Page 1

User Guide

WherePort III User Guide

______________________________________________________________________________________ 1

WherePort III User Guide D948 Rev C

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 2

Typographical Conventions

_________

____________

____________

User Guide

Warnings call attention to a procedure or

practice that could result in personal injury if

not correctly performed. Do not proceed until

you fully understand and meet the required

conditions.

____________

CAUTION

____________

_________

Note

Cautions call attention to an operation

procedure or practice that could damage the

product if not correctly performed. Do not

proceed until understanding and meeting these

required conditions.

Notes provide information that can be helpful in

understanding the operation of the product.

______________________________________________________________________________________

WherePort III User Guide D948 Rev C

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

2

Page 3

User Guide

Document Revision History

Revision Change Description

A Release per ECO C01013 2/23/06 G.Phillips

B Updated per ECO C02336 12/07/10 D. Bowman

Date Initials

______________________________________________________________________________________

WherePort III User Guide D948 Rev C

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

3

Page 4

User Guide

Contents

WherePort III User Guide .................................................................................... 1

1 Regulatory Information ............................................................................... 6

1.1 FCC and IC Requirements ........................................................................ 6

1.2 EU Compliance Information (WPT-3200) ................................................. 6

1.3 Regulatory - Other ..................................................................................... 7

CMIIT ID: 2007DJ4325The WherePort ............................................................... 7

The WherePort .................................................................................................... 8

1.4 This Guide ................................................................................................. 9

1.5 The WherePort........................................................................................... 9

1.6 Health Tag ................................................................................................ 10

1.7 WherePort Mounting ............................................................................... 10

2 The WhereTag ............................................................................................ 12

2.1 WhereTag Responses ............................................................................. 12

2.2 Using the WherePort ID .......................................................................... 15

3 Magnetic Communication Basics ............................................................. 16

3.1 Magnetic Fields ....................................................................................... 16

3.2 Coverage Areas ....................................................................................... 18

3.3 Power Level ............................................................................................. 20

3.4 Phases ..................................................................................................... 22

3.5 Sequencing .............................................................................................. 23

3.6 Dual WherePorts ..................................................................................... 24

3.7 Interference ............................................................................................. 25

3.8 The Field Meter ........................................................................................ 26

3.9 The WherePort LED ................................................................................ 26

3.10 Capture Area Simulator ....................................................................... 27

4 WherePort in the Field ............................................................................... 27

4.1 Zones ....................................................................................................... 28

4.2 Area Coverage ......................................................................................... 28

4.3 Portals ...................................................................................................... 28

4.4 Multi-Floor Installations .......................................................................... 31

4.5 Locked WherePorts ................................................................................ 31

4.6 Multiple WherePorts ............................................................................... 32

4.7 Sequenced WherePorts .......................................................................... 35

4.8 Summary .................................................................................................. 36

5 Working through an Application .............................................................. 38

5.1 Warehouse and Shipping Facility .......................................................... 38

5.2 Positioning the WherePorts ................................................................... 40

6 Using the Simulator ................................................................................... 42

______________________________________________________________________________________

WherePort III User Guide D948 Rev C

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

4

Page 5

User Guide

6.1 Simulator Controls and Features ........................................................... 42

6.2 WherePort Configuration ....................................................................... 43

6.3 Sample Graphs ........................................................................................ 46

6.4 Adjacent WherePorts .............................................................................. 49

7 Command Summary .................................................................................. 50

7.1 Initial Power Up ....................................................................................... 50

7.2 Passwords ............................................................................................... 50

7.3 Command Execution .............................................................................. 51

7.4 Tag Responses to Commands ............................................................... 51

7.5 Commands .............................................................................................. 52

7.5.1 Message Length .......................................................................................... 52

7.5.2 Power .......................................................................................................... 52

7.5.3 Phase ........................................................................................................... 52

7.5.4 WherePort ID .............................................................................................. 53

7.5.5 Tag Id .......................................................................................................... 53

7.5.6 Response ..................................................................................................... 53

7.5.7 Count ........................................................................................................... 54

7.5.8 Interval ........................................................................................................ 54

7.5.9 Trigger......................................................................................................... 54

7.5.10 Data ............................................................................................................. 54

7.5.11 EXE ............................................................................................................. 55

7.5.12 Sequence Mode ........................................................................................... 55

7.5.13 Sequence Mode Message Number .............................................................. 55

7.5.14 Version ........................................................................................................ 56

7.5.15 XPW ............................................................................................................ 56

7.5.16 HWT (1) ...................................................................................................... 56

7.5.17 Loader ......................................................................................................... 56

7.5.18 GQ ............................................................................................................... 56

8 Installation .................................................................................................. 60

8.1 WherePort Parts ...................................................................................... 60

8.2 Also Required (not included) ................................................................. 61

8.3 Installation Procedure ............................................................................ 62

______________________________________________________________________________________

WherePort III User Guide D948 Rev C

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

5

Page 6

User Guide

1 REGULATORY INFORMATION

1.1 FCC and IC Requirements

This device complies with Part 15 rules. Operation is subject to the

following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation. The user is

cautioned that any changes or modifications not expressly

approved by Zebra Enterprise Solutions could void the user’s

authority to operate the equipment.

See the FCC registration label, located on the bottom of the equipment for

the FCC registration and identity.

Canadian DOC Compliance Statement

This device complies with Industry Canada licence‐exempt RSS standard(s).

Operation is subject to the following two conditions: (1) this device may not

cause interference,and (2) this device must accept any interference, including

interferencethatmaycauseundesiredoperationofthedevice.

LeprésentappareilestconformeauxCNRd'IndustrieCanadaapplicablesaux

appareilsradioexemptsdelicence.L'exploitationestautoriséeauxdeux

conditionssuivantes:(1)l'appareilnedoitpasproduiredebrouillage,et(2)

l'utilisateurdel'appareildoitacceptertoutbrouillageradioélectriquesubi,

mêmesilebrouillageestsusceptibled'encompromettre

lefonctionnement.

1.2 EU Compliance Information (WPT-3200)

Table 1EU Compliance - Approved for use in the following countries

AT BE BG CY CZ DK EE

FI FR DE GR HU IE IT

LV LT LU MT NL PL PT

RO SK SI ES SE GB

IS LI NO CH

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 7

User Guide

1.3 Regulatory - Other

CMIIT ID: 2007DJ4325

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 8

User Guide

THE WHEREPORT

The WherePort III is a location indicator that is part of the Zebra Enterprise Solutions

(ZES) Real Time Locating System (Figure 1). The WherePort transmits a localized

magnetic field. Since the field is confined (programmable from approximately 3 feet to

25 feet) it is a reliable indicator of the location of key sites in the facility. When

WhereTags pass through the WherePort field they transmit the ID of the WherePort. The

WhereTag response can be programmed to indicate needed information about the status

of the asset or object to which the tag is attached.

WherePorts are mounted to fixed locations such as gates, loading docks, or cells

along an assembly line so that information required about the movement of assets

through the facility will be gathered by the RTLS. As tagged assets pass through the

fields the tag transmits the WherePort ID that pinged it and any other programmed status

information.

Status LED

Figure 1 WherePort

The VSS system is programmed with the location of each WherePort and their ID. When

a WhereTag transmits a message that includes the ID of the WherePort field that it is in,

the system knows where the WhereTag is. This is particularly important when locating

transitions is important or where the layout of the site makes it difficult to have enough

sensors to accurately locate the tag using RTLS.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 9

User Guide

1.4 This Guide

This guide presents the basic principles of WherePort communication and the major

issues for placing them on a site. It is intended to support both the planning for and the

implementation of an RTLS application using WherePorts.

It describes the WherePort, the WhereTag and its responses, the characteristics of

the magnetic field, and how the WherePort is used in a variety of applications. For more

detailed information about the WhereTag see the WhereTag Users Guide.

Also included is a description of the simulator program and how it is used to

determine effective WherePort site placement and configuration.

1.5 The WherePort

The WherePort is a round, dome shaped device, (9 inches in diameter and 5.25 inches

high). It is powered by either 24 VAC or 36 VDC. A mobile version is available that

uses only DC power (12-36 VDC; 1.5A). The complete specifications are shown in Table

2. The wiring schematic is shown in Figure 2.

The WherePort is configured using commands sent through the RS-232 interface.

These commands are described in Appendix B.

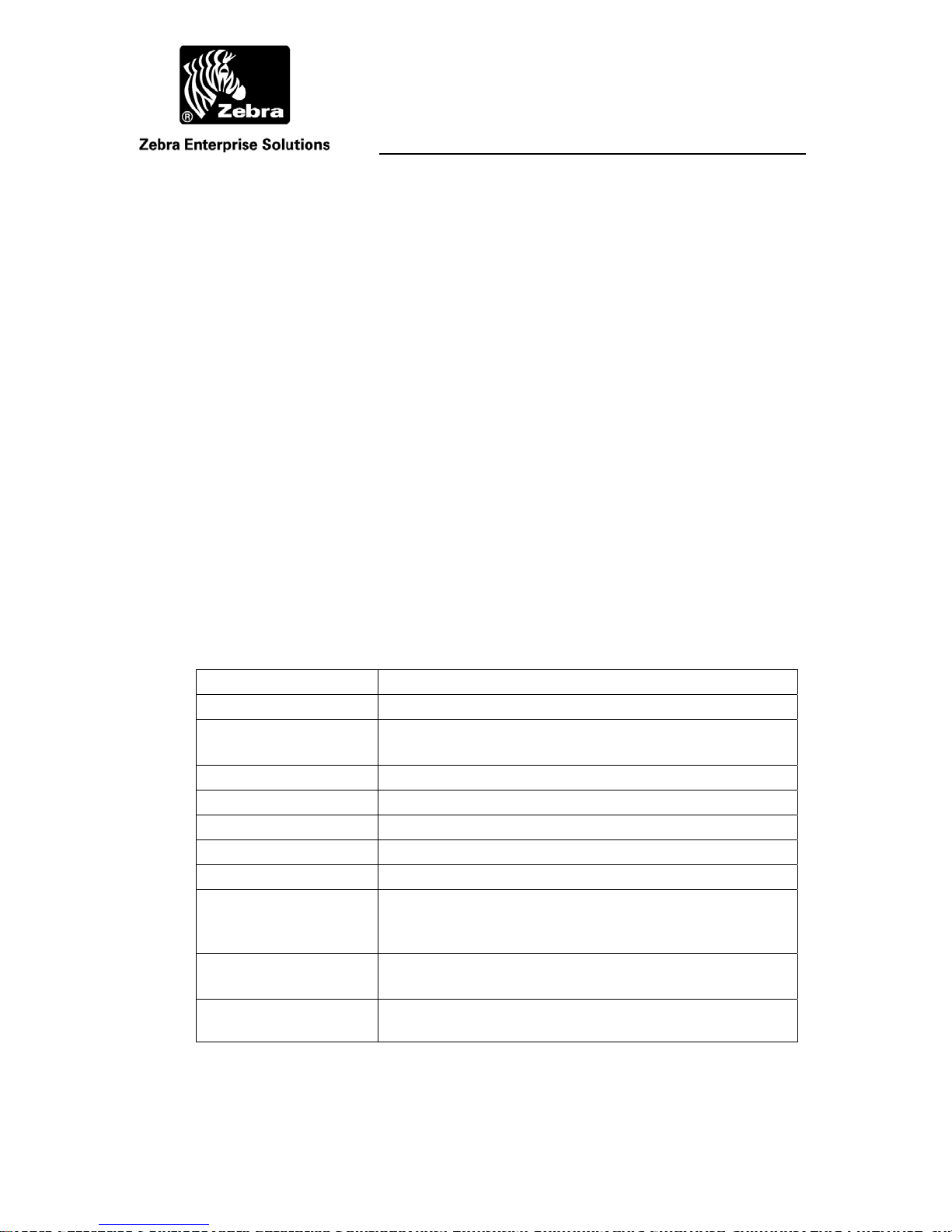

Table 2 WherePort Specifications

Size 9.0 x 5.25 in. (229 x 133 mm)

Weight 2.3 lbs (1.0 Kg)

Voltage 24 VAC or 36 VDC Voltage (standard)

12-36VDC (AC Voltage is not allowed) (mobile)

Current 250 mAmp max (standard) 1.67A Max. (mobile)

PwrDiss 4.2 Watts (max)

Operating Temperature -40 to +55 ºC

Storage Temperature -40 to +70 ºC

Humidity 0 to 100% Non-condensing

AC/DC Power

Connection

Phase Synchronization 2 wires from previous WherePort (green/orange)

Configuration Interface

2 wires (black and white)

For mobile versions, positive input is connected to white

wire and negative input is connected to black wire.

