Page 1

1-1

CONTENTS

SECTION 1 . . . . SUMMARY

SECTION 2 . . . . EXPLODED VIEWS

SECTION 3 . . . ELECTRICAL

SECTION 4 . . . REPLACEMENT PARTS LIST

Page 2

1-2

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS .................................. 1-3

SAFETY CHECK AFTER SERVICING ............................................................................................ 1-4

SPECIFICATIONS ............................................................................................................................ 1-5

Page 3

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

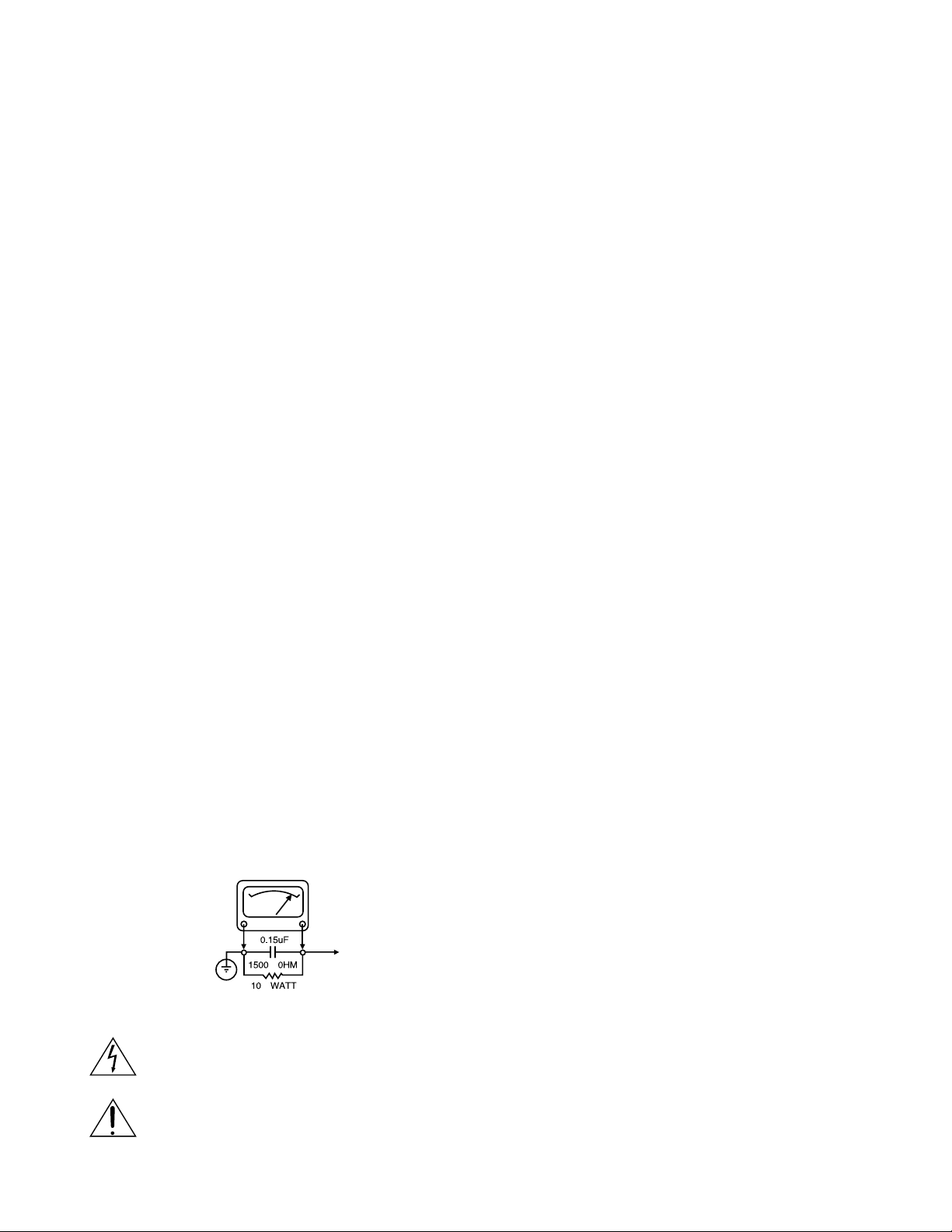

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 4

1-4

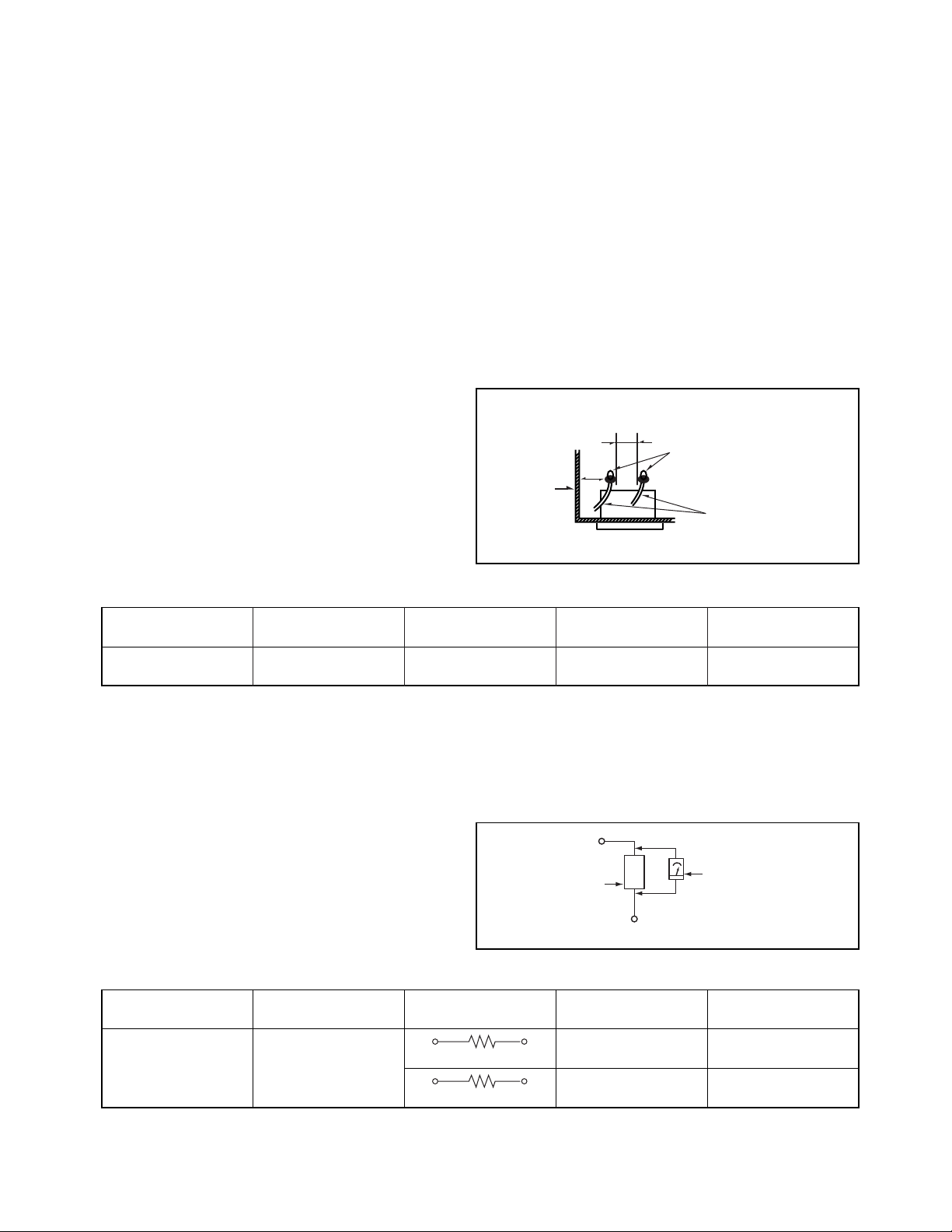

Fig. 3

SAFETY CHECK AFTER SERVICING

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

• Insulation resistance test

confirm the specified insulation resistance or greater between power cord plug prongs and externally exposed

parts of the set (RF terminals, antenna terminals, video and audio input and output terminals, incrophone jacks,

earphone jacks, etc.) See table below.

• Dielectric strength test

Confirm specified dielectric strength or greater between power cord prongs and exposed accessible parts of

the set (RF terminals, antenna terminals, video and

audio input and output terminals, incrophone jacks,

earphone jacks, etc.) See table below.

• Clearance distance

When replacing primary circuit components, confirm

specified clearance distance (d), (d') between soldered terminals, and between terminals and surrounding metallic parts. See table below.

Table 1 : Ratings for selected areas

* Class II model only.

Note. This table is unofficial and for reference only. Be sure to confirm the precise values for your particular

country and locality.

• Leakage Current test

Confirm specified or lower leakage current between B(earth ground, power cord plug prongs) and externally

exposed accessible parts (RF terminals, antenna terminals, video and audio input and output terminals, microphone jacks, earphone jacks, etc.)

Measuring Method: (Power ON)

Insert load Z between B(earth ground, power cord

plug prongs) and exposed accessible parts. Use an

AC voltmeter to measure across both terminals of

load Z. See figure and following table.

Table 2:Leakage current ratings for selected areas.

Note. This table is for IEC member only. Be sure to confirm the precise values for your particular country and

Note. locality.

Fig. 2

AC Line Voltage

AC Line Voltage

100 to 130 V

200 to 240 V

*100 to 130 V

*200 to 240 V

Europe

Australia

Europe

Australia

Other terminals

Antenna earth

terminals

i

E 0.7m A peak

i E 2m A DC

i E 0.7m A peak

i E 2m A DC

F 10 MΩ/500 V DC

4kV 1 minute

F 6mm(d)

F 8mm(d)

(a Power cord)

Region

Load Z Leakage Current(i)

Earth Ground

(B) to :

Region

Insulation

Resistance

Dielectric

Strength

Clearance

Distance(d),(d)

2k

Ω

50k

Ω

d

Primary circuit terminals

Chassis

a

Exposed

accessible

part

Load

Z

Earth Ground,

Power cord plug prongs

B

AC Voltmeter

Page 5

1-5

SPECIFICATIONS

General

ITEM SPECIFICATIONS

DISC FORMAT DVD Disc: DVD VIDEO Specification Book.

CD-DA Disc: RED Book.

CD-R/RW Disc

VIDEO SYSTEM PAL, NTSC

DATA MULTIPLEXING MPEG-2(ISO/IEC 13818-1)

VIDEO DECODING Standards MPEG-1, MPEG-2

AUDIO COMPRESSION Dolby Digital: ATSC Standard for ATV

MPEG-1, MPEG-2

AUDIO DIGITAL I/F S/P DIF(IEC-1937/958)

REGULATIONS Safety:CSA UL

Laser: FDA CFR21

EMC: CSA FCC

Regional code Refer to DVD VIDEO Specification Book.

RATING

ITEM SPECIFICATIONS

POWER REQUIREMENT DC Adaptor 9.8V, Battery 8.0V

POWER CONSUMPTION 10W With Battery

OPERATING TEMPERATURE RANGE 0°C ~ 40°C

STORAGE TEMPERATURE RAGE -20°C ~ 60°C

STANDARD CONDITION 25°C, 65%RH

ACCESSORIES

ITEM SPECIFICATIONS NOTE

RCA A/V CABLE Cable Length 1.5m

S-CABLE Cable Length 1.5m optional

ADAPTOR UNIT DC 9.8V Cable Total Length 1.1m

(Include Adaptor)

