Zenith Autoboil 3 Litre White, Autoboil 5 Litre Stainless Steel, Autoboil 3 Litre Stainless Steel, Autoboil 5 Litre White, Autoboil 7.5 Litre White Installation And Operating Instructions Manual

...Page 1

Zenith Autoboil

Installation and Operating Instructions

™

303652 Zenith Autoboil 3 Litre White

303651 Zenith Autoboil 3 Litre Stainless Steel

305652 Zenith Autoboil 5 Litre White

305651 Zenith Autoboil 5 Litre Stainless Steel

307652 Zenith Autoboil 7.5 Litre White

307651 Zenith Autoboil 7.5 Litre Stainless Steel

804545NZ - BW_AB Small_09.18 v1.02 Page 1 of 24

Page 2

Contents

Read These Warnings First ..................................................................................................................................3

Installation Requirements .....................................................................................................................................3

Installation Procedures .........................................................................................................................................4

Step 1 – Positioning .........................................................................................................................4

Step 2 – Fastening ..........................................................................................................................4

Step 3 – Connecting ........................................................................................................................5

3.1 Plumbing .........................................................................................................................5

3.2 Venting ...........................................................................................................................5

3.3 Electrical .........................................................................................................................6

Step 4 – Installing Filter Guide ........................................................................................................6

Step 5 – Installing Tap ....................................................................................................................6

Step 6 – Installing Filter ..................................................................................................................7

Step 7 – Commissioning - Filter Flush & Calibrate ........................................................................7

Menu Operation ...................................................................................................................................................9

Wall Mounting Template Dimensions ................................................................................................................17

Spare Parts ..........................................................................................................................................................18

Exploded View Diagram .......................................................................................................................................19

Problem Solving ...................................................................................................................................................20

Earthing Continuity Verification ............................................................................................................................21

Operating Procedures ..........................................................................................................................................21

Filter Replacement ...............................................................................................................................................22

Cleaning ...............................................................................................................................................................23

End of Life Disposal .............................................................................................................................................23

Contact Details .....................................................................................................................................................24

Note:

All plumbing must comply with the relevant parts of AS/NZS 3500

All electrical must comply with the relevant parts of AS/NZS 60335/3000

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

For products sold in Europe, this appliance can be

used by children aged from 8 years and above and

persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge

if they have been given supervision or instruction

concerning use of the appliance in a safe way and

understand the hazards involved. Children should

be supervised to ensure that they do not play with the

appliance. Cleaning and user maintenance shall not

be made by children without supervision.

This appliance is intended to be used in household

and similar applications such as

- Staff kitchen areas in shops, ofces and other working environments;

- Farm houses and by clients in hotels, motels and

other residential type environments;

- Bed and breakfast type environments;

- Catering and similar non-retail applications.

Page 2 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 3

Read These Warnings First

Please read all installation requirements, installation procedures and

precautions before installing any Zenith Autoboil instant boiling water

heater.

Never attempt to install any Zenith Autoboil instant boiling water heater

without reading all of the applicable instructions.

In some hard water areas where mineral scale accumulation in the boiling

chamber of the Zenith Autoboil may become a problem, consideration

should be given to the maintenance required. A suitable form of water

treatment may be necessary.

The cold water supply to this appliance must be potable and fall within your

local authority’s guidelines.

All plumbing connections must be made in accordance with local

regulations.

The Zenith Autoboil instant boiling water heater is not intended for use by

young children or infirm people without supervision.

Young children should be prevented from having access to ensure that they

are not able to use or play with the heater.

This appliance must be earthed. If the power supply cord is damaged it

must be replaced by a Zenith authorised agent or a qualified electrician.

Do not remove the cover of the heater under any circumstances without first

isolating the heater from the power supply.

Do not use strong, corrosive or abrasive cleaners to clean the case of the

heater.

Frost protection: If this heater is located where ambient air temperature

could fall below 5ºC when the heater is not in use, do not turn off the

appliance electrically. This safeguide does not offer the same protection to

the connecting pipework and fittings.

The ambient temperatures this unit must operate within is 5ºC - 50ºC.

This heater is intended only for indoor use and should never be installed

outdoors or be exposed to the elements of nature.

This unit must not be positioned in an area that may be cleaned by a water

jet. This unit must not be cleaned by a water jet.

Installation Requirements

Before installing, ensure that the following are available:

a) Sufficient space to position the heater so there is at least 100 mm

clearance above the heater for service access, 150 mm to its left and

20 mm to its right – the tap outlet must be positioned at least

300 mm above a draining board or drip tray.

b) Standard 220- 240 volt power cable positioned as shown on the paper

mounting template for connection from the rear of the heater to the

terminal block within the heater, OR a standard 10 amp 220- 240 volt

power outlet on the wall within 1500 mm of the heater. This switch must

provide all-pole disconnection and a contact separation of at least 3 mm

installed in accordance with wiring rules, see Step 3 - 3.3).

c) Cold water supply with a minimum working pressure of 70 kPa and a

maximum working pressure of 700 kPa connected via an isolation valve.

d) Outlet drainage to a sink draining board or to a drip tray.

