Page 1

FS/VS Smart

Camera Series

Industrial Ethernet Guide

MN-003811-01EN Rev A

Page 2

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2021

Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/linkoslegal

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

2

Page 3

Revision History

Revision Description

MN-003811-01 Rev. A 6/21 Initial Rev A. Release

3

Page 4

Contents

Terms of Use ......................................................................................................................... 2

Proprietary Statement ......................................................................................................... 2

Product Improvements ........................................................................................................ 2

Liability Disclaimer .............................................................................................................. 2

Limitation of Liability ............................................................................................................ 2

Revision History .................................................................................................................... 3

About This Guide

Service Information ............................................................................................................... 7

Initial Setup

Hardware/Software Prerequisites ......................................................................................... 8

Activating Industrial Ethernet ................................................................................................ 9

Configuring Industrial Ethernet Input & Output ................................................................... 10

User Control Data ............................................................................................................. 10

Results Data ..................................................................................................................... 11

Industrial Ethernet Interface

Job Control/Status ............................................................................................................... 12

Trigger Control/Status ......................................................................................................... 14

Results Control/Status ........................................................................................................ 15

User Data Control/Status .................................................................................................... 16

Error Codes Control/Status ................................................................................................. 16

User Control and Data Structure ......................................................................................... 17

User Data Format for Raw Mode (Mode = 1) ................................................................... 17

User Data Format for Entry Mode (Mode = 0) .................................................................. 18

Results Status and Data Structure ...................................................................................... 18

Results Data Format Raw Mode (Mode = 1) .................................................................... 19

Results Data Format for Entry Mode (Mode = 0) .............................................................. 19

Entry Type List .................................................................................................................... 20

Fixed Scanning Barcode Results Structure ........................................................................ 20

Pattern Match Results Structure ......................................................................................... 21

4

Page 5

EtherNet/IP

Contents

Electric Data Sheet (EDS) File ............................................................................................ 22

TCP/IP Interface Object ...................................................................................................... 22

I/O Assemblies .................................................................................................................. 22

Status and Results Assembly (Device to PLC) ........................................................... 22

I/O Connections ................................................................................................................ 23

Exclusive Owner Connection ...................................................................................... 23

Configuring Rockwell ControlLogix Communication ........................................................... 24

Register the FS/VS EDS File ............................................................................................ 24

Method One: Download from the Device ............................................................................ 24

Method Two: Manually Install from the Developer Zip File ......................................... 24

Adding the FS/VS Smart Camera to the I/O Configuration ............................................... 25

FS/VS Smart Camera I/O Tags ........................................................................................... 26

Status and Results Input Assembly .................................................................................... 27

Job Control and Setup Assembly ........................................................................................ 28

Fixed Scanner Add-On Instruction (AOI) ............................................................................ 29

Creating a New Project that Uses AOI_FixedScanner ...................................................... 29

Using the Fixed Scanner Add-On Instruction ...................................................................... 35

PROFINET Interface

GSDML File ......................................................................................................................... 36

PROFINET IO Modules ....................................................................................................... 36

Command IO Module ........................................................................................................ 36

CommandData32 IO Module ............................................................................................ 37

CommandData64 IO Module ............................................................................................ 37

CommandData128 IO Module .......................................................................................... 37

Response IO Module ........................................................................................................ 38

ResponseData32 IO Module ............................................................................................. 39

ResponseData64 IO Module ............................................................................................. 39

ResponseData128 IO Module ........................................................................................... 39

Configuring Siemens S7 Communications .......................................................................... 40

Register the GSDML File .................................................................................................. 40

Finding the Device and Configuring the Device Name ..................................................... 40

Adding the FS/VS Smart Camera to the I/O Configuration ................................................. 42

Fixed Scanner Function Block (FB) .................................................................................... 44

Creating a Project that uses FB_FixedScanner ................................................................ 44

Using the Fixed Scanner Function Block .......................................................................... 48

Modbus TCP Interface

Modbus Register Locations ................................................................................................. 49

Command Registers Mapping ............................................................................................. 50

Command Data Registers Mapping .................................................................................... 50

Response Register Mapping ............................................................................................... 50

Response Data Registers Mapping .................................................................................... 51

Typical Use Case for Triggering a Job ................................................................................ 52

5

Page 6

Error Codes

Contents

6

Page 7

About This Guide

The FS/VS Smart Camera Industrial Ethernet Guide provides instructions for setting up and programming

the device for Industrial Ethernet applications.

IMPORTANT: If you have a problem with your equipment, contact Zebra Global Customer Support for your

region. Contact information is available at: zebra.com/support

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at: zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

7

Page 8

Initial Setup

Refer to the FS/VS Smart Camera Product Reference Guide for detailed information on:

• Connection Diagrams, including how to power the device.

• Status Indicators (LED and Beeper) and their meanings.

• Default Factory Settings, including how to restore Factory Settings.

• Ethernet Setup, including how to discover a device and set an IP address.

• Firmware update methods.

• Building and deploying Jobs, including configuration of Trigger modes.

• Accessing the Web HMI

• Licensing and Security

Hardware/Software Prerequisites

The following list of components is required for initial setup, testing, and development of Industrial Ethernet

applications that use the FS/VS Smart Camera.

• An FS/VS Smart Camera with Ethernet support that is configured to the correct Industrial Ethernet

Protocol and IP address. The device should be configured with the Jobs required to perform the work

needed by the Industrial Ethernet application.

• An M12 X-Coded cable that can connect the FS/VS Smart Camera Ethernet port to your network.

• The appropriate cabling and power supply necessary to power the FS/VS Smart Camera.

• A PC running Windows 7 or higher (Windows 10 recommended) to view the Web HMI, Zebra’s Aurora

Application, and development software for PLC applications.

• An Ethernet switch or router (if not connecting FS/VS Smart Camera directly to a PLC).

• An Industrial Ethernet PLC (Programmable Logic Controller) that supports one of the supported protocols

(EtherNet/IP, PROFINET, or Modbus TCP) and an Ethernet switch or router (if not connecting the device

directly to a PLC).

NOTE: Industrial Ethernet testing has been performed with the following PLCs and software:

Rockwell Compact Logix 5069-L306ER and Logix Studio 5000 v32.02.00 Software

Siemens S7 1500/1200 PLC and Totally Integrated Automation (TIA) v15.1 Software.

• FS/VS Smart Camera Industrial Ethernet Developer Files (CAAFSS00-001-Rxx.zip)