POWER CABLE Cable Lenth 1.4m

BATTERY PACK Li-ion, Rechargable, 5600mAh

REMOTE CONTROL UNIT

BATTERY FOR REMOTE Lithium * 1EA

OWNERS MANUAL

Page 6

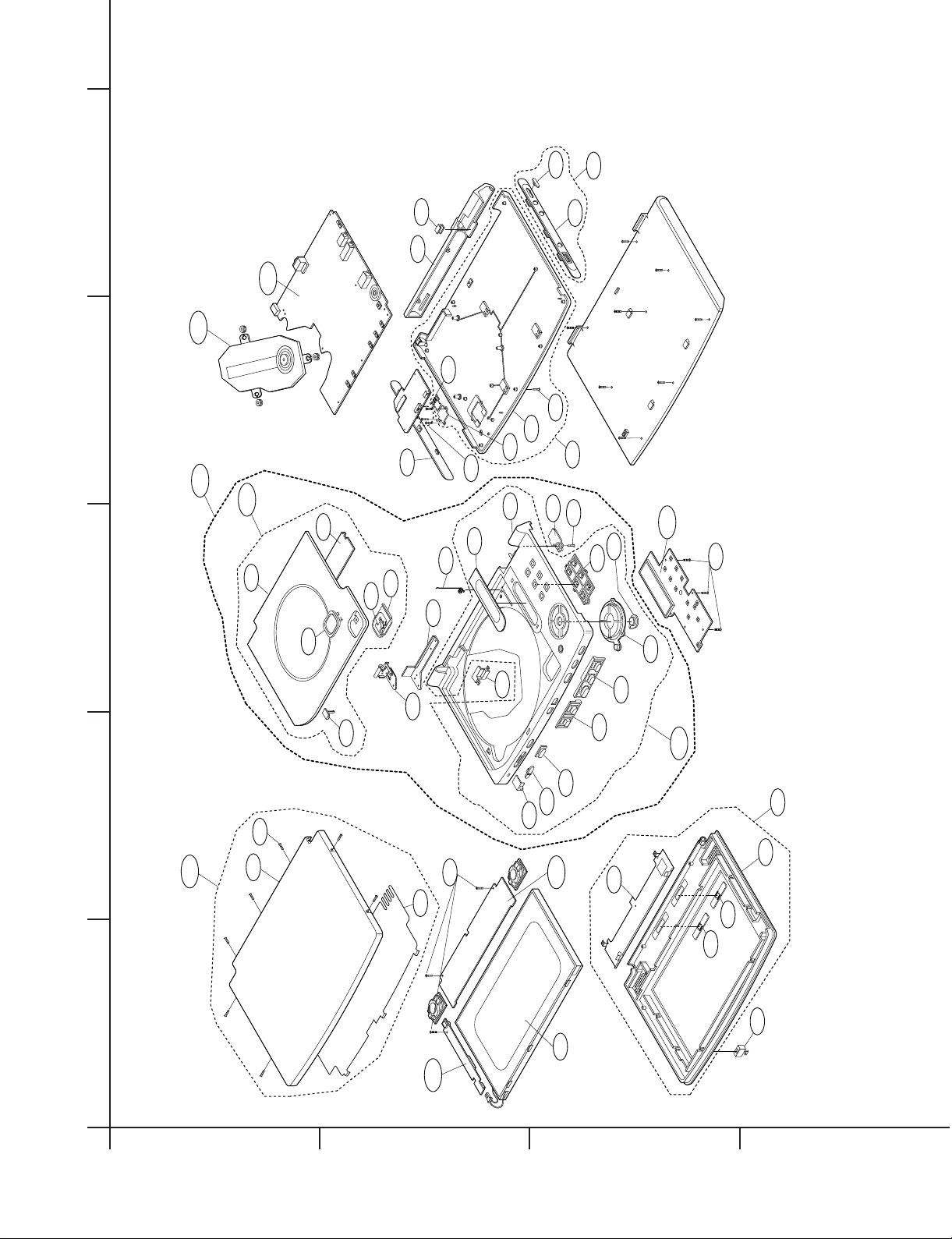

2-1

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

Cabinet and Main Frame Section ..............................................................................................2-2

Deck Mechanism Section ...........................................................................................................2-3

Packing Accessory Section .......................................................................................................2-4

Page 7

2-2

EXPLODED VIEWS

• Cabinet and Main Frame Section

270

A46

451

271

451

290

268

260

261

262

264

269

267

266

263

251

250

278

451

279

254

255

252

253

257

258

256

272

A49

276

273

274

275

452

286

452

280

A47

282

265

284

283

287

281

285

A48

451

A43A

A44B

A44A

A43

A43B

A49A

A00

A41

A

5

4

3

2

1

BCD

Page 8

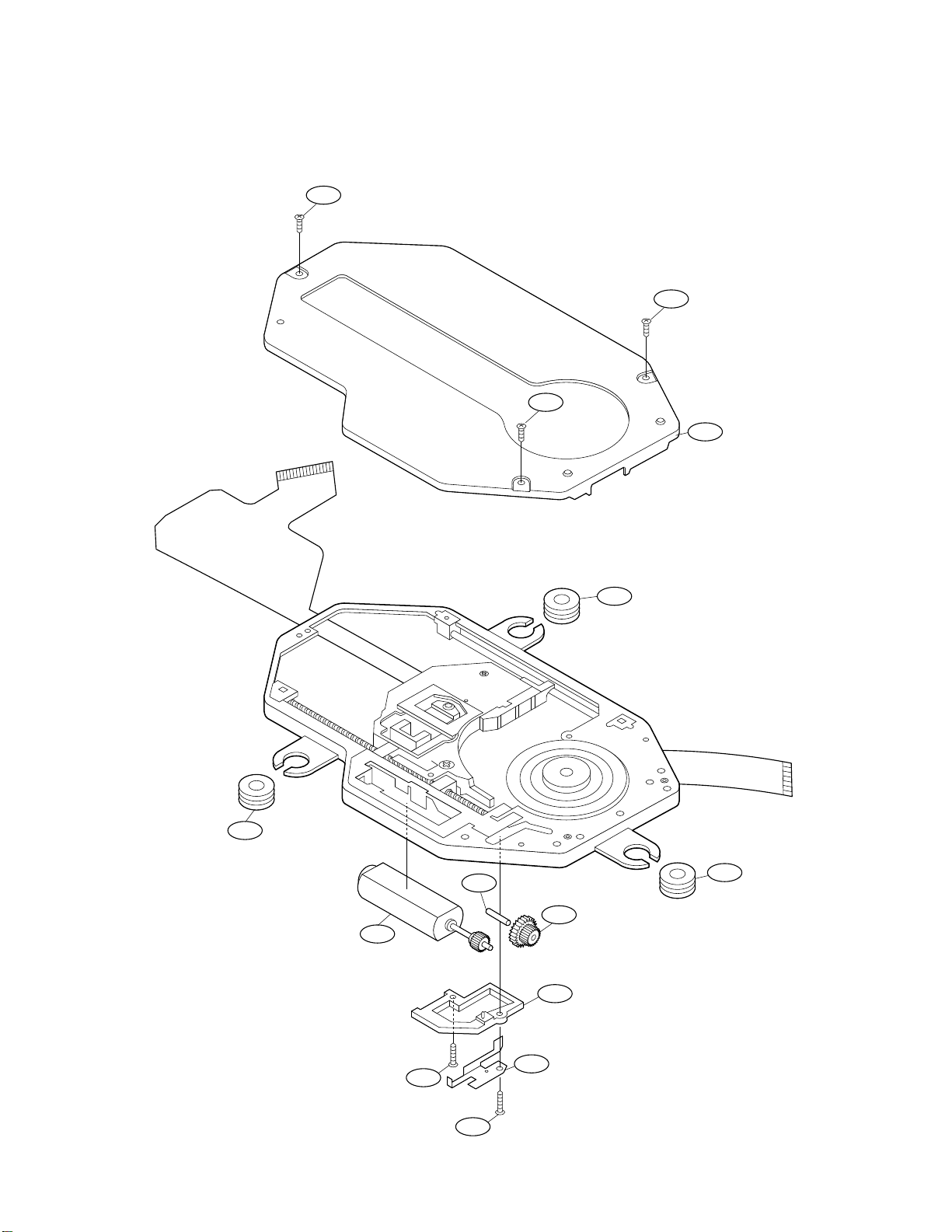

2-3

• Deck Mechanism Section

430

430

001

430

002

002

006

005

004

003

002

431

431

007

Page 9

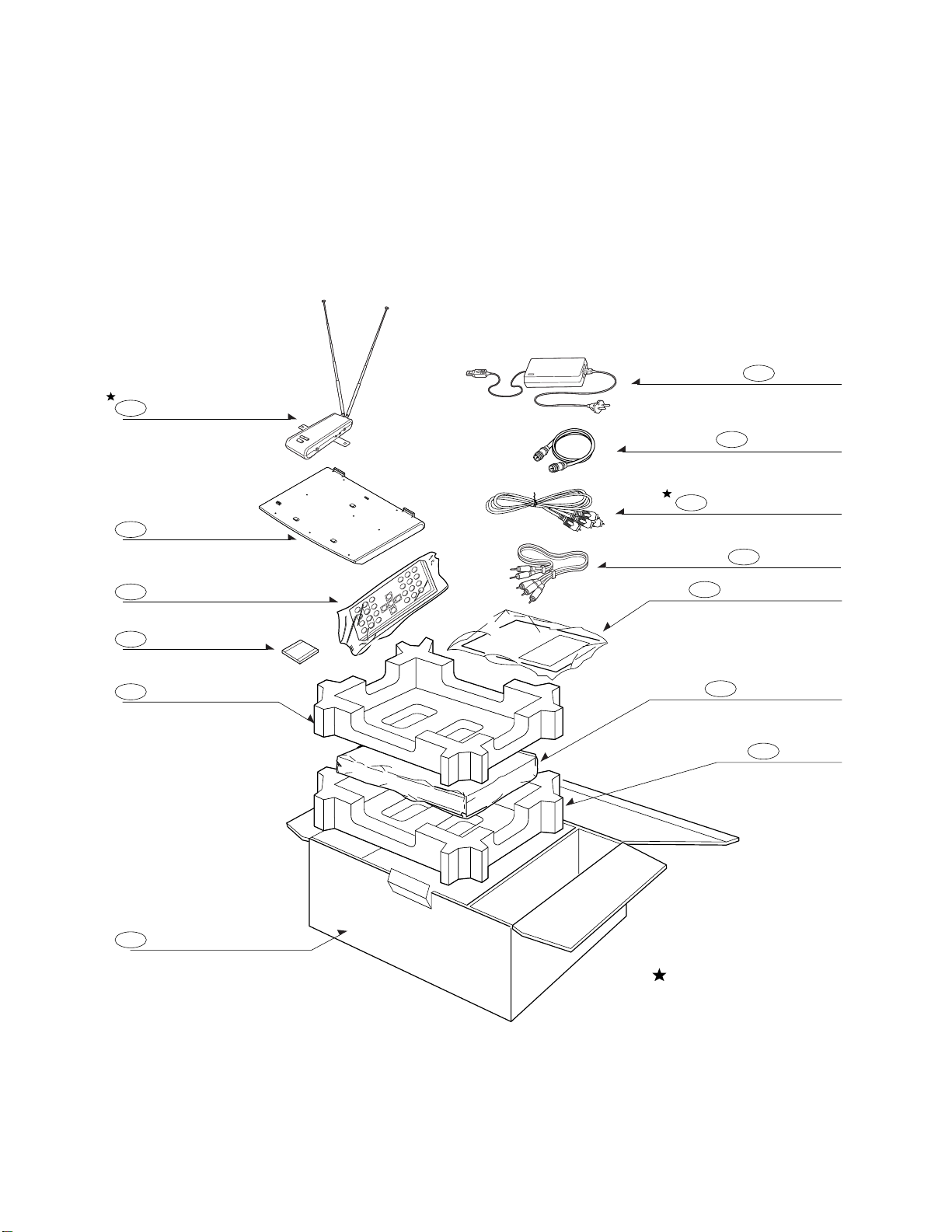

2-4

• Packing Accessory Section

PACKING SHEET

804

PACKING

OPTIONAL PARTS

803

OWNER'S MANUAL

801

REMOCON

900

R/C BATTERY

808

BOX CARTONX

802

PACKING

803

812

830

PLUG ASS'Y 2WAY

ADAPTER

814

PLUG ASS'Y

813

S-VHS CABLE

BATTERY

TUNER

809

820

Page 10

3-1

SECTION 3

ELECTRICAL

CONTENTS

LCD PART ................................................................................................................3-2

