Page 1

UMAN-QL3 Rev.F August, 2002

Page 2

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation. It is

intended solely for the information and use of parties operating and maintaining the equipment described herein. Such proprietary information may not be used, reproduced, or

disclosed to any other parties for any other purpose without the expressed written permission of Zebra Technologies Corporation.

Product Improvements

Since continuous product improvement is a policy of Zebra Technologies Corporation, all

specifications and signs are subject to change without notice.

FCC Compliance Statement

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

WARNING: Exposure to Radio Frequency radiation. To conform to FCC RF exposure

requirements this device shall be used in accordance with the operating conditions and

instructions listed in this manual. Note that there are several radio options available with

this printer. Additional regulatory information is contained in later sections devoted to

each radio type.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded

cables must be used with the unit to insure compliance

Changes or modifications to this unit not expressly approved by Zebra Technologies Corporation could void the user’s authority to operate this equipment.

Canadian Compliance Statement

"IC:" before the equipment certification number signifies that the Industry Canada technical specifications were met. It does not guarantee that the certified product will operate to

the user's satisfaction.

Liability Disclaimer

Inasmuch as every effort has been made to supply accurate information in this manual,

Zebra Technologies Corporation is not liable for any erroneous information or omissions.

Zebra Technologies Corporation reserves the right to correct any such errors and disclaims liability resulting therefrom.

No Liability for Consequential Damage

In no event shall Zebra Technologies Corporation or anyone else involved in the creation,

production, or delivery of the accompanying product (including hardware and software) be

liable for any damages whatsoever (including, without limitation, damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss)

arising out of the use of or the results of use of or inability to use such product, even if

Zebra Technologies Corporation has been advised of the possibility of such damages.

Because some states do not allow the exclusion of liability for consequential or incidental

damages, the above limitation may not apply to you.

Copyrights

The copyrights in this manual and the system described therein are owned by Zebra

Technologies Corporation. All rights are reserved. Unauthorized reproduction of this

manual or the software in any of the system modules may result in imprisonment of up to

one year and fines of up to $10,000 (17 U.S.C.506). Copyright violators may be subject

to civil liability.

All products and brand names are trademarks of their respective companies. All rights

reserved.

©

2002 Zebra Technologies Corporation

ii QL 320 User’s Guide

Page 3

Mobile Printer

User’s Guide

Page 4

Contents

Introduction ............................................7

Unpacking and Inspection .............................................. 7

Reporting Damage.......................................................... 7

Getting Ready to Print.............................9

Battery............................................................................. 9

Installing the Battery........................................................ 9

Charging the Battery........................................................ 9

Loading the Media ........................................................ 10

Installing the Media........................................................ 10

Operator Controls ......................................................... 13

Standard Keypad........................................................... 13

LCD Control Panel......................................................... 15

Verify the Printer Is Working ......................................... 18

Printing a Configuration Label ....................................... 18

Connecting the Printer .................................................. 18

Cable Communications ................................................. 19

IR Communications ....................................................... 20

SRRF Communications ................................................. 21

Zebra SRRF Network Overview .................................... 21

Bluetooth™ Networking Overview................................. 22

Wireless Local Area Network (WLAN) Module Using CF

Radio ............................................................................. 24

Wireless Local Area Network (WLAN) Module Using

PCMCIA Radio .............................................................. 25

Setting Up the Software................................................ 26

Adjustable Shoulder Strap ............................................ 27

Belt Clip......................................................................... 28

Preventive Maintenance........................29

Extending Battery Life................................................... 29

Cleaning........................................................................ 31

Troubleshooting....................................32

Standard Control Panel ................................................ 32

Optional LCD Control Panel ......................................... 32

Troubleshooting Topics .....................................................

Troubleshooting Tests ................................................... 34

Printing a Configuration Label ....................................... 34

Sample Configuration Label .......................................... 35

Communications Diagnostics ........................................ 37

Calling the Help Desk .................................................... 37

iv QL 320 User’s Guide

Page 5

Specifications .......................................38

Printing Specifications .................................................. 38

Memory/Communications Specifications...................... 38

Label Specifications...................................................... 39

Font/Bar Code Specifications ....................................... 39

Physical/Environmental/Electrical Specifications ......... 40

Communications Port ................................................... 41

...................................................................................... 41

Agency Approvals ......................................................... 42

Accessories................................................................... 42

Appendix A...........................................43

Interface Cables

Appendix B...........................................46

Media Supplies

Appendix C ..........................................47

Maintenance Supplies

Appendix D ...........................................48

Product Support

Index ............................................. 49

Patent Information ....... inside back cover

QL 320 User’s Guide v

Page 6

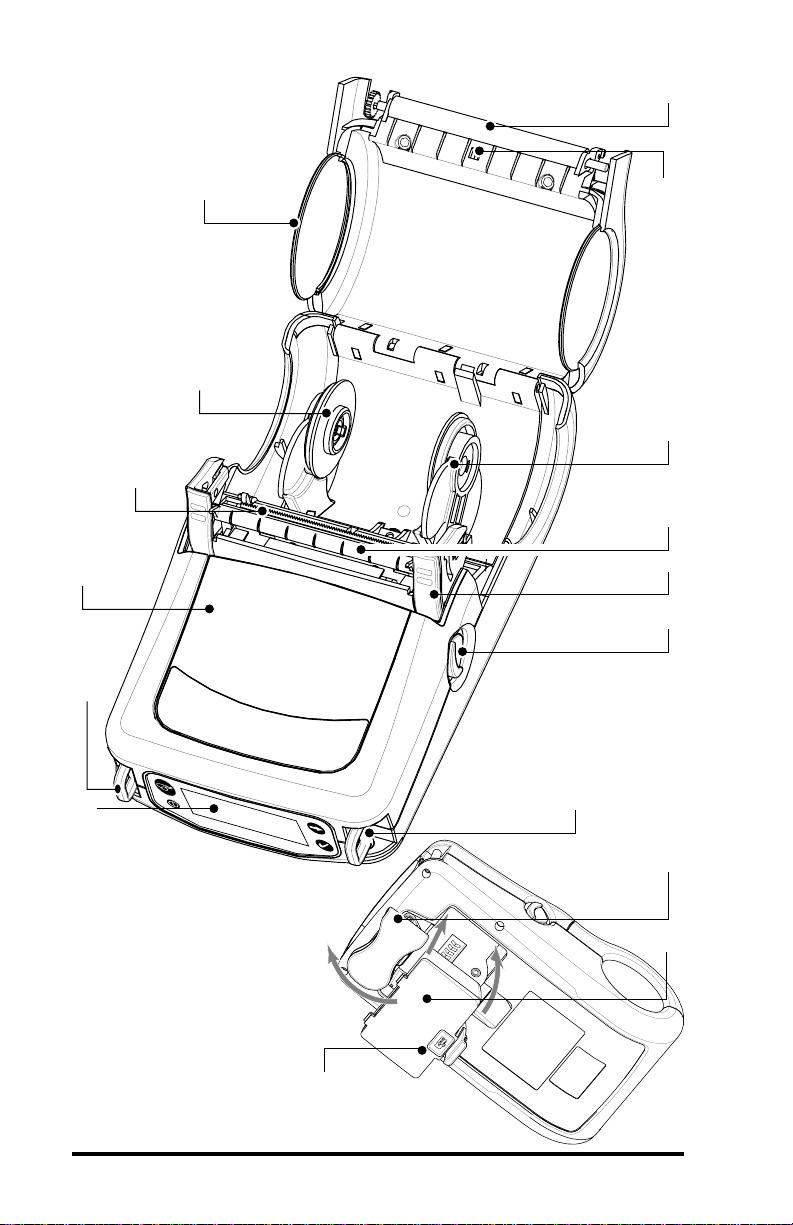

1

12

11

10

9

7

2

3

4

5

6

8

1 Platen Roller

2. Bar Sensor

3. Media Support

4. “EZ-Peel” Peeler

5. Latch

6. Latch Release Lever

7. “D” Rings

8. Control Panel

9. QuickLink™ Module

10. Print Head

11. Media Support Disks

12. Media Cover

13. Belt Clip

14. Battery

15. Battery Charging

Receptacle

15

6QL 320 User’s Guide

7

13

14

Page 7

Introduction

Thank you for choosing our Zebra QL 320 Mobile Printer. This

rugged printer is sure to become a productive and efficient addition to your workplace thanks to its innovative design. Because

it’s made by Zebra Technologies Corporation, you’re assured of

world-class support for all of your bar code printers, software,

and supplies.

• This user’s guide gives you all the information you’ll need

to operate the QL 320 printer.

• The QL 320 uses the CPL programming language. To create and print labels using the CPL language, refer to the

Mobile Printer Programming Guide (availale on our website at:

Label Vista™ label creation program.

• The QL 320 has an optional interpreter for the ZPL II

gramming Language which interprets commands up to X.8

firmware. The printer must be equipped with the optional

memory upgrade and appropriate application in order to

use this function. A ZPL II Program Guide (part #46530L)

can be used as reference for the ZPL II label design programming language. If either manual was not ordered

with the printer, simply call your re-seller or Zebra Technologies Corporation or visit the Zebra web site.

http://www.zebra.com/SS/manuals.htm)

Unpacking and Inspection

Inspect the printer for possible shipping damage:

• Check all exterior surfaces for damage.

• Open the media cover (refer to “Loading the Media” in the

Getting Ready to Print section) and inspect the media

compartment for damage.

In case shipping is required, save the carton and all packing

material.