2 wires to following WherePort (red/blue)

12 pin round, weather tight connector (provided by Zebra

Enterprise Solutions) with custom cable (com port)

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 10

User Guide

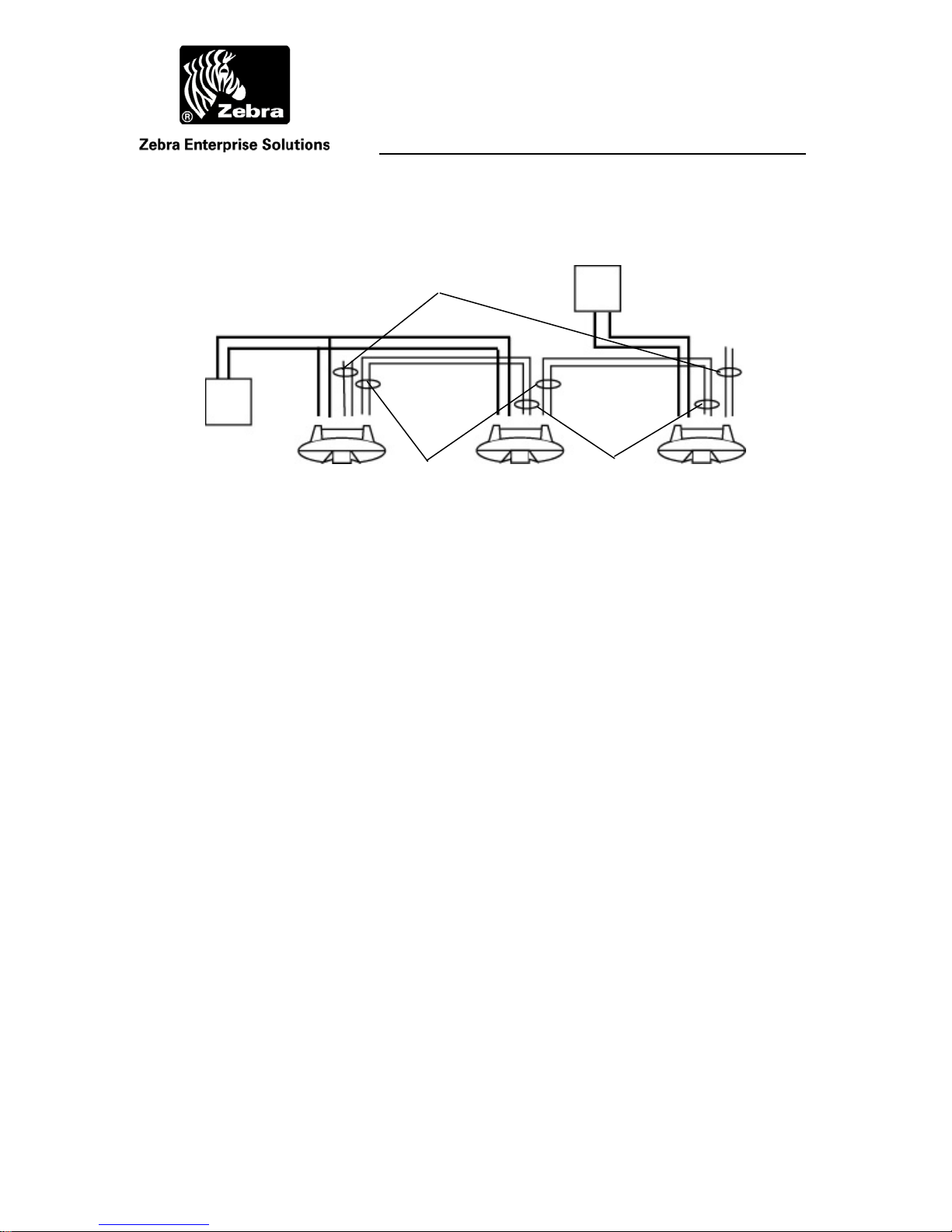

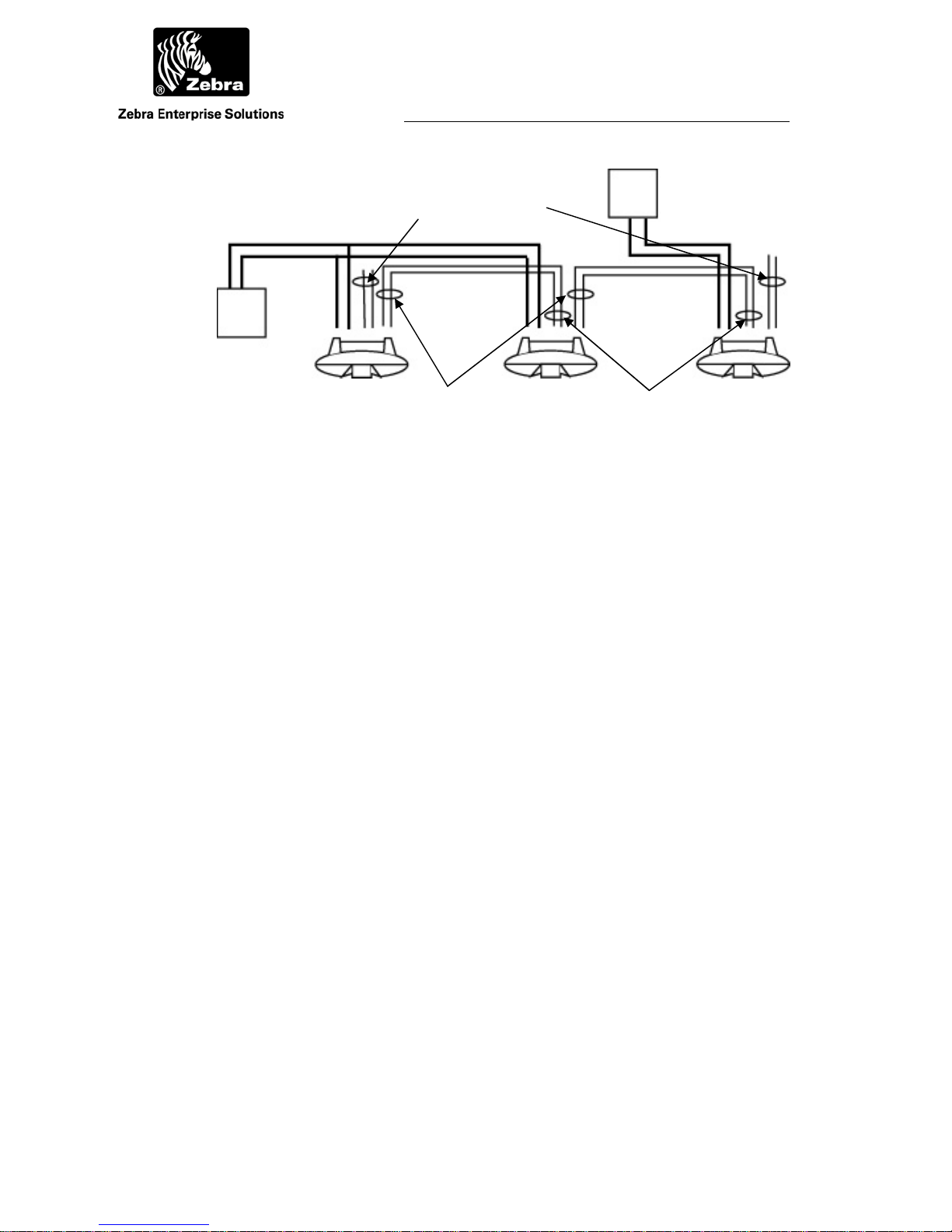

Power

Black & White

24 VAC

Transformer

Figure 2 Wiring Schematic for Power and Synchronization

Unused: Do Not

Terminate

Output Sync:

Red and Blue

Each 24 VAC transformer supports no more than two

WherePorts.

24 VAC

Transformer

Input Sync:

Green and Orange

1.6 Health Tag

A WhereTag that is programmed to blink when there is no signal from the WherePort

may be mounted to each WherePort. This optional tag is called a health tag because a

signal from this tag indicates that there is something wrong with the WherePort that has

caused it to stop signaling.

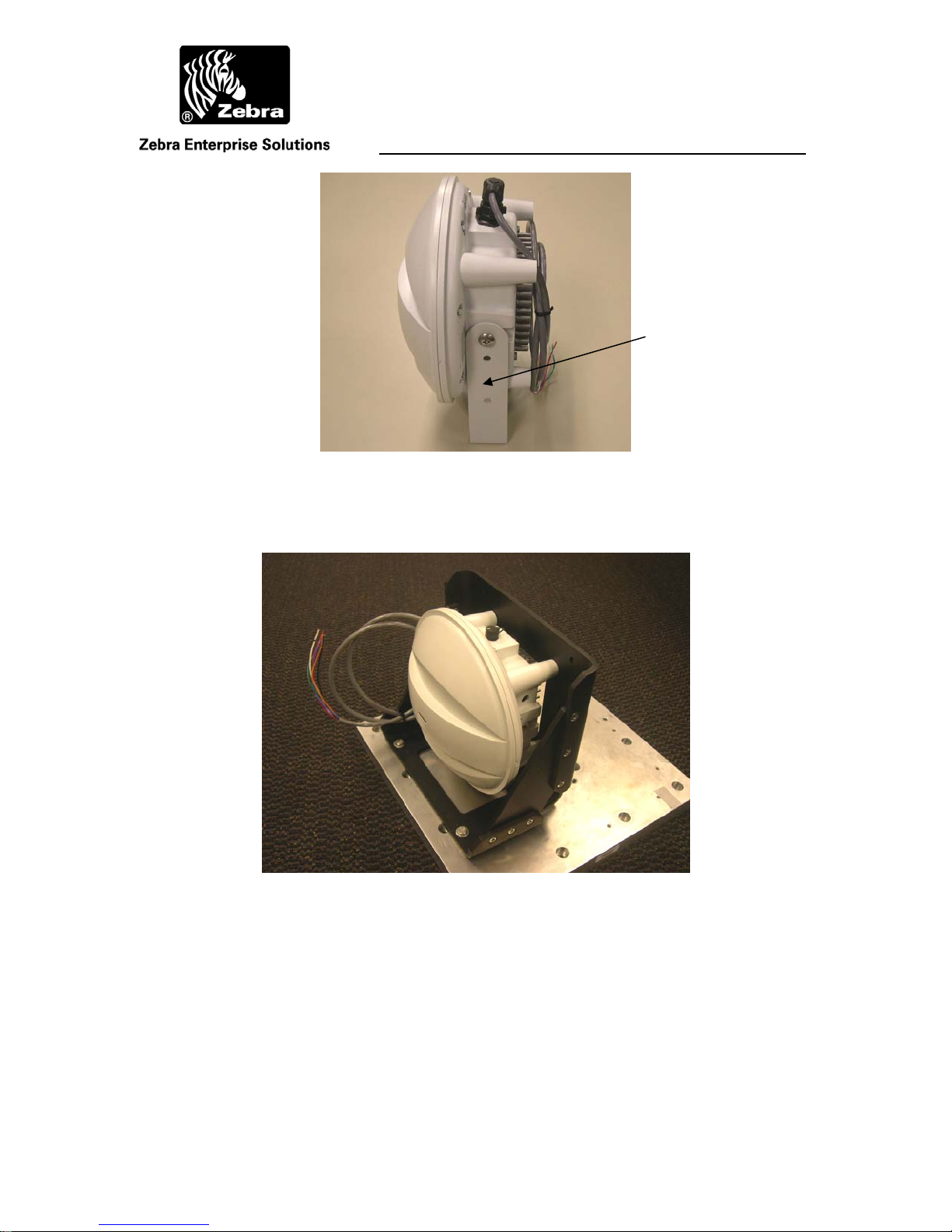

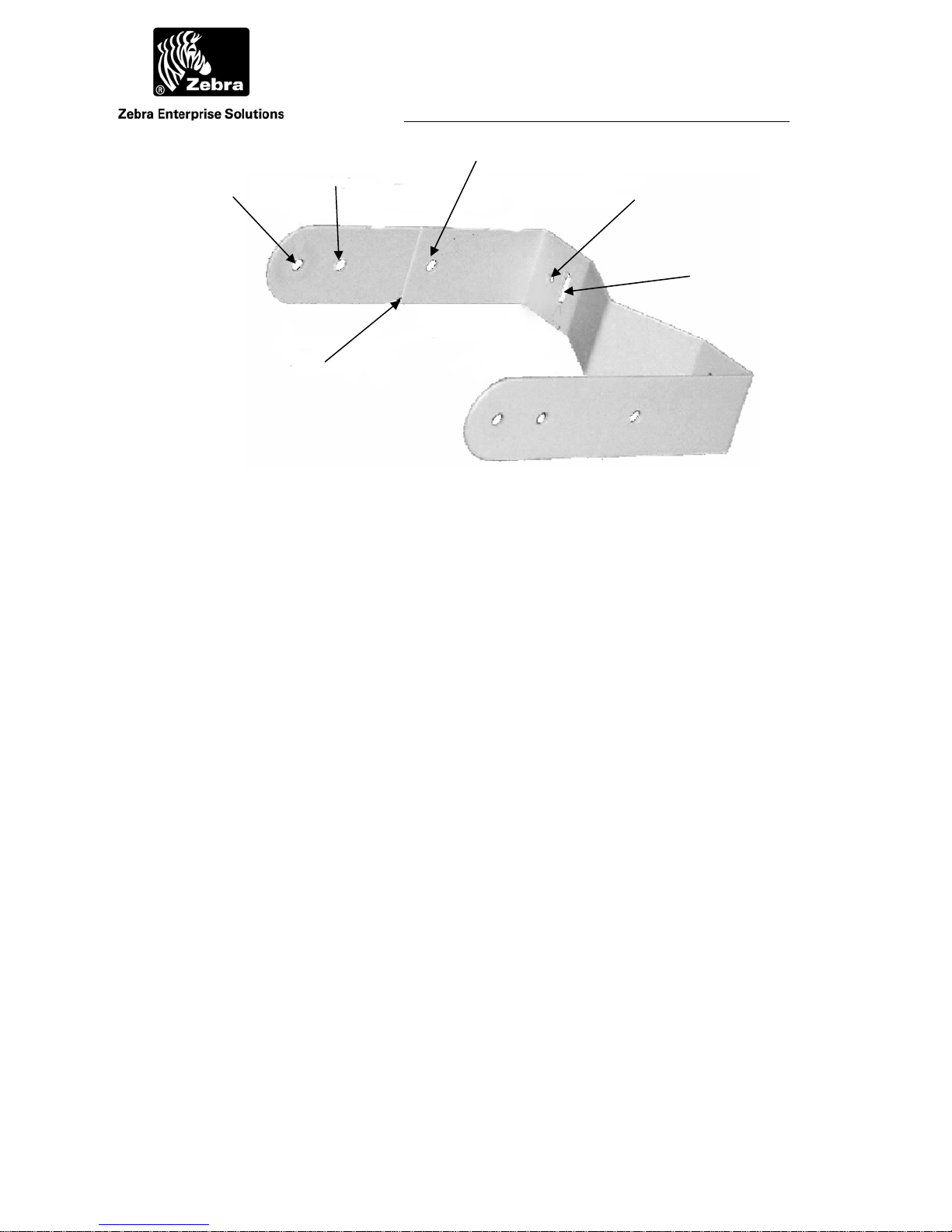

1.7 WherePort Mounting

The WherePort is mounted using a bracket (Figure 3). It can be mounted from the back,

the top, or the bottom. For details on installing the WherePort see the Installation

Instructions. A ruggedized mounting bracket is also available (Figure 4).

