Operation & Options

This section helps you get the most from your printer.

You must use programming to control many of the printer’s functions. A

few examples:

■

The

~JL

command controls label length.

■

The

^XA^MTD^XZ

thermal; the

thermal transfer.

■

The

^XA^JUS^XZ

For detailed information about creating labels using ZPL II, refer to the ZPL

II Programming Guide or visit our web site at www.zebra.com.

To improve print quality, changing both print speed and density may be

required to achieve the desired results. Your application’s printer driver

provides control of the speed and heat (density).

command changes the printing mode to direct

^XA^MTT^XZ

command saves the new settings to flash memory.

command changes the printing mode to

Thermal Printing

The print head becomes hot while printing. To protect from damaging the

print head and risk of personal injury, avoid touching the print head. Use

only the cleaning pen to perform maintenance.

The discharge of electrostatic energy that accumulates on the surface of the

human body or other surfaces can damage or destroy the print head or

electronic components used in this device. You must observe static-safe

procedures when working with the print head or the electronic components

under the top cover.

You must use the correct media for the type of printing you require. When

printing without a ribbon, you must use direct thermal media. When using

ribbon, you must use thermal transfer media. The printer’s ribbon sensor

detects motion of the supply spindle.

980476-001A 21

Replacing Supplies

If labels or ribbon run out while printing, leave the printer power on while

reloading (data loss results if you turn off the printer). After you load a new

label or ribbon roll, press the Feed button to restart .

Always use high quality, approved labels, tags and ribbons. If adhesive

backed labels are used that don’t lay flat on the backing liner, the exposed

edges may stick to the label guides and rollers inside the printer, causing the

label to peel off from the liner and jam the printer. Permanent damage to the

print head may result if a non-approved ribbon is used as it may be wound

incorrectly for the printer or contain chemicals corrosive to the print head.

Approved supplies can be ordered from your dealer.

Adding a New Transfer Ribbon

If ribbon runs out in the middle of a print job, the indicator lights red and

the printer waits for you to add a fresh roll.

1. Keep the power on as you change ribbon.

2. Open the top cover, then cut the used ribbon so you can remove the

cores.

3. Load a new ribbon roll. If necessary, review the Ribbon Loading steps.

4. Close the top cover.

5. Press the Feed button to restart printing.

Replacing a Partially Used Transfer Ribbon

To remove used transfer ribbon, perform the following steps.

1. Cut the ribbon from the take-up roll.

2. Remove the take-up roll and discard used ribbon.

3. Remove the supply roll and tape the end of any fresh ribbon to prevent

it from unwrapping.

When reinstalling a partially used supply roll, tape the cut end onto the

empty take-up roll.