Reporting Damage

If you discover shipping damage:

• Immediately notify and file a damage report with the shipping company. Zebra Technologies Corporation is not responsible for any damage incurred during shipment of the

printer and will not cover the repair of this damage under

its warranty policy.

• Keep the carton and all packing material for inspection.

• Notify your authorized Zebra re-seller.

and our

®

Pro-

QL 320 User’s Guide 7

Page 8

Belt Clip

LI72 Charger

Charger Jack

F

IGURE

Battery

2

F

IGURE

3

8QL 320 User’s Guide

Charger Jack

Page 9

Getting Ready to Print

Battery

Installing the Battery

NOTE: Batteries are shipped uncharged.

Remove protective shrink-wrap and labels from new

battery packs prior to use.

1. If the printer is so equipped, rotate the Belt Clip to allow

access to the Battery compartment.

2. Insert the battery into the printer as shown in Figure 2,

3. Rock the Battery into the printer as shown until it locks in

place.

When the battery is first installed, the Control Panel indicators

may briefly turn on and then go off which indicates the battery is

not fully charged (see “Charging the Battery” below and “Operator Controls”).

Charging the Battery

Refer to Figure 3. Your battery charger may look slightly different from the ones illustrated.

If you are using the LI 72 battery charger:

1. Install the battery in the printer and plug the Charger into

the appropriate A.C. wall receptacle. Then insert the

charge cable into the battery charger jack.

2. The charger LED will indicate the status of the charger as

follows:

• A steady light indicates the battery is undergoing a fast

charge.

•A slow blinking light indicates the charger is in trickle

mode. The battery is ready for use.

•A rapidly blinking light indicates a problem with the battery.

The battery may have an internal short, or its charge monitoring circuitry may be malfunctioning. The battery should

not be used any further.

• Battery Packs may be charged either when installed in the

printer or when removed.

Do not attempt to charge batteries with the LI 72

while printing. Attempting to print while charging can

result in improperly charged batteries.

QL 320 User’s Guide 9

Page 10

Loading the Media

You can operate this printer in one of two different modes:

Tear-Off or Peel-Off. Tear-Off mode allows you to tear off each

label (or a strip of labels) after it is printed. In Peel-Off mode, the

backing material is peeled away from the label as it is printed.

After you remove this label, the next one is printed.

Installing the Media

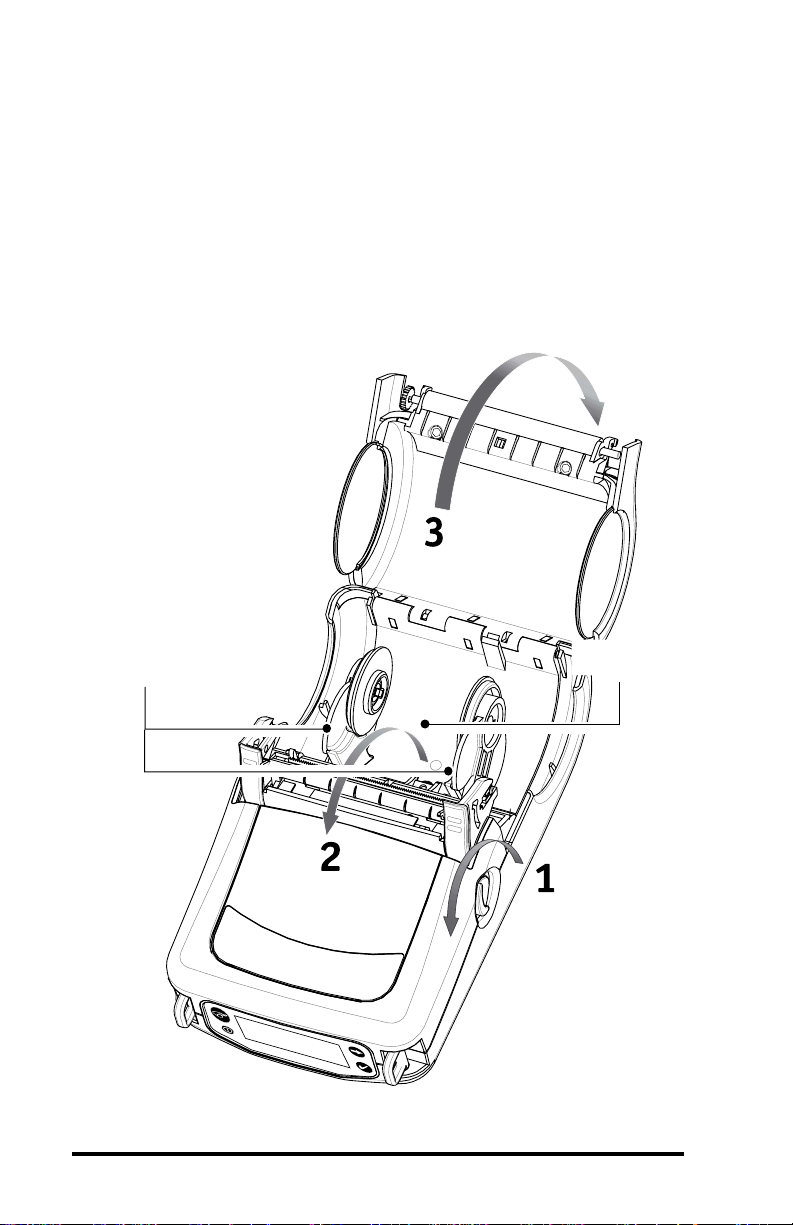

1. Open the printer: Refer to Figure 4.

•Rotate the latch release levers on each side of the printer

as shown at “1” below.

The latch assembly

will flip open automatically as shown

at “2”.

•Rotate the media

Cover back as

shown at “3”, exposing the media

compartment

and the adjustable media supports.

Media Supports

Media

Compartment

F

IGURE

4

10 QL 320 User’s Guide

Page 11

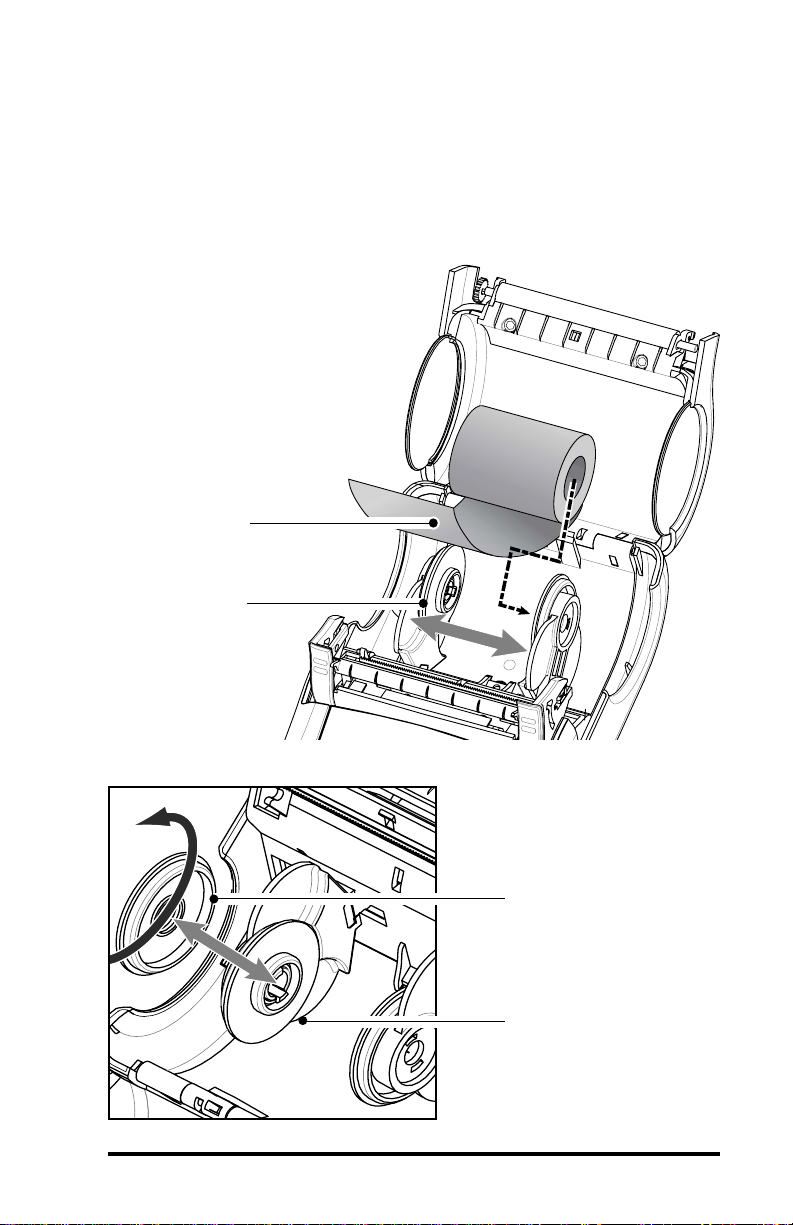

2. Load the media: Refer to Figure 5.

•Determine that the core diameter of the media roll matches the setting of the Media Disks. If it does not, adjust the

media disks per Figure 6 below.

• If the media support setting is correct, pull the media supports apart, insert the roll of media between them, and let

the media supports close. Insure that the media pulls off

the core in the direction

shown in Figure 5. The

supports will adjust

themselves to the

width of the media,

and the media

should be able to

spin freely on the

supports.

Media Roll

Note direction

media pulls off the

roll.

Media Disk

must match

diameter of

Media Core.

