Page 1

P1055866-001 Rev. A

Zebra® TTP 2030

Windows® CE

Printer Driver

User Guide

Page 2

© 2013 ZIH Corp. The copyrights in this manual and the software and/or firmware in the printer described

therein are owned by ZIH Corp. and Zebra’s licensors. Unauthorized reproduction of this manual or the software

and/or firmware in the printer may result in imprisonment of up to one year and fines of up to $10,000

(17 U.S.C.506). Copyright violators may be subject to civil liability.

This product may contain ZPL

®

, ZPL II®, and ZebraLink™ programs; Element Energy Equalizer™ Circuit; E3™;

and Monotype Imaging fonts. Software © ZIH Corp. All rights reserved worldwide.

ZebraLink, Element Energy Equalizer, E

3

and all product names and numbers are trademarks, and Zebra, the Zebra

head graphic, ZPL and ZPL II are registered trademarks of ZIH Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders. For additional trademark

information, please see “Trademarks” on the product CD.

Proprietary Statement This manual contains proprietary information of Zebra Technologies Corporation and its

subsidiaries (“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed

to any other parties for any other purpose without the express, written permission of Zebra Technologies Corporation.

Product Improvements Continuous improvement of products is a policy of Zebra Technologies Corporation.

All specifications and designs are subject to change without notice.

Liability Disclaimer Zebra Technologies Corporation takes steps to ensure that its published Engineering

specifications and manuals are correct; however, errors do occur. Zebra Technologies Corporation reserves the right

to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hard ware and software) be liab le for any damages

whatsoever (including, without limitation, consequential damages including loss of busin ess profi ts, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to use such

product, even if Zebra Technologies Corporation has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation

or exclusion may not apply to you.

Page 3

Contents

1 • Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Who Should Use This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

How This Document Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Document Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 • Windows CE Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Windows CE Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Printer Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Port Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Print Spooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Status Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Panel Extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TTP2000CPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Printer and Driver Parameter Setting and Maintenance . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CE Driver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Firmware Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

UI Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Command Line Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Printer Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Device Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

About . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Setting Black Mark Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

04/14/2013 TTP 2030™ Technical Manual P1055866-001

Page 4

iv

3 • Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Light Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

LED States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Media Sensing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Black Mark Calibration Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Other Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contact Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

P1055866-001 TTP 2030™ Technical Manual 04/14/2013

Page 5

Who Should Use This Document

This guide is intended for use by any person who needs to setup the TTP 2030 printer for use

with a Windows CE device.

1

Introduction

How This Document Is Organized

The manual is set up as follows:

Introduction Contact information, document conventions.

Windows CE Driver Installation, updates, preferences, and properties.

Troubleshooting Status light description, user interface, error handling,

and fixes to common printing problems.

This manual will be updated from time to time as printer functions and features may be added

or amended. You will always find the latest edition on our website at www.zebra.com.

If you require information for functions not found in this manual edition, please contact

Technical Support for your region or the Zebra partner the printer was purchased from.

Document Conventions

The following conventions are used in this document to convey certain information.

Alternate Color – Cross-references contain links to other sections in this guide. If you are

viewing this guide online, click the blue text to jump to its location.

Indicates information that emphasizes or supplements important points of the main text.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 6

