produce radiation in excess of desirable levels.

2. Only factory-specified CRT anode connectors must be used.

3. It is essential that the service personnel have available an accurate and

reliable high-voltage meter.

4. When the high-voltage circuitry is operating properly, there is no possibility

of an x-radiation problem. Every time a color chassis is serviced, the

brightness should be run up and down while monitoring the high voltage

with a meter, to be certain that the high voltage does not exceed the

specified value and that it is regulating correctly.

5. When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

6. Refer to HV, B+, and shutdown adjustment procedures described in the

appropriate schematics and diagrams (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated

air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a factor,

etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product mounted

to a shelf or platform must retain its original feet (or the equivalent

thickness in spacers) to provide adequate air flow across the bottom. Bolts

or screws used for fasteners must not touch any parts or wiring. Perform

leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed

by Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same or

larger screen size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

i

Page 3

TABLE OF CONTENTS

SECTION 1 GENERAL INFO / REMOTE CONTROL

SPECIFICATIONS .......................................................... 1-1

SECTION 2 SERVICING

DISASSEMBLY INSTRUCTION .......................................... 2-1

SERVICE MODE LIST ..................................................... 2-3

ALIGNMENT INSTRUCTION ............................................. 2-4

ELECTRICAL ADJUSTMENT ............................................. 2-4

MAJOR COMPONENTS LOCATION GUIDE ........................... 2-7

SECTION 3 EXPLODED VIEW

EXPLODED VIEW .......................................................... 3-1

SECTION 4 PARTS LIST

COMPONENT PARTS LIST ............................................... 4-1

SECTION 5 SCHEMATIC

H13A02D/02X POWER SUPPLY CIRCUIT ........................... 5-1

H13A02D/02X DEFLECTION CIRCUIT ............................... 5-2

H13A02D/02X MAIN MICRO & TUNER CIRCUIT .................. 5-3

H13A02D/02X CHROMA CIRCUIT .................................... 5-4

H13A02D/02X AUDIO CIRCUIT ....................................... 5-5

H13A02D/02X PCB LAYOUT TOP ..................................... 5-6

H13A02D/02X PCB LAYOUT BOTTOM ............................... 5-7

CM153 TOC MX474C - TOC

Page 4

Page 5

SPECIFICATIONS

MODEL

ITEMS

TV STANDARD NTSC-M

POWER INPUT AC 120V 60 Hz

POWER CONSUMPTION

TUNING SYSTEM Frequency Synthesizer ( FS ) Tuning System

TUNING RANGES

SOUND OUTPUT

SPEAKER

ANTENNA INPUT IMPEDANCE 75 ohm Unbalanced

AUXILIARY

INPUT TERMINAL

INTERMEDIATE

FREQUENCIES

Picture IF Carrier Frequency : 45.75 MHz

H13A02D / H13A02X

54W

VHF : 2 ~ 13 (12)

~

~

1.0 W

Front :

Rear:

69 (56)

181 (181)

UHF : 14

CATV : 1

1 W 8 ohm

Ear Phone Jack

VHF/UHF Antenna Input

Sound IF Carrier Frequency : 41.25 MHz

REMARKS

REMARKS

CM153 1-1 MX474C - GENERAL INFO

Page 6

Page 7

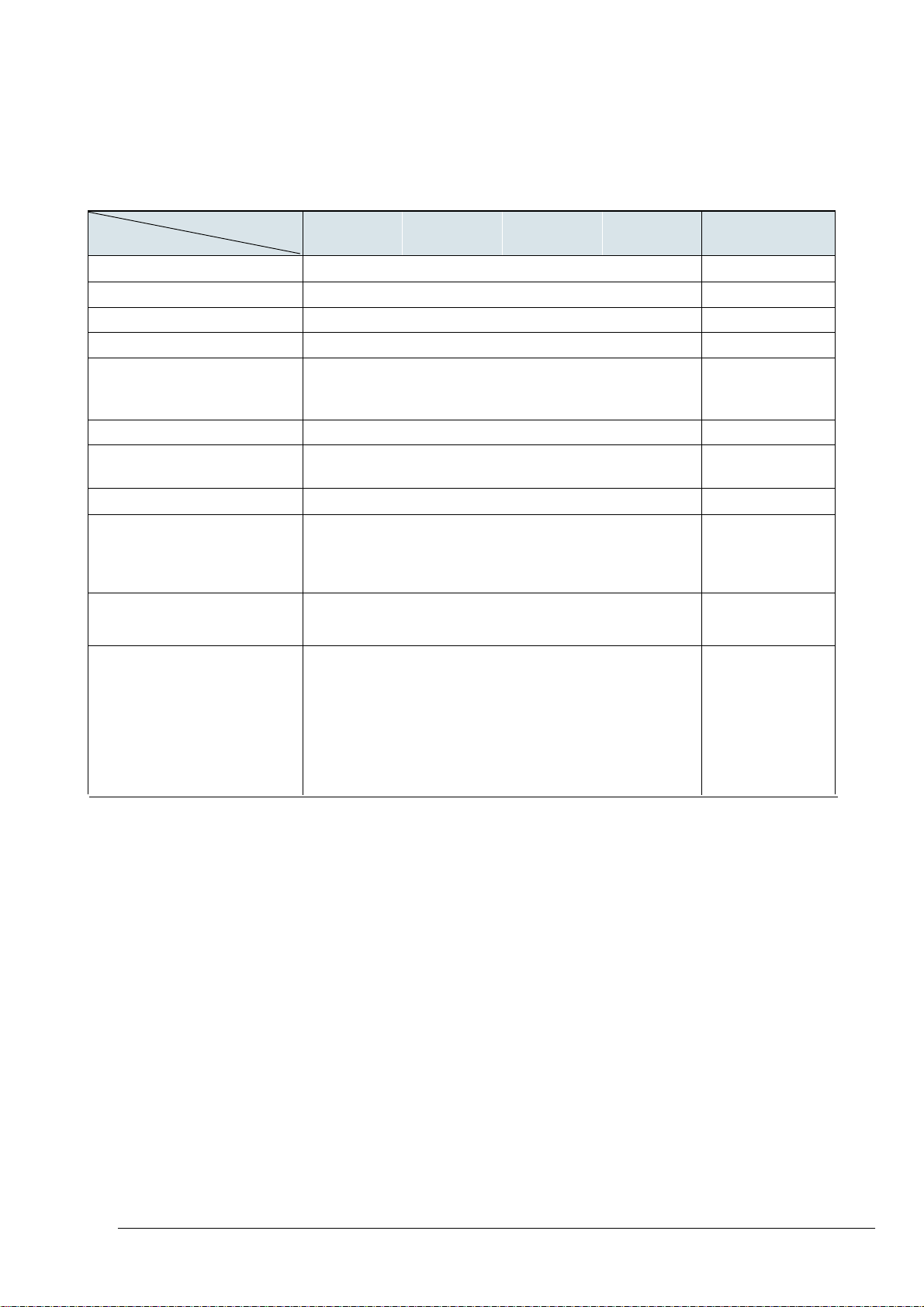

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter the Service Mode, press both set key and remote control key for more than 1 second.

Set Key Remocon Key Operations

VOL. (-) MIN

VOL. (-) MIN 1

VOL. (-) MIN

VOL. (-) MIN 8

VOL. (-) MIN 9

0

6

Releasing of V-CHIP PASSWORD.

Initialization of the factory.

NOTE: Do not use this for the normal servicing.

POWER ON total hours is displayed on the screen.

Refer to the "CONFIRMATION OF USING HOURS".

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "NOTE FOR THE REPLACING OF MEMORY IC".

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

CONFIRMATION OF USING HOURS

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel

button (6) on the remote control for more than 1 second.

3.

After the confirmation of using hours, turn off the power.

ADDRESS DATA

INIT 00 83

CRT ON

0010

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

NOTE FOR THE REPLACING OF MEMORY IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

Table 1

09

INI

0A

FF

ADDRESS

DATA

1.

Enter DATA SET mode by setting VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 1 second.

ADDRESS and DATA should appear as FIG 1.

3.

ADDRESS is now selected and should "blink". Using the SET + or - keys on the remote, step through the ADDRESS until

required ADDRESS to be changed is reached.

4.

Press ENTER to select DATA. When DATA is selected, it will "blink".

5.

Again, step through the DATA using SET + or - until required DATA value has been selected.

6.

Pressing ENTER will take you back to ADDRESS for further selection if necessary.

7.

Repeat steps 3 to 6 until all data has been checked.

8.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

The unit will now have the correct DATA for the new MEMORY IC.

