Page 1

Selector Guide

Genuine Zebra™ Supplies

Not all thermal labels are created equal.

Purchasing genuine Zebra supplies

means you have access to a large

selection of quality, pre-tested, supplies

manufactured by a thermal industry

expert, reducing your risk of noncompliance.

Quality

• Zebra uses consistent processes

and materials

• ISO 9001:2008 certified

• We never substitute materials,

ensuring consistent print quality

• Materials are selected to ensure

we deliver consistent highquality products.

Pre-Tested

• Zebra extensively tests all materials

we offer in Zebra printers

• Testing includes print quality,

chemical resistance, adhesive

strength and printer wear and

tear.

Reliable

• Expertise in converting thermal

media.

• Zebra is one of the largest

thermal label convertors in North

America.

• We use inks, varnishes, tooling,

equipment and inspection

techniques specifically suited

for the special requirements of

thermal materials.

• Zebra can custom-manufacture

supplies that meet the needs

of most applications, whether

a specialty material, size,

configuration or pre-print is

needed.

Key Applications

Retail / Shelf-labeling,

Markdown, Pharmacy, Item

Labeling and Tagging

Healthcare / Patient Identification,

Specimen Collection, Lab

Specimen Processing

Transportation and Logistics /

Shipping, Pallet Labeling,

Packing Lists

Manufacturing / Product

Identification, Work-in-Process,

Parts Identification

Page 2

San Diego, California

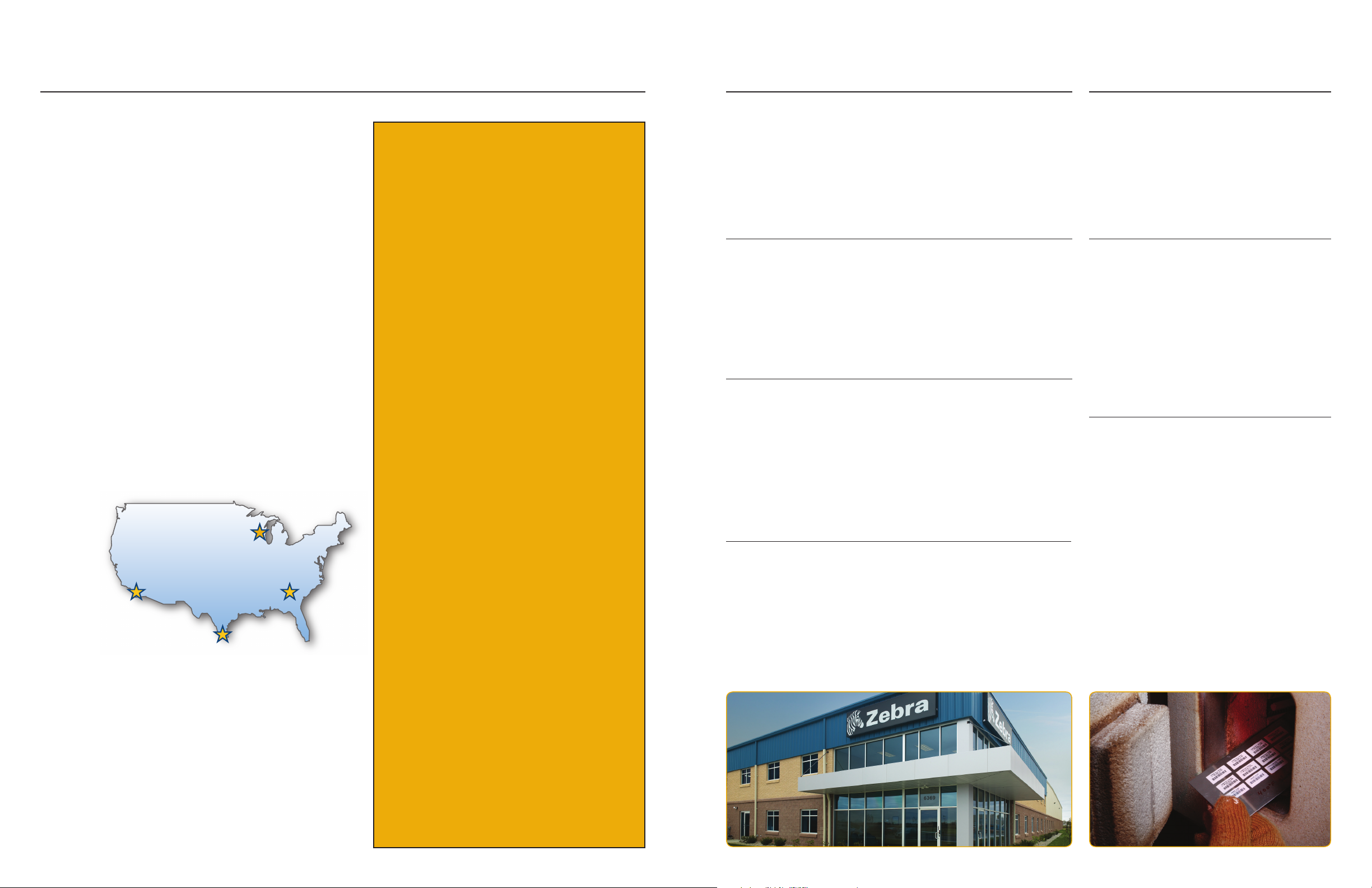

WHY CHOOSE GENUINE ZEBRA™ SUPPLIES? MANUFACTURING CAPABILITIES R&D CAPABILITIES

Meet end-user needs and requirements with genuine Zebra

supplies. With access to over 1,000 combinations of highquality labels, tags, receipt paper, wristbands and ribbons, in

addition to 500 stock ZipShipSM products, you will be able

to meet the durability requirements of most applications. In

addition, Zebra has:

• 4 U.S. locations, ensuring quick delivery.

• Inventory managment programs that improve cost and

delivery time.

• A printhead protection program that awards end-users who

purchase genuine Zebra supplies with free printheads.

• Extensive manufacturing capabilities, which include

laminating, perforations, face and back slits, custom sizes

and color pre-printing.

• An experienced Supplies R&D team who pre-tests all

materials on Zebra® printers and conducts additional testing

to ensure it will meet the needs of the application.

• ISO 90001:2008 registered, which ensures you’ll always

receive consistent, quality products.

With more than 1,000 combinations of highquality and reliable labels, tags, receipt paper,

wristbands, and ribbons, Zebra has a media

solution for virtually any application. Whether

you’re facing shipping, electronic component

manufacturing, prescription labeling, or even

electronic citation applications, Zebra and our

certified partners can provide an in-stock or