804545NZ - BW_AB Small_09.18 v1.02 Page 3 of 24

Page 4

Installation Requirements

Approximate Weight When Filled

3.0 Litre models 12.5 kg

5.0 Litre models 16.5 kg

7.5 Litre models 20.5 kg

COLD

INLET

100 mm

minimum

clearance

150 mm

VENT

OUTLET

INLET

POSITION

VENT

POSITION

20 mm

minimum

clearance

from right

edge to wall

300 mm

e) Access to drainage from a vent situated at the base of the heater.

f) If the water pressure is likely to exceed 700 kPa, a 350 kPa pressure

reducing valve must be installed in the cold water supply line.

f) In all installation instances the walls of the heater must be vertical and

the base horizontal, there can be no exceptions to this rule.

Installation Procedures

Before You Begin

Refer to the mounting-hole template on page 17.

Read the installation and operating instructions completely.

Decide whether to install with concealed or exposed plumbing and/or

electrical connections. Concealed connections are preferred for superior

appearance.

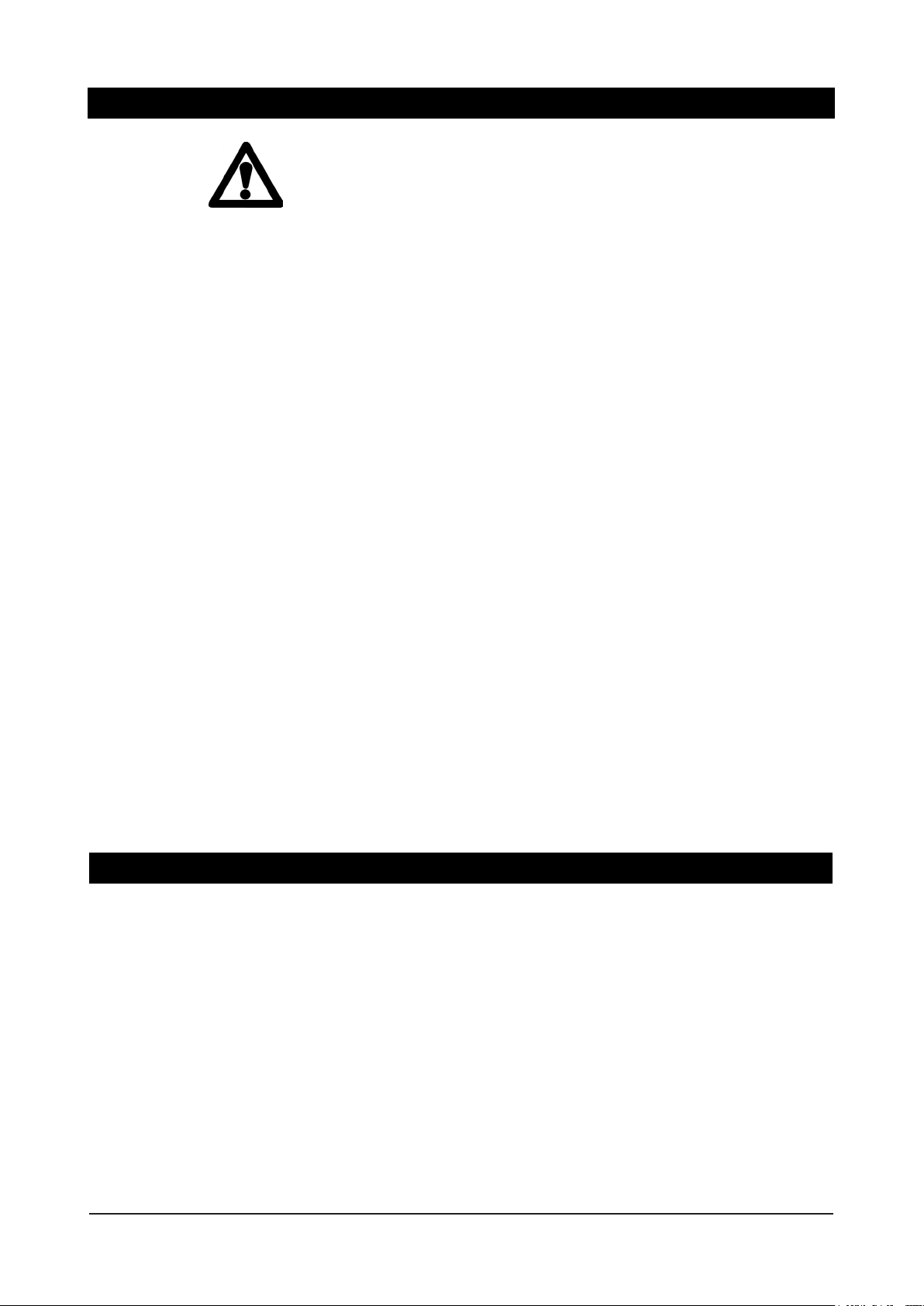

Step 1 – Positioning

Position the heater so the tap will drain on to a draining board or drip tray.

Position the base of the tap to be not less than 300 mm above the

draining board (height should be increased only if essential for filling larger

vessels).

Provide clearance for service access of not less than 100 mm top, 150 mm

left, 20 mm right.

