Page 1

Zebra® TTP 8000

Kiosk Receipt Printer

Technical Manual

P1003638-003 Rev. A

Page 2

2

© 2009 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer described

therein are owned by ZIH Corp. and Zebra’s licensors. Unauthorized reproduction of this manual or the software

and/or firmware in the printer may result in imprisonment of up to one year and fines of up to $10,000

(17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL

and Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink, Element Energy Equalizer, E

head graphic, ZPL and ZPL II are registered trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders. For additional trademark

information, please see “Trademarks” on the product CD.

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the express, written permission of Zebra Technologies Corporation.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies Corporation.

All specifications and designs are subject to change without notice.

®

, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer™ Circuit; E3™;

3

and all product names and numbers are trademarks, and Zebra, the Zebra

Liability Disclaimer Zebra Technologies Corporation takes steps to ensure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies Corporation reserves the right

to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and software) be liable for any damages

whatsoever (including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies Corporation has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 3

Contents

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Updating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 • Product Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Control Board Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Feed Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Using the Feed button: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 • Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrostatic Discharges, and Earth Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ambient Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting to the Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the Parallel Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Using the USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Making a Test Printout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Paper Path Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Paper Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Paper Level Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing a Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 4

Contents

4

4 • Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Installing a Paper Roll . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Using Auto Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Using Manual Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Self-test Printout and Other Power ON Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Power ON Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5 • Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

How the commands are described . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Summary Of Control Codes & Escape Sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Software Command Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Black Mark (Top-Of-Form) Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Text Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graphics commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Print commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Cut and Present Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

System Related Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Status reporting commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

File Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Character Bitmap Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Logotypes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

File Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Status Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6 • Default Parameter Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

How the Parameters are Described . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Serial Interface Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Parallel Port Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Print Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Fixed Document Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7 • Page Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Aligning Preprint and Thermal Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Parameters Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Black-mark Sensing from Within Windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 5

Contents

8 • Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9 • Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Clean the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Firmware and Hardware Revisions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10 • Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Serial Interface Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Text Modes (Non-Windows Applications) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Character Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Printer Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Paper Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Thermal Coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Perforation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Preprinting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Black Mark Size and Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Part Number List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

5

11 • 中国 RoHS 材料声明

(China RoHS Material Declaration) . . . . . . . . . . . . . . . . . . 125

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 6

Contents

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

6

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 7

About This Manual

This manual contains the information required to install the printer and to run it from a host

computer such as a PC.

1

Introduction

Updating

The TTP 8000 series consists of TTP 8200 with a resolution of 203 dpi, and TTP 8300 with a

resolution of 300 dpi. This manual applies to both versions and notes are made where they

differ.

Programming on page 31 gives the applicable control-codes and escape-sequences supported

by the printer processor firmware.

Other chapters of the manual contain information about the printer status codes,

communications parameters, test print functions, specifications, etc.

This manual will be updated as, from time to time, printer functions and features may be added

or amended. You will always find the latest edition on our web site (http://www.zebra.com).

If you require functions not found in this manual edition please contact Technical Support for

your region or the Zebra partner the printer was purchased from.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 8

About This Document

8

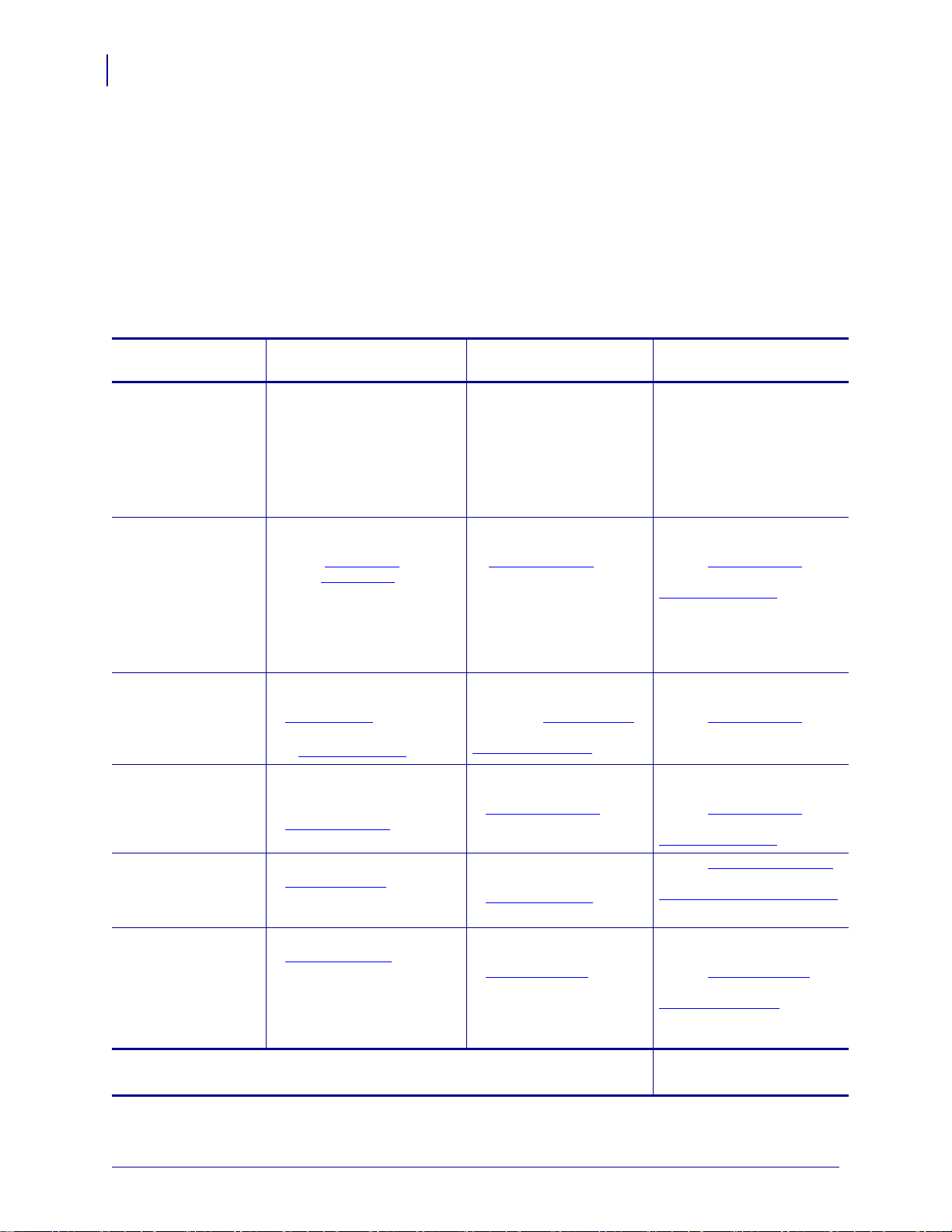

Contacts

Contacts

Technical Support via the Internet is available 24 hours per day, 365 days per year.

Web Site: www.zebra.com

E-mail Back Technical Library:

E-mail address: emb@zebra.com

Subject line: Emaillist

Self Service Knowledge Base: www.zebra.com/knowledgebase

Online Case Registration: www.zebra.com/techrequest

Which Department

Do You Need?

Regional Headquarters

Technical Support

For questions on the

operation of Zebra

equipment and software,

please call your distributor.

For additional assistance,

contact us.

Please have your model and

serial numbers available.

Repair Service

Department

For back-to-base service and

repair.

Technical Training

Department

For Zebra product training

courses.

Inquiry Department

For product literature and

distributor and dealer

information.

Customer Service

Department (US)

Internal Sales

Department (UK)

For printers, parts, media,

and ribbon, please call your

distributor or contact us.

Key:

T: Telephone

F: Facsimile

E: E-mail

The Americas

Zebra Technologies Corporation

475 Half Day Road, Suite 500

Lincolnshire, IL 60069 USA

T: +1 847 634 6700

Toll-free +1 866 230 9494

F: +1 847 913 8766

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 913 2578

Hardware: ts1@zebra.com

Software: ts3@zebra.com

Kiosk printers:

T: +1 866 322 5202

E: kiosksupport@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

F: +1 847 821 1797

E: repair@zebra.com

To request a repair in the U.S.,

go to www.zebra.com/repair

T: +1 847 793 6868

T: +1 847 793 6864

F: +1 847 913 2578

E: ttamerica@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: inquiry4@zebra.com

T: +1 877 ASK ZEBRA (275 9327)

E: clientcare@zebra.com

.

Europe, Middle East,

and Africa

Zebra Technologies Europe Limited

Dukes Meadow

Millboard Road

Bourne End

Buckinghamshire, SL8 5XF

United Kingdom

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

T: +44 (0) 1628 556039

F: +44 (0) 1628 556003

E: Tseurope@zebra.com

T: +44 (0) 1772 693069

F: +44 (0) 1772 693046

New requests: ukrma@zebra.com

Status updates:

repairupdate@zebra.com

T: +44 (0) 1628 556000

F: +44 (0) 1628 556001

E: Eurtraining@zebra.com

T: +44 (0) 1628 556037

F: +44 (0) 1628 556005

E: mseurope@zebra.com

T: +44 (0) 1628 556032

F: +44 (0) 1628 556001

E: cseurope@zebra.com

Asia Pacific

and India

Zebra Technologies Asia Pacific

Pte. Ltd.

120 Robinson Road

#06-01 Parakou Building

Singapore 068913

T: + 65 6858 0722

F: +65 6885 0838

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: +65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

T: + 65 6858 0722

F: +65 6885 0838

E: China: tschina@zebra.com

All other areas:

tsasiapacific@zebra.com

E: China: GCmarketing@zebra.com

All other areas:

APACChannelmarketing@zebra.com

T: +65 6858 0722

F: +65 6885 0836

E: China: order-csr@zebra.com

All other areas:

csasiapacific@zebra.com

P1003638-003 TTP 8000 Technical Manual 10/19/09

Page 9

2

Product Presentation

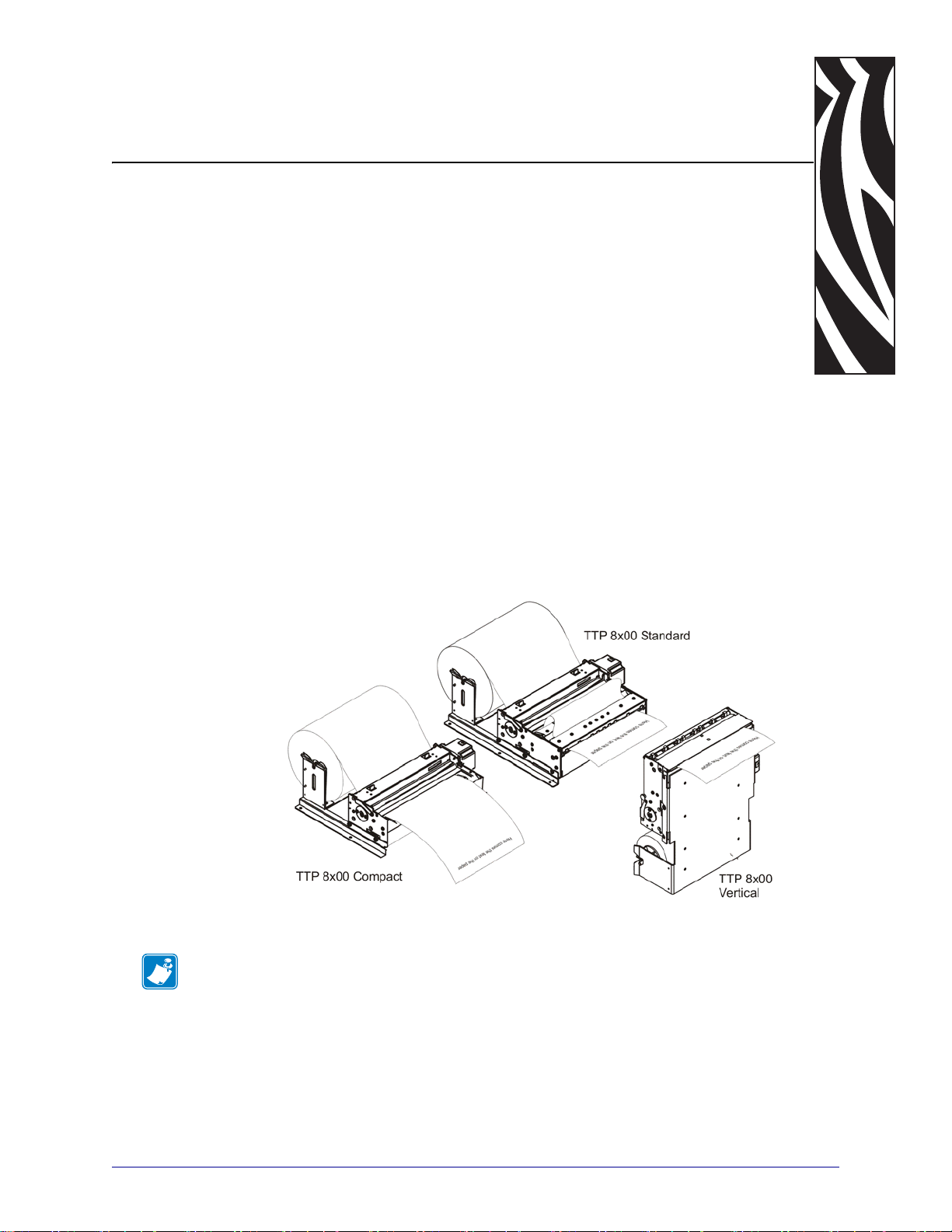

The TTP 8000 kiosk printer series consists of a family of printers that will print A4 or Letter

paper width depending on the printer configuration. Different configurations and paper

handling options are available.

