Page 1

Zebra® T300™ Printer

Maintenance Manual

Part # 547001L Rev. 2

Page 2

Zebra® T300 Printer

Maintenance Manual

Revision 2

Registration Form

ZEBRA TECHNOLOGIES CORPORATION

To receive maintenance manual revisions

and updates, complete this form and fax

o r mail it t o Zebra Technologies at th e

fax number or ad dress shown below.

COMPANY

ADDRESS

CITY

STATE, ZIP

PHONE # ( )

CONTACT:

Zebra Technologies Corporation

333 Corpor ate Woods Parkway

Vernon H ills, Illino is 60060-3109 U.S.A.

ATTN: Technical Training Group

Part # 547001L Rev. 2 Page i

FAX Number: +1 (847) 821-1492

Page 3

NOTES

Page ii Part # 547001L Rev. 2

Page 4

Zebra T300 Printer Maintenance Manual

Table of Contents

TABLE OF CONTENTS

INTRODUCTION

................................................................................................................................

IMPORTANT NOTES

SPECIFICATIONS

SETTING UP THE PRINTER AND SOFTWARE

Operating the Printer.......................................................................................................................................................5

Printer Operating Modes.............................................................................................................................................5

Printing Method..........................................................................................................................................................5

Operator Controls........................................................................................................................................................5

Printer Troubleshooting Indicator Lights.....................................................................................................................7

Initial Printer Power-Up ..............................................................................................................................................7

Adjusting for Different Media Widths.........................................................................................................................8

Adju s ting for Di ffe rent Ribbon Widths........................................................................................................................8

Ribbon Loading Procedure..........................................................................................................................................9

Media Loading Procedure..........................................................................................................................................10

Calibration Procedure................................................................................................................................................11

.....................................................................................................................ii

.........................................................................................................................

..............................................................................................................................

............................................................................

1

1

1

5

Setting Up the Software................................................................................................................................................. 12

BAR-ONE System Requirements..............................................................................................................................12

BAR-ONE Installation..............................................................................................................................................12

TROUBLESHOOTING

PREVENTIVE MAINTENANCE PROCEDURES

Lubrication................................................................................................................................................................15

CORRECTIVE MAINTENANCE PROCEDURES

Fine Pr i nthead Adjust ment ............................................................................................................................................16

Platen Roller Replacement.............................................................................................................................................17

Remove the old Platen Roller ....................................................................................................................................17

Install the new Platen Roller......................................................................................................................................18

Ribbon Handler Rep lacem ent.........................................................................................................................................19

Remove the old Ribbon Ha ndle r Assembly................................................................................................................19

Install the new Ribbon Handler Assembly. ................................................................................................................19

Pri nthea d Rep lacement .................................................................................................................................................. 20

Remove the old Printhead..........................................................................................................................................20

Install the new Printhead...........................................................................................................................................21

......................................................................................................................

...........................................................................

..........................................................................

13

15

16

Part # 547001L Rev. 2 Page iii

Page 5

Zebra T300 Printer Maintenance Manual

Replacing the Main Logic Board ...................................................................................................................................22

Remove the old Main Logic Board............................................................................................................................22

Install the new Main Logic Board .............................................................................................................................22

Control Panel Circuit Board Replacement......................................................................................................................24

Remove the old Circuit Board...................................................................................................................................24

Install the new Circuit Board ....................................................................................................................................25

Dri ve Mot or Replacement ..............................................................................................................................................26

Remove the old Drive Motor.....................................................................................................................................26

Install the new Drive Motor......................................................................................................................................27

Media Sensor Harness Assembly Replacement...............................................................................................................28

Remove the old Media Sensor Harness Assembly...................................................................................................... 28

Install the new Media Sensor Harness Assembly.......................................................................................................28

MAIN CIRCUIT BOARD LAYOUT

MECHANICAL DRAWINGS

Replacement Parts.........................................................................................................................................................31

............................................................................................................

.................................................................................................

List of Tables

Table Description

1 Specifications........................................................................................................................................ 1

2 Feed Key Troubleshooting Modes......................................................................................................... 6

3 Printer Troubleshooting Indicator Lights.............................................................................................. 7

4 System Requirements...........................................................................................................................12

5 Troubleshooting Chart.........................................................................................................................13

6 Cleaning Schedule...............................................................................................................................15

7 Replacement Parts ...............................................................................................................................31

8 Maintenance Kits.................................................................................................................................31

30

31

Page iv Part # 547001L Rev. 2

Page 6

Zebra T300 Printer Maintenance Manual

List of Illustrations

Figure Description

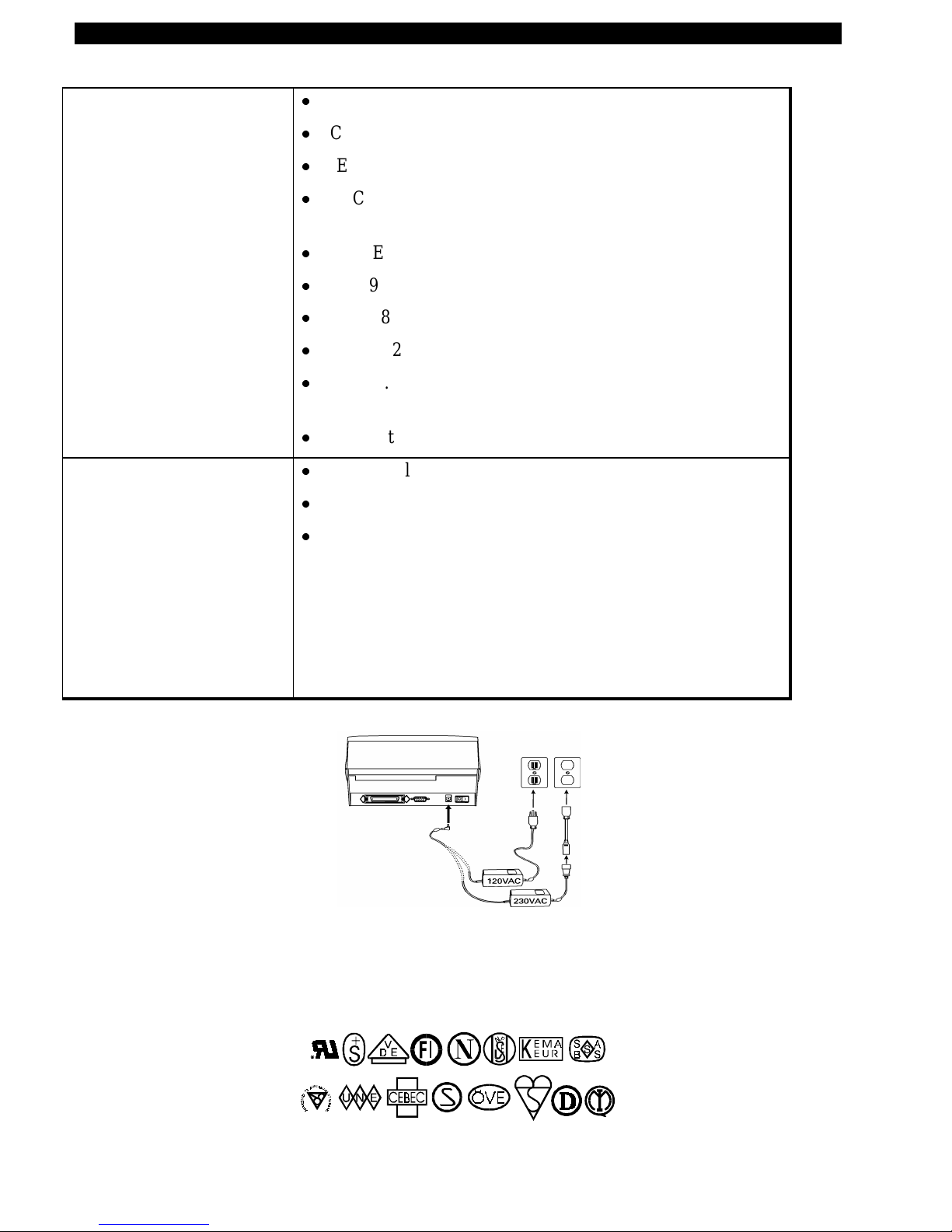

1 120 and 230 VAC Power Line Cords .................................................................................................... 4

2 Examples of International Safety Organizations Symbols...................................................................... 4

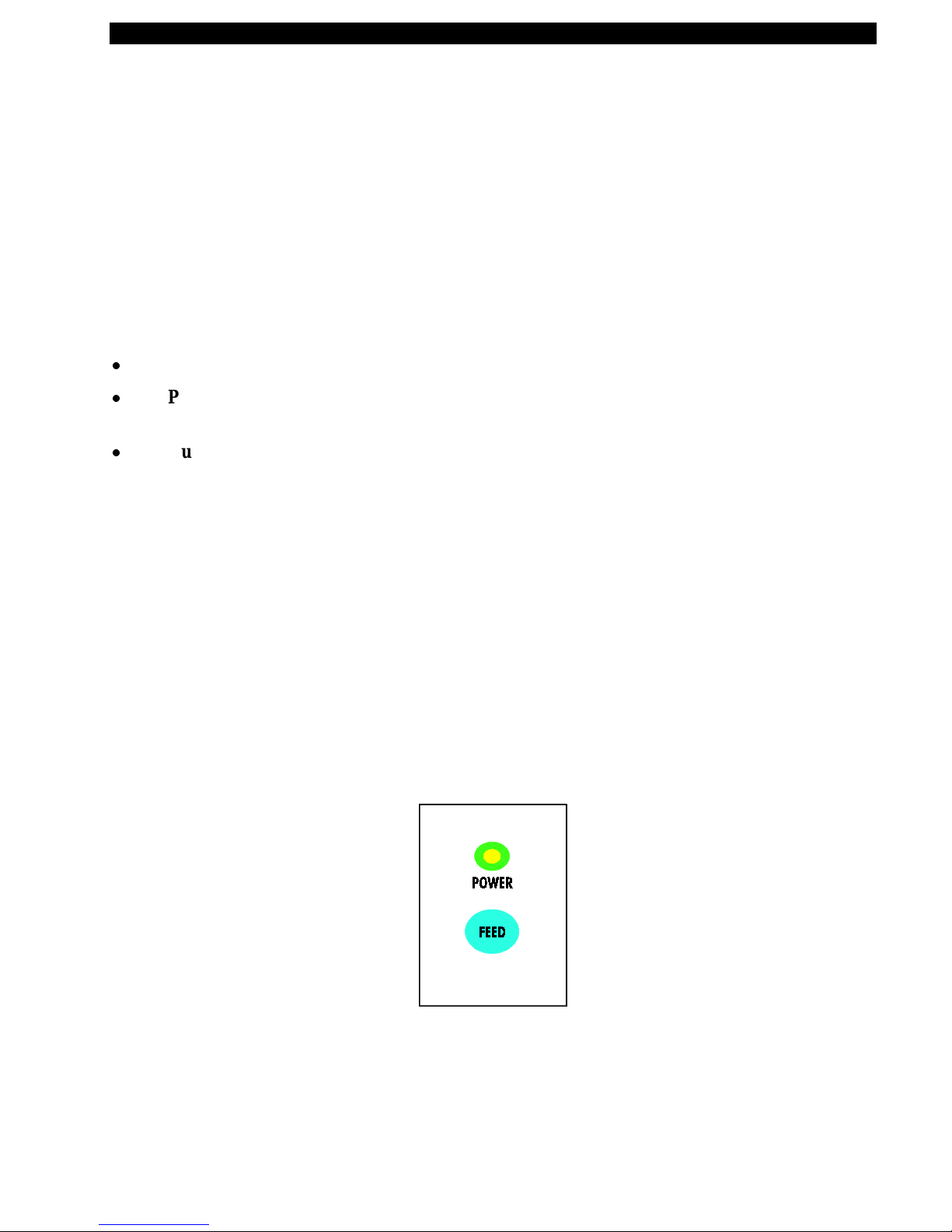

3 Operator Controls................................................................................................................................. 5

