Page 1

Installation and Operating Instructions

®

Zenith HydroTap

Filtered boiling and chilled drinking water for kitchens and tea rooms.

Commercial Models

37671 Zenith HydroTap BC60/85

30271 Zenith HydroTap BC100/125

30281 Zenith HydroTap BC150/175

37201 Zenith HydroTap B10OF

38201 Zenith HydroTap B150F

37691 Zenith HydroTap B60

37291 Zenith HydroTap B100

38291 Zenith HydroTap B150

Disabled Models

37676 Zenith HydroTap BCD60/85

37276 Zenith HydroTap BCD100/125

38286 Zenith HydroTap BCD150/175

37206 Zenith HydroTap BD10OF

38206 Zenith HydroTap BD150F

37696 Zenith HydroTap BD60

37296 Zenith HydroTap BD100

38296 Zenith HydroTap BD150

81467 - February 2005

Domestic models

30009 Zenith HydroTap HT60

30609 Zenith HydroTap HTD60

36051 Zenith HydroTap HT60/85

36651 Zenith HydroTap HTD60/85

37606 Zenith HydroTap BFD60 (Ambient)

37601 Zenith HydroTap BF60 (Ambient)

Page 2

Contents

Read These Warnings First . . . . . . . . . . . . . . . . . . . . . . . . . .3

Models covered by these instructions . . . . . . . . . . . . . . . . . .4

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Special tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Step A - Installing the tap (all models) . . . . . . . . . . . .5

Step B - Installing the undersink unit (all models) . . .6

Step C - Connecting the tap, BC & B models . . . . . . .6

Step D - Connecting the Water Supply (all models) . .7

Step E - Testing and commissioning . . . . . . . . . . . . .7

Font Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating the Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Replacing the Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Pull-out Font Template pages . . . . . . . . . . . . . . . . . . . . . .a, b, c, d.

Setting the Energy Saver Timer . . . . . . . . . . . . . . . . . . . . . . .15

AuxillIiary Fan Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Hot Safety Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Exploded view Chiller Module and Spares . . . . . . . . . . . . . . .18

Exploded view Boiler Module and Spares . . . . . . . . . . . . . . .19

Exploded view HT series boiler only . . . . . . . . . . . . . . . . . . .20

Intentionally blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Intentionally blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Intentionally blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

NOTE:

All plumbing must comply with AS3500.4.1 & AS3500.4.2

All electrical must comply with AS3350.1,AS3350.2.15

Page 2 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 3

The power point must be located within

reach of it’s cable.The appliance must be

positioned so that the plug is accessable.

Read These Warnings First

Safety

Do not allow young children, handica pped or infirm persons, to use the Zenith

HydroTap without supervision.

Refrigerant

The Zenith HydroTap Chilling unit contains 134A refrigerant under pressure. No

part of the unit should be exposed to a naked flame. Maintenance of the

refrigeration unit must be carried out by an accredited service provider or

qualified refrigeration mechanic.

Qualifications

If any power cord or plug is damaged it must be repaired only by a qualified

technician.To avoid hazards,all installation procedures must be carried out by

a suitably qualified tradesperson.The power cord and general power outlet

must be in a safe visible position for connection.

Venting

Sometimes steam and / or boiling water may discharge through a vent outlet at

the mouth of the tap. If the ta p is not installed using the Font pedestal, ensure

the tap body is located so the tap outlet safely drains into the sink bowl area.

NOTE: On startup, the controls take the system through a calibration process

which causes the unit to over-boil for a period of 90 secs.This is normal

operation, once this mode is completed the system reverts back to normal

operation.

Zip Hydrotap undersink assembly.

The appliance must be placed in a

horizontal position, as shown above.

Lifting

Take care when lifting the Zenith HydroTap undersink unit.Some units may exceed

safe lifting limits. Do not lift without assistance. The weights of the units are

given in the table under the heading “Installation Requirements”.Do not lift the

unit by the doors.

Airflow

The ambient temperatures this unit should operate within are 5ºC - 35ºC. Proper

air circulation must be provided.The system will operate satisfactorily only if

the recommended air gaps are provided, these are 65mm min rear clearance

and 50mm side clearance.An air vent is provided with each unit for high usage

applications, this must be installed in the top half of the cupboard door as a

matter of course.An optional fan kit is available and should be used to ensure

adequate ventilation. Make sure that the ventilation grilles of the undersink unit

are not obstructed.

Altitude (not HT boiling only series)

The Zenith HydroTap is equipped with a self-calibrating program which caters for

altitude adjustment.

Filter For models : BC, BD, BF

The Zenith HydroTap filter control is preset to 6000 Litres to provide trouble-free

flow and operation in most installations. Local water quality conditions may

require an alteration to this capacity.In areas where the water has a high

concentration of sediment, the preset litre ca pacity may be shortened to avoid

poor flow,taste or odour situations. In areas where the water quality is above

average, lengthening the preset capacity may be desirable, but not essential. If

any of these changes is needed, follo w the instructions on page 11 or contact

your Zenith Service Provider.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 3 of 20

Page 4

# Section Heading# Section Heading

Read These Warnings First continued

Frost Protection

If this appliance is located where the ambient air temperature could fall below 5ºC

when the heater is not in use, do not turn off the a ppliance electrically.This

safeguard does not offer the same protection to the connecting pipework and

fittings.

Installation Environment Considerations

This unit is intended for indoor use only and should never be installed outdoors

or exposed to the elements of nature.This unit must not be positioned in an

area that may be cleaned by a water jet.This unit must not be cleaned by a

water jet.