Figure 1 • TTP 8000 Printers

Note • Roll holders shown in Figure 1 are options.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 10

Product Presentation

10

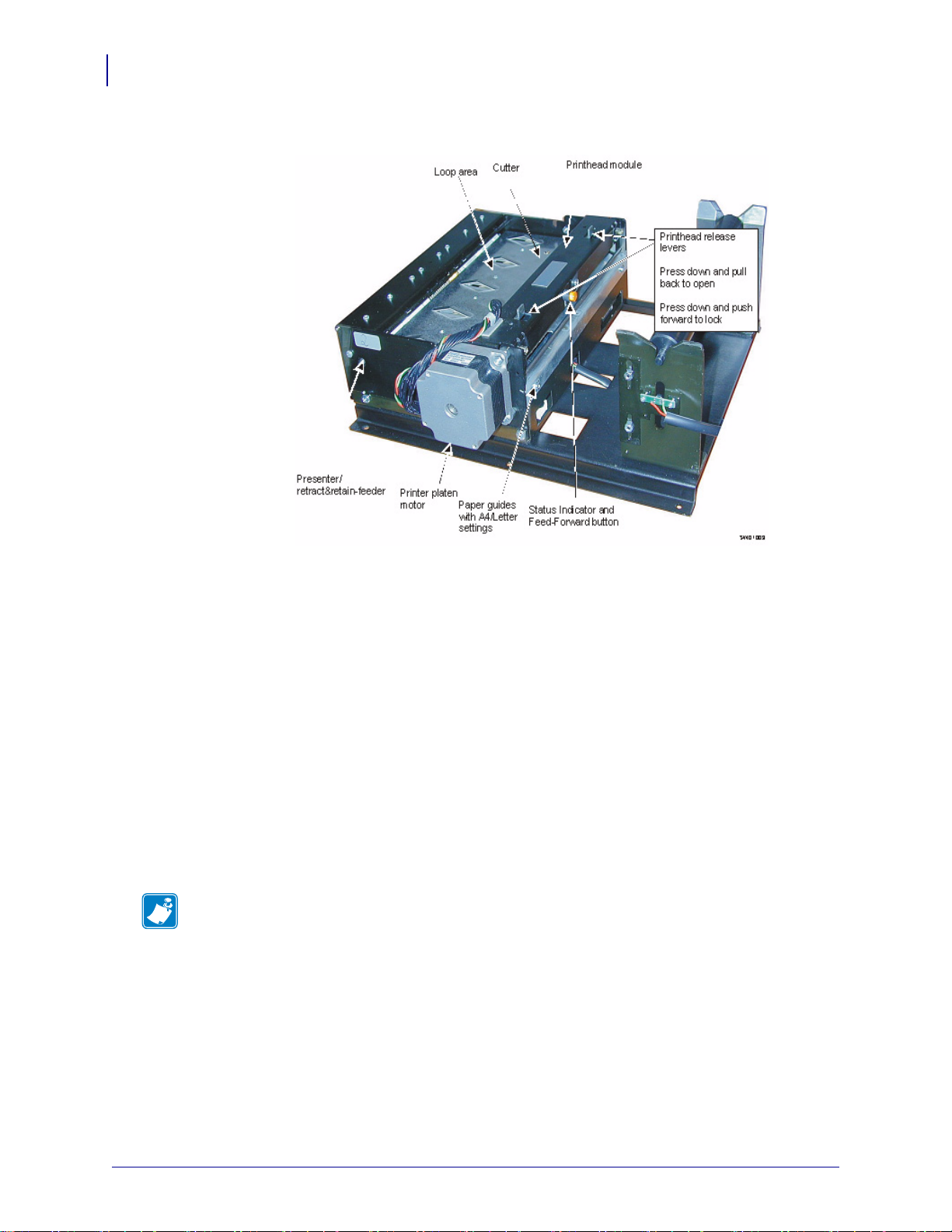

Figure 2 • Printer Exterior, Side View

The TTP 8000 series of kiosk printers use direct thermal printing. The print speed is up to

100 mm per second.

The printer has an integrated control board that communicates with the host computer through

either an USB orIEEE-1284 bi-directional parallel port. Printer drivers for Microsoft Windows

are available. The USB and parallel interface printers are compatible with the Plug and Play

standard. It is also possible to address the printer directly from the kiosk software without

using a driver.

The flip-up printhead and presenter modules give the operator complete access to the paper

path for maintenance purposes.

The loop generating presenter mechanism handles documents of various lengths. It holds the

printout until printed, then cuts and presents the complete printout to the customer. The

“retract and retain” function can retract uncollected printouts into a wastebasket inside the

kiosk.

Note • The compact version of the printer does not have presenter or retract function, and the

vertical printer has limited use of retract as the retract path faces the same direction as the

normal eject path.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 11

Figure 3 • Printer Exterior, Rear View

Product Presentation

11

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 12

Product Presentation

12

Indicators

Indicators

The status indicator flashes in various sequences to indicate specific statuses or warnings.

The status indicator (see Figure 3, Printer Exterior, Rear View, on page 11) has several

functions:

ON constantly The printer is operational.

Flashes rapidly Indicates error. Hold down the feed-forward button and the number of

flashes will reflect the status-code. See Table 1.

Flash, pauses,

flash

Number of

Flashes

1

2

3

4

5

6

7

Fast flashes

Steady light

Off

Indicates warnings of non-severe error. The number of flashes reflects

the warning-code. See Table 2.

Table 1 • Status Codes

Status Code Description

Paper jam in presenter

Cutter cannot return to home position

Out of paper

Printhead lifted

Note • Only available on printers with printhead open sensor

installed.

Paper wrapped around platen (under head)

Temp error, printhead is above 60°C

Presenter not rotating

Checksum error, firmware

Wrong firmware type

No firmware is loaded, or wrong firmware checksum

Status-codes are reset:

• When the conditions causing them are removed.

• When the printer is turned off/on.

• When the printhead is lifted and then lowered. On printers without printhead lifted sensor,

remove paper, install again, and press the Feed button to reset.

• When the hardware reset command is received.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 13

Table 2 • Warning Codes

Product Presentation

Indicators

13

Number of

Flashes

Warning Code Description

2 Paper low

3 Weekend low*

*. Warning-codes are reset automatically when the cause for them are removed.

Control Board Indicators

The control board has two power indicators behind the power connector. To see the indicators,

open the printhead and look down between the platen and the printer frame.

Green indicator constantly ON 24 V present

Red indicator constantly ON 5 V OK (generated on control board)

Note • This signaling is disabled by default. It can be

disabled/enabled through parameter setup

Table 3 • Control Board Indicators

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 14

Product Presentation

14

Feed Button

Feed Button

Using the Feed button:

When you have inserted the paper under the printhead, press the Feed button and the printer

will feed it forward, cut and eject a printout, then switch to on-line mode. Each press on the

Feed button will feed, cut, and present one form length.

Is there paper in the presenter section of the printer?

If… Then…

No Press the Feed button once to make a Form Feed. (Feed, cut, and present a

complete page.) In black mark mode, the page will be synchronized with the

black mark.

Yes Press the Feed button once to clear the presenter.

When auto-loading paper, and the paper does not feed straight:

1. Press the Feed button once to stop the loading process.

2. Correct the error.

3. Press the Feed button once more to commence with the loading.

When loading paper manually:

1. After closing the printhead, press the Feed button to feed-cut-eject one page.

2. Press and hold the Feed button while turning on the power to print a self-test printout. See

page Making a Test Printout on page 21.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 15

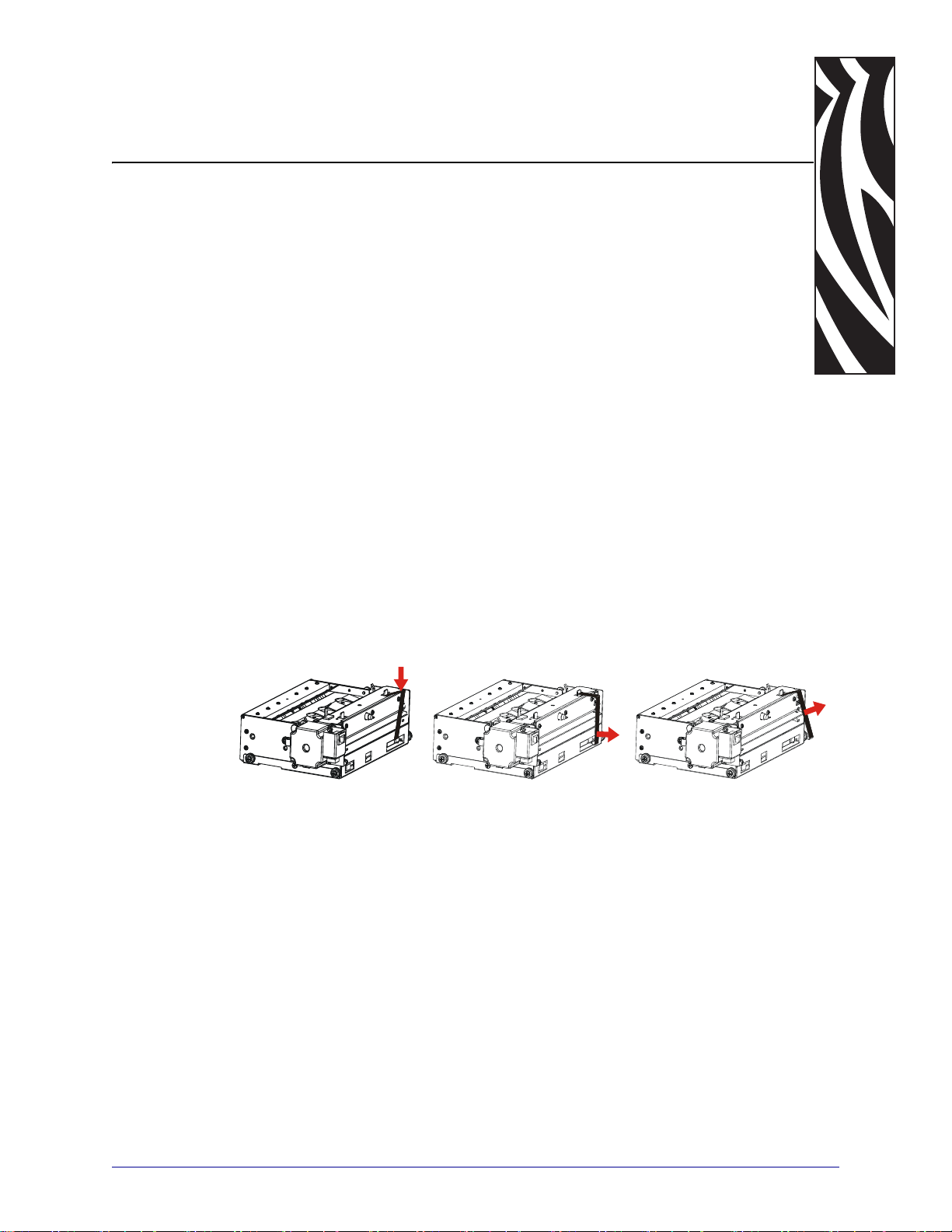

Unpacking

Press down

Remove

Unhook

When a new printer is delivered the printhead is secured with a shipping strap. Remove this by

pressing it downwards and disengage it from the parallel interface hole, then turn it up and

remove the shipping strap.