4 Configuration Label (Sample) ............................................................................................................... 6

5 Adjusting for Different Media Widths...................................................................................................8

6 Adju s ting for Di ffe rent Ribbon Widths.................................................................................................. 8

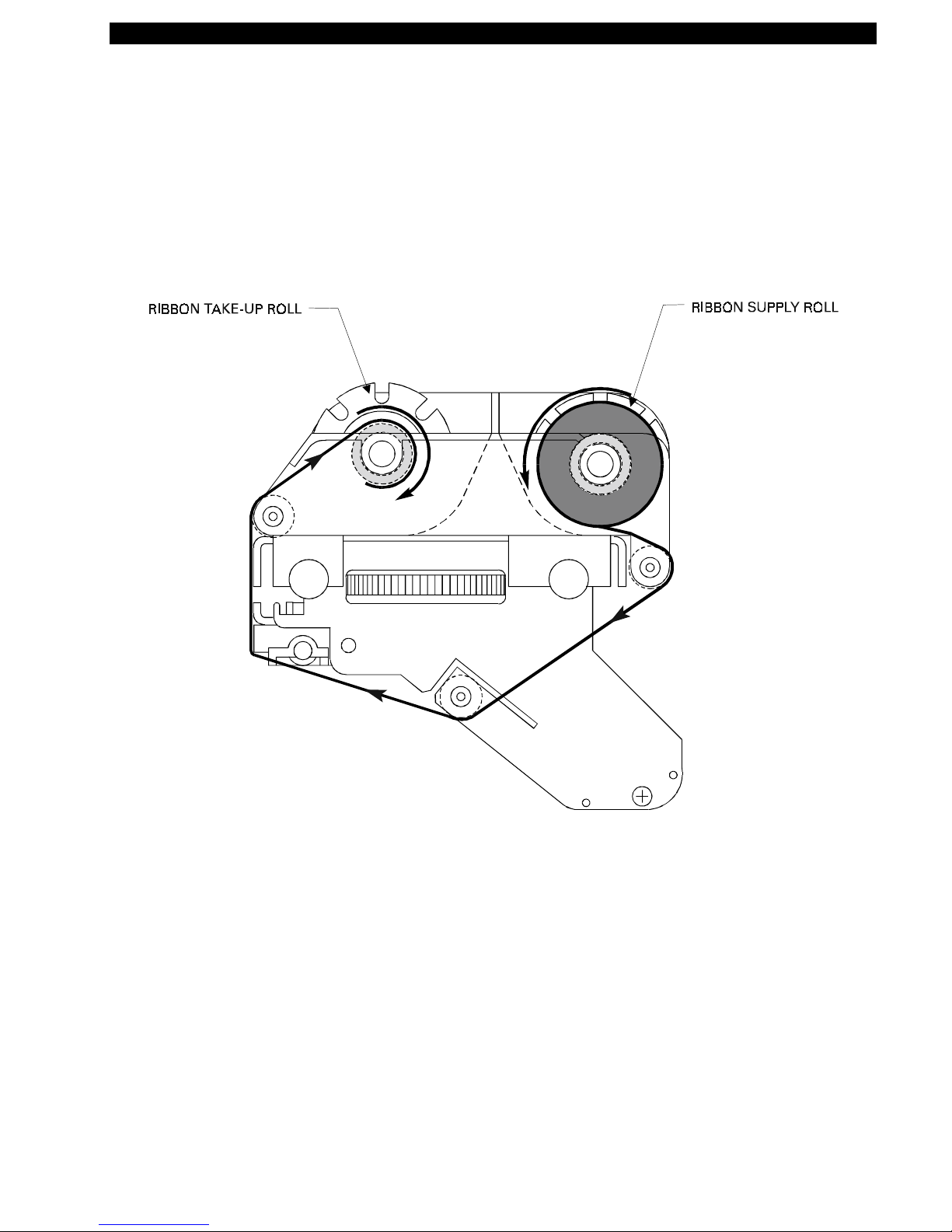

7 Ribbon Loading Di agram...................................................................................................................... 9

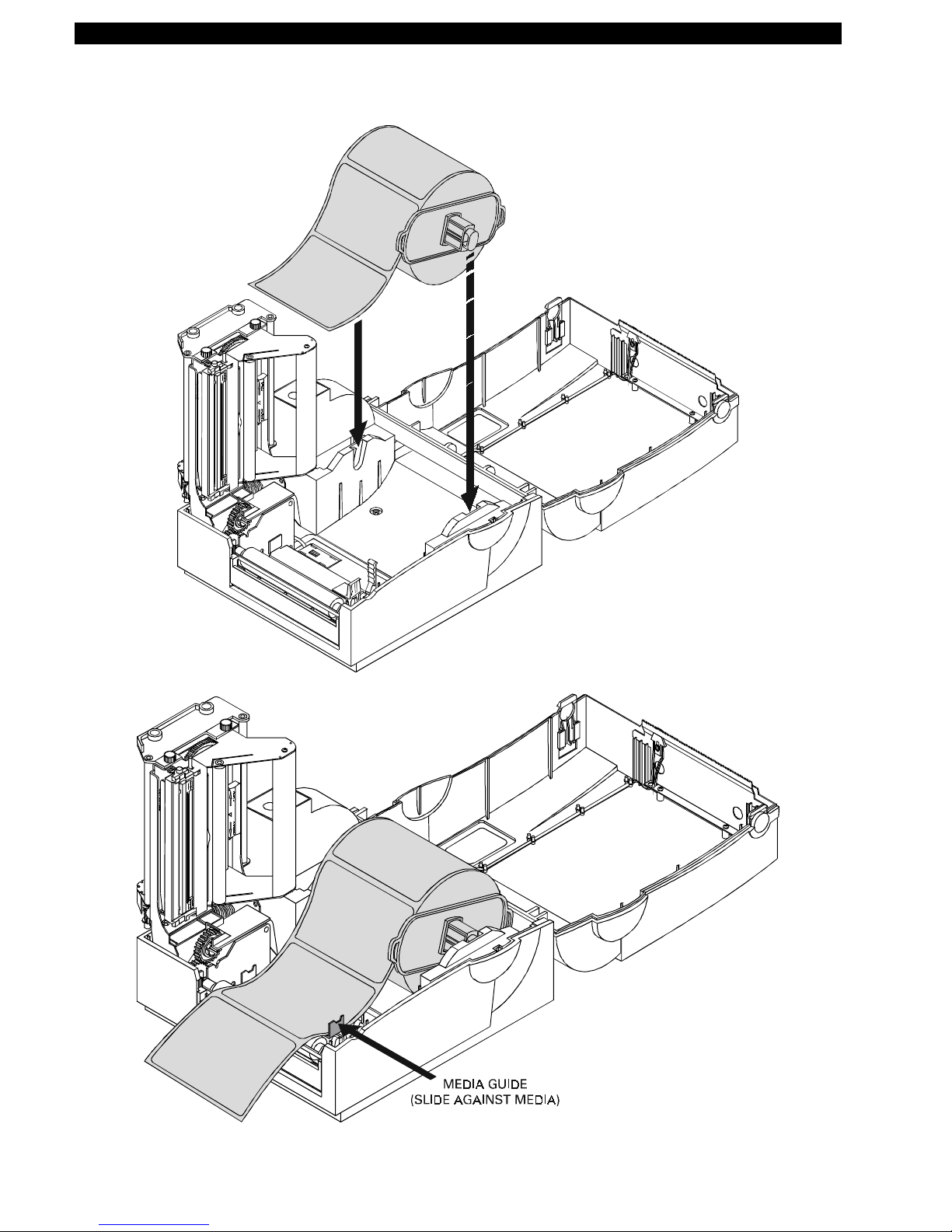

8 Media Loading Diagram..................................................................................................................... 10

9 Media Sensor Profile (Profile).............................................................................................................11

10 Disassembling and Cleanin g of the Ribbon Supply and Take-up Spindles ........................................... 14

11 Fine Printhead Adjustment..................................................................................................................16

12 Installation and Removal of the Platen Roller...................................................................................... 17

13 Cover Removal and Electrical Connector Location.............................................................................. 18

14 Ribbon Handler Assembly Replacement .............................................................................................. 19

15 Removal of the Printhead Cable and Screw.........................................................................................20

16 Main Logic Board Removal/Reinstall..................................................................................................23

17 Tower Enclosure Removal................................................................................................................... 24

18 Control Panel Circuit Board Installation ....................................................................................... ...... 25

19 Drive Motor Replacement...................................................................................................................26

20 Removal of the Media Sensor Harness Assembly................................................................................. 29

21 Main Circuit Board Layout ................................................................................................................. 30

22 Media Support Kit .............................................................................................................................. 32

23 Cutter Module Kit............................................................................................................................... 32

24 Media Guide Kit.................................................................................................................................33

25 Ribbon Out Se nsor Assembly Kit ........................................................................................................ 33

All trademarks are the property of their respective owners. Zebra is a registered trademark of Zebra Technologies

Corporation.

© 1997 Zebra Technologies Corporation. All rights reserved.

