Zebra FS40-SR20D4, VS40-WA20S4, VS70-CM20S5, FS70-CM20F5, VS70-CM20P5 Product Reference Guide

FS/VS Smart

Camera Series

Product Reference Guide

MN-003810-02EN Rev. A

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners.

©2021 Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/linkoslegal

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

2

Contents

Getting Started

xS40 Configurations .............................................................................................................. 2

xS70 Configurations .............................................................................................................. 4

FS/VS Smart Camera Accessories ....................................................................................... 5

External Lighting ................................................................................................................. 5

Internal Ring Lighting (xS40 Only) ...................................................................................... 7

Internal and External Filters ................................................................................................ 9

Internal Filters (xS40 Only) ............................................................................................... 11

C-Mount Lenses (xS70 Only) ............................................................................................ 12

Lens Covers (xS70 Only) .................................................................................................. 12

Communication Cables ..................................................................................................... 13

Brackets ............................................................................................................................ 15

Power Supplies ................................................................................................................. 16

FS/VS Smart Camera Specifications .................................................................................. 17

xS40 Specifications .......................................................................................................... 17

xS70 Specifications ....................................................................................................................... 19

Installation

Dimensional Drawings ........................................................................................................ 21

xS40 Dimensional Drawings ............................................................................................. 21

xS70 Dimensional Drawings ............................................................................................. 23

Connection Interfaces ......................................................................................................... 24

xS40 Connections ............................................................................................................. 24

xS70 Connections ............................................................................................................... 25

Torque Specification ......................................................................................................... 26

Power Sources .................................................................................................................... 27

12 Pin M12 Power Input ................................................................................................... 27

Power Over Ethernet ........................................................................................................ 27

USB Type C ...................................................................................................................... 27

Grounding for Electro-Magnetic Compliance and ESD Safe .............................................. 28

Cable Pin Outs .................................................................................................................... 29

Power and I/O Connector ................................................................................................. 29

Ethernet Connector ........................................................................................................... 30

External Light Connector .................................................................................................. 31

Setting up an FS/VS Smart Camera ................................................................................... 32

3

Contents

General Mounting Instructions .......................................................................................... 32

Mounting the Device Using the L-Bracket Accessory (BRKT-LMNT-U000) ..................... 32

Illumination System Installation (xS40 Only) ....................................................................... 35

Illumination System Disassembly (xS40 Only) .................................................................... 35

Threaded Lens Cover Assembly Installation ....................................................................... 36

C-Mount Lens Installation (xS70 Only) ............................................................................... 36

Setting Focus .................................................................................................................... 38

USB Type C ........................................................................................................................ 39

Supported Display Resolutions ......................................................................................... 39

User Interface ...................................................................................................................... 40

Decode LEDs .................................................................................................................... 40

User Interface Label ......................................................................................................... 41

LED and Beeper Indicators ................................................................................................. 42

User Interface Framework Codes ..................................................................................... 44

Data Capture ....................................................................................................................... 47

Aiming Patterns ................................................................................................................ 47

xS40 Decode Ranges ....................................................................................................... 47

xS70 Minimum Focus Distances ....................................................................................... 48

General Purpose Input and Outputs ................................................................................... 48

Optically Coupled GPIO .................................................................................................... 48

Digital Industrial GPIO ...................................................................................................... 50

Analog Output ................................................................................................................... 51

Power and Thermal Management ....................................................................................... 52

Zebra Aurora Software Overview

Human-Machine Interface (HMI) ....................................................................................... 53

Industrial Ethernet Information .......................................................................................... 53

Zebra Aurora Features ........................................................................................................ 53

Device Discovery ................................................................................................................ 54

Ethernet Setup .................................................................................................................. 56

Configuring Device Settings ................................................................................................ 57

Communication Settings ................................................................................................... 58

General Settings ............................................................................................................... 59

GPIO Mapping .................................................................................................................. 60

Building and Deploying Fixed Scanning (FS) Jobs ............................................................. 61

Building and Deploying Vision System (VS) Jobs ............................................................... 62

Using the QuickDraw Tool ................................................................................................ 62

Accessing the Web Human-Machine Interface (HMI) ......................................................... 64

Live Monitoring with the Web HMI .................................................................................... 65

Accessing the Device using the Web-HMI ........................................................................ 66

Factory Reset ...................................................................................................................... 67

Software License Activation Methods ................................................................................. 68

Supported Symbologies ...................................................................................................... 69

Machine Vision Toolsets ..................................................................................................... 69

4

Troubleshooting

Maintenance

Contents

Communicating with the Device .......................................................................................... 72

Pinging the Device via IP .................................................................................................. 72

Pinging the Device via Hostname ..................................................................................... 72

Device Discovery Troubleshooting Methods ....................................................................... 73

Factory Reset the Device .................................................................................................. 73

Power Cycling the Device ................................................................................................. 73

Security Settings ................................................................................................................. 74

Zebra Aurora Communication Port Usage .......................................................................... 75

Maintenance ........................................................................................................................ 76

Known Harmful Ingredients ............................................................................................... 76

Approved Cleaning Agents ............................................................................................... 76

Tolerable Industrial Fluids and Chemicals ................................................................................. 77

Cleaning the Device .......................................................................................................... 77

5

About This Guide

The FS/VS Smart Camera Series Product Reference Guide provides general instructions for integrating,

setting up, and programming the device.

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at: zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

1

Getting Started

This section outlines the configurations, accessories, and specifications of the FS/VS Smart Camera

Series.

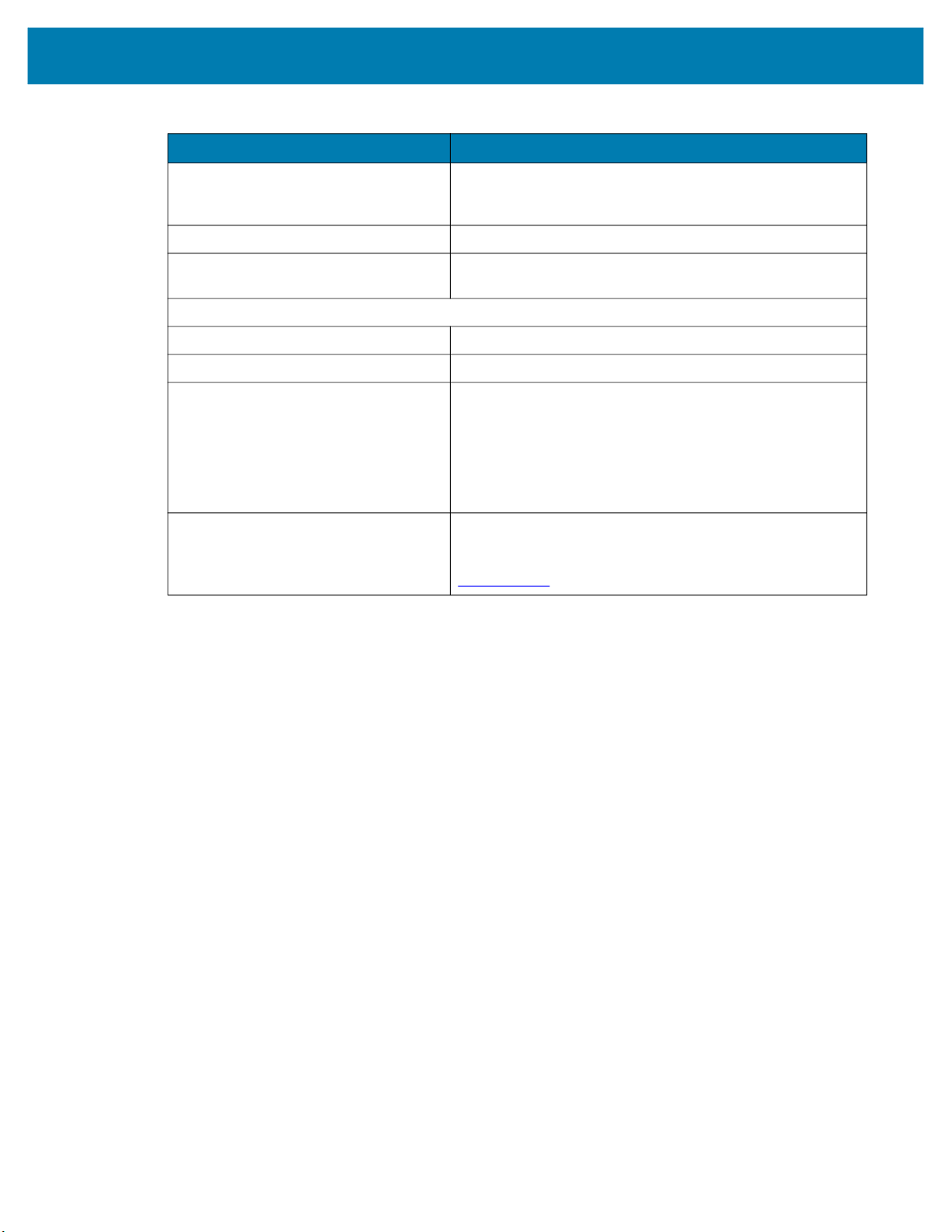

xS40 Configurations

Table 1 xS40 Configurations

Model SKU Toolset Focus Range Res. Illumination

FS40 Standard Range

FS40-SR20D4-2C00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-SR20D4-3X00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-SR20D4-6C00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-SR20F4-2C00W Fast 2D Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-SR20F4-5C00W Fast 2D Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-SR20F4-6C00W Fast 2D Barcode

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

Auto Standard

Range

Auto Standard

Range

Auto Standard

Range

Auto Standard

Range

Auto Standard

Range

Auto Standard

Range

2.3 MPRed Illumination

No Filter

2.3 MPWhite Illumination

RGB Filter

2.3 MPRed, White and

Infrared

Illumination

No Filter

2.3 MPRed Illumination

No Filter

2.3 MPInfrared

Illumination

No Filter

2.3 MPRed, White and

Infrared

Illumination

No Filter

2

Getting Started

Table 1 xS40 Configurations

Model SKU Toolset Focus Range Res. Illumination

FS40-SR20Z4-2C00W Standard 2D

Barcode Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40 Wide Angle

FS40-WA20D4-2C00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20D4-3X00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20D4-6C00W DPM with Fast 2D

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20F4-2C00W Fast 2D Barcode

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20F4-5C00W Fast 2D Barcode

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20F4-6C00W Fast 2D Barcode

Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

FS40-WA20Z4-2C00W Standard 2D

Barcode Decoder

Ethernet with PoE,

Serial, USB and

Industrial Protocols

VS40 Standard Range

VS40-SR20S4-2C00W Sensor Toolset

Ethernet with PoE,

Serial, USB and

Industrial Protocols

VS40-SR20S4-2R00W Sensor Toolset

Ethernet with PoE,

Serial, USB and

Industrial Protocols

Auto Standard

Range

Auto Wide

Angle

Auto Wide

Angle

Auto Wide

Angle

Auto Wide

Angle

Auto Wide

Angle

Auto Wide

Angle

Auto Wide

Angle

Auto Standard

Range

Auto Standard

Range

2.3 MPRed Illumination

No Filter

2.3 MPRed Illumination

No Filter

2.3 MPWhite Illumination

RGB Filter

2.3 MPRed, White, and

Infrared

Illumination

No Filter

2.3 MPRed Illumination

No Filter

2.3 MPInfrared

Illumination

No Filter

2.3 MPRed, White, and

Infrared

Illumination

No Filter

2.3 MPRed Illumination

No Filter

2.3 MPRed Illumination

No Filter

2.3 MPRed Illumination

Red Bandpass

Filter

3

Table 1 xS40 Configurations

Model SKU Toolset Focus Range Res. Illumination

VS40 Wide Angle

VS40-WA20S4-2C00W Sensor Toolset

VS40-WA20S4-2R00W Sensor Toolset

xS70 Configurations

Table 2 xS70 Configurations

Model SKU Toolset Res. Illumination

FS70 FS70-CM20D5-0C00W DPM with Fast 2D Barcode

FS70-CM20F5-0C00W Fast 2D Barcode Decoder

VS70 VS70-CM20S5-0C00W Sensor Toolset

VS70-CM20P5-0C00W DPM with Fast 2D Barcode

Getting Started

Auto Wide

Ethernet with PoE,

Serial, USB and

Industrial Protocols

Auto Wide

Ethernet with PoE

Serial, USB and

Industrial Protocols

Decoder

Dual Ethernet (1 PoE), Serial,

USB and Industrial Protocols

Dual Ethernet (1 PoE), Serial,

USB and Industrial Protocols

Dual Ethernet (1 PoE), Serial,

USB and Industrial Protocols

Decoder

Dual Ethernet (1 PoE), Serial,

USB and Industrial Protocols

2.3 MPRed Illumination

Angle

2.3 MPRed Illumination

Angle

2.3 MP Lens Not Included

2.3 MP Lens Not Included

2.3 MP Lens Not Included

2.3 MP Lens Not Included

No Filter

Red Bandpass

Filter

4

Getting Started

FS/VS Smart Camera Accessories

External Lighting

Table 3 External Lighting Accessories

Part Number Description

LGHT-B100RD-0000 LED Bar light, 100MM, red-625

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers

LGHT-B100BL-0000 LED Bar light, 100MM, blue-465

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers

LGHT-B100WH-0000 LED Bar light, 100MM, white wavelength,

5-Pin male M12 connector, semi-diffused,

includes transparent and opaque diffusers

LGHT-B100IR-0000 LED Bar light, 100MM, IR-850 wavelength,

5-Pin male M12 connector, semi-diffused,

includes transparent and opaque diffusers

LGHT-B300RD-0000 LED Bar light, 300MM, red-625

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers.