CM153 2-1 MX474C - SERVICING

INI00INI01INI02INI03INI04INI05INI06INI07INI08INI

0809A00106B324992125

Page 8

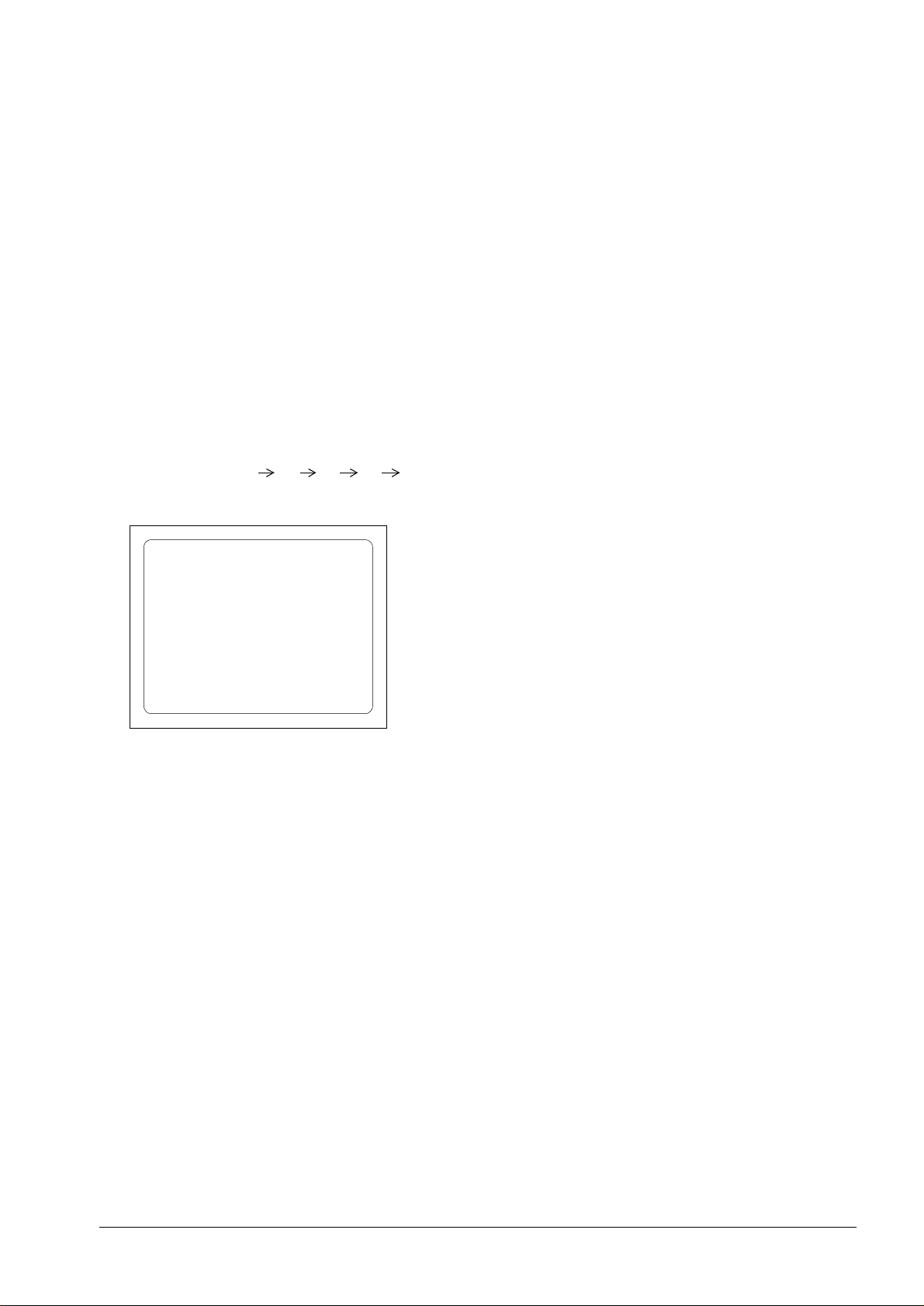

ALIGNMENT INSTRUCTIONS

1. SERVICE MODE ADJUSTMENS

Follow the steps below whenever service adjustment is required. See Table- A and Table- B to determine if

service adjustments are required.

NOTE

\

To perform the service mode for model H13A02D/02X, please perform the following steps on part OS101.

1) Remote control PN# 924-10053 is needed to complete the following.

2) Remove 3pin terminal at location OS101 and add IR sensor PN# 942-10065.

3) Enter the Service mode and adjust.

4) Remove IR pre Amp after all menu adjustments have been completed.

1) How to enter the service mode using your remote control.

•

Turn the set on.

•

Direct the remote control to the reception window of TV.

•

Push buttons of remote control in sequence as follows.

Menu (5 sec.)

•

Then, the screen will appear as follows.

9

8

7

6

S2 SCRN

S5 IFC

S6 GEO

S8 W/B

S9 DP

S12 FACT

S10 SOUND

REM Zenith

NOTE

If you changed the setting of “REM Zenith” item, then your remote control will not work. In that case, unplug your

power cord and plug it again.

•

Using the channel up or channel down button, select the item you wish to adjust.

(The color of selected item turns

•

Press the volume up or down button to enter in the service mode you wish to adjust.

red.)

CM153 2-2 MX474C - SERVICING

Page 9

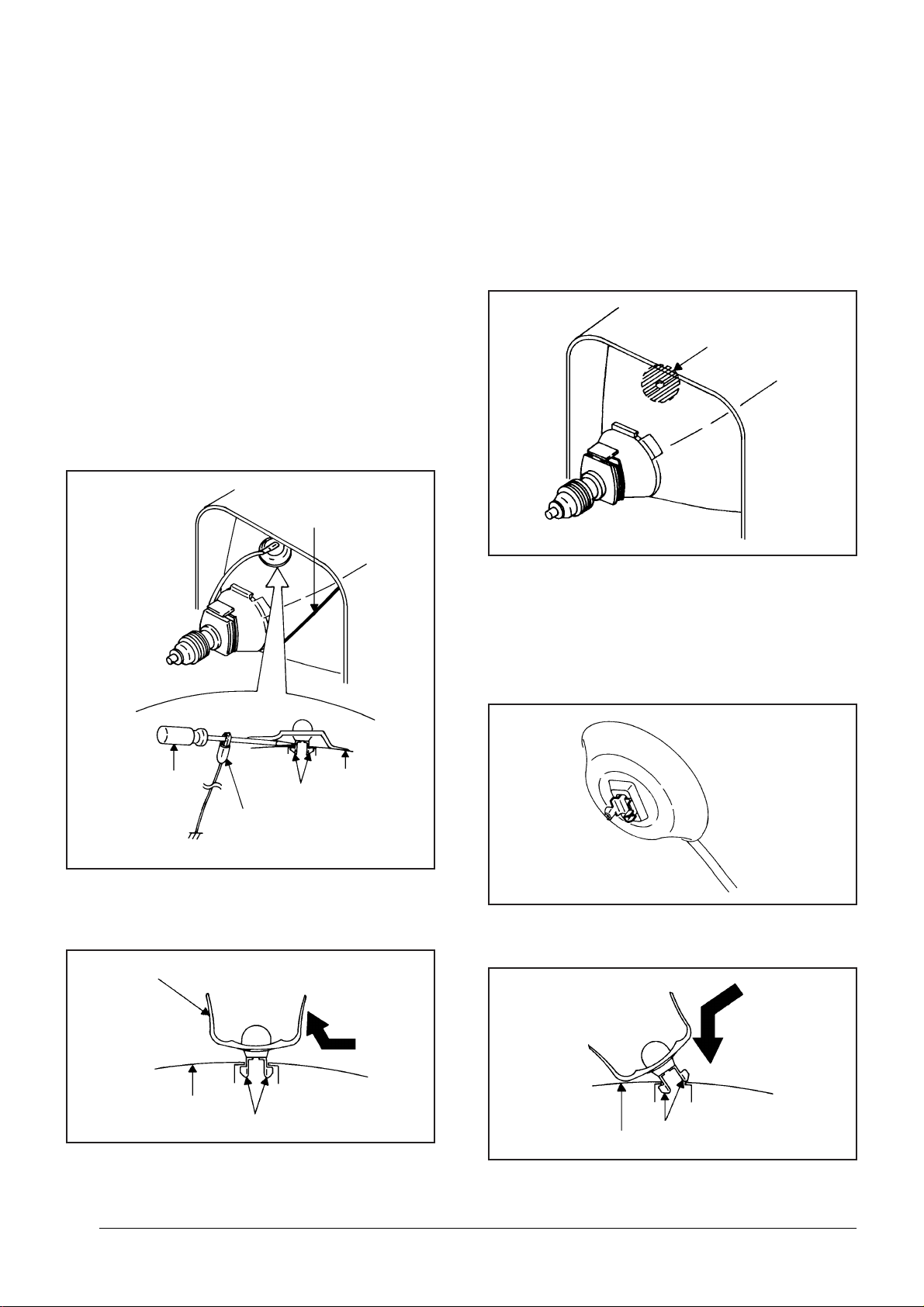

DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF ANODE CAP

Read the following NOTED items before starting work.

*

After turning the power off there might still be a potential

voltage that is very dangerous. When removing the

Anode Cap, make sure to discharge the Anode Cap's

potential voltage.

*

Do not use pliers to loosen or tighten the Anode Cap

terminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.

(Refer to Fig. 1-1.)

Connect one end of an Alligator Clip to the metal part of a

flat-blade screwdriver and the other end to ground.

While holding the plastic part of the insulated Screwdriver,

touch the support of the Anode with the tip of the

Screwdriver.

A cracking noise will be heard as the voltage is discharged.

GND on the CRT

3. After one side is removed, pull in the opposite direction to

remove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a small

amount of alcohol. (Refer to Fig. 1-3.)

Location of Anode Cap

Fig. 1-3

NOTE

Confirm that there is no dirt, dust, etc. at the spot where

the cap was located.

2.3.Arrange the wire of the Anode Cap and make sure the

wire is not twisted.

Turn over the Rubber Cap. (Refer to Fig. 1-4.)

Screwdriver

Alligator Clip

GND on the CRT

Flip up the sides of the Rubber Cap in the direction of the

2.

arrow and remove one side of the support.

(Refer to Fig. 1-2.)

Rubber Cap

CRT

Support

Support

CRT

Fig. 1-1

Fig. 1-2

Fig. 1-4

4. Insert one end of the Anode Support into the anode button,

then the other as shown in Fig. 1-5.

Support

CRT

5.6.Confirm that the Support is securely connected.

Put on the Rubber Cap without moving any parts.

