Page 1

TM2000

Installation Guide

MN-003211-01 Rev. A

Page 2

TM2000 Installation Guide

Copyright

© 2018 ZIH Corp. and/or its affiliates. All rights reserved. ZEBRA and the stylized Zebra head are trademarks of ZIH

Corp., registered in many jurisdictions worldwide. All other trademarks are the property of their respective owners.

COPYRIGHTS & TRADEMARKS: For complete copyright and trademark information, go to www.zebra.com/copyright.

WARRANTY: For complete warranty information, go to www.zebra.com/warranty.

END USER LICENSE AGREEMENT: For complete EULA information, go to www.zebra.com/eula.

For Australia Only

For Australia Only. This warranty is given by Zebra Technologies Asia Pacific Pte. Ltd., 71 Robinson Road, #05-02/03,

Singapore 068895, Singapore. Our goods come with guarantees that cannot be excluded under the Australia Consumer

Law. You are entitled to a replacement or refund for a major failure and compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of acceptable quality

and the failure does not amount to a major failure.

Zebra Technologies Corporation Australia’s limited warranty above is in addition to any rights and remedies you may have

under the Australian Consumer Law. If you have any queries, please call Zebra Technologies Corporation at

+65 6858 0722. You may also visit our website: www.zebra.com

for the most updated warranty terms.

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries (“Zebra

Technologies”). It is intended solely for the information and use of parties operating and maintaining the equipment

described herein. Such proprietary information may not be used, reproduced, or disclosed to any other parties for any other

purpose without the express, written permission of Zebra Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are subject to

change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are correct; however,

errors do occur. Zebra Technologies reserves the right to correct any such errors and disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the accompanying

product (including hardware and software) be liable for any damages whatsoever (including, without limitation,

consequential damages including loss of business profits, business interruption, or loss of business information) arising out

of the use of, the results of use of, or inability to use such product, even if Zebra Technologies has been advised of the

possibility of such damages. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