8

Page 9

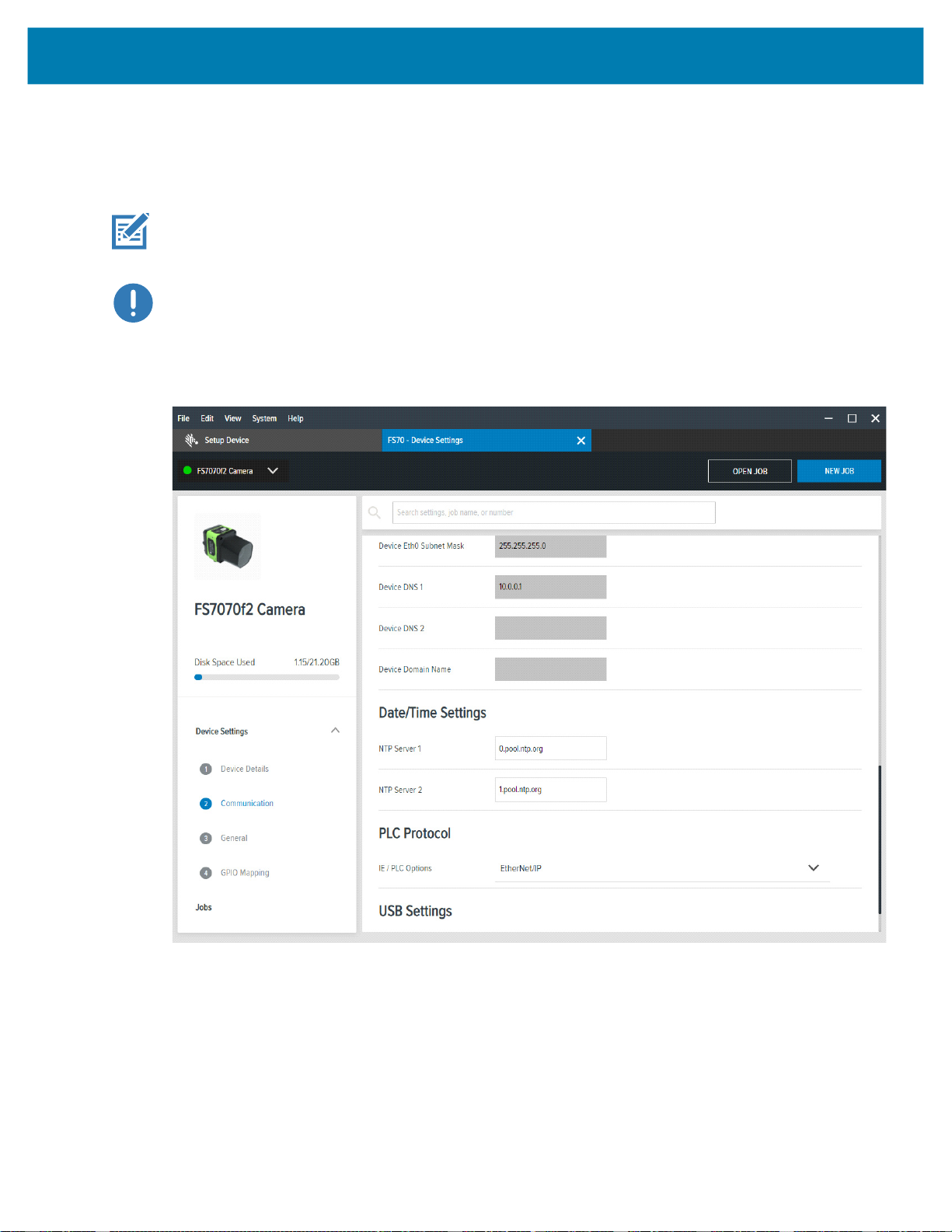

Activating Industrial Ethernet

The Zebra Aurora Application device settings provide an option to select which PLC protocol can be

enabled on the device, as shown in the PLC Protocol selection in the figure below.

IMPORTANT: It is required that on any PLC Protocol change, the device must be rebooted for the

change to go into effect.

IMPORTANT: After enabling PROFINET protocol support, the FS/VS Smart Camera is only

accessible on the network through the PROFINET protocol. It is recommended that after enabling the

protocol you use the TIA Portal to find all the accessible devices and set the PROFINET device name

of the FS/VS Smart Camera.

Figure 1 PLC Protocol

Initial Setup

9

Page 10

Initial Setup

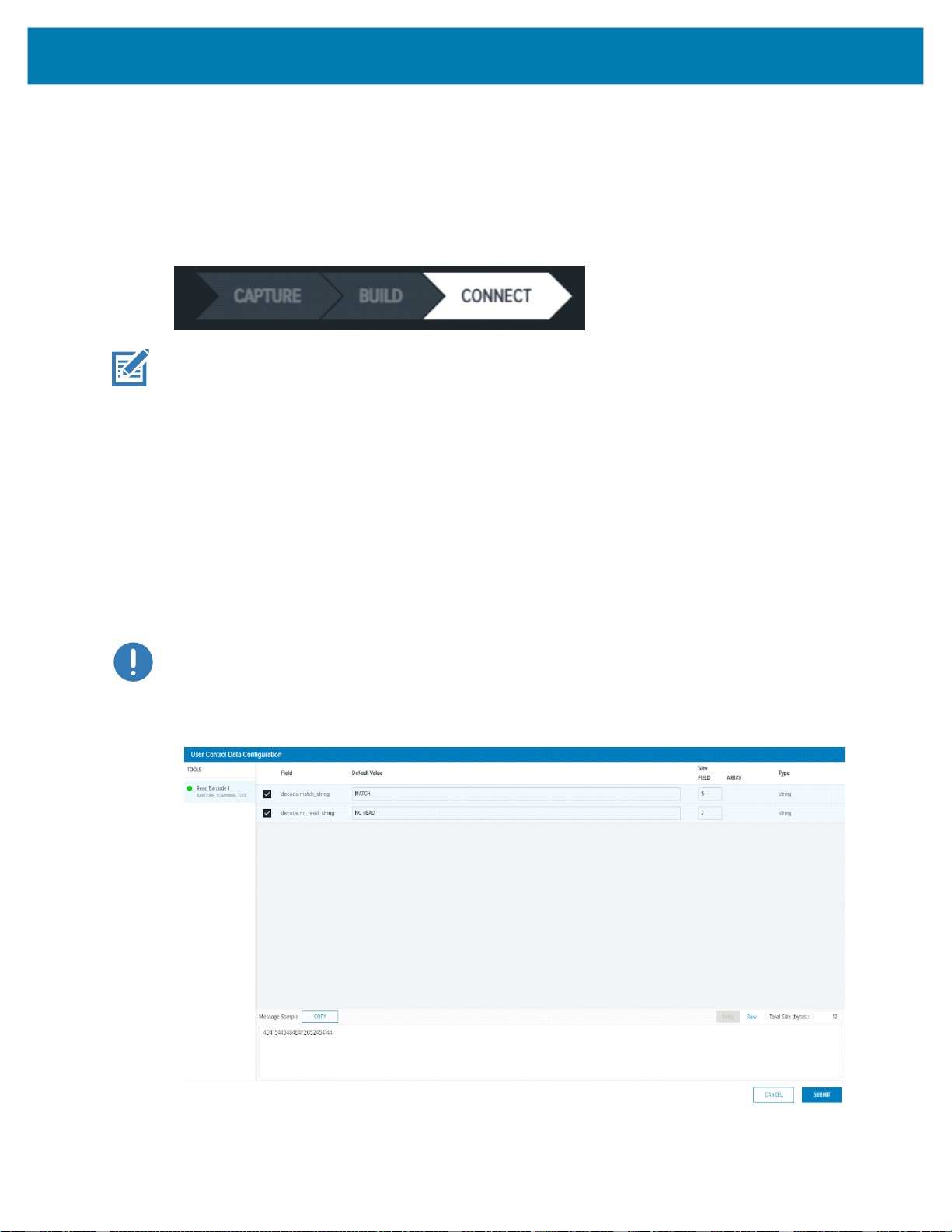

Configuring Industrial Ethernet Input & Output

Users can specify what results and configuration is provided to the PLC through the Zebra Aurora

applications Connect workflow. When Connect is selected, click the Industrial Ethernet list item on the

left of the application.

Figure 2 Connect

NOTE: The updated Job must be deployed and set as active on the device for any changes to be seen

from the PLC.

User Control Data

The User Control Data user interface allows for the PLC to make runtime changes to Job input parameters,

such as Barcode Match Strings or No Read strings.

Click the Add or Edit button to display the User Control Data Configuration dialog and the possible input

parameters. Check the specific input parameter to be changed from the PLC and configure the default

value and the size. Refer to the Message Sample window for a view of what the data must look like when

sent from the PLC to the device. For User Control Data, it is recommended that Raw Mode is selected.

This removes the need to set the proper Entry header for Entry mode. When the form is complete, click the

Submit button. From the main window, reorder the input parameters using a drag and drop technique.

IMPORTANT: Default value changes do not affect the job, they are used for Message Sample preview

only.

