Page 1

SERVICE MANUAL

Product Type: 5 DISC DVD HOME THEATER

Chassis: CMR-0538

Manual Series: DVT654

Manual Part #: 3829RGN005H

Model Line: C

Product Year: 2006

GENERAL

ELECTRICAL

EXPLODED VIEWS

SPEAKER PART

REPLACEMENT PARTS LIST

1

2

3

4

5

................................................

...........................................

.................................

......................................

..................

Published March 2006

by Technical Publications

Zenith Electronics Corporation

201 James Record Road

Huntsville, Alabama 35824-1513

Copyright © 2006 by Zenith Electronics Corporation

Printed in U.S.A

Model Series:

CONTENTS

DVT654

Page 2

- 1-1 -

[CONTENTS]

SECTION 1.GENERAL

• SERVICING PRECAUTIONS ................................................................................................ 1-2

• ESD PRECAUTIONS............................................................................................................. 1-4

• SPECIFICATIONS...................................................................................................................1-5

SECTION 2. ELECTRICAL

• AUDIO TROUBLESHOOTING GUIDE .................................................................................. 2-1

• DVD TROUBLESHOOTING GUIDE ...................................................................................... 2-5

• DVD DETAILS AND WAVEFORMS ON SYSTEM TESTAND DEBUGGING..................... 2-13

• WIRING DIAGRAM.............................................................................................................. 2-25

• BLOCK DIAGRAMS............................................................................................................. 2-26

• AUDIO PART SCHEMATIC DIAGRAMS ............................................................................. 2-31

• DVD PART SCHEMATIC DIAGRAMS................................................................................. 2-47

• PRINTED CIRCUIT DIAGRAMS ......................................................................................... 2-53

• CIRCUIT VOLTAGE CHART................................................................................................ 2-63

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION .............................................................................. 3-1

• DECK MECHANISM EXPLODED VIEW .............................................................................. 3-3

• PACKING ACCESSOR Y SECTION ...................................................................................... 3-5

SECTION 4. SPEAKER PART .................................................................................. 4-1

SECTION 5. REPLACEMENT PARTS LIST ............................................................. 5-1

Page 3

- 1-2 -

SECTION 1. GENERAL

SERVICING PRECAUTIONS

NOTES REGARDING HANDLING OF THE PICK-UP

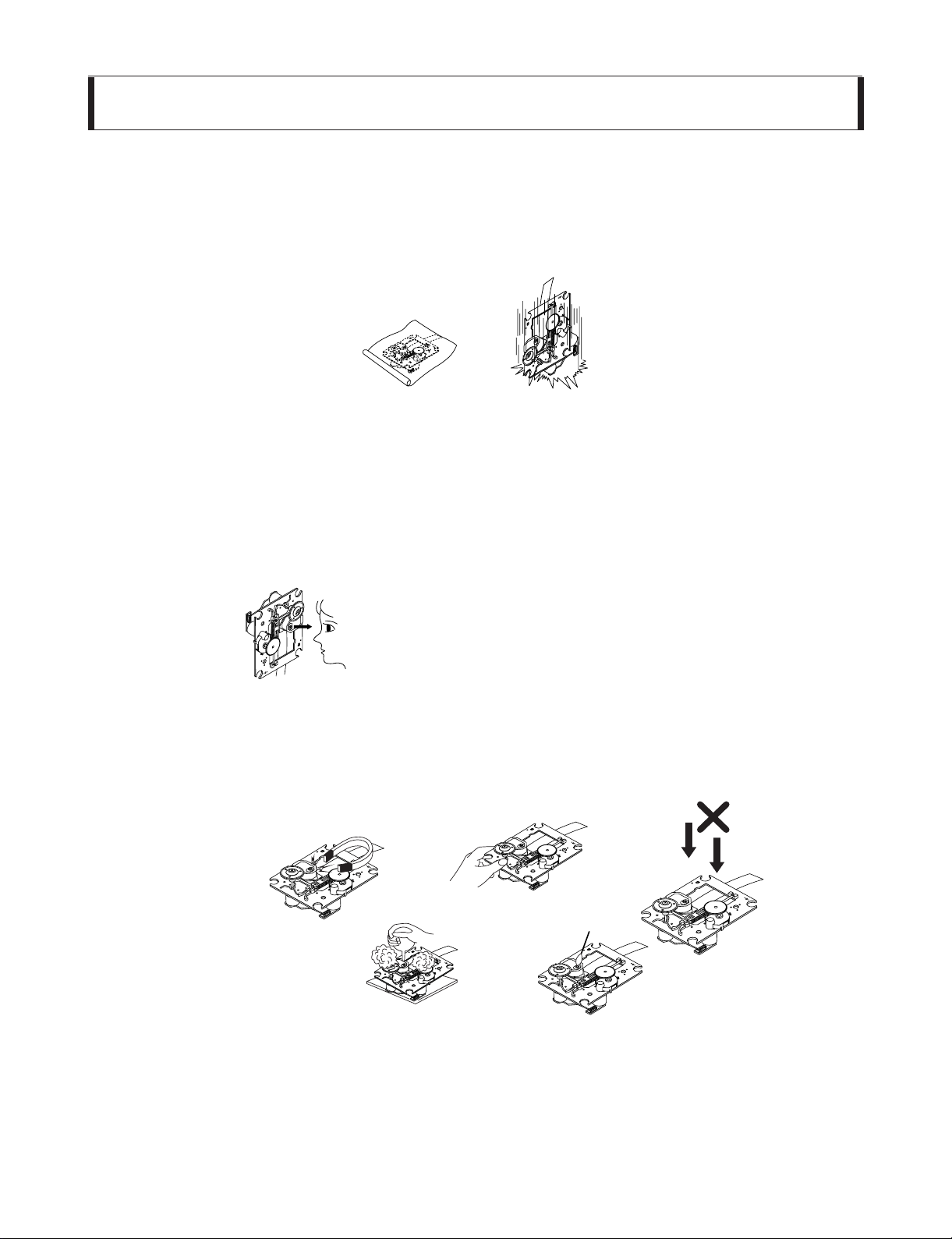

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Conductive Sheet

Cotton swab

Pressure

Pressure

Page 4

- 1-3 -

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong magnetism is present, or where there is excessive dust.

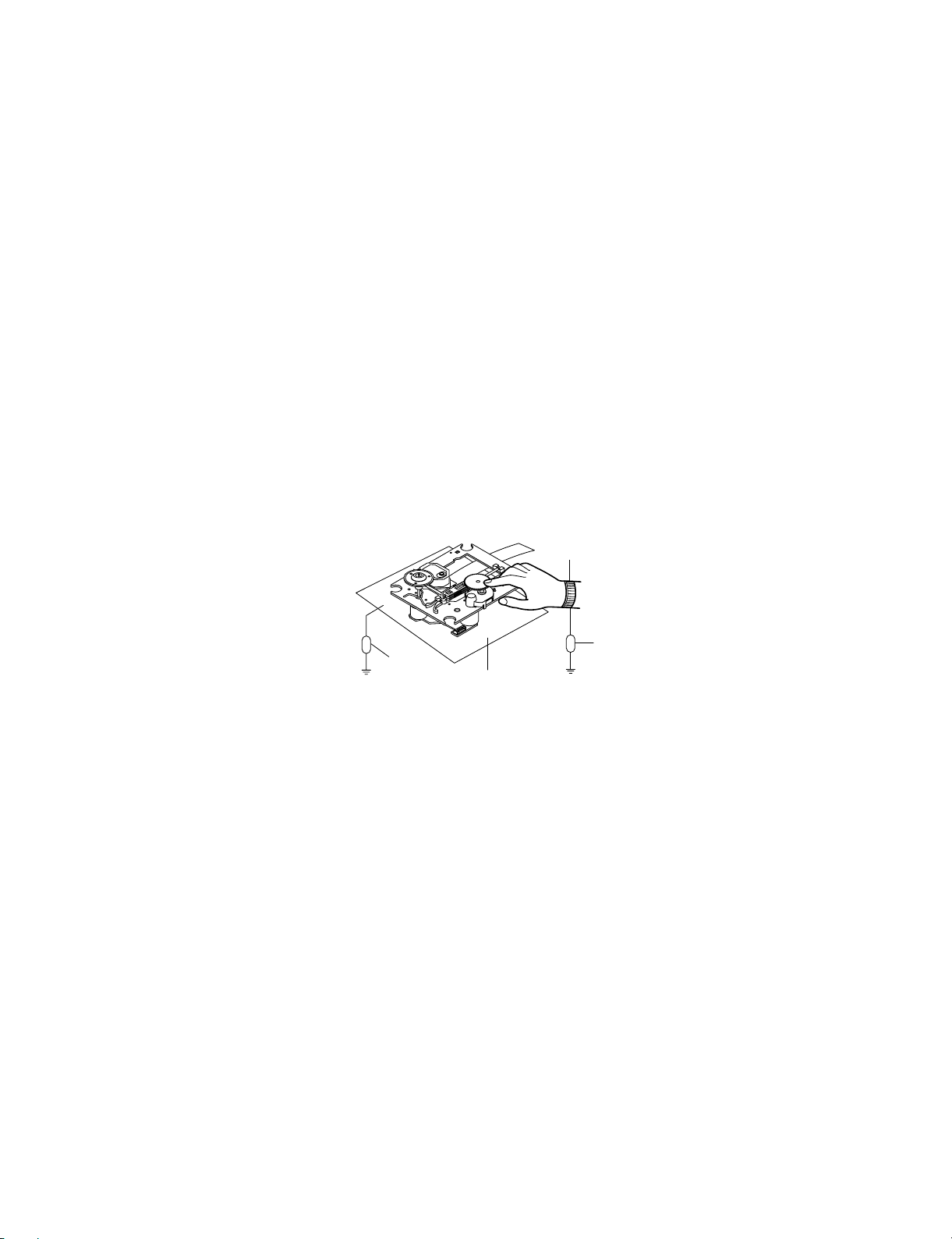

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1M Ω)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Resistor

(1 Mohm)

Conductive

Sheet

Resistor

(1 Mohm)

Armband

Page 5

- 1-4 -

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive sur-

face such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNELTO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE ARISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINTWITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANTSAFETY INFORMATION IN SERVICE

LITERATURE.

Page 6

- 1-5 -

SPECIFICATIONS

GENERAL

Power supply Refer to main label

Power consumption Refer to main label

Mass 5.5 kg

External dimensions (W x H x D) 435 x 54 x 350 mm

Operating conditions Temperature: 5°C to 35°C, Operation status: Horizontal

Operating humidity 5% to 85%

CD/DVD

Laser Semiconductor laser, wavelength 650 nm

Signal system NTSC 525/60

Frequency response (audio) 150 Hz to 18 kHz

Signal-to-noise ratio (audio) More than 75 dB (1 kHz, NOP -6 dB, 20 kHz LPF/A-Filter)

Dynamic range (audio) More than 70 dB

Harmonic distortion (audio) 0.5 % (1 kHz, at 1W position) (20 kHz LPF)

VIDEO

Video input 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 2

Video output 1.0 V (p-p), 75 Ω, negative sync., RCA jack x 1

S-video output (Y) 1.0 V (p-p), 75 Ω, negative sync., Mini DIN 4-pin x 1

(C) 0.3 V (p-p), 75 Ω

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, RCA jack x 1

(Pb)/(Pr) 0.7 V (p-p), 75 ohms, RCA jack x 2

TUNER

FM

Tuning Range 87.5 - 108.0 MHz or 65.0 - 74.0 MHz, 87.5 - 108.0 MHz

Intermediate Frequency 10.7 MHz

Signal-to Noise Ratio 60 dB (Mono)

Frequency Response 150 - 8,000 Hz

AM[MW]

Tuning Range 520 - 1,720 kHz

Intermediate Frequency 450 kHz

AMPLIFIER

Stereo mode 150W + 150W (6Ω at 1 kHz, THD 10 %)

Surround mode Front: 150W + 150W (THD 10 %)

Center*: 150W

Surround*: 150W + 150W (6Ω at 1 kHz, THD 10 %)

Subwoofer*: 250W (4Ω at 30 Hz, THD 10 %)

SPEAKERS

Front/Rear Speaker Center speaker Passive Subwoofer

(LHS-75SGS) (LHS-75SGC) (LHS-75SGW)

Type 2 Way 2 Speaker 2 Way 2 Speaker 1 Way 1 Speaker

Impedance 6 Ω 6 Ω 4 Ω

Frequency Response 145 - 20,000 Hz 120 - 20,000 Hz 50 - 1,500 Hz

Sound Pressure Level 85 dB/W (1m) 85 dB/W (1m) 83 dB/W (1m)

Rated Input Power 150 W 150 W 250 W

Max. Input Power 300 W 300 W 500 W

Net Dimensions (W x H x D) 104 x 235 x 120 mm 220 x 115 x 120 mm 195 x 398 x 419 mm

Net Weight 1.0kg 1.0kg 6.6kg

(* Depending on the sound mode

settings and the source, there may

be no sound output.)