Mark corner positions for the heater on the wall so as to position the paper

mounting-hole template.

Step 2 – Fastening

Position mounting-hole template on wall and drill holes where shown.

Remove cover fastening screws from heater and lift whole cover off heater.

Remove filter guide as shown in picture above.

Install plumbing and wiring and prepare pipe ends and wiring ends as

shown.

Screw heater chassis to the wall using screws or bolts suited to the wall.

Screws or bolts must be capable of supporting the heater weight when

filled.

Page 4 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 5

Installation Procedures

1

45 mm

Concealed

Inlet

Concealed

Vent

Warning: If pressure is likely

to exceed 700 kPa, a pressure

limiting valve must be installed

in the cold water supply line.

Zenith recommends a valve

rated at 350 kPa for this application.

2

Remove Filter Guard

Step 3 – Connecting

THE FOLLOWING PROCEDURE IS TO BE DONE BY AN AUTHORISED

INSTALLER ONLY.

3.1 Plumbing

For exposed plumbing connection, connect the cold water inlet pipe from the

base of the heater directly to the 12.7 mm compression fittings.

For concealed plumbing connections, connect the cold water pipe through

the rear of the chassis using a 12.7 mm capillary elbow (# 63 Swivel

Elbows).

Cold water pipes must be flushed before connection to the inlet. Any

clogging due to sediment or fines will adversely affect the operation of the

heater.

It is recommended that the heater be installed with a stop cock which allows

it to be isolated from the mains supply for servicing.

Water pressure requirements:

Minimum - 70 kPa maximum - 700 kPa.

3.2 Venting

A vent at the base of the heater must be plumbed to a safe visible location

as, under certain conditions, it may discharge cold or boiling water and/or

steam.

For exposed vent plumbing, connect vent outlet from the base of heater to

a 12.7 mm pipe which has a continuous fall, is no more than 3 metres long,

has no more than 3 right angle bends, and visibly discharges to a waste

water drain.

Alternatively attach a tundish to the wall as shown and plumb away to

waste.

Vent line

804545NZ - BW_AB Small_09.18 v1.02 Page 5 of 24

Visible Tundish

Note: when routing the plumbing for the vent / tundish installed and mains

inlet line, ensure you do not obstruct filter access for filter replacement.

Page 6

Installation Procedures

3.3 Electrical

Warning: Do not turn on the power until instructed. Water must first be available from the tap

outlet to prevent damage.

This unit is designed for connection to a 220-240 volt AC

power supply via either a concealed electrical connection or

an exposed electrical connection.

For an exposed electrical connection, the pre-fitted flex

and plug cable is plugged into the PCB as shown. Use a

standard 10 amp, 220-240 volt power outlet within 1500

mm from the heater with adequate power for the unit.

For a concealed electrical connection, disconnect the

pre-fitted flex and plug cable at the PCB connector and

discard. Connect the Live (Active) and Neutral wires of the

concealed power cable through the rear access opening to

the green terminal block on the PCB. Crimp a 6.3 mm QC

female spade connector to the earth wire of the concealed

power cable and attach to the chassis earth male terminal.

For a concealed electrical connection, an isolation switch

should be installed.

Check that the earth is connected through the PCB to the

chassis with an ohm meter.

Warning: Do not connect both options. It is essential that the flex and plug cable is removed

from the PCB if the concealed connection is used. Otherwise the GPO plug will become live.

