Page 1

User Guide

Model TFF-2235

WhereCall V and WhereCall V PLC

User Guide

Part Numbers:

TFF-2235-00AA

TFF-2235-00AA-K

TFF-2236-00AA

TFF-2236-00AA-K

____________________________________________________________________________________________ 1

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 2

User Guide

_

Typographical Conventions

____________

____________

____________

CAUTION

____________

_________

Note

________

Warnings call attention to a procedure or practice that

could result in personal injury if not correctly performed.

Do not proceed until you fully understand and meet the

required conditions.

Cautions call attention to an operation procedure or

practice that could damage the product if not correctly

performed. Do not proceed until understanding and meeting

these required conditions.

Notes provide information that can be helpful in

understanding the operation of the product.

____________________________________________________________________________________________ 2

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 3

User Guide

REGULA T ORY AGENCY INFORMA TION

Unless otherwise specified, the following regulatory agency information is for Model

TFF-2235 devices, which include part numbers TFF-2235-00AA and TFF-223600AA.

RF Notice

Any changes or modifications to Zebra Enterprise Solution (ZES) equipment not

expressly approved by ZES could void the user’s authority to operate the equipment.

FCC Compliance Statement

This device complies with Part 15 rules. Operation is subject to the following two

conditions:

(1) This device may not cause harmful interference

(2) This device must accept any interference which may cause undesired operation

Contains FCC ID: XWX-TFF2005

This equipment has been tested and found to comply with the limits for both Class A

and Class B devices, pursuant to Part 15 of the FCC Rules & Regulations.

Canadian DOC Compliance Statement

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du

Canada.

Contains IC: 8701A-TFF2005

____________________________________________________________________________________________ 3

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 4

User Guide

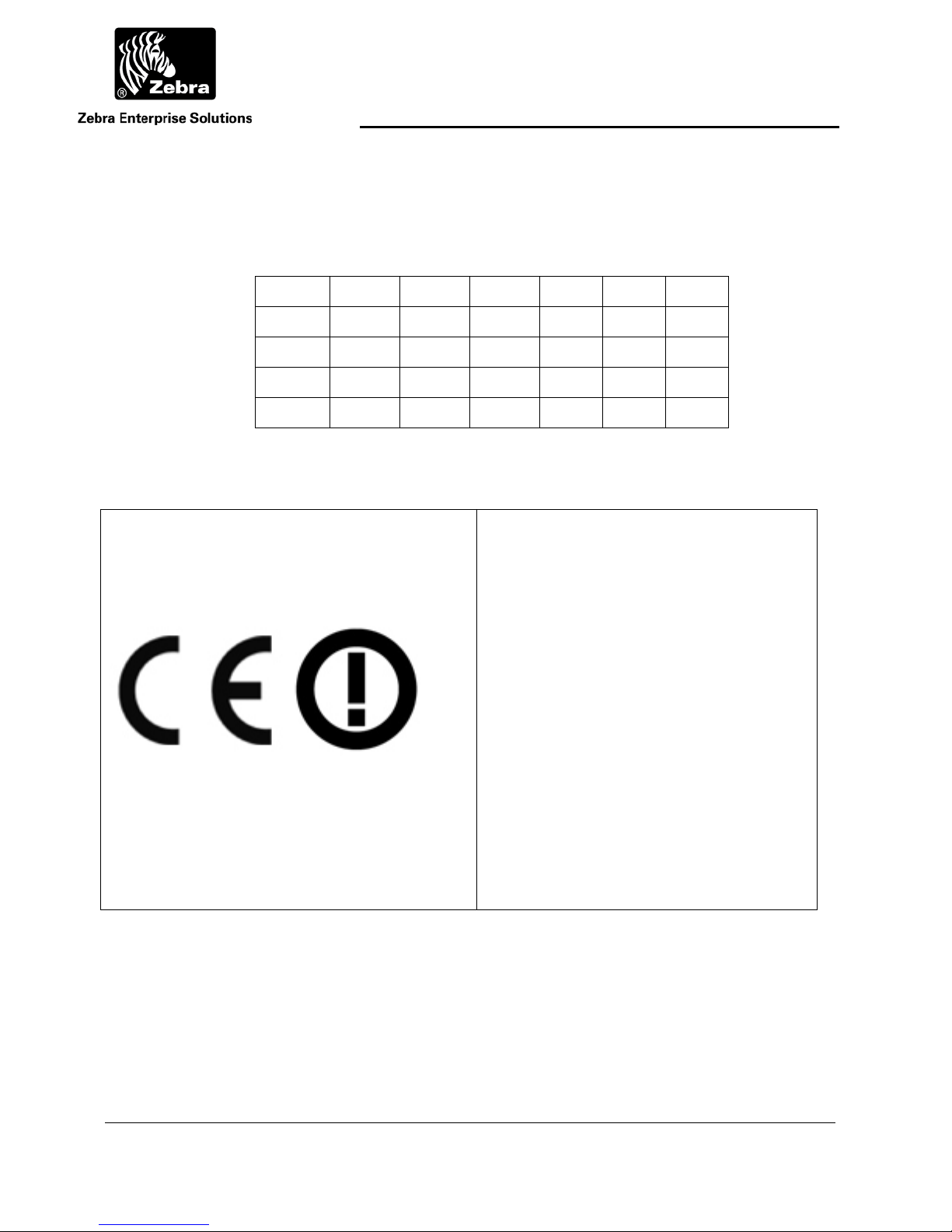

EU Compliance Information

Approved for use in the following countries.