3

Installation

Figure 4 • Removing the Shipping Strap

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 16

Installation

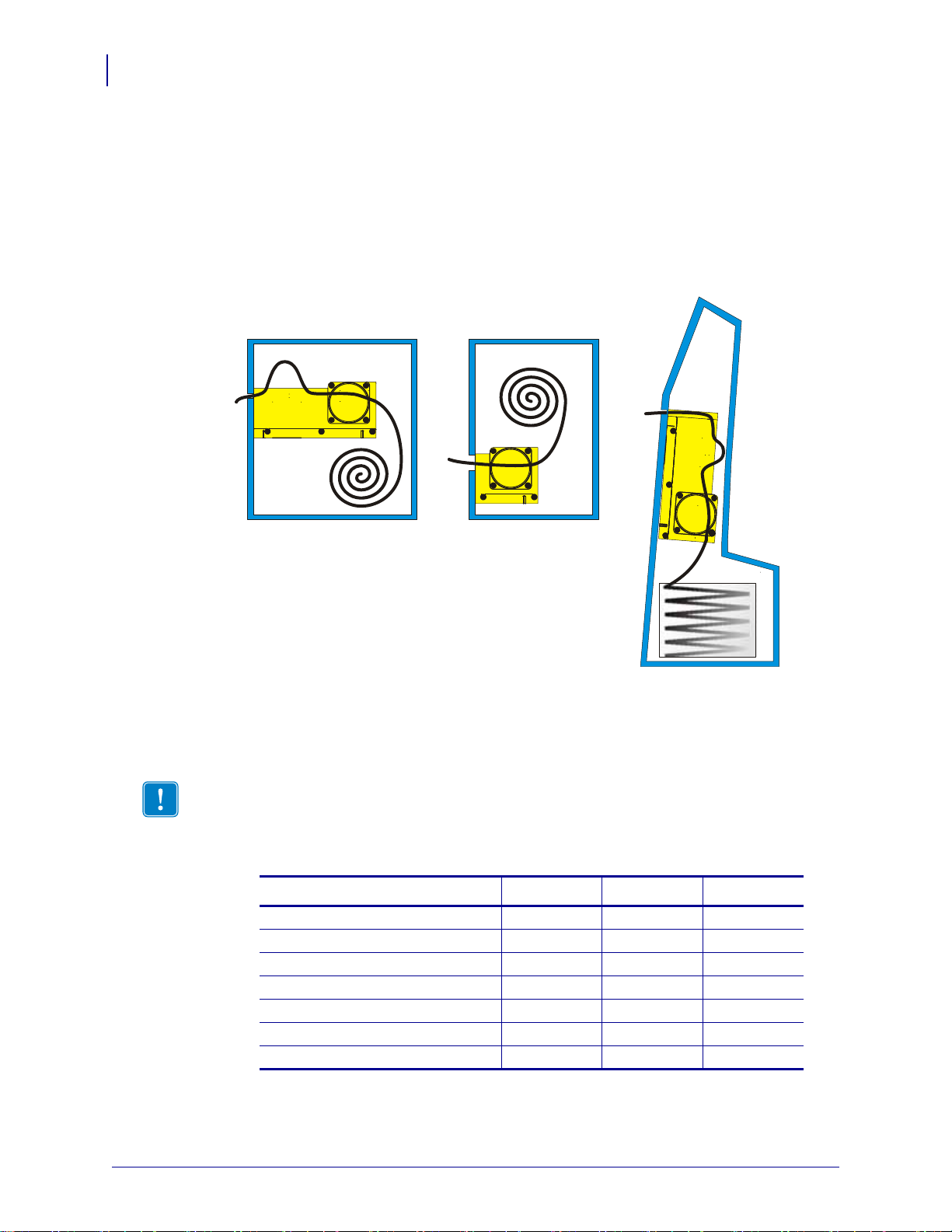

SW01006B

Roll under or behind;

Looping presenter version

Roll over or behind;

Compact version

Narrow kiosk fit,

fan fold paper;

Vertical version

Roll under or behind;

Standard version with

looping presenter

Roll over or behind;

Compact version

Narrow kiosk fit,

fanfold paper;

Vertical version

16

Installation Considerations

Installation Considerations

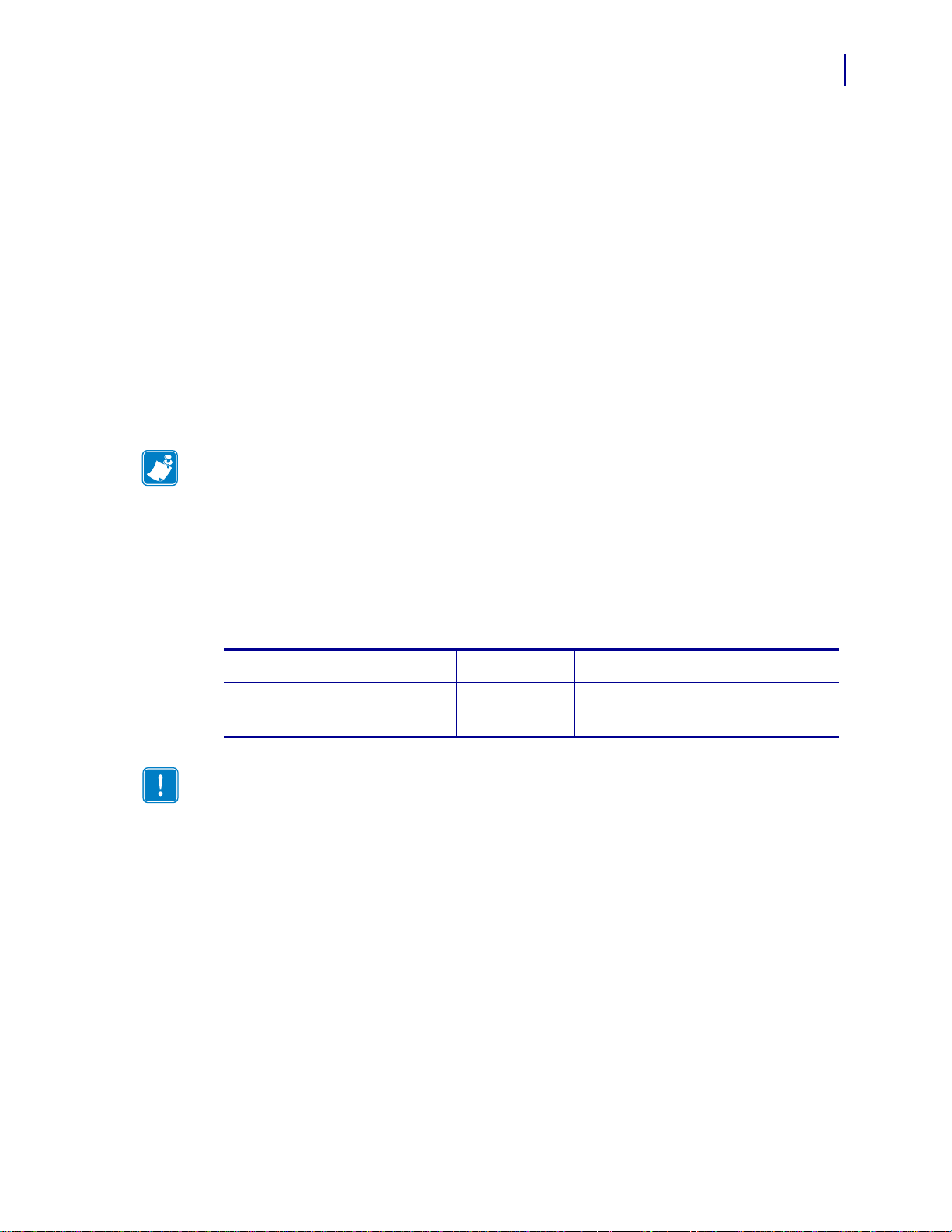

There are a number of printer mounting options available to install the TTP 8000 printer in a

self-service kiosk enclosure, as illustrated in Figure 5. See also Printer Dimensions

on page 113.

Figure 5 • Installation Options

)

Additional space is required for paper replenishment and paper jam removal. Consider

mounting the printer on a movable platform so that the printer can be maintained outside the

kiosk enclosure.

Important • It is essential for the function of the printer that the paper is rolled in the correct

direction for the model of printer that you have.

Table 4 • Media Mounting Configurations

Media Type Standard Vertical Compact

Roll media XXX

Fanfold media X X X

Roll behind printer X X X

Roll under printer X X X

Roll above printer X

Thermal coating outside of roll X X X

Thermal coating inside of roll X

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 17

Electrostatic Discharges, and Earth Currents

Preventing ESD and earth currents from affecting the printer operation requires proper

connection of the printer chassis to protective earth through a mounting platform or through a

separate earth conductor. The signal ground is not connected to protective earth (chassis)

inside the printer.

See Figure 6. Fasten an earth cable to the printer using an M4x6 screw. Always put a lock

washer between the chassis and the connector.

Figure 6 • Attach Earth Cable

Installation

Installation Considerations

17

Ambient Light

There are optical sensors just inside the paper exit at the front of the printer.

To ensure proper printer operation, design the printer enclosure so that it prevents direct

sunlight or light from indoor lamps from reaching the sensor through the paper exit.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 18