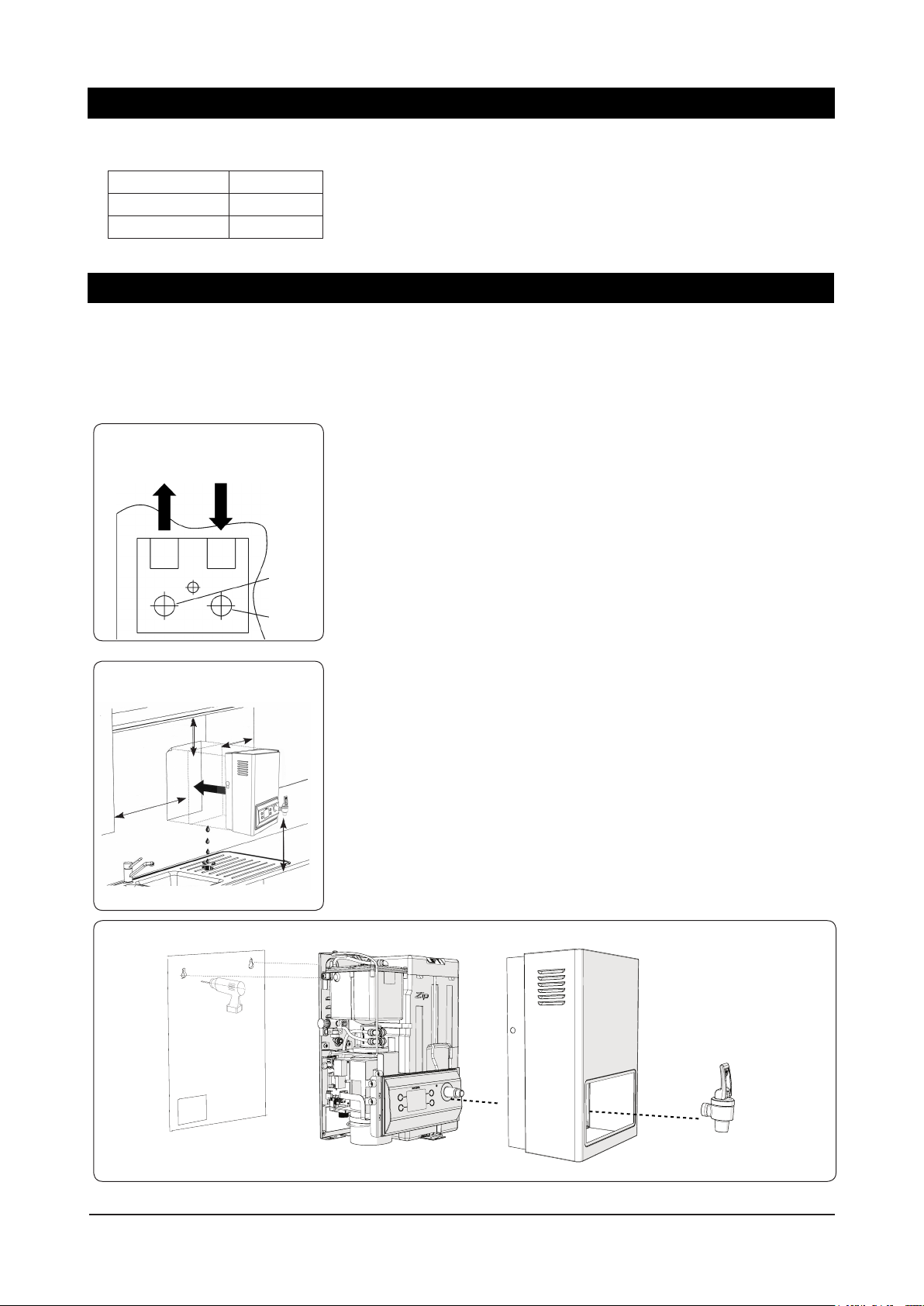

Step 4 – Installing Filter Guide

Assemble the lter guide provided with the unit, make sure it is locked in position, then put the cover back on.

1. Push the lter guide upwards 2. Rotate clockwise until locked

Step 5 – Installing Tap

Thread Tape

1. After the lter guide is installed, t the cover to the

unit and x with screws top and bottom.

Page 6 of 24 804545NZ - BW_AB Small_09.18 v1.02

2. Before installing the tap, ensure sufcient

thread tape is applied to the thread.

Page 7

Installation Procedures

FILTER FLUSH

FILTERED

Lock nut

3. After the cover is tted, turn the tap fully clockwise to

the end stop and stopped at upright position.

4. Use the spanner supplied to tighten the lock nut

anti-clockwise.