LGHT-B300BL-0000 LED Bar light, 300MM, blue-465

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers.

LGHT-B300WH-0000 LED Bar light, 300MM, white wavelength,

5-Pin male M12 connector, semi-diffused,

includes transparent and opaque diffusers.

LGHT-B300IR-0000 LED Bar light, 300MM, IR-850 wavelength,

5-Pin male M12 connector, semi-diffused,

includes transparent and opaque diffusers.

5

Getting Started

Table 3 External Lighting Accessories (Continued)

Part Number Description

Rings

LGHT-R100BL-0000 LED Ring light, 100MM, blue-465

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers.

LGHT-R100WH-0000 LED Ring light, 100MM, white wavelength,

5-Pin male M12 connector, semi-diffused,

includes transparent and opaque diffusers.

LGHT-R100IR-0000 LED Ring light, 100MM, IR-850

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers.

LGHT-R100RD-0000 LED Ring light, 100MM, red-625

wavelength, 5-Pin male M12 connector,

semi-diffused, includes transparent and

opaque diffusers.

Polarizers

LGHT-A100BP-0000 100MM Bar Light Polarizer

For use with 100mm External Light Bars

(LGHT-B100xx-0000).

Not for use with IR-850 wavelengths or

when IR image capture is required.

LGHT-A300BP-0000 300MM Bar Light Polarizer

For use with 300mm External Light Bars

(LGHT-B300xx-0000).

Not for use with IR-850 wavelengths or

when IR image capture is required.

LGHT-A100RP-0000 Light Polarizer

For use with 100mm External Ring Lights

(LGHT-R100xx-0000).

Not for use when IR image capture is

required.

6

Getting Started

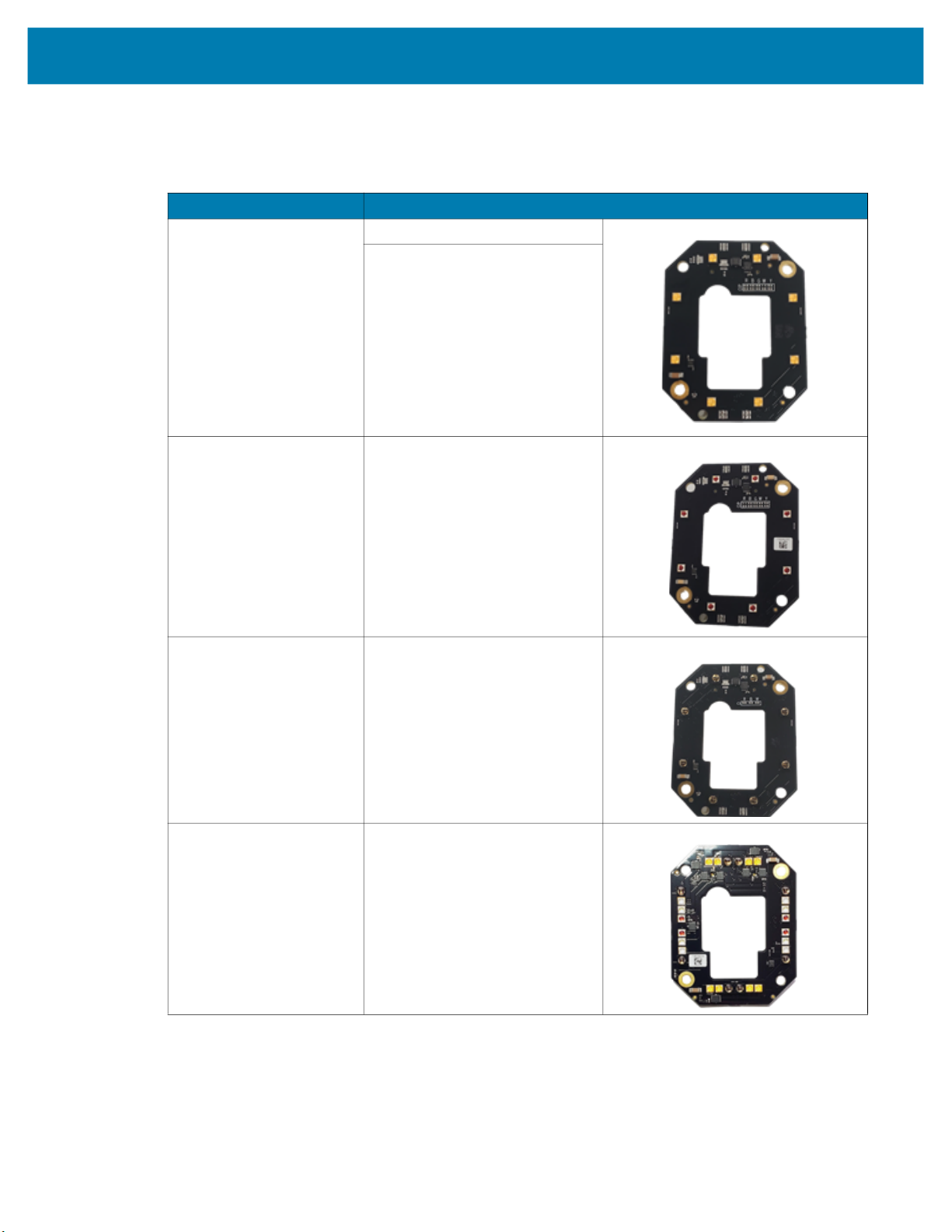

Internal Ring Lighting (xS40 Only)

Table 4 Internal Ring Lighting

Part Number Description

ZLED-XS40WH-0000 xS40 Internal Ring Light, White LED

For use with 100mm External Ring

Lights (LGHT-R100xx-0000).

Not for use when IR image capture

is required.

ZLED-XS40RD-0000 xS40 Internal Ring Light, Red LED

Red lighting is typically used to

capture images on paper.

ZLED-XS40IR-0000 FS40/VS40 Internal Ring Light, IR

LED

IR lighting is typically used in

environments where users do not

want to see any external lighting,

when detecting clear liquids, or

when inspecting produce.

ZLED-XS40MC-0000 FS40/VS40 Internal Ring Light,

Multi-Color - White, Red, Blue, IR

LED

White LEDs are controllable in

individual banks of 4 LEDs.

IR and Red are controllable in

individual banks of 2 LEDs.

7

Getting Started

Table 4 Internal Ring Lighting

Part Number Description

Replacement Ring Light Covers

ZLED-XS40PW-0000 Integrated Light Cover

(Replacement) Cross Polarizer

For use with Wide Angle (WA) xS40

configurations only.

Not for use when IR image capture

is required.

ZLED-XS40PS-0000

ZLED-XS40CW-0000 Integrated Light Cover

ZLED-XS40CS-0000

Integrated Light Cover

(Replacement) Cross Polarizer

For use with Standard Range (SR)

xS40 configurations only.

Not for use when IR image capture

is required.

(Replacement)

For use with Wide Angle (WA) xS40

configurations only.

Integrated Light Cover

(Replacement)

For use with Standard Range (SR)

xS40 configurations only.

8

Internal and External Filters

Table 5 Internal and External Filters

Part Number Description Compatibility

Internal Filters (In Between C-Mount Lens and Imager - xS70 Only)

FLTR-BP635-25400 Red Bandpass Filter, 635NM, 25.4MM

FLTR-BP850-25400 IR Bandpass Filter, 850NM, 25.4MM

Getting Started

For use between C-mount lens and

imager.

For use between C-mount lens and

imager

FLTR-BP550-25400 IR/UV Block Bandpass Filter, 550NM,

25.4MM

For use between C-mount lens and

imager.

External Filters (on the End of the C-Mount Lens - xS70 Only)

FLTR-BP550-25500 IR/UV Block B Filter, 550NM, 25.4MM

For use on the end of the C-mount lens.

9

Getting Started

Table 5 Internal and External Filters

Part Number Description Compatibility

FLTR-BP635-25500 Red Bandpass Filter, 635NM, 25.4MM

For use on the end of the C-mount lens.

FLTR-BP850-25400 IR Bandpass Filter, 850NM, 25.4MM

For use on the end of the C-mount lens.

Not for use with IR lighting.

FLTR-BP470-25500 Blue Bandpass Filter, 470NM, 25.5MM

For use on the end of the C-mount lens.

FLTR-PZ120-25500 Ultra High Contrast Polarizer Filter,

25.4MM

For use on the end of the C-mount lens.

Not for use with IR lighting.

10

Internal Filters (xS40 Only)

Table 6 Internal Filters

Part Number Description

ZFLT-XS40RD-0000 Red Bandpass Zebra Filter

ZFLT-XS40BL-0000 Blue Bandpass Zebra Filter

Getting Started

ZFLT-XS40IR-0000 IR Bandpass Zebra Filter

ZFLT-XS40MC-0000 IR Blocker Zebra Filter

11

C-Mount Lenses (xS70 Only)

Table 7 External Lenses (xS70)

Part Number Description

LENS-M0800-0100 C-mount Lens

8MM focal length, 25.5 filter thread

LENS-M1200-0100 C-mount Lens

12MM focal length, 25.5 filter thread

LENS-M1600-0100 C-mount Lens

16MM focal length, 25.5 filter thread

LENS-M2500-0100 C-mount Lens

25MM focal length, 25.5 filter thread

LENS-M3500-0100 C-mount Lens

35MM focal length, 25.5 filter thread

Lens Covers (xS70 Only)

Getting Started

Table 8 xS70 Lens Covers

Part Number Description

LENS-XTC70-0000

LENS-XRC70-0000 Replacement IP67 Lens Cover

Threaded Lens Cover Adapter

12

Communication Cables

Table 9 Cables

Part Number Description Compatibility

USB Cables

CBL-USB02000-USC00 USB 2M, IP67 locking USB-C to USB C,

CBL-USB04000-USC00 USB 4M, IP67 locking USB-C to USB C

Getting Started

SuperSpeed

Compatible with all FS/VS devices.

Compatible with all FS/VS devices.

CBL-USB02000-USA00 USB 2M, IP67 locking USB-A to USB-C,

SuperSpeed

Compatible with all FS/VS devices.

CBL-USB04000-USA00 USB 4M, IP67 locking USB-A to USB C

Compatible with all FS/VS devices.

13

Getting Started

Table 9 Cables (Continued)

Part Number Description Compatibility

Ethernet Cables

CBL-ENT05001-M1200 5M length, X-Coded M12 to RJ45

connectors

Compatible with all FS/VS devices that

include an Ethernet port.

CBL-ENT15001-M1201 15M length, X-Coded M12 to RJ45

connectors

Compatible with all FS/VS devices that

include an Ethernet port.

External Light Control Cables

CBL-LGT00000-M1200 5-pin M12 to 5-pin M12 External Light

Control C, 0.3M length

Only compatible with xS40 and xS70

devices that include an external light port.

CBL-LGT00201-M1200 5-pin M12 to 5-pin M12 External Light

Control C, 2M length

Only compatible with xS40 and xS70

devices that include an external light port.

Power Cables

CBL-PWR05001-M1200 12-pin M12 to flying lead breakout cable

Compatible with all FS/VS devices.

14

Getting Started

Table 9 Cables (Continued)

Part Number Description Compatibility

CBL-PWR15001-M1200 12-pin M12 to flying lead breakout cable

Compatible with all FS/VS devices.

CBL-USB00200-USC00 USB-C Cable, 4M length

Compatible with all FS/VS devices.

CBL-USB00400-USC00 USB-A Cable, 2M length

Compatible with all FS/VS devices.

Brackets

CBL-USB00200-USA00 USB-A Cable, 4M length

Compatible with all FS/VS devices.

Table 10 L-Mount Bracket

Part Number Description

BRKT-LMNT-U000

L-Mount Bracket

For use with Wide Angle (WA)

xS40 configurations only.

See

Mounting the Device Using

the L-Bracket Accessory

(BRKT-LMNT-U000) on

page 32

for mounting instructions.