Figure 3 User Control Data Configuration

10

Page 11

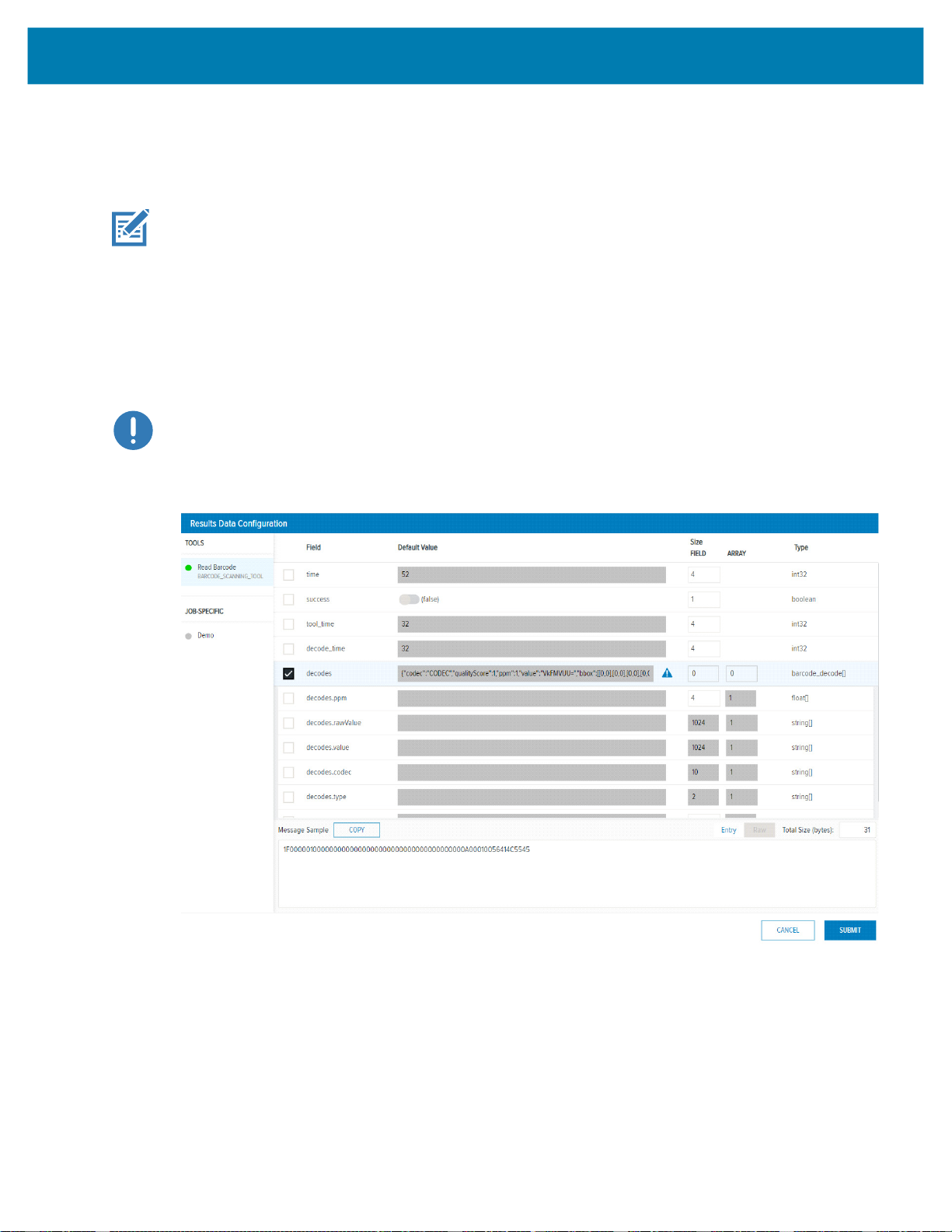

Results Data

The Results Data user interface allows for the user to control which results are sent to the PLC upon Job

completion.

NOTE: The default barcode job on the FS/VS device is configured to provide the FS Barcode

Structure to the PLC. Also, new FS Jobs have FS Barcode Structure automatically configured as the

result output to the PLC.

Click the Add (or Edit) button to display the Results Data Configuration Dialog and the possible tools and

output parameters that can be added to the Result Data. Check the result parameter you intend to receive

from the FS/VS Smart Camera when a Job completes. Refer to the Message Sample window for a view of

what the data looks like when sent to the PLC. Entry or Raw mode can be selected, for more information

on these modes refer to the Results Status and Data Structure on page 18. Once complete, click the

Submit button. From the main window, reorder the result data items using a drag and drop technique.

IMPORTANT: Default value changes do not affect the job, they are used for Message Sample preview

only.

Figure 4 Results Data Configuration

Initial Setup

11

Page 12

Industrial Ethernet Interface

All Industrial Ethernet protocols supported by the FS/VS Smart Camera use the interface described in this

chapter. Review this section before proceeding to the specific Industrial Ethernet protocol section relevant

to your use case.

Job Control/Status

The FS/VS Smart Camera runs scripts, also known as Jobs, to decode barcodes and solve machine vision

problems. This section includes information on Job Control and Status features available to the PLC

programmer.

Table 1 Job Control/Status Features

Name Direction

Job

Control

Reset

Counters

Job Slot

Control

Job Slot

Number

PLC to Device 1 Job Control sets the state of the Job. When set to 0, the Job is

PLC to Device 1 When this bit is toggled from 0 to 1, all Job counters are reset.

PLC to Device 1 Job Slot Control is used in conjunction with the Job Control bit.

PLC to Device 2 This number field is used in conjunction with the Job Slot

Size

(Bits)

Description

inactive (stopped, for example, no Job loaded or not active).

When the value is set to 1 while the Job Slot Control bit is 0, the

default (or last active) Job will be loaded and set to the loaded

or active state. If the Job Slot Control bit is 1, the Job specified

by the Job Slot Number is loaded and set to the Loaded or

Active state.

If a Job load fails, an error code will be provided as specified in

Error Codes section.

the

As a result, the Job sequence number will be reset to 1 and any

remaining results in the Result Queue will be cleared.

When this bit is set to 1 and the Job Control bit is toggled from 0

to 1, a Job slot switch occurs. The Job that is loaded and made

active is then specified in the Job Slot Number field.

Control bit and the Job Control bit. When the Job Slot Control

bit is set and the Job Control bit is toggled from 0 to 1, this

number will indicate the Job that will be Loaded and made

active. If the number is 0, the Job will be unloaded (made

inactive).

12

Page 13

Industrial Ethernet Interface

Table 1 Job Control/Status Features (Continued)

Name Direction

Job Status Device to PLC 1 Job Status indicates whether a Job is in the loaded or active

Active Job

Slot

Number

Results

Job Slot

Number

Job Pass Device to PLC 1 This bit is set to 1 if the Job results pass, or set to 0 if the Job

Job Fail Device to PLC This bit is set to 1 if the Job results fail, or set to 0 if the Job

Echo

Register

Control

Echo

Register

Status

Device to PLC 16 The Active Job Slot Number represents the Current Job Slot.

Device to PLC 16 The Results Job Slot Number represents the Results Job Slot.

PLC to Device 16 This 16-bit value is reflected in the PLC based on the value that

Device to PLC 16 This 16-bit value matches the value that the PLC writes to its

Size

(Bits)

Description

state or in the Unloaded Stopped state. Depending on the Jobs

trigger type, a Loaded Job may either be Running or Idle

(waiting on trigger).

0 = Stopped/Unloaded, 1 = Active/Loaded.

Under normal conditions (non-error conditions) this bit matches

the Job Control bit.

This 16-bit integer corresponds to the Job slot of the currently

Loaded or Active Job.

This 16-bit integer corresponds to the Job slot of the Job that

was run to produce the results in the Results data section.

results fail.

results pass.

Some error conditions may not be considered to be a fail, refer

Error Codes section for additional information.

to the

the PLC writes to it. This field allows the PLC programmers to

verify that the output assembly has been written to the camera

when this value matches the written value.

Echo Register Control. This field allows the PLC programmers

to verify that the output assembly has been written to the

camera when this value matches the written value.

13

Page 14

Trigger Control/Status

Each Job will have one of the following trigger modes:

• Single Shot

• Continuous

• Presentation

• Burst

• Level

Depending on the Trigger Mode, the action that the device takes when an external Trigger is initiated may

differ. For example, when a Job is set for Single Shot, a PLC/GPIO Trigger initiates a single run of that Job.

However, if the Job is set to Continuous, a PLC/GPIO Trigger may produce no change in behavior. Refer

to the Trigger Modes Configuration section in the FS/VS Smart Camera Series Product Reference Guide

for additional information.

The following table describes the control and status of Trigger functionality as it relates to Industrial

Ethernet.

Table 2 Trigger Modes

Industrial Ethernet Interface

Name Direction

Trigger Enable

Control

Trigger PLC to Device 1

PLC to Device 1 Set to 1 to enable triggering

Size

(Bits)

Description

Set to 0 to ignore trigger

When changed from 0 to 1, the current Job begins

running or processing. This bit is only acted upon when

the following conditions are met:

• Job Status is 1 (Job is loaded/active)

• Trigger Ready is 1 (Device is ready to accept

triggers)

Trigger Ready Device to PLC 1 Indicates when the device is ready to accept a new

trigger. This bit is set to 1 when Trigger Enable Control

is 1 and the active Job Slot is not 0. If the bit is set to 0,

the triggers will be ignored.

Trigger Status Device to PLC 1 This bit is set to 1 when the Job is currently executing or

running. This bit is cleared when the Job is stopped or

idle.

