Page 1

Page 2

WhereLAN III User Guide

© 2011 Zebra Enterprise Solutions Corp.

The copyrights in this manual and the software and/or firmware and hardware described therein are owned by Zebra

Enterprise Solutions Corp. and Zebra’s licensors. Unauthorized reproduction of this manual or the software and/or

firmware may result in imprisonment of up to one year and fines of up to $10,000 (17 U.S.C.506). Copyright

violators may be subject to civil liability.

ZEBRA and the Zebra logo are registered trademarks of ZIH Corp. WhereNet is a registered trademark of Zebra

Enterprise Solutions Corp. All rights reserved worldwide.

All other brand names, product names, or trademarks belong to their respective holders.

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries. It is intended

solely for the information and use of parties operating and maintaining the equipment described herein. Such

proprietary information may not be used, reproduced, or disclosed to any other parties for any other purpose without

the express, written permission of Zebra Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are subject to

change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are correct;

however, errors do occur. Zebra Technologies reserves the right to correct any such errors and disclaims liability

resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever (including, without

limitation, consequential damages including loss of business profits, business interruption, or loss of business

information) arising out of the use of, the results of use of, or inability to use such product, even if Zebra

Technologies has been advised of the possibility of such damages. Some jurisdictions do not allow the exclusion or

limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

2 D1675 rev B May 2011

Page 3

WhereLAN III User Guide

_____________

_____________

____________

Note

____________

____________

____________

Typographical Conventions

Warnings call attention to a procedure or practice that could result in

personal injury if not correctly performed. Do not proceed until you fully

understand and meet the required conditions.

Cautions call attention to an operation procedure or practice that could

damage the product, or degrade performance if not correctly performed.

Do not proceed until understanding and meeting these required

conditions.

Notes provide information that can be helpful in understanding the

operation of the product.

May 2011 D1675 rev B 3

Page 4

WhereLAN III User Guide

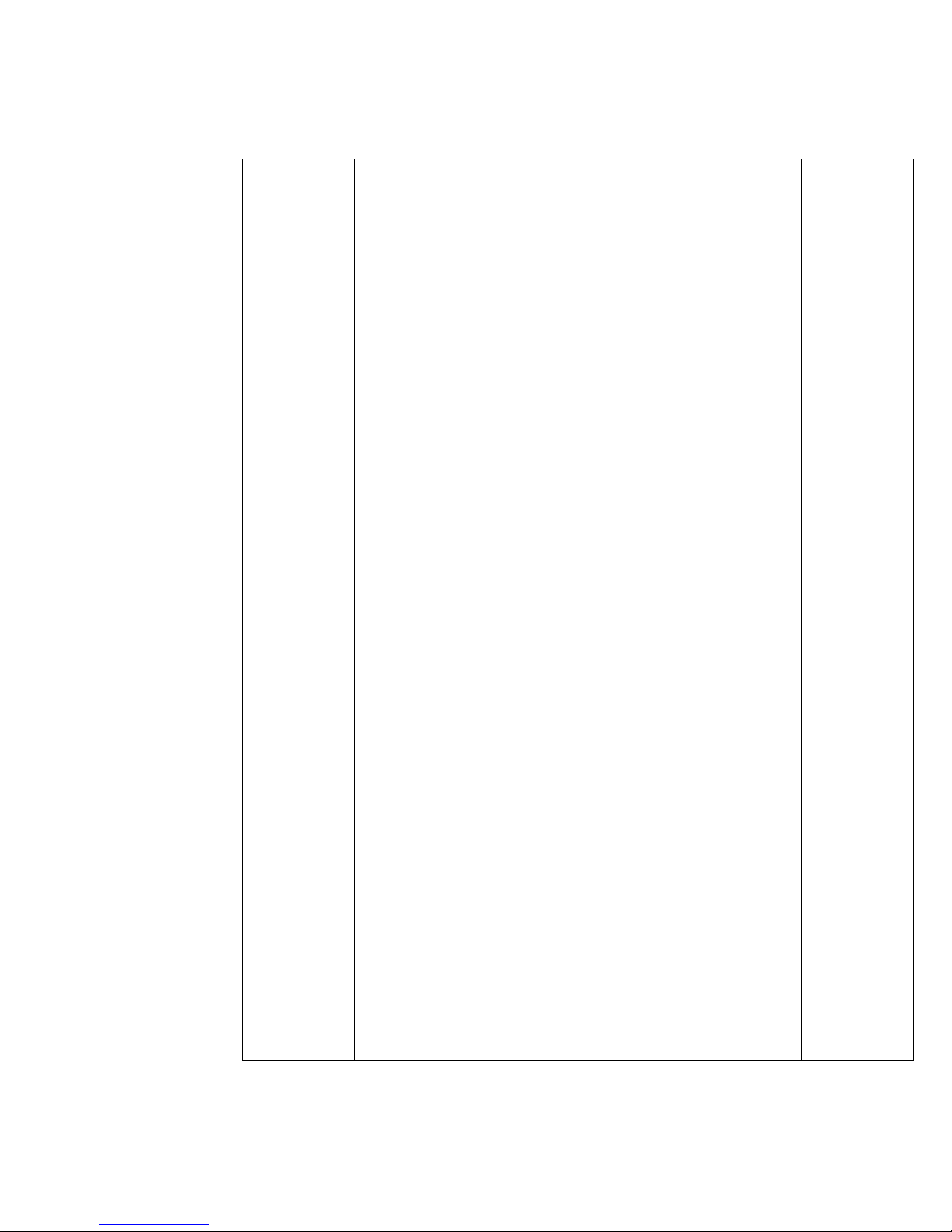

Revision

Description of Changes

Date

Approved

A B Initial Release

Per ECO C02532

10/20/10

05/09/11

GLC

GLC

Document Revision History

4 D1675 rev B May 2011

Page 5

WhereLAN III User Guide

Table of Contents Page

1 DOCUMENT OVERVIEW ................................................................................................. 7

2 PRODUCT DESCRIPTION AND FEATURES ................................................................ 7

3 PRODUCT SPECIFICATIONS .......................................................................................... 8

3.1 MECHANICAL ................................................................................................................... 8

3.2 ELECTRICAL ..................................................................................................................... 8

3.3 ENVIRONMENTAL ............................................................................................................. 8

3.4 EXTERNAL CONNECTIONS ................................................................................................ 9

4 ACCESSORIES .................................................................................................................. 10

