Page 1

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 2

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the STB covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the STB AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this STB or any of its

assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this STB and/or any of its electrical assemblies unless all solid-state device heat sinks

are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 3

2-2

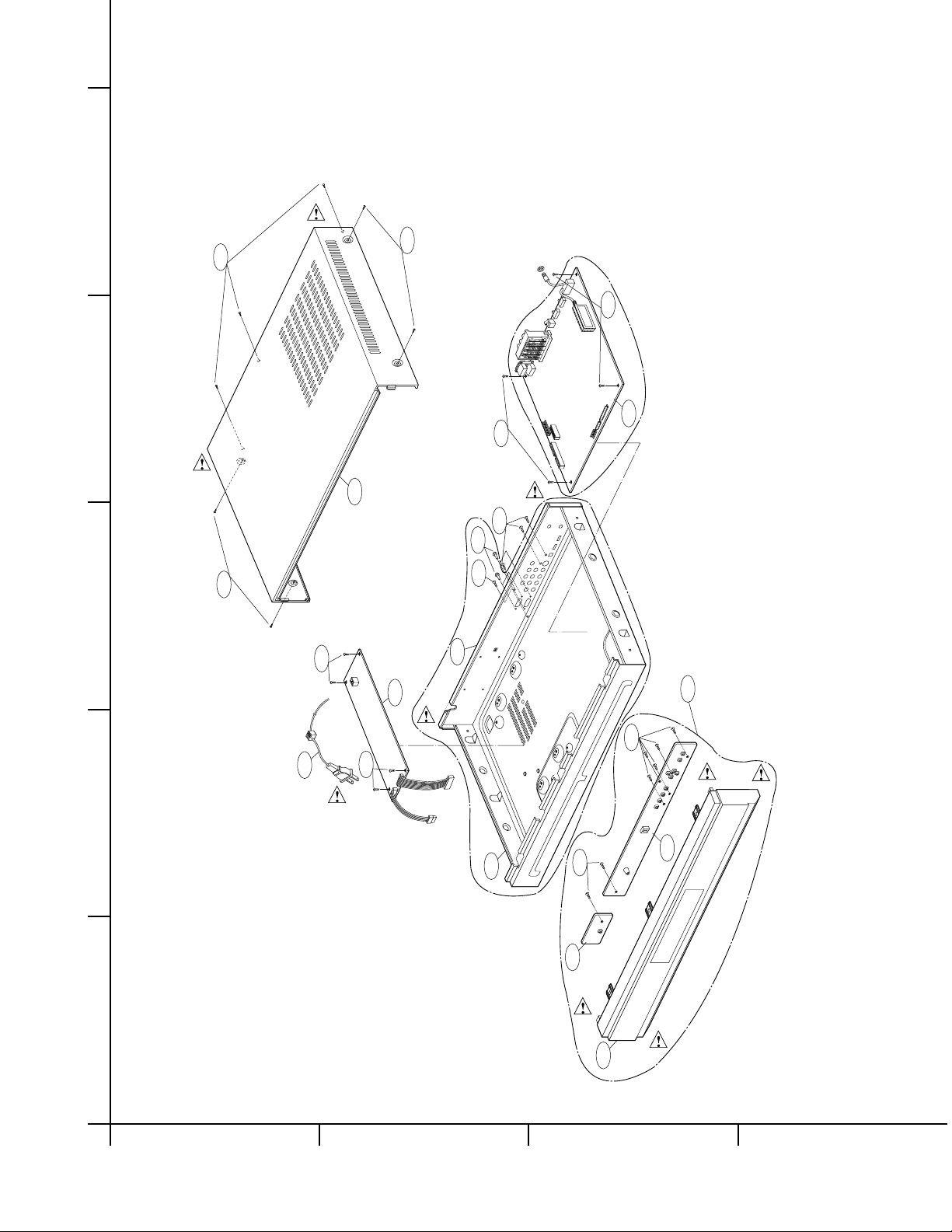

EXPLODED VIEWS

1. Cabinet and Main Frame Section

463

280

260

A42

A49

A46

A44

250

320

463

463

463

463

463

457

465

466

452

A43

452

463

300

A

5

4

3

2

1

BCD

Page 4

2-32-3

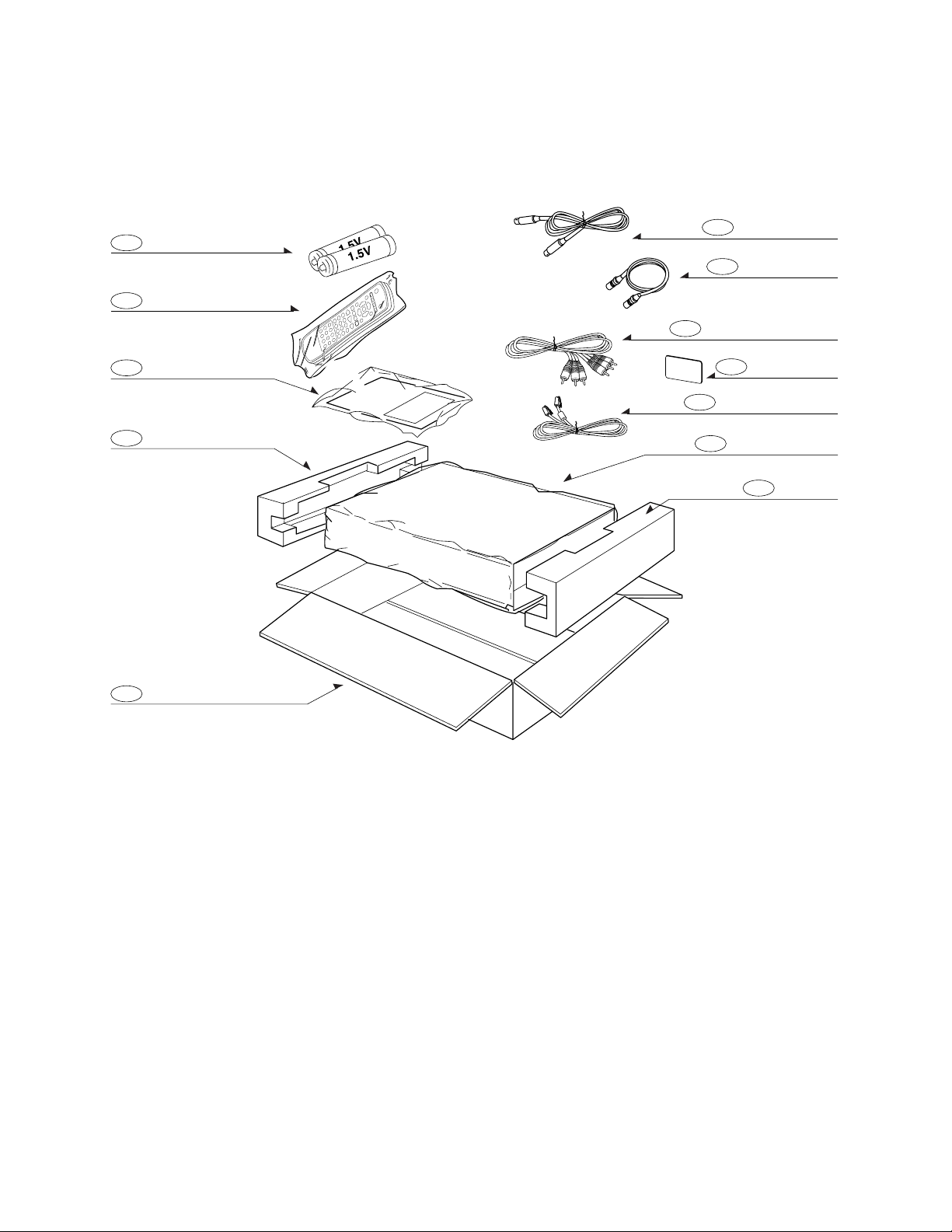

2.Packing Accessory Section

808

804

803

801

900

802

803

813

S-VIDEO CABLE

806

RF CABLE(2EA)

822

SMART CARD

823

TELEPHONE LINE

820

COMPONENT CABLE

PACKING SHEET

PACKING

BATTERY

REMOCON

BOX CARTONX

OWNER'S MANUAL

PACKING

Page 5

3-5

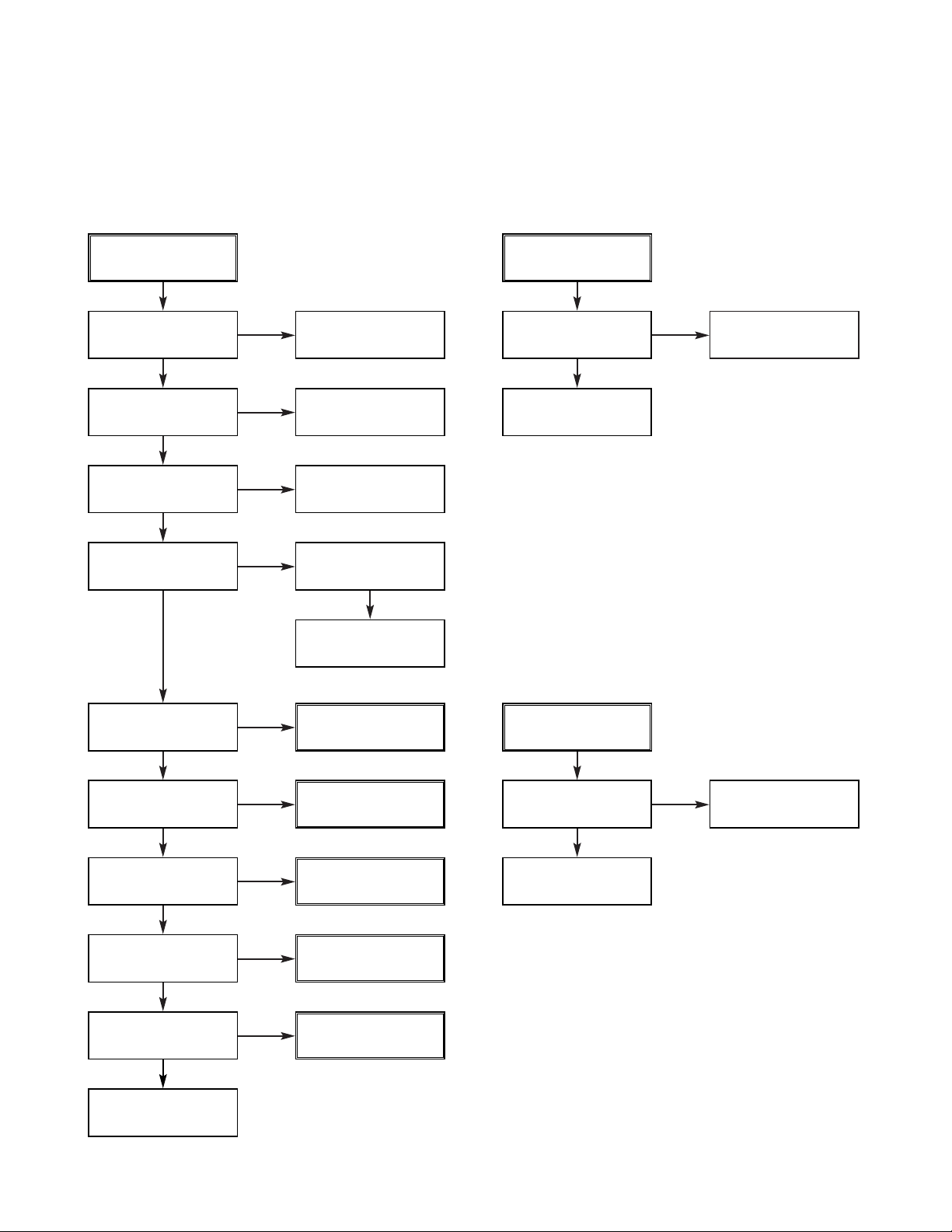

ELECTRICAL TROUBLESHOOTING GUIDE

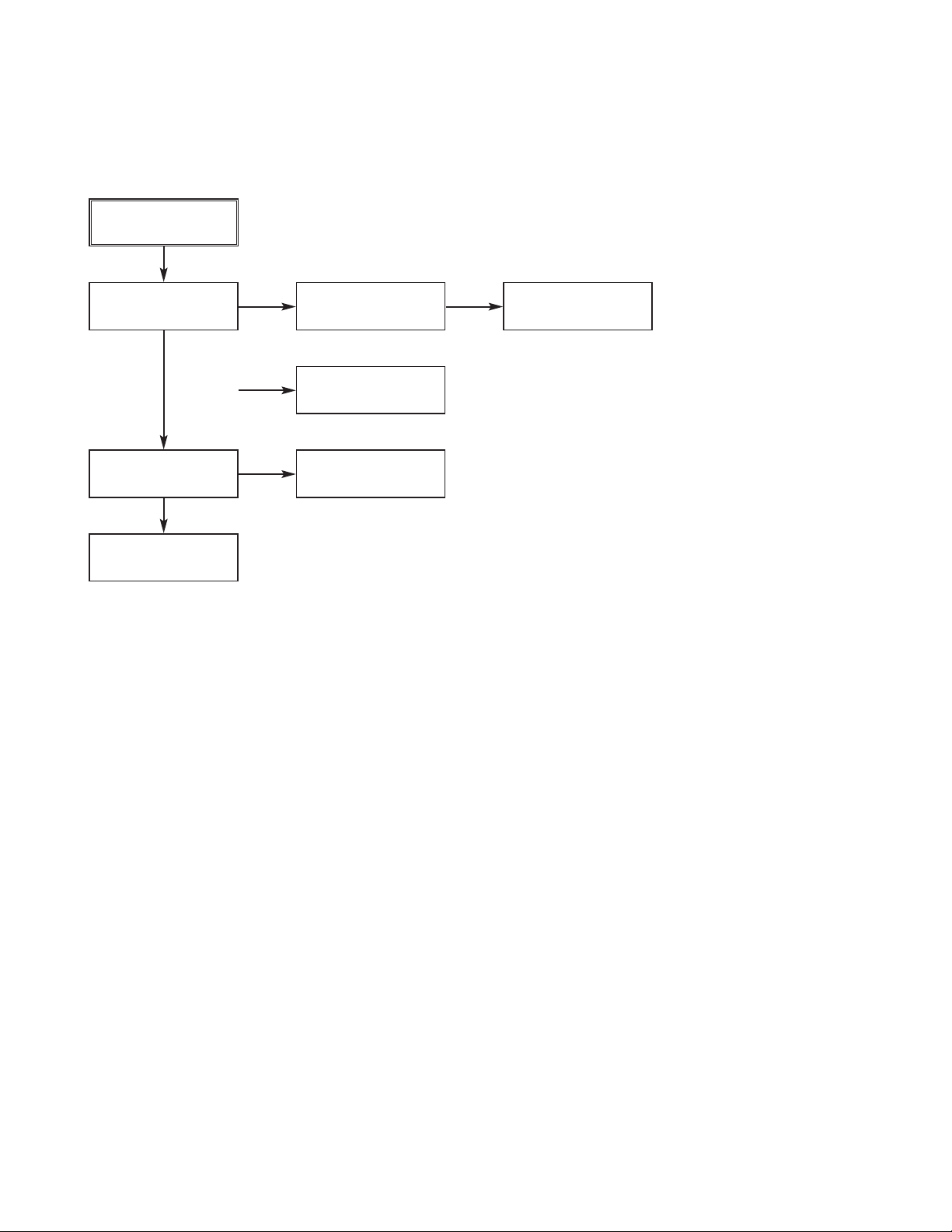

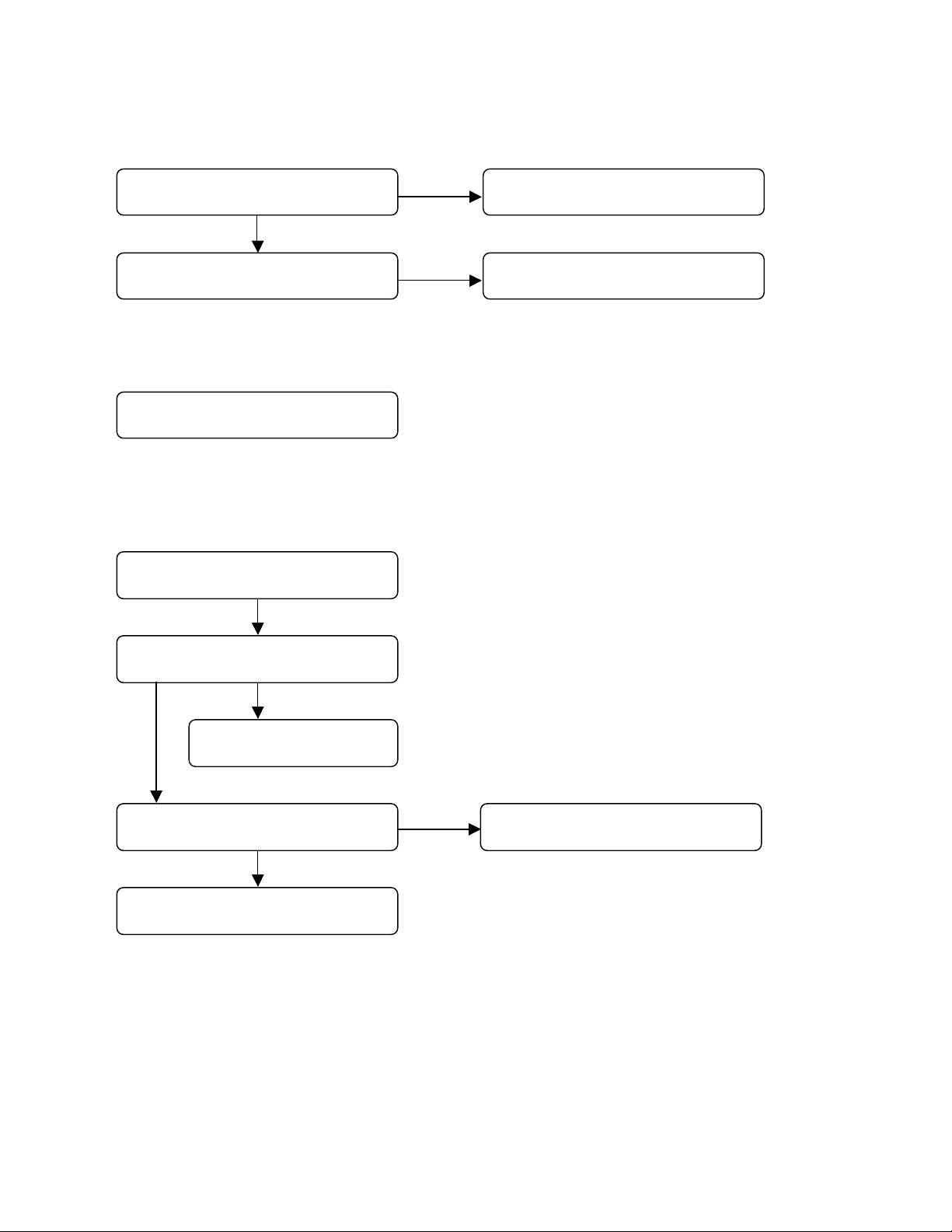

1. POWER(SMPS) CIRCUIT

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

YES

(1) No 3.8VA

Check or Replace

the D129, D130.