14

Page 15

Results Control/Status

Job results are made available upon completion of the Job. The result data is dependent upon the type of

Job that is run and the Job that was configured. If multiple results are made available before the PLC can

process them, it is suggested that Results Buffering is enabled to ensure that no results are lost.

Table 3 Results Data

Industrial Ethernet Interface

Name Direction

Results Buffer

Control

Results Ack PLC to Device 1 This bit is only applicable when Results Available is set to

Results

Available

Results Buffer

Overflow

Results Queue

Count

Result Data Device to PLC Array of

Results Packet

Sequence

PLC to Device 1 Results Buffer Control enables the queuing of result data

Device to PLC 1 Indicates that a new set of read results are available. This

Device to PLC 1 Indicates that the device has discarded a set of read results

Device to PLC 8 Results Queue Count records the number of results

PLC to Device 16 This number is used in conjunction with Results Ack. It is

Size

(Bits)

Bytes

Description

(queue size is set to 32). If set to 1, new results are queued

on the device and remain present until acknowledged. To

retrieve the next set of results from the queue on the

Results Ack, the bit must transition from 0 to 1. The device

responds to this acknowledgment by clearing the Results

Available bit when no more results are queued on the

device. See the Results Queue Count row in this table for

more information on how results are queued on the device.

If results buffering is not enabled (set to 0), newly received

read results overwrite the content of the Result Data in the

Response/Status section of the Input Assembly.

The Results Overflow bit is set when this bit is set and there

is no more space in the queue to accept a new result.

1. When this bit transitions from 0 to 1, the PLC is then sent

the next set of results. If there are no additional results

queued on the device, the Results Available bit is cleared.

bit is cleared when the results are acknowledged.

because the results queue is full. This is cleared when the

next set of results are successfully queued.

currently in the queue on the device. This bit is set to 0 if

there are no results in the queue.

Results Status and Data Structure on page 18 for

See

more information on contents of the Results Data Structure.

expected to be changed before Results Ack is set to ensure

that Result Ack is not missed by the device.

15

Page 16

User Data Control/Status

A PLC program can modify Job input parameters at runtime through User Data Control. Updating Job input

parameters are not permanent and are reset to the Job defaults if the Job is reloaded.

Table 4 User Data

Name Direction Size (Bits) Description

User Data

Control

User Data

Status

User Data PLC to

PLC to

Device

Device to

PLC

Device

Industrial Ethernet Interface

1 When this bit is toggled from 0 to 1, the current Job’s

User Data will be overwritten with data provided by the

PLC. See the User Data Status bit description to know

when the User Data has taken affect. When this bit is

cleared, the User Data Status bit will also be cleared.

1 When set to 1, this bit indicates that the new User Data

has taken affect. This bit is cleared when User Data

Control is cleared.

Array of

Bytes

See User Data Structure for more information on the

contents of User Data Structure.

Error Codes Control/Status

If any errors occur on the device, codes will provided to the PLC to determine the cause. See the Error

Codes for a list of error codes and their meaning. The table below describes interpret and utilize error

codes.

Table 5 Error Code Descriptions

Name Direction Size (Bits) Description

Error Buffer

Enable

Error Ack PLC to

Error

Overflow

Error

Available

Error Code Device to

PLC to

Device

Device

Device to

PLC

Device to

PLC

PLC

1 Enables queuing of Error Codes. If enabled, the current

Error Code will remain in the Error Code field until

acknowledged (even if new Error Codes arrive). To clear

the Error Code, toggle the Error Ack bit from 0 to 1. If

another Error Code is queued, the current code is

replaced with the queued code after each 0 to 1

transition of the Error Ack.

If this field is set to 0, no Error Codes will be queued and

only the latest Error Code will be available in the Error

Code field, all other codes will be overwritten.

1 Toggle this bit from 0 to 1 to acknowledge or clear the

current Error Code. This bit clears both the Error

Available bit and Error Code field if there are no other

Errors in the queue.

1 Indicates that the device has discarded an error code

because the error queue is full. This bit is cleared when

the current Error Code is acknowledged.

1 When set to 1, this bit indicates that there is data in the

Error Code field. This bit is cleared when the error is

acknowledged and there are no more errors queued.

16 This bit represents the number (16-bit integer) of an error

that has occurred on the device. See

more information on specific Error Codes.

Error Codes for

16

Page 17

Industrial Ethernet Interface

User Control and Data Structure

The User Control and Data Structure can be sent to the FS/VS Smart Camera from the PLC to change Job

input parameters at runtime. The User Data Structure is configured using two different formats, Entry Mode

and Raw Mode. When a Job is configured to use Entry Mode, each data entry that is provided by PLC

needs to be proceeded by a 4-byte header. This header includes information on data length and the type

of data provided. When a Job is configured to use Raw Mode, there is no additional metadata provided

(raw data is provided).

.

Table 6 FS Job Results

Name Offset

User Control Global Header

Sequence Number 0 4 Not currently used. Can be 0.

Total Length 4 2 Total size in bytes of the User Data. This length value does

Fragment # 6 2 Not currently used. Can be 0.

Fragment Total Count 8 2 Not currently used. Can be 0.

Mode 10 1 Specifies the User Data format. This bit is 0 for Entry Mode

Status 11 1 Not currently used. Can be 0.

Time 12 2 Not currently used. Can be 0.

Count 14 2 Number of data entries in User data. The count should be 0

Size

(Bytes)

Description

not include the 16 bytes taken up by the Global Header. The

count starts at User Data and includes all the bytes

following it. It is required that the Total Length value

matches the length as specified in the Job’s Industrial

Ethernet User Data configuration.

and 1 for Raw Mode.

if no data exists in User data. The count never exceeds 1

when the mode is set to Raw.

NOTE: User data typically follows the Global Header. However, refer to the Industrial Ethernet protocol

section for more information on where the User Data resides for the given protocol.

User Data Format for Raw Mode (Mode = 1)

Table 7 User Data Format for Raw Mode

Name

Raw Data Varies All of the associated data that is sent from the PLC to the device

Size

(Bytes)

to change the Job input parameters. The data provided is based

on the Industrial Ethernet User Control Data Configuration for the

Job.

17

Description

Page 18

Industrial Ethernet Interface

User Data Format for Entry Mode (Mode = 0)

Table 8 User Data Format for Entry Mode

Name

Entry Length <n> 2 Size in bytes of the data in Entry <n> + 4 (the Entry meta data)

Entry Device # <n> 1 Device number (always 0)

Entry Type <n> 1

Size

(Bytes)

Specifies the type of the entry. Refer to the

page 20

Entry Data <n> Varies Data associated with the Entry <n>. The data provided is based

on the Industrial Ethernet User Control Data Configuration for the

Job.

<n+1, n+2 to “Count”> ...

Results Status and Data Structure

The Results Data Structure is provided in the Results Data array following the completion of Job run. The

Results Data Structure can be configured using two different formats, Entry Mode and Raw Mode. When a

Job is configured to use Entry Mode, each data entry that is provided by the device to the PLC is

proceeded by a 4-byte header. This header will include information on data length and type of data

provided. When a Job is configured to use Raw Mode, there is no additional metadata provided (raw data

is provided).

.

Table 9 Results Data Structure

Description

Entry Type List on

for more information on valid Entry Types.

FS Job Result Offset

Results Status Global Header

Sequence Number 0 4 The sequence number for the Results. This is tied to the Job

Total Length 4 2 Total size in bytes of the Results Data. This length value does

Fragment # 6 2 For multi-fragment results, this entry indicates which fragment

Fragment Total Count 8 2 For multi-fragment results, this entry indicates how many total

Mode 10 1 Specifies the Results Data format. 0 for Entry Mode, 1 for Raw

Size

(Bytes)

Description

Sequence Number. A Job Sequence Number is a counter that

automatically increments every time a Job is run.

not include the 16 bytes taken up by the Global Header. The

count starts at the beginning of Result Data and includes all the

bytes following it.

For multi-fragment results, this count would include the total

size of Result Data after stitching all the data fragments

together.

is the current fragment being provided. For non-fragmented

results, this entry will be set to 1.

fragments make up the complete result.

For non-fragmented results, this entry is set to 1.

Mode.

18

Page 19

Industrial Ethernet Interface

Table 9 Results Data Structure (Continued)

FS Job Result Offset

Status 11 1 Provides the overall job status information. 0 for Fail, 1 for

Time 12 2 In milliseconds, the time it took to run the Job.