Page 7

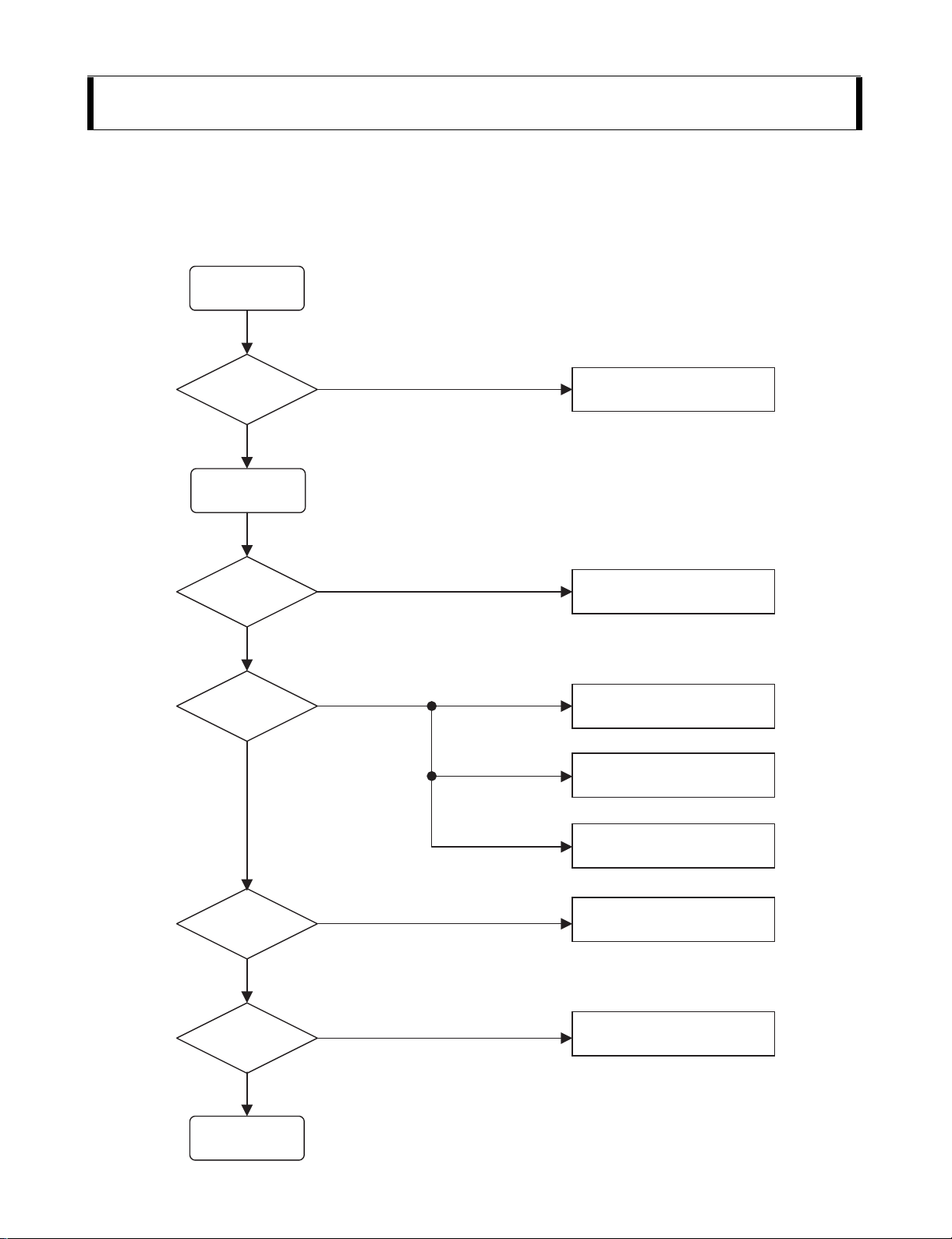

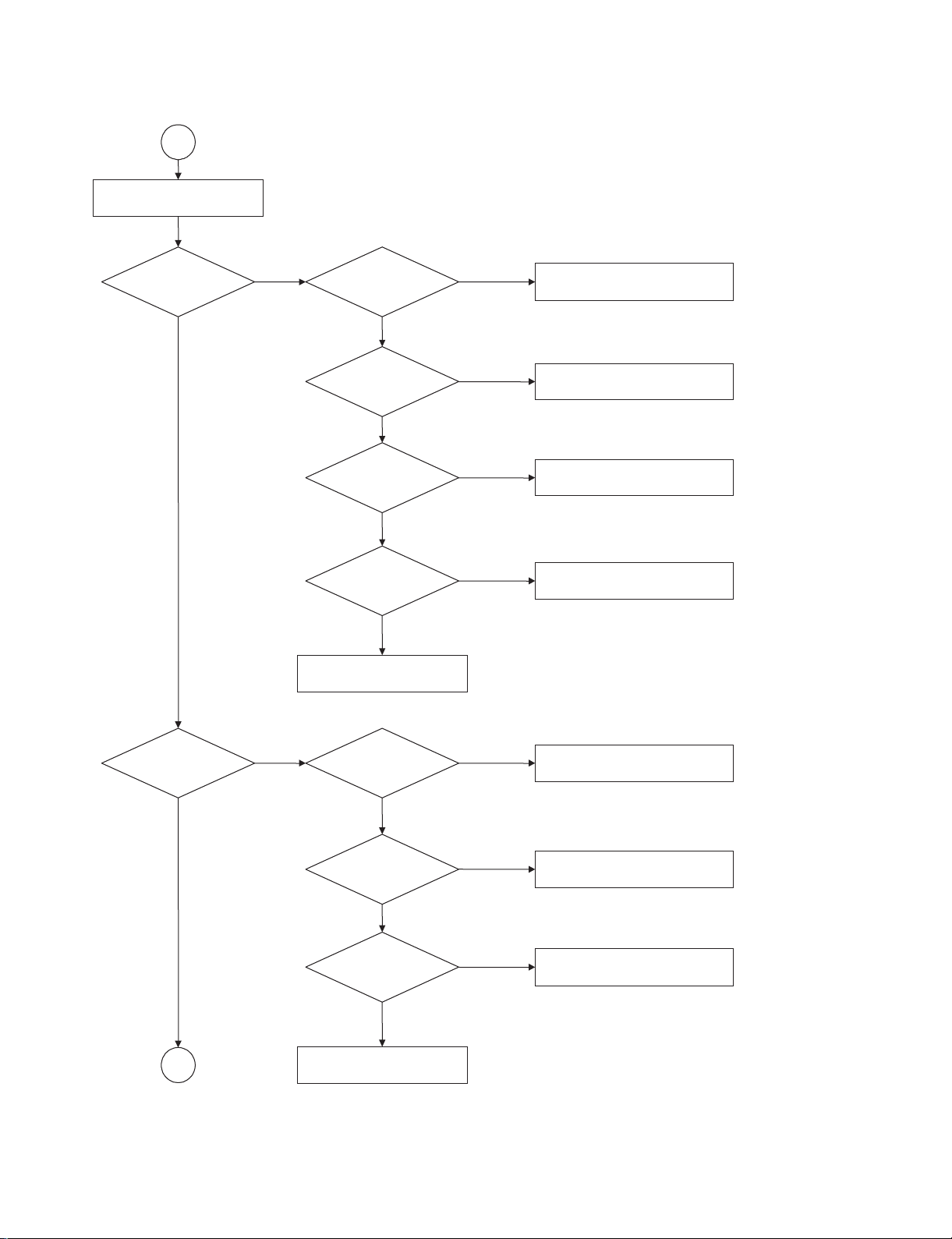

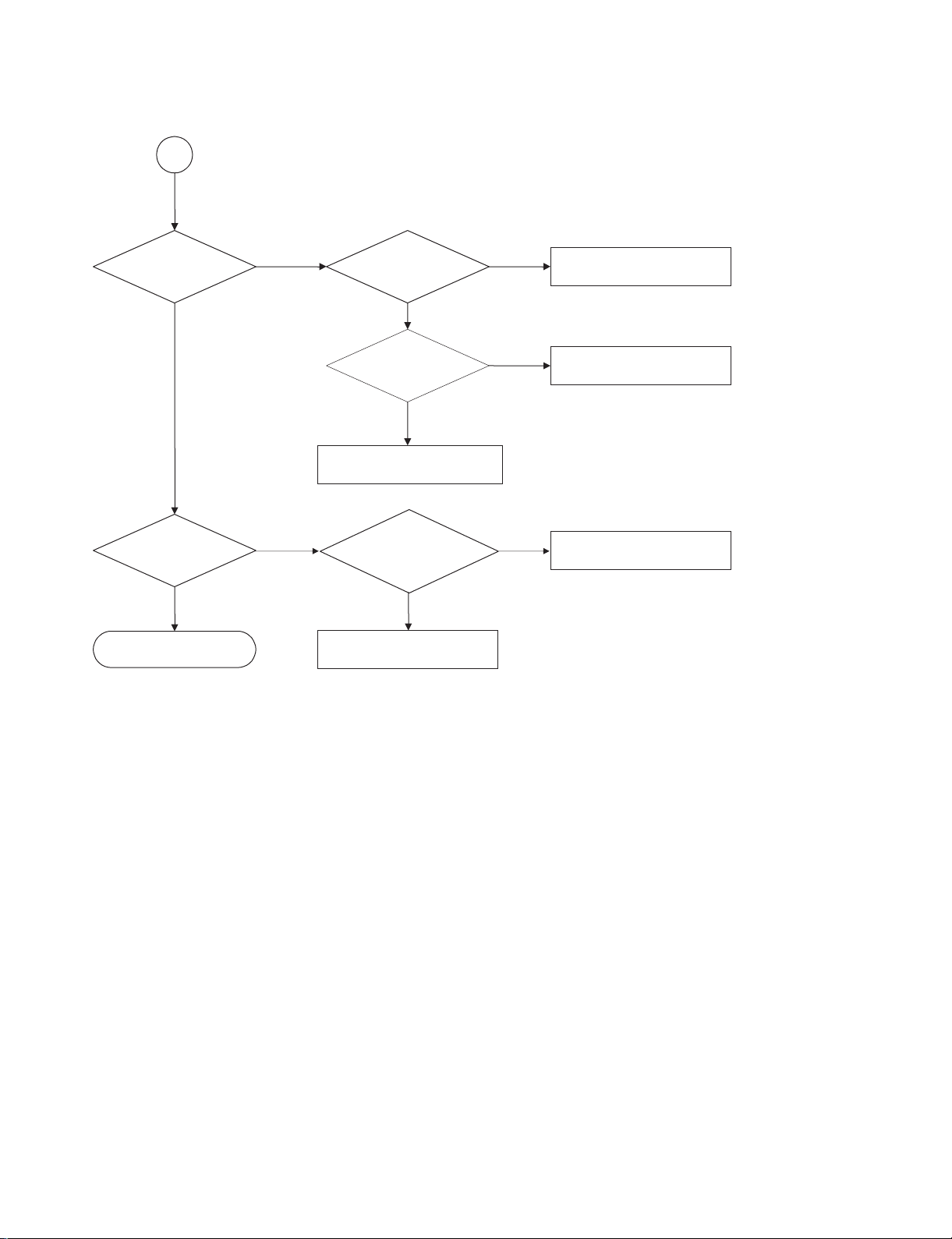

SECTION 2. ELECTRICAL

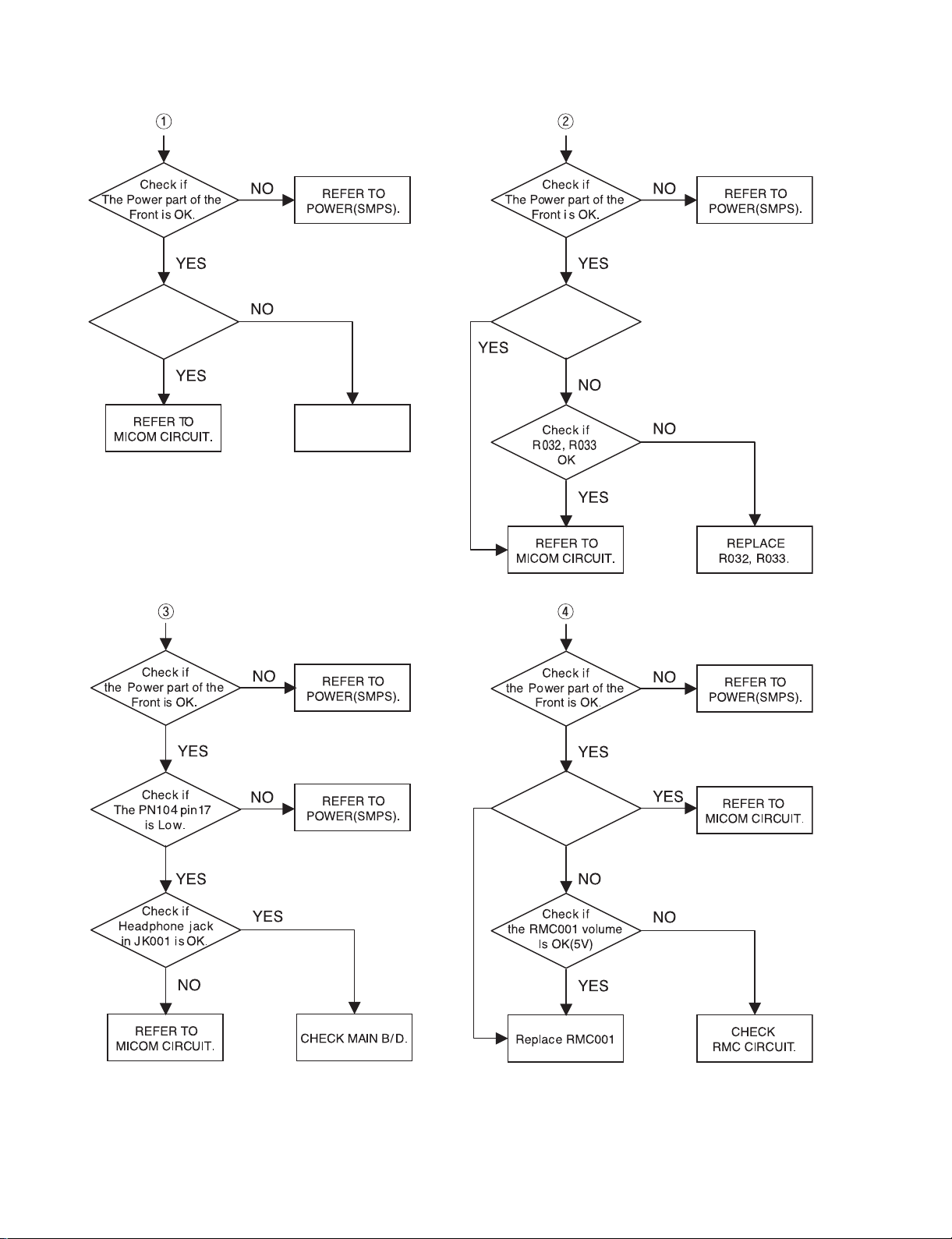

AUDIO TROUBLESHOOTING GUIDE

1. POWER CHECK FLOW

INSERT

WER CORD.

PO

RED LED

ON?

TURN PO

WER ON?

IS PO

DOES INITIAL

WORK?

READ

YES

WER ON.

YES

YES

NO

NO

NO

CHECK POWER PLUG

AND POWER SUPPLY CIRCUIT

CHECK POWER SUPPLY CIRCUIT.

CHECK LASER CIRCUIT

CHECK FOCUS CIRCUIT

.

.

.

PLAY?

DOES IT

YES

DOES IT OUTPUT

AUDIO?

YES

OK

NO

NO

- 2-1 -

CHECK DISC.

CHECK TRACKING SERV

CHECK AUDIO CIRCUIT.

O CIRCUIT.

Page 8

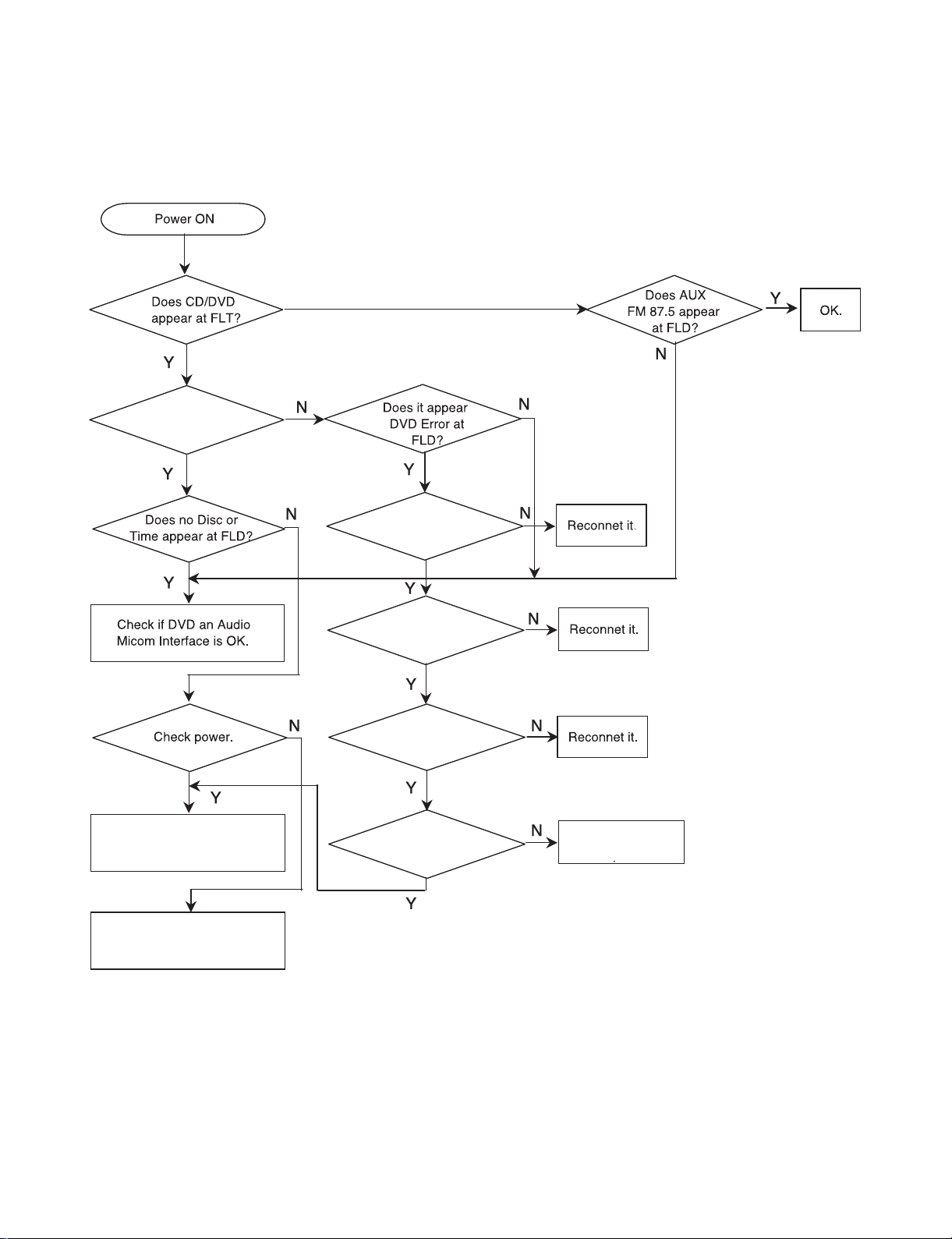

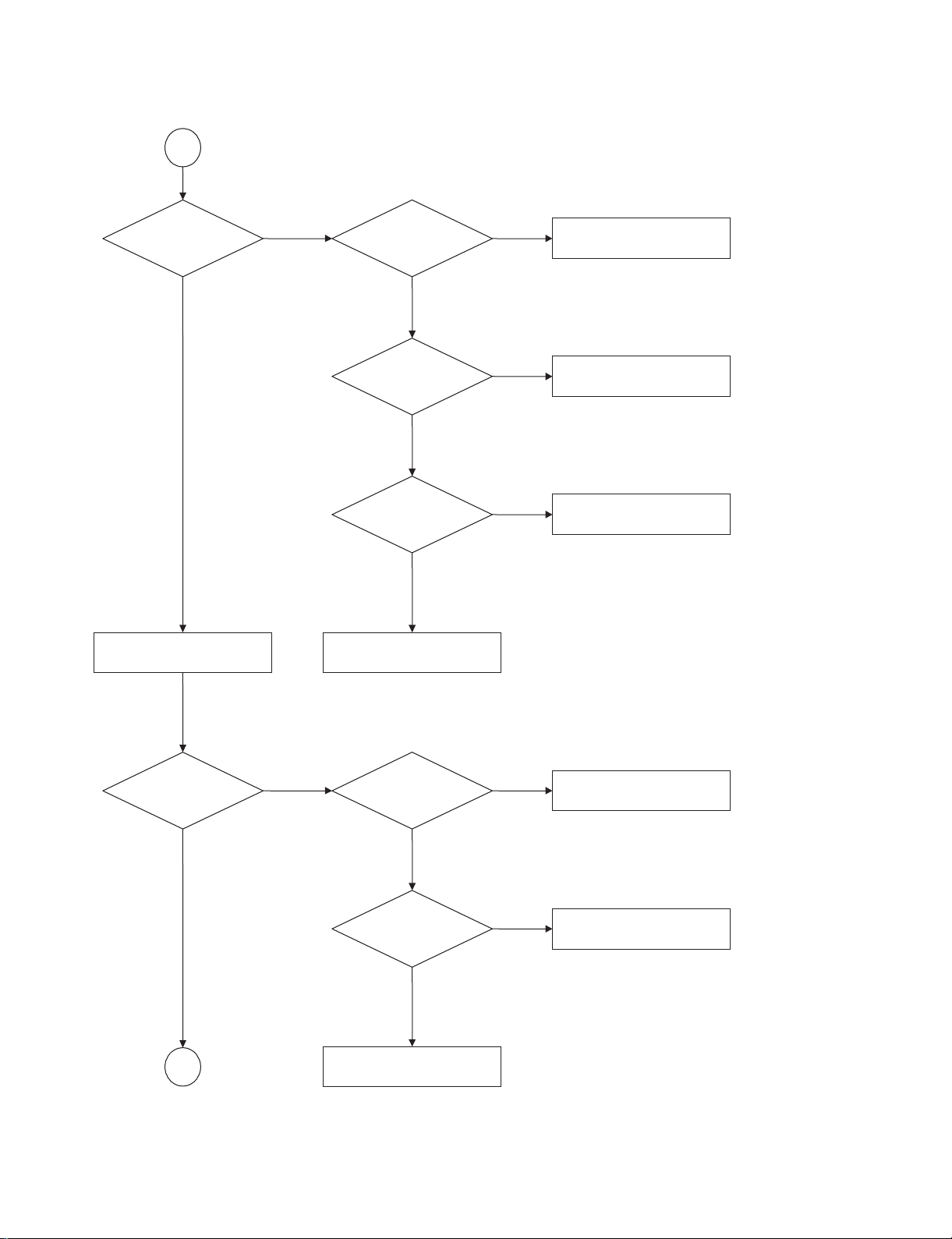

2. AUDIO µ-COM CIRCUIT

POWER ON

Does CD/DVD

appear at FLD?

Does

AV 1/2 FM87.5

appear at FLD?

OK.

Does READING

appear at FLD?

Does no Disc or

Time appear at FLD?

Check if DVD an Audio

Micom Interface is OK.

Check power.

Check DVD Module.

Check SMPS.

Does DVD Error

appear at

FLD?

Check

Connector(PN902)

Check power part

of Main B/D.

Check oscillator

of x101.

Check if IC101

PIN80 is High.

Reconnect PN902.

Refer to SMPS

Refer to oscillator

Circuit.

Check DVD Reset Waveform.

Check if IC101

PIN92 is High.

Check if IC101 PIN

31, 32, 51, 88 are high

(5V).

Check if IC101

PIN96 is High.

Replace IC101.

Check IC101 Reset Wavefrom.

Check 5V line.

Check Power section Circuit.

- 2-2 -

Page 9

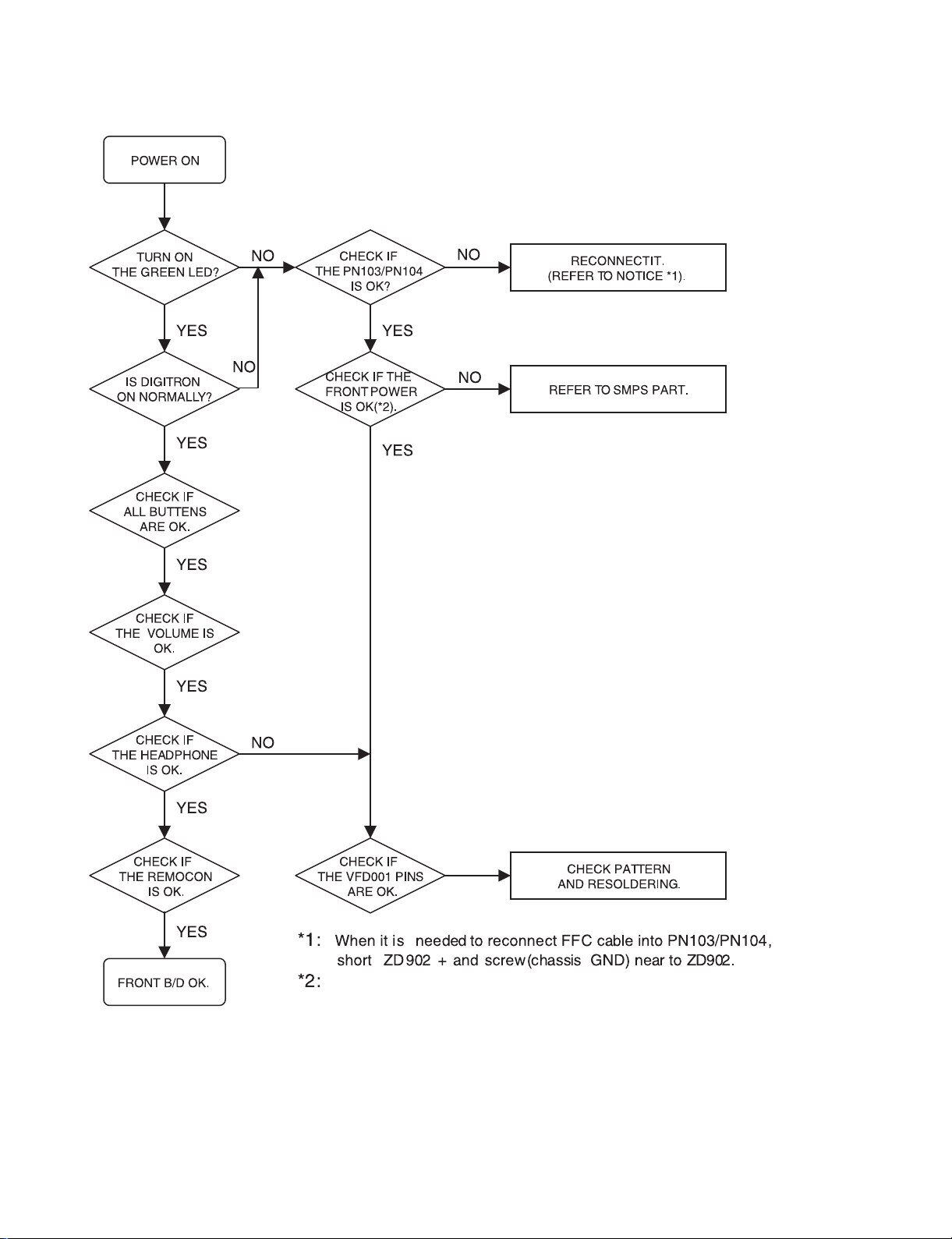

- 2-3 -

3. FRONT CIRCUIT (1/2)

PIN104 Pins

PIN : -27V

PIN 6 : -18V

PIN7 : -22V

PIN : 5V

Page 10

- 2-4 -

4. FRONT CIRCUIT (2/2)

CHECK

IF R029, R036~R040,

R046~R051

OK.

REPLACE R029,

R036~R040,

R046~R051

Check

if PN104 pins10, 11

Waveform OK.