NO

YES

YES

(2) No 24VA (TO CAP, DRUM MOTOR)

NO

YES

YES

(3) No 30VA

NO 3.8VA.

Is the F101 normal?

Is the YH01

normal?

Is the BD101

normal?

Is Vcc(14~22V) supplied to IC101 Pin3?

Are the D121/D122

normal?

Is there about 2.5V

at the IC103 Pin1?

Is the D129/D130

normal?

Is the D125

normal?

YES

Power in Main PCB is

short?

Replace the F101.

(Use the same Fuse)

Replace the

BD101.

Replace the TH01.

Is the D102

normal?

Check or Replace

the D102.

Replace the

D121/D122.

Replace the D106.

Replace the

D129/D130.

Replace the

D125.

Replace the

D124.

NO 30VA.

Is there about 30V

at the IC151 Pin1?

Check or Replace

the Q151.

Check or Replace

the D129/D130.

Is there about 30V

at the IC151 Pin1?

Check or Replace

the IC151.

Is the D124

normal?

NO 24VA.

Page 6

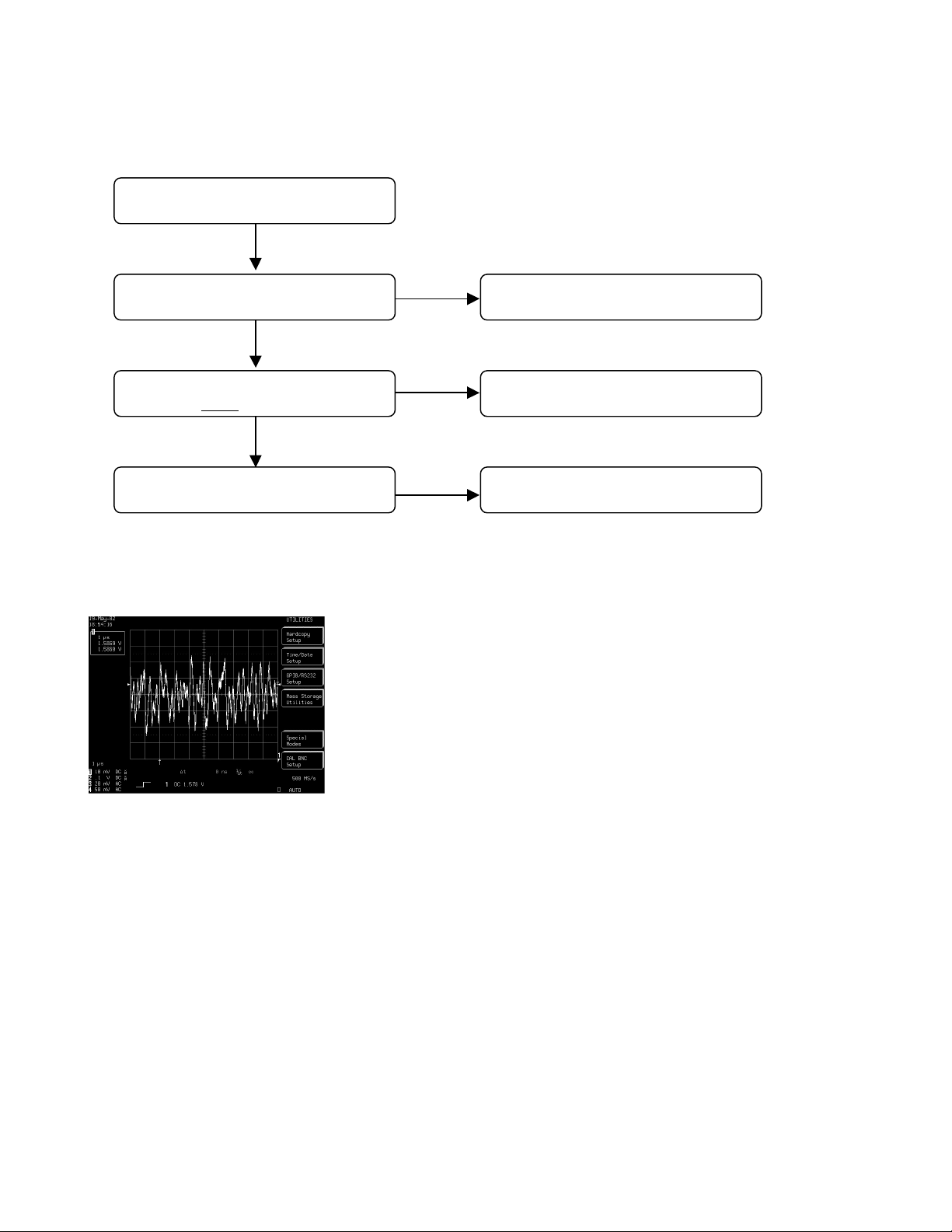

NO 30VA.

Is the F103

normal?

Is there about 33V

at the IC152 Pin1?

Is the ZD152

normal?

NO

Replace the F103.

(Use the same Fuse)

NO

NO

NO

Check or Replace

the D126.

Check or Replace

the ZD152.

YES

YES

YES

Check or Replace

the ZD152.