Count 14 2 Number of data entries in the Results data. Count will be 0 if no

Size

(Bytes)

Pass.

data exists in the Result data. Count will never exceed 1 when

Mode is set to Raw.

NOTE: Result data typically follows the Global Header. However, refer to the specific Industrial

Ethernet protocol chapter for more information on where the Result Data resides for the given protocol.

Results Data Format Raw Mode (Mode = 1)

Table 10 User Data Format for Raw Mode

Name

Raw Data Varies All the data associated with the Job run result. The data provided

Size

(Bytes)

is based on the Industrial Ethernet Results Configuration for the

Job.

Description

Description

Results Data Format for Entry Mode (Mode = 0)

Table 11 User Data Format for Entry Mode

Name

Entry Length <n> 2 Size in bytes of the data in Entry <n> + 4 (the Entry meta data)

Entry Device # <n> 1 Device number (always 0)

Entry Type <n> 1

Entry Data <n> Varies Data associated with this Entry <n>. The data provided is based

<n+1, n+2 to “Count”> ...

NOTE: For items of array format (such as Manycode), each item will include its own Entry header.

Size

(Bytes)

Specifies the type of the entry. Refer to the

page 20

on the Industrial Ethernet User Control Data Configuration for the

Job.

for more information on valid Entry Types.

Description

Entry Type List on

19

Page 20

Entry Type List

Table 12 Entry Type List

Industrial Ethernet Interface

Entry Type

Number

0 Generic unknown data array of bytes. Varies

1 Fixed Scanning Barcode Structure array. Also

referred to as decodes in Aurora. Refer to

Scanning Barcode Results Structure

information on individual members that make up the

structure

2 String that includes an array of characters that may

be multiple bytes in length.

3 Integer 4

4 Byte 1

5 Pattern Match Structure array. Also referred to as

pattern_match_result[] in Aurora. See the

Match Results Structure

information on individual members that make up the

structure.

6 String Array. Note that some single strings may be

presented as a string array with a single string.

7 Integer array Varies (multiple of 4)

8 Float, a single precision floating point value. 4

9 Float array. Array of single precision floating point

values.

10 Boolean 1

11 Boolean array Varies

12 Single Fixed scanning barcode structure Varies

13 Single Pattern Match Result Varies

Entry Data Description Size (bytes) of Entry Data

Varies

Fixed

for more

Varies

20

Pattern

section for more

Varies

Varies (multiple of 4)

Fixed Scanning Barcode Results Structure

Table 13 Fixed Scanning Barcode Results Structure

Name Size (Bytes) Description

Code Type 2 Symbology type of the Barcode. This value is always 0 for

OCR.

Location 16 Bounding box coordinates of the barcode. (4 x,y

coordinates)

Quality 2 Barcode Quality Metrics Overall value. Always 0 for OCR.

PPM 2 Pixel Per Module (PPM). The PPM value is multiplied by 10

to allow for 1 decimal place. Always 0 for OCR.

Data Varies Barcode or OCR data. No read strings (if set) will be output

here as well.

20

Page 21

Industrial Ethernet Interface

Pattern Match Results Structure

Table 14 Pattern Match Results Structure

Name Size (Bytes) Description

Center_x 4 Single precision float includes x position of found pattern.

Center_y 4 Single precision float includes y position of found pattern.

Rotation 4 Single precision float includes rotation of matched result in

Scale 4 Single precision float includes scale of the matched

Score 4 Single precision float includes the score associated with

degrees.

pattern in relation to the original model.

the result. 0 to 100, where 100 is a perfect match.

21

Page 22

EtherNet/IP

The EtherNet/IP interface on the FS/VS Smart Camera supports CIP Adapter functionality. The device can

receive or be the target of I/O connections from a CIP Scanner. However, it is not able to originate

connections itself.

IMPORTANT: By default, the FS/VS Smart Camera Requested Packet Interval is set to 10 ms. The

configurable range of RPI values is 10 ms to 1000 ms. Ladder logic operations that occur quicker than

the RPI may result in lost transitions. For example, if ladder logic toggles the Results Ack bit with a

pulse of 1 ms, the FS/VS Smart Camera may miss the logic change and take no action.

Electric Data Sheet (EDS) File

An EtherNet/IP EDS file describes the Identity and I/O capabilities of the device. The FS/VS Smart Camera

EDS file must be registered with the Studio 5000 software before adding the device as an I/O module. The

EDS file can be registered by downloading it from the device or obtaining it from the Developer Files ZIP

and manually registering it.

TCP/IP Interface Object

The TCP/IP Interface object provides the ability to get and set TCP/IP configuration parameters, such as IP

address and Hostname. However, these changes require a device reset.

I/O Assemblies

The EtherNet/IP interface includes two assembly object instances that hold parameters and data used in the

transfer of data received from and sent by the device to the controller.

Status and Results Assembly (Device to PLC)

Instance: 101

Access: Get

Size:

496 bytes

The Status and Results assembly holds the current status of the FS/VS Smart Camera and the results data, if

available. The format of the assembly data is described in the Status and Results Input Assembly section.

22

Page 23

EtherNet/IP

Job Control and Setup Assembly (PLC to Device)

Instance: 150

Access: Set

Size:

496 bytes

The Job Control and Setup assembly is used for Job, Results, and Error management. The format of the

assembly data is described in the Job Control and Setup Assembly section.

I/O Connections

The EtherNet/IP interface supports an I/O connection to transfer the assemblies.

Exclusive Owner Connection

Trigger and Transport: Class 1, Cyclic

RPI Range:10 - 1000 ms

O > T

Connection Point: 150

Size:

496 bytes

Format:

T > O

Assembly instance 150

Connection Point: 101

Size:

496 bytes

Format:

Assembly instance 101

23

Page 24

EtherNet/IP

Configuring Rockwell ControlLogix Communication

Register the FS/VS EDS File

Before the communication to the FS/VS Smart Camera can be configured, the EDS file must be registered

with RSLogix. Only do this once. There are two methods that can be used to register the EDS file.

Method One: Download from the Device

NOTE: The FS/VS Smart Camera must be network accessible from the PC in order for the steps below

to be completed successfully.

1. Using the RSLogix Classic, choose the Ethernet adapter.

2. Next, select the FS/VS device and right click

3. Select Upload EDS File From Device. The EDS Wizard displays. Click Next.

4. The EDS File Installation Test Results displays. Ensure that the EDS file is selected and click Next.

5. The Change Graphic Image displays. Click Next. The Final Task Summary displays. Click Next.

6. Click Finish.

Method Two: Manually Install from the Developer Zip File

1. From the Logix Studio 5000 Designer menu, select Tools > EDS Hardware Installation Tool.

2. The EDS Wizard displays. Click Next.

3. Select the Register an EDS File radio button, and click Next.

4. Select the Register a Single File radio button.

5. Browse to the location of the unzipped Developers Zip file and select the FS/VS EDS file from its

contents.

6. The Change Graphic Image displays. Click Next.

7. The Final Task Summary displays. Click Next.

8. Click Finish.

24

Page 25

EtherNet/IP

Adding the FS/VS Smart Camera to the I/O Configuration

For the PLC to communicate with the FS/VS Smart Camera, it must be added to the I/O configuration in the

program.

To add the I/O configuration:

1. Expand the I/O Configuration tree in the Controller Organizer pane to display the Ethernet network.

Figure 5 I/O Configuration Tree

NOTE: In the figure above, A1/A2 is used as the Ethernet interface. Depending on the application, a

different type of Ethernet Interface module may be used.

2. Right-click on the Ethernet node in the tree and select New Module. Alternatively, if the FS/VS Smart

Camera is on the same network and configured for EtherNet/IP support, you can also select Discover

Modules.

3. The Select Module Type dialog displays. Change the vendor filter to only select Zebra Technologies.

The FS/VS Smart Camera displays in the device list.

4. Select the FS/VS Smart Camera from the list and click the Create button.The New Module dialog

displays.

5. Enter the desired name and IP address of the FS/VS Smart Camera.

25

Page 26

EtherNet/IP

Figure 6 New Module, Setting Name and IP Address

6. Set an appropriate name for the module and click OK.

NOTE: All I/O connection parameters and I/O Tags are automatically configured when the module is

added to the I/O Configuration.