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 11

User Guide

Mounting Bracket

Figure 3 WherePort Mounting Bracket

Figure 4 Ruggedized Mounting Bracket

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 12

User Guide

2 THE WHERETAG

The WhereTag (Figure 5) is pinged by the WherePort and responds by transmitting a

data message to the RTLS. The WhereTag is a small device with a magnetic pick up coil

and a RF transmitter. It is mounted to movable assets such as trailers, vehicle assemblies,

or storage bins. It transmits a programmable blink signal. When operating without the

WherePort, the blink is received by at least three sensors which enable the system to

locate the tag accurately on the site.

The WherePort signal is received by a pick up coil in the WhereTag. In the

WhereTag III the coil is oriented along the length of the tag. In WhereTag II it is rotated

30º away from the length of the tag.

Coil Orientation

Figure 5 The WhereTag III and WhereTag III ST

The solid line shows the orientation of the pick up coil for both

WhereTags.

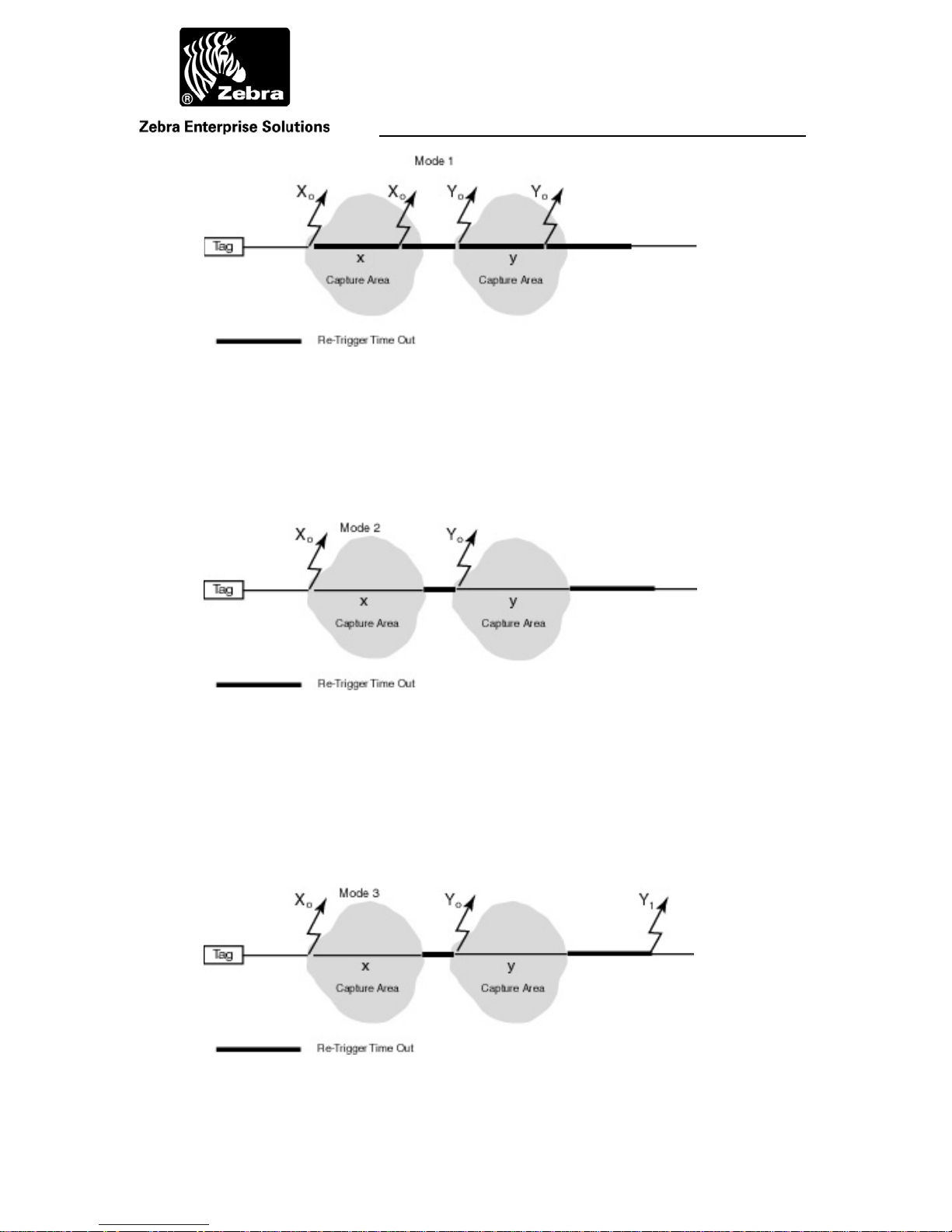

2.1 WhereTag Responses

The tag can be programmed to respond in a variety ways when it detects a WherePort

signal. There are three defined modes (see Figure 6).

Mode 1 The tag enters the field, blinks and then blinks again if it is still in

the field after the retrigger time out.

Mode 2 The tag enter the field, blinks and then does not blink again until it

leaves the field and the retrigger time out expires.

Mode 3 The tag enters the field, blinks and then blinks again after it has left

the field and the retrigger time out expires.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 13

User Guide

Figure 6 The WhereTag in a WherePort Capture Area

In mode 1, the re-trigger is set for a time interval after the WherePort blink. When this

interval elapses, the tag will transmit a blink if the tag is still in the same WherePort field.

Without the re-trigger interval being set, the tag will continue blinking in response to the

WherePort signal.

If the tag enters a new field, it will transmit a blink, even if the set interval has not

elapsed (see Figure 2).

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 14

User Guide

Figure 7 Retrigger Mode 1 and a New Capture Area

In mode 2 the tag must both leave the WherePort field and the specified interval

elapse before a WherePort blink will occur. If the tag enters a new WherePort field it will

immediately transmit a blink (Figure 2).

Figure 8 Retrigger Mode 2 and a New Capture Area

In mode 3, the set interval must elapse and the tag leave the field, and then the tag

will transmit a blink to indicate that it has left the field. If the tag enters a new field, the

tag transmits a blink when it enters the field. If the re-trigger time out is reached before a

new field is entered a blink is transmitted which indicates the tag is out of the field.

Figure 9 Retrigger Mode 3 and a New Capture Area

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 15

User Guide

2.2 Using the WherePort ID

The tag response can also be changed by the WherePort. Ports with ids from 0 to 255 are

used only when the alternate blink mode is required. These reserved ids are split evenly

between IDs (128 – 255) to mark the entrance of tag into the field and ids (0 - 127) to

mark the exit of a tag from the field. The significance of other tag IDs is shown in Table

3.

WherePorts can turn tags on and off as they enter and leave a site. As an example,

WhereTags can be permanently mounted to trailers. These trailers need to be tracked

while they are on the site, but not after they leave. There is no need for the tag to continue

to blink while it is off site. WherePorts positioned at entry and exit gates can turn the tags

on when the trailers enter the yard, and off when they leave.

Table 3 WherePort IDs

ID Range Tag Response

Standard WP

Response

0 - 127 Yes Exit Alternate Blink Mode

128 - 255 Yes Enter Alternate Blink Mode

256 - 32,767 Yes

32,768 - 65,534 Yes (ID - 32,768 reported)

65,535 Yes + Response is data register

Added Function

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 16

User Guide

3 MAGNETIC COMMUNICATION BASICS

The WherePort signal is carried by a magnetic field. The field’s shape and size is

determined by the orientation of the coil and the power level. It is not possible to aim the

field. One of the characteristics of a magnetic field is that it drops off rapidly. This

produces a well-defined, localized field. These characteristics make the WherePort an