Check

if the Remocon

Waveform of the

PN104 pin16

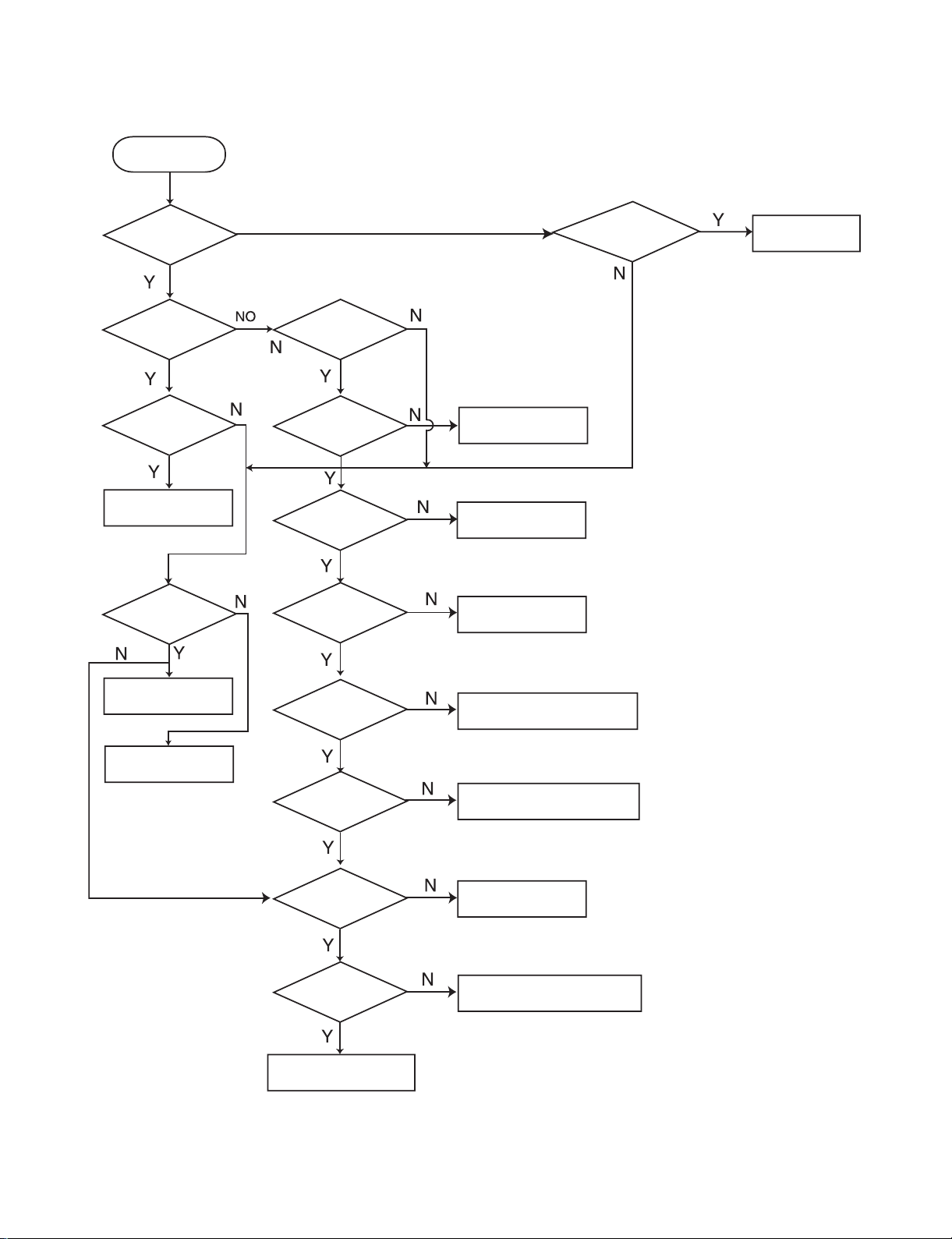

Page 11

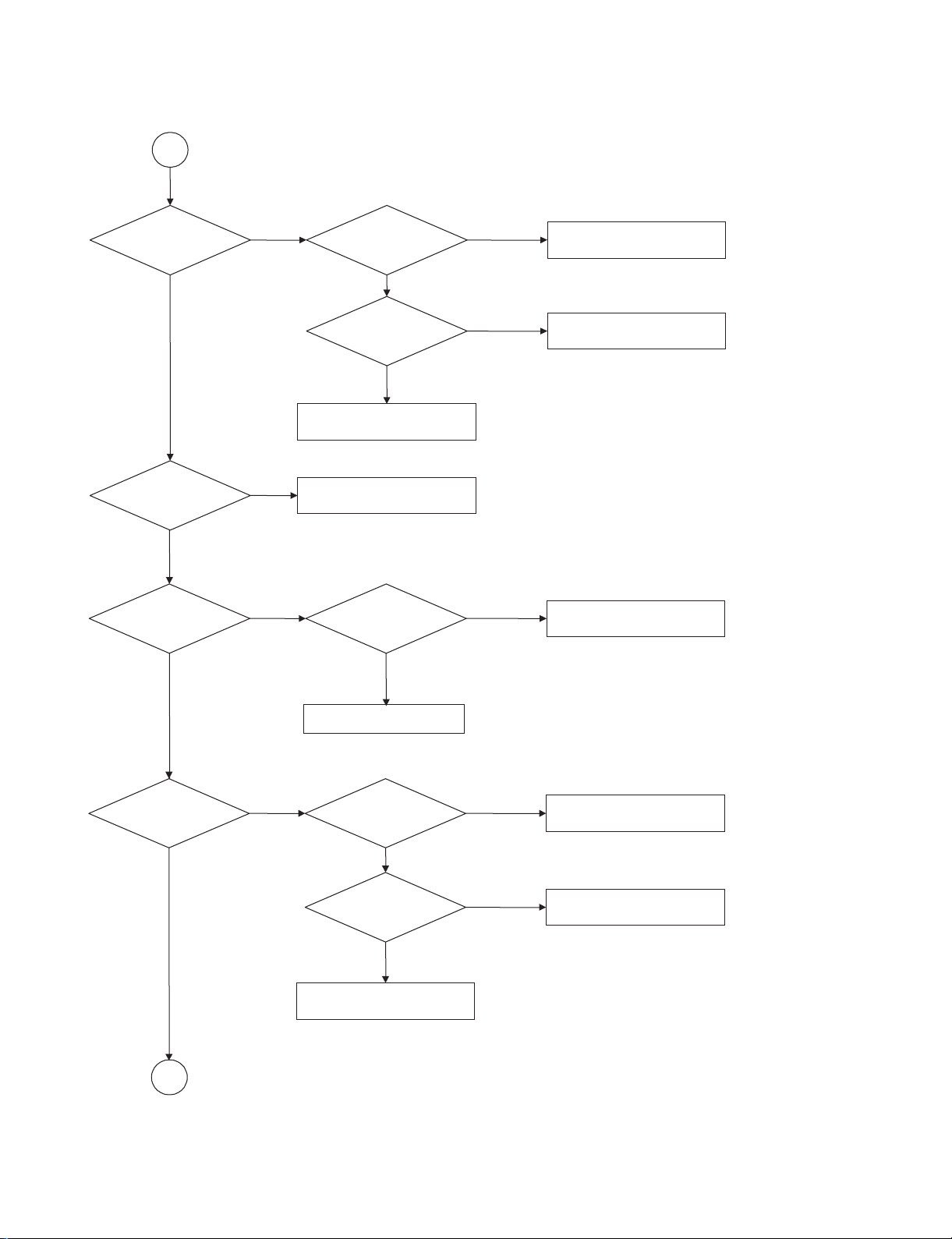

- 2-5 -

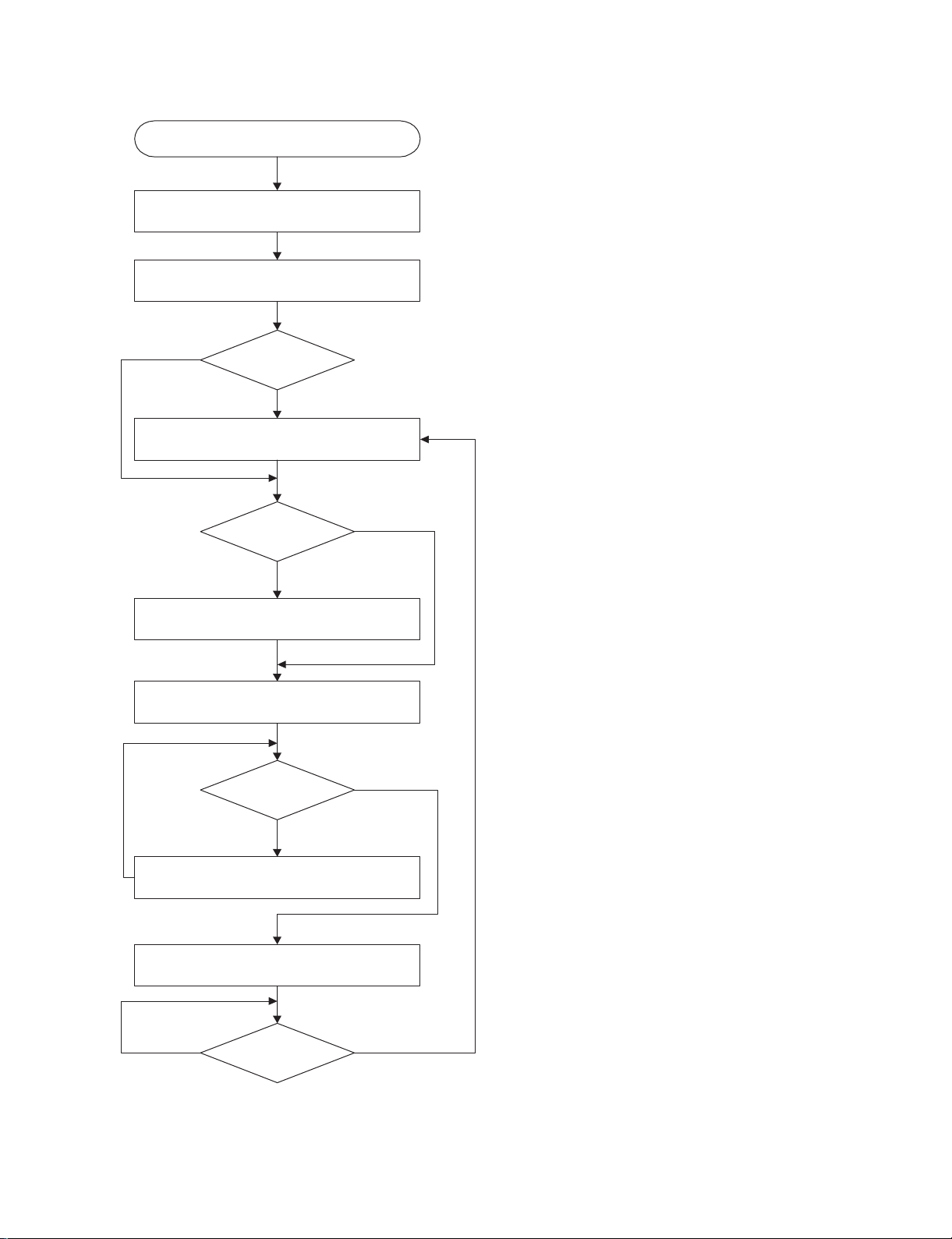

1. POWER CHECK FLOW

DVD TROUBLESHOOTING GUIDE

READING appear at FLD?

Does

Check DVD SECTION

Check

Connector(CN201)

if is normally.

Check

Connector CN202

Check

Connector CN203

Check

voltage each pin for PN902

Check SMPS

board regulator

Check Connector PN902

Page 12

- 2-6 -

2. SYSTEM OPERATION FLOW

Power On

1. 8032 initializes SERVO, DSP & RISC registers

2. Write RISC code to SDRAM

3. Reset RISC

Show LOGO

YES

Tray Closed?

NO

Tray Close to Closed position

SLED at Inner

Side ?

NO

SLED Moves to Inner Positi on

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Reci eve

OPEN/CLOSE

Key?

YES

YES

NO

1. Execute Pressed Key & IR Key

2. System operation Routine Loop

1. Stop Playback & Open Tray

2. Display tray open message & LOGO

NO

Receive

CLOSE Key?

YES

Page 13

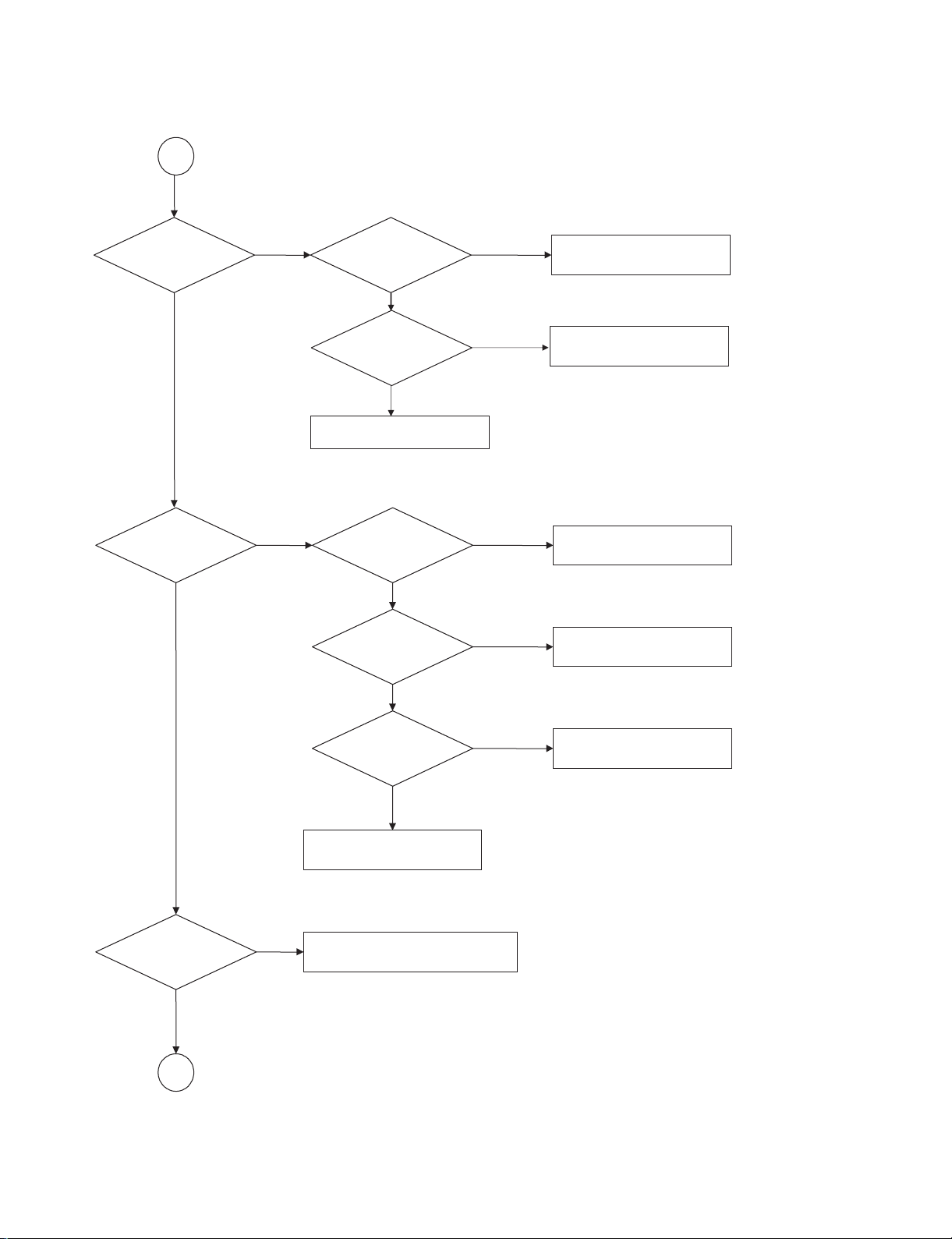

- 2-7 -

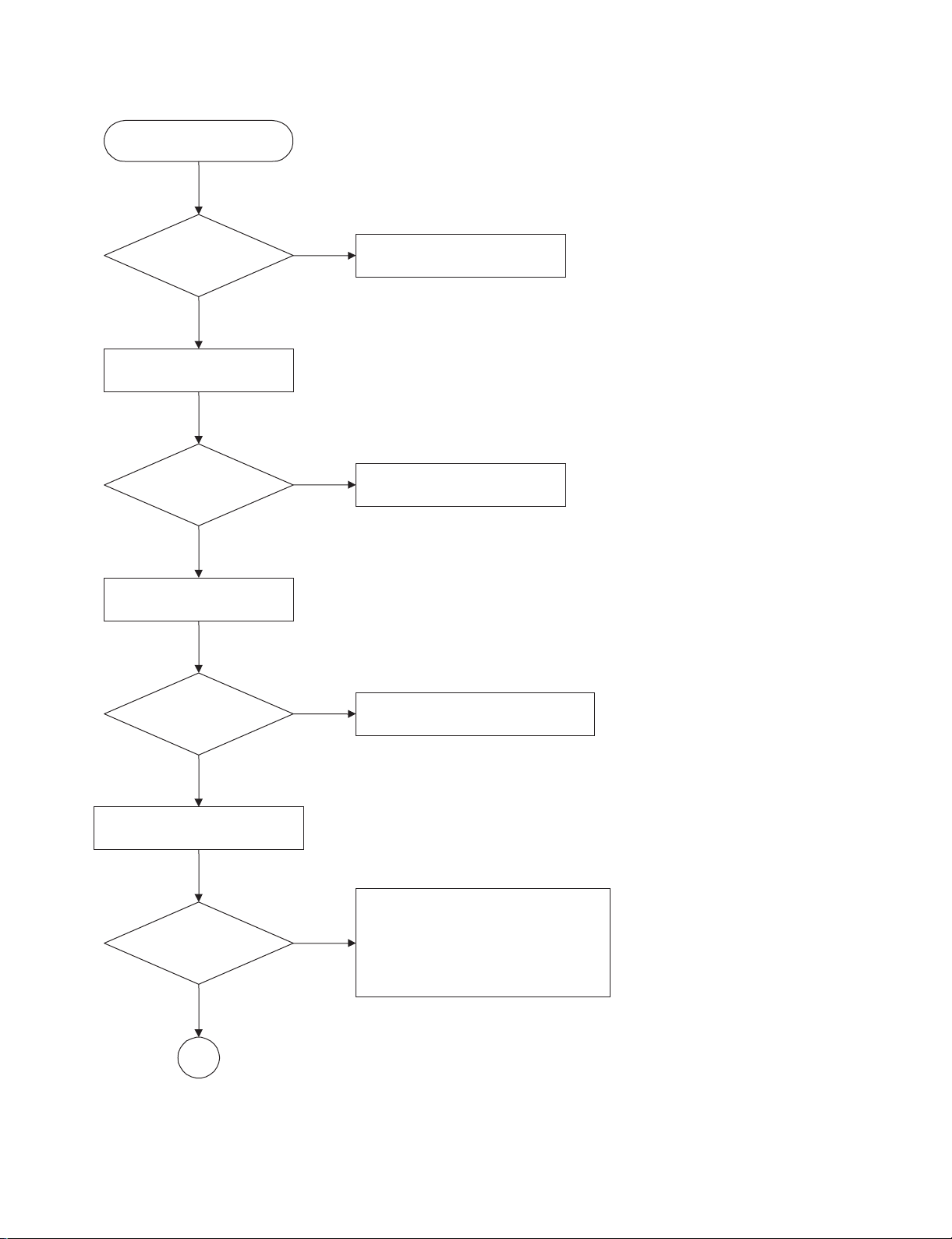

3. TEST & DEBUG FLOW

TEST

Check the AC Voltage

Power PCBA(120V)

YES

Switch on the Power PCBA

Is the DC Voltage

outputs OK?

(5V,3.3V, 8V, 12V, -12V, 11.5V)

YES

Make sure the main PCBA don't

short on VCCs and switch it on.

NO

NO

Replace power PCBA or

AC transformer.

Repair or Replace P ower PCBA

Is 3.3V and 1.8V DC

outputs normal on main

PCBA?

YES

Connect to PC RS232 Cable and

update the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

Check the regulators or related diodes.

1. Check 27MHz system clock.

NO

2. Check system reset circuit.

3. Check FLASH R/W enable signal PRD,RWR.

4. Check RS232 SIGNALS.

5. Check FLASH Memory related circuit.

Page 14

- 2-8 -

A

RESET or Power On.

Show LOGO?

NO

Flash Memory operates

properly?

YESYES

SDRAM works properly?

YES

MT1389 VIDEO outputs

properly?

YES

Have TV signal output?

YES

Check AV cable connection

to TV set.

NO

NO

NO

NO

Check connection lines between FLASH

& MT1389 and the FLASH access time

whether is suitable or not.

Check connection lines between

SDRAM & MT1389 and the SDRAM

is damaged.

Check the related circuit of MT1389.

Check the filtering and amp circuit of

TV signal.

Does Tray move

inside when it is not

at closed position?

YES

B

NO NO

Normal TROUT &

TRIN signals?

YES

Normal TRCLOSE &

TROPEN signal?

YES

Normal LOAD+ &

LOADsignal?

YES

Check the cable connection

between main PCBA and loader.