FS/VS Smart Camera I/O Tags

When the FS/VS Smart Camera is added to the I/O configuration, a set of tags is created to allow the PLC

logic to read and write data to the device through the I/O connection. Figure 7

created.

Figure 7 FS/VS Smart Camera Related Tags

NOTE: The tag names are based on the name that was configured in the New Module dialog when

the device was added to the I/O Configuration. In the example in Figure 7, the module is named s40.

shows the tags that are

26

Page 27

EtherNet/IP

Status and Results Input Assembly

The input assembly provides status information, process state, and decode results.

Table 15 Response/Status Input Assembly (Device to PLC)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Error

Available

1 User

2 GPIO 7 GPIO 6 GPIO 5 GPIO 4 GPIO 3 GPIO 2 GPIO 1 GPIO 0

3 GPIO 9 GPIO 8

4 ECHO Register

5

6 Active Job Slot Number

7

8

9

10

11

12 Result Queue Count

13 Reserved

14 Results Job Slot Number

15

16...

495

Error

Overflow

Result Data (See

Results

Overflow

Results Status and Data Structure on page 18 for more information)

Results

Fragment

Error Code

Results

Available

Trigger

Status

Data

Status

Trigger

Ready

Job Fail Job Pass

Job Run

Status

27

Page 28

EtherNet/IP

Job Control and Setup Assembly

The output assembly contains control signals, software event signals, and any user data required for the

trigger and decode.

Table 16 Job Control and Setup Assembly (PLC to Device)

Byte

0 Error

1 Reset

2 Reserved

3

4 ECHO Register

5

6 Job Slot Number

7

8 Packet Sequence Number

9

10

11

12

13

14

15

16...

499

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Ack

Counters

User Data (See

Error

Buffer

Control

Results

Buffer

Control

Job Slot

Control

Results

Ack

Reserved

User Control and Data Structure on page 17 for more information)

Trigger Trigger

Enable

User Data

Control

Job

Control

28

Page 29

EtherNet/IP

Fixed Scanner Add-On Instruction (AOI)

The Fixed Scanner Add-On Instruction (AOI) provides a simple abstraction for handling Fixed Scanning

Jobs.

Included within the AOI is support for the following:

• Easy control of multiple Zebra Fixed Industrial Scanners.

• User friendly naming of Input and Output parameters with no Add-On Profile required.

• The automatic stitching together of barcodes larger than 464 bytes using fragmentation.

• Extraction of Fixed Barcode Structure data into easy-to-use user defined types, including support for

Manycode, in which multiple barcodes are parsed and provided in an array

Creating a New Project that Uses AOI_FixedScanner

1. Obtaining the AOI. Obtain the AOI by unzipping the Industrial Ethernet Developer Zip file

(CAAFSS00-001-xxxB0.zip). The exported AOI file can be found under the EtherNet/IP and Logix

folder (AOI_FixedScannerVxx.L5X).

2. Creating a new project. Create a new project by launching Logix Studio 5000 and selecting Create a

New Project. Next, select the appropriate PLC controller and name for the project. Proceed through

the wizard and click Finish to create the new project.

NOTE: Logix Studio 5000 version 32 was used during development and testing.

3. Setting up the PLC communication path from Studio 5000. Click the Communications dropdown menu

and select Who Active.

a. From the Who Active dialog, expand the network Interface driver and select the PLC controller.

b. Once selected, click Set Project Path to set the selected controller path to the project. Following the

Path selection, click Close to exit the Who Active dialog.

NOTE: The controller path appears under Path in the project.

29

Page 30

EtherNet/IP

4.

Add the FS/VS Smart Camera to the project. Click on the controller’s Ethernet port from the left pane

and select New Module.

5. Next, filter the catalog for the appropriate model (S40/S70/S20) that matches the device and click

Create. Upon clicking Create in the Select Module Type dialog, the New Module dialog displays.

6. From this dialog, provide a name and set the IP address of the device.

7. Once complete, click OK and the new module is added to the project.

30

Page 31

EtherNet/IP

Figure 8 New Module Settings

8. Importing the Add-On Instruction (AOI) to the project. Import an AOI to the project by expanding the

asset folder from project’s left pane and right click on Add-On Instruction.

9. From the dropdown menu, select the Import Add-On Instruction option.

10. Browse to the unzipped AOI_FixedScannerVxx.L5X and click OK to import it into the project. The

Import Configuration Dialog displays. From this dialog users can rename the AOI.

11. Click OK to complete the import process.

Figure 9 AOI Import Configuration

31

Page 32

EtherNet/IP

Modify the AOI. By default, the AOI is created to support up to five barcodes with a data size of up to

12.

1024 bytes long. Since this may not match a specific use case, these sizes can be modified.

To modify the sizes in AOI, follow the steps below:

a. Go to Assets > Data Types > User-Defined and open the BARCODE_DECODE_DATA structure.

b. Modify the array size of Data field as per the required length of each barcode decode data and click

OK.

Figure 10 Barcode Decode Data Structure

c. To adjust the size in internal logic of AOI, navigate to Assets > Add-On Instructions and open

Parameter and Local Tags. Change the value of the tag names in MAX_BARCODE_LENGTH to a

value equal to the Data size. Change the MAX_RAW_DATA_SIZE if the maximum raw data size is

less than the size given by default (5250).

Figure 11 Max Barcode Length

d. Next, modify the default sizes in AOI’s internal structure. To do so, go to Assets > Add-On

Instructions and open the properties of AOI_FixedScanner AOI by right clicking and selecting

Properties. From the AOI’s properties window, go to the Parameters tab and modify the size of

parameters below:

i. BarcodeData – Modify the array index to the max number of expected barcodes

ii. RawData – Modify the array size to same value of “” as mentioned in point ‘d’ above.

32

Page 33

Figure 12 AOI Definition

EtherNet/IP

e. Once done, click Apply and OK to accept the changes.

13. Creating ladder logic using the AOI. Once imported successfully, the AOI is found under

Assets/Add-On Instructions located on the left-hand pane of Studio 5000. The AOI can now be used in

the ladder logic program to communicate with the FS/VS Smart Camera. Add the AOI to the main

program RUNG by clicking the Add-On Element Group and clicking the AOI.

Figure 13 AOI Fixed Scanner

33

Page 34

EtherNet/IP

Once added, assign the tag name to the newly added AOI and create a new tag by right clicking on the

14.

tag name.

Figure 14 Assigned TAG Name

Assign IAssemblyData with FS40:I.Data and OAssemblyData with FS40:O.Data such that FS40 is the

name of created module for the FS/VS Smart Camera.

15. Creating the required tags. After adding the AOI to the main RUNG, assign tags to the IN/OUT AOI

parameters (ResultsStatus, BarcodeData, RawData, and UserData). Create a new tag by right clicking

and selecting “New Tag...”.

Figure 15 Creating Required TAGs

34

Page 35

EtherNet/IP

Loading the project and verifying communication. Load the project by performing a download and going

16.

online. Next, verify that the communication is working as expected, by modifying a value in the

EchoRegCtrl field in the AOI. If the same value is read back in the EchoRegStatus field, the connection

is successful between the PLC and the Device.

Figure 16 Load the Project and Verify Communication

Using the Fixed Scanner Add-On Instruction

The typical usage sequence for a fixed scanner AOI is defined below:

1. Set the current Job to be active by setting JobCtrl to 1.

2. Enable Trigger control by setting TriggerEnableCtl to 1.

3. Check that the TriggerReady bit is set to true.

4. Enable Result Buffering on the device by setting ResultBufferCtrl to 1.

5. Trigger the job to run by toggling the Trigger from 0 to 1.

6. Check that WaitingForResultsAck is set to true to indicate that Job results are available.

7. Act on the result data provided by ResultStatus, RawData, and BarcodeData.

8. Clear WaitingForResultsAck by toggling ResultsAck from 0 to 1.

35

Page 36

PROFINET Interface

The PROFINET interface on the FS/VS Smart Camera supports PROFINET-IO Device functionality. The

device is able to receive, or be the target of, I/O connections from a PROFINET Controller, but it is not able

to originate connections itself.

GSDML File

The PROFINET GSDML file describes the identity and I/O capabilities of the FS/VS Smart Camera. The

file is used by the controller configuration tools to configure the I/O connections and data tags that allow for

communication with the FS/VS Smart Camera over the PROFINET network.

The GSDML file can be found in the Developer Zip file.