(4) No 30VA

3-6

Page 7

3-7

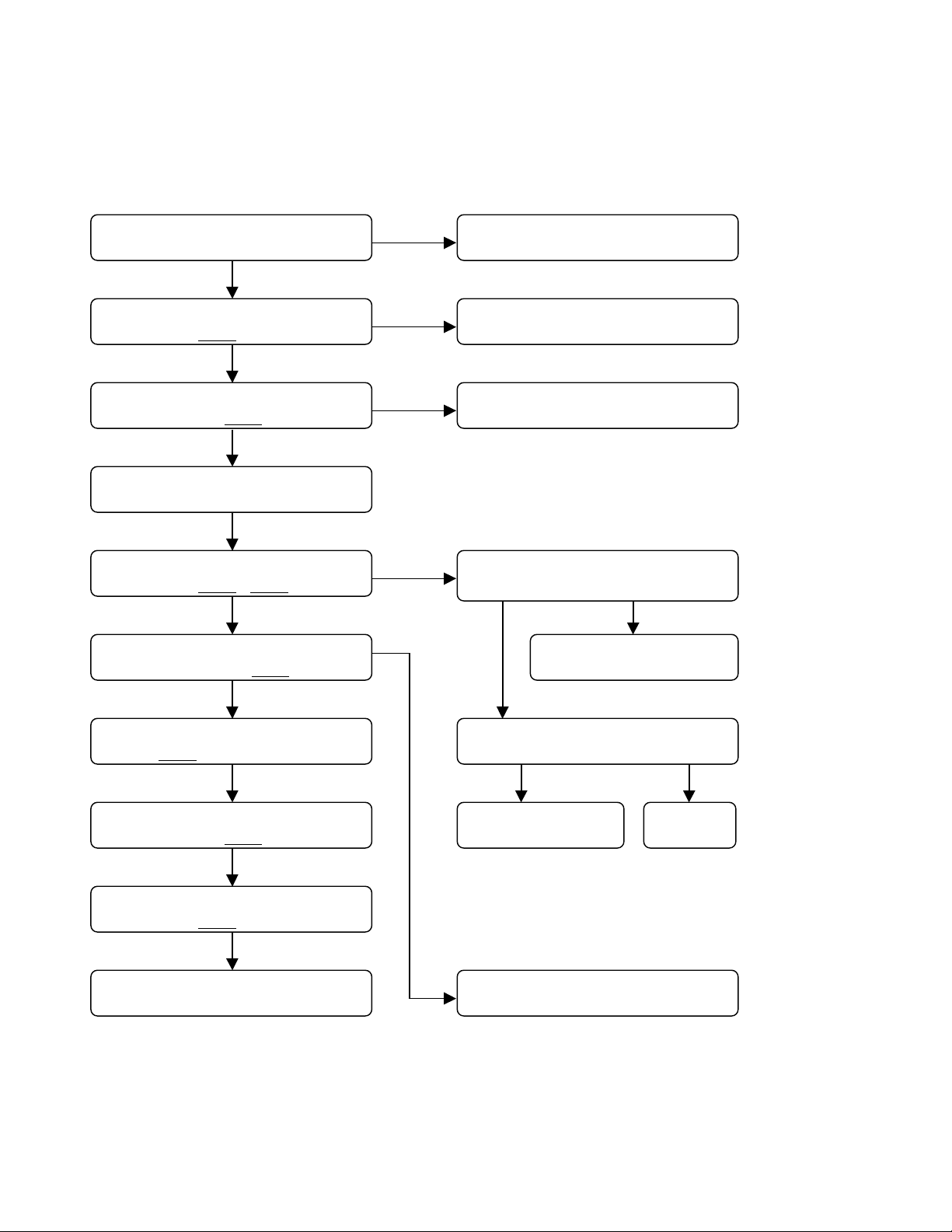

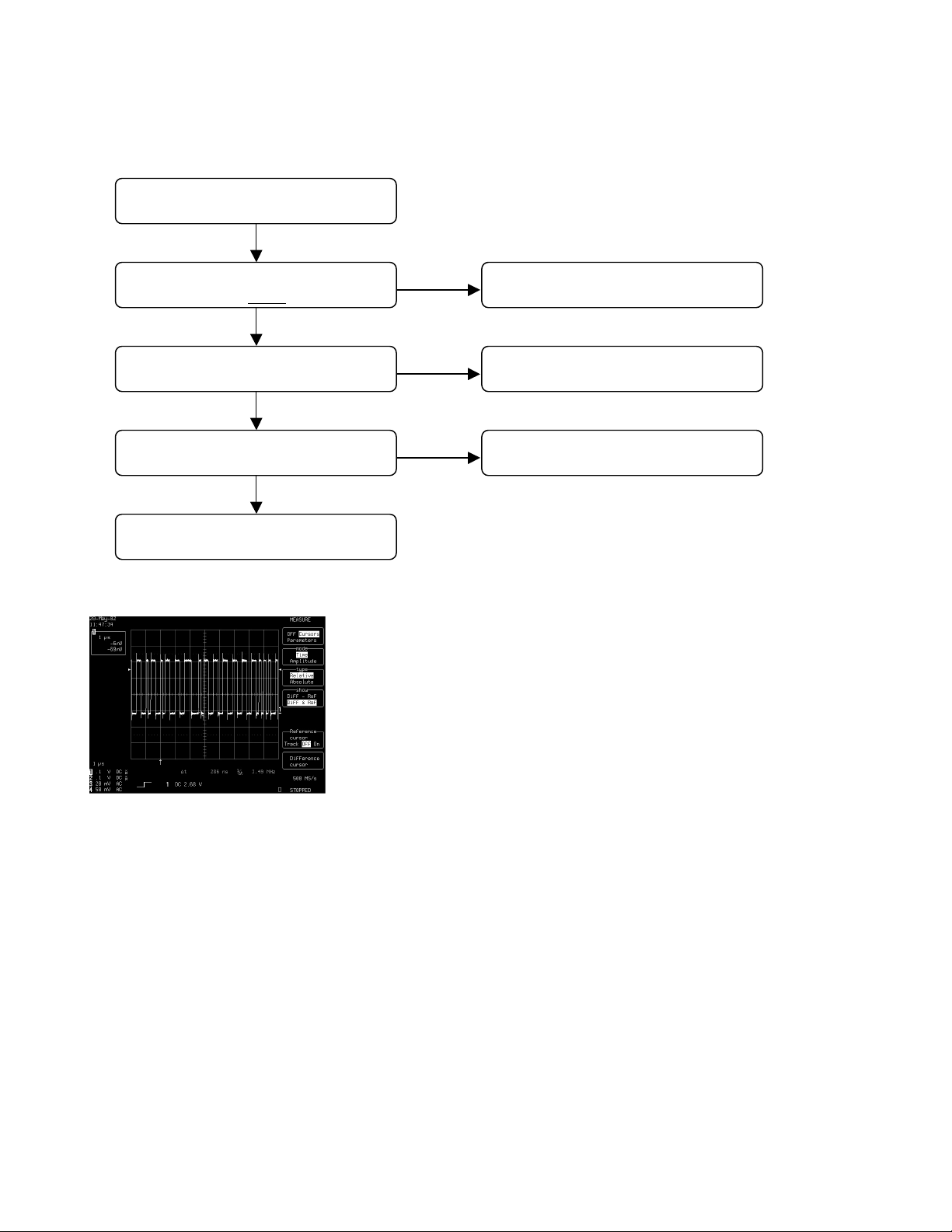

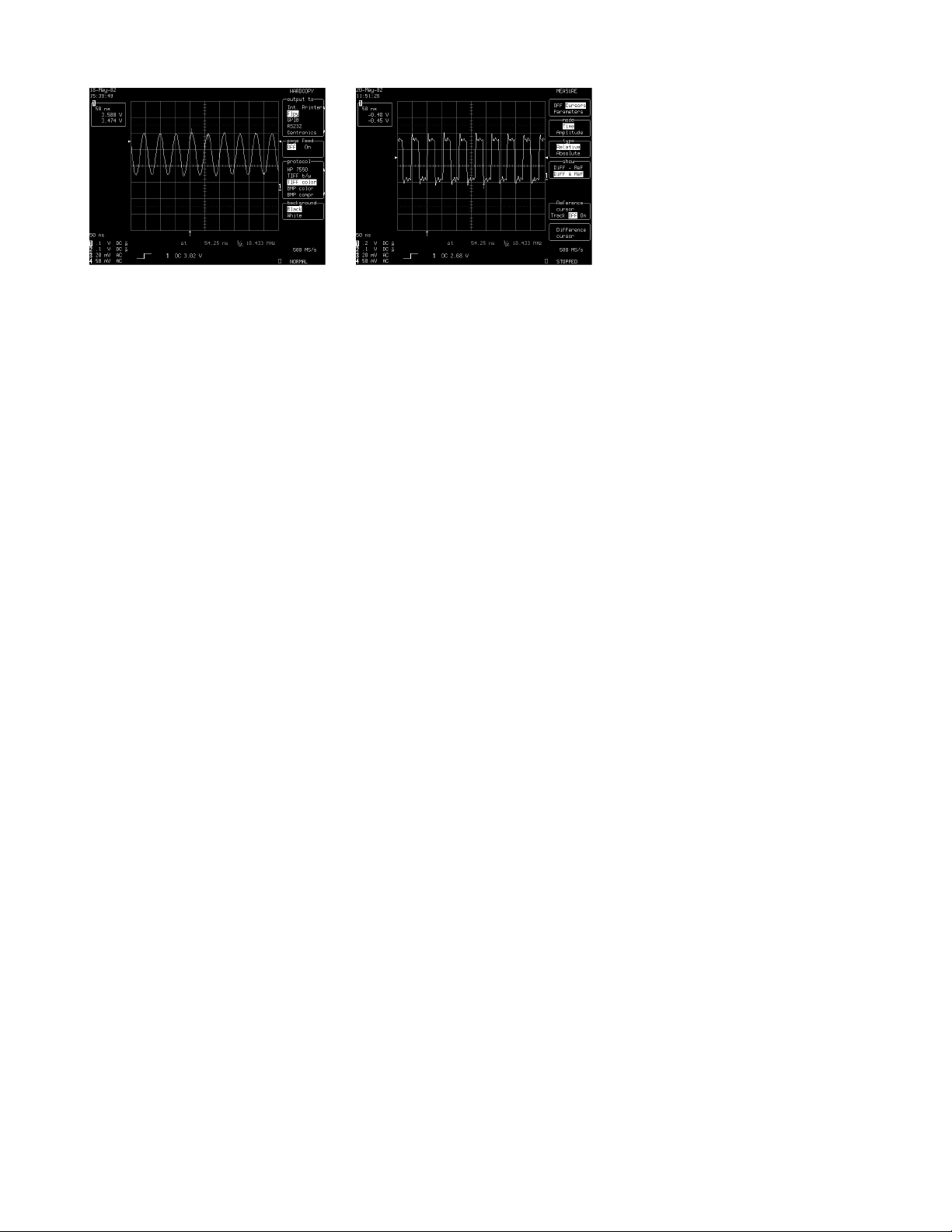

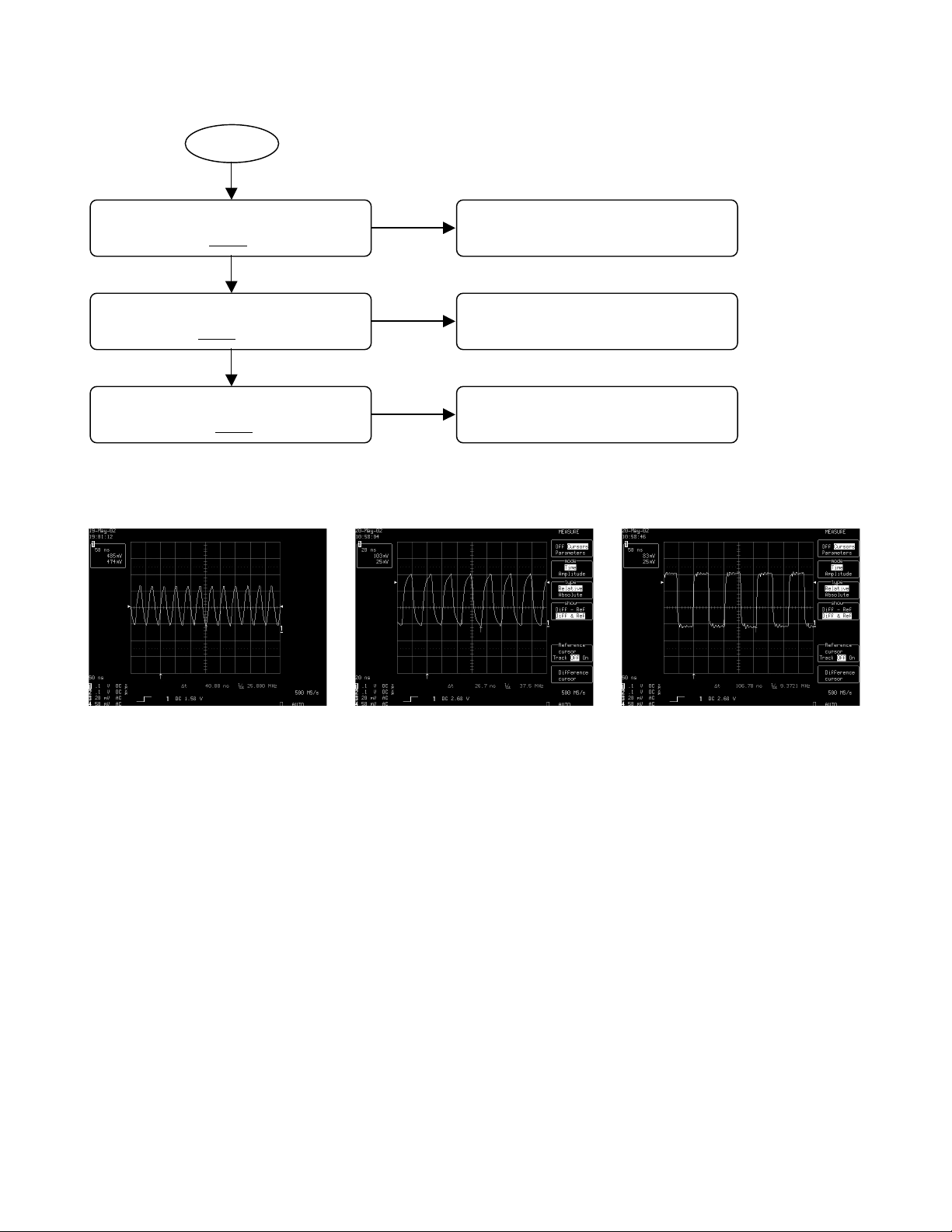

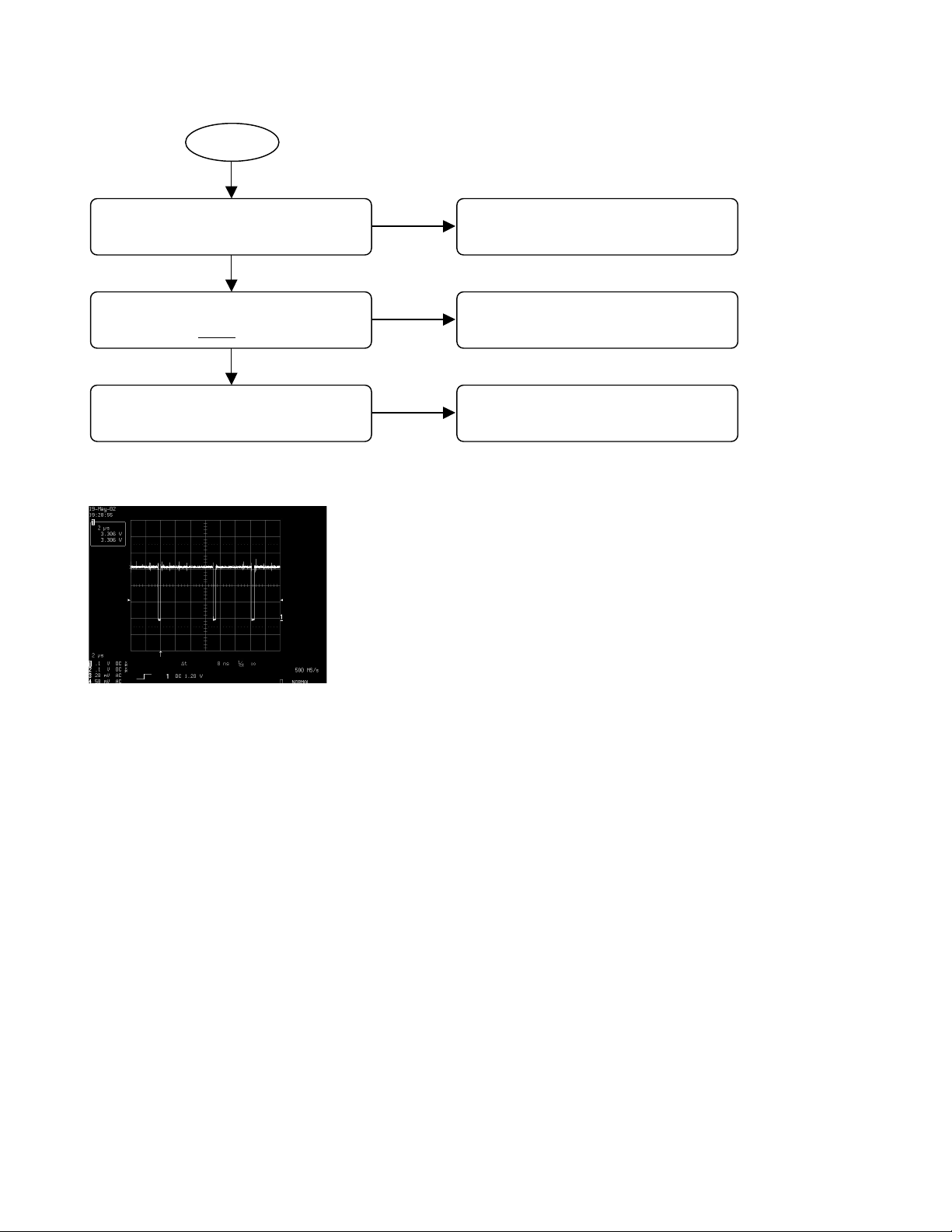

2. Audio Troubleshooting Flow

YES

YES

YES

YES

NO

NO

NO

YES

YES

YES

YES

NO

NO

NOYES

NOYES

Is 3.3V supplied to the pin 77 and

78 of IC701?

Is 27MHz Clock input into the pin

36 of IC701? Fig01

Is 33MHz Clock is output from the

pin 26 of IC701? Fig02

(1) NO ATSC Audio

Is 27MHz Clock is output from the

Pin 3 of IC603

Check R702, C707, C708

Is the pin 59 of IC701 is grounded?

Is 18.432MHz clock output from

the pin 67 of IC701? Fig05

Check R701, C703, C704

Is Data output from the pin 73 of

IC701? Fig06

Is 3.072MHz clock output from the

pin 63 of IC701? Fig07

Is 48kHz clock output from the pin

64 of IC701? Fig08

Check the surroundings of IC701

Check the Power Supply Part

Is pulse input into the pin 40 and

41 of IC701? Fig03, Fig04

Is Logic Low Input into the pin 1 of

IC711 and Logic High into the pin 1

of IC503 respectively?

Check the pin 56, 36 of

the IC201.

Check IC503, IC711

Check

IC500

Are pulses input into the pin 3, 6 of

IC503?