15

Power Supplies

Table 11 Power Supplies

Part Number Description

PWR-24V03A-0000 Power Supply, 24VDC 3.3AMP, DIN

PWR-24V05A-0000 Power Supply, 24VDC 5AMP, DIN

Getting Started

Rail Mount

Rail Mount

PWR-POE30W-0000 Power over Ethernet Injector, 30W

POE+, AC Input

16

Getting Started

FS/VS Smart Camera Specifications

The tables below describe the design, performance, environment and regulatory characteristics of the

FS/VS Smart Camera series.

xS40 Specifications

Table 12 xS40 Specifications

Item Description

Physical Characteristics

Dimensions 2.1 in. H x 2.5 in. W x 3.6 in. D

54.0 mm H x 64.0 mm W x 91.4 mm D

Weight 14.1 oz./400.0 g

Power 10 to 30 VDC external power supply, 36W max at 24V

• Class 4 PoE+ source, 25.5W max

• Class 3 PoE source, 13W max

• USB Type-C host, 7.5W max at 5V 1.5A or 15W max at 5V 3.0A

Configurable IO (4) Four opto-isolated GPIO: GPIO0,1,2,3

(5) Five non-isolated GPIO: GPIO4,5,6*,7*,8*

*Unavailable when External Light Mode is enabled

Interface Ports (1) M12 X-Coded 1000/100/10 Mbps Ethernet

(1) M12 12-pin Power/GPIO

(1) M12 5-pin External Light Power & Control/GPIO

(1) USB 3.0 SuperSpeed Type-C with DisplayPort

Alt Mode is Available with one or two Ethernet ports

Communication Protocols Ethernet/IP, PROFINET, CC-Link, Modbus TCP, TCP/IP

Performance Characteristics

Image Sensor Monochrome: 2.3 MP (1920 x 1200 pixels) CMOS

Sensor with Global Shutter and 3.0 um Pixel Size

Acquisition Rate Up to 60 frames/second

Aimer Red Class II Laser; 8-point sunburst pattern

Illumination Field replaceable modules:

• (8) 660nm Red LEDs

• (8) 850nm IR LEDs

• (8) 2700K (Color Temperature) White LEDs

• (4) 660nm Red LEDs + (8) 850nm IR LEDs + (8) 2700K (Color

Temperature) White LEDs

Imager Field of View

SR (Standard Range): 10.8mm Liquid Lens

(30° H x 19° V Nominal)

WA (Wide Angle): 6.8mm Liquid Lens

(46° H x 29° V Nominal)

17

Table 12 xS40 Specifications

Item Description

User Environment

Getting Started

Operating Temperature

Storage Temperature -40°F to 113°F / -40° to 70°C

Vibration Resistance EN 60068-2-6, 14 mm @ 2 to 10 Hz, 1.5 mm @ 13 to 55

Shock Resistance EN 60068-2-27, 30g; 11 ms; 3 shocks on each axis

Environmental Sealing IP65 & IP67

Humidity 5% to 90% RH (Non Condensing)

Light Immunity Product must operate in: Incandescent 450 ft candles, Sunlight

Electrostatic Discharge ±15 kV Air, ±8 kV Contact, ±8 kV Indirect

Trigger Durability Withstand 1,000 cycles of operation with no degradation in

Regulatory

Environmental EN 50581:2012

Electrical Safety IEC 62368-1 (Ed.2)

32° F to 113° F/0° C to 45° C (10-30VDC external power supply,

duty cycle-dependent)

32° F to 104° F/0° C to 40° C (POE, duty cycle dependent)

Hz; 2 g @ 70 to 500 Hz; 2 hours on each axis

<6000 ft candles, Florescent 450 ft candles, Mercury Vapor 450

ft candles, Sodium Vapor 450 ft candles, LED 450 ft candles

functionality

EN IEC 63000:2018

EN 62368-1:2014/A11:2017

Laser Safety (xS40 Only) 21CFR1040.10 & 21CFR1040.11

IEC/EN 60825-1:2014 (Ed.3)

LED Safety IEC 62471: 2006 (Ed.1)

EN 62471: 2008

EMI/EMS EN 55032:2015/A11: 2020

EN 55035:2017/A11: 2020

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 61000-6-2: 2005,2019

FCC 47 CFR Part 15, Subpart B

ICES-003, Issue 7

EU Declaration of Conformity 2014/30/EU; 2014/35/EU; 2011/65/EU.

Refer to the Declaration of Conformity (DoC) for details of

compliance to the current standards. The DoC is available at:

zebra.com/doc

18

xS70 Specifications

NOTE: The xS70 is only to be used with the metal assembly in order to pass the ESD safe

specification.

Table 13 xS70 Environmental Specifications

Physical Characteristics

Dimensions 2.5 in. H x 2.5 in. W x 3.75 in. D

Weight 22.9 oz./650.0 g

Power 10 to 30 VDC external power supply, 36W max at 24V

Configurable IO (4) Four opto-isolated GPIO: GPIO0,1,2,3

Getting Started

Item Description

63.0 mm H x 64.0 mm W x 95.0 mm D

• Class 4 PoE+ source, 25.5W max

• Class 3 PoE source, 13W max

• USB Type-C host, 7.5W max at 5V 1.5A or 15W max at 5V 3.0A

(5) Five non-isolated GPIO: GPIO4,5,6*,7*,8*

*Unavailable when External Light Mode is enabled

Interface Ports (2) M12 X-Coded 1000/100/10 Mbps Ethernet*

(1) M12 12-pin Power/GPIO/RS-232

(1) M12 5-pin External Light Power & Control/GPIO

(1) USB 3.0 SuperSpeed Type-C with DisplayPort Alt Mode

*Available with one or two Ethernet ports, PoE is only supported

by the primary Ethernet port

Communication Protocols Ethernet/IP, PROFINET, CC-Link, Modbus TCP, TCP/IP

Performance Characteristics

Image Sensor Monochrome: 2.3 MP (1920 x 1200 pixels) CMOS

Sensor with Global Shutter and 3.0 um pixel size

Acquisition Rate 60 frames/second

Illumination Supports many standard external illumination systems while

powered by 24 VDC supply

Imager Field of View Flexible; dependent upon C-mount lens selection

User Environment

Operating Temperature 32° F to 113° F/0° C to 45° C (10-30VDC external power supply,

duty cycle-dependent)

32° F to 104° F/0° C to 40° C (POE, duty cycle-dependent)

Storage Temperature -40° F to 158° F/-40° C to 70° C

Vibration Resistance EN 60068-2-6, 14 mm @ 2 to 10 Hz, 1.5 mm at 13 to 55 Hz; 2 g

at 70 to 500 Hz; 2 hours on each axis

Shock Resistance EN 60068-2-27, 30 g; 11 ms; 3 shocks on each axis

Environmental Sealing IP65 and IP67

Humidity 5% to 90% RH, non-condensing

19

Getting Started

Table 13 xS70 Environmental Specifications (Continued)

Item Description

Light Immunity Product must operate in: Incandescent 450 ft candles, Sunlight

<6000 ft candles, Florescent 450 ft candles, Mercury Vapor 450

ft candles, Sodium Vapor 450 ft candles, LED 450 ft candles

Electrostatic Discharge ±15 kV Air, ±8 kV Contact, ±8 kV Indirect

Trigger Durability Withstand 1,000 cycles of operation with no degradation in

functionality

Regulatory

Environmental EN 50581:2012; EN IEC 63000:2018

Electrical Safety IEC 62368-1 (Ed.2); EN 62368-1:2014/A11:2017

EMI/EMS EN 55032:2015/A11: 2020

EN 55035:2017/A11: 2020

EN 61000-3-2: 2014

EN 61000-3-3: 2013

EN 61000-6-2: 2005,2019

FCC 47 CFR Part 15, Subpart B

ICES-003, Issue 7

EU Declaration of Conformity 2014/30/EU; 2014/35/EU; 2011/65/EU.

Refer to the Declaration of Conformity (DoC) for details of

compliance to the current standards. The DoC is available at:

zebra.com/doc

20

Installation

This section describes the steps to mount the FS/VS Smart Camera with an L-bracket and install an

illumination system into the xS40 or a C-mount lens onto the xS70.

Dimensional Drawings

The dimensional drawings below illustrate the mounting patterns supported by the FS/VS Smart Camera.

For additional information on mounting the device with the L-bracket accessory, see Mounting the Device

Using the L-Bracket Accessory (BRKT-LMNT-U000) on page 32.

xS40 Dimensional Drawings

Figure 1 xS40 Side Dimensions

59.25

2X M3 X 0.50 THD

X DEPTH 4.5 MM MAX

29.00

29.23

25.00

12 PIN M12 CONN

38.70

Optical Axis

2X M3 X 0.50 THD

X DEPTH 4.5 MM MAX

Optical Axis

29.23

19.63

5 PIN M12 CONN

25.00

8 PIN M12 CONN

32.75

USB C CONN

38.70

54.00

59.25

91.40

29.00

21

Figure 2 xS40 Bottom Dimensions

64.00

2X 38.50

2X 19.25

Optical Axis

Installation

78.00

58.50

33.80

4X M3 X 0.50 THD

X DEPTH 4.5 MM MAX

22

xS70 Dimensional Drawings

Figure 3 xS70 Side Dimensions

69.50

49.23

11.35

Installation

3X M3 X 0.50 THD

X DEPTH 4.5 MM MAX

49.23

11.35

Optical Axis

3X M3 X 0.50 THD

X DEPTH 4.5 MM MAX

12.70

8 PIN M12 CONN

39.63

5 PIN M12 CONN

45.00

8 PIN M12 CONN AND

12 PIN M12 CONN

52.75

USB C CONN

58.70

Figure 4 xS70 Bottom Dimensions

64.00

2X 38.50

2X 19.25

29.00

59.25

91.40

Optical Axis

59.25

29.00

58.70

Optical Axis

4X M3 X 0.50 THD

X DEPTH 4.0 MM MAX

17.42

M12 CONN

17.42

M12 CONN

2X 58.50

78.00

2X 33.80

23

Connection Interfaces

xS40 Connections

The xS40 supports connections for USB-C with DisplayPort, power serial and GPIO, x-coded Ethernet and

external lighting. For additional information about the connection interfaces, see Cable Pin Outs on

page 29.

Figure 5 xS40 Connection Interfaces

Installation

1

2

3

4

1 External Lighting

2 X-Coded Ethernet Port

3 USB-C (with DisplayPort)

4 Power Serial and GPIO

24

xS70 Connections

The xS70 supports connections for USB C with DisplayPort, power serial and GPIO, x-coded Ethernet,

and external lighting. For additional information about the connection interfaces, see Cable Pin Outs on

page 29.

Figure 6 xS70 Connection Interfaces

Installation

1

2

3

4

5

1 X-Coded Ethernet Port (Secondary)

2 External Lighting

3 X-Coded Ethernet Port

4 USB C (with DisplayPort)

5 Power Serial and GPIO

25

Torque Specification

To guarantee an IP65 & IP67 product specification, Zebra cables and/or connector covers must be torqued

to the following specification:

• Torque for M12 Zebra cables: 24.0 in-lbs

• Torque for connector covers: 10.0 in-lbs

Installation

NOTE:

covers must be torqued at installation to guarantee an IP65 and IP67 specification if cables are not

used.

To ensure proper connector cover seating, see Figure 7 for the reference dimension (in mm) of the 12 pin

M12.

Figure 7 12 Pin M12 Reference Dimension

Connector covers are hand tightened from the factory to allow for easy hand removal. The

5.80 mm

For additional information on Zebra cables, see Communication Cables on page 13.

26

Power Sources

The xS40 and xS70 devices can be powered through the 12-pin M12 connector, Power over Ethernet

(PoE), or USB Type C for maximum flexibility. A power priority scheme selects power from the M12

connector over PoE, and PoE over USB-C to ensure the least restrictive power source is utilized. Changes

to the power source trigger a reboot.

Since power from any source is finite, a budget is automatically derived by the vision system and

dynamically allocated to prevent an overload condition. Allocation is based on sensor type and enabled

features such as Ethernet PHY’s, digital outputs, and advertised USB Type C port current. Models with

internal illumination reduce illumination intensity or duration to operate within budget, and may disable

internal illumination entirely if necessary.

NOTE: It is recommended to develop jobs with power sources and auxiliary equipment in the final

intended configuration to prevent mismatch at deployment.

12 Pin M12 Power Input

If the input voltage is above 21.5 V, the vision system enables up to 1.5 A output to the USB Type C

connector and allows for simultaneous operation of internal and external illumination. If the external light

connector is placed in external light mode, power is shunted from the power supply directly to the light

through a bypass circuit able to support the high peak currents of strobe lights. A self-resettable fuse

prevents physical overload of the 12 pin M12 connector.

Installation

If less than 21.5 V is provided to the device, the advertised USB Type C current is lowered to 500 mA and

overall power budget is reduced. This may impact allowable internal illumination configurations. As a

result, a 24 V industrial power supply capable of high pulse currents of long duration is recommended for

best performance.

Power Over Ethernet

The xS40 and xS70 devices support operation from power sourcing equipment meeting the 802.3at class

4 (30 W) or 802.3af class 3 (15.4 W) IEEE Power Over Ethernet (PoE) standards. These are commonly

referred to as PoE+ and PoE respectively by equipment providers.

Peak power draw must be strictly maintained within the power envelope of the power sourcing equipment.

If the external light connector is enabled in external light mode, the vision system generates 24 V to power

the external light with the following limitations in place:

• Simultaneous activation of the internal and external illumination is not permitted.

• Auto-strobe lights with high pulse current are not supported and trip over current protection in the vision

system, disabling the external light connector.

• External lights with adjustable intensity may be used, provided the peak current draw is below the over

current protection limit. It is recommended to start with the lowest intensity setting and work upwards, or

to use the auto-tune feature.

Power over Ethernet requires an extra regulation step which incurs additional thermal buildup within the

device. As a result, the specified operating temperature range is reduced when powered by PoE.

USB Type C

USB Type C allows for novel and cost-effective installations provided the following constraints are

acceptable:

• Digital GPIO are unavailable

27

Installation

• Optocoupled GPIO is still functional provided the COMMON_IN and COMMON_OUT are properly

terminated.

• The External Light Connector is disabled and cannot be used in GPIO or External Light modes.

• 0 V to 10 V analog output is disabled.

• Internal illumination is limited or requires a USB power source with further capabilities to be enabled at

any capacity.

CAUTION: The xS40 and xS70 devices boot from legacy USB host ports, however, current draw is

not guaranteed to be under 500 mA and device functionality may be restricted to the extent that

performance can be impaired. An override mode can be enabled for legacy host ports that are known

by the operator to be capable of supplying up to 1.5 A. Ports of this type are often described as having

USB BC1.2 or USB charging support.

Grounding for Electro-Magnetic Compliance and ESD Safe

The vision system is designed with a rugged metal chassis connected internally to ground for robust

Electro-Magnetic Compliance (EMC) and ESD Safe operation. Do not mount to any conductive object,

body, structure, or mechanism that may become connected to line voltage or a voltage potential other than

Protected Earth Ground. Chassis grounding via cable shield, mounting screws, or low inductance ground

strap to a local Protected Earth Ground is acceptable.

NOTE: There is no galvanic connection to Earth Ground when the device is powered over an

unshielded Ethernet cable. In this scenario, grounding to local Earth Ground through another cable

shield, mounting screw, or ground strap is required for ESD Safe compliance and best practice for

EMC.