AT BE BG CY CZ DK EE

FI FR DE GR HU IE IT

LV LT LU MT NL PL PT

RO SK SI ES SE GB

IS LI NO CH TR

Note: -Countries there are crossed out there is restrictive use for this

device!

Important Notice:

This RF device is intended for indoor and

outdoor use in all EU and EFTA with the

following limitations.

France: Outdoor use limited to 10 mW e.i.r.p.

within the band 2454-2483.5 MHz

Italy: For private use, a general authorization

is required if WAS/RLAN’s are used outside

own premises. For public use, a general

authorization is required.

Luxembourg: General authorization required

for network and service supply.

Norway: Wideband Data Transmission systems

2400.0-2483.5 MHz does not apply for the

geographical area within a radius of 20 km

from the centre of Ny-Ålesund

____________________________________________________________________________________________ 4

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 5

User Guide

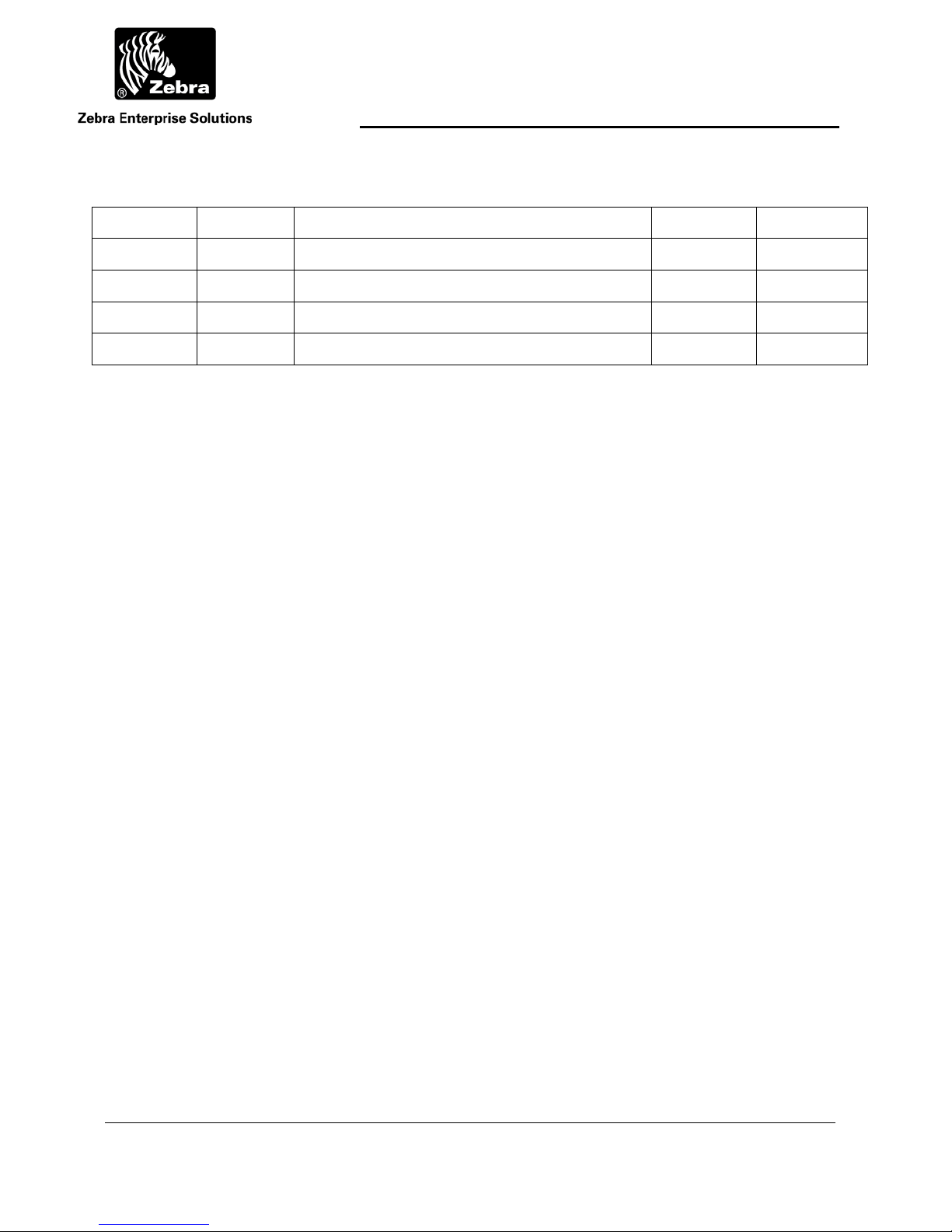

Document Revision History

Revision Change Change Description Date Initials

A C02338 Initial Release 1/5/11 DBowman

____________________________________________________________________________________________ 5

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 6

User Guide

Table of Contents Page

REGULATORYAGENCYINFORMATION........................................................................................................................3

1 OVERVIEW........................................................................................................................................................8

2 COMPONENTS...................................................................................................................................................9

3 INSTALLATION&MOUNTING...........................................................................................................................10

3.1 POLY‐LOCK................................................................................................................................................................10

3.2 MOUNTINGWHERECALLVWITHPOLY‐LOCK...................................................................................................................11

3.3 WHERETAGFOAMTAPESQUARES.................................................................................................................................12

3.4 MOUNTINGWHERECALLVWITHFOAMTAPESQUARES.....................................................................................................13

3.5 MOUNTINGWHERECALLVWITHSCREWS.......................................................................................................................15

3.6 HANGINGCABLEBRACKET(TM‐216‐00).......................................................................................................................16

3.7 INSTALLINGWHERECALLVWITHHANGINGCABLEBRACKET...............................................................................................16