1.1 Check IC701 and Surroundings

Page 8

3-8

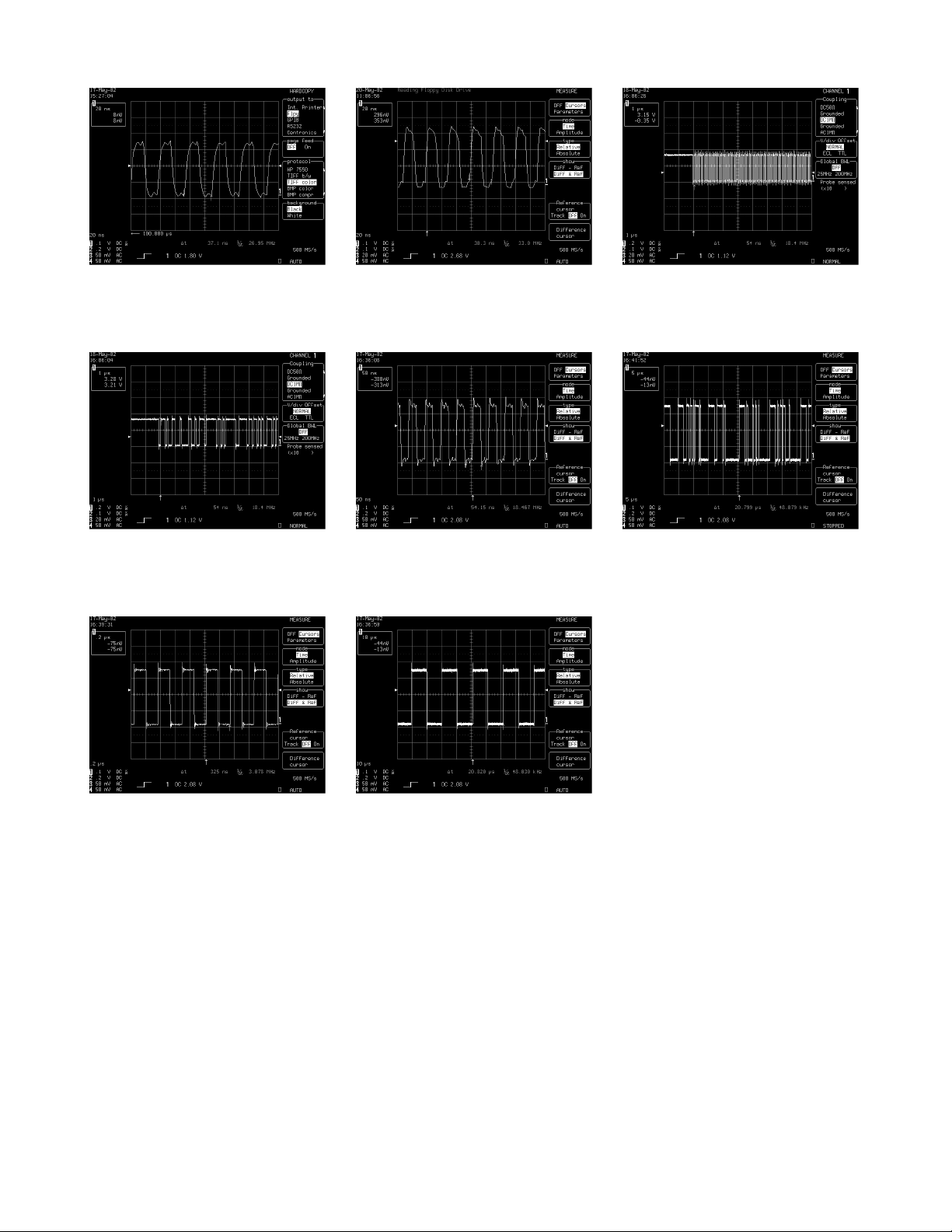

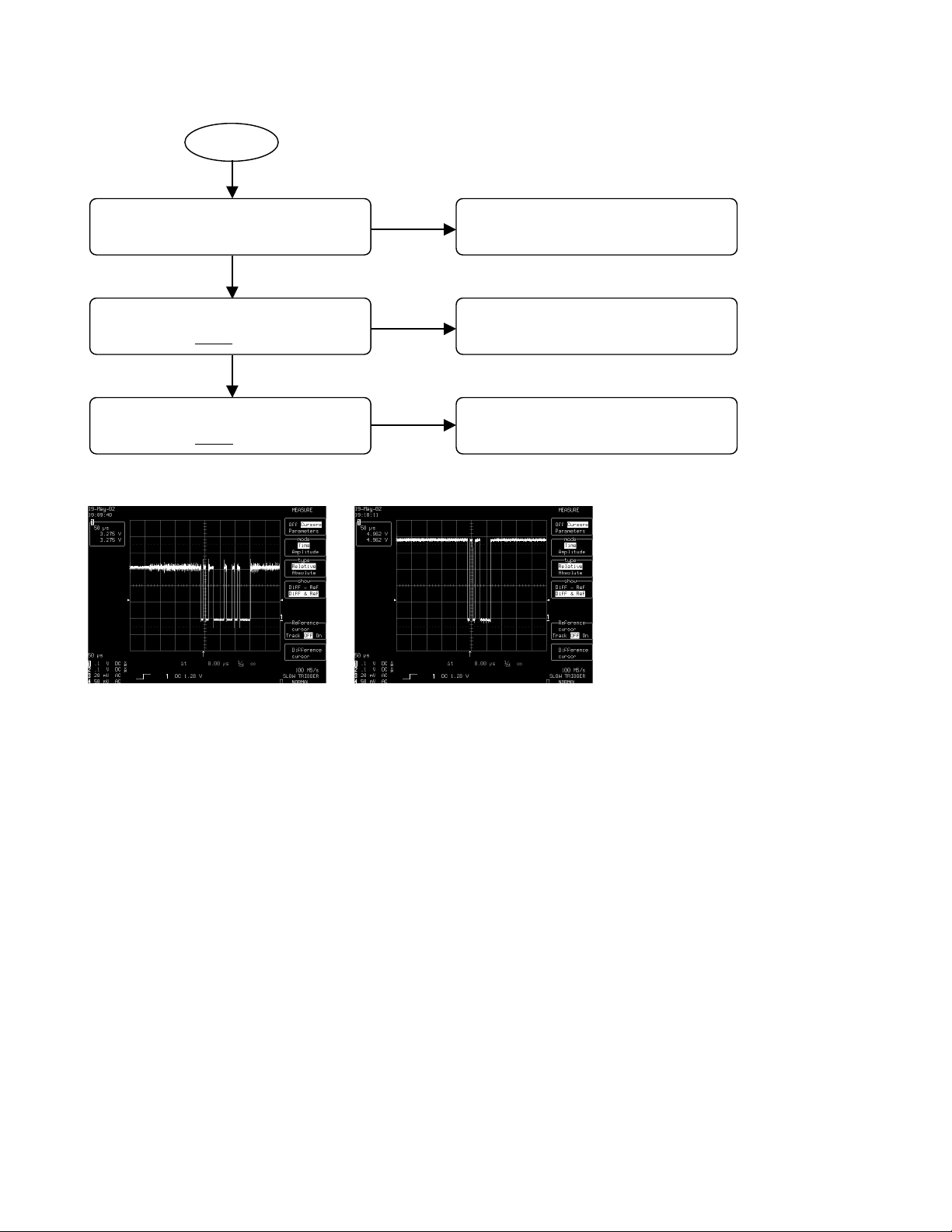

Fig.01 Fig.02 Fig.03

Fig.04 Fig.05 Fig.06

Fig.07 Fig.08

Page 9

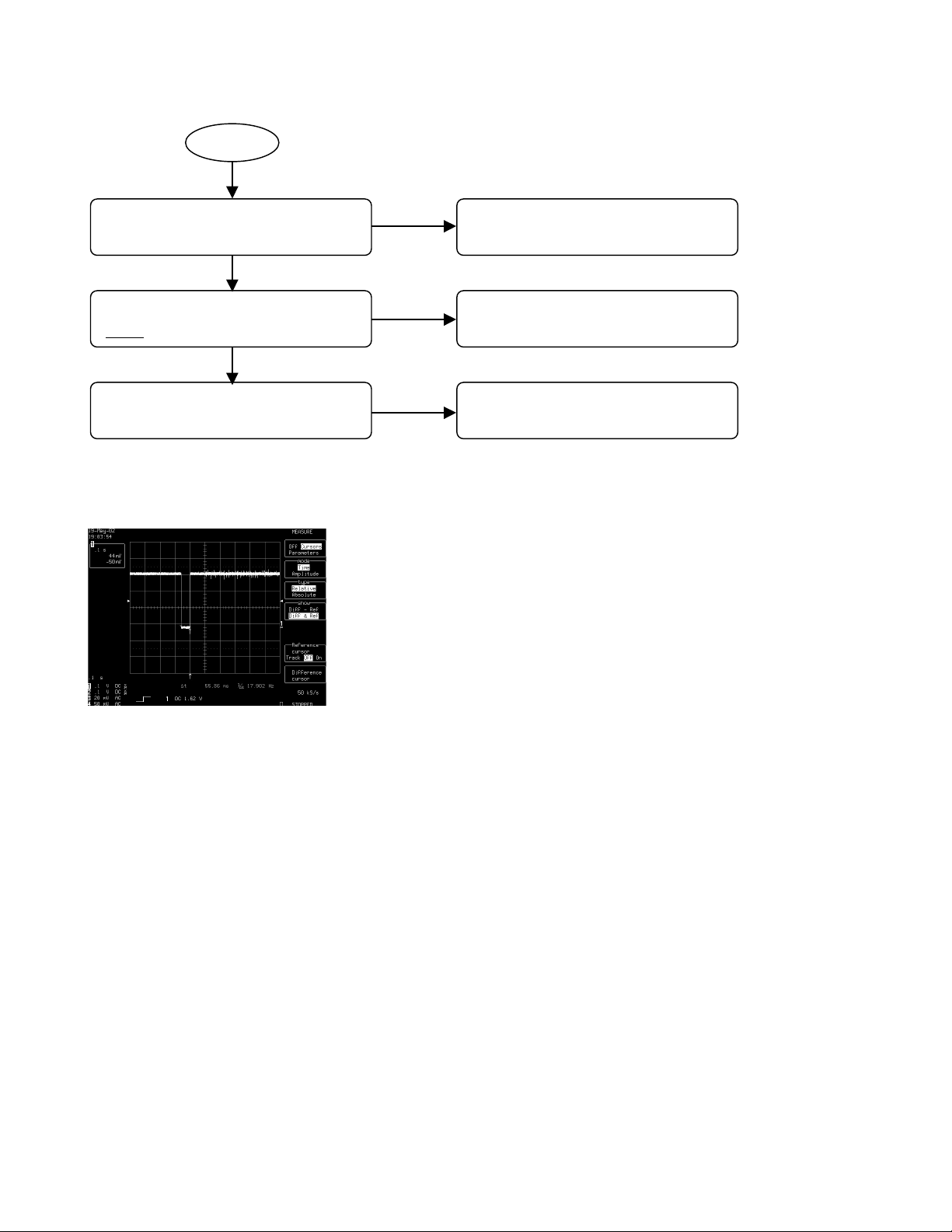

3-9

Fig.09

YES

YES

YES

NO

YES

NO

YES

NO

NO

NO

Is data pulse input into the pin 6

of IC801?

Is 48kHz clock is input into the pin

4 of IC801?

Are analog audio output from the

Pin 28, 29 of IC801? Fig09

Check IC702 and surroundings

1.2 Check MSP4448G and Surroundings

Is 5V supplied to the pin 10, 16, 49,

63 of IC801?

Check Power Supply Part

Is 8V supplied to the pin 31 of

IC801?

Is 10V is supplied to the pin of

IC805?

Is 18.432MHz Clock input into the

Pin 54, 55 of IC801?

Check Power Supply Part

Check IC713

Check IC713

NO

Page 10

3-10

NO

1.3 Check IC804 and Surroundings

YES

NO

1.4 Check Output Jack and Surroundings

Is analog audio signal output from

The pin 1, 7 of IC804?

Check IC804 and surroundings

Is 9V supplied to the pin 8 of

IC804?

Check Power Supply Part

Check Q803, Q804, Q805, Q806,

JA600 and their surroundings

(2) No DirecTV Audio

YES

YES

NO

NO

Is ATSC audio OK?

Check the pin 56, 36 of

the IC201.

Is pulse input into the pin 39, 40 of

IC503?

Check IC503, IC711 and their

Surroundings.

Check IC1950 and surroundings

Is Logic Low Input into the pin 1 of

IC711 and IC503?

Page 11

3-11

NO

YES

YES

NO

YES

NO

(3) No NTSC Audio

Is SIF signal input into the pin 50

of IC801? Fig10

Check TU300

Is SIF signal input into the Base

of Q304?

Are ATSC & DirecTV Audio OK?

Check Q304

Is analog audio signal output from

the pin 17, 18 of IC801?

Check IC801 and surrounding

Fig.10

Page 12

3-12

NO

NO

NO

(4) No SPDIF Out for ATSC & DirecTV

Is SPDIF pulse output from the

pin 51 of IC701? Fig11

Is 5V supplied into the pin 2 of

JA702?

Check JA702 and surrounding

YES

YES

Check IC701 and surrounding

Is ATSC & DirecTV Audio OK?

YES

Is SPDIF pulse output from the

pin 4 of IC710?

YES

Check IC710 and surrounding

Check Power Supply Part

Fig.11

Page 13

3-13

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

NO

YES

(5) No SPDIF for NTSC

Is data pulse output from the pin

5 of IC801?

Check IC801

Is ATSC & DirecTV Audio OK?

Is 18.432MHz clock output from

the pin 57 of IC801? Fig12

Check IC801

Is ATSC & DirecTV SPDIF OK?

Is 18.432MHz clock output from

the pin 3 of IC713? Fig13

Check IC713

Is NTSC Audio OK?

Is Logic Low input into the pin 19

of IC713?

Is Logic Low input into the pin 64

of IC201?

Check IC201

Is analog audio output from the

pin 25, 26 of IC801?

Check IC801

Page 14

3-14

Fig.12 Fig.13

Page 15

3-15

YES

YES

YES

NO

YES

NO

(6) No 3/4 RF Audio

Is ATSC & DirecTV Audio OK?

Is ATSC & DirecTV & NTSC SPDIF

OK?

Is analog audio output from the pin

18 of IC801?

Check IC801

Is analog audio output from the

Emitter of Q802?

Check Q802

Check TU301

Page 16

3-16

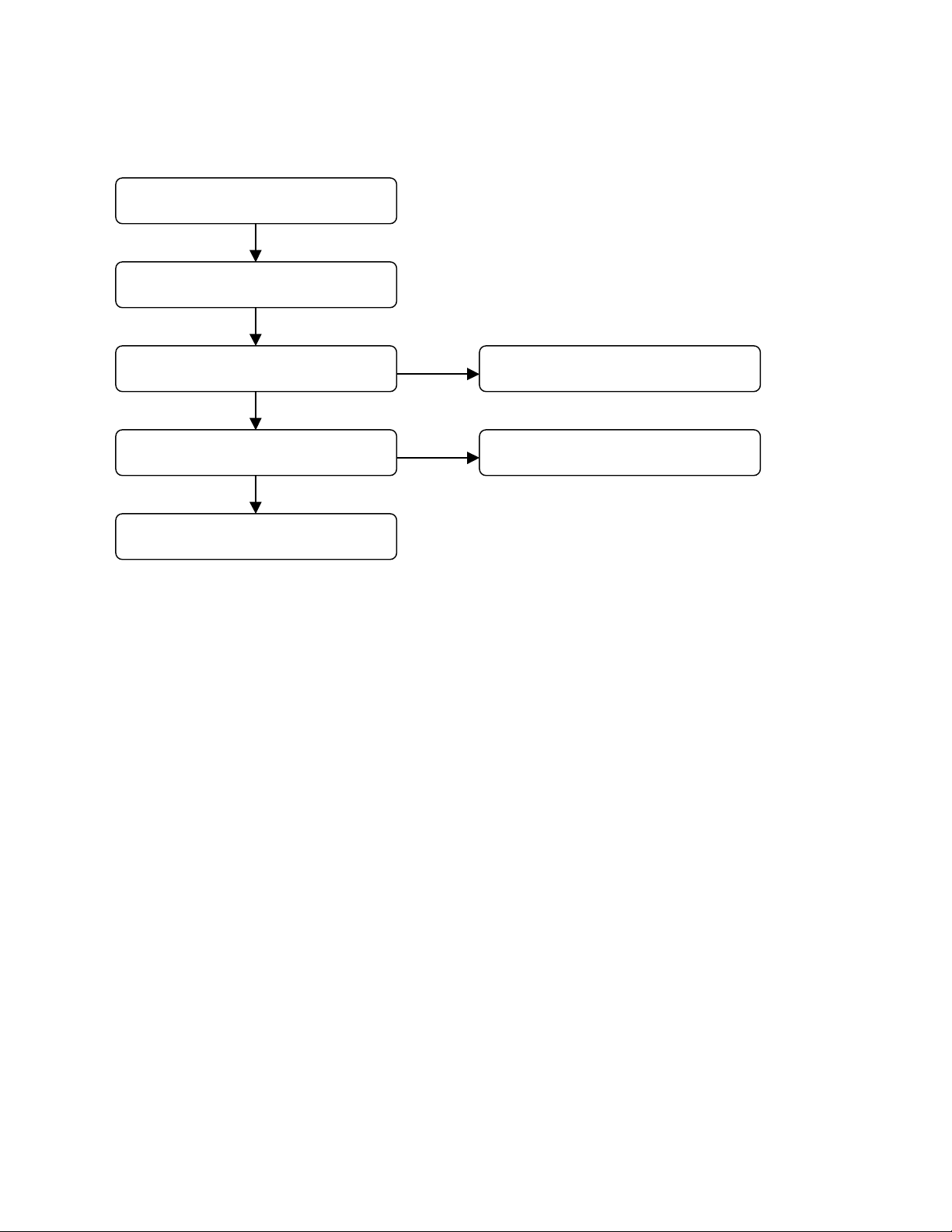

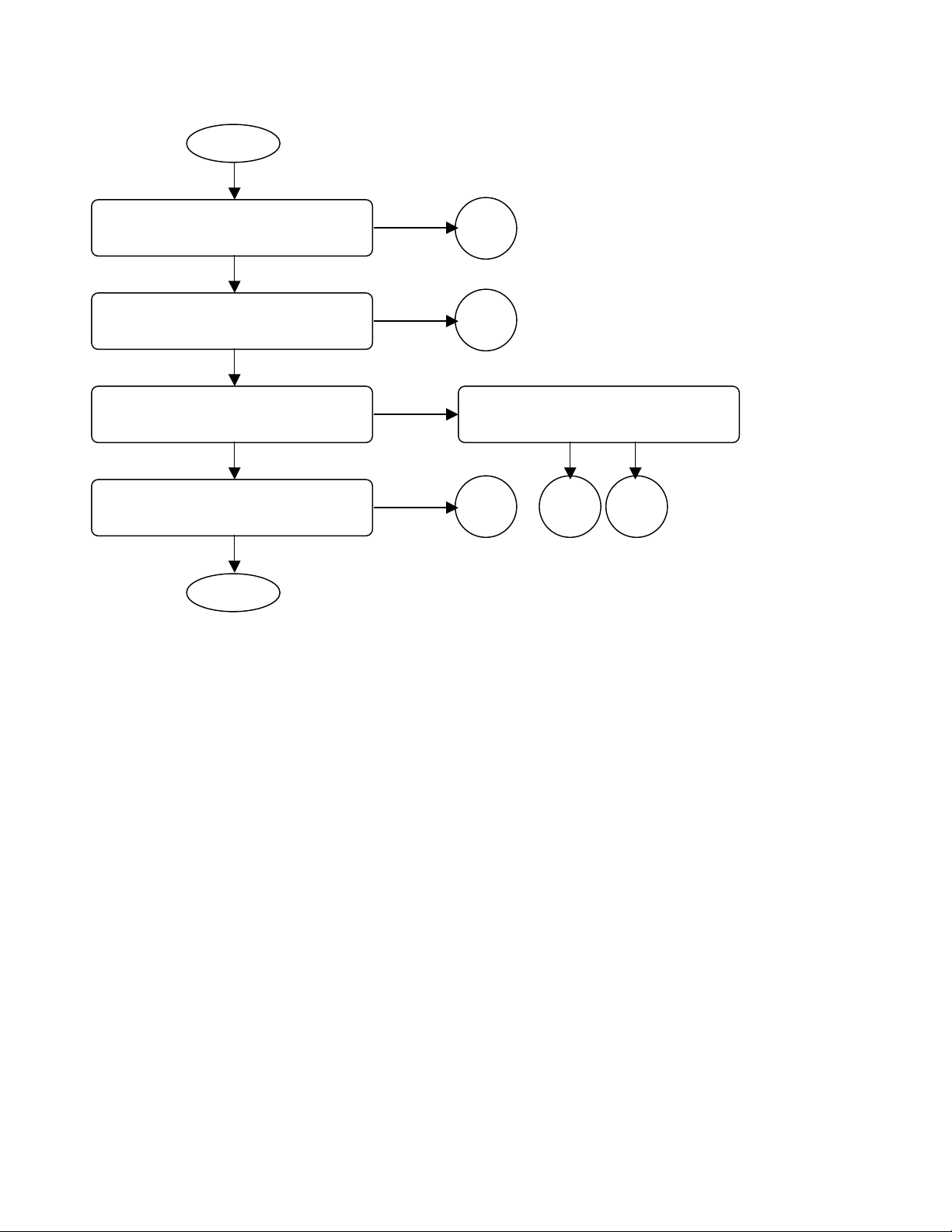

3. DIRECTV FRONT PANEL Troubleshooting Flow

NO

NO

NO

NO

NO

(1) If front panel board is not working

Is the IC -28, -24, -21.5V power

supplied normally?

Does the clock #1 operate normally?

Does the signal #2 operate normally?

Check IC100(5) clock waveform

: See Fig.01

Check IC100(8) clock waveform

: See Fig.02

YES

YES

YES

Check Connector P101(3), P101(2),

P101(1) voltage : -28, -24, -21.5V

Does the signal #3 operate normally?

Check IC100(42) clock waveform

: See Fig.03

YES

END

START

Is the IC 5V power

supplied normally?

