Zebra VS40 Industrial Machine Vision FS/VS Smart Camera Series Industrial Ethernet User Guide

FS/VS Smart

Camera Series

Industrial Ethernet Guide

MN-003811-01EN Rev A

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in

many jurisdictions worldwide. All other trademarks are the property of their respective owners. ©2021

Zebra Technologies Corporation and/or its affiliates. All rights reserved.

Information in this document is subject to change without notice. The software described in this document

is furnished under a license agreement or nondisclosure agreement. The software may be used or copied

only in accordance with the terms of those agreements.

For further information regarding legal and proprietary statements, please go to:

SOFTWARE:zebra.com/linkoslegal

COPYRIGHTS:zebra.com/copyright

WARRANTY:zebra.com/warranty

END USER LICENSE AGREEMENT: zebra.com/eula

Terms of Use

Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and

maintaining the equipment described herein. Such proprietary information may not be used, reproduced,

or disclosed to any other parties for any other purpose without the express, written permission of Zebra

Technologies.

Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever

(including, without limitation, consequential damages including loss of business profits, business

interruption, or loss of business information) arising out of the use of, the results of use of, or inability to

use such product, even if Zebra Technologies has been advised of the possibility of such damages. Some

jurisdictions do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you.

2

Revision History

Revision Description

MN-003811-01 Rev. A 6/21 Initial Rev A. Release

3

Contents

Terms of Use ......................................................................................................................... 2

Proprietary Statement ......................................................................................................... 2

Product Improvements ........................................................................................................ 2

Liability Disclaimer .............................................................................................................. 2

Limitation of Liability ............................................................................................................ 2

Revision History .................................................................................................................... 3

About This Guide

Service Information ............................................................................................................... 7

Initial Setup

Hardware/Software Prerequisites ......................................................................................... 8

Activating Industrial Ethernet ................................................................................................ 9

Configuring Industrial Ethernet Input & Output ................................................................... 10

User Control Data ............................................................................................................. 10

Results Data ..................................................................................................................... 11

Industrial Ethernet Interface

Job Control/Status ............................................................................................................... 12

Trigger Control/Status ......................................................................................................... 14

Results Control/Status ........................................................................................................ 15

User Data Control/Status .................................................................................................... 16

Error Codes Control/Status ................................................................................................. 16

User Control and Data Structure ......................................................................................... 17

User Data Format for Raw Mode (Mode = 1) ................................................................... 17

User Data Format for Entry Mode (Mode = 0) .................................................................. 18

Results Status and Data Structure ...................................................................................... 18

Results Data Format Raw Mode (Mode = 1) .................................................................... 19

Results Data Format for Entry Mode (Mode = 0) .............................................................. 19

Entry Type List .................................................................................................................... 20

Fixed Scanning Barcode Results Structure ........................................................................ 20

Pattern Match Results Structure ......................................................................................... 21

4

EtherNet/IP

Contents

Electric Data Sheet (EDS) File ............................................................................................ 22

TCP/IP Interface Object ...................................................................................................... 22

I/O Assemblies .................................................................................................................. 22

Status and Results Assembly (Device to PLC) ........................................................... 22

I/O Connections ................................................................................................................ 23

Exclusive Owner Connection ...................................................................................... 23

Configuring Rockwell ControlLogix Communication ........................................................... 24

Register the FS/VS EDS File ............................................................................................ 24

Method One: Download from the Device ............................................................................ 24

Method Two: Manually Install from the Developer Zip File ......................................... 24

Adding the FS/VS Smart Camera to the I/O Configuration ............................................... 25

FS/VS Smart Camera I/O Tags ........................................................................................... 26

Status and Results Input Assembly .................................................................................... 27

Job Control and Setup Assembly ........................................................................................ 28

Fixed Scanner Add-On Instruction (AOI) ............................................................................ 29

Creating a New Project that Uses AOI_FixedScanner ...................................................... 29

Using the Fixed Scanner Add-On Instruction ...................................................................... 35

PROFINET Interface

GSDML File ......................................................................................................................... 36

PROFINET IO Modules ....................................................................................................... 36