28

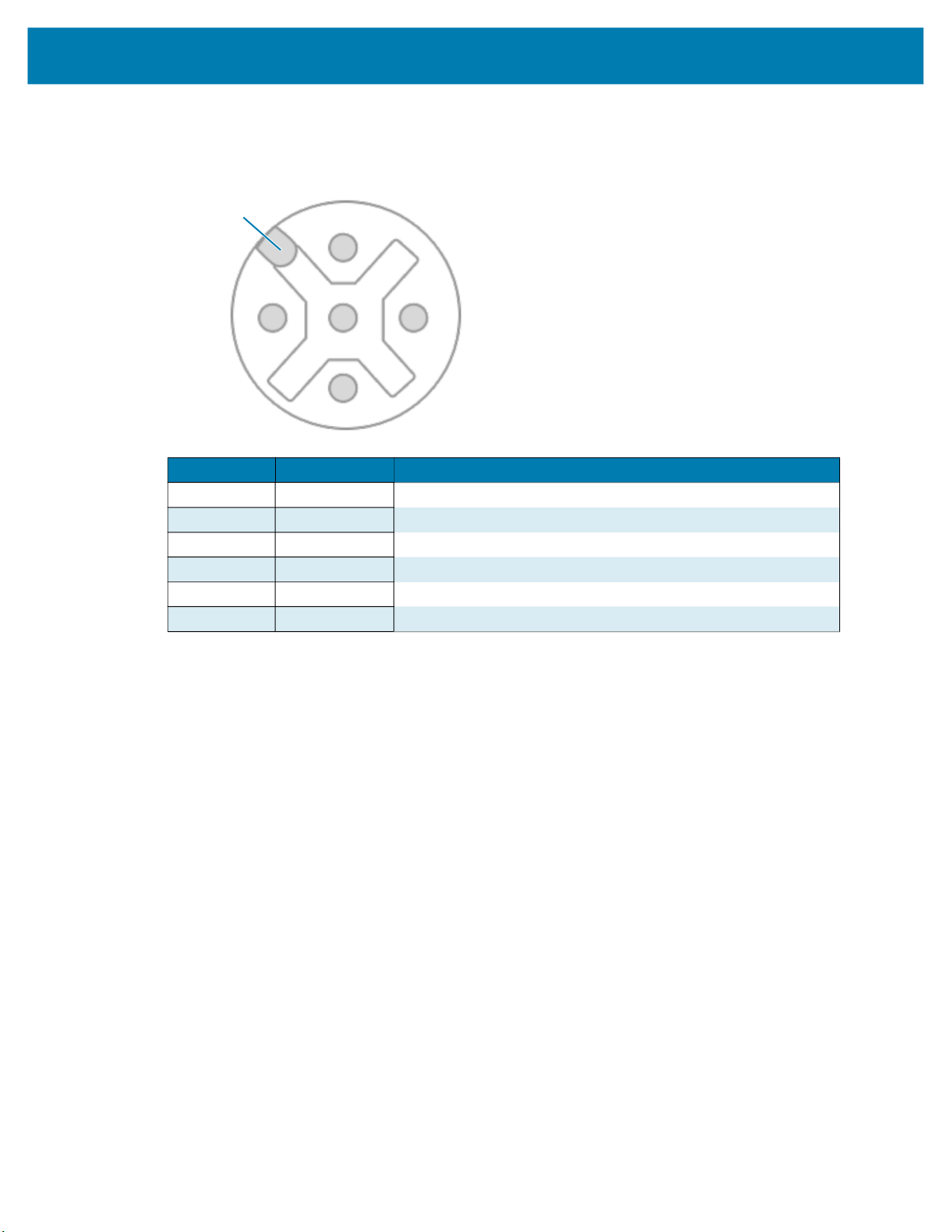

Cable Pin Outs

This section provides pin and cable color information for the power and I/O, Ethernet, and external lighting

connectors.

Power and I/O Connector

Figure 8 Power and I/O Connector - 12 Pin Diagram

Installation

Key Position

3

4

11

5

6

2

10

12

7

1

9

8

Pin Color Description

1 Yellow GPIO2

2 White / Yellow TXD

3 Brown RXD

4 White / Brown GPIO4

5 Violet GPIO5

6 White / Violet COMMON_IN

7 Red DC_IN

8 Black GND

9 Green COMMON_OUT

10 Orange GPIO0

11 Blue GPIO1

12 Grey GPIO3

SHELL Bare SHIELD

29

Ethernet Connector

Figure 9 Ethernet Connector - 8 Pin Diagram

Key Position

Installation

2

3

1

8

7

4

5

6

Pin Description

1 TP1+

2 TP1-

3 TP2+

4 TP2-

5 TP4+

6 TP4-

7 TP3-

8 TP3+

SHELL SHIELD

30

External Light Connector

Figure 10 External Light Connector - 5 Pin Diagram

Key Position

Installation

4

1

2

Pin Color Description

1 Brown DC_OUT / GPIO8

2 White GPIO7

3 Blue GND

4 Black GPIO6

5 Gray ANALOG_OUT

SHELL Bare SHIELD

3

31

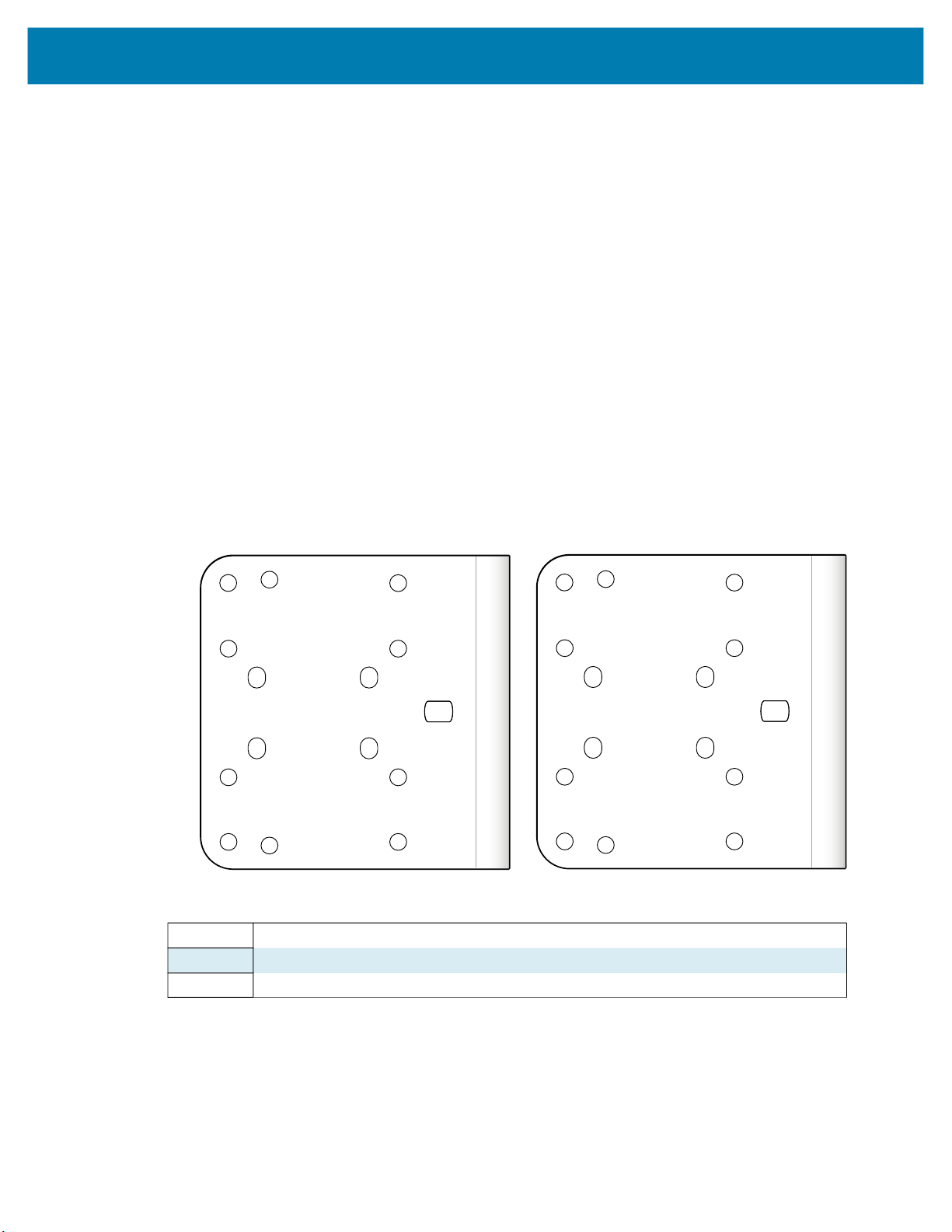

Installation

Setting up an FS/VS Smart Camera

The sections below describe the steps to mount the xS40 or xS70 to the L-bracket accessory using Figure

11 and Figure 12 to understand its hole positions.

General Mounting Instructions

1. Align the holes on the mounting surface with the mounting holes on the device.

2. Insert screws into the mounting holes and tighten. It is recommended to use four M3 screws to attach

the camera on the bottom surface using a tightening Torque of 6.0 in-lbs.

3. See Dimensional Drawings on page 21 for mounting hole placements on the devices to determine the

proper screw lengths needed based on the provided tapping depths into the camera.

Mounting the Device Using the L-Bracket Accessory (BRKT-LMNT-U000)

1. Use the mounting screws provided with the kit to attach the camera to the bracket. The recommended

Toque is 6.0 in-lbs.

2. Refer to the L-bracket mounting options outlined below.

Figure 11 Bottom and Side Mounting Hole Patterns

6

1

3

Bottom Surface Mounting Options

2

4

5

7

8

1-4 Bottom Surface Mounting Holes for the xS40 and xS70

5-8 Side Mounting Holes for the xS40

5-9 Side Mounting Holes for the xS70

9

Side Mounting Options

32

Installation

Figure 12 Mounting to the Structure Hole Pattern

3

2

5

1

4

1-2 M5 Clearance

3-4 1/4-20 Clearance

5 M8 Clearance

6 M8 Clearance Slots

6

Figure 13 Side Mounting Option

33

Figure 14 Bottom Mounting Option

Installation

34

Installation

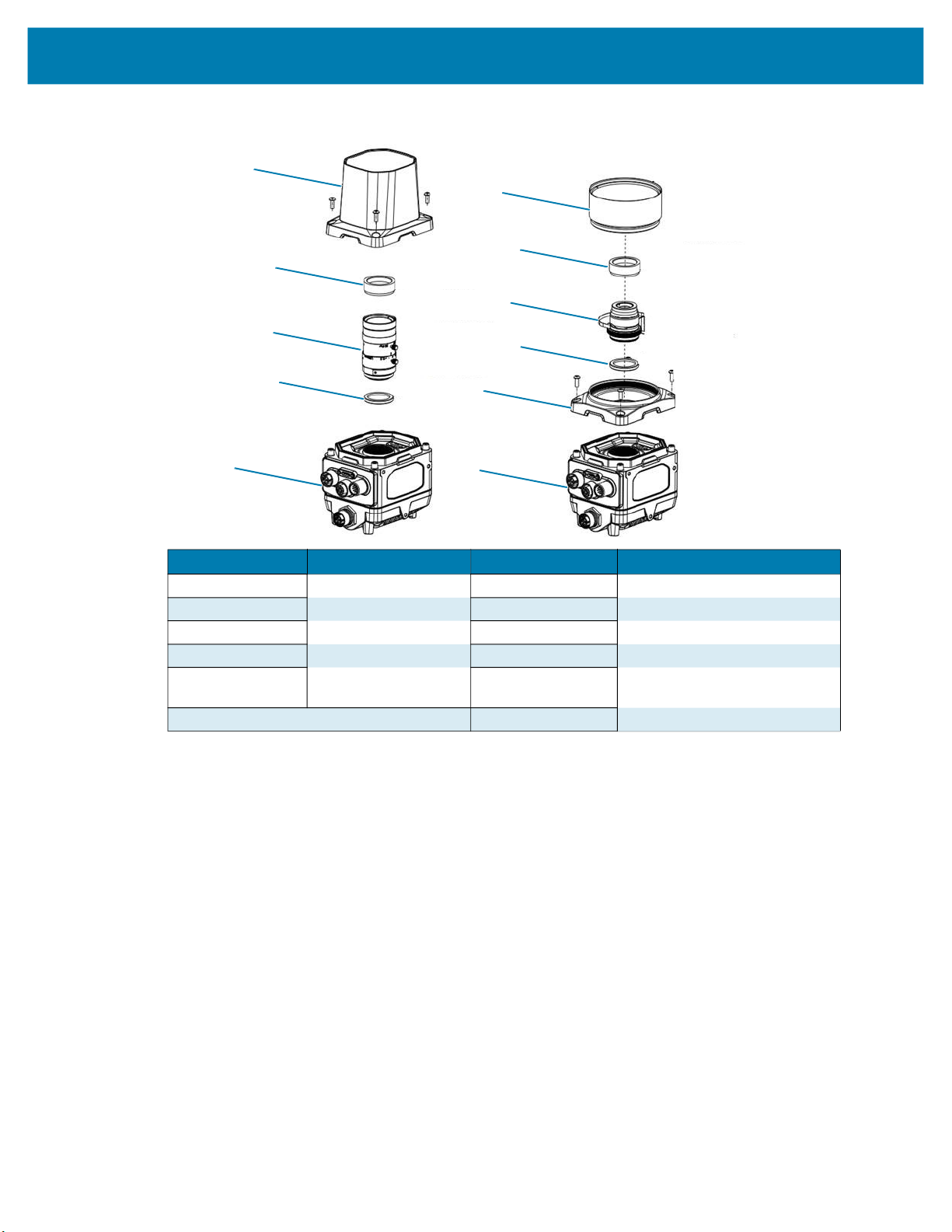

Illumination System Installation (xS40 Only)

To install the illumination system on the xS40, follow the steps below:

1. Place the gasket onto the camera.

2. Attach the Illumination PCB to the camera via the board to board connector and secure it with two

screws. The recommended Torque is 6.0 in-lbs using the Torx T8 fasteners.