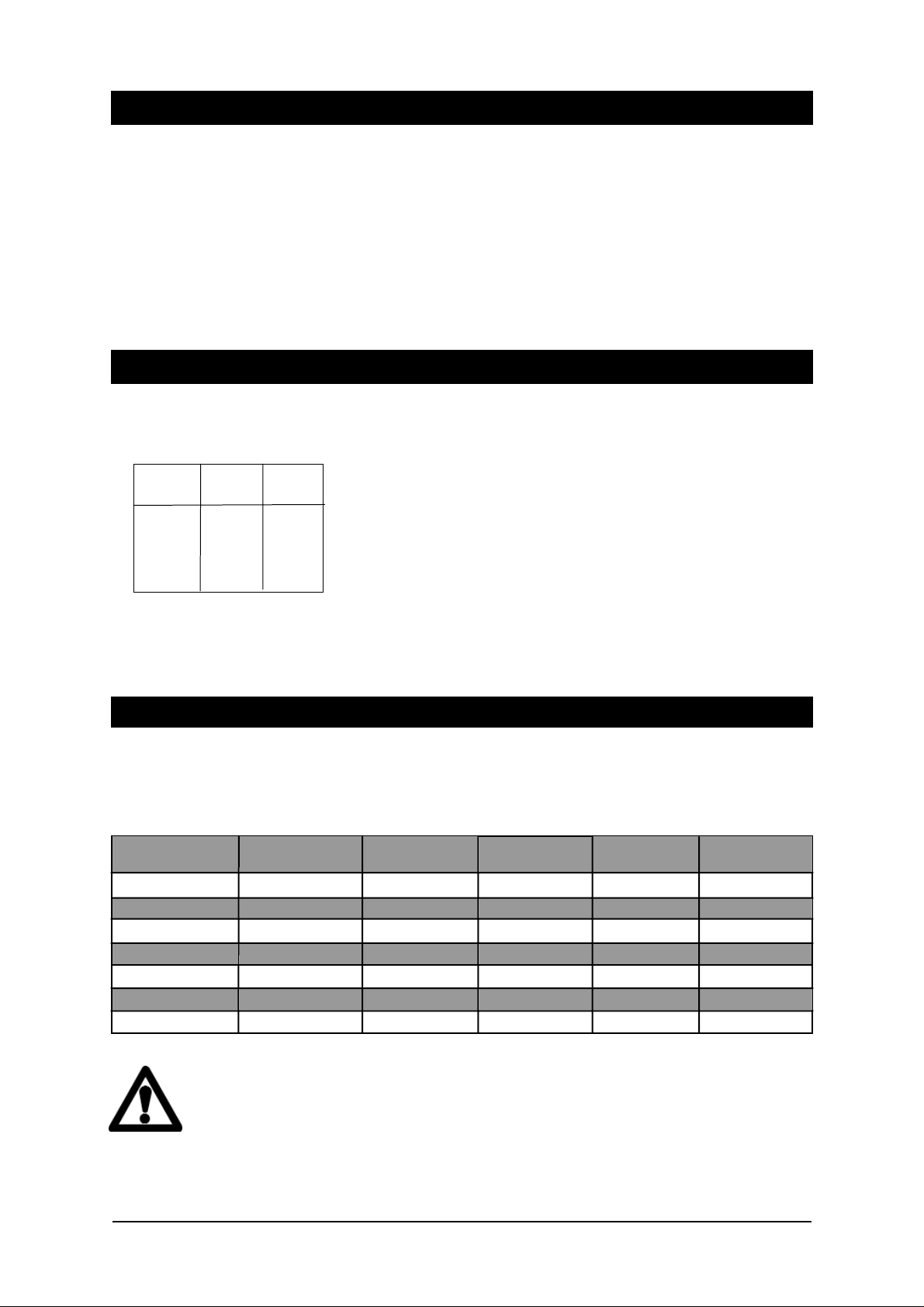

Models covered by these instructions

These Installation Instructions cover the entire Zenith HydroTap range.Use the

chart on the left to identify the model you are using:

Commercial and Domestic Models:

BC = Boiling and Chilled, Filtered, Timer

BC

Model

100

Cups of

Boiling Water

per Hour

125

Glasses of

Chilled Water

per Hour

BF = Boiling, Filtered

BD = Boiling and Ambient Filtered

B = Boiling only (unfiltered)

D = Disabled Lever controls, (Optional order only)

HT = Domestic Models (boiling only are unfiltered, boiling/chilled are filtered)

Boiling Water Capacity:

100 = 100 cups in one hour 150 = 150 cups in one hour

Chilled Water Capacity: (BC only)

125 = 125 glasses in one hour 175 = 175 glasses in one hour

Filtration: (BC, BD and BF only)

Note: The Cup measurement = 167mls, the Glass measurement = 200mls.

Model

BC & HT 60/85

BC 100/125

BC 150/175

BD 60

B 150

B 100

B 60

Installation Requirements

Before installing ensure that the following have been provided at the

installation site:

• Sufficient space in the cupboard to install the undersink unit in accordance

with these Installation Instructions.A table of dimensions is given below.

Height

mm (inch)

337 (13.2) 430 (16.9) 440 (17.3) 28 (61.7) 34.5 (76)

337 (13.2) 430 (16.9) 28 (61.7) 35 (77.1)

395 (15.5) 465 (18.3) 500 (19.6) 29.5 (65) 38 (83.7)

353 (13.8) 320 (12.5) 9 (19.8)

409 (16.1) 340 (13.3) 321 (12.6) 10 (22) 14 (30.8)

353 (13.8) 320 (12.5) 9.5 (20.9) 12 (26.4)

353 (13.8) 320 (12.5) 290 (11.4) 9 (19.8) 11.5 (25.3)

NOTE: Add 65mm to the Depth to the under-sink unit to allow for Water and Electrical connections

• A water supply connection with isolating valve inside the cupboard within

Depth

mm (inch)

reach of the 750 mm flexible connection and positioned so that the

connection point and the stop cock will not be obstructed when the

undersink unit is installed.

Width

mm (inch)

440 (17.3)

290 (11.4)

290 (11.4)

Weight empty

kg’s lbs

Weight full

kg’s lbs

11.5 (25.3)

• Power supply 220-240 Volt AC,for connection to the heater via a 10 amp

G.P.O.

Page 4 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 5

Installation Requirements continued

• This switch must provide all-pole disconnection and a contact separation

of at least 3mm installed in accordance with wiring rules.

• Cold water supply with a minimum working pressure of 175 kPa and a

maximum working pressure of 700 kPa connected via an isolation valve.If

pressure is likely to exceed 700 kPa,install a 500 kPa Pressure Limiting

Valve.

• The fitting of an air flow vent cut into the top half of the cupboard door

concealing the HydroTap requiring a cut size of approximately 100mm

circular, to provide adequate warm air displacement. In installations where

high volume draw-off will occur,the fitting of the accessory exhaust fan is

essential.

Important: Do not proceed with the installation if these requirements are

not met.

Special tools required

In addition to normal tools, the following will be required:

• 38mm diameter sheet metal hole punch for sink tops.(not supplied)

• 38mm diameter hole saw for timber bench tops.(not supplied)

• Nut runner tube spanner (supplied) for fixing tap assembly.

