VC8300

8" Vehicle-Mounted Computer

User Guide

for Android™ 10

MN-003872-02EN Rev. A

ZEBRA and the stylized Zebra head are trademarks of Zebra Technologies Corporation, registered in many

jurisdictions worldwide. Google, Android, Google Play and other marks are trademarks of Google LLC; All

other trademarks are the property of their respective owners. ©2021 Zebra Technologies Corporation and/or

its affiliates. All rights reserved.

COPYRIGHTS & TRADEMARKS: For complete copyright and trademark information, go to

zebra.com/copyright

.

WARRANTY: For complete warranty information, go to zebra.com/warranty

END USER LICENSE AGREEMENT: For complete EULA information, go to zebra.com/eula

Terms of Use

• Proprietary Statement

This manual contains proprietary information of Zebra Technologies Corporation and its subsidiaries

(“Zebra Technologies”). It is intended solely for the information and use of parties operating and maintaining

the equipment described herein. Such proprietary information may not be used, reproduced, or disclosed to

any other parties for any other purpose without the express, written permission of Zebra Technologies.

• Product Improvements

Continuous improvement of products is a policy of Zebra Technologies. All specifications and designs are

subject to change without notice.

• Liability Disclaimer

Zebra Technologies takes steps to ensure that its published Engineering specifications and manuals are

correct; however, errors do occur. Zebra Technologies reserves the right to correct any such errors and

disclaims liability resulting therefrom.

• Limitation of Liability

In no event shall Zebra Technologies or anyone else involved in the creation, production, or delivery of the

accompanying product (including hardware and software) be liable for any damages whatsoever (including,

without limitation, consequential damages including loss of business profits, business interruption, or loss of

business information) arising out of the use of, the results of use of, or inability to use such product, even if

Zebra Technologies has been advised of the possibility of such damages. Some jurisdictions do not allow

the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may

not apply to you.

.

.

Revision History

Changes to the original guide are listed below:

Change Date Description

-01 Rev A 9/2020 Initial release

-02 Rev A 10/2021 Updated GMS Restricted topic.

2

Table of Contents

About This Guide.............................................................................................................................. 11

Introduction .................................................................................................................... 11

Configurations................................................................................................................ 11

Software Versions.......................................................................................................... 11

Chapter Descriptions...................................................................................................... 12

Notational Conventions.................................................................................................. 12

Related Documents and Software ................................................................................. 13

Service Information ........................................................................................................ 13

Getting Started.................................................................................................................................. 14

Introduction .................................................................................................................... 14

Unpacking ...................................................................................................................... 14

Removing the Protective Film from the Display...................................................... 14

Safety............................................................................................................................. 14

Initial Operation Safety Considerations .................................................................. 15

Power Supply/Cable Safety.................................................................................... 15

External Devices Safety ......................................................................................... 15

Features......................................................................................................................... 16

Front Keys and LED Indicators ..................................................................................... 19

Front Keys .............................................................................................................. 19

LED Indicators ........................................................................................................ 19

Integrated Keyboard....................................................................................................... 20

Soft Input Panel.............................................................................................................. 22

Powering Up the Device................................................................................................. 22

Powering Down the Device............................................................................................ 22

Setting Up WLAN........................................................................................................... 22

Device Settings .............................................................................................................. 22

Heater Status ................................................................................................................. 22

3

Table of Contents

Installation......................................................................................................................................... 23

Introduction .................................................................................................................... 23

Overview ........................................................................................................................ 23

Mounting Instructions..................................................................................................... 23

Installing the Device....................................................................................................... 23

Electrical Installation............................................................................................... 23

Wiring Guidelines ............................................................................................. 24

Wiring Vehicle Power to the VC8300............................................................................. 25

External Antenna Installation.................................................................................. 26

Positioning the VC8300 in the Vehicle ................................................................... 26

Overview of the Assembly Steps............................................................................ 26

Cable Dust Cover ................................................................................................... 26

Strain Relief ............................................................................................................ 27

Installing the VC8300 on a Forklift.......................................................................... 27

Forklift Battery Replacement Conditions........................................................................ 28

Starting from Cold Soak................................................................................................. 28

Pre-Heat Mode ....................................................................................................... 29

Installing the Power Pre-Regulator ................................................................................ 29

Non-Vehicle Installations................................................................................................ 30

Screen Blanking Wiring.................................................................................................. 31

Connecting Switch for Screen Blanking ................................................................. 31

Using the Device............................................................................................................................... 33

Home Screen ................................................................................................................. 33

Setting Home Screen Rotation ............................................................................... 34

Status Bar............................................................................................................... 34

Notification Icons.............................................................................................. 35

Status Icons ..................................................................................................... 36

Managing Notifications ........................................................................................... 37

Opening the Quick Access Panel ........................................................................... 37

Quick Access Panel Icons................................................................................ 38

Editing Icons on the Quick Settings Bar ................................................................. 38

Battery Management...................................................................................................... 39

Monitoring Battery Usage ....................................................................................... 39

Low Battery Notification.......................................................................................... 39

Waking the Device ......................................................................................................... 39

USB Communication...................................................................................................... 40

Transferring Files.................................................................................................... 40

Transferring Photos ................................................................................................ 40

Disconnect from the Host Computer ...................................................................... 40

Transferring Files ........................................................................................................... 40

4

Table of Contents

Using a USB Drive.................................................................................................. 41

Disconnecting USB Drive ....................................................................................... 41

Applications ...................................................................................................................................... 42

Accessing Apps.............................................................................................................. 45

Switching Between Recent Apps............................................................................ 45

Battery Manager............................................................................................................. 45

Opening Battery Manager ...................................................................................... 45

Battery Manager Information Tab........................................................................... 45

DataWedge Demonstration............................................................................................ 47

Scanner Selection .................................................................................................. 48

Heater Control............................................................................................................... 49

Temperatures ......................................................................................................... 49

Serial Port Heater ................................................................................................... 49

USB Port Heater..................................................................................................... 49

Battery Heater ........................................................................................................ 49

Touch Panel Heater................................................................................................ 50

Keyboard Heater .................................................................................................... 50

PTT Express Voice Client .............................................................................................. 50

Speaker/Microphone Setup .................................................................................... 50

PTT Audible Indicators ........................................................................................... 50

PTT Notification Icons ............................................................................................ 51

Enabling PTT Communication................................................................................ 51

Selecting a Talk Group ........................................................................................... 52

PTT Communication............................................................................................... 52

Creating a Group Call ...................................................................................... 52

Responding with a Private Response .............................................................. 52

Disabling PTT Communication ............................................................................... 52

RxLogger....................................................................................................................... 53

RxLogger Configuration.......................................................................................... 53

Configuration File ................................................................................................... 53

Enabling Logging.................................................................................................... 53

Disabling Logging ................................................................................................... 53

Extracting Log Files ................................................................................................ 53

Backing Up ............................................................................................................. 53

RxLogger Utility ...................................................................................................... 54

Initiating the Main Chat Head........................................................................... 54

Removing the Main Chat Head ........................................................................ 54

Viewing Logs.................................................................................................... 54

Removing a Sub Chat Head Icon..................................................................... 54

Backing Up In Overlay View............................................................................. 54

VC Settings ................................................................................................................... 55

5

Table of Contents

Display.................................................................................................................... 55

Peripheral Power .................................................................................................... 55

Ignition Detection.................................................................................................... 55

WIFI Antenna Switching ......................................................................................... 55

Built-In Speaker ...................................................................................................... 55

Screen Blanking ..................................................................................................... 55

Velocity........................................................................................................................... 56

Data Capture ..................................................................................................................................... 57

Imaging ......................................................................................................................... 58

Operational Modes ................................................................................................. 58

Laser Scanning .............................................................................................................. 58