Part # 547001L Rev. 2 Page v

Page 7

Zebra T300 Printer Maintenance Manual

NOTES

Page vi Part # 547001L Rev. 2

Page 8

Zebra T300 Printer Maintenance Manual

INTR ODUCTION

For information on any of the following topics, please refer to t he T300 User’s Guide:

x

Unpacking and inspection

x

Additional requirements

x

Setting up the printer and software

x

Preventive maintenance

x

Troubleshooting

x

Specifications

x

Additional information specific to particular configurations of the T300 printer.

IMPORTANT NOTES

Any maintenance performed by unauthorized personnel on a T300 printer voids the warranty.

WARNING:

DANGER OF ELECTRICAL SHOCK IF POWER SUPPLY IS DISASSEM BLED!

THERE ARE NO SERVICEABLE COMPONENTS INSIDE THE POWER

SUPPLY. SERIOUS SHOCK HAZARDS ARE PRESENT INSIDE THE POWER

SUPPLY CASE, EVEN WITH TH E PO WER S W ITCH OFF.

SPECIFICATIONS

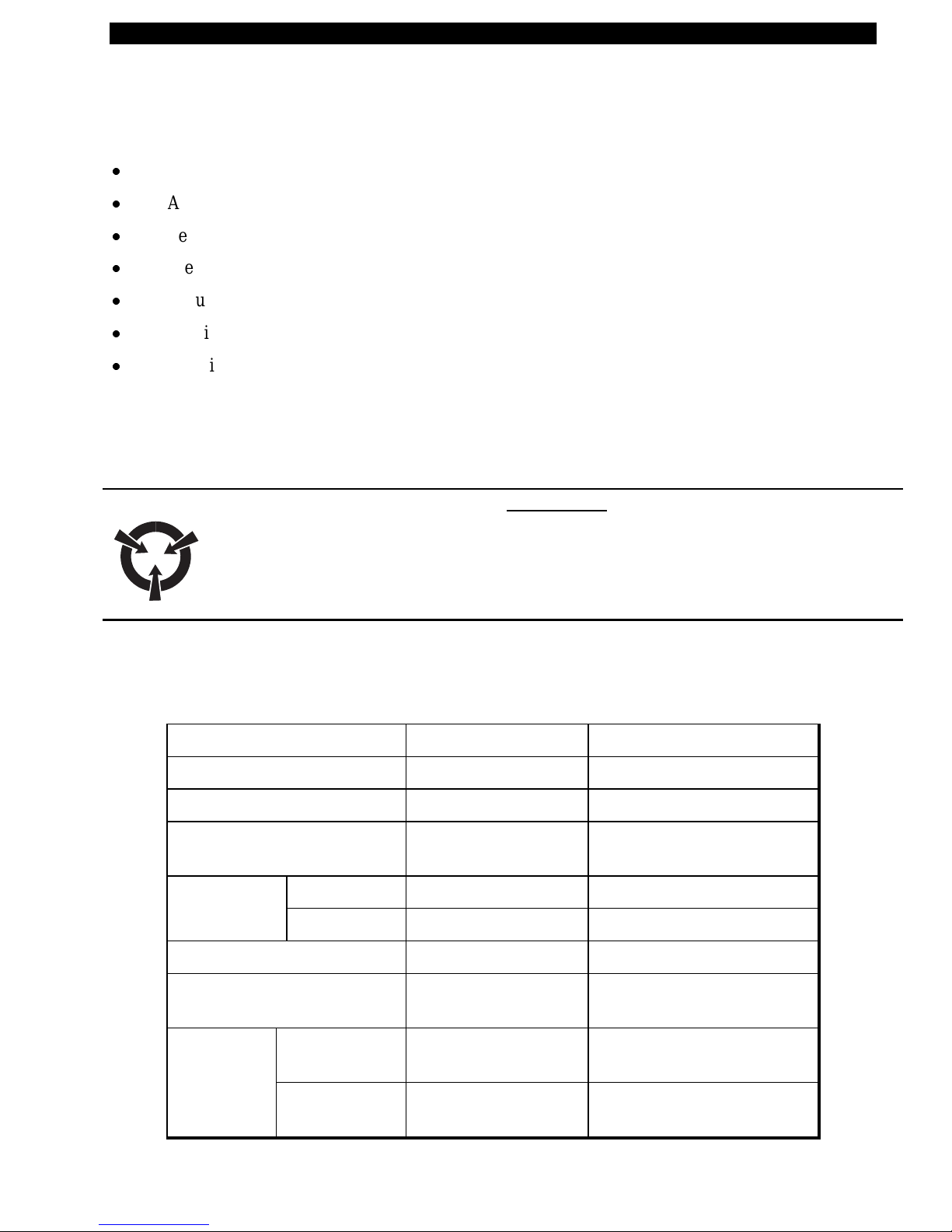

Table 1. Specifications

Print density 203 dots/inch 8 dots/mm

Print width 1 to 4.125 inches 25.4 mm to 104.0 mm

Print Speed 2 in/sec., 1.5 in/sec. 50 mm/sec, 38 mm/sec

Label width (including

backing material, if any)

Label length Tear off 0.50 to 18 in. 12 mm to 457 mm

Cutoff/Peel 1 to 18 in. 25.4 mm to 457 mm

1.0 in to 4.65 in. 25.4mm to 118 mm

Interlabel gap 0.08 to 0. 16 in. 2 mm to 4 mm

Label t hickness (includ ing

backing material, if any)

La bel roll Ma x. outer

diameter

Size Min. inner

core diameter

Part # 547001L Rev. 2 Page 1

0.003 to . 010 in. 0.076 mm to 0.25 mm

4.0 in. 101 mm

1.0 in. 25.4 mm

Page 9

Zebra T300 Printer Maintenance Manual

Registration Horizontal ± 0.059 in. ± 1.5 mm

tollerance Vertical ± 0.0393 in. ± 1.0 mm

Inter-label gap .08 in to .16 in. 2 mm to 4 mm

First dot location (from outer

0.060 to 0. 140 1.5 mm to 3.5 mm

media edge)

Ribbon r oll

size

Max. outer

diameter

Min. inner c ore

1.5 in. 38 mm

0.50 in. 13.0 mm

diameter

Max. Length/Ribbon Roll 360 ft. 110 mm

Ribbon Mar. Width/Roll 1.0 in. to 4.25 in. 25.4 mm to 108 mm

Physical size (LxWxH) 10.1 x 8.8 x 6.2

256mm x 223mm x 157mm

in.

Weight (without media) 7 lbs 3.18 kg

Shipping Weight 10 lbs 4.54 kg

Temperature Operating 40° to 100° F 4° to 38° C

range Storage -4° to 140° F -20° to 60° C

Re lat iv e humidit y, o peration and

10 to 90% non c ondensing

sto rage

Media requirements Zebra recommends using Zebra-brand thermal transfer media

that is outside-wound (the label or printing surface is wound

on the out side of the backing). Media may be roll or fanfold,

transmissive or reflective (black-mark) sensing; continuous,

die-cut or not ched.

Notched media:

notch must be 1/4 inch wide x 3/32 inch

long located on the left side of the label as viewed from the

front of the printer.

Black-mark media:

marks must be located w ithin 1 mm o f

the left edge of the media as viewed from the front of the

printer;

Mark thickness: 0.12 - 0.43 inches (3 mm - 11 mm);

Mark width: 0.43 inches (11 mm) - full media width; mark-

to-mark leading edge registration tolerance ±0.016 inch (± 0.4

mm);

Mark density >1.0 ODU (Optical Density Unit);

Ma ximum density of th e back of the media on wh ich the

black mark is printed: 0.5 ODU.

Page 2 Part # 547001L Rev. 2

Page 10

Zebra T300 Printer Maintenance Manual

Ribbon r equirements Zebra recommends use of Zebra-brand ribbon which is

inked on the inside surface. (Use tape to see which

side is inked.)

Fonts available

Bar codes available

x

CG Triumvirate Bold Condensed (6, 8, 10, 12, 14,

18 pt)

x

Zebra fonts A, B, C, D, E (OCR-B), F, G, H

(OCR-A), IBM® Code Page 850 (International

Characters, Gr aphics symbols)

x

Codabar (supports

ratios of 2:1 to 3:1)

x

Code 11

x

Code 128 (support s

se rialization in all

subsets and UCC

Case Codes)

x

Code 39 (support s

ratios of 2:1 to 3:1)

x

Code 93

x

EAN Version 8 and

13, EAN

Extensions

x

Industrial 2 of 5,

x

Interleaved 2 of 5

(supports rat ios of 2:1 to

3:1, Modulus 10 Check

Digit)

x

LOGMARS

x

MaxiCode

x

PDF 417

x

MSI

x

Plessey

x

POSTNET

x

UPC Versions A and E,

UPC Extens ions with 2

and 5 digit supplements.

Standard 2 of 5

Electrical External 120 or 230 VAC power supply, depending on

which model you order. Additional custom line cords

may also be available.

Communications 36-pin Centronics® compatib le pa rallel port; 9-pin RS-

232 serial port

Processor 32-bit microprocessor, 512 K Ram

Seria l data cable Sh ould us e twisted shielded pairs, not lo nger than 6 ft

(1.8 mm) a s recommend ed in the Appendix of the

TIA/EIA-485 Specification

Para llel da ta cable For maximum reliability, us e a p arallel data ca ble no

longer than 6 ft (1.8 mm)