Installation

18

Connecting to the Computer

Connecting to the Computer

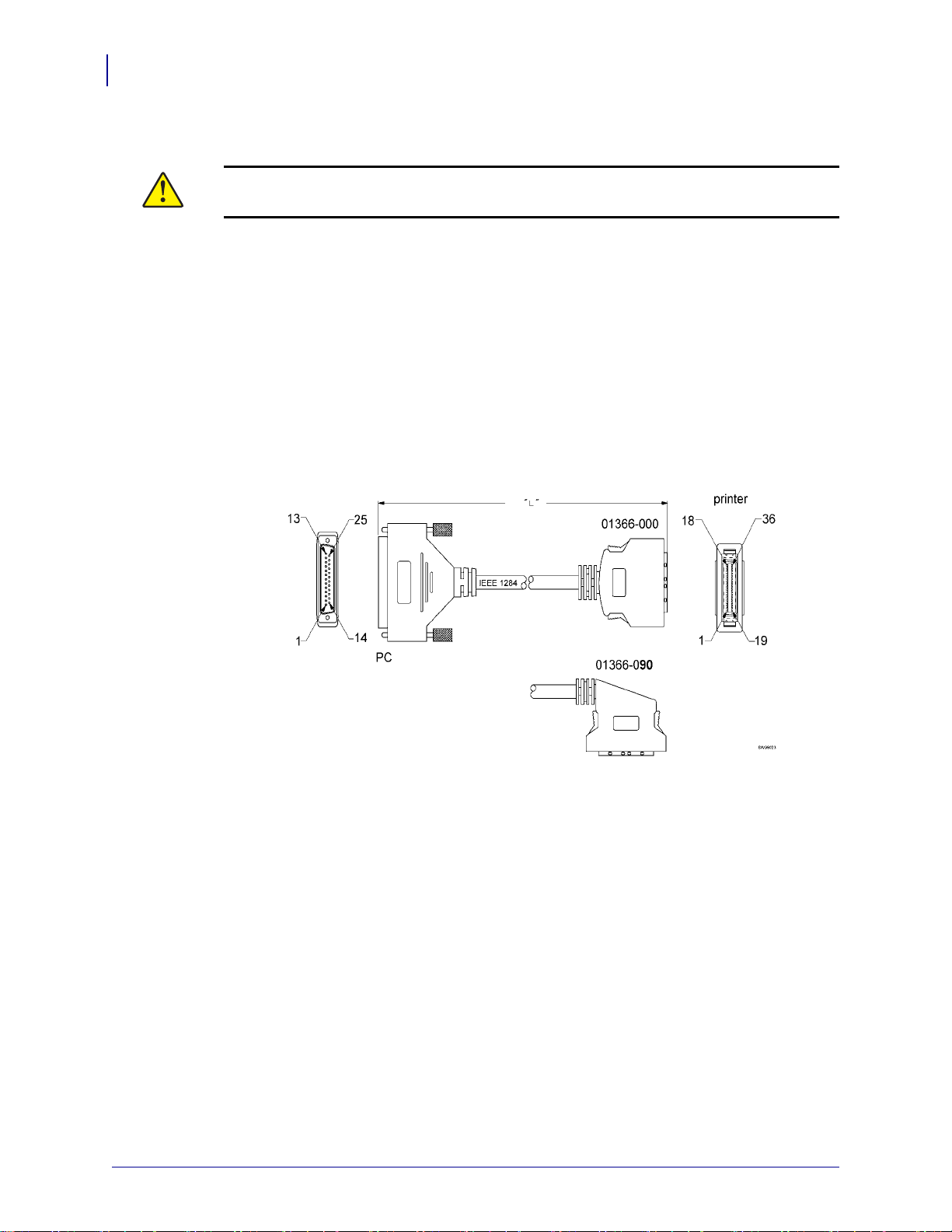

Caution • Using a non-approved cable with the printer may void the FCC and other EMC

approvals of the printer.

Using the Parallel Interface

1. Connect the printer to the parallel port of the computer to be used.

2. Connector J10 is an IEEE-1284 type C, 36-pole mini Centronics, with clip latches. See

Figure 21 on page 96 for pin assignment of J10.

3. Use only certified cables marked IEEE-1284. See Part Number List on page 124 for

cables from Zebra Technologies.

Figure 7 • IEEE-1284 cable with Type A and Type C Connectors

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 19

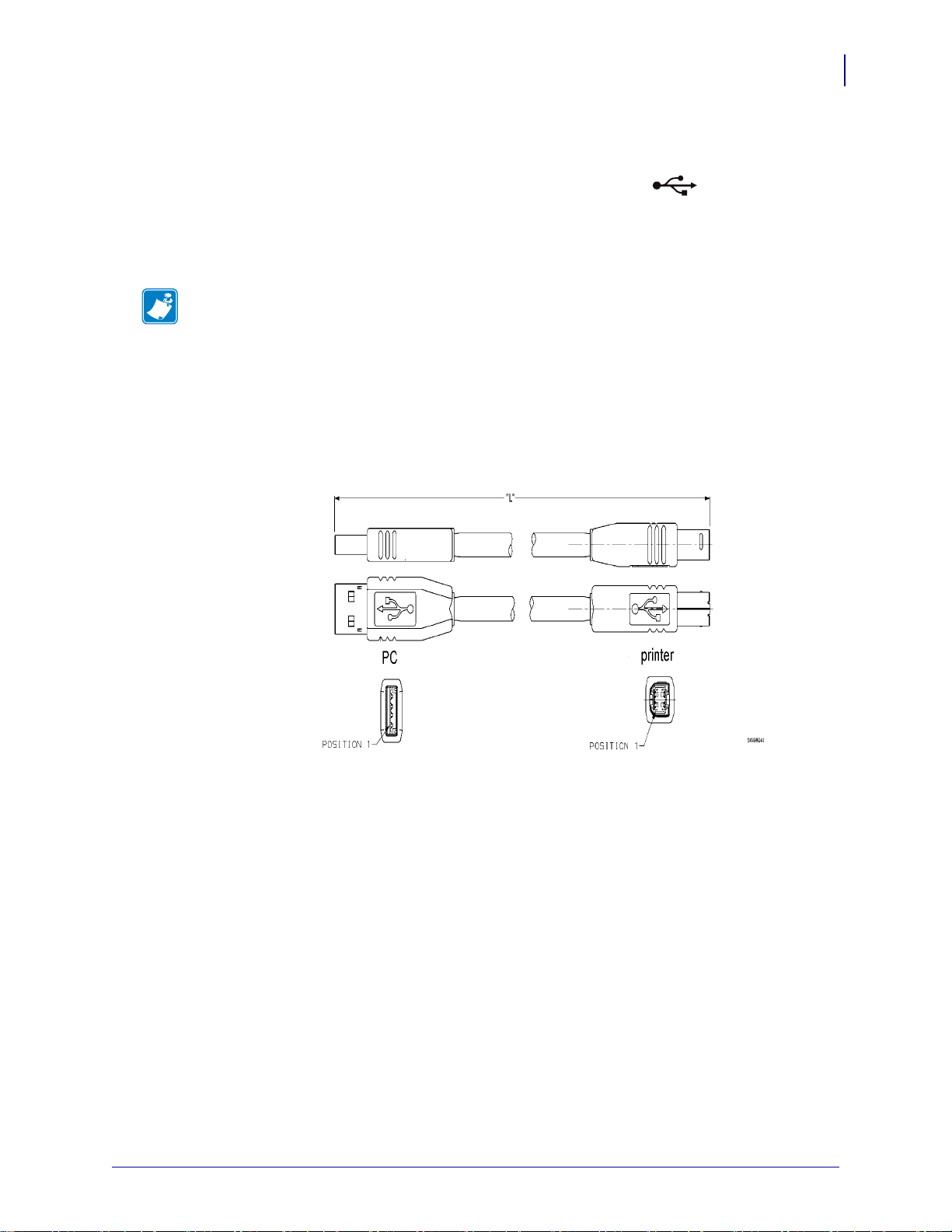

Using the USB Interface

1. Connect J13 of the printer to the USB port of the computer or the USB hub to be used.

USB connectors can be recognized by the following symbol: .

2. Connector J13 is a 4-pin USB type B connector. See USB on page 98 for pin assignment.

A suitable cable is available from Zebra, see Part Number List on page 124 for part number.

Note • The USB interface on printers with hardware revision A does not trigger enumeration

in Windows when the printer is reset. Reset occurs after font, logotype, firmware and

parameter storage. This means that the printer will disappear from the list of available

printers at reset, and appear again when the PC is restarted. In normal operation this will not

happen. Powering off/on the printer starts enumeration.

You can see the hardware revision on the self-test printout.

Figure 8 • USB Cable with Type A and Type B Connectors

Installation

Connecting to the Computer

19

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 20

Installation

20

Connecting to the Computer

Connecting the Power

Caution • Use only the recommended Zebra power supply (see Part Number List

on page 124

1. Attach a ground cable to the ground screw on the printer.

2. Connect the cable from the power supply to J8.

3. Connect the power cable to the line outlet.

4. Apply power to the printer.

for part number).

If you use another type of power supply unit, connect the voltages according to the following

illustration.

Important • The ground and the 24 V ground must be separated in the power supply to avoid

ground loops!

At the printer end of the cable, use a Tyco Mate-N-Lok connector housing and two

contact-sockets:

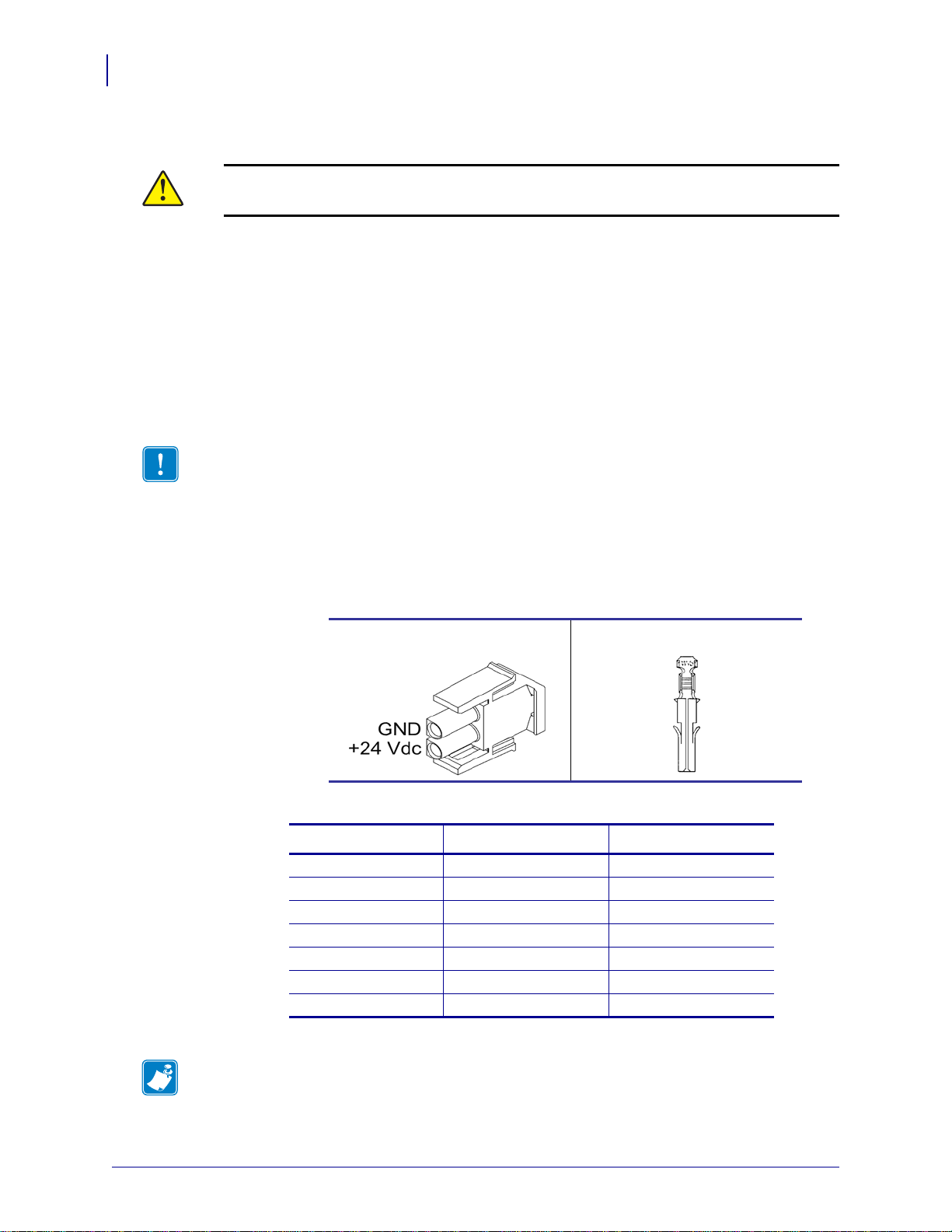

Figure 9 • Power Connection

Tyco No. 350777-1 Tyco No. 350689-1

Table 5 • Current Consumption at Factory Default Settings

Print Density TTP 8200 TTP 8300

None (Idle) 0.15 A 0.15 A

10% coverage 1 A 2 A

20% coverage 2 A 3 A

30% coverage 3 A 4 A

40% coverage 4 A 5 A

50% coverage 5 A 6 A

All black printing 10 A 12 A

Note • Print speed, burn time, and temperature affects these values.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 21

Making a Test Printout

You can make a self-test printout if you want to verify that the printer operates correctly. See

Self-test Printout and Other Power ON Modes on page 29.

Paper Path Adjustment

Paper Width

When delivered, the paper width is adjusted to 210-mm for A4, and 216-mm for Letter paper

versions of the printer. To adjust the width, do as follows:

1. Loosen the two screws on each side that holds the guide wings (see Figure 2, Printer

Exterior, Side View, on page 10).