5 CONFIGURATION & CONTROL .................................................................................. 11

5.1 LOCATION SENSOR SELF-BOOT ..................................................................................... 11

5.2 LOCATION SENSOR INTERFACE ...................................................................................... 11

5.3 LOCATION SENSOR MAC/ IP ADDRESS CONFIGURATION .............................................. 12

5.4 WLAN CLIENT CONFIGURATION (LOS-5000-00AB ONLY) .......................................... 16

6 INSTALLATION AND MOUNTING .............................................................................. 17

6.1 SAFETY AND INSTALLATION WARNINGS AND CAUTIONS ............................................... 17

6.2 MOUNTING ..................................................................................................................... 18

6.3 3/8THS THREADED ROD ................................................................................................. 20

6.4 POLE MOUNT KIT .......................................................................................................... 22

7 ANTENNAS......................................................................................................................... 28

7.2 VERTICAL DIVERSITY MOUNTING ................................................................................. 31

7.3 ANTENNA WLAN 802.11 .............................................................................................. 34

8 CABLING ............................................................................................................................ 35

8.1 POWER, AC ................................................................................................................... 36

8.1 ETHERNET ...................................................................................................................... 37

8.2 TIMING CABLE INTERCONNECTION GUIDELINES ............................................................ 37

8.3 LOCATION SENSOR OPERATIONAL VERIFICATION ......................................................... 43

9 REGULATORY INFORMATION ................................................................................... 45

9.1 RF NOTICE ..................................................................................................................... 45

9.2 EU COMPLIANCE INFORMATION (LOS-5000-00AA & LOS-5000-00AB) .................... 45

APPENDIX A: LOS-5000 EFFECTIVE PROJECTED AREA (EPA) ................................. 47

APPENDIX B: LOS-5000 WEIGHT ....................................................................................... 48

May 2011 D1675 rev B 5

Page 6

WhereLAN III User Guide

Table of Figures Page

Figure 1 Example of LOS-5000-00AB Label ............................................................................... 13

Figure 2 Safety and Warnings ....................................................................................................... 17

Figure 3 Mounting Points ............................................................................................................. 18

Figure 4 Safety Lanyard................................................................................................................ 19

Figure 5 Threaded-Rod ................................................................................................................. 20

Figure 6 Safety Lanyard................................................................................................................ 21

Figure 7 Pole Mount Kit ............................................................................................................... 22

Figure 8 Bracket Mount ................................................................................................................ 23

Figure 9 Retaining Bolts ............................................................................................................... 24

Figure 10 Location Sensor Mounted ............................................................................................. 25

Figure 11 Pole mount on Pole ....................................................................................................... 26

Figure 12 Location Sensor on Pole ............................................................................................... 27

Figure 13 Office Omni .................................................................................................................. 28

Figure 14 All Weather Omni ........................................................................................................ 28

Figure 15 Minimum clearance to metallic structures .................................................................... 29

Figure 16 Corner mount industrial application ............................................................................. 29

Figure 17 Office omnidirectional in corridor ................................................................................ 30

Figure 18 Vertical Diversity 5ft, ................................................................................................... 32

Figure 19 Vertical Diversity +11ft. ............................................................................................... 33

Figure 20 Vertical Diversity Connections .................................................................................... 34

Figure 21 Location Sensor Connections ....................................................................................... 35

Figure 22 Drip Plug ...................................................................................................................... 35

Figure 23 Timing cable wiring pin out ......................................................................................... 38

Figure 24 Timing Cable Trim ....................................................................................................... 39

Figure 25 Timing Cable Jacket ..................................................................................................... 39

Figure 26 Timing Cable Trim ....................................................................................................... 40

Figure 27 Timing Cable Pull Jacket.............................................................................................. 40

Figure 28 Timing Cable Crimp ..................................................................................................... 41

Figure 29 Test setup for CAT5 cable using Fluke 620 ................................................................. 42

Figure 30 Correct readout when testing 2 pair cable. ................................................................... 43

Figure 31 Location Sensor LED indicators ................................................................................... 43

6 D1675 rev B May 2011

Page 7

WhereLAN III User Guide

1 DOCUMENT OVERVIEW

This document describes the basic configuration and recommendations on

physical installation of the WhereLAN III product, which is part of the

Location Sensor product line. The site design and placement is detailed in the

Location Sensor Placement Guide D0406 and WhereLAN III Installation

Guide 26913.

2 PRODUCT DESCRIPTION AND FEATURES

The WHERELAN III is the next generation of WhereLAN products that

receives the signals transmitted by WhereTags (ISO 24730-2), and provides

data to the Location Algorithm processor. The WhereLAN III Location

Sensor has improved performance and uses less power than the previous

WhereLAN Location Sensor. The “received tag blinks” are decoded, time

stamped, and routed to a PC or ZLA (Zebra Location Appliance) for

additional processing. The locate algorithm running on the PC or ZLA

calculates the tag position based on the time stamps of multiple Location

Sensors, and reports that position to the database where it is displayed by

Resource Manager.

There are three base WhereLAN III configurations:

LOS-5000-00AA(Wired Ethernet, POE 802.3af compliant)

LOS-5000-00AB (with 802.11b/g Wireless LAN Client, POE 802.3af

Compliant)

LOS-5000-01AA (no embedded transmissions, Wired Ethernet, POE

802.3af Compliant)

Both the LOS-5000-00AA and LOS-5000-00AB configurations also include a

low power an embedded transmitter, which complies with the ISO 24730-2

standard, is used to distribute configuration data, health, and timing signals to

other Location Sensor units.

The embedded transmitter uses channels, both left and right, to transmit and

receive, which is not compatible with the legacy LOS/LAP 4000 series

WhereLAN products. However, by default the WHERELAN III will be

shipped in G2 emulation mode. During site launch with System Builder, the

user will be able to select full WHERELAN III mode to take advantage of the

enhanced features, provided it is not being used to replace the WhereLAN

infrastructure. Note: The LOS-5000-01AA has this embedded transmitter

function disabled.

May 2011 D1675 rev B 7

Page 8

WhereLAN III User Guide

Size:

10.3 x 1.7 x 12.0

261 x 43 x 305

in (HxDxW)

mm

Weight:

7.0

3.2

Lbs

Kg

Voltage:

36 to 57

48V nominal

Vdc

Current:

.350 (max)

Amps

Power Dis.:

13.0 (max)

Watts

Power:

Can be powered by a Zebra

approved, limited AC to DC power

supply or Power Over Ethernet

(POE). See Accessories List.