2

Page 3

TM2000 Installation Guide

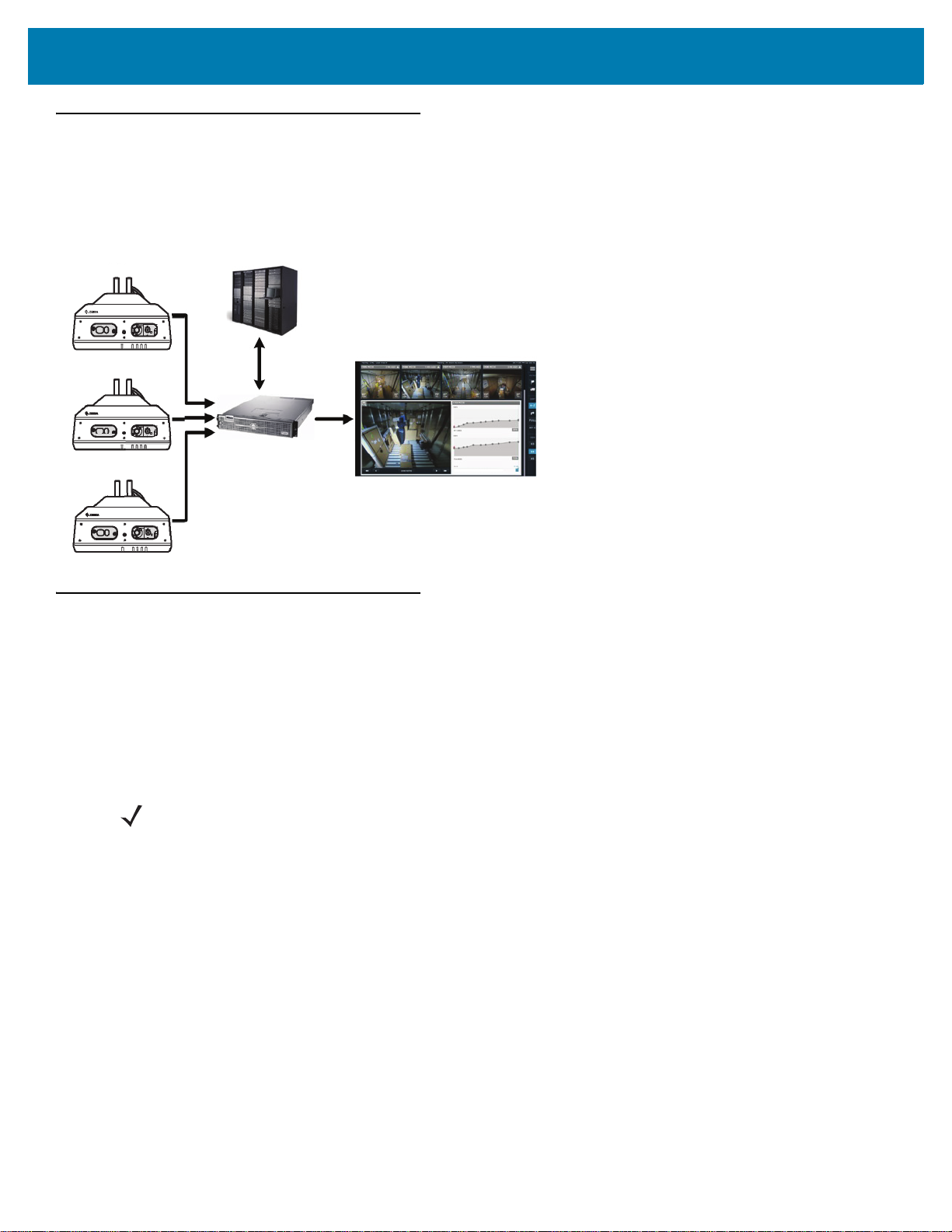

Introduction

The TM2000 captures trailer load information using an onboard RGB camera and 3D sensor, processes the captured data,

and sends the results to a server over a wired or wireless connection. The TM2000 is installed on dock doors at loading

facilities to monitor trailer load progress and provide real time data about important load metrics. The Trailer Load Analytics

(TLA) Dashboard displays this data in a web based interface.