Introduction

2

Document Conventions

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 7

Description

APPLICATION

GDI

DISPLAY DRIVER

PRINTER DRIVER

PORT MONITOR

USB

PORT

PRINTER

Windows CE Driver

2

Windows CE Driver

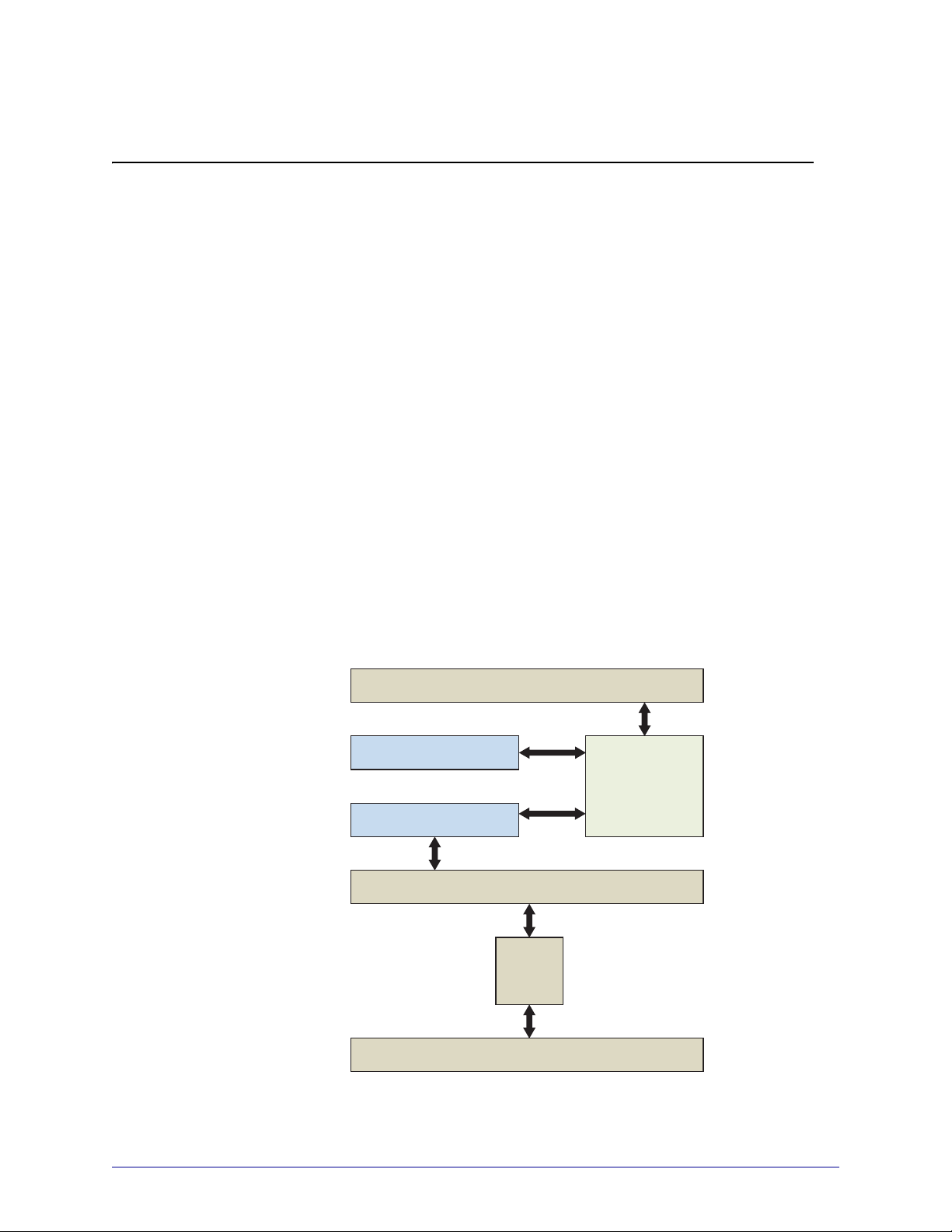

The following description applies to CE 6 and EC 7.

The illustration shows the relationship between the various system components involved in

printing.

Figure 1 • System Flowchart

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 8

Windows CE Driver

4

Description

Printer Driver

The printer driver for the TTP 2030 is named TTP2000.DLL. The Windows CE graphics

device interface (GDI) and display driver perform most of the work involved in printing. At

the beginning of the printing process, GDI creates a device context with attributes that are

retrieved from the printer driver during a call to DrvEnablePDEV. The display driver, not the

printer driver, is used to render subsequent drawing commands that are issued from the

application into the device context. Therefore, some drawing functi on s that are present in a

printer driver, such as DrvStrokePath, are never called because the printer driver only renders

the document internally.

The printer driver converts the bitmap data from a GDI bitmap format into the format that is

recognized by the printer. This can include such operations as color reduction to the color

space of the printer, data compression, and data conversion into the format that is used by the

printer – a format sometimes known as a page-description language (PDL). Then, the printer

driver calls the port monitor to send the rendered image to the printer.

Only a small number of the graphics driver functions defined for printer drivers are required in

printer drivers for Windows CE. Printer drivers are required to implement only those graphics

driver functions that are necessary for gathering printer metrics, setting up the printer, starting

and ending print jobs, and preparing content for printing.

The following table shows the functions implemented in the driver:

Table 1 • Driver Functions

Function Description

DrvCopyBits Translates between device-managed raster surfaces and

graphics device interface (GDI) standard format bitmaps.

DrvDisablePDEV Used by MGDI to notify a driver that the specified PDEV

structure is no longer needed.

DrvDisableSurface Used by the GDI to notify a driver that the surface created

by the DrvEnableSurface function for the current device

is no longer needed.

DrvEnableDriver Specifies the initial driver entry point exported by the

driver DLL for devices that link directly to GWES, such

as display drivers and printer drivers. It fills a

DRVENABLEDATA structure with the driver version

number and calling addresses of functions supported by

the driver.

DrvEnablePDEV Enables a device context for drawing and returns device

metrics for the target printer or display device in a

GDIINFO structure. Printer drivers call a disp la y d ri ve r's

DrvEnablePDEV function to create and initialize the

device context, and then substitute the printer's device

metrics before returning the device context to the GDI for

bitmap rendering.

DrvEnableSurface Sets up a surface to be drawn on and associates it with a

specified PDEV.

DrvEndDoc Called by the GDI to finish or abort a print job.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 9

Windows CE Driver

Description

Table 1 • Driver Functions

Function Description

DrvGetModes Lists the modes supported by a specified device.

DrvStartDoc Called by the GDI to start a print job.

DrvStartPage Called by the GD I to start printing the next page of a print

job.

GetPrinterInfo Obtains information about printers, such as the name of

the printer or whether the printer can print in color.

PrinterClose Closes a printer handle previously opened by a call to the

PrinterOpen function.

PrinterOpen Op ens a specified printer port and returns a handle to the

printer.

PrinterSend Sends a block of data to a printer.

ReportPrinterStatus Returns the status of a printer or printing op eration t hat is

in progress.

GetPrinterStatus Returns a specific TTP 2030 status.

5

Port Monitor

The port monitor for the TTP 2030 is called TTPPort.DLL. Printing is supported over

universal serial bus (USB) port only. The printing architecture provides application

programming interfaces (APIs) that are exposed by the Graphics, Windowing, and Events

Subsystem (GWES) to communicate with the printer driver. The printer driver communicates

with the port driver that sends the print data over the supported bus. Therefore, the printer

driver is independent of the bus and the corresponding bus driver.

Print Spooling

No separate printer spooler component exists in Windows CE, unlike the desktop versions of

the Windows OS. With Windows CE, spooling or background printing is implemented in the

printer driver itself. However, because print spooling typically consumes a lot of memory,

limited memory might be a problem. A practical print spooler usually has to implement a

complicated compression scheme to store spooled documents before printing .

Status Monitoring

In order to allow applications to get status from the printer, there are two functions

implemented:

• ReportPrinterStatus – the default function described in the MSDN documentation.