4 OPERATIONOFTHEWHERECALLV...................................................................................................................17

4.1 CALLMODE...............................................................................................................................................................17

4.2 SWITCHMODE...........................................................................................................................................................18

4.3 TURNINGWHERECALLVOFF........................................................................................................................................19

4.4 SWITCHINGWHERETAGVMODES.................................................................................................................................19

4.5 CHANGINGSYSTEMPROTOCOLS....................................................................................................................................20

4.6 WHERECALLVSOFTMESSAGES....................................................................................................................................21

5 SPECIFICATIONS:WHERECALLVDEVICE............................................................................................................25

6 WHERECALLVPLCOVERVIEW..........................................................................................................................28

7 WHERECALLVPLCINSTALLATION&MOUNTING..............................................................................................29

8 CONNECTINGTHEWHERECALLVPLC...............................................................................................................30

8.1 WHERECALLVPLCCABLEANDCONNECTOR...................................................................................................................30

8.2 WHERECALLVPLCELECTRICALCONNECTION..................................................................................................................31

8.3 WHERECALLVPLCSWITCHOPERATION.........................................................................................................................33

9 BATTERYREPLACEMENTPROCEDURE...............................................................................................................34

9.1 DESCRIPTION.............................................................................................................................................................34

9.2 REQUIREDMATERIALSANDTOOLS.................................................................................................................................34

9.3 PROCEDURE...............................................................................................................................................................36

____________________________________________________________________________________________ 6

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 7

User Guide

Table of Figures Page

FIGURE1:POLY‐LOCKFASTENERWITHADHESIVEBACKING................................................................................................................10

FIGURE2:POLY‐LOCK&FOAMTAPEPOSITIONS..............................................................................................................................11

FIGURE3:FOAMTAPESQUARES..................................................................................................................................................12

FIGURE4:SCREWMOUNTINGTEMPLATE(DRAWINGISACTUALSIZE)...................................................................................................14

FIGURE5:COVERSCREWS..........................................................................................................................................................15

FIGURE6:HANGINGCABLEBRACKET,TM‐216‐00.........................................................................................................................16

FIGURE7:FRONT&REARVIEWHANGINGBRACKETINSTALLED...........................................................................................................16

FIGURE8:PHOTOGRAPHOFTHEWHERECALLVPLCWITHANINTERFACECABLEATTACHED....................................................................28

FIGURE9:THEEXTERNALSWITCHISCONNECTEDACROSSPINS1AND3ASINDICATED............................................................................31

FIGURE10ELECTRICALBLOCKDIAGRAM.......................................................................................................................................32

____________________________________________________________________________________________ 7

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 8

User Guide

1 OVERVIEW

The Zebra Enterprise Solutions (ZES) WhereCall System allows users in manufacturing and

assembly operations to request service or specific parts without leaving their workstations.

Specific parts or service requests may be assigned to individual WhereCall V devices so

that users may indicate which item is needed. For example, an assembly worker using

several parts: Each part is associated with a separate WhereCall V device located in the

workstation. By pressing the green button on the WhereCall V device, a radio signal is sent

by the WhereCall System to the computer system in the supply area, indicating which

workstation requires the specified part or service. The display will first blink CALL , and

then alternate between CALL and the time since the button press. This message can

be customized to site preferences.

The WhereCall V also operates in an optional SWITCH mode. This mode can be used to

indicate a status; the display will blink either -- ON -- or - OFF -- to indicate a functional

status. The status will toggle each time the button is pressed. These messages can also be

customized to site preferences. Each status can display a multi-word message on up to two

different screen buffers.

To insure that the WhereCall system is in constant operation, real-time monitoring using an

“I’m Still Alive” blinking transmission advises the system supervisor of the status of each

WhereCall V device. Battery status is also included in these “I’m still alive” messages as

well as in the switch blinks, as well as in the button initiated blinks.

WhereCall V devices may be individually labeled for identification by applying a usersupplied label to the recessed area on the front panel below the green button.

The WhereCall V may be mounted in a work area with removable fasteners, double-sided

foam tape or with mounting brackets and screws. Overhead installation is also possible by

using cable mounting (Refer to Section 3, Installation and Mounting).

____________________________________________________________________________________________ 8

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 9

User Guide

2 COMPONENTS

The WhereCall System consists of four major components: the WhereCall V device; a

location antenna; a location processor and a ZES computer server. This document details

only the WhereCall V device.

The WhereCall V is a palm-sized device approximately 3 inches by 5 inches, 1 inch thick, in

a yellow and gray colored case. A green colored actuator button is in the center of the

device. A liquid crystal display (LCD) screen is located above the button.

The ZES Location Sensor receives radio signals from the WhereCall V device when the

work station user sends a call requesting parts by pressing the green button on the

WhereCall V. These signals are transferred by cable to the ZES Location Processor.

The ZES Location Processor converts signals from the antenna(s) and sends them to the

ZES computer server. A message is generated by the server and sent to the user’s

computer system indicating that a part is needed at the location of the WhereCall V device.

If necessary, the WhereWand hand-held communicator allows the ZES technician to

configure the WhereCall V device. The WhereWand is not required for most applications.

____________________________________________________________________________________________ 9

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 10

User Guide

3 INSTALLATION & MOUNTING

The WhereCall V may be mounted in a work area with removable fasteners, double-coated

foam tape, hanging brackets, or with mounting screws. Overhead installation is also

possible using cable mounting.

Each WhereCall V must be mounted in a location to provide an unobstructed view in at least

one direction. To maintain communication with the Location Antennas, do not install the

WhereCall V inside a metal enclosure such as a metal cabinet.