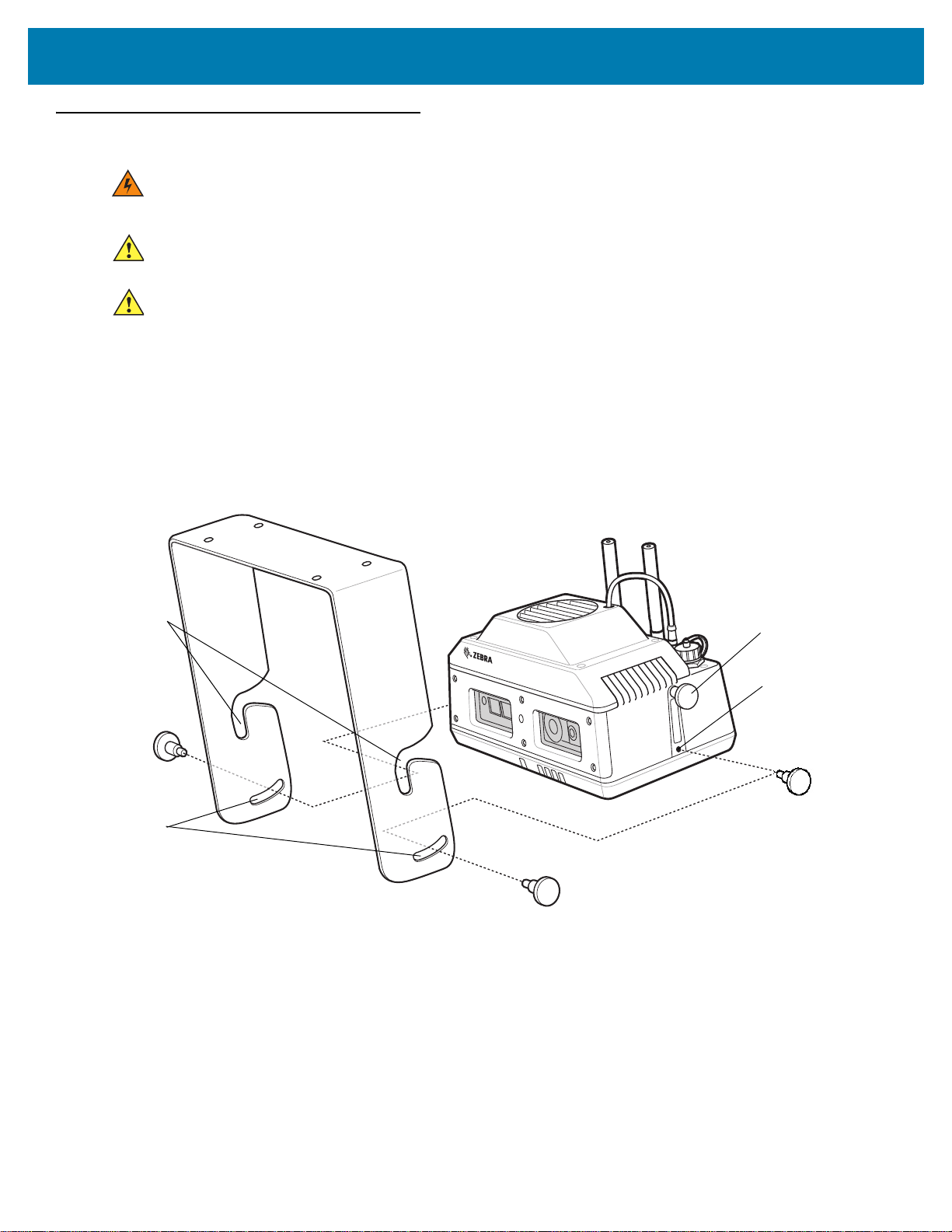

Box Contents and Unpacking

The TM2000 box contains the following items:

• TM2000

• Four mounting screws

• TM2000 Regulatory Guide.

Carefully remove the device from the packaging to avoid damaging the hardware. Inspect the device for damage.

NOTE The mounting bracket is sold separately. For information or to purchase the mounting bracket, contact

your Zebra sales representative.