F

IGURE

5

Remove Media Disk,

rotate 180° and replace

for 1 3/8” core

Media Disk set for 3/4”

core (factory default).

F

IGURE

6

QL 320 User’s Guide 11

continued on next page

Page 12

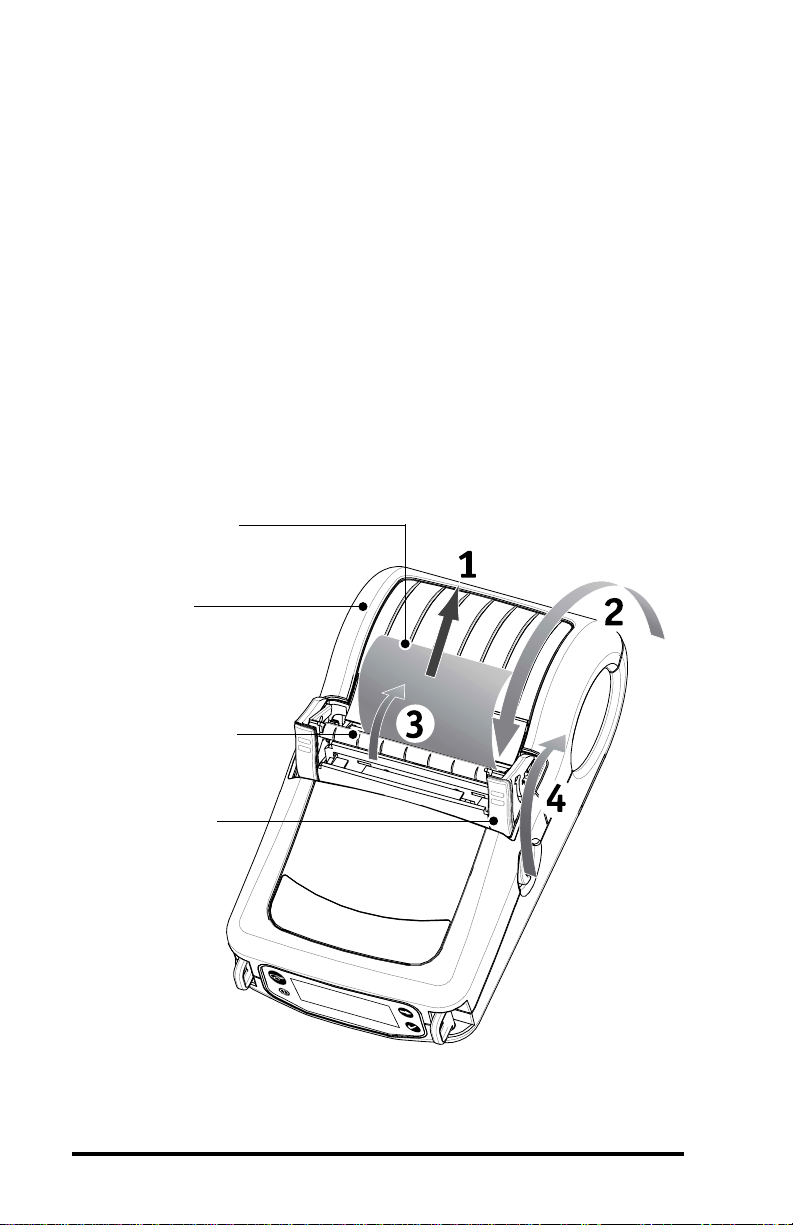

3. Refer to Figure 7. Close the Media Cover

• If you plan to use the printer in the tear-off mode, close the

media cover as shown at “2”, then rotate the latch assembly as shown until it locks into place, as shown at “4”.

• If you plan to use the printer in the peel-off mode, peel a

few labels off of the media roll and pull it out of the printer

as shown at “1”. Close the media cover as shown at “2”.

Rotate the “EZ-Peel” peeler bar until it locks into place on

the latch, as shown at “3”, then rotate the Latch as shown

until it locks into place, as shown at “4”.

•Turn on the printer or press the Feed button if the printer

is already on.

The printer will advance the media to the next label, if

printing labels. If you are printing on journal media, the

printer will advance a short strip of media and will then be

ready for printing.

Pull Media out of

Printer

Media Cover

“EZ-Peel” Peeler Bar

Flip down if using

media in the peeloff mode.

Latch Assembly

F

IGURE

7

12 QL 320 User’s Guide

Page 13

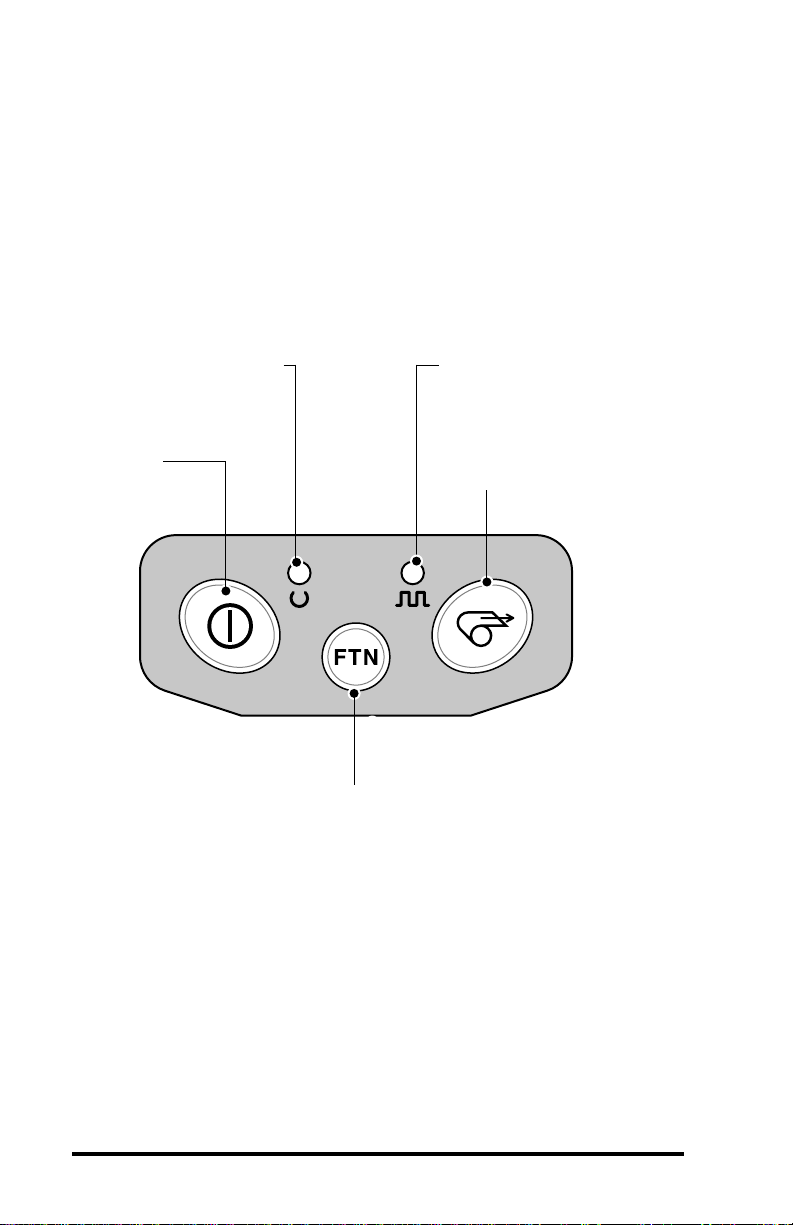

Operator Controls

The QL 320 will come with one of two possible control panels.

The standard control panel is detailed below and in Figure 8.

The optional control panel (Figure 9) features an LCD which allows easy display and selection of many printer functions and is

detailed on following pages.

Standard Keypad

The standard keypad has three control buttons and two multipurpose indicators.

• The Power button turns the QL 320 on and off.

• The Feed button advances a length of media which is determined by the type of media being used. Label media

will be advanced to the next gap or bar sense marker.

Journal (plain) media will be advanced a length determined by the printer’s software.

• The Function button is controlled by a printer’s specific application to support such functions as:

Print a battery Level reporting

Print the Local Area Network (LAN) status

Print a Short Range Radio Frequency (SRRF) status

Print a Media supply report

The green LED on the left side of the control panel indicates

the status of several printer features:

•A slowly blinking sequence indicates the printer’s battery

needs charging.

• Printers with a wireless QuickLink module installed: a

quickly blinking sequence indicates the printer has not established a link to either a Local Area Network or a compatible wireless equipped terminal.

• Printers with a wireless QuickLink module installed: A

steadily lit indicator shows that the printer has established

a wireless link, either to the LAN or to a compatible terminal.

A steadily lit green indicator on a non-wireless printer is a

power-on indicator.

The yellow LED on the right side of the control panel has two

indication conditions.

•A rapidly blinking yellow LED and a chime indicate that no

application has been loaded into the printer.

• Printers with a wireless QuickLink module installed: a rap-

QL 320 User’s Guide 13

Page 14

idly blinking LED indicates normal data transmission.

•A steadily lit yellow LED indicates an error condition. This

can be caused by one of the following:

1. The media cover is not completely closed and latched.

2. The printer is out of media.

Yellow LED

Green LED

Steady Light indicates power on

and/or established RF link.

Fast Blink indicates no RF link (on

RF equipped units only)

Slow Blink means low battery

Steady Light indicates error condition: out of media or media

cover not closed.

Fast Blink indicates RF activity (on

RF equipped units only)

Fast blink with beeper indicates

no application loaded

Power Button

Press to turn unit

on. Press again to

turn unit off

F

IGURE

Function Button

Specific functions are under

printer application control.