3.1 Poly-Lock

A plastic, adhesive-backed fastener, Poly-Lock uses mushroom-shaped contact points that

overlap and snap together, forming a strong attachment that can be separated by a forceful

pull. Poly-Lock is not included with the WhereCall V, but is available from ZES in precut

squares. Contact your ZES account manager for information.

Figure 1: Poly-Lock fastener with adhesive backing

____________________________________________________________________________________________ 10

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 11

User Guide

Figure 2: Poly-Lock & foam tape positions

Apply Tape

Apply Tape

3.2 Mounting WhereCall V with Poly-Lock

____________

CAUTION

____________

Do not apply the poly-lock when the temperature is below 60F (15C) or above

90F (32C).

1) Select the desired location in the workstation to mount the WhereCall V.

2) Clean the mounting surface and the back plate of the WhereCall V with

isopropyl alcohol.

3) Select a pair (they are shipped in attached pairs)of Poly-Lock squares,

remove the adhesive backing and press them to the mounting surface,

sticky side down (see Figure 2).

4) Remove the adhesive backing from three additional pairs of Poly-Lock

squares and affix them to the back plate of the WhereCall V to match the

fastener locations on the mounting surface.

____________________________________________________________________________________________ 11

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 12

User Guide

_

5) You should now have four pairs of Poly-Lock attached to the back of the

WhereCall V. Remove the adhesive backing from all four squares.

6) While holding the WhereCall V, aligned with the fasteners on the

mounting surface. Gently press the unit against the mounting surface to

assure that the adhesive on the squares is bonded to the both surfaces.

3.3 WhereTag Foam Tape Squares

WhereTag foam tape, both sides adhesive, provides a secure, semi-permanent mounting

method for the WhereCall V device. Foam tape is not included with the WhereCall V.

Contact your ZES Account Manager for information.

_________

Note

________

____________________________________________________________________________________________ 12

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Figure 3: Foam tape squares

“Double sticky” tape applies a layer of permanent adhesive film to both

surfaces. Care should be taken in the application of foam tape; once applied it

is difficult to remove.

Page 13

3.4 Mounting WhereCall V with Foam Tape Squares

____________

CAUTION

____________

User Guide

Do not apply the foam tape when the temperature is below 60F (15C) or above

90F (32C).

1. Select the desired location to mount the WhereCall V.

2. Clean the mounting surface and the back plate of the WhereCall V with

isopropyl alcohol.

3. Select two foam tape squares, remove the adhesive backing from one

side only and apply them to the back plate of the WhereCall V as shown

in Figure 2.

4. Remove the adhesive backing from the exposed surface of the tape

squares.

5. While holding the WhereCall V, aligned to the desired position. Gently

press the unit onto the mounting surface.

____________________________________________________________________________________________ 13

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 14

User Guide

Remove cover

screws; Insert #6

Figure 4: Screw mounting template (drawing is actual size).

screws here

Dimension from

center to center of

screws =

2.696”

Housing depth at

screw = 1.10”

____________________________________________________________________________________________ 14

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 15

User Guide

3.5 Mounting WhereCall V with screws

The WhereCall V may be directly mounted to a surface such as a wall, post, or desk. For

correct screw placement, use the Screw Mounting Template provided in this User’s Guide

(see Figure 4).

Remove cover

screws, replace

with #6 screws

____________

CAUTION

____________

Figure 5: Cover screws

1. Select the desired location to mount the WhereCall V.

2. Position the mounting template on the mounting surface.

3. Place a pencil, pen or metal scribe on the ‘Insert screw here’ points as shown in

Fig. 4, puncture the template and mark the mounting surface.

4. Drill screw pilot holes as needed into the mounting surface.

5. Remove front cover screws as shown in Figure 5.

6. Inserts #6 screws through holes in the front panel of the WhereCall V and gently

tighten to a snug fit (12 to 15 in-ozs). Do not distort case by over-tightening.

Do not over-tighten screws. Damage to the WhereCall V might result if screws

are over-tightened.

____________________________________________________________________________________________ 15

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 16

User Guide

3.6 Hanging Cable Bracket (TM-216-00)

The WhereCall V may be installed from an overhead cable for ease of use in a workstation

where mounting on flat surfaces is unsafe or inconvenient. Hanging cable brackets are not

included with the WhereCall V but are available from ZES. Contact your ZES Account

Manager for information.

Figure 6: Hanging cable bracket, TM-216-00

3.7 Installing WhereCall V with Hanging Cable Bracket

1. Remove front panel screws as shown in Figure 5. Insert #6 threaded screws

provided with bracket through holes in front panel of WhereCall V.

2. Align the holes in the Hanging Cable Bracket to the screws.

3. Attach hanging cable to Hanging Cable Bracket using cable loop.

Figure 7: Front & rear view hanging bracket installed

____________________________________________________________________________________________ 16

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 17

User Guide

4 OPERATION OF THE WHERECALL V

The WhereCall V is a wireless messaging device that is capable of transmitting simple

messages to the ZES Infrastructure. These messages can range from a call for parts for

line side material replenishment to a request for supervisor assistance. There are three

modes of operation:

Button or CALL Tag Mode

Messaging or SWITCH Tag Mode

OFF Mode

The WhereCall V is shipped in the “OFF” mode. There is also a battery change mode

that is used to condition the tag to for installation of replacement batteries.

When the WhereCall V is on the OFF mode, the display shows PWR OFF . To turn the

WhereCall V on when it is in the OFF mode, press the button once and the tag will

resume operation in either the CALL mode or the SWITCH mode depending on the

mode it was in when the OFF mode was selected.