3. Place the filter onto the camera exit window, lining up the corner chamfer of the filter to the corner

chamfer of the camera housing (if required).

4. Place the illumination plate assembly onto the camera.

5. Attach the top cover and secure with four screws. The recommended Torque is 6.0 in-lbs using the

Torx T8 fasteners.

Illumination System Disassembly (xS40 Only)

To disassemble the illumination system on the xS40, follow the steps below:

1. Remove the four screws and remove the top cover.

2. Remove the illumination plate assembly.

3. Remove the filter (if applicable).

4. Remove the two screws and gently lift the PCB to disconnect it from the camera.

The gasket can be left in place unless damaged. Replace the gasket if it is damaged to maintain its IP67

specification.

Figure 15 Illumination System Installation

1

2

3

4

5

6

35

Installation

1 ESD Safe Cover (Four Screws)

2 Illumination Plate Sub-Assembly

3 Filter Assembly

4 Illumination PCB (Two Screws)

5 Illumination Plate Gasket

6 Main Assembly

Threaded Lens Cover Assembly Installation

If a threaded lens cover assembly is preferable over the IP67 cover provided with the xS70, follow the

instructions below for installation.

NOTE: The threaded lens cover assembly can only be used with C-Mount lenses.

1. Remove the lens cover.

2. Place threaded lens adapter accessory onto reader (HN-001466-01).

3. Insert and tighten the screws. The recommended torque is 6.0 in-lbs using the Torx T8 fasteners.

4. Install filter into reader (if required).

5. Thread the lens into the reader.

6. Place the reader at the desired working distance from the focal point.

7. Adjust lens (if necessary).

8. Thread on appropriate length cover to accommodate chosen lens.

C-Mount Lens Installation (xS70 Only)

To install the c-mount lens onto the xS70, follow the steps below:

1. Remove the lens cover.

2. Install the filter into the reader (if required).

3. Thread the lens into the reader.

4. Place the reader at the desired working distance from the focal point.

5. Adjust the lens (if necessary).

6. Attach the front cover.

7. Insert and tighten the screws. The recommended Torque is 6.0 in-lbs using the Torx T8 fasteners.

36

Installation

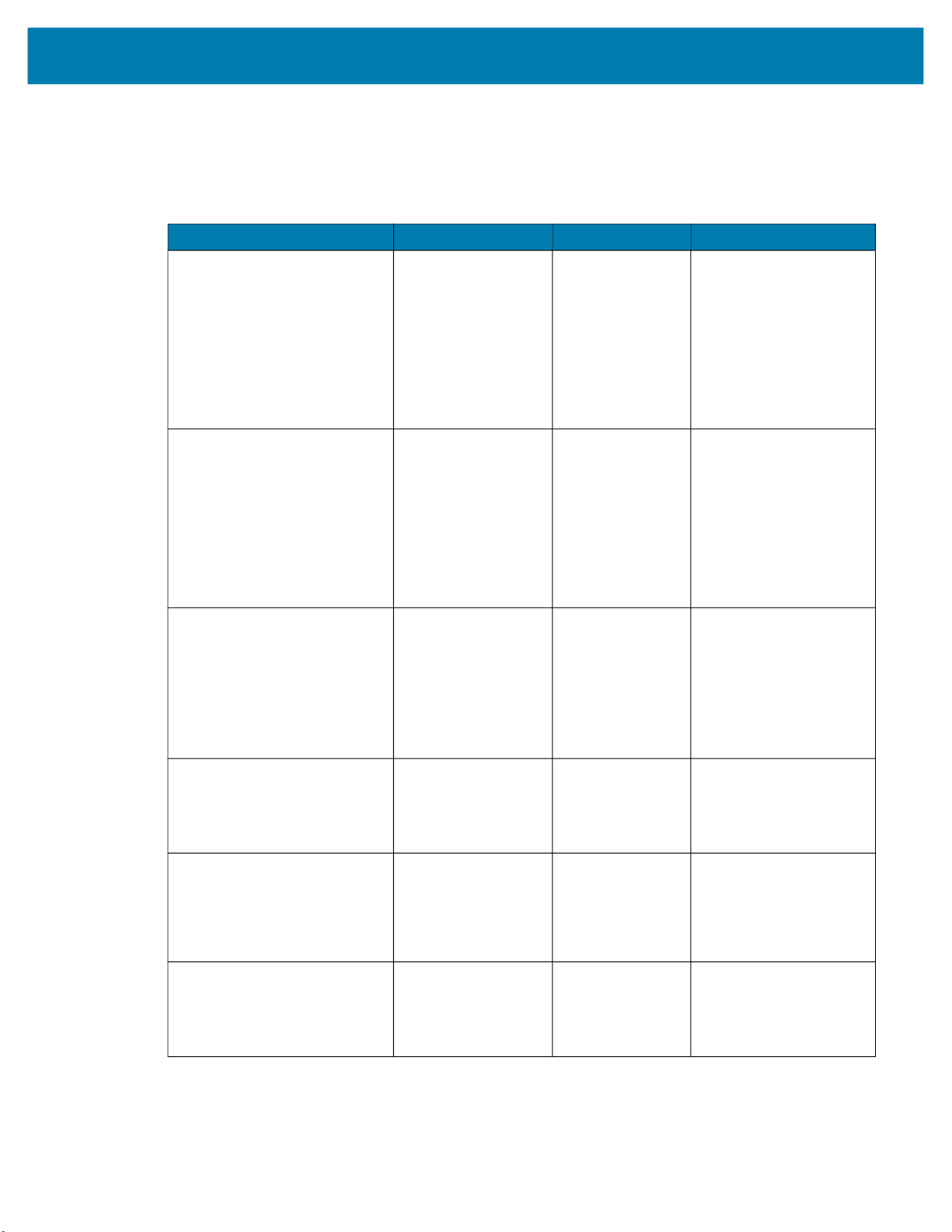

Figure 16 Optional Accessory Assembly Drawings

1

1

2

2

3

3

4

5

4

5

6

Number Description Number Description

1

2 Polarizer 2 Polarizer

3

4 Filter 4 Filter

5 Assembly 5 Threaded Lens Cover Bracket

Lens Cover

C-Mount Lens

1

3

6 Assembly

Threaded Lens Cover

C-Mount Lens

(HN-001466-01)

37

Setting Focus

To focus the device upon first use, calibrate the gain and exposure settings by utilizing the Live View

feature in the Web HMI of the Zebra Aurora application. Users can also manually adjust the focus and the

aperture of the C-mount lenses. For additional information on using the Web HMI, see Accessing the Web

Human-Machine Interface (HMI) on page 64.

NOTE: The set screws must be loosened before adjusting the lens. The set screws are fixed after the

optimum focus and aperture are set.

Installation

38

Using the Smart Camera

This section describes using the FS/VS Smart Camera and optimizing the device’s utility for its use

case by leveraging its connection interfaces.

USB Type C

The xS40 and xS70 devices implement a full capability 5 Gbps USB 3.0 USB Type C port with support

for DisplayPort Alt Mode. The sealed port implements a standard USB Type C dual screw lock

mechanism for secure connections. When paired with the IP67 series of Zebra screw locking cables,

the interface maintains a full IP67 seal.

CAUTION: The sealing gasket on IP67 series Zebra USB Type C cables require adequate

pressure for proper seal and connector engagement. Always tighten the locking screws when

using these cables, even if IP67 sealing is not required.

When connected as a peripheral to a USB host, the xS40 and xS70 devices can be configured to

support the following functionality:

• RNDIS Ethernet over USB

• HID keyboard

When operating as a host, the USB Type C port supports many types of accessories and functionality,

including:

• Native USB-C displays

• USB-C to Display Port and USB-C to HDMI adaptors

• HID compliant mice, keyboards, and trackpads

• USB mass storage devices for firmware updates

• USB docks and hubs

NOTE: DisplayPort output is only supported over USB Type C to Type C cables capable of

SuperSpeed data rates. High speed cables, often described as charging cables, do not have

the necessary data wires for DisplayPort functionality.

Supported Display Resolutions

Display resolution is automatically negotiated upon connection. Displays with at least 1920 x 1080

resolution provide the best user experience.

The FS/VS Smart Camera series supports the following resolutions:

• 1024 x 768

39

• 1280 x 800

• 1280 x 1024

• 1366 x 768

• 1600 x 900

• 1600 x 1050

• 1920 x 1080

• 1920 x 1200

NOTE: Monitors with USB-C input offer an efficient method for quick and easy configuration over a

single USB Type C to Type C cable. An attached xS40 or xS70 device powers directly from the

monitor’s USB Power Delivery and output the Human Machine Interface (HMI) directly to the display.

A USB mouse and keyboard attached to the monitor hub ports provide the user with interface control.

Battery powered portable USB Type C monitors are also compatible for easy status or manipulation in

the field.

User Interface

The FS/VS Smart Camera provides various forms of feedback in the form of decode LEDs, beeper

indications, label LEDs, and UIF codes that keep the user aware of specific device states.

Decode LEDs

The xS40 and xS70 have 360° LED decode indicators that flash green upon successful decode and red

upon job failure. For information on configuring the 360° LEDs, see General Settings on page 59.

Figure 17 xS40 and xS70 360° Decode LED

xS40

xS70

40

User Interface Label

The xS40 and xS70 devices provide the user with LED indicators and switches to indicate

the device state and optimize focus. Table 14 below lists all LED indications for the FS/VS Smart Camera

series. The xS40 and xS70 have trigger and tune buttons that are controlled by two switches on the sensor

PCB. The TRIG switch acts a trigger, and the TUNE switch allows the user to adjust and optimize focus.

For additional information on trigger configuration, see Configuration of Trigger Modes on page 60.

Figure 18 FS/VS Smart Camera Series UI Labels

1

2

6

xS40 xS70

4

3

5

7

1

7

3

2

4

5

6

8

Number xS40 Indicator Number xS70 Indicator

1 Power 1 Power

2 Power over Ethernet (PoE) 2 Ethernet

3 Online 3 Power over Ethernet (PoE)

4 Focus 4 Online

5 Warning 5 Focus

6 Trigger 6 Warning

7 Tuning 7 Trigger

8 Tuning

For additional information on using the TRIG button to perform a factory reset on the device, see Factory

Reset the Device on page 75

41

LED and Beeper Indicators

The table below describes the LED and beeper indications of the FS/VS Smart Camera upon device

events such as power up, running a job, maintenance operations, and parameter programming.

Table 14 LED Indicators

Device

Event Beeper 360° LEDs Power

Power Up

Bootup - Uboot

(Bootloader)

Bootup - Linux,

Low power

(Developer

Mode)

Bootup - Linux,

Full Power

Device States

Ready (Job

Loaded /Active)

Running (Job

Triggered)

Stop High, Low Off - Off Off Off No Activated

Setup None Off - Off Off Off Job editing in

Error (Job Error) Low, Low Off - Solid

Maintenance Operations

Firmware

Update Start

Firmware

Update Success

Firmware

Update Fail

None Off Solid

Low,

Medium,

High

Low,

Medium,

High

Low, High Off - Green

As

Configured

- Red Blinking - Red

- - - - - - Firmware

Low, Low Solid Red - Solid

Green

(Single

Blink)

Green

(Single

Blink)

As

Configured

Red

Green

(Slow

Blink)

Solid

Green

- Solid

Status

Off Off Off Hardware

Off Off Off Linux booted,

Off Off Off Linux booted,

Blinking

Green

Red

Blinking

Red

Focus

Status

Off Off Job is waiting on

As

Configured

Off Solid Red Job has failed to

Off Off Firmware

Off Off Firmware

Error

Status

As

Configured

Description

Controlled

Core Services

not running yet,

Low Power

Condition

applies to low

USB or PoE

Power.

Core Services

not running yet

Trigger (Core

Services in

Standby state)

Job is currently

running (Core

Services in Run

state)

Jobs (Core

Services in

Stopped state)

progress (Core

Services in App

Connected

state)

complete

properly

Update in

progress

Update

completed

successfully. No

success

indication, boot

normally.

Update has

failed

42

Table 14 LED Indicators (Continued)

Device

Event Beeper 360° LEDs Power

Reset to

Defaults

(Hold Trigger on

Powerup)

AutoTune Start Medium Off - - Green

AutoTune

Success

AutoTune Fail Low, Low Off - - Solid Red Off AutoTune has

Parameter Programming

Parameter Entry

Accepted

Parameter

Number Entry

Parameter Entry

Error

Long

Medium

(on

success by

Config

Manager)

High, High Off - - Solid

High, Low,

High, Low

High, Low Green

Low, High Red (Single

Red (20s),

Yellow

(10s),

Normal

bootup

Green

(Single

Blink)

(Single

Blink)

Blink)

- Red 1s,

- Green

- Green

- Red

Status

Green

1s

alternati

ng,

Normal

bootup

(Single

Blink)

(Single

Blink)

(Single

Blink)

Focus

Status

Off Off To Reset

Blinking

Green

Off Off Successful

Off Off Number

Off Off Input error:

Error

Status

Off AutoTune in

Off AutoTune

Description

Defaults, hold

trigger during

Powerup and

release when

360 LED is

yellow. (Not

Factory defaults.