8: S

TANDARD CONTROL PANEL

Feed Button

Press to advance the media

one blank label or a software

determined length of journal

media.

14 QL 320 User’s Guide

Page 15

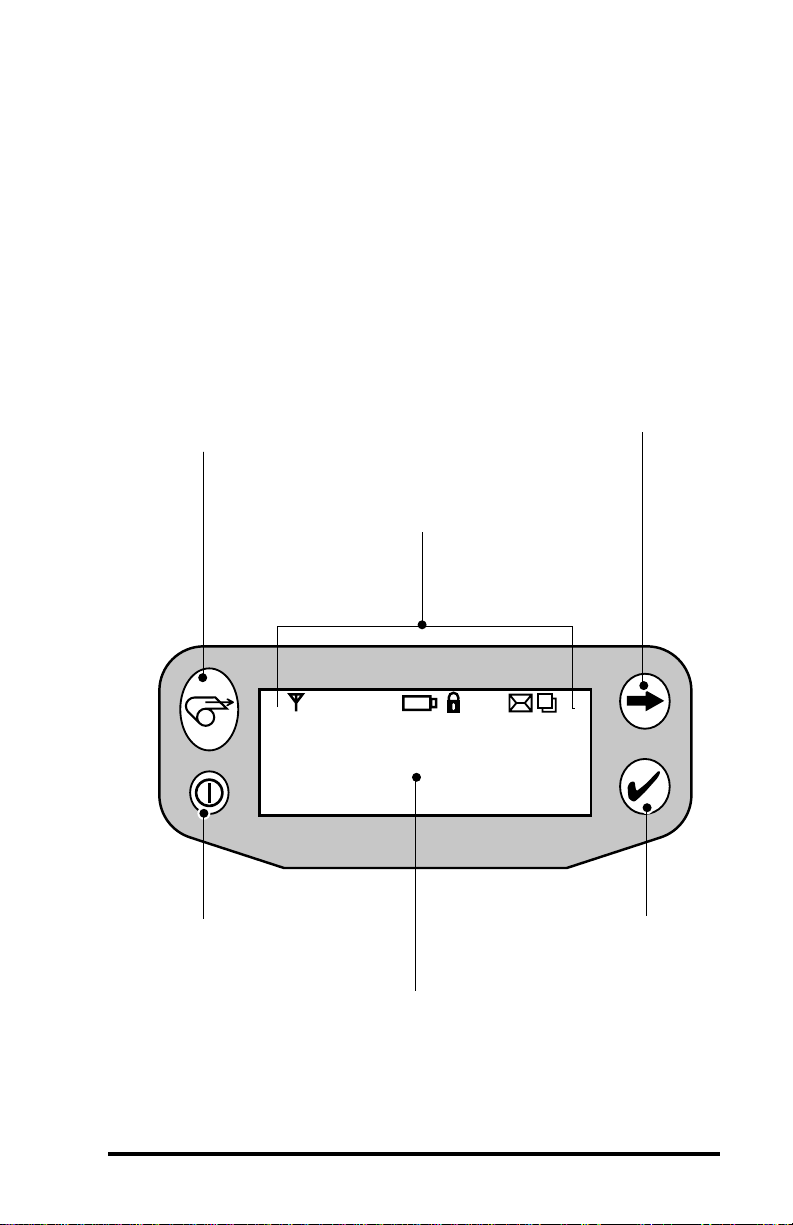

LCD Control Panel

The optional LCD control panel has buttons for the power on/

off and media feed functions just as in the standard control panel. In addition, it has two keys which allow easy navigation and

selection of menu options affecting many printer functions.

The “Scroll” button allows scrolling through the various options

and settings. The “Select” button allows selection of the option

or function displayed on the screen.

Feed Button

Press to advance the

media one blank

label or a software

determined length of

journal media.

Power Button

Press to turn unit on.

Press again to turn unit

off

Scroll Button

Press to scroll

through the menu

choices on the

LCD.

Printer Status Icons

Indicates the status

of several printer

functions

Select Button

Press to select a menu

choice on the LCD.

LCD

See LCD Functions Table for an

overview of menu options

F

IGURE

9: O

PTIONAL

LCD C

ONTROL PANEL

QL 320 User’s Guide 15

Page 16

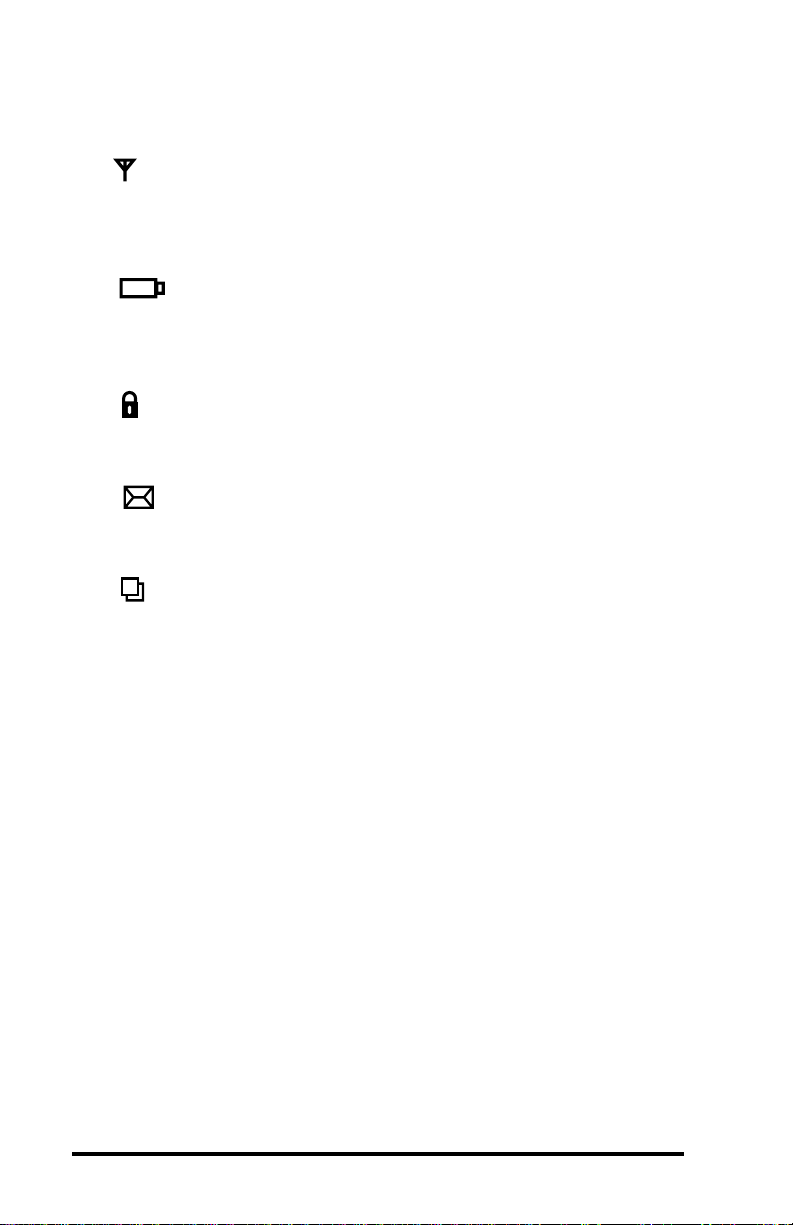

The top of the screen has a row of status icons which indicate

the state of various printer functions:

Indicates that the printer is associated with a wireless Local Area Network (LAN). This icon is functional only with

QL 320N network printers.

A flashing icon indicates low battery status. You

should suspend any printing operations and recharge or

replace the Battery Pack as soon as is convenient.

A flashing icon indicates that the media cover is open or

not properly latched.

A flashing icon indicates that a file is being download-

ed to the printer.

A flashing icon indicates that the printer does not detect

any media. This could indicate an out of media condition,

or improperly loaded media.

In addition to the status icons, the LCD control panel can display many of the printer’s settings and functions as text. Applications can be written to allow the user to view and /or modify

these settings using the scroll and select keys on the display.

Refer to the “LCD Functions Table” on the following page for the

full set of printer features that can be made available with the

LCD panel.

The LCD has a backlighting option which allows viewing of the

screen in a dark environment, or provides better contrast in a

very bright environment. Use of the display backlight will decrease the time the printer will run between charges.

16 QL 320 User’s Guide

Page 17

LCD Functions

Function Default setting Scroll & Select Options

Sensor Type Gap • Bar

Print Width Factory Set • Increase (+120 dots max.)

Value • Decrease (-120 dots max.)

Baud Rate 19200 • 9600

Data Bits 8 • 7

WLAN ID* Factory Set N/A

Value

Label Top 000 • Increase (+120 dots max.)

Left Position 000 • Increase (+120 dots max.)

LCD Contrast 0 • Increase

No-activity Timeout 60 sec. • 60 sec.

Print Darkness 00 • Increase (+10 max.)

(Head Temperature) • Decrease (-10 max.)

• Gap

• 19200

• 32400

•8

• Decrease (-120 dots max.)

• Decrease (-120 dots max.)

• Decrease

•5 min.

• 10 min.

• 30 min

• Custom*

Tear-off Position 00 • Increase (+120 dots max.)

Media Type Label • Label

LCD Backlight Off • On

Factory Reset No • No

(Resets all to • Yes

factory set values)

* Some parameters, such as the WLAN ID number and non-standard no-activity

time out values can be set using a PC running Zebra’s Label Vista label creation

program and a data cable link to the printer.