4.1 Call Mode

In CALL mode the WhereCall V can be used for parts call and other operations that do

not require an indication as to whether the request was fulfilled. In this mode, the

operator presses the button to send the request message, and the WhereCall V will

transmit blinks with “Switch ID 0” which has status 2. The display on the WhereCall V

will flash

was made. This lets the operator easily verify how long it has been since they made their

request. The display is capable of counting up to 9 days, 23 hours, and 59 minutes

shown as

9d23h59m but the elapsed time will not increment any further.

CALL for one minute and then start to count up in minutes since the call

9d23h59m after which it will continue to alternate between CALL and

____________________________________________________________________________________________ 17

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 18

User Guide

The displayed CALL can be replaced with any other 8-character custom message.

The custom message will blink for one minute after each button push, and then the

custom message will alternate with the elapsed time.

4.2 Switch Mode

In switch mode, the display toggles between -- ON -- and -- OFF --. The normal

starting state is OFF. If the operator presses the button, then the WhereCall will send a

message signaling the change in state and the display will change to -- ON --. The

resulting transmission blink includes “Switch ID 0” which has status 2. The next button

press will cause a new message to be transmitted with “Switch ID 1” which has status 4.

This signals the change of state and the display will change back to - OFF --. In the

SWITCH mode the WhereCall V will send multiple transmissions at increasing intervals

after each button press. The first set of blinks occurs as soon as the button is pressed,

then repeats at 1 minute after the button press. The message is then repeated at the

following periods after the initial button press: 5 minutes, 10 minutes, 15 minutes, and

then 30 minutes.. After completing that sequences, the WhereCall V then continue

sending a set of blinks every 60 minutes.

The displayed -- ON -- and - OFF – messages can be replaced to show any one or a

pair of 8-character custom messages. If the message is replaced with a pair of custom

messages, then the display will not flash, but instead alternate between the pair of

custom messages. When the button is pressed, the display will alternate between the

other pair of messages.

____________________________________________________________________________________________ 18

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 19

User Guide

4.3 Turning WhereCall V Off

The WhereCall V can be switched to the Power OFF mode from either CALL mode or

SWITCH mode. In order to do this, press and hold the button until the display shows

******** and then release the button. The display will show the tag firmware version

TAG 2109 for a few seconds and then show the PIC Microcontroller firmware PIC 1017

version for a few seconds, the show PWR OFF . Note that the displayed version number

may differ than those shown above. The WhereCall V is now OFF and all transmissions

are disabled. The magnetic receiver in the tag is also disabled.

4.4 Switching WhereTag V Modes

To change modes between CALL mode and Switch mode or visa versa, press and hold the

button. After about 5 seconds, the display will show ********. DO NOT release the button

while the display shows *********, but continue to keep the button depressed until the

display shows:

- CALL ? if the WhereCall V is currently in SWITCH mode

- SWITCH ? if the WhereCall V is currently is CALL mode.

When either of these is displayed, release the button , and then press and release the

button again within five seconds. This will change the operational mode.

If the WhereCall V has been changed from CALL mode to SWITCH mode, the tag will send

SW ID 1 with status 4 and the display will show

- OFF --.

If the WhereCall V has been changed from SWITCH mode to CALL mode, the tag will send

SW ID 0 with status 2 and the display will show CALL .

____________________________________________________________________________________________ 19

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 20

User Guide

4.5 Changing System Protocols

To change the WhereCall V mode between ISO 24730, CCX, and dual mode, the

WhereCall V must be in OFF mode and display

PWR OFF . Press and hold the button for

several seconds until the display starts to cycle between these options…

ISO MODE, CCX MODE, DUALMODE, and CNG BATT.

To switch to ISO 24730 mode, keep the button pressed until the display is showing

ISO MODE, then release the button, then click the button again to activate the mode. This

mode will disable all CCX blinks and the WhereCall V will only send ISO 24730 blinks. In

ISO 24730 mode, the decimal point in the lower right most corner of the LCD will flash.

To switch to CCX mode, keep the button pressed until the display is showing CCX MODE, then

release the button, then click the button again to activate the mode. This mode will disable

all ISO 24730 blinks and the WhereCall V will only send CCX blinks. In CCX mode, the

apostrophe in the upper left most corner of the LCD will flash.

To switch to dual protocol mode, keep the button pressed until the display is showing

DUALMODE, then release the button, then click the button again to activate the mode. In this

mode, the WhereCall V send both ISO 24730 and CCX blinks. In dual protocol mode, both

the decimal in the lower right most corner and the apostrophe in the upper left most corner

of the LCD will flash.

If the user has inadvertently released the button at the wrong time and the WhereCall V is

displaying the wrong mode, do not click the button again. The tag will timeout and return to

OFF mode and the display will show

PWR OFF . The user can now start the changing

protocol sequence again.

____________________________________________________________________________________________ 20

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 21

User Guide

4.6 WhereCall V Soft Messages

The WhereCall V supports soft messaging which allows the user to replace the displayed

messages

CALL , - - ON - - and/or - OFF - - with custom messages. Setting or

changing the soft message will require a WhereWand to enter and program the messages

to the WhereCall V magnetically.

If a custom message is configured in CALL mode, then the custom message will be

displayed. , instead of CALL blinking or alternating with elapsed time, There is no

change to the air protocol blink content .

In SWITCH mode, each of the two messages can be replaced with a single message or a

pair of messages.