Fig. 1-5

CM153 2-3 MX474C - SERVICING

Page 10

ELECTRICAL ADJUSTMENTS

1. BEFORE MAKING ELECTRICAL

ADJUSTMENTS

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any

service on this chassis.

•

Before removing the anode cap, discharge electricity

because it contains high voltage.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

Inferior silicon grease can damage IC's and transistors.

•

When replacing IC's and transistors, use only specified

silicon grease (YG6260M).

Remove all old silicon before applying new silicon.

Prepare the following measurement tools for electrical

adjustments.

1. Synchro Scope

2. Digital Voltmeter

On-Screen Display Adjustment

1. In the condition of NO indication on the screen.

Press the VOL. DOWN button on the set and the

Channel button (9) on the remote control for more than

1 second to appear the adjustment mode on the screen

as shown in Fig. 1-1.

TV

00 OSD 15

Fig. 1-1

2.3.Use the Channel UP/DOWN button or Channel button

(0-9) on the remote control to select the options shown

in Fig. 1-2.

Press the MENU button on the remote control to end

the adjustments.

FUNCTION

NO.

00

01

02

03

04

05

06

07

08

09

10

11

12

OSD H

CUT OFF

RF DELAY

VIF VCO

H VCO

H PHASE

V SIZE

V SHIFT

R DRIVE

B DRIVE

R BIAS

G BIAS

B BIAS

FUNCTION

NO.

BRIGHTNESS

13

CONTRAST

14

COLOR

15

TINT

16

SHARPNESS

17

FM LEVEL

18

LEVEL

19

SEPARATION 1

20

SEPARATION 2

21

TEST MONO

22

TEST STEREO

23

X-RAY TEST

24

Fig. 1-2

2. BASIC ADJUSTMENTS

2-1: RF AGC DELAY

1.

Place the set with Aging Test for more than 15 minutes.

2.

Receive a 64dB monoscope pattern.

3.

Connect the digital voltmeter to TP001.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (02) on the remote control to

select "RF DELAY".

5.

Press the VOL. UP/DOWN button on the remote control

until the digital voltmeter is 2.6V.

2-2: CUT OFF

1.

Adjust the unit to the following settings.

R DRIVE=10, B DRIVE=10, R BIAS=64, G BIAS=64,

B BIAS=64, BRIGHTNESS=100, CONTRAST=64

2.

Place the set with Aging Test for more than 15 minutes.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (01) on the remote control to

select "CUT OFF".

4.

Adjust the Screen Volume until a dim raster is obtained.

2-3: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

1.

Place the set with Aging Test for more than 10 minutes.

2.

Receive the white 100% signal from the Pattern

Generator.

3.

Using the remote control, set the brightness and contrast

to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (10) on the remote control to

select "R.BIAS".

5.

Using the VOL. UP/DOWN button on the remote control,

adjust the R.BIAS.

6.

Press the CH. UP/DOWN button on the remote control to

select the "R.DRIVE", "B.DRIVE", "G.BIAS" or "B.BIAS".

7.

Using the VOL. UP/DOWN button on the remote control,

adjust the R.DRIVE, B.DRIVE, G.BIAS or B.BIAS.

8.

Perform the above adjustments 6 and 7 until the white

color is looked like a white.

2-4: SUB BRIGHTNESS

1.

Receive the black pattern*. (RF Input)

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (13) on the remote control to

select "BRIGHTNESS".

4.

Press the VOL. UP/DOWN button on the remote

control until the screen begin to shine.

5.

Receive the black pattern*. (Audio Video Input)

6.

Press the TV/AV button on the remote control to set to

the AV mode. Then perform the above adjustments

2~4.

*The Black Pattern means the whole black raster signal.

Select the "RASTER" of the pattern generator, set to

the OFF position for each R, G and B.

CM153 2-4 MX474C - SERVICING

Page 11

ELECTRICAL ADJUSTMENTS

2-5: SUB CONTRAST

Activate the adjustment mode display of Fig. 1-1 and

1.

press the channel button (14) on the remote control to

select "CONTRAST".

Press the VOL. UP/DOWN button on the remote

2.

control until the contrast step No. becomes "78"

Press the TV/AV button on the remote control to set to

3.

the AV mode. Then perform the above adjustments

1~2.

2-6: SUB TINT/SUB COLOR

Receive the color bar pattern.

1.

Connect the synchro scope to TP023.

2.

Activate the adjustment mode display of Fig. 1-1 and

3.

press the channel button (16) on the remote control to

select "TINT".

Press the VOL. UP/DOWN button on the remote control

4.

until the waveform becomes as shown in Fig. 2-1.

Connect the synchro scope to TP022.

5.

Press the CH DOWN button once to set to "COLOR"

6.

mode.

Press the VOL. UP/DOWN button on the remote control

7.

until the red color level is adjusted to 100% of the white

level. (Refer to Fig. 2-2)

Receive the black pattern*. (Audio Video Input)

8.

Press the TV/AV button on the remote control to set to

9.

the AV mode. Then perform the above adjustments 2~7.

2-8: HORIZONTAL PHASE

1.

Receive a Crosshatch pattern.

2.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (05) on the remote control to

select "H. PHASE".

3.

Press the VOL. UP/DOWN button on the remote

control until the SHIFT quantity of the OVER SCAN on

right and left becomes minimum.

2-9: VERTICAL SIZE

1.

Receive a Crosshatch pattern.

2.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (06) on the remote control to

select "V. SIZE".

3.

Press the VOL. UP/DOWN button on the remote

control until the SHIFT quantity of the OVER SCAN on

right and left becomes 10 ± 2%.

2-10: VERTICAL SHIFT

1.

Receive a Crosshatch pattern.

2.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (07) on the remote control to

select "V. SHIFT".

3.

Press the VOL. UP/DOWN button on the remote

control until the horizontal line of the color bar comes to

approximate center of the CRT.

2-11: OSD HORIZONTAL

1.2.Activate the adjustment mode display of Fig. 1-1.

Press the VOL. UP/DOWN button on the remote

control until the difference of A and B becomes

minimum. (Refer to Fig. 2-3)

White 0%

0%

100%

Red Level

White 100%

2-7: FOCUS

1.

Receive a Crosshatch pattern.

2.

Turn the Focus Volume fully counterclockwise once.

3.

Adjust the Focus Volume until picture is distinct.

Fig. 2-1

Fig. 2-2

TV

00 OSD 15

A

2-12: VIF VCO

1.

Place the set with Aging Test for more than 10 minutes.

2.

Receive an 80dB monoscope pattern.

3.

Connect the digital voltmeter between the pin 5 of

CP601 and the GND.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (03) on the remote control to

select "V. VCO".

5.

Press the VOL. UP/DOWN button on the remote control

until the digital voltmeter is 2.5V.

2-13: CONSTANT VOLTAGE

1.

Connect the digital voltmeter to TP401.

2.

Set condition is AV MODE without signal.

3.

Adjust the VR501 until the DC voltage is 135 ± 1V.

B

Fig. 2-3

CM153 2-5 MX474C - SERVICING

Page 12

ELECTRICAL ADJUSTMENTS

3.

PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

Turn the unit on and let it warm up for at least 30

1.

minutes before performing the following adjustments.

Place the CRT surface facing east or west to reduce the

2.

terrestrial magnetism.

Turn ON the unit and demagnetize with a Degauss Coil.

3.

3-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

Tighten the screw for the magnet. Refer to the adjusted

1.

CRT for the position. (Refer to Fig. 3-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

Receive the green raster pattern from the color bar

2.

generator.

Slide the deflection yoke until it touches the funnel

3.

side of the CRT.

Adjust center of screen to green, with red and blue on the

4.

sides, using the pair of purity magnets.

Switch the color bar generator from the green raster

5.

pattern to the crosshatch pattern.

Combine red and blue of the 3 color crosshatch pattern

6.

on the center of the screen by adjusting the pair of

4 pole magnets.

Combine red/blue (magenta) and green by adjusting the

7.

pair of 6 pole magnets.

Adjust the crosshatch pattern to change to white

8.

by repeating steps 6 and 7.

3-2: PURITY

NOTE

Adjust after performing adjustments in section 3-1.

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the

color on the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole

screen is green.

4.

Confirm red and blue colors.

5.

Adjust the slant of the deflection yoke while watching the

screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

3-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

3-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-3.

1.2.Adjust the differences around the screen by moving

the deflection yoke upward/downward and right/left.

(Refer to Fig. 3-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 3-2-b)

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

WEDGE

WEDGE POSITION

R

G

B

Fig. 3-2-a

WEDGE

WEDGE

Fig. 3-2-b

R G B

PURITY MAGNETS

6 POLE MAGNETS

4 POLE MAGNETS

Fig. 3-1

CM153 2-6 MX474C - SERVICING

Page 13

MAJOR COMPONENTS LOCATION GUIDE

T502

VR501

TP401

J352

TP001

TU001

FB401

CP601

FOCUS VOLUME

SCREEN VOLUME

MAIN

TP023

TP022

J801

CRT

CM153 2-7 MX474C - SERVICING

Page 14

Page 15

SECTION 4

Y

PARTS

All MX474 models are module level repair only. Parts

contact information is below.