• Decrease (-120 dots max.)

• Journal

•Off

• Momentary On w/

time delay

QL 320 User’s Guide 17

Page 18

Verify the Printer Is Working

Before you connect the printer to your computer or portable

data terminal, make sure that the printer is in proper working order. You can do this by printing a configuration label using the

“two key reset” method. If you can’t get this label to print, refer to

“Troubleshooting”.

Printing a Configuration Label

1. Turn the printer off. Load the media compartment with

journal media (media with no black bars printed on the

back)

2. Press and hold the Feed Button.

3. Press and release the Power button and keep the Feed

button pressed. When printing starts, release the Feed

button.

The unit will print a line of interlocking “x” characters to insure all elements of the print head are working, print out the version of software loaded in the printer and then print two reports.

The first report indicates model, ROM version, serial number,

baud rate, etc. The second report prints out more detailed information on the printer’s configuration and parameter settings.

If no second report appears, there is no application loaded. (See

the Troubleshooting Section for a sample print-out and a further

discission on how to use the configuration label as a diagnostic

tool.)

Connecting the Printer

The printer must establish communications with a host terminal

which sends the data to be printed. Communications occur in

four basic ways:

• By a cable between the printer and its host terminal

• Linking to a host terminal via Infrared (usually by means of

the industry standard IrDA protocol)

• By means of a Short Range Radio Frequency (SRRF) link.

• By means of a wireless LAN (Local Area Network). This

applies to QL 320N Network Printers only.

18 QL 320 User’s Guide

Page 19

Cable Communications

CAUTION. The power should be turned off before

connecting or disconnecting the communications cable.

All QL 320 printers can communicate by cable; the specific cable supplied with your printer will vary with the host terminal. The

8- pin circular connector on your communications cable plugs

into the serial communications port on the side of the QL 320

printer. It is keyed to assure correct alignment; do not try to force

it if it does not plug in. The other end of the cable must be

plugged into the host terminal as shown in Figure 10, or to a serial port on a computer (Figure 11.) Communications between the

terminal and the printer are controlled by the applications running

on the terminal and the printer.

QL 320

Communications Port

Communications Cable to Terminal

Part number varies. Refer to Appendix A.

F

IGURE

10

Serial Communications Cable to

Computer

Refer to Appendix A for part numbers.

F

IGURE

11

QL 320 User’s Guide 19

Page 20

IR Communications

Printers equipped for infrared (IR) communications are identified by a small “IR” logo on the unit’s label. IR allows wireless

communications between the printer and the host terminal. IR

units can also communicate with a cable as detailed above, however, IR functions are disabled when the cable is plugged in. QL

320 units with the IR option can be configured to conform to the

standard IrDA communications protocol

Linking a Printer to an IrDA Host

IrDA compliant terminals will automatically initiate communications to the printer. First insure that there is a direct line of sight

between the printer and the terminal that will be sending data.

The IR window on the front of the QL 320 must face the corresponding window on the terminal to properly send and receive

signals. An IrDA compliant terminal will seek out any linkable devices and establish communications between them, even turning

the printer on if necessary.

Area of IR Window

F

IGURE

12

20 QL 320 User’s Guide

1M (39”)

Page 21

SRRF Communications

Both the printer and the device it communicates with must follow either the Bluetooth standard or Zebra’s proprietary SRRF

protocol. The communications protocol is determined by the

specific QuickLink module installed in the printer.

Printers equipped for short range radio frequency communications (SRRF) allow wireless communication with their host terminals from any direction. Reliable transmission distances will vary

but usually exceed 1m. (39”) under worst conditions. SRRF

printers can be identified by reading the printer’s model number

label on the front of the unit, which will show the radio module’s

identification number and/or its operating frequency. QL 320

printers equipped with a Bluetooth wireless module will have the

Bluetooth logo on the model number label.

Zebra SRRF Network Overview

Zebra’s short range RF network operates as a collection of

linked pairs of terminals and printers. There is no base station or

centralized control; control of the network is distributed across

the entire network.

Before SRRF operation can begin, the QL 320 must be “linked”

to a terminal with a compatible short-range radio. Linking means

that addresses are exchanged between the terminal and the

printer. Once linked, the terminal and the printer become a

“linked pair” and communicate exclusively with each other. The

terminal and the printer can be turned on and off without affecting

the link; it remains valid until another link is deliberately created.

Thus it is not necessary to perform a link every time that the

equipment is used. So long as the linked pair is kept together,

they remain linked indefinitely. If the linked pair is not stored together, then the terminal and printer selected should be linked

prior to use.

Multiple linked pairs can be operated in close quarters and

each terminal will only communicate with its linked printer. Each

SRRF radio module has a unique device address (terminal or

printer), based on the device serial number.

Linking From the Terminal to the Printer

The linking operation can be activated from either the terminal

or the printer. If the terminal has a scanner available, then the

bar-coded serial number on the back of every printer can be

scanned and used to establish the printer’s unique address.

Once the printer’s address is established, the terminal can then

initiate a link to that printer. If no scanner is available the user

QL 320 User’s Guide 21

Page 22

can manually enter the serial number of the printer; however, this

method is not recommended. The terminal can only capture the

desired printer using this type of link.

The terminal must be programmed to guide the user through

scanning the printer serial number bar-code, then execute an algorithm which converts the serial number into an address. Zebra

can provide C source code to licensed OEM customers that handles the conversion from serial number to address.

Linking From the Printer to the Terminal

When no scanner is available, and/or no additional software is

to be written for the terminal, then the linking operation can be

initiated solely by the printer.

In this procedure the printer broadcasts a message seeking an

available terminal. If a terminal “hears” the broadcast and is

available, it will respond by linking to the printer.

To insure a secure link, the user must perform the link operation far enough away from other operating terminals so that the

printer does not inadvertently capture some other user’s terminal.

Any other terminal that hears the broadcast message from the

printer may try to link to it, therefore you should insure that only

one terminal is within broadcast range. Feedback is available

from the printer as to the outcome of the link operation.

Bluetooth™ Networking Overview

The following section only applies when the Bluetooth Module (FCC ID: I28MD-BTC2-E)

is installed in the QL320 printer (note that only one of the radio options can be installed in the printer at one time).

Exposure to Radio Frequency Radiation

The radiated output power of this internal wireless radio is

far below the FCC radio frequency exposure limits.

Nevertheless, this Bluetooth radio must be used in such a

manner that the antenna is 2.5 cm or further from the

human body.

The radio and antenna are mounted internally in this

printer in such a way that, when the printer is used in a

standard configuration (belt clip, soft case, shoulder

strap), the 2.5 cm distance from the users body will be

met. Do not use the printer in an unauthorized manner.

The internal wireless radio operates within guidelines

found in radio frequency safety standards and

recommendations. The level of energy emitted is far less

22 QL 320 User’s Guide

Page 23

than the electromagnetic energy emitted by wireless

devices such as mobile phones.

“Bluetooth” is a worldwide standard for the exchange of data

between two devices via radio frequencies. Bluetooth radios are

relatively low powered to help prevent interference with other devices running at similar radio frequencies. This limits the range

of a Bluetooth device to about 10 meters (about 32 feet).

In order to exchange data, two Bluetooth enabled devices

must establish a connection. Bluetooth software is always running in the background, ready to respond to connection requests.

One device (known as the

connection with another. The second device (the

server

) then accepts or rejects the connection. A Bluetooth enabled QL 320 will normally act as a slave, but in theory any Bluetooth device can be either a master or a slave. This miniature

network is sometimes referred to as a “piconet” and can consist

of several Bluetooth enabled devices.

Each Bluetooth QL 320 has a unique Bluetooth Device Address

(BDA) loaded into its Quick Link module when manufactured.

A Typical Bluetooth Connection Sequence

In this simplified sequence “Joe’s Terminal” is a Bluetooth

ready hand held terminal running an application that needs access to a printer.

1. Joe’s Terminal performs a search of its “piconet” (a Device

Inquiry) and determines that there are four Bluetooth devices in

the vicinity.

2. Joe’s Terminal queries each of the four nearby devices to

determine which services they provide (a Service Discovery).

The Bluetooth enabled QL 320 “Sandy’s Printer” offers the printing service.

3. Joe’s Terminal sends a print connection request to Sandy’s

Printer.

4. Sandy’s Printer evaluates the request and determines that

Joe’s Terminal is permitted to use the print service,

master

correct password is submitted

5. Sandy’s Printer queries Joe’s Terminal for the password (Authentication).

6. Joe’s Terminal returns the correct password and the print

connection is established.

7. After Joe’s Terminal is finished printing it disconnects with

.

or the

client)

must request a

slave

or the

but only if the

QL 320 User’s Guide 23

Page 24

Sandy’s Printer. (Some Bluetooth services disconnect automatically, others must be closed manually.)

There are several layers of security in the Bluetooth system, so

this sequence may not be a completely accurate representation

of how your printer may function in a Bluetooth environment. For

the most part, communications using the Bluetooth protocol are

initiated and processed without any operator intervention, much

like the IrDA system described previously.

Wireless Local Area Network (WLAN) Module Using CF Radio

The following section only applies when the CF (Compact Flash) WLAN module (Contains FCC ID: H9PLA4137) is installed in the QL320 printer (note that only one of the

radio options can be installed in the printer at one time). The FCC ID number label is

on the front of the module and can be read with the module installed.