Scanning Considerations ............................................................................................... 58

Barcode Capture with RS6000 Bluetooth Ring Scanner................................................ 59

Barcode Capture with RS507/RS507x Hands-Free Imager........................................... 60

Bar Code Capture with RS5100..................................................................................... 61

Bar Code Capture with Zebra Scanner.......................................................................... 63

Connecting an RS-232 Scanner .................................................................................... 63

Connecting a USB Scanner ........................................................................................... 65

Connecting Using Simple Serial Interface........................................................ 65

Connecting Using HID Mode............................................................................ 66

Pairing the Ring Scanner ............................................................................................... 66

Pairing Using Simple Serial Interface ..................................................................... 66

Pairing Using Human Interface Device................................................................... 67

Pairing a DS3678 Scanner............................................................................................. 68

Pairing Using Simple Serial Interface ..................................................................... 68

Pairing a DS3678 Scanner Using Human Interface Device ................................... 69

DataWedge .................................................................................................................... 69

Enabling DataWedge.............................................................................................. 69

Disabling DataWedge............................................................................................. 70

DataWedge .................................................................................................................... 70

Enabling DataWedge.............................................................................................. 70

Disabling DataWedge............................................................................................. 70

Supported Decoders............................................................................................... 70

Wireless............................................................................................................................................. 73

Wireless Local Area Networks ....................................................................................... 73

Connecting to a Wi-Fi Network............................................................................... 74

Removing a Wi-Fi Network..................................................................................... 74

WLAN Configuration ...................................................................................................... 74

6

Table of Contents

Configuring a Secure Wi-Fi Network ...................................................................... 74

Manually Adding a Wi-Fi Network .......................................................................... 75

Configuring for a Proxy Server ............................................................................... 76

Configuring the Device to Use a Static IP Address ................................................ 77

Wi-Fi Preferences................................................................................................... 77

Additional Wi-Fi Settings ........................................................................................ 78

Wi-Fi Direct............................................................................................................. 79

Zebra Mobility Extensions.............................................................................................. 79

Bluetooth........................................................................................................................ 79

Adaptive Frequency Hopping ................................................................................. 80

Security................................................................................................................... 80

Bluetooth Profiles ................................................................................................... 80

Bluetooth Power States .......................................................................................... 81

Bluetooth Radio Power........................................................................................... 82

Enabling Bluetooth ........................................................................................... 82

Disabling Bluetooth .......................................................................................... 82

Discovering Bluetooth Device(s) ............................................................................ 82

Changing the Bluetooth Name ............................................................................... 82

Connecting to a Bluetooth Device .......................................................................... 83

Selecting Profiles on the Bluetooth Device............................................................. 83

Unpairing a Bluetooth Device ................................................................................. 83

Cast................................................................................................................................ 83

Accessories and Mounting.............................................................................................................. 84

Introduction .................................................................................................................... 84

Accessories.................................................................................................................... 84

VC8300 Antenna Options .............................................................................................. 85

VC8300 Mounting Accessories...................................................................................... 87

MT43XX RAM Mount.............................................................................................. 88

Optional Mounts ..................................................................................................... 88

Plate Bases for MT35XX Mounts ..................................................................... 90

MT4200 Quick Release Mount ............................................................................... 92

Assembling MT4200 ........................................................................................ 92

Attaching MT4200 to VC8300 ................................................................................ 93

MT4210 Adapter Bracket........................................................................................ 94

Settings.............................................................................................................................................. 95

Accessing Settings......................................................................................................... 95

Display Settings ............................................................................................................. 95

Setting the Screen Brightness Manually................................................................. 95

Setting Night Light .................................................................................................. 95

7

Table of Contents

Setting Screen Rotation.......................................................................................... 96

Setting Screen Timeout .......................................................................................... 96

Lock Screen Display............................................................................................... 96

Setting Font Size .................................................................................................... 96

Touch Panel Mode ................................................................................................. 97

Setting the Date and Time ............................................................................................. 97

Keyboard Backlight ........................................................................................................ 98

General Sound Setting................................................................................................... 98

Sound Options........................................................................................................ 98

Remapping a Button ...................................................................................................... 99

Keyboards...................................................................................................................... 99

Keyboard Configuration.......................................................................................... 99

Enabling Keyboards ......................................................................................... 99

Switching Between Keyboards....................................................................... 100

Using the Android and Gboard Keyboards........................................................... 100

Edit Text ......................................................................................................... 100

Entering Numbers, Symbols, and Special Characters ................................... 100

Using the Enterprise Keyboard............................................................................. 100

Numeric Tab................................................................................................... 100

Alpha Tab....................................................................................................... 101

Additional Character Tab ............................................................................... 101

Scan Tab........................................................................................................ 101

Soft Input Panel............................................................................................................ 103

Language Usage.......................................................................................................... 104

Changing the Language Setting ........................................................................... 104

Adding Words to the Dictionary ............................................................................ 104

Notifications.................................................................................................................. 104

Setting App Notifications ...................................................................................... 104

Viewing Notification Settings for All Apps ...................................................... 105

Controlling Lock Screen Notifications ............................................................ 105

Blink Light....................................................................................................... 105

Application Deployment................................................................................................................. 106

Security ........................................................................................................................ 106

Secure Certificates....................................................................................................... 106

Installing a Secure Certificate ...................................................................................... 106

Configuring Credential Storage Settings .............................................................. 107

Development Tools ...................................................................................................... 107

Android Application Development ........................................................................ 107

Development Workstation .............................................................................. 107

Enabling Developer Options .......................................................................... 107

EMDK for Android................................................................................................. 108

8

Table of Contents

StageNow ............................................................................................................. 108

GMS Restricted............................................................................................................ 108

ADB USB Setup........................................................................................................... 108

Enabling USB Debugging..................................................................................... 108

Application Installation ................................................................................................. 109

Installing Applications Using a USB Drive ............................................................ 109

Installing Applications Using the USB Connection ............................................... 110

Installing Applications Using the Android Debug Bridge ...................................... 110

Uninstalling an Application ................................................................................... 112

Performing a System Update....................................................................................... 112

Downloading the System Update Package .......................................................... 112

Performing a System Update Using USB Drive ................................................... 112

Performing a System Update Using ADB............................................................. 113

Verifying System Update Installation.................................................................... 114

Enterprise Reset .......................................................................................................... 114

Performing an Enterprise Reset From Device Settings........................................ 114

Downloading the Enterprise Reset Package ........................................................ 114

Performing an Enterprise Reset Using ADB......................................................... 115

Performing a Factory Reset ......................................................................................... 116

Downloading the Factory Reset Package ............................................................ 116

Performing a Factory Reset Using ADB ............................................................... 117

Storage......................................................................................................................... 118

Random Access Memory ..................................................................................... 118

Viewing Memory............................................................................................. 118

Internal Storage .................................................................................................... 118

Viewing Internal Storage ................................................................................ 118

External Storage................................................................................................... 119

Viewing External Storage............................................................................... 119

Formatting a USB Drive as Portable Storage ................................................ 119

Enterprise Folder .................................................................................................. 119

Managing Apps ............................................................................................................ 119

App Details ........................................................................................................... 119

Managing Downloads................................................................................................... 120

Maintenance and Troubleshooting ............................................................................................... 121

Introduction .................................................................................................................. 121

Cleaning....................................................................................................................... 121

Housing Cleaning ................................................................................................. 121

Touchscreen Cleaning.......................................................................................... 121

Touchscreen ................................................................................................................ 121

Troubleshooting ........................................................................................................... 122

9

Table of Contents

Resetting the Device ............................................................................................ 122

Performing a Soft Reset................................................................................. 122

Performing a Hard Reset ............................................................................... 122

VC8300................................................................................................................. 123

Specifications ................................................................................................................................. 126

Drill Hole Dimensions................................................................................................... 126

Index ................................................................................................................................................ 127

10

About This Guide

Introduction

This guide provides instructions for setting up, operating, configuring, and maintaining the VC8300 8 inch

vehicle-mount computer.