3

Page 4

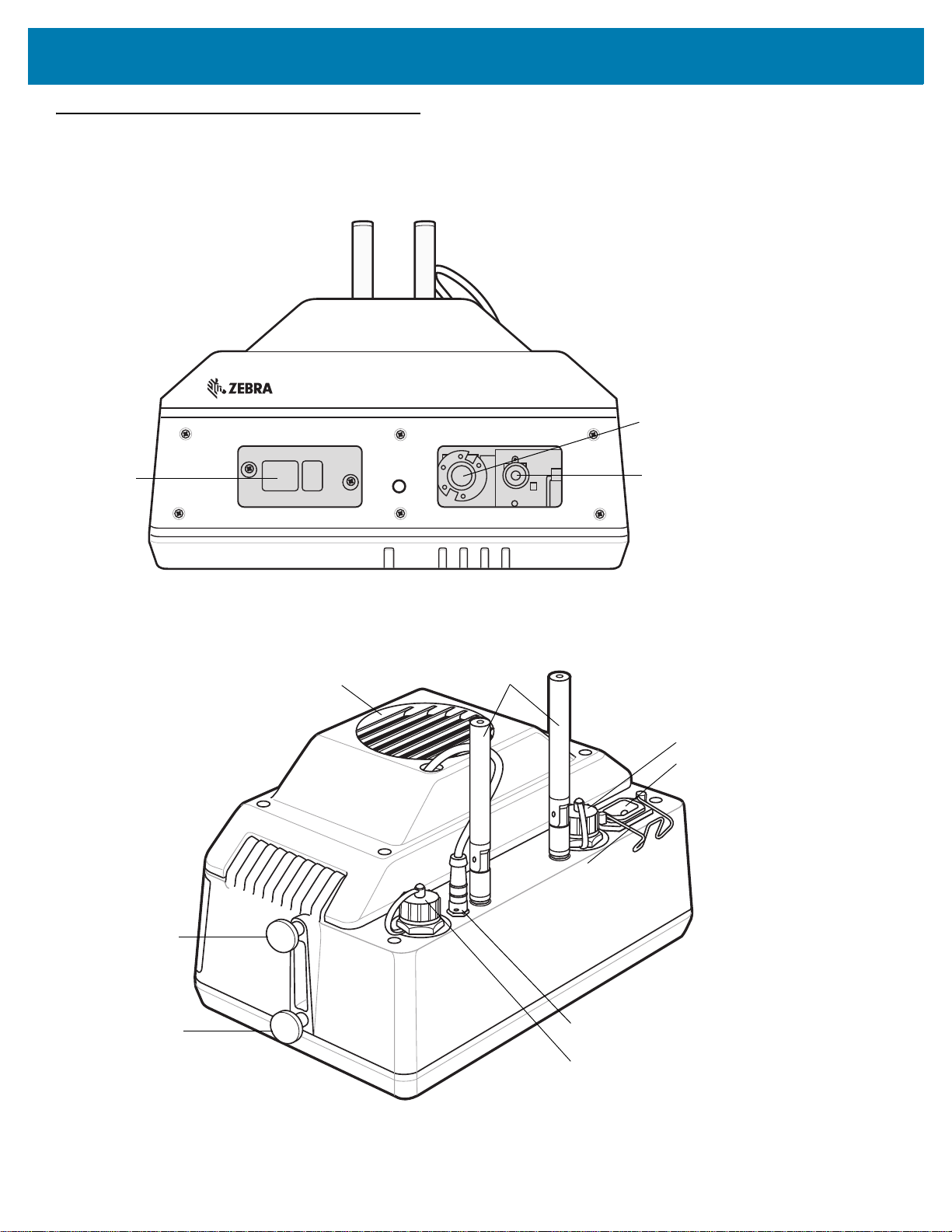

TM2000 Features

Illumination

Source

3D Camera

RGB Camera

Antenna (2)

Locking Screw (2)

Ethernet Connector

Pivot Screw (2)

