Zenith A50M91W1, A60M91D, IQA32M46W7, IQA56M98W5, IQA56M98W User Manual

...

SERVICE MANUAL

Model Series:

Product Type: Projection/Directview CTV

Chassis: GM

Manual Series: CM-150 and PV-150

Manual Part #: 923-3364R1

Model Line: A

Product Year: 1998

REVISED EDITION

This revised edition includes the original GM manual

(923-03364) and the first addendum (923-03419).

A50M84D

A50M84W

A50M84W1

A50M84W5

A50M84W9

A50M91D

A50M91W

A50M91W1

A50M91W5

A50M91W9

A56M91D

A56M91W

A56M91W1

A56M91W5

A56M91W9

A60M91D

A60M91W

A60M91W1

A60M91W5

A60M91W9

IQA32M46W

IQA32M46W4

IQA32M46W7

IQA32M46W74

IQA36M46D

IQA36M46W

IQA36M46W4

IQA56M98D

IQA56M98W

IQA56M98W1

IQA56M98W5

IQA56M98W9

IQA60M98D

IQA60M98W

IQA60M98W1

IQA60M98W5

IQA60M98W9

RA46M84D

RA46M84D1

RA46M84D9

RA46M84W

RA46M84W9

RA50M84D1

RA50M84D9

RA50M84W

RA50M84W1

RA50M84W5

RA50M84W9

RA56M91D

RA56M91D9

Printed in U.S.A.

ZEN REV2 600

CONTENTS

General Info/Remotes .................................... 1

Service Menus ............................................... 2

Troublshooting/Adjustments .......................... 3

Model Parts List ............................................ 4

Mechanical Drawings ...................................... 5

Schematics and PCB Layouts ........................... 6

Published by Technical Publications

Zenith Electronics Corporation

201 James Record Road - Huntsville, Alabama 35824-1513

ÓCopyright February 1999 by Zenith Electronics Corporation

Revised Edition August 1999

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service

technicians.

When servicing this product, under no circumstances should the original

design be modified or altered without permission from Zenith Electronics

Corporation. All components should be replaced only with types identical to

those in the original circuit and their physical location, wiring and lead dress

must conform to original layout upon completion of repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component

designators and are required to maintain safe performance. No deviations are

allowed without prior approval by Zenith Electronics Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into

the set is not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform

customized installations without manufacturer’s approval. Unauthorized

modifications will not only void the warranty, but may lead to property damage

or user injury.

Service work should be performed only after you are thoroughly familiar with

these safety checks and servicing guidelines.

GRAPHIC SYMBOLS

The exclamation point within an equilateral triangle is intended

to alert the service personnel to important safety information in

the service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence

of noninsulated “dangerous voltage” that may be of sufficient

magnitude to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an

equilateral triangle is intended to convey to the service personnel

the following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ALL FUSES WITH THE SAME TYPE AND RATING AS MARKED

NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock.

After the original service problem has been corrected, make a check of the

following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of

adjacent component shorts. This is especially important on items transported to and from the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers,

shields, strain reliefs, power supply cords, and other hardware have been

reinstalled per the original design. Be sure that the safety purpose of the

polarized line plug has not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign

particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a receiving tube or a resistor rated at

1 watt or more. Lead tension around protruding metal surfaces must be

avoided.

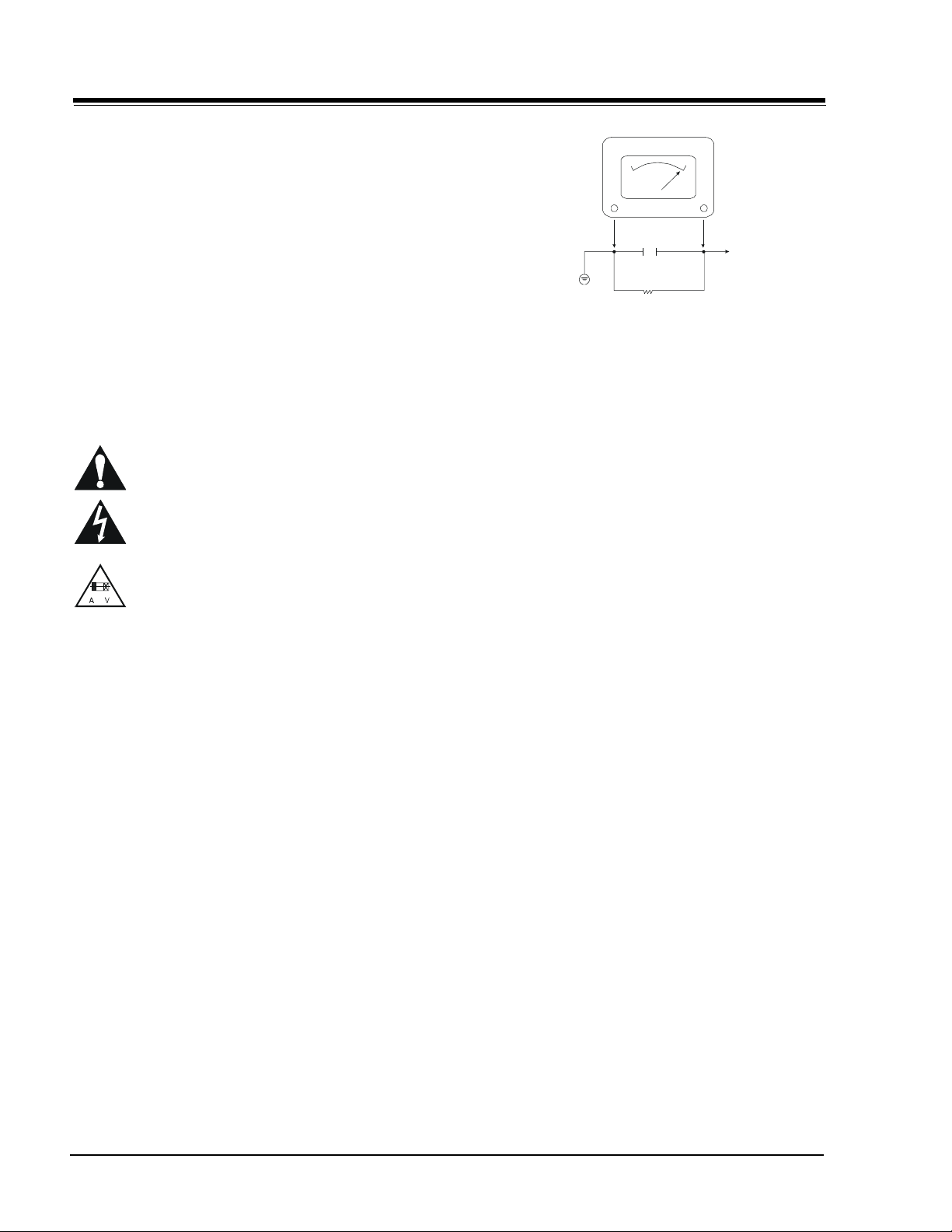

6. After re-assembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS

TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity in

the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by

a .15 mfd 150V AC type capacitor between a known good earth ground

water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC voltage across the combination of 1500 ohm resistor and

.15 mfd capacitor. Reverse the AC plug by using a non-polarized adaptor

and repeat AC voltage measurements for each exposed metallic part. Voltage

measured must not exceed 0.75 volts RMS. This corresponds to 0.5 milliamp

AC. Any value exceeding this limit constitutes a potential shock hazard and

must be corrected immediately.

A.C. Voltmeter

Good Earth Ground

such as the Water

Pipe, Conduit, etc.

0.15uF

1500 OHM

10 WATT

Place this probe

on each exposed

metal part.

X-RADIATION

1. Be sure procedures and instructions to all service personnel cover the

subject of x-radiation. The only potential source of x-rays in current TV

receivers is the picture tube. However, this tube does not emit x-rays when

the HV is at the factory-specified level. The proper value is given in the

applicable schematic. Operation at higher voltages may cause a failure of

the picture tube or high-voltage supply and, under certain circumstances

may produce radiation in excess of desirable levels.

2. Only factory-specified CRT anode connectors must be used.

3. It is essential that the service personnel have available an accurate and

reliable high-voltage meter.

4. When the high-voltage circuitry is operating properly, there is no possibility

of an x-radiation problem. Every time a color chassis is serviced, the

brightness should be run up and down while monitoring the high voltage

with a meter, to be certain that the high voltage does not exceed the

specified value and that it is regulating correctly.

5. When troubleshooting and making test measurements in a product with a

problem of excessively high voltage, avoid being unnecessarily close to

the picture tube and the high voltage power supply. Do not operate the

product longer than necessary to locate the cause of excessive voltage.

6. Refer to HV, B+, and shutdown adjustment procedures described in the

appropriate schematics and diagrams (where used).