Operating Temp.1:

Storage Temperature:

-40 to +60

-40 to +70

ºC

Ingress Protection:

54

IP

Humidity

5 to 95%

Non-condensing

3 PRODUCT SPECIFICATIONS

3.1 Mechanical

3.2 Electrical

3.3 Environmental

1

See power supply limits

8 D1675 rev B May 2011

Page 9

WhereLAN III User Guide

Antenna (2):

MCX (Jack)

DC Power:

2.5 ID/ 5.5 OD mm (Jack)

Opt. WiFi Antenna:

SMB (Jack)

Ethernet:

RJ45 (Jack) 10/100 and 802.3af POE

Timing (3):

RJH (4-wire telephone handset Jack)

3.4 External Connections

The Location Sensor utilizes standard 10/100 802.3 Ethernet connectivity via

Cat-5 cables. The WhereLAN III must be wired to a nearby hub, which is in

turn connected to the network containing the database CPU. The maximum

Ethernet cable run is 328 ft (100 m). If additional distance is required, hubs,

repeaters, and fiber (with 10BaseT converters) can be used to extend the

distance. Refer to IEEE guidelines for Ethernet cabling. It is also compliant

with 802.3af POE standard.

May 2011 D1675 rev B 9

Page 10

WhereLAN III User Guide

Accessories

Model Number

All Weather Omni Antenna

(standard)

AK-210-10

Office Omni Antenna1 (indoor

only)

AK-110-10

DC power cable extender, 50 ft,

Plenum Rated (Indoor Only)

DC power cable extender, 50ft.,

Outdoor Rated.

PX-010-00

PX-050-00

Power Over Ethernet injector

EP-025-00

Power Supply

PS-040-00

Pole Mount Kit:

LAN Antenna Kit

LAN Antenna Indoor 2.2dBi

LAN Antenna Omni 5.2dBi

LAN Antenna Directional

13.5dBi

RM-510-00

TBD

AK-170-00

AK-151-00

AK-153-00

4 ACCESSORIES

The accessories indicated below are required to complete the installation of

the Location Sensor. Ordering information is supplied where applicable.

Note: Not all accessories are globally available. Check with local sales representative

regarding availability.

10 D1675 rev B May 2011

Page 11

WhereLAN III User Guide

____________

Note

____________

____________

Note

____________

5 CONFIGURATION & CONTROL

5.1 Location Sensor Self-Boot

Upon power up, the Location Sensor (LS) executes a self boot process. The

boot process takes between 45 to 60 seconds. If a fault occurs during the boot

process, the unit may reset and restart the boot process. During that process,

the four LEDs blink in a sequence to indicate the current stage of the power

up boot process. Once the boot process is complete, the LEDs revert to their

standard functions indicating power/health, tag status, Ethernet, and WLAN.

5.2 Location Sensor Interface

After the Location Sensor has completed its boot process, it is possible to

communicate with the unit via the following methods.

Do not attempt to communicate with the Location Sensor until it has

completed the first stage of the boot process (i.e., left LED is solid). Doing so

will stop the boot process. The unit must be reset to clear this condition.

These units are configured using:

Telnet/SSH via Ethernet (preferred)

iSensor (Sensor Analyzer)

WhereWand

Hyperterminal (or any terminal emulation software) via serial port

Telnet/SSH is the preferred method of communicating with the Location

Sensor, once installed. Use the HyperTerminal for initial setup before

being installed on a network for setting static IP addresses, if DHCP is not

used.

Telnet/SSH via Ethernet

Communication Parameters:

10/100 Mb/s

Cat-5 cable/ RJ-45 plug.

To connect via telnet, open a DOS command prompt window and type

telnet <IP address>,where the IP address is iSensor (Sensor Analyzer)

May 2011 D1675 rev B 11

Page 12

WhereLAN III User Guide

____________

Note

____________

Hyperterminal via Serial Port

Communication Parameters:

Null-modem cable, 9-pin female to 9-pin female

19200 baud

8 data bits, 1 stop bit, no parity, no hardware flow control

Hyperterminal is used in only two instances. The first is for initial

configuration where the Location Sensor has been configured for DHCP, but

there is no DHCP server available. The second instance is if a fault occurs

during the first stage of the boot process, or if visibility to the boot process is

needed for debugging installation problems.

5.3 Location Sensor MAC/ IP Address Configuration

Location Sensors communicate over an Ethernet interface using TCP/IP. For

the LOS-5000-00AB, both the Location Sensor and the embedded Client Card

must be independently configured with their own unique IP addresses. The IP

address of each LS must be recorded and entered into the ZES site file, which

contains the configuration information for each LS, including its location, and

MAC address.

Failure to configure the Location Sensor prior to operation may result in

an inoperative unit.

Each Location Sensor is shipped with a label set containing one label (Figure

1) with the bar coded MAC address of the Location Sensor and Wifi Client

and three labels with the last six characters of the Location Sensor’s MAC

address in large type. Ensure that the label is correct by matching the MAC

address(es) on the loose label set with the MAC address(es) listed on the back

of the Location Sensor. Place the loose bar code label in the site design

document where indicated, and place one or more of the large type, six

character labels on the exterior of the Location Sensor in positions that are

visible after installation.+

12 D1675 rev B May 2011

Page 13

WhereLAN III User Guide

Last 6 LS

MAC digits

Wifi Client

MAC Address

Location Sensor

MAC Address

Location Sensor

Serial Number

____________

Note

____________

____________

Note

____________

The MAC address label must be clearly marked on the exterior of the

Location Sensor housing in a position visible after installation.

`

Figure 1 Example of LOS-5000-00AB Label

Like other network equipment, the Location Sensor IP address(es) must be set

to a predetermined address. While there is no restriction to the IP address, it

must match the address in the Site file for that particular Location Sensor.

The IP address(es) can be static assigned, or dynamically assigned via DHCP.

If assigned through DHCP, the DHCP server must contain the MAC address

and corresponding IP address for each of the Location Sensors (and WLAN

Client).

For networks utilizing DHCP, the MAC addresses of the Location Sensor

and Wifi Client (LOS-5000-00AB only) must be entered in the DHCP

server.