ELECTRICAL TROUBLE SHOOTING GUIDE ......................................................3-17

BLCOK DIAGRAMS ..............................................................................................3-26

CIRCUIT DIAGRAM ................................................................................................3-32

PRINTED CIRCUIT DIAGRAMS ............................................................................3-62

Page 11

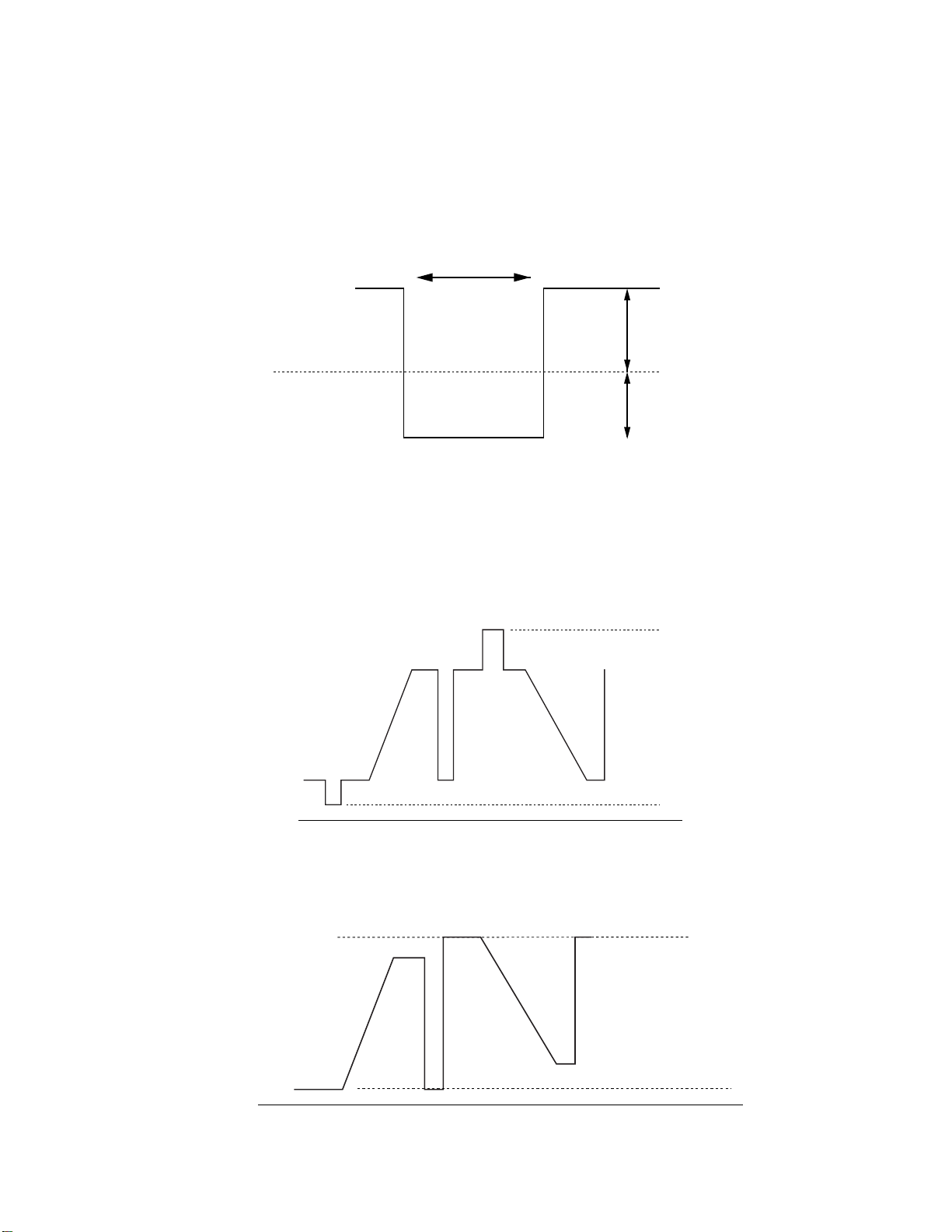

3-2

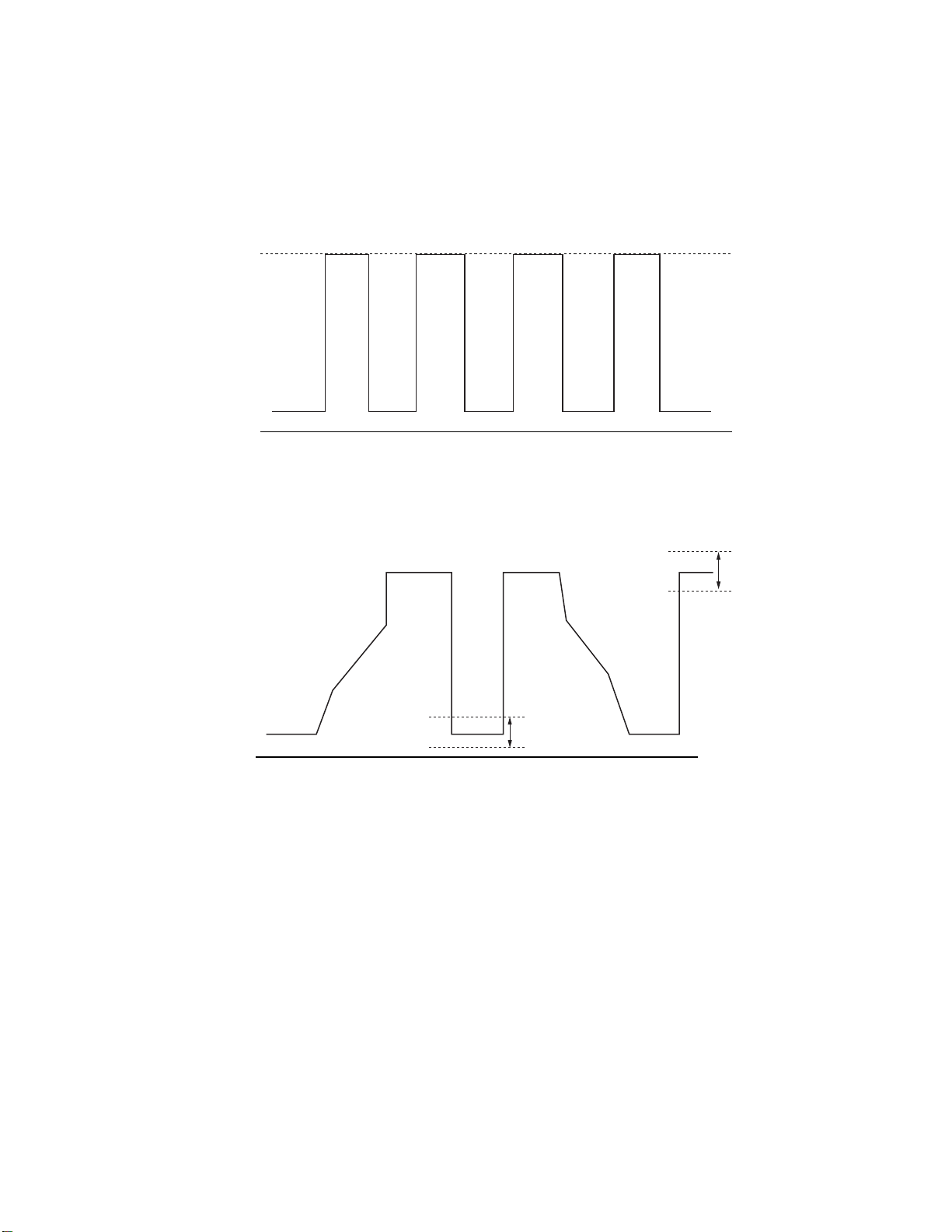

How to adjust LCD COLOR

1) Connect CON 803, power apply, and then check DC power(DC 9.8V).

(CE8G1: -15V, CE8F9: +17V, CE8F8: +7.5V, CE8F6: +5V, CE8F7: +3.3V)

2) VCO adjusting; Sync. adjusting

* VR801 adjust 6.5Vp-p while viewing TP(VCOM)’s waveform, and VR815 adjust with 63.5us(center in display).

3) RGB-AMP adjusting; Black Level adjusting --- Fixed

Input RAMP (or 5STEP) signal, TP(G) waveform adjust while viewing.

(Adjust between 0.5V ~ 4.5V)

4) BRIGHT adjusting; adjusts Brightness(Black Level variable)(VR808: 2V±0.1)

* Input RAMP signal, adjust black LEVEL while viewing TP(G) waveform.

6.5Vp-p

GND

4V

2.5V

4.5V

0.5V

GND

White

Black

4.5V

0.5V

GND

White

White

Black

Black

63.5uS

LCD PART

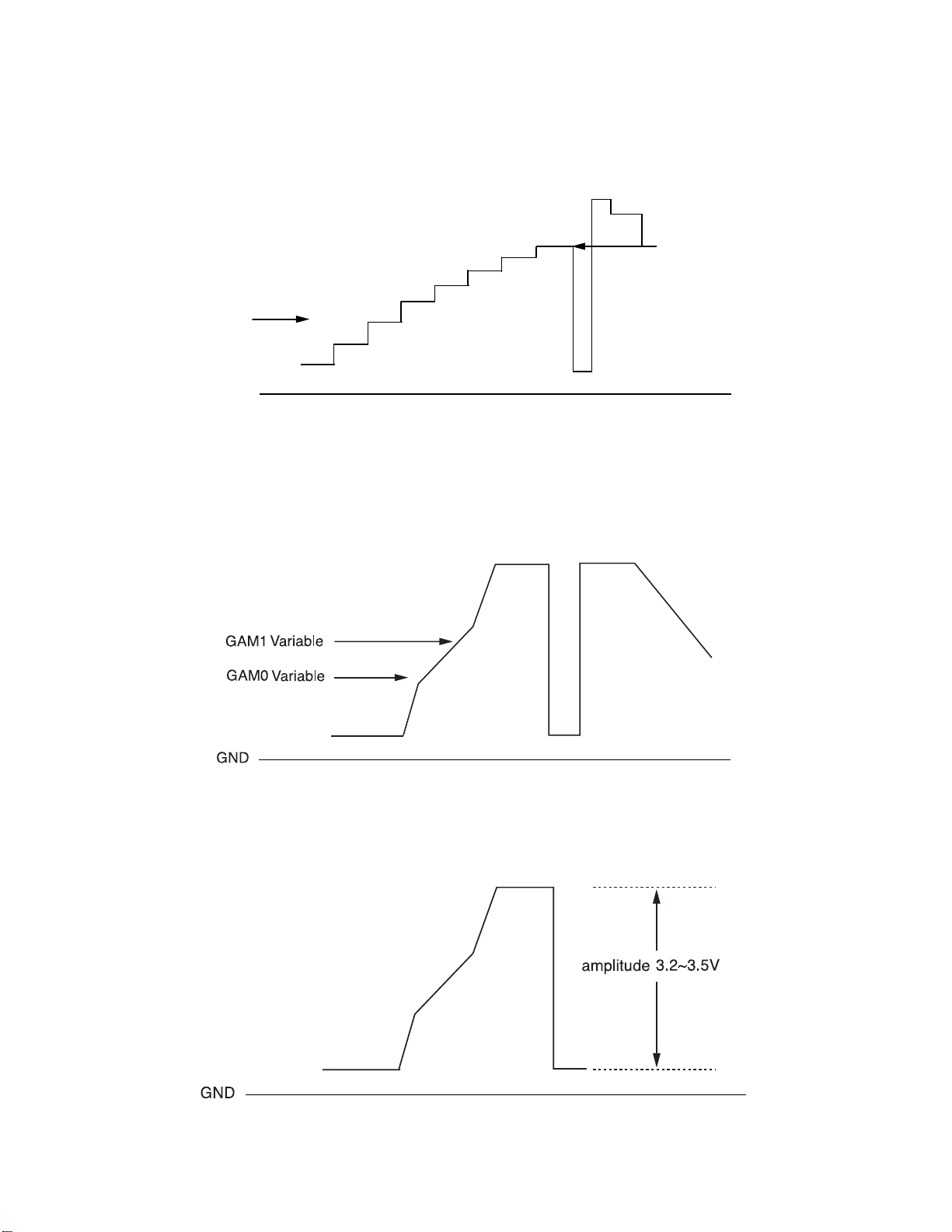

Page 12

3-3

* To set final settings, fit best display guality while viewing screen.

• or, after inputting 5STEP signal, adjust as CONT adjusting as shown below.(COLER MAX)

• adjust best results while viewing oscilloscope and Screen.

5) GAM0, GAM1 (GAM0: Black side, GAM1: White side) - Fixed(VR810, 811)

* Input RAMP signal and view TP(G) waveform, deside that GAM0 is black side knee point and GAM1 iswhite-

side knee point.

• GAM0 and GAM1 adjusting performs with CONT(VR803), because the amplitude linked.

6) CONT(VR803); White LEVEL Variable (2.8±0.1V)

Input RAMP signal, View TP(G) wareform, adjust amplitude to 3.2 ~ 3.5.

(VR803) (2.9V)

3.4

3.2

3.1

2.7

1.5

1

2.1

0.6

GND

BRIGHT

Black

(VR808)(2V)

Page 13

3-4

7) TINT(VR805); Color Adjusting(3V±0.1)

* Input COLOR BAR signal, view TP(B) waveform.

• adjusts White, Cyun, Magenta, Blue Signal conformity.

8) BLK1(VR814), BLK2(VR813); SIDE BLOCK Adjusting - Fixed.

• Input RAMP signal and SIDE1 S/W ON, view the TP(G) waveform.

• RGB-AMP adjusts same as LIMIT LEVEL.

Following items, adjust best display while viewing screen.

9) VCOM(VR817); Flicker adjusting

• Input 1 Line opposite signal, adjust Black maximum.

• or, Input 10 STEP signal, adjust Black maximum.

• Adjust best signal in ZOOM condition.

10) WB-B(VR807)(2.1V), WB-R(VR806)(2.3V); Brighness adjusting

• Input 5STEP, 10STEP and Black and White signal, adjusts Brightness Balance while viewing screen.

* adjust WB-B: whole screen changes Blue

) yellow.

* adjust WB-R: whole screen changes Red

) green.

• or, adjust color Brightness

11) COLOR(VR804); Color density adjusting - External Volume

• Adjust best condition with inputting screen, it is relation with S/N

12) Shapeless(VR802); Fixed

• Adjust not so much because in relation with S/N.