IMPLOSION

1. All direct view picture tubes are equipped with an integral implosion

protection system; take care to avoid damage during installation.

2. Use only the recommended factory replacement tubes.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely

fitting shelf space over, or close to, a heat duct, or in the path of heated

air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations

where dew is a factor, near steam radiators where steam leakage is a factor,

etc.

3. Avoid placement where draperies may obstruct venting. The customer

should also avoid the use of decorative scarves or other coverings that

might obstruct ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit

must follow the factory-approved mounting instructions. A product mounted

to a shelf or platform must retain its original feet (or the equivalent

thickness in spacers) to provide adequate air flow across the bottom. Bolts

or screws used for fasteners must not touch any parts or wiring. Perform

leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a

tilted position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small

casters across thresholds or deep pile carpets.

7. Caution customers against using a cart or stand that has not been listed

by Underwriters Laboratories, Inc. for use with its specific model of

television receiver or generically approved for use with TVs of the same or

larger screen size.

8. Caution customers against using extension cords. Explain that a forest of

extensions, sprouting from a single outlet, can lead to disastrous

consequences to home and family.

CM151 GM - SAFETY

i

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

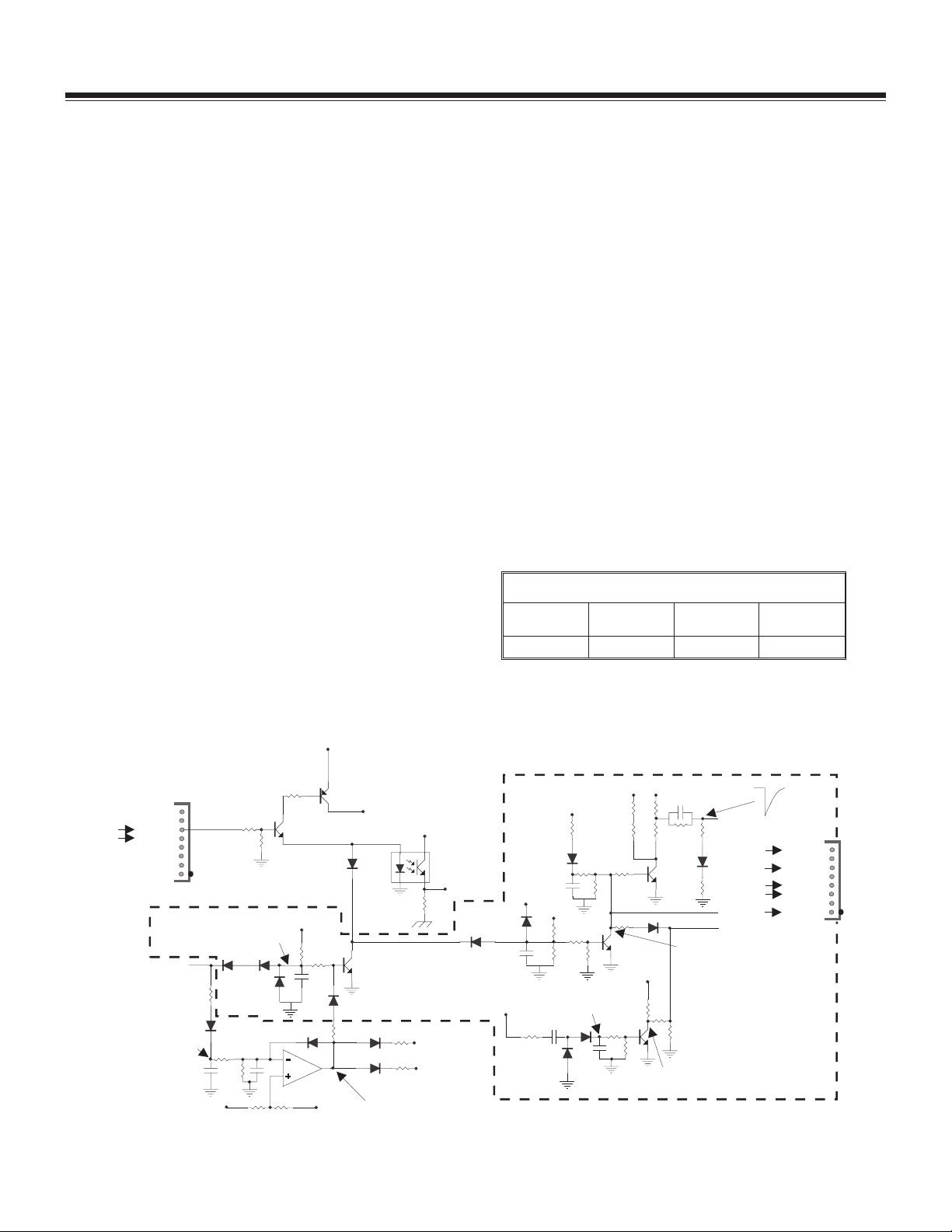

HV SHUTDOW N FOR DIRECT VIEW

THEORY OF OPERATION (SHUTDOW N CIRCUIT)

The HV shutdown circuit appears on sheet 5 of the

schematics for 9-1979. The basic HV shutdown circuit is

illustrated below.

The peak pulse voltage from deflection transformer

TX3204 is rectified by D3205 and C3217. The resulting

37 volts is then divided by RX3015 and RX3019M to

approximately 8.5 volts. It is applied to the

non-inverting input of one of the op-amps in ICX3200

(pin 10). This op-amp is used as a voltage comparitor.

It’s inverting input (pin 9) is held at a reference voltage

of 9.1 voltsby the Zenerdiode ZDX3004 andRX3025.

Any failure in the deflection circuit that would cause

excessively high, High Voltage at the CRT will also cause

an increase in the sampled 37 volts. This increase will

result in an increase in the voltage at the non-inverting

input to op-amp IC3200 (pin 10). When this increased

voltage exceeds its reference 9.1 volts, the op-amp

output goes from low to high. DX3009 provides a

feedback path that holds the non-inverting input high

so that the op-amp stays

GM Direct View CRT Protection Circuit Diagram

latched with its output high until power is removed by

turning the TV off. DX3009 and RX3016M pull pin 2 of

3N2 high (about 12 volts). This is the horizontal drive

signal pin from the video processor in the small signal

module. The video processor turns off horizontal drive

when its output is pulled high.

When the high voltage shutdown circuit is activated,

IC3200 is no longer supplied with 23 volts to its power

input pin (pin 4) because the 23 volt supply comes from

the deflection transformer, which has been shutdown.

QX3410 and QX3411 provide a connection to another

supply at this time.

The shutdown circuit may be tested for operation by

momentarily connecting a 1k ohm resistor in parallel

with RX3015. This will boost the non-inverting input

above 9.1volts and trigger shutdown.

GM Directview HV & B+

Chassis B+ [VDC] HV (nominal

@ 0 beam kV)

135 32.0 33.0

HV (max @ 0

beam kV)

3A6

PW R CTRL

12VSW

From Small Signal

Module

50VPSW

15VSW

20V

normal

G1

-250V

G1SK

Blank

Daughter Module

A - 17821 - XX

shut down

6.3VAC Fil

Fil. Gnd

Blank

15VSW

To Video Output

Modules

Gnd

250V

G1

nc

3B5

8

1

15VSW

IC3200

1K

CR3405

8

ABL SW

QX3408

Q3000

CR3012

1K

CRX3008

CRX3009

15VSB

1

2

0V = normal

12V = fail

15V Ref

to ICX3401-15

H Drive DR SC

1K

(not used GZ/GM)

1K

4

ICX3405

3

1K

CDisable

To ICX3401-14

SW On

CR3005

CR3006

0.47uF

VSense

PwrCntrl

100

CR3212

15VSW

8.56K

8.56K

CR3001

4.7uF

10uF

+

1.8K

15VSB

+

-

10K

CR3002

10K

1K 1K

15K

2V

with

scan

+

10uF

1K

8

1

CR3003

CRX3012

30V

5.6K

2K

1uF

9.1V

Ref

470

10K

CR3016

CR3004

9.76K

-5V

with

scan

100uF

Q3410

10K

CRX3010

1010

9

110K

390K

330K

1K

Q3001

Q3002

10K

740V

1M

56K

CR3014

15VSW

1K

250V

51K

10K

4.7uF

+-

2.2M

Q3202

10K

L = normal

H = fail

130K

1K

L = normal

H = shut down

CR3210

ii

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO-VIDEO PRODUCTS

HV SHUTDOW N FOR PROJECTION TV

SERVICE SAFETY NOTES

When servicing chassis, under no circumstance should

the original design be modified or altered without

permission from Zenith Electronics Corporation. All

components should be replaced only with types identical

to those in the original circuit, and their physical

location, wiring, and lead dress must conform to original

layout upon completion of repairs.