May 2011 D1675 rev B 13

Page 14

WhereLAN III User Guide

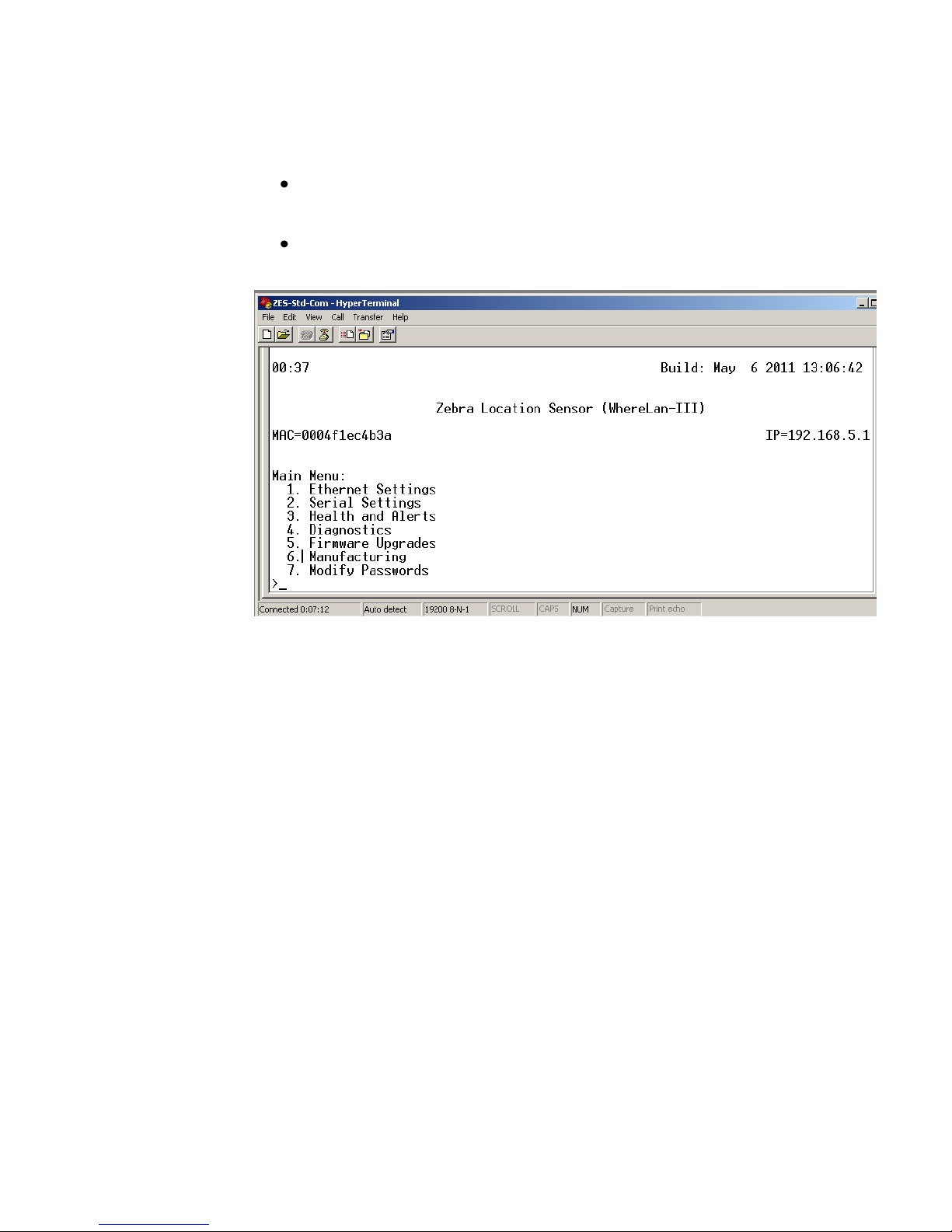

To configure the IP address of the Location Sensor:

Note the following configuration examples are done thru HyperTerminal.

Connect to the Location Sensor using Telnet (preferred), or

HyperTerminal.

Select 1 and confirm the unique MAC address for the Location Sensor.

14 D1675 rev B May 2011

Page 15

WhereLAN III User Guide

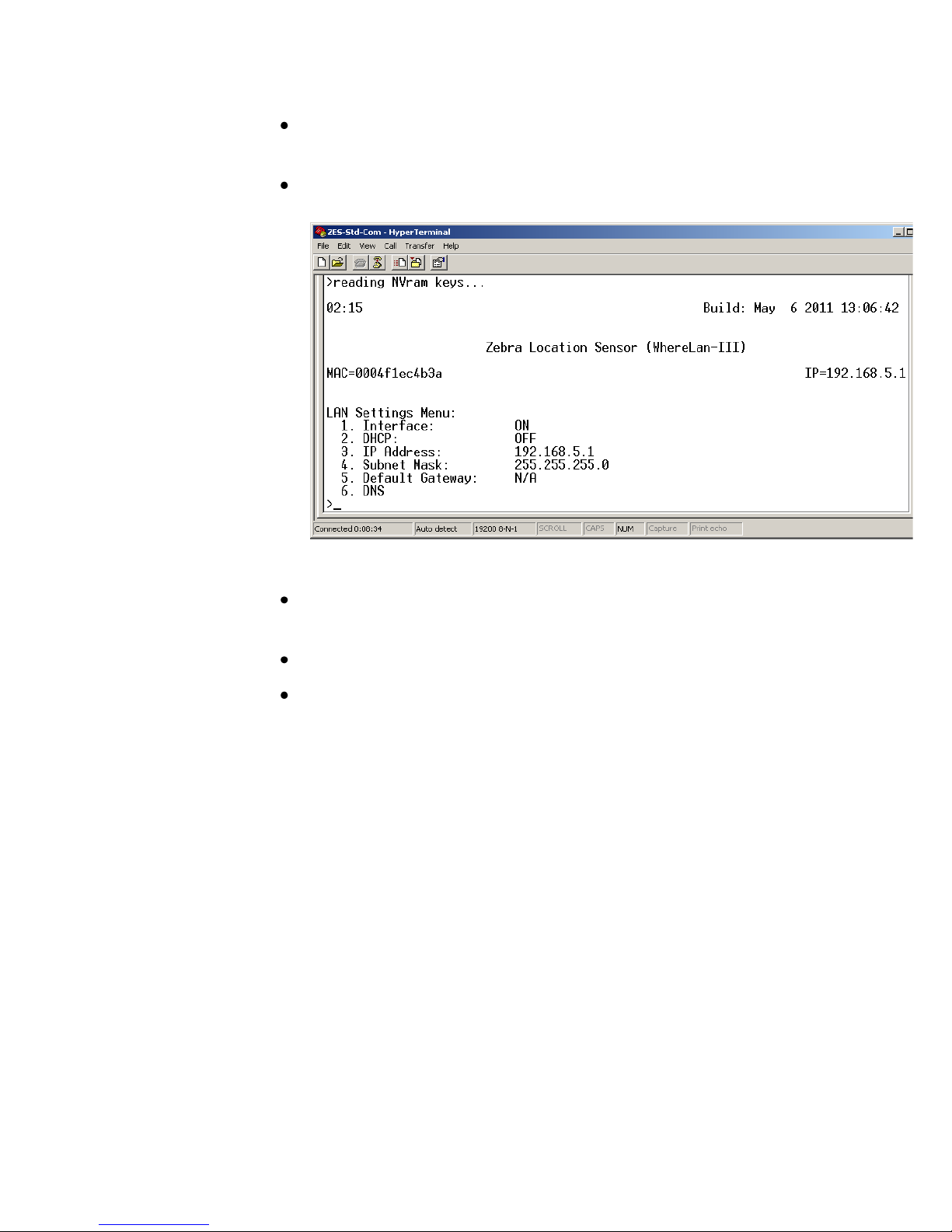

Select 1 for setting Boot Method, Flash for internal image or Network

for image.