Fan Connector

USB Connector

A/C Power Connector

Fan

Front View

TM2000 Installation Guide

Top View

4

Page 5

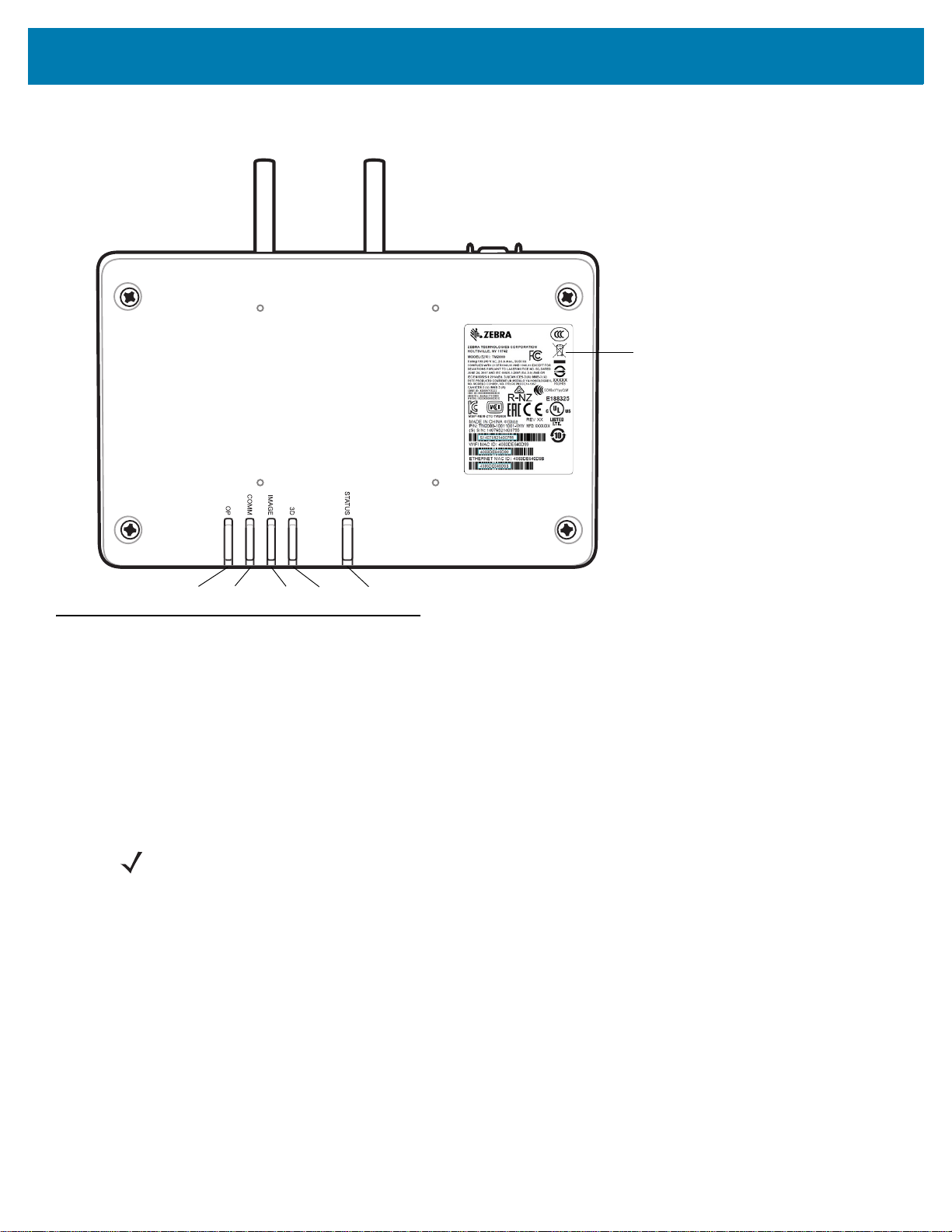

Bottom View

Label

COMM

3D

Image

Status

OP

TM2000 Installation Guide

Installation Requirements

Tools

• Impact drill (an 8mm allen wrench or ratchet hand socket wrench can also be used although it is not as time

efficient)

• Torque wrench with 6 mm allen key

• 3/8 in. hex socket for screws.

Hardware

NOTE Hardware requirements are based on mounting to structural steel.

• Mounting bracket, p/n BRKT-10002-02R (sold separately)

• Four #12 x 1 in., type F, galvanized steel, thread cutting screws (no washers needed) for attaching the mounting

bracket to the door frame (not provided)

• Mounting screws for attaching the device to the mounting bracket

• Power receptacle located near (approximately 1 ft) the top of the dock door frame

• Ladder or step stool.

Software

• Add TM2000 Wi-Fi MAC addresses to the site access point control list (contact your local IT support person).

• If using an ethernet connection, the ethernet MAC address must be added to the control list (contact your local IT

support person).

5

Page 6

TM2000 Installation Guide

Facing Dock

Facing into

Trailer Door

Dock and Trailer markings are located

under the top of the mounting bracket.

Mounting Bracket Holes

Mounting Bracket Installation

IMPORTANT The device power cord is three feet in length. Ensure the electrical receptacle is easily accessible and

located within proper distance to the device.

Installing Mounting Bracket With Template

To install the mounting bracket using the TMU Mounting Bracket Template included in the bracket box:

1. Place the TMU Mounting Bracket Template in the center of the trailer door. Position the edge of the template, facing

the dock, 2 in. from the edge of the dock door frame and tape the template in place.

2. Drill the mounting bracket holes.

3. Remove the template.

4. Install the bracket using four #12 x 1 in. thread cutting screws.

Installing Mounting Bracket Without Template

To install the mounting bracket (without the use of the TMU Mounting Bracket Template):

1. Place the mounting bracket in the center of the trailer door. Position the edge of the bracket, facing the dock, 2 in. from

the edge of the dock door frame.

2. While holding the mounting bracket in position, mark the surface with a pencil through each of the four mounting

bracket holes to determine the location of the screw holes to drill. It is recommended to use four screws to mount the

bracket securely. Use two screws on each side. If there is a center hole (not shown), do not use the center hole.