Special components are also used to prevent

X-Radiation, shock, and fire hazard. These components

are indicated by the letter “X” included in the item

number. This designates critical components in circuits

which are required to maintain safe performance. No

deviations are allowed without prior approval by the

product compliance and evaluation department.

The circuit diagrams may occasionally differ from the

actual circuit used. This way, implementations of the

latest safety and performanceimprovement changes into

the set is not delayed until the new service literature is

printed.

B+ AND HIGH VOLTAGE SHUTDOW N CIRCUIT

These sets utilizesafety circuits for protection.In case of

a failure involving the seal B+ adjustment, high voltage

adjustment, or high voltage shutdown, follow these

instructions closely. Failure to do so many violate

Federal X-RAY limits. Some sets may use a high voltage

shutdown adjustment potentio in place of fixed

resistors. If it should become necessary to replace one of

these factory controls use only the exact Zenith factory

replacement part number. You must also adjust the

replaced controls to factory specified values (B+ to VDC)

and high voltage adjust to 31.5kV). For the high voltage

shutdown adjustment after replacing the high voltage

shutdown adjustment potentiometer or fixed resistors,

follow the following procedure. A functional test of the

high voltage shutdown circuit must be performed to

check for proper operationif you service these setsin the

shutdown circuitry.

1. Measure the DC voltage across capacitor CX3006. It

should be approximately 7.6VDC. Temporarily

connect a 1K 5% 1/2W resistor across RX3015. High

voltage should shutdown. This checks out the

shutdown circuit operation. Remove the temporary

resistor and recycle the ON/OFF button. A more

elaborate test to determine the actual high voltage

value at which high voltage shutdown will occur can

be made as follows:

Caution: It will normally not be necessary to perform

this test unless the set keeps shutting down

under normal operation, the high voltage

shutdown resistors or adjustment pot had

to be replaced, or the operational test described in the previous paragraph was

unsuccessful. It should be recognized that

significantly elevated high voltage will be

produced during this test and adequate care

should be taken to avoid high voltage

arcing.

2. Connect a 40kV high voltage meter in place on one of

the CRTs at the high voltage block. Connect the

negative lead of a 500mA 12 volt power supply, with

a 1K OHM resistor in series, to the junction of RX3438

and RX3439 and the positive lead to ground side of

RX3439.

Turn the set ON and ensure that the brightness and

contrast are set at minimum. Increase the 12 volt

bench supply until shutdown occurs, Shutdown must

occur in the range from 34.3 to 36.5kV, If not,

shutdown occurs, the circuit must be repaired and

the test repeated.

When you have completed all the adjustments and

tests, use a “hot melt glue” gun to permanently seal

the B+, HV and/or shutdown, if any of these controls

had been used, to render them not adjustable. This is

to ensure continued compliance with the Federal TV

X-RAY Standard.

NOTE: Any board which cannot be repaired to pass

the functional test above should be

exchanged.

iii

TABLE OF CONTENTS

Section 1

Overview (General Information) . . . . . . . . . . . 1-1

MBR3457 Remote Control (Keys Defined) . . . . . 1-2

TRK400 Remote Control (Keys Defined) . . . . . . 1-3

Programming Remote . . . . . . . . . . . . . . . . . . 1-4

Remote Control Programming Codes. . . . . . . . . 1-5

Section 2

Service Menu . . . . . . . . . . . . . . . . . . . . . . . 2-1

Servicing Small Signal Module Replacement . . . 2-4

Stereo Coefficients . . . . . . . . . . . . . . . . . . . . 2-5

Projo Convergence Setup MBR3457/TRK4000. . . 2-6

Convergence Setup Worksheet. . . . . . . . . . . . . 2-8

Convergence Setup Illustrations . . . . . . . . . . . 2-9

Section 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 3-1

Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Service Adjustments . . . . . . . . . . . . . . . . . . . 3-7

GM CRT Assembly . . . . . . . . . . . . . . . . . . . . . 3-9

GM Direct View - Small Signal Diagram . . . . . . 3-10

GM Direct View - Large Signal Diagram. . . . . . . 3-11

GM Projo - Small Signal Diagram . . . . . . . . . . . 3-12

GM Projo - Large Signal Diagram . . . . . . . . . . . 3-13

Section 4

Model Parts List . . . . . . . . . . . . . . . . . . . . . 4-1

Section 5

Mechanical Drawings

32/36” Stereo Table Top, Exploded View . . . . . 5-1

Inteq Projection Set, Exploded View . . . . . . . . 5-2

46/50” Projection Set , Exploded View. . . . . . . 5-3

56/60” Projection Set , Exploded View. . . . . . . 5-4

Section 6

Schematics and PCBs

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . 6-1

Interconnect Diagram . . . . . . . . . . . . . . . . . . 6-2

9-1650-02 Single PIP . . . . . . . . . . . . . . . . . . 6-3

9-1650-02 Single PIP PCB Layout . . . . . . . . . . 6-4

9-1689-02 Single PIP . . . . . . . . . . . . . . . . . . 6-5

9-1689 Two Tuner Single PIP . . . . . . . . . . . . . 6-6

9-1689-02 Two Tuner Single PIP PCB Layout . . 6-7

9-1783A IF/Audio . . . . . . . . . . . . . . . . . . . . 6-8

9-1783A IF/Stereo . . . . . . . . . . . . . . . . . . . . 6-9

9-1912/1913/1914 Small Signal Chassis . . . . . 6-10

9-1912/1913/1914 Main Small Signal Carrier . . 6-11

9-1912/1913/1914 Small Signal Audio . . . . . . 6-12

9-1912/1913/1914 Small Signal Chassis . . . . . 6-13

9-1912/1913/1914 Scan Velocity Modulator . . . 6-14

9-1912/1913/1914 Main Small Signal Carrier . . 6-15

9-1920/1922 A/V Switch . . . . . . . . . . . . . . . 6-16

9-1920/1922 A/V Switch & Jackpack . . . . . . . . 6-17

9-1920/1922 A/V Switch . . . . . . . . . . . . . . . 6-18

9-1924 2H Comb Filter . . . . . . . . . . . . . . . . . 6-19

9-1924 Signal Processor . . . . . . . . . . . . . . . . 6-20

9-1924 Video Module PCB Layout . . . . . . . . . . 6-21

9-1925/1927 & 9-2034 3D Comb Filter . . . . . . 6-22

9-1925/1927 & 9-2034 3D Comb Filter . . . . . . 6-23

9-1925/1927 & 9-2034 3D Comb Filter . . . . . . 6-24

9-1925/27 & 9-2034 PCB Layout

3D Comb Filter . . . . . . . . . . . . . . . . . . . . . . 6-25

9-1932 Microcontroller . . . . . . . . . . . . . . . . . 6-26

9-1932 PCB Layout Microcontroller . . . . . . . . . 6-27

9-1934/1935 DV Video Output . . . . . . . . . . . . 6-28

9-1936/1938 Projo Video Output . . . . . . . . . . 6-29

9-1978 Projo Power Supply . . . . . . . . . . . . . . 6-30

9-1978 Projo Power Supply . . . . . . . . . . . . . . 6-31

9-1978 Projo Power Supply . . . . . . . . . . . . . . 6-32

A-17821-05 Projo Supply Daughter Board . . . . 6-33

9-1978 Projo Power Supply PCB Layout . . . . . . 6-34

9-1916/79 Direct View Switch Mode

Power Supply . . . . . . . . . . . . . . . . . . . . . . . 6-35

9-1916/1979 Direct View Deflection. . . . . . . . 6-36

A-18347 Two Tuner Antennas Switch . . . . . . . 6-37

Voltage Waveforms . . . . . . . . . . . . . . . . . . . . 6-38

CM150/PV150 TOC GM CHASSIS

OVERVIEW

GENERAL INFORMATION

New Video features include a comb filter for processing

incoming signals to provide fine detail images. Auto

skin tone circuitry automatically maintains natural skin

tones. Black level enhancement/white level and peak

white level compression circuitry maintains black/white

contrast ratio and peak luminance level for detail in

both light and dark video areas.

Audio features include SoundRite volume control. This

circuitry automatically compensates for the volume

changes during commercials and limits the audio to a

set volume level.

The BBE featurehas been addedto most audio systems.

The circuitry adjusts the phase relationships of the low,

mid and high frequencies. The circuit also augments the

higher and lower frequencies.

The BBE system provides a dynamic program-driven

augmentation which combines with the phase

compensation feature to restore the clarity of the

original line sound.

THE GM SERIES CHASSIS CONTAINS 10 MODULES

The 9-1912 (small signal) module and 9-1916 (large

signal) are used in the GM-Direct View 32” set.

The 9-1913 (small signal) and 9-1979 (large signal)

modules are used in the GM-Direct View 36” set.

The 9-1914 (small signal) module is used in the

GM-Projo 84 Series.