Select 2 for wired LAN Port IP setting or 3 WLAN client IP/DHCP

setting.

Save the configuration changes by using ESC key entering the

password “ff2”.

Note changes take effect on unit reboot/reset.

Confirm communication to the Location Sensor by “pinging” the

device from a DOS prompt.

May 2011 D1675 rev B 15

Page 16

WhereLAN III User Guide

5.4 WLAN Client Configuration (LOS-5000-00AB only)

The WLAN embedded in the Location Sensor must be configured with the

proper IP address and Interface must be ON.

Under Ethernet Menu, select 3 WLAN.

Set 1. Interface to ON, then IP/DHCP settings.

Save the configuration changes by using ESC key entering the

password “ff2”.

16 D1675 rev B May 2011

Note changes take effect on unit reboot/reset.

Page 17

WhereLAN III User Guide

Earth Ground Locations.

Bolt Size 8mm. Max

Length 25mm.

6 INSTALLATION AND MOUNTING

Read Installation and Instruction sheet included with the Location Sensor as

well as all Safety and Installation Warnings/Cautions before installing. Follow

the Site Design document for installed location.

6.1 Safety and Installation Warnings and Cautions

Warning - Electrical Shock: A protective earthing conductor with

green and yellow insulation, minimum of 18 AWG, shall be installed to the

protective earthing terminal of the metal enclosure. National electrical codes

shall be followed to install facility protective earthing conductor to the

protective earthing terminal.

Figure 2 Safety and

Warnings

Warning - Electrical Shock: No operator serviceable parts inside. Refer

servicing to qualified personnel. To prevent electrical shock, do not remove

covers.

Caution - The Location Sensor hardware must be installed by a qualified

service technician.

Caution - Use of Zebra external power supply is limited to indoor use

and a max 40° C environment.

May 2011 D1675 rev B 17

Page 18

WhereLAN III User Guide

____________

Note

____________

Safety Lanyard Points

Nut Pocket

Mounting Bracket Points

6.2 Mounting

The site design specifies the location of the Location Sensor(s) to provide

optimum system performance. It is critical that the Location Sensor is

mounted in a position which provides good RF visibility to the tracked assets.

Thus the Location Sensor must be mounted exactly in the position specified in

the site design document.

The Location Sensor has two methods of mounting.

The first can be hung using nut pocket on top for attachment to accept

a 3/8 in (10 mm) threaded rod and jam nut, useful when using a beam

clamp type of hanger.

The second method of mounting is a pole mount hardware kit. This kit

is available separately, ZES Part Number RM-510-00 Mounting

Bracket, Pole Mount.

Figure 3 Mounting Points

Failure to mount the Location Sensor in the exact position specified in the

site design will result in erroneous or non-locates of the tracked assets.

18 D1675 rev B May 2011

Page 19

____________

____________

WhereLAN III User Guide

For safety, it is strongly recommended that a Safety Lanyard be employed

with either mounting method. The Safety Lanyard points are large enough

to accept a 1/8” loop style wire rope. Stainless Steel Rope is recommended.

Figure 4 Safety Lanyard

May 2011 D1675 rev B 19

Page 20

WhereLAN III User Guide

6.3 3/8ths Threaded Rod

The Location Sensor can be hung via a 3/8 inch (10 mm) threaded rod per the

following instructions. The required supports, threaded rod, nuts, etc., are not

included.

Cut the threaded rod to the desired length and install it directly above

the desired Location Sensor position.

Thread one nut up 2 in (50 mm) from the bottom of the threaded rod,

with Lock Washer and Washer.

Place the second nut onto threaded rod, flush with the end of the

threaded rod and install the Location Sensor.

Tighten the upper nut down on top of the Location Sensor housing.

Figure 5 Threaded-Rod

20 D1675 rev B May 2011

Page 21

WhereLAN III User Guide

6.3.1 Safety Lanyard with Threaded Rod

For Location Sensor installation using the Threaded Rod Mounting, it must

also be secured to the building infrastructure with a safety lanyard through the

one of the rectangular loops on top of the casting. See below in Figure 6

Safety Lanyard.

Figure 6 Safety Lanyard

May 2011 D1675 rev B 21

Page 22

WhereLAN III User Guide

Top of Bracket

6.4 Pole Mount Kit

The pole mount kit, catalog number RM-510-00, must be ordered separately.

The pole mount kit will allow the Location Sensor to be mounted to either a

pole or 1-1/4” metal channel framing, per the instructions included with the

pole mount kit.

Figure 7 Pole Mount Kit

22 D1675 rev B May 2011

Page 23

WhereLAN III User Guide

6.4.1 Pole Mount on Metal Frame

1. Mount bracket to metal frame in location, orientation and height specified

in the site design, with support hooks up and retaining slots down, using

supplied clamp.

Figure 8 Bracket Mount

May 2011 D1675 rev B 23

Page 24

WhereLAN III User Guide

Retaining Bolts

2. Loosen the retaining bolts on each side of the Location Sensor but do not

remove them.

Figure 9 Retaining Bolts

3. Hang the Location Sensor on the bracket and tighten retaining bolts

securely.

24 D1675 rev B May 2011

Page 25

WhereLAN III User Guide

4. Install safety lanyard through one of the Location Sensor’s lanyard points,

and the other end of the lanyard to a point above the Location Sensor.

Figure 10 Location Sensor Mounted

May 2011 D1675 rev B 25

Page 26

WhereLAN III User Guide

6.4.2 Pole Mount on Pole

1. First mount bracket to pole at height location, orientation and height

specified in the site design, with support hooks up and retaining slots

down, using supplied clamp.

Figure 11 Pole Mount on Pole

2. Loosen the retaining bolts on each side of the Location Sensor, but do not

remove them. (See Figure 9 Retaining Bolts).

3. Hang the Location Sensor on the bracket and tighten retaining blots

securely.

4. Install safety lanyard through one of the Location Sensor’s lanyard points,

and the other end of the lanyard to a point above the Location Sensor.

26 D1675 rev B May 2011

Page 27

WhereLAN III User Guide

Figure 12 Location Sensor on Pole

May 2011 D1675 rev B 27

Page 28

WhereLAN III User Guide

7.1.1 All Weather Omni

7 ANTENNAS

Two different antennas are available for the Location Sensor. The standard

antenna is the All Weather Omni AK-210-10, which can be bolted directly to

the Location Sensor housing. The Office Omni AK-110-10 is available for

indoor only installations where appearance is critical. The choice of antenna

will be specified in the site design.