3. Drill the holes and install the bracket using four #12 x 1 in. thread cutting screws.

6

Page 7

TM2000 Installation Guide

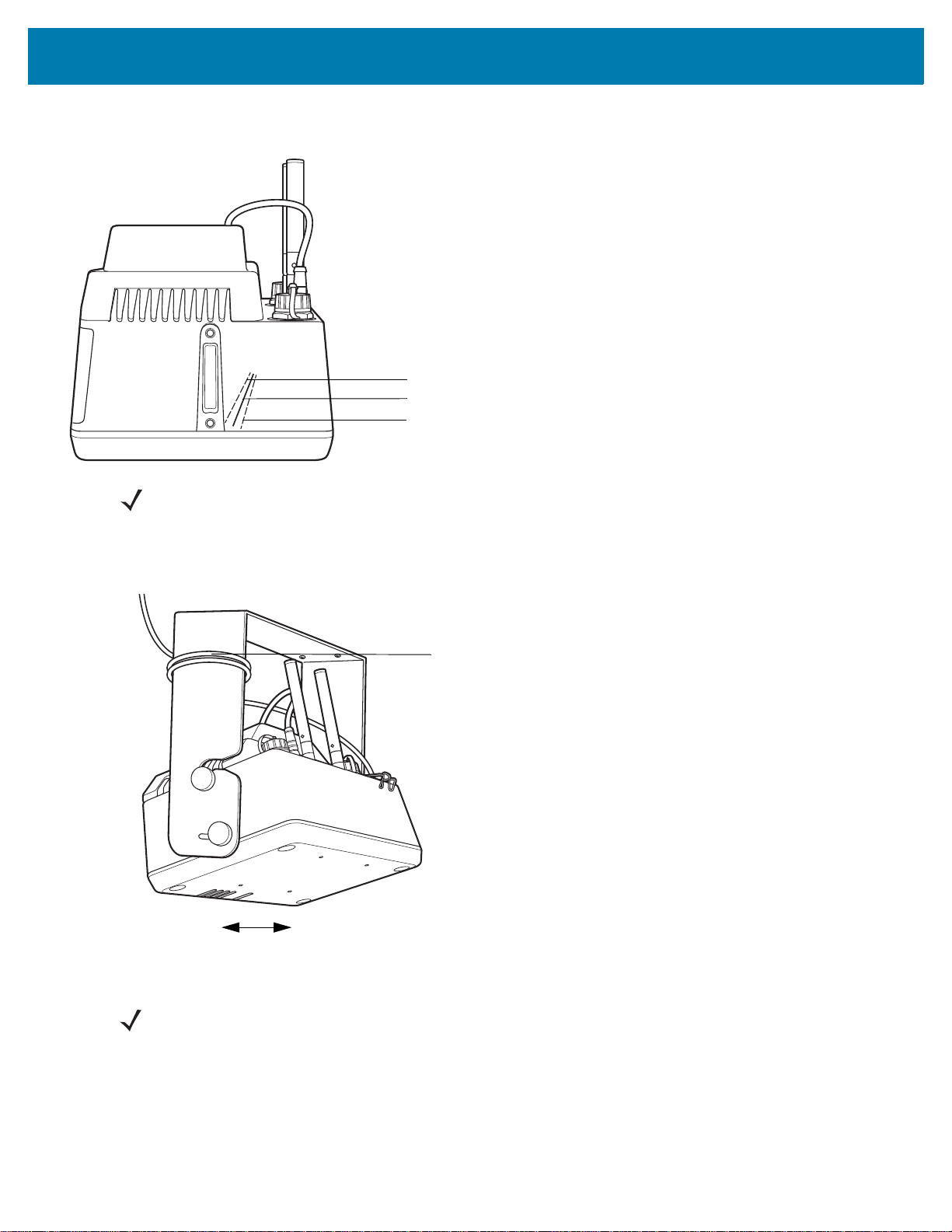

Non-adjustable

Top Mounting

Bracket Pivots

Angle

Adjustment

Slots

Non-adjustable

Top Pivot Screws

(one on each side)

Angle Adjustment

Locking Screws

(one on each side)

TMU Installation

WARNING! Use of controls or adjustments or performance of procedures other than those specified herein may

result in hazardous radiation exposure.

CAUTION Always utilize professional installers to safely install, mount, and supply power to the device. Always ensure

device mounting and power routing meets regional building codes.

CAUTION Double Pole/Neutral Fusing: If a fuse in the neutral conductor is out, the fuse in the line conductor may still be

intact which can result in internal parts remaining energized. Take extreme caution when servicing the unit.

1. Screw and torque the non-adjustable top pivot screws on each side of the device to 4.5 ft-lbs.

2. Make sure the required installation tools are within reach (see Tools on page 5).

3. Place a ladder or step stool at the trailer door.

4. Hang the device on the mounting bracket (see Mounting Bracket Installation on page 6) by sliding the two

non-adjustable top pivot screws into the non-adjustable top mounting bracket pivots.