The 9-1942 (small signal) modules are only used on

GM-Projo 91 Series.

The 9-1943 (small signal) modules are only used on

GM-Projo 98 Series.

All 9-1978 (large signal) modules are only used in

the GM-Projo sets.

THE GM SERIESCHASSIS FEATURES TW ENTY ONE IC’S.

IC6003 EPROM Memory.

IC6002 ROM is the EAROM Memory.

IC6000 Microprocessor located on the 9-1932

Module.

IC3200 Quad Op Amp IC, controlling Pin Cushion/

Over-voltage protect/ Auto Kine Bias/ and ABL, and

is located on 9-1916 and 9-1979 Modules.

IC2900 Audio/Video switch located on A/V 9-1920/

1922 Module.

IC2401M D/A converter for 3D series 9-1925/27,

9-2034 Modules.

IC2400 Digital Comb filter for 2H series.

IC2400M Digital Comb filter for 3D series 9-1925/

27, 9-2034 Modules.

IC2300 Video Processor

IC2200 Signal Processor and handles Video, Sync

and Sweep Drive Processing on 9-1924 Module.

IC2100 Handles Vertical Sweep.

IC2001 PIP Digital Processor.

IC2000 PIP Analog Processor located on the 9-1650

Module.

IC1201 IF/Detector IC

IC1402 BBE Audio Processor

IC1400 Volume Limiter

IC850 Left and right surround sound output IC,

Located on 9-1912/13/14 Modules.

IC800 Left and right audio out put IC, located on

9-1912/13/14 Modules.

ICX3405 Optoisolator IC and is in the Switch Mode

Power Supply.

ICX3402 Regulator IC and is in Switch Mode Power

Supply 9-1978/1979.

ICX3401 Second Regulator IC Controller in the

Switch Mode Power Supply.

CM150/PV150 1-1 GM CHASSIS

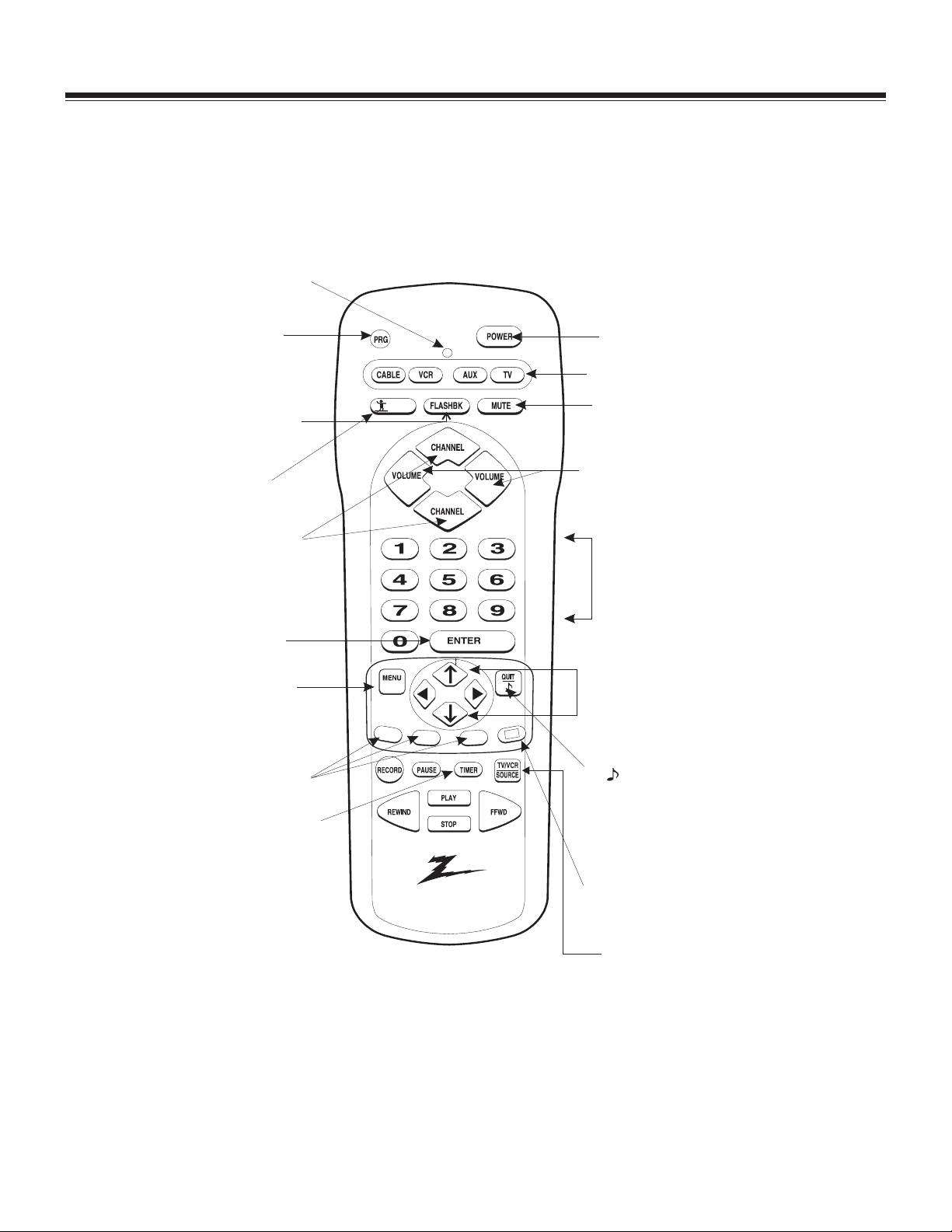

MBR3457 REMOTE CONTROL - KEYS DEFINED

Indicator Light

PRG (Program)

Programs remote to

operate other products.

FLASBK (Flashback)

Returns to previous

channel

SURF

Activates TV channel

"Surf" feature.

CHANNEL (Up or Down)

Selects next channel

When "Surf" option is On,

you receive only channels

set as "Surf" channels.

ENTER

Shows Channel/Time

display. Press after

channel numbers for

fast selection.

MENU

Displays on-screen

menus for TV mode.

A, B, C, KEYS

Special features on

some TV's.

TIMER

Displays the Sleep Timer

Menu. Press repeatedly to

set TV shut-off time. Specifies

AM or PM when you set the

clock or use a timer feature.

SURF

GUIDE

A

B

CC

C

Remote Control Part Number

124-212-37

POW ER

Turn TV On or Off

TV

Selects TV operation

MUTE

Turns sound Off and On

While picture remains.

VOLUME Left/Right

Changes TV's sound

level.

NUMBERS

Selects channels directly

and enter numeric values

for some options.

Up/Down and

Left/Right Arrows

The Up/Down arrows

select options.

The Left/Right arrows

adjust options.

Quit/

Removes on-screen

display from view.

If no display is on,

switches front speaker

surround sound On and

Off for some TVs.

CC (Closed Captioning)

Displays closed caption

menu

TV/VCR - Source

Switches between watching

TV via the available sources,

ANTENNA/CABLE, VIDEO IN, etc.