WARNING: Use of the QL320 with the radio module

marked “Contains FCC ID: H9PLA4137 meets the FCC

requirements for radio frequency (RF) radiation exposure

in the standard body worn configuration with no

minimum separation. In this configuration, which applies

whether the belt clip or shoulder strap is used, the face of

the printer from which paper is transported is facing away

from the user’s body. The standard configuration must

always be used when the printer is body worn.

The printer with this radio option has been SAR tested. The

maximum SAR value measured was 0.26 W/kg averaged

over 1 gram.

Printers equipped for Wireless Local Area Network (WLAN)

communications using the industry standard 802.11 or 802.11b

protocols are known as QL 320N Printers. These printers allow

wireless communication as a node within a local area network,

and its wireless capabilities allow communications from any point

within the LAN’s perimeter. Methods of establishing communications to the QL 320 will vary with each LAN application.

QL 320N printers can be identified by the model number on

the front of the unit.

24 QL 320 User’s Guide

Page 25

Wireless Local Area Network (WLAN) Module Using PCMCIA Radio

The following section only applies when the PCMCIA WLAN module (FCC ID: I28QL320352) is installed in the QL320 printer (note that only one of the radio options can

be installed in the printer at one time). The FCC ID number label is on the front of the

module and can be read with the module installed.

WARNING: Use of the QL320 with the radio module

marked with FCC ID: I28-QL320352 meets the FCC

requirements for radio frequency (RF) radiation exposure

in the standard body worn configuration with no

minimum separation. In this configuration, which applies

whether the belt clip or shoulder strap is used, the face of

the printer from which paper is transported is facing away

from the user’s body. The standard configuration must

always be used when the printer is body worn. This

configuration maintains the required 1cm separation

distance.

The printer with this radio option has been SAR tested. The

maximum SAR value measured was .819 W/kg averaged

over 1 gram.

Printers equipped for Wireless Local Area Network (WLAN)

communications using the industry standard 802.11 or 802.11b

protocols are known as QL 320N Printers. These printers allow

wireless communication as a node within a local area network,

and its wireless capabilities allow communications from any point

within the LAN’s perimeter. Methods of establishing communications to the QL 320 will vary with each LAN application.

QL 320N printers can be identified by the model number on

the front of the unit.

QL 320 User’s Guide 25

Page 26

Setting Up the Software

The QL 320 uses Zebra’s CPL Programming language which

was designed for mobile printing applications. CPL is fully described in the Mobile Printing Systems Programming Manual,

which is available in Portable Document Format (.pdf) on-line at

Zebra’s website.

You can also use Label Vista™, Zebra’s Windows™ based label creation program which uses a graphical interface to create

and edit labels in the CPL language. Label Vista is available either on-line at Zebra’s website, or on a CD (part number

AC15065-1).

The QL 320 with its optional memory upgrade can support an

interpreter for ZPL II

desktop printers. To use ZPL II, refer to the ZPL II Programming

Guide. If you choose to use a third party label preparation system, follow the installation instructions included in the package.

®

, the programming language used by Zebra

26 QL 320 User’s Guide

Page 27

Adjustable Shoulder Strap

Refer to Figure 14, below.

Snap each end of the shoulder strap into the “D” rings in the

top of the printer. Slide the buckle away from or towards the

printer until you achieve the desired length.

Pull Strap here

to shorten

Hold Buckle

Pull Strap here

to lengthen

Snap in to “D”

rings on printer

F

IGURE

14

QL 320 User’s Guide 27

Page 28

Belt Clip

If the QL 320 is equipped with a belt clip, hook the clip over

your belt, and ensure that the clip is securely attached to the belt.

The belt clip will pivot to allow you to move freely while wearing

the printer.

Dress cables

through this

slot

Clip printer to

belt

Printer can

pivot freely

F

IGURE

15

28 QL 320 User’s Guide

Page 29

Preventive Maintenance

WARNING: To avoid possible personal injury or

damage to the printer, never insert any pointed or sharp

objects into the printer.

Extending Battery Life

•Never expose the battery to direct sunlight or temperatures over 104° F (40° C).

• Always use a Zebra charger designed specifically for Lithium-Ion batteries. Use of any other kind of charger may

damage the battery.

•Choose the media that is easiest to “burn.” An authorized

Zebra re-seller can help you determine the optimum media for your application.

• If you print the same text or graphic on every label, consider using a pre-printed label.

•Choose the correct print darkness, and print speed for

your media.

•Use software handshaking (XON/XOFF) whenever possible.

• Select Tear-Off mode whenever possible (Peel-Off mode

uses more power).

• If your printer has the optional LCD display: Use the display backlight only when necessary. Turn it off whenever

it is not needed. The LCD backlight consumes a great

deal of power.

• Pull the battery out of the printer if the printer won’t be

used for a day or more and you’re not performing a maintenance charge.

•Consider purchasing an extra battery.

•Remember that any rechargeable battery will lose its ability to maintain a charge over time. It can only be recharged a finite number of times before it must be replaced.

QL 320 User’s Guide 29

Page 30

Peeler Bar Rollers

Tear Bar

Printhead

Elements

Bearing Points

Linerless Platens only

Peeler Bar

Platen surface

Avoid using alcohol

on linerless platen

surface

Bar Sensor

Label Presence

Sensor

Gap Sensor

Edge Guides, Inner

surfaces on both

sides.

Units with linerless

platens only.

F

IGURE

16

30 QL 320 User’s Guide

Page 31

Cleaning

CAUTION.- Use only the cleaning agents indicated.

Zebra Technologies Corporation will not be responsible

for damage caused by any other cleaning materials

used on this printer.

Never use any sharp objects on the printer mechanism

as they could damage the print head and platen. Clean

the printer with either the cleaning pen supplied with the

printer or a cotton swab saturated with alcohol.

Area Method Interval

Use the supplied cleaning pen or 70%

isopropyl alcohol on a cotton swab to

clean the print elements from end to end

(the print elements are located in the thin

Printhead

(Figure 16)

Platen Roller

(Figure 16)

gray line on the printhead).

If print quality has not improved after

performing this procedure, try cleaning

the printhead with a Cleaning Pad. This

specially prepared material removes

contamination buildup without damaging

the printhead. Refer to Appendix C for

more information.

Rotate the platen roller and clean it

thoroughly with the cleaning pen or 70%

isopropyl alcohol and a cotton swab.

Units with linerless platens: Rotate platen

& clean bearing points only.

Avoid use of

alcohol on the surface of linerless

platens!

After every five

rolls of media

(or more often,

if needed)

Linerless media

requires more

frequent

cleaning.

Peel bar

(Figure 16)

Tear bar

(Figure 16)

Exterior

Interior

(Figure 16)

Clean thoroughly with the cleaning pen or

70% isopropyl alcohol and a cotton swab.

Clean thoroughly with the cleaning pen or

70% isopropyl alcohol and a cotton swab.

Water-dampened cloth

Brush/air blow. Insure the Bar Sensor, Gap

Sensor and Label Present Sensor windows

are free of dust.

Units with linerless platens:

Clean inside surfaces of edge guides and

media support rollers with the supplied

cleaning pen or 70% isopropyl alcohol on a

cotton swab.

QL 320 User’s Guide 31

As needed

After every five

rolls of media

(or more often,

if needed)

Page 32

Troubleshooting

Standard Control Panel

If the printer is not functioning properly, refer to the chart below

to find the state of the two LEDs on the Control Panel. Then refer to the Troubleshooting topic referenced in the chart to resolve

the problem.

Green LED Yellow LED Indication Ref. to Topic

Steady Off Normal Operation, n/a

Off Off Power Off 1

Fast Blink Off No RF Link 6, 11

Slow Blink Off Low Battery 3, 6, 7

Steady Steady Out of media, or 9, 11

Steady Fast Blink Normal RF activity 8

Steady Fast Blink, No application 8

Beeper Sounds

and/or RF Link established

Media Cover not closed

Optional LCD Control Panel

The top of the display shows several icons which indicate various printer functions. Check the indicator status, then refer to the

Troubleshooting topic referenced in the chart to resolve the problem.

Status Icon Condition Indication Ref. to Topic

Steady RF Link established n/a

Off No RF Link 6

Flashing Low Battery 3, 6, 7

Flashing Head latch not closed 9, 11

Flashing Printer is receiving a file 8

Flashing Out of media, 9, 11

Blank Screen n/a No application 1,13

32 QL 320 User’s Guide

Page 33

Troubleshooting Topics

1. No power

• Check that battery is installed properly

• Recharge or replace battery as necessary.

2. Media does not feed:

• Be sure print head is closed and latched.

• Check spindle holding media for any binding.

• If unit is equipped with label presence sensor:

Insure most recently printed label is removed.

Also insure label sensor is not blocked.

3. Poor or faded print or flashing:

•Clean print head.

• Check battery and recharge or replace as necessary

• Check quality of media.

4. Partial/missing print:

• Check media alignment

•Clean print head.

•Insure printhead is properly closed and latched.

5. Garbled print:

• Check baud rate.

6. No print:

• Check baud rate

• Replace battery

• Check cable to terminal

• Establish RF Link (Wireless units only) or restore LAN

associativity (QL 320N models only)

•Invalid label format or command structure — put printer in

Communications Diagnostic (Hex Dump) Mode to diagnose

problem.

7. Reduced battery life

• Check battery date code — if battery is one to two years old,

short life may be due to normal aging.

• Recondition battery.

• Replace battery.

8. Yellow error light or flashing:

• No application or application corrupted: reload program.

• If using wireless communications: flashing indicator is normal

while data is being transmitted or received.

continued on next page

QL 320 User’s Guide 33

Page 34

9. Yellow error light always on, or flashing:

• Check media is loaded and print head is closed and

securely latched.