custom-made solution for you.

»

McAllen, Texas »

Greenville, Wisconsin »

Atlanta, Georgia »

Custom Supplies

We specialize in manufacturing supplies to meet the

exact requirements of an end-user. Whether a specialty

material, configuration or pre-print is needed, we can

meet your needs.

• Experts available to assist in material selection.

To simplify the selection process, please provide the

following information:

Printer model

Resistance—chemical, scratch, etc.

Environment— indoors or outdoors, temperature, etc.

Surface—metal, plastic, rough, curved, etc.

Size—length, width, perforations, slits, etc.

• Expedite service offered to reduce lead time

• Free dies on all custom media orders

• Over 8,000 dies available

Inventory Management Programs

We offer an array of inventory management programs for

custom supplies.

• Blanket Orders

» Price protection

» Pre-scheduled shipments

» Low minimum requirements

• 3, 4, 5 and 6 month Make and Hold options

» Cost based on larger run quantity

» Flexible shipment dates and quantities

• Inventory Management Service

» Custom product stocked for you

» Immediate shipments

Sample Program

We offer many options to obtain sample materials.

• Sample Packs

» Contain an array of materials

» ZipShip, synthetic, wristbands, receipt paper

• Strip of Material

» Evaluation of adhesive, thickness and durability

• Sample Roll

» Available in select sizes for most materials

» Evaluation of adhesive, thickness and durability

» Ability to print many labels

• ZipShip Roll

» Available in several sizes for our most popular materials

» Full evaluation to test in application

• Pilot Run

» Exact size and configuration

» Full evaluation to test in application

A world-class convertor of labels, tags, receipt paper and

wristbands, Zebra specializes in narrow-web flexographic printing

on thermal materials. By making and testing our own printer

supplies, we can assure you receive the highest-quality products

performance-matched to your Zebra printer and application. Our

multiple manufacturing locations provide convenient shipping

throughout North America.

Printing

• Up to eight-color printing with special water-based inks for

thermal materials

• Up to three UV colors or coatings

• Front- and back-side printing

• Computerized vision-inspection systems

• UL mark

Converting

• Roll-to-roll and fanfolding

• Press widths from 7 inches to 20 inches

• Laminating

• Die cutting up to five stations

• Perforations, face slits, and back slits

• Adhesive deadening and spot coating

• UL/cUL and CSA recognized

Finishing

• 3/4-inch to 6-inch cores

• Shrink-wrapping

• Custom kits

With more than 25 years of experience working

with thermal print technology, Zebra’s Supplies

R&D team has unparalleled knowledge of

supplies for Zebra printers. With access to

all Zebra printers and thousands of different

materials, we can find the right material for

your application.