Command IO Module ........................................................................................................ 36

CommandData32 IO Module ............................................................................................ 37

CommandData64 IO Module ............................................................................................ 37

CommandData128 IO Module .......................................................................................... 37

Response IO Module ........................................................................................................ 38

ResponseData32 IO Module ............................................................................................. 39

ResponseData64 IO Module ............................................................................................. 39

ResponseData128 IO Module ........................................................................................... 39

Configuring Siemens S7 Communications .......................................................................... 40

Register the GSDML File .................................................................................................. 40

Finding the Device and Configuring the Device Name ..................................................... 40

Adding the FS/VS Smart Camera to the I/O Configuration ................................................. 42

Fixed Scanner Function Block (FB) .................................................................................... 44

Creating a Project that uses FB_FixedScanner ................................................................ 44

Using the Fixed Scanner Function Block .......................................................................... 48

Modbus TCP Interface

Modbus Register Locations ................................................................................................. 49

Command Registers Mapping ............................................................................................. 50

Command Data Registers Mapping .................................................................................... 50

Response Register Mapping ............................................................................................... 50

Response Data Registers Mapping .................................................................................... 51

Typical Use Case for Triggering a Job ................................................................................ 52

5

Error Codes

Contents

6

About This Guide

The FS/VS Smart Camera Industrial Ethernet Guide provides instructions for setting up and programming

the device for Industrial Ethernet applications.

IMPORTANT: If you have a problem with your equipment, contact Zebra Global Customer Support for your

region. Contact information is available at: zebra.com/support

Service Information

If you have a problem with your equipment, contact Zebra Global Customer Support for your region.

Contact information is available at: zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

7

Initial Setup

Refer to the FS/VS Smart Camera Product Reference Guide for detailed information on:

• Connection Diagrams, including how to power the device.

• Status Indicators (LED and Beeper) and their meanings.

• Default Factory Settings, including how to restore Factory Settings.

• Ethernet Setup, including how to discover a device and set an IP address.

• Firmware update methods.

• Building and deploying Jobs, including configuration of Trigger modes.

• Accessing the Web HMI

• Licensing and Security

Hardware/Software Prerequisites

The following list of components is required for initial setup, testing, and development of Industrial Ethernet

applications that use the FS/VS Smart Camera.

• An FS/VS Smart Camera with Ethernet support that is configured to the correct Industrial Ethernet

Protocol and IP address. The device should be configured with the Jobs required to perform the work

needed by the Industrial Ethernet application.

• An M12 X-Coded cable that can connect the FS/VS Smart Camera Ethernet port to your network.

• The appropriate cabling and power supply necessary to power the FS/VS Smart Camera.

• A PC running Windows 7 or higher (Windows 10 recommended) to view the Web HMI, Zebra’s Aurora

Application, and development software for PLC applications.

• An Ethernet switch or router (if not connecting FS/VS Smart Camera directly to a PLC).

• An Industrial Ethernet PLC (Programmable Logic Controller) that supports one of the supported protocols

(EtherNet/IP, PROFINET, or Modbus TCP) and an Ethernet switch or router (if not connecting the device

directly to a PLC).

NOTE: Industrial Ethernet testing has been performed with the following PLCs and software:

Rockwell Compact Logix 5069-L306ER and Logix Studio 5000 v32.02.00 Software

Siemens S7 1500/1200 PLC and Totally Integrated Automation (TIA) v15.1 Software.

• FS/VS Smart Camera Industrial Ethernet Developer Files (CAAFSS00-001-Rxx.zip)