• GetPrinterStatus – the function that returns the actual printer status (described below).

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 10

Windows CE Driver

6

Description

GetPrinterStatus

TTP 2030 Status codes

This function gets the specific Printer status for the TTP 2030.

Syntax DWORD WINAPI GetPrinterStatus(HANDLE hPrinter,

LPPRINTERSTATUS status)

Parm

hPrinter - HANDLE - Handle to the printer

status - LPPRINTERSTATUS - The status to be set.

Return DWORD - Returns

ERROR_SUCCESS if everything went Ok, else :

ERROR_UNKNOWN_PORT - If hPrinter is INVALID_HANDLE_VALUE

ERROR_READ_FAULT - If read fail

ERROR_WRITE_FAULT - If write fail

ERROR_NOT_SUPPORTED - If hPrinter is not supported

The following table shows all status codes that can be reported by the TTP 2030 printer from

the application.

Table 2 • Status Codes

Status

Meaning

code

ACK OK (printer is operable).

NAK 1 Paper left in presenter module. Attempt to clear the paper path failed.

NAK 2 Cutter jammed.

NAK 3 Out of paper.

NAK 4 Printhead lifted.

NAK 5 Paper-feed error. No paper detected in presenter although 10 cm has been printed.

Paper might be wound around the platen or, in some way, has be en forced above the

presenter module.

NAK 6 Temperature error. The printhead temperature has exceeded the 60 °C maximum

limit.

NAK 7 Presenter not running.

NAK 8 Paper jam during retract.

NAK 0A Black mark not found.

NAK 0B Black mark calibration error.

NAK 0C Index error.

NAK 0D Checksum error.

NAK 0E Wrong firmware type or target for firmware loading.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 11

NAK 0F Firmware cannot start because no firmware is loaded or firmware checksum is

wrong.

NAK 10 Retract function timed out. If the customer doesn’t take the paper and the printer

clears the presenter due to a timeout, the pending error bit is set and error code NAK

10h is reported.

Types of Status Monitoring

In order to incorporate the way status monitoring works for the TTP 2030 printer setup, it is

important to understand what happens in a kiosk when you print, and when status monitoring

should take place.

Status monitoring can be handled in two ways:

• Monitoring in the printing application

• Monitoring in a separate application

Table 2 • Status Codes

Windows CE Driver

Description

7

When monitoring takes place in the printing application, normally the printer is observed

before sending a print job to see if the printer is ‘OK’ and then send the print job. After the

print job is signaled as being printed, the status is checked again to see i f the printer has any

errors or if the paper has been taken, etc.

Monitoring in a separate application usually doesn't allow direct interaction with the printed

job so the printer is polled as often as possible to get most accurate information on what the

printer is doing. This is usually very time consuming and care must be taken to achieve

synchronization and control over the current print job .

Monitoring While Printing

Status monitoring has been implemented in the internal printing structure of the driver . When a

document is opened, printed, and closed, the driver will check the printer status before and

after printing and will also react to write errors if any occur. It will then set the printer status

and raise the error event.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 12

Windows CE Driver

8

Description

Monitoring While Idle

In order to get status any time a status thread has to be implemented which reads printer status

and provides changed status information in the same manner. The following code snippet in

C# may be used as a guide to develop such an application. The code is using the

TTPConfig DLL.

TTPConfig config = new TTPConfig();

config.Load();//Load settings from registry

string msg = "";

try

{

config.open("LPT1:");

//getStatus is not synchronized with other read/write

functions

byte status = config.getStatus();

msg = "Status : " + status;

config.close("LPT1:");

}

catch (Exception ex)

{

msg = ex.Message;

MessageBox.Show("Status : " + msg);

Control Panel Extension

In order to open the control panel an d double c lick the prog ram icon, a co ntrol panel ext ension

is supplied with the driver.

TTP2000CPL

This component enables users to change settings for the printer and printer driver. You can

access the Control Panel through Start > Settings > Control Panel.

Printer and Driver Parameter Setting and Maintenance

To provide an easy interface to set printer and driver parameters on the CE device, an

application is provided that handles device settings, and offers a Tools tab (see Tools

on page 16) to perform certain maintenance functions and print a printer configuration sheet.

The driver settings are done via the TTP 2030 Settings application that can be found in the

Control Panel.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 13

Installation

CE Driver Installation

The Zebra CE driver ZIP package includes the following files:

• TTP2000CPL.CPL – The Control Panel that enables users to change settings for the

printer and printer driver

• TTP2000.DLL – the Printer Driver

• TTPPort.DLL – the Port Monitor

• TTPErr.DLL – the error handler

• TTP2030.CPY – a sample copy file

• TTPDevice.EXE – the Parameter setup application

• TTPConfig.DLL – a helper DLL for the parameter setup application

• FWDownload.EXE – the firmware update application

Windows CE Driver

Installation

9

Extract the Zebra CE driver files for the TTP 2030 fro m the ZIP file and depl oy the driver files

(TTP2000, TTPPort, TTPErr and TTP2000CPL) to the Windows directory. The sample copy

file (TTP2030.CPY) is included as a template for writing a copy file. This file is used during

each restart to copy files from permanent storage to their respective directories.

Firmware Update

UI Option

Check the firmware version installed on the printer by printing a config uration label (see Tools

on page 16), the firmware version will be shown.

To update the firmware

1. Go to the Zebra Website at www.zebra.com and follow the instructions to download the

latest version to your computer.

2. Copy the firmware package to the device to which the printer is connected and that runs

the driver .