10. Skips labels:

• Check media for top of form sense mark or label gap.

• Check that the maximum print field has not been exceeded

on label.

•Insure bar/ or gap sensor is not blocked or

malfunctioning

11. Communication Error:

• Check media is loaded, head is closed and error

light is off.

• Check baud rate.

• Replace cable to terminal.

12. Label Jam:

• Open head release latch and media cover.

• Generously apply alcohol to printer in area of

jammed label.

13. Blank LCD Screen (only for units with optional LCD

control panel)

• No application loaded or application corrupted: reload

program.

Troubleshooting Tests

Printing a Configuration Label

To print out a listing of the printer’s current configuration follow

these steps:

1. Turn the printer off. Load the media compartment with

journal media (media with no black bars printed on the

back)

2. Press and hold the Feed Button.

3. Press and release the Power button and keep the Feed

button pressed. When printing starts, release the Feed

button.

34 QL 320 User’s Guide

Page 35

Sample Configuration Label

Print Head Test

End of First Report

Unit Serial Number

Application Number

Report appears only on

units with wireless

options installed.

Units with no wireless

options will print an

empty line and resume

This example has a

Bluetooth™ module

installed. (refer to

pages 23-24 for more

details.)

F

IGURE

17

continued on next page

QL 320 User’s Guide 35

Page 36

Sample Configuration Label (continued)

Peripherals installed:

In this example the

LCD display option is

not installed.

Flash Memory Size

Maximum Label Size

F

IGURE

17

A

36 QL 320 User’s Guide

Resident Fonts

Pre-scaled font (.cpf)

listed separately

Files Loaded in Printer

Memory (will include

Pre-scaled or Scalable

Fonts)

Amount of Memory

Available

Page 37

Communications Diagnostics

If there’s a problem transferring data between the computer

and the printer, try putting the printer in the Communications Diagnostics Mode (also referred to as the “DUMP” mode). The

printer will print the ASCII characters and their and their text representation (or the period ‘.’, if not a printable character) for any

data received from the host computer

To enter Communications Diagnostics Mode:

1. Print a configuration label as described on pg. 34.

5. At the end of 2nd diagnostics report, the printer will print:

“Press FEED key to enter DUMP mode”.

6. Press the FEED key. The printer will print: “Entering

DUMP mode”.

Note: If the FEED key is not pressed within 3 seconds, the printer will print “DUMP mode

not entered” and will resume normal operation.

7. At this point, the printer is in DUMP mode and will print the

ASCII hex codes of any data sent to it, and their text representation (or “.” if not a printable character).

Additionally, a file with a “.dmp” extension containing the ASCII

information will be created and stored in the printer’s memory. It

can be viewed, “cloned” or deleted using the Label Vista application. (Refer the Label Vista documentation for more information.)

To terminate the Communications Diagnostics Mode and return

the printer to normal operations:

1. Turn the printer OFF.

2. Wait 5 seconds.

3. Turn the printer ON.

Calling the Help Desk

If the printer fails to print the configuration label, or you encounter problems not covered in the Troubleshooting Guide, contact

the Help Desk. Help Desk addresses and phone numbers for

your area can be found in Appendix D of this manual. The Help

Desk will need the following information:

•Model number/type (e.g. QL 320)

•Unit serial number (Found on the large label on the back

of the printer, also found in the configuration label printout.

Refer to Figure 17)

• Product Configuration Code (PCC) (15 digit number found

on the small label on the back of the unit)

QL 320 User’s Guide 37

Page 38

Specifications

NOTE.- Printer specifications are subject to change without notice.

Printing Specifications

Print Density 203 dots/inch (8 dots/mm)

Print Width Up to 2.9“ (71.2 mm)

Print Speed 4” per second (101.6 mm per

Print Head Life, 1,964,160” (50 Km) nominal

calculated

Distance from .571” (14.5 mm)

Print Element 116 dots

to Top of Form

second)

Memory/Communications Specifications

Flash Memory 1 MB flash (standard); 2MB flash (optional)

SRAM Memory 1MB SRAM (standard); 2 MB SRAM (optional)

Standard RS-232 serial port (8 Pin circular DIN connector)

Communications Configurable Baud rate (from 9600 to 57.6 Kbps),

Optional Wireless Bluetooth compatible 2.4 GHz SRRF link

Communications

parity and data bits.

Software (X-ON/X-OFF) or hardware (DTR/STR)

communication handshake protocols.

Infrared wireless link (meets IrDA 1.1 communications

specifications) 2,400 to 115,200 Baud rate

Optional SRRF frequencies of 916 MHz and 2.4 GHz

per Zebra proprietary wireless protocol.

Optional wireless LAN capabilities comply with 802.11

and 802.11b protocols

38 QL 320 User’s Guide

Page 39

Label Specifications

Label/Tag Width 1.5" to 3.1" (38.1 mm to 78.4 mm)

Max. Label/ 16" (406.4 mm) with standard memory

Tag Length

Inter-label Gap. .08" to .16" (.12" preferred)

Label/Tag Thickness .0025” to .0065” (.064 mm to .165 mm)

Label Roll Size:

Max. Diameter 2.625" (66.7 mm) O.D.

Inner Core .75" (19 mm) std, 1.38” (35.05 mm) optional

Diameter Use Zebra-brand direct thermal media that is outside

Media Requirements the centerline of the roll.

2 mm to 4 mm (3 mm preferred)

wound. Media may be reflective (black mark) sensing

or transmissive (gap) sensing, die-cut, continuous or

linerless.

For die-cut labels, use only full auto dies.

The reflective media black marks should extend past

Minimum Black Mark Dimensions:

Mark width: 0.5” (12.7mm) perpendicular to the edge

of the media, centered within the width of the roll.

Mark length: 0.094” (2.4 mm) parallel to the edge of

the media.

Font/Bar Code Specifications

Fonts Available Five resident scalable and rotatable fonts

available from 12-48 pt.

Downloadable pre-scaled fonts via Label Vista™

software

Optional international character sets

Codabar

UCC/EAN 128

1D Bar Codes Available Code 93

2D Bar Codes Available MaxiCode

Rotation Angles 0°, 90°, 180°, and 270°

Code 39

EAN 8/JAN 8, 2 and 5 digit extensions

EAN 13/JAN 13, 2 and 5 digit extensions

lnterleaved 2 of 5

MSI/Plessey

FIM/POSTNET

UPC-A, 2 and 5 digit extensions

UPC E, 2 and 5 digit extensions

PDF 417

QL 320 User’s Guide 39

Page 40

Physical/Environmental/Electrical Specifications

3.1”

[78.7 mm]

8.3”

[210.2 mm]

4.60”

[116.8 mm]

F

IGURE

3.9”

[97.9 mm]

18 O

VERALL DIMENSIONS

8.0”

[203.2 mm]

Weight

w/ battery 1.65 lbs. (.75 kg. )

excluding media.

Temperature

Operating 5° to 122° F (-15° to 50° C)

Storage -13° to 158° F (-25° to 70° C) Range

Relative Humidity

Operation 10% to 80% (non-condensing)

Storage 10% to 90% (non-condensing)

Electrical Battery: 7.4V Lithium-Ion

Charger: External battery charger, 120-230 VAC

depending on model selected.

40 QL 320 User’s Guide

Page 41

Communications Port

Signal

Pin# Name Type Description

1 RXD input Receive Data

2 TXD output Transmit Data

3 CTS input Clear To Send from host

4RTS output Request T o Send

set high when printer

is ready to accept command

/data

5GND Ground

6NCNo Connect

7 DSR input Data Set Ready

low to high transition turns

printer on, high to low

transition turns printer off

(if enabled)

8 DTR output Data Terminal Ready

set high when printer is on

(set to battery voltage for

“S” versions)

2

4

1

6

5

3

7

8

F

IGURE

19 C

OMMUNICATIONS PORT

(8 pin Circular DIN)

QL 320 User’s Guide 41

Page 42

Agency Approvals

•FCC Part 15 Subpart B Class A Electromagnetic Radiation

Standard

• Built to UL, CUL and TUV standards

•EN50082-1 International lmmunity Standard

•EN55022 Class B European Electromagnetic Radiation Standard

• NOM/NYCE (Mexico)

•C-Tick (Australia)

Accessories

• Adjustable shoulder strap

• Protective soft case

• Extra battery packs

• 120-230 VAC battery charger

•Desk Mount

•Data cables

For details, call your authorized Zebra re-seller.

Page 43

Appendix A

Interface Cables

Part Number ´BL11757-000; 8-Pin DIN to 9-Pin DB PC Cable

This part is also available as a coiled cable under Part Number

BL15063-1.

For Use With a Personal Computer

Pin 9

DB-9 Pin

Female Plug

(to P.C.)