GND

3.5V

0.6V

Magenta BlueCyanWhite

GND

BLK1

BLK2

Page 14

3-5

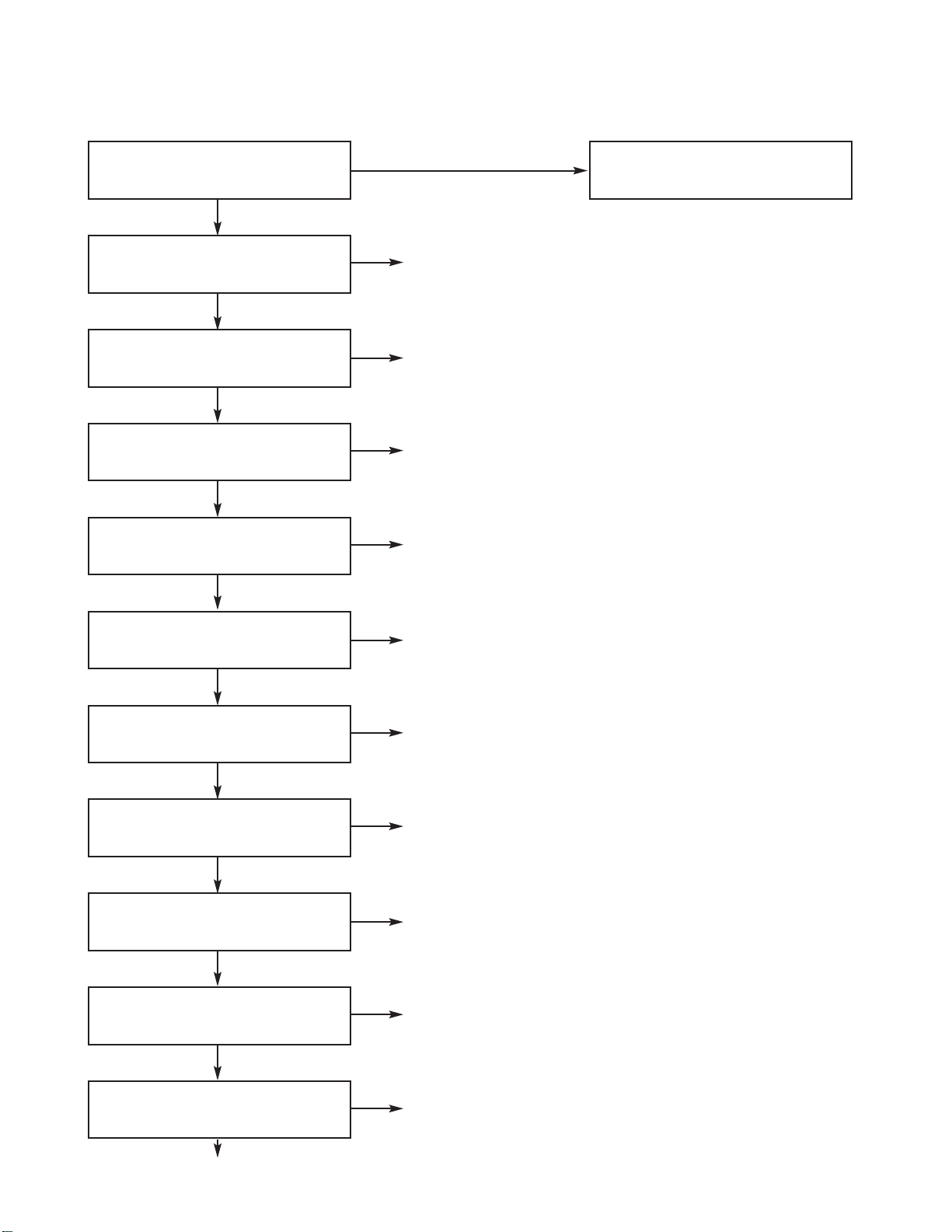

DESPLAY CONDITION? INVERTOR ABNORMAL

appear shadow form interference

in black background

There is only bright light.(LCD B/D abnormal)

FUSE Replace

IC8F1, IC8F2 Check and Replace

T801, D8F1, D8F2, D8F3 Check

IC8F3, IC8F4 Check and Replace

A/V IN S/W Check

X801, C832 Replace

IC801, IC803, Q806 Check and Replace

IC808, Q811, Q812, QQ813 Check and Replace

D801, L809, IC806 VCO Check and Replace

Q810, IC807 Check and Replace

FUSE(F801)Normal?

Q8F1 Normal operate?

7.5V, 17V, -15V Normal?

+5V, +3.3V Normal?

Y/C Display signal?

X801 operate?

R.G.B signal output?

VCOM signal?(6.5Vpp)

VCO Normal operate?

H/V SYNC?

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

LCD TROUBLE SHOOTING GUIDE(1/2)

Page 15

3-6

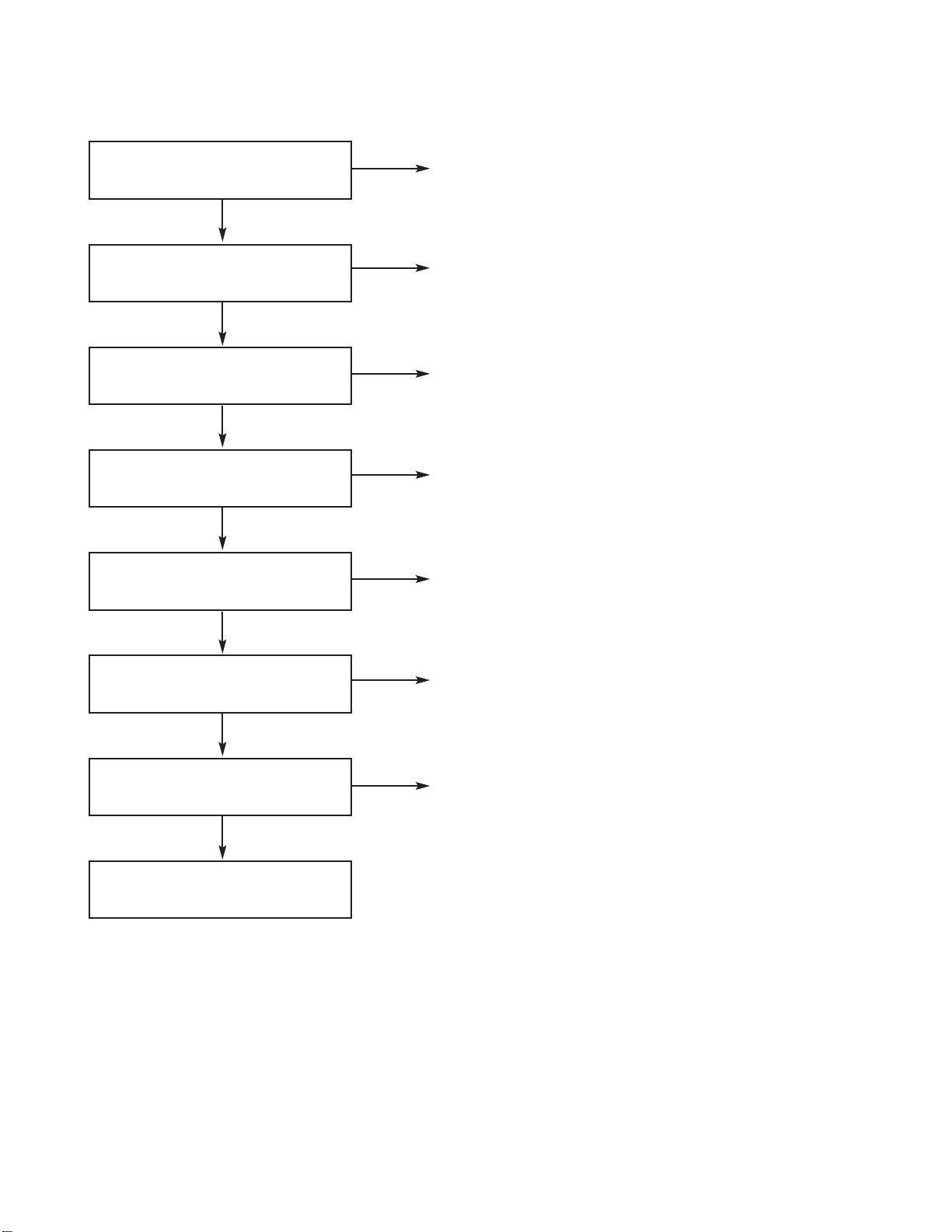

IC805’s CLK and CONT signal?

IC805 Replace

MAIN B/D Check

LCD MODE CONT signal?

ALL “LOW”(NORMAL condition)

TFT LCD pressure voltage?

+17V, -15V, +5V, +3.3V

Power source and D803, D804 Check

TFT LCD Normal?

Replace

Color Adjusting Normal?

Readjust as adjustement standard.

Each CONNECTOR?

Replace and Reassemble

INVERTOR Normal?

Replace

END

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

LCD TROUBLE SHOOTING GUIDE(2/2)

Page 16

3-7

LCD BLOCK DIAGRAM

CON

8

0

3

INVERTER

TFT LCD

CROMA

IC

IR3Y29BM

CONTROL

IC

MN5814

POWER

LCD MODE CONTROL

Y/C,COMPOSITE

DC9V

AC550V

SYNC

SEP

VCO

H,V

R.G.B

CONTROL

+3.3V

+5V

7.5V

-17V

-15V

Page 17

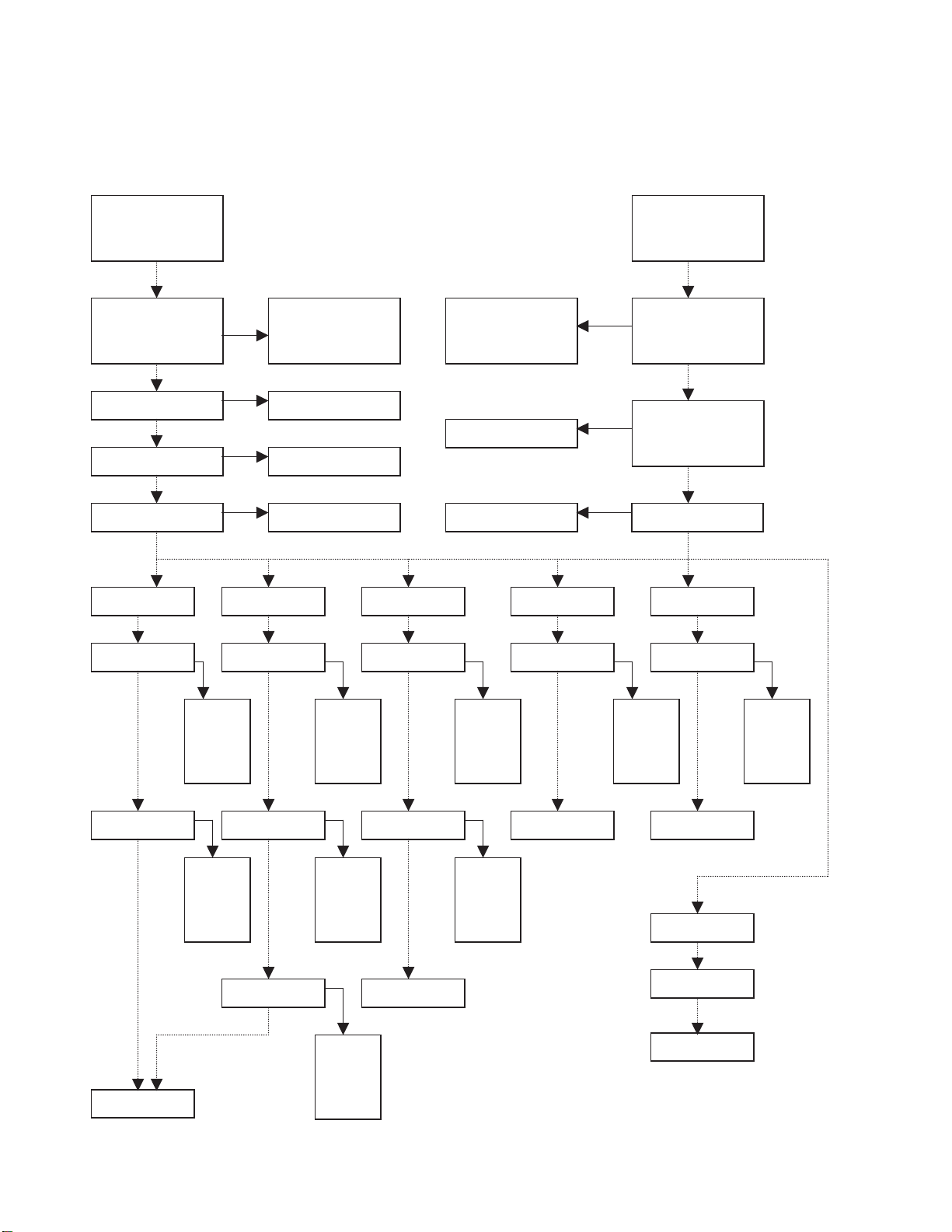

3-17

ELECTRICAL TROUBLE SHOOTING GUIDE

1. Power (DC-DC Converter) Circuit

A.

NO POWER ON

by ADAPTOR

NO POWER ON

by BATTERY

Is ADAPTOR

OUT 9.8V?

Is BATTERY

OK?

Is F901 OK?

Is F101 OK?

Is LF101 OK?

Replace F101

YES

Is D101 OK?

Replace D101

Replace ADAPTOR

NO +1.8V

Is Q109 OK?

NO +12VNO + 5V

NO +3.3V

NO LCD POWER

Replace

Q109

Is E+5V OK?

Is Q112 OK ?

Is Q113 OK?

Replace

Q110

Replace

Q112

Replace

Q113

Is Q108 OK?

Replace

Q108

Is Q106 OK?

Replace

Q106

Replace IC104

Replace IC109 Replace L462

Is Q101 OK?

Is Q101 OK?

Is Q107 OK?

Replace

Q101

Replace

Q101

Replace

Q107

Replace IC108

Is Q105 OK?

Replace Q105

Replace BAT TERY

Replace F901

Replace LF101

NO

NO

YES

NO +5V_DAC

Check +12V

Replace IC120

Page 18

3-18

AUDIO OUT ABNORMAL

VIDEO OUT ABNORMAL

Check Audio Jack &

Mode S/W

Check +12V, +5V_DAC

Check Signals from MPEG

Is Q401 OK ?

Is IC413 OK ?

Is IC403 OK ?

Is IC402 OK ?

Replace IC401

Replace

Q401

Replace

IC413

Replace

IC403

Check Video Jack &

Mode S/W

Check Video signals

from MPEG

Check TR. Buffer

(Q471,Q472,Q473)

Check LC Filter

AUDIO IN/SPEAKER

ABNORMAL

Check Audio Jack &

Mode S/W

Is Q481 OK ?

VIDEO IN ABNORMAL

Ch

eck Video Jack &

Mode S/W

Is IC461 OK ?