Part # 547001L Rev. 2 Page 3

Page 11

Zebra T300 Printer Maintenance Manual

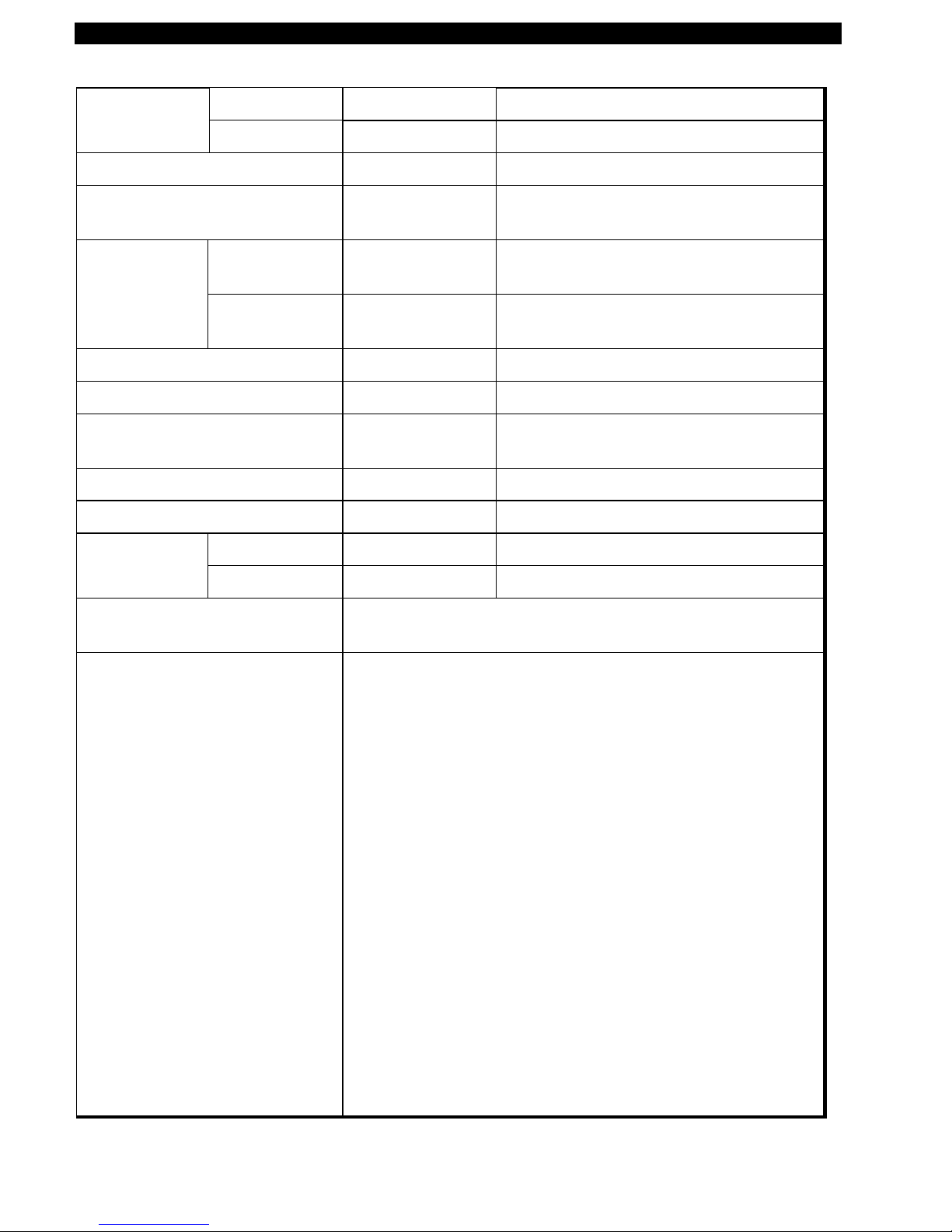

Agency approvals

Power line cord

x

UL 544 Medical Equipment Standard Part 42.5

x

CSA 22.2 No. 950 Canadian Safety Standard

x

IEC 950/EN 60950 International Safety Standard

x

FCC Part 15 Subpart B Level A Electro magnetic Radiation

Standard

x

AAME Medical Standard part 4.3. 2

x

UL 1950 Domestic Safety Standard

x

SOR/88-475 Canadian Electromagnetic Radiation Standard

x

EN50082-1 International Immunity Standard

x

C.I.S. P . R. -22 Class B European Electromagnetic Radiation

Standard

x

Ca rries the CE ma rk of compliance

x

Th e overall length must be less than 12.5 ft (3.8 meter s)

x

It must be rated for a least 3A, 250V.

x

The chassis ground (earth) MUST be connected t o assure

safety and reduce electromagnetic interference. The ground

connection is handled by the third wire (earth) in the power

line cord. (See Figure 1.)

The AC power plug and IEC 320 connector must bear the

certification mark of at least one international safety

organization. (See Figure 2.)

Figure 1. 120 and 230 VAC Power Line Cords

Figure 2. Examples of International Safety Organizations Symbols

Page 4 Part # 547001L Rev. 2

Page 12

Zebra T300 Printer Maintenance Manual

SETTING UP THE PRINTER AND SOFTWARE

Operating the Printer

To create a label for the Zebra T300, you may either use the BAR-ONE® software t o create the label

format or write o ne in ZPL II®, which is Zebra’s pro gramming language for crea ting labe ls. If you are

using BAR-ONE® software, refer to the BAR-ONE help files (us_man.exe). If you are using, or plan

t o use the ZPL II programming language to for mat your labels, make su re you h ave a copy of th e

II Programming Guide

Printer Operating Modes

x

Tear-Off Mode.

x

Peel-Off Mode.

waits until t he o perator remov es the label, then the n ext labe l is print ed.

x

Cutter Mode.

cut automatically af ter it is print ed.

(Zebra PN 46469L).

The operator tears off a single label (or a strip of labels) after printing.

The backing material is peeled away from the label as it is printed, the printer

(A vailab le only with factory in stalled Optio nal Cutter Module. ) Each label is

ZPL

Printing Method

Thermal Transfer.

onto the media to form an image.

Operator Controls (See Figure 3)

Power Switch.

connecting or disconnecting an y cables

Feed Key.

the printer to feed a blank label. The Feed Key also activates a number of specialized functions that

are described in Table 2.

In normal u se, pr essin g t he Fe ed Key once when the pr inter is idle (no t p rinting) will c aus e

(Requires use of thermal transfer ribbon.) The printer t r ansfers ink from a ribbon

Located o n t he rear of the printer

.

. The power switch should b e t u rned off before

Part # 547001L Rev. 2 Page 5

Figure 3. Operator Controls

Page 13

Zebra T300 Printer Maintenance Manual

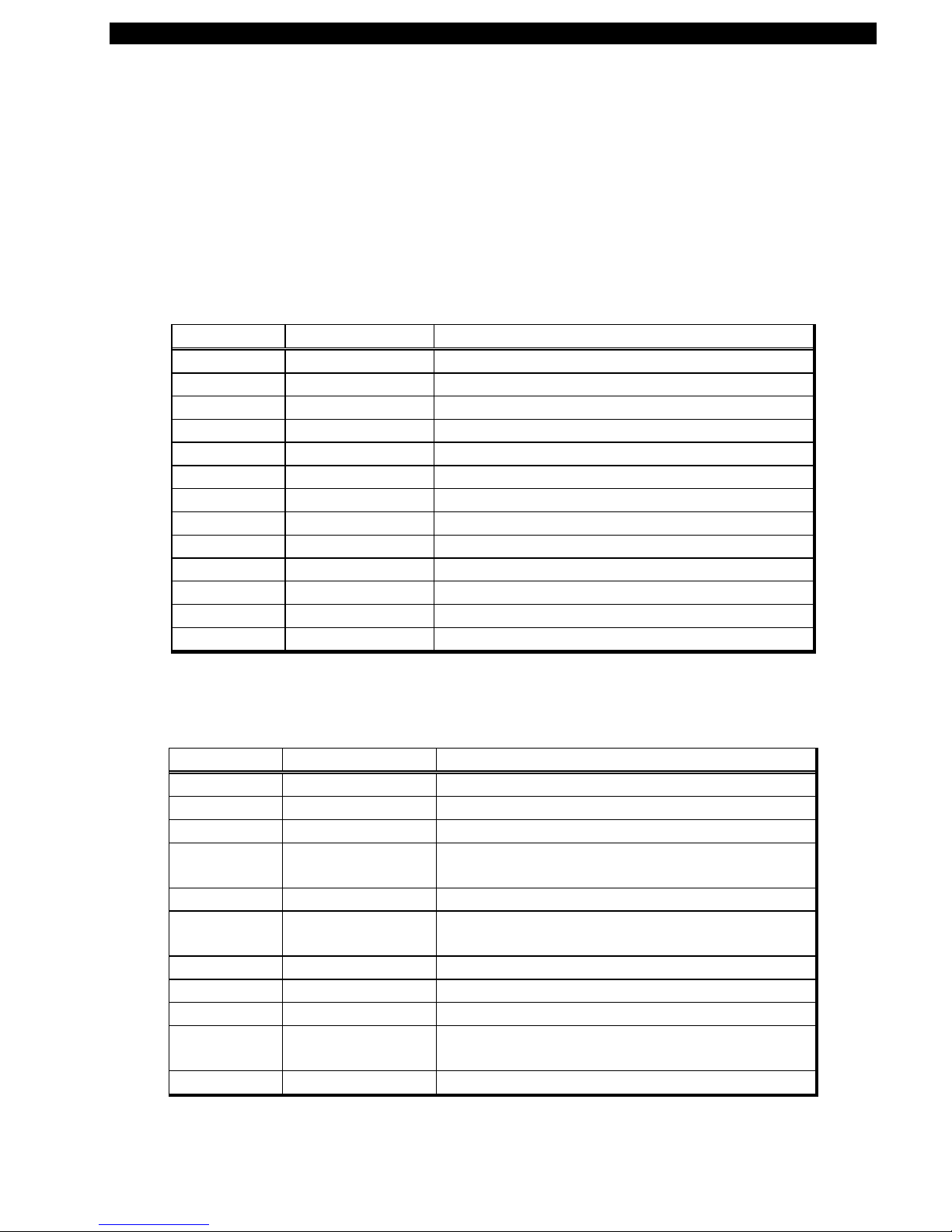

Table 2: Feed Key Troubleshooting Modes

Power Off Mode (Communications Diagnostics Mode)

With the printer power off, press and hold the Feed key while you turn the power on. The

printer prin ts out a listing of its current configu ratio n (configuration label). ( See Figure 4.)

For best results, use media that is at least 4 inches wide by 4 inches long. After printing the

label, the prin ter will automatically enter a diag nos tic mode in wh ich the printer print s out a

literal representation of all data subsequently received (communications diagnostics). To

exit this mode , t urn the prin ter power off.

Power On Modes

With the printer powered on, printhead closed, and Power light on, press and hold the Feed

key for sev eral seconds a n d t h e Power Light will begin t o step th ro ugh a series of flash

sequences. Each sequence consists of a different number of flashes as shown in the

following table. The correspo nding explanation indicates what happens when you release

the Feed key after each flash sequence.

Sequence Number of

Results

flashes

1 1 The label sho wing the curre nt con figuration of the printer is

printed. For best results, use media that is at least 4 inches wide

by 4 inches long. (See Figure 4.)

2 2 The media sensor calibration process is started (see calibration

procedure).

3 3 The serial commu nication parameters are reset to 9600 baud, 8

bit word length, no parity and 1 st op bit

4 4 Reset the printer to factory defaults. Once this mode is entered,

t he Power light will flas h rapidly. Press and release th e Feed k ey

one more time and the factory default values are saved into

memory.

Figure 4. Configuration Label (Sample)

Page 6 Part # 547001L Rev. 2

Page 14

Zebra T300 Printer Maintenance Manual

Printer Troubleshooting Indicator Lights.