NOTE: Screens and windows pictured in this guide are samples and can differ from actual screens.

WARNING: Before transporting, assembling, and starting the computer, please read this manual carefully

and follow all the safety guidelines and requirements.

Configurations

The VC8300 offers different configurations to suit various work requirements. Some of the configuration

options include:

• Qualcomm Snapdragon 660 octa-core 2.2 GHz

• 4 GB RAM/ 32 GB Flash

• Sunlight Readable Display

• Internal and External Antenna

• Freezer Condensing

• Android 10 Google ™ Mobile Services (GMS)

• Basic I/O.

NOTE: For detailed configuration and part number information, contact your Zebra representative.

Software Versions

To determine the current software versions:

1. Swipe down from the Status bar to open the Quick Settings bar.

2. Touch > System.

3. Touch About phone.

4. Scroll to view the following information:

• Model

11

• Android version

• Android security patch level

• Kernel version

• Build number.

To determine the device serial number, touch About phone> Status.

• Serial number

Chapter Descriptions

Topics covered in this guide are as follows:

• Getting Started provides information on safety guidelines and initial VC8300 setup.

About This Guide

• Installation

• Using the Device provides information for operating the VC8300.

• Applications provides information on using applications installed on the VC8300.

• Data Capture explains how to capture data using the optional scanners.

• Wireless provides information on the various wireless options.

• Accessories and Mounting describes the accessories and mounting options available for the VC8300.

• Settings provides the settings for configuring the VC8300.

• Application Deployment provides information for developing and managing applications.

• Maintenance and Troubleshooting includes instructions on cleaning the VC8300 and provides

troubleshooting solutions for potential problems during device operations.

• Specifications summarizes the device’s intended operating environment and technical specifications.

provides instructions on installing the VC8300.

Notational Conventions

The following conventions are used in this document:

• Bold text is used to highlight the following:

• Dialog box, window and screen names

• Drop-down list and list box names

• Check box and radio button names

• Icons on a screen

• Key names on a keypad

• Button names on a screen.

• Chapters and sections in this guide

• Bullets (•) indicate:

• Action items

• Lists of alternatives

• Lists of required steps that are not necessarily sequential.

• Sequential lists (e.g., those that describe step-by-step procedures) appear as numbered lists.

12

About This Guide

Related Documents and Software

The following document provides more information about the VC8300 vehicle-mount computer.

• VC8300-8 Quick Reference Guide, p/n MN-003394-xx - includes setup information and regulatory

information.

• U-Mount Bracket Installation Guide, p/n MN-002931-xx - includes the instructions to install the U-Mount

Bracket Kit (KT-U-MOUNT-VC80-R) and dimensions.

• Adapter Bracket Kit for VC50 U-Mount Installation Guide, p/n MN-002932-xx - provides instruction on

installing the Adapter Bracket Kit (MNT-VC80-ADPA1-1) to attach the VC8300 to the VC5090 U-Mount.

• Adapter Bracket Kit for Honeywell U-Mount Installation Guide, p/n MN-002934-xx - provides instruction

on installing the Adapter Bracket Kit (MNT-VC80-ADPB1-1) to attach the VC8300 to the Honeywell

U-Mount Bracket.

For the latest version of this guide and all guides, go to: zebra.com/support

Service Information

If you have a problem with your equipment, contact Zebra Customer Support for your region. Contact

information is available at: zebra.com/support

When contacting support, please have the following information available:

• Serial number of the unit

• Model number or product name

• Software type and version number.

Zebra responds to calls by email, telephone or fax within the time limits set forth in support agreements.

If your problem cannot be solved by Zebra Customer Support, you may need to return your equipment for

servicing and will be given specific directions. Zebra is not responsible for any damages incurred during

shipment if the approved shipping container is not used. Shipping the units improperly can possibly void

the warranty.

If you purchased your Zebra business product from a Zebra business partner, contact that business

partner for support.

.

.

13

Getting Started

Introduction

The VC8300 is a rugged, vehicle mounted computer running Android 10 operating systems. Wireless

communications are supported over a 802.11 WLAN network. The Bluetooth module supports Bluetooth

printers and scanners. The VC8300-8 contains an integrated keyboard in either QWERTY or AZERTY

alphanumeric keyboard layout. It features 54 keys, 12 direct function keys, and a power button.

The VC8300 is intended for use in commercial and industrial applications with a focus on real time wireless

data transactions with options suiting materials handling applications in warehouses, manufacturing

facilities, ports, yards, and freezers.

Unpacking

CAUTION: Before operating the unit for the first time, carefully read Safety on page 14.

NOTE: Configure the VC8300 before fastening it to machines or vehicles.

Carefully remove all protective material from the device and save the shipping container for later storage

and shipping.

Inspect the equipment for damage. If any equipment is missing or damaged, contact the Zebra Support

Center immediately. See Service Information on page 13 for contact information.

Removing the Protective Film from the Display

The front display of the VC8300 is protected during transport by a transparent film. This film should remain

on the front display during assembly to avoid damage to the front display surface. Only remove the film

once all of the assembly work has been completed.

Safety

In order to prevent injury and damage, observe the following safety guidelines prior to assembly and

commissioning. The VC8300 is a multifunction vehicle computer for stationary and mobile use in

commercial environments such as, warehouses, manufacturing, yard/ports, and freezers. Different or

extraordinary usage is not permitted. For resulting damage, the user/operator of the VC8300 is solely

responsible. This also applies to any changes that you make to the device. Compliance with the safety

guidelines is particularly important for the proper use of this device. The manufacturer assumes no liability

for any and all damages that can be attributed to non-compliance with these guidelines.

14

Getting Started

Initial Operation Safety Considerations

• Installation/Initial Operation - Perform VC8300 installation in accordance with Installation on page 23.

Specifically, pay special attention to the various electrical potentials of the vehicle. Some vehicles have

a chassis that is connected to one of the battery supply lines (DC+ or DC-), while most

electrically-driven forklift vehicles have floating chassis, connected to neither DC+ or DC-. See Wiring

Vehicle Power to the VC8300 on page 25 for required wiring of vehicle power and fusing for the

VC8300.

• Risk of injury during transit or installation - The unit can fall during transit or installation and cause

injury. Always ensure that there are two persons available when installing or removing the device.

• Ensure that no persons are injured in case the mounting bracket breaks - The VC8300 may not be

installed in such a way that persons can be injured during a breaking of the mounting bracket (e.g.

fatigue break). If the device is mounted in a place where people can be injured if the bracket breaks,

apply appropriate safety measures (e.g. install a security cable in addition to the device bracket).

Power Supply/Cable Safety

The main power cord shall comply with the national safety regulations of the country where the equipment

is to be used.

• Operation in an emergency - In case of an emergency (such as damage to the power cable or housing,

or ingress of liquid or other foreign bodies), disconnect the device immediately from the power supply.

Contact technical support staff at once.

• Protection of the power supplies - If, after replacement, the fuse fed by the internal power supply blows,

send the device for servicing immediately.

• Danger of electrocution when cleaning/servicing the device - In order to avoid electrocution, always

disconnect the VC8300 from the power supply before cleaning or servicing the device.

• Do not exceed maximum voltage when charging the vehicle battery - While charging the vehicle

battery, disconnect the VC8300 from the battery or ensure that the maximum allowed input voltage of

the VC8300 is not exceeded.

• Do not switch on devices with damaged cables or plugs - Do not use the VC8300 if a cable or plug is

damaged. Replace damage parts immediately.