Check TR. Buffer

(Q471,Q472,Q473)

Is VR401 OK ?

Replace

Q481

Replace

VR401

Is Speakers OK ?

Replace

Speakers

Replace IC414

Replace

IC461

Refer to LCD part

B. Audio Out abnormal C. Video Out abnormal

D. Audio In/Speaker abnormal E. Video In abnormal

Page 19

3-19

Check the disc.

If OK

YES (If OK)

YES (If OK)

Refer to Servo part

Check MPEG_CLK Signal

of MPEG part

Check DSP

Check MPEG

YES (If OK)

Replace B/D

PICTURE ABNORMAL

Check Disc

YES (If OK)

YES (If OK)

Refer to Servo part

Replace B/D

DISC ERROR

Check the

connection of CON 901

Check IC303 Pins 89, 82

YES

NO

NO

YES

YES (If OK)

YES

Reconnect it.

Refer to SERVO part.

Check the connection of MD.

OPEN/CLOSE ABNORMAL

F. Picture abnormal

H. Open/Close abnormal

G. Disc Error

Page 20

3-20

2. MPEG Circuit

Power is on

Does Logo appear

on the screen?

Does the

moving picture of the DVD Disc

play on the screen

normally?

Is MPEG data signal normal?

Is error signal normal?

Is MPEG data signal normal?

Is Clock normal?

Does the audio

signal output from MPEG

decoder?

Does the

moving picture of the video

CD play on the screen

normally?

Does the audio sound

output normally?

END

Check power & clock.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check CD/DVD DSP output

signal.

Check MPEG Decoder input

signal.

Check clock signal

Check clock signal

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

OK

OK

OK

OK

NO

NO

NO

NO

NO

OPTION

If included VCD function.

Page 21

3-21

3. Front Circuit(Dogotrpm & Key)

NO

NO

NO

START

Does remote control

work normally?

Do all the

buttons work

normally?

Check waveform of

IC701 Pin 46,47.

Check waveform

of IC701 Pin 59.

Is Digitron on normally?

Check waveform of

IC701 Pin52, 54, 55, 56?

LED ON?

Check waveform

of IC701

Check and Replace

IC 2M5

Pin 67.

when power S/W turn on,

Is oscillation of X704

normal?

- Check and Replace C704,

R709, R710, R711

- Solder defective parts again

T701

Check the connection

of CON901, CON701.

Check waveform

of IC701 Pin 46,47.

Does pulse

waveform of RC901 Pin 1

appear?

Is IC701

Pin 49 connected to

RC901 Pin 1 ?

Is RC901 Pin 2 5V?

Power on.

Check

-R701~706, R728~R736, R743, R738

-R551~R558

and replace

Check and Replace

Q701, Q501.

Solder defective parts

Replace IC701.

Solder Key part.

Check Power.

Replace IC702.

Replace IC701.

Replace LED903 .

Replace RC901.

Re-solder.

Recheck

Replace IC701.Complete repairing Front B/D.

NO

NO

NO

NO

NO

NO

NONONO

NO

YES

YES YES

YES

YES YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Page 22

3-22

4. RF/Servo Circuit

A.

Does signal goes

"High" to IC207 Pin 186 when

the power is on?

Does

33.8688MHz clock input

to IC207 Pin59.

Replace IC207

Check power circuit.

Replace X201 or IC211

(33.8688MHz

clock defect)

CHECK POINT(General)

Is IC203

Pin79, 80, 84, 88

about 2.2V?

END

NO

NO

NO NO

NO

YES

YES

YESYES

YES

Does signal pulse

input IC201 pin53, 54, when

the power is on?

Does Ic207 Pin67 signal

goes from high to 20W when the

power is on?

Page 23

3-23

B.

Does tray open or close?

Does the pick-up

slide inner or outer

track?

Fig.1. SLED Driver waveform

Fig.2. Focus Driver waveform

Does

the voltage change

at CON203 Pins 15,16 more than

2V on the basis of

2.2V?

Pressing

the open/close key

repeatedly, check the voltage of IC2M1

Pin17

change

0V to 5V

Does

CON203 Pin1 change

high to low?

Does

the pick-up lens move up

and down?

Check Focus Driver output.

(IC207 Pin 88, IC2M1 Pins 13, 14)

Check SLED Driver output.

IC201 Pin 80, IC2M1 Pin 15, 16.

IC207 Pin 80 no output : IC207 is defective

IC2M1 Pin 15 no output : IC2M1 is defective

IC201 Pin 88 no output : IC201 is defective

IC2M1 Pins 13, 14 no output : IC2M1 is defective

DECK assembly is defective.

Slide the pick-up to

inner track.

.Power on

Check loading Part.

Push Pick-up to inner track to

the end by hand.

DECK assembly is defective.

(Limit sw)

check µ-COM Part.

Replace IC2M1.

No disc

END

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 24

3-24

C.

FOCUS ON?

Check

the focus error moving the

lens up and down.

(IC2A1 Pin 42)

Does the

TTL level change at IC207

Pin 121 and 152 moving

the lens?

Does the disc turn?

IC207 Pin105 is "High"?

Is OK the track jump.

Does the signal

pulse appear at IC2A1 Pins

39, 29?

Does the screen appear?

OPEN/CLOSE

Replace -COM or IC201.

Replace IC207.

Check IC2A1 Pin 11,12,13,14

in DVD Mode

Fig.3. FOCUS ERROR waveform

IC201 no output : Pick-up is defective.

Check IC207 and IC2M1 when CON203 Pin 3 is abnormal

Check IC2M6 Pin 8, CON203

Pin 3 turn when the IC2M6

Pin 8 is less than 1.65V

Check A

Video Part is defective.

Check "5.MPEG Circuit."

Check "7.OSD/Video Circuit."

Replace -COM part.

IC2A1 is defective.

DISC IN

END

NO

NO

NO

NO NO

NO

NO

NO

YES

YES

YES

YES

YES

YES YES

YES

Page 25

3-25

D.

Is the eye-pattern vivid?

Does the

sawtooth waveform emit

at IC2A1 Pin 41?

Does the 1.6V emit?

Check RF Eye-Pattern.

RF : 1.5-1.6V(IC2A1 Pin 57)

Fig.5. RF

waveform

Check IC2A1 Pins 5, 6, 7, 8.

No signal: Pick-up is defective

Replace IC207.

Check IC207 Pin84.

No signal at IC207 : IC207 is defective

Check IC207 Pin 165.

Check the clock at the IC207 Pin 138.

Both are normal : IC207 is defective

Replace IC2A1.

CHECK A

END

NO

NO NO NO

YES

YES YES YES

-

-

-

Page 26

3-26

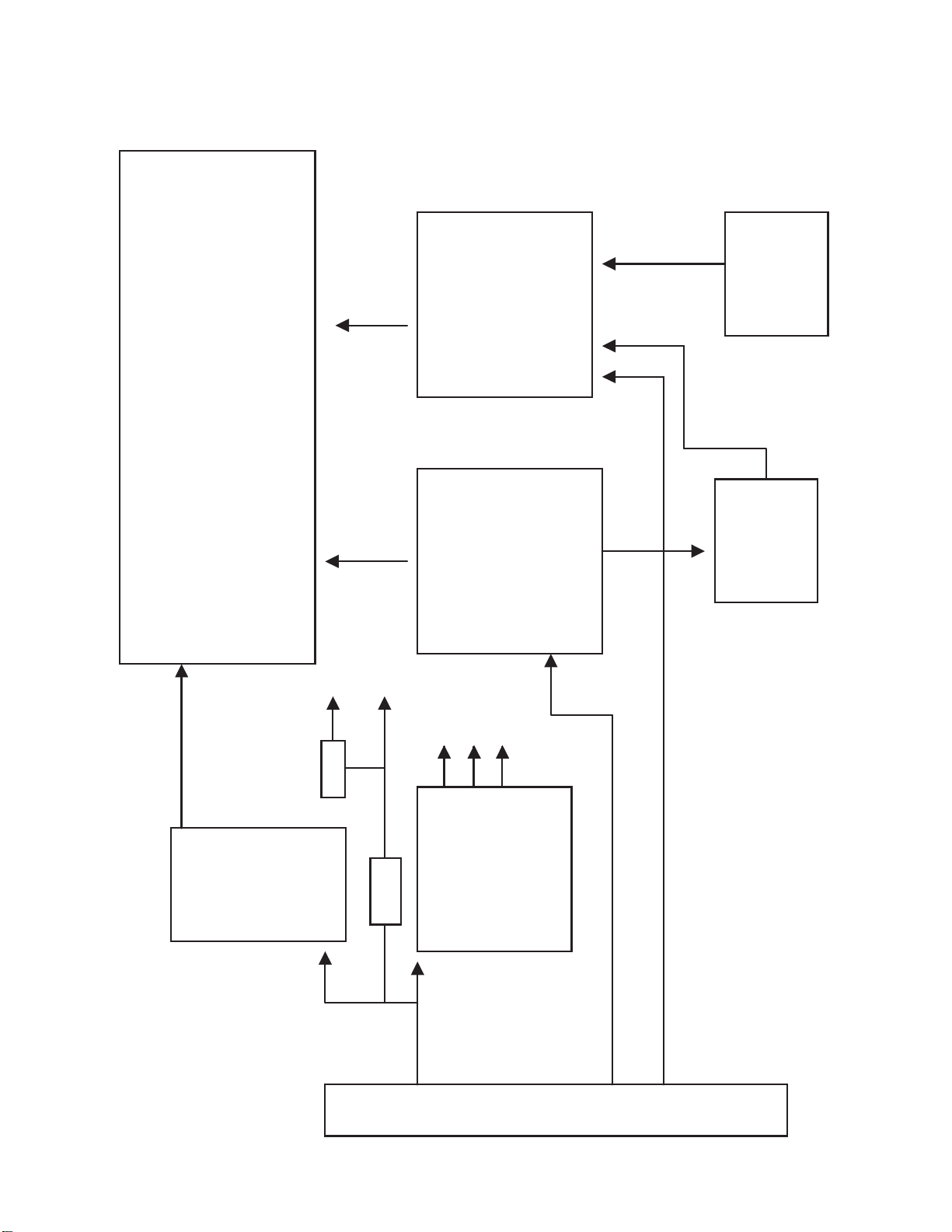

BLOCK DIAGRAMS

1. OVERALL BLOCK DIAGRAM

M

DISC

Deck Mechanism

LCD Part

Front Micom Part

RC901

IC104

1.8V3.3V5V

IC108

IC109

IC2M6

IC2M1

IC207

IC2A1

IC218

IC501 IC401

IC414

IC801/IC805

IC8F1

-15V, +17V

+7.5V, +5V, +3V

IC414

IC301IC302

IC303

Pick-up

F/T/S Drive

CD/DVD

Decoder

&

Servo

RF IC

SDRAM

Battery

DC-DC

Converter

Builten

BATT Charger

System Power Supply

Power

Control

AC

Adapter

Spindle

Drive

SDARM FLASH

CPU

&

MPEG

Deconder

&

TV Enconder

Tuner

LCD Power

Speaker

Power

Amp

Optical

Drive

Y/C

CVBS

Audio

Out

Headphone

out

Audio

Amp

Audio

DAC

Front Panel

Interface

Pront Micom

&

LCD Driver

CPLD Port Expand

TN LCD

Remocon

Interface

Card type

IR Remocon

Power

Amp

TFT LCD

Module

DC-DC

Chroma & Timing

Control

Page 27

3-27

2. POWER(DC-DC CONVERTER)BLOCK DIAGRAM

DC_JACK

J101

9.8V

FUSE

F101

LINE FILTER

LF101

BATTERY S/W

Q105

SI6965

BATTERY

CON.

CON902

7.2V

LOAD S/W

Q109

SI3863

DC-DC CON.

IC104

MAX1744

DC-DC CON.

IC108

MAX1775

DC-DC CON.

IC109

MAX1605

FET

Q106

SI9407

FET

Q107

SI9939

FET

Q108

SI1403

+5V

LOAD S/W

Q110

SI3865

LOAD S/W

Q113

SI3865

LOAD S/W

Q112

SI3865

LCD PW

+3.3V

+12V

+1.8V

E+5V

+5V

REG.