CM150/PV150 1-2 GM CHASSIS

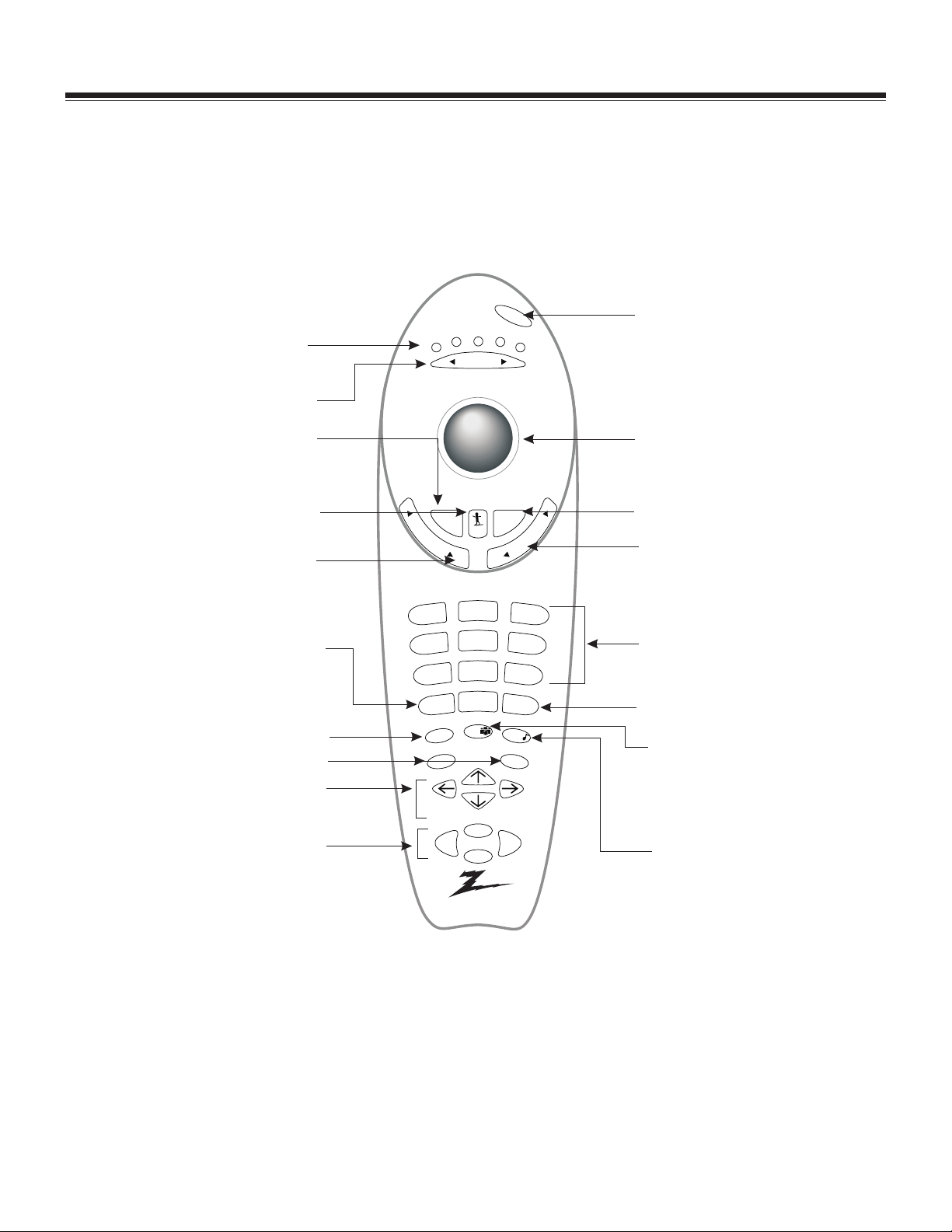

TRK4000 REMOTE CONTROL - KEYS DEFINED

INDICATOR LIGHTS

Illuminate to show which

mode remote is in.

MODE LEFT/RIGHT

Adjust which mode remote

is working in.

MUTE

Press once for Soft Mute, again

for Full Mute, and a third time to

return to normal volume.

SURF

Use the regular channel selection or

customized channel Surf lists.

VOLUME LEFT/RIGHT

Increases/descreases sound level.

SOURCE

Push to switch between

available sources connected to

your Entertainment Machine.

MENU

Displays functions on VCR

RECORD, PAUSE

Control functions on VCR

ARROW KEYS

Allows user to move through

on-screen menu choices.

REW , FFD, PLAY, STOP

Controls functions on VCR

power

cable

aux 1

vcr

tv

mode

aux 2

POW ER

Turn your Entertainment Machine

or any other programmed equipment

on or off, depending on mode

TRAKBALL

Click and move the on-screen pointer.

FLSHBK

mute

v

o

l

u

m

e

surf

flshbk

l

e

n

n

a

h

c

Return immediately to the last

channel viewed.

CHANNEL UP/DOW N

Scroll through your available

channels.

7

menu

record

2

3

5

6

8

9

0

enter

pip

quit/

pause

NUMBER PAD

For direct channel selection

and programming functions.

ENTER

Push to accept menu choices or after

channel numbers for faster transfer.

PIP SNAPSHOT

press to capture and freeze main

1

4

source

picture within large PIP frame. Press

a second time and receive PIP from

another channel or source. Press a

third time to remove PIP.

QUIT

Leaves programming menus and

rew

play

stop

f.fwd

clears screen of displays, and provides

audio swap.

Remote Control Part Number

124-219-01

CM150/PV150 1-3 GM CHASSIS

PROGRAMMING THE REMOTES

PROGRAMMING THE MBR3457 REMOTE

If you’re using Zenith products, the remote is already

programmed for the most common codes: TV = 101, VCR

= 201, CABLE= 353, and AUX= 401. For otherbrands, or

if your remote fails to control your Zenith products,

you’ll have to program the remote.

1. Make sure batteries are installed.

2. Press and hold PRG using a blunt pointed object.

Release PRG after indicator light turns on.

3. Press and release button for product being

programmed.

4. Enter 3-digit product code from Remote Control

Programming Codes in this section.

5. Press and release ENTER to save code.

6. Point remote at product and press POW ER to test

product operation. If it does not turn on, reprogram

remote using a different code.

TO AUTO FIND A CODE

1. Turn On the product you want to operate.

2. Press and hold PRG using a blunt object.

3. Press the key to beprogrammed: CATV, VCR, AUX, or

TV.

4. Enter “0-0-0,” then pressENTER within twoseconds.

5. Point remote at the product.

6. Press and release POW ER repeatedly, about once a

second, until your product turns Off.

7. Press ENTER immediately to save the code.

8. Press POW ER to turn On your product.

9. Test your product. If the remote fails to operate the

functions you use mostoften, use Auto Find again to

search for a better code. (Auto Find resumes its

search after thelast code that wasentered and saved

in step 7.)

NOTE: If the indicator light stays on as you press

POWER, Auto Find has tried all of the codes.

If the product you want to control has not

turned off, your remote will not work with

that product.

To cancel Auto Find, press PRG at any time.

PROGRAMMING THE TRK4000 REMOTE

1. Select equipment needed to be programmed, turn to

page2-5tofind the programming code appropriate

for the type and brand of equipment. Make sure the

equipment is turned on.

2. Point the MBR Trakball remote at the piece you’re

programming, press MUTE and FLSHBK at the same

time. Hold until one of the mode indicator LEDs

lights.

3. Use the MODE Right/Left button to select the

appropriate mode for equipment.

4. With the Number Keypad, enter the three digit code

found in step 1 and press ENTER. If the code is

accepted, the mode indicator Led will blink three

times, If it is not accepted, the Led will not blink.

NOTE: The TV and VCR modes will only accept codes

for those types of products. The AUX 1, AUX

2, and Cable modes will accept codes for any

kind of product.

5. Push the POW ER buttonto turn off theequipment. If

nothing happens, repeat the process from step 1,

and try the next code number.

NOTE: To get out of Programming before you enter

a code, just press the QUIT button on remote.

TO AUTO FIND A CODE

1. Turn on device you want to operate.

2. Press and hold MUTE and FLSHBK until the indicator

light turns on.

3. Press MODE Left/Right until the indicator light is

underneath the device needed to be programmed.

4. With the NUMBER keypad, enter the code 0-0-0

(zero-zero-zero), then press the ENTER key right

away.

5. Aim remote at correct device and push the POW ER

button. Allow a second to pass, then push the Power

button again. Repeat until the device turns off.

6. Push Enter to save the code. The indicator light on

the remote willblink three timesand then turnoff.

7. Press Power to turn the device back on.

NOTE: You can get out of Auto Find quickly by

pressing the Quit button.

If the indicator light does not turn off while

you push the Power key, all the codes have

been tried and your device can’t be

programmed.