excellent device for monitoring tagged assets

3.1 Magnetic Fields

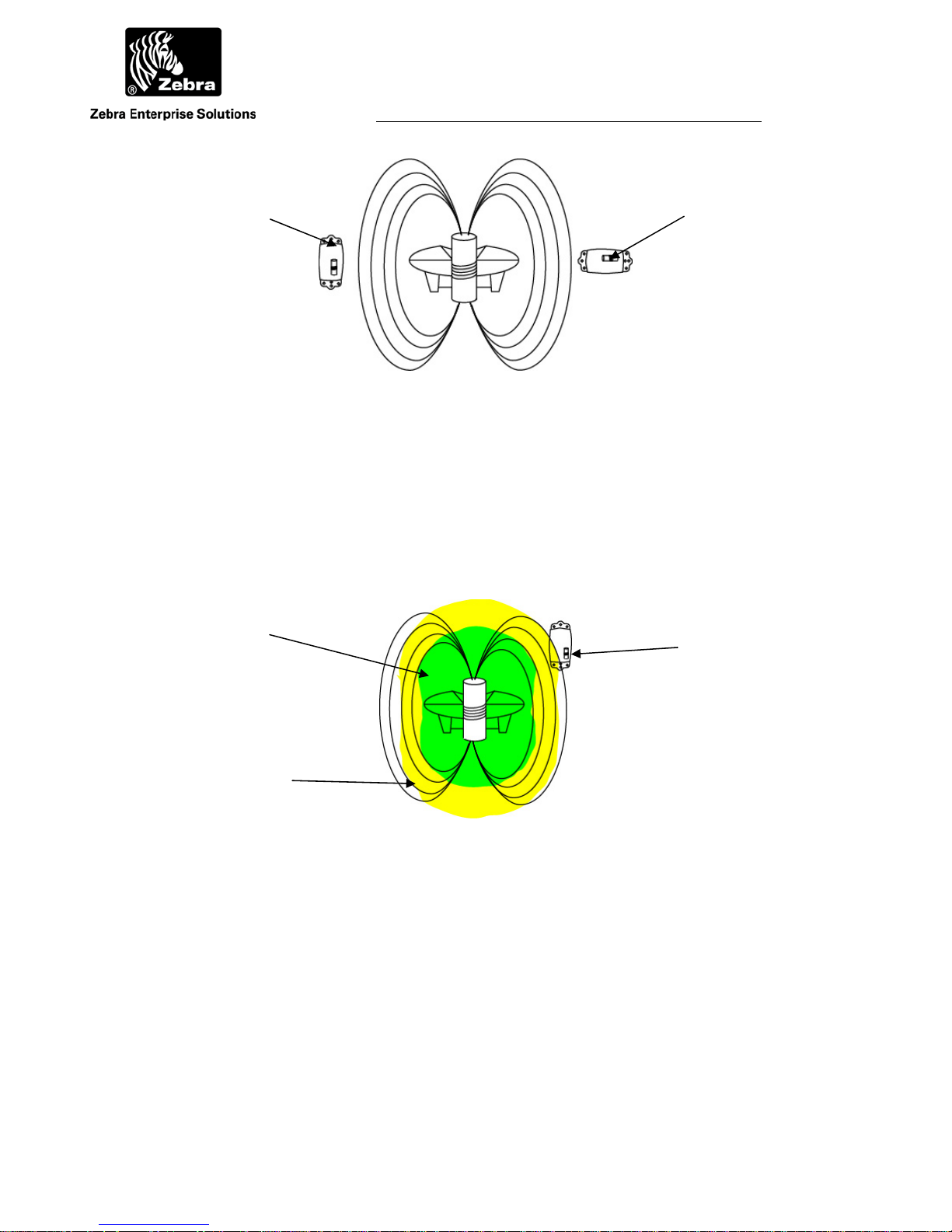

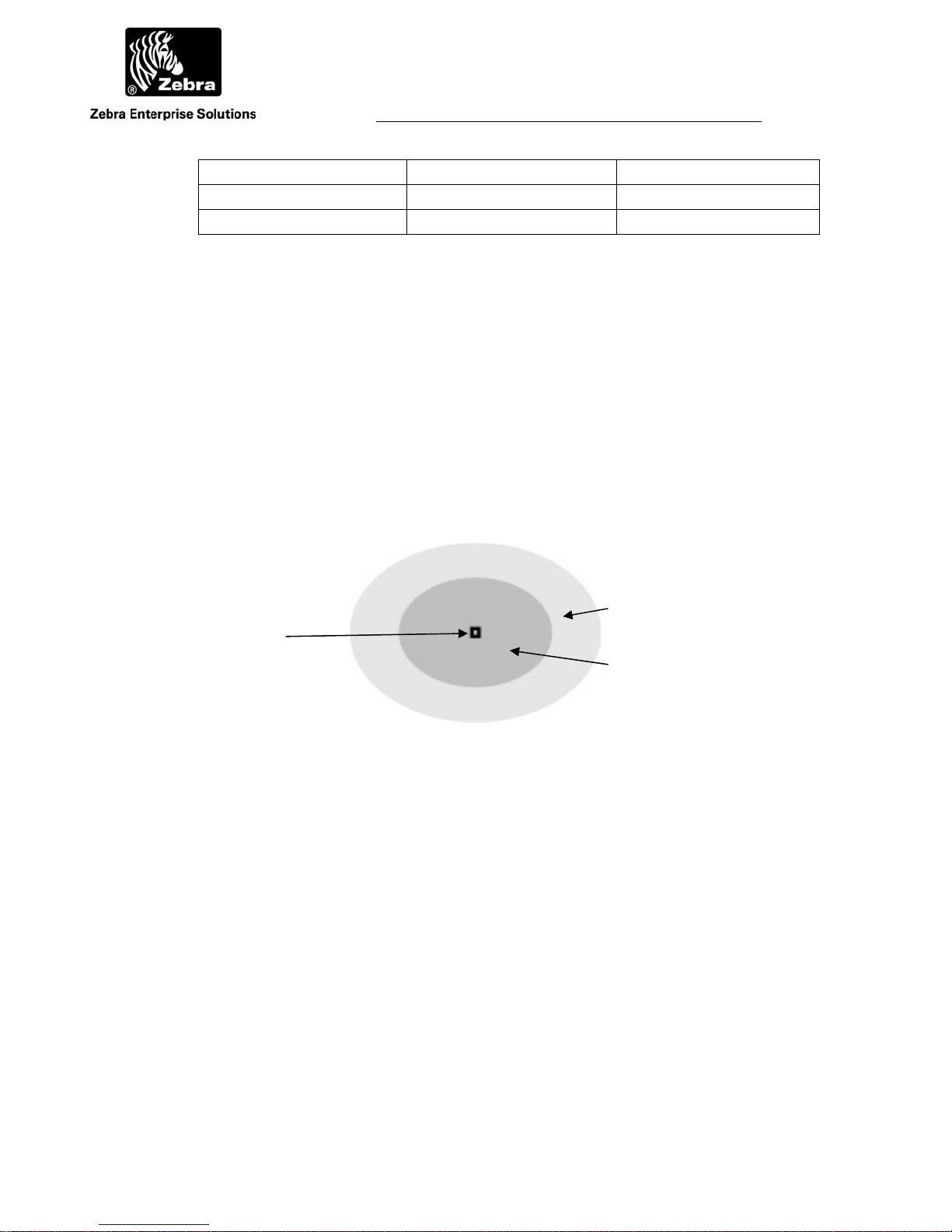

The magnetic field of the WherePort extends nearly equally in all directions creating an

elliptical field (Figure 10). The field has a direction that is determined by the position of

the coil that creates it.

Field Lines

WherePort Coil

Figure 10 WherePort Field

The field extends in all directions around the WherePort. The

direction of the field is suggested by the way the field lines are

drawn from the coil.

The field is detected and the signal received by a coil in the WhereTag. The orientation of

the WherePort’s coil in relation to the orientation of the tag’s coil affects its ability to

detect the signal. The optimum orientation is when the WherePort coil and the WhereTag

coil are parallel to each other. The worst orientation is when the coils are perpendicular to

each other. As the coils move from optimum to worst the ability of the Tag to detect the

WherePort signal decreases (Figure 11).

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

All other trademarks are the property of their respective owners. ZES Confidential

Page 17

User Guide

Parallel Coils

Perpendicular

Coils

Figure 11 Orientation

When the coil in the tag and the port are parallel the range is the

greatest. When the coils are perpendicular the range is the

shortest.

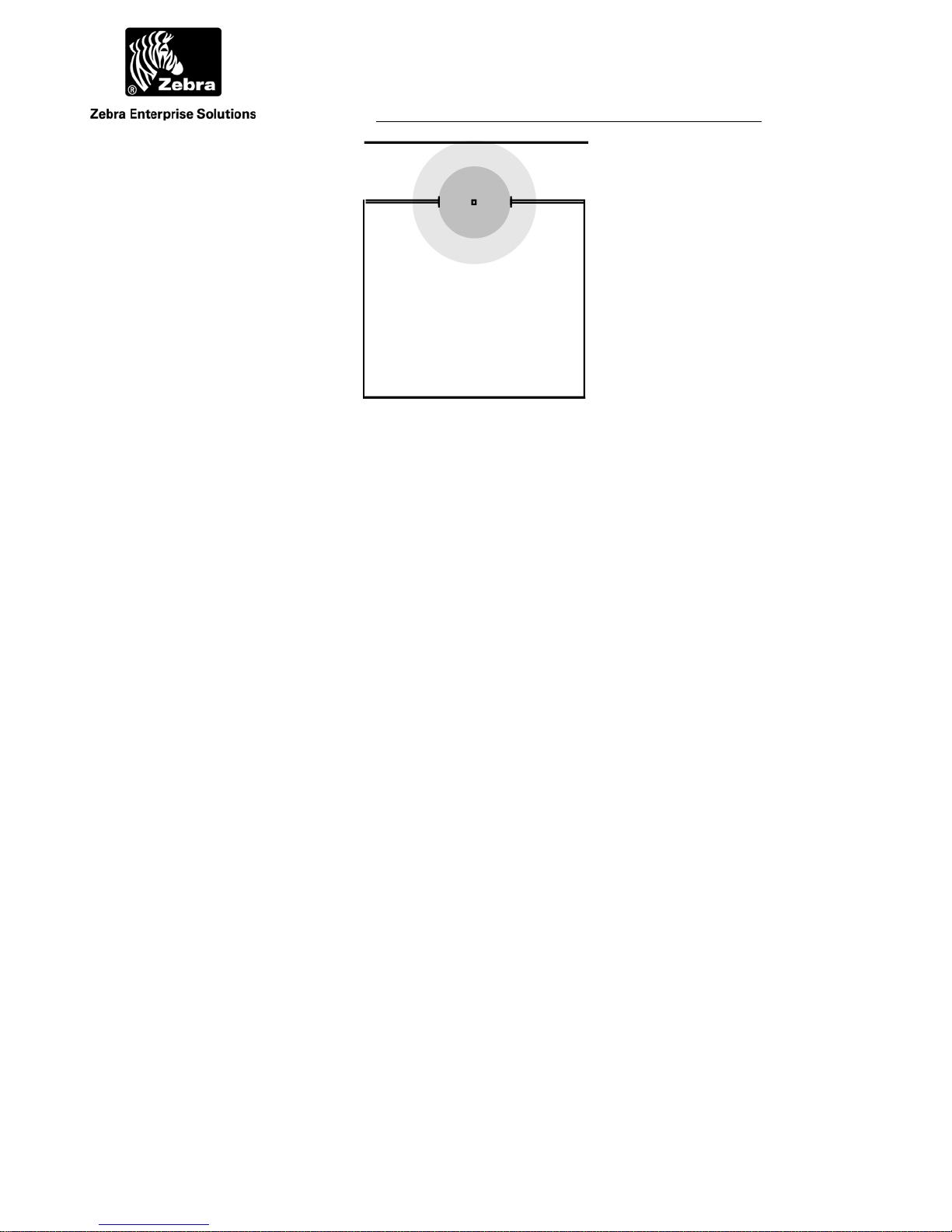

The relative positions of the two coils, WherePort transmitting and WhereTag receiving,

determine the range in which the tag will receive the signal. This range is the coverage

area, or guaranteed capture area (Figure 12). The guaranteed capture area is different for

each orientation of the tag and the power level of the WherePort.

Guaranteed

Capture Area

Tag Orientation 2

Uncertainty Area

Figure 12 Capture Area

The capture area is shown by the dark shaded area. This shape

varies with the orientation of the tag and the power level of the

WherePort. The lightly shaded area is the uncertainty area.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 18

User Guide

3.2 Coverage Areas

The size of the coverage area is significant as well as its location or placement. It is

important that the tag be released from a field when it is no longer in the area being

monitored by the WherePort.

There are three areas that are described for the field.

Guaranteed Capture All WhereTags at a given orientation will always be

pinged in this area.

Uncertainty A WhereTag may or may not be pinged in this area.

Guaranteed Release A WhereTag will never be pinged beyond this

range.

Since a tag may or may not be pinged in the uncertainty area, this area presents the most

challenge for a planner. If a single WherePort is installed, a tag that needs to be pinged

may not be and a tag that needs to be released may not be. These coverage areas must be

well understood to be able to set up a site. In the examples that follow these principles

will be translated into real applications.

A WhereTag moving through a WherePort field will typically change its orientation with

respect to the WherePort. As the orientation changes the effective range of the WherePort

will change.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 19

User Guide

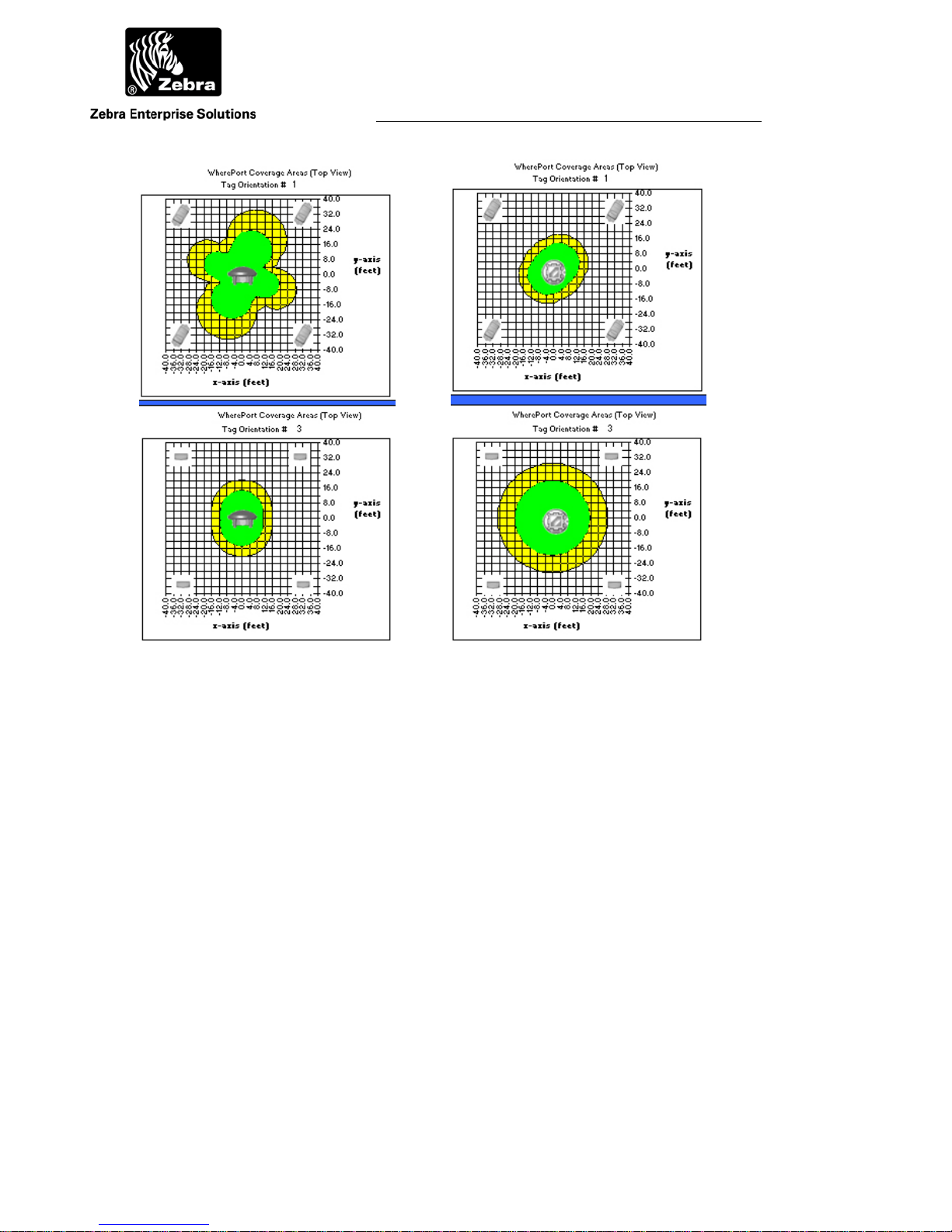

Figure 13 Orientation and Capture Area

Two maps are shown for two different WherePort mountings,

horizontal (left) and vertical (right). The two maps show two

different tag orientations for each of the mountings.