Do not lose

licenses or

Jobs).

progress

completed

successfully

failed

program exit with

change in

parameter

setting.

expected. Enter

value using

numeric bar

codes.

incorrect bar

code,

programming

sequence, or

Cancel scanned.

43

User Interface Framework Codes

The table below describes specific system events and the feedback that the interface provides to convey

certain device states to the user.

Table 15 UI Codes

UIF Name System Event Beeper LED

LINUX_BOOTUP_LOW_POWER Not used One medium

LINUX_BOOTUP_FULL_POWER Not used One medium

JOB_READY Not used One medium

volume, low tone,

short duration beep.

One medium

volume, medium

tone, short duration

beep

One medium

volume, high tone,

short duration beep

volume, low tone,

short duration beep.

One medium

volume, medium

tone, short duration

beep.

One medium

volume, high tone,

short duration beep.

volume, low tone,

short duration beep.

One medium

volume, high tone,

short duration beep.

The decode LED flashes

green for 250 ms once.

The power LED

continuously flashes green

at 1 Hz with 50% duty cycle

The run mode, focus, and

warning LEDs are off.

The decode LED flashes

green for 250 ms once.

The power LED stays ON in

green.

The run mode, focus and

warning LEDs are off.

The run mode LED

continuously flashes in

green at 2 Hz with 50% duty

cycle.

The power LED responds

as configured.

JOB_RUNNING Not used No beeper

feedback.

JOB_STOP Not used One medium

volume, high tone,

short duration beep.

One medium

volume, low tone,

short duration beep.

JOB_SETUP Not used No beeper

feedback.

The decode, focus and

warning LEDs are off.

The run mode LED stays on

in green.

The power, decode, focus,

and warning LEDs respond

as configured.

The power LED responds

as configured

The decode, run mode,

focus, and warning LEDs

are off.

The power LED responds

as configured.

The decode, run mode,

focus, and warning LEDs

are off.

44

Table 15 (Continued)UI Codes

UIF Name System Event Beeper LED

JOB_ERROR The device becomes

underpowered.

FIRMWARE_UPDATE_START Firmware update

Starts.

FIRMWARE_UPDATE_END Firmware update ends. The beeper is off. The power LED responds

Two medium

volume, low tone,

short duration

beeps.

No beeper

feedback.

The run mode LED stays on

in red.

The warning LED stays on

in red.

The power LED responds

as configured.

The decode and focus

LEDs are off.

The decode LED

continuously flashes red at

2 Hz with 50% duty cycle.

The run mode LED

continuously flashes red at

2 Hz with 50% duty cycle

The power LED responds

as configured.

The focus and warning

LEDs are off.

as configured.

FIRMWARE_UPDATE_FAIL Firmware update

failure.

AUTOTUNE_START Autotune job starts One medium

One medium

volume, low tone,

long duration beep.

volume, medium

tone, short duration

beep.

The decode, run mode,

focus, and warning LEDs

are off.

The decode LED

continuously flashes in red

at 5 Hz with 50% duty cycle

The run mode LED

continuously flashes in red

at 5 Hz with 50% duty cycle.

The power LED responds

as configured.

The focus and warning

LEDs are off.

The focus LED

continuously flashes in

green at 2Hz with 50% duty

cycle.

The power LED responds

as configured.

The run mode LED

responds as configured.

The decode and warning

LEDs are off.

45

Table 15 (Continued)UI Codes

UIF Name System Event Beeper LED

AUTOTUNE_SUCCESS Autotune job

completes

AUTOTUNE_FAIL Autotune job failure. One low volume,

BARCODE_DECODE_START PreDecodeProcedure

(asynchronous)

One high volume,

high tone, short

duration beep.

low tone, short

duration beep.

The beeper is off. The run mode LED stays on

The focus LED stays on in

green.

The power LED responds

as configured.

The run mode LED

responds as configured.

The decode and warning

LEDs are off.

The focus LED stays on in

red.

The power LED responds

as configured.

The run mode LED

responds as configured.

The decode and warning

LEDs are off.

in amber

The decode LED is off.

BARCODE_DECODE_SUCCESS PostDecodeProcedure

when beep_on_decode

is false.

BARCODE_DECODE_FAILURE PostDecodeProcedure

when a decode fails.

FACTORY_RESET Factory Reset starts Two medium

One high volume,

medium tone, short

duration beep by

default.

No beeper

feedback.

volume, medium

tone, short duration

beeps.

The power, focus and

warning LEDs respond as

configured.

The run mode LED is off.

The decode LED flashes in

green for 50 ms once by

default.

The power, focus and

warning LEDs respond as

configured.

The run mode LED is off.

The decode LED flashes

red for 50 ms once by

default.

The power, focus, and

warning LEDs respond as

configured.

The decode LED

continuously flashes in red

at 5Hz with 50% duty cycle.

The power, run mode,

focus, and warning LEDs

respond as configured.

46

Data Capture

This section describes aiming patterns and decode ranges for the xS40 as well as minimum focus

distances for the xS70 while using a C-mount lens.

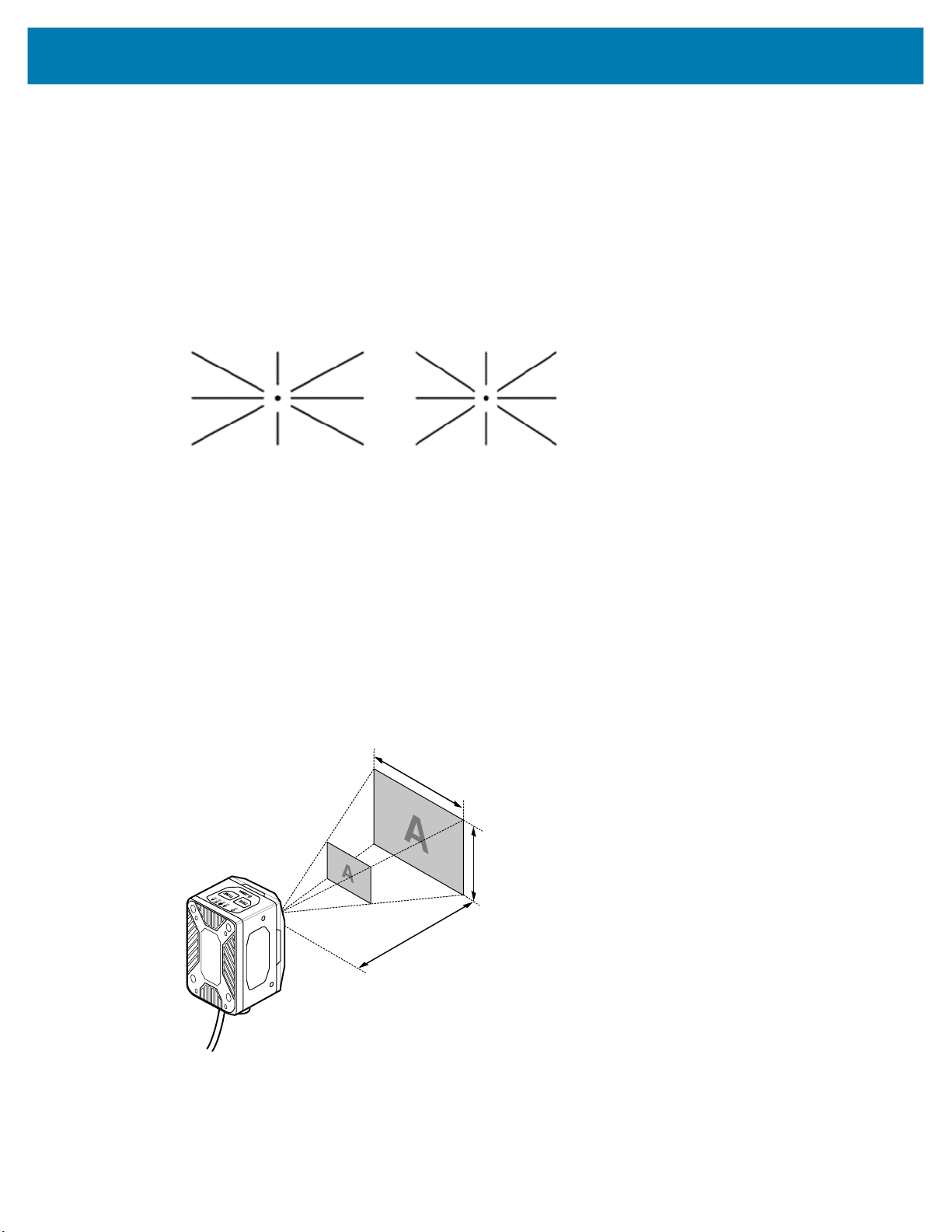

Aiming Patterns

The xS40 has a red Class II laser aimer that generates the pattern shown below in Figure 19. The aimer

indicates the center and size of the field of view including diagonal corners 24 in. away from the subject.

Figure 19 xS40 Laser Aiming Pattern

xS40

(46° FoV)

xS40 Decode Ranges

The xS40 features a 30° and 46° field of view lens that meets the decode ranges specified in Table 16 at

room temperature under ambient conditions.

The device has two imaging FoVs:

• 30 (H) x 19 (V)

• 46 (H) X 29 (V)

Figure 20 xS40 Imaging Fields of View

xS40

(30° FoV)

47

Table 16 xS40 Decode Ranges

Symbology

Typical Near Typical Far Typical Near Typical Far

5 mil Code 128 8 cm (3 in.) 61 cm (24 in.) 8 cm (3 in.) 36 cm (14 in.)

10 mil Code 128 8 cm (3 in.) 124 cm (49 in.) 8 cm (3 in.) 76 cm (30 in.)

15 mil Code 128 8 cm (3 in.) 178 cm (70 in.) 8 cm (3 in.) 107 cm (42 in.)

20 mil Code 128 8 cm (3 in.) 234 cm (92 in.)* 8 cm (3 in.) 142 cm (56 in.)*

5 mil Data Matrix 8 cm (3 in.) 33 cm (13 in.) 8 cm (3 in.) 20 cm (8 in.)

10 mil Data Matrix 8 cm (3 in.) 71 cm (28 in.) 8 cm (3 in.) 46 cm (18 in.)

15 mil Data Matrix 8 cm (3 in.) 102 cm (40 in.) 8 cm (3 in.) 69 cm (27 in)

30 mil Data Matrix 8 cm (3 in.) 198 cm (78 in.)* 8 cm (3 in.) 132 cm (52 in.)*

NOTE: Near distance is limited by barcode width and will focus no closer than 3 in.

*May be limited by illumination output from the power source, wavelength, or polarizer accessory (non-IR). The

above ranges are also applicable to 24 VDC powered unpolarized red illumination without ambient light.

xS70 Minimum Focus Distances

The table below outlines the minimum focus distances for C-mount lenses, provided by Zebra for use with

the xS70 device. Decode ranges are dependent upon the selected lens effective focal length, focusing

distance setting, and lens aperture setting.

FS40-SR 30° Mono FS40-WA 46° Mono

Table 17 Minimum Focus Distances

C-Mount Moritex Lens 8 MM 12 MM 16 MM 25 MM 35 MM

Minimum Focus Distance

from the Lens

6.35 cm

(2.5 in.)

11.43 cm

(4.5 in.)

General Purpose Input and Outputs

The xS40 and xS70 devices have two types of general-purpose inputs and outputs (GPIO). GPIO0

through GPIO3 are optically coupled to provide electrical isolation and wiring flexibility. GPIO4 through

GPIO8 are 24 V Digital GPIO, which are not isolated and source power from the external power supply or

Power over Ethernet (PoE). Digital GPIO is unavailable when the system is powered by USB, however,

optocoupled GPIOs remain functional when COMMON_IN and COMMON_OUT are terminated

appropriately.

Optically Coupled GPIO

Optocoupled GPIO have the advantage of being electrically isolated from the rest of the vision system and

require external reference through the COMMON_IN and COMMON_OUT wires. The termination of

COMMON_IN and COMMON_OUT to an external voltage or ground determines if the input or output is

Sinking (also known as NPN) type or Sourcing (also known as PNP) type.

In output mode, these GPIO perform similarly to switches connecting the GPIO pin to COMMON_OUT.

When disabled, the GPIO pin is disconnected from COMMON_OUT and allowed to float. As a result,

optocoupled outputs turn on relatively quickly, while the turn off time is dependent upon how quickly the

connected load dissipates charge.

10.16 cm

(4 in.)

11.43 cm

(4.5 in.)

19.05 cm

(7.5 in.)