• Do not connect or disconnect cables during storms - Cables must never be connected or disconnected

during an electrical storm.

External Devices Safety

The use of additional wiring and other peripheral devices, which are not recommended or sold by the

manufacturer, can result in fire, electrocution or personal injury.

• If a power supply is used, only use the power supply recommended by the manufacturer.

• Before connecting or disconnecting peripheral devices (exception: USB devices), disconnect the

VC8300 from the power supply to avoid serious damage to both the VC8300 and the connected

devices.

15

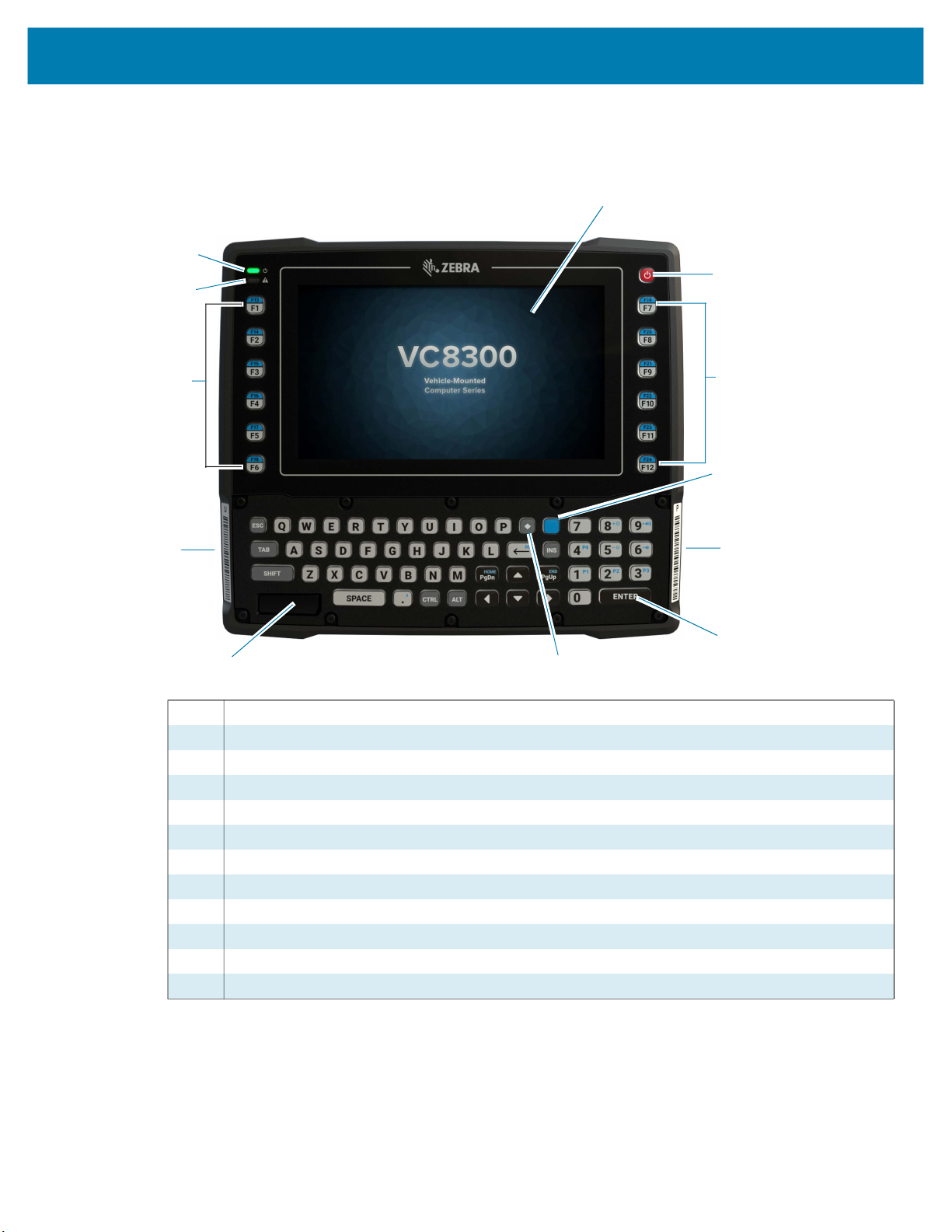

Features

Getting Started

Figure 1 VC8300 8 inch Front View

1

12

2

11

10

9

8

1 Capacitive Touch Screen

2 Power Button

3 Programmable Keys

4 Blue Modifier Key

5 Pairing Bar Code

6 Enter Key

7 Diamond Key

8 Speaker

9 Unpairing Bar Code

10 Programmable Keys

11 Warning LED

12 Power LED

3

4

5

6

7

16

Figure 2 VC8300 8 inch Top View

802.11 a/b/g/n/ac Radio External Antenna Connectors

Getting Started

1

ANT 1 - Reverse Polarity SMA Jack (WLAN & BT) / External Main Antenna

ANT 2 - Reverse Polarity SMA Jack (WLAN) / External Aux Antenna

2

1 ANT 1

2 ANT 2

NOTE: Optional external Wi-Fi antennas are not shipped with the device and must be ordered as a

separate accessory. The device can be switched between internal and external antenna. For a complete

list of configurations see Table 12 on page 84.

Figure 3 VC8300 Back View with Dust Cover

1

5

4

1 UPS Battery

2 Dust Cover

3 Strain Relief (four)

4 Vent

5 RS-232 (two)

3

2

17

Getting Started

Figure 4 VC8300 Back View without Dust Cover

6

5

1 Standard USB

2 Powered USB

3 Speaker/Mic for M1000 only

4 Strain Relief

5 Power

6 Ground Lug

1

4

2

3

18

Front Keys and LED Indicators

The device has the following front bezel keys and LEDs:

Front Keys

Table 1 VC8300 8 inch Front Keys

Front Function

Power Powers the device on or off. Use to reset the device. See Resetting the Device

on page 122.

Diamond Key Opens the special character SIP.

Blue Modifier Key Modifies programmable macro keys allowing for an additional six programmable

keys. Press the Blue Modifier key twice to lock the key on and to unlock, press

the key once again.

Function Keys

Keyboard Use to enter text.

Bar Codes

Pairing Bar Code Pair peripheral Bluetooth scanners to the VC8300.

Unpairing Bar Code Un-pair peripheral Bluetooth scanners to the VC8300.

Speaker

Front Speaker Located on front bezel.

Function keys perform special, custom-defined functions within an application.

These keys are accessed by pressing one of the dedicated function keys on the

keyboard, or through the appropriate [Blue] key sequence.

Getting Started

LED Indicators

Table 2 LED Indicators

Indicator State Description

Power Off The device has no power and cannot be turned on.

Warning Off No battery or charger faults.

Amber The device has power and can be turned on.

Flashing Amber The unit is pre-heating.

Solid Green The unit is ON, operating from external power.

Slow Flashing Green The device is running with UPS/Internal Battery power, no

external power available.

Fast Flashing Green The device is in Sleep mode. Press Power button to wake the

device.

Solid Red Battery temperature is out of range for charging.

Blinking Red Any other battery/charging fault, e.g. communication fault,

charge timeout, or defective battery pack.

19

Integrated Keyboard

The device is available with an integrated keyboard in either QWERTY or AZERTY alphanumeric

keyboard layout. It features 54 keys, 12 direct function keys, and a power button.

Most of the keys on the keyboard operate much like a desktop computer. Where a key or key function is

not consistent with the keyboard, those differences are described in the following sections.

There are a number of modifier keys that provide access to additional keys and system functions.

See Keyboard Backlight on page 101 for information on adjusting the keyboard backlight.