Figure 13 shows the effects of WherePort and Tag orientation on the guaranteed capture

area. These maps are taken from the Simulation software.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 20

User Guide

3.3 Power Level

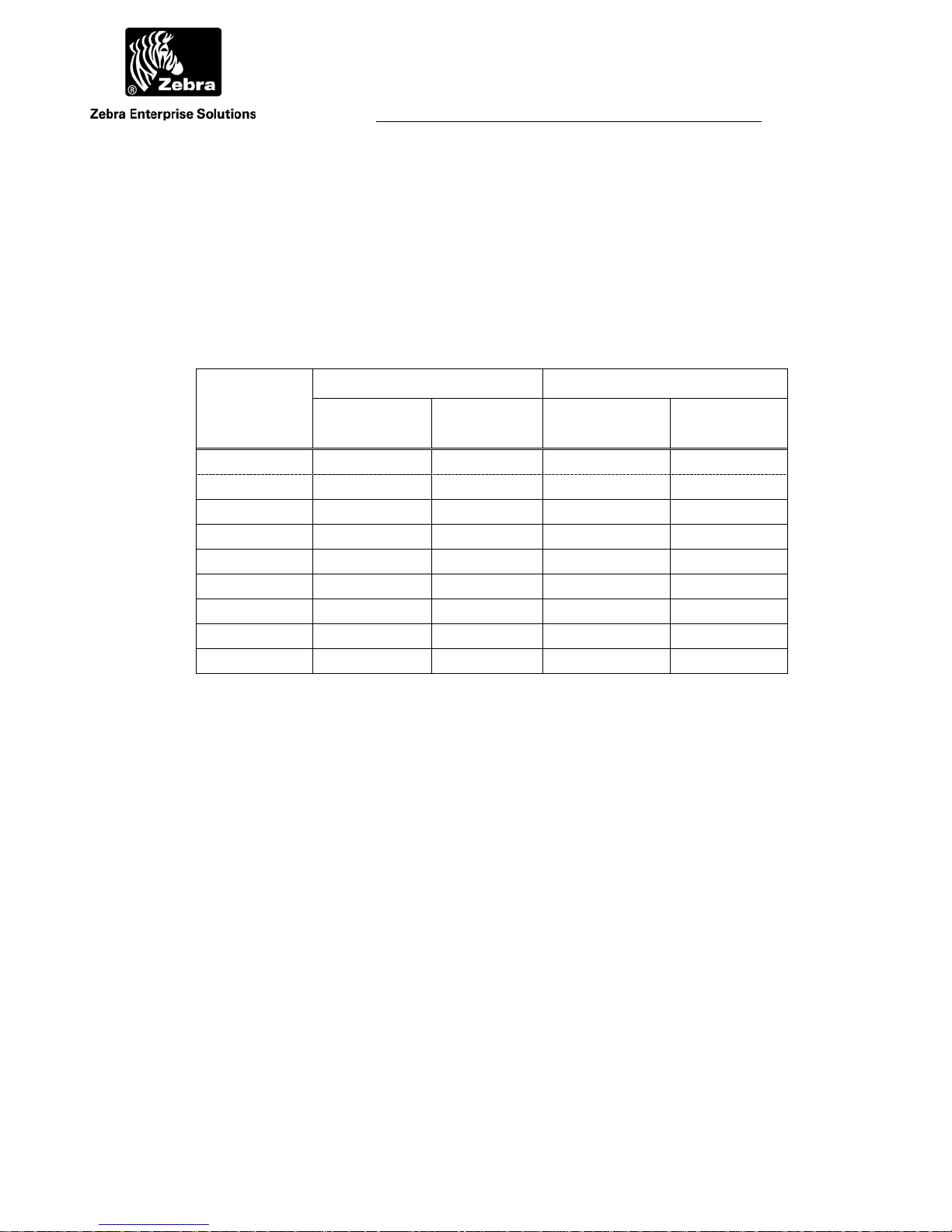

The size of the field is determined by the power setting for the WherePort. There are nine

power levels for the WherePort III. Setting the power level to 0 turns off the WherePort

magnetic field. Table 4 shows the approximate capture and release ranges for each of the

power levels when the tag’s orientation is random and when it is fixed as it moves

through the field.

Table 4 Power Levels, Random and Optimum Fixed Tag Orientations

Power Level Capture Range Release Range

Random Optimum

Fixed

0 Off Off Off Off

1 1.0 2.5 4.0 4.0

2 2.o 3.8 6.0 6.0

3 3.0 6 9.0 9.0

4 4.0 8 12.0 12.0

5 6.0 11 17.0 17.0

6 8.0 14 21.0 21.0

7 10.0 19 30.0 30.0

8 12.0 25 37.5 37.5

Random Optimum

Fixed

Random orientation means that the tag may take any of the possible positions relative to

the WherePort. Fixed tag orientation means that the motion of the object to which the tag

is attached will always present the tag in the same position relative to the WherePort. A

major difference between the random and the fixed orientation is the size of the

uncertainty area. It is significantly reduced when the tag has both a fixed and an optimum

orientation in the field.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 21

User Guide

Field Overlap

Figure 14 Overlapping Uncertainty Areas

Coverage Overlaps

When positioning WherePorts it is not always possible to prevent their fields from

overlapping. Overlapping the uncertainty areas of two WherePorts does not produce a

guaranteed capture area. It produces an area where a tag may be pinged by either one or

the other WherePorts or none.

When the fields of two WherePorts must be overlapped to cover a large area

(Figure 14) it is necessary to set the phases of the two WherePorts. Both WherePorts (or

more if more fields are overlapping) must also have the same ID number. If the phases

are not set, it may be impossible or difficult for a tag in the field to accurately report the

ID of the WherePort for the field it is in.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 22

User Guide

3.4 Phases

When two are more WherePorts are used to cover a large area they must be phased to

reduce the interference between the two fields. WherePorts mounted on the ceiling might

be set to 0º and on a wall 90º. Figure 15 shows the correct phase settings for four

orientations of the WherePort. The phases are set with reference to the orientation of the

master WherePort.

A WherePort set to 0º phase is defined as the master and all the other WherePorts

are then connected to it using the phase wire connections. Phased WherePorts must all

have the same ID.

90º

0º Master

180 º

270 º

Figure 15 Phase and WherePort Orientation

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 23

User Guide

3.5 Sequencing

WherePorts that have been connected electronically can also operate in the sequence

mode. Sequenced WherePorts do not transmit at the same time. The first WherePort

sends its message and then shuts off its field while the next WherePort in the sequence

sends its message. The number of times each WherePort sends its message is set using

the CMCn command. The number of WherePorts in the chain is set using the CMWn

command. See Figure 16 through Figure 18.

The master WherePort LED in a group of sequenced WherePorts is green when

active. The slave WherePort LEDs are yellow when they are active. The LEDs are all off

when the WherePorts are not active.

Inactive

Master WP #1

Active

Slave WP #2

Slave WP #3

Figure 16 Mode 1

One WherePort is active at a time. A master and two slaves are

shown. WhereWand WPSeq Count (or RS232 CMWn) = 2.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 24

Master WP #1

Slave WP #2

Slave WP #3

User Guide

Slave WP #4

Figure 17 Mode 2

Master WP #1

Slave WP #2

Figure 18 Mode 3

More than one WherePort may be active at a time. A master and

three slaves are shown. One and three are active while 2 and 4

are inactive. WhereWand WPSeq Count (or RS232 CMWn) = 1.

All WherePorts may be off part of the time. A master and one

slave are shown. One is active, then two, then both are inactive.

WhereWand WPSeq Count (or RS232 CMWn) = 2 or higher.

With sequencing, WherePorts that might have conflicting fields if they were on at the

same time, can be placed to indicate position or transitions. An example is narrow

parking lanes in a warehouse facility.

3.6 Dual WherePorts

The dual WherePort is a bracket with two WherePorts mounted to it, oriented 90º from

each other (Figure 19). They ensure a guaranteed capture range and eliminate the need

for multiple mounting sites. Typically the dual WherePort is used when the orientation of

the tag can not be fixed. They also simplify placement in locations that are larger than the

guaranteed capture range of a single WherePort (see Figure 20). Dual WherePorts are

always phased with one set as the master at 0º and the other at 90º.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 25

User Guide

Figure 19 Dual Where Port

A

B

C

Figure 20 Coverage Pattern

A single (A), adjacent (B), and dual WherePort (C) field are

shown. The fields shown are for WherePorts at power level 8

and mounted at the same height as the WhereTag.

3.7 Interference

Steel objects and some devices can interfere with the WherePort field and change its

shape and range.

Some kinds of structures will affect the range of the WherePort. Mounting the

WherePort on the broad face of a steel I-beam reduces the coverage on the front and back

of the WherePort.

The field can also be extended or ducted by steel in windows, metal studs,

conduit, or duct work. This is most likely to occur when the WherePort is within one to

two feet of the steel and the tag is also close to the steel. This could lead to an unwanted

increase in the size of the field.

Magnetic interference can block communication between the WherePort and the

tag. The most common sources of magnetic interference are CRT monitors, electric

motors, vehicle RFID anti-theft ignition systems, and other WherePorts. A WherePort

may not ping a tag that is within one to two feet of an operational monitor or industrial

motor. The field strength meter can be used to check for interference.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 26

User Guide

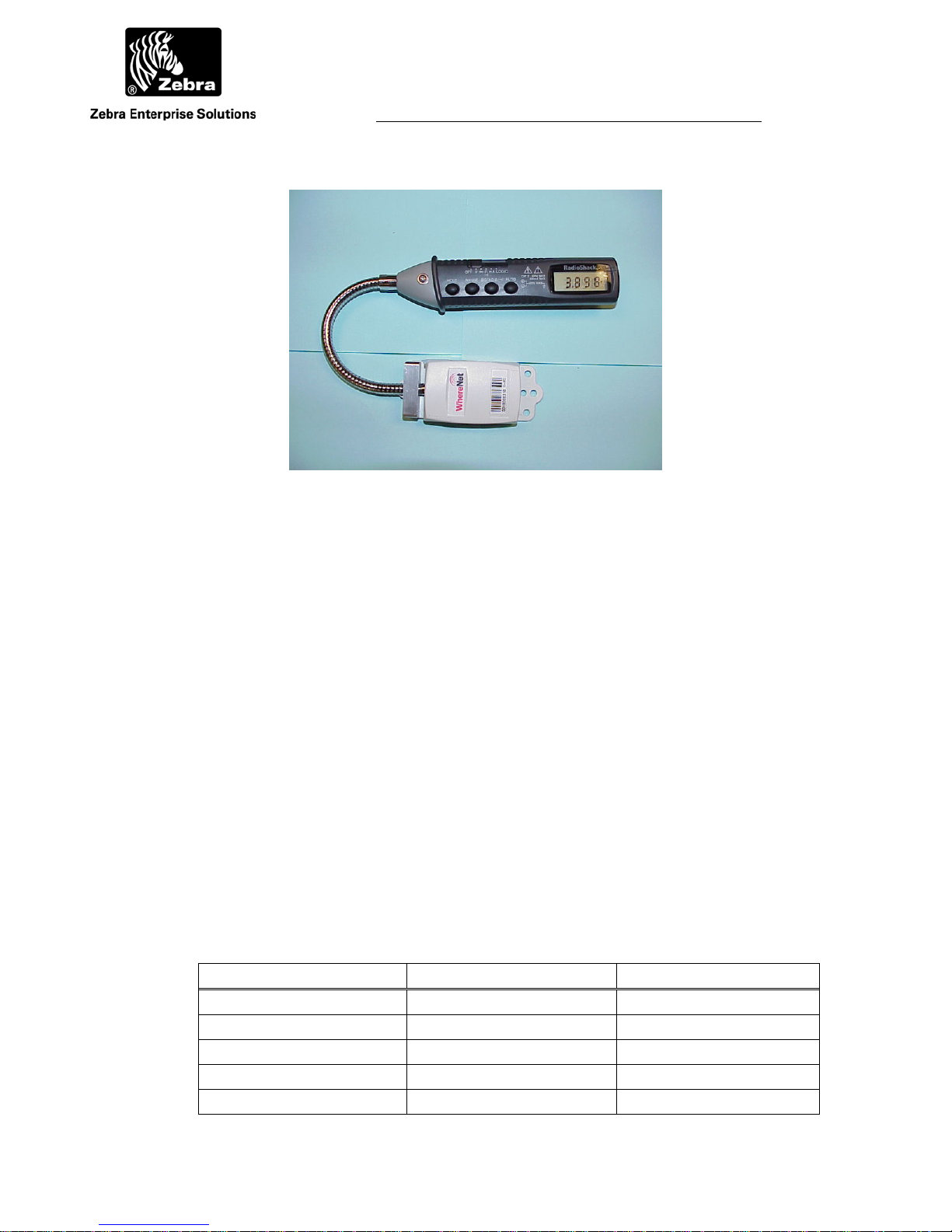

Figure 21 Magnetic Field Meter

3.8 The Field Meter

The field meter is a WhereTag connected to a voltage meter so that it can detect and

display the strength of the WherePort field (Figure 21). By walking around an installed

WherePort the strength of the signal throughout the area to be monitored can be

measured. The tag can be positioned to match its mounting position on the tracked asset.

Experimenting with the field meter can help to clarify the coverage area of the

WherePort.

After the installation of WherePorts at a facility, the field meter is used to test that

the field coverage is as it was planned to be. If gaps or problems with the coverage are

found they can be corrected before the facility is put into operation. See the Magnetic

Field Meter User’s Guide (P/N D0755).

3.9 The WherePort LED

On the top of the WherePort is an LED that indicates the status of the WherePort (see

Table 5).

Table 5 LED Status Indicator

Condition WherePorts LED Status

Power up reset All Red

Power = 0 All Red

Phased Master Green

Phased Slave Yellow

Sequenced Master, field on Green

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 27

User Guide

Sequenced Master, field off No color

Sequenced Slave, field on Yello

Sequenced Slave, field off No color

3.10 Capture Area Simulator

The capture area simulator calculates and maps the capture area for several different

WherePort and WhereTag orientations. The simulator is described in Chapter 6.

4 WHEREPORT IN THE FIELD

The basic principles of the WherePort must be translated into applications in the field.

Doors, corridors, rooms, parking lots do not necessarily conform to the requirements of

the WherePort field. In this chapter several common situations are discussed in order to

illustrate how the characteristics of the WherePort affect their positioning on a site.

Uncertainty Coverage

WherePort

Guaranteed Coverage

Figure 22 WherePort Coverage

In the applications that follow the WherePort field will be illustrated as shown in Figure

22. The illustration shows only two dimensions of what is always a three dimensional

field. The field can be imagined as a series of waves that are further apart as they move

out from the coil. The overall shape is like an ellipsoid, an egg shaped object, extending

out in all directions from the WherePort.