If custom messages are configured and the WhereCall V is in the SWITCH mode ON state,

instead of - - ON - - blinking, the display will either blink the custom ON mode single

message or alternate between the pair of custom ON mode messages.

If custom messages are configured and the WhereCall V is in the SWITCH mode OFF state,

instead of

- OFF - - blinking, the display will blink either the custom OFF mode single

message or alternate between the pair of custom OFF mode messages.

A variant of WhereCall V, the WhereCall V PLC, provides for automated call requests by

replacing the call button with a sealed connector that can be interfaced to intelligent shop

floor equipment.

The WhereCall V provides long battery life, typically in excess of 5 years. Additionally, the

batteries are replaceable providing a long product life.

____________________________________________________________________________________________ 21

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 22

User Guide

Display

Message

“CALL ”

(flashing)

CustCall

(flashing)

“CALL ”

10h 42m

(alternating)

CustCall

10h 42m

(alternating)

--“ON --

(flashing)

Cust ON1

(flashing)

Cust ON1

Cust ON2

(alternating)

- “OFF --

(flashing)

CustOFF1

(flashing)

CustOFF1

CustOFF2

(alternating)

********

PWR OFF

Display Meaning Comments Action required

CALL mode button blinks

are being transmitted.

This display follows the

Call” display and indicates

the elapsed time from the

last button press.

This mode will continue for

60 seconds following a

button press.

The time advances from

1m until it reaches

9d23h59m then holds until the

button is pressed again.

None

None

In SWITCH mode, each

SWITCH mode where the

tag will transmit Switch ID

button press will toggle

between

None

0 with tag status 2.

-- ON -- and - OFF --.

In SWITCH mode, each

SWITCH mode where the

tag will transmit Switch ID

button press will toggle

between

None

0 with tag status 4.

-- ON -- and - OFF --.

Indicates that the user has

held the button for several

seconds and the unit will

turn off when released

After the button is release,

the unit will display its

firmware versions before

turning off.

Release the

button to turn the

WhereCall IV off.

Pressing the button will turn

Indicates that the

WhereCall IV is in PWR

OFF mode

the unit on again into the

mode (CALL or SWITCH)

that the unit was in prior to

None

being turned off.

____________________________________________________________________________________________ 22

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 23

User Guide

Display

Message

CALL ?

SWITCH ?

ISO MODE

CCX MODE

DUALMODE

CNG BATT

(cycling)

CCX MODE

DUALMODE

CNG BATT

ISO MODE

(cycling)

Display Meaning Comments Action required

To change modes release

the button and then press

Indicates that the user has

held the button for several

seconds and can now

change mode from

SWITCH mode to CALL

mode if desired.

the button again within 5

seconds. Pressing the

button again will initiate

CALL mode and issue Call

blinks. Releasing the button

without pressing it again will

Release the

button, then

press the button

again to initiate

“CALL”

operation.

cause the WhereCall IV to

enter OFF mode.

To change modes release

the button and then press

Indicates that the user has

held the button for several

seconds and can now

change mode from CALL

mode to SWITCH mode if

desired.

the button again within 5

seconds. Pressing the

button again will initiate

SWITCH mode and issue

Switch ID 0 blinks. Releasing

the button without pressing it

again will cause the

Release the

button, then

press the button

again to initiate

“SWITCH”

operation.

WhereCall IV to enter OFF

mode.

ISO MODE indicates the

user has pressed and held

the button for several

seconds while in PWR

OFF state and can now put

the tag into ISO 24730

transmit mode

CCX MODE indicates the

user has pressed and held

the button for several

seconds while in PWR

OFF state and can now put

the tag into an unsupported

mode

The display will cycle

between the various protocol

modes and the change

battery mode. The user

must release the button

when the 24730 mode is

shown then click the button

again to activate the mode.

The display will cycle

between the various protocol

modes and the change

battery mode. The user

must release the button

when the desire mode is

shown then click the button

again to activate the mode.

Release the

button, then

press the button

again to turn the

WhereCall IV on

in ISO 24730

mode.

Release the

button, then wait

until the

WhereCall IV

returns to

POWER OFF

mode

____________________________________________________________________________________________ 23

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 24

User Guide

Display

Message

DUALMODE

CNG BATT

ISO MODE

CCX MODE

(cycling)

CNG BATT

ISO MODE

CCX MODE

DUALMODE

(cycling)

CHANGE

BATTERY

(alternating)

LOW BATT

(alternating)

Display Meaning Comments Action required

DUALMODE indicates the

user has pressed and held

the button for several

seconds while in PWR

OFF state and can now put

the tag into an unsupported

mode

The display will cycle

between the various protocol

modes and the change

battery mode. The user

must release the button

when the desire mode is

shown then click the button

again to activate the mode.

Release the

button, then wait

until the

WhereCall IV

returns to

POWER OFF

mode.

The display will cycle

CNG BATT indicates the user

has pressed and held the

button for several seconds

while in PWR OFF state

and can now put the tag

into battery change mode

between the various protocol

modes and the change

battery mode. The user

must release the button

when CNG BATT is shown

then click the button again to

Release the

button, then

press the button

again to put the

WhereCall IV into

battery change

mode.

activate the mode.

The user should remove the

Indicates that the

WhereCall IV is in battery

change mode.

bottom cover and replace the

batteries within 5 minutes of

starting the mode. To exit

the mode, click the button

Replace batteries

or click the

button to exit the

mode.

again.

Indicates that the

WhereCall IV has detected

a low battery. The user

should enter battery

change mode and change

This message will alternate

or cycle with the existing

messages in either CALL or

SWITCH mode.

Enter battery

change mode

and replace the

batteries.

the batteries.