Table 3: Printer Troubleshooting Indicator Lights

Power Light Printer Condition

Off Power is off or printer not r eceiving power

On Power is on

Flashes once

every 3 seconds

Printer failed internal diagno stics. Call a

Service Technician.

after power-up

x

Paper out or not sensed

x

Ribbon out

Flashing

x

Needs calibration

x

Printhead is over temperature

x

Cutter error

Initial Printer Power-Up

Turn the pr inter on by toggling the P ower Switch on the rea r o f the pr inter. The Powe r ligh t will tu rn

on. The printer performs a set of internal diagnostics, and after the diagnostics have been completed

(within 1-10 s e conds), the motor may sta rt briefly.

If loading the printer with media for the first time or if you are changing the type of media you’re

using, perform the calibration procedures (see calibration procedure).

Part # 547001L Rev. 2 Page 7

Page 15

Zebra T300 Printer Maintenance Manual

Adjusting for Different Media Widths

The thumbwheel on the side of the Printhead allows the Printhead pressure to be adjusted. To adjust,

rot ate the thumbwheel in a clockwise direction to reduce the pressure o n t he right edge of the

Printhead. If the right edge printing seems to be too light, then rotate the thumbwheel slightly

counte rclockwise to achieve unifor m prin t quality across the label. (See Figure 5.)

Figure 5. Adjusting for Different Media Widths

Adjusting for Different Ribbon Widths

Refer to Figu re 6. If you are using narrow ribbon, hold the r ibbon spindle while turning the ribbon

t ension adjustment knob clockwise. For full-width ribbon, turn t he knob counter -clockwise until it

reaches the stop . I f your ribbon is somewhere in-between, experiment until you achieve acceptable

print quality.

Figure 6. Adjusting for Different Ribbon Widths

Page 8 Part # 547001L Rev. 2

Page 16

Zebra T300 Printer Maintenance Manual

Ribbon Loading Procedure (See Figure 7)

Part # 547001L Rev. 2 Page 9

Figure 7. Ribbon Loading Diagram

Page 17

Zebra T300 Printer Maintenance Manual

Media Loading Procedure (See Figure 8)

Figure 8. Media Loading Diagram

Page 10 Part # 547001L Rev. 2

Page 18

Zebra T300 Printer Maintenance Manual

Calibration Procedure

This calibration procedure should be performed the first time you use the printer and any time you

change the type of media in t he printer.

1.

2.

Turn the pr inter p ower on if it is not already on.

Re move sev eral labe ls from a s ection of b ack ing material s o that o nly th e backing mater ial is

under the printhead mechanism and media sensor .

3.

Pres s and ho ld the Feed K ey until the Power light flash es twic e in a row. (Fir st it will flash

once, then twice in a row at which point you release the key.)

4.

The printer will adjust the me dia s ensor level for the media backing you are using. After it is

done making t his adjustment, the Power light will flas h rapidly.

5.

6.

Reload the media so that a label is under the printhead and over the media sensor.

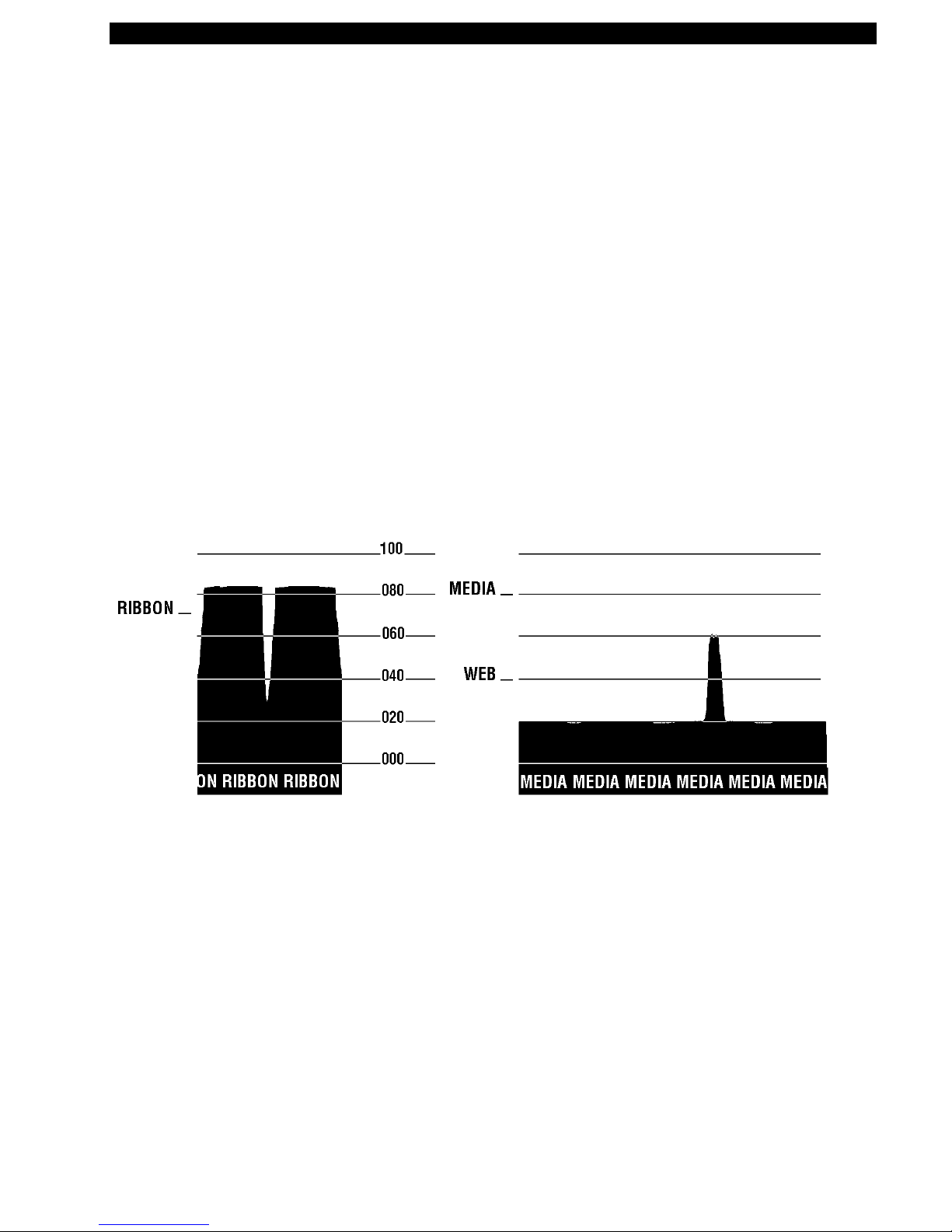

Pres s and re lease the Feed K ey. A profile of the media sens or settings will print. See Figure 9.

When comple te, the p rinter will save the new settin gs in memory and the printer is read y for

normal operation.

Part # 547001L Rev. 2 Page 11

Figure 9. Media Sensor Profile (Sample)

Page 19

Zebra T300 Printer Maintenance Manual

Setting Up the Software

Note:

If you plan to use BAR-O NE s oftwa re to create your labels, you w ill need to ins tall the

software on you computer before you can operat e your printer.

You will not need to use BAR-ONE s oftware if you a re printing label formats cr eated in ZPL II. To

print ZPL II, you may use practic ally any tex t p ro gram on any comp uter tha t w ill send ASCII text to

the printer via either the serial or parallel port. For more information, refer to the

Programming Guide

(Zebra PN 46469L).

BAR-ONE System Requirements

BAR-ONE software works with most IBM compatible per sonal computers available today. The

software may b e installed an d up-and- running w ithin a few minutes. Re fer to the on-line help syst em

and to the Read-Me file for further information and/or last-minute updates. The BAR-ONE software

may be installed on any personal computer that meets the system requirements in Table 4:

Table 4. System Requirements

BAR-ONE Software Minimum Recommended

ZPL II

Processor 486SX 486DX

Hard disk 3 MB 10 MB

Memory 4 MB RAM 8MB RAM

Interface RS-232 Parallel

Display VGA SVGA

Floppy drive 3-1/2 Inch

Operating system Windows™ 3.1 or higher, NT,

95; OS/2.2.1 or later

Mouse RS-232 or PS/2

BAR-ONE Installation

The Zebra T300 printer uses the Windows™ based BAR-ONE software or ZPL II Pro gr amming

La nguage commands. To install BAR -ONE software:

1.

2.

3.

Start Windows.

Insert disk 1 of the BAR-ONE software in your floppy disk drive (A: or B:).

In Program Manager, click on the

from th e

Start

menu.)

File

menu. Select

Run

. (Windows 95 users: select

Run

4.

5.

Page 12 Part # 547001L Rev. 2

Type

A:\SETUP

B:\SETUP

(or

Follow the o n-screen instructions to complete the installa tion.

) and then press OK.

Page 20

Zebra T300 Printer Maintenance Manual

TROUBLESHOOTING

Table 5. Troubleshooting Chart

SYMPTOM DIAGNOSIS ACTION

Po wer light does not

turn on when Power

sw itc h is turn ed on.

Whe n pr in ter is first

powered on, t he Power

light flashes every 3

seconds.

Po wer light is flashing.

For more information,

see Table 3.

Long tracks of missing

print (blank vertical

lines) on several la bels.

Printer is not receiving

power.

Make sure that the power supply is plugged into

the printer and into a wall outlet, power st rip, or

other source of power.

Printer Failed an in ternal

Turn printer off and then back on.

diagnostic test .

Out of media/ribbon or

media/ribbon incorrectly

loaded.

Load media correctly. Make sur e that the media

is placed to t he left edge of the platen roller and

that it feeds under the Printhead, otherwise, it

may not be detected by the media sensor.

Printhea d is overheated. Allo w print er to cool. Pr inting resumes

automatically when the Printhead cools to

operat ing temperature.

Needs calibra tion Ca librate the pr inter (see Calibration procedures).

Cutter (optional) error. Clean the cutter.

Printhead is dirty. Clean the Printhead. (See Table 6.)

Print element is damaged. Call a service technician to r eplace the Printhead.

Poor p rint quality. Printhead is dirty. Clean the P rinthead. (See Table 6.)

Ribbon tension is not set

correct ly.

Change the ribbon tension knob to t he ot her

se tting. Ge n erally, set it clockwise for narrow

ribbon a nd cou nter-clockwise for wid e ribbon.

Media Width adjustment

incorrect.

Adjust the media width thumbwheel on the side

of the printhead (see adjusting for different media

widths, figure 5).

Mis-registration

(location of printed

Printer needs to be

calibrated.

Recalibrate the printer. (See Calibration

procedure).

information changes on

t he lab el, from label to

label).