In the examples that follow, the WherePort field is described. It must be

remembered that the capture area is what is important. The field is shown to simplify the

presentation.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks. All othe

Page 28

User Guide

A

4.1 Zones

In some applications it is not necessary to be able to determine the precise position of an

asset. All that is needed is to know when the asset is in one or more key zones of the

facility. Fewer antennas are required to define zones.

While accuracy may not be essential, reliability will be. By placing one or more

WherePorts in a zone, the system can reliably determine that a tag asset has entered and

is still in a zone.

4.2 Area Coverage

There may, however, be many areas where different activities occur that must be

monitored. Well positioned WherePorts can define these areas of interest by pinging

tagged assets as they enter them. Examples are assembly stations in a factory, loading

docks, or different types of rooms in a hospital. One or more WherePorts mounted at the

station will ping a tag whenever the tag enters the area. If more than one port is placed in

a large area, they must all have the same ID.

The WherePort can be particularly important if the structure of the facility

obstructs the line of sight visibility to location sensors or location antennas. The garages

in a repair facility may have metal walls. Multiple sensors, likely four, would need to be

mounted around the bay to guarantee a signal that locates a vehicle in the bay.

When more areas are to be monitored, more issues must be considered in planning

the location of the WherePorts.

• What will the orientation of the tag be as it moves through the area?

• Will tags be pinged while they are moving past but not through the area?

• Are there sources of interference that may restrict the capture area?

• Will WherePorts be close enough to each other that their fields may

overlap?

4.3 Portals

An additional complexity may arise if the best way to monitor assets is to detect when an

asset enters or leaves the area through a door, gate, or similar portal. WherePorts

mounted at the portals of these areas will ping a tag, indicating that the tagged asset has

passed through and is not in the area.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 29

User Guide

A

Corridor

Functional Area

Figure 23 WherePort in a Doorway

To enter the room, an object must pass through the guaranteed

capture range of the WherePort.

The placement of a WherePort in the doorway might seem simple. Figure 23 shows this

installation. Any tagged asset passing through the doorway must pass through the

guaranteed capture range. However, an object passing down the corridor would also be

pinged by the WherePort. If the WherePort is mounted to the top of the doorway, it

might be below a space on the floor above that is part of the application as well. The

WherePort field might extend far enough into the second floor to ping a WhereTag

moving through a completely separate part of the facility.

The WherePort may need to be mounted inside the room to prevent pinging traffic

along the corridor. Its power level may need to reduced so that the range does not extend

beyond the actual portal. The placement of the tag on the asset may need to be adjusted,

perhaps by placing it closer to top of a vehicle, so that only the portal WherePort will

ping it.

When an area is monitored using portals, all portals must be covered. If a path

into the area is not covered by a WherePort, tagged assets may enter or leave through the

uncovered path.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 30

User Guide

A

Figure 24 Loading Dock Doors

Spacing of loading dock doors makes it impossible to assign

unique WherePort IDs to each of the doors.

If, instead of a single door, a series of doors (for example on a loading dock) or bays are

too close together, the fields may overlap so that it is not possible to assign a unique

WherePort ID to each of the doors. Even if the doors are far enough apart so that the

fields do not overlap, the fields may cover so much of the adjacent area that false pings

are created by tags that are passing by and not arriving at the doors (see Figure 24).

Some of these issues might be solved by sequencing the WherePorts, which will

be covered later in this chapter.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 31

User Guide

A

Figure 25 Multi-Floor Schematic

Shows a floor configuration so that the WherePort field extends

into the second floor.

Drop Ceiling

Floor 2

Utility Space

Drop Ceiling

Floor 1

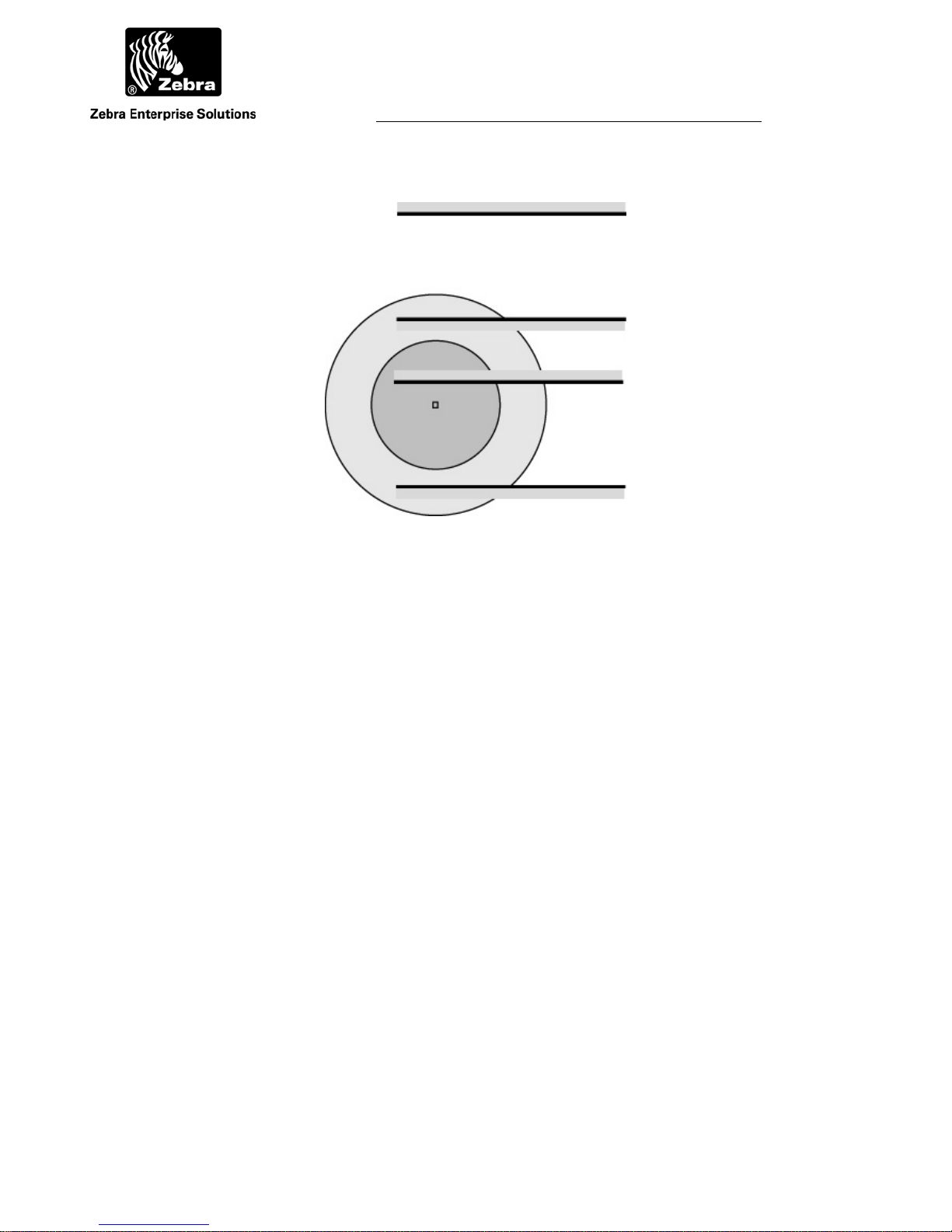

4.4 Multi-Floor Installations

When activities are tracked on several floors, the vertical position of the WherePort and

the extent of its field must be carefully considered. If the field extends into the floor

above, a tag moving on the upper floor may be activated by the WherePort on the lower

floor. This will produce an incorrect location for the tag.

The height of the floor together with the utility space between floors must be

considered so that the WherePort is mounted at a height that prevents tags on the floor

above from being activated (Figure 25).

The WherePort power setting can be set so that the range is reduced. The tags

may also be mounted lower on the asset to permit lower placement of the WherePort.

4.5 Locked WherePorts

There may be areas on a site where once a tagged asset has entered it should not be

located using RTLS. Movement along an assembly line may be more accurately tracked

using only the WherePort signals. Where room coverage is needed the RTLS algorithm

could indicate that a tag is outside a room when it is not.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 32

User Guide

A

WherePorts are defined as locked using the software of the SystemBuilder. No

setting in the WherePort is needed. After a tag pings that it has detected a locked

WherePort the tag will be ignored until it is unlocked. It is unlocked by detecting an

unlocked WherePort.

Tag movement must be clearly understood to make sure that a tag that enters a

locked WherePort field will also enter an unlocked WherePort field. If a tag is

inadvertently locked by a WherePort it will be ignored by the system until it enters the

field of an unlocked WherePort.

Typically locked WherePorts are used to track tags into a relatively small and

confined space. While tags are in this space they will be ignored. Upon leaving the space

they will pass an unlocked WherePort and from then on be tracked normally.

4.6 Multiple WherePorts

Some locations require more than one WherePort to insure adequate coverage. Examples

include a large parking lot, a long corridor, a large number of loading dock doors, or a

large doorway.

If a space is large enough, separate WherePorts with separate IDs may be used.

Problems arise with areas that must be monitored uniquely that are larger than the

coverage area of single WherePort. In this case the possible mounting options must be

considered.

The placement of WherePorts with overlapping coverage requires attention to a

number of issues. The first is phasing. Whenever the coverage fields of two or more

WherePorts overlap, the phases of the WherePorts must be set. When WherePorts are

phased, one is always designated as the master with its phase set to 0 (see Figure 26) and

all phased WherePorts must be set to the same ID.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 33

User Guide

A

180 º

Figure 26 Phasing for Wall Mounted WherePorts

Viewed from the top.

0º Master

Figure 26 shows a corridor or large space with WherePorts mounted on the different

walls to effectively cover the entire area. This means that the phase of each WherePort

must be set as indicated.

90 º

0º Master

180 º

Figure 27 Phasing for Ceiling and Wall WherePorts

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 34

User Guide

A

A large doorway may require three WherePorts to reliably detect the passage of a tagged

asset through it. In the example shown in Figure 27 coverage requires a WherePort on

each side of the doorway and on the ceiling. Again each WherePort must be phased

accordingly.

0 º

0 º

180 º

Figure 28 Loading Dock Door Options

Viewed from the side.

Loading dock doors are frequently too close together for each of them to be monitored by

a different WherePort. If unique identification of passage through a given door is

required, a more complex solution will be required.

Figure 28 and Figure 29 show two ways of solving the problem. The example in

Figure 28 uses a WherePort to cover two doors. Since these WherePorts are mounted in

different orientation on the walls, their phases must be set as well. Figure 29 shows a

WherePort mounted above each door. The phases for these ports can all be set to 0 but

they must still be phased together with one of the ports identified as the master.

The orientation of the tags will also affect the location of the WherePorts. If the

tag orientation is horizontal, then the top solution is best so that the WherePort field will

be maximized. If the tags are oriented vertically, then the lower solution, with the

WherePorts mounted over the doors, will be best.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 35

User Guide

A

Figure 29 Over the Door WherePort Mounting

The dotted line ellipse shows the approximate shape of the

coverage area if the tag is oriented horizontally rather than

vertically.

1

2

3

4

Figure 30 Sequenced WherePorts on Parking Lanes

4.7 Sequenced WherePorts

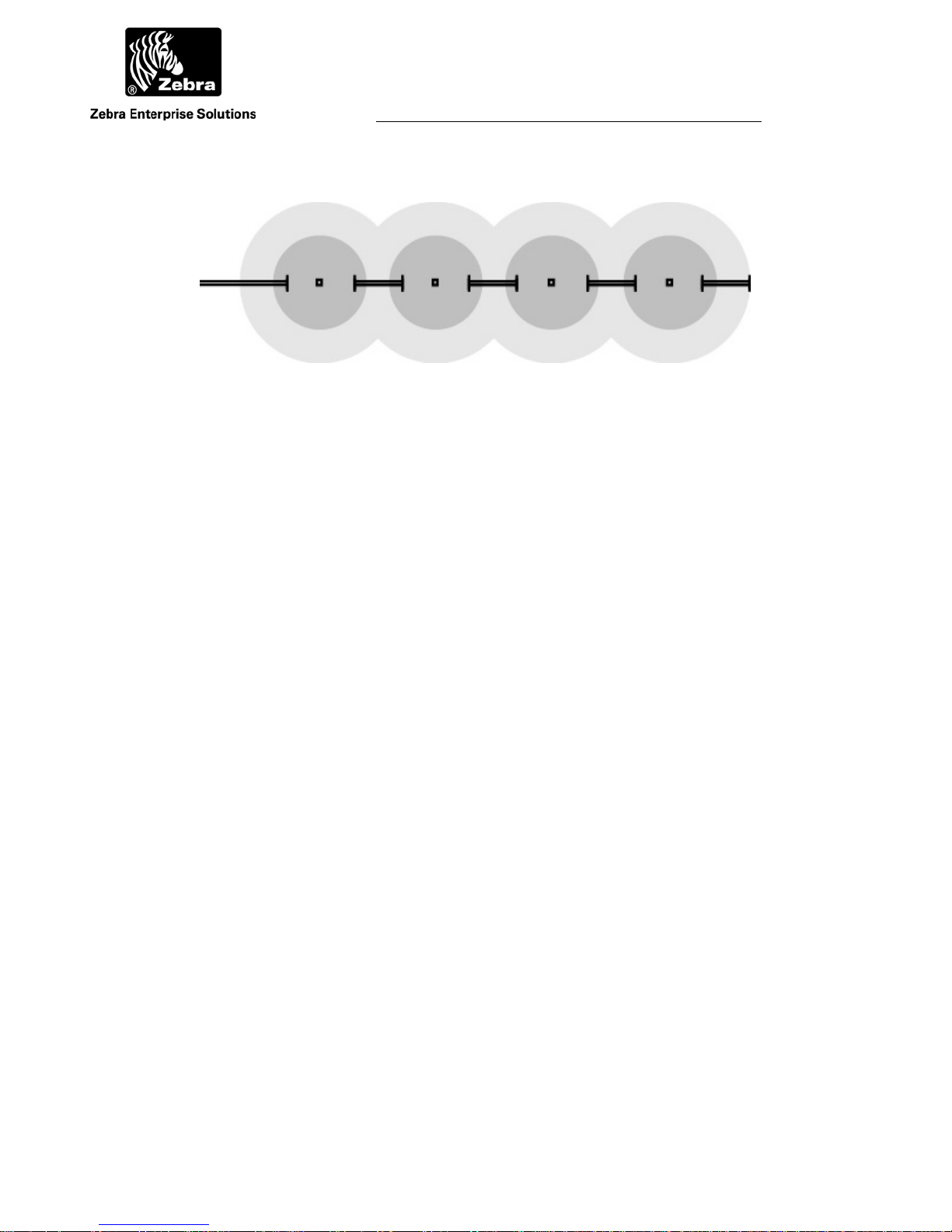

Figure 30 shows the use of sequenced WherePorts to accurately identify which lane a

vehicle has entered. Sequenced WherePorts are turned on and off. WherePorts 1 and 3 are

on while 2 and 4 are off and then 2 and 4 are on while 1 and 3 are off. If a tag is pinged

by 1 and 2 it is in lane 1. If it is pinged by 3 and 2 it is in lane 2.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 36

User Guide

A

4.8 Summary

Each application will present a unique combination of the principles demonstrated by the

examples in this chapter and thus require different configurations to create a successful

application. In the next chapter, guidelines for planning and designing an application will

be discussed.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 37

Page 38

User Guide

A

5 WORKING THROUGH AN APPLICA TION

To effectively place WherePorts the site and the required information from the site must

be carefully studied. In this chapter a simple site will be presented and issues about

WherePort placement will be discussed and mounting locations for WherePorts found.