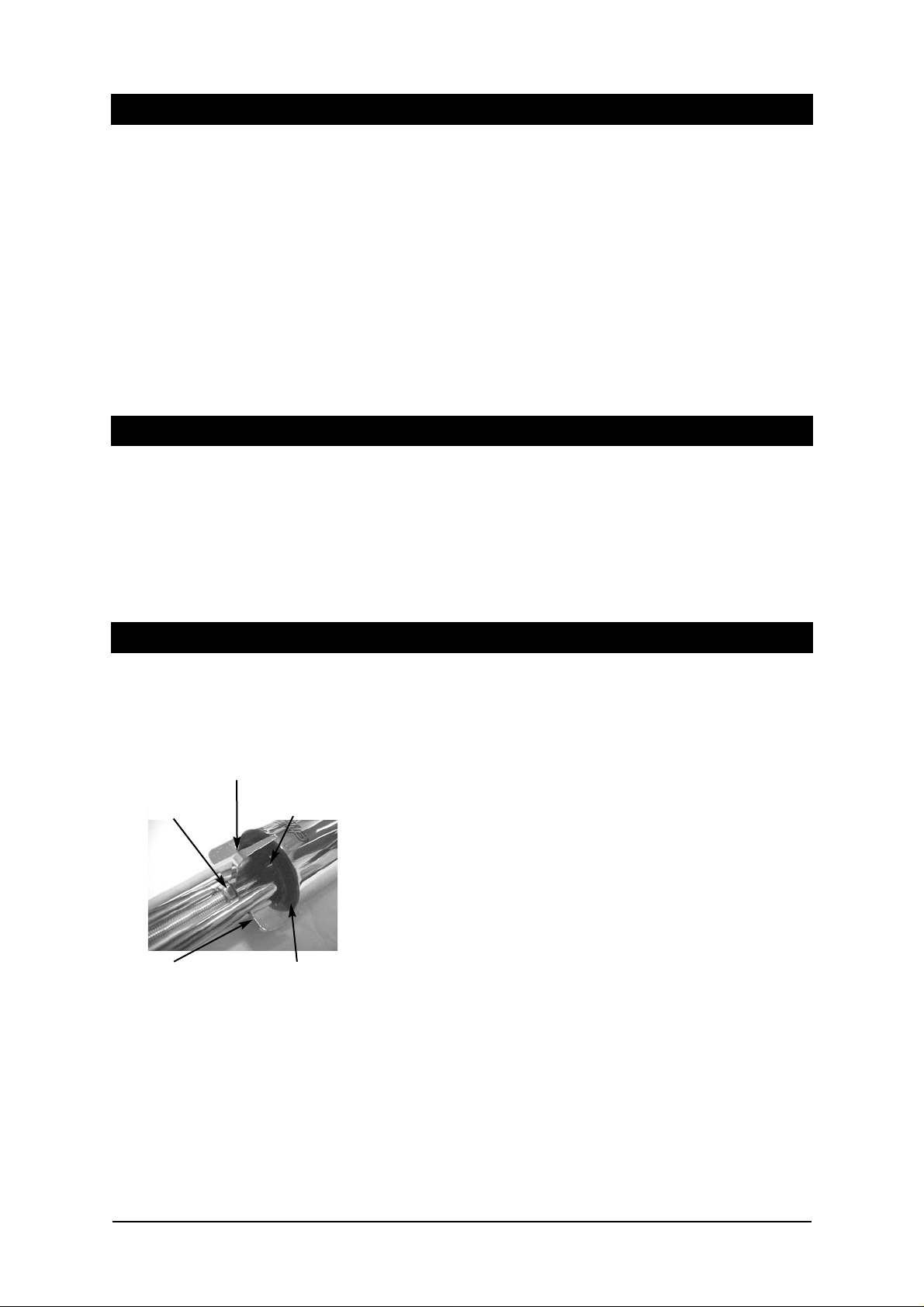

Note: A stainless steel washer is

supplied to go in between the

Spider Clamp and the underside

of the sink top. Position it here.

Fixing nut Black spacer

Spider clamp Smear silicon

on underside

flat surface

When installing a Font unit:

• 108mm diameter sheet metal or hole saw to suit surface being cut.

Installation procedure

Step A - Installing the tap (all models)

1. Make sure that the ta p location will allo w the nozzle to drain into the sink.

2. Install the 38mm hole in the bench / sink top.

3. Remove the “Spider Clamp” and S/S washer by undoing the 6mm nut

located on the “All Thread” at the base of the Tap Head Assembly.

A tube spanner is supplied in your installation kit for this job.

4. Ensure the black plastic spacer remains in place as this is the moisture

seal against the bench / sink top.A light smearing of silicon sealant on the

underside of the spacer will ensure a watertight fit.

5. Pass all three hoses through the 38mm hole and carefully locate the Head

Assembly and black spacer on the bench / sink area.

6. From the underside of the bench / sink area re-locate the S/S washer and

“Spider Clamp” by feeding each of the three tubes and electrical cable

evenly in between the legs of the “Spider Clamp”. Slide it up to meet the

“All Thread”,and pass the “All Thread”through the center of the “Spider

Clamp”.

7. Hold the “All Thread”steady and re-fit the 6mm nut to the “All Thread”

using the tube spanner supplied in the kit. Check the Tap Head position

before securing it tightly against the bench / sink top.

NOTE 1: The tap assembly must not be positioned more than 1m above

the HydroTap unit. Failure to do this may result in poor water delivery.

NOTE 2: Under no circumstances should the Tap be twisted after the

installation is complete.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 5 of 20