NO

NO

Check the load OPEN & CLOSE

switch

Check the Tray control IO pins on

MT1389 & IP4504.

Check the Tray control amplifying

circuit on Motor driver.

Page 15

- 2-9 -

B

Does

the SLED move

to inner side when it is at

outter position?

YES YES

NO NO

Motor Driver STBY

Pin is High?

Check the connection line of

STBY signal.

Do not put in disc and tray

close.

Optical Lens has

movements for searching

Focus?

Is FMSO DC Level higher

than 1.4V?

YES

SL+ and SL- output

properly?

YES

Check the cable connection with

NO NO

MECHA.

Proper FOSO outputs

to motor driver?

NO

NO

Check the related circuit of

FMSO.

Check the amp circuit on motor

driver.

Check FOSO connection on

MT1389 and motor dirver.

YESYES

Proper F+ & F- outputs?

YES

C

Check cable connect on with

pick-up head.

NO

Check the amp circuit on motor

dirver.

Page 16

- 2-10 -

C

Laser turns on when

reading disc?

YES

Put disc in? Laser off

YES

Disc ID is correct?

NO

NO

NO

LD01 or LD02 output

properly?

Collector voltage of

power transistor is OK?

Check cable connection between

transistor ouput and pick-up

head.

Proper RFL signal

on MT1389?

YES

YES

YES

NO

NO

NO

Check the laser power circuit

on MT1336 and connecting to

power transistor.

Check the related circuit on

laser power transistor

Check the related circuit

on MT1389 RFL signal.

YES

Does spindle rotate?

YES

D

NO

Check LDO1 & LDO2 signal

Proper DMSO signal on

MT1389

YES

SP+ & SP- output

properly?

YES

Check the cable connection

between spindle and main PCBA.

NO

NO

Check DMSO related

circuit on MT1389.

Check the spindle control

amp circuit of motor

driver.

Page 17

- 2-11 -

D

YES

Focus ON OK?

YES

Track On OK?

YES

NO NO

NO

Proper signals on

A,B,C,D of MT1389

YES

Check FEO signal

on MT1389

YES

Check FOSO signal on MT1389

Normal TEO Signal on

MT1389?

YES

Properly TRSO signal

on MT1389?

YES

NO

NO

NO

Check connections between

MT1389 and pick-up head.

Check the FOSO connection on

MT1389 and motor driver.

Check the related

circuit on MT1389

Check the TRSO

connection on MT1389

and motor dirver.

Disc is play ?

YES

E

NO

T+ & T- output

properly?

YES

Check cable connection on

pick-up head.

Check RFO & RFLVL signal waveform.

NO

Check the tracking control

amp circuit on motor

driver.

Page 18

- 2-12 -

E

Normal Audio output

when disc playback?

YES

Normal IR.VFD & Front

pannel key functions?

YES

TEST END

NO NO

NO

Audio PWM IC received

correct data stream?

YES

Normal Audio PWM IC

out?

YES

Check Audio filter,amplify,mute

IR.VFD Front pannelkey & MT1389

Check the cable connection on

circuit.

Communications between

is normally?

YES

Front pannel.

NO

NO

Check connection between MT1379

& Audio PWM IC.

Check the related

circuit of Audio PWM IC.

Check communication lines on

MT1389.

Page 19

- 2-13 -

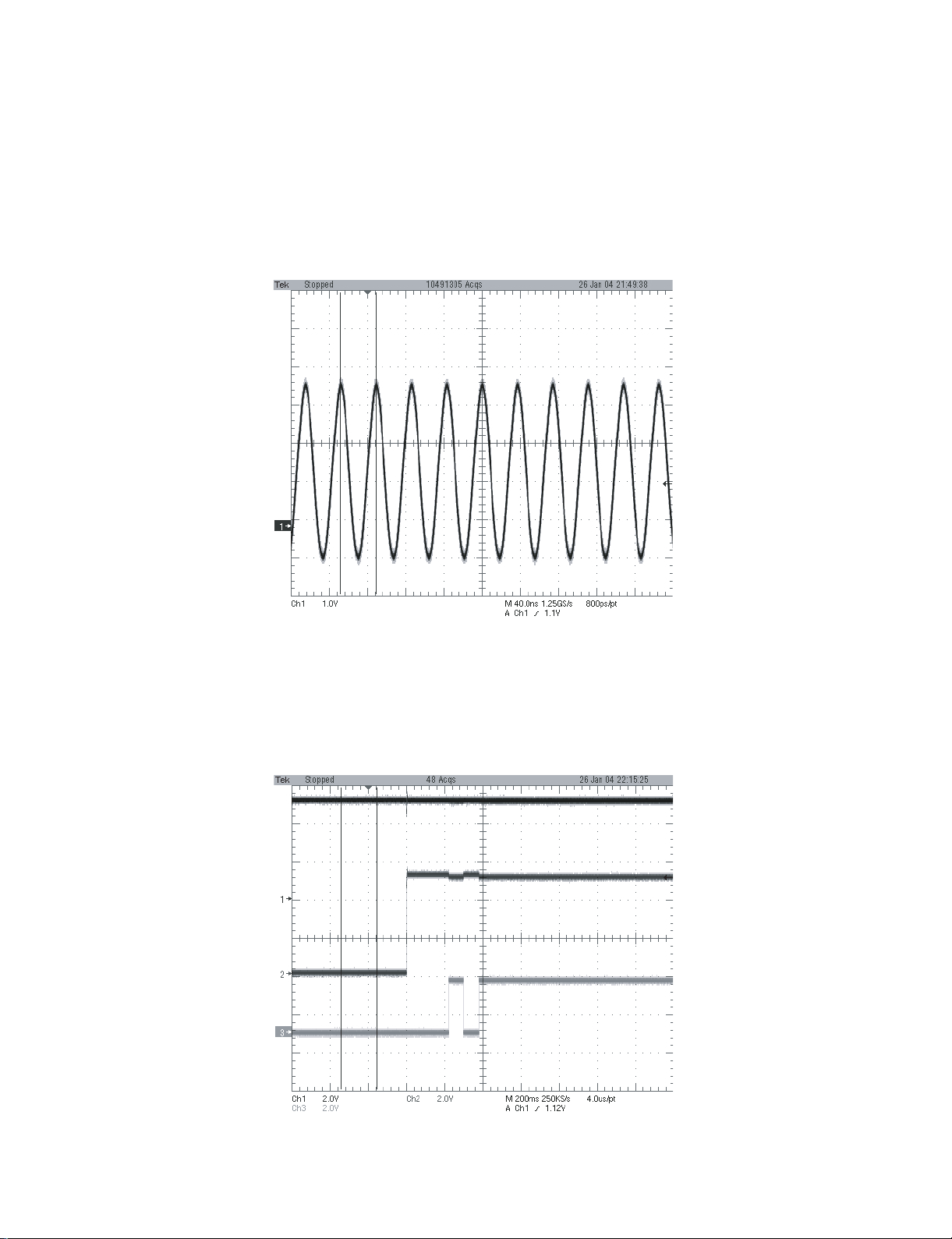

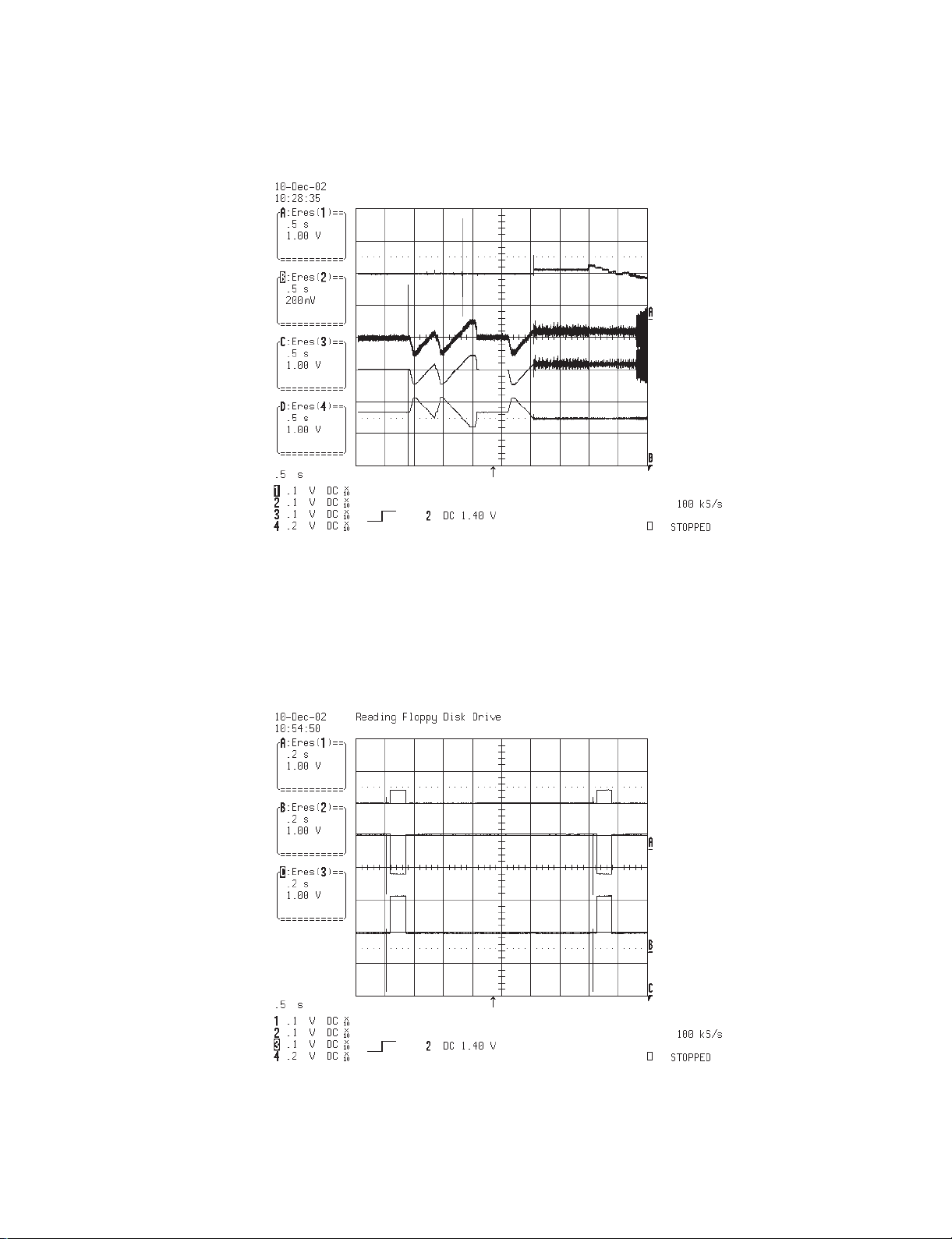

DVD DETAILS AND WAVEFORMS ON SYSTEM

TEST AND DEBUGGING

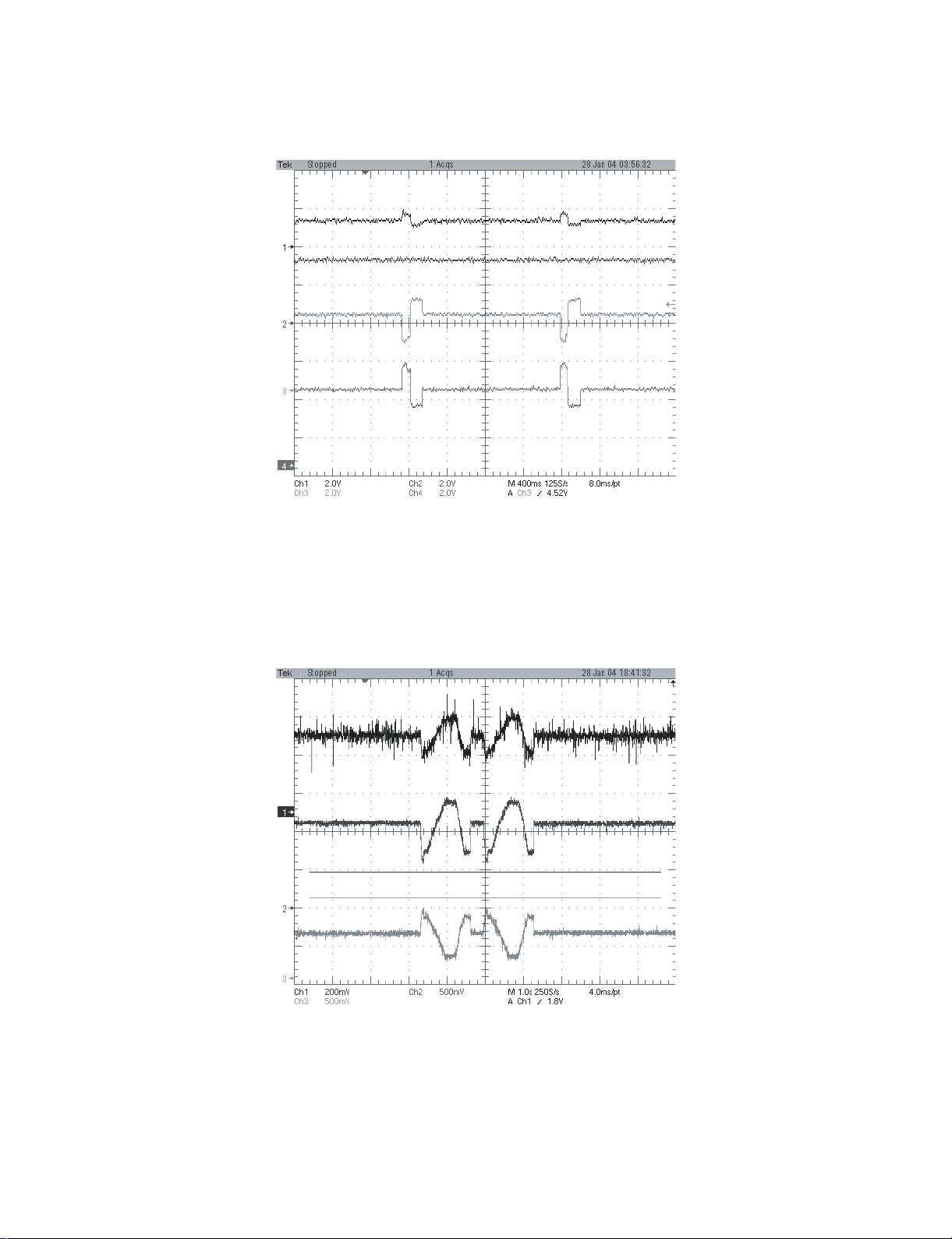

1. SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1) MT1389 main clock is at 27MHz(X601)

2) MT1389 reset is high active

FIG 1-1

FIG 1-2

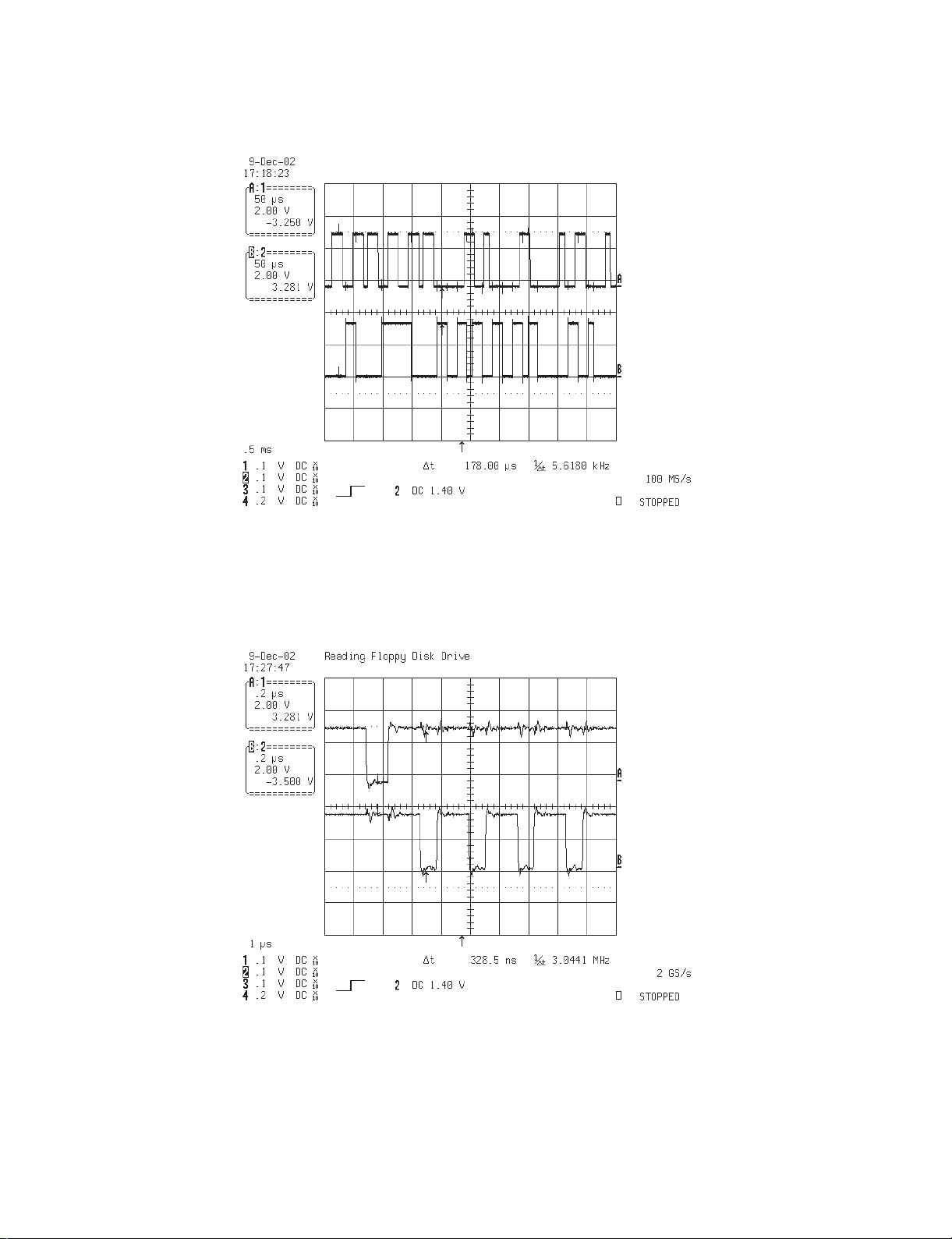

Page 20

- 2-14 -

3) RS232 waveform during procedure(Downloading)

4) Flash R/W enable signal during download(Downloading)

FIG 1-3

FIG 1-4

Page 21

- 2-15 -

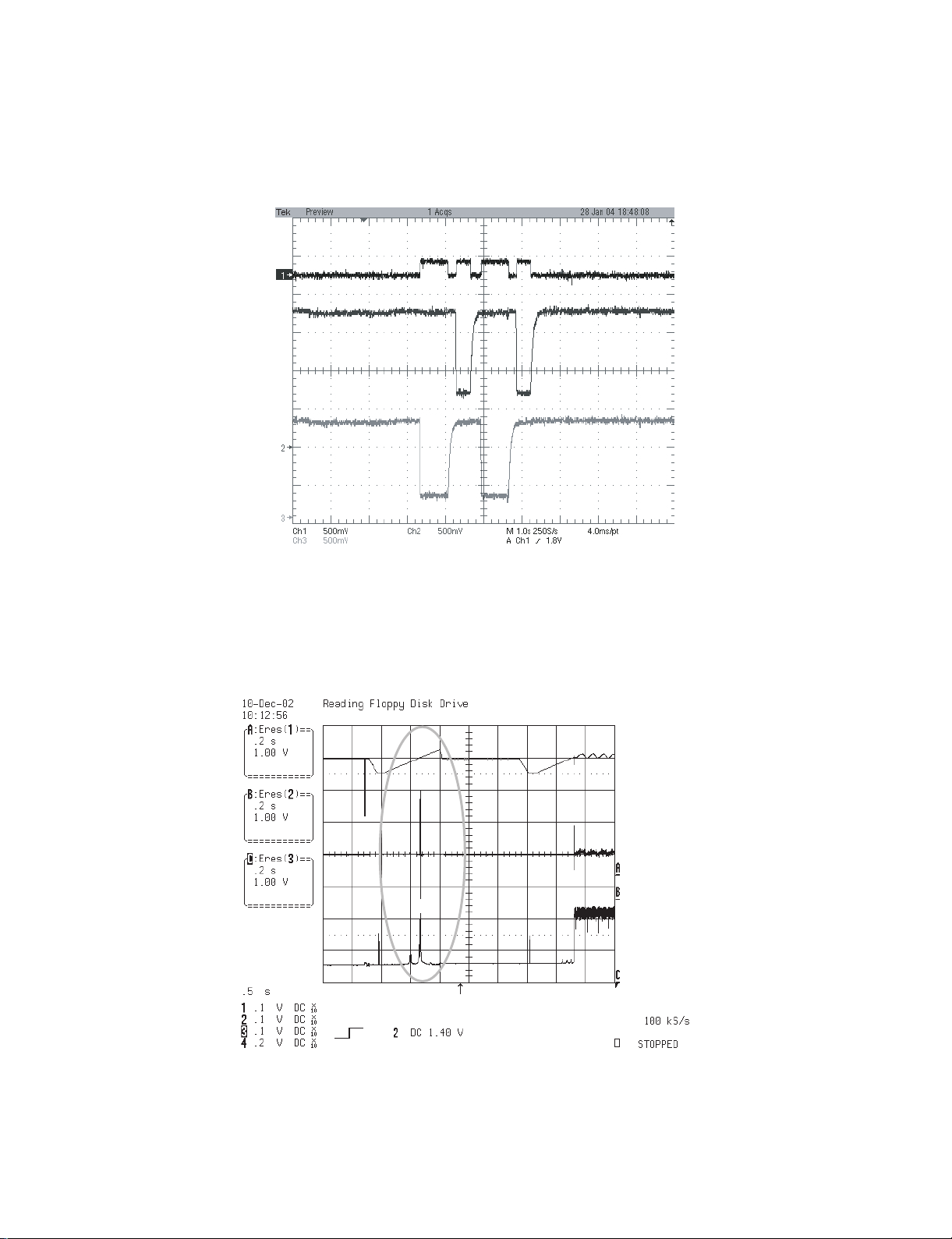

2. SDRAM CLOCK

1) MT1389 main clock is at 27MHz(X601)