8

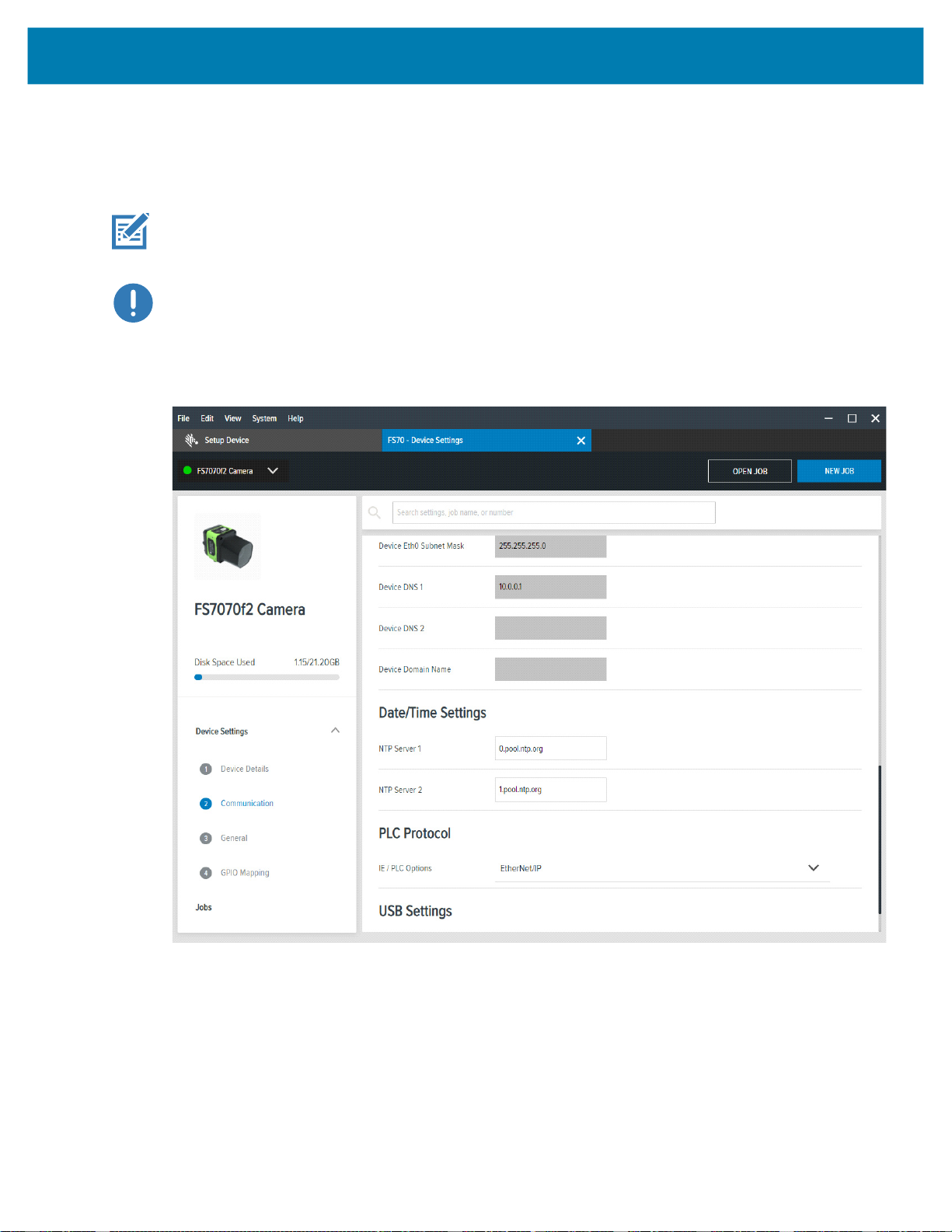

Activating Industrial Ethernet

The Zebra Aurora Application device settings provide an option to select which PLC protocol can be

enabled on the device, as shown in the PLC Protocol selection in the figure below.

IMPORTANT: It is required that on any PLC Protocol change, the device must be rebooted for the

change to go into effect.

IMPORTANT: After enabling PROFINET protocol support, the FS/VS Smart Camera is only

accessible on the network through the PROFINET protocol. It is recommended that after enabling the

protocol you use the TIA Portal to find all the accessible devices and set the PROFINET device name

of the FS/VS Smart Camera.