22 980476-001A

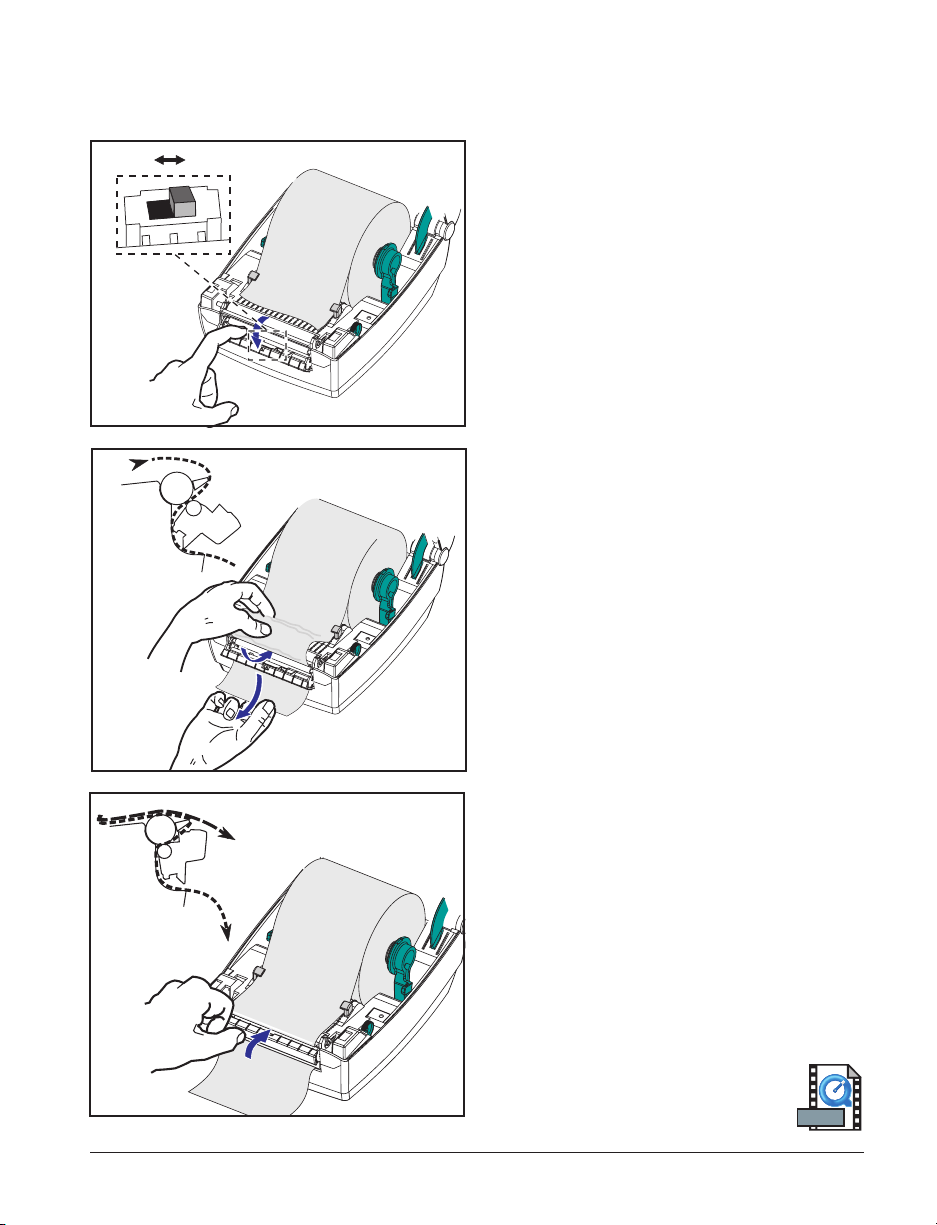

Printing in Peel-Mode

ON OFF

The optional dispenser allows you

to print in “peel-mode” where the

label backing follows a different path and

the labels are presented one at a time for

subsequent placement.

Before using peel-mode, you must send

the programming commands

^XA ^MMP ^XZ

^XA ^JUS ^XZ

to the printer. Refer to your ZPL II

Programmer’s Manual.

1. Remove several labels from the

backing material.

2. Open the top cover.

3. Open the dispenser door.

4. Switch on the label-taken sensor.

5. Insert the backing in front of the peel

bar and behind the peel roller.

6. Close the dispenser door.

7. Close the top cover.

8. Press the Feed button to advance the

label.

During the print job, the printer will peel

off the backing and present a single label.

Take the label from the printer so it will

print the next label.