For A4-paper Pull the wings together as much as possible, and then tighten the

For Letter paper Push the wings apart as much as possible, and then tighten the

screws.

screws.

Installation

Making a Test Printout

21

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 22

Installation

22

Paper Path Adjustment

Paper Level Sensors

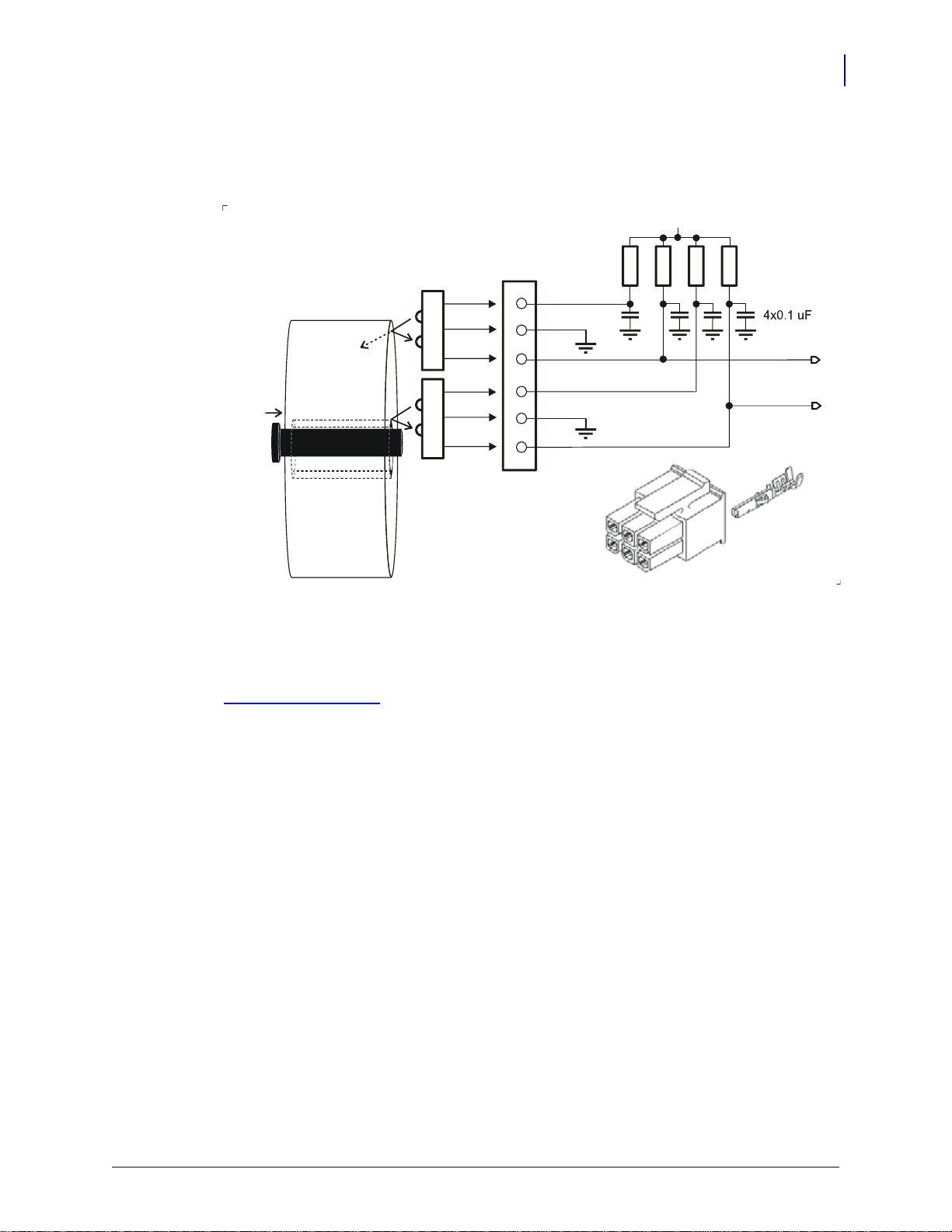

The printer has inputs for two paper level sensors.

Sensor status is reported to the host computer when it asks the printer for status. If you want

the indicator on the printer to flash to show paper level sensor status, you must enable

signaling using parameter No. 52, see Default Parameter Settings on page 71.

Figure 10 • Sensors on Large Roll Holder

The paper-near-end sensor alerts the system when a couple of meters of paper remain. The

purpose of this sensor is to get an early alert so that you can replace the paper in time in

remotely located kiosks.

The weekend sensor should alert when the remaining paper does not last over a weekend. A

reason to use this sensor is that it is more expensive to get a service technician out on a

weekend or holiday, than it is to replace the paper before it is totally empty.

The Zebra 150 mm paper roll holder can be equipped with one paper-near-end sensor, while

the larger paper holders have both paper-near-end and weekend sensors.

When installing the Zebra paper holder just connect the cable from the roll holder to connector

J1 at the back of the printer. See Printer Exterior, Rear View on page 11.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 23

Installation

Paper-nearend sensor

5

4

6

J1

Sharp GP2S40

Near

end

Roll holder shaft

Weekend sensor

Gray

Red

Blue

Black

2

1

3

PL SENSE

WE SENSE

+5 V

Sharp GP2S4

0

21436

5

SW97081D

M

o

l

e

x

4

3

0

2

5

-

0

6

0

0

M

o

l

e

x

4

3

0

3

0

-

0

0

8

200

Ω200

Ω47 kΩ47 k

Ω

Green

Green

Installing a Printer Driver

If you use custom designed paper holders, connect the sensors according to Figure 11.

Figure 11 • Paper-near-end Sensor Connection

23

Installing a Printer Driver

A printer driver for Microsoft Windows™ is available on the Zebra web site

http://www.zebra.com

and refer to the Kiosk Driver Reference Guide, Part Number P1006873-001, available on

www.zebra.com for detailed driver information.

10/19/2009 TTP 8000 Technical Manual P1003638-003

. Please follow the installation instructions that accompany the drivers

Page 24

Installation

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

24

Installing a Printer Driver

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 25

4

Operation

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 26

Operation

26

Installing a Paper Roll

Installing a Paper Roll

Preparations

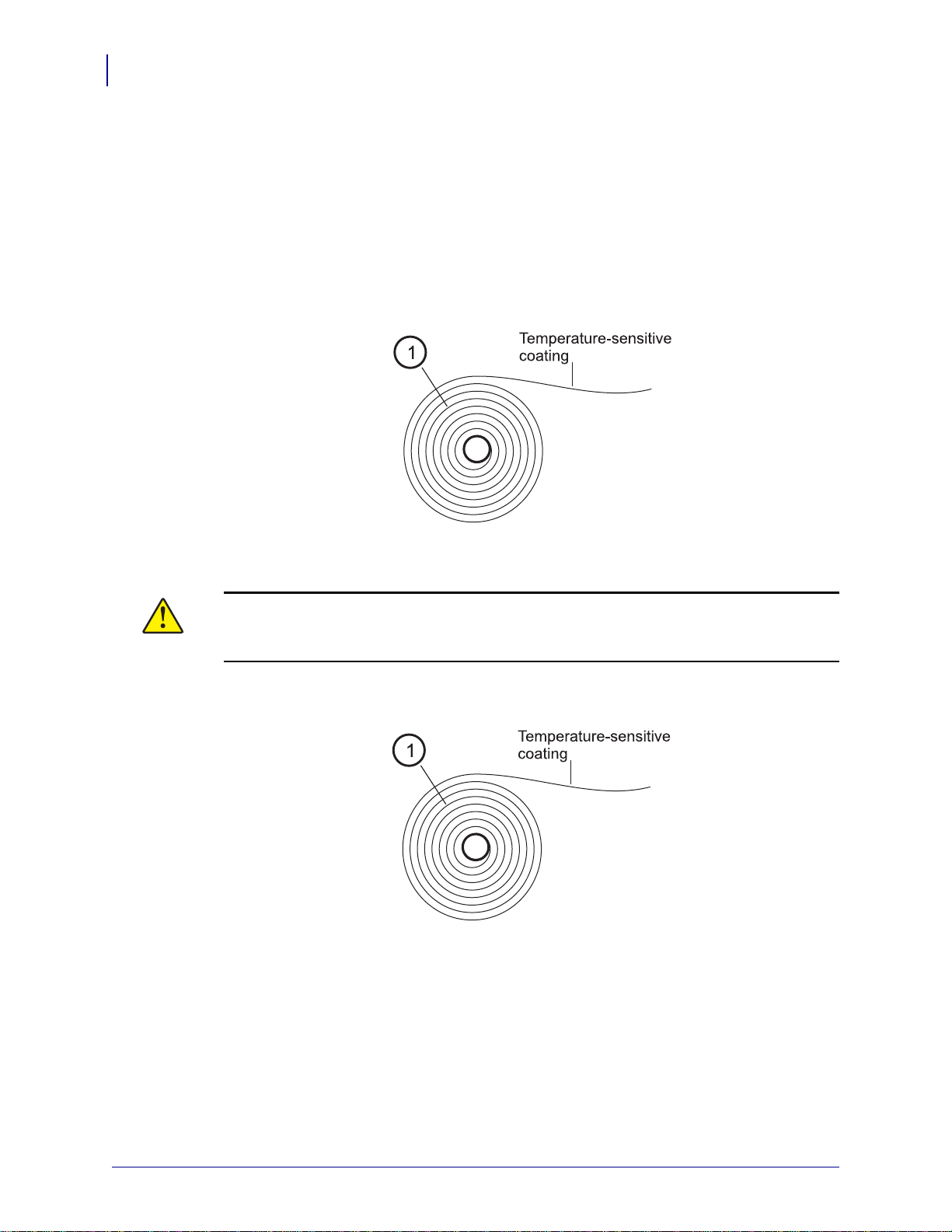

1. Turn the new paper roll as shown. The paper should be inserted into the printer with the

temperature-sensitive side up.

Figure 12 • Paper Roll Orientation

2. Tear off approximately 0.5 m from the new paper roll.

Caution • This is important since the outer end of the paper is usually fixed to the roll with

some type of glue or self-adhesive substance that might otherwise cause paper jam or

even printhead damage.

Figure 13 • Tear Off 0.5 m from the New Paper Roll

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 27

Using Auto Load

1. Make sure the printer is turned ON.

2. Make sure the front edge of the paper is straight.

3. Enter the paper between the guide wings and feed it straight into the printer.

4. The platen should grip the paper, feed one form length, cut and eject, and set the printer

online.

Note • Autoloading works if the printer is on, the head is down and locked, and the Paper

Out flashing sequence is showing on the status indicator. If you see that the paper does not

pull straight, press the Feed button to stop the loading, then straighten the paper, and press

the button again to commence.