Figure 13 Office Omni

Figure 14 All Weather Omni

As its name suggests, the All Weather Omni provides omni-directional

coverage and is suitable for outdoor environments. It should be attached

directly to the Location Sensor housing, and therefore requires no additional

mounting. For this reason, it is the preferred antenna for the Location Sensor.

Because it is an omni-directional antenna, the coverage pattern of the All

Weather Omni can be degraded if mounted too close to metallic structures.

Therefore, the All Weather Omni must be mounted a minimum of 12 inches

(305 mm) from nearby metallic structures.

28 D1675 rev B May 2011

Page 29

WhereLAN III User Guide

Min 12 inches

(305 mm) from

metal wall

I Beam

Right

antenna

Left

antenna

Min 12 inches

(305 mm) from

metal wall

Location

Sensor

Wall

Mount

Bracket

Right

Antenna

Left

Antenna

_____________

_____________

Figure 15 Minimum Clearance to Metallic Structures

The All Weather (and Indoor Office) Omni antennas must be mounted a

minimum of 12 inches (305 mm) away from metal walls.

For best diversity reception, the Location Sensor should be mounted in an

orientation in which the antennas are at a diagonal (45 deg) orientation with

respect to surrounding walls and aisles. The RM-250 Wall Mount Bracket

can be utilized to provide the necessary clearance from nearby metallic

surfaces.

Figure 16 Corner Mount Industrial Application

May 2011 D1675 rev B 29

Page 30

WhereLAN III User Guide

Ceiling tile

Diagonal orientation

of antennas

Minimum 12 in

(305 mm) clearance

to metal walls

17 in

(432 mm)

24 in

(610 mm)

7.1.2 Indoor Omni

The indoor omni is designed to be mounted directly to the ceiling. It has a

small profile designed to be unobtrusive in an office environment. Like the

All Weather Omni antenna, it must be mounted a minimum of 12 inches from

metal walls. There is no spacing requirement for drywall or other nonmetallic walls. For best diversity reception, mount the antennas in a diagonal

orientation 24 in (610 mm) from each other, in the center of the corridor (if

applicable), as shown in Figure 17 below. Be certain to note which antenna is

on the left, and which is on the right, and connect them to the appropriate

ports on the Location Sensor during installation.

30 D1675 rev B May 2011

Figure 17 Office Omnidirectional in Corridor

Page 31

WhereLAN III User Guide

____________

____________

7.2 Vertical Diversity Mounting

For outdoor installation requiring the maximum location accuracy and

consistency, the use of vertical diversity for antenna placement should be

implemented. Installations such as Yard Sites and Marine Terminal Sites will

require that vertical diversity be installed. Zebra Location Solutions offers

three different vertical diversity cable kits for installation.

it is recommended that the Right antenna be higher than the Left Antenna.

Consult instruction sheet included in each kit and WhereLAN III Installation

Guide D1677 for further installation information.

1) Antenna Extension Cable Kit,

CBL-010-10

, which is a 5ft. cable kit is

typically used for Yard Sites.

2) Antenna Extension Cable Kit, CBL-015-10 a 15ft. standard cable kit is

used for Marine Terminals.

3) Cable Kit CBL-015-11, Low Loss Antenna Extension, Location Sensor,

15ft. may be used for Marine Terminals.

The most critical item in placing and installing the Location Sensors is to

ensure that the antennas are not blocked by nearby structures. Detailed

instructions with several examples are provided in the Location Sensor

Placement Guide D0406.

For accurate locate performance, the position of the left and right antennas

must be individually specified in the site design. System Builder requires the

center point and orientation of the antennas.

The left and right antenna must be correctly oriented per the site design.

Inadvertently reversing the left and right antenna will result in a two foot

location error.

For all installations,

May 2011 D1675 rev B 31

Page 32

WhereLAN III User Guide

7.2.1 Example Configuration Using CBL-010-10:

The following diagram is an example of how to achieve vertical diversity,

using ¾” PVC schedule 40 conduit and ¾” PVC conduit fitting.

Carefully coil excess cable for Right Channel.

Figure 18 Vertical Diversity 5ft.

*Use Splicing tape and ZES GS-888-00 connect sealant, install weather tight

cover. For Both Right and Left Antenna Connections.

32 D1675 rev B May 2011

Page 33

WhereLAN III User Guide

7.2.2 Example Configuration Using CBL-015-10:

Below is a picture of a ZES Location Sensor installed on a 100’ light pole.

Note the Vertical Diversity (“VD”) created by extended antennas above and

below the Location Sensor. The installer will have to achieve at a minimum

the vertical distance of 11’ see below, the VD can be greater than 11’. This

installation calls for 12’ of diversity.

The picture shows ¾” electrical metallic tubing extending the “bullhorn”

antennas (white).

Figure 19 Vertical Diversity +11ft.

May 2011 D1675 rev B 33

Page 34

WhereLAN III User Guide

LAN Antenna Indoor 2.2dBi

LAN Antenna Omni 5.2dBi

LAN Antenna Directional

13.5dBi

AK-170-00

AK-151-00

AK-153-00

7.2.3 Vertical Diversity Connections

Make appropriate connection to the Location Sensor, as shown below.

Figure 20 Vertical Diversity Connections

7.3 Antenna WLAN 802.11

For the LOS-5000-01AB, there are three antenna options, and require the

WLAN cable and mounting bracket kit. (Contact ZES Project Manager or

Sales Rep. for appropriate part number). See instruction sheet included with

cable mounting bracket kit regarding installation. See Site Design for specifics

of WLAN antenna choice and orientation.

34 D1675 rev B May 2011

Page 35

WhereLAN III User Guide

8 CABLING

Figure 21 (below) labels the appropriate connections which must be made to

the Location Sensor in normal operation. The connector types and

recommended cable types are detailed in Section 3.

Figure 21 Location Sensor Connections

For all outdoor installations:

Use part GS-888-00 grease (supplied with unit) in ALL Connecter

Jacks. Fill each of the following connections with Nyogel Weather

Sealant; these include the Left and Right antenna, Timing connections,

Wifi Client, Ethernet, Serial interface, and Power connection. This is

to help weatherproof the connections from water and corrosion.

Routing the cables through the Drip Plug, supplied with unit, plug

cables into units and fully (carefully) install Drip Plug into connector

well.