CM150/PV150 1-4 GM CHASSIS

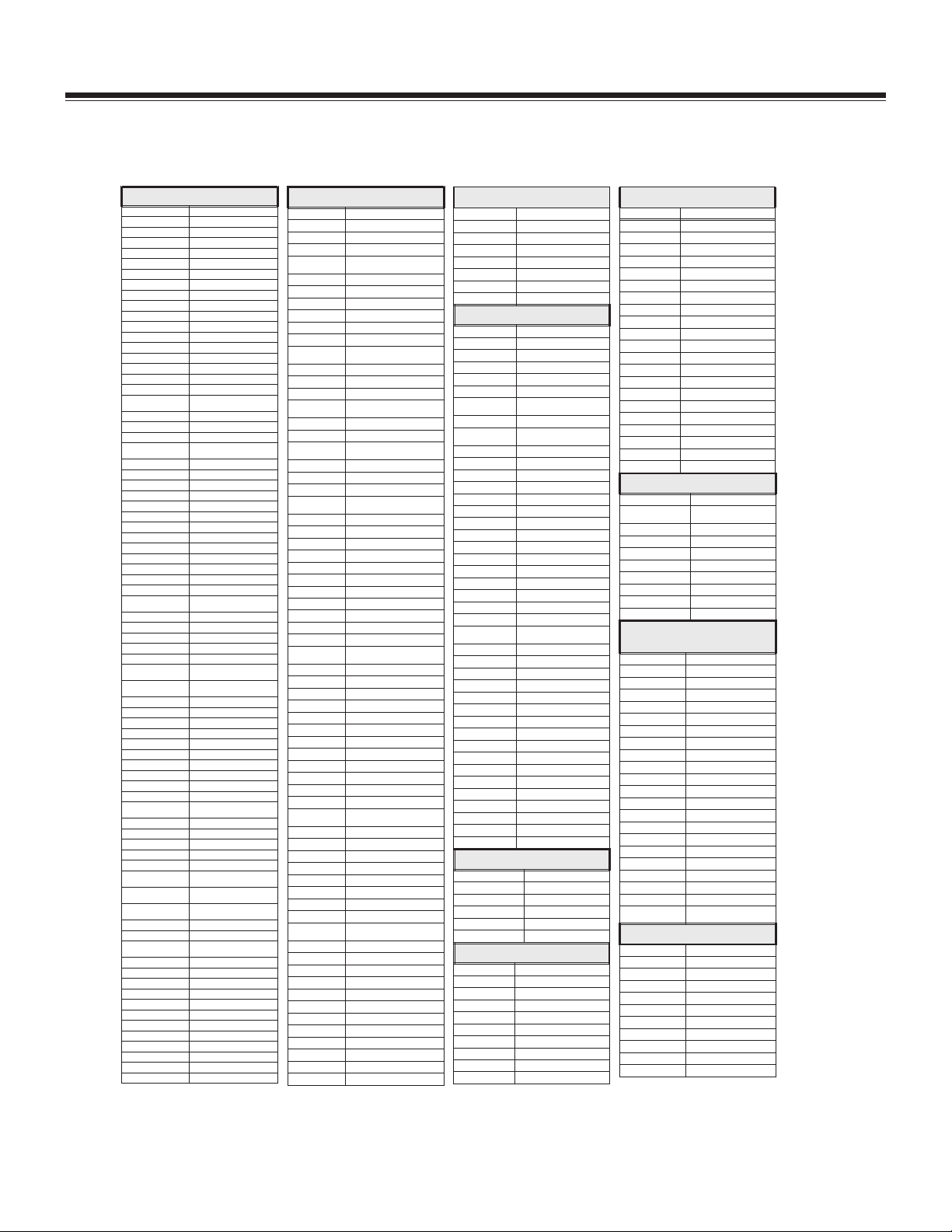

PROGRAMMING CODES MBR3457/TRK4000

PROGRAMMING CODES BY BRAND NAME

TVS

Admiral 116, 121, 130, 133

Adventura TV/VCR 154

Akai 104

Amark 103, 146

AOC 104

Bell & Howell 121

Broksonic 131, 136, 182

Candle 139

Centurion 119

Citizen 121, 139

Contec 141

Coronado 103

Crown 103

Curtis Mathes 116, 119, 121

Daewoo 149, 159

Daewoo TV/VCR 148

Daytron 119

Elektra 121

Emerson 103,104,123,124, 131, 136,

Emerson TV/VCR 158

Fisher 109, 118

Funai TV/VCR 154

General

Electric

Goldstar 103, 104, 119, 147, 184

Goldstar TV/VCR 153

Hitachi 102, 103, 129, 163, 121

Inteq 101

J.C. Penney 104, 110, 114, 117, 119

JVC 125, 132, 164

KMC 103

KTV 103, 104, 138

Kurazai 121

LG 184

Lodgenet 121

Logik 121

LXI 133, 137

Magnavox 103, 112, 113, 117, 119,

Magnavox TV/VCR 173, 181

Majestic 121

Marantz 104, 120, 155

Megatron 146

Memorex 121

MGA/

Mitsubishi

Montgomery Ward 103, 104, 105, 113, 114,

NEC 104, 119

Orion 176

Panasonic 106, 107, 160, 166

Panasonic TV/VCR 174

Philco 103, 104, 112, 113, 139

Philips 112, 113

Pioneer 135

Portland 103

ProScan 116, 157, 162, 167

Quasar 106, 107

RCA 104, 116, 126,

Realistic 105, 123, 124

Sampo 119

Samsung 103, 119, 134, 141

Sanyo 108, 109, 118

Scott 119, 124

Sears 103, 108, 109, 110, 111, 118,

Sharp 103, 105, 122, 133, 137, 156,

Signature 2000 103, 104, 105, 113, 114,

Sony 115, 143, 151, 170

Soundesign 139

Sylvania 112, 113, 117, 119, 127, 128,

Symphonic TV/VCR 15 4

Tatung 106

Teknika 103, 112, 121, 124, 139

Telerent 103, 121

Toshiba 110, 111, 134, 171

XR1000 121, 154

Yorx 119

Zenith 101, 142, 149, 177

Zenith Star Sight 175

Zenith TV/VCR 153, 154, 172

145, 176

106, 107, 114, 116, 117, 161

127, 128, 130, 139, 165

104, 119, 120, 130, 133,

140, 155, 169, 178

119, 121, 130, 133

157,161,162,167,168

134

169

119, 121, 130, 133

139

VCRS

Admiral 208, 261

Adventura 231

Aiwa 231

Akai 223, 238, 241

Audio

Dynamics

Bell & Howell 206, 247

Broksonic 221, 226, 233, 250, 255

Canon 214

Citizen 209

Craig 212

Criterion 239

Curtis

Mathes

Daewoo 244, 246, 248, 254

Daytron 236, 246

DBX 202, 218

Emerson 203, 209, 221, 223, 226, 233,

Fisher 211, 212, 213, 247

Funai 231

General

Electric

Goldstar 209, 273

Go Video 256, 262, 263, 275

Hitachi 215, 231, 257

Instant

Replay

Inteq 273

J.C. Penney 214, 215, 218, 227

JVC 202, 224, 225, 258, 263

Kenwood 202

Logik 239

LXI 209, 231

Magnavox 207, 214, 231

Marantz 207, 218

Marta 209

Memorex 206, 212, 214, 231

Mitsubishi 204, 222, 252, 264

Montgomery

Ward

Multi Tech 239

NEC 202, 218

Optimus 208, 209, 259

Orion 233, 250

Panasonic 214, 251, 259

Pentax 215

Philco 207, 214

Philips 207, 214, 227

Pioneer 210, 215

Portland 246

Pro Scan 216, 260

Quasar 214, 259

RCA 215, 216, 220, 227, 240, 242,

Realistic 206, 208, 212, 214, 231

Samsung 220, 230, 238

Sansui 239

Sanyo 206, 212, 247

Scott 204, 205, 233, 243

Sears 206, 209,211, 212, 215

Sharp 208, 261, 272

Shintom 239

Signature 2000 208, 214, 216, 219, 231, 249,

Sony 217, 232, 237, 274

Sylvania 207, 214, 227

Symphonic 231

Tashiko 209

Tatung 202

Teac 202, 231

Teknika 209, 234

Toshiba 205, 215, 271

XR1000 239

Vector Research 204, 218

Yamaha 202, 218

Zenith 201, 224, 225, 229, 237

202, 206, 218, 247

214, 259

235, 243, 250

214, 216, 220

214, 227

208, 214, 216, 219, 231, 249

244, 260

261

TV/VCR

Hitachi TV/VCR 154

LXI 154

RCA 179

Samsung 180

Sansui 182

Sharp 179

Sylvania 154

CABLE/SATELLITE Set-Ups

Allegro 358, 362

Allegro A/B Switch 36 1

Amerkast 383

Dish Network 389

Gemini 305, 331, 338

General Electric 367

General

Instrument

Hamlin 302, 303, 345, 365, 366

Jerrold 304, 307, 308, 309, 310, 318,

Kale Vision 335

Macom 314, 321

Magnavox 334

NSC 335, 339, 368, 369, 370

Oak 311, 332, 342

Panasonic 313, 320

Paragon 333

Philips 347, 350, 352, 354, 355

Pioneer 315, 343

Primstar 388

Radio Shack 362

RCA DSS 373, 394

Regal 366

Regency 329

Samsung 335

Scientific

Atlanta

Sony DSS 387

Sprucer 313

Standard Comp 335

Stargate 379

Texscan 339, 356, 371

Tocom 317, 318, 346

Toshiba DSS 391

Unika 348, 362

United Satellite 344

Universal 358, 362

Vid Tech 340

Video Way 349

Viewstar 354, 355, 372

Zenith 301, 353

Zenith HD Set Top 385

Zenith N/C Set Top 384, 395

Zenith Satellite 312, 328, 330, 351

305, 306

360, 363

316, 323, 336, 364

LASER DISK

Denon 402, 403

Mitsubishi 403

Pioneer 402, 403, 405

Sanyo 401

Sony 404

Zenith 401

AUDIO CD PLAYERS

Akai 409, 424

Carver 510

Crown 410

Denon 411

Fisher 412, 438

Goldstar 460

Harman/ Kardon 413

JVC 415

Kenwood 412, 416, 417, 441

Magnavox 421, 422, 433, 434

AUDIO CD PLAYERS (continued)