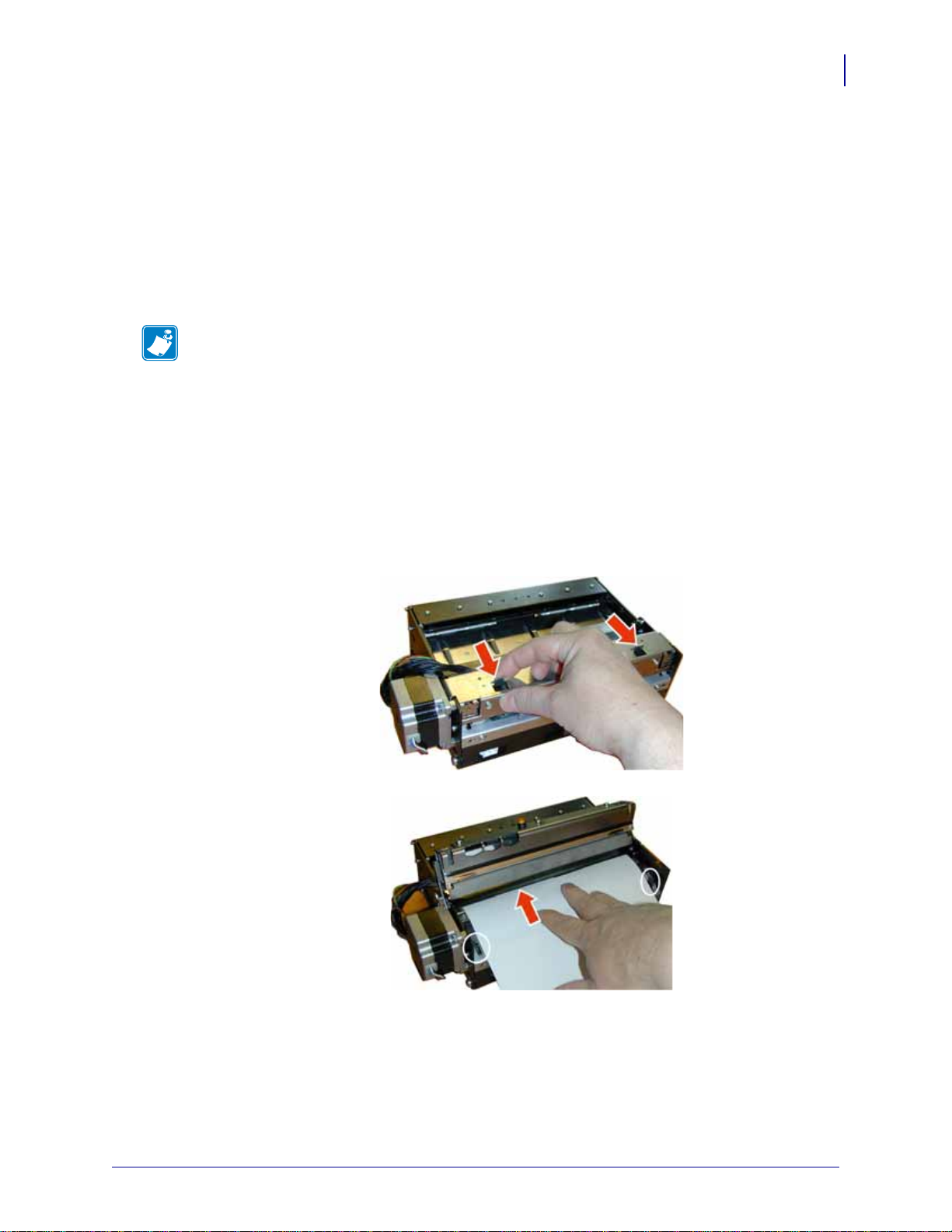

Using Manual Load

1. Open the printhead by pulling the two release levers back and tilt up the printhead.

Operation

Installing a Paper Roll

27

Figure 14 • Manual load of new paper

2. Position the paper on the shelf so that it passes the rubber platen roller.

3. Close the printhead. Remember to push the printhead release levers forward. Note that the

paper must be between the guides (circled in the above picture), and under the black plate

(arrow).

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 28

Operation

28

Clearing Paper Jams

4. Press the Feed button and the paper will feed, cut and eject a printout, and then

automatically go online.

Clearing Paper Jams

Should a paper jam occur, follow the procedure below:

1. Open the presenter top plate by loosening the two thumbscrews, and lifting up the plate.

2. Tear off the jamming paper against the fixed cutter blade, remove all jammed paper, and

make sure the paper path is clear.

3. Close the presenter top, and press it down while tightening the screws.

Figure 15 • Loosen both thumbscrews and flip open the presenter top.

Figure 16 • Tear off the jamming paper against the fixed cutter blade.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 29

Self-test Printout and Other Power ON Modes

Self-test Printout and Other Power ON Modes

1. Remove power from the printer.

If your printer has a power switch, turn the power off. If it does not, remove power to the

printer.

2. Hold the feed-forward button depressed while powering ON the printer. Keep the button

depressed until the presenter motor buzzes.

This produces a printout showing the firmware program version and date, control board

revision number and serial number, name of loaded fonts and logotypes, parameter settings,

and the set printhead burn-time.

3. Each successive press of the button will produce a test printout.

4. To exit self-test mode, switch the printer OFF and ON, or send a reset command.

Note • You can also print a self-test printout by sending the command <ESC>P<0> to the

printer.

Operation

29

Power ON Modes

Normally the printer is immediately ready for use when you switch it ON. You can enable

several test and maintenance functions by giving simulating sensor signals while switching

ON the power.

Print Mode Feed button Paper Printhead

Normal Released Don't care Don’t care

Self-test printout Pressed Loaded Down

Important • For printers without head up sensor, modes requiring printhead-up are not

supported.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 30

Operation

Notes • ___________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

__________________________________________________________________________

30

Self-test Printout and Other Power ON Modes

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 31

5

Programming

There are two different ways of setting up the printout: Text oriented and driver oriented style.

Command code The printout can be seen as the page of a simple word processor. You send text and

graphics to the printer, which prints the information in the same sequence as the data is

received. Design features are limited to the font stored in the flash PROM of the printer.

Text and logotypes can also be printed in landscape orientation.

There are two text cursors, one for portrait, and one for landscape. The start positions of

the cursors are the upper left corner for the portrait cursor, and the upper left corner for the

landscape cursor, see Figure 17, Printout Styles, on page 32.

You can switch between these cursors at any time; the cursor will retain its last position on

the printout.

Driver oriented When a Windows driver is used, you can use any Windows program to design the printout

with text, graphics, bar codes or whatever you want to print and in any orientation you

want.

The Windows driver issues all the necessary commands. The cut, present, and black-mark

commands to send are indirectly selected through the settings in the Windows dialogue

boxes.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 32

Programming

32

Figure 17 • Printout Styles

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 33

How the commands are described

Description of command

Mnemonic

Decimal representation of command

Hex representation of command

Mnemonic

Is the popular command name that should be easy to remember

Hex

Programming

How the commands are described

33

Give the command in hex representation

Decimal

Give the command in decimal representation

Values

n1, n2, etc. represents values that you set with the commands. What you should enter here

depends on what you want the command to do.

Examples

Command examples are formatted in Courier and typed in the same way as used in the

Zebra Toolbox:

<ESC>&P<1><19>

<ESC> means the escape character 27 decimal (hex 1B). Numbers between less-than

Where

and greater-than characters, for example <15>, means 15 decimal (hex F). When the numbers

indicate a hex value, h is appended to the number.

Example • <65>, <h 41> and A are three different ways of expressing the character A.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 34

Programming

34

Summary Of Control Codes & Escape Sequences

Summary Of Control Codes & Escape Sequences

Table 6 • Control Codes and Escape Sequences in Alphabetical Order

Command Hex Decimal Function

BS 08 8 Backspace page 40

CAN 18 24 Cancel page 41

CR 0D 13 Carriage return page 41

EM n 19 n1 25 n1 Enforced Clear Presenter page 51

ENQ 05 5 Clear Presenter page 51

ESC ACK n1 1B 06 n1 27 6 n1 Acknowledge Marker page 63

ESC ! n1 1B 21 n1 27 33 n1 Select Font page 38

ESC # 1B 23 n1 27 35 n1 Calibrate Blackmark Sensor page 36

ESC & 0 1B 26 00 27 38 0 Load Font page 53

ESC & 1 1B 26 01 27 38 1 Load Logotype page 52

ESC & 4 1B 26 04 27 38 4 Store current Parameter Values page 52

ESC & 5 1B 26 05 n1 27 38 5 n1 Set default Profile Pointer to n page 53

ESC & C 1B 26 43 27 38 67 Erase all Fonts page 53

ESC & D 1B 26 44 27 38 68 Erase Fonts 4 to 7 page 53

ESC & F n1 1B 26 46 n1 27 38 70 n1 Recall Parameter Profile page 54

ESC & L 1B 26 4C 27 38 76 Erase all Logotypes page 52

ESC & P n1...n2 1B 26 50 n1...n2 27 38 80 n1...n2 Set Parameter Value page 54

ESC ? 1B 3F 27 63 Reset (full) page 52

ESC @ 1B 40 27 64 Reset (initialize) page 52

ESC 3 n1 1B 33 n1 27 51 n1 Line spacing page 42

ESC b n1...n5 1B 62 n1...n5 27 98 n1...n5 Print Bitmap at XY-position page 43

ESC B 1B 42 n1 27 66 n1 Bold page 38

ESC d n 1 1B 64 n1 27 100 n1 Make n Linefeeds page 41

ESC ENQ 1 1B 05 01 27 5 1 Status Enquiry page 56

ESC ENQ 2 1B 05 02 27 5 2 Paper-near-end Enquiry page 57

ESC ENQ 4 1B 05 04 27 5 4 Fonts and Logotype Enquiry page 58

ESC ENQ 6 1B 05 06 27 5 6 Status Report page 59

ESC ENQ 7 1B 05 07 27 5 7 Firmware-version Enquiry page 60

ESC ENQ 9 1B 05 09 27 5 9 Serial-number Enquiry page 60

ESC ENQ 10 1B 05 0A 27 5 10 Control board revision Enquiry page 60

ESC ENQ 11 1B 05 0B 27 5 11 Head temperature Enquiry page 61

ESC ENQ 12 1B 05 0C 27 5 12 Bootware version Enquiry page 61

ESC ENQ c 1B 05 63 27 5 99 Device ID Enquiry page 61

ESC ENQ E 1B 05 45 27 5 69 Read extended status page 62

ESC ENQ P n1 1B 05 50 n1 27 5 80 n1 Parameter-setting data Enquiry page 63

ESC F 1B 46 n1...n16 27 70 n1...n16 Set Horizontal Tabs page 43

ESC FF n1 1B 0C n1 27 12 n1 Eject (run presenter) page 51

ESC g n...n5 1B 67 n1...n5 27 103 n1...n5 Print Logotype page 47

ESC h n1 1B 68 n1 27 104 n1 Text Height page 39

Page

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 35

Programming

Summary Of Control Codes & Escape Sequences

Table 6 • Control Codes and Escape Sequences in Alphabetical Order

Command Hex Decimal Function Page

ESC i n1 1B 69 n1 27 105 n1 Italics page 38

ESC J n1 1B 4A n1 27 74 n1 Paper Advance page 49

ESC j n1 1B 6A n1 27 106 n1 Paper Reverse page 49

ESC l 1B 6C n1...n2 27 108 n1...n2 Send dot-line, 300 dpi page 45

ESC N n1 1B 4E n1 27 78 n1 Align Text page 37

ESC NUL 1B 00 27 0 Load Firmware page 55

ESC o n1 1B 6F n1 27 111 n1 Text and Logotype Orientation page 37

ESC p 1B 70 27 112 Print page 48

ESC P n1 1B 50 n1 27 80 n1 Print Self-test Printout page 48

ESC Q 1B 51 n1...n2 27 81 n1...n2 Quick Advance page 48

ESC r n1...n9 1B 72 n1...n9 27 114 n1...n9 Print Ruler Line page 46

ESC RS 1B 1E 27 30 Cut only, no Eject page 50

ESC s n1 1B 73 n1 27 115 n1 Send dot-line, 203 dpi page 44

ESC t n1...n5 1B 74 n1...n5 27 116 n1...n5 Print Text at XY page 40

ESC T n1 1B 54 n1 27 84 n1 Reversed/Inversed Text page 39

ESC u n1 1B 75 n1 27 117 n1 Underline page 39

ESC w n1 1B 77 n1 27 119 n1 Text Width page 40

ESC Z 1B 5A 27 90 Go to next Top of Form page 36

FF 0C 12 Form Feed page 42

HT 09 9 Horizontal Tabulation page 42

LF 0A 10 Linefeed page 41

RS 1E 30 Cut and Eject page 50

35

Note • In all responses from the printer the most significant byte (MSB) is transmitted first.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 36

Programming

36

Software Command Syntax

Software Command Syntax

The commands in this section are grouped after what they do, and these groups are sorted in a

theoretical usage sequence. It starts with commands for specifying the printed page — through

text-and-graphics commands — to cut-and-present commands. System and status commands

are presented at the end.

Black Mark (Top-Of-Form) Commands

See also Aligning Preprint and Thermal Print on page 89.