Page 6

Installation procedure continued

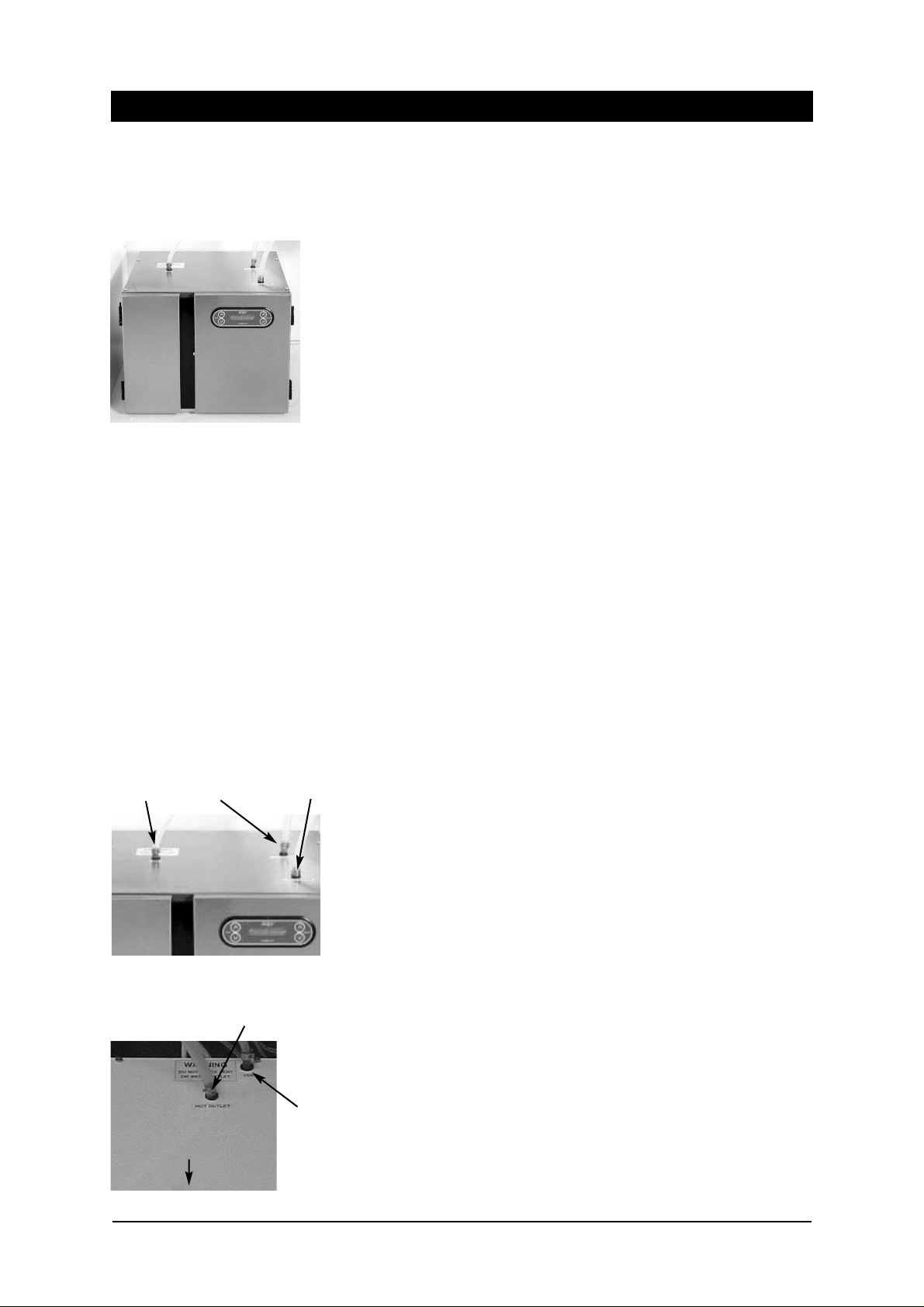

Step B - Installing the undersink unit (all models)

SPECIAL NOTE: The HydroTap undersink units are heavy,take note of the

weights listed in the table on page 4. If you think you cannot lift the unit

safely,get help and avoid possible injury.

Before positioning the heater connect the braided water inlet hose (supplied) to the

cold water inlet on the unit.This is located at the rear of the unit.

Position the Zenith HydroTap undersink unit as close as possible to directly beneath

the Zenith HydroTap tap head.

The connection tubes supplied with the tap head assembly CANNOT be lengthened.

Leave at least a 50 mm air-gap without obstruction on each side of the unit.

Adjust both cupboard door hinges and attach the supplied rubber door buffers to

the doors to create a 4 mm air-gap between the doors and the cupboard.This is

the minimum ventilation requirement for low usage installations.

Important Note: Proper air circulation must be provided for all Boiling and Chilled

models.The system will operate correctly only if the recommended air gaps are

achieved during installation.A ventilation hole measuring 100mm must be cut into

the top half of the cupboard door to accommodate the air vent provided. Make

sure that the undersink unit ventilation grilles are not obstructed in any way.

This instruction is critical!

Cupboard ventilation for Boiling only and Boiling Ambient models is recommended

but not essential.

Step C - Connecting the tap

Model BC and HT (boiling/chilled models)

Measure and trim the blue tube and connect it to the chilled water outlet located on

the top front, right hand side of the nder-sink unit. Use spring clamps provided.

Measure and trim the red marked tube and connect it to the hot water outlet

located on the top center,right hand side of the undersink unit. Use spring clamps

provided.

Measure and trim the unmarked tube and connect it to the vent outlet located on

the top center, left hand side the top of the undersink unit.Use spring clamps

Vent line

Chilled line Hot line

provided.

NOTE: All tubes must have a continuous fall back to the undersink unit.

Connect the tap USB connector to the USB connector attached to the undersink

unit. Orient the USB plug carefully and connect, do not force the plug. Once

connected, fix the cable to the wall, ensure it is away from any possible water

splashes and is off the floor.

Note: When trimming any silicon tubes trim to minimum length, do not loop any

excess or allow kinking of the tubes.When connecting, slide the tube over the pipe

at least 25mm.

Model B, BD and HT (boiling only models)

Hot Outlet

Measure and trim the red marked tube and / or the blue marked tube and connect

it to the hot water outlet and amblient outlet if a BD model, on the top of the

undersink unit. Use spring clamps provided.

Measure and trim the unmarked tube and connect it to the vent outlet on the top of

the undersink unit. Use spring clamps provided.

Vent

Front

NOTE: All tubes must have a continuous fall back to the undersink unit.

Connect the tap USB connector to the USB connector attached to the undersink

unit. Orient the USB plug carefully and connect, do not force the plug. Once

connected, fix the cable to the wall, ensure it is away from any possible water

splashes and is off the floor.

Page 6 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 7

Installation procedure continued

Step D - Connecting the water supply (all models)

To prevent sediment from entering the Zenith HydroTap at connection,flush water

through the supply line thoroughly before connection to the Zenith HydroTap.

Open the access door and check that the filter is in place and secure. Connect

the water supply to the undersink unit using the attached flexible hose.

Turn on water and check for leaks. If no leaks are evident turn the poer on.

Step E - Testing and commissioning (all models except boiling only HT models)

Use these buttons to

scroll through the menu

Use these buttons to

activate and de-activate

the program selected

Filter Flush Mode (filtered models only)

The display screen will show which model you have.