YES

Check IC100(13), IC100(43), IR100(2)

voltage : 5V

Legend : IC100(5)

IC number

IC pin number

Page 17

3-17

FIG.01

IC100 VFD Chip Clock

(about 460KHz)

FIG.02

IC100 VFD Control Clock Signal

FIG.03

IC100 VFD Chip Grid1 Pulse

Page 18

3-18

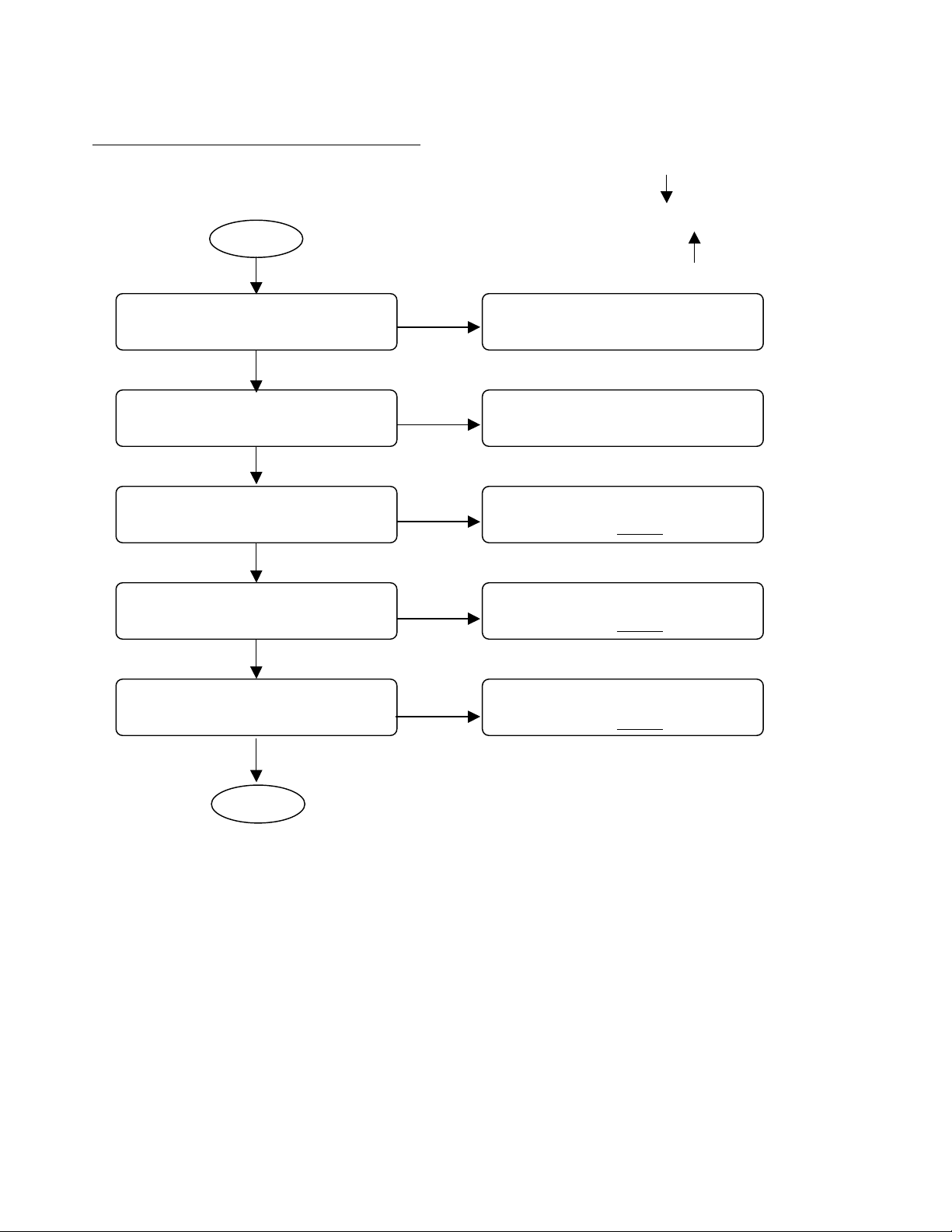

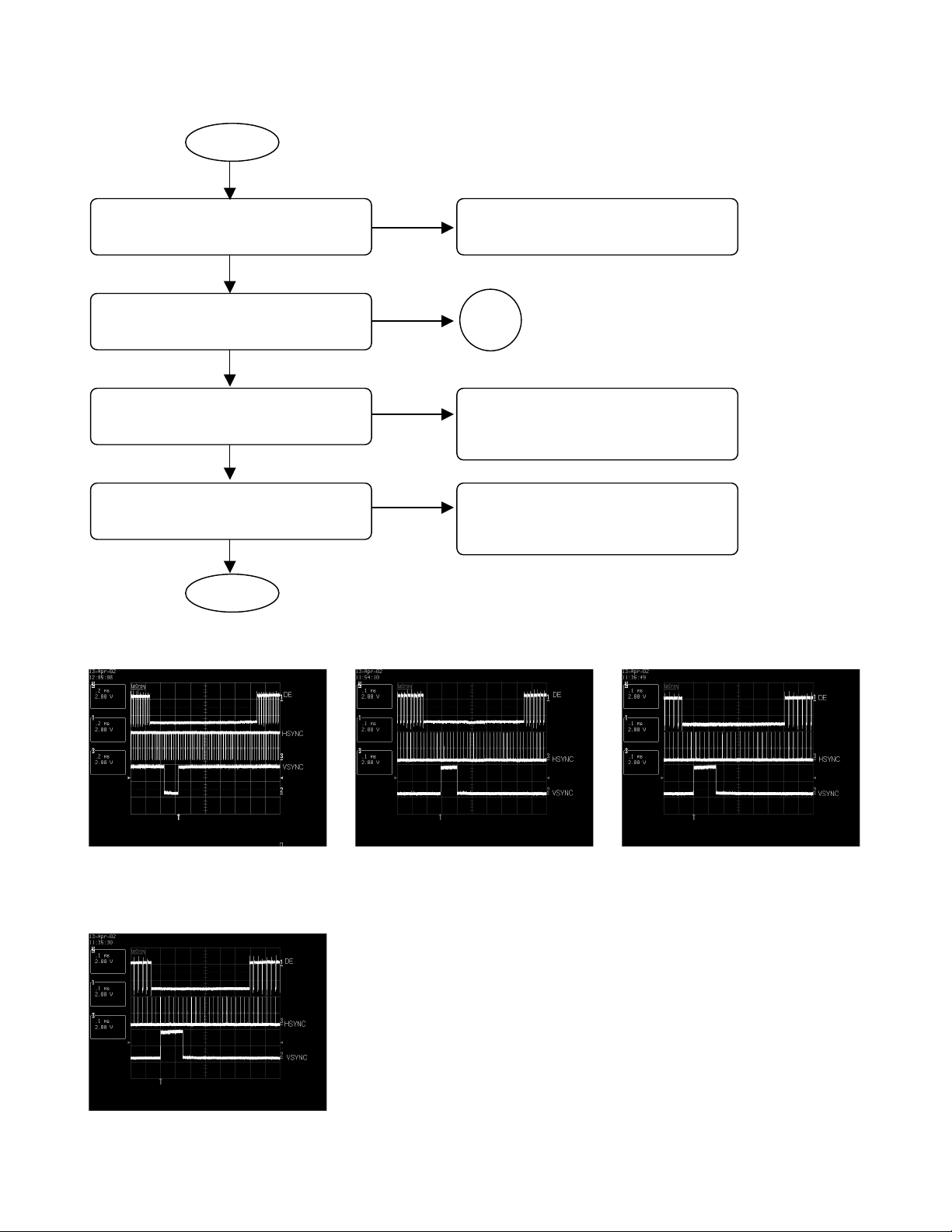

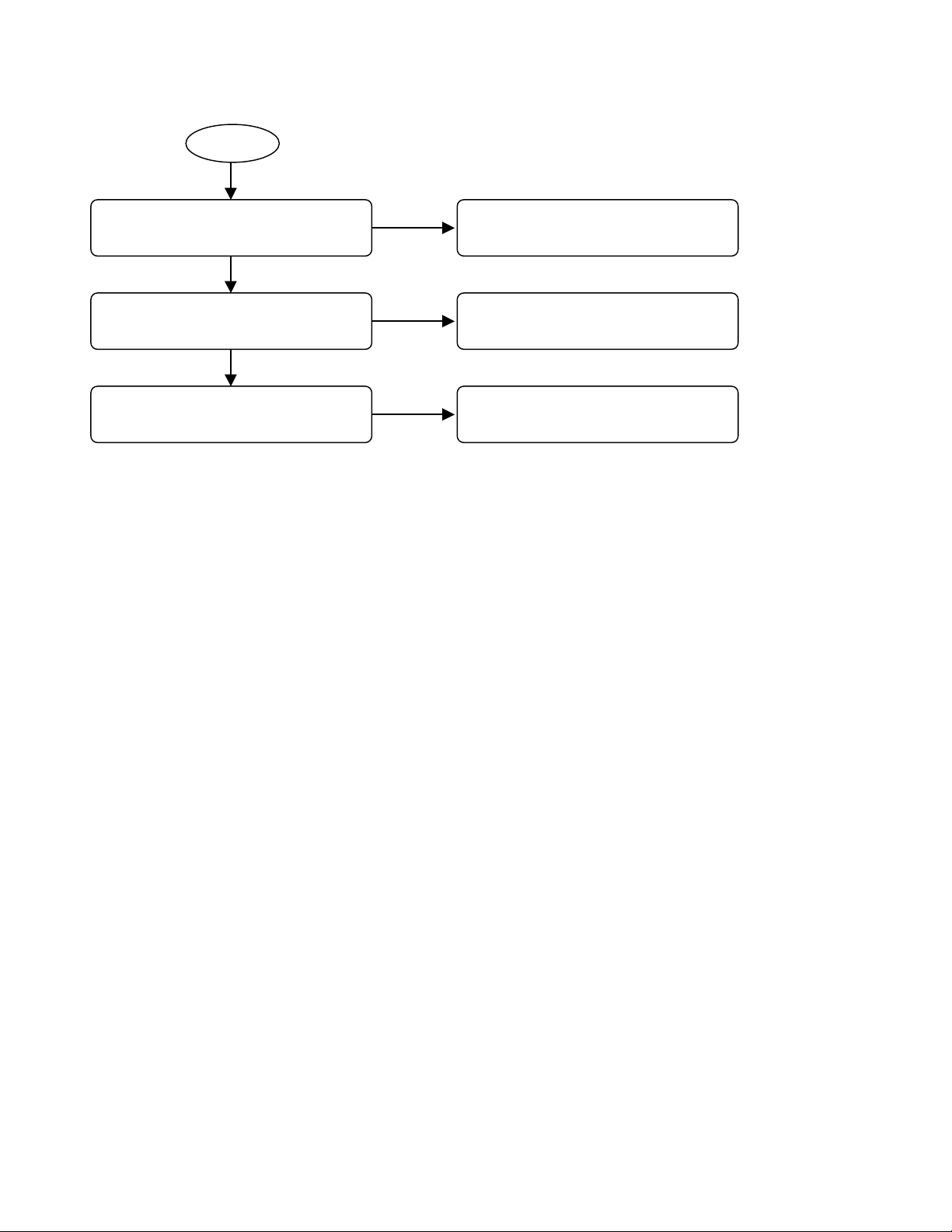

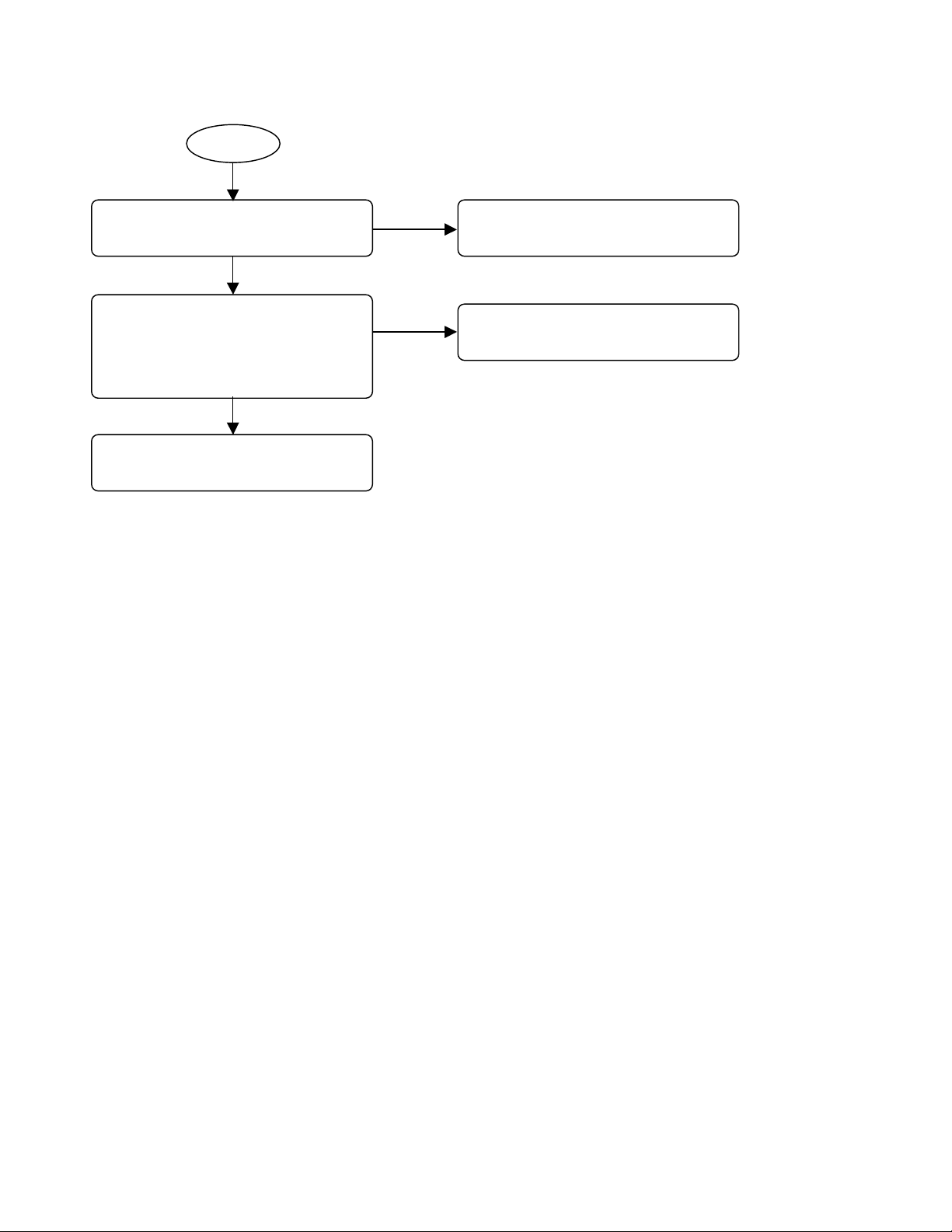

4. DVI Troubleshooting Flow

END

DVI cable is pulg in ?

DVI ICON display ?

480P picture right ?

START

YES

YES

YES

NO

NO

NO

NO

720P, 1080I picture right ?

YES

Connect DVI cable

(A)

Check IC404 pin57(IDCK+),pin2(DE),

pin4(HSYNC),pin5(VSYNC)

The IDCK_ clock shall be 27MHz.

Refer to Fig.1

Check IC404 pin57(IDCK+),pin2(DE),

pin4(HSYNC),pin5(VSYNC)

The IDCK_ clock shall be 74.25MHz.

Refer to Fig2, Fig3 and Fig4.

Fig.01 Fig.02 Fig.03

Fig.04

Page 19

3-19

(A)

Color Space Switch is RGB side ?

IC404 pin 11 is high volt ?

The emitter of Q409 is high volt ?

Change Switch to RGB side

Change the DVI chip

Use another DVI cable

or

Turn on the receiver monitor.