3. TRAY OPEN/CLOSE SIGNAL

FIG 2-1

FIG 3-1

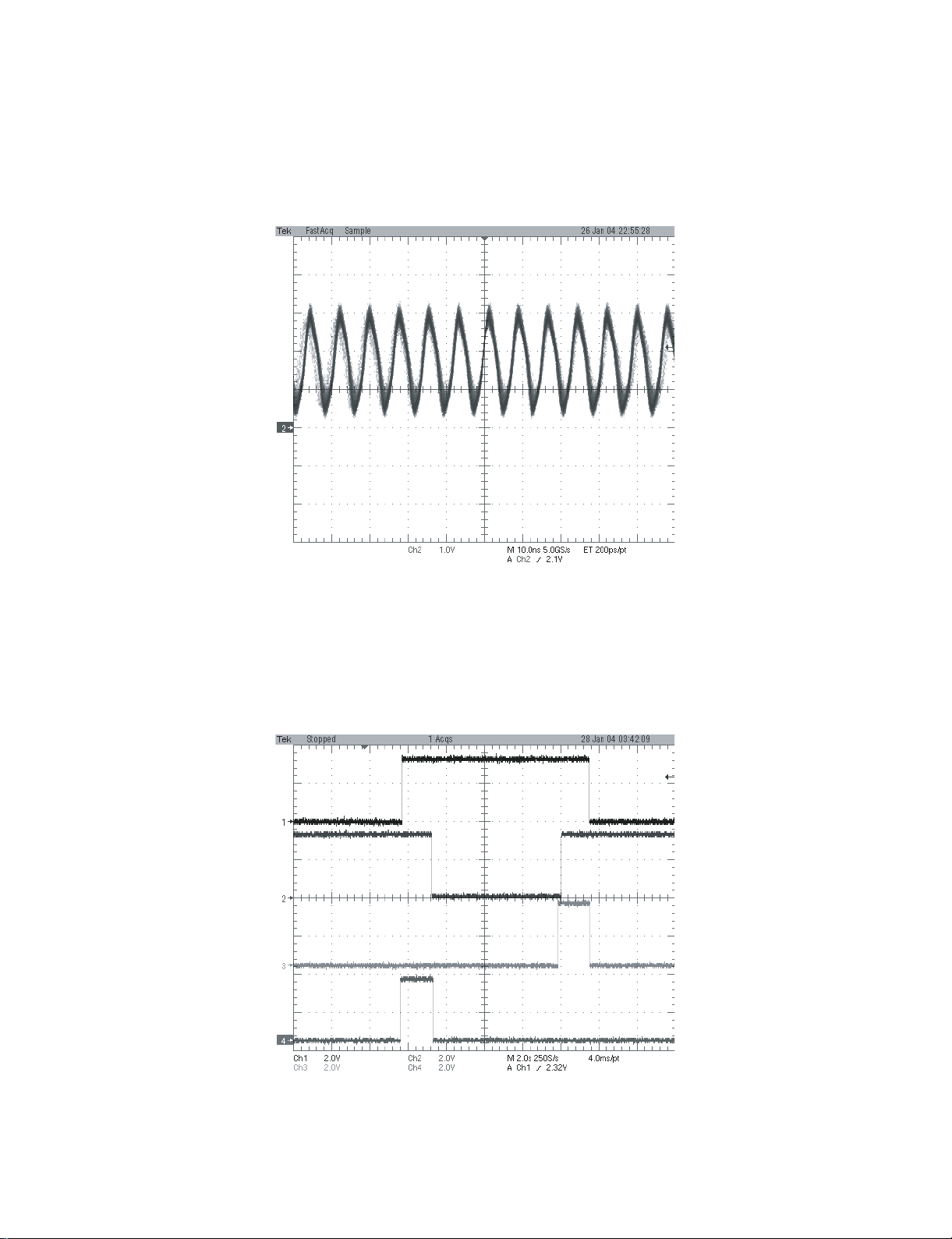

Page 22

- 2-16 -

4. SLED CONTROL RELATED SIGNAL

(NO DISC CONDITION)

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

FIG 4-1

FIG 5-1

Page 23

- 2-17 -

6. LASER POWER CONTROL RELATED SIGNAL

(NO DISC CONDITION)

7. DISC TYPE JUDGEMENT WAVEFORM

FIG 6-1

FIG 7-1

Page 24

- 2-18 -

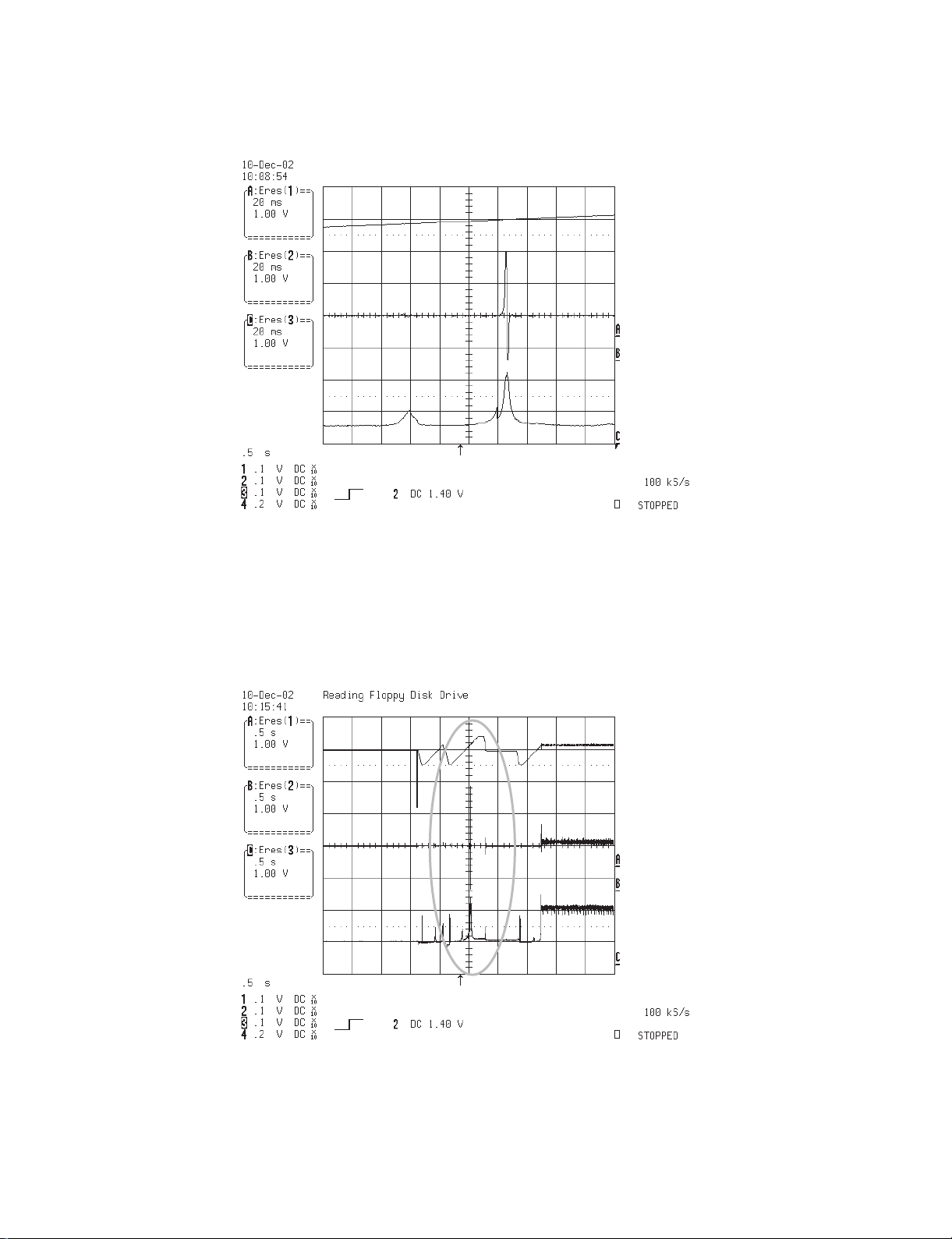

FIG 7-2 (DVD)

FIG 7-3 (CD)

Page 25

- 2-19 -

8. FOCUS ON WAVEFORM

FIG 7-4 (CD)

FIG 8-1 (DVD)

Page 26

- 2-20 -

FIG 8-2 (CD)

9. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

FIG 9-1

Page 27

- 2-21 -

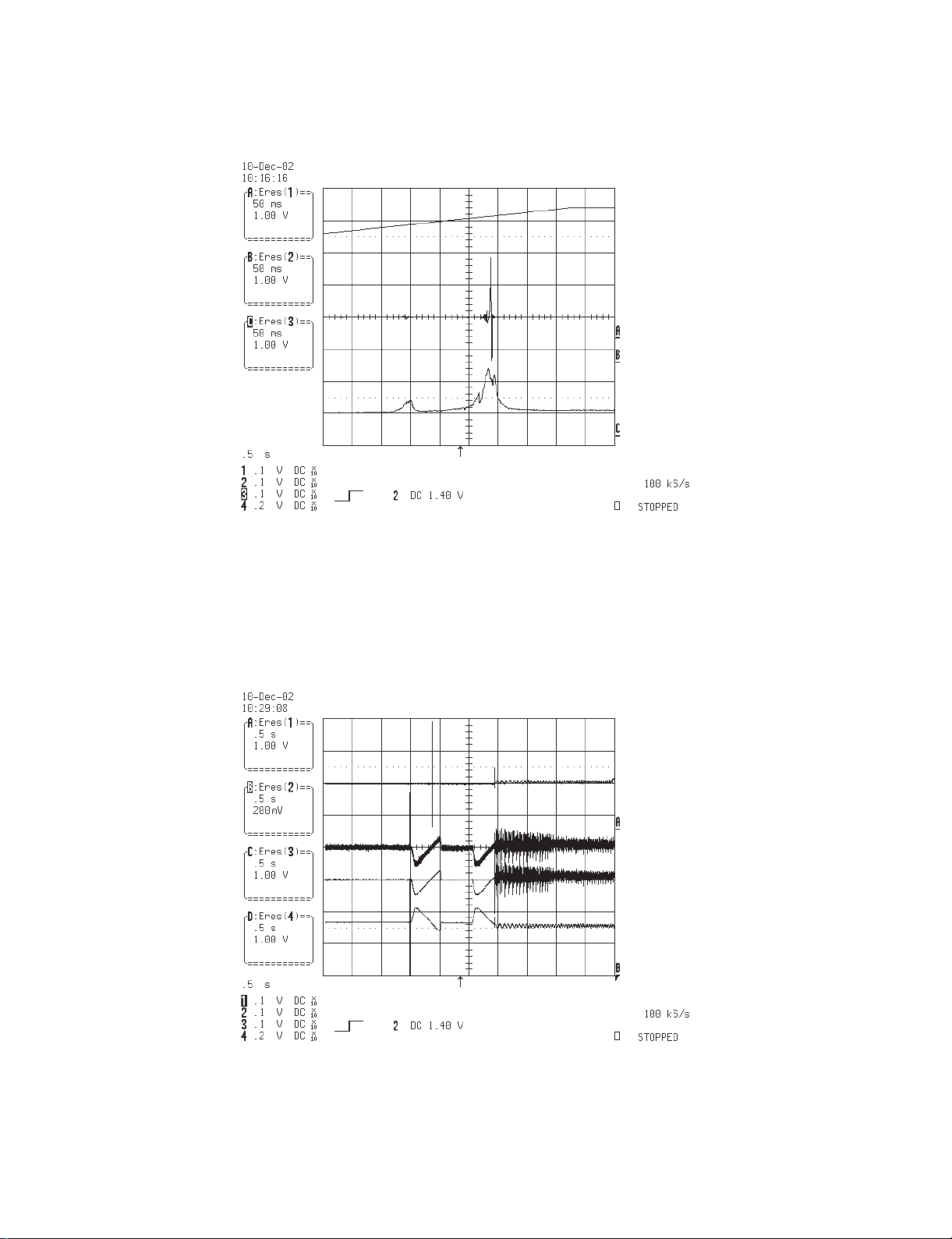

10. TRACKING CONTROL RELATED SIGNAL

(System checking)

FIG 10-1 (DVD)

FIG 10-2 (CD)

Page 28

- 2-22 -

11. MT1389 AUDIO OPTICAL AND COAXIAL INPUT

(SPDIF)

12. MT1389 VIDEO OUTPUT WAVEFORM

1)100%

FIG 11-1 (DVD)

FIG 12-1

Page 29

- 2-23 -

2) COMPOSITE VIDEO SIGNAL

13. MT1389 AUDIO OUTPUT TO PWM IC

FIG 12-2

ADAT0~3

FIG 13-1

Page 30

- 2-24 -

14. AUDIO OUTPUT FROM PWM IC

FIG 14-1

Page 31

- 2-25 -

WIRING DIAGRAM

Page 32

- 2-26 -

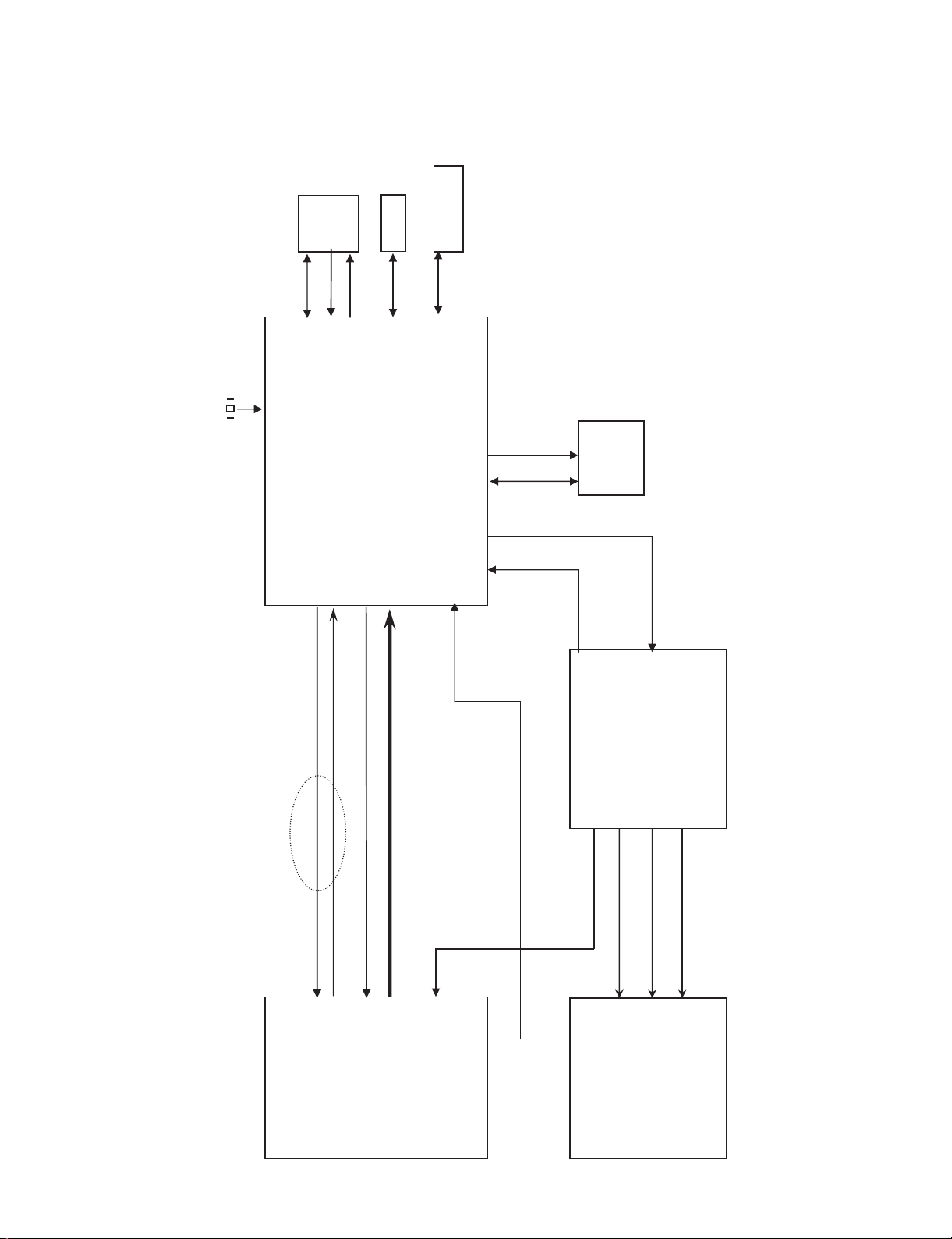

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

5V

MEMORY SLOT

IC603

M12L64164A

SD33

JK601

HDMI OUT

CONNECTO

3.3V-D1

HDMI PCB ASSY

3.3V-D1,1.8V-D1

ASSY

(7 IN 2)

12MHz

USB_M, USB_P

DCS#, DRAS#, DCAS#,

BA[0:1], SDCLK, SDCKE

64Mb, SDRAM

DDC CLK,DATA

+5V

R

HOT PLUG DET

DATA0~2/+-

IC602

64Mb, SDRAM

HY57V643220CT

13.5MHz

X601

DQ0~31

DAD0~10

IC601

FLI2301

RESOLUTION UP

UP

PICK

M

MOTOR

SPINDLE

A29LV800TA-70

DV33

1M, 8BIT FLASH

DWE#

DQ[00:15]

DQM[0:1]

MA[00:11]

HDMI

IC603

SIL9190

3.3v-D1, 3.3V-M

IC605

MM1234

SWITCHING IC

AV33, DV33

Y,Pb,Pr

FDATA0~7

M_VSYNC, M_HSYNC

LOADING

SLED

(Resolution up)

LOAD+, LOAD-

M

MOTOR

M

MOTOR

IC602

A[00:21]

SPDIF

TX0+,TX0-, TX1+,TX1-,

TX2+,TX2-, TXC+,TXC-,

F+, F-, T+, T-

SP+, SP-

SL+, SL-

AD[0:7]

AV33, DV33

IC606

KS24C021CS

2Kb,

EEPROM

DV33

CN601

RS-232

TXD

PCE#, PRD#, PWR#

IC601

AMCLK

SCL,SDA

LIMIT

RXD

27MHz

MT1389FE

MPEG & DSP

CD : RFO, A, B, C, D, E, F

DVD : RFO, A, B, C, D

Y,Pb,Pr(Analog)

Y,Pb,Pr(Analog or Digital)

SCL

X601

SDA

ALRCK, ABCK

REG_ 12V

IC303

V1P4

TROUT, TRIN, ADIN

V2.0, MDI1

AVCC, APC

LD01, LD02, IOA,

TUNER_L, R

TROPEN, TRCLOSE, TRSO, FOSO, DMSO, FMSO, STBY

DVD_DATAOUT

DVD_CE, DVD_CLK, DATAIN

ADATA

AMCLK

BU4052

X101

12.5MHz

DVD_RESET

AUDIO S/W

JK002

JK003

JK004

AV2_AUDIO L, R_VIDEO

AV2_L, R

4052_SW1,SW2

REG_5VA

IC101

JK503

TMP88CU77F

OPT.