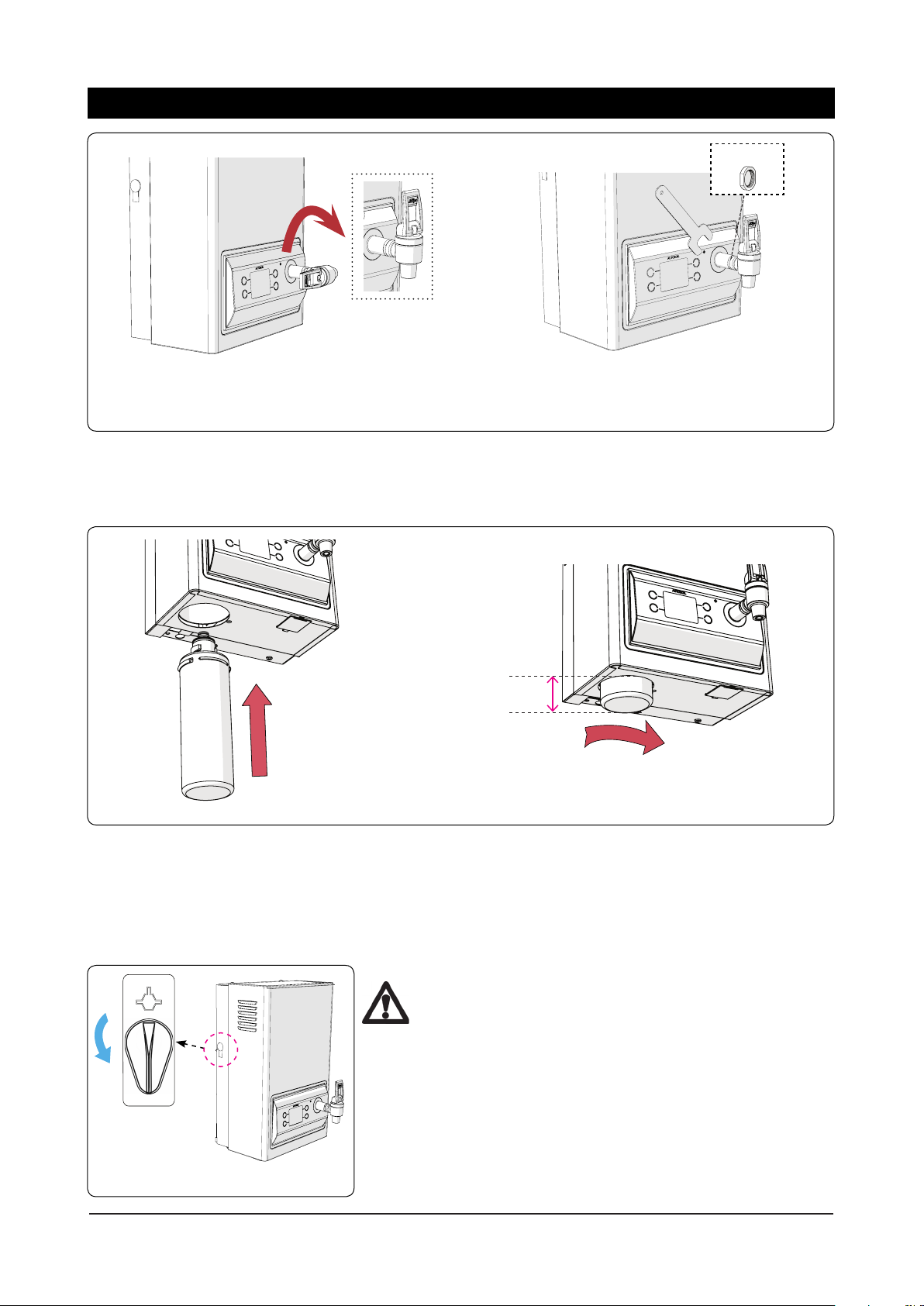

Step 6 – Installing Filter

To install a lter, insert the lter into the base of the unit as shown and turn 90° until a click or stop point is reached, see

images below. There should be approximately 20mm of the lter protuding when installed.

20mm

1. Insert the lter

2. Turn the lter through 90° until

fully engaged

NOTE: For safe operation, the filter cartridge should be replaced every 6-12 months, or earlier if you notice a

persistent reduction in water pressure from the appliance or an unpleasant taste or odour in the water. Refer to

Filter Replacement section on page 21 for instructions of changing lter.

Step 7 – Commissioning - Filter Flush & Calibrate

Warning: Do not turn on the power until instructed.

Water must first be available from the tap outlet to

prevent damage.

1. The filter flush valve switch is located on the left side of the

unit. Check that it is in the correct position to perform a filter

Rotate lter switch

to FILTER FLUSH

Fig.1

804545NZ - BW_AB Small_09.18 v1.02 Page 7 of 24

flush. Rotate the filter flush switch (either way) to point down

to the “FILTER FLUSH” position, as shown in Fig.1.

2. Turn on the mains water. Allow at least 5 litres of water to

flush through the filter. Make sure there is water flowing from

Page 8

Installation Procedures

FILTER FLUSH

FILTERED

the vent outlet (i.e. the valve setting is correct). Water should not flow

into the tank.

3. Once the filter flush is complete, rotate the filter valve switch 180°

(either way) to point up to the “FILTERED” position (Fig.2).

Rotate switch to

FILTERED

Fig.2

Depress

4. Open the tap (push the lever backwards) into the locked open

position (Fig.2) and allow the tank to fill until water flows from the tap

outlet.

5. Once the water is available from the tap, turn off the mains water and

close the tap outlet.

6. Turn on the power to the unit (water must be in the tank).

7. Touch the white circle next to the left of the [Tick] to “Continue”

Inlet water

15°C 10°C

temp

3.0 Litre models 16 min 17 min

5.0 Litre models 16 min 17 min

7.5 Litre models 23 min 24 min

For screen operation, see the section on “Menu Operation”.

8. Boiling Calibration will commence. It will take several minutes for the

water to boil.

Calibrating Completed

9. When it completes (as prompted), turn on the mains water supply.

10. Select to

Continue

11. The home screen will be shown (see section 2.1).

12. The tank will fill and heat. It will take the initial times shown in the

table to reach the final state.

Page 8 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 9

1. Understanding Icons and Buttons

Menu Operation

The Autoboil uses a display and button menu system for

setup and operation adjustment.

The display does not have a touch screen feature. The side

buttons are used to navigate, perform selections and modify

values.

The icon changes according to the button action. A button

has no function when no icon is shown.

2. Home Screen Content

Move to the next item able to be highlighted.

Move to the previous item able to be highlighted.

Confirm menu selection.

Move to the previous menu.

Perform one of 3 functions:

1. Move to the menu titled by the highlighted item.

2. Select the currently highlighted item to adjust it.

3. Confirm the value of a selected item.

Increment the item selected.

Decrement the item selected.

2.1 Normal Mode

Button 2 shows faults information.

Button 3 shows more information about the lter life.

Fault Indication:

There are no current faults.

Shown red, there are current faults.

804545NZ - BW_AB Small_09.18 v1.02 Page 9 of 24

Page 10

Menu Operation

Using to navigate to the lter life settings

menu.

Button 4 will show more information about the sleep

mode settings.

Using to navigate to the sleep mode settings

menu.

Filter Indication:

Days remaining of lter life.