3. Select the port that the target printer is connected to and then click Select FW.

4. Navigate to the firmware file and click Download Firmware.

5. To confirm the installation, click Yes.

The status light on the printer flashes intermittently between green and red indicating that

a firmware update is in progress. The printer resets when it has finished the upload.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 14

Windows CE Driver

75#\Application\Zebra\FWDownload.exe /P LPT1: /F \Application\Zebra\V1819.3.86

Number of

characters in

the command

line including

spaces and

quotes

/P is the

port used

to send

data to the

printer

/F is the firmware file including

directory location where the file

is stored

Length of string

Command line

Firmware download application

including directory location

where the file is stored

Note • You must use quotation marks if the file resides in a directory with spaces,

such as “\Program Files”.

10

Firmware Update

Command Line Option

The download application offers a command lin e option to allow for remote deploymen t of the

firmware file and application, and execution via a shortcut.

To create a shortcut file

1. Create a shortcut link file (.lnk) using an edito r like Notepad. Name the file

ShortCutTest.lnk. The format for the shortcut link is:

<length of string>#<command line>

An example of a shortcut link and how it is formed is shown below.

Figure 2 • Example Shortcut Link

2. Place the shortcut link on the first line of the shortcut link file.

3. Save the shortcut link file, and copy it to th e \Windows\Start Menu directory on the

Windows CE or Pocket PC device.

The shortcut appears on the Start menu.

Note • After the program has finished, a log file (TTP2030FWDownload.log) showing the

actions and results during the update process is saved to the system root directory.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 15

Printer Settings

Device Settings

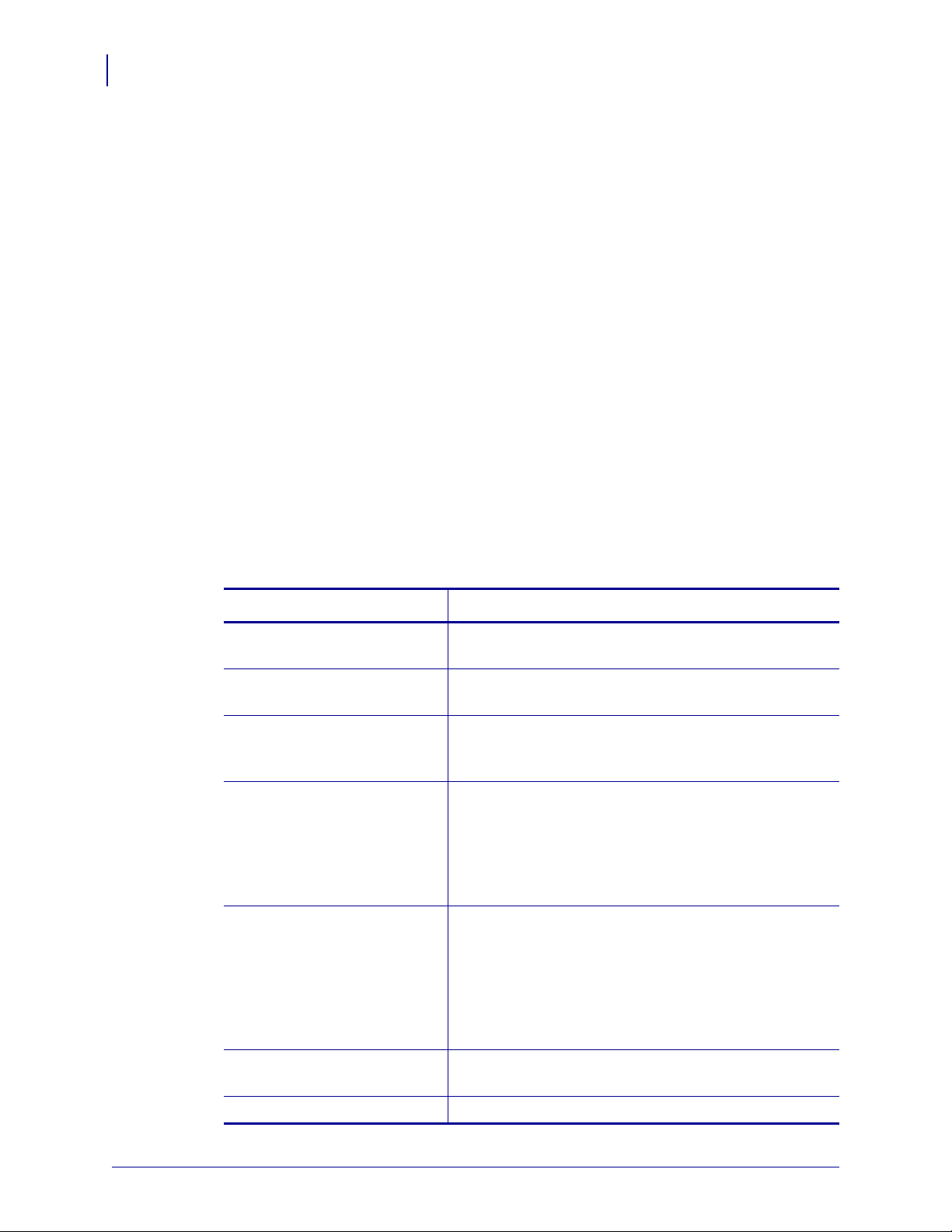

The TTP 2030 Settings dialog box controls the printer and driver settings.