Figure 5 Integrated Keyboard

Getting Started

20

Getting Started

Table 3 Key Descriptions

Key Function

Regular Keys

The Arrow Keys The arrow keys are located near the bottom of the keyboard, and are represented

on the keyboard as triangles pointing in different directions. The keys move the

cursor around the screen in the direction of the arrow: up, down, left, and right.

The left arrow key should not be confused with the backspace DEL key which is

depicted as a left arrow. The cursor is the flashing box or underline character that

indicates where the next character you type will appear.

The DEL Key The DEL key (represented on the keyboard as an arrow pointing left) is the

backspace key that moves the cursor one character to the left, erasing the

previous key stroke.

The [Blue] + DEL keys erase the character at the current cursor position.

The SHIFT Key

The CTRL and

ALT Keys

The TAB Key

The ESC Key

The SPACE Key

The INS Key

Function Keys

F1 - F12 Function keys perform special, custom-defined functions within an application.

The SHIFT key is used to display uppercase alpha characters. appears in the

status bar. Pressing the SHIFT key a second time locks the keys that all alpha

characters are uppercase. appears in the status bar. Press the SHIFT key

again to return to the default keypad functions.

The CTRL and ALT keys modify the function of the next key pressed and are

application dependent. or appears in the status bar. Pressing the CTRL or

ALT key a second time locks the keys. or appears in the status bar. Press

the key again to return to the default keypad functions.

Typically, the TAB key moves the cursor to the next field to the right or downward.

Generally, this key is used as a keyboard shortcut to close the current menu,

dialog box, or activity.

Pressing this key inserts a blank space between characters. In a dialog box,

pressing the SPACE key enables or disables a check box.

The INS key inserts a character at the cursor position.

These keys are accessed by pressing one of the dedicated function keys on the

keyboard, or through the appropriate [Blue] key sequence.

To access the blue function keys, first press the [Blue] key followed by the

appropriate function key.

Function keys can be used with the operating system or another application.

Programmable Keys

P1 - P5 The device keyboard is equipped with a series of programmable keys that can be

programmed to replace frequently used keystrokes, along with the function of

executable keys like the ENTER key, the [BACKSPACE] key, any function key,

arrow key, etc.

Special Keys

Diamond Key The Diamond key provides access to commonly used symbolic characters.

Pressing the key brings up the soft input panel (SIP) on-screen keyboard, with

symbols mapped to each key.

Blue Key The [Blue] key provides access to additional keys. These functions are color

coded in blue print on the key caps.

21

Soft Input Panel

The SIP provides additional commonly used symbolic characters that do not appear on the integrated

keyboard. Press the Diamond key to show the SIP. Press the Diamond key a second time to lock the SIP

in place. Press the Diamond key a third time to hide the SIP. Press and hold up arrow/down arrow key and

slide up and down to re-position the SIP on the screen.

Figure 6 Soft Input Panel

Powering Up the Device

Power up the device after connecting all of the devices.

Getting Started

To power up the device, connect to an appropriate power supply and press the Power button (see Figure 1

on page 16) or the ignition signal.

CAUTION: Make sure there is a suitable disconnecting device such as a power switch or circuit breaker in

the power supply circuit. See Installing the Device on page 23 for more information.

Powering Down the Device

Always shut down the device as follows:

1. Press the Power button until the menu appears on the screen.

2. Touch Power off.

Setting Up WLAN

To connect to a WLAN, see Wireless on page 73.

Device Settings

The user can configure the device setting:

• Date and Time settings. See Setting the Date and Time on page 40.

• Display settings, see Display Settings on page 38.

• Sound settings, see General Sound Setting on page 41.

Heater Status

The device offers a unique heater system that enables continuous operations in freezer environments. See

Heater Control on page 49 for information about the heater settings.

22

Installation

Introduction

This chapter provides instructions on installing the device.

Overview

The device can be installed in a variety of ways:

• Position the device horizontally on a desk or mounted on a vehicle console.

• Wall mount the device using the optional wall mount (see VC8300 Mounting Accessories on page 87).

• Overhead mount on a lift truck cage using mounting hardware.

Depending on the vibration resistance and pivoting demands, mounting brackets, clamp foots or RAM

mount elements can also be used to attach the device. Contact your Zebra sales office to find out more

about the range of available installation options.

WARNING: The unit could fall during transit or installation/mounting and cause injury. Always ensure that

there are two people available when installing or removing the device.

Mounting Instructions

Follow and retain the mounting instructions included with assembly kit when installing the device. See

Safety on page 14 for safety instructions.

Installing the Device

Electrical Installation

There are various electrical potentials when installing the unit on a vehicle such as a forklift.

23

Installation

WARNING: Most electrically driven forklift vehicles have floating chassis connected to neither DC+ or DC-.

However, electrical faults can cause the battery + or - to be connected to the chassis via low resistance

paths. All connected peripherals must be completely isolated.

The device accepts DC power sources with a minimum of 10 VDC nominal and 48 VDC nominal. A Power

Pre-regulator is required for voltages above 48 VDC nominal.

Applying a voltage above 48 VDC nominal without the pre-regulator or reversing polarity may result in

permanent damage to the device and voids the product warranty.

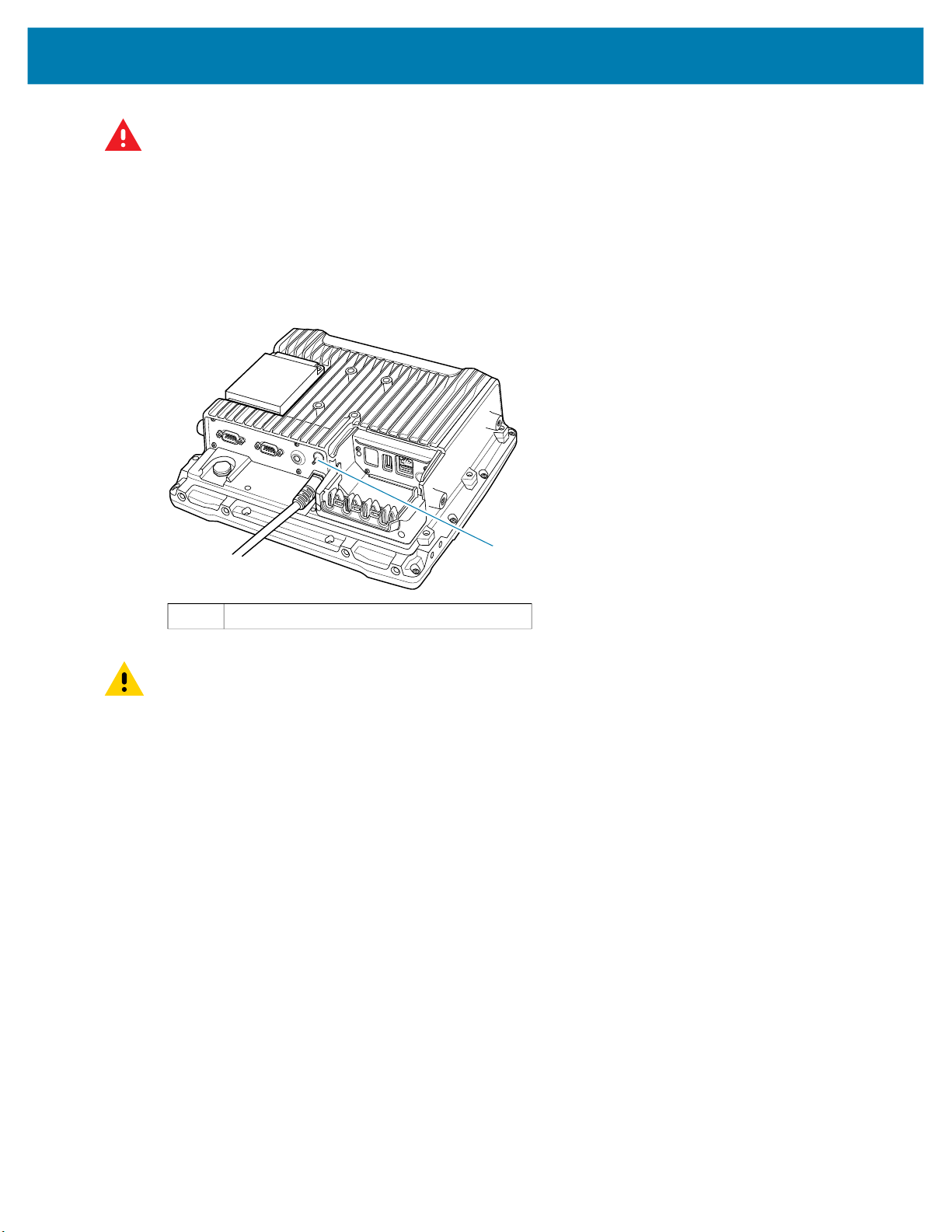

Figure 7 Ground Lug

1 Ground lug

CAUTION: Attach the device connecting cable as close to the battery as possible. Connecting the device