Figure 1 PLC Protocol

Initial Setup

9

Initial Setup

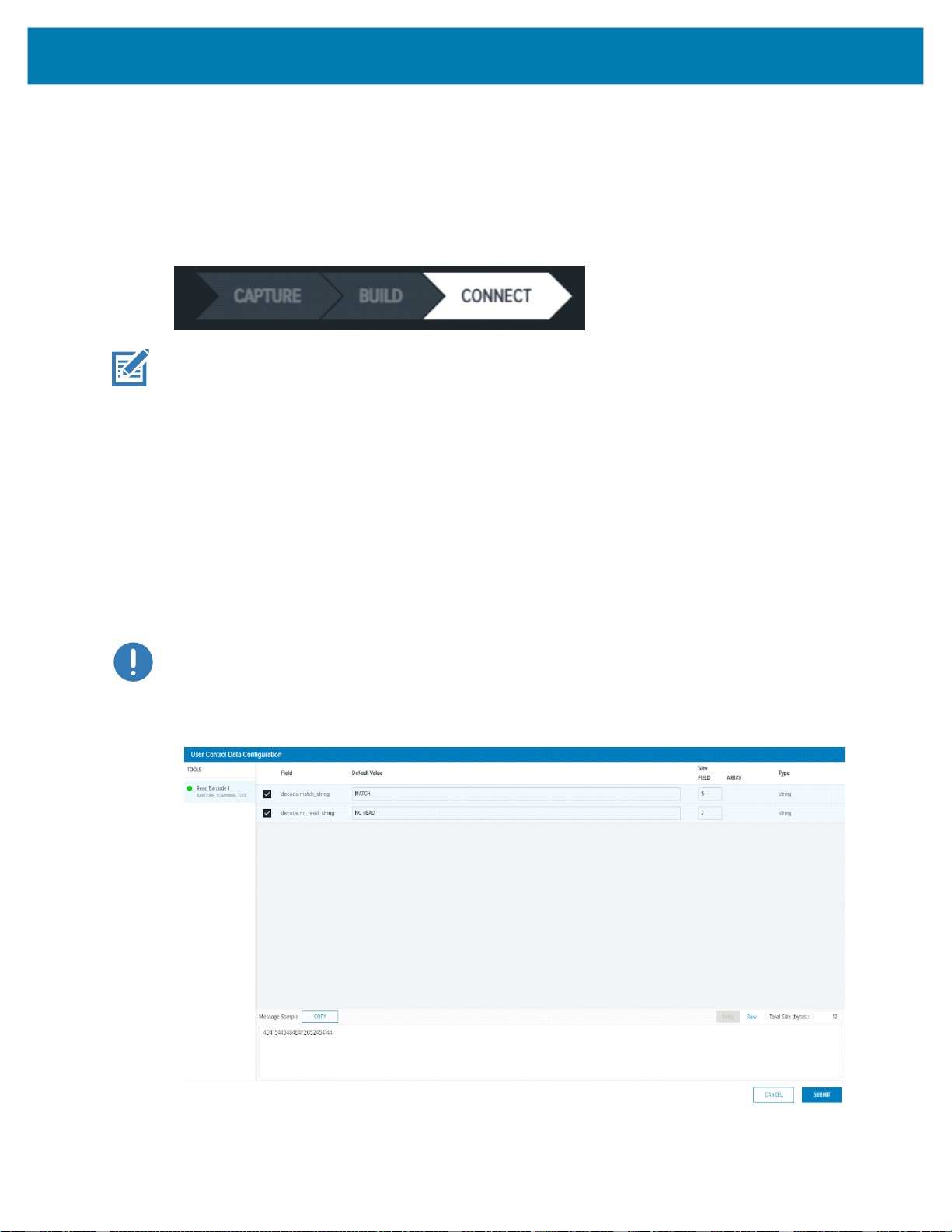

Configuring Industrial Ethernet Input & Output

Users can specify what results and configuration is provided to the PLC through the Zebra Aurora

applications Connect workflow. When Connect is selected, click the Industrial Ethernet list item on the

left of the application.

Figure 2 Connect

NOTE: The updated Job must be deployed and set as active on the device for any changes to be seen

from the PLC.

User Control Data

The User Control Data user interface allows for the PLC to make runtime changes to Job input parameters,

such as Barcode Match Strings or No Read strings.