Windows CE Driver

Printer Settings

11

Figure 3 • Device Settings Tab

The following table describes the values and defaults of the parameters:

Table 3 • Parameter Settings and Defaults

Parameter Value Range Default Value

Media Width 58 mm, 60 mm, 80 mm,

82.5 mm

Media Height 90 mm to 600 mm 150 mm

Darkness 1 to 15 9

Max Print Speed (mm/s) 47 mm to 150 mm 150 mm

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

80 mm

Page 16

Windows CE Driver

12

Printer Settings

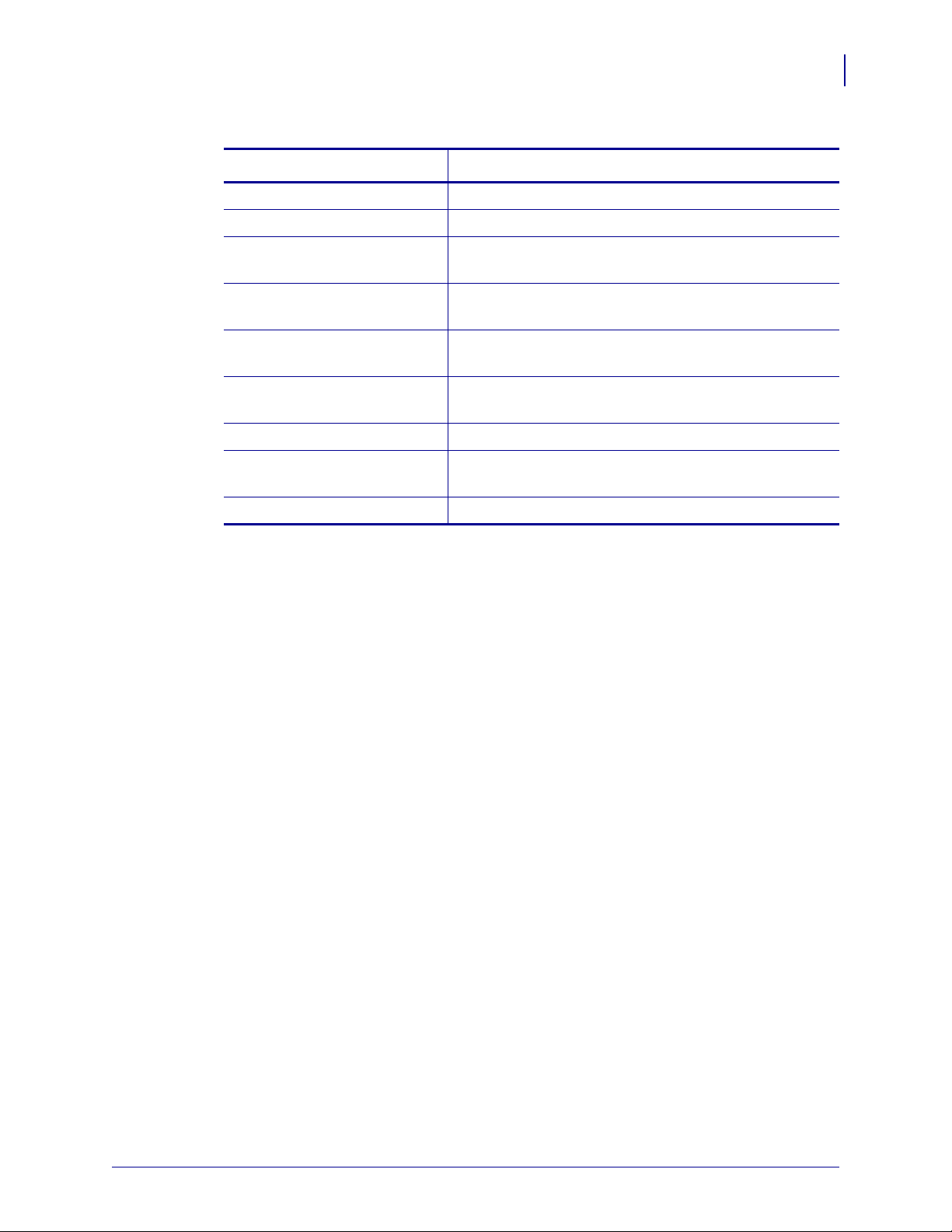

Table 3 • Parameter Settings and Defaults

Parameter Value Range Default Value

Media Tracking Continuous, Variable Length,

Mark Sensing

Top Margin (mm) 2 mm to 10 mm 10 mm

Bottom Margin (mm) 0 to 9 mm 0

Cutter Mode None, Every Page, End of

Document

Partial Cut Width 0, 10 mm to 60 mm 0

Presenter Loop Length 0 to 600 mm 416 mm

Eject Length 20 mm to 600 mm 50 mm

Present Length Addition 0 to 255 mm 0

Presenter Timeout 0 to 300 seconds 0

Clear Presenter Disable, Enable Disable

Presenter Mode Eject, Retract Eject

• OK – applies the settings and exits the program

• Cancel – does not apply the settings and exits the program

• Apply – applies the settings but does not exit the program

Variable Length

Every Page

• Default – sets all settings to factory default

The following parameter settings are sent to the printer during each print job.

Media Width

The media width can be set to 58 mm, 60 mm, 80 mm and 82.5 mm. The default setting is

80 mm.

Media Height

The media height can be set between the minimum page length of 90 mm and the maximum

page length of 600 mm. The default setting is 150 mm.

Darkness

The Darkness can be set between 1 and 15 with 1 being the lightest. The default setting

is 9.

Max Print Speed

The max print speed can be set between 47 mm and 150 mm per second (mm/s). The default

setting is 150 mm/s. The actual print speed may vary depending on the darkness and the

content printed.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 17

Media Tracking

Media Tracking sets Continuous, Variable Length, or Mark Sensing with the default set to

Variable Length. When media tracking is set to Continuous, the driver sends the full page size

to the printer (Page Mode), the page length will always be the same as the selected paper size

(e.g., if 58 mm x 200 mm Media is selected, the print will be 200 mm long in Page Mode).