ESC #

Hex

decimal

ESC Z

1B 5A Hex

27 90 Decimal

Calibrate Blackmark Sensor

Refer to TTP 2000 Technical Manual (Zebra part number P1002902) for correct format.

Looks for a black mark, measures the contrast of the mark and sets parameter n51 to a suitable

value for the detected voltage, then reverses to the start position.

To make the calibration permanent, send <ESC>&<4>, store parameter values.

Note • Be sure to first set up the length of the black mark and the distance between two black

marks in the parameter setup.

ESC # is available in hardware revision B or higher.

Go to next Top of Form

In black mark mode, an ESC Z

starts looking for a black mark at the current position and

continues for one page length. If no black mark is found, the printer stops and bit 3 in status

byte 2 is set to 1 (See ESC ENQ 6 page 59).

When black mark mode is disabled, ESC Z will perform a form feed without cut (disregarding

the setting of parameter 34 on page 80).

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 37

Text Commands

Text received by the printer is printed with the currently selected font and font attributes. Text

exceeding the page width is wrapped with the line spacing selected.

Programming

Text Commands

37

ESC o n1

1B 6F n1 hex

27 111 n1 decimal

ESC N n1

1B 4E n1 hex

27 78 n1 decimal

Text and Logotype Orientation

Changes the orientation of text and logotypes.

n = 0 Gives portrait orientation

n = 1 Gives landscape orientation

Portrait and landscape can be mixed on the same printout. There are two cursors, one for

portrait and one for landscape. The cursor always starts at the top left corner of the document.

Looking at the paper when it exits the printer, the portrait cursor is at the top left corner of the

printout, moving to the right as text is typed, while the landscape cursor is at the top right

corner, moving downwards.

Note • Landscape orientation can only be used with fixed document mode.

Align Text

Changes the alignment of text and logotypes.

ESC N 0=Left

ESC N 1=Center

2=Right

ESC N

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 38

Programming

38

Text Commands

ESC ! n1

1B 21 n1 hex

27 33 n1 decimal

Select Font

This command selects one of eight fonts. The font design depends on which fonts have been

1

loaded

into the printer. Make a test printout to see which fonts are available in your printer.

Table 7 • Font selection commands

ESC ! 0 selects normal font (font 0) ESC ! 4 selects font 4

ESC ! 1 selects font 1 ESC ! 5 selects font 5

ESC ! 2 selects font 2 ESC ! 6 selects font 6

ESC ! 3 selects font 3 ESC ! 7 selects font 7

Lines, too long to be printed in the selected font, are automatically wrapped around.

Different fonts can be used on the same line.

Selecting an empty or invalid font location, will set bit 4 of byte 1 in the status enquiry

response to ”1". See Parameter-setting Data Enquiry on page 63.

Note • If more than 256 characters are sent to the printer before an LF, the first part of the

buffer contents is printed-out automatically. The text is formatted according to the already

received formatting commands.

ESC B

Hex

decimal

ESC i n1

1B 69 n1 Hex

27 105 n1 decimal

BoldNormal Bold

n = 0 Turns OFF bold (Normal)

n = 1 Turns ON bold

Bold is designed for normal character width and shows less and less as the width increases.

ItalicsNormal Italics

n = 0 Turns OFF Italics (Normal)

n = 1 Turns ON Italics

1. For font loading, see Loading on page 67.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 39

Programming

Text Commands

39

ESC T n1

1B 54 n1 Hex

27 84 n1 decimal

Selects normal or reversed print.

n = 0 Gives normal print, black on white

n = 1 Gives reversed print, white on black

Single words, characters, or complete text lines can be reversed.

Note • Reverse text and underline swaps the background with the foreground. This means

that the order in which the commands are issued affect the printout if one text overlaps

another.

ESC u n1

1B 75 n1 hex

27 117 n1 decimal

Characters, single words, or complete text lines can be underlined.

n = 0 Turns OFF underline

n = 1 Turns ON a 1 pixel wide underline

Reversed/Inversed Text

Underline

n = 2 Turns ON a 2 pixel wide underline, etc. up to n=7.

ESC h n1

1B 68 n1 hex

27 104 n1 decimal

Applicable n values are 0 — 15.

n = 1 Increases the character height to 2 times the basic character height.

n = 2 Increases the character height to 3 times the basic character height etc.

n = 0 Resets the character height to the basic character height.

In combination with variable character width (<ESC>w<n1>), give highly legible characters

depending on the font to which the command has been applied.

Different fonts and heights can be mixed on the same print line.

Text Height

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 40

Programming

40

Text Commands

ESC w n1

1B 77 n1 hex

27 119 n1 decimal

Applicable n values are 0 — 7.

n = 1 Increases the character width to 2 times the basic character width.

n = 2 Increases the character width to 3 times the basic character width etc.

n = 0 Resets the character width to the basic character width.

In combination with variable character height (<ESC>h<n1>), give highly legible characters

depending on the font to which the command has been applied.

Different fonts and widths can be mixed on the same print line.

ESC t n1...n5

1B 74 n1...n5 data hex

27 116 n1...n5 data decimal

data

Prints a text string at the specified X-Y position. The string will use the formatting set by font,

reversed, width, height, bold, italics, and underline commands.

n1n2 Two byte definition of the X print position (in pixels).

Text Width

Print Text at XY

BS

08 Hex

8 Decimal

n3n4 Two byte definition of the Y print position (in pixels).

n5 The number of characters in the string.

data The text string. The length must be exactly the number of characters

specified by n5, otherwise the printer will stop, waiting for more

characters.

After the string has been printed, the cursor will return to the position it had before the string

command was issued.

Note • The <ESC>t command clears any text preceding it on the same line. Commands will

not be cleared.

Note • The Y print-position only works if fixed page length is used.

Backspace

Moves the print-position one step to the left. Backspace can be used to combine characters.

For instance to print a Ø, send text commands O BS / to the printer, and the slash will

overprint the O.

Only one backspace can be used at a time. Excessive backspaces will be ignored.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 41

Programming

Text Commands

41

CAN

18 hex

24 decimal

CR

0D hex

13 decimal

LF

0A hex

10 decimal

Cancel

Cancels text and attributes sent before the <CAN> command on the same line.

Commands, are not cancelled.

Carriage Return

By default, carriage return is ignored.

By changing the default settings, you can:

1. Interpret it as <CR> which returns print position to beginning of line without line feed.

2. Interpret <CR> as <CR><LF> which inserts line space as specified by the line spacing

setting (see parameter 13 on page 78), and returns the print position to beginning of the

line.

See CR/LF Behavior on page 79.

Linefeed

ESC d n 1

1B 64 n1 hex

27 100 n1 decimal

Linefeed is interpreted as <CR><LF> by default. This inserts line spaces as specified by the

line spacing setting (see parameter p13), and returns the print position to beginning of the line.

LF also converts text from the input buffer to pixel lines and stores them in the line buffer,

ready to be printed.

By changing the default settings, you can:

• Interpret <LF> as Linefeed. This inserts line space as specified by the line spacing setting

(see parameter p13), without returning the print position to the beginning of the line.

• Ignore <LF>.

See CR/LF Behavior on page 79.

Make n Linefeeds

Executes the number of linefeeds as defined by variable n1. The length of each line feed is

determined by the default value for selected font (see parameter 13 on page 78).

The print position is returned to the beginning of the line. Any text on the line is lost. To avoid

losing text, send an <LF> before sending <ESC>d.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 42

Programming

42

Text Commands

ESC 3 n1

1B 33 n1 hex

27 51 n1 decimal

FF

0C hex

12 decimal

Line Spacing

This command is used to increase the line spacing.

Note • Obsolete command, may disappear from future program releases. Use parameter 13

on page 78 instead.

Form Feed

Prints data from the input buffer and feeds the paper to the top of the next page.

In fixed document length (FORM-mode) this command prints data in the input buffer and

feeds the paper to the top of next page.

In variable document length mode the Feed button advances to the minimum page length. If

the printout already is longer than the minimum page length, the Feed button does not feed the

paper at all.

In black-mark mode, the <FF> command looks for a black mark, see <ESC>Z.

If "Auto cut" is set to 1 (see Auto Cut after FF on page 80), the Feed button effects form-feed,

cut, and eject.

HT

09 hex

9 decimal

Note • Use parameters p37 and p38 to define page length.

Horizontal Tabulation

Shifts the current print position to the next Tab position.

Set tab positions with parameters 15 to 30 on page 79.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 43

Programming

Text Commands

43

ESC F

1B 46 n1...n16 hex

27 70 n1...n16 decimal

This command defines the desired horizontal tab positions. Variables n1...nx represent each

tab position. Up to 16 tab positions are allowed. Minimum allowed value is “1”.

Tab position 255 sets a tab stop on the last position of the line. Use this if you want underline

or reversed text to extend across the full paper width. Note that the tab positions are always

expressed in number of 2.5-mm steps.

n = 1 Means 2.5 mm from the left-hand edge of the print window.

N = NUL Ends the string

Example • Sets tab stops at 12.5, 25, 37.5, 50, and 62.5 mm.

Send→ ESC F 5 10 15 20 25 0

Note • Do not use value n = 0. The values must be sorted from low to high numbers.

Graphics commands

Set Horizontal Tabs

For the TTP 8200, the line length in bytes is 1 x, see parameter 48 on page 84.

For the TTP 8300, the line length in bytes is 1.5 x, see parameter 48 on page 84.

In the TTP 8200, that is 210 bytes for the A4 printer and 216 bytes for the Letter size printer.

ESC b n1...n5 data

1B 62 n1...n5 Data hex

27 98 n1...n5 Data decimal

Prints a black & white Windows bitmap (BMP-file with 1-bit color depth) at the specified X-Y

position. The bit-map must be a complete uncompressed Windows bitmap where the data

starts with BM. Max size is limited to the free RAM printed on the self-test printout.

n1 Always 0

n2n3 Two byte definition of the X print position (in pixels).

n4n5 Two byte definition of the Y print position (in pixels).

data Bitmap data.

After the bitmap has been printed, the cursor will return to the X-position that it had before the

bitmap command was issued.

Selecting horizontal mode (with <ESC>o<0>) prints the image in portrait orientation, while

selecting the vertical mode (with <ESC>o<1>) prints the image in landscape orientation.

Print Bitmap at XY-position

Note • The Y print-position and horizontal/vertical orientation only works if fixed page

length is used.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 44

Programming

44

Text Commands

ESC s n1 data

1B 73 n1 Data Hex

27 115 n1 Data Decimal

Send Dot-Line, 203 dpi

Sends one line of dot data. This command is used to build images, one dot line at a time by the

printer driver and should not be combined with text commands.

n Determines the number of bytes. Range: 1-255.

<data> 1 – x bytes, where x is the printhead width in bytes. The printhead width is in the

spec. of the printer.

Example • 58 mm printers use 48 bytes

Example • 80 mm printers use 72 bytes

Example • 112 mm printers use 104 bytes

Example • A4 and Letter-size printers use 216 bytes

Caution • Always send the No. of bytes that you specify!

If more than the specified No. of bytes are received, the rest of the bytes will be interpreted as

text or commands. This can cause any kind of problems in the printer as graphics data can

contain any hex value.

If you specify less data then the actual printhead width, the printer will fill the rest of the dot

line with spaces.

Data Compression

The Windows drivers use line based compression to decrease the time it takes to transfer

graphics data to the printer.

<ESC>s<0><0> or <ESC>l<0><0><0> disables compression

<ESC>s<0><1> or <ESC>l<0><0><1>

enables compression

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 45

Programming

Text Commands

45

ESC l data

1B 6C n1...n2 data hex

27 108 n1...n2 data decimal

Sends one line of dot data. This command is used to build images, one dot line at a time.

n1 n2 Determines the number of bytes: n2 is the low byte and n1 is the high

<data> 1–320 bytes of data for a 216 mm printer

Caution • Always send the No. of bytes that you specify!

If more than the specified No. of bytes are received, the rest of the bytes will be interpreted as

text or commands. This can cause any kind of problems in the printer as graphics data can

contain any hex value.

If you specify less data then the actual printhead width, the printer will fill the rest of the dot

line with spaces.