PROFINET IO Modules

The FS/VS Smart Camera I/O interface includes multiple I/O modules that provide access to Command

and Response data.

NOTE: Only a single Command Data and Response Data modules can be used at one time by

selecting 32, 64, or 128 version for the given slot.

Command IO Module

Module ID: 11

Submodule ID: 1

Access: Output

Output Size:16 bytes

The Command Module contains provides control and configuration of the FS/VS Smart Camera.

Table 17 Command Module (PLC to Device)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Error

Ack

1 Reset

Counters

Error

Buffer

Enable

Results

Buffer

Control

Job Slot

Control

Results

Ack

Trigger Trigger

Enable

User Data

Control

Job

Control

36

Page 37

PROFINET Interface

Table 17 Command Module (PLC to Device) (Continued)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

2 Reserved

3

4 ECHO Register

5

6 Job Slot Number

7

8 Packet Sequence Number

9

10

11

12

13

14

15

Reserved

CommandData32 IO Module

Module ID: 12

Submodule ID: 1

Access: Output

Output Size: 32 bytes

CommandData Modules allow for the user to control Job input parameters at runtime by updating

UserData.

CommandData64 IO Module

Module ID: 13

Submodule ID: 1

Access: Output

Output Size: 64 bytes

CommandData Modules allow for the user to control Job input parameters at runtime by updating

UserData.

CommandData128 IO Module

Module ID: 14

Submodule ID: 1

Access: Output

Output Size:128 bytes

37

Page 38

CommandData Modules allow for the user to control Job input parameters at runtime by updating

UserData.

Response IO Module

Module ID: 21

Submodule ID: 1

Access: Input

Output Size: 32 bytes

The response module provides status information and process state.

Table 18 Response Module (Device to PLC)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Error

Available

1 User Data

2 GPIO 7 GPIO 6 GPIO 5 GPIO 4 GPIO 3 GPIO 2 GPIO 1 GPIO 0

3 GPIO 9 GPIO 8

4 ECHO Register

5

6 Active Job Slot Number

7

8 Error Code

9

10

11

12 Result Queue Count

13 Reserved

14 Results Job Slot Number

15

16 Result Sequence Number

17

18

19

20 Result Total Length

21

22 Result Fragment Number

23

24 Result Fragment Total Count

25

26 Result Mode

27 Result Status

Error

Overflow

PROFINET Interface

Results

Overflow

Results

Fragment

Results

Available

Trigger

Status

Status

Trigger

Ready

Job Fail Job Pass

Job Status

38

Page 39

Table 18 Response Module (Device to PLC) (Continued)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

28 Result Time

29

30 Result Count

31

ResponseData32 IO Module

Module ID: 22

Submodule ID: 1

Access: Input

Output Size:32 bytes

ResponseData Modules provide the user with the resultant data associated with a Job run.

ResponseData64 IO Module

PROFINET Interface

Module ID: 23

Submodule ID: 1

Access: Input

Output Size:64 bytes

ResponseData Modules provide the user with the resultant data associated with a Job run.

ResponseData128 IO Module

Module ID: 24

Submodule ID: 1

Access: Input

Output Size:128 bytes

ResponseData Modules provide the user with the resultant data associated with a Job run.

39

Page 40

PROFINET Interface

Configuring Siemens S7 Communications

Register the GSDML File

Before the communication to the FS/VS Smart Camera can be configured, the GSDML file must be

registered with TIA Portal. This is done only once.

Follow the steps below to register the GSDML file using TIA Portal:

1. In the project view menu, select: Options > Install General Station Description File (GSD).

2. Locate and select the FS/VS Smart Camera GSDML file.

3. Click Install.

NOTE: The GSDML file is found in the Industrial Ethernet Developer ZIP file under the PROFINET

folder.

Finding the Device and Configuring the Device Name

After enabling PROFINET protocol support as described in the Activating Industrial Ethernet section, the

FS/VS Smart Camera will only be accessible on the network through the PROFINET protocol. It is

recommended that after enabling the protocol you use TIA Portal to find all accessible devices and set the

PROFINET device name of the FS/VS Smart Camera.

To set the FS/VS Smart Camera PROFINET Device Name using TIA Portal:

1. From the TIA portal’s online access in the project tree, click on the network adapter that is used to

access the device and click on Update Accessible Devices to list all PROFINET devices on the

network.

Figure 17 TIA Portal Project Tree

If not previously configured, the FS/VS Smart Camera should display as an accessible device, and the

MAC address shown will match the one printed on the device label.

2. Click on the device to be configured and click Online and Diagnostics to go online with the device.

3. From the online properties, select Functions and Assign PROFINET device name. Fill out the

PROFINET device name field and click Assign name.

40

Page 41

PROFINET Interface

Figure 18 Assigning a PROFINET Device Name

41

Page 42

PROFINET Interface

Adding the FS/VS Smart Camera to the I/O Configuration

For the controller to communicate with the FS/VS Smart Camera, it must be added to the I/O configuration

in the controller program.

NOTE: These steps assume a PLC and a PROFINET network were configured in the project and the

GSDML file has been installed.

To add the FS/VS Smart Camera to the controller’s I/O configuration using TIA Portal:

1. Double click on Devices and Networks in the project tree and open the network view tab.

2. Find the FS/VS Smart Camera from the hardware catalog.

Figure 19 Hardware Catalog

3. Select the appropriate model from the list and drag it into the network view. By default, the new device

will be not be assigned. Click on the text and assign to the appropriate PLC port.

Figure 20 Network View

42

Page 43

PROFINET Interface

Next, double-click the device in the network view. The Device Overview tab displays the module I/O

4.

data mapping. By default, Command_1 and Response_1 are set to slots 1 and 3, respectively. Drag the

desired size for CommandData and ResponseData from the hardware catalog over to slots 2 and 4.

IMPORTANT: The same size should be selected for both CommandData and ResponseData.

Figure 21 Device Overview

5. From the device view, double-click the device module to bring up the properties for the device. The

Ethernet address properties allow users to set the PROFINET device name the project expects to find

the device using.

NOTE: If Set IP address in the project is enabled, the project will reconfigure the device to use that

IP address if it is found on the network.

Figure 22 General Device Properties

43

Page 44

PROFINET Interface

Fixed Scanner Function Block (FB)

The Fixed Scanner Function Block provides a simple abstraction for handling fixed scanning Jobs. The

Function Block supports the following:

• Easy control of multiple Zebra Fixed Industrial Scanners.

• User friendly naming of Input and Output parameters.

• The automatic stitching together of barcodes and/or data larger than 464 bytes using fragmentation.

• Extraction of Fixed Barcode Structure data into easy-to-use user defined types, including support for

Manycode, which multiple barcodes are parsed and provided in an array.

Creating a Project that uses FB_FixedScanner

To obtain the Function Block Global Library, unzip the Industrial Ethernet Developer Zip file

(CAAFSS00-001-xxxB0.zip). The exported Global Library file is found under the PROFINET and TIA15_1

folder. (FB_FixedScannerLibV5.zal15_1).

1. Creating a new project. Launch the TIA Portal 15.1 or higher and choose to create a new project. Next,

open the Project View. From the Project View, click Add new device from the project tree and select

the PLC being used.

NOTE: Users can also select the Unspecified version of your PLC and use the detect logic to assign

it to the correct hardware. Click detect and assign the PLC found on your network.

Figure 23 Unspecified PLC Version

2. Adding the FS/VS Smart Camera to your project. Click Devices and networks from the project tree.

From the Hardware Catalog window, search for Zebra. Under Other Field devices and I/O, find the

appropriate model for the fixed scanner.

44

Page 45

PROFINET Interface

Next, drag and drop the model to the Network View window. Assign the fixed scanner to the PLC by

3.

clicking Not assigned and select the appropriate PLC network port to be used while in the Network

View tab.

Figure 24 Devices and Networks

4. Configure the device by clicking the Device View tab. From the Properties window, set the appropriate

PROFINET device name and IP address for use within the project.

Figure 25 Properties Window

5. Assigning Data I/O to the fixed scanner. Assign CommandData and ResponseData modules to the

fixed scanner by using the Device Overview tab. This is where the device will reside in I/O space.

IMPORTANT: Take note of I and Q address locations and size. The size for both CommandData and

ResponseData should match.