NO

NO

NO

YES

YES

Page 20

3-20

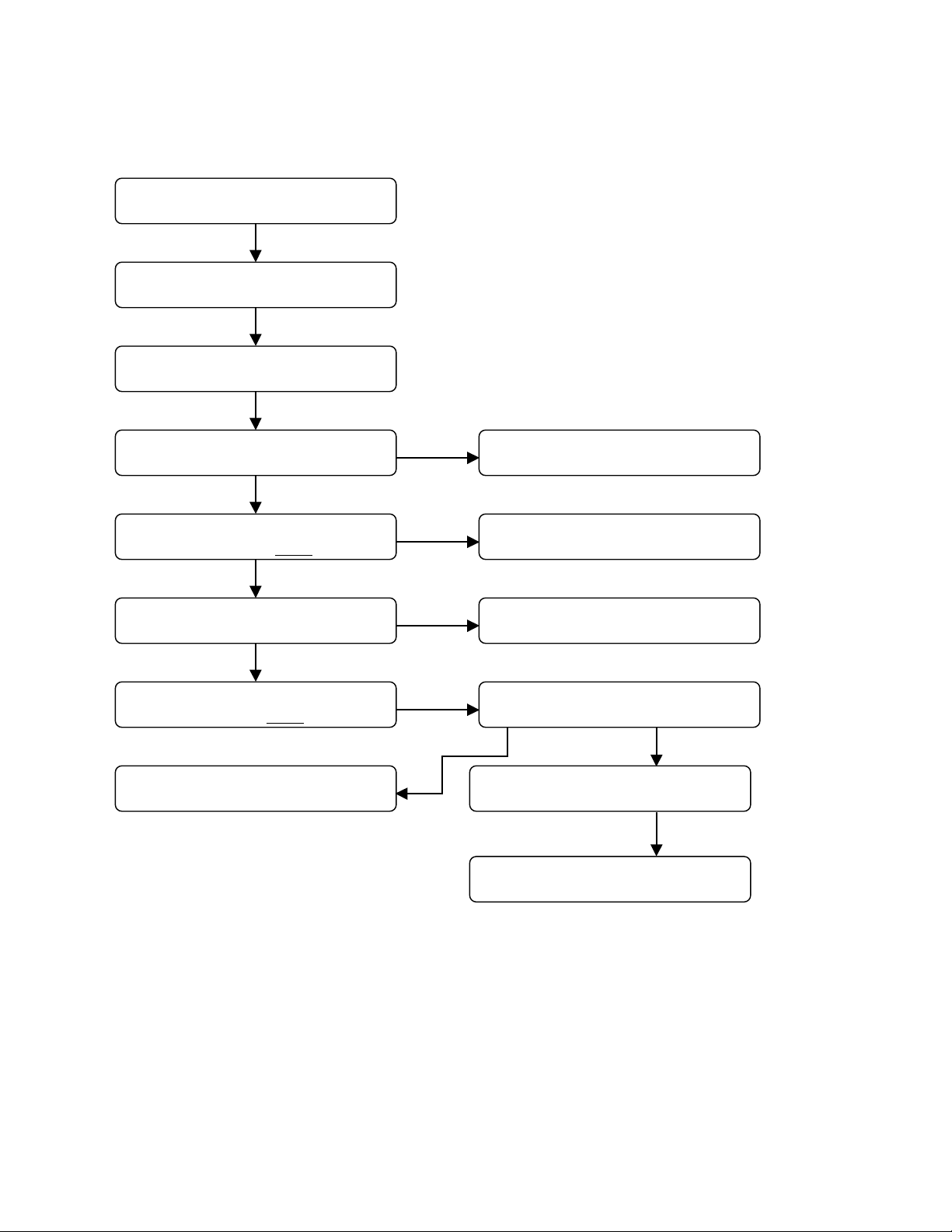

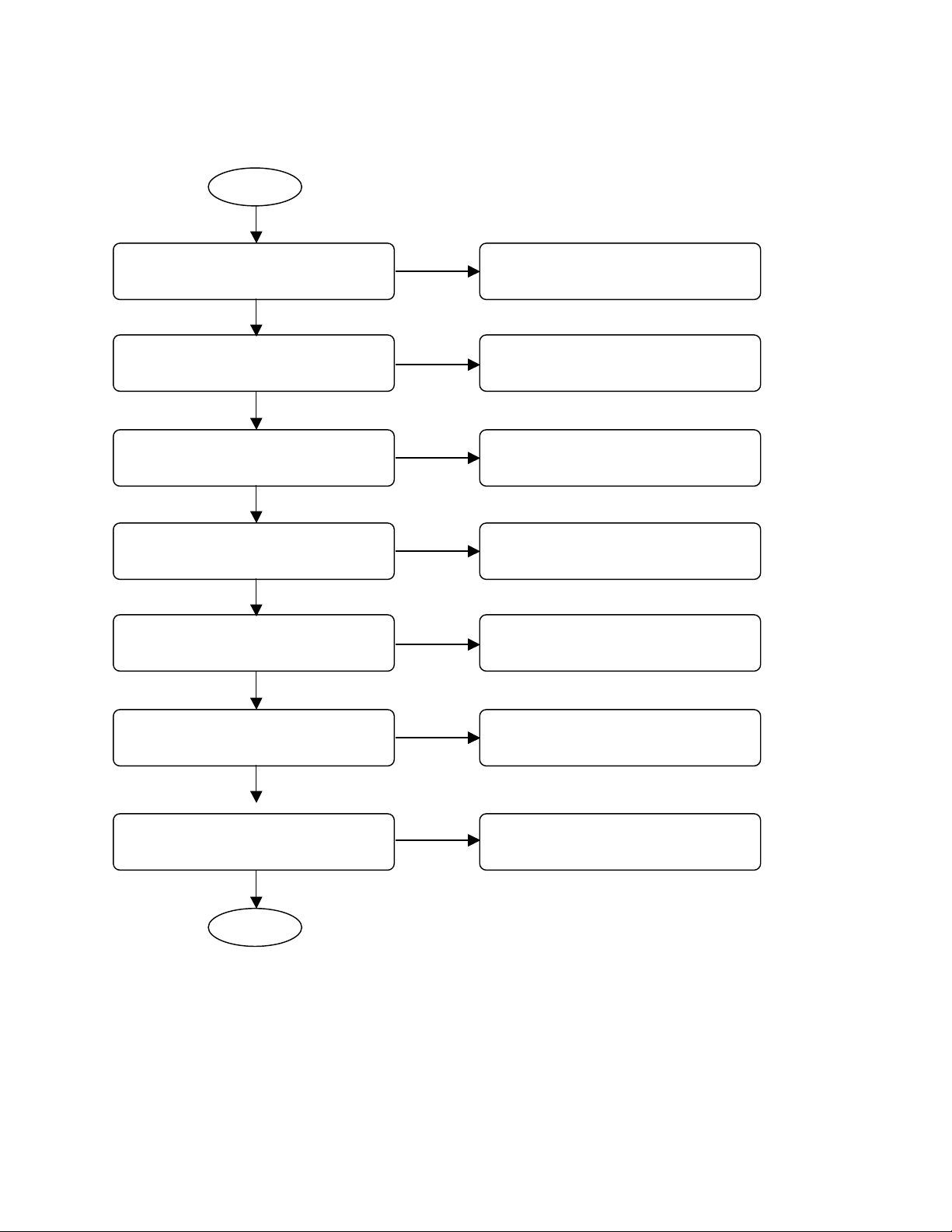

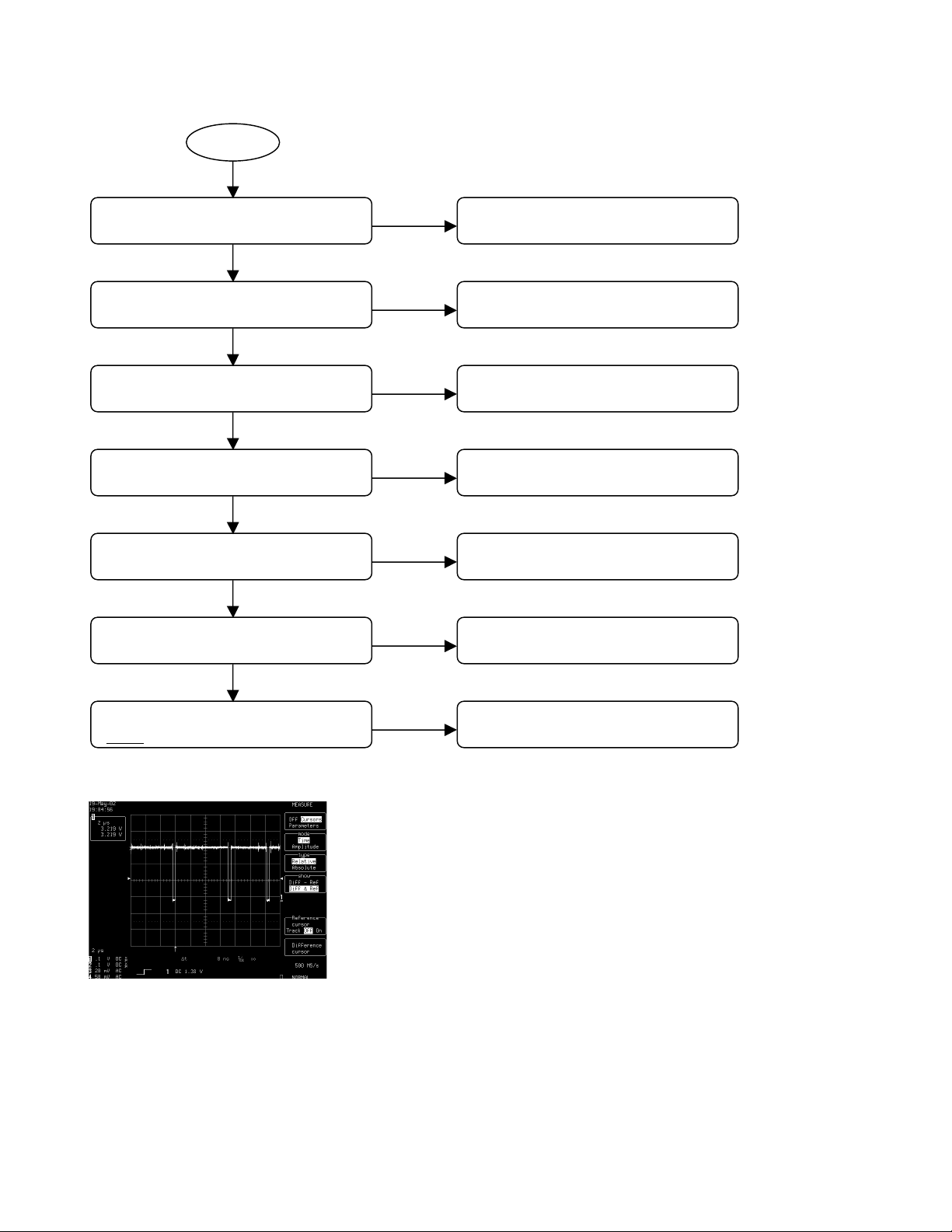

5. CPU Troubleshooting Flow

END

Is power supplied normally?

Is each clock OK?

Is each reset OK at the time of

power-on reset?

Is each chip selection OK?

Is each I2C channel OK?

Start

(1) outline

Check Power : Refer to (A)

Check each clock : Refer to (B)

Check reset circuit : Refer to (C)

Check each chip selection :

Refer to (D)

Check each I2C channel :

Refer to (E)

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Is each interrupt signal OK?

Check each interrupt signal :

Refer to (F)

NO

Are messages output through

RS-232C port on PC terminal?

Check RS-232C circuit :

Refer to (G)

NO

YES

Page 21

3-21

(A)

Is 2.5V supplied to L101 and 3.3V

to L102?

Is 3.3V supplied to the pin 47 of

IC104, IC105, the pin 1 of IC 102,

103, and the pin 51 of IC201?

Power Supply Check

IC904 : 2.5V

IC902 : 3.3V

Power Supply Check

IC902 : 3.3V

YES

NO

NO

YES

Check IC101, 102, 103, 104, 105

Page 22

3-22

(B)

Is 25MHz clock output from the

pin 3 of X101? Fig01

Is 37.5MHz clock input into the pin

87 of IC201? Fig02

Check X100

Check IC101 & IC201

YES

YES

NO

NO

Is 9.375MHz clock input into the

pin 1 of IC202? Fig03

Check IC201 & IC202

NO

Fig.01 Fig.02 Fig.03

Page 23

3-23

(C)

Is the pin 3 of IC108 reset?

Are the pin 42, 57, 61, 81, 83,

94, 92, 97 of IC201 reset?

Are the pin 4 of IC106 reset?

Fig04

IC108 Check

Check IC101 & 201

IC106 Check

YES

YES

NO

NO

NO

Fig.04

Page 24

3-24

(D)

Is logic low pulse seen at R138?

Is logic low pulse seen at R142?

Is logic low pulse seen at R144?

Check IC101, 104, 105

Check IC101, IC701

Check IC101, IC500

YES

YES

NO

NO

NO

Is logic low pulse seen at R143?

Check IC101, IC201

NO

YES

YES

Is logic low pulse seen at R108?

Check IC101, IC102

NO

Is logic low pulse seen at R141?

Fig05

YES

Check IC105, IC205, IC206, IC207

NO

Is logic low pulse seen at R140?

Check IC101, IC1950

NO

YES

Fig.05

Page 25

3-25

(E)

Are IIC SCL and SDA signal input

Into the pin 2, 5 of IC209 from

IC101?

Check IC101, IC209

YES

NO

Are IIC SCL and SDA signal output

from the pin 4, 6 of IC209?

YES

Check IC209

NO

Are the IIC SCL and SDA signal

output from the pin of IC202?

Fig06 & Fig07

Check IC202

NO

Fig.06 Fig.07

Page 26

3-26

(F)

Is logic low pulse output into the

pin 31 of IC100?

Is logic low pulse output into the pin

57 of IC701? Fig08

Check IC100, IC500

Check IC100, IC701

YES

YES

NO

NO

Is logic low pulse output into the pin

75 of IC1950?

Check IC100

NO

Fig.08

Page 27

3-27

YES

NO

NO

NO

(G)

Is the pin 11 of IC204 OK?

(TxD signal) Fig09

Is the pin 12 of IC204 OK?

(RxD signal) Fig10

Check IC101, IC204

Check IC101, IC204

Is the RS-232C port setup is OK?

(Baudrate, Parity, Data Bit, Stop Bit)

Modify RS-232C port setup

YES

Fig.09 Fig.10

Page 28

3-28

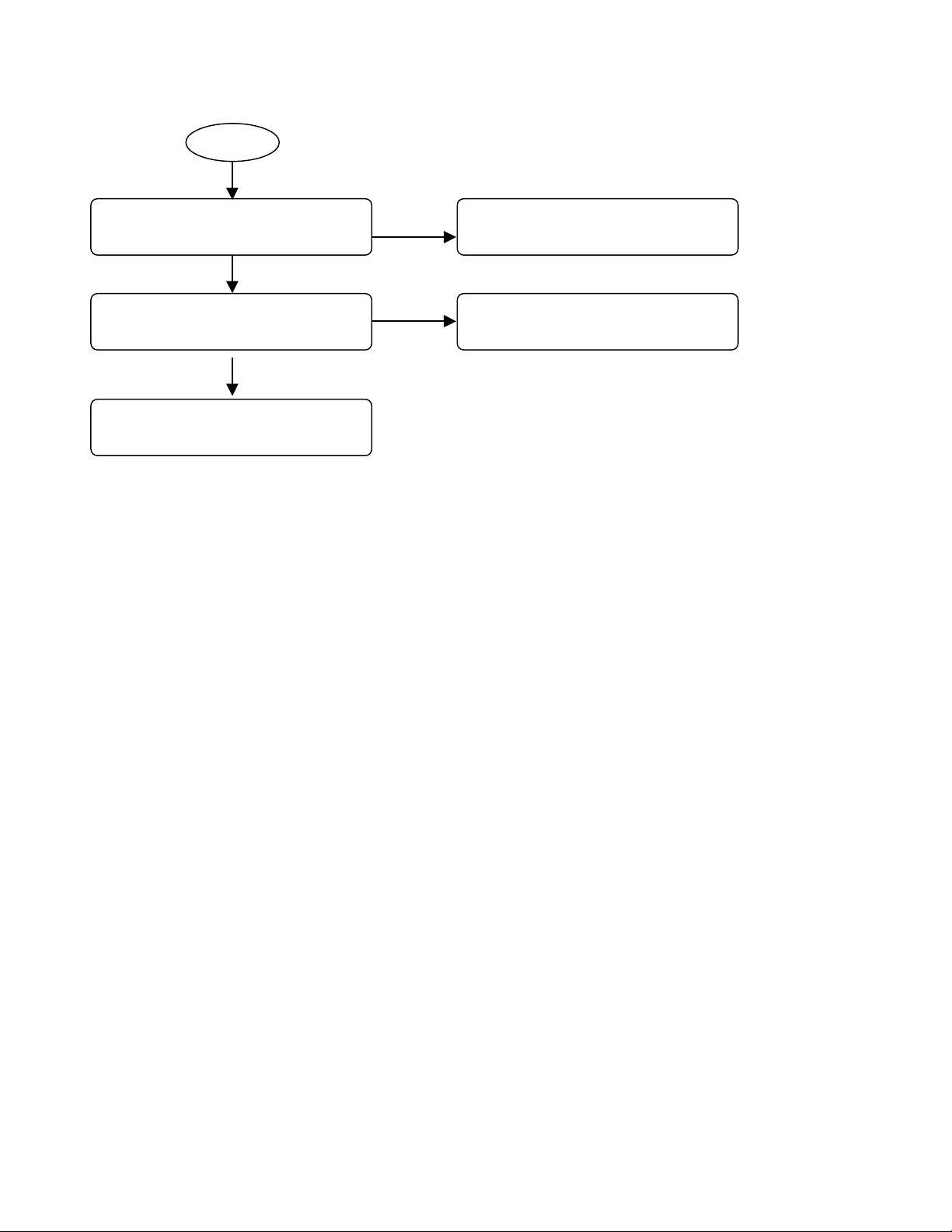

6. VIDEO Troubleshooting Flow

End

No HV sync OUT?

Any problem in OSD ?

Any problem in main picture?

Start

NO

NO

NO

YES

YES

YES

YES

Is there any problem in AV out?

NO

(A)

(B)

(C1)(D)

What is the main picture source?

DTV or NTSC.

(C2)

DTV

NTSC

Page 29

3-29

(A)

Is power supplied to IC500?

Chage CSC switch to RGB mode

and check HV sync.

Is there any problem ?

Is VDP clock(IC602 pin28) supplied

to HD1? FIG.01

Check L500( 2.5V) L501(3.3V)

If HV sync exist in IC613 pin6,7

( FIG.03)(FIG.04)

then check IC613 pin1 is low.

If not, check IC201 pin45.

Check IC601 pin5 and IC612 pin4

in SD and HD respectively.

YES

YES

NO

NO

YES

Check IC601 pin1 and IC612 pin1

if there exist 27MHz clock. FIG.02

NG

Fig.01 Fig.02 Fig.03

Fig.04

Page 30

3-30

(B)

Check analog mute ON?

Check analog buffers.

IC610,IC609 for 480i,

IC607 for component YPbPr,

IC608 for RGB analog

NO

YES

NG

OK

No OSD is not a problem.

Check DVI output.

Check A9V is supplied.

Jump to (A) flow

Page 31

3-31

NO

NO

YES

YES

YES

When DTV is main

OK

(C1)

Check input stream existence.

Any problem?

Is there any decoding problem?

Is there any problem in selecting

ATSC and DSS?

Check signal strength.

If OK, check system clock 27MHz.

(X600 pin 3,IC602 pin 31)

Stream Input Check (IC501,502,503)

Terr. : check VSB(IC303 ) block. FIG.05

DSS: check TPN ( IC1950 ) block.