____________________________________________________________________________________________ 24

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 25

User Guide

5 SPECIFICATIONS: WHERECALL V DEVICE

Specifications are subject to change without notice.

Mechanical

Dimensions 2.9 x 4.9 x 1.4 Inches (7.8 cm x 12.5 cm x 3.6 cm)

Weight 6.4 Ounces (181.5 g) check the weight

Color High Visibility Yellow and Gray

Attachments Mounting devices

Form Factor Wall Mounted-Rugged Aesthetics

Durability

Drop 4 feet to concrete

Temperature +32°F to +122°F, ( 0° to +50°C )

Humidity 0% to 100% condensing

Pressure Wash Unit to withstand windblown dust and rain (IP 54)

Button Functional after 1 million cycles

ESD Functional per IEC-1000-4-2 Level 4

Battery

Battery Type Two, “AA” Lithium Thionyl Chloride Cells

Battery Life Typical 5 years (Batteries are customer replaceable)

Connector (used with WhereCall V PLC)

Connector Waterproof, 4 pin, mates with Turck RS-44T or compatible..

____________________________________________________________________________________________ 25

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 26

User Guide

Configurable Parameters

Configuration

Frame

Button Function Push button 1st time, Tag emits 3 DSSS blinks with

Button

Characteristics

Autonomous Transmission

Characteristics Device sends one DSSS blink at user’s desired blink

Purpose Indicates device is present and functional even if no parts

Configurable WhereWand or Hand Held Communicator can vary rate of

Status Word

Some functions can be changed via a WhereWand.

Contact your ZES service representative for more

information.

status bit 1 set (xxlx). Sub-blinks per blink as

configured. The LCD timer starts, counts up to 24:00

and then holds. Push button 2nd time, the timer clears,

cycle starts over.

A green, .47-inch diameter button, with tactile

feedback.

rate. (Factory preset: to send transmission every 128

seconds) with no status bits set (other than low battery

bit, if active).

requested.

autonomous blinks from 2 seconds to 9 hours. Note: The

WhereCall V will not communicate with the HHC if the

display reads “OFF”

Length 4 bits

Battery low bit bit 0 (xxx1), ‘1’ = battery low.

Call mode Button

bit 1 (xx1x), ‘1’ = button 1 pressed.

Push or

Message mode =

“ON”

Message mode =

bit 2 (x1xx), ‘1’ = button 1 pressed.

“OFF”

Timer and Display Characteristics

Number of

8

Characters

Format 14-Segment with apostrophe and decimal for each

character

Function Check previous page

Digit Size .28 inch [7 mm] high

____________________________________________________________________________________________ 26

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 27

User Guide

Back Lit No

WhereCall V PLC User & Interface Guide

____________________________________________________________________________________________ 27

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 28

User Guide

6 WHERECALL V PLC OVERVIEW

This document describes how to mount and interface the WhereCall V PLC to your

equipment via the external industrial connector.

The WhereCall V PLC is a variation of the standard WhereCall V. It allows the call tag to be

used with a remote switch in external equipment. The external equipment can “press the

button” to initiate a call. This enables the WhereCall V PLC and the user equipment to

operate unattended and to send a call message via the ZES system.

Figure 8: Photograph of the WhereCall V PLC with an interface cable attached.

(This cable is not included with the WhereCall V PLC.)

For more information regarding the operation and installation of the

WhereCall VPLC, please refer to the WhereCall V User Guide.

In this document the Terms WhereCall V PLC and TFF-2236 are used

interchangeably and will have the same meaning.

____________________________________________________________________________________________ 28

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 29

User Guide

_

7 WHERECALL V PLC INSTALLATION & MOUNTING

The WhereCall V PLC may be mounted in a work area with removable fasteners, doublecoated foam tape, hanging brackets, or with mounting screws. Overhead installation is also

possible using cable mounting.

Each WhereCall V PLC must be mounted in a location to provide an unobstructed view to a

location antenna in at least one direction. To maintain communication with the Location

Antennas, do not install the WhereCall V PLC inside a metal enclosure such as a metal

_________

Note

________

cabinet.

In selecting the mounting location keep in mind that the cable from the equipment

to the WhereCall V PLC must not exceed 3 meters (10 feet).

____________________________________________________________________________________________ 29

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 30

User Guide

_

8 CONNECTING THE WHERECALL V PLC

The WhereCall V PLC can be connected to a remotely mounted switch that is used to

initiate a “button blink”. This product works very much like the WhereCall V except that

“button” actuation is provided from another device.

8.1 WhereCall V PLC Cable and Connector.

The TFF-2236 is to be connected using a Turck, RS 4.4T-X cord-set. The length of the

cable is limited to 3.0M (10 feet). When this cord set is used the connection will be

watertight.

This cord-set can be purchased from:

Turck USA

Other Turck locations are listed on the web site.

____________

CAUTION

____________

_________

Note

________

3000 Campus Drive

Minneapolis, MN 55441

1-800-588-8725

WWW.TURCK.COM

The cable length between the TFF-2236 and the remote device must not exceed

3.0 Meters (10 feet).

ZES does not supply the cord sets and connectors for the WhereCall V PLC.

____________________________________________________________________________________________ 30

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 31

User Guide

_

8.2 WhereCall V PLC Electrical Connection.

Pins one (1) and three (3) are to be connected to the remote switch.

Figure 9: The external switch is connected across pins 1 and 3 as indicated

_________

Use the reference detail on the connector to identify the pin numbers.

Note

________

The connector may not be oriented the same on all units.