Voice: 1-888-3-ZENITH

Fax: 1-888-6-ZENITH

Mail: Zenith National Parts

201 James Record Road

Huntsville, AL 35824-1513

KE

MODEL INDENTIFIER

H13A02D A

H13A02X B

AB 000 206-03642 Instruction Book

A 101 857-10321 Cabinet, Front Ass’Y

B 101 857-10384 Cabinet, Front Ass’Y

A 102 857-10320 Cabinet, Front

B 102 857-10385 Cabinet, Front

AB 103 843-10055 Guide, Remocon

A 104 959-10097 Button, Frame

B 104 959-10116 Button, Frame

AB 105 841-10111 Button, Holder

AB 106 882-10015 Spring, Earth

AB 107 NSP Metal Spacap, Electror

AB 109 NSP Heat Sink

A 111 814-10143 Cabinet, Back

B 111 814-10223 Cabinet, Back

AB 116 841-10112 Speaker Holder

AB 201 NSP Screw, Tapping(B0) Truss 4x16

AB 202 NSP Screw, Tap Tite(P) Brazier 3x12

AB 203 NSP Screw, Tap Tite(P) Brazier 3x10

AB 204 NSP Screw/Washer(A) M3x8

AB 205 NSP Screw, Tapping(B0) Gw20 5x28

AB ANT001 801-10008 Antenna Rod T4-216BNK-BK

AB BT001 NSP Battery, Mangan R03(AB)E_20_T

AB BT002 NSP Battery, Mangan R03(AB)E_20_T

AB C002 822-11327 Cap, Electro 470 UF 6.3V

AB C003 822-11335 Cap, Electro 2.2 UF 50V

AB C004 822-11347 Cap, Poly 0.022 UF 50V

AB C007 822-11327 Cap, Electro 470 UF 6.3V

AB C101 822-11310 Cap, Ceramic 0.01 UF 16V

AB C113 822-11314 Cap, Ceramic 10 PF 50V

AB C114 822-11314 Cap, Ceramic 10 PF 50V

AB C115 822-11334 Cap, Electro 0.1 UF 50 V

AB C116 822-11313 Cap, Ceramic 270 PF 50V

AB C117 822-11313 Cap, Ceramic 270 PF 50V

AB C118 822-11327 Cap, Electro 470 UF 6.3V

AB C119 822-11356 Cap, Metal Plastic 0.68 UF 50V

AB C120 822-11321 Cap, Ceramic 0.001 UF 25V

AB C121 822-11311 Cap, Ceramic 200 PF 50V

AB C122 822-10389 Cap, Electro 1 UF 50V

AB C123 822-11332 Cap, Electro 10 UF 16V

AB C124 822-11334 Cap, Electro 0.1 UF 50 V

AB C125 822-11334 Cap, Electro 0.1 UF 50 V

AB C126 822-11312 Cap, Ceramic 220 PF 50V

AB C127 822-11312 Cap, Ceramic 220 PF 50V

AB C129 822-11334 Cap, Electro 0.1 UF 50 V

AB C130 822-11310 Cap, Ceramic 0.01 UF 16V

AB C134 822-11356 Cap, Metal Plastic 0.68 UF 50V

AB C135 822-11310 Cap, Ceramic 0.01 UF 16V

AB C136 822-11312 Cap, Ceramic 220 PF 50V

AB C137 822-11334 Cap, Electro 0.1 UF 50 V

AB C138 822-11318 Cap, Ceramic 560 PF 50V

AB C139 822-11310 Cap, Ceramic 0.01 UF 16V

AB C351 822-10389 Cap, Electro 1 UF 50V

AB C352 822-11333 Cap, Electro 47 UF 16V

AB C354 822-11116 Cap, Electro 470 UF 10V

AB C355 822-11334 Cap, Electro 0.1 UF 50 V

AB C356 822-11332 Cap, Electro 10 UF 16V

AB C357 822-11349 Cap, Poly 0.0068UF 50V

AB C402 822-11350 Cap, Poly 0.012 UF 200V

AB C403 822-11324 Cap, Electro 470 UF 35V

AB C406 822-11306 Cap, Ceramic 22 PF 500V

AB C407 822-11309 Cap, Ceramic 56 PF 50V

AB C411 822-11316 Cap, Ceramic 150 PF 50V

AB C414 822-11101 Cap, Electro 100 UF 35V

AB C415 822-11306 Cap, Ceramic 22 PF 500V

AB C417 822-11342 Cap, Electro 3.3 UF 50V

AB C418 822-11323 Cap, Electro 1000 UF 25V

AB C420 822-11304 Cap, Ceramic 0.001 UF 500V

AB C422 822-11354 Cap, Metal Plastic 0.15 UF 100V

AB C427 822-11341 Cap, Electro 10 UF 50V

AB C430 822-11345 Cap, Poly 0.012 UF 100V

AB C434 822-11330 Cap, Electro 22 UF 100V

AB C435 822-11353 Cap, Metal Plastic 0.1 UF 100V

AB C437 822-11351 Cap, Metal Polyprop 0.47 UF 250V

AB C439 822-11306 Cap, Ceramic 22 PF 500V

AB C440 822-11305 Cap, Ceramic 470 PF 500V

AB C443 822-11352 Cap, Metal Polyprop 0.0047UF 1.25KV

AB C446 822-11343 Cap, Electro 1 UF 160V

AB C448 822-11339 Cap, Electro 22 UF 200V

AB C501 822-11349 Cap, Poly 0.0068UF 50V

AB C502 822-11304 Cap, Ceramic 0.001 UF 500V

AB C503 822-11304 Cap, Ceramic 0.001 UF 500V

AB C505 822-11098 Cap, Metal Poly 0.22 UF 250V

AB C507 822-11302 Cap, Ceramic 0.0047UF 125V

AB C509 822-11348 Cap, Poly 0.047 UF 50V

AB C510 822-11328 Cap, Electro 47 UF 16V

AB C511 822-11329 Cap, Electro 1 UF 50V

AB C512 822-11305 Cap, Ceramic 470 PF 500V

AB C514 822-11301 Cap, Ceramic 680 PF 2KV

AB C515 822-11111 Cap, Electro 470 UF 16V

AB C517 822-11140 Cap, Ceramic 470 PF 2KV

AB C519 822-11340 Cap, Electro 470 UF 16V

AB C521 822-11338 Cap, Electro 100 UF 160V

AB C526 822-11325 Cap, Electro 220 UF 200V

AB C601 822-11326 Cap, Electro 1000 UF 6.3V

AB C603 822-10389 Cap, Electro 1 UF 50V

AB C604 822-10389 Cap, Electro 1 UF 50V

AB C605 822-11337 Cap, Electro 0.47 UF 50V

AB C606 822-11336 Cap, Electro 0.22 UF 50 V

AB C607 822-11310 Cap, Ceramic 0.01 UF 16V

AB C609 822-11307 Cap, Ceramic 0.01 UF 16V

AB C612 822-11116 Cap, Electro 470 UF 10V

AB C613 822-11355 Cap, Metal Plastic 1 UF 50V

AB C614 822-11310 Cap, Ceramic 0.01 UF 16V

AB C616 822-11315 Cap, Ceramic 15 PF 50V

AB C618 822-11317 Cap, Ceramic 22 PF 50V

AB C621 822-11310 Cap, Ceramic 0.01 UF 16V

AB C622 822-11346 Cap, Poly 0.015 UF 50V

AB C623 822-11097 Cap, Poly 0.0033UF 50V

AB C624 822-11328 Cap, Electro 47 UF 16V

AB C625 822-10389 Cap, Electro 1 UF 50V

AB C626 822-11321 Cap, Ceramic 0.001 UF 25V

AB C627 822-11322 Cap, Electro 1 UF 50 V

AB C630 822-10395 Cap, Electro 47 UF 10 V

AB C632 822-11335 Cap, Electro 2.2 UF 50V

CM153 - 923-03459 3-1 MX474C - MODEL PARTS

Page 16

PARTS

AB C634 822-11310 Cap, Ceramic 0.01 UF 16V

AB C635 822-11333 Cap, Electro 47 UF 16V

AB C636 822-11310 Cap, Ceramic 0.01 UF 16V

AB C638 822-11344 Cap, Electro 4.7 UF 50V

AB C639 822-11310 Cap, Ceramic 0.01 UF 16V

AB C643 822-11321 Cap, Ceramic 0.001 UF 25V

AB C645 822-11331 Cap, Electro 47 UF 16 V

AB C646 822-11310 Cap, Ceramic 0.01 UF 16V

AB C655 822-11321 Cap, Ceramic 0.001 UF 25V

AB C661 822-11310 Cap, Ceramic 0.01 UF 16V

AB C801 822-11308 Cap, Ceramic 330 PF 50V

AB C804 822-11319 Cap, Ceramic 680 PF 50V

AB C805 822-11320 Cap, Ceramic 820 PF 50V

AB C806 822-11320 Cap, Ceramic 820 PF 50V

AB C819 822-11303 Cap, Ceramic 0.001 UF 2KV

AB CD351 823-10189 Cord, Connector CH12403B

AB CD501 811-10037 Cord, Ac 7614908

AB CD501 811-10038 Cord, Ac 0R614908

AB CF601 820-10601 Filter, Saw SAF45MFY220ZR

AB CF603 905-10588 Filter, Cap, Electroramic EFCT4R5YS5A

AB CF604 905-10589 Filter, Cap, Electroramic EFCT4R5MW5

AB CP352 823-10187 Connector Pcb Side TID-X02P-B2

AB CP401 823-10188 Connector Pcb Side B05B-DVS

AB CP501 910-10014 Cord, Ux Connector THL-P03P-B1

AB CP502 823-10118 Connector Pcb Side TV-50P-02-A1

AB CP601 823-10185 Connector Pcb Side 173979-6

AB CP801 823-10186 Connector Pcb Side TBS-X01X-A1

AB CP802A 841-10110 Wire Holder 51048-1000

AB CP802B 841-10110 Wire Holder 51048-1000

AB D001 903-10391 Diode, Zener MTZJ30B T-77

AB D104 903-10402 Diode, Zener MTZJ6.8B T-77

AB D106 903-10402 Diode, Zener MTZJ6.8B T-77

AB D107 903-10402 Diode, Zener MTZJ6.8B T-77

AB D401 903-10481 Diode, Zener MTZJ27B T-77

AB D402 903-10478 Diode, Zener MTZJ11B T-77

AB D403 903-10470 Diode, Silicon 11E1-EIC

AB D404 903-10482 Diode, Zener MTZJ6.2B T-77