Shown red, lter needs replacement.

Sleep Mode Indication:

Unit will enter sleep mode at the time shown.

Unit will enter sleep mode when it is dark.

All sleep saving modes are disabled.

2.2 Sleep Mode

Trigger Indication:

Unit will exit sleep mode at the time shown.

Unit will exit sleep mode when ambient light returns to normal (bright room).

Page 10 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 11

2.3 Sleep Override Mode

Menu Operation

Awake time remaining:

Unit will return back to sleep mode after this time.

3. Settings Menu

Select on the home screen to navigate to the main menu.

Choose

Settings

and select

Choose an option and select

Main Menu Settings Menu

804545NZ - BW_AB Small_09.18 v1.02 Page 11 of 24

Page 12

Menu Operation

3.1 Settings - Date/Time

From the settings menu choose

and select

Navigating using and

Perform a selection or confirm an adjusted value using

Adjust the date/time values using and

Note: Time can be in 12hr or 24hr mode.

To set up time choose a selection, then

Settings

3.3 Settings - Sleep Modes

From the settings menu choose

and select

Sleep Modes

3.3.1 Sleep Trigger

Choose

Conrm using and return to the previous menu.

Sleep Trigger

to select the trigger for the unit to enter its sleep mode.

and select , and

Adjust value by using and then to conrm.

Follow similar steps to set up date.

3.2 Settings - Temperature

From the settings menu choose

select and to adjust boiling point.

Confirm using and return to the previous menu.

Note: Setting the temperature above 98°C may require

boiling calibration to prevent excessive steam release

or high energy usage (see section 4.2).

Settings

and

Disabled

Timer

Ambient Light

the unit will not enter its sleep mode.

the unit will use the on/off timer settings to enter and exit its sleep mode.

the unit will enter its sleep mode when

darkness is detected and will exit its

sleep mode when the ambient light

returns to a normal level (bright room).

3.3.2 Sleep Action

Choose

to select the heating mode action when the unit is in its

sleep mode. Conrm using and return to the previous

menu.

Sleep Action

and select and

Page 12 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 13

Menu Operation

68°C

While the unit is in its sleep mode the

set point of the water will be reduced

to 68°C.

Off

While the unit is in its sleep mode no

heating of the water will occur.

3.3.3 Timer Settings

Choose

Conrm using and return to the previous menu.

Timer Settings

and select and

to select the trigger for the unit to enter its sleep mode.

► Saving changes

to exit the timer settings menu. A confirmation menu will

be shown.

Choose

confirm. Choose

Continue

to save changes and to

Cancel

to discard changes

and to confirm.

3.4 Settings - Filter

Everyday

Adjust on/off timer settings for all 7 days

simultaneously.

Weekdays

Adjust on/off timer settings for all 5

weekdays simultaneously.

Weekends

Adjust on/off timer settings for the 2

weekend days simultaneously.

Adjust on/off timer settings for the 7

Individual Days

days separately.

►Individual Days Settings

Choose item and adjust value, then to confirm.

From the settings menu choose

Filter

and select

3.4.1 Internal / External Filters

Choose

Internal

or

and select

Choose one of the following options and select

External

Note: There is a similar set of menus for both internal

and external lters.

804545NZ - BW_AB Small_09.18 v1.02 Page 13 of 24

Page 14

Menu Operation

3.4.2 Filter Life / Usage

This allows modication of lter life and usage parameters.

Filter Life – Options are:

► Disabled (no lter replacement reminder will be shown on

home screen)

► 1-14 months (Default 12 months)

Filter Usage – Automatically increments daily. This is reset to

“0 Days” when a lter reset is performed. Can be adjusted if a

partially used lter is inserted.

The days remaining of the lter shown on this menu and on

the home screen are based on these 2 parameters.

Choose

the lter usage counter.

Continue

and select to reset

3.4.2 Filter Log

The log shows the dates that the lter usage counter was reset

and the “days used” before the reset was performed.

Use and to scroll through the log history.

3.4.3 Replace Filter

This action will reset the lter usage counter. A reminder is

shown to ush the new lter before doing this (see page 21 -

Filter Replacement).

Select to continue after ushing.

4. Install Menu

Select on the home screen to navigate to the main menu.

Choose

Install

and select

Page 14 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 15

4.1 Install - Light Calibration

Menu Operation

From the install menu choose

select

Before continuing ensure the unit is in its normal typical light

environment and the front panel is not covered.

Select to perform the calibration. It will complete after 6

seconds.

Continue

and

The unit will heat the water for boiling calibration. This

may take several minutes depending on the initial water

temperature. When it completes the screen will automatically

return to the install screen.

4.3 Install - Power Cycle

From the install menu choose

select

This will turn the unit briey off then on (restart). All custom

settings will be retained.

Choose

the power cycle.

Continue

Power Cycle

and select to perform

and

Select to continue.

4.2 Install - Boiling Calibration

This automatically corrects for boiling point differences at

each installation site. The unit was calibrated by the installer

at installation; however the installation environment may have

changed requiring recalibration of the boiling point.

Incorrect boiling calibration points may cause excessive

steam vent releases, or increased energy usage.