Mitsubishi 423, 424

NAD 425, 426, 447

Nakamichi 427, 428

NEC 429

Onkyo 430

Panasonic 431, 432

Philips 421, 433, 434

Pioneer 431, 435

Quasar 432

Radio Shack 431, 436, 439, 440, 441

RCA 437

Sanyo 438, 439

Scott 440

Sharp 441, 442

Sony 443, 444, 445

Soundesign 461, 498, 501, 502

Sylvania 433

Teac 446

Technics 432, 459

Toshiba 447

Yamaha 448

Zenith 460, 461, 498, 501, 502

AUDIO TAPE DECKS

Denon 455

Harman/

Kardon

JVC 457

Kenwood 450

Onkyo 458

Philips DCC 454

Pioneer 451, 478

Sony 452

Technics 454, 497

Yamaha 453

AUDIO TUNERS

AND AMPLIFIERS

Denon 462, 463

Fisher 464

Goldstar 460

Harman Kardon 465

JVC 466

Kenwood 468, 469, 506

Marantz 472, 503

Onkyo 473

Philips 475, 476

Pioneer 477, 478, 479

Radio Shack 487, 488

Realistic 480

Sanyo 481

Scott 482

Sharp 483

Sherwood 487, 488

Sony 489, 490, 491, 492

Soundesign 461, 498, 501, 502

Teac 494, 495

Technics 497, 509, 567,

Yamaha 496

Zenith 460, 461, 498, 501, 502,

456

504, 505

DVD PLAYERS

Denon 523, 524

Marantz 521

Mitsubishi 525

Panasonic 523, 524

Philips/Magnavox 521

Pioneer 527

Proscan 526

RCA 526

Sony 522

Toshiba 521

Zenith 521

CM150/PV150 1-5 GM CHASSIS

CM150/PV150 1-6 GM CHASSIS

SERVICE MENU

GM CHASSIS A-LINE LINE SERVICE SETUP DIRECTVIEW AND PROJO

Accessing The Service Menu

You may access the menu by using the keyboard or a

remote control. If you use the keyboard press and hold

the MENU key until the customer menu disappears and

then quickly press the ADJUST RIGHT and CHANNEL

UP keys atthe same time. Ifyou use the remotecontrol

press and hold the MENU key until the customer menu

disappears and then quickly press the number keys 9,

8, 7, 6, and ENTER. Following either procedure should

bring you to the Service Menu. The menu will display

one control at a time. Please note that FACTORY MODE

should always be OFF in the field. If FACTORY MODE is

turned ON there will be situations that cause customer

menu settings to randomly change just by turning the

set off andthen on again.FACTORY MODE canbe turned

OFF simply by setting the clock feature in the customer

menu.

Please note color tracking is done by the Video

Processing circuit. There are no manual color controls.

Even if COLOR LEVEL, on the customer menu, is turned

all the way down there will always be some color on

(unless the video signal is black and white with no

color burst).

A-18728-04 1.30

EPROM

Part Number

09 Horz Pos 12

Menu

Item

Item

Name

02/05/97

Software

version

Current Setting

Software

version

TE = 10110000

MENU TERMS GLOSSARY

The items listed below are Service Menu items you may

have to adjust for a particular television. Please note

that some of these, if set wrong, may cause symptoms

similar to a circuit failure.

AC Pwr ON - Turns set on when AC line power is

applied. Power key is disabled. Automatically enabled

if factory mode is on.

Audio Coefficients (VCO addition, SAP VCO, SAP LPF,

LPF addition, Spectral, and W ideband) - Settings for

the audio processor’s stereo decode system. Values, for

Service Menu features 74 through 80, are found on a bar

code label on top of the Tuner/IF/Audio module.

A/V Lock - Disables all audio and video inputs - gives

blue screen and menus only.

Band/AFC - Allows setting of tuning band and AFC

mode. Allows manual override of the BAND and AFC

selection of Auto Program.

Note: If Auto Program is run, it will automatically

reset the manual BAND/AFC selection.

Bright AUX and Bright RF - Allows balance of AUX and

RF viewed video brightness levels.

Chan Lock - Locks set to one channel use only.

Feat. Level - 0 =11 jack,1=18jack,2=21jack. Factory

mode must be onto switch the setting. Aftermaking the

change be sure to turn off the factory mode feature.

Horz Pos and Vert Pos - Sets horizontal and vertical

position of on screen displays. Does not affect position

of the picture video.

Key Deft - Disables menu use of the keyboard keys:

MENU, ENTER, ADJUST, and SELECT.

Max Vol - Sets maximum volume limit.

Min Vol - Sets minimum volume limit.

Preset PX (also Theater, Game, Sports, Daylight, and

W eak) -Stores special customer video menu setup assix

different presets. To change, enter the customer video

menu and select video pref. feature. Select preset (i.e.

Preset, Theater, Game, etc.) that is to be changed and

customize it. Enter the Service Menus and access the

feature that was just changed (Preset PX, Theater PX,

Game PX etc.) and press adjust to store the change. The

new setup is stored as the new “video controls preset”

for that item.

Proj Mode - When enabled, adds the Projo Setup feature

to the customer setup menu. Enables customer static

setup (red and blue centering offset) display for the

projo TVs.

RGB Brite and RGB Cont - Controls on screen display

video.

Sub Contr -Sets operating rangeand offset ofcontrast.

CM150/PV150 2-1 GM CHASSIS

SERVICE MENU

GM Service Menu A-18728-03 Ver. 1.30

INTEQ INTEQ AVI AVI INTEQ

32V DV 36V DV ‘84 PV ‘91 PV ‘98 PV

3D comb 4x5W 3D comb 4x5W 2H Comb 2x5W 2H Comb 4x5W 3D comb 4x5W

0 Factory Mode 11111

1 Preset Preset N/A N/A N/A N/A N/A

2 Theater Preset N/A N/A N/A N/A N/A

3 Game Preset N/A N/A N/A N/A N/A

4 Sports Preset N/A N/A N/A N/A N/A

5 Daylight Preset N/A N/A N/A N/A N/A

6 Weak Signal Preset N/A N/A N/A N/A N/A

7 Vert OSD Position 15 15 15 15 15

8 Horz OSD Position 44 44 44 44 44

9 Keyboard Defeat 00000

10 Channel Lock 00000

11 Minimum Volume 00000

12 Maximum Volume 63 63 63 63 63

13 AC Power On 00000

14 A/V Lockout 00000

15 Feature Level 22012

16 Band/AFC 00000

17 Projection Mode 00111

18 Horz Gemstar Pos 00000

19 Vert Gemstar Pos 00000

20 RGB OSD/PIP Brightness 45 45 45 45 45

21 RGB OSD/PIP Contrast 60 60 50 50 50

22 Base Brightness Rf 76 76 76 76 76

23 Base Brightness Aux 76 76 76 76 76

24 Base Brightness YUV 76 76 76 76 76

25 Sub Contrast Rf 16 16 16 16 16

26 Sub Contrast Aux 16 16 16 16 16

27 Sub Contrast YUV 16 16 16 16 16

28 Sub Color Rf 10 10 10 10 10

29 Sub Color Aux 10 10 10 10 10

30 Sub Color YUV 10 10 10 10 10

31 Low Green/Red Drive 103 103 90 90 90

32 Med Green/Red Drive 117 117 80 80 80

33 High Green/Red Drive 113 113 70 70 70

34 Low Blue Drive 37 37 30 30 30

35 Med Blue Drive 51 51 40 40 40

36 High Blue Drive 57 57 50 50 50

37 Low Red Cutoff 200 200 195 195 195

38 Low Green Cutoff 100 100 230 230 230

39 Low Blue Cutoff 89 89 121 121 121

40 Med Red Cutoff 180 180 175 175 175

41 Med Green Cutoff 100 100 230 230 230

42 Med Blue Cutoff 118 118 141 141 141

43 High Red Cutoff 168 168 165 165 165

44 High Green Cutoff 100 100 230 230 230

45 High Blue Cutoff 144 144 159 159 159

46 Custom Color Setup 10 10 10 10 10

47 Preset Color Setup 10 10 10 10 10

48 Theater Color Setup 14 14 14 14 14

49 Game Color Setup 10 10 10 10 10

50 Sports Color Setup 10 10 10 10 10

51 Daylight Color Setup 10 10 10 10 10

52 Weak Sig Color Setup 10 10 10 10 10

53 Custom Black Stretcher 33333

54 Preset Black Stretcher 33333

55 Theater Black Stretcher 33333

56 Game Black Stretcher 33333

agmchas/p1 2-2

SERVICE MENU

GM Service Menu A-18728-03 Ver. 1.30 (continued)

INTEQ INTEQ AVI AVI INTEQ

32V DV 36V DV ‘84 PV ‘91 PV ‘98 PV

3D comb 4x5W 3D comb 4x5W 2H Comb 2x5W 2H Comb 4x5W 3D comb 4x5W

57 Sports Black Stretcher 27 27 27 27 27

58 Daylight Black Stretcher 33333

59 Weak Sig Black Stretcher 33333

60 Black Level Priority 00000

61 Color Decode Phase/Gain 169 169 169 169 169

62 OSD Control 00000

63 DVD YUV Tint Offset 63 63 63 63 63

64 Luma Setup 194 194 194 194 194

65 VSM Phase/Gain 70 70 70 70 70

66 DC Restoration 00000

67 Dynamic ABL Point Gain 22222

68 ABL Point/Gain 56 56 56 56 56

69 Horz Video Position 22 22 16 16 16

70 Vert Freq (Auto/60Hz) 22222

71 TOF Freq/Q 00000

72 PIP Horz Position 128 128 112 112 112

73 Input Level 66666

74 * VCO Adjust 31 31 31 31 31

75 * SAP VCO (Always 0) 00000

76 * SAP LPF (Always 0) 00000

77 * LPF Adjust 26 26 26 26 26

78 * Spectral Adjust 35 35 35 35 35

79 * Wideband Adjust 39 39 39 39 39

80 * Bass Boost 00000

* These settings must match the bar code label on top of the 9-1789 module.