AB D405 903-10471 Diode, Silicon AU02A-EIC

AB D410 903-10471 Diode, Silicon AU02A-EIC

AB D411 903-10471 Diode, Silicon AU02A-EIC

AB D501 903-10472 Diode, Silicon RM11C-EIC

AB D502 903-10472 Diode, Silicon RM11C-EIC

AB D503 903-10472 Diode, Silicon RM11C-EIC

AB D504 903-10472 Diode, Silicon RM11C-EIC

AB D505 903-10392 Diode, Schottky 21DQ09N-TA2B1

AB D506 903-10479 Diode, Zener MTZJ15B T-77

AB D507 903-10479 Diode, Zener MTZJ15B T-77

AB D508 903-10390 Diode, Silicon 1SS133T-77

AB D509 903-10480 Diode, Zener MTZJ18B T-77

AB D510 903-10388 Diode, Silicon RU2AM V1

AB D512 903-10390 Diode, Silicon 1SS133T-77

AB D513 903-10392 Diode, Schottky 21DQ09N-TA2B1

AB D514 903-10390 Diode, Silicon 1SS133T-77

AB D518 903-10390 Diode, Silicon 1SS133T-77

AB D519 903-10390 Diode, Silicon 1SS133T-77

AB D528 903-10394 Diode, Zener MTZJ5.6B T-77

AB D601 903-10390 Diode, Silicon 1SS133T-77

AB D602 903-10483 Diode, Zener MTZJ8.2B T-77

AB D603 903-10209 Diode, Zener MTZJ12B T-77

AB D605 903-10470 Diode, Silicon 11E1-EIC

AB D610 903-10209 Diode, Zener MTZJ12B T-77

AB D611 903-10209 Diode, Zener MTZJ12B T-77

AB D612 903-10209 Diode, Zener MTZJ12B T-77

AB F501 936-10042 Fuse 233004-MB000

AB FB401 895-10095 Transformer Flyback 3214029F

AB FH501 862-10003 Holder, Fuse EYF-52BC

AB FH502 862-10003 Holder, Fuse EYF-52BC

AB IC101 905-10593 I/C, OEC7044B

AB IC199 905-10590 I/C, S-24C02BDP-11

AB IC351 905-10447 I/C, AN7511

AB IC401 905-10591 I/C, LA78040

AB IC506 962-00054 Photo Coupler TLP621(D4-GR-LF2

AB IC601 905-10592 I/C, M61203CFP

AB J352 844-10081 Jack, Resistor, Carbona 3.5 HSJ1403-01-010

AB J801 878-10016 Socket, Cathode Ray Tube HPS3200-010501

AB L001 820-10596 Coil 10 UH

AB L101 820-10599 Coil 3.3 UH

AB L402 820-10598 Coil 18 UH

AB L501 820-10566 Coil, Line Filter 9-000074

AB L503 820-10600 Coil, Degauss 8F140025

AB L601 820-10595 Coil 1.2 UH

AB L603 820-10597 Coil 22 UH

AB L605 820-10594 Coil 1 UH

AB L606 820-10558 Coil 2.2 UH

AB L607 820-10552 Coil 15 UH

AB L801 820-10560 Coil 100 UH

AB OS101 942-10065 Remote Recap, Electroiver PIC-28141SY-2

A PCB010 809-10511 TV MT PCB Ass’Y

B PCB010 809-10777 TV MT PCB Ass’Y

A PCB110 809-10512 CRT PCB Ass’Y

B PCB110 809-10778 CRT PCB Ass’Y

AB Q401 921-10261 Transistor, Silicon 2SD2627LS-CBC11

AB Q402 921-10260 Transistor, Silicon 2SC1473A-TA-(RQ)

AB Q501 921-10259 Transistor, Field Effect 2SK2662

AB Q502 921-10202 Transistor, Silicon 2SC2120Y(TPE2)

AB Q507 921-10200 Transistor, Silicon 2SC1740SP(R,S) TP

AB Q603 921-10104 Transistor, Silicon 2SD734(E,F)-AA

AB Q604 921-10104 Transistor, Silicon 2SD734(E,F)-AA

AB Q605 921-10104 Transistor, Silicon 2SD734(E,F)-AA

AB Q606 921-10104 Transistor, Silicon 2SD734(E,F)-AA

AB Q801 921-10260 Transistor, Silicon 2SC1473A-TA-(RQ)

AB Q802 921-10260 Transistor, Silicon 2SC1473A-TA-(RQ)

AB Q803 921-10260 Transistor, Silicon 2SC1473A-TA-(RQ)

AB R001 863-11463 Resistor, Carbon 18K Ohm 1/2W

AB R002 863-11463 Resistor, Carbon 18K Ohm 1/2W

AB R006 863-11504 Resistor, Carbon 270 Ohm 1/8W

AB R007 863-11504 Resistor, Carbon 270 Ohm 1/8W

AB R101 863-11514 Resistor, Carbon 560 Ohm 1/8W

AB R102 863-11516 Resistor, Carbon 680 Ohm 1/8W

AB R103 863-11516 Resistor, Carbon 680 Ohm 1/8W

AB R104 863-11516 Resistor, Carbon 680 Ohm 1/8W

AB R105 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R106 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R107 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R110 863-10537 Resistor, Carbon 1K Ohm 1/4W

AB R111 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R112 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R113 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R114 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R115 863-11513 Resistor, Carbon 47K Ohm 1/8W

AB R116 863-11513 Resistor, Carbon 47K Ohm 1/8W

AB R117 863-11513 Resistor, Carbon 47K Ohm 1/8W

AB R119 863-11491 Resistor, Carbon 1K Ohm 1/8W

AB R120 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R121 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R122 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R123 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R124 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R126 863-11505 Resistor, Carbon 2.7K Ohm 1/8W

AB R127 863-11505 Resistor, Carbon 2.7K Ohm 1/8W

AB R128 863-11514 Resistor, Carbon 560 Ohm 1/8W

AB R129 863-11494 Resistor, Carbon 1M Ohm 1/8W

CM153 - 923-03459 3-2 MX474C - MODEL PARTS

Page 17

PARTS

AB R130 863-11491 Resistor, Carbon 1K Ohm 1/8W

AB R131 863-11510 Resistor, Carbon 47 Ohm 1/8W

AB R134 863-11511 Resistor, Carbon 470 Ohm 1/8W

AB R352 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R353 863-11517 Resistor, Carbon 68K Ohm 1/8W

AB R354 863-11506 Resistor, Carbon 270K Ohm 1/8W

AB R356 863-11464 Resistor, Carbon 27 Ohm 1/2W

AB R357 863-11493 Resistor, Carbon 100K Ohm 1/8W

AB R359 863-11513 Resistor, Carbon 47K Ohm 1/8W

AB R401 863-11331 Resistor, Metal 100K Ohm 1/4W

AB R402 863-11467 Resistor, Carbon 6.8 Ohm 1/2W

AB R403 863-11472 Resistor, Carbon 22K Ohm 1/4W

AB R405 863-11484 Resistor, Metal 18K Ohm 1/4W

AB R406 863-11491 Resistor, Carbon 1K Ohm 1/8W

AB R407 863-11480 Resistor, Metal Oxide 2.2 Ohm 1W

AB R408 863-11315 Resistor, Metal 15K Ohm 1/6W

AB R409 863-11354 Resistor, Metal 5.6K Ohm 1/6W

AB R410 863-11465 Resistor, Carbon 330 Ohm 1/2W

AB R413 863-11461 Resistor, Carbon 1.2K Ohm 1/2W

AB R415 863-11460 Resistor, Carbon 1K Ohm 1/2W

AB R416 863-11459 Resistor, Carbon 1 Ohm 1/2W

AB R417 863-11485 Resistor, Metal 11K Ohm 1/6W

AB R418 863-11352 Resistor, Metal 22K Ohm 1/6W

AB R419 863-11497 Resistor, Carbon 1.2K Ohm 1/8W

AB R420 863-11508 Resistor, Carbon 3.3K Ohm 1/8W

AB R421 863-11473 Resistor, Carbon 220K Ohm 1/4W

AB R424 863-11487 Resistor, Metal 6.8K Ohm 1/6W

AB R426 863-11474 Resistor, Carbon 2.7K Ohm 1/4W

AB R427 863-11468 Resistor, Carbon 100 Ohm 1/4W

AB R428 863-11488 Resistor, Cap, Electroment 12K Ohm 5W

AB R429 863-11335 Resistor, Fuse 3.3 Ohm 1W

AB R445 863-11473 Resistor, Carbon 220K Ohm 1/4W

AB R446 863-11466 Resistor, Carbon 4.7K Ohm 1/2W

AB R500 863-11351 Resistor, Carbon 2.7M Ohm 1/2W

AB R501 863-11489 Resistor, Cap, Electroment 2.2 Ohm 5W

AB R504 863-11482 Resistor, Metal Oxide 33 Ohm 3W

AB R505 863-11479 Resistor, Metal Oxide 220 Ohm 1W

AB R506 863-11477 Resistor, Carbon 680 Ohm 1/4W

AB R508 863-11474 Resistor, Carbon 2.7K Ohm 1/4W

AB R509 863-10567 Resistor, Carbon 2.2K Ohm 1/4W

AB R510 863-11471 Resistor, Carbon 1.2M Ohm 1/4W

AB R511 863-11471 Resistor, Carbon 1.2M Ohm 1/4W

AB R512 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R513 863-11515 Resistor, Carbon 5.6K Ohm 1/8W