SPDIF

REG_5VA

FRONT

REAR

RIN, LIN

C/SW

ALRCK, ABCK

DN_MIX

IC305

IC304,

OPAMP

V_MUTE1

V_MUTE2

AUDIO MICOM

COMPONET-OUT

COAXIAL IN

IC302

CS42516

CODEC & DIR

AV1_L, R

PS9829_DATA

JK501

AV1-IN

COAXIAL IN

AV1 AUDIO_L, R_VIDEO

PS9829_CLK, RESET, PDN

510_PDN

510_FAULT, TH_WAR

Y, Pb, Pr

MONITOR OUT

AV1_VIDEO

AV2_VIDEO

REG_3.3VA

SL+/

JK502

S-VIDEO

MM1623XFBE

VIDEO 6dB AMP

C+/

FL+/

REG_3.3VA, 34.5VA

L703

L.P.F

Y_OUT, C_OUT

IC605

IC301

PS9829

L702

IC502

V_MUTE1

X301

MODULAT

8CH. PWM

STA510

IC701, IC702

IC703, IC704

L708

S/W

VIDEO

NJM2244

CVBS

V_MUTE2

12.288MHz

OR

FR+/

SW+/

LL705

LL706

JK001

H/PHONE

HEAD PHONE L, R

IC501

H/PHONE+/

SR+/

OPAMP

L710,L711,L712

P_DI

MUTE

IC201

IP4504A

MOTOR DRIVER

RVCC2, +P8V

TUN101

OPTION

RDS_CLK, DATA

P_CE, P_CLK, P_DO

RADIO TUNER MODULE

REG-9V

C

F.L

R.L

SW

JK701

F.R

R.R

SPEAK ER TERMINAL

Page 33

- 2-27 -

2. SMPS BLOCK DIAGRAM

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

TO I/O

5.3VA

(PSV01)

RECTIFIER &

SMOOTING BLOCK

(D927,C931,L925,C932)

C925)

RECTIFIER &

(D921,C921,L921

SMOOTING BLOCK

T901

!

!

SNUBBER

3.8VA

13VA

GND

GND

(IC956,R950,C953)

(IC953,R947,C928)

12V REG & S/W Block

12VT REG & S/W Block

RECTIFIER &

SMOOTING BLOCK

(D922,C922,L922,C926)

BLOCK

(D901,C905,R901)

GND

33VA

33V S/W Block

(Q923,R943,R934)

RECTIFIER &

SMOOTING BLOCK

54

DRIVE & S/W BLOCK

FL-

FL+

-29VA

R945,C920)

5.0VD S/W Block

5.0VT S/W Block

(Q920,R942,R944

(Q924,R940,R935,R936

FEED-BACK

(D925,C929,)

RECTIFIER &

(D923,C923,L923)

SMOOTING BLOCK

7

C909,C910,R906,

(IC901, D902, D903,

!

2

ZD901,ZD902)

D934,C934)

PHOTO COUPLER

TIMER ‘H’ Block

BLOCK

(R930,R931,

(PC910)

PWR CTL Block

(Q925,R956,R957)

(Q926,R964,R965)

R926,R927,

R928,C930)

(IC941)

ERROR AMP

T902

!

RESET

BLOCK

(D905,D906)

35.5V

TO AMP

(PSW01)

REGULATION BLOCK

RECTIFIER &

SMOOTING BLOCK

1

GND

P-con

P-sen

(L951,C953,C954)

(R951,R952)

RECTIFIER &

(D91,C951,C952)

SMOOTING BLOCK

5

C919,ZD912)

(IC902,R919,

C916, C917,C918,

DRIVE & S/W BLOCK

4

BLOCK

R949,R950,

(R946,R947,

FEED-BACK

(PC912)

PHOTO COUPLER

!

R955,C943)

(IC942)

ERROR AMP

TH901

BD901

+

C903,C904

1

!

3

8

BLOCK

(CM901,L902,

NOISE FILTER

3

2

Y-CAP

C900

!

!

Y-CAP

C901,C902

!

FUSE

L901, CM902)

(F901)

BR BL

(BK)(WH)

Page 34

- 2-28 -

3. SERVO Block Diagram

EEP

ROM

SCL, SDA

PRD#, PWR#

PCE#

MT1389

DVDPLAYER

X601

27MHz

X-TAL

AD[0:7]

ROM

FLASH

A[0:20]

IC601

ONE CHIP

RS232C(MTK)

RXD, TXD

MA[0:11]

DQM0 ,DQM1

WE#,CAS#,RAS#

CS#,BA0,BA1

SDCLK

SDCKE

IC603

SDRAM

DQ[0:15]

4M x 16bit

ALPC

LD0 1, LDO 2, IOA

MDI 1

TRCLOSE

ADIN

IC201

IP4504

STBY,V1P4

FOSO,TRSO,FMSO

DMSO,,TROPEN

Motor Driver

V20, PICKSEL

DVD: A,B,C,D, RFO

CD: A,B,C,D, E, F,RFO

LIMIT,TRIN,TROUT

F+, F-, T+, T-

SL+, SL-

SP+, SP-

LOAD+, LOAD-

UP

PICK

M/D

Page 35

- 2-29 -

4. MPEG & MEMORY Block Diagram

VIDEO

Interface

IC606

EEPROM

Y2(Y),Y3(Color)

Y4(Y),Y5(Cb),Y6(Cr)

ASPECT(16:9)

SCL,SDA

ACLK,ALRCK,ABCK

MUTE,VSCK,VSDA

e

AUDIO

Interfac

ASPDIF

ASTB,SCL,SDA

ASDTA[0:3]

AD[0:7]

A[0:20]

IC602

PWR,PCE,PRD

(16 M )

IC603

SDRAM

64M

FLASH MEMORY

CS,DCKE,MA[0:10]

DCLK,WE,CAS,RAS

DQ[0:15]

DQM0,DQM1

M_REQ

VFD_TXD

VFD_SCK

MT1389

SCKO,TXDO,M-REQ

IC601 (MPEG + DSP + RF)

X601

27MHz

VFD_RXD

URST,S_REQ

AUDIO MICOM

Page 36

- 2-30 -

5. VIDEO & AUDIO Block Diagram

M

A/V

JACK

CVBS

HDMI BOARD

COMPONENT(Y.Pb.Pr)

Amp

IC605

VIDEO 6dB

REAR R

FRONT R

SUPER VIDEO (Y/C)

IC701 Digital

POWER IC

REAR L

FRONT L

IC702 Digital

POWER IC

CENTER

WOOFER

IC303, IC704

Digital POWER IC

5.1CH BOARD

IC301

IC

PWM

(5.1CH)

MODULATOR

FDATA

[0:7]

(Y/C)

(Y.Pb.Pr)

MPEG

ACLK

LRCK

PEG

ADATA2

ADATA1

ADATA3

Page 37

2-31 2-32

AUDIO PART SCHEMATIC DIAGRAMS

• SMPS-1 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 38

• SMPS-2 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

2-33 2-34

Page 39

2-35 2-36

• MICOM SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 40

2-37 2-38

• I/O SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 41

2-39 2-40

• AMP SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 42

2-41 2-42

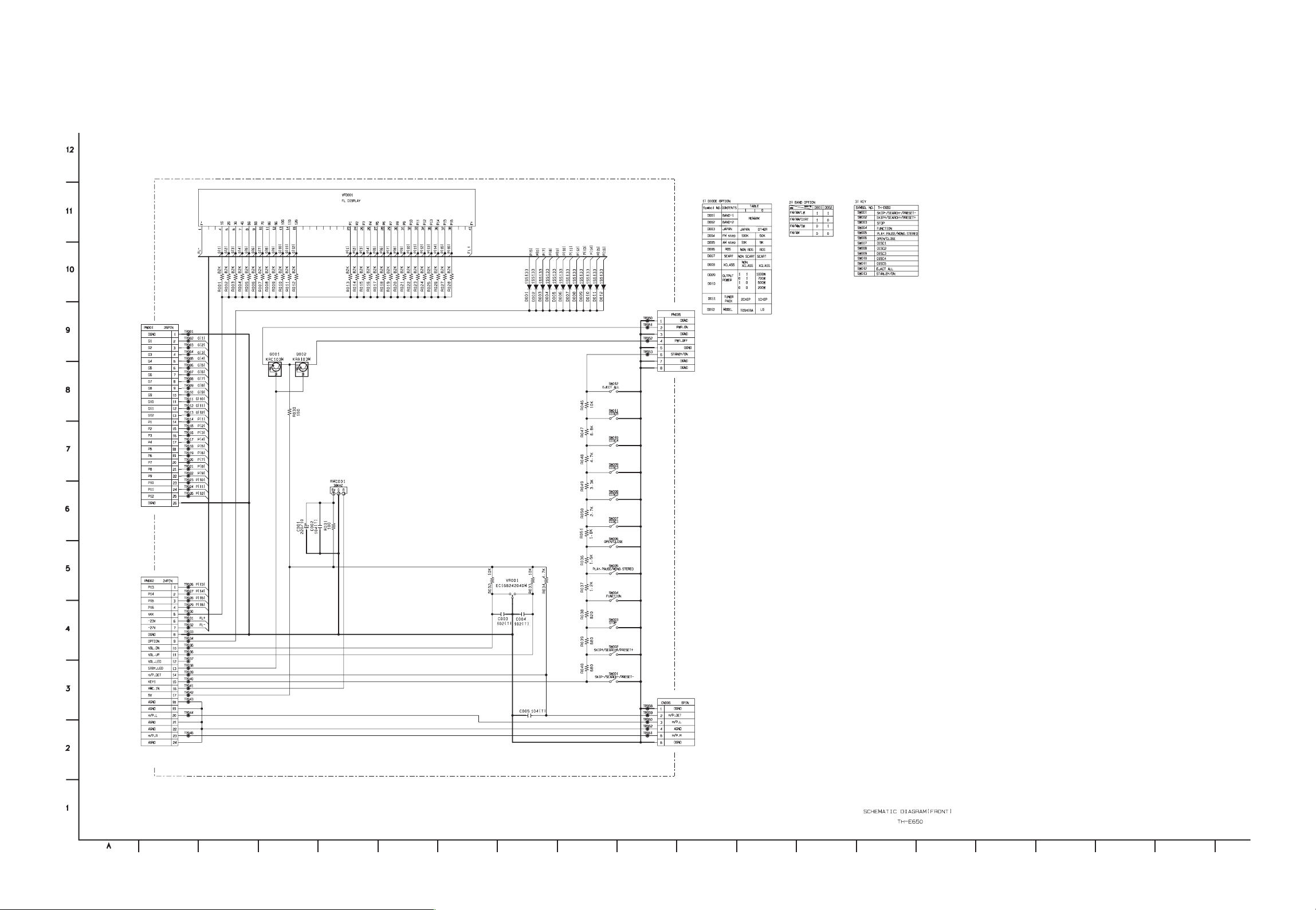

• FRONT SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 43

2-43 2-44

• H/PHONE SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 44

2-45 2-46

• AV2 SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 45

2-47 2-48

DVD PART SCHEMATIC DIAGRAMS

• MPEG SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 46

2-49 2-50

• DSP SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 47

2-51 2-52

• SERVO SCHEMATIC DIAGRAM

A B C D E F G H I J K L M N O P Q R ST

Page 48

3-53 3-54

PRINTED CIRCUIT DIAGRAMS

• MAIN P.C. BOARD (TOP SIDE)

Page 49

3-55 3-56

• MAIN P.C. BOARD (BOTTOM SIDE)

Page 50

2-57 2-58

• FRONT P.C.BOARD (TOP SIDE)

• FRONT P.C.BOARD (BOTTOM SIDE)

Page 51

2-59 2-60

• H/PHONE P.C.BOARD (TOP SIDE)

• H/PHONE P.C.BOARD (BOTTOM SIDE)

• AV JACK P.C.BOARD (TOP SIDE)

• AV JACK P.C.BOARD (BOTTOM SIDE)

Page 52

2-61 2-62

• POWER P.C.BOARD

LOCATION GUIDE

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

Page 53

2-63 2-64

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

12).IC703(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

13).IC704(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

11).IC702(STA510)

10

2 17.7

3 17.7

4 34.5

50

60

7 34.5

8 17.7

9 17.7

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

19 0

20 NC

21 NC

22 NC

23 NC

24 4.93

25 0

26 NC

27 NC

28 NC

29 NC

30 NC

31 NC

32 NC

33 NC

34 NC

35 NC

36 NC

37 NC

38 0

39 0

40 0

41 4.94

42 NC

43 NC

44 NC

45 NC

46 NC

47 NC

48 0

49 0

50 NC

51 3.26

52 0

53 3.26

54 0

55 0

56 NC

57 NC

58 NC

59

1.66(12.288MHz)

60 0.32

61 0.32

62 0

63 NC

64 NC

6).IC303(BU4052)

12.75

20

32.75

40

5NC

60

7 -6.25

80

90

10 0

11 0

12 2.75

13 2.75

14 NC

15 0

16 5.95

7).IC304(UTMC4580)

12.84

22.84

32.84

4 -12.31

52.84

62.84

72.84

8 11.68

8).IC305(UTMC4580)

12.86

22.86

32.86

4 -12.32

52.86

62.86

72.86

8 11.69

9).IC501(UTMC4580)

10

20

30

4-11.42

50

60

70

8 11.23

9).IC502(NJM2244M)

12.04

24.82

31.97

44.82

52.82

64.76

72.06

80

10).IC701(STA510)

10

217.7

317.7

434.5

50

60

734.5

817.7

917.7

10 17.7

9 4.95

10 0

11 3.27

12 4.95

13 0

14 0.9

15 0

16 4.91

17 0

18 4.91

19 0

20 4.95

3).IC103(KIA7042)

1 5.1

20

3 5.1

20).IC201(IP4504)

1 1.37

2 2.56

3 2.52

4 2.61

5 2.41

6 2.44

7 2.46

80

9 1.42

10 4.35

11 0

12 0

13 3.94

14 3.94

15 3.19

16 4.7

17 3.9

18 4

19 7.9

20 1.42

21 1.62

22 1.39

23 3.25

24 4.91

25 2.58

26 2.39

27 2.52

28 2.49

4).IC301(PS9829)

10

20

3 2.44

4 4.92

5 3.28

6 2.42

71

80

90

55 -23

56 -23

57 -23

58 -23

59 -23

60 -23

61 -23

62 -23

63 -23

64 -23

65 -23

66 2.5

67 0

68 0

69 4.9

70 4.9

71 0

72 4.8

73 4.8

74 4.8

75 4.4

76 0

77 0

78 0

79 4.8

80 3.9

81 0

82 0

83 0

84 4.8

85 4.8

86 4.8

87 -26

88 4.9

89 1.8

90 0

91 1.8

92 4.8

93 4.35

94 0

95 0

96 5.1

97 4.9

98 0.3

99 0.3

100 0

2).IC102(74HCT244)

10

2 2.48

30

4 2.47

50

6 1.5

70

8 3.27

Volt (V)

MODE

PIN NO.

IC101

(AUDIO MICOM)

10

21.04

34.75

40

50

60

7 4.9

8 4.9

9 4.9

10 4.9

11 2.4

12 4.9

13 0

14 0

15 0

16 0.6

17 5.1

18 0

19 0

20 0

21 0

22 4.9

23 4.9

24 5.1

25 0

26 0

27 5.1

28 0

29 0

30 0

31 5.1

32 4.9

33 -23.4

34 -23.4

35 -23.4

36 -23.4

37 -23.4

38 -23.4

39 -23.4

40 -23.4

41 -23.4

42 -23.4

43 -23.4

44 -23.4

45 -23.4

46 -23.4

47 -23.4

48 -23.4

49 -23.4

50 -23

51 4.88

52 -23.7

53 -23

54 -23

Volt (V)

MODE

PIN NO.

IC102

(74HCT244)

Volt (V)

MODE

PIN NO.

IC103

(KIA7042)

IC201

(IP4504)

IC301

(PS9829)

Volt (V)

MODE

PIN NO.

10 3.28

11 0

12 0

13 2.44

14 0

15 0

16 0

17 0

18 0

19 1.63

20 1.63

21 0

22 3.28

23 1.23

24 1.23

25 1.23

26 1.23

27 NC

28 0

29 3.28

30 NC

31 NC

32 NC

33 NC

34 2.44

35 0

36 NC

37 NC

38 0

39 3.28

40 1.63

41 1.63

42 2.44

43 0

44 0

45 1.63

46 1.63

47 3.28

48 1.63

49 1.63

50 0

51 1.63

52 1.63

53 0

54 1.63

55 1.63

56 3.28

57 0

58 1.63

59 1.63

60 0

61 1.63

62 1.63

63 0

64 0

Volt (V)

MODE

PIN NO.

IC302

(CS42516)

65 3.28

66 2.44

67 1.63

68 1.63

69 0

70 1.63

71 1.63

72 3.28

73 0

74 1.63

75 1.63

76 3.28

77 0

78 0.5

79 0.5

80 2.44

81 0

82 3.28

83 3.28

84 0

85 0

86

1.65(12.288MHz)

87 3.28

88 NC

89 NC

90 NC

91 2.44

92 0

93 NC

94 3.28

95 0

96 4.92

97 NC

98 NC

99 NC

100 NC

1NC

2NC

3NC

43.27

50

64.93

70.65

80

9 0.2

10 0.11

11 0

12 4.93

13 2.83

14 2.83

15 2.83

16 2.83

17 2.75

18 0

Volt (V)

MODE

PIN NO.

IC303

(BU4052)

Volt (V)

MODE

PIN NO.

IC304

(UTMC4580)

IC305

(UTMC4580)

IC501

(UTMC4580)

IC502

(NJM2244M)

IC701

(STA510)

Volt (V)

MODE

PIN NO.

IC702

(STA510)

Volt (V)

MODE

PIN NO.

IC703

(STA510)

IC704

(STA510)

Volt (V)

MODE

PIN NO.

IC601

(MT1389)

10 17.7

11 17.7

12 34.5

13 0

14 0

15 34.5

16 17.7

17 17.7

18 NC

19 0

20 0

21 4.89

22 4.89

23 3.3

24 0

25 3.18

26 3.16

27 3.16

28 3.28

29 1.63

30 1.63

31 1.63

32 1.63

33 26.36

34 26.36

35 31.42

36 31.42

10

2 1.67

3 1.67

4 1.67

5 1.67

6 1.67

7 1.67

8 1.99

92

10 2

11 2

12 1

13 1

14 1

15 1

16 1

17 1

18 2

19 2

20 0.18

21

22 2.34

23 3.21

24 3.2

25 1.55

26 1.93

27 0

Volt (V)

MODE

PIN NO.

28 2.71

29 2

30 1.37

31 1.32

32 1.33

33 1.33

34 2.8

35 2.78

36 2.34

37 2.04

38 1.33

39 0

40 1.37

41 1.37

42 1.4

43 0

44 1.57

45 1.57

46 3.28

47 2.84

48 3.28

49 0

50 3.24

51 0

52 2

53 2.12

54 1.89

55 1.76

56 1.45

57 1.72

58 2.23

59 1.5

60 0.02

61 0

62 0

63 1.7

64 0

65 3.1

66 3.27

67 0.27

68 0.62

69 0.65

70 3

71 1.3

72 1.8

73 3.27

74 1.71

75 2.51

76 0

77 0

78 2.08

79 0

80 3.27

81 1.53

82 1.52

Volt (V)

MODE

PIN NO.

83 1.23

84 0.96

85 0

86 1.3

87 1.68

88 1.32

89 0

90 1.17

91 1.34

92 0.31

93 1.88

94 0

95 1.8

96 3.22

97 1.8

98 2.51

99 2.51

100 3.25

101 3.25

102 3.27

103 3.27

104 2.5

105 1.3

106 2.51

107 3.27

108 3.27

109 0

110 3.9

111 2.52

112 2.6

113 1.93

114 0.02

115 1

116 0

117 1.25

118 1.07

119 0

120 1.82

121 2.35

122 1.8

123 1.14

124 1.13

125 1.27

126 1.33

127 3.27

128 1.3

129 1.4

130 1.3

131 1.2

132 1

133 1

134 0

135 1.2

136 3.28

137 2

Volt (V)

MODE

PIN NO.