IC120

LM1117I

+5V_DAC

PWRCTL1

PWRCTL4

PWRCTL3

PWRCTL3

PWRCTL2

R

Page 28

3-28

8

SENS, F OK,

DEFECT,DSP

_

SENSE

IC2M6

AN8473NSA

Sp indle Moto

CD: A, B,C, D / E, F

4

4

MIRR, TZC

8

4

3

4

SQSO, SQCK, SCOR

6

E_OUT, E _DR, SCLK

,

SDATA

UCOM

I/F

focus, tracking,, sled

Spindle

M/D

PICK

UP

MCK

IC 207

HDC25D811

CD / DVD DSP

DVD SERVO

IC2A1

333P3721

RF Signal

Processor

FDO, TDO,FMO

UCOM

I/F

DVD: A,B, C

,

D,

FE,TE, PI,SBADD

4

DVD/CD RF

DRAM

256K

x

16bit

16

9

ICADDR[0:8]

ICD

A

T

A

[00:15]

DO

[0:

7]

AO[0:5]

DVD_ DATA

[

0

:

7

]

MON, MDP

SPIN

DL

E_FG

2

DS P_CS , /WR, /RD3

8

IC2M1

BA5929FP

SLED M

ot

or,

r,

3. DVD-PLAYER RF/CD DSP/DVD DSP/DVD SERVO BLOCK DIAGRAM

Page 29

3-29

/SRST

COMM_OUT

COMM_CLK

/DAC_CS1

IC401

PCM1716

Audio DAC

SPEAKER

LEFT

L

J405

EARPHONE

JACK

DA_LRCK

AOUT3

DA_BCK

PCMCLK

R

IC402

NJM4580

OP AMP

R

L IC413

NJM4580

OP AM

P

L

R

IC403

NJU4052

ANALOG

MUX

IC414

BA7786

SPEAKER

EARPHONE

AMP

J404

Audio

I/O

Jack

VIDEO_IO_CON

SPEAKER

RIGHT

4. AUDIO BLOCK DIAGRAM

Page 30

3-30

IC303

XC9572XL

CPLD

IC501

PANTERA2

_LE

LC FILTER

LC FILTER

LC FILTER

IC461

NJM2233

BUFFER

BUFFER

BUFFER

LCD BOARD

CVBS

C

Y

VIDEO_IO_CON

LCD[1:5]

CVBS I/O

JACK

S-VIDEO

JACK

5. VIDEO BLOCK DIAGRAM

Page 31

3-31

IC501

PANTERA-LE

IC302

XC9572VL

CPLD

I/O PORT 72

IC302

SDRAM

16/32BIT

64M

IC502

FM93C86ALM8

EEPROM

IC301

FLASH

MEMORY

IC310/IC311

LATCH

AD[0:7] 8

DSP

I/F

DVD[0:7]

8

LA[0:3]

4

SCLK,SDATA

SQCK,SQS0

SDCLK1,PSYNC

DSP_INT

SENSE

/DSP_CS

AD[00:20]

RF &

MOTOR

I/F

MIRR

LDON

S

CLK,SDATA

EE_CS

F_IN

32

MD[00:31]

MCLK2

CKE

MA[00:10]

MA12,13

/CS0

/RAS/

/CAS

/WE

/DQM[0:3]

SPINDLE_FG

ALE

AD[04:19]

16

LADD[04:19]

16

LA[0:3]

4

AD[00:15]

16

AUDIO

I/F

DA_DATA[0:3}

DA_BCK,DA_LRCK,DA_XCK

1

DAC_L0,DAC_L1

DAC_RST(/SRST)

A/V

JACK

I/F

C

Y

CVBS

PSENB

REOP

RF_LAT

/RD

/PWED

A_MUTE

V_MUTE

6. DVD-PLAYER MPEG & MEMORY BLOCK DIAGRAM

Page 32

MEMO

Page 33

3-8 3-9

LCD CIRCUIT DIAGRAM

LCD1 CIRCUIT DIAGRAM

No power

No power

No power

No power

Not operate

+5V, +3.3V Line dead

+3.3V Line dead

2002. 02.01 R14121A

Page 34

3-10 3-11

LCD2 CIRCUIT DIAGRAM

Display abnormal(Black)

Display abnormal(unstable)

Color abnormal

Color abnormal

No display

Side black abnormal

Speaker 1

Dimmig abnormal

No Display(Black background)

Speaker 2

2002. 02.01 R14119A

Page 35

3-12 3-13

LCD3 CIRCUIT DIAGRAM

Display unstable

Display unstable

brightness abnormal

Interface Line occur

(Vcom abnormal)

Display abnormal

2002. 02.01 R14120A

Page 36

LCD VOLTAGE SHEET

PIN NO VOLT WAVEFORM

1 2.5 Y signal(0.5)

2 3.1

3 2.5 Y signal(0.5)

4 0.2

5 2.8 C signal(0.5)

6 3.6

7 3.5

81

92

10 2

11 2.1

12 3

13 3.2

14 4.3 CLK(0.4)

15 2.6

16 3 CLK(0.4)

17 0

18 0

19 4.4 R(0.6-4.4)

20 2.9

21 4.4 G(0.6-4.4)

22 2.9

23 7.5 VCC

24 4.4 B(0.6-4.4)

25 2.9

26 2.5

27 2.5

28 2.5

29 1.9

30 2.5

31 1.7

32 2.6 HQ(0-2.6)

33 2.6 HQ(0-2.6)

34 3.4 SYNC(0-3.4)

35 3 C.SYNC

36 2.4 Y signal(0.5)

37 2.1

38 4.7 COM(3-4.7)

39 0

40 2

41 2

42 2

43 5 VCC

44 1.3

45 2.7

46 2.9

47 3.2

48 2.7

PIN NO VOLT WAVEFORM

10

2 3.3 HD(0-3.3)

30

40

5 3.3 VD(0-3.3)

6 2.8 HQ-OUT

7 2.8

80

9 3.2

10 0

11 0

12 0

13 2.7

14 2.8 0-2.8

15 0

16 2.6 0-2.6

17 2.6 0-2.6

18 2.6 0-2.6

19 2.6 0-2.6

20 0

21 2.6 0-2.6

22 0

23 2.6 0-2.6

24 2.6 0-2.6

25 2.6 CLK 0-2.6

26 0

27 2.6 CLK 0-2.6

28 0

29 2.6 CLK 0-2.6

30 3.3 VCC

31 0

32 3.3 VCC

33 1.6

34 3.3 VCC

35 3.3 VCC

36 3.3 VCC

37 2.6 VCC

38 0

39 2.2

40 3.3

41 0

42 3.3

43 3.3

44 0

45 0

46 0

47 3.3

48 0

IC801 IR3Y29BM

3-14

Page 37

3-15 3-16

LCD P.C. BOARD

LOCATION GUIDE

LOCATION GUIDE

Page 38

MEMO

MEMO

Page 39

3-32 3-33

CIRCUIT DIAGRAMS

1. POWER CIRCUIT DIAGRAM

IC401 & 106 are defective

E +5V is bad

Q110 is defective

E +5V is bad

Q101 is defective

+1.8V & +3.3 ard bad

IC108 is defective

+1.8V & +3.3V are bad

IC109 is defective

+12V is bad

Q107 is defective

+3.3V is bad

Q108 is defective

+12V is bad

IC120 is defective

+5V_DAC is bad

Q112 is defective

+3.3V is bad

Q110 is defective

E +5V is bad

2002. 02.01 R14108A

Page 40

3-34 3-35

2. DRIVER CIRCUIT DIAGRAM

Sled Not mone

Tracking

Sled

Spindle

Focuse

waveforms(page 3-58 ~ 3-59)

2002. 02.01 R14109A

Page 41

3-36 3-37

3. RF CIRCUIT DIAGRAM

CD/DVD LD abnormal

CD/DVD picture abnomal

DVD LD abnormal

DVD LD abnormal

Tracking

Focuse

waveforms(page 3-58 ~ 3-59)

2002. 02.01 R14110A

Page 42

3-38 3-39

4. DSP CIRCUIT DIAGRAM

Focus Servo Fail

Tracking Servo FailSled Servo Fail

Spindle Motor abnormal

DRAM control

MPEG Signal

Tracking

Sled

Spindle

Focuse

2002. 02.01 R14111A

Page 43

3-40 3-41

5. DRAM CIRCUIT DIAGRAM

Q2A2 are defective

CD LD will not be on

Q2A1 are defective

DVD LD will not be on

Q2A3 are defective

NO focus Arocking Control

IC 212 is defective

Scratched LD audio abnormal

2002. 02.01 R14112A

Page 44

3-42 3-43

6. PANTER CIRCUIT DIAGRAM

waveforms(page 3-58 ~ 3-59)

2002. 02.01 R14113A

Page 45

3-44 3-45

7. MEMORY CIRCUIT DIAGRAM

2002. 02.01 R14114A

Page 46

3-46 3-47

8. X-BUS CIRCUIT DIAGRAM

Q501 is defective.

Key S/W voltage abnormal.

2002. 02.01 R14115A

Page 47

3-48 3-49

9. CPLD CIRCUIT DIAGRAM

2002. 02.01 R14116A

Page 48

3-50 3-51

10. VIDEO CIRCUIT DIAGRAM

Q472 is defective

C signal is bad

Q471 is defective

Y signal is bad

COMP Video

S Video (Y)

S Video (C)

2002. 02.01 R14117A

Page 49

3-52 3-53

11. AUDIO CIRCUIT DIAGRAM

IC402 is defective

ICH Audio Out Bad

IC413 is defective

ICH Audio

IC403 is defective

2CH Audio out is bad

IC414 is defective

speakers & earphone

are bad

Q406 is defective

Optical out is bad

IC401 is defective

2CH Audio out bad

Audio L

Audio L

Eprphone L

Eprphone R

2002. 02.01 R14118A

Page 50

3-54 3-55

12. FRONT CIRCUIT DIAGRAM

System not

operate

System not operate

Power not control

Q701 is defective

key S/W voltage abnormal

2002. 02.01 R14122A

Page 51

3-56 3-57

13. REMOCON CIRCUIT DIAGRAM

Remocon not operate.

Q902 is defective.

LED not operate

2002. 02.01 R14123A

Page 52

3-58 3-59

WAVEFORMS

CH1. IC2A1 Pin41,

Tracking Error

CH1. IC2A1 Pin41, VBR Tracking Error

CH2. IC2M1 Pin4, Tracking Drive(TDO)

CH1. IC2A1 Pin42, Focus Error

CH2. IC2A1 Pin36, Pi

Focus Search Case IC501 Pin 112, Chrominance

(Super video out Mode)

IC501 Pin 114, Luminance

(Super video out Mode)

IC501 Pin 99

MPEG Clock(27MHz)

CH1. IC2A1 Pin42, Focus Error

CH2. IC2M1 Pin21, Focus Drive

Disc Detection Case

CH1. IC2A1 Pin42, Focus Error

CH2. IC2M1 Pin21, Focus Drive

IC501 Pin 118, Composite

2.50MS/s

Tek

Stop :

4 Acqs

[T ]

T

3

Glitch

500mV

Ch3

M20.0 s

Ch1

2 Apr 1999

14:47:27

Page 53

3-60 3-61

CIRCUIT VOLTAGE CHART

PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY PIN EE

EEEE

EE PLAY

PLAYPLAY

PLAY

DSP

DSPDSP

DSP SERVO

SERVOSERVO

SERVO MPEG

MPEGMPEG

MPEG AUDIO

AUDIOAUDIO

AUDIO MEMORY

MEMORYMEMORY

MEMORY POWER

POWERPOWER

POWER FRONT

FRONTFRONT

FRONT

IC201

IC201IC201

IC201 IC2A3

IC2A3IC2A3

IC2A3 IC501

IC501IC501

IC501 IC401

IC401IC401

IC401 IC301

IC301IC301

IC301 IC104

IC104IC104

IC104 IC701

IC701IC701

IC701

1 0.00 3.10 1 1.65 1.64 1 3.08 3.06 1 1.672 1.669 1 0.00 0.00 1 0.00 0.00 1 4.94 4.94

2 3.30 2.60 2 1.64 1.64 2 2.33 1.30 2 0 1.25 2 0.02 0.00 2 4.94 4.95 2 4.94 4.94

3 3.30 2.60 3 1.64 1.64 3 2.38 1.40 3 1.666 1.664 3 0.00 0.00 3 1.17 1.18 3 4.94 4.94

4 3.30 2.60 4 0.00 0.00 4 1.80 1.80 4 2.324 2.348 4 0.02 0.00 4 4.94 4.95 4 3.21 3.24

5 3.30 2.60 5 1.64 1.64 5 2.33 1.50 5 1.637 1.648 5 0.00 0.00 5 4.93 4.95 5 1.62 1.62

6 3.30 2.60 6 1.64 1.64 6 0.00 0.00 6 2.738 2.704 6 0.00 0.00 6 4.94 4.96 6 0.00 0.00

7 3.30 2.60 7 1.64 1.64 7 2.17 1.50 7 0 0 7 0.00 0.00 7 8.44 8.44 7 2.38 2.42

8 3.30 2.60 8 4.94 4.94 8 2.62 1.40 8 5 5 8 0.00 0.00 8 3.30 3.22 8 2.42 2.42

9 0.00 2.60 9 2.09 1.60 9 5 5 9 2.40 2.75 9 7.08 6.20 9 2.42 2.42

10 3.30 2.60 IC2M1

IC2M1IC2M1

IC2M1 10 3.08 3.06 10 0 0 10 0.18 0.20 10 8.44 8.44 10 2.42 2.43

11 3.30 2.60 1 0.20 0.20 11 0.00 0.70 11 2.49 2.491 11 3.07 3.05 11 2.43 2.46

12 3.30 2.60 2 0.20 0.20 12 0.21 0.15 12 0 0 12 3.05 2.99 IC108

IC108IC108

IC108 12 2.43 2.45

13 3.30 2.60 3 4.34 4.32 13 0.00 0.15 13 2.509 2.512 13 1.19 1.36 1 5.43 5.44 13 2.43 2.44

14 3.30 2.60 4 2.18 2.19 14 0.00 0.00 14 0 0 14 0.00 0.02 2 3.26 3.31 14 2.43 2.40

15 3.30 2.60 5 2.18 2.17 15 3.12 0.00 15 5 5 15 1.20 1.55 3 0.00 0.00 15 2.43 2.45

16 3.30 2.60 6 2.18 2.17 16 3.12 1.70 16 2.508 2.509 16 3.10 0.73 4 1.42 1.61 16 2.43 2.45