Figure 22 Drip Plug

May 2011 D1675 rev B 35

Page 36

WhereLAN III User Guide

_____________

_____________

_____________

_____________

8.1 Power, AC

WhereLAN III location sensor, can either be powered via POE (Power Over

Ethernet, 802.3af compliant) or directly with a standalone DC power supply.

If the standalone DC power supply option is used, the customer must provide

100-240Vac power 50/60 Hz to the specified Location Sensor position. The

Location Sensor units require DC 36-57V, 250mA for operation (12 Watts).

The recommended power supply (PS-040-00), which must be purchased

separately, has a 6 ft. (2 m) AC cable and a 6 ft. (2 m) DC cable. The

electrician should verify that the AC power is available within 6 ft. (2 m) of

the position of the Location Sensor. This allows a 6 ft. (2 m) “service loop”

margin if the Location Sensor position must be readjusted after the AC power

is installed.

The Location Sensor must always be used with the specified power

supply. The use of a different power supply could result in equipment

damage and/or electric shock or fire hazard.

Two optional 50 ft. (15 m) DC power extension cables are available for

installations where it is not desirable to route the AC power within 6 ft. (2 m)

of the Location Sensor. One is for indoor use only and is Plenum Rated, ZES

Part Number PX-010-00. The other is an outdoor rated (UV stable), ZES

Part Number PX-050-00. Consult your ZES Account Manager for

recommended wire size if additional lengths are required for a particular

installation.

Power Supplies have a limited safe operating temperature rating, please

check with the account representative concerning limitations or

availability of extended temperature range power supply, such as PS-040-

00. In outdoor installations, the power supply must be installed within a

suitable waterproof housing per applicable building codes. The use of a

non-qualified housing could result in equipment damage and/or electric

shock or fire hazard.

36 D1675 rev B May 2011

Page 37

WhereLAN III User Guide

____________

Note

____________

____________

Note

____________

____________

____________

8.1 Ethernet

The Location Sensor utilizes standard 10/100 802.3 Ethernet connectivity via

Cat-5 cables. The Location Sensor must be wired to a nearby hub, which is in

turn connected to the network containing the database CPU. The maximum

Ethernet cable run is 328 ft. (100 m). If additional distance is required, hubs,

repeaters, and fiber (with 10BaseT converters) can be used to extend the

distance. Refer to IEEE guidelines for Ethernet cabling.

Do not exceed the maximum Ethernet cabling length of 328 ft. (100 m).

8.2 Timing Cable Interconnection Guidelines

For some applications, the Location Sensor requires a timing cable to be

connected to other nearby Location Sensor units. The site design document,

provided by the site designer, will specify which Location Sensors will be

connected together. Each of the three timing ports on the Location Sensor is

an identical bi-directional link. The cable and connector types are specified in

section 0 above.

The following rules must be applied when connecting timing cables between

the Location Sensors:

Do not connect the timing cable from one Location Sensor back to the

same Location Sensor.

Do not connect two timing cables between the same two Location

Sensors.

The maximum timing cable length is 1000 ft. (305 m).

Do not exceed the maximum timing cabling length of 1000 ft. (305 m).

Install the Location Sensor timing cables from one unit to the next, as

specified in the site design document, using the specified 2-pair or 4-pair*

cable and RJ22 (telephone handset 4c4p) connectors. (* see 8.2.1.) Incorrect

routing of the timing cables between the Location Sensors may result in

decreased location accuracy.

May 2011 D1675 rev B 37

Page 38

WhereLAN III User Guide

8.2.1 Timing Cable Pin-Out

RJ22

2 Pair Cat-

To pin 1 white/orange

To Pin 2 orange

To pin 3 white/blue

To pin 4 blue

____________

Note

____________

This Cat-5 two-pair cable should be constructed with straight through wiring,

with pin 1 on one end routed to pin 1 on the other end. For the 2 pair Cat-5

cable, the following pin out must be used. (see Figure 23).

Pair 1: Orange/white wire is pin 1; orange wire is pin 2.

Pair 2: White/blue wire is pin 3; blue wire is pin 4.

Figure 23 Timing Cable Wiring Pin Out

For a reliable system operation, the jacket of the timing cable must be

securely crimped inside the RJ-22 (4p4c) connector. It is recommended

that a 2-pair cable be utilized to ensure a proper crimp. Standard eight

conductor Cat-5 cable may be used, and follow the steps in Section 8.2.2

of this guide.

38 D1675 rev B May 2011

Page 39

WhereLAN III User Guide

8.2.2 Cat-5 Four-Pair Installation

Steps:

1. Trim out Jack back approximately ½ inch.

Figure 24 Timing Cable Trim

2. Pull Back Jack until at least 1-1/4” inches of wire is exposed. Separate

Blue/White and Orange/White pair from Green/White and Brown/White

pair.

Figure 25 Timing Cable Jacket

May 2011 D1675 rev B 39

Page 40

WhereLAN III User Guide

3. Trim the Green/White and Brown/White Pairs flush with outer jacket.

Figure 26 Timing Cable Trim

4. Pull outer jacket back up leaving only ¼ inch of wire exposed. Separate

wires as shown in Figure 27 and trim wires evenly.

Figure 27 Timing Cable Pull Jacket

40 D1675 rev B May 2011

Page 41

WhereLAN III User Guide

8.2.3 Timing Cable Test Procedure

5. Insert into RJ-22(4p4c) as shown and crimp with appropriate tool. Note

outer cable jacket is captured by strain relief.

The timing cables must be properly wired in order for the timing signal to be

transmitted from one Location Sensor to the other. It is recommended that

this test be completed on each cable by the installer prior to operation. This

test requires two 4-pair to 2-pair connector adapters (ZES p/n 21204), and a

Fluke 620 CableMeter. Brief instructions are provided below; consult the

Fluke CableMeter instruction manual for detailed instructions.

Figure 28 Timing Cable Crimp

May 2011 D1675 rev B 41

Page 42

WhereLAN III User Guide

2 pair adapters

Cable

under test

Setup

Connect adapter #1 between the Fluke 620 CableMeter and the near end of the

cable to be tested. Connect the Fluke Cable ID unit and adapter #2 to the far

end of the cable to be tested using an RJ-45 coupler.

Figure 29 Test setup for CAT5 cable using Fluke 620

Procedure

1. Use the SETUP to select cable type, wire standard, category and wire size

on the Fluke CableMeter:

Cable: UTR

Wiring: 10BaseT 2PR

Category: Cat5

Wire Size: AWG24

2. Turn the Fluke CableMeter rotary switch to WIRE MAP. The correct

readout when testing 2-pair cable is shown in Figure 30 below. If a

different readout appears, the cable was not constructed properly and must

be corrected.