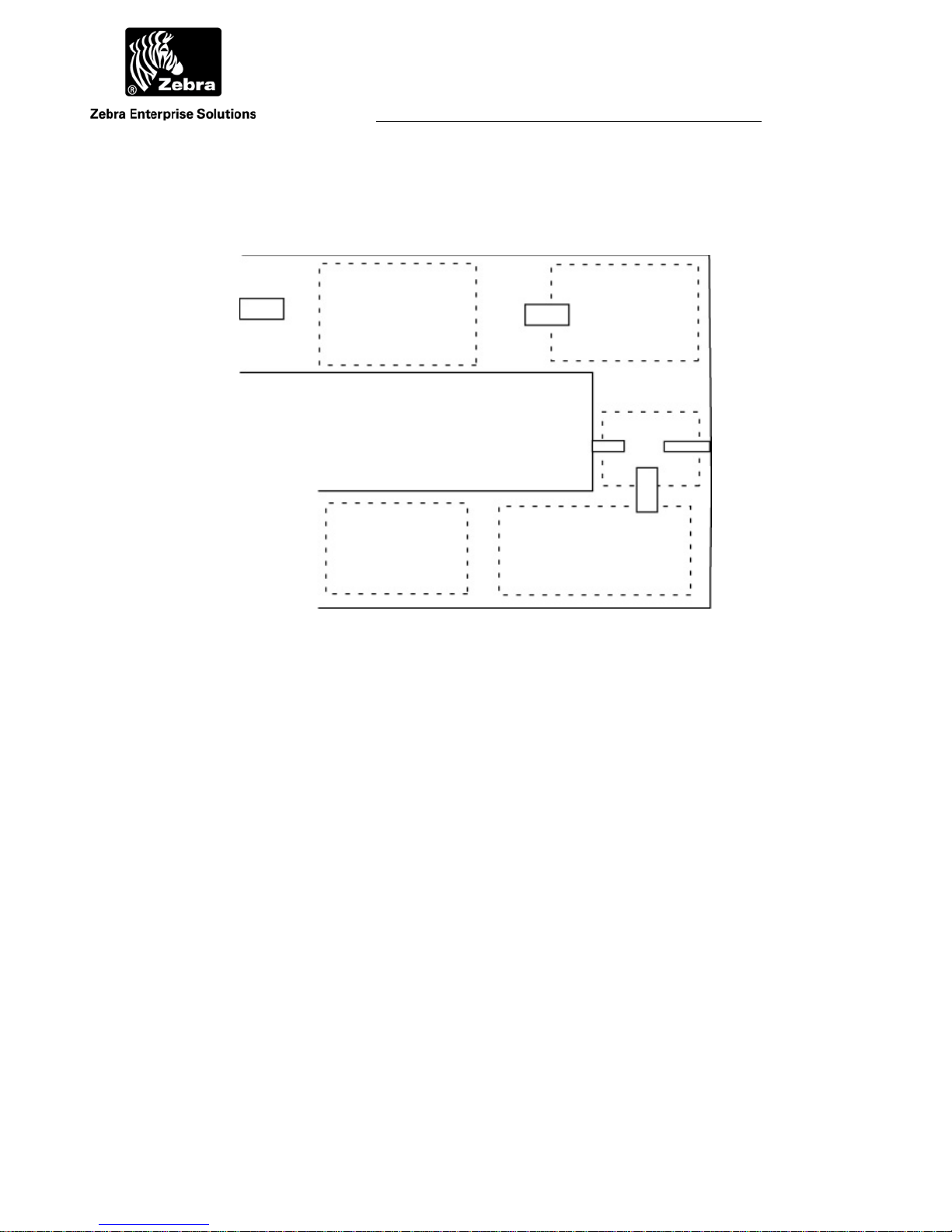

Figure 31 The Warehouse Site

5.1 Warehouse and Shipping Facility

Events or positions that need to be monitored in some way.

What must be tracked.

Trailers entering the yard

Trailers at the loading dock

Trailers in the waiting, parking area

Trailers leaving the yard

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 39

User Guide

A

Issues affecting the placement of the WherePort.

Are there any obstacles or structures that will affect the field?

Where will the WhereTags be mounted?

Will their orientation be controlled while they are in a WherePort field?

The first and most important step in creating a successful WherePort application is to

define what information must be obtained from the WherePort. Is the passage of an asset

past a particular point important?

How does the use of WherePorts fit with the RTLS? Is it impossible to mount enough

sensors or do physical barriers make it impossible to get reliable location signals? Is the

RTLS unable to accurately track when an asset has reached a precise location? Both

aspects of the installation must be considered to make sure that the most accurate and

reliable information that is critical to operation is obtained.

Within a large area covered by RTLS more precise information about the location

of an asset may be needed. This can be done by installing a WherePort at this location.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 40

User Guide

A

Figure 32 WherePorts Mounted on the Site

5.2 Positioning the WherePorts

What will the tags be mounted to and how will the objects move? Will the tag maintain

its orientation as it moves through the site or will it move? Will it move only in the

horizontal dimension or will it be set up on end and changed vertically as it moves? Will

the tag be mounted close to the floor or some distance above it? How much flexibility

will there be in the mounting of the tag? The orientation of the tag with respect to the

WherePort is one of the most important determinants of the coverage field.

What kinds of interference are on the site?

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 41

User Guide

A

identifying where on the site this information must be gathered, and determining

Creating a map of the site.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 42

User Guide

©

s

6 USING THE SIMULATOR

The WherePort simulator (ZES p/n D0910) is a tool for exploring the best solutions for

WherePort placement and for better understanding the basic characteristics of WherePort

communication.

Because of the number of variables that affect the response of the tag to the

WherePort field, it is helpful to examine the response using the simulator. The number

and placement of WherePorts, the orientation of the tag while it is in the field, and the

distance of the WherePort from the tag all interact to determine this response.

6.1 Simulator Controls and Features

Figure 33 Starting the WherePort Simulator

Figure 33 shows the starting screen of the simulator. There are seven options for

WherePort placement:

Single WherePort Mounted vertically

Single WherePort Mounted horizontally

Dual WherePort Mounted horizontally

Dual WherePort Mounted Vertically

WherePort III User Guide

2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademark

All other trademarks are the property of their respective owners.

D948 Rev B

Page 43

User Guide

A

Two Adjacent WherePorts Mounted vertically, facing sideways

Two Adjacent WherePorts Mounted vertically, facing forward

Two Adjacent WherePorts Mounted horizontally

The magnetic field extends in all directions from the WherePort. Its position does,

however, affect the direction of the field and therefore its relation to the position of the

tag. It is the direction of the field that is important when reviewing the different

orientations of the WherePort.

Figure 34 Configuration Screen

6.2 WherePort Configuration

The WherePort position to be simulated is configured on the WherePort configuration

screen (Figure 34). There are two parameters that must be set:

Power Level Select a power lever from 1 to 8. The highest power

Tag to WherePort Height (feet) The relationship between the height of the

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

level is 8.

WherePort position and the WhereTag position (0 to

20 feet).

Page 44

User Guide

A

Figure 35 Tag Orientations for the Graphs

The graphs are calculated based on the tags maintaining the

same orientation while it moves. Its orientation to the field will

therefore change.

For each WherePort position, graphs are drawn for six different WhereTag orientations.

These orientations and the number designations of each are shown in Figure 35 The tag

orientation is with reference to the position of the WherePort.

There are also options for controlling the presentations of the graphs. The scale sets the

dimensions of the graph. A five foot scale displays the capture area for five feet in each

direction. A sample graph is shown in Figure 36.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 45

User Guide

A

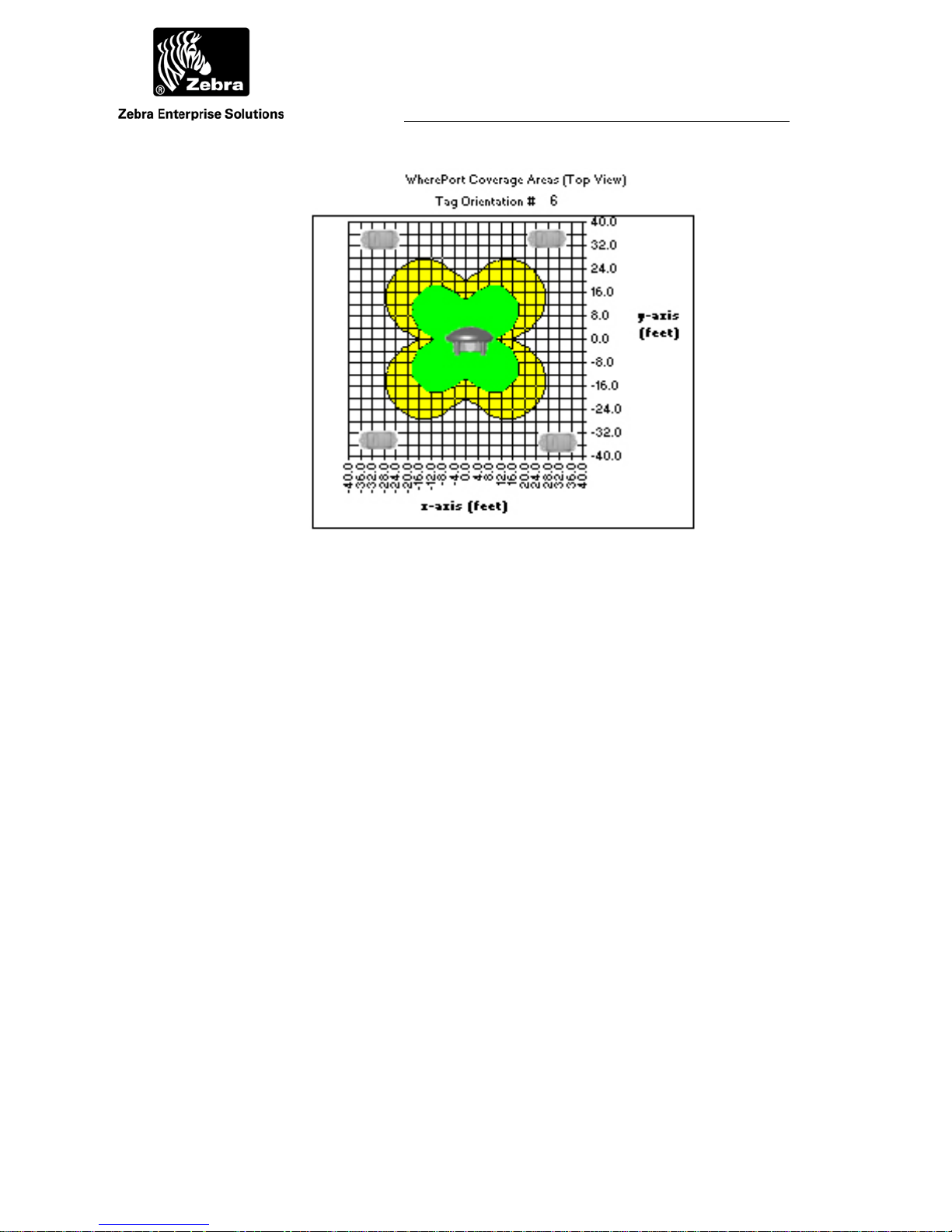

Figure 36 Sample Graph

The graph shows the guaranteed capture area in green and the

uncertainty area in yellow for a single WherePort, mounted

horizontally, with a power level of 4, and a tag to WherePort

height of 4 feet for a tag with orientation 2. The scale is 10.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 46

User Guide

A

Figure 37 Sample Graph

Shows the same configuration as Figure 4 except the tag is in

the 6 orientation.