____________________________________________________________________________________________ 31

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 32

User Guide

Remote

device

WhereCall V PLC

Momentary switch

operated by user's

LCD Window

Not Used

4

3

Not Used

1

2

Cord Set, not to

exceed 3

meters

1.The connector on the WhereCall III+ PLC may not be oriented as

Notes:

2. The Cord is not supplied by WhereNet. Please see instructions.

3. The momentary switch will initiate a "button Blink" when it is

closed for 100 milliseconds and then released. The switch must not

remained closed for more than 3.0 seconds or the tag will

transition to the OFF mode .

Figure 10 Electrical Block Diagram

____________

The cable should be connected and routed to prevent large voltage

CAUTION

____________

spikes and static discharges from being carried into the tag via the

switch cable. This may result in false “Button Calls” being generated or

in extreme cases the TFF-2236 could be damaged.

____________________________________________________________________________________________ 32

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 33

User Guide

_

8.3 WhereCall V PLC Switch Operation

The switch used to operate the TFF-2236 must be a momentary type. The TFF-2236 will

initiate a “Button Blink” sequence when the switch breaks after having been closed for at

least 100 ms and less than 5 seconds. It the switch is closed for less than 100 ms the unit

will not react. See Table 1 for more information.

_________

Note

________

If the switch remains closed for three (3) seconds or more, the unit will change to

the “OFF” mode.

____________________________________________________________________________________________ 33

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 34

User Guide

9 BATTERY REPLACEMENT PROCEDURE

9.1 Description

WhereCall V Tags have a nominal battery life of 5 years. After that nominal battery life, it is

possible to replace the batteries to extend the life of the tag itself; however, ZES does not

provide personnel or Services for this process.

To avoid damaging the WhereCall V tags, the proper screwdrivers with the correct settings

must be used. This procedure must be followed or the WhereCall V may become nonoperational and there is no field recovery method if this occurs. Batteries should be replaced

before they are completely dead.

ZES assumes no responsibility for damage to or failure of the WhereCall Tags resulting

from this battery replacement procedure.

9.2 Required Materials and Tools

9.2.1 Materials

____________

CAUTION

____________

Qty. 2 per tag 3.6V Lithium battery

(ZES P/N 20057, SAFT P/N LS 14500)

SAFT 12 company address - rue Sadi Carnot 93170 BAGNOLET - France

Tel.: +33 (0)1 49 93 19 18 Fax: +33 (0)1 49 93 19 50

Caution: Use only the exact battery and manufacturer specified above.

Note: It is recommended that new batteries be marked with a marker prior to use to

avoid inadvertent confusion with old batteries while replacement is being done.

____________________________________________________________________________________________ 34

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 35

User Guide

9.2.2 Tools

One, adjustable torque screwdriver with a # 2 Phillips tip and the torque set to 26 inch

pounds for the two screws on the Face of the tag.

One, adjustable torque screwdriver with a # 1 Phillips tip and the torque set to 6 inch

pounds for the four screws in the back of the tag.

One, “small, pocket size” flat blade screw driver use to remove batteries from the

battery holder.

One, ESD wrist strap or equivalent static protection device.

ZES does not provide the required materials and tools for changing batteries in the

WhereCall V Tags.

____________________________________________________________________________________________ 35

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 36

User Guide

9.3 Procedure

____________

CAUTION

____________

Caution: Personnel changing batteries must use an ESD wrist strap to prevent

damage of the tag circuit board due to static discharge. Follow the manufacturer’s

instructions for proper use of the static prevention device.

1) To change the WhereCall V batteries, the WhereCall V must be in OFF mode and

display PWR OFF . See section 4.3 for instructions on turning the WhereCall V off.

2) From the OFF mode, enter battery change mode as follows:

Press and hold the button for several seconds until the display starts to cycle

between these options…ISO MODE, CCX MODE, DUALMODE, and CNG BATT. Release

the button when the display shows CNG BATT, then click the button again to

activate the mode. The WhereCall IV is now in a mode that draws more current in

bursts to ensure the circuitry fully discharges when the batteries are removed.

This mode will expire in 5 minutes, so the batteries should be replaced within 5

minutes to ensure proper restart of the internal processors.

3) Proceed with the battery replacement procedure. Use the #2 Phillips screwdriver

to remove the 2 screws from the face of the tag.

4) With the tag sitting face down, use the #1 Phillips screwdriver to remove the 4

screws near the corners on the back of the tag.

5) With the tag face down, grasp the yellow bezel with one hand and remove the

white back cover with the other hand. Place the cover aside with the screw points

down noting the orientation for ease of reassembly. Take care not to invert the

cover as the screws can fall out and may be lost.

____________________________________________________________________________________________ 36

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Page 37

User Guide

6) Note the positive/negative orientation of one of the batteries and insert the tip of

the flat blade screw driver between the Positive (+) end of the battery and the

plastic case and gently pry it loose. Insert a new battery insuring the correct

positive/negative orientation before removing the second battery. Replace the

second battery.

Note battery orientation. The arrows

point to the + side of the 2 batteries

____________

CAUTION

____________

7)

8)

9) To restore the tag to operation press the button and the tag will resume normal

Caution: Inserting a battery with the wrong orientation

may damage the batteries and/or the tag

Confirm that the display indicates OFF. This confirms that the battery

replacement was successful.

Reassemble the tag using the screws removed earlier

operation.

.

____________________________________________________________________________________________ 37

User Guide for WhereCall V and WhereCall V PLC D1722 Rev A

©2008 ZES WhereCall III, WhereCall V and all product names and numbers are ZES trademarks. All other trademarks are the property of their respective owners.

Loading...

Loading...