Boiling calibration is recommended when the temperature

setting is close to 100°C (section 3.2).

From the install menu choose

select

Continue

and

804545NZ - BW_AB Small_09.18 v1.02 Page 15 of 24

Page 16

Menu Operation

5. Info Menu

Select on the home screen to navigate to the main menu.

Choose

Info

and select

5.2 Info - Current Fault

From the info menu choose

Current Fault

6. Service Menu

Note: The service menu is used by technicians only for

diagnostic purposes.

Choose value then select

5.1 Info - Product

From the install menu choose

Product

Page 16 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 17

Wall Mounting Template Dimensions

250 (7.5L)

52 (7.5L)

250 (5L)

52 (5L)

37 (3L)

235 (3L)

37 (1.5L)

235 (1.5L)

561 (7.5L)

448 (5L)

414 (3L)

329 (1.5L)

70

40

25

37

55

56

Cold

Inlet

76

Positioning pin

Vent

External Plumbing

Electrical Wiring

Internal Plumbing

273 (1.5L & 3L)

302 (5L & 7.5L)

542 (7.5L)

429 (5L)

395 (3L)

310 (1.5L)

804545NZ - BW_AB Small_09.18 v1.02 Page 17 of 24

Page 18

Spare Parts

Item Kit Number Description

EB & AB 3 Ltr Tank Assy

EB & AB 5 Ltr Tank Assy

EB & AB 7.5 Ltr Tank Assy

AB Fascia & PCB assy

AB Fascia & PCB assy Grey

Escutcheon

Tap Lock Nut

Tap Top Assy

Flow Insert

Tap Body

Hot Tank NTC

Loom, PCB to Overload

Ribbon Cable

Plug, HB Outlet

PCB, AB Powerboard

0.2 mic Zenith MicroPurity Filter 2 size

Cistern Tank

Ball Valve assy

Cistern Gasket

Cistern Lid EB & AB

Elbow Stem 1/4"

Grommet, Cistern to Tank

Overload

Side release plug

Seal transfer tube

10

12

13

14

15

16

17

18

19

20

21

22

94443NZ

1

2

3

4

5

6

7

8

9

11

94444NZ

94445NZ

94479NZ

94480NZ

94447NZ

94448NZ

90501NZ

93730NZ

94478NZ

91440NZ

94449NZ

94481NZ

94451NZ

94482NZ

93704NZ

94454NZ

94455NZ

94456NZ

94457NZ

93118NZ

90100NZ

94458NZ

94459NZ

94460NZ

Item Kit Number Description

23

24

25

26

27

28

29

30

31

32

33

34

35

36

38

39

40

94483NZ

94461NZ

90485NZ

90486NZ

94484NZ

94485NZ

94486NZ

94487NZ

94488NZ

94489NZ

94470NZ

90493NZ

90494NZ

94471NZ

94472NZ

90506NZ

94473NZ

94474NZ

94490NZ

94491NZ

94492NZ

94493NZ

94494NZ

94495NZ

Metering Tube 1.5 & 3 Ltr

Metering Tube 5 & 7.5 Ltr

Element assy 1500W 1.5 & 3

Element assy 2400W 5 & 7.5

Bush Vent assy 3 ltr

Bush Vent assy 5 ltr

Bush Vent assy 7.5 ltr

Inlet assy

AB Fascia Kit

AB Fascia Kit Grey

Tap assy

Metering tube kit 1.5 & 3 Ltr

Metering tube kit 5 & 7.5 Ltr

Cistern Gasket kit

Cistern assy

Tap Outlet

Hot Tank Gasket kit 1.5 & 3 Ltr

Hot Tank Gasket kit 5 & 7.5 Ltr

PCB Splash Guard

Filter Flush Valve

Filter Head Kit (no Bracket)

PCB & Filter Bracket

Filter Guide

Grommet

Page 18 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 19

Exploded View Diagram

18

17 20

31

36

21

35

16

40

15

14

12

34

19

29

26

30

2322

9

25

24

33

1

38

39

32

11

13

10

7 6 5

28

8

234

27

804545NZ - BW_AB Small_09.18 v1.02 Page 19 of 24

Page 20

Problem Solving

Symptom Possible Cause Solution

Fails to dispense water.

Water not boiling.

Runs out of boiling water and

fails to refill.

Outlet tap drips.

Overflow from vent.

Excessive steam from vent.

Power “on” but no heat.

Overload repeatedly tripping with

excessive steam.

Overload repeatedly tripping

without

excessive steam.

Sleep/Wakes incorrectly when

room is light/dark.

Incorrect filter flush valve setting.

Incorrect filter insertion.

Water isolating valve turned off.

Blocked filter, blocked meter tube,

blocked strainer, jammed ball

valve assembly.

Incorrect temperature setting.

Incorrect sleep mode setting.

No power.

Faulty thermostat, faulty element,

faulty cutout.

Requires boiling calibration.

Incorrect filter flush valve setting.

Incorrect filter insertion.

Internal adjustment.

Requires light calibration.

Incorrect sleep modes settings.

Check filter flush valve position

(see Step 7, page 8).

Check filter is inserted correctly

(see page 21).