AB R514 863-11475 Resistor, Carbon 39K Ohm 1/4W

AB R515 863-11472 Resistor, Carbon 22K Ohm 1/4W

AB R516 863-11476 Resistor, Carbon 560 Ohm 1/4W

AB R517 863-11483 Resistor, Metal Oxide 5.6 Ohm 3W

AB R518 863-11486 Resistor, Metal 2.2K Ohm 1/6W

AB R519 863-11507 Resistor, Carbon 330 Ohm 1/8W

AB R520 863-11462 Resistor, Carbon 150K Ohm 1/2W

AB R542 863-11481 Resistor, Metal Oxide 0.68 Ohm 1W

AB R601 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R602 863-11491 Resistor, Carbon 1K Ohm 1/8W

AB R603 863-11498 Resistor, Carbon 1.5K Ohm 1/8W

AB R604 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R605 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R606 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R608 863-11499 Resistor, Carbon 1.8K Ohm 1/8W

AB R609 863-11511 Resistor, Carbon 470 Ohm 1/8W

AB R611 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R612 863-11478 Resistor, Carbon 6.8K Ohm 1/4W

AB R613 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R614 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R615 863-11511 Resistor, Carbon 470 Ohm 1/8W

AB R617 863-11491 Resistor, Carbon 1K Ohm 1/8W

AB R618 863-11469 Resistor, Carbon 10M Ohm 1/4W

AB R619 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R620 863-11495 Resistor, Carbon 12 Ohm 1/8W

AB R621 863-11505 Resistor, Carbon 2.7K Ohm 1/8W

AB R622 863-11496 Resistor, Carbon 120 Ohm 1/8W

AB R623 863-11470 Resistor, Carbon 120 Ohm 1/4W

AB R624 863-11500 Resistor, Carbon 2K Ohm 1/8W

AB R625 863-11502 Resistor, Carbon 2.2K Ohm 1/8W

AB R626 863-11503 Resistor, Carbon 22K Ohm 1/8W

AB R627 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R628 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R629 863-11482 Resistor, Metal Oxide 33 Ohm 3W

AB R630 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R631 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R632 863-11501 Resistor, Carbon 220 Ohm 1/8W

AB R633 863-11518 Resistor, Carbon 8.2K Ohm 1/8W

AB R634 863-11492 Resistor, Carbon 10K Ohm 1/8W

AB R635 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R636 863-11509 Resistor, Carbon 33K Ohm 1/8W

AB R638 863-11503 Resistor, Carbon 22K Ohm 1/8W

AB R639 863-11490 Resistor, Carbon 100 Ohm 1/8W

AB R641 863-11352 Resistor, Metal 22K Ohm 1/6W

AB R642 863-11503 Resistor, Carbon 22K Ohm 1/8W

AB R802 863-11474 Resistor, Carbon 2.7K Ohm 1/4W

AB R803 863-11325 Resistor, Metal Oxide 15K Ohm 1W

AB R804 863-11474 Resistor, Carbon 2.7K Ohm 1/4W

AB R805 863-11325 Resistor, Metal Oxide 15K Ohm 1W

AB R806 863-11474 Resistor, Carbon 2.7K Ohm 1/4W

AB R807 863-11325 Resistor, Metal Oxide 15K Ohm 1W

AB R809 863-11501 Resistor, Carbon 220 Ohm 1/8W

AB R811 863-11501 Resistor, Carbon 220 Ohm 1/8W

AB R813 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R814 863-11501 Resistor, Carbon 220 Ohm 1/8W

AB R815 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB R816 863-11512 Resistor, Carbon 4.7K Ohm 1/8W

AB SP351 849-10034 Speaker C908-8-03A

AB SW101 885-10045 Switch, Tact SKHVBED010

AB SW102 885-10045 Switch, Tact SKHVBED010

AB SW103 885-10045 Switch, Tact SKHVBED010

AB SW104 885-10045 Switch, Tact SKHVBED010

AB SW105 885-10045 Switch, Tact SKHVBED010

AB T401 895-10114 Trans, Horizontal Drive 305Y001

AB T502 895-10115 Transformer, Switching 8129018S

AB TH501 820-10602 Degauss Element PTH451A3R0Q11

AB TM101 924-10072 Transmitter R25-1422

AB TU001 975-10045 Tuner, VHF-UHF NJH3022U268

AB V801 900-10043 Color Picture Tube W/Dy A34JXV70X28N45

AB VR501 863-11519 Volume, Semi Fixed RH063LCN2R

AB X101 903-10469 Cap, Electroramic Oscillator CSTS0800MG03-T2

AB X602 903-10410 Crystal Hc-49/C 3.579545MHz

CM153 - 923-03459 3-3 MX474C - MODEL PARTS

Page 18

Page 19

EXPLODED VIEW

201

201

201

201

111

106

V801

205

205

L503

205

205

J801

104

PCB110

(CRTPCB)

105

203

202

FB401

107

109

PCB010

(MAINPCB)

107

109

204

201

204

107

TU001

203

103

202

118

102

CM153 4-1 MX474C - EXPLODED VIEW

101

SP351

Page 20

Page 21

Page 22

Page 23

H13A02D/02X Power Supply Circuit

B

12345678910

G

FORCONTINUEDP ROTECTION AGAINST FIRE HAZARD,CAUTION:

REPLACEONL Y WITH THESAME TYPE4A 125V (F501)

4A125V

F

FUSE.

D505

21DQ09N

C519

470uF

16V

R517

5.63W

SOUND+B

SOUND_GND

GND

To S heet 5

Audio

R500

L501

9-000074

+-10%

2.7M

1/2W

R501

B

D503

POWER

Q501

2SK2662

4.8

2SC2120Y

HS501

D502

RM11C-EIC

Q502

0.0

2.25W

C526

220uF

200V

R505

2201W

4.8

0.1

12

45

3

NC

C507

0.0047 uF

125V

RM11C-EIC

RM11C-EIC

D501

D504

R504

C502

0.001uF500V

W804

3W

33

C514

680pF

2KV

0.681W

R542

0.1

C503

0.001u F500V

RM11C-EIC

144

D

G

S

763WSA0005

R506

680

1/4W

C501

0.0068uF

D509

MTZJ18B

C509

0.047uF

D507

MTZJ15B

R508

2.7K

1/4W

R510

1.2M

1/4W

R511

1.2M

1/4W

D508

1SS133

R509

2.2K

1/4W

L503

8F140025

E

D

120V60 Hz

CD501

0R614908

BLACK

WHITE

LADE

WIDE

CP502

TV-50P-02-A1

1

2

12

CP501

TH501

PTH451 A3R0Q11

FH501

BLACK

WHITE

W821

4A125V

F501

4A125V

233004-MB000

FH502

C505

0.22uF

250V

21

21

C

B

This schematic ref ers to

the following models

H13A02D

H13A02X

A

HOT COLD

1.7

8

NC

7

144.0

6

NC

5

10.3

4

6.6

3

10.3

2

D512

1SS133

C511

50V

1uF

D506

MTZJ15B

FEEDBACK

IC506

TLP621(D4-GR-LF2)

T502

8129018S

11.510.5

0.19.6

W840

5.6

10

NC

11

0.0

12

132.3

13

0.0

14

0.0

15

11. 2

16

NC

17

NC

18

R512

2.2K

1

2

34

R513

5.6K

D528

MTZJ5.6B

FEEDBACK

SWITCHING

Q507

2SC1740SP

C510

47uF

W825

D518

1SS133

R520

150K1/2W

5.5

16V

9.5

6.0

+B ADJ.