When media tracking is set to Variable Length, the driver will shorten the length of the pa ge to

the length of the printed element. The driver will end the page after the last printed element

(text, barcode, or graphic) then send a feed, cut, and eject command. The page length may vary

from page to page but will always be a minimum of 76 mm. When Mark Sensing is set, the

driver will send the page size to the printer , the printer will restrict the print to the area between

the black marks. If the printed area is larger than the space between the black marks, it will

print additional pages (receipts). The margin values in the receipt application must be

corrected after setting the driver values. If t he margin in the application is set to 9 mm and the

driver is set to 2 mm, the application setting will be enforced unless the driver is changed

accordingly.

Top Margin

The Top Margin is the equivalent to the distance between the cutter and the print head and is

by default 10 mm. If it is set between the minimu m of 2 mm or 10 mm it will reverse the paper .

Windows CE Driver

Printer Settings

13

Bottom Margin

The Bottom margin can be set between 0 and 9 mm and will be added to the bottom of the

page in Variable Mode and will limit the printable area in Continuous Mode and Mark Sensing.

The default is 0.

Cutter Mode

Cutter Mode can be set to None, Every Page and Cut at the document end. The default is Every

Page. When set to Every Page and a multi-page document is printed each page will be cut. If

set to Cut at document end and a multi-page document is printed all pages will print and only

one cut at the end of the document will be issued. Partial Cut Width is used with Cut at

document end.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 18

Windows CE Driver

10 mm

Page 1

Page 2

Page 1

Page 2

Cut

Not Cut

60 mm

14

Printer Settings

Partial Cut Width

Partial cut leaves multi-page receipts attached at th e specified wid th. The partia l cut widt h can

be set to 0 and between 10 and 60 mm; the default is 0 and it disables partial cut (full cut).

Partial cut can only be used with the Cut at document end selection in Cutter Mode.

Figure 4 • Partial Cut Diagram

Presenter Loop Length

Presenter Loop Length determines how much paper is held in the presenter loop. The presenter

loop length can be set between 0 and 600 mm and the default value is 416 mm. A setting of 0

disables the presenter loop and media feed directly through the presenter.

Eject Length

Eject Length determines how much paper is exposed for the customer. The range is from

20mm to 600mm with the default set to 50mm. If the eject length is set larger than the length

of the receipt, the printer will retain a portion of the receipt in the presenter unless the “Clear

Presenter” option is set to “Enable”.

Present Length Addition

Presenter Length Addition is an additional len gt h t o c omp ensa te fo r th e th ickness of the kiosk

wall. The range is from 0 to 255 mm with the default set to 0.

Presenter Timeout

Presenter Timeout determines how long the presenter will hold the receipt before ejecting it.

The range for the timeout is from 0 to 300 seconds with the default set at 0.

Note • Presenter timeout value must have a minimum of 10 seconds in order to work

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

properly.

Page 19

Clear Presenter

Clear Presenter determines if a receipt is retained, or if it is ejected from the presenter after the

timeout.

Presenter Mode

The Presenter Mode determines if a receipt will be ejected or retracted when a new receipt

enters the presenter. In either case, the receipt will be retracted if the timeout occurs.

Windows CE Driver

Printer Settings

15

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 20

Windows CE Driver

16

Printer Settings

Tools

The Tools tab enables printer maintenance functions.

Figure 5 • Tools Tab

Printer Port setting – tells the driver to which port the printer is connected

Clear Kiosk Presenter – ejects any media in the presenter

Send PRN File – sends a saved PRN file to the printer

Set Black Mark Mode – sets the printer to use black mark media

Set Continuous Mode – sets the printer to print continuous pages

Save Parameter – saves the Parameter Settings

Feed One Receipt – feeds a single blank receipt

Print Config Label – prints a page with the printer configuration information

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 21

About

The About tab shows the current driver version.

Windows CE Driver

Printer Settings

17

Figure 6 • About Tab

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 22

Windows CE Driver

18

Setting Black Mark Mode

Setting Black Mark Mode

The printer is optimized to detect black marks printed with IR sensit ive ink and ignore preprint

in IR blind ink as follows:

• 80 and 82.5 mm media – the black marks are centered 30 mm to the right of the paper

center when viewing the imaged side of the receipt and print direction is downward

• 58 and 60 mm media – the black marks are centered 22 mm to the left of the paper when

viewing the imaged side of the receipt and the print direction is downward

The printer supports media with black mark thickness in p rinting di rection of 2. 5-9.0 mm, and

a width of 5.0-10.0 mm when the black mark is centered on the sensor.

Refer to the TTP 2000 Series Technical Manual (P1002902) available at

www .zebra.com/support for black mark media requirements and media guide installation

instructions.

To set blac k mark mode:

1. Choose the correct media guide for the desired media width.

2. Load the desired media.

3. In the Tools tab of the Windows driver, click Set Black Mark Mode.

A dialog box appears asking you to confirm your selection.

4. Click Yes.

The printer feeds the media, detects the black marks, and ejects the media.

5. Press the Feed button on the printer several times to confirm the printer i s cut ting directly

in the center of the black marks.

6. In the Device Settings tab of the Windows driver, set the Media Tracking to

Mark Sensing.

Note • If you revert back to Continuous mode, set the Media Tracking back to Continuous

or Variable.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 23

Troubleshooting

Status Light Descriptions

LED States

3

Immediately after power is applied to the printer, a brief self test is performed and the status

light will report the following conditions:

Table 1 • LED States

Solid Green 0 - OK This code is reported when no other

codes are active. It indicates the

printer is functioning normally.