Click the Add or Edit button to display the User Control Data Configuration dialog and the possible input

parameters. Check the specific input parameter to be changed from the PLC and configure the default

value and the size. Refer to the Message Sample window for a view of what the data must look like when

sent from the PLC to the device. For User Control Data, it is recommended that Raw Mode is selected.

This removes the need to set the proper Entry header for Entry mode. When the form is complete, click the

Submit button. From the main window, reorder the input parameters using a drag and drop technique.

IMPORTANT: Default value changes do not affect the job, they are used for Message Sample preview

only.

Figure 3 User Control Data Configuration

10

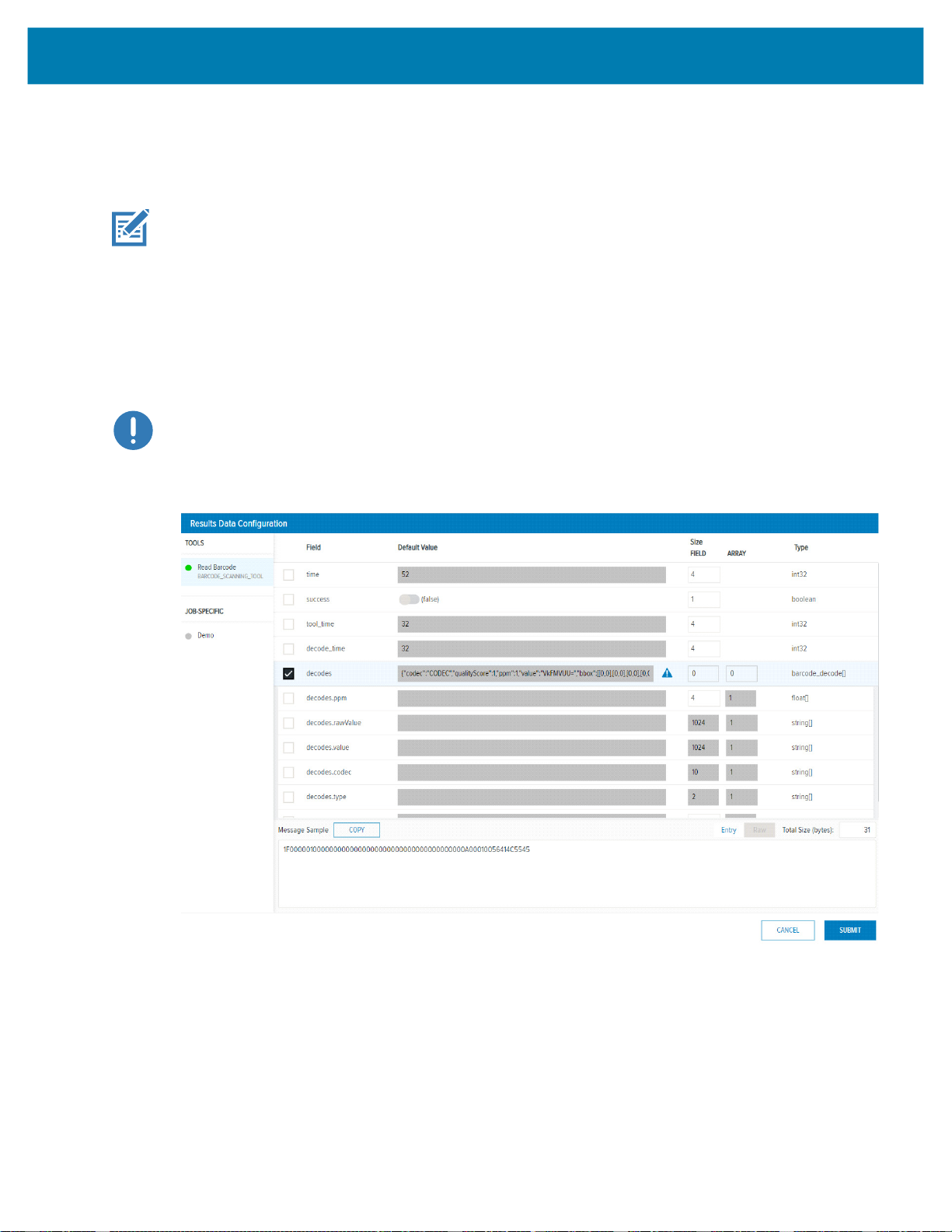

Results Data

The Results Data user interface allows for the user to control which results are sent to the PLC upon Job

completion.