Have a bucket or similar container (not supplied) at the ready to

hold a quantity of water that is ejected while the Filter Flush Mode is in

operation. Open the filter access door on the front of the HydroTa p and the

filter cartridge will be exposed. Located to the rear RHS of the cartridge is a

fixed flush line, approx 600mm long and the flush line stop cock. Place the

free end of the flush line into the bucket or container (not supplied).

Turn “ON” both water and electricity supplies and open the flush line stop

cock.The display will show Filter Flush Mode. To activa te press adjust ∧. Run

at least 7.5 Ltrs of water through to activate the filter membrane. Press the

adjust ∧ button again to stop the Filter Flush Mode.Turn OFFthe Filter Flush

stop cock and re-locate the tube and stop cock in the filter compartment.

Turning OFF the Filter Flush Mode puts the HydroTap into calibration mode.

Press adjust ∧ to start calibration.The element will now cycle On and heat the

water to 95ºC maintaining it at that temperature for a short stabilization

period.

Once stabilized, the element will cycle On, bring the water to boiling point

and hold it there for a short period.

The unit now carries out a self calibration function to ensure correct

temperatures are maintained. During this period the Red LED on the Tap Head

assembly flashes slowly until the calibration function is complete.

Boiling Water Lever Chilled Water Lever

Red Light White Light Blue Light

Boiling Filter Status Chilled

Once this step is complete (approx 5 minutes) the unit will default to normal

operation.

When starting, both Boiling and Chilled cycles activate similtaneously after

calibration has taken place, the descriptions belo w indicate what ha ppens

during each cycle.

Boiling

The unit is now running in normal operating mode.The Red LED will flash until

usable temperature is reached.

Before using the HydroTap wait 5 minutes after this point to allow adequate fill

time.The unit is now ready for use. Testwater delivery from the tap and check

for appropriate temperatures. Use cable clips to tidy and secure wiring.

Chilled

When water and power is turned On, the Blue LED flashes slowly on the Tap

Head assembly.The compressor activa tes and water begins to fill the chiller

tank at the prescribed rate.When the water is chilled to 10ºC the Blue LED on

the Tap Head assembly stops flashing and stays illuminated. The compressor

continues to chill down to 5º after which it will cycle Off.

Ensure that the clock matches your local time. If not refer to page 15 “Set

time”. If Energy Sa ver Settings are required, the instructions for installing

these are described on on page 11 “Setting the Energ y Saver Timer”.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 7 of 20

Page 8

Cut a 10mm

slot for stud

Tap assy

hole 38mm

Font installation procedure

1. Position the Font template (provided) on the bench area. Ensure the

position you select is within the length of the supply tube and USB cable

fixed to the Tap Head Assembly.These cannot be extended.

2. Check a gain for correct positioning. The supply hoses must have

constant fall back to the tank assembly.Cut the holes as shown on

the template.

3. Once holes are cut, locate the Font base in position, from the underside,

lightly tighten the securing rod with the nut and washer provided.

4. Now take the Tap Head Assembly and remove the fixing nut, washer and

“Spider Clamp” from the “All Thread”.Apply a light smear of silicon

sealant to the underside of the black base ring, this will provide a water

tight seal against the Font base when clamped.

5. Feed the hoses and USB cable through the Font base, then through the

plastic spacer that sits under the font base but on the bench top, this

stops warping of the base plate. Ensure the Tap spout is directly centered

over the Font drain.Refit the “Spider Clamp”, nut and washer onto the “All

Thread”. Have all the supply tubes and USB cable located evenly between the

Spider Clamp legs.When satisfied with the positioning, tighten the fixing nut

with the Tube Spanner provided in the kit.

Fixing stud

Hole required for Font

recess 108mm

View from underside

Black ring

LARGE HOLE

Spider clamp

Drain elbow

All-thread

NOTE: The “All Thread” is a “floating” component, it locks into place once

tension is applied by the fixing nut and washer.

6. Tighten the securing pin so the Font base is flush with the bench top.

NOTE: The fixing nut above the drain elbow can be loosened to correctly

position the direction of the elbow.Ensure when the re-positioning is

complete the nut is re-tightened to ensure a water tight seal.

7. Connect a drain hose (22mm ID) from the Font base outlet elbow to the

closest drain trap spigot available. If a spigot is not available use the sna p

on spigot and worm drive clamps supplied in the kit.

8. Ensure the positioning of the snap-on spigot is on the “sink” side of the

trap and not the “waste”side. Once positioned, a hole (13mm ID) will

need to be drilled to provide waste access to the drain line.The snap-on

unit will require suitable sealant to keep it water tight against the waste

pipe. Finish by fitting the worm drive clamps tightly on either side of the

spigot and fitting worm drive clamps to either end of the drain hose.The

drain hose from the Font must have constant fall

9. Connect the Tap headAssembly supply hoses and vent as per the instructions

contained in the installation procedure section of this document.

Page 8 0f 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 9

Note: On the Boiling only models

the Chilled LED is blank.

Operating the Tap

Blue Chilled Water Light

On all the time:

This indicates that the chilled water temperature is within the usable range.

Flashing slowly :

This indicates that the chilled water is not at the right temperature. Wait up to

20 minutes.When the chilled water is ready,the light will stop flashing.

Note: The Zenith HydroTap is designed to dispense chilled water in the temperature

range 5°C to 10°C. During heavy usage, the temperature can rise out of this range.

Red Boiling Water Light

On all the time:

This indicates that the boiling water is ready.

Flashing slowly :

This indicates that the boiling water is below usable temperature.

Filter Change Light Off:

This indicates the filter is operating within its normal specified lifespan.

Filter Change Light Flashing slowly :

The light will flash slowly when the filter is due for replacement and the LCD will

show “Filter Change”. Refer to "Replacing the filter" section of this document.

Boiling Water Lever

Depressing the “Red” lever allows dispensing of boiling water.Pulling up the

Red lever allows the tap to operate in a “no-touch” mode. Water will flow for a

maximum time of 15 seconds. To reset,return the handle to the “Off ” position

and repeat the step.The lever has to be manually returned to the “Off” position.

Chilled Water Lever

Depressing the “Blue” lever allows dispensing of chilled water. Pulling up the

Blue lever allows the tap to operate in a “no-touch” mode. Water will flow for a

maximum time of 15 seconds. To reset,return the handle to the “Off ” position and

repeat the step.The lever has to be manually returned to the "Off" position.