One Red Flash 1 - Paper Jam in

Presenter

Two Red Flashes 2 - Cutter Jam This code indicates that the printer

This code indicates that media is stuck

in the presenter . This error is set when

the printer attempts to eject the media

but cannot complete the operation.

This error is cleared by removing the

media from the presenter sensor.

could not find the cutter blade or could

not properly manage its position. The

error is set when the printer attempts

to cut but fails after three retries. This

error is cleared by cycling the power

off and on.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 24

Troubleshooting

20

Status Light Descriptions

Table 1 • LED States

Three Red Flashes 3 - Out of Paper This code indicates that the selected

EOP sensor has detected no media

present. This value is signaled when

the mark engine has detected a mark

larger than "TOF marker length” plus

5mm, or when the A/D reading of the

EOP sensor drops below the “End of

paper threshold”. This error is cleared

after successful media load (either via

calibration or via regular media load).

Four Red Flashes 4 - Print Head Lifted This code indicates that the print head

has been lifted. This error is cleared

by returning the print head to its

locked position.

Five Red Flashes 5 - Paper Fe ed Error This code indicates that the paper

failed to reach the presenter sensor

within the expected amount of time.

The error is signaled if the media does

not reach the presenter sensor after

feeding the length from the cutter to

the sensor plus 15mm. This error is

cleared by opening and closing the

print head, or by cycling power off and

on.

Y ellow Flashing 6 - Head Temperature

Error

Rapid Amber

Flashing

Firmware missing or

corrupt

This code indicates that the print head

has exceeded the maximum permitted

temperature. This status code is set

when the print head temperature

exceeds 65° C (149° F). When this

condition occurs, the printer feeds

100mm (4 inches) of blank media,

cuts, and presents. This error is

cleared automatically when the print

head temperature falls below 55° C

(131° F).

This code indicates that the bootware

has detected an incorrect or missing

checksum in the firmware. This error is

cleared when the firmware is reloaded

or updated. Refer to the TTP 2000

Series Technical Manual for firmware

upload procedure.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 25

Status Indicator

The orange status indicator has several functions:

• ON constantly – the printer is operational

• Flash, flash, pause, flash, flash – is the warning-code for paper low. The warning-code is

reset automatically when the condition causing it is removed. This behavior can be

enabled by setting parameter 52 (Warning Level) to 001.

• Flashes rapidly – indicates error. Press and hold the Feed button and the number of flashes

will reflect the status-code.

10 Black mark not found (on media load)

11 Black mark calibration error

Fast flashes Checksum error at firmware loading

Steady light Wrong firmware type

1 Presenter jam, paper cannot be ejected / retracted

2 Cutter cannot return to home position

3 Out of paper

4 Printhead lifted

5 Paper feed error (under head)

6 Temp error, printhead is above 60°C

7 Paper jam during present

8 Paper jam during retract

Troubleshooting

Print Quality Problems

21

Status codes are reset when the:

• Conditions causing them are removed

• Printer is power cycled (turned off/on)

• Printhead is lifted and then lowered to clear a paper jam

Print Quality Problems

No print on the label

• The media may not be direct thermal media.

• Is the media loaded correctly? Is the thermal media coating facing upward?

• The printhead may be dirty or damaged.

• The printhead is dirty. Clean the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The printhead is damaged. Replace the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 26

Troubleshooting

22

Print Quality Problems

The printed image does not look right

• The printhead cable may be damaged or not connected properly.

• Check the cable connections at the printhead and the main logic board.

• Check for damage to the cable. Replace the cable if damaged.

• The printhead is dirty. Clean the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The printhead has worn out. The printhead is a consumable item and will wear out due to

friction between the media and printhead. Using unapproved media may shorten life or

damage your printhead. Replace the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• Adjust the print darkness and/or print speed. See Device Settings on page 11.

• The Windows printer driver or application software can change these settings and

may require a change to optimize print quality.

• The media being used is incompatible with the printer. Be sure to use the recommended

media for your application, and always use Zebra-approved media.

• The platen (driver) roller may be losing traction due to foreign objects attached to its

surface or the rubbery smooth surface may have become polished and slippery.

• The platen may need cleaning or replacement. Refer to the TTP 20 00 Service Ma nual

(P1002903) available at www.zebra.com/partners for instructions.

There are long tracks of missing print (blank vertical lines) on

several labels

• The printhead may be dirty or damaged.

• The printhead is dirty. Clean the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The printhead is damaged. Replace the printhead. Refer to the TTP 2000 Service

Manual (P1002903) available at www.zebra.com/partners for instructions.

• The printhead has worn out. The printhead is a consumable item and will wear out due to

friction between the media and printhead. Using unapproved media may shorten life or

damage your printhead. Replace the printhead. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

The printing does not start at the top of the receipt or misprinting of

one to three receipts

• Reload the media. Refer to the TTP 2000 Service Manual (P1002903) available at

www.zebra.com/partners for instructions.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 27

Media Sensing Problems

The TTP 2030™ printer default media mode is Variable. The printer will remain in this mode

until it is changed by the Windows Driver.

Black Mark Calibration Process

Important • In variable and fixed page mode, only the paper out level will be calibrated

while in black mark mode all parameters affecting black mark detection will be calibrated.