Check voltage of IC501,502,503 pin1.

ATSC: 3.3V, DSS: 0V

Check HD 1 chip Interrupt

(R503) FIG.06

Fig.05 Fig.06

Page 32

3-32

YES

(C2)

Is there any quantize noise?

Check NTSC decoder.

Check tuner block(TU300)

power check; L606 5V

Analog input: IC611 pin 44

Reference clock oscillation:X600 FIG.08

Hsync out: 15.7KHz negative

pulse in IC611 pin 36. FIG.09

Vsync out: 59.94Hz negative

pulse in IC611 pin 35. FIG.10 top

Field ID : 29.97Hz pulse in

IC611 pin 34. FIG.10 bottom

Pixel clock: 13.5MHz continuous

Clock in IC611 pin 28. FIG.11

IIC: IC611 pin10(SCL) pin 11(SDA)

NG

NG

OK

YES

When NTSC is main

Check digital output pin short

in IC611 pin 12~19, 23~26, 30~33.

Check tuner output composite signal

(C649) FIG.07

Fig.07

Fig.08 Fig.09

Fig.11

Fig.10

Page 33

3-33

(D)

Check NTSC encoder(IC403)

Check current display mode is 480i

Using VFD message.

Change display format to 480i

by pressing front format button.

OK

NO

NG

Check NTSC mute signal is low.

Check Q403,404,405 base voltage.

Must be low.

If not, check IC201 pin 44

OK

NG

power check; L401 3.3V

Analog output:

IC403 pin 30(composite) FIG.12,

pin 27(Y), pin 24 (C). FIG.13

Pixel clock: 27MHz continuous

Clock in IC403 pin 4. FIG.14

IIC: IC403 pin41(SCL) pin 42(SDA)

FIG.15

Is there any quantize noise

or unstable sync timing?

OK

Check digita input data short

IC403 pin9~16.

YES

Fig.12 Fig.13 Fig.14

Fig.15

Page 34

3-34

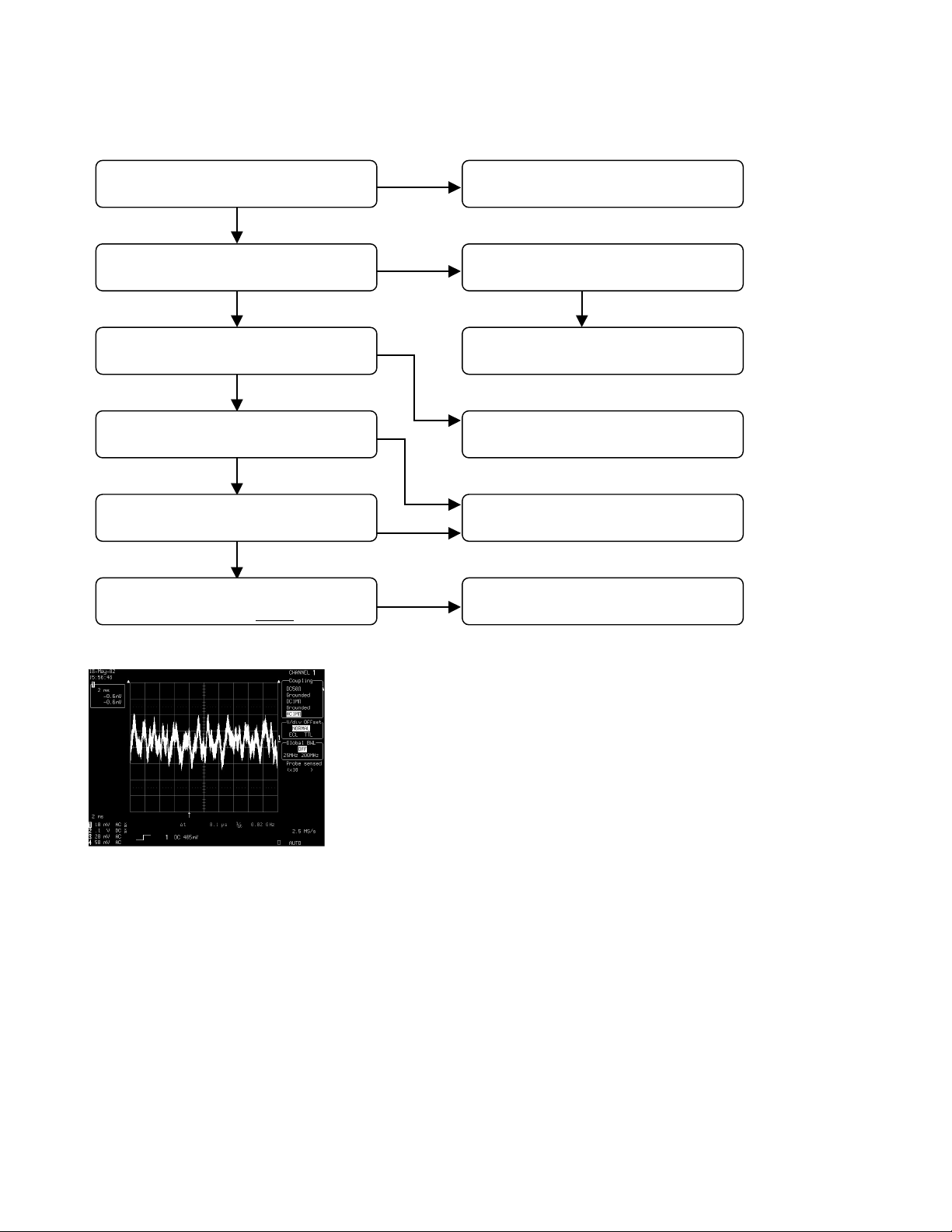

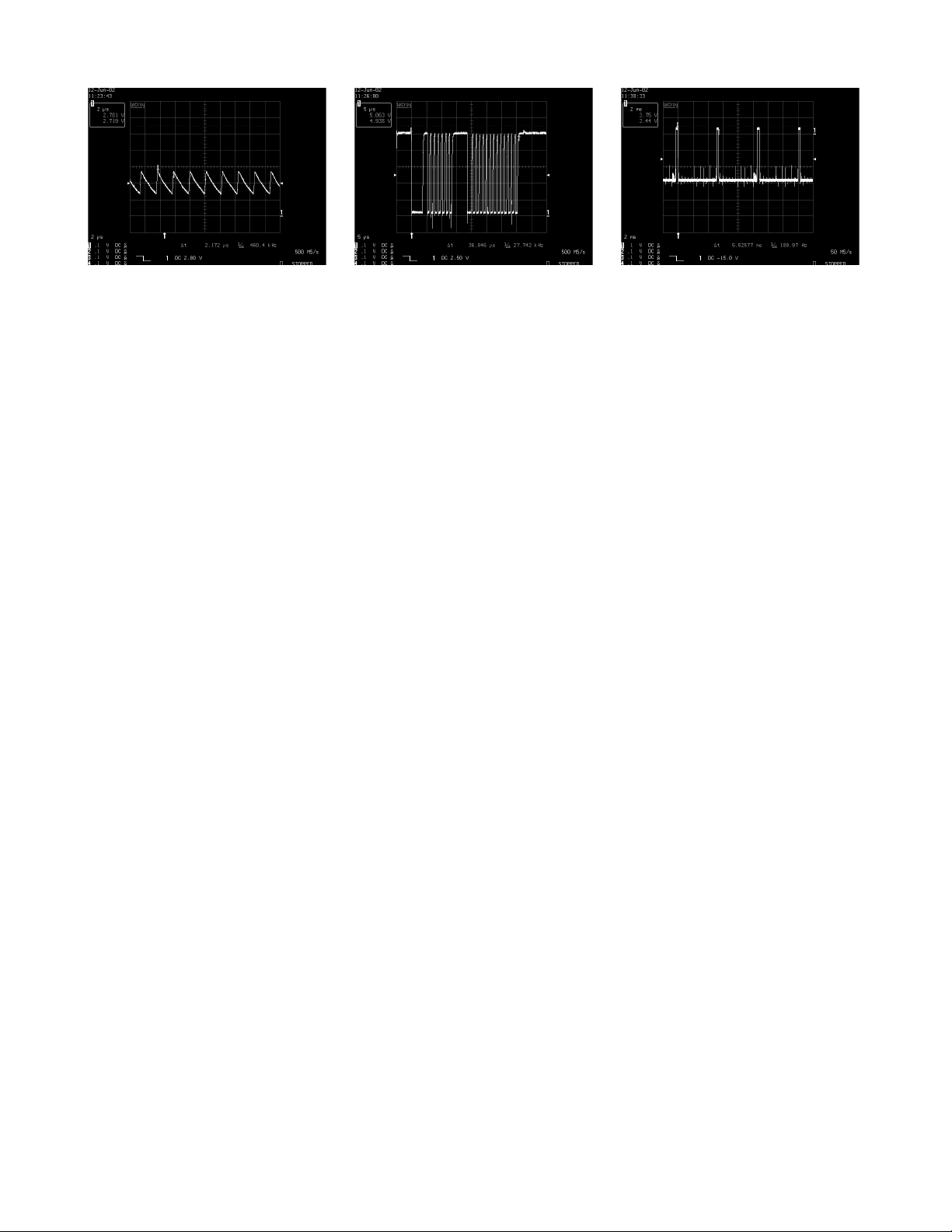

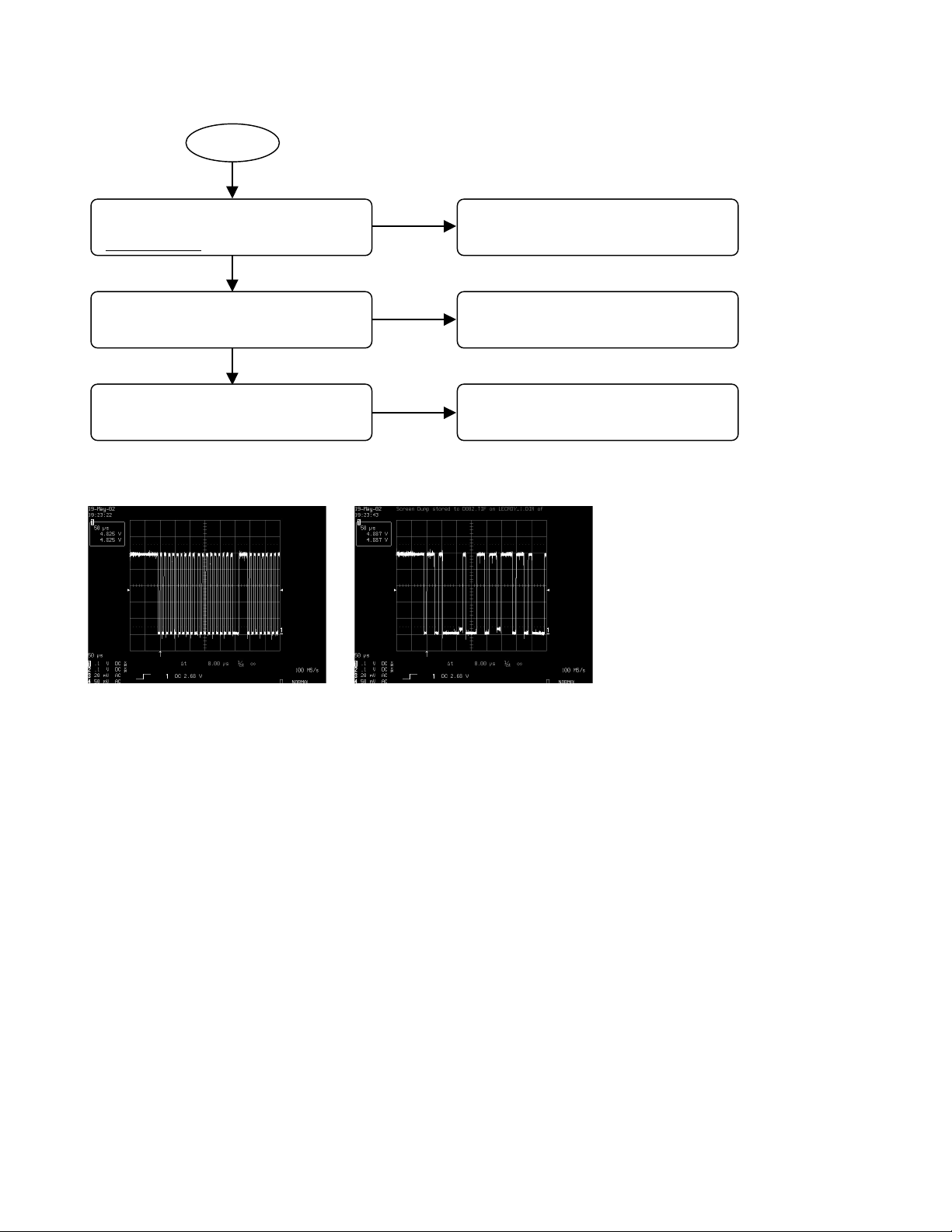

7.DIRECTV TP-Demux/Smart-Card/Modem Troubleshooting Flow

NO

NO

NO

NO

NO

NO

NO

(1) If satellite channel setup is fails and display “No Signal”

(First check QPSK part)

Is the IC 1.8V power

supplied normally?

Does the clock #1 operate normally?

Does the clock #2 operate normally?

Check IC1950(13) clock waveform

: See FIG.01

Check IC1951(35) clock waveform

: See FIG.02

YES

YES

YES

Check IC1950(1)

voltage : 1.8V

Does the reset signal

operate normally?

Check IC1950(68) voltage : 3.3V

YES

Does the clock #3 operate normally?

Check IC1950(31) clock waveform

: See FIG.03

YES

Does the smart card part

operate normally?

Refer the smart card

troubleshooting guide.(page 2)

YES

END

START

Is the IC 3.3V power

supplied normally?

YES

Check IC1950(19), IC1951(1)

voltage : 3.3V

Legend : IC1950(19)

IC number

IC pin number

Page 35

3-35

(2) If smart card does not operate normally

NO

NO

NO

NO

NO

NO

NO

Does the satellite channel setup

succeed?

Did you insert the smart card?

Does the clock #5 operate normally?

Check IC980(9) voltage : 0V

Check P980(9) voltage : 2.8V

Check IC980(25) clock waveform

: See FIG.05

YES

YES

YES

Refer the smart card

troubleshooting guide.(page 1)

Does the clock #6 operate normally?

Check IC980(15) clock waveform

: See FIG.06

YES

Does the GPO control operate?

Check IC980(1) voltage : 0V

Check IC980(2) voltage : 3.3V

YES

END

START

Is the IC 5V, 3.3V power

supplied normally?

YES

Check IC980(6) voltage : 5V

Check IC980(21) voltage : 3.3V

Does the clock #4 operate normally?

Check IC1950(41) clock waveform

: See FIG.04

YES

Page 36

3-36

(3) If modem IC does not operate normally

Is the IC 3.3V power

supplied normally?

Does the clock #7 operate normally?

Does the clock #8 operate normally?

Check IC1901(2) clock waveform

: See FIG.07

Check IC1901(3) clock waveform

: See FIG.08

YES

YES

YES

NO

NO

Check IC1901(4) voltage : 3.3V

NO

Does the UART pin control operate?

Check IC1901(5) voltage : 3.3V

Check IC1901(6) voltage : 3.3V

YES

NO

Is the IC1902 power supplied

normally with connecting phone line?

Check IC1902(9) relative IC1902(3)

voltage : about 3.6V range

YES

NO

Is the modem part component solder

properly with connecting phone line?

Check IC1901(13) voltage

: about 4.6V range

YES

NO

END

START

Is the modem part component solder

properly with connecting phone line?

Check JA1901(3) relative

JA1901(4) voltage : about +/- 48V

YES

NO

Page 37

3-37

FIG.01

IC1950 Main System Clock

(27MHz)

FIG.02

IC1950 SDRAM Clock(108MHz)

FIG.03

IC1950 Video Data Clock

(13.5MHz)

FIG.04

IC1950 Smart Card Clock

(36.864MHz)

FIG.05

IC980 Chip Clock(18.432MHz)

FIG.06

IC980 Smart Card Clock

(4.608MHz)

FIG.07

IC1901 Modem Chip Clock

(4.9152MHz)

FIG.08

IC1901 Modem PLL Out Clock

(9.8MHz)

Page 38

3-38

8. ATSC/NTSC Front-End Troubleshooting Flow

NO

NO

NO

NO

NO

NO

NO

Is power supplied normally?

Is RF signal?

(using Spectrum Analyzer)

Is tuner’s output signal?

(using Spectrum Analyzer)

Is SAW filter’s output signal?

(using Spectrum Analyzer)

Check Down-Converter(IC302)’s

output signals.

(using Spectrum Analyzer)

START

Check the power line

referring the circuit diagram

Change channel with DTV signal

Check SAW Filter and peripheral parts

Check 38MHz Crystal’s output

(Fig.01)

Check the status of connection

on PCB. And check 25MHz

OSC’s output (X101) (Fig.05)

Check the AVSB and peripheral parts

Check the connection between tuner

and IIC line/power/peripheral parts

YES

YES

YES

YES

YES

Check AVSB(IC303)’s output signals

of DATA(Fig.02)

(pin 47,49,50,51,52,54,56,57),

packet clock(Fig.03)(pin 61) and

Byte clock(pin 64)(Fig.04)

Check Error flag.