17 3.30 2.60 7 4.94 4.90 17 0.00 0.00 17 0 0 17 0.00 0.00 5 3.42 3.34 17 2.45 2.42

18 3.30 0.50 8 4.37 4.37 18 0.00 0.00 18 2.493 2.494 18 0.00 0.00 6 8.49 8.43 18 2.45 2.45

19 3.30 3.30 9 0.20 0.20 19 3.12 3.06 19 0 0 19 0.00 0.00 7 6.80 6.62 19 2.44 2.44

20 0.00 0.50 10 0.20 0.20 20 0.00 1.60 20 5 5 20 0.00 0.00 8 4.20 4.12 20 2.44 2.42

21 3.30 0.50 11 2.51 2.48 21 0.00 0.00 21 5 5 21 0.00 2.23 9 1.18 1.18 21 2.43 2.42

22 0.00 0.30 12 2.51 2.48 22 1.64 1.60 22 3.359 3.355 22 0.00 2.13 10 1.18 1.18 22 2.43 2.40

23 0.00 0.20 13 2.50 2.49 23 0.00 0.00 23 0 0 23 0.00 2.22 11 3.37 3.37 23 2.43 2.42

24 3.30 3.30 14 2.50 2.52 24 3.12 3.10 24 5 5 24 0.00 0.15 12 3.35 3.35 24 2.39 2.42

25 3.30 0.30 15 2.12 2.21 25 0.00 1.70 25 5 5 25 3.04 0.74 13 0.90 0.90 25 2.42 2.42

26 0.00 0.40 16 2.15 1.99 26 0.00 1.40 26 0 0 26 3.04 3.05 14 0.00 0.00 26 2.47 2.47

27 0.00 0.20 17 3.32 3.32 27 3.12 3.06 27 5 5 27 0.00 0.00 15 3.35 3.35 27 2.42 2.42

28 0.00 0.20 18 0.00 0.00 28 0.00 1.50 28 3.345 3.34 28 3.04 3.05 16 1.79 1.79 28 2.42 2.42

29 0.00 1.20 19 4.94 4.91 29 0.00 0.15 29 3.03 3.00 29 2.42 2.47

30 0.00 2.60 20 2.19 2.16 30 0.00 0.00 IC402

IC402IC402

IC402 30 3.03 3.00 IC109

IC109IC109

IC109 30 2.46 2.42

31 0.00 0.00 21 2.19 2.19 31 0.00 0.00 1 5.8 5.8 31 3.03 3.00 1 3.30 3.29 31 2.42 2.42

32 0.00 0.00 22 2.19 2.19 32 0.00 0.70 2 5.8 5.8 32 3.03 3.00 2 4.93 4.93 32 2.42 2.42

33 0.00 3.01 23 2.19 2.18 33 3.12 1.50 3 5.8 5.8 33 3.03 2.99 3 0.00 0.00 33 2.42 2.47

34 3.30 3.02 24 2.19 2.18 34 1.80 1.80 4 0 0 34 3.04 2.99 4 8.50 8.43 34 2.46 2.42

35 3.30 3.12 25 2.19 2.18 35 3.12 2.00 5 5.8 5.8 35 3.04 3.00 5 4.93 4.93 35 2.42 2.40

36 0.00 0.00 36 3.12 3.06 6 5.8 5.8 36 3.04 3.00 6 1.22 1.18 36 2.41 2.45

37 1.87 1.86 IC2M4

IC2M4IC2M4

IC2M4 37 3.12 2.90 7 5.8 5.8 37 3.04 3.00 37 0.00 0.00

38 0.00 0.00 1 1.64 1.64 38 3.12 2.20 8 11.59 11.59 38 3.03 0.40 IC120

IC120IC120

IC120 38 4.71 4.89

39 0.00 0.00 2 1.64 1.64 39 3.12 2.90 39 3.03 3.00 1 0.00 0.00 39 4.94 4.94

40 0.00 0.00 3 1.64 1.64 40 0.00 0.00 IC403

IC403IC403

IC403 40 3.03 3.00 2 4.96 4.96 40 4.94 4.94

41 0.00 0.00 4 0.00 0.00 41 0.00 0.00 1 0 0 41 3.03 3.00 3 11.91 11.92 41 0.00 0.00

42 0.00 0.00 5 1.64 1.64 42 0.00 0.00 2 0 0 42 3.02 2.99 4 4.96 4.96 42 4.58 4.58

43 0.00 0.00 6 1.64 1.64 43 2.80 1.60 3 43 3.02 3.00 43 0.00 0.00

44 0.00 0.00 7 1.63 1.55 44 3.12 3.06 4 44 3.03 3.00 IC2M5

IC2M5IC2M5

IC2M5 44 3.60 3.58

45 0.00 3.29 8 4.94 4.94 45 0.37 1.60 5 0 0 45 3.02 3.00 1 0.00 0.00 45 0.00 0.00

46 0.00 1.60 46 0.86 1.50 6 0 0 46 0.00 0.00 2 0.00 3.32 46 0.00 0.00

47 0.00 0.62 IC2M6

IC2M6IC2M6

IC2M6 47 0.00 0.00 7 0 0 47 3.03 3.03 3 0.00 0.00 47 0.00 0.00

48 0.00 2.62 1 4.94 0.74 48 2.34 1.40 8 0 0 48 0.00 0.00 4 2.83 2.83 48 0.00 0.00

49 3.30 3.30 2 4.94 1.69 49 0.00 0.00 9 11.51 11.53 5 4.94 0.00 49 4.73 4.73

50 0.00 0.00 3 4.94 1.69 50 2.32 1.20 10 11.57 11.59 6 3.32 3.31 50 4.89 4.89

51 0.00 0.84 4 4.94 2.55 51 2.20 1.70 11 1 3.05 3.07 7 0.00 4.94 51 4.90 4.92

52 0.00 0.84 5 4.94 2.56 52 2.60 1.20 12 0 0 2 2.32 2.56 8 1.00 1.00 52 4.20 4.10

53 0.00 0.00 6 4.94 3.42 53 3.05 3.06 13 3 3.05 3.06 9 4.94 0.00 53 0.00 0.00

54 3.30 3.30 7 4.94 3.42 54 2.04 1.60 14 4 2.30 2.65 10 0.00 0.00 54 0.00 0.00

55 0.00 0.00 8 1.63 1.51 55 2.33 1..4 15 0 0 5 2.36 2.59 11 3.31 0.00 55 4.60 4.60

56 3.30 3.30 9 1.64 1.64 56 2.30 1.50 16 11.57 11.59 6 0.00 0.00 12 1.40 1.60 56 4.92 4.92

57 0.00 0.00 10 0.00 1.85 57 0.00 0.00 7 2.57 2.60 13 0.00 3.32 57 0.00 0.00

58 1.39 1.39 11 0.00 4.94 58 2.37 1.60 IC413

IC413IC413

IC413 8 2.57 2.78 14 4.93 4.93 58 3.30 3.30

59 2.12 2.12 12 4.89 8.10 59 2.60 1.40 1 5.75 5.75 9 3.06 3.06 15 3.33 0.00 59 0.00 0.00

60 0.00 0.00 13 0.00 2.72 60 3.13 1.50 2 5.75 5.75 10 2.40 2.81 16 4.20 4.10 60 0.00 0.00

61 3.30 3.30 14 4.43 6.83 61 3.13 1.40 3 5.75 5.75 11 2.87 2.37 17 0.00 0.00 61 4.93 4.94

62 0.00 0.00 15 0.00 0.00 62 3.13 3.06 4 0 0 12 0.00 0.00 18 0.00 4.94 62 4.93 4.94

63 3.30 3.30 16 4.94 4.94 63 3.13 1.00 5 5.75 5.75 13 2.23 2.69 19 0.00 0.00 63 4.90 4.91

64 0.00 0.00 17 4.94 4.94 64 3.13 1.50 6 5.75 5.75 14 0.00 0.00 20 4.94 4.94 64 4.93 4.94

65 0.00 0.00 18 4.94 4.93 65 0.00 0.00 7 5.75 5.75 15 3.06 3.06 65 4.88 4.88

66 0.00 1.85 19 0.00 0.00 66 0.18 0.50 8 11.59 11.59 16 0.00 0.00 Q105

Q105Q105

Q105 66 4.91 4.93

67 0.00 0.00 20 0.00 0.00 67 0.00 0.00 17 3.02 3.03 1,8 0.00 0.00 67 4.88 4.89

68 3.30 3.30 21 0.00 3.50 68 1.56 1.58 IC414

IC414IC414

IC414 18 2.70 2.76 2,3 0.00 0.00 68 2.82 2.83

69 0.00 1.20 22 0.00 3.50 69 0.00 0.00 1 2.314 0 19 2.97 2.98 4,5 8.79 8.74 69 2.34 2.34

70 3.30 3.30 23 0.00 0.00 70 0.00 3.10 2 2.518 2.516 20 2.62 2.68 6,7 8.50 8.45 70 0.00 0.00

71 0.00 0.00 24 0.00 3.50 71 0.00 1.20 3 0 3.324 21 0.00 0.00 71 4.94 4.94

72 3.30 3.30 25 0.00 3.50 72 0.00 1.20 4 2.518 2.516 22 0.04 0.03 Q106

Q106Q106

Q106 72 0.00 0.00

73 0.00 0.00 26 0.00 0.00 73 0.00 1.20 5 2.512 2.51 23 2.16 0.85 1,2,3 8.50 8.45 73 0.00 0.00

74 0.00 0.00 27 0.00 3.50 74 0.00 1.20 6 2.515 2.513 24 0.09 0.08 4 7.05 6.05 74 0.00 0.00

75 0.70 0.73 28 0.00 3.50 75 3.10 3.06 7 4.55 4.55 25 1.26 1.23 5,6,7,8 4.90 4.94 75 0.00 0.00

76 1.43 1.43 29 0.00 0.00 76 1.58 1.65 8 1.5 1.49 26 0.94 0.84 76 4.91 4.91

77 0.73 0.73 30 4.94 4.93 77 1.80 1.80 9 2.518 2.51 27 2.17 0.84 Q107

Q107Q107

Q107 77 4.91 4.91

78 0.73 0.73 31 4.94 4.93 78 1.54 1.50 10 2.525 2.523 28 0.00 0.00 1 0.00 0.00 78 4.91 4.91

79 2.17 2.17 32 4.94 4.93 79 1.57 1.50 11 2.51 2.51 29 3.06 3.06 2 1.79 1.76 79 4.91 4.91