48

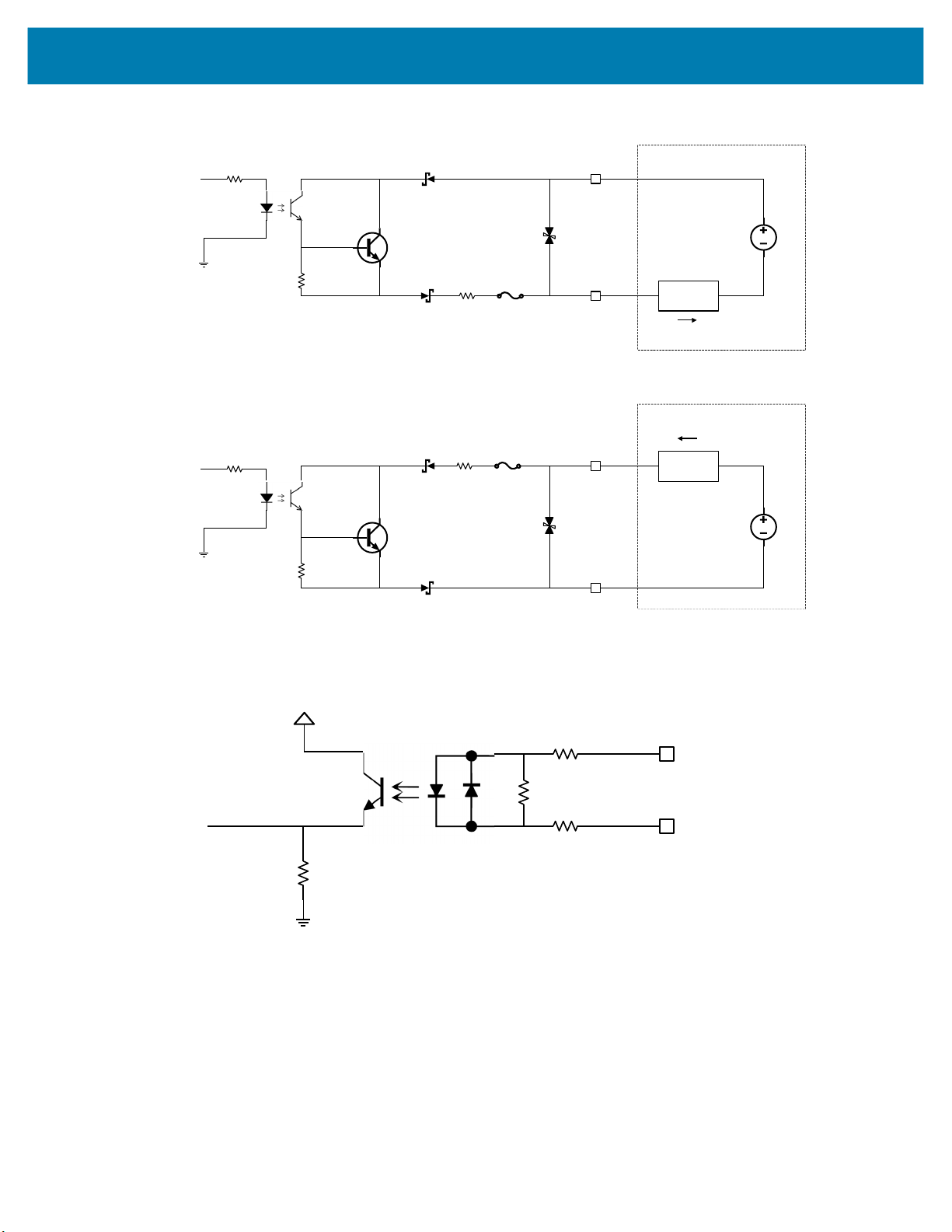

Figure 21 Output Mode Equivalent Circuit Diagram for NPN and PNP Mode

ConnectedEquipment

COMMON_OUT

GPI Opin

PNPSourc ing

OutputMode

CPU

10Vto30VDC

LOAD

I

LOAD

ConnectedEquipment

COMMON_OUT

CPU

10Vto30VDC

LOAD

GPIO pin

NPNSinking

OutputMode

I

LOAD

3.3V

COMMON_IN

GPIOpin

Inputmode

CPU

Optocoupled inputs are enabled when voltage is applied across the GPIO pin and COMMON_IN.

Figure 22 Input Mode Equivalent Circuit Diagram for NPN and PNP Mode

Optocoupled GPIO can be operated in a non-isolated fashion by terminating COMMON_IN and

COMMON_OUT to the DC_IN or GND wires used to power the device.

49

The following table provides a useful reference for such connections.

Table 18 Connection References

Wire Termination Configuration

COMMON_IN GND Sinking Input (NPN)

COMMON_IN DC_IN Sourcing Input (PNP)

COMMON_OUT GND Sinking Output (NPN)

COMMON_OUT DC_IN Sourcing Output (PNP)

While it is possible to configure inputs and outputs of the same type, this is not recommended as inputs

and outputs must be of opposite type to be compatible. All optocoupled GPIO share the COMMON_IN for

input mode and COMMON_OUT for output mode. Therefore, all inputs must be of the same type and all

outputs must be of the same type. For example, it is not possible to simultaneously configure sinking

output on GPIO0 and sourcing output on GPIO1.

In practice, sinking inputs paired with sourcing outputs is very common. This combination is compatible

with widely available digital industrial GPIO, which typically only support sinking type inputs.

NOTE: Refer to the documentation of the connected auxiliary equipment to ensure a compatible

configuration, and remember to leave unused GPIO in a disabled state.

Optocoupled outputs are individually fused to protect against damage from short circuit or overload events.

Since no power is consumed from the vision system, optocoupled GPIO are always available regardless of

power source and have no impact on power budgeting.

Digital Industrial GPIO

Unlike optocoupled GPIO, digital GPIO actively drive the output signal high and low for significantly faster

turn on and turn off time. Digital GPIO is not isolated, and therefore referenced to the power supply and

ground of the vision system. COMMON_IN and COMMON_OUT do not need to be terminated to use

digital GPIO.

NOTE: Refer to the documentation of the connected auxiliary equipment to ensure a compatible

configuration, and remember to leave unused GPIO in a disabled state.

IMPORTANT: A digital GPIO can be configured as a 24 V output and wired back in to COMMON_IN

or COMMON_OUT to create the necessary bias voltage to operate optocoupled GPIO when the

system is powered by PoE. It is important to be aware of the 100 mA total current budget per digital

GPIO when attaching loads to any optocoupled outputs powered this way.

Digital inputs on xS40 and xS70 devices are of the sinking (NPN) input type and do not support the less

common sourcing (PNP) input configuration. Voltage above the specified threshold relative to the vision

system ground must be applied for a logic high to register. Drive these inputs with a sourcing (PNP) or

push-pull output.

Configuring the 5-pin M12 External Light connector to GPIO Mode makes GPIO6 through GPIO8 available

for general use. Configuring the External Light connector to External Light Mode switches GPIO8 into a

high current output to provide power and sets up GPIO6 and GPIO7 to control the connected light.

IMPORTANT: When the vision system is powered by an external power supply, and the External Light

connector is configured for External Light mode, GPIO8 operates in a bypass mode capable of

shunting input power directly to high power strobe lights. Extremely high peak currents are possible

with adequate power supply capability, minimized cable losses, and observing duty cycle limits that

keep average current into the entire system below 1500 mA.

50

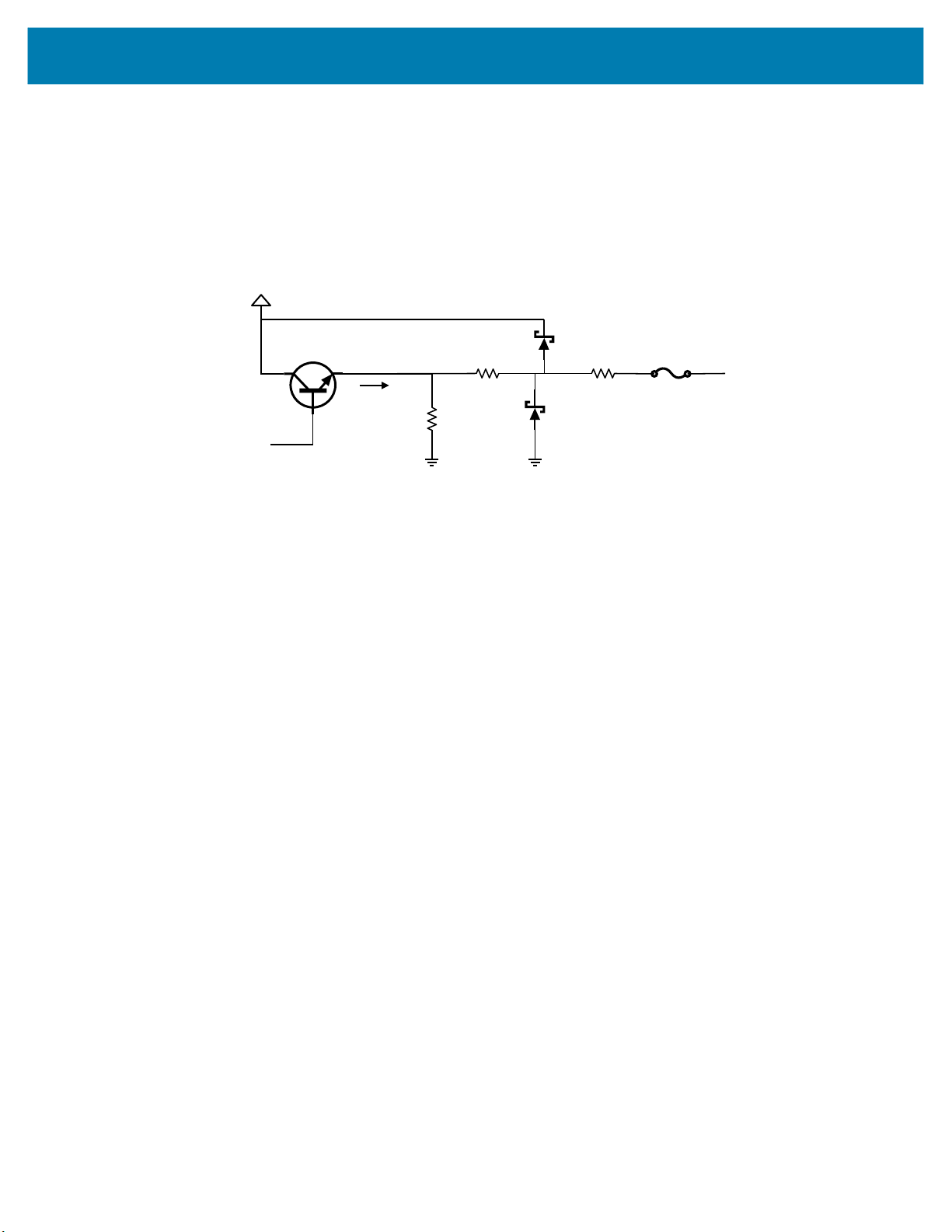

Analog Output

390ohms

10Vto30V

Analogcontrol

2.2K

ANALOG_OUT

I

out

10ohms

The vision system is equipped with an analog output on the External Light connector capable of generating

between 0 V and 10 V. An output impedance of approximately 400 ohms protects the analog output driver

against overload conditions, however, this introduces an offset in output voltage that is directly proportional

to the output current. For optimal accuracy, connect devices with low input bias current.

Figure 23 Analog Output Equivalent Circuit Diagram

51

Power and Thermal Management

Sophisticated algorithms keep operation of the machine vision system within acceptable power and

thermal parameters to ensure reliable operation over the product lifetime.

CAUTION: If the available power budget is not adequate for configured settings, a warning is indicated to the

user. In some cases, the user can choose to ignore or override the warning, in which case, operational stability of

the system should be evaluated by the integrator.

Temperature is actively monitored at critical points within the system. Whenever a safe limit is exceeded

the system response may include disabling of certain features, reduction of processor performance, or

stopping active jobs.

If overheating is a problem, effective mitigation strategies include:

• Reducing the average system power consumption

• Avoiding continuous trigger mode

• Lowering trigger rate

• Using external illumination

• Avoiding operating from PoE

• Operating in a cooler environment

• Actively cooling with a fan

• Heatsinking the chassis to a large thermally conductive mounting surface through a thermally

conductive mounting system

For optimal performance, ensure that the device does not exceed the recommended operating ranges

listed below

:

Table 19 Operating Temperature

Temperature Operating Range

Ambient Temperature

Note 1: If temperatures exceed the operating range, additional heat sinking strategies may be necessary,

i.e. mounting to a metal infrastructure or forced convection via an external fan. Use of the Zebra Universal

Mounting Bracket (BRKT-LMNT-U000) provides multiple options to mount to a metal infrastructure.

0°C - 40°C (POE, duty cycle-dependent)

0°C - 45°C (non-POE, duty cycle-dependent)