45

Page 46

PROFINET Interface

Figure 26 Device Overview

6. Importing Global Library Function Blocks (FB) to the project. To import the Global Library Function

Block (FB_FixedScannerLibVx.zal15_1) to the project, select Global Libraries and Retrieve Library...

from the Options menu. Next, browse to the FB_FixedScannerLibVx folder and select

FB_FixedScannerLibVx.al15_1 to load it into the project.

Figure 27 Global Libraries Function Block

46

Page 47

PROFINET Interface

Copy the Library contents to the project. Program blocks, PLC tags, and PLC data types are to be

7.

copied to their respective locations within the project. For Program blocks, it is only necessary to copy

over the size of the Function Block that matches the CommandData and ResponseData sizes.

IMPORTANT: Adjust FixedScannerTagTable to match the appropriate I and Q addresses of the fixed

scanner as shown in the Device Overview tab.

Figure 28 Tag Table

8. Modifying the Function Block (FB). By default, the FB is created with support of up to 5 barcodes with a

data size of up to 512 bytes long and Total Max data of a single result is 2560 Bytes. Since this may not

match your use case, these sizes can be modified. This step is optional.

9. Creating ladder logic using the Function Block (FB). To create ladder logic using the Function Block,

add the Fixed Scanner Function Block to the Main program by clicking on the empty box and adding it

to Network 1 rung. Replace the empty data with the FB_FixedScanner function block type. This will

prompt necessitate the creation of a DataBlock for it.

10. Click OK to create a DataBlock.

11. Next, connect Command, CommandDataxx, Response, and ResponseDataxx to the tags from the

FixedScannerTagTable. Add tags for the User Defined Data Types: ResultStatus, BarcodeData,

RawData, and UserDataxx.

47

Page 48

Figure 29 Adding Tags

PROFINET Interface

12. Loading the project and verifying communication. Load the project by performing a compile and

download to the device. Use the monitor feature to see the runtime values from the fixed scanner. To

verify that the communication is working as expected, modify the value in EchoRegCtrl by mapping it to

a memory location tag (%MWx.x). The EchoRegStatus register should automatically match the control

value if the device communication is working.

Figure 30 Perform Compile and Download Icon

Using the Fixed Scanner Function Block

Typical usage sequence is defined as follows:

1. Set the current Job to be active by setting JobCtrl to 1.

2. Enable Trigger control by setting TriggerEnableCtl to 1.

3. Check that TriggerReady bit is true.

4. Enable Result Buffering on the device by setting ResultBufferCtrl to 1.

5. Trigger the job to run by toggling Trigger from 0 to 1.

6. Check that WaitingForResultsAck is set to true to indicate that Job results are available.

7. Act on result data in provided by ResultStatus, RawData, and BarcodeData.

8. Clear WaitingForResultsAck by toggling ResultsAck from 0 to 1.

48

Page 49

Modbus TCP Interface

This chapter provides information about using the Modbus TCP interface to send and receive data from

the FS/VS Smart Camera. The Modbus TCP interface supports Modbus TCP server functionality. The

device can receive, or be the target of, I/O connections from a Modbus TCP client, but is not able to

originate connections itself.

Modbus Register Locations

The Modbus TCP interface provides access to the registers that hold parameters and data. Command

registers can be written while Response registers are read only. The following tables list all of the

addressable locations available on the fixed scanner.

Table 19 Modbus Register Locations

Offset (0x)

Name

Command 16 Write

Command

User Data

Response 3 Read

Response

Data

Access

Code

16 Write

3 Read

Access

Function

Multiple

Registers

Multiple

Registers

Holding

Registers

Holding

Registers

Address

Space

Holding 1000 (41000) 16 Allows PLC to control

Holding 1000 (41100) 250 Used by PLC to

Holding 2000 (42000) 16 Provides PLC with

Holding 2100 (42100) 250 Provides PLC with

Holding

Regular

Location

Size

(Bytes)

Description

device and generate

triggers.

change Job input

parameters

status information from

the device.

results data associated

with a specific Job run.

49

Page 50

Modbus TCP Interface

Command Registers Mapping

The command registers provide control over the FS/VS Smart Camera. The following table describes the

byte and bit locations of the controllable features.

Table 20 Command Registers Mapping

Name

Command 16 Write

Command

User Data

Response 3 Read

Response

Data

Access

Code

16 Write

3 Read

Access

Function

Multiple

Registers

Multiple

Registers

Holding

Registers

Holding

Registers

Offset (0x)

Address

Space

Holding

Regular

Size

(Bytes)

Description

Location

Holding 1000 (41000) 16 Allows PLC to control

device and generate

triggers.

Holding 1000 (41100) 250 Used by PLC to

change Job input

parameters

Holding 2000 (42000) 16 Provides PLC with

status information from

the device.

Holding 2100 (42100) 250 Provides PLC with

results data associated

with a specific Job run.

Command Data Registers Mapping

Command data is an array of bytes that allow for runtime changes to Job input parameters based on the

Jobs Industrial Ethernet User Data configuration.

Response Register Mapping

The response module provides status information and process state. The following table provides byte and

bit locations for reading data from the FS/VS Smart Camera.

Table 21 Response IO Module - Byte and Bit Locations

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Error

Available

1 Job Fail Job Pass

2 GPIO 7 GPIO 6 GPIO 5 GPIO 4 GPIO 3 GPIO 2 GPIO 1 GPIO 0

3 GPIO 9 GPIO 8

4 ECHO Register

5

6 Active Job Slot Number

7

8 Error Code

9

10

11

Error

Overflow

Results

Overflow

Results

Fragment

Results

Available

Trigger

Status

Trigger

Ready

Job Status

50

Page 51

Modbus TCP Interface

Table 21 Response IO Module - Byte and Bit Locations (Continued)

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

12 Result Queue Count

13 Reserved

14 Results Job Slot Number

15

16 Result Sequence Number

17

18

19

20 Result Total Length

21

22 Result Fragment Number

23

24 Result Fragment Total Count

25

26 Result Mode

27 Result Status

28 Result Time

29

30 Result Count

31

Response Data Registers Mapping

Response data is an array of bytes that provide results for a given Job currently being run. The result data

is based on the Industrial Ethernet Result Configuration set in the Job.

51

Page 52

Modbus TCP Interface

Typical Use Case for Triggering a Job

1. Set the current Job to be active by setting JobCtrl to 1.

2. Enable Trigger control by setting TriggerEnableCtl to 1.

3. Check that TriggerReady bit is true.

4. Enable Result Buffering on the device by setting ResultBufferCtrl to 1.

5. Trigger the job to run by toggling the Trigger from 0 to 1.

6. Check that ResultsAvailable bit is set to true to indicate that Job results are available.

7. Read in the Response and Response Data.

8. Clear ResultsAvailable bit by toggling ResultsAck from 0 to 1.

52

Page 53

Error Codes

The following table provides a list of potential Error Codes that be received by the PLC.

Table 22 Error Codes List

Error Code Description

0030064 Service Error: Task Cleanup failure

0030065 Service Error: Failed to unload Industrial Ethernet service

0030066 Service Error: Failed to unload Industrial Ethernet service

0030067 Service Error: Failed to push command to Industrial Ethernet core

0030068 Job Error: Failed to load job into job slot

0030069 Job Error: Failed to load currently active job

003006A Job Error: Failed to load last valid job

003006B Job Error: No valid job to load

003006C Job Error: Failed to load job

003006D Network Error: Unable to receive data

003006E Network Error: Invalid assembly ID for response data

003006F Network Error: No response packet

0030070 Network Error: Malformed data

0030071 Memory Error: Invalid buffer for reading result

0030072 Memory Error: Failed to allocate memory for job result

0030073 Memory Error: Failed to allocate memory for decode data

0030074 Memory Error: Failed to assign decode data

0030075 Memory Error: Failed to push result buffer

0030076 Memory Error: No task slots available

0030077 Memory Error: Failed to create command process thread

0030078 Memory Error: Failed to allocate memory for command data

0030079 Memory Error: Failed to initialize command processing task

003007A Memory Error: Receive response not initialized properly

003007B Internal Communications Error: IPC interface not found

003007C Internal Communications Error: Call failed

53

Page 54

Error Codes

Table 22 Error Codes List (Continued)

Error Code Description

003007D Internal Communications Error: Interface Error

003007E Internal Communications Error: Invalid Command Handle

003007F Internal Communications Error: Unknown

54

Page 55

www.zebra.com

Loading...

Loading...