80 2.17 2.10 80 3.14 3.10 12 0 0 30 0.00 0.00 3 8.52 8.44 80 4.91 4.91

81 3.29 3.29 81 2.95 3.10 13 0 0 31 2.57 2.60 4 6.73 6.61

82 3.29 3.29 82 0.00 0.00 14 0 0 32 0.00 0.00 5,6,7,8 3.40 3.40

83 1.97 1.97 83 3.13 3.10 15 4.92 4.92 33 2.55 2.28

84 2.16 2.15 84 0.00 3.70 16 2.51 2.509 34 2.56 2.37 Q108

Q108Q108

Q108

85 0.00 0.00 85 0.00 0.00 17 2.527 2.523 35 3.06 3.06 1,2,5,6 11.93 11.94

86 0.00 0.00 86 0.00 0.10 18 3.765 3.772 36 2.57 1.73 3 11.94 11.95

87 1.97 1.97 87 3.13 3.10 19 5 5 37 2.56 1.84 4 9.60 9.55

88 2.17 2.16 88 3.14 3.10 20 2.514 2.51 38 0.00 0.00

89 1.97 1.97 89 1.80 1.80 21 2.514 2.51 39 2.40 2.76 Q109

Q109Q109

Q109

90 1.61 1.61 90 0.00 3.10 22 0 0 40 2.87 2.72 1 0.00 0.00

91 0.76 0.76 91 3.14 3.06 23 2.514 2.51 41 3.06 3.06 2,3 8.51 8.44

92 2.43 2.43 92 0.00 0.00 24 2.514 2.51 42 2.24 2.37 4 8.51 8.44

93 1.56 1.59 93 3.06 3.05 25 5 5 43 3.06 3.06 5 3.31 3.31

94 1.62 1.62 94 3.06 3.04 44 0.00 0.00 6 0.00 0.00

95 1.36 2.71 95 0.00 0.00 IC461

IC461IC461

IC461 45 0.00 2.42

96 1.58 1.71 96 3.06 0.00 1 2.988 2.977 46 0.00 0.00 Q110

Q110Q110

Q110

97 1.62 1.62 97 0.00 0.00 2 0 0 47 2.86 2.73 1 0.00 0.00

98 0.00 0.00 98 0.95 0.95 3 3.028 3.017 48 2.41 2.78 2,3 4.94 4.93

99 0.00 0.00 99 0.85 0.85 4 49 30.60 3.08 4 4.94 4.95

100 1.62 1.62 100 0.00 0.00 5 50 2.56 2.69 5 3.30 3.29

101 3.29 3.29 101 1.80 1.80 6 5 5 51 2.55 2.67 6 0.00 0.00

102 3.29 3.29 102 3.08 3.06 7 2.256 2.17 52 0.00 0.00

103 2.06 2.06 103 0.00 0.00 8 0 0 53 2.53 2.68 Q112

Q112Q112

Q112

104 2.05 2.05 104 0.00 0.00 54 2.52 2.66 1 0.00 0.00

105 0.00 3.30 105 0.00 0.00 55 30.60 3.07 2,3 3.32 3.31

106 0.00 0.00 106 0.00 0.00 56 2.52 2.28 4 3.35 3.35

107 0.00 3.30 107 0.00 2.10 57 0.00 0.00 5 4.93 4.94

108 0.00 3.30 108 1.80 1.80 58 0.00 0.00 6 0.50 0.00

109 0.00 0.00 109 0.00 0.00 59 0.00 0.00

110 0.00 0.50 110 0.98 0.80 60 1.10 1.50 Q113

Q113Q113

Q113

111 0.00 0.00 111 0.76 0.90 61 2.17 1.54 1 0.00 0.00

112 0.00 0.00 112 1.19 1.30 62 2.07 1.54 2,3 1.74 1.73

113 0.00 0.00 113 3.03 3.05 63 2.08 1.78 4 1.78 1.78

114 0.00 0.00 114 0.88 0.78 64 2.14 1.66 5 4.93 4.94

115 0.00 0.00 115 0.00 0.00 65 0.06 0.15 6 0.00 0.00

116 0.00 0.00 116 1.13 1.26 66 0.06 0.25

117 0.00 0.00 117 2.29 2.33 67 3.05 3.04

118 0.00 0.00 118 0.86 0.08 68 1.64 1.61

119 0.00 0.00 119 1.13 1.20 69 0.00 0.09

120 3.30 3.30 120 1.90 2.00 70 0.00 0.08

121 1.10 0.50 121 0.00 0.00 71 0.00 0.00

122 3.30 3.30 122 3.06 3.10 72 0.00 0.00

123 3.30 3.30 123 3.07 3.10 73 0.00 0.00

124 0.00 0.00 124 3.07 3.10 74 2.23 0.00

125 3.30 3.30 125 3.07 3.06 75 3.06 3.03

126 3.30 3.30 126 3.07 3.06 76 2.86 1.70

127 0.00 2.32 127 3.07 3.06 77 2.40 1.76

128 0.00 0.00 128 3.07 3.06 78 0.00 0.00

IC302

IC302IC302

IC302

129 3.30 3.30 129 3.07 3.05 79 2.55 1.86

130 3.30 3.30 130 3.07 3.05 80 2.57 1.92

131 3.30 3.30 131 3.07 3.06 81 3.06 3.06

132 0.00 1.40 132 0.00 0.00 82 2.54 1.84

133 0.00 0.00 133 3.06 3.06 83 2.54 1.66

134 3.30 3.30 134 3.06 3.06 84 0.00 0.00

135 3.30 3.30 135 1.80 1.80 85 0.00 1.77

136 0.00 0.00 136 3.07 3.05 86 0.00 0.03

137 1.38 1.38 137 3.07 3.10

138 2.12 2.12 138 3.06 3.10

139 0.00 0.00 139 3.06 3.10 1 0.00 3.01

140 0.00 0.00 140 3.07 3.06 2 0.22 0.00

141 0.00 3.25 141 3.06 3.10 3 0.03 3.01

142 3.30 3.30 142 3.06 3.10 4 0.00 0.00

143 1.10 0.50 143 3.06 3.10 5 3.00 3.02

144 0.00 0.00 144 3.06 3.10 6 0.00 0.00

145 0.00 0.00 145 3.06 3.10 7 0.00 0.00

146 0.00 0.00 146 3.06 3.10 8 0.00 3.03

147 2.33 0.00 147 0.00 0.00 9 0.00 0.00

148 0.00 2.32 148 3.06 3.10 10 3.00 3.00

149 0.00 0.00 149 3.04 3.10 11 0.00 3.00

150 1.10 0.50 150 3.04 3.10 12 3.00 3.00

151 0.00 1.20 151 3.03 3.10 13 3.00 3.00

152 0.00 3.30 152 3.04 3.10 14 3.00 3.00

153 0.00 0.00 153 3.03 3.10 15 0.01 0.01

154 1.00 0.50 154 3.06 3.06 16 0.00 2.96

155 0.00 0.50 155 3.05 3.10 17 3.82 0.00

156 3.30 3.30 156 3.07 3.10 18 4.61 4.53

157 3.30 3.30 157 3.05 3.10 19 0.00 0.00

158 0.00 0.00 158 3.05 3.10 20 0.00 0.00

159 0.00 0.00 159 1.80 1.80 21 0.00 0.00

160 0.00 0.00 160 1.54 1.50 22 2.98 0.00

161 2.71 2.70 161 3.07 3.10 23 3.00 2.75

162 3.29 3.29 162 0.00 0.00 24 3.00 0.01

163 3.29 3.29 163 3.06 0.00 25 0.00 0.10

164 2.08 2.08 164 3.05 3.10 26 3.01 3.00

165 2.07 2.07 165 3.05 3.10 27 3.01 3.01

166 2.08 2.08 166 3.05 3.10 28 3.01 3.00

167 1.47 1.47 167 3.05 3.10 29 0.00 3.00

168 0.00 0.00 168 3.05 3.10 30 0.00 0.00

169 1.62 1.60 169 3.08 3.06 31 0.00 2.98

170 0.00 3.29 170 3.08 3.10 32 0.00 3.00

171 0.00 1.80 171 0.00 0.00 33 3.01 0.01

172 3.30 3.01 172 3.05 3.10 34 0.20 0.01

173 3.30 3.29 173 3.05 3.10 35 3.05 3.02

174 3.30 3.30 174 3.05 3.10 36 3.04 3.03

175 3.30 3.29 175 0.40 1.50 37 3.04 3.04

176 0.00 0.00 176 3.05 3.10 38 3.03 3.01

177 3.30 3.30 177 0.00 0.00 39 3.05 3.02

178 3.30 3.30 178 3.05 3.10 40 3.05 3.02

179 3.30 3.21 179 3.05 3.10 41 3.05 3.02

180 0.00 1.50 180 3.05 3.10 42 3.05 3.02

181 0.00 0.00 181 3.06 3.06 43 0.01 0.00

182 0.00 0.00 182 3.06 3.18 44 0.00 0.00

183 0.00 0.00 183 0.00 0.09 45 3.01 3.00

184 0.00 0.00 184 3.07 3.00 46 0.00 0.01

185 0.00 0.00 185 0.00 2.40 47 3.01 3.00

186 3.30 3.30 186 0.00 2.30 48 3.01 2.41

187 0.48 0.70 187 0.00 0.00 49 3.05 3.02

188 3.30 3.30 188 0.00 0.00 50 3.05 3.02

189 0.48 1.60 189 3.08 3.10 51 3.01 3.02

190 0.47 0.50 190 0.00 0.00 52 3.04 3.02

191 0.48 0.50 191 0.00 0.02 53 3.05 3.02

192 0.10 0.10 192 1.80 1.80 54 3.05 3.02

193 3.28 1.60 193 3.07 3.10 55 3.05 3.02

194 2.45 0.50 194 3.07 3.10 56 3.05 3.02

195 0.51 0.43 195 0.03 0.00 57 3.03 3.01

196 0.00 0.00 196 3.07 3.06 58 3.05 3.01

197 0.00 3.07 197 0.00 1.30 59 3.05 3.01

198 0.00 1.60 198 3.07 3.10 60 3.05 3.02

199 0.00 0.10 199 3.07 3.10 61 0.40 0.39

200 0.00 3.10 200 3.07 3.10 62 0.00 0.00

201 0.00 0.10 201 0.00 0.00 63 3.05 3.00

202 0.00 0.10 202 0.00 2.30 64 3.05 2.99

203 0.00 0.10 203 3.07 3.10 65 3.05 2.93

204 0.00 0.10 204 0.00 0.00 66 3.05 2.93

205 3.30 2.90 205 3.03 3.10 67 3.07 2.96

206 0.00 1.59 206 3.06 3.10 68 3.03 2.95

207 0.00 3.29 207 3.58 3.10 69 0.02 0.00

208 0.00 3.29 208 4.78 1.50 70 0.00 2.93

208 0.00 3.29 209 3.06 3.10 71 3.07 2.94

210 3.06 3.06 72 0.03 0.02

211 0.00 0.02 73 0.00 0.02

212 1.80 1.80 74 3.07 2.95

213 3.03 3.19 75 0.00 0.00

214 0.00 2.69 76 3.03 2.91

215 1.50 1.50 77 0.00 0.00

216 3.02 2.90 78 3.03 2.89

217 0.00 2.59 79 0.00 2.84

218 0.00 0.00 80 0.00 0.00

219 0.00 2.29 81 3.03 2.99

220 0.00 2.08 82 3.03 2.99

221 0.00 2.30 83 0.27 2.83

222 0.00 2.30 84 0.00 0.00

223 0.00 2.49 85 0.00 2.86

224 3.05 3.06 86 3.03 0.05

225 0.00 3.10 87 3.00 0.02

226 0.00 2.40 88 3.03 3.00

227 3.00 2.40 89 4.40 4.35

228 0.00 0.00 90 0.00 0.00

229 2.50 1.52 91 0.00 4.35

230 0.00 0.00 92 3.00 0.02

231 2.51 1.60 93 3.03 3.00

232 2.53 1.60 94 0.00 0.00

233 3.04 3.06 95 3.03 0.00

234 2.55 1.60 96 0.00 0.00

235 2.37 1.60 97 3.01 2.98

236 2.87 1.60 98 3.03 3.00

237 0.00 0.00 99 3.03 3.00

238 2.22 1.60 100 0.08 0.00

239 2.55 1.40

240 2.53 1.50

1 0.00 0.00

IC502

IC502IC502

IC502 2 0.40 0.39

1 0.00 0.00 3 2.93 2.99

2 5.09 5.08 4 2.92 2.97

3 0.00 0.00 5 2.90 2.98

4 3.72 3.72 6 2.99 2.98

5 0.00 0.00 7 3.00 2.97

6 5.06 5.01 8 2.99 2.95

7 0.00 0.00 9 2.96 2.95

8 5.06 5.02 10 0.02 0.00

1 0.00 0.00 11 0.00 0.00

2 5.09 5.08 12 0.00 0.00

3 0.00 0.00 13 0.00 0.00

4 3.72 3.72 14 0.00 0.00

5 0.00 0.00 15 0.00 0.00

6 5.06 5.01 16 0.00 0.00

7 0.00 0.00 17 0.00 0.00

8 5.06 5.02 18 0.00 0.00

19 0.00 2.30

IC303

IC303IC303

IC303

IC310IC310

IC310

20 3.01 3.06

1 0.00 0.00

2 3.02 2.99

3 3.02 2.99

4 2.97 2.99

5 2.94 3.00

6 2.95 3.00

7 2.97 2.99

8 2.95 2.98

9 2.94 3.00

10 0.00 0.00

11 0.00 0.00

12 2,89 2.70

13 3.04 0.70

14 0.00 0.00

15 0.00 0.00

16 0.00 0.00

17 0.00 0.00

18 0.00 0.00

19 0.00 0.00

20 3.03 3.04

IC311

IC311IC311

IC311

PIN STOP PLAY

POWER

Q105

1, 8

2, 3

4, 5

6, 7

0.00 0.00

0.00 0.00

8.79 8.74

8.50 8.45

Q109

1

2, 3

4

5

0.00 0.00

8.51 8.44

8.51 8.44

3.31 3.31

6

0.00 0.00

Q104

1

2, 4

3

5

0.00 0.00

4.94 4.95

1.17 1.18

4.93 4.96

6

4.94 4.96

7,10

8.44 8.44

8

3.30 3.22

9

7.08 6.20

Q106

1, 2, 3

5, 6, 7,8

4

8.50 8.45

7.05 6.05

4.90 4.94

Q110

1

4

5

6

2, 3

8.50 8.45

7.05 6.05

4.90

3.30

4.94

3.29

0.00

0.00

Q101

1

3

2

5.43 5.44

0.00 0.00

4.88 4.88

Q108

1, 2, 5, 6

4

3

11.56 11.94

11.94 11.95

9.60 9.55

IC120

4

3

2, 4

0.00 0.00

4.96 4.96

11.91 11.92

Q107

1

3

2

0.00 0.00

1.79 1.76

8.52 8.44

4

6.73 6.61

5, 6, 7, 8

3.40 3.40

Q113

1

4

2, 3

0.00 0.00

1.74 1.73

1.78 1.78

5

4.93 4.94

6

0.00 0.00

Q112

1

4

2, 3

0.00 0.00

3.32 3.31

3.35 3.35

5

4.93 4.94

6

0.50 0.00

IC109

1

3

2, 5

3.30 3.29

4.93 4.93

0.00 0.00

4

8.50 8.43

6

1.22 1.18

IC108

1

3

2, 5

5.43 5.44

3.26 3.31

0.00 0.00

4

1.42 1.61

5

3.42 3.34

6

8.49 8.43

7

6.80 6.62

8

4.20 4.12

9

1.18 1.18

10

1.18 1.18

11

3.37 3.37

12, 15

3.35 3.35

13

0.90 0.90

14

0.00 0.00

16

1.79 1.79

Page 54

3-62 3-63

PRINTED CIRCUIT DIAGRAMS

1. MAIN P.C. BOARD

LOCATION GUIDE

LOCATION GUIDE

Page 55

3-64 3-65

2. FRONT & KEY P. C. BOARD

LOCATION GUIDE

LOCATION GUIDE

Page 56

MEMO

MEMO

Loading...

Loading...