MOVIE

980476-001A 23

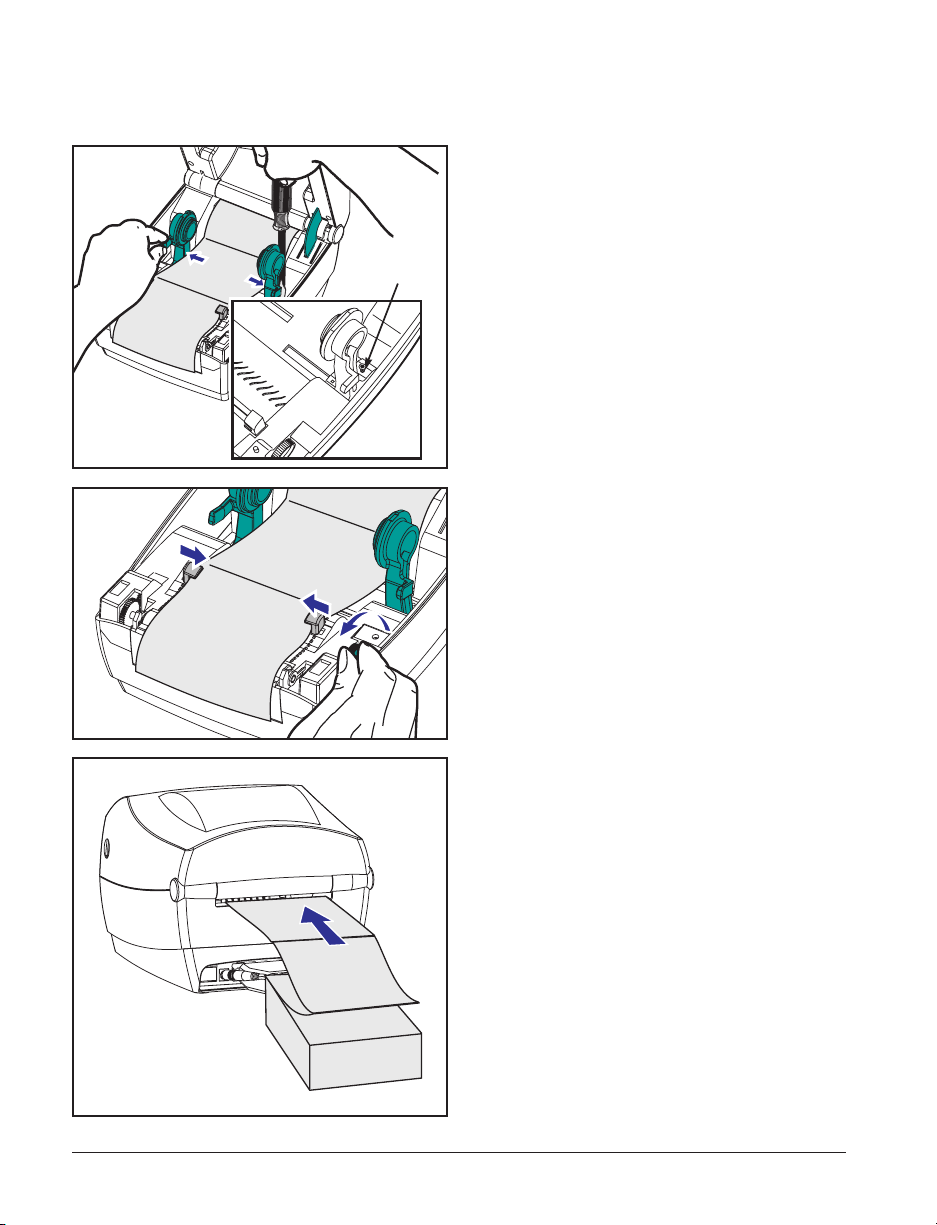

Printing on Fan-Fold Media

Printing on fan-fold media requires you to

set both the media hangers and the media

guides in position.

Lock-down

Screw

1. Open the top cover.

2. With a sample of your media, adjust

the media hangers to the width of the

media. The hangers should just touch,

but not restrict, the edges of the

media.

3. Tighten the screw using a small

Phillips driver #1.

4. With a sample of your media, adjust

the guides to the width of the media.

The guides should just touch, but not

restrict, the edges of the media.

5. Insert the media through the slot at the

rear of the printer.

6. Run the media between the hangers

and guides.