to large electrical loads, such as converters for the forklift motor may result in random restarts,

malfunctions and/or irreparable damage to the device.

To connect devices fed by other power sources to the device, such as printers, power up the peripheral

devices at the same time or after the device to avoid start-up problems, malfunctions or irreparable

damage to the device.

Wiring Guidelines

The metal chassis of the device is equipped with a ground lug (located on the underside adjacent to the

power cable) to provide additional ground to the vehicle. It is strongly recommended that a grounding strap

is used to connect the ground stud on the vehicle-mount to a solid, reliable contact point on the main

portion of the vehicle chassis. It must not be connected to battery negative or terminal block.

As with other vehicle cables, carefully consider the routing of the ground strap to ensure it does not pose a

hazard to the operator or the safe operation of the vehicle. If necessary, secure the ground strap with cable

ties or some other mechanical means to prevent loops or loose lengths of wire from catching on stationary

items when the vehicle is in motion.

1

Before installing the cables between the mount and other devices, consider the following:

• Ensure that drilling holes do not damage the vehicle or its wiring.

• Protect cable runs from pinching, overheating and physical damage.

• Use grommets to protect cables that pass through metal.

24

Installation

• Use plastic straps and tie-downs to secure cables and connectors in their desired location, away from

areas where they may get snagged or pulled.

• Keep cables away from heat sources, grease, battery acid and other potential hazards.

• Keep cables away from control pedals and other moving parts that may damage the cables or interfere

with the operation of the vehicle.

CAUTION: Make sure the cables run inside the roll cage of the vehicle.

If the device is installed in an environment where earth ground is present such as a vehicle with metal

wheels running on a metal track, or is powered by the AC/DC adapter in a permanent installation, the

ground lug must be connected to the ground structure.

Wiring Vehicle Power to the VC8300

WARNING: Applying voltage above the input voltage rating or reversing polarity may result in permanent

damage to the VC8300 and void the product warranty.

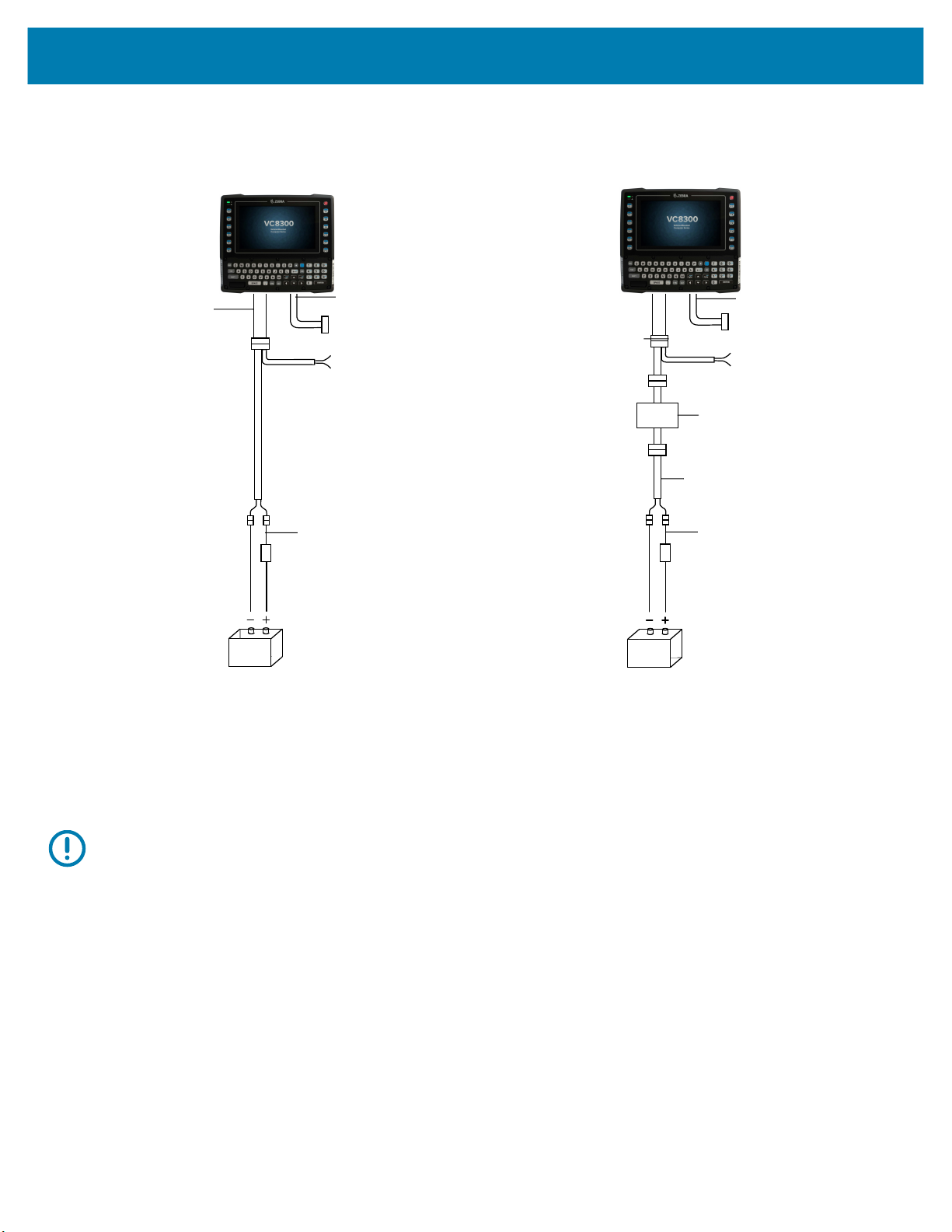

An extension power cable is used to wire the VC8300 to the truck battery (order cable separately, see

Accessories on page 84). Wire this cable to a filtered, fused (15A max) accessory supply on the vehicle.

Follow the installation instructions supplied with the extension cable.

Additional wiring (minimum 14 gauge), connectors or disconnects used should be rated for at least 300

VDC, 15A.

When connecting the extension power cable:

• If a power extension cable with ignition sense is used, ensure that the ignition sense wires (18AWG

wires in red and black leads) and the power wires (14AWG in red and black leads) are reliably secured

away from each other, or are separated with reliably secured certified insulation. Minimum 2.8 mm

distance, or 0.4 mm distance through insulation is required for the separation.

• The red lead of the 14AWG power cables attach to the vehicles battery positive terminal. The 14AWG

black lead connects to the vehicle’s battery negative terminal. This should be connected to a proper

terminal block and not to the vehicle body. An optional grounding strap wire (sourced separately) may

be connected to the ground lug of the VC8300 terminal connector bay and to the vehicle chassis.