138 3.1

139 2.7

140 3.1

141 3.27

142 2.57

143 1.54

144 0

145 1.6

146 0.06

147 0.6

148 0

149 1.95

150 2

151 1.46

152 1.8

153 0.37

154 1.48

155 3.27

156 1.66

157 1.7

158 0

159 0

160 0

161 0

162 1.43

163 0

164 1.45

165 1.59

166 1.43

167 3.27

168 3.27

169 0.77

170 0

171 2.8

172 2.9

173 1.8

174 3.28

175 0

176 3.28

177 3.26

178 0

179 2.89

180 0

181 0.8

182 3.28

183 0.13

184 3.12

185 0.13

186 3.12

187 0.13

188 0

189 3.27

190 1.23

191 1.23

192 2.28

CIRCUIT VOLTAGE CHART

Page 54

2-65 2-66

1 300V

2 GND

3 20V

4 0 ~ 6.5V

5 0 ~ 5V

1 5.6V

25V

3 GND

4 2.5V

1 13V

2 12V

3 GND

4 3.3V

1 4.5V

2 3.3V

3 GND

4 2.5V

1 12V

2 GND

38V

1 2.5V

2 GND

3 4.8V

1 2.5V

2 GND

3 30V

52 0

53 1.1

54 0

17).IC604(LD1117A)

13.27

2 1.8

30

18).IC605(MM1623)

1 4.9

22.33

3 4.9

4 1.1

50

6 1.5

70

82.37

90

10 1.47

11 0

12 2.33

13 4.9

14 2.33

15 0

16 2.39

17 0

18 2.39

19 0

20 1.88

21 1.76

22 0

23 1.74

24 0

25 0

26 0

27 2.38

28 4.9

19).IC606(EEPROM)

10

20

30

40

5 3.2

6 3.2

70

8 3.2

1 GND

2 1 ~ 5V

3 GND

4 0 ~ 6V

5 GND

6 300V

7 12V

8 0 ~ 6V

46 0

47 0

48 0.45

13.27

2 1.2

33.26

41.07

5 1.4

60.12

71.09

81.33

93.27

10 0.96

11 0.7

12 0

13 0.8

14 3.27

15 2

16 3.2

17 2.8

18 3.1

19 2.8

20 2

21 1.72

22 0.06

23 1

24 1.91

25 1.97

26 1.58

27 3.27

28 0

29 1.6

30 1.5

31 1.5

32 1.5

33 0.03

34 0.03

35 0.04

36 NC

37 1.6

38 1.6

39 2

40 NC

41 0

42 1.2

43 3.26

44 1.2

45 0.9

46 0

47 1.5

48 1.5

49 3.26

50 1.3

51 1.3

248 1.9

249 0

250 1

251 1

252 1.6

253 1.53

254 1.5

255 0.9

256 3.2

1 0.4

2 0.8

3 0.8

43

5 2.8

6 0.7

7 0.9

8 1.7

90

10 0

11 3.2

12 3.9

13 3.27

14 3.27

15 1.5

16 0

17 0.3

18 1.9

19 2.5

20 2.3

21 1.4

22 1.9

23 2.2

24 1.95

25 2

26 0

27 0

28 0

29 1.6

30 1.1

31 1.7

32 1

33 1.1

34 0.11

35 1.1

36 0.16

37 3.27

38 1.5

39 1

40 1.5

41 1.2

42 1.3

43 1.2

44 1.4

45 2.09

Volt (V)

MODE

PIN NO.

IC101

(AUDIO MICOM)

193 0

194 0.48

195 3.28

196 0.69

197 0

198 2.9

199 3.27

200 0.5

201 0

202 0.71

203 0.69

204 3.28

205 2.9

206 4.2

207 2.9

208 1.48

209 1.3

210 1.64

211 1.58

212 3.28

213 1.63

214 1.63

215 1.63

216 0

217 1.21

218 1.15

219 1.2

220 0.07

221 1.82

222 1.2

223 0

224 0

225 1.64

226 0

227 1.82

228 0.67

229 0.84

230 1.4

231 1.41

232 0

233 0

234 3.24

235 1.81

236 1.66

237 1.66

238 1.56

239 3.24

240 1.4

241 0

242 1.7

243 1.1

244 3.24

245 1.59

246 1.37

247 1.3

Volt (V)

MODE

PIN NO.

IC602

(FLASH ROM)

Volt (V)

MODE

PIN NO.

IC603

(SDRAM)

IC604

(LD1117A)

IC605

(MM1623)

IC606

(EEPROM)

IC901

Volt (V)

MODE

PIN NO.

Volt (V)

MODE

PIN NO.

IC902

IC902

IC922

IC923

IC924

IC941

IC942

Page 55

3-1 3-2

SECTION 3. EXPLODED VIEWS

• CABINET AND MAIN FRAME SECTION

NOTE) Refer to “SECTION 5 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

A43

A50

452

A42

274

A49

283

292

452

463

255

463

A26

252

A60

463

A47

463

A40

463

250

NOTES) Warning

NOTES) Parts that are shaded are critical

NOTES) With respect to risk of fire or

NOTES) electricial shock.

463

279

280

A49A

452

261

261

260

463

253

266

261

A44

463

468

264

300

265

267

A46

463

263

468

Page 56

3-3 3-4

• DECK MECHANISM EXPLODED VIEW

003

004

005

006

038

434

013

012

049

008

010

011

014

054

434

052

055

044

017

045

431

435

046

048

061

019

030

020

431

058

431

021

059

024

050

022

023

026

057

434

043

042

434

056

051

027

025

007

001

436

002

435

016

039

040

041

060

434

009

037

034

047

433

438

432

036

437

032

035

033

062

028

029

015

A26

031

018

434

Page 57

Page 58

- 3-5 -

• PACKING ACCESSORY SECTION

811

PLUG ASS'Y 1WAY(YELLOW)

826

FILTER(CIRC)

808

BATTERY

900

REMOCON

SHEET

804

812

PLUG ASS'Y 2WAY

824

ANTENNA LOOP(AM)

825

ANTENNA (FM)

OWNER'S MANUAL

801

PACKING, CASING

803A

PACKING, CASING

803B

803C

PACKING, CASING

PACKING, CASING

803

802

BOX

Page 59

Page 60

- 4-1 -

SECTION 4. SPEAKER PART

1. WOOFER SPEAKER SECTION

• MODEL: LHS-75SGW

950

952

A900

954

953

959

955

951

957

958

Page 61

- 4-2 -

2. SPEAKER CENTER SECTION

• MODEL: LHS-75SGC

A700

755

758

754

750

751

753

756

759

756

Page 62

- 4-3 -

3. SPEAKER REAR/FRONT SECTION

• MODEL: LHS-75SGS

A800

859

855

850

851

853

857

854

856

858

Page 63

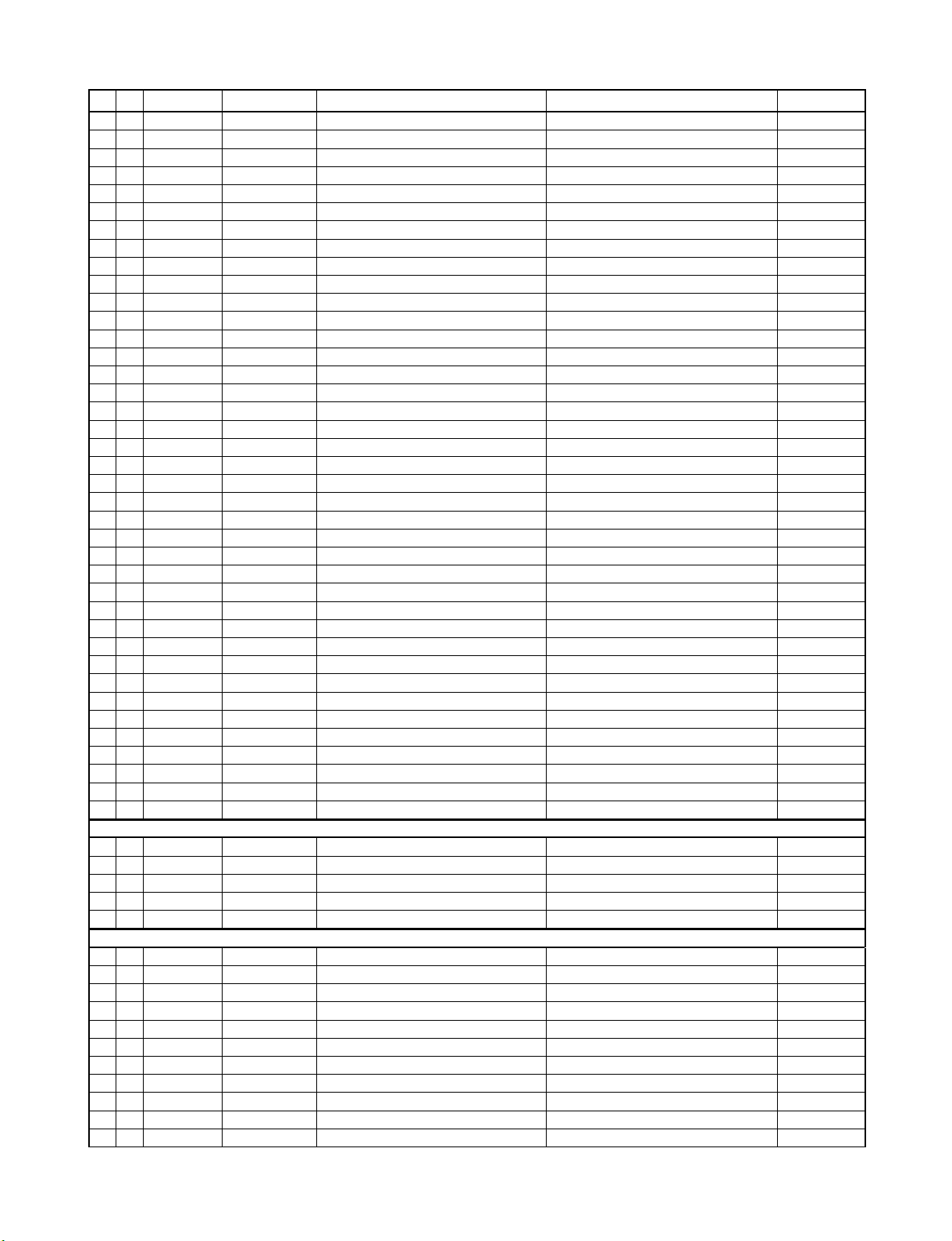

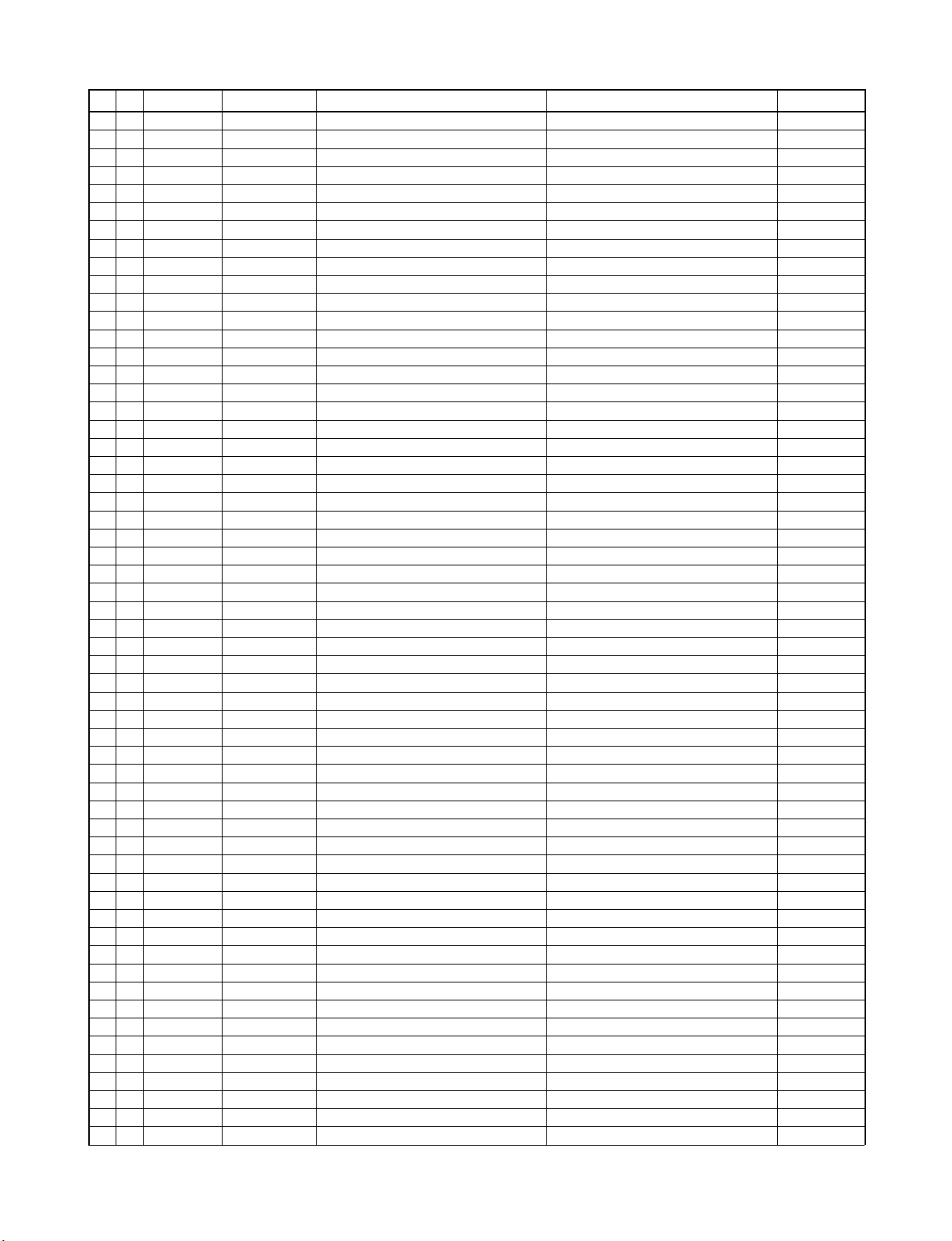

Page 64

NOTES)

If you want to purchase

Flash memory, you must order

" IC602A "

NOTES)

Warning

Parts that are shaded are critical with

respect to risk of fire or electrical

shock.

SECTION REPLACEMENT PARTS LIST

MODEL :5LH-E750SG(LGEUS)

RUN DATE : 18-JANUARY-06

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

*** INDIVIDUAL PARTS ***

250 3090RCT001B CABINET LH-E6740 PRESS TOP NO LG LOGO

279 4940RCV658A KNOB HOME THEATER LH-E6740 MOLD VOL

283 3581R-T172A DOOR ASSEMBLY HOME THEATER LH-E750

300 6410RAHK06A POWER CORD KJ-10W(ST-HS:250MM WITH CORE)

452 1SZZR-0097K SCREW,DRAWING + 2 D3.0 L10.0 MSWR3/FZB 3 CR

452 1SZZR-0097K SCREW,DRAWING + 2 D3.0 L10.0 MSWR3/FZB 3 CR

463 1SZZR-0098G SCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FZMCW-1 3C

463 1SZZR-0098G SCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FZMCW-1 3C

801 3835RH0145A INSTRUCTION ASSEMBLY HOME LH-E750SG NA1ULZA LGEUS E

802 3890RCC203D BOX,MASTER LH-E750SG NA1ULLA DW2 LGEUS

803 3920R-E145A PACKING HOME LH-E750 0.2 AUDIO

804 3880SCS001E BAG EPE 600 500 0.03 AUDIO FOR SET NSP

808 534-008C BATTERY,MANGANESE AAAM(R03) SEOTONG 1-5 V - 1PA

811 6850R-PAA8F CABLE,COAXIAL 1 WAY COAXIAL DT_HY_HIT_SEIL 1

812 6850R-PBA8H CABLE,COAXIAL 2 WAY COAXIAL RED_WHITE DT_HY

824 5010R-L002B ANTENNA,LOOP S0160BL-09 (LS0160BL-X000009-0

825 5010R-T001E ANTENNA,T T13021N-2 KWANGSUNG FM T ANTEN

826 6200JB8010K FILTER(CIRC),EMC ZCAT2132-1130-M-K TDK BK JACKE

900 6710CDAK01B REMOTE CONTROLLER DA1 66KEY OHSUNG LH-E750 ZENIT

CABLE 6850R-GX10Z CABLE,FLAT P=1.0 FFC UL2896(0.05X0.65) 24

CABLE 6850R-GZ10Y CABLE,FLAT P=1.0 FFC UL2896(0.05X0.65) 26 ALTERNATE

803A 3920RME171A PACKING SPK LHS-C640 0 TOP

803B 3920RME171B PACKING SPK LHS-C640 0 MIDDLE

803C 3920RME171C PACKING SPK LHS-C640 0 BOTTOM

*** LHS-75SGC ***

A700 6401RM0158C SPEAKER ASSEMBLY MSF-90SB90L-1 SAMMI LHS-75SGC

WIRE70 6871RU9271N PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75TBC CENTER CI-4M GREEN C

750 3530RMP044B GRILLE LHS-E6740C PRESS BK 0.6T

751 3720RMM015A PANEL,AUDIO SPK LHS-E6740T/C MOLD FRONT

753 6400GSMD01A SPEAKER,FULLRANGE MSF-90SB90L-1 SAMMI FULL-RANGE

754 3110RMP072A CASE LHS-E6740C MOLD REAR

755 6871RU0092A PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75SG STANDARD 2P TERMINAL

756 3040RMP036A BASE LHS-E6740C MOLD BOTTOM STAND

757 3610RM0044A FOOT SPK LHS-T6540T/C OTHER EVA PHI

758 353M025H SCREW,DRAWING TAPTITE, 3X16 FZMY

759 353M025G SCREW,DRAWING TAPTITE, 3X10 FZMY

*** LHS-75SGW ***

A900 6401RM0158D SPEAKER ASSEMBLY 111A11-001 BALHAE LHS-75SGW SV

WIRE90 6871RU9271P PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75TBW WOOFER CI-4M ORANGE

951 3720RMM013B PANEL,AUDIO SPK LHS-C640W MOLD SILK PRINT

952 3701RM0110A NET ASSEMBLY SPK LHS-T6540W NET ASSY

953 6400WBHM01A SPEAKER,WOOFER 178A04A-01 BALHAE WOOFER 4OHM

954 3091RMW107D CABINET ASSEMBLY SPK LHS-75SG CABINET ASSY

955 4766RM0110A FELT 63*115*2T BLACK DUCT EVA

957 3610RM0009A FOOT SPK LHS-25SCW OTHER FOOT BK EV

958 353M025G SCREW,DRAWING TAPTITE, 3X10 FZMY

959 353M050C SCREW,DRAWING BH 3.5X16 FBK

1-5

Page 65

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

*** LHS-75SGS ***

A800 6401RM0158B SPEAKER ASSEMBLY MSF-90SB90L-1 SAMMI LHS-75SGS

WIRE80 6871RU9271L PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75TBS RIGHT CI-4M RED COLO

WIRE81 6871RU9271M PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75TBS LEFT CI-4M WHITE COL

WIRE82 6871RU9271D PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T REAR WIRE(10M) R/CH

WIRE83 6871RU9271E PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T REAR WIRE(10M)/ L/C

850 3530RMP044A GRILLE LHS-E6740T PRESS BK 0.6T

851 3720RMM015A PANEL,AUDIO SPK LHS-E6740T/C MOLD FRONT

853 6400GSMD01A SPEAKER,FULLRANGE MSF-90SB90L-1 SAMMI FULL-RANGE

854 3110RMP073A CASE LHS-E6740T MOLD REAR

855 6871RU0092A PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-75SG STANDARD 2P TERMINAL