RH063LCN2R

VR501

D513

21DQ09 N

C512

500VB

470pF

D510

RU2AM

C517

2KV

470pF

R514

39K

1/4W

R515

22K

1/4W

R516

680

1/4W

R518

2.2K+-1 %

C515

16V

470uF

R519

+B

C521

160V

100uF

D514

1SS133

D519

1SS133

330

GND

UNREG+12V

+B

GND

To Sheet 2

Deflection

To Sheet 4

Chroma

To Sheet 3

Micro/Tuner

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

5-1

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 1

Page 24

H13A02D/02X Deflection Circuit

v

CD802

12345678910

G

CLAMP

To Sheet 4

Chroma

G.OUT

R.OUT

B.OU T

B

F

E

To S hee t 3

D

Micro/Tuner

X-RAY

R401

100K

1/4W

+-1%

G

R

IC401LA78040V-OUT

THERMAL

PROTECTION

-

HS401

763WSA0005

R409

5.6K+ -1%

C415

500V

22pF

+

C414

100uF

35V

SL

1234567

3.524.72.00.012.025.03.5

18

W814

C411

150pF

D401

MTZJ27B

R426

2.7K

1/4W

R405

18K

1/4W

+-1%

D402

MTZJ11B

R406

3.3K

R408

15K+-1%

R424

6.8K+-1%

R417

11K+ - 1%

PUMP

UP

R418

22K+- 1%

R419

22

D403

11 E 1 - E I C

C430

C422

0.15uF

100V

R416

1

1/2W

R410

330

1/2W

R415

1K1/2 W

C427

50V

10uF

R429

1W

3.3

0.012 uF

R420

3.3K

1.2K

C417

3.3uF

50V

R407_1

2.21W

100V M

C418

1000uF

25V

23

CD802A

GND

1

CLAMP

2

G.OUT

3

R.OUT

4

B.OUT

5

NC

6

HEATER

7

GNDGND

8

NC

9

180V

10

5

4

3

2

NC

22uF100V

C434

1

D411

AU02A -EIC

2E0A3001

V801

A34JXV70X28N45

9

10

8

6

11

CP401

B05B-DVS

1

2

3

4

5

6

7

8

9

10

R

G

B

CD802B

GND

CLAMP

G.OUT

R.OUT

B.OUT

NC

HEATE R

NC

180V

CD801_1

175

CP801

TBS-X01X-A1

1

REDOUT

Q801

2SC1473A

3.2

2.7

R802

2.7K

1/4W

R813

4.7K

G

B

GREENOUT

Q802

2SC1473A

3.2

98.4

2.7

C804680pF

R809220

R815

4.7K

TP024TP022

R805

R804

15K

2.7K

1W

1/4W

C805820pF

R807

BLUEOUT

Q803

2SC1473A

3.2

95.4

2.7

TP023

R806

2.7K

1/4W

C806820pF

R811220

2625

15K

1W

14 0.5V 5ms/div

R814

220

R816

4.7K

15 20V 20µs/div

19 10.0V 5ms/div

20 20.0V 20µs/di

R

1

L801

100uH

0607

R803

15K

1W

100.6

24

T401

19

C439

22pF500V

GND

Chroma

To Sheet 1

Power

V_FEEDBACK

V_OUT

ABCL

H_OUT

H_SYNC

+B

TUNER+B

W802

GND

To Sheet 4

C

B

H.DRI VE

Q402

2SC1473A

27.0

0.3

0

TP40 1

A

305Y001

34

2

NC

1

R42812K5W

C4461

160V

MHE

HS402

763WSA0005

6

20

R427

200V

R446

4.7K

1/2W

B

500V

C440470P

1001/4W

C402

130.0

0

W832

W826

0.012uF

21

H.OU TPUT

Q401

2SD2627LS-CBC11

0

L402

18uH

6.81/2W

MTZJ6.2B

R402

W828

D404

C443

1.25KV

0.0047uF

C407

56pF

C437

0.47uF

250V

R403

22pF1/4W

C406

22pF

AU02A- EIC

D405

C420

0.001uF

500V

AU02A-EIC

D410

1.1K

132.5

132.5

48.0

5.4

10

0.0

NC

4.3

FB4013214029F T402

COL

1

VIDEO

6

B+

2

AFC

9

HEA

TER

GND

8

E12

4

E25

3

C801

330pF

CAUTIO N:DIG IT AL TRANSIS TOR

B

R

HV

F

S

0.0

GND

11

ABL

4.3

7

0.0

GND

8

NC

E8

5

FOCUS

SCREEN

R

G

B

SCREEN

Red Drive

Green Drive

Blue Drive

FOCUS

CP806

1

C819

0.001pF

2KV

6.4

0

0

6

101.6

HPS3200-010501

96.4

3

4

5

7

8

9

J801

Vertical

Horizontal

G

CAUTIO N:DIG IT AL TRANSIS TOR

0

1

F

99.6

This schematic ref ers to

the following models

H13A02D

H13A02X

16 2.0V 20µs/div

17 200V 20µs/div

21 20V 20µs/div

22 20V 20µs/div

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

C403

35V

470uF

C448

200V

22uF

R445

220K

1/4W

5-2

C435

100V

0.1uF

R421

220K

1/4W

18 5.0V 5ms/div

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 2

Page 25

H13A02D/02X Main Micro & Tuner Circuit

v

SYNC

12345678910

R107

R112

2.2K

R113

L101

3.3uH

TU001NJH3022U26 8

IF

10

11

1415

0.0

0.0

W823

C0040.022uF

C136

220pF

10K

2.2K

C114

10pF

2.7K

R127

C113 10pF

C119

0.68uF

BTL

NC

30.0

D001MTZJ30B

C117270pF

R105

4.7K

C116270pF

R106

4.7K

W809

C115

BPL

V.S

SCL

SDA

89

0.0

NC

6.3V

C007470uF

0.1

C135

50V

56

NC

6.3V

C002470uF

R006270

5678

4

5.0

5.0

R007270

D106

MTZJ6.8B

D107

MTZJ6.8B

5.05.0

SCL

SDA

VSS

E2

7

5.0

0.01Y

AGC

ADRES

3

2

1

1213

4.6

6.2

1.3

NC

NC

TP001

JWF-50K-1

C003

50VKA

2.2uF

R1234.7K

R1224.7K

R1214.7K

R1204.7K

R103

680

220pF

C126

R104

POWER

SW105

SKHVBED0 10

R102

680

R119

1K

W819

C134

0.68uF

C101

0.01uF

0.0

MODE

E1

1234

0.00.00.00.0

W820

5.0

VCC

MEMORY

IC199

P/L

E0

This schematic ref ers to

the following models

W801

R124

680

4.7K

220pF

C127

R101

560

VOL DOWN

SW104

SKHVBED01 0

H13A02D

H13A02X

R126

2.7K

C137

50V

0.1uF

C125

50V

0.1uF

10uH0607

R002

18K1/2W

C129

50V

0.1uF

VOL UP

SW103

SKHVBED01 0

L001

R001

18K1/2W

R128

560

CHDOWN

SW102

SKHVBED010

R

G

B

CHUP

SW101

SKHVBED01 0

FROM/TOCHROMA

TUNER+5V

AGC

IF

I2C_OFF

VD

HD

OSD_R

OSD_G

OSD_B

OSD_BLK

FROM/TOSOUND/A V

AUDIO_MUTE

POWER

FROM/TOPOW ER

GND

DEGAUSS_H

TUNER+B

FROM/TODE FLECTION/CR T

X-RAY _TEST

X-RAY

FROM/TOCHROMA

AFT

SCL

SDA

RESET

POWER

AT+5V

Y_VID EO

G

R

Red Drive

G

Green Drive

B

Blue Drive

F

1

0.5V 50 ns/di

E

2 0.5V 20µs/div

D

3 1.0V 20µs/div

C

B

4 1.0V 5ms/div

OS101

PIC-28141SY-2

2

1

GNDB+Vout

3

C123

10uF

16V

R131

R114

R115

47

10K

47K

C130

0.01uF

R116

47K

R111

10K

D104

MTZJ6.8B

C122

R1301K

150V

C121

200PCH

C124

0.1uF

50V

X101_1

CSTS0800MG03-T2

R110

1K

1/4W

R117

47K

C120

0.001Y

1

2

3

R129

R134

470uF

1M

MICON

IC101OEC7044B

3

1

P50/H.SYNC

4.0

4

P51/V.SYNC

2

4.7

3

P00/EXT MUTE

0.0

P01/I2C_OFF

4

4.8

P02/AUDIOMUTE

5

0.0

P03/(Surround)

6

0.0

P04

7

0.0

8

P05/(Center_SP)