7. Close the top cover.

24 980476-001A

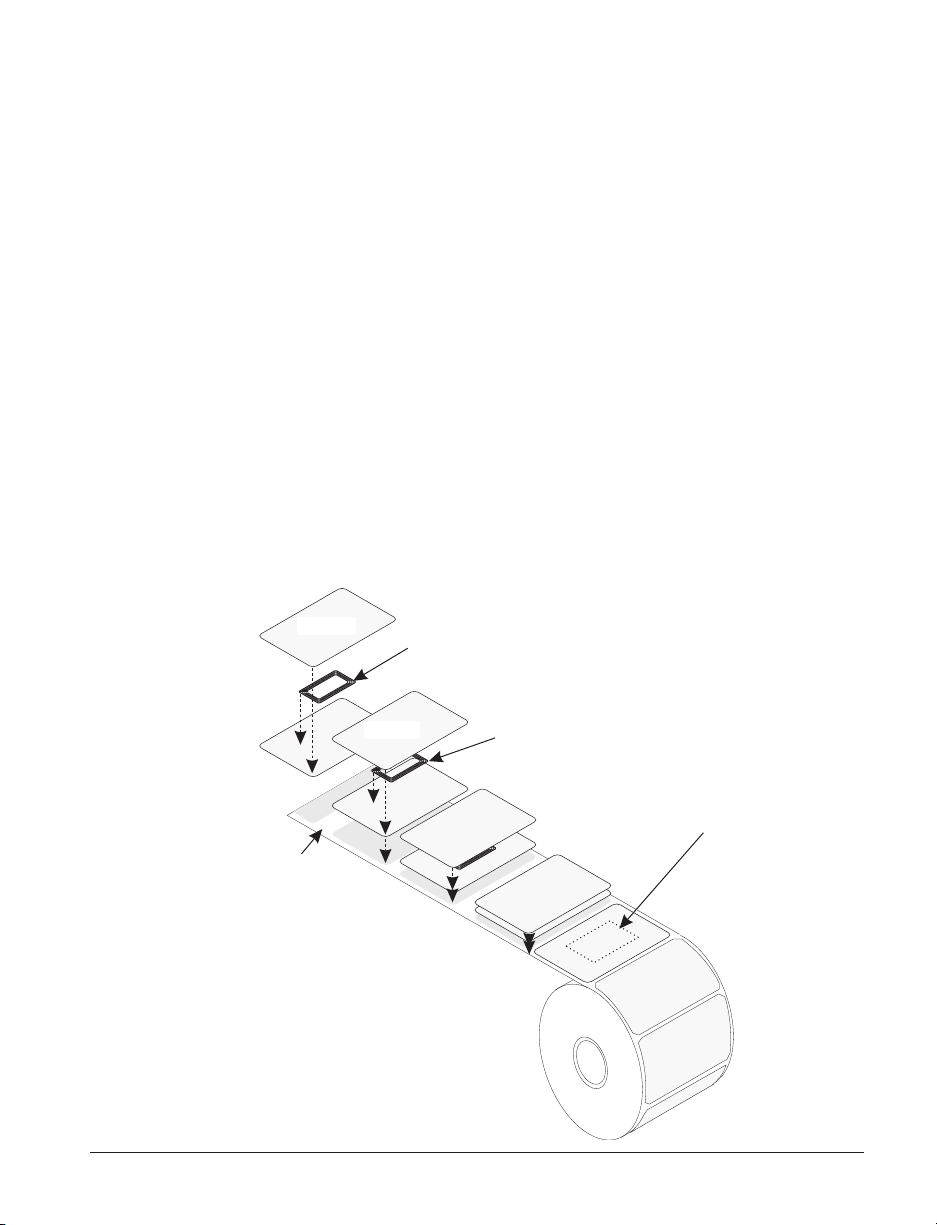

RFID Guidelines

The Zebra R2844-Z Smart Label Printer and Encoder serves as dynamic

tool for both printing and programming smart labels and tags. These labels

and tags are usually made from two components, media and an RFID (radio

frequency identification) transponder.

■

The media is comprised of synthetic- or paper-based material that can be

printed upon using direct thermal or thermal transfer printing techniques.

The media is typically made from the same materials and adhesives used

by a standard barcode printer.