PC Signals Printer Signals

Pin 1

(TXD)

(RXD)

(RTS)

(CTS)

(GND)

(DTR)

(DSR)

Shield

3

2

7

8

5

4

6

1

2

3

4

5

7

8

(RXD)

(TXD)

(CTS)

(RTS)

(GND)

(DSR)

(DTR)

Shield

3

5

7

8

6

4

1

8 Pin

Male Plug

(to printer)

2

QL Series User’s Guide Appendices 43

Page 44

Appendix A

INTERFACE CABLES

Adapter - Symbol PN#25-12059-01

Cable Cord Terminal Printer

Terminal Part Number Lgth/Type Connector Connector Notes

COMPSEE

Apex II BL12093-3 8’ Coiled RJ45 8 Pin DIN

LXE

MX1,MX3 BL17757-000 6’/Straight 9 Pin DB 8 Pin DIN

1380,1390,1590 BL17757-000 6’/Straight 9 Pin DB 8 Pin DIN

2325 BL12093-1 8’/Coiled RJ45 8 Pin DIN Power On/Off (+5V)

NORAND

RT1100/1700 Series BL11537-1 8’ /Coiled 6 Pin MinDIN 8 Pin DIN Over-molded

RT1100/1700 Series BL11537-2 12’/Coiled 6 Pin MiniDIN 8 Pin DIN Over-molded

RT5900 Series BL12803-1 8’ /Coiled 15 Pin D-Sub 8 Pin DIN

RT1100/1700 Series BL12804-1 8’ /Coiled 6 Pin MiniDIN 8 Pin DIN -Locking

RT1100/1700 Series BL13298-1 8’ /Coiled 6 Pin MiniDIN 8 Pin DIN Over-molded Auto ON/OFF

RT1100/1700 Series BL13309-1 8’ /Coiled 6 Pin Mini DIN 8Pin DIN Auto ON/OFF

6400 BL11757-000 6’/Straight 9 Pin DB 8 Pin DIN

SYMBOL

PDT3300 Series BL11391-000 8’ /Coiled DB25 male 8 Pin DIN

44 QL Series User’s Guide Appendices

PDT4100 Series BL11757-000 6’ /Straight 9 Pin DB Fem. 8 Pin DIN Must be used with Symbol RS232

PDT3100/3500 BL12093-1 8’ /Coiled RJ45 8 Pin DIN a. Power On/Off (+5V) b. Used for the

/6100 Series Percon Falcon

PDT3100 Series BL12093-2 8’ /Coiled RJ45 8 Pin DIN Power On/Off (DTR Line)

Page 45

Appendix A

INTERFACE CABLES (continued)

Cable Cord Terminal Printer

Terminal Part Number Lgth/Type Connector Connector Notes

SYMBOL (CONT.)

SPT1700 Series BL15483-1 9’ /Coiled Cradle 8 Pin DIN No Power On/Off (DTR Line)

SPT2700 Series BL15482-1 9’ /Coiled Cradle 8 Pin DIN Power On/Off (DTR Line)

LRT/LDT3800 Series CC11371-3 6’ /Coiled PIM Optical 8 Pin DIN “S” Printers Only

LRT/LDT3800 Series CC11371-14 6’ / Coiled PIM Optical 8 Pin DIN “S” Printers Only

(2 Way)

LRT/LDT3800 CC11371-14 6’ / Coiled PIM Optical 8 Pin DIN “S” Printers Only

& 6800 Series

LRT/LDT3800 CC11371-15 6’ / Coiled PIM Optical 8 Pin DIN “S” Printers Only

& 6800 Series

TEKLOGIC

7030 ILR BL13285-2 Coiled 36 Pin IDC Fem 8 Pin DIN

7025 ILR BL13285-1 Coiled 15 Pin DB male 8 Pin DIN

TELXON

960 BL11122-1 8’ /Coiled RJ45 8 Pin DIN

960SL Adapter CC13711-1 n/a n/a n/a

for BL11122-1

960 (BL11122-1) CP74005 n/a n/a n/a

& 960SL (CC13711-1)

960 BL12996-1 8’ /Coiled RJ45 8 Pin DIN-Locking

860 & 912 CL11314-000 8’ /Coiled DB25 8 Pin DIN

QL Series User’s Guide Appendices 45

Page 46

Appendix B

Media Supplies

To insure maximum printer life and consistent print quality and

performance for your individual application, it is recommended

that only media produced by Zebra be used. These advantages

include:

•Consistent quality and reliability of media products.

• Large range of stocked and standard formats.

• In-house custom format design service.

• Large production capacity which services the needs of

many large and small media consumers including major

retail chains world wide.

•Media products that meet or exceed industry standards.

For more information call Zebra Technologies Corporation at

+1.401.739.5800 and ask to speak to a Media Sales Representative.

46 QL Series User’s Guide Appendices

Page 47

Appendix C

Maintenance Supplies

In addition to using quality media provided by Zebra, it is recommended that the printer be cleaned as prescribed in the maintenance section. The following items are available for this

purpose:

•Cleaning Pen (10 pack), Reorder No. AN11209-1

•Cleaning Kit with Cleaning Pen, and Cotton Swabs, Reorder No. AT702-1

QL Series User’s Guide Appendices 47

Page 48

Appendix D

Product Support

When calling with a specific problem regarding your printer,

please have the following information on hand:

•Model number/type (e.g. QL 320)

•Unit serial number (Found on the large label on the back

of the printer)

• Product Configuration Code (PCC) (15 digit number found

on the small label on the back of the unit)

Contact the Help Desk at:

Zebra Technologies Corporation

30 Plan Way

Warwick, Rhode Island 02886-1012 USA

Telephone: +1 401.739.5800

Fax: +1 401.732.7808

e-mail: risupport@zebra.com

In Europe:

Zebra Technologies Europe, Limited

Zebra House

The Valley Centre, Gordon Road

High Wycombe

Buckinghamshire HP13 6EQ, United Kingdom

Telephone: +44 1494 768298

Fax: +44 1494 768210

e-mail: tseurope@zebra.com

Ask for Customer Support

48 QL Series User’s Guide Appendices

Page 49

Index

A

Accessories 42

Agency Approvals 42

B

Battery, charging 9

while printing 9

Battery, installing 9

Battery life, tips 29

Belt clip 28

Bluetooth Device Address

(BDA).

See

Communications:

short range radio frequency

(SRRF): Bluetooth™

C

Charger, battery 9

Cleaning

edge guides 31

Exterior 31

Interior 31

Linerless platen roller 31

Peel bar 31

Platen roller 31

Printhead 31

Sensors 31

Tear bar 31

Communications

Connector signals 41

infrared (IR) 20

SRRF 21

Bluetooth™ 22

Zebra propietary protocol 21

with a cable 19

Communications diagnostics 37

Configuration label 34

sample printout 35, 36

D

Damage, shipping 7

H

Help Desk, contacting 37

L

Label Vista 17, 26

use in troubleshooting 37

LAN.

See

Wireless communica-

tion: Local Area Network

M

Manual

CPL Programming 7, 26

ZPL II Programming 7, 26

QL 320 User’s Guide Index 49

Media, loading 10

adjusting for core diameter 11

peel-off mode 12

tear-off mode 12

O

Operator Controls 13

LCD Keypad 15

functions displayed 17

Standard Keypad 13

error indicator 14

power-on indicator 13

P

piconet.

See

Communications: SRRF: Bluetooth™

Platen

linerless 31

Programming language

CPL 7

ZPL II 26

interpreter for 7

Q

QuickLink™ module 13

S

Shoulder Strap, adjusting 27

Software 26

Specifications

Font/bar Code 39

Label 39

Memory/communications 38

Physical 40

printing 38

T

Troubleshooting

entering Communications

Diagnostics Mode 37

entering Communications

Diagnostics Mode Diagnosti 37

LCD Control Panel 32

Standard control panel indicators

32

Troubleshooting tests 34

printing a configuration label 18

Troubleshooting Topics 33

W

Wireless communication

Local Area Network 13

Local Area Network using CF

Radio 24

Local Area Network using

PCMCIA Radio 25

Page 50

Page 51

Patent Information

This product and/or its use may be covered by one or more of the

following US patents and corresponding international patents

worldwide

D275,286

D347,021

D389,178

D430,199

D433,702

3,964,673

4,019,676

4,044,946

4,360,798

4,369,361

4,387,297

4,460,120

4,496,831

4,593,186

4,607,156

4,673,805

4,736,095

4,758,717

4,816,660

4,845,350

4,896,026

4,897,532

4,923,281

4,933,538

4,992,717

5,015,833

5,017,765

5,021,641

5,029,183

5,047,617

5,103,461

5,113,445

5,140,144

5,132,709

5,142,550

5,149,950

5,157,687

5,168,148

5,168,149

5,180,904

5,229,591

5,230,088

5,235,167

5,243,655

5,247,162

5,250,791

5,250,792

5,262,627

5,267,800

5,280,163

5,280,164

5,280,498

5,304,786

5,304,788

5,321,246

5,335,170

5,364,133

5,367,151

5,372,439

5,373,148

5,378,882

5,396,053

5,396,055

5,399,846

5,408,081

5,410,139

5,410,140

5,412,198

5,415,482

5,418,812

5,420,411

5,436,440

5,444,231

5,449,891

5,449,893

5,468,949

5,479,000

5,479,002

5,479,441

5,486,057

5,503,483

5,504,322

5,528,621

5,532,469

5,543,610

5,545,889

5,552,592

5,570,123

5,578,810

5,589,680

5,612,531

5,642,666

5,657,066

5,768,991

5,790,162

5,791,796

5,806,993

5,813,343

5,816,718

5,820,279

5,848,848

5,860,753

5,872,585

5,874,980

5,909,233

5,976,720

5,978,004

5,995,128

5,997,193

6,004,053

6,010,257

6,020,906

6,034,708

6,036,383

6,057,870

6,068,415

6,070,805

6,095,704

6,109,801

6,123,471

6,147,767

6,151,037

6,201,255B1

6,231,253B1

6,261,009

6,261,013

6,267,521

6,270,072B1

6,285,845B1

6,292,595

6,296,032

6,364,550

6,379,058B1

6,409,401B1

6,411,397B1

Page 52

Loading...

Loading...