1

52

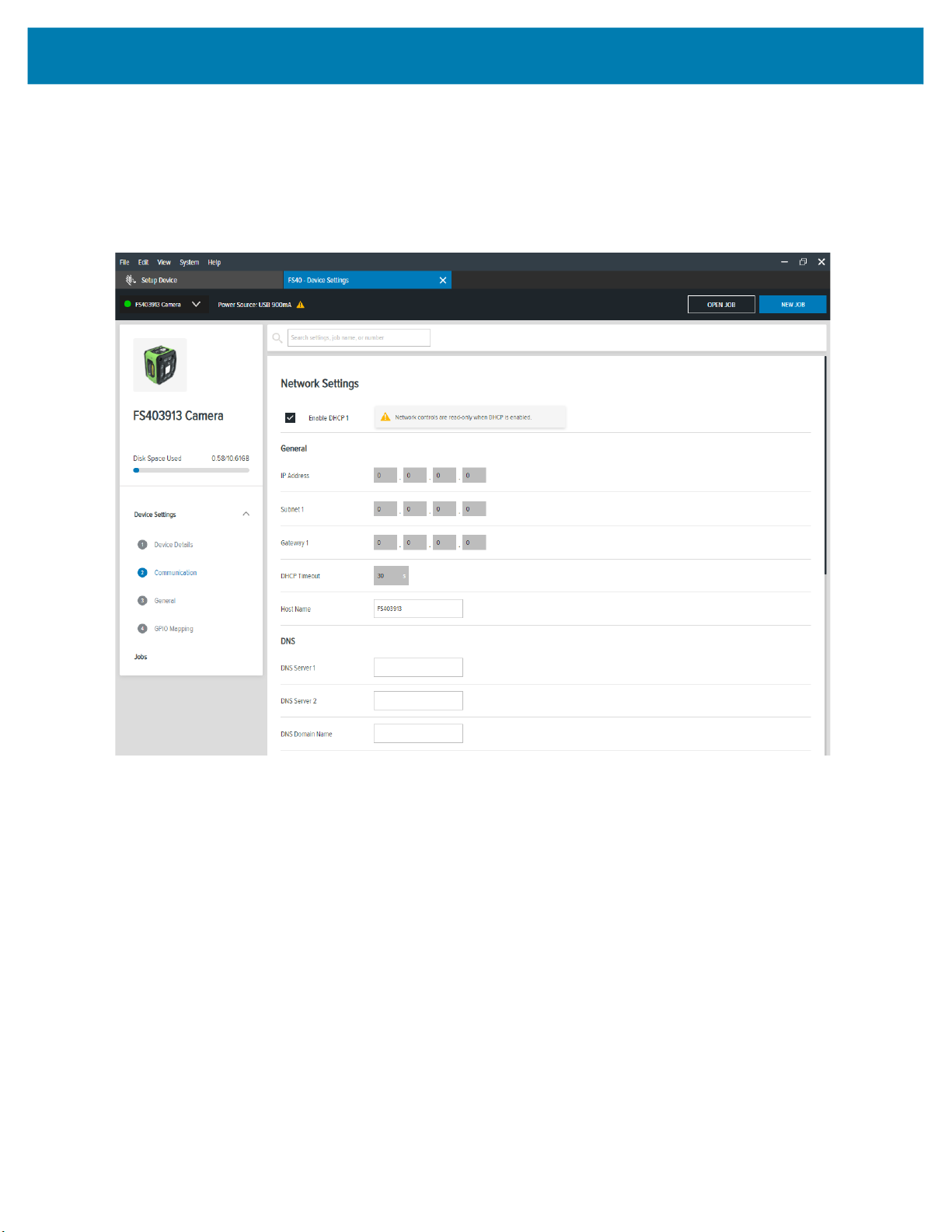

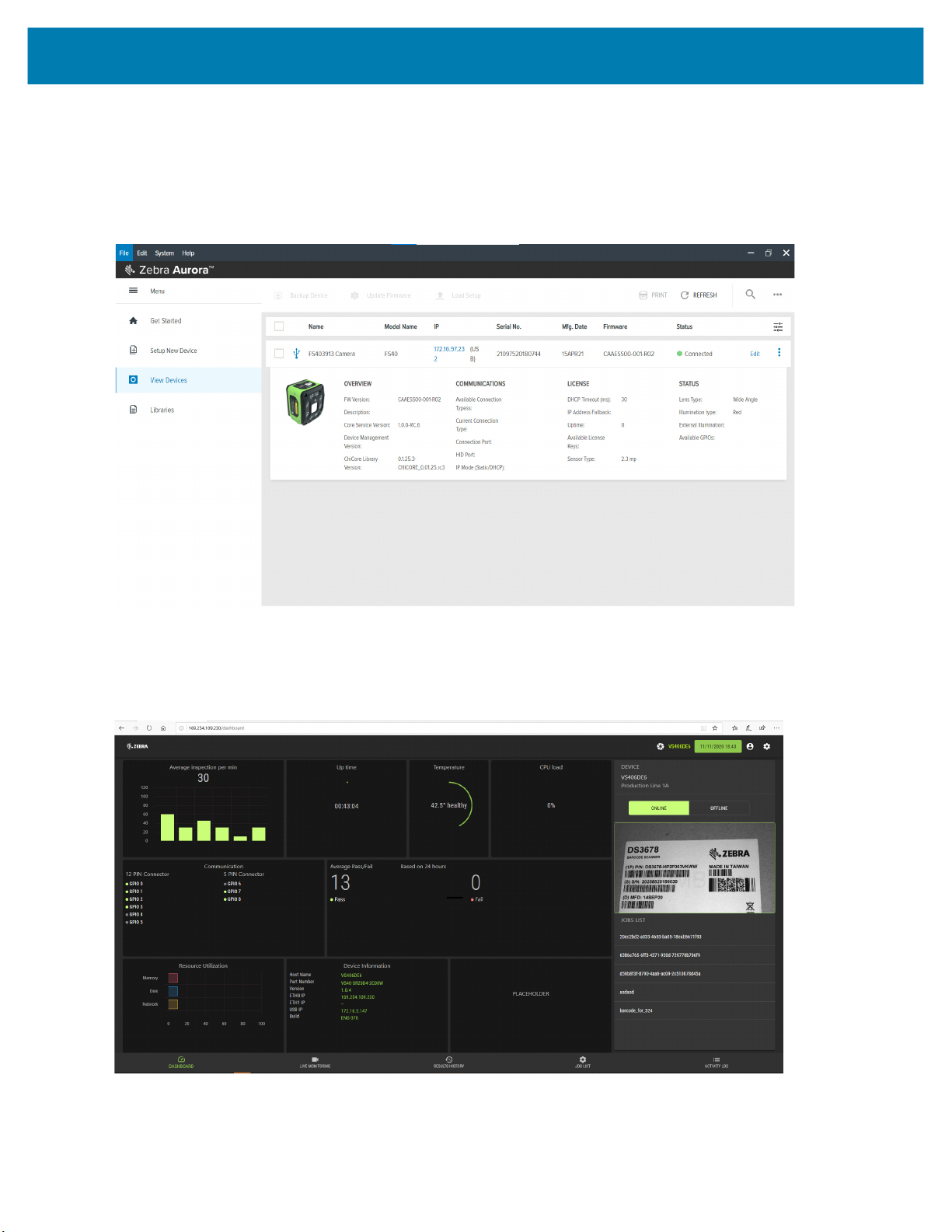

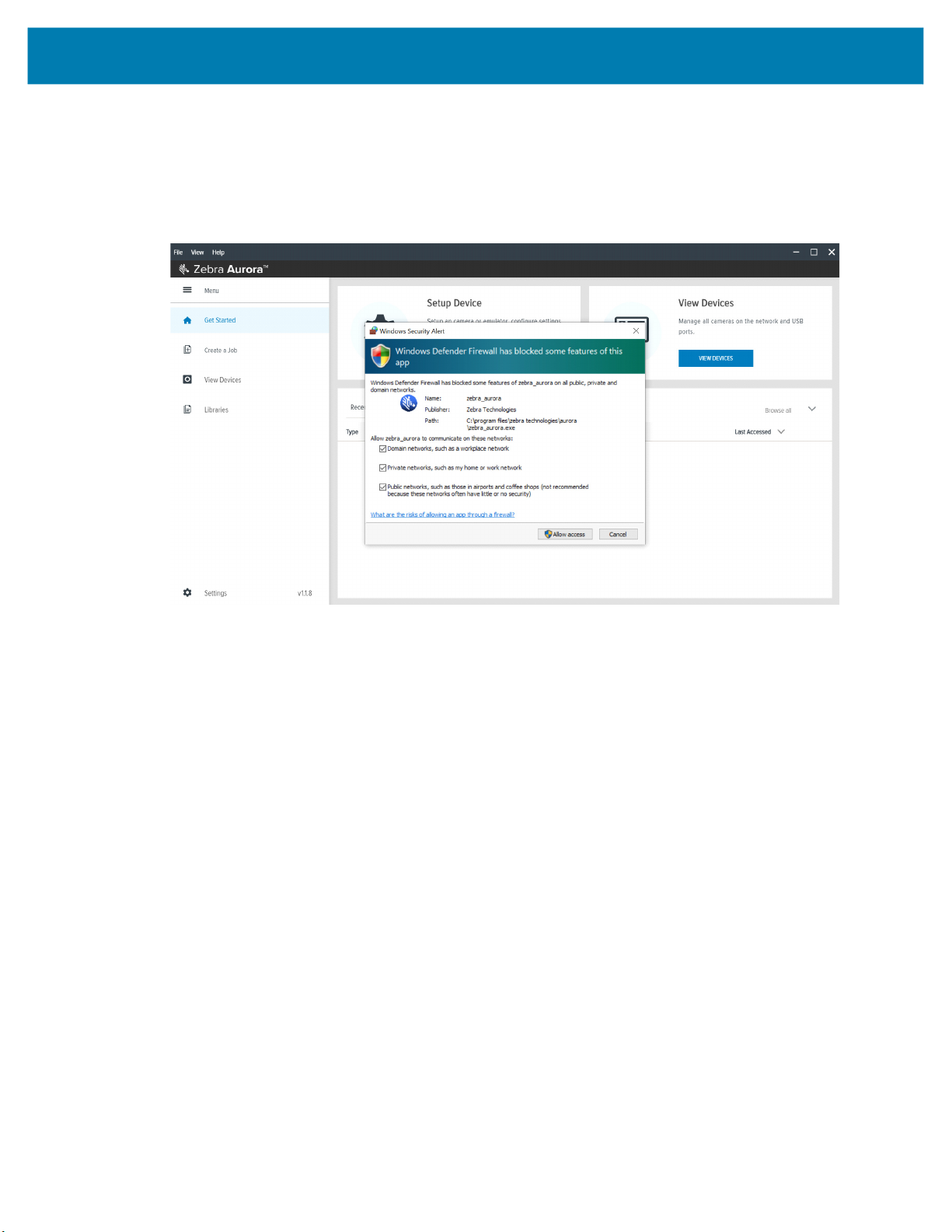

Zebra Aurora Software Overview

The Zebra Aurora application provides a unified platform with an intuitive interface for setting up, deploying, and

running Fixed Industrial Scanning or Vision System jobs to control enterprise-wide manufacturing and logistics

automation solutions. This tool also has the capacity to scale in support of new codes and increase scanning

speed with the potential to upgrade to machine vision functionality via software license upgrade.

Human-Machine Interface (HMI)

Using the Web Human-Machine Interface (HMI), operators can view and interact with the Zebra Aurora Human

Machine Interface (HMI) dashboard via web browser or by connecting a monitor directly to the xS40.

Industrial Ethernet Information

For information regarding built-in EtherNet/IP, PROFINET or other network protocols to integrate with any common

PLC or host system, refer to the FS/VS Smart Camera Industrial Ethernet User Guide.

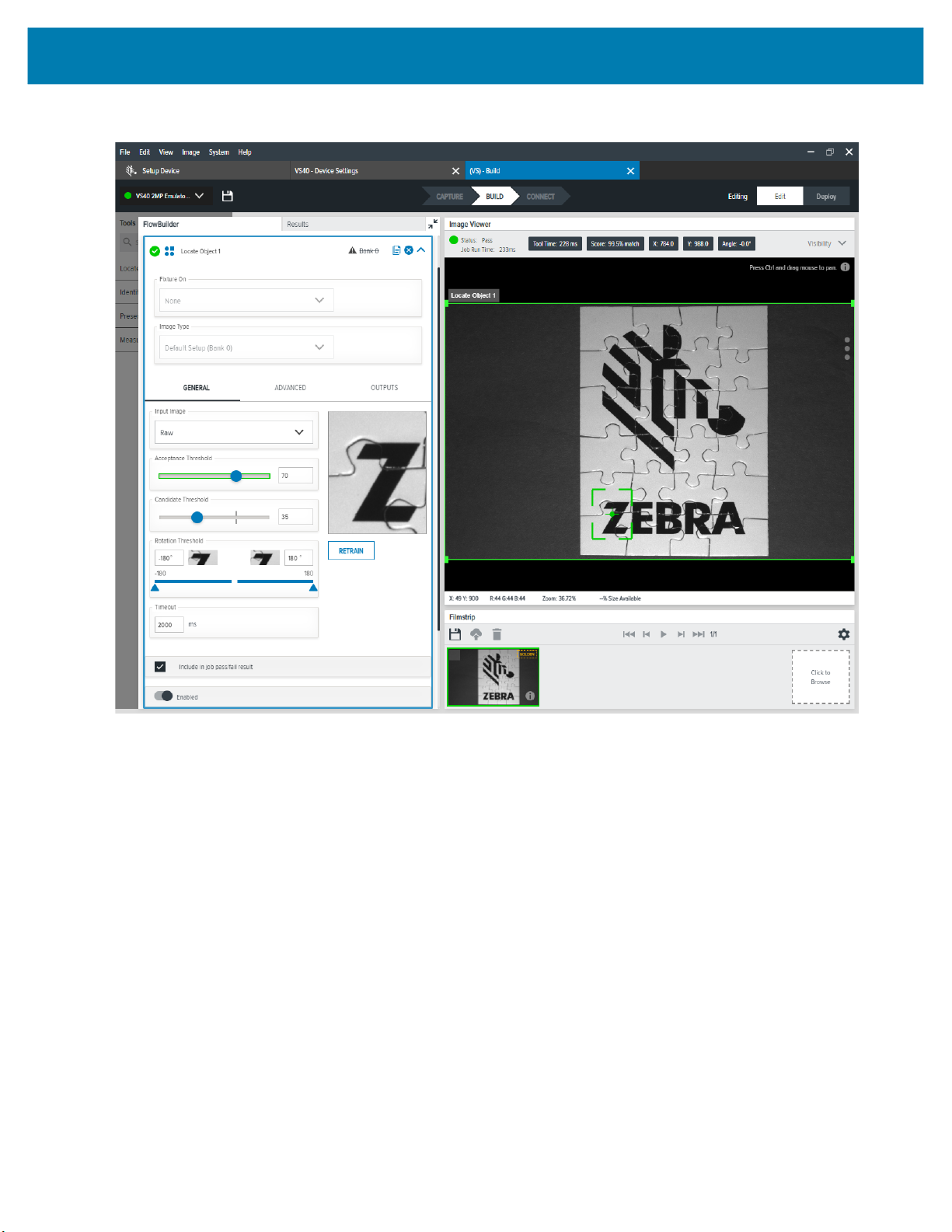

Zebra Aurora Features

Zebra Aurora provides several differentiating features to rapidly process, evaluate and compare multiple images in

various lighting conditions without altering any hardware configurations.