Ribbon tension is not set

correct ly

Change the ribbon tension knob to t he ot her

se tting. Ge n erally, set it clockwise for narrow

ribbon a nd cou nter-clockwise for wid e ribbon.

Part # 547001L Rev. 2 Page 13

Page 21

Zebra T300 Printer Maintenance Manual

SYMPTOM DIAGNOSIS ACTION

A lab el format wa s

sent to the printer but

Communications

parameters are incorrect.

not reco gnized.

Problem with the data

cable.

Ribbon Wrinkle Print head Pressur e

Misadjusted

In the Peel Mode, liner

Liner is slipp ing Open the Peel-off Lever. Pull the liner until it is

bulges out from the

Peel Bar and may

block the Label

Present Sensor .

Ribbon T ake-U p

Spindle rotation is not

smooth and c onsiste nt.

Dirt build-up on the R ibbon

Supply and Ribbon Take-

Up Spindle Hubs.

Ribbon may exit

printer still bonded to

t he lab el.

For serial communication, make sure that the

baud rates of the printer and the computer match.

Also, make sure that the correct com port o n t he

PC is connected to the printer.

Make sure the data cable is installed correct ly.

For serial operation, make sure you are using a

“null modem” cable.

Rotate the Printhead Pressure Adjustment

Thumbw heel until wr inkle is eliminated. (Light

print will r esult if the Thumbwhe el is turned too

far) . Change ribbon te ns ion setting if pro blem

persists. A fine printhead adjus tment may be

required (see Figure 11).

re-tensioned against the Peel Bar. Close the

Peel-Off Lever.

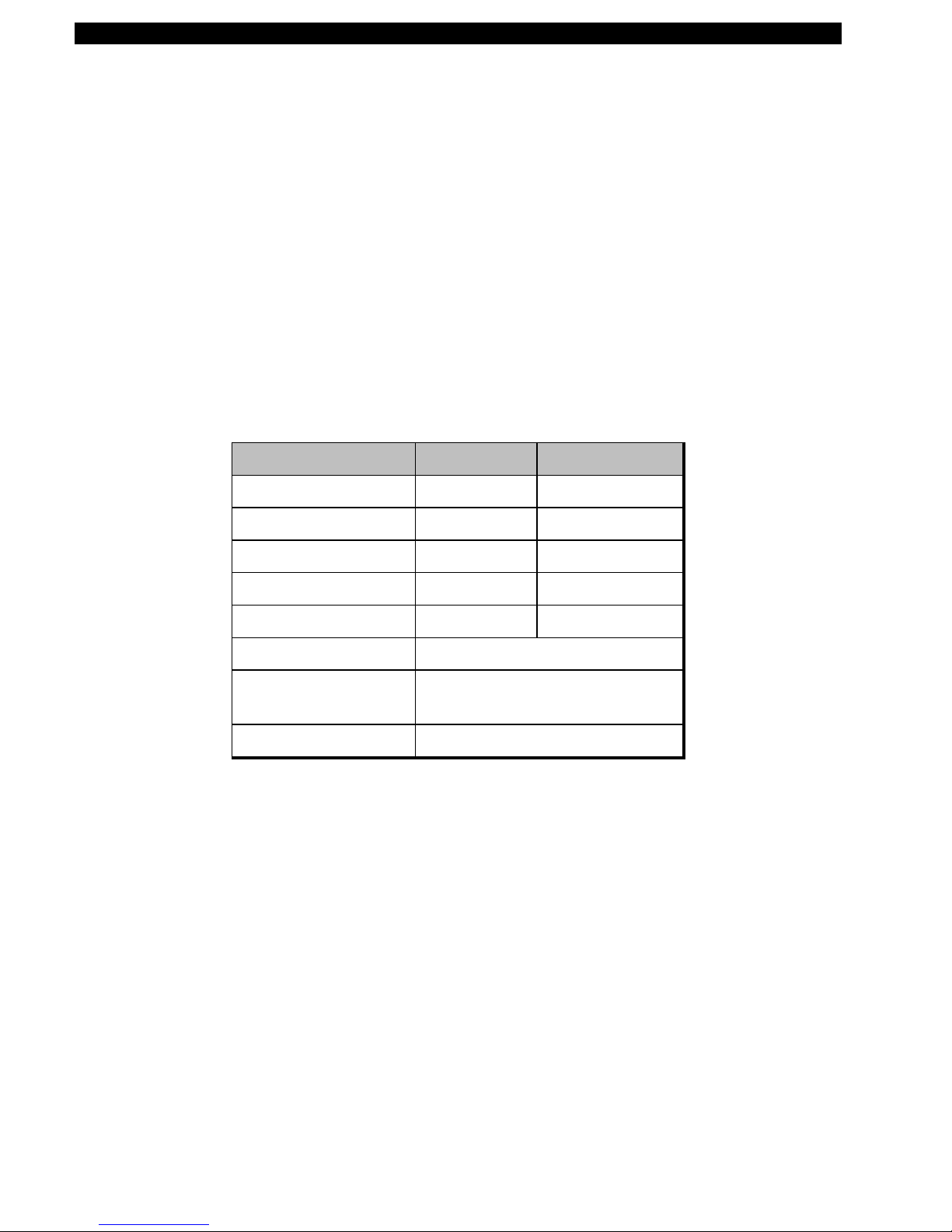

Refer to Figure 10 and disassemble the Ribbon

Supply and Ribbon Take-up Hub mechanisms.

Clean the indicated areas with swabs saturat ed

with 70% Isopropyl Alcohol (see Table 6).

Printer appears to

operat e, but nothing

prints.

Figure 10. Disassembling and Cleaning of the Ribbon Supply and Take-up Spindles

Ribbon is wound the wrong

way.

Use Zebra-brand ribbon that is wound with t he

ink/wax on the inside surface.

Page 14 Part # 547001L Rev. 2

Page 22

Zebra T300 Printer Maintenance Manual

PREVENTIVE MAINTENANCE PROCEDURES

Table 6. Cleaning Schedule

AREA METHOD INTERVAL

Printhead

Platen Roller With the power t ur ned off, rot ate the platen roller and clean it

Peel-Off Roller Rotate the peel-off roller and clean it thor oughly with solvent*

Media Path Solvent* and cotton swabs

Peel/Tear Bar Solvent* and cotton swabs As needed.

Media Sensor Air blow Monthly (or

Spindles Take apart and clean with solvent* As needed.

Ribbon Handler

Assembly

Note:

You do not need to turn the printer off prior to cleaning

the Printhead. Use solvent* on a cotton swab to clean the print

elements from end to end. ( T he print elements are the thin gray

line on the Printhead). (See Figure 12.)

thoroughly with solvent* and a cotton swab or a clean lint-free

cloth.

and a cott on swab or a clean lint-free cloth.

Take apart and clean with solvent* and cotton swabs (See

Figure 10).

After every

roll of media

(or 500 ft. of

fanfold

media).

depending on

environment

conditions).

As needed

(or

depending on

environment

conditions).

Exterior Mild detergent or desktop cleaner. As needed.

Interior Brush/vacuum cleaner As needed.

*Z ebr a recommend s us ing solve n t c ontaining 70% isopropyl a lcoh ol, 30% distilled water. Zebra

also recommends using Part Number 01429 Preventive Maintenance Cleaning Kit.

Lubrication

NO LUBRICATING AGENTS OF ANY KIND SHOULD BE USED ON THIS PRINTER! IF

USED, SOME COMM ERCIALLY AVAILABLE LUB RICANTS WILL DAMAGE THE FINISH

AND THE MECHANICAL PARTS.

Part # 547001L Rev. 2 Page 15

CAUTION:

Page 23

Zebra T300 Printer Maintenance Manual

CORRECTIVE MAINTENANCE PROCEDURES

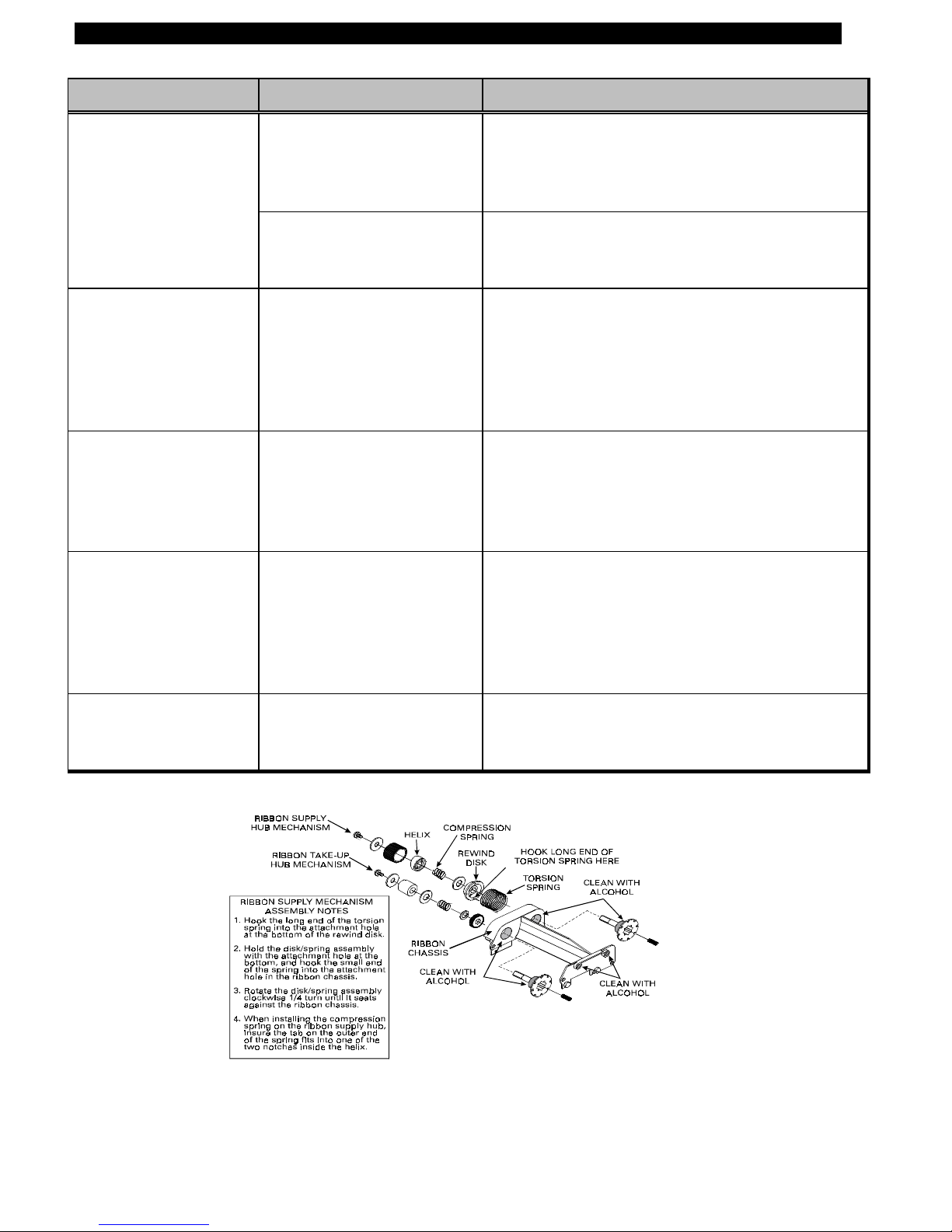

Fine Printhead Adjustment

An Allen set screw is located on top of the Printhead Carrier Assembly that can be adjusted for

controlling prin t quality.

adjusting.

may be necessar y. To adjust the Prin thead, remove tur n the se t screw until optimum print quality is

obtained. Some trial and error may be necessary (see Figure 11).