5. Allow the device to rotate backwards and come to a stop. Release the unit and hand thread the angle adjustment

locking screws. Do not tighten the locking screws in this position.

7

Page 8

TM2000 Installation Guide

Solid Angle Marking = 20°

Dashed Angle Marking = 12.5°

Dashed Angle Marking = 27.5°

Power Cord Placement

Facing Dock

Facing into

Trailer Door

6. Rotate the device to the proper operating orientation of 20° (minimum angle marking is 12.5°; maximum angle marking

is 27.5°). The angle markings on the device are guidelines only.

NOTE When the TM2000 is connected to the server, it can be viewed on the TLA Dashboard to confirm it has the

proper angle for maximum viewing coverage of the trailer.

7. Torque the angle adjustment locking screws to 4.5 ft-lbs.

8. Wrap the power cord around the bracket. Leave adequate length for the cable to reach the power receptacle at the

trailer door. Do not plug the device in until the installation is complete.

9. Ensure that the antenna’s are positioned vertically.

NOTE The preferred antenna orientation is vertical or 45 degrees (90 degree antenna orientation is not

recommended).

10. Plug the power cord into a socket outlet with earthing connection, which is grounded in accordance with local

regulations. It may take 2-3 minutes for the device to boot up

8

Page 9

11. Check the LEDs for normal operation.

Facing Dock

Facing into

Trailer Door

TM2000 Installation Guide

LED Indicators

The device LED indicators display to indicate status.

• Image - RGB camera indicator lights to indicate the device is taking an image.

• 3D - Depth sensor indicator lights when acquiring a depth image.

• COMM - Wi-Fi communication lights when Wi-Fi is running.

• Status - Provides current operational status of the device.

• OP - Lights to indicate that the device has power.

The standard LED indicators are defined as follows:

Image 3D COMM Status OP Description

--- --- --- --- On Device has power.

--- --- On --- On Wi-Fi is running and accessible.

--- --- Off --- On Wi-Fi interference does not have an IP address or cannot

connect to an AP.

Off On --- --- On Acquiring depth image.

On Off --- --- On Acquiring RGB image.

On On --- --- On Writing PCD or JPG RGB image to file.

Off Off --- --- On Processing scene.

--- --- --- Blinking

Red

(---)

Indicates that the LED may or may not be illuminated

On Depth camera not operational due to the device overheating.

9

Page 10

TM2000 Installation Guide

TM2000 Specifications

Feature Description

Operating System Linux OS with associated drivers for USB, UART, SDIO, I2C, Ethernet and Wi-Fi

CPU 1.5GHz dual-core ARM Cortex A9

NAND Flash 64 GB

SDRAM 1 GB

Environmental

Operating Temperature -30°C to 50°C

Storage Temperature -40°C to 70°C

Dust and Water IP IP54 of IEC529

Power Consumption Maximum: 100W

Initial inrush current: 40A max when operating from 115VAC.

Case Dimensions 11.3 in. x 7.1 in. x 6.3 in.

Depth Sensor

Working Range and Resolution Resolve a1x1x2 ft^3 (X*Y*Z) brown cardboard box at 54 feet

FOV 57.5° x 45°

Image Size 320 x 240

Laser Safety Class 1

Data Interference USB 2.0

Power Consumption Less than 2.5 watts

RGB Camera

Field of View 120°

Data Interference USB 2.0

Power Consumption Less than 2 watts continuous

Frame Rate 30 frames per second

Image Size 1920 x 1080

Depth Capture Rate One per 15 sec

Exposure Time 64 ms max

10

Page 11

TM2000 Installation Guide

Cleaning and Maintenance

Perform routine cleaning and maintenance. To keep the sensor window free of dust and debris, clean regularly using a dry,

soft duster on a long pole.

Service Information

To return a faulty device:

1. Complete a repair return request (RMA) form at: www.zebra.com/repair.

2. Place a clean cloth over the device camera window to protect it from damage during transit.

3. Put the device in a container provided by the on-site contact.

Ship to the repair depot address identified in the RMA.

11

Page 12

www.zebra.com

Loading...

Loading...