■

The transponder is usually comprised of an antenna coil that is bonded

to an integrated circuit (IC) chip. The IC contains the drivers, coders,

decoders and memory. At a minimum, the transponder has memory that

can be read, while the vast majority also have memory that can be

programmed by the user as well.

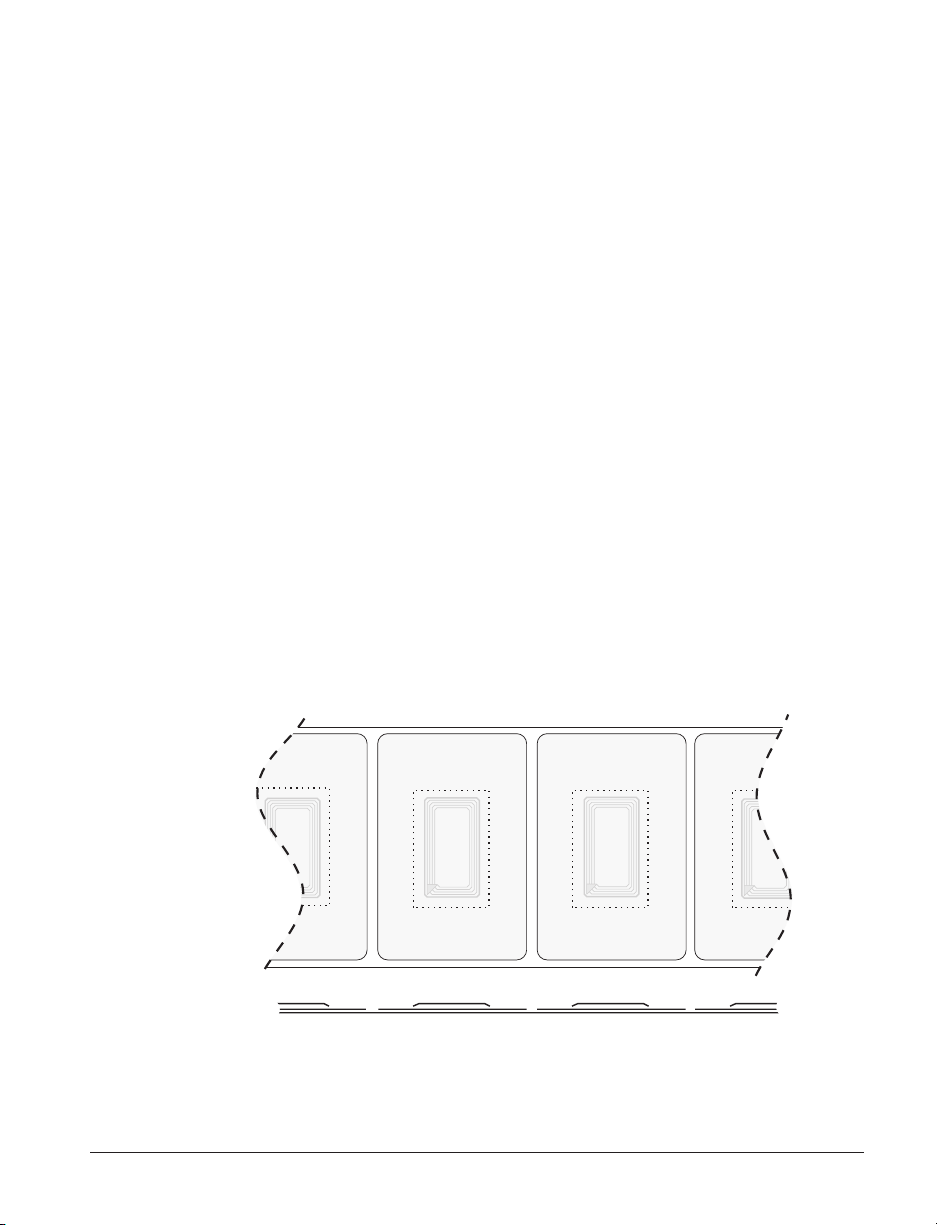

Media

Liner

Transponder

Media

Transponder

Outline of

transponder

(

shape varies

by manufacturer

Media

Supply

)

980476-001A 25

The communication between the RFID tag and the printer is established

when the transponder lines up with the printer’s antenna.