However, due to a wide variety of media and ribbon that is available, some adjustment

This adjustment is set at the factory and should not need further

Figure 11. Fine Printhead Adju stment

Page 16 Part # 547001L Rev. 2

Page 24

Zebra T300 Printer Maintenance Manual

Platen Roller Replacement

(Use Maintenance Kit PN 503011M)

Remove the old Platen Roller (see Figure 12)

1.

2.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove all media and ribbon from the printer.

3.

Remove the four screws securing the Printhead Assembly and the Media Guide to the printer.

Remove the Media Guid e. ( see Figure 13).

4.

Loosen and remove the three hex screws that secure the Tower Enclosure to the printer. Slide

the Tower E nclosure forward and tilt up to unplug the Control Panel connector from J0004

connector located on the Main Logic Board. Remove the To wer E nclosure.

5.

Loosen and remove the screw securing the ground wire to t he Main Logic Board. Remove all

other connectors from the Main Logic Board. Lift out the Printhead Assembly from the

printer.

6.

Re move the C- Rings (see Figure 12) and w hile pulling slightly fo rward on the Pee l-Off Release

lever, remove the outside bushing from the Platen Roller Shaft. Slide the Platen Roller shaft

out from the gear end and remove the roller.

GEAR ASSEM BLY

Figure 12. Installation and Removal of the Platen Roller

Part # 547001L Rev. 2 Page 17

Page 25

Zebra T300 Printer Maintenance Manual

Figure 13. Cover Removal and Electrical Connector Location

Install the new Platen Roller

1.

While holding the Gear Assembly in place, slide the Platen Roller shaft into the gear assembly.

While pulling slig htly forwar d on the Pe el-Off Release lever, replace the outside bushing and

the ot her shaft end and secure in place with the C-Rings (see Figure 12).

2.

Place the Printhead Assembly back int o the printer. Reconnect all cables (including the ground

wire) to t he Main Logic Board (see Figure 13 for prop er r econnection of connectors).

3.

Reconnect the Cont r ol Panel connector to the Main Logic Board. Lower the Tower Enclosure

back into position on the printer and secure using the three hex screws.

4.

Replace the Media Guide and secure using previously removed hardware. Secure the

Printhea d Assembly using previo usly removed har dwa re.

5.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

6.

Turn the power o n and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)).

Page 18 Part # 547001L Rev. 2

Page 26

Zebra T300 Printer Maintenance Manual

Ribbon Handler Replacement

Remove the old Ribbon Handler Assembly

1.

2.

3.

4.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove all media and ribbon from the printer.

Remove the two thumbscrews on the side of the Printhead Assembly. Disconnect the Ribbon

Sensor connector fro m the sensor (see Figure 14).

While holding the ribbon handler asse mbly, pu s h up the right side (where the thumbscrews

have been removed) and slide the assembly towards the left of the Printhead Assembly.

Remove the ribbon handle a ssembly from the printhead assemb ly.

(Use Maintenance Kit PN 503017M)

Figure 14. Ribbon Handler Assembly Replacement

Install the new Ribbon Handler Assembly (see Figure 14).

1.

Using the two locating pins on the left side of the ribbon handler assembly, place the locating

pin s inside the holes on the Pr inthead assembly. Press the left sid e of the ribbon handler

assembly until the unit snaps into place.

2.

3.

4.

Reinstall and tighten the two thumbscrews. Reconnect the ribbon sensor connector.

Close the Printhead assembly.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

5.

Turn the printer power on and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)).

Part # 547001L Rev. 2 Page 19

Page 27

Zebra T300 Printer Maintenance Manual

Printhead Replacement

Remove the old Printhead

1.

2.

3.

4.

5.

6.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove all media and ribbon from the printer.

Re move the guide underneath the Printhead by pulling up to remove the tab from th e Print head

assembly and unlatch the bottom from the pin.

OBSERVE PROPER ELECTROSTATIC SA FETY PRECAUTIONS WH EN

REMOVING, HANDLING AND REPLACING THE PRINTHEAD.

Carefully unplug the Printhead Connectors from the back of the Printhead (see Figure 15).

Loosen the capt ive Printhead screw that secures t he Printhead to the Printhead Assembly (see

Figure 15).

Remove the two phillips he ad s crews tha t secu re the Printhead to t he Printhead Carriag e.

Remove the Printhead from the carriage.

(Use PN 14500M for Replacement)

CAUTION:

Figure 15. Removal of the Printhead Cable and Screws

Page 20 Part # 547001L Rev. 2

Page 28

Install the new Printhead

OBSERVE PROPER ELECTROSTATIC SA FETY PRECAUTIONS WH EN

REMOVING, HANDLING AND REPLACING THE PRINTHEAD.

1.

Secure the Prin thead Assembly to the Printhead Car riage by rep lacing the two phillips he ad

mounting screws (see Figure 15).

2.

Position the Printhead Assembly on the Printhead bracket and tighten the captive Printhead

screw (see Figure 15).

3.

4.

5.

Connect the Printhead Connector s to the new Printhead (see Figure 15).

Re install the G uide

Ensure that the Printhead Cables are not pinched. Clean the Printhead according to the

Preventive Maintenance Procedures (see Table 6 Cleaning Schedule).

Zebra T300 Printer Maintenance Manual

CAUTION:

6.

7.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

Turn the printer power on and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)). If print quality needs to be adjusted, refer to Figure 11.

Part # 547001L Rev. 2 Page 21

Page 29

Zebra T300 Printer Maintenance Manual

Replacing the Main Logic Board

(Use PN 580000M for Replacement)

Remove the old Main Logic Board

1.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

IMPORTANT:

DO NOT ALLOW THE BOTTOM PLATE TO DROP DOWN FROM THE PRINTER.

THERE ARE CONNECTORS ATTACHED TO THE MAIN LOGIC BOARD THAT

MUST BE REM O VED FIRST.

2. Remove the six screws securing the Bottom Plate to t he printer. ( see Figure 16).

CAUTION:

OBSERVE PROPER ELECTROSTATIC SA FETY PRECAUTIONS WH EN

REMOVING, HANDLING AND REPLACING THE MAIN LOGIC BOARD.

3.

Carefully lower the bottom plate a few inches so that the connectors plugged into the Main

Logic Board can be removed.

4.

5.

Remove the connectors from the Main Logic Board and note their orientation and location.

Remove the Main Logic Board mounting screw which secures the ground wire from the Main

Logic Board.

6.

Once the Bottom Plate Assembly is free from the printer, the Main Logic Board can be

removed. Loosen and remove the remaining three Main Logic Board screws.

7.

8.

Loosen and remove the two scr ews that secure the Parallel Port connector to the bottom plate.

Loosen and remove the two S er ial Port hex nuts which secure the connector t o the bott om

plate. Remove the Main Logic Board from the Bottom Plate.

Install the new Main Logic Board

OBSERVE PROPER ELECTROSTATIC SA FETY PRECAUTIONS WH EN

REMOVING, HANDLING AND REPLACING THE MAIN LOGIC BOARD.

1.

Install the new Main Logic Board to the Bottom Plate and secure it using the screws

previously re moved.

2.

Connect all the connectors and the ground wire to the Main Logic Board making sure that all

connectors ar e installed in the correct locations (see Figure 13 for cor r ect connector

placement).

3.

4.

Install and secure the Bottom Plate Assembly to the printer using the six Bottom Plate Screws.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

CAUTION:

5.

Turn the power o n and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)).

Page 22 Part # 547001L Rev. 2

Page 30

Zebra T300 Printer Maintenance Manual

Figure 16. Main Logic Board Removal/Reinstall

Part # 547001L Rev. 2 Page 23

Page 31

Zebra T300 Printer Maintenance Manual

Control Panel Circuit Board Replacement

PN 503014M)

Remove the old Circuit Board

1.

2.

3.

4.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove media and ribbon from the printer.

Loosen and remove the three hex screws that secure the Tower Enclosure to the printer (see

Figure 17). Slide the Tower Enclosure forward and tilt up to unplug the Control Panel

connector from J0004 connector locat ed on the Main Logic Board (see Figure 13). Remove

the Tower E nclosure.

Remove the two screws secur ing the Contr ol Panel Circuit Board to the Tower E nclosure (see

Figure 18).

(Use Maintenance Kit

Figure 17. Tower Enclosure Removal

Page 24 Part # 547001L Rev. 2

Page 32

Zebra T300 Printer Maintenance Manual

Install the new Circuit Board

1.

Position the Control Panel Circuit Board into t he Tower Enclosure and secure it using the two

screws (see Figure 18).

2.

3.

Plug the Control Panel connector into J0004 on the Main Logic Board (see Figure 13).

Lower the Tower Enclosure back into position on the printer and secure it using the three hex

screws.

4.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

5.

Print a configuration label (see Table 2 Power Off Mode (Communications Diag nos tic s

Mode)).

Figure 18. Control Panel Circuit Board Installation

Part # 547001L Rev. 2 Page 25

Page 33

Zebra T300 Printer Maintenance Manual

Drive Motor Replacement

Remove the old Drive Motor

1.

2.

3.

4.

5.

6.

7.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove media and ribbon from the printer.

Unlatch the Printhead and remove the four screws securing the Printhead Assembly and the

Media Guide to the printer. Remove the Media Guide (see Figure 13 for Media Guide screw

location).

Loosen and remove the three hex screws that secure the Tower Enclosure to the printer. Slide

the Tower E nclosure forward and tilt up to unplug the Control Panel connector from J0004

connector located on the Main Logic Board (see Figure 13). Remove the Tower Enclosure.