NOTE: The default barcode job on the FS/VS device is configured to provide the FS Barcode

Structure to the PLC. Also, new FS Jobs have FS Barcode Structure automatically configured as the

result output to the PLC.

Click the Add (or Edit) button to display the Results Data Configuration Dialog and the possible tools and

output parameters that can be added to the Result Data. Check the result parameter you intend to receive

from the FS/VS Smart Camera when a Job completes. Refer to the Message Sample window for a view of

what the data looks like when sent to the PLC. Entry or Raw mode can be selected, for more information

on these modes refer to the Results Status and Data Structure on page 18. Once complete, click the

Submit button. From the main window, reorder the result data items using a drag and drop technique.

IMPORTANT: Default value changes do not affect the job, they are used for Message Sample preview

only.

Figure 4 Results Data Configuration

Initial Setup

11

Industrial Ethernet Interface

All Industrial Ethernet protocols supported by the FS/VS Smart Camera use the interface described in this

chapter. Review this section before proceeding to the specific Industrial Ethernet protocol section relevant

to your use case.

Job Control/Status

The FS/VS Smart Camera runs scripts, also known as Jobs, to decode barcodes and solve machine vision

problems. This section includes information on Job Control and Status features available to the PLC

programmer.

Table 1 Job Control/Status Features

Name Direction

Job

Control

Reset

Counters

Job Slot

Control

Job Slot

Number

PLC to Device 1 Job Control sets the state of the Job. When set to 0, the Job is

PLC to Device 1 When this bit is toggled from 0 to 1, all Job counters are reset.

PLC to Device 1 Job Slot Control is used in conjunction with the Job Control bit.

PLC to Device 2 This number field is used in conjunction with the Job Slot

Size

(Bits)

Description

inactive (stopped, for example, no Job loaded or not active).

When the value is set to 1 while the Job Slot Control bit is 0, the

default (or last active) Job will be loaded and set to the loaded

or active state. If the Job Slot Control bit is 1, the Job specified

by the Job Slot Number is loaded and set to the Loaded or

Active state.

If a Job load fails, an error code will be provided as specified in

Error Codes section.

the

As a result, the Job sequence number will be reset to 1 and any

remaining results in the Result Queue will be cleared.

When this bit is set to 1 and the Job Control bit is toggled from 0

to 1, a Job slot switch occurs. The Job that is loaded and made

active is then specified in the Job Slot Number field.

Control bit and the Job Control bit. When the Job Slot Control

bit is set and the Job Control bit is toggled from 0 to 1, this

number will indicate the Job that will be Loaded and made

active. If the number is 0, the Job will be unloaded (made

inactive).

12

Industrial Ethernet Interface

Table 1 Job Control/Status Features (Continued)

Name Direction

Job Status Device to PLC 1 Job Status indicates whether a Job is in the loaded or active

Active Job

Slot

Number

Results

Job Slot

Number

Job Pass Device to PLC 1 This bit is set to 1 if the Job results pass, or set to 0 if the Job

Job Fail Device to PLC This bit is set to 1 if the Job results fail, or set to 0 if the Job

Echo

Register

Control

Echo

Register

Status

Device to PLC 16 The Active Job Slot Number represents the Current Job Slot.

Device to PLC 16 The Results Job Slot Number represents the Results Job Slot.

PLC to Device 16 This 16-bit value is reflected in the PLC based on the value that

Device to PLC 16 This 16-bit value matches the value that the PLC writes to its

Size

(Bits)

Description

state or in the Unloaded Stopped state. Depending on the Jobs

trigger type, a Loaded Job may either be Running or Idle

(waiting on trigger).

0 = Stopped/Unloaded, 1 = Active/Loaded.

Under normal conditions (non-error conditions) this bit matches

the Job Control bit.

This 16-bit integer corresponds to the Job slot of the currently

Loaded or Active Job.