1. Prepare the printer for calibration:

Troubleshooting

Media Sensing Problems

23

If your Firmware is

version…

Then…

3.54 or higher Set Parameter 35 (Black Mark Mode) to a value of 1

3.50 or lower Set Parameter 36 (Document Mode) to a value of 2

2. Open the printhead by pushing the lever on top.

3. Remove the paper from the printer.

4. With the printhead open, hold the Feed button for five seconds.

5. While still holding the Feed button, close the printhead.

6. When the Status light goes off, let go of the Feed button.

7. Insert the paper. The printer performs a calibration and stops. If the status light is on and

not flashing after calibration, the calibration is successful.

8. Open the printhead, remove the paper, then close the printhead and insert the paper into

the printer. The printer is now ready to be used.

To confirm that the calibration was successful, press the Feed button once. If the printer feeds

and cuts at the correct position, the printer is calibrated correctly. If the printer cuts at the

incorrect position, repeat steps 1-7 above.

To fine tune the cut, modify the value of parameter 46 (Black Mark Sensor Calibration) or

change the Cut position value in the driver.

If the printer does not detect blacklines (or notches with black mark sensing) after feeding the

media the default maximum label length distance of 24 inch es (6 10 mm), then th e prin ter will

report a media error.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 28

Troubleshooting

24

Media Sensing Problems

The printer will not load the media

• The leading edge of the media is not cut straight, so the media sensor does not see the

media to auto-feed it. Cut the paper at 90 degree angle to the sides and try again.

• The media has changed or a different media guide has been installed.

• Make sure the appropriate media guide is installed for the media being used. Refer to

the TTP 2000 Series Technical Manual (P1002902) available at

www .zebra.com/support for instructions.

• Load the media manually. Refer to the TTP 2000 Series Technical Manual

(P1002902) available at www.zebra.com/support for instructions.

• The platen (driver) roller may be losing traction due to foreign objects attached to its

surface or the rubbery smooth surface may have become polished and slippery.

• The platen may need cleaning or replacement. Refer to the TTP 20 00 Service Ma nual

(P1002903) available at www.zebra.com/partners for instructions.

• The media sensor may be dirty or damaged. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The printhead assembly is not closed.

• Check the status light on either side of the printer. If the status light is showing four

red flashes then the printhead is not closed. Push down on the printhead assembly

until it locks into place.

• There is a paper jam under the printhead. Refer to the TTP 2000 Series Technical Manual

(P1002902) available at www.zebra.com/support for instructions.

• The large media roll may be over torquing the feed motor. Install the large media roll

adapter. Refer to the TTP 2000 Series Technical Manual (P1002902) available at

www .zebra.com/support for instructions.

The printer will not eject the media

• The presenter rollers are dirty or damaged. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• There is a jam under the presenter. Refer to the TTP 2000 Service Manual (P1002903)

available at www.zebra.com/partners for instructions.

• The presenter sensor may be dirty or damaged. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The presenter has not cleared the previous receipt.

• Check the status light on either side of the printer. If the status light is showing one

flash, then the printer is reporting media in the presenter. Remove any media that may

be in the presenter.

• The presenter motor may need to be replaced. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

• The presenter drive gears may be damaged or worn. Refer to the TTP 2000 Service

Manual (P1002903) available at www.zebra.com/partners for instructions.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Page 29

Other Problems

The receipts are not cutting properly

• The cutter blade may be worn. Replace the cutter blades. Refer to the TTP 2000 Service

Manual (P1002903) available at www.zebra.com/partners for instructions.

• The cutter tensioner may be worn or damaged. Replace the cover plate assembly . Refer to

the TTP 2000 Service Manual (P1002903) available at www.zebra.com/partners for

instructions.

• Check the Cutter Mode setting, and the Partial Cut Width setting in the Windows CE

driver. See Device Settings on page 11.

• The cutter motor may need to be replaced. Refer to the Refer to the TTP 2000 Service

Manual (P1002903) available at www.zebra.com/partners for instructions.

• The cutter drive gear, drive pin, or cutter actuator may be damaged or worn. Refer to the

TTP 2000 Service Manual (P1002903) available at www.zebra.com/partners for

instructions.

• Check for the latest firmware and driver version.

Troubleshooting

Other Problems

25

There are no lights on the printer

• Make sure there is power applied to the printer.

• The main logic board may be damaged. Refer to the TTP 2000 Service Manual

(P1002903) available at www.zebra.com/partners for instructions.

A receipt format was sent to but not recognized by the printer

• If the status LED is on or flashing, refer to LED States on page 19.

• Make sure the USB cable is correctly installed. Refer to the TTP 2000 Series Technical

Manual (P1002902) available at www.zebra.com/support for instructions.

The receipts are not cutting at the black mark

• Make sure you are using the appropriate media gu ide for the desired media w idth. Refer to

the TTP 2000 Series Technical Manual (P1002902) available at www.zebra.com/support

for media guide installation instructions.

• Make sure you are using the appropriate media. Refer to the TTP 2000 Series Technical

Manual (P1002902) available at www.zebra.com/support for black mark media

requirements.

• Use the Windows CE driver to set the printer to black mark mode. See Setting Black Mark

Mode on page 18.

• Reload the media. Refer to the TTP 2000 Series Technical Manual (P1002902) available

at www.zebra.com/support for instructions.

4/14/2013 TTP 2030™ Windows CE Software Integrator Guide P1055866-001

Page 30

Troubleshooting

26

Contact Technical Support

Contact Technical Support

Technical Support via the Internet is available 24 hours per day, 365 days per year at

www.zebra.com.

For questions on the operation of Zebra equipment and software, please call your distributor.

For additional assistance, contact us.

Please have your model and serial numbers available.

P1055866-001 TTP 2030™ Windows CE Software Integrator Guide 4/14/2013

Loading...

Loading...