Loosen and remove the screw securing the ground wire to the Main Logic Board (see Figure

13). Remove all other co nnectors from the Main Logic Board and lift out the Printhead

Assembly from the prin ter.

Cut the cable tie that bundles the motor harness with the other printer harnesses.

Remove the two screws that secure the drive motor to the Printhead Assembly (see Figure 19).

Slide the drive motor assembly to wards the back of the Printhead Assembly so the moto r gear

can go through t he access hole.

(Use Maintenance Kit PN 503013M)

Figure 19. Drive Motor Replacement

Page 26 Part # 547001L Rev. 2

Page 34

Zebra T300 Printer Maintenance Manual

Install the new Drive Motor

1.

Install the new Motor with the gear going through t he access hole and sliding the motor

forward. Secure the new motor with the two screws previously removed. Replace the cable

tie w hich bundles all the ha rness wire s tog ether ( see Figure 19).

2.

Replace all the connectors previously removed from the Main Logic Board (see Figure 13 for

correct connector placement). Place the Printhead Assembly and Media Guide back in the

printer, secure wit h four screws.

3.

Connect the Contro l Panel connector (J0004) back onto the Main Logic board and secure the

Tower Enclosure using the three hex screws previously removed.

4.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

5.

Turn the power o n and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)).

Part # 547001L Rev. 2 Page 27

Page 35

Zebra T300 Printer Maintenance Manual

Media Sensor Harness Assembly Replacement

Maintenance Kit PN 562001)

Remove the Media Sensor Harness Assembly (see Figure 20)

1.

2.

3.

4.

5.

6.

7.

Turn the printer power o ff and disconnect the power cord from the back of the printer.

Open the printer’s top cover and unlatch the Printhead Assembly by pushing back on the

Printhead Release Lever. Remove all media and ribbon from the printer.

Unlatch the Printhead Assembly and remove the four screws secur ing the Printhead Assembly

and the Media Guide to t he printer. Remove the Media Guide. (see Figure 13).

Loosen and remove the three hex screws that secure the Tower Enclosure to the printer. Slide

the Tower E nclosure forward and tilt up to unplug the Control Panel connector from J0004

connector located on the Main Logic Board. Remove the To wer E nclosure.

Loosen and remove the screw securing the ground wire to t he Main Logic Board. Remove all

other connectors from the Main Logic Board. Lift out the Printhead Assembly from the

printer.

Under the Printhead assembly, press in the four plastic tabs on the sensor and remove the

se nso r from the P rinthead As sembly (see Figure 20).

Cut the cable tie that bundles the media sensor harness with the other printer harnesses.

Re move th e assembly.

(Use

Install the new Media Sensor Harness Assembly

1.

Under the Printhead assembly, press in the four plastic tabs on the sensor and install the new

sensor harness assembly on the Printhead Assembly. . Replace the cable ties which bundles all

the harness wires together.

2.

Replace all the connectors previously removed from the Main Logic Board (see Figure 13 for

correct connector placement). Place the Printhead Assembly and Media Guide back in the

printer, secure wit h four screws.

3.

Connect the Contro l Panel connector (J0004) back onto the Main Logic board and secure the

Tower Enclosure using the three hex screws previously removed.

4.

Replace Media and Ribbon back into the printer, close the cover and reconnect po wer to the

printer.

5.

Turn the power o n and print a configuration label (see Table 2 Power Off Mode

(Communications Diagnostics Mode)).

Page 28 Part # 547001L Rev. 2

Page 36

Zebra T300 Printer Maintenance Manual

Figure 20. Removal of the Media Sensor Harness Assembly

Part # 547001L Rev. 2 Page 29

Page 37

Zebra T300 Printer Maintenance Manual

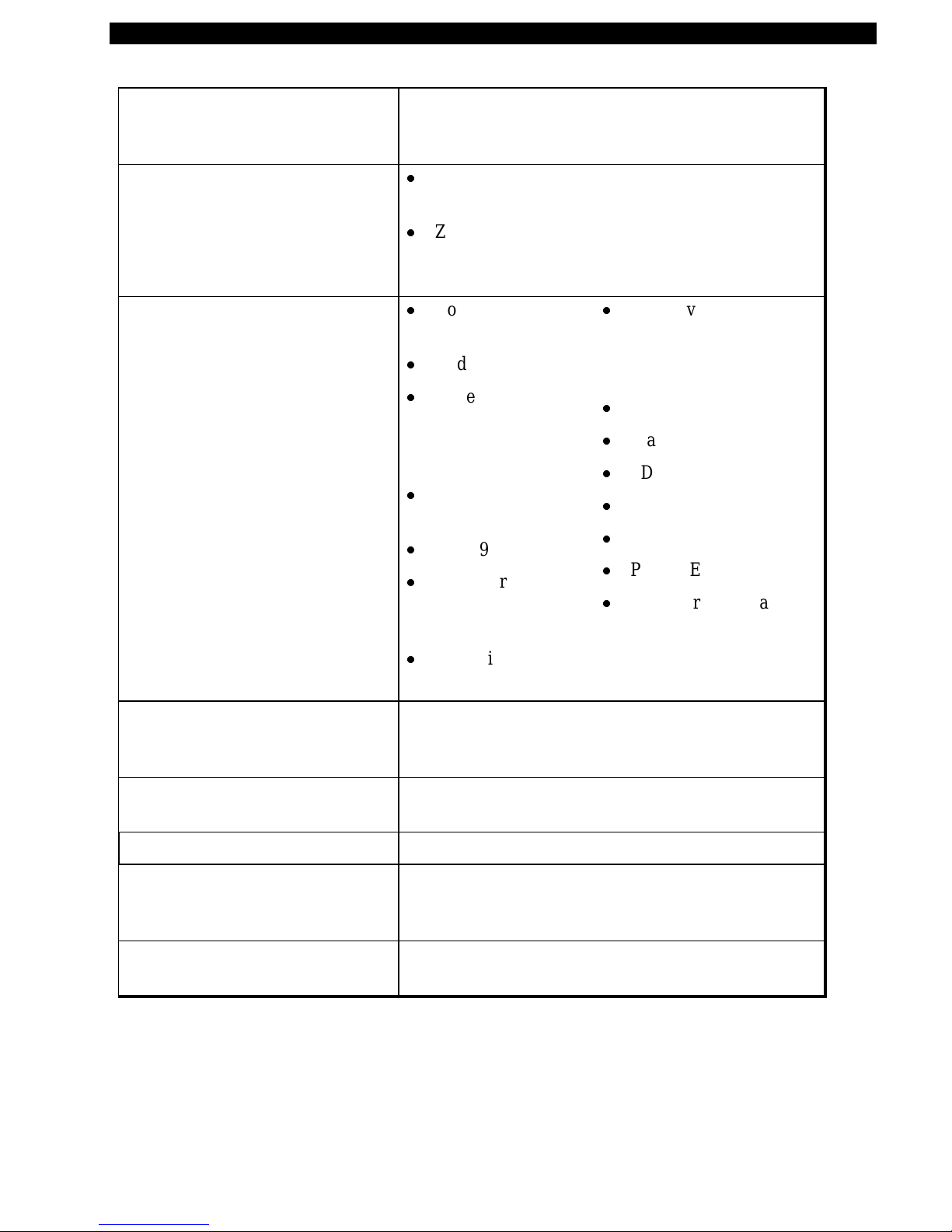

U5 IS UNUSED

MAIN CIRCUIT BOARD LAYOUT

CONTROL PANEL

CONNECTOR (J0004)

GROUND

WIRE

STEPPER

MOTOR

CONNECTOR

(J0003)

PRINTHEAD CONNECTOR

(J0001)

RIB. SE N S OR

TRANS LED

REF LED

COM DET

CONNECTOR

(J0002)

LABEL

PRESENT

CONNECTOR

(J0012)

SERIAL

PORT

EPROM IN S TALLED

IN POSITION U1

Figure 21. Main Circuit Board Layout

Page 30 Part # 547001L Rev. 2

PARALLEL

PORT

Page 38

Zebra T300 Printer Maintenance Manual

MECHANICAL DRAWINGS

Replacement Parts

Replacement parts and pricing are available by contacting your Zebra distributor. Table 7 lists

replacement parts available for the T300 printer. Table 8 is a list of Maintenance Kits available for the

T

300 printer. These are only available in kit form, no piece parts in these kit are available separately.

Table 7. Replacement Parts

QUANTITY PART NUMBER DESCRIPTION

1 14500M Printhead (See Figure 15)

1 506009 Enclosure, Bottom (See Figure 16)

1 506010 Fascia, Front (See Figure 16)

4 506017 Bumper, Button (See Figure 16)

2 506020 Skewer, Ribbon (See Figure 11)

1 506024 Cover, Cutter (See Figure 23)

1 510000 Bar, Peel (See Figure 12)

1 548003 Label, Power/Feed (See Figure 3)

1 562000 Assy., Printhead Cable (See Figure 15)

1 562001 Harness, Sensors (See Figure 20)

1 569000 T ake Label Sensor (No t Illustrated)

1 580000M PCB Main (See Figure 21)

1 510012 Ribbon Guide Bracket (See Figure 15)

Table 8. Maintenance Kits

QUANTITY PART NUMBER DESCRIPTION

1 503009M Kit, Top Enclosure T300 printer (See Figure 16)

1 503010M Kit, Media Support T300 printer (See Figure 22)

1 503011M Kit, Platen Roller T300 printer (See Figure 12)

1 503012M Kit, Latch Printhead Assy. T300 printer (See

Figure 14)

1 503013M Kit, Stepper Mo tor T300 printer (See Figure 19)

1 503014M Kit, Control Panel PCB T300 printer (See Figure

18)

1 503015M Kit, Cutter Module T300 printer (See Figure 23)

1 503016M Kit, Media Guide T300 printer (See Figure 24)

1 503017M Kit, Ribbon Handler Assy. (See Figure 14)

1 503018M Kit, Sensor Assy. Ribbon Out T300 printer (See

Figure 25)

1 503019M Kit, Screw T300 printer (Not Illustrated)

Part # 547001L Rev. 2 Page 31

Page 39

Zebra T300 Printer Maintenance Manual

Figure 22. Media Support Kit PN 503010M

Figure 23. Cutter Module Kit PN 503015M

Page 32 Part # 547001L Rev. 2

Page 40

Zebra T300 Printer Maintenance Manual

Figure 24. Media Guide Kit PN 503016M

Figure 25. Ribbon Out Sensor Assembly Kit PN 503018M

Part # 547001L Rev. 2 Page 33

Loading...

Loading...