Child Proof Lock (boiling / chilled models)

The child proof lock can be activated to prevent boiling water flowing if the hot

lever is inadvertently activated. To activate,first press the safety button then

depress the Blue chilled water lever for a period of approximately ten seconds. The

safety lock indicator light will now be illuminated. To de-activate, first press the

safety button then depress the Blue chilled water lever for a period of

approximately ten seconds.The safety lock indicator light will now extinguish. To

operate when the lock is "ON", depress both the Red lever and the safety button

simultaneously.

Child Proof Lock (all boiling only models except HT models)

To activate the child safety lock, go to the LCD display,using menu ∧ or ∨ scroll to

the Child Safety Lock display.To turn ON adjust ∧ to turn OFF adjust ∨ button.

After about 10 secs the screen will default to the selected mode. When activated

Child safety Lock

the LED on the safety lock will be illuminated. When de-activated the LED will be off.

Child Proof Lock (HT boiling only models)

Pressing the safety button rapidly three times will either activate or de-activate the lock.

Indicator light ON means the lock is active, indica tor OFF means the lock is inactive.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 9 of 20

Page 10

Cleaning

Do not use strong, corrosive, spray or abrasive cleaners. Clean with a soft cloth

or brush and mild soap and water.

Do not spray water over the tap as it may damage the low-voltage electronics.

Undersink units must never be cleaned with water jets.

Replacing the Filter (filtered models only)

The Zenith HydroTap notifies the user when filter replacement is due. The default

seting is 6000L. When a filter change is due, the Change Filter light flashes once

a minute and remains so until reset.The filter status light is located between the

Red and Blue Lights on the tap head assembly.Depending on local water quality

conditions and usage, the filter change period can be set in increments of 1000L

from 1,000L to 10,000L.The filter may also need to be replaced if unpleasant

odours or tastes occur.

Some water may drip from the filter head during replacement. Keep a bucket and

towel handy to catch drips and mop up any spills. To change the filter:

1. Scroll through the screen menu to “Filter Flush Off” this isola tes supply.

2. Relieve system pressure via the filter flush stop cock, a quick open and

close will do.

3. Grasp filter cartridge and twist right to left one quarter turn until it stops.

4. Ease cartridge downwards to detach it from the filter head (socket).

5. Do not tilt the cartridge as dirty water may spill from it if tilted.

6. Unpack replacement cartridge and write today’s date where shown on the

label.

7. Avoid touching the filter “O” rings and filter opening as this may cause

bacterial contamination of the cartridge.

8. Align cartridge tabs with the slots on the under-side of the filter head.

9. Slide cartridge upward into head and rotate left to right until it stops.

10. Locate the filter flush hose situa ted behind the filter cartridge and run to a

container ready for flushing. Open the flush hose ta p lever.On the control

panel press adjust ∧, this will start the water flushing the cartridge. Allow

at least 7.5 Ltrs of water to run through to activate the filter and then

press adjust ∧ to stop the flow.

11. Isolate the filter flush stop cock and re-fit behind the filter cartridge.

12. Wipe up any spills and dispose of spent filter cartridge and packaging

thoughtfully.

13. Scroll through the menu to “Litres Filtered”, press adjust ∧ to reset litre

counter. Then it asks “are you sure” press adjust ∧ a gain to lock in the

command.After approx 10 secs it will default to the selected mode.

Warning: If the Zenith HydroTap is switched off for a long period of time, e.g. longer

than a weekend, run water through the chilled wa ter outlet for at least 5 minutes

before consumption.

Page 10 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 11

Setting the Energy Saver Timer (products with this feature only)

Mode Plus Button

Mode Minus Button

Plus Adjust Button

Minus Adjust Button

Normal Operation (not available on HT boiling only series)

Set Time

To change time, press either Mode ∧ or Mode ∨ button until Set Time is on

the display screen. Press ∧ Adjust button to increase time or ∨ Adjust button

to decrease time.Time increases or decreases in increments of one minute.

Hold the Adjust buttons down for rapid increases or decreases.

Set Day

Press either Mode ∧ or Mode ∨ button until Set Day is displayed.

Press ∧ Adjust or ∨ Adjust to select day.

Filter Life ( factory set at 6000 litres )

Press either Mode ∧ or Mode ∨ button until Filter Life is displayed.

Press ∧ Adjust button to increase Filter Life or ∨ Adjust button to decrease

Filter Life.

Filter Life increases in 1000 Ltr increments to a maximum of 10000 Ltrs.

Reset Litres Filtered

This function is to reset the Filter Change display after a filter has reached the

end of its life (refer to “Replace Filter I

nstructions” section of this document).

Press either Mode ∧ or Mode ∨ button until Litres Filtered is displayed. Press

∧ Adjust once and “Reset Counter” will be displayed, press ∧ Adjust button

once and “Are You Sure”will be displayed.

Press ∧ Adjust once and Litres Filtered will be reset to 0.

Activating Sleep Mode

This mode allows the HydroTap to go into Energy Saving mode.In this mode

the unit will go to “sleep” after a pre-determined period of inactivity.Press either

Mode ∧ or Mode ∨ button until Sleep Mode is displayed. Press ∧ Adjust once

to select 2 Hours or twice to select 4 Hours.When the period of inactivity

passes, the display will show “Sleep Mode”. During sleep mode the Red LED on

top of the tap lever will flash slowly.

Activating On / Off Mode

Press either Mode ∧ or Mode ∨ button until "Monday On" is displayed.To set the

time for the unit to turn on press ∧ Adjust button until required time is reached.

To set the time for the unit to turn Off press Mode ∧ button once and Monday Off

will be displayed. Now press ∧ Adjust until required time is reached.

If each individual day is to have an “On / Off ” time, these steps need to be

repeated for each day and for each "On / Off" time.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 11 of 20

Page 12

Auxiliary Fan Attachment (excluding HT boiling only models)

Auxiliary fan

connection

Cold water

connection

Electrical

connections

The HydroTap is equipped with an auxiliary connection point for an exhaust fan

on the rear panel close to the cold water inlet / flex and plug area.The fan kit

is available as a spare part.The fan operates in parallel with the Condensor

fan helping to remove heat from the cupboard space.This fan should be

purchased and fitted to the HydroTap if the airfow characteristics of the

cupboard space are inadequate for the effective removal of hot air thereby

adversly affecting the operation of the HydroTap.