856 3040RMP037A BASE LHS-E6740T MOLD BOTTOM STAND

857 3610RM0044A FOOT SPK LHS-T6540T/C OTHER EVA PHI

858 353M025G SCREW,DRAWING TAPTITE, 3X10 FZMY

859 353M025H SCREW,DRAWING TAPTITE, 3X16 FZMY

*** PLATE ASSEMBLY ***

A40 3301RLH650A PLATE ASSEMBLY TH-E650 SHIELD SMPS ASSY

252 3300RLH655A PLATE TH-E650 OTHER PVC(PC) SHIELD S

253 3300RLH650A PLATE TH-E650 PRESS SHIELD SMPS

*** MECHANISM ASSEMBLY ***

A60 4405RLH650A MECHANISM ASSEMBLY TOTAL ASSY PIGEON 5 CHANGER DV

A26 4405RCH500A MECHANISM ASSEMBLY 5 ELEVATOR PIGEON DVD CHANGE

001 3210RZM001A FRAME CMR-0538 DRAWER-L MOLD 66-264-

002 3210RZM002A FRAME CMR-0538 DRAWER-R MOLD 66-264-

003 3390RZ0002A TRAY DECK/MECHA CMR-0538 ASSY-CARRI

004 3390RZ0002B TRAY DECK/MECHA CMR-0538 ASSY-CARRI

005 3390RZ0002C TRAY DECK/MECHA CMR-0538 ASSY-CARRI

006 3390RZ0002D TRAY DECK/MECHA CMR-0538 ASSY-CARRI

007 3390RZ0002E TRAY DECK/MECHA CMR-0538 ASSY-CARRI

008 3210RZM003A FRAME CMR-0538 FRAME-LG MOLD 66-219-

009 4260RZ0001A ARM DECK/MECHA CMR-0538 ARM-SW-A M

010 4260RZ0001B ARM DECK/MECHA CMR-0538 ARM-SW-B M

011 4260RZ0001C ARM DECK/MECHA CMR-0538 ARM-SW-C M

012 4470RZ0005A GEAR DECK/MECHA CMR-0538 GEAR-D1 MO

013 4470RZ0005B GEAR DECK/MECHA CMR-0538 GEAR-D2 MO

014 4260RZ0002A ARM DECK/MECHA CMR-0538 ARM-D-SW M

015 4260RZ0002B ARM DECK/MECHA CMR-0538 ARM-CC-SW

016 4260RZ0002C ARM DECK/MECHA CMR-0538 ARM-P-SW M

017 4260RZ0003A ARM DECK/MECHA CMR-0538 ARM-LOCK M

018 4510RZ0001A LEVER DECK/MECHA CMR-0538 LEVER-GC M

019 4810RZ0003A BRACKET DECK/MECHA CMR-0538 S-BRACKET

020 4470RZ0006A GEAR DECK/MECHA CMR-0538 GEAR-PULLE

021 3550RZ0001A COVER DECK/MECHA CMR-0538 COVER-S PR

022 4861RZ0002A CLAMP ASSEMBLY DECK/MECHA CMR-0538 ASSY-CLAMP

023 4260RZ0004A ARM DECK/MECHA CMR-0538 ARM-CLAMPE

024 3210RZM004A FRAME CMR-0538 LIFT-SLIDER-L MOLD 66

025 3210RZM004B FRAME CMR-0538 LIFT-SLIDER-R MOLD 66

026 4510RZ0002A LEVER DECK/MECHA CMR-0538 PP-SLIDER

027 3210RZM005A FRAME CMR-0538 FL-BASE MOLD 66-211-2

028 3210RZM006A FRAME CMR-0538 UD-BASE CMS-S71 MOLD

029 3210RZM007A FRAME CMR-0538 UD-SLIDER MOLD 66-239

030 3140RZM001A CHASSIS CMR-0538 CHASSIS MOLD 66-210-1

031 6768RZVP01A DECK MECHANISM PARTS CMR-0538 ASSY- SOLENOID 66-093

032 4681RZ0001A MOTOR ASSEMBLY DECK/MECHA CMR-0538 ASSY-MOTOR

033 4260RZ0005A ARM DECK/MECHA CMR-0538 ARM-LIFT M

034 4470RZ0007A GEAR DECK/MECHA CMR-0538 GEAR-E MOL

035 4470RZ0008A GEAR DECK/MECHA CMR-0538 GEAR-F MOL

2-5

Page 66

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

036 4350RZ0001A RING DECK/MECHA CMR-0538 GEAR-E-COL

037 6871RZ0022A PWB(PCB) ASSEMBLY,OTHERS CMR-0538 ASSY PCB 66-093-4195H

038 6871RZ0023A PWB(PCB) ASSEMBLY,OTHERS CMR-0538 ASSY-PCB-SW 66-093-40

039 4470RZ0009A GEAR DECK/MECHA CMR-0538 GEAR-B MOL

040 3300RZM001A PLATE CMR-0538 PLATE-CAM MOLD 66-219

041 4470RZ0010A GEAR DECK/MECHA CMR-0538 GEAR-CAM M

042 4510RZ0003A LEVER DECK/MECHA CMR-0538 LEVER-CL-1

043 4510RZ0004A LEVER DECK/MECHA CMR-0538 LEVER-CL-2

044 4470RZ0011A GEAR DECK/MECHA CMR-0538 GEAR-1 MOL

045 4470RZ0012A GEAR DECK/MECHA CMR-0538 GEAR-2 MOL

046 4766RZ0001A FELT CMR-0538 BLACK CIRCULAR-FELT 6

047 4970RZ0001A SPRING COIL CMR-0538 GEAR-E-SPRING 01

048 4970RZ0002A SPRING COIL CMR-0538 GEAR-1-SPRING 01

049 4970RZ0003A SPRING COIL CMR-0538 GEAR-D-SPRING 01

050 4620RZ0001A STOPPER DECK/MECHA CMR-0538 STOP-SPR-L

051 4620RZ0002A STOPPER DECK/MECHA CMR-0538 STOP-SPR-R

052 4970RZ0004A SPRING COIL CMR-0538 SPRING 01-082-46

053 4970RZ0005A SPRING COIL CMR-0538 SPRING-SW-A 01-0

054 4970RZ0006A SPRING COIL CMR-0538 SPRING-B 01-082-

055 4970RZ0007A SPRING COIL CMR-0538 SPRING-C 01-082-

056 4970RZ0008A SPRING COIL CMR-0538 LEVER-CL-1SP 01-

057 4970RZ0009A SPRING COIL CMR-0538 SPRING-2 01-082-

058 4970RZ0010A SPRING COIL CMR-0538 SPRING-SL-B 01-0

059 4970RZ0011A SPRING COIL CMR-0538 SPRING-SR-B 01-0

060 4970RZ0012A SPRING COIL CMR-0538 SPRING-GEAR-B 01

061 1WZZRZ0001A WASHER,DRAWING DECK/MECHA CMR-0538 WASHER MOL

062 4400RZ0002A BELT DECK/MECHA CMR-0538 BELT OTHER

431 6768RZCP01A DECK MECHANISM PARTS CMR-0538 COVER SCREW GSL20A260

432 6768RZCP02A DECK MECHANISM PARTS CRM-0538 MOTOR SCREW GSP14A250

433 6768RZCP03A DECK MECHANISM PARTS CMR-0538 PCB SCREW GSL15A2616

434 6768RZCP04A DECK MECHANISM PARTS CMR-0538 L SCREW GSL15A2608

435 6768RZCP05A DECK MECHANISM PARTS CMR-0538 PLATE SCREW 03-300-45

436 6768RZCP06A DECK MECHANISM PARTS CMR-0538 DRAWER SCREW 03-300-4

437 6768RZCP07A DECK MECHANISM PARTS CMR-0538 GEAR-E SCREW 03-300-4

438 6768RZCP08A DECK MECHANISM PARTS CMR-0538 SOL-SIDE SCREW 03-300

255 4930RC0185A HOLDER HOME LH-E750 PRESS MD HOLDER

463 1SZZR-0098G SCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FZMCW-1 3C

CABLE 6850R-JW29Z CABLE,FLAT P=1.0 FFC UL2896(0.035X0.7) 23

CABLE 6850R-HQ24Y CABLE,FLAT P=1.25 FFC UL2896(0.05X0.8) 17 ALTERNATE

*** CHASSIS ASSEMBLY ***

A44 3141R-H028D CHASSIS ASSEMBLY LH-E750 CHASSIS ASSY ZENITH

260 3140RCT001A CHASSIS LH-E6740 PRESS MAIN

261 5040R-5040A RUBBER HOME LH-D6549 OTHER FOOT D19

266 4930RL0650A HOLDER HOME TH-E650 MOLD PCB (SMPS+CA

463 1SZZR-0098G SCREW,DRAWING + 2 D3.0 L8.0 MSWR3/FZMCW-1 3C

*** SUB PWB(PCB) ASSEMBLY ***

A46 6885R-7071C SUB PWB(PCB) ASSEMBLY 55 53 00 65 82 05 EC B2 LH-E75

263 4930RC0119A HOLDER HOME LH-T6742 MOLD HEAT SINK M

264 5900R-D006C FAN,DC FD124010LB 2N3 YS TECH 40X40X1

265 5040R-0093A RUBBER VCR LH-CA5335AM OTHER IC

267 4920R-E010B HEAT SINK AL EX 124 X 39 X 42 LH-E750 PI

468 353-025H SCREW,DRAWING TAPTITE 3X16 FZMY

C706 0CE337EK638 CAPACITOR,FIXED ELECTROLYTIC 330UF KMG 50V 20% FM5 TP 5

C726 0CE337EK638 CAPACITOR,FIXED ELECTROLYTIC 330UF KMG 50V 20% FM5 TP 5

C746 0CE337EK638 CAPACITOR,FIXED ELECTROLYTIC 330UF KMG 50V 20% FM5 TP 5

C760 0CE337EK638 CAPACITOR,FIXED ELECTROLYTIC 330UF KMG 50V 20% FM5 TP 5

C901 0CE228EK650 CAPACITOR,FIXED ELECTROLYTIC 2200UF KMG 50V 20% FM7.5 BULK

3-5

Page 67

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

JK501 6612J00050D JACK,RCA RCA-910A-03-01 YUQIU LH-E6740

JK502 6612BBBHN5A JACK,DIN SCN556S4GTTB000 S-VIDEO HYUSUN

JK503 6612K00010B JACK,FIBER OPTIC JSR1164-B SOLTEAM

JK701 664000009AA TERMINAL BLOCK PTB-1201C-02 yuqiu 6P AC450V 1

L702 6140RCC007D COIL,RF 15UH 2 DRUM COIL -DVD RCV

L703 6140RCC007D COIL,RF 15UH 2 DRUM COIL -DVD RCV

L705 6140RCC007D COIL,RF 15UH 2 DRUM COIL -DVD RCV

L706 6140RCC007D COIL,RF 15UH 2 DRUM COIL -DVD RCV

L708 6140RCC007D COIL,RF 15UH 2 DRUM COIL -DVD RCV

L710 6140RCC007G COIL,RF 2 DRUM CHOKE COIL 22 UH , 7 A

L711 6140RCC007G COIL,RF 2 DRUM CHOKE COIL 22 UH , 7 A

L712 6140RCC007G COIL,RF 2 DRUM CHOKE COIL 22 UH , 7 A

L901 6140RCC002A COIL,CHOKE 20UH/6A BAR CORE 20UH KWANGS

PN101 561-711E CONNECTOR (CIRC),WAFER GIL-S-05P-S2T2-EF LG CABLE 5PI

PN105 561-661B CONNECTOR (CIRC),HOUSING 5267-02A MOLEX 2PIN 2-54MM STR

PN901 561-715J CONNECTOR (CIRC),WAFER GIL-G-10P-S3T2-E LG CABLE 10PI

PN902 561-715N CONNECTOR (CIRC),WAFER GIL-G-14P-S3T2-E LG CABLE 13PI

TUN101 6700FM0131A TUNER KST-ML000MV0-65S KWANG SUNG FM

X301 6204R-HK01C OSCILLATOR KXO-210 BUBANG AXIAL 12.288MHZ

C106 0CE2276F618 CAPACITOR,FIXED ELECTROLYTIC 220UF SMS,SG 16V 20% FL TP 5

C110 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C111 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C113 0CE3356K618 CAPACITOR,FIXED ELECTROLYTIC 3.3UF SMS,SG 50V 20% FL TP 5

C114 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C116 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C117 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C118 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C119 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C121 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C201 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C205 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C206 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C213 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C223 0CE2274C638 CAPACITOR,FIXED ELECTROLYTIC 220UF SRA,SS 6.3V 20% FM5 TP 5

C225 0CE2274C638 CAPACITOR,FIXED ELECTROLYTIC 220UF SRA,SS 6.3V 20% FM5 TP 5

C227 0CE2274C638 CAPACITOR,FIXED ELECTROLYTIC 220UF SRA,SS 6.3V 20% FM5 TP 5

C229 0CE2274C638 CAPACITOR,FIXED ELECTROLYTIC 220UF SRA,SS 6.3V 20% FM5 TP 5

C301 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C302 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C303 0CE2276F618 CAPACITOR,FIXED ELECTROLYTIC 220UF SMS,SG 16V 20% FL TP 5

C306 0CE2276F618 CAPACITOR,FIXED ELECTROLYTIC 220UF SMS,SG 16V 20% FL TP 5

C331 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C335 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C337 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C339 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C342 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C343 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C347 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C349 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C352 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C354 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C356 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C357 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C366 0CE4756K618 CAPACITOR,FIXED ELECTROLYTIC 4.7UF SMS,SG 50V 20% FL TP 5

C368 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C371 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C377 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

4-5

Page 68

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

C383 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C387 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C389 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C392 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C394 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C397 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C505 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C506 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C507 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C508 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C519 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C520 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C521 0CE1066F618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 16V 20% FL TP 5

C523 0CE1076D618 CAPACITOR,FIXED ELECTROLYTIC 100UF SMS,SG 10V 20% FL TP 5

C524 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C530 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C531 0CE4766F618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 16V 20% FL TP 5

C532 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C533 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C538 0CE1066J618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 35V 20% FL TP 5

C539 0CE1066J618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 35V 20% FL TP 5

C540 0CE1066J618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 35V 20% FL TP 5

C541 0CE1066J618 CAPACITOR,FIXED ELECTROLYTIC 10UF SMS,SG 35V 20% FL TP 5

C551 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C552 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C553 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C554 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C555 0CE4776D618 CAPACITOR,FIXED ELECTROLYTIC 470UF SMS,SG 10V 20% FL TP 5

C616 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6A1 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6A3 0CE2276F618 CAPACITOR,FIXED ELECTROLYTIC 220UF SMS,SG 16V 20% FL TP 5

C6A5 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C6A7 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C6A8 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C6B0 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C6B1 0CE1054K638 CAPACITOR,FIXED ELECTROLYTIC 1UF SRA,SS 50V 20% FM5 TP 5

C6B9 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C1 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C2 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C3 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C4 0CE1064F638 CAPACITOR,FIXED ELECTROLYTIC 10UF SRA,SS 16V 20% FM5 TP 5

C6C5 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C6 0CE4764F638 CAPACITOR,FIXED ELECTROLYTIC 47UF SRA,SS 16V 20% FM5 TP 5

C6C7 0CE1074F638 CAPACITOR,FIXED ELECTROLYTIC 100UF SRA,SS 16V 20% FM5 TP 5

C6C9 0CE2274C638 CAPACITOR,FIXED ELECTROLYTIC 220UF SRA,SS 6.3V 20% FM5 TP 5

C719 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C720 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C735 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C740 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C754 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C769 0CQ4742L439 CAPACITOR,FIXED FILM 0.47UF S 63V 5% M/PE NI TP5

C903 0CK1040K945 CAPACITOR,FIXED CERAMIC(HIGH D 0.1UF D 50V 80%,-20% F(Y5V) TR

C904 0CE4766K618 CAPACITOR,FIXED ELECTROLYTIC 47UF SMS,SG 50V 20% FL TP 5

C906 0CE107CK638 CAPACITOR,FIXED ELECTROLYTIC 100UF SHL,SD 50V 20% FM5 TP 5

C908 0CE476CD638 CAPACITOR,FIXED ELECTROLYTIC 47UF SHL,SD 10V 20% TP 5 FM5

C910 0CE2256K618 CAPACITOR,FIXED ELECTROLYTIC 2.2UF SMS,SG 50V 20% FL TP 5

D101 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

5-5

Page 69

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

D102 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D103 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D104 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D105 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D106 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D107 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D201 0DD133009AA DIODE,SWITCHING 1SS133 TP ROHM KOREA - - - - -

D203 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D301 0DR104009AB DIODE,RECTIFIERS RL104 R. TP GULF SEMICONDUCTOR

D901 0DD133009AA DIODE,SWITCHING 1SS133 TP ROHM KOREA - - - - -

IC103 0IKE704200B IC,KEC KIA7042P 3P 4.2V RESET(TAPING)

L201 0LR0102J025 INDUCTOR,RADIAL LEAD 10UH 5% TP 4 X 5 TR5 -

L203 0LR0102J025 INDUCTOR,RADIAL LEAD 10UH 5% TP 4 X 5 TR5 -

Q101 0TR103009AE TRANSISTOR,BIPOLARS KRC103M(KRC1203) KEC TP TO92M

Q102 0TR103009AE TRANSISTOR,BIPOLARS KRC103M(KRC1203) KEC TP TO92M

Q103 0TR126709AB TRANSISTOR,BIPOLARS KTA1267-Y KEC TP TO92M -50V -1

Q104 0TR103009AF TRANSISTOR,BIPOLARS KRA103M(KRA2203) KEC TP TO92M

Q206 0TR320509AB TRANSISTOR,BIPOLARS KTC3205-TP-Y (KTC2236A)KEC

Q207 0TR319809AC TRANSISTOR,BIPOLARS KTC3198 TP KEC - - -BL (KTC181

Q501 0TR103009AF TRANSISTOR,BIPOLARS KRA103M(KRA2203) KEC TP TO92M

Q502 0TR130209AA TRANSISTOR,BIPOLARS KTD1302 MUTING TP KEC TO92 -

Q505 0TR130209AA TRANSISTOR,BIPOLARS KTD1302 MUTING TP KEC TO92 -

Q506 0TR130209AA TRANSISTOR,BIPOLARS KTD1302 MUTING TP KEC TO92 -

Q507 0TR126709AB TRANSISTOR,BIPOLARS KTA1267-Y KEC TP TO92M -50V -1

Q508 0TR126709AB TRANSISTOR,BIPOLARS KTA1267-Y KEC TP TO92M -50V -1

Q901 0TR128109AA TRANSISTOR,BIPOLARS KTA1281Y TP KEC TO-92L -

Q902 0TR320509AB TRANSISTOR,BIPOLARS KTC3205-TP-Y (KTC2236A)KEC

Q903 0TR320509AB TRANSISTOR,BIPOLARS KTC3205-TP-Y (KTC2236A)KEC

Q904 0TR319809AC TRANSISTOR,BIPOLARS KTC3198 TP KEC - - -BL (KTC181

Q905 0TR103009AF TRANSISTOR,BIPOLARS KRA103M(KRA2203) KEC TP TO92M

SW101 556-219B SWITCH,TACT THV10910G TACT DC 12 V 5-0 A V

X101 6212AA2125K RESONATOR,CRYSTAL HC-49S KONY 12.5MHZ +/- 30 PPM

ZD101 0DZ910009BE DIODE,ZENERS UZ-9.1BSC 26MM PYUNG CHANG TP

ZD901 0DZ272609BA DIODE,ZENERS UZ-27BSD 26MM TP PYUNG CHANG

ZD902 0DZ910009BE DIODE,ZENERS UZ-9.1BSC 26MM PYUNG CHANG TP

ZD903 0DZ512609BA DIODE,ZENERS UZ-5.1B TP PYUNG CHANG DO34 0.

C101 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C103 0CH1682K562 CAPACITOR,FIXED CERAMIC(TEMP.C 6800PF 50V 10% X7R(X) 1608 R/T

C104 0CH1682K562 CAPACITOR,FIXED CERAMIC(TEMP.C 6800PF 50V 10% X7R(X) 1608 R/T

C107 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C108 0CH4220K412 CAPACITOR,FIXED CERAMIC(HIGH D 22PF 50V 5% NP0 1608 R/TP

C109 0CH4220K412 CAPACITOR,FIXED CERAMIC(HIGH D 22PF 50V 5% NP0 1608 R/TP

C112 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C115 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C120 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C122 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C202 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C203 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C204 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C208 0CH1222K562 CAPACITOR,FIXED CERAMIC(TEMP.C 2200PF 50V 10% X7R(X) 1608 R/T

C210 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C211 0CH1821K562 CAPACITOR,FIXED CERAMIC(TEMP.C 820PF 1608 50V 10% X7R R/TP

C212 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C215 0CH1222K562 CAPACITOR,FIXED CERAMIC(TEMP.C 2200PF 50V 10% X7R(X) 1608 R/T

C216 0CH1102K562 CAPACITOR,FIXED CERAMIC(TEMP.C 1000PF 50V 10% X7R(X) 1608 R/T

C221 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C222 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

6-5

Page 70

SALLOCA. NO. PART NO. DESCRIPTION SPECIFICATION REMARKS

C226 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C228 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C230 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C307 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C308 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C309 0CH1102K562 CAPACITOR,FIXED CERAMIC(TEMP.C 1000PF 50V 10% X7R(X) 1608 R/T

C310 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C311 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C312 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C313 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C314 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C315 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C316 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C317 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C318 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C319 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C320 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C321 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C322 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C323 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C324 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C325 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C326 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C327 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C328 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C329 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C330 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C332 0CH1473K562 CAPACITOR,FIXED CERAMIC(TEMP.C 47000PF 50V 10% X7R(X) 1608 R/

C333 0CH1102K562 CAPACITOR,FIXED CERAMIC(TEMP.C 1000PF 50V 10% X7R(X) 1608 R/T

C334 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C336 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C338 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C340 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C341 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C344 0CH4471K412 CAPACITOR,FIXED CERAMIC(HIGH D 470PF 50V 5% NP0 1608 R/TP

C345 0CH4471K412 CAPACITOR,FIXED CERAMIC(HIGH D 470PF 50V 5% NP0 1608 R/TP

C346 0CH1272K512 CAPACITOR,FIXED CERAMIC(TEMP.C 2700PF 50V 10% B(5YP) 1608 R/T

C348 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C350 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C351 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C353 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C355 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C363 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C365 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C367 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C372 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C373 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C374 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C375 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C376 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C378 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C379 0CH1104K942 CAPACITOR,FIXED CERAMIC(TEMP.C 0.1UF 50V 80%,-20% Y5V(F) 1608

C380 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T

C381 0CH1103K562 CAPACITOR,FIXED CERAMIC(TEMP.C 0.01UF 50V 10% X7R(X) 1608 R/T