(using Oscilloscope)

High:normal, Low:Error

YES

END

Page 39

3-39

FIG.01 FIG.02 FIG.03

FIG.04 FIG.05

Page 40

Sales Model Loc No. P/Part No C/Part No Price(USD) Description

LSS-2200Z 250 LSS-2200Z.AA 3110R-P014D 2.15 CASE

LSS-2200Z 260 LSS-2200Z.AA 3141R-0062Q 3.89 CHASSIS ASSEMBLY

LSS-2200Z 280 3501R-4030D 3721R-F276D 6.56 PANEL ASSEMBLY,FRONT

LSS-2200Z 300 LSS-2200Z.AA 6410RAHC02Z 0.77 POWER CORD

LSS-2200Z 320 3141R-0062Q 3720R-D059C 0.87 PANEL,VIDEO

LSS-2200Z 452 3501R-4030D 353-051A 0.1 SCREW,DRAWING

LSS-2200Z 452 3501R-4030D 353-051A 0.1 SCREW,DRAWING

LSS-2200Z 452 3501R-4030D 353-051A 0.1 SCREW,DRAWING

LSS-2200Z 457 3141R-0062Q 353-046N 0.1 SCREW,DRAWING

LSS-2200Z 457 3141R-0062Q 353-046N 0.1 SCREW,DRAWING

LSS-2200Z 457 3141R-0062Q 353-046N 0.1 SCREW,DRAWING

LSS-2200Z 463 LSS-2200Z.AA 353-051G 0.1 SCREW,DRAWING

LSS-2200Z 463 LSS-2200Z.AA 353-051G 0.1 SCREW,DRAWING

LSS-2200Z 463 LSS-2200Z.AA 353-051G 0.1 SCREW,DRAWING

LSS-2200Z 465 LSS-2200Z.AA 353-046K 0.1 SCREW,DRAWING

LSS-2200Z 465 LSS-2200Z.AA 353-046K 0.1 SCREW,DRAWING

LSS-2200Z 465 LSS-2200Z.AA 353-046K 0.1 SCREW,DRAWING

LSS-2200Z 466 LSS-2200Z.AA 1BK-0512391 0.1 BOLT,HEXAGON SOCKET

LSS-2200Z 801 LSS-2200Z.AA 3835RS0035H 1.7 INSTRUCTION ASSEMBLY

LSS-2200Z 802 3921R-0124N 3890R-C049J 1.59 BOX,MASTER

LSS-2200Z 803 3921R-0124N 3920R-E059A 0.46 PACKING,CASING

LSS-2200Z 806 LSS-2200Z.AA 6850R-CAA22 0.45 CABLE,COAXIAL

LSS-2200Z 806 LSS-2200Z.AA 6850R-CAA22 0.45 CABLE,COAXIAL

LSS-2200Z 806 LSS-2200Z.AA 6850R-CAA22 0.45 CABLE,COAXIAL

LSS-2200Z 808 LSS-2200Z.AA 6910R-AB02A 0.29 BATTERY,ALKALINE

LSS-2200Z 811 LSS-2200Z.AA 6850R-DDA81 0.8 CABLE,DIN

LSS-2200Z 813 LSS-2200Z.AA 6850R-ZAE03 1.24 CABLE,COAXIAL

LSS-2200Z 820 LSS-2200Z.AA 6611R3G001A 1.32 PLUG ASSEMBLY

LSS-2200Z 821 LSS-2200Z.AA 6611R3G002A 1.43 PLUG ASSEMBLY

LSS-2200Z 900 LSS-2200Z.AA 6711R1N094A 5.8 REMOTE CONTROLLER AS

LSS-2200Z A42 3501R-4030D 6871R-9223A 0.1 PWB(PCB) ASSEMBLY,TO

LSS-2200Z A43 LSS-2200Z.AA 3501R-4030D 14.8 BOARD ASSEMBLY

LSS-2200Z A44 LSS-2200Z.AA 3501R-2249E 15.72 BOARD ASSEMBLY

LSS-2200Z A46 LSS-2200Z.AA 6871R-4520B 408.66 PWB(PCB) ASSEMBLY,TO

LSS-2200Z A49 3501R-4030D 6871R-9222A 7.63 PWB(PCB) ASSEMBLY,TO

LSS-2200Z AR111 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR111 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR112 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR112 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR113 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR113 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR114 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR114 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR117 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR117 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR118 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR118 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR135 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR135 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR136 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR136 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR201 6882RN4520A 0RRZVTA001J 0.1 RESISTOR,DRAWING

LSS-2200Z AR201 6882RN4520A 0RRZVTA001M 0.1 RESISTOR,DRAWING

LSS-2200Z AR300 6882RT4520A 0RRZVTA001G 0.1 RESISTOR,DRAWING

LSS-2200Z AR300 6882RT4520A 0RRZVTA001K 0.1 RESISTOR,DRAWING

LSS-2200Z AR301 6882RT4520A 0RRZVTA001G 0.1 RESISTOR,DRAWING

LSS-2200Z AR301 6882RT4520A 0RRZVTA001K 0.1 RESISTOR,DRAWING

LSS-2200Z AR501 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

Page 41

LSS-2200Z AR501 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z AR502 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

LSS-2200Z AR502 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z AR503 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

LSS-2200Z AR503 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z AR504 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

LSS-2200Z AR504 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z AR505 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

LSS-2200Z AR505 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z AR506 6882RY4520A 0RR1002Q62C 0.1 RESISTOR,DRAWING

LSS-2200Z AR506 6882RY4520A 0RRZVTA001R 0.1 RESISTOR,DRAWING

LSS-2200Z BD01 6875R-2249E 636-004C 0.1 CORE (CIRC),BEAD

LSS-2200Z BD01 6875R-2249E 636-004C 0.1 CORE (CIRC),BEAD

LSS-2200Z BD01 6875R-2249E 636-004C 0.1 CORE (CIRC),BEAD

LSS-2200Z BD101 6874R-2249E 0DRGF00011A 0.78 DIODE,RECTIFIERS

LSS-2200Z BD101 6874R-2249E 0DRGF00011A 0.78 DIODE,RECTIFIERS

LSS-2200Z BD101 6874R-2249E 0DRGF00011A 0.78 DIODE,RECTIFIERS

LSS-2200Z BD1901 6882RM4520A 0DR160009AC 0.15 DIODE,RECTIFIERS

LSS-2200Z C100 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C100 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C100 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C101 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C101 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C101 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C101 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C101 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C101 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C101 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C101 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C102 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C102 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C102 6874R-2249E 624-088F 0.1 CAPACITOR,DRAWING

LSS-2200Z C102 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C102 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C102 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C102 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C102 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C103 6874R-2249E 0CE227RR6A0 1.14 CAPACITOR,FIXED ELEC

LSS-2200Z C103 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C103 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C103 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C103 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C104 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C104 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C104 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C104 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C105 6875R-2249E 0CQ1031Y519 0.1 CAPACITOR,FIXED FILM

LSS-2200Z C105 6875R-2249E 0CQ1031Y519 0.1 CAPACITOR,FIXED FILM

LSS-2200Z C105 6875R-2249E 0CQ1031Y519 0.1 CAPACITOR,FIXED FILM

LSS-2200Z C105 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C105 6875R-9222A 0CE2264K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C105 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C105 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C106 6875R-2249E 624-087B 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C106 6875R-2249E 624-087B 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C106 6875R-2249E 624-087B 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C106 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C106 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C106 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C106 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

Page 42

LSS-2200Z C106 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C107 6875R-2249E 0CE3354K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6875R-2249E 0CE3354K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6875R-2249E 0CE3354K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C107 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C107 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C108 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C108 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C108 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C108 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C108 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C108 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C108 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C108 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C109 6875R-2249E 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C109 6875R-2249E 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C109 6875R-2249E 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C109 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C109 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C109 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C109 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C109 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C110 6874R-2249E 0CG1020U630 0.1 CAPACITOR,SEMI CERAM

LSS-2200Z C110 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C110 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C110 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C110 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C110 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C111 6874R-2249E 0CG2220U630 0.1 CAPACITOR,SEMI CERAMIC

LSS-2200Z C111 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C111 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C111 6875R-9222A 0CX2200K408 0.1 CAPACITOR,FIXED TUBULAR(Temp.compensate)

LSS-2200Z C111 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C111 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C112 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C112 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C112 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C112 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C112 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C113 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C113 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C113 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C113 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C113 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C114 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C114 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C114 6875R-9222A 0CN1040K948 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C114 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C114 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C115 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C115 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C115 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C115 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C115 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C116 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C116 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

LSS-2200Z C116 6875R-9222A 0CN2210K518 0.1 CAPACITOR,FIXED TUBULAR(High dielectric)

Page 43

LSS-2200Z C116 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C116 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C117 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C117 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C117 6875R-9222A 0CE4764F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C117 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C117 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C118 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C118 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C119 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C119 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C120 6875R-2249E 0CE1054K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C120 6875R-2249E 0CE1054K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C120 6875R-2249E 0CE1054K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C120 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C120 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C121 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C121 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C121 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C121 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C122 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C122 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C122 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C122 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C123 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C123 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C123 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C123 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C123 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C124 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C124 6874R-2249E 0CE2282F611 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C124 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C124 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C125 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C125 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C126 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C126 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C126 6875R-2249E 624-082H 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C126 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C126 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C127 6874R-2249E 0CE108EH610 0.13 CAPACITOR,FIXED ELEC

LSS-2200Z C127 6874R-2249E 0CE108EH610 0.13 CAPACITOR,FIXED ELEC

LSS-2200Z C127 6874R-2249E 0CE108EH610 0.13 CAPACITOR,FIXED ELEC

LSS-2200Z C127 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C127 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C128 6875R-2249E 624-082G 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C128 6875R-2249E 624-082G 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C128 6875R-2249E 624-082G 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C128 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C128 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C129 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C129 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C129 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C129 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C129 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C130 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C130 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C131 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C131 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C131 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

Page 44

LSS-2200Z C131 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C131 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C132 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C132 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C132 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C132 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C132 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C133 6875R-2249E 0CE2276F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C133 6875R-2249E 0CE2276F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C133 6875R-2249E 0CE2276F638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C133 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C133 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C134 6874R-2249E 0CE337EK630 0.1 CAPACITOR,AL.ELECTRO

LSS-2200Z C134 6874R-2249E 0CE337EK630 0.1 CAPACITOR,AL.ELECTRO

LSS-2200Z C134 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C134 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C135 6882RN4520A 0CH8106F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C135 6882RN4520A 0CH8106F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C136 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C136 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C137 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C137 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C138 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C138 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C139 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C139 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C140 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C140 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C141 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C141 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C142 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C142 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C143 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C143 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C144 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C144 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C145 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C145 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C146 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C146 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C147 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C147 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C148 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C148 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C149 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C149 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C150 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C150 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1500 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1500 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1501 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1501 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1502 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1502 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1503 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1503 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1504 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1504 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1505 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1505 6883RY4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

Page 45

LSS-2200Z C151 6875R-2249E 0CE1064K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C151 6875R-2249E 0CE1064K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C151 6875R-2249E 0CE1064K638 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C151 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C151 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C152 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C152 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C152 6875R-2249E 624-085D 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C152 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C152 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C153 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C153 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C154 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C154 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C155 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C155 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C156 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C156 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C157 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C157 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C160 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C160 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C161 6882RN4520A 0CH8476F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C162 6882RN4520A 0CH8106F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C162 6882RN4520A 0CH8106F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C163 6883RN4520A 0CH4101K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C163 6883RN4520A 0CH4101K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C163 6883RN4520A 0CH4101K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C163 6883RN4520A 0CH4101K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1901 6882RM4520A 0CK151J366A 0.19 CAPACITOR,FIXED CERA

LSS-2200Z C1903 6882RM4520A 0CK224CF56A 0.1 CAPACITOR,FIXED CERA

LSS-2200Z C1904 6882RM4520A 0CK151J366A 0.19 CAPACITOR,FIXED CERA

LSS-2200Z C1905 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1905 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1906 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1906 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1907 6882RM4520A 0CK561DR66A 0.1 CAPACITOR,FIXED CERA

LSS-2200Z C1908 6882RM4520A 0CK561DR66A 0.1 CAPACITOR,FIXED CERA

LSS-2200Z C1909 6882RM4520A 0CK223DR66A 0.1 CAPACITOR,FIXED CERA

LSS-2200Z C1910 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1910 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1912 6882RM4520A 0CE105VK6DC 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C1913 6882RM4520A 0CK224CF56A 0.1 CAPACITOR,FIXED CERA

LSS-2200Z C1916 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1916 6882RM4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1918 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1918 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1918 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1918 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1919 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1919 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1919 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1919 6882RM4520A 0CH1392K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1920 6882RM4520A 0CH1103K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1920 6882RM4520A 0CH1103K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1920 6882RM4520A 0CH1103K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1920 6882RM4520A 0CH1103K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1922 6882RM4520A 0CH1182K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1922 6882RM4520A 0CH1182K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1922 6882RM4520A 0CH1182K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

Page 46

LSS-2200Z C1924 6882RM4520A 0CK102J356A 0.4 CAPACITOR,FIXED CERA

LSS-2200Z C1925 6882RM4520A 0CK102J356A 0.4 CAPACITOR,FIXED CERA

LSS-2200Z C1926 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1926 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1926 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1927 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1927 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1927 6882RM4520A 0CH4270K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1930 6882RM4520A 0CH4100K112 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1930 6882RM4520A 0CH4100K112 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1930 6882RM4520A 0CH4100K112 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1930 6882RM4520A 0CH4100K112 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1931 6882RM4520A 0CK102J356A 0.4 CAPACITOR,FIXED CERA

LSS-2200Z C1932 6882RM4520A 0CK102J356A 0.4 CAPACITOR,FIXED CERA

LSS-2200Z C1950 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1950 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1951 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1951 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1952 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1952 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1953 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1953 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1954 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1954 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1955 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1955 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1956 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1956 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1957 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1957 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1958 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1958 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1959 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1959 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1960 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1960 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1961 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1961 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1962 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1962 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1963 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1963 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1964 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1964 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1965 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1965 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1966 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1966 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1967 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1967 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1968 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1968 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1969 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1969 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1970 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1970 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1971 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1971 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1972 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1972 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

Page 47

LSS-2200Z C1973 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1973 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1974 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1974 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1975 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1975 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1976 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1976 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1977 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1977 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1978 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1978 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1979 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1979 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1980 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1980 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1981 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1981 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1982 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1982 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1983 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1983 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1984 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1984 6883RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1985 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1985 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1986 6882RD4520A 0CH8476F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C1987 6882RD4520A 0CH8476F611 0.1 CAPACITOR,FIXED ELECTROLYTIC

LSS-2200Z C1988 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1988 6882RD4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C1989 6883RD4520A 0CH4470K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1989 6883RD4520A 0CH4470K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C1989 6883RD4520A 0CH4470K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C201 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C201 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C202 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C202 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C203 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C203 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C204 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C204 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C205 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C205 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C206 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C206 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C207 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C207 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C208 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C208 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C209 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C209 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C210 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C210 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C211 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C211 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C212 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C212 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C213 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C213 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C214 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

Page 48

LSS-2200Z C214 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C215 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C215 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C216 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C216 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C217 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C217 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C218 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C218 6883RN4520A 0CH4331K412 0.1 CAPACITOR,FIXED CERAMIC(High dielectric)

LSS-2200Z C219 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C219 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C219 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C219 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C220 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C220 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C220 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C220 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C221 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C221 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C221 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C221 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C222 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C222 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C222 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C222 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C224 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C224 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C225 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C225 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C226 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C226 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C226 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C226 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C227 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C227 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C227 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C227 6883RN4520A 0CH1102K562 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C228 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C228 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C229 6882RN4520A 0CH8226F611 0.1 CAPACITOR,CHIP[AL. ELECTROLYTIC]

LSS-2200Z C230 6882RN4520A 0CH8226F611 0.1 CAPACITOR,CHIP[AL. ELECTROLYTIC]

LSS-2200Z C231 6882RN4520A 0CH8107F611 0.1 CAPACITOR,CHIP[AL. ELECTROLYTIC]

LSS-2200Z C231 6882RN4520A 0CH8107F611 0.1 CAPACITOR,CHIP[AL. ELECTROLYTIC]

LSS-2200Z C231 6882RN4520A 0CH8107F611 0.1 CAPACITOR,CHIP[AL. ELECTROLYTIC]

LSS-2200Z C232 6882RN4520A 0CE105VK6DC 0.1 CAPACITOR,FIXED ELEC

LSS-2200Z C233 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C233 6882RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C234 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C234 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)

LSS-2200Z C235 6883RN4520A 0CH1104K512 0.1 CAPACITOR,FIXED CERAMIC(Temp.compensate)