Note • The transponder position, prior to encode/decode, is critical. The optimal

transponder position varies with antenna coil size and type of RFID IC used. It is

important to use media and tags that have been specifically designed for use in this

printer. Failure to do so may result in the inability to read or program the embedded

RFID tags.

Printing and programming of smart labels is handled through the use of

Zebra's printer programming language, ZPL. The printer segments the

received ZPL's RFID-specific and printing-related commands. The printer

will execute the RFID commands first, followed by those for printing

barcodes and text. Each transponder has blocks of addressable memory that

are written to and read from through ZPL commands. Many transponders

also contain a pre-programmed unique ID/serial number. The ZPL

commands also provide for exception handling, such as setting the number

of read/write retries before declaring the transponder defective.

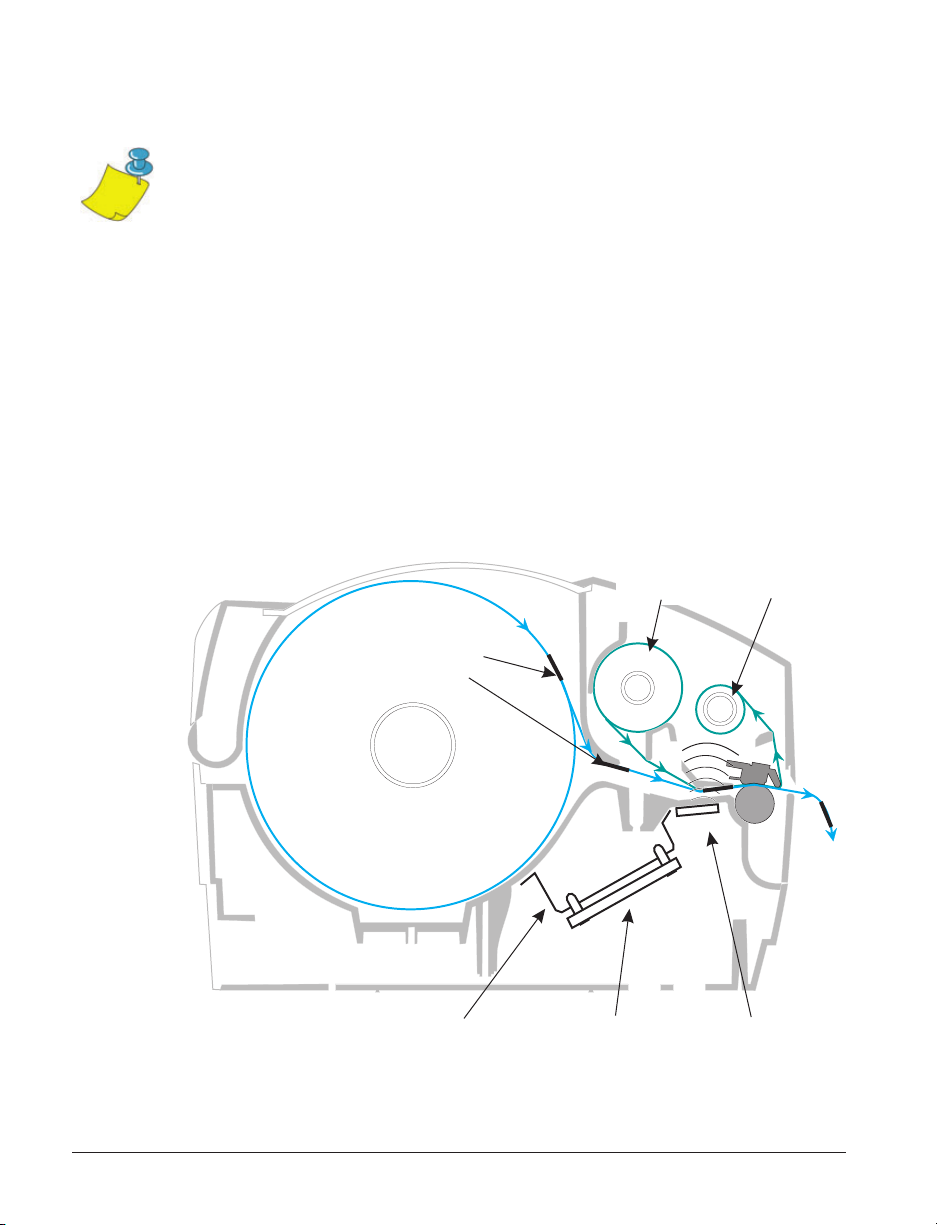

Transponders

imbedded

in media

Media

Supply

Bracket

Ribbon

Supply

Reader/Writer

Board

Ribbon

Take-up

Antenna

26 980476-001A

If an RFID tag is declared defective (fails to program correctly or cannot be

detected) the printer ejects it and prints the word "void" across the entire

label (see samples on page 45). If problems persist, this process—using the

same data and format—will continue from one to ten tags; you set the

retries using a parameter in the RFID Setup command (^RS). After the last

tag is ejected the printer removes the customer format from the print queue,

and proceeds with the next format (if one exists in the buffer).

Print Quality Over the Transponder

There is a raised area on each label immediately around the location of the

IC chip where the printer may print with low quality.

Design your printed label around the location of the chip in the type of

approved smart label you select. For best results, do not print barcodes

directly over the transponder. If in doubt, check the print quality and adjust

the label format, or obtain smart labels with an alternate transponder

placement.

Top View

Profile

980476-001A 27

Supported Transponders

Use transponders specifically approved for use in the R2844-Z printer.

Failure to do so may result in the inability to read or write to imbedded