6.3 Sample Graphs

The importance and usefulness of the simulator can be shown by looking at two graphs

showing two different tag orientations while all other options are identical. Figure 36,

with orientation 2, shows a guaranteed capture area that is approximately ten feet long

and four feet wide. Figure 37, with orientation 6, has four very small guaranteed capture

areas that are not contiguous. These settings would likely not be effective for any

application.

Figure 38 and Figure 39 use the same settings as Figure 36 and Figure 37 except

the power setting is 8 instead of 4.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 47

User Guide

A

Figure 38 Power Level Comparison Tag Orientation 2

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 48

User Guide

A

Figure 39 Power Level Comparison Tag Orientation 6

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 49

User Guide

A

Figure 40 Adjacent WherePort Configuration

6.4 Adjacent WherePorts

Adjacent WherePorts require that some additional variables be set:

Power Level Select a power lever from 1 to 8. The highest power

level is 8.

Tag to WherePort Height Set from 0 to 20 feet.

Distance between WherePorts (feet) 0 to 50 feet in five foot increments.

Are the WherePorts Synchronized Yes or no (wired together).

WherePort #1 Phase 0, 90, 180, or 270.

WherePort #2 Phase 0, 90, 180, or 270.

WherePort III User Guide D948 Rev B

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 50

User Guide

A

7 COMMAND SUMMARY

This section describes the commands used to configure the WherePort.

All commands and responses are ASCII character strings.

ACK responses are the three character string ‘ACK’ and not the 0x06 nonprintable character. Similarly, NAK responses are the three character string ‘NAK’ and

not the 0x15 non-printable character.

All numbers (represented by ‘n’ in command list) sent are the ASCII

representation of the value. For example, the number 14 is sent as the two ASCII

character string ‘14’ and not the single byte 0x0E. The number 7 is sent as the single

ASCII character ‘7’ and not the single byte 0x07.

7.1 Initial Power Up

When theWherePort is initially powered up, it will transmit the following string.

{CR}{LF}

WhereNet{CR}{LF}

WherePort vx.xx <CR><LF> (where x.xx is the firmware version)

7.2 Passwords

Every command must start with a four character password followed by a colon. For

example, if the passwore is 1234 the query command would be entered as follows:

1234:VER?<CR><LF>

The WherePort will respond with NAK to any command that does not start with the

correct password.

The WherePort ignores space characters, carriage return characters, and the line feed

character because it signals the end of a command. These three characters (0x0D, 0x0A,

0x20) may not be used in passwords. All other byte values are legal.

The password is set to the default value of 1234. The only command that does not require

the password is the HWT n command. The HWT n command sets and queries the

password. To access the password, the host must send the following three commands in

order. Any other command, or any change to the sequence will reset the access flags. The

sequence of commands is:

HWT 3 Set flag 1 of 3 only if all 3 flags are cleared.

HWT 4

HWT 5

HWT 6

Set flag 2 of 3 only if flag 1 is set and 2 and 3 are clear.

Set flag 3 of 3 only if flags 1 and 2 are set and 3 is clear.

Set password to 1234 only if all 3 access flags are set.

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 51

User Guide

A

The password can be set using the ****:XPW **** command. Changes to the password

will take effect immediately. The changes affect only the current session unless the host

sends the WherePort an execute command (****:EXE). Only after receiving an execute

command will the new password be written into flash memory and read on power up.

Without the execute command, the password will return to its previous value if the

WherePort is powered down.

7.3 Command Execution

The following commands require the execute command (****:EXE) before they will be

saved in flash memory and sent to the magnetic field generator:

MSG, PWR, PHS, WID, TID, RSP, CNT, INT, TRG, DAT, CMW, CMC, XPW

A query command will return the newly entered values, even though the execute

command has not been sent. The WherePort will not be operating under these values until

the execute command is sent.

7.4 Tag Responses to Commands

Unless noted otherwise, all commands will produce one of the following responses by the

WhereTag

ACK message OK

NAK message not recognized or bad format

NAK2 message parameter out of range

There are two other possible acknowledgments that are used primarily by data

commands. Their use will be noted in the command summary.

NAK3 The tag is busy and will not blink data

BSY…ACK The tag is busy with a WherePort blink. The command

will be responded to when the tag completes the

WherePort blink and is not busy, at which time a ACK

response will be sent.

SSS n Response to a query where SSS is the command and n

is the parameter.

All tag response strings consist of a carriage return / line feed, the actual response string,

another carriage return / line feed, and are followed by the > prompt character.

{CR}{LF} ACK{CR}{LF}>

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 52

User Guide

A

7.5 Commands

7.5.1 Message Length

Set the length, in bits, of the WherePort message. There are six possible values.

n Value

1

2

3

4

5

6

Example

MSG 1<cr>

10 bit

28 bit

44 bit

144 bit

144 bit with payload CRC1

144 bit with payload CRC2

Sets the message length to 10 bits.

Considerations

Message length affects the dwell time when using sequenced WherePorts.

7.5.2 Power

Set power level, from 0 to 8. When set to 0 the WherePort power is off.

PWR n<cr>

Increasing the power level increases the range.

Example

PWR 8<cr>

Sets the power level to 8.

Considerations

Lower power levels are used to make sure the capture area of the WherePort is restricted

to the zone or area to be monitored.

7.5.3 Phase

Set the phase.

PHS n<cr>

Valid range for n is 0 through 3 where 0 equals 0º, 1-90 º, 2-180 º, and 3-270 º.

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 53

User Guide

A

Example

PHS 2<cr>

Sets the phase to 2.

Considerations

When WherePort fields overlap, the phase of each WherePort must be set to match to

placement of the ports.

7.5.4 WherePort ID

Sets the WherePort Id. The valid range is 0 to 32,767.

WID n<cr>

Example

WID 4<cr>

Sets the WID to 4.

Considerations

WherePort IDs 0 through 255 are used for an alternate blink mode. When a WhereTag is

pinged by a WherePort with an ID less than or equal to 255 the tag is converted to the

alternate blink mode.

CAUTION Do not use the alternate blink mode without consulting the Zebra

Enterprise Solutions technical staff.

7.5.5 Tag Id

Set the tag ID (for 144 bit messages only). The valid range is 0 to 4,294,967,295.

TID n<cr>

Example

TID 4<cr>

Sets the tag id to 4.

Considerations

The tag ID is only set using a 144 bit message.

7.5.6 Response

Sets the tag WherePort response blink type (applies only to 27 bit and 44 bit messages)

RSP n<cr>

1 72 bit

2 144 bit

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 54

User Guide

A

Example

RSP 1<cr>

Set the response blink type to 72 bits.

7.5.7 Count

Set the WherePort response blink count (44 bit message only).

CNT n<cr>

Valid range for n is 0 through 15.

Example

CNT 4<cr>

Sets the blink count to 4.

7.5.8 Interval

Set the WherePort response blink interval (44 bit message only ) where n is 0 to 7.

INT n<cr>

7.5.9 Trigger

Set the re-trigger response (44 bit message only).

TRG n<cr>

Where n is a value 0 through 15.

Example

TRG 4<cr>

Sets the re-trigger response to .

7.5.10 Data

Set the 96 bit data payload (144 bit message only).

DAT [string]<cr>

String of 24 ASCII-HEX characters; set the 96 bit data payload (144 bit message only).

String of 22 ASCII-HEX characters: set the 96 bit data payload, payload CRC

automatically calculated (144 bit message only).

Example

DAT string<cr>

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 55

User Guide

A

A string of 24 ASCII-HEX characters to set the 96-bit data payload of the WherePort.

7.5.11 EXE

EXE n<cr>

Send message to magnetic field generator and the flash memory.

7.5.12 Sequence Mode

Set number of WherePort in the chain for sequencing mode.

CMW n<cr>

Where n is a value of 1 through 15. A value of 0 disables sequence mode. A value of 1

means that there is a master and 1 slave.

Example

CMW 2<cr>

Sets the number of WherePorts in the chain to 3, one master and 2 slaves.

7.5.13 Sequence Mode Message Number

CMC n<cr>

N is a value from 0 to 15. Sets the number of messages to send for each WherePort in

sequence mode. 0 disables sequencing mode.

The dwell time (how long it takes to send the programmed number of messages)

increases as the number of messages increases. Table 1 lists the dwell times for the

available combinations of message lengths and message numbers. The types are listed in

the left column. The number of messages are listed in the body of the table. The dwell

time is shown in the header column.

Table 1 Dwell Time (in seconds)

Message

Type

1

2

3

4

5

6

0.2 0.5 1.0 2.0 3.0 4.0 5.0 10 15 20

25 64 128 255

12 30 60 120 181 255

8 20 41 82 123 164 205

3 7 14 27 41 55 68 137 205 255

3 7 14 27 41 55 68 137 205 255

3 7 14 27 41 55 68 137 205 255

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 56

User Guide

A

7.5.14 Version

Set the software version number.

VER m.nn<cr>

Where m is the major version and nn is the minor version.

Example

VER 2.01<cr>

Sets the WherePort software version number to 2.01.

7.5.15 XPW

Set the password to the four character ssss.

XPW ssss<cr>

7.5.16 HWT (1)

Used to test the ISP port pins and set the WherePort password access flags.

HWT n<cr>

Where n is a value of 1 through 6. A value of 6 sets the default password.

Example

HWT 2<cr>

7.5.17 Loader

LDR n/a WherePort Loader vm.nn

Enter loader mode to allow firmware update. Will time out after 80 seconds if there

is no transfer. Transfer format is xmodem 128 byte.

7.5.18 GQ

There are five different GQ commands. A number of arguments are possible for several

of these commands. The commands govern the operation of the WherePort when the

mode is changed by the system in response to a particular tag.

GQ1

Set message length = 10 bit

Execute immediately

GQ1 n

Set WPID = n, where 0 ≤ n ≤ 7

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 57

User Guide

A

Set message length = 10 bit

Execute immediately

GQ2

Set message length = 28 bit

Execute immediately

GQ2 n

Set WPID = n, where 0 ≤ n ≤ 32,767

Set message length = 10 bit

Execute immediately

GQ3 n,m,p,q

n = 0x0-0x7FFF

m = 0x0-0xF

p = 0x1-0x7

q = 0x0-0xF

Arguments are in upper case ASCII-Hex format

Set message length = 44 bit

Set WPID = n

Set CNT = m

Set INT = p

Set TRG = q

Execute immediately

GQ4

Set message length = 144 bit

Execute immediately

GQ4 n

Set Tag ID n = 0 to 7FFF

Argument is in ASCII-Hex format

Set message length = 144 bit (CRC)

Execute immediately

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 58

User Guide

A

GQ4 s

Set message length = 144 bit (CRC)

Set data string = s (22 or 24 chars)

String is in ASCII-Hex format

Execute immediately

GQ4 n,s

n = 0 to 7FFF

s = string

Set message length = 144 bit (CRC)

Set Tag ID = n

Set data string = s (22 or 24 chars)

Execute immediately

GQ5 n

N = 0 to 7FFF

Set message length = 144 bit (CRC)

Set Tag ID = n

Execute immediately

GQ5 s

Set message length = 144 bit (CRC)

Set data string = s (22 or 24 chars)

Execute immediately

GQ5 n,s

n = 0 to 7FFF

s = string

Set message length = 144 bit (CRC)

Set Tag ID = n

Set data string = s (22 or 24 chars)

Execute immediately

GQ6 n

0 to 7FFF

Set message length = 144 bit (CRC)

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 59

User Guide

A

Set Tag ID = n

Execute immediately

GQ6 s

Set message length = 144 bit (CRC)

Set data string = s (22 or 24 chars)

Execute immediately

GQ6 n,s

n = 0 to 7FFF

s = string

Set message length = 144 bit (CRC)

Set Tag ID = n

Set data string = s (22 or 24 chars)

Execute immediately

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 60

User Guide

A

8 INSTALLATION

The lists of required parts, both supplied with the WherePort (Figure 41) and required

but not supplied, and the instructions for mounting WherePorts in typical locations

follow.

Caution - Use of Zebra external power supply is limited to indoor use

and a max 40° C environment. Outdoor installations will require

installation of a limited power source by the installer.

Warning - Electrical Shock: No operator serviceable parts inside.

Refer servicing to qualified personnel. To prevent electrical shock, do not

remove covers.

Caution - The WherePort III must be installed by a qualified service

technician.

Caution – Sync cable use is limited to indoor to indoor installation or

outdoor to outdoor installation. Sync cables must not be installed between

indoor and outdoor installations.

8.1 WherePort Parts

1. 1/4 x ½ in (12mm) screw (2)

2. Lock washer 2)

3. Flat washer (2)

4. Rubber bushing (2)

5. Bracket (1)

6. WherePort (1)

7. Tag Bracket (1)

8. Power/Sync Cable (1)

WherePort III User Guide

©2010 Zebra Enterprise Solutions. WherePort and all product names and numbers are Zebra Enterprise Solutions trademarks.

ll other trademarks are the property of their respective owners.

Page 61

A

Lock Washer (2x)

½ inch Screw (2x)

User Guide

WherePort

Flat Washer (2x)

Tag Bracket

Bracket

Figure 41 Installation Kit

The power/synchronization cable is not shown.

8.2 Also Required (not included)

1. Power supply, North American PS-025-00

2. Power supply, International PS-030-00

3. Power supply, vehicle 12 V, PS-200-00

4. Interconnect cabling Belden p/n 9156

5. WhereWand Programmer WND-2010 or WND-2200

6. Cable Assembly, WhereWand I to WherePort III CBL-300-00

7. Cable Assembly, WhereWand II to WherePort III CBL-320-00

Rubber Bushing (2x)

WherePort III User Guide