• You may have the option to connect power before or after the key switch. Though the VC8300 is

equipped with a UPS, a proper shut down is recommended using the Power Off procedure. If it is wired

after the key switch, the operator must shut down the VC8300 using the Power Off procedure before

turning off the vehicle. If it is wired before the key switch, then to avoid excessive drain on the vehicle

battery, either the operator should shut it down when the vehicle is to be left off for an extended period,

or the ignition cable shut down wire should be connected and the VC8300 configured to shut down

automatically.

• An appropriate fuse type must be used with the power extension cable according to the installation

instructions. For main power cable, use 3AB, 15A, 250V, slow blow fuse. For ignition sense input, use

3AB, 0.3A, 250V, slow blow fuse.

NOTE: The VC8300 supports the ignition sense feature that detects when the ignition switch or key switch

is On or Off to allow automatic computer start up or shut down (with delay as needed).

When wiring the ignition sense wires (18AWG in red and black), the red 18AWG wire is connected to a

positive DC voltage source switched on by the ignition. The black 18AWG wire is connected to ground

reference of this switched ignition source.

25

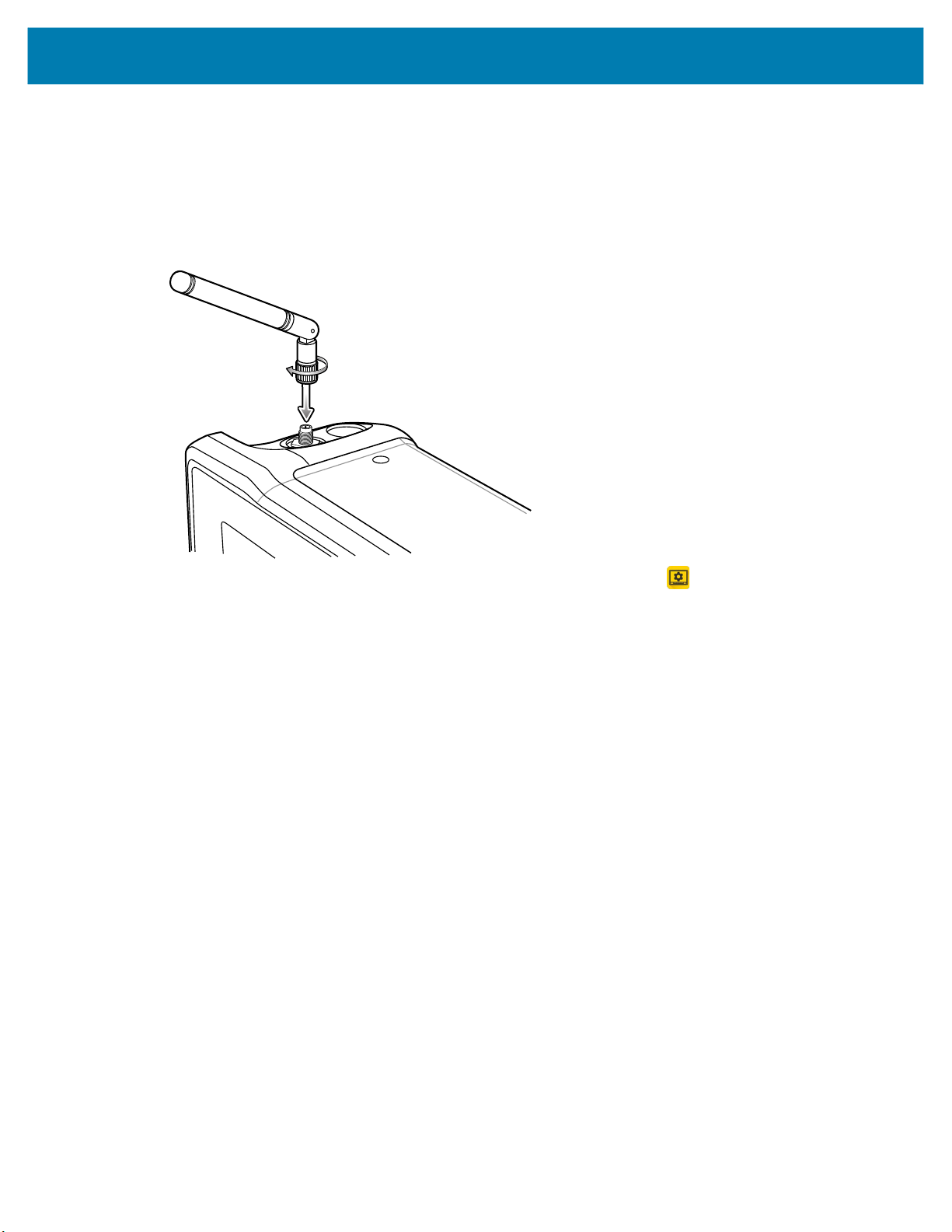

External Antenna Installation

To install an external antenna:

1. Align the antenna connector with the connector on top of the VC8300.

2. Insert the antenna connector onto the VC8300 connector.

3. Tighten the antenna connector.

Installation

4. Swipe up from the bottom of the Home screen and touch VC Setting .

5. Touch Choose Antenna.

6. Touch External Antenna.

7. Touch Home.

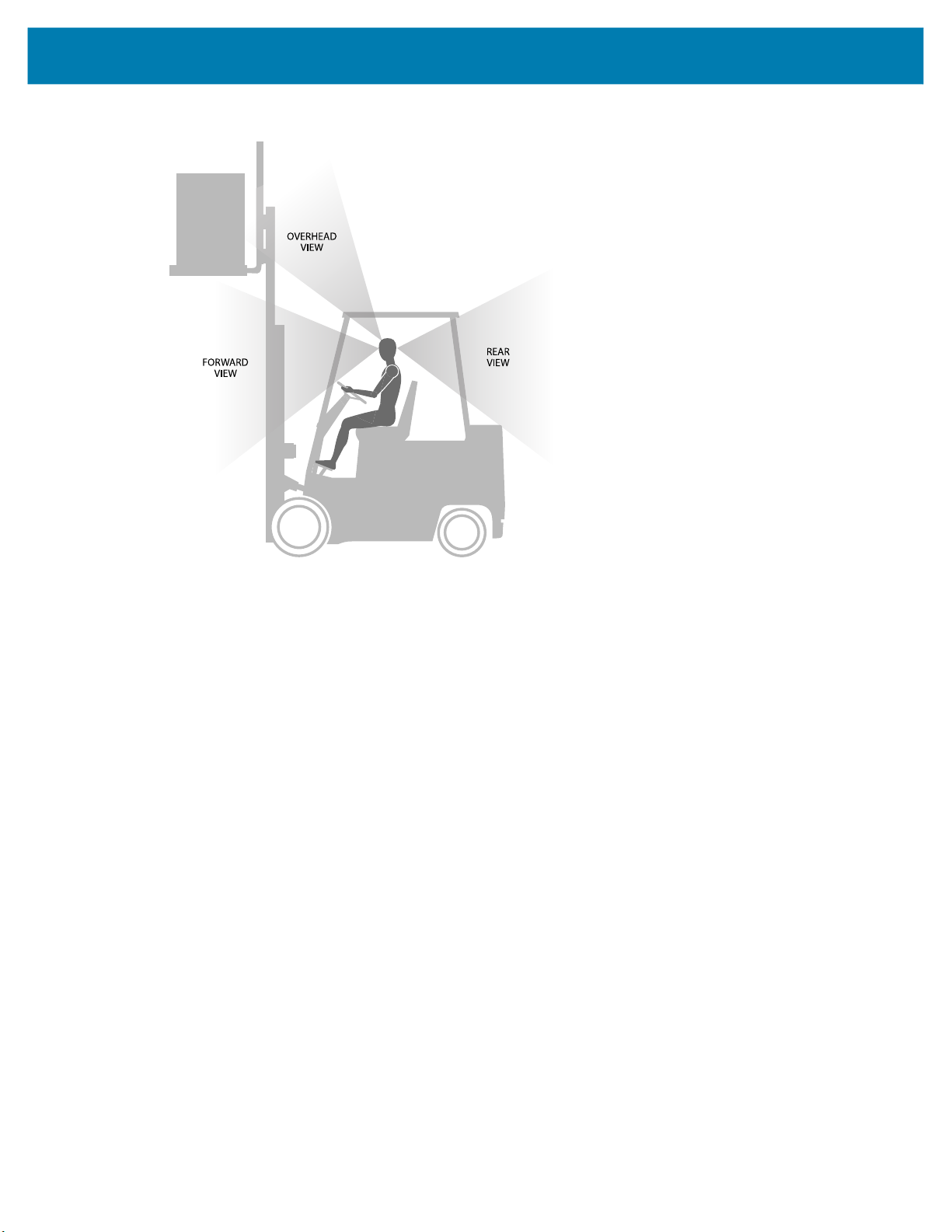

Positioning the VC8300 in the Vehicle

When positioning the VC8300 on the vehicle:

• The driver's field of view must be kept free.

• Plan for sufficient space if a keyboard and scanner are installed with the VC8300.

• No part of the VC8300 system may project beyond the vehicle.

Overview of the Assembly Steps

Before fastening the VC8300 to the vehicle:

• Configure shut down automation.

• Prepare the forklift such as ignition connection and correct voltage.

• It is recommended to fasten the bracket to the vehicle and then install the VC8300 to the bracket.

Cable Dust Cover

For the dust cover location, see VC8300 Back View with Dust Cover on page 17.

26

CAUTION: Turn on external peripheral devices with their own power supply at the same time or after the

VC8300. If this is not possible, ensure that the VC8300 is adequately protected from power leakage

caused by an external device.

Strain Relief

CAUTION: For safety reasons, install the supplied cable cover for the external ports prior to using the

VC8300.

After the VC8300 and bracket are fastened, prepare the strain relief as follows:

1. Install the cables loosely on the strain relief rail (see Figure 4 on page 18).

2. As far as possible, route cables leading to or away from the unit next to one another without crossing.

3. Fasten the cables into the strain relief rail precisely at the positions at which the cable openings in the

cable cover are located.

Installing the VC8300 on a Forklift

CAUTION: Tighten peripherals with thumbscrews by hand only. Do not use tools for tightening

thumbscrews.

Installation

NOTE: If installing peripherals, allow enough space when selecting a mounting location.

1. Attach the desired mount to the VC8300. See VC8300 Mounting Accessories on page 87 for detailed

mounting options and instructions.

2. Attach the mounted VC8300 to the vehicle and position in a location that does not obstruct the

operator’s view.

3. If using an external antenna, connect antenna in a vertical position to the VC8300.

4. Connect peripherals to the VC8300. Place the cables in the strain relief brackets inside the dust cover

and replace the dust cover (see Figure 3 on page 17).

5. Connect the VC8300 to the vehicle DC supply.

6. Press the Power button to turn the device

On or Off

(see

Figure 2 on page 17).

27

Installation

Figure 8 View Obstruction Considerations

Forklift Battery Replacement Conditions

The VC8300 maintains normal function of applications and connections during and after forklift battery

replacement.

Replace the forklift battery at any point during a shift and/or while the VC8300 is fully running.

The forklift battery may be replaced under following condition: VC8300 external temperature range: -30°C

to +50° C (-22°F to 122°F).

During forklift battery replacement (VC8300 is running on UPS battery), both Android and the VC8300 are

monitoring remaining UPS battery capacity. The default Low Battery notification threshold is set to 30%.

The Critical Battery threshold is set to 7%. If UPS battery is discharged below 7%, the VC8300

automatically shuts down.

Starting from Cold Soak

The VC8300 can to start up from a saturated cold soak at -30°C (or above) internal VC8300 temperature

when a valid external DC power source is present.

The VC8300 design minimizes wait time from -30°C cold soak to load the OS and have internal heaters to

assist system warm up.

From a -30°C cold soak condition, the VC8300 battery heater may be activated to warm the UPS battery to

an acceptable charging temperature if charging is needed. The conditions and time to heat the battery are

managed by the system. The OS load time and VC8300 ready for use time is independent of warming the

battery.

28

Installation

Pre-Heat Mode

When the device is powered down or suspended and the system temperature is below -25°C (-13°F), the

device enters pre-heat mode when the user presses the power key. This warms up critical internal

components with the heater elements prior to boot up.

When in Pre-heat mode the Power LED blinks amber.

The pre-heat mode lasts no longer than 15 minutes. The freezer configuration spends less time in Pre-heat

mode due to the additional Touch Panel heater.

The device remains powered down or suspended during Pre-heat mode. Once the system reaches the

adequate temperature, the device automatically boots up. The user is not required to press the power

button.

The device does not enter Pre-heat mode if it is outside the operating temperature range (-30°C to 50°C

(-22°F to 122°F)).

Installing the Power Pre-Regulator

IMPORTANT: The Zebra power extension cable positive lead is red and the negative lead is black.

It is recommended that all connections be secured with electrical tape or heat shrink to prevent

contaminants from degrading the connection.

To install the power pre-regulator:

1. Attach the pre-regulator cable male connector to the Zebra power extension cable which is installed on

the vehicle.

2. Connect the pre-regulator cable female connector either directly to the VC8300 power cable, or to the

power extension cable. See Figure 9.

29

Figure 9 Connections To Vehicle DC Supply

M1M7M2M8M3M9M4

M10M5M11M6M12

Installation

Without Power Pre-regulator

For vehicles with DC power 48V or less

Power Cable

Power Extension

without Ignition Sense

(p/n CA1210)

Power Extension

with Ignition Sense

(p/n CA1220)

Negative

Connection

Fuse

Positive Connection

DB9 Cable

Lines to screen-blanking

sensor (optional)

Lines to ignition switch

(optional)

Extension Wire

With Power Pre-regulator

For vehicles with DC power greater than 48V

Power Cable

Power Extension for

Pre-Regulator with

Ignition Sense (p/n

CA1230)

Negative

Connection

Power Extension

without Ignition Sense

(p/n CA1210)

Fuse

Positive Connection

DB9 Cable

Lines to screen-blanking

sensor (optional)

Lines to ignition switch

(optional)

Power pre-regulator

Extension Wire

Vehicle DC Power Source

(12 VDC to 48 VDC nominal)

Non-Vehicle Installations

Using AC power, the VC8300 Vehicle-Mount Computer can be mounted at fixed locations adjacent to cross-dock

doors, manufacturing stations, or in offices.

Use the 100/240 VAC Power Supply (p/n PS1450) to power the computer from an AC source.

IMPORTANT: The AC/DC power supply is only intended for use at room temperature condition such as an office

environment.

Power On/Off with Ignition

The VC8300 is equipped with an ignition sense feature which shuts down the VC8300 when the vehicle ignition is

turned off and can power on the VC8300 when the ignition is switched on. To use this feature, a power extension

cable with ignition sense wires must be used and installed properly on the vehicle.

The cable in Figure 10 is the power extension cable (p/n CA1220) with two wires used to connect to vehicle ignition.

The red and black leads of the two 18AWG wires that connect to the key switch of the ignition and ground,

respectively. Once the wires are connected, the VC8300 may switch on or off depending on the state of the vehicle

ignition key. See VC Settings on page 56 to select power settings.

Vehicle DC Power Source

(12 VDC to 48 VDC nominal)

30

Loading...

Loading...