Data compression

The Windows drivers use line based compression to decrease the time it takes to transfer

graphics data to the printer.

Send Dot-Line, 300 dpi

byte. The value of n1+n2 must be 1 or more.

For 320 bytes n1 should be 1, and n2 should be 64.

<ESC>l<0><0><0> or <ESC>s<0><0> disables compression

<ESC>l<0><0><1> or <ESC>s<0><1> enables compression

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 46

Programming

<ESC>r<0><0><0><0><1><193><0><24><3>

X start Y start

X stop Y stop

Fill:

0=black

1=fine

2=medium

3=coarse

SW99006B

46

Text Commands

ESC r n1...n9

1B 72 n1...n9 hex

27 114 n1...n9 decimal

Prints a ruler line across the paper.

A ruler line is normally used to divide the printout into logical parts to make it easier to read. A

ruler line is actually an area defined by a start X-Y position and a stop X-Y position. This area

is filled with black or a checkered pattern.

n1n2 Two byte definition of the X start position

n3n4 Two byte definition of the Y start position

n5n6 Two byte definition of the X stop position (must be larger than n1n2)

n7n8 Two byte definition of the Y stop position (must be larger than n3n4)

n9 Fill pattern, 0=black, 3= Checkered

Print Ruler Line

Figure 18 • Printout with checkered ruler line

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 47

Programming

Text Commands

47

ESC g n...n5

1B 67 n1...n5 hex

27 103 n1...n5 decimal

Prints a customized logotype2 stored in the flash PROM. See also Logotypes on page 67.

n1 One-byte logotype identification No. (0—15)

n2n3 Two-byte definition of desired print position in X-direction measured

Print Logotype

from left-hand edge of the page (see Page Setup on page 87 regarding

definition of “page”). X-direction is perpendicular to the paper transport

direction.

2. For logotype loading, see "ESC & 1" under System Related Commands on page 52.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 48

Programming

48

Text Commands

Print commands

ESC p

1B 70 Hex

27 112 Decimal

ESC P n1

1B 50 n1 Hex

27 80 n1 decimal

Print

This command makes the printer print the contents of the line buffer.

Text is converted from text to pixel lines and stored in the line buffer when an <LF> is

received. If the line buffer is empty when <ESC>p is received, nothing is printed.

Text to be printed <LF><ESC>p prints "Text to be printed" on the paper.

Printout occurs automatically at:

Cut <RS> and <ESC><RS>

Form feed <FF>

Clear presenter <ENQ>

Run presenter <ESC><FF><n1>

Print buffer full

Press on Feed

button

Print Self-test Printout

This command makes the printer generate a self-test page based on the current parameter

settings and print that page. The parameter values printed are the ones currently being used.

They can differ from Power-ON default values if for example a printout from Windows has

been done before ESC P is sent to the printer. To make a self test printout with the Power-ON

default settings, power up the printer with the Feed button pressed.

n = 0 Gives standard self-test printout.

n = 1 Gives a character set printout using the font selected by parameter p14.

ESC Q

1B 51 n1...n2 hex

27 81 n1...n2 Decimal

The value n1 n2 represents high byte and low byte of the number of dot lines the paper is to be

transported forwards. Minimum value is 0, and maximum value is 32767.

• For 203 dpi printers, a dot line is 0.125 mm, and 32767 equals approximately 4.1 m.

• For 300 dpi printers, a dot line is 0.0833 mm, and 32767 equals approximately 2.7 m.

• For 203 dpi printers a dot line is 0.125 mm, and 255 dot lines equal approximately 32 mm.

• For 300 dpi printers, a dot line is 0.0833 mm, and 255 dot lines equal approximately 21.25

mm.

Quick Advance

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 49

Programming

Text Commands

49

ESC J n1

1B 4A n1 hex

27 74 n1 decimal

ESC j n1

1B 6A n1 hex

27 106 n1 decimal

Paper Advance

The value n represents the number of dot lines the paper is to be transported forwards. Range:

1–255.

Note • This command is supported for compatibility with older printers. We recommend you

to use <ESC>Q<n> instead.

Paper Reverse

The value n represents the number of dot lines the paper is to be transported backwards.

Range: 1–255.

Caution • Paper reverse may cause problems when used at the top of the page. Doing so

may cause paper jam when feeding forward again. You may also lose grip of the paper.

NEVER reverse more than 10 mm at top of page!

• For 203 dpi printers a dot line is 0.125 mm, and 255 dot lines equal approximately 32 mm.

• For 300 dpi printers, a dot line is 0.0833 mm, and 255 dot lines equal approximately 21.25

mm.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 50

Programming

50

Cut and Present Commands

Cut and Present Commands

RS

1E Hex

30 Decimal

ESC RS

1B 1E Hex

27 30 Decimal

Cut and Eject

Effects a paper cut-off and an eject through the presenter module. The RS command

automatically gives the eject length of 50 mm in addition to the factor stored in parameter p47.

If the printout length is too short, paper-feed is added until the minimum printout length (set by

parameters 37 and 38) is reached, before execution of the Cut command.

Note • The cut position is 19 mm before the print line. This makes the last 5 lines on a page

end up in the beginning of the next page. To get the cut after the text, Please set parameter 49

to auto, see parameter 49 on page 85.

You can also use <RS> together with the paper advance command:

<ESC>J<160><RS> or <ESC>J<230><RS> for TTP 8300.

Gives a cut & eject after the last text line.

Cut only, no Eject

Effects paper cut-off only.

Eject can be effected with the <ESC><FF><n> command (see Eject (run presenter)

on page 51).

To avoid thin strips of paper in the printer, multiple cut commands without paper feed inbetween will not be performed. If the printout length is too short, paper-feed is added until the

minimum printout length is reached, before execution of the cut command.

See Also Note on cut position for the <RS> command above.

Note • Use the cut command if you want full control over the printer from your system. But

remember that you also must add commands to feed to the correct cut position and eject the

paper so that the customer can get hold of it.

Note • Top margin settings that move the paper count as paper feed.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 51

Programming

Cut and Present Commands

51

ESC FF n1

1B 0C n1 hex

27 12 n1 decimal

Eject (run presenter)

<ESC><FF><n> ejects the document through the presenter module. Variable n represents the

eject-length in steps. The setting of parameter n47 is always added to the eject n in all forms

of eject.

The range for n is 1 to 127 mm. The range 128-255 is reserved for future use.

Place this command after a cut command (<ESC><RS>) to partially eject the printout to the

customer. Set the eject length so that the customer sees that the printout comes out of the kiosk

wall. The pull-detector gives motorized eject of the rest of the printout when the customer

pulls the paper.

EM n

19 n1 Hex

25 n1 Decimal

ENQ

05 Hex

5 Decimal

Note • The cut and eject command <RS>, automatically give the eject length of 50 mm in

addition to the factor stored in parameter n47.

Note • The resolution of the sensor is ± 3 mm so small changes in the parameter setting may

not show.

Longer ejects are more accurate than shorter ones because acceleration and retardation of the

rollers affects the eject less. Allow for ± 10 mm variations on short ejects.

Enforced Clear Presenter

Same function as ENQ but overrides the Retract and Retain parameter (p45) with another

presenter behavior. The function of n can be 0 to 255 0-99 ejects while 100-255 retracts (see

the description of parameter 45). The command will clear the presenter immediately (with

printing synchronization).

<EM><0> Ejects the presented page

<EM><100> Retracts the presented page

Clear Presenter

Clear the paper-path in the presenter of printouts. For example, to eject a document not

removed during the previous print/cut/eject operation. Parameter No. 45 controls how the

presenter is cleared, see parameter 45 on page 83.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 52

Programming

52

System Related Commands

System Related Commands

ESC ?

1B 3F Hex

27 63 Decimal

ESC @

1B 40 Hex

27 64 Decimal

ESC & 1

1B 26 01 Hex

27 38 1 decimal

Reset (full)

Restarts the printer with a complete reset.

This is the same as power off/on.

Reset (initialize)

Terminates the processing and initializes the control board. The control board is reset to

default-values (same as after power ON). Do not use this command as part of a print data

command string.

Load Logotype

Stores a logotype bitmap in the flash PROM. The logotype is printed with the ESC g

commands, see ESC g n...n5 on page 47. Also see Logotypes on page 67.

Note • If the logo width exceeds the print width, the operation is aborted.

ESC & L

1B 26 4C Hex

27 38 76 decimal

ESC & 4

1B 26 04 Hex

27 38 4 decimal

Erase all Logotypes

Erases all logotypes stored in the flash PROM.

Note • This command is only executed if at least one logotype has been loaded.

Store Current Parameter Values

Stores the current setting of all parameter values in the setting memory. These parameters are

then used as default parameters. Storing takes approximately 4 seconds. The printer activates

the presenter motor temporarily to indicate that storing is complete.

See also ESC & 5 on page 53 (Set default profile pointer) and ESC P n1 on page 48 (Set

temporary default parameters).

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 53

Programming

System Related Commands

53

ESC & 5

1B 26 05 n1 hex

27 38 5 n1 decimal

ESC & 0

1B 26 00 hex

27 38 0 decimal

Set Default Profile Pointer to n

Redirects any parameter storage initiated by <ESC>&<4> to another storage location.

These settings can later be recalled by <ESC>&<F><n>. A reset command or power OFF/ON

will return the parameters to the default settings stored in n=10.

n = 1 – 5 Settings that can be stored by the user

n = 10 Zebra factory default setting

Load Font

This command is used to load a font to the printer flash PROM. The font is placed in the first

free address position in the order of load sequence.

A Zebra font-file consists of a header containing data describing the font as well as data for

each individual character in the font.

Fonts can be designed with the font editor and loaded or deleted with the software available for

download from the Zebra web site. The font loading and deleting commands described here

should only be used if you do not work in the Windows environment.

ESC & C

1B 26 43 Hex

27 38 67 Decimal

ESC & D

1B 26 44 Hex

27 38 68 Decimal

For complete specification of the font format, see Fonts on page 64.

Note • The available font memory is printed on the self-test printout. A maximum of 8 fonts

can be addressed. Exceeding any of these limits will cause this command to fail.

Erase all Fonts

Erases all fonts stored in the flash PROM.

Note • This command is only executed if at least one font has been loaded.

Erase Fonts 4 to 7

Erases fonts number 4–7. Fonts 0–3 are not affected by this command.

The operation is complete when the printer resets automatically and activates the presenter

motor temporarily. Takes approximately 4 seconds.

10/19/2009 TTP 8000 Technical Manual P1003638-003

Page 54

Programming

54

System Related Commands

ESC & F n1

1B 26 46 n1 Hex

27 38 70 n1 decimal

ESC & P n1...n2

1B 26 50 n1...n2 hex

27 38 80 n1...n2 decimal

Reset Parameter Profile

This command resets the parameters of the printer to default or any previously stored setup.

n = 1 – 5 Settings that can be stored by the user

n = 10 Zebra factory default setting

Temporarily sets all parameters to predefined values that are stored in the printer. To keep the

values as default, store them in the flash PROM with command <ESC>&<4>.

Unless you save the parameters, a reset command or power OFF/ON will return the

parameters to the settings stored in the flash PROM.

Set Parameter Value

A number of bytes in the flash PROM hold various parameter values called default

parameters. One or several of them can be overridden temporarily with this command.

n1 Parameter number, range 1 -255.

n2 Parameter value.

See Default Parameter Settings on page 71.

The permanently stored parameters will be used again after a printer-reset command or at

power ON.

The temporary values can, however, be stored in the flash PROM as permanent values with

command <ESC>&<4>.

Set several parameters at once

<ESC>&P<0><FromPar><ParCount><Data>

FromPar is the parameter number to start writing and ParCount is the number of bytes being

sent. For every byte sent the parameter number is incremented.

Example • Sets the first 5 tabs to 5, 10, 15, 20, and 25. (FromPar 15, ParCount 5).

<ESC>&P<0><15><5><5><10><15><20><25>.

P1003638-003 TTP 8000 Technical Manual 10/19/2009

Page 55

Programming

System Related Commands

55

ESC NUL