This 16-bit integer corresponds to the Job slot of the Job that

was run to produce the results in the Results data section.

results fail.

results pass.

Some error conditions may not be considered to be a fail, refer

Error Codes section for additional information.

to the

the PLC writes to it. This field allows the PLC programmers to

verify that the output assembly has been written to the camera

when this value matches the written value.

Echo Register Control. This field allows the PLC programmers

to verify that the output assembly has been written to the

camera when this value matches the written value.

13

Trigger Control/Status

Each Job will have one of the following trigger modes:

• Single Shot

• Continuous

• Presentation

• Burst

• Level

Depending on the Trigger Mode, the action that the device takes when an external Trigger is initiated may

differ. For example, when a Job is set for Single Shot, a PLC/GPIO Trigger initiates a single run of that Job.

However, if the Job is set to Continuous, a PLC/GPIO Trigger may produce no change in behavior. Refer

to the Trigger Modes Configuration section in the FS/VS Smart Camera Series Product Reference Guide

for additional information.

The following table describes the control and status of Trigger functionality as it relates to Industrial

Ethernet.

Table 2 Trigger Modes

Industrial Ethernet Interface

Name Direction

Trigger Enable

Control

Trigger PLC to Device 1

PLC to Device 1 Set to 1 to enable triggering

Size

(Bits)

Description

Set to 0 to ignore trigger

When changed from 0 to 1, the current Job begins

running or processing. This bit is only acted upon when

the following conditions are met:

• Job Status is 1 (Job is loaded/active)

• Trigger Ready is 1 (Device is ready to accept

triggers)

Trigger Ready Device to PLC 1 Indicates when the device is ready to accept a new

trigger. This bit is set to 1 when Trigger Enable Control

is 1 and the active Job Slot is not 0. If the bit is set to 0,

the triggers will be ignored.

Trigger Status Device to PLC 1 This bit is set to 1 when the Job is currently executing or

running. This bit is cleared when the Job is stopped or

idle.

14

Results Control/Status

Job results are made available upon completion of the Job. The result data is dependent upon the type of

Job that is run and the Job that was configured. If multiple results are made available before the PLC can

process them, it is suggested that Results Buffering is enabled to ensure that no results are lost.

Table 3 Results Data

Industrial Ethernet Interface

Name Direction

Results Buffer

Control

Results Ack PLC to Device 1 This bit is only applicable when Results Available is set to

Results

Available

Results Buffer

Overflow

Results Queue

Count

Result Data Device to PLC Array of

Results Packet

Sequence

PLC to Device 1 Results Buffer Control enables the queuing of result data

Device to PLC 1 Indicates that a new set of read results are available. This

Device to PLC 1 Indicates that the device has discarded a set of read results

Device to PLC 8 Results Queue Count records the number of results

PLC to Device 16 This number is used in conjunction with Results Ack. It is

Size

(Bits)

Bytes

Description

(queue size is set to 32). If set to 1, new results are queued

on the device and remain present until acknowledged. To

retrieve the next set of results from the queue on the

Results Ack, the bit must transition from 0 to 1. The device

responds to this acknowledgment by clearing the Results

Available bit when no more results are queued on the

device. See the Results Queue Count row in this table for

more information on how results are queued on the device.

If results buffering is not enabled (set to 0), newly received

read results overwrite the content of the Result Data in the

Response/Status section of the Input Assembly.

The Results Overflow bit is set when this bit is set and there

is no more space in the queue to accept a new result.

1. When this bit transitions from 0 to 1, the PLC is then sent

the next set of results. If there are no additional results

queued on the device, the Results Available bit is cleared.

bit is cleared when the results are acknowledged.

because the results queue is full. This is cleared when the

next set of results are successfully queued.

currently in the queue on the device. This bit is set to 0 if

there are no results in the queue.

Results Status and Data Structure on page 18 for

See

more information on contents of the Results Data Structure.

expected to be changed before Results Ack is set to ensure

that Result Ack is not missed by the device.

15

User Data Control/Status

A PLC program can modify Job input parameters at runtime through User Data Control. Updating Job input

parameters are not permanent and are reset to the Job defaults if the Job is reloaded.