0.0

INT2/P.FAIL

9

4.0

INT1/RE MOCON

10

4.8

P23/SYNC

11

0.8

P24

NCNC

12

NC

13

P25/ON_TIMER

0

AVC C

14

4.9

HLF

15

1.9

V.HO LD

16

0.2

2

CVIN

17

2.6

C138

560pF

CNVSS

18

0

1

Xin

19

2.3

Xout

20

1.6

VSSVCC

21

0

OUT1/BLANKBL

P10/DEGAUSS_H

AD1/X_RAY_TEST

C118

6.3V

470uF

REDR

BLUEB

P20/AV2

P21/AV1

P22/POWER

SCL1

SCL2

SDA1

SDA2

X-RAY

AD4/AFT

AD5/KEY1

AD6/KEY2

RESET

OSC1

OSC2

42

0.0

41

0.0

40

0.0

39

0.0

38

NC

NC

37

36

4.9

35

0.0

34

33

NC

32

4.8

31

30

0.0

29

0.0

28

0.0

27

4.9

26

4.8

25

2.5

24

2.5

23

2.5

22

4.9

A

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

5-3

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 3

Page 26

H13A02D/02X Chroma Circuit

11 0.5V 20µs/div

6 0.5V 20µs/div

7 200mV 20µs/div

8 2.0V 20µs/div

9 0.5V 20µs/div

12 0.5V 20µs/div

13 0.5V 20µs/div

10 0.5V 5ms/div

5 100mV 1ms/div

T

D

12345678910

G

To Sheet 1

Power

F

E

To Sheet 5

Audio

D

C

To Sheet 3

Micro/Tu ner

B

To Sheet 3

Micro/Tu ner

A

UNREG+12V

AUDIO_OUT

GND

Y_VI DEO

AT+5V

SYNC

TUNER+5V

RESET

AFT

AGC

IF

GND

HD

POWER

OSD_B

OSD_BLK

OSD_G

VD

OSD_R

I2C_OFF

SDA

SCL

3W

R629

REG

Q604

2SD734

4.97.2

5.5

47uF

16V

R628

100

39440

5vREG

YSWOUT

34EXT Cin

338.7VREGO UT

32X’T AL

17VOUT

16BOUT

SDA

101 112 13141516

9

C603

50V

1uF

R604

100

R605

4.7K

7.24.9

C630

47uF

10V

AFCFIL TER

33

REG

Q605

2SD734

3738

C6070.01u F

5.5

C627

50V

NP

1

VIDEO/CHROMA GND

INVFBP OUT

D610MT ZJ12B

C625

R633

2.55.6

3.2

TV/Y IN

CHROMA APCFILTER

VPULSEOU T

FASTBLK

SPOT KILLER

VIDEOCHROMA Vcc

VRAMP CAP

VRAMP FEEDBAC K

STRAT UP Vcc

ROUT

POWERONCONT

D611M T ZJ12B

R6142.2K

R6192.2K

150V1uF

8.2K

C643

0.001uF

1.9

GOUT

fscOUT

GOUT

C622

0.015uF

33343536

RIN

BIN

R6252.2K

REG

Q606

2SD734

7.9

11. 3

8.5

R639

100

C616

15pF

8.5

X602

3.5795 45MHz

32

3.3

31

2.6

30

0

29

4.7

28

0

27

0

NC

26

7.0

NC

25

2.8

24

4.9

23

4.9

4.7

21

2.8

20

0

19

7.9

18

7.9

17

3.6

C612

10V

470uF

13

12

11

D612

MTZJ12B

R641

22K+-1%

R642

22K

R627100

R630100

R631100

R6171K

R63822K

C6610.01uF

11 E1 - EI C

C613

1uF

D603

MTZJ12B

R620

12

C638

4.7uF

50V

D605

R

G

C645

47uF

16V

L603

22uH060 7

B

10

B

G

R

Ver tical

Hori zontal

R

G

B

Red Drive

Green Drive

Blue Drive

This schematic ref ers to

the following model

H13A02D

H13A02X

V_OUT

ABCL

V_FEED BACK

GND

H_OUT

H_SYNC

B.OUT

G.OUT

R.OUT

CLAMP

TEST POINT

CP6011739 79-6

B.OUT

INT.MONI

IICOFF

SDA

SCL

GND

6

5

4

3

2

1

6

R623

120

1/4W

8.8

REG

5.5

4.9

C621

0.01uF

CF603

W818

50V

5

C618

22pF

L607

15uH

R622

120

L606

2.2uH

2.3

2.4

2.2

3.0

2.9

3.2

8.7

3.2

2.2

1.9

2.8

4.6

C606

2.9

0.22uF

50V

1uH

L605

R621

2.7K

Q603

2SD734

EFCT4R5YS5A

1uF50V

C624

47uF

16V

CF601SAF45 MFY220ZR

OUTOUTGININ

1234

1.5K

R634

10K

C6550.001u F

C6230.003 3uF

C6322.2uF

C605

50V

0.47uF

R609

470uF

C626

0.001uF

SAW FIL TER

5

6.8K1/4W

W817

W834

B

G

R

R612

R632

220

R61110 K

C604

R61810M

1/4W

D602

MTZJ8.2B

D601

1SS133

R606

10K

L601

1.2uH

R603

7

CF604

EFCT4R5MW5

R615

470

49

AUDIOOUT ACL/ABCL

50

AUDIOBYP ASS

51

EXT AUDIOIN

52

FMDIRE CT OUT

53

VIFVCOF/B

54

VREGVcc

55

VIFAPCFILTER

56

VIFVIDEOOUT

57

VIFGND

58

0

59

0

AFT OUT

60

QIFIN

61

RF AGCOUT

62

RF AGCFIL TER

63

64

1.5

C634

0.01uF

C609

0.01uF

1000uF

R608

C636

1.8K

0.01uF

3.0

0000000

2.2

47

48

1

1.54.94.94 .94.93.43.94.92. 02.02.0

C601

45

46

HiVcc

HVCOF/B

VIFVcc

2

3

00000

C639

0.01uF

R624

2K

R636

33K

4344

INTELLIGENT MONI

46SWREGCONT

47L IMITER IN

48IF AGC

49QIFOUT

64VIFIN

1VIFIN

SCL

6

5

W805

R626

22K

8

R602

R613

100

R635

100

C635

0.01uF

C646

C6140.01 uF

5.77.9

4142

MCURESET

5.7VREGOUT( FORCPU)

CHROM A

IC60 1

M61203BFP

HOUT

DEF

FBP IN

789

R601

4.7K

1K

W829

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

5-4

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 4

Page 27

H13A02D/02X Audio Circuit

iv

E

1

0

M

12345678910

G

C13A03/05 Only

J703

FROM/TOCHROMA

AUDIO_IN

F

VIDEO_I N

To Sheet 4

Chroma

GND

R701

75

1/4W

R702

47K

R703

820

1/4W

C701

PROV

E

HTJ-032-05AW

23

HNC

23

HNC

J702

HTJ-032-05AY

E

1

A_IN

E

V_IN

1

23 100mV 1ms/d

24

C352

R356

27

47uF

16V

1/2W

Powe r

AUDIO_MUTE

POWER

SOUND+B

SOUND_GND

GND

W803

R359

47K

C354

470uF

10V

R353

68K

R357

100K

SOUND AM P

IC351

AN7511

R354

270K

5678

C351

50V

3.5

0

0.3

08.2

-+

1234

0.3

3.95.1

This schematic ref ers to

1uF

C356

10uF

16V

D

C

To Sheet 3

Micro/Tuner

To Sheet 1

B

2

3

1

HEADPHONE_J ACK

J352

HSJ1403-01-010

CP352 TID-X02P-B2

SP OU T

SOUNDGND

the following models

H13A02D

H13A02X

1

2

CD351

CH12403 B

1

2

SPEAK

SP35

C908-8-

8OH

24 0.5V 1ms/div

C357

To Sh eet 4

A

Chroma

AUDIO_OUT

0.0068

C355

0.150V

W833

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

R352

10K

5-5

23

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

MX474C SHEET 5

IS NORMAL.

Page 28

H13A02D/02X PCB Layout Top

12345678910

G

CP802B

Q803

C137

W005

C125

W018

W019

R110

F501

R806

R802

TP023

R612

W049

W004

R500_1

CP501

CD802B

C801

W058

C134

C118

C115

W016

CC002

FH501

Q801

TP022

R807_1

C351

C357

W002

W003

D104

TP024

C356

W833

R803_1

W055

W809

C130

Q802

L801

R804

C355

D106

W061

C135

C121

C124

TH501

D505

W840

C635

C609

C614

C621

W821

R623

C517_1

W078

C625

L605

L501_1

D510

W803

W053

Q603

C622

X602

C634

W050

CP352

C645

C639

C819_1

R517

C630

W017

C603

W067

C638

W805

W057

D610

W068

W820

W819

C612

C607

D611

J801

R641

W829

C354

C661

D612

C505

CP801

IC351

C101

W006

D603

W043

C601

CP806

L603

C613

W042

FH502

IC199

C129

W081

C526_1

R520

W010

C509

C512

RISK OF FIRE

D513

R516

R515

R514

W052

Q606

W011

L607

R618

CP502

D501

- REPLACE AS MARKED.

D507

W825

CF603

F

R402

C402

W069

R407_1

COL

B+

FB401

W026

W074

L402

W891

C443

C446

C440

W832

C435

CP401

W034

HEATER

AFC

GND

ABL

E

D410

C406

R403

R429

C407

D404

C418

CP601

W024

CP802A

W070

C427

W025

R409

R416

CD802A

C422

C417

C415

C430_1

R413

D

C

C420

W023

R418

C414

180V

C448

R417

W814

IC401

D405

D411

8V

W022

R445

C403

C434

R408

R424

HS401

W033

D403

W896

R446

Q401_1

W020

W021

D509

HS501

W036

T401

C439

Q402_1

R427

C437

D506

W828

Q501

R506

C511

W826

R511

W804

R508

D518

R510

C510

D528

Q507

TP401

R509

D512

HS402

R002

R504

R505

D601

IC506

R428

C514

C501

D514

Q502

D508

R542

R518

W802

R401

R001

B

C004

W076

W801

W077

L001

C007

W817

D602

C604

C002

C623

W009

CF604

C632

W030

W028

W027

A

W029

R415

W032

R426

W031

TU001

R405

D402

C003

W823

R410

R421

TP001

D401

D001

D605

W047

C606

C515

W079

W080

L606

T502

W007

C624

W082

R501

W075

W008

D502

VR501

W046

D519

W834

D504

L601

C502

C503

W818

D503

C605

C627

W014

C507

C519

C521

R629

Q604

Q605

C646

C636

W012

W013

CF601

C123

R805_1

C352

D107

W063

W064

C122

J352

OS101

R356

SW104SW105

SW103

SW102

SW101

W062

L101

C119

C139

X101_1

W001

W056

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

5-6

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 6

Page 29

H13A02D/02X PCB Layout Bottom

12345678910

G

R638

R625

R642

R604

R619

R605

R614

R601

R603

R621

R624

R519

R512

R606

R513

R636

R620

R617

C411

R406

R613

R626

1

C616

IC601

33

C643

17

C626

49

R608

R635

R633

R628

R639

C618

R609

R634

R615

R622

R611

C655

R632

R602

R006

R420

R007

C126

C127

R419

C113

F

C114

C138

R127

R134

*

C120

IC101

R130

R129

R115

R114

C136

R116

R107

E

R117

R113

R112

R128

R111

R101

D

R126

R359

R354

R120

R119

R352

R121

R123

R627

R124

R122

R357

R631

R630

R104

R102

C116

R103

R105

R353

C117

R106

C

C804

R809

C806

R814

R813

R816

R811

R815

C805

B

R131

A

CRITICAL SAFETY COMPONENTS ARE IDENTIFIED BY THE SYMBOL .

REPLACE ONLY WITH PART NUMBERS SPECIFIED.

5-7

NOTE: THE DC VOLTAGE AT EACH PART WAS MEASURED WITH A COLOR

BROADCAST BEING RECEIVED IN GOOD CONDITION AND THE PICTURE

IS NORMAL.

MX474C SHEET 7

Loading...

Loading...