42 D1675 rev B May 2011

Page 43

WhereLAN III User Guide

Location Sensor

Outdoor

Omni

Antenna

Power/

Health

Tag

Reception

Ethernet

WLAN

12 36 ID

12 36 #1

Figure 30 Correct Readout when Testing 2-pair cable.

8.3 Location Sensor Operational Verification

Prior to optimizing locate performance, the operation of the Location Sensor

must be verified. The checklist below specifies the verification of the

configuration and basic operation.

Figure 31 Location Sensor LED Indicators

May 2011 D1675 rev B 43

Verify that each Location Sensor is operational by verifying that the

left Power/ Health LED is illuminated solid red.

Page 44

WhereLAN III User Guide

Initial

Date

Comments/ Exceptions

For wired 802.3 Location Sensors, verify that the Ethernet LED is

solid red when connected and blinking red when activity is present.

Verify that the RX detects LED is blinking red indicating reception of

tag blinks.

For wireless 802.11b Location Sensors, verify that the WLAN activity

LED is blinking red during power up state and solid red otherwise.

Confirm that the site Location Sensor channel assignment is correct by

running “display locate” from the LP Manager tool with a tag placed

directly under each LS. Verify that the nearest Location Sensor, as

indicated by a “0” in the display locate report, is that Location Sensor

nearest the tag.

Verify that detects are received on the channel by using either LP

Manager Detect History, or WTLPHealth. LS detects when a tag is

placed at a distance from each Location Antenna equivalent to the

maximum required range from that Location Antenna. Typical tag to

Location Antenna range is 1000 ft (305 m) (Unobstructed/outdoor),

350 ft. (107 m) Minimally Obstructed (indoor office/ light

commercial), 250 feet (76 m) Significantly Obstructed (heavy

industrial).

Section Signoff

44 D1675 rev B May 2011

Page 45

WhereLAN III User Guide

AT

BE

BG

CY

CZ

DK

EE

FI

FR

DE

GR

HU

IE

IT

LV

LT

LU

MT

NL

PL

PT

RO

SK

SI

ES

SE

GB IS

LI

NO

CH TR

9 REGULATORY INFORMATION

FCC & IC Requirements

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

This equipment has been tested and found to comply with the limits for Class A

devices, pursuant to Part 15 of the FCC Rules.

This ISM device complies with Canadian ICES-001.

Cet appareil ISM est conforme à la norme NMB-001 du Canada.

9.1 RF Notice

Any changes or modifications to ZES Corp. equipment not expressly approved by

ZES could void the user’s authority to operate the equipment.

FCC Radiation Exposure Statement

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with

minimum distance 20 cm between the radiator and your body. This transmitter must

not be co-located or operating in conjunction with any other antenna or transmitter.

9.2 EU Compliance Information (LOS-5000-00AA & LOS-

5000-00AB)

Approved for use in the following countries.

Note: Use is restricted for countries that are grayed out. See below for

limitations.

May 2011 D1675 rev B 45

Page 46

WhereLAN III User Guide

Important Notice:

This RF device is intended for indoor and outdoor

use in all EU and EFTA with the following

limitations.

France: Outdoor use limited to 10 mW e.i.r.p.

within the band 2454-2483.5 MHz

Italy: For private use, a general authorization is

required if WAS/RLAN’s are used outside own

premises. For public use, a general authorization is

required.

Luxembourg: General authorization required for

network and service supply.

Norway: Wideband Data Transmission systems

2400.0-2483.5 MHz does not apply for the

geographical area within a radius of 20 km from

the centre of Ny-Ålesund

46 D1675 rev B May 2011

Page 47

WhereLAN III User Guide

APPENDIX A: LOS-5000 EFFECTIVE PROJECTED

AREA (EPA)

LOS Housing

Housing Size (Inches) [cm]: 12.0” [30.4] Wide, 10.3” High [26.2], 1.7” [4.3] Deep

Housing Size with 1/2" Radial Ice (Inches) [cm]: 12.5” [31.8] Wide, 10.8” High [27.4], 2.3” [5.8]

Deep

Maximum Projected Area with Ice (Square Inches): 135.0” [2212 cc]

Shape Factor (CD per EIA-222-F) 1.4

Effective Projected Area with Ice (Square Inches) 189 [3097cc]

Omni Antenna (One Antenna)

Antenna Size (Inches) [cm]: 1.3 [3.3] Diameter 19.0 [302] Long

Antenna Size with 1/2" Radial Ice (Inches): 2.3 [5.8] Diameter 20.0 [50.8] Long

Maximum Projected Area with Ice (Square Inches): 46.6 [763cc]

Shape Factor (CD per EIA-222-F) 0.8

Effective Projected Area with Ice (Square Inches) 37.3 [611cc]

LOS-5000 Effective Projected Area (EPA)

LOS Housing with Ice (Inches): 189 [3097cc]

Omni Antenna #1 with Ice (Inches): 37.3 [611cc]

Omni Antenna #2 with Ice (Inches): 37.3 [611cc]

Total Effective Projected Area with 0.5 inch Radial Ice

Effective Projected Area, Total (Square Inches): 263.6 [4319cc]

Note: The above does not include conduit/cabling for Omni Antenna polarization diversity and

LOS-5000 power.

May 2011 D1675 rev B 47

Page 48

WhereLAN III User Guide

APPENDIX B: LOS-5000 WEIGHT

LOS-5000 Housing

Housing Weight (Pounds): 7.0 [3.17.0Kg]

Ice Volume at 0.5 inch [12.7mm] Radial Thickness: 94.7 Cubic Inches [1552cc]

Assumed density of Ice: 0.032 pounds per cubic inch [0.90 g/cc]

Mass of Ice: 3.0 pounds [1.4Kg]

Housing and Ice Mass: 10.0 pounds [4.53Kg]

Omni Antenna (One Antenna)

Antenna Weight: 0.8 pounds [0.36Kg]

Ice Volume at 0.5 inch [12.7mm] Radial Thickness: 58.9 Cubic inches [965 cc]

Assumed density of Ice: 0.032 pounds per cubic inch [0.90 g/cc]

Ice Weight: 1.9 pounds [.86Kg]

Antenna and Ice Weight: 2.7 pounds [1.22Kg)

Total Weight with 1/2" Radial Ice

LOS Housing Ice: 10.0 pounds [4.53Kg]

Omni Antenna #1 with Ice: 2.7 pounds [1.22Kg]

Omni Antenna #1 with Ice: 2.7 pounds [1.22Kg]

Weight, Total: 15.4 pounds [6.98Kg]

Note: The above does not include conduit/cabling for Omni Antenna polarization diversity and

LOS-5000 power.

48 D1675 rev B May 2011

Loading...

Loading...