Table 4 User Data

Name Direction Size (Bits) Description

User Data

Control

User Data

Status

User Data PLC to

PLC to

Device

Device to

PLC

Device

Industrial Ethernet Interface

1 When this bit is toggled from 0 to 1, the current Job’s

User Data will be overwritten with data provided by the

PLC. See the User Data Status bit description to know

when the User Data has taken affect. When this bit is

cleared, the User Data Status bit will also be cleared.

1 When set to 1, this bit indicates that the new User Data

has taken affect. This bit is cleared when User Data

Control is cleared.

Array of

Bytes

See User Data Structure for more information on the

contents of User Data Structure.

Error Codes Control/Status

If any errors occur on the device, codes will provided to the PLC to determine the cause. See the Error

Codes for a list of error codes and their meaning. The table below describes interpret and utilize error

codes.

Table 5 Error Code Descriptions

Name Direction Size (Bits) Description

Error Buffer

Enable

Error Ack PLC to

Error

Overflow

Error

Available

Error Code Device to

PLC to

Device

Device

Device to

PLC

Device to

PLC

PLC

1 Enables queuing of Error Codes. If enabled, the current

Error Code will remain in the Error Code field until

acknowledged (even if new Error Codes arrive). To clear

the Error Code, toggle the Error Ack bit from 0 to 1. If

another Error Code is queued, the current code is

replaced with the queued code after each 0 to 1

transition of the Error Ack.

If this field is set to 0, no Error Codes will be queued and

only the latest Error Code will be available in the Error

Code field, all other codes will be overwritten.

1 Toggle this bit from 0 to 1 to acknowledge or clear the

current Error Code. This bit clears both the Error

Available bit and Error Code field if there are no other

Errors in the queue.

1 Indicates that the device has discarded an error code

because the error queue is full. This bit is cleared when

the current Error Code is acknowledged.

1 When set to 1, this bit indicates that there is data in the

Error Code field. This bit is cleared when the error is

acknowledged and there are no more errors queued.

16 This bit represents the number (16-bit integer) of an error

that has occurred on the device. See

more information on specific Error Codes.

Error Codes for

16

Industrial Ethernet Interface

User Control and Data Structure

The User Control and Data Structure can be sent to the FS/VS Smart Camera from the PLC to change Job

input parameters at runtime. The User Data Structure is configured using two different formats, Entry Mode

and Raw Mode. When a Job is configured to use Entry Mode, each data entry that is provided by PLC

needs to be proceeded by a 4-byte header. This header includes information on data length and the type

of data provided. When a Job is configured to use Raw Mode, there is no additional metadata provided

(raw data is provided).

.

Table 6 FS Job Results

Name Offset

User Control Global Header

Sequence Number 0 4 Not currently used. Can be 0.

Total Length 4 2 Total size in bytes of the User Data. This length value does

Fragment # 6 2 Not currently used. Can be 0.

Fragment Total Count 8 2 Not currently used. Can be 0.

Mode 10 1 Specifies the User Data format. This bit is 0 for Entry Mode

Status 11 1 Not currently used. Can be 0.

Time 12 2 Not currently used. Can be 0.

Count 14 2 Number of data entries in User data. The count should be 0

Size

(Bytes)

Description

not include the 16 bytes taken up by the Global Header. The

count starts at User Data and includes all the bytes

following it. It is required that the Total Length value

matches the length as specified in the Job’s Industrial

Ethernet User Data configuration.

and 1 for Raw Mode.

if no data exists in User data. The count never exceeds 1

when the mode is set to Raw.

NOTE: User data typically follows the Global Header. However, refer to the Industrial Ethernet protocol

section for more information on where the User Data resides for the given protocol.

User Data Format for Raw Mode (Mode = 1)

Table 7 User Data Format for Raw Mode

Name

Raw Data Varies All of the associated data that is sent from the PLC to the device

Size

(Bytes)

to change the Job input parameters. The data provided is based

on the Industrial Ethernet User Control Data Configuration for the

Job.

17

Description

Loading...

Loading...