Check water supply valve.

Contact Zenith authorised agent.

Check temperature setting

(see section 3.2).

Check sleep mode settings (see section

3.3) or reset settings from service menu.

Check power supply.

Contact Zenith authorised agent.

Perform boiling calibration

(see section 4.2).

Check filter flush valve position

(see Step 7, page 8).

Check filter is inserted correctly

(see page 21).

Contact Zenith authorised agent.

Perform light calibration

(see section 4.1).

Check sleep mode settings (see section

3.3) or reset settings from service menu.

Page 20 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 21

Earthing Continuity Verification

If required, an earth continuity test

can be performed by testing between

the earth pin on the products lead

and a exposed piece of metal on the

case and the tap body.

Warning: this appliance must be earthed.

Following remedial service the earthing continuity of the heater must be

checked by a qualified technician using an appliance tester, or continuity

tester of accuracy Class 5 or better. Class 5 denotes an accuracy of 5% full

scale deflection.

1. Isolate power supply.

2. Set meter to 0 ohm with leads connected together.

3. Connect one test lead to the earth pin on the three pin plug.

4. Connect the other test lead to a bare patch of metal (preferably on the

edge) of the top of the cover, then to the front cover of the unit, and then to

the tap.

Warning- the water may be boiling - show extra care.

5. Test that in every instance the electrical resistance does not exceed 1

ohm.

Operating Procedures

Tap Operation

Boiling water

Zenith Autoboil is fitted with a two-way tap for filtered instant boiling

water.

For instant boiling water, gently pull the top of the tap forward.

Boiling water will flow until the tap handle is released.

This operation gives fingertip flow control for safe filling of cups and

mugs.

To fill larger vessels such as teapots and saucepans, rotate the tap

180 degrees and depress it until it locks into a horizontal position.

Boiling water will flow until the tap is returned to its normal vertical

position. This operation allows the vessel to be filled without

holding your hand where it may be affected by steam.

804545NZ - BW_AB Small_09.18 v1.02 Page 21 of 24

Page 22

Filter Replacement

NOTE: For safe operation, the filter cartridge should

be replaced every 6-12 months, or earlier if you notice

a persistent reduction in water pressure from the

appliance or an unpleasant taste or odour in the water.

To Replace Filter:

• Turn the filter anti-clockwise (Fig.1) and pull the cartridge down

(Fig.2). Have an absorbent cloth ready as a small amount of

water will be released as the filter is removed. The cartridge

should release from the filter head.

1. Turn the lter anti-clockwise.

Fig.1

Fig.2

2. Remove the

lter by gently

pulling down.

• Replace with a new filter by gently pushing up, engaging the

key and turning the filter clockwise until the filter clicks or

locks into place.

• Perform filter flush by following the steps 1 - 4 only on pages

7-8 (Step 7 - Commissioning).

• Go to [Replace Fitler] screen to reset the lter usage counter.

Follow the instructions on page 14 (3.4.3 Replace Filter)

section for details of menu operation.

Warning! Not changing filtration cartridges when

required may cause the water to become biologically

unsafe.

If the Zenith Autoboil is switched off for a long period of time (e.g.

more than a weekend), run water through the outlet for at least 5

minutes before consumption.

Use only Zenith Filters in this product to ensure effective filtration

and operation. Replacement filter cartridges can be obtained

through plumbing suppliers or directly from Zenith.

Filter replacement instructions are included with the filter cartridge

spare part kits.

Please dispose of the filter cartridge responsibly.

Page 22 of 24 804545NZ - BW_AB Small_09.18 v1.02

Page 23

Cleaning

Cleaning Case

Do not use strong, corrosive, spray or abrasive cleaners. Clean the

case with a soft cloth or sponge and mild soapy water.

End of life disposal

In order to help preserve our environment we ask that you dispose

of this product correctly. Please contact your local city council for

collection centre details.

804545NZ - BW_AB Small_09.18 v1.02 Page 23 of 24

Page 24

Contact Details

New Zealand Head Office

Zenith Heaters Limited

IRD/GST No. 95 640 729

Unit 2/15 Moselle Avenue

Henderson

Auckland 0610

New Zealand

www.zenithwater.co.nz

Telephone +(64 9) 838 8612

Free Call 0800 558 055

As Zenith’s policy is one of continuous product improvement, changes to

specifications may be made without prior notice. Images in this booklet have been

modified and may not be true representations of the finished goods.

The standard cup referred to in this publication is 167 ml (6 fl oz).

The standard glass is 200 ml (7 fl oz).

The terms “Zenith” “Hydroboil”, “Autoboil”,” Econoboil”, “Power-Pulse”, “GlobalPlus”,

“MicroPurity” are trademarks of Zip Heaters (Aust) Pty Ltd.

Products described in this publication are manufactured under one or more patents

and further patent applications are pending.

One or more products described in this publication are also registered designs of

Zip Heaters (Aust) Pty Ltd.

Please check the website for the latest user manual

www.zenithwater.co.nz

© 2018 Zenith Heaters Ltd. All Rights Reserved.

Page 24 of 24 804545NZ - BW_AB Small_09.18 v1.02

Loading...

Loading...