The fan can be installed so that it extracts air from, or forces air into the

cupboard space, whichever is the most effective for your installation.

Application of the fan is of paramount importance in situations where the

cupboard space reaches temperatures greater than 35ºC.

Boiling Water Safety Isolation (excluding HT boiling only models)

The HydroTap if equipped with a safety mode that allows protection against

accidental operation by Infirmed or disabled persons.

1. On the LCD scroll through the menu to Hot Isolation.

2. Press adjust ∧ to activate.

3. Press the safety button on the tap head (3) three times rapidly. The LEDs

will scroll from left to right (3) three times. This operation confirms the

activation.

4. This isolates the boiling tap only.The LCD shows isolation mode is active.

5. To de-activate, press the safety button (3) three times rapidy.

The LED’s will scroll from right to left (3) three times. This operation

confirms de-activation.

6. The LCD will show Normal Operation.

7. If de-activation mode is required, de-activate by scrolling through the

menu and selecting de-activate when Hot Isolation Mode is

displayed on the screen.

Page 12 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 13

Trouble Shooting

Symptom Possible Cause Solution

No LED display,no tap head

lights or, no water when tap

levers are operated.

No water flow.

Slow water recovery after

use.

Water not hot.

No power.

Plug is not located in power

socket.

Tap loom is not connected to

HydroTap unit.

Possible internal fault.

Program in OFF cycle

Water supply isolated.

Water supply not connected.

Power supply not connected.

Tap loom is not connected to

HydroTap unit.

Possible internal fault.

Program in OFF cycle.

Filter may require replacement.

Unit in Sleep Mode.

Unit has just come out of OFF

cycle.

Check power supply.

Ensure power plug is correctly fitted and switch is

turned ON.

Check loom connection.

Contact local Zenith service provider.

Check LCD for information.

Check water supply is on.

Check to ensure plumbing connecting is made.

Check power plug is correctly fitted and switch is

turned on.

Check for loom connection

Contact local Zenith service provider.

Check LCD for information.

Check filter usage on LCD screen, if “filter

change” is displayed follow instructions

on page 13.

Touch Hot lever and wait for Red LED to stop

flashing.

Wait for Red LED to stop flashing.

Water not chilled.

Possible internal fault.

Excessive use, unit refilling or

chilling down to temperature.

Possible internal fault.

Contact local Zenith service provider.

Wait for Blue LED to stop flashing.

Contact local Zenith service provider.