CM150/PV150 2-3 GM CHASSIS

SERVICING - SMALL SIGNAL MODULE REPLACEMENT

SMALL SIGNAL (MAIN) MODULE REPLACEMENT

AND TOUCHUP CONVERGENCE

IMPORTANT! All convergencedatais stored in

IC6002, the eight pin Serial EEPROM located

on the Micro Module. A complete re-conver-

gence will be required unless this data is

retrieved fromtheoriginalmodule either by recording

the convergence values or transferring IC6002 to the

replacement module.

Small Signal Replacement Convergence Procedure

Replacing Small

Signal Module

Dead Set

Transfer IC6002

from original

Module

Record convergence

values to worksheet

Set has OSD Display

Record convergence

values to worksheet

Install convergence

values or transfer

IC6002 to new

Module

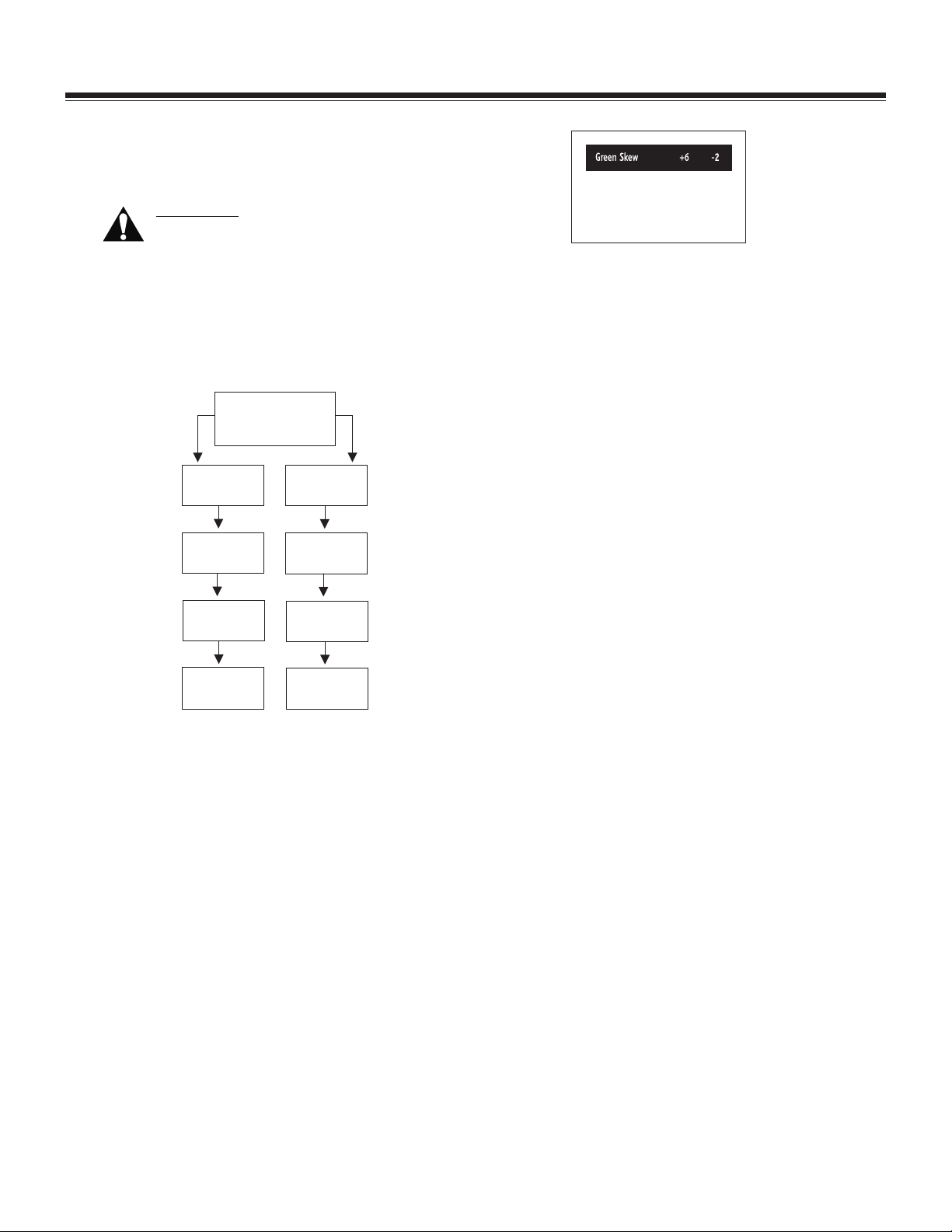

Green Convergence Mode Display

3. Start by pressing 1 on remote. Write down the

convergence values on the Digital Convergence

Numbers For Rear Projo TV sheet provided. Where

there are more than one set of numbers, press the

number again to see the second set.

4. After all the Green settings have been recorded,

press MUTE to access the Blue settings. Repeat

procedure and record all of the BLUE settings. When

BLUE is finished, press SURF for RED and record all of

the RED settings.

5. When all of the settings have been recorded, press

QUIT to exit the Convergence Mode.

NOTE: REMEMBER - Avoid any mechanical adjust-

ments on the CRTs or adjustment of the

Horizontal and Vertical size controls on the

Power Supply Module, if only replacing the

Main Module.

Proceed with

minor convergence

Proceed with

minor convergence

NOTE: If the small signal (Main) Module is the

cause of a Dead Set condition, and IC6002 is

faulty, the replacement module may require

a complete convergence setup.

If set still has on-screen display, use the following

procedure:

1. Remove shield from the Micro Module on the

original Small Signal Module and the replacement

module. Remove IC6002 from original module and

exchange it with IC6002 from the replacement

module. Replace both shields making sure to reinstall IC6002 on DUD Module.

2. Press and hold MENU on remote until User Menu

display disappears. Then press “999" and ENTER.

Set will now be in the GeometryAdjustment Mode; it

is not necessary to save GEOMETRY settings. Press

FLASHBACK to access the Green Convergence Sett ings. The left side of the bar describes the adjustment name. The two numbers on the right side of

the bar are the Horizontal and Vertical settings:

Horizontal on the left and Vertical on the right.

6. Remove defective module and install replacement

module. Ensure that all connectors are plugged in

securely.

7. Place the set in the Convergence Mode and install all

of the convergence values. Start with Green and

follow with Red, then Blue.

NOTE: To save the convergence values just entered,

press QUIT. “Do You Want To Save The

Changes - YES/NO” will appear. Use the

ADJUST button to select YES or NO, then press

ENTER to save. Do this after each “Green,

Red, Blue” sequence to avoid losing all of

your work should a power interruption occur.

8. If, after installing all of the original values, set still

needs some touchup of the convergence, attach a

crosshatch generator to set and follow the procedure

provided. Use the small Left/Right arrows for horizontal adjustments and the small Up/Down arrows

for vertical adjustments. Pressing ENTER lets you

toggle between the control’s stored setting and the

adjustment just made.

9. Access the Service Menu and enter the Stereo

coefficients as shown on the bar code label on small

signal Module.

agmchas/p1 2-4

SERVICE - SMALL SIGNAL MODULE REPLACEMENT (continued)

ENTER THE STEREO COEFFICIENTS

(Bar code data) Will be found on a label attached to the

chassis. Enter these settings in their appropriate

locations in the Service Menu items 74 through 80

(starting with the left-most two digits for item 74)

TYPICAL CHASSIS BAR CODE LABEL

LOCATED ON THE MAIN MODULE

COEFFICIENTS

SERVICE MENU ITEMS

06 19 06 07 18 61 34

74 75 76 77 78 79 80

0370v

CM150/PV150 2-5 GM CHASSIS

Loading...

Loading...