RFID tags. For a current list of approved transponders, contact Zebra

Technologies Corporation or visit the website (http://www.rfid.zebra.com).

As new transponders become commercially available, Zebra will evaluate

them for compatibility with the R2844-Z printer.

Important • Function of an encoded smart label in an application depends on factors

such as where the label is placed on an item (such as a carton or a pallet) as well as

on the contents of the items (such as metals or liquids). Contact the supplier of your

external RFID reader for assistance with these types of issues. Zebra can only

support issues regarding printing and encoding smart labels.

28 980476-001A

Transmission and Identification Standards

ISO-15693

ISO-15693 is an international standard for 13.56 MHz RFID devices. As

this is a public standard, tags and integrated circuits may be produced by a

wide variety of manufacturers. The current standard stipulates that

manufacturers may configure memory in various ways (up to 256 blocks

comprising a block size up to 256 bits (32 bytes)). The standard also

stipulates that a manufacturer may, or may not, use the recommended

methods of reading and writing to the tag as stipulated in the standard. For

these reasons, the printer may not be compatible with every manufacturer's

ISO-15693 transponders. Contact your technical support representative for

the latest list of supported ISO-15693 transponders.

For more information, see the International Standards Organization web

site at:

http://www.iso.org

Electronic Product Code™ (EPC™)

The Electronic Product Code™ (EPC™) is a product numbering standard

that can be used to identify a variety of items using RFID technology. The

EPC format contains 12-bytes (96-bits) of data defining the manufacturer,

product, and serial number. The EPC can link to an online database,

providing a secure way of sharing product-specific information along the

supply chain.

For more information, see the EPCglobal web site at:

http://www.epcglobalinc.org

980476-001A 29

Manufacturers and Brands

In your printer, you can use these brands of transponders:

■

Texas Instruments® Tag-it™

■

Philips® I•Code

■

Inside Technologies Picotag® 2K

■

Infineon Technologies® my-d vicinity

30 980476-001A

Loading...

Loading...