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 13 of 20

Page 14

Exploded View Chiller Module and Spare Parts

Item Kit No. Description Item Kit No. Description

1

plumbing fittings kit 14

braided hose

2

safety solenoid kit 15

level sensor kit cold tank BC100/125

3

double solenoid kit 15

level sensor it BC150/175

4

gasket and elbows kit cold tank 16

relay compressor kit BC100/125

5

dryer-filter kit nut and tube 16

relay compressor kit BC150/175

6

evaporator kit BC100/125 17

compressor kit BC100/125

6

evaporator kit BC150/175 17

compressor kit BC150/175

7

sensor probe kit 18

fan motor kit BC100/125

8

pump kit cold 18

fan motor kit BC150/175

9

PCB kit BC100/125 & BC150/175 19

capacitor kit BC100/125

9

PCB kit domestic BC60/85 19

capacitor kit BC150/175

9

PCB kit B100 & B150 20

loom level sensor kit

9

PCB kit domestic B60 21

transformer kit-auxillary fan

9

PCB kit boiling B100F & B150F 22

second solenoid boiling only model

9

PCB kit domestic B60F 23

38mm chassis punch

9

Pcb kit domestic ambient BF60 24

3ag-10amp fuse

10

transformer kit 25

2ag-2amp fuse

11

leak sensor kit 26

2ag-1amp fuse

12

control panel kit

13

stop valve and john guess fitting kit filter

Z90613

Z90614

Z90615

Z90631

Z90626

Z90632

Z90641

Z90633

Z90634

Z90622

Z90663

Z90664

Z90665

Z90666

Z90667

Z90668

Z90623

Z90624

Z90625

Z90628

Z90056

Z90635

Z90627

Z90636

Z90024

Z90637

Z90023

Z90639

Z90640

Z90437

Z90020

Z90185

Z90652

Z90657

Z90041

Z90671

Z90670

Z90669

Page 14 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 15

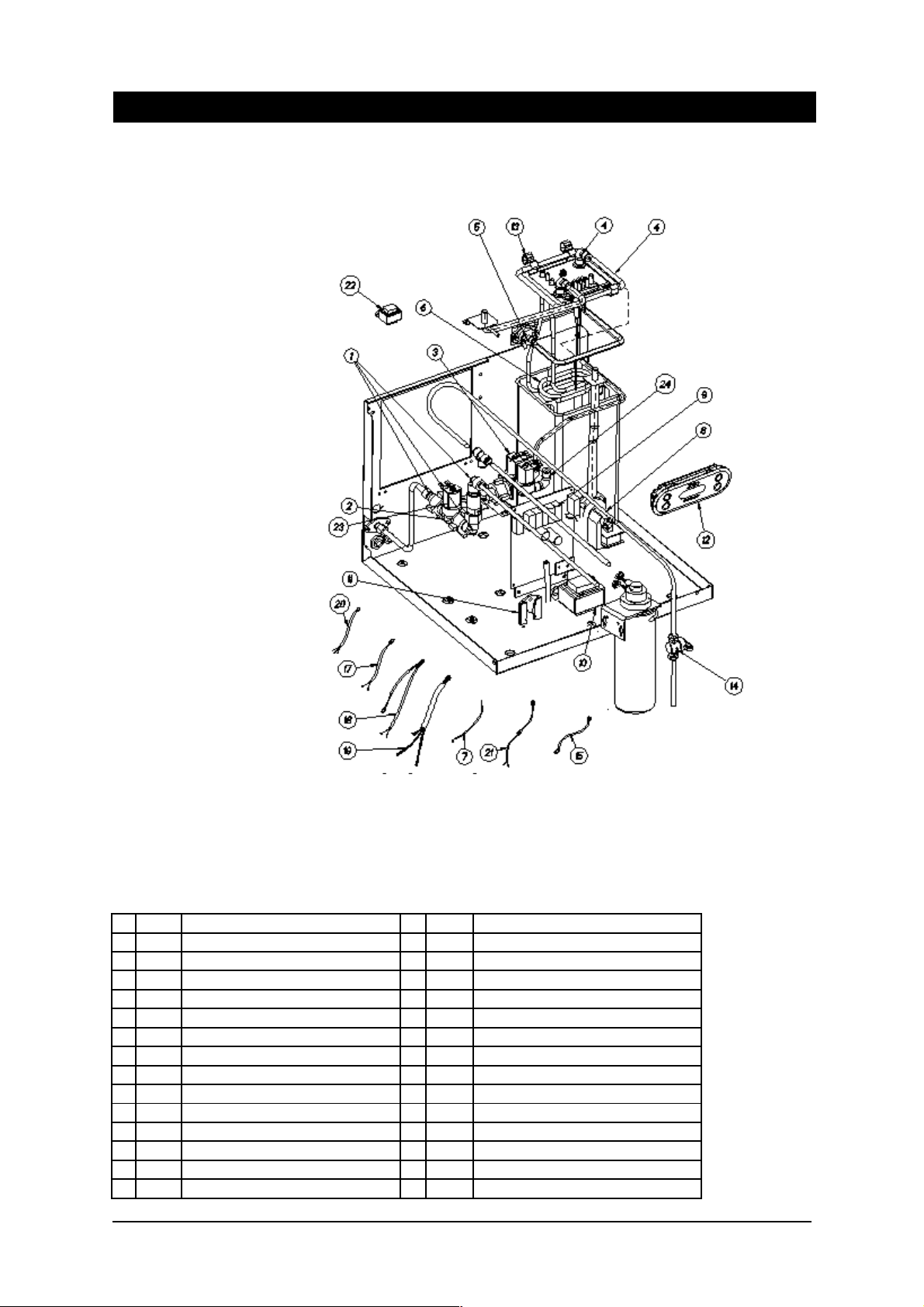

Exploded View Boiler Module and Spare Parts

Item Kit No. Description Item Kit No. Description

1

plumbing and fittings kit 13

clips kit

2

safety solenoid kit 14

stop valve and john guess fittings kit for filter

3

double solenoid kit 15

braided hose inlet

4

gasket and elbow kit BC 100/125 16

level sensor kit hot tank BC100/125

4

gasket and elbow kit BC 150/175 16

level sensor kit hot tank BC150/175

5

overload kit 17

loom-overlad kit

6

element 1500W kit 18

loom-compressor to fan kit

6

element 1800W kit 19

loom-solenoid kit

7

sensor probe kit 20

loom-level sensor kit hot

8

pump kit hot 21

loom+gland main PCB to tap

9

PCB kit BC 100/125 & BC 150/175 22

transformer kit auxillary fan

10

transformrer kit 23

secondary solenoid boiling only models

11

leak sensor kit 24

elbow and gasket kit BC 150/175

12

control panel kit

Z90613

Z90614

Z90615

Z90616

Z90617

Z90579

Z90618

Z90619

Z90620

Z90621

Z90622

Z90623

Z90624

Z90625

Z90130

Z90628

Z90056

Z90629

Z90630

Z90186

Z90187

Z90188

Z90189

Z90190

Z90652

Z90657

Z90617

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 15 of 20

Page 16

Exploded View HT Series Boiling Only and Spare Parts

ITEM KIT NO. DESCRIPTION

1

Plumbing and Fittings kit

2

Safety Solenoid Kit

3

Single Solenoid Kit

4

Gasket and Elbow Kit BC 100/125

5

Overload Kit

6

Element 1500 watt Kit

7

Sensor Probe Hot

8

Pump Kit Hot

9

PCB Kit Boiling Only

10

Leak Sensor Kit

11

Clips Kit

12

Flexible Inlet Hose Kit

13

Level Sensor Kit Hot Tank H/T 60/85

14

Loom-Overload Kit

15

Loom-Solenoids Kit

16

Loom-Level Sensor Kit Hot

17

Loom and Gland Main PCB to Tap

Page 16 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Z90656

Z90614

Z90657

Z90658

Z90579

Z90618

Z90620

Z90621

Z90689

Z90624

Z90130

Z90056

Z90690

Z90186

Z90661

Z90189

Z90190

Page 17

Notes

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 17 of 20

Page 18

Notes

Page 18 of 20 Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005

Page 19

Notes

Zenith Hydro Tap Installation and Operating Instructions - 81467 - February 2005 Page 19 of 20

Page 20

The Zenith appliance you have chosen is precision-built from the finest materials

available and should give many years of trouble free service.

Certain warranties may be implied by law into your contract with Zenith. The

warranty provided below is additional to these implied warranties and nothing

set out below shall limit your statutory rights or rights at law.

Parex Appliances warrants that, should any part fail within 12 calendar

months of installation, that part will be repaired or replaced free of charge by

Parex Appliances or its Distributor or Service Provider, except as set out below,

provided the appliance is installed and used strictly in accordance with the

instructions supplied, and that failure is not due to accident, misuse, abuse,

unsuitable water conditions, or to any alteration, modification or repair by any party

not expressly nominated by Parex Appliances.

No costs are payable by the customer other than any mileage or travelling-time

charges incurred by a Zenith Service Provider or the cost of removal, cartage and

re-installation of any component of the appliance if it needs to be returned for

repair its Distributor.

This warranty does not cover damage resulting from non-operation of the

appliance or consequential damage to any other goods, furnishings or property.

No warranty applies to the life of any filtration cartridge installed with the

appliance as cartridge life may vary according to water quality and the rate of

water consumption.

Parex Appliances does not exclude, restrict or modify any liability that cannot be

excluded, restricted or modified or which cannot, except to a limited extent, be

excluded, restricted or modified as between the owner or user and Parex Appliances

under the laws applicable.

Head Office

Parex Appliances

103 Central Park Dr

Henderson Auckland

Email: info@parex.co.nz

Website:www.parex.co.nz

Telephone (09) 836 6566

Facsimile (09) 836 6033

Furthermore, this warranty does not displace any statutory warranty, but, to the

extent to which Parex Appliances is entitled to do so, the liability of Parex Appliances

under any statutory warranty will be limited at Parex Appliances option to the

replacement of the appliance or supply of equivalent appliance, the payment of the

cost of replacing the appliance or acquiring an equivalent appliance, or the payment

of the cost of having the appliance repaired or the repair of the appliance.

Zenith Hydrotap - Installation & Operating Instructions - 81438 - June 2004 Page 20 of 20

Loading...

Loading...