We Can Test

• Image abrasion/durability

• Accelerated outdoor life

• Adhesion strength on various materials

• Temperatures from -112º F/-80º C to

1,000º F/538º C

• Material tear strength

• Harsh chemicals

• Printhead life

Services Offered

• Application assistance and testing

• New material development

• Exact-match samples

• UL/cUL and CSA approvals

• UID approvals

• IMDS approvals

32

Page 3

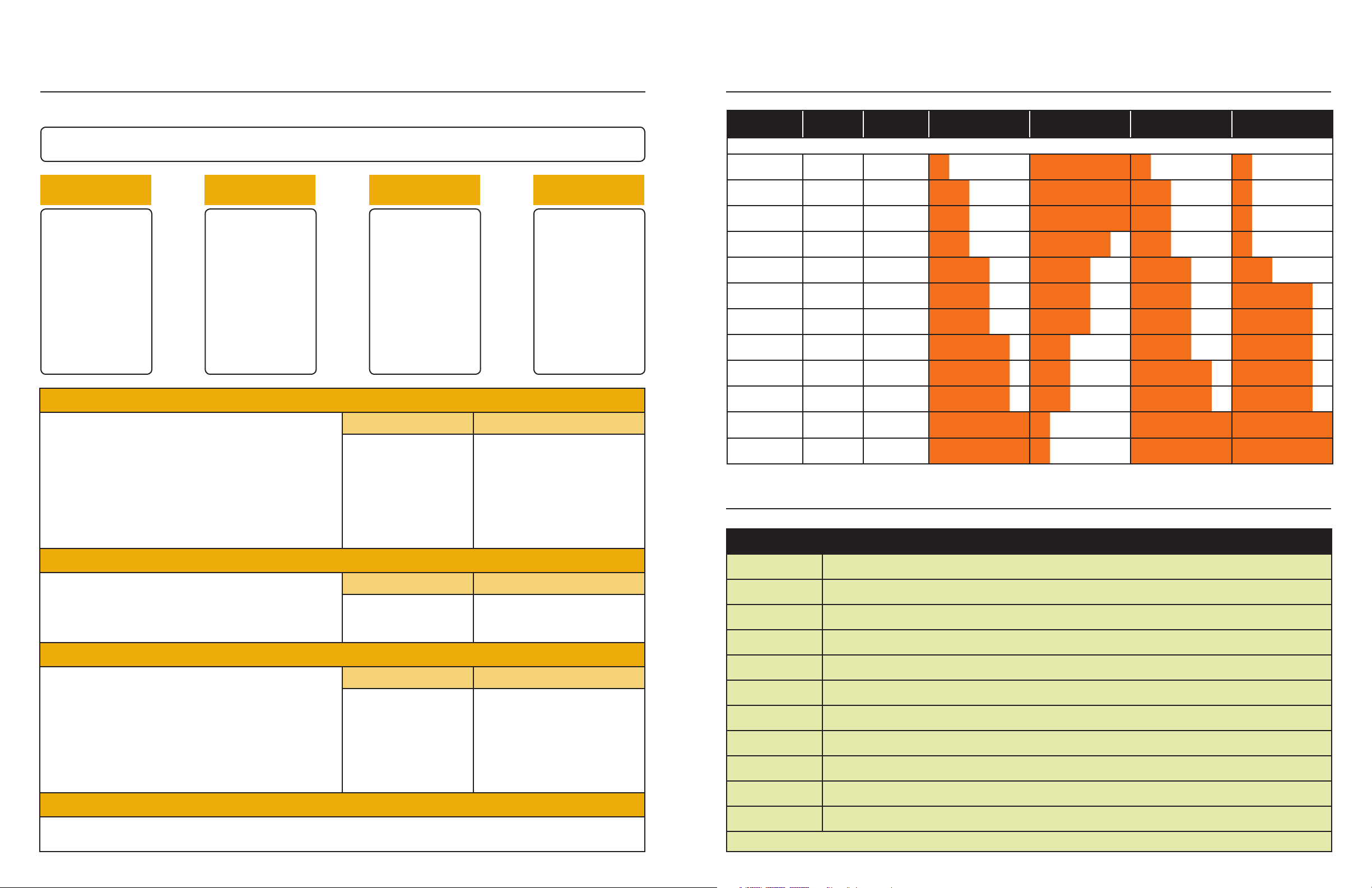

MATERIAL NAMING CONVENTION COMPARISON OF THERMAL TRANSFER RIBBONS

Example: 8000T Piggyback

Specialty 8000 T Piggyback

Family

Classification

Print

Technology

Z-Perform™

Z-Select™

IQ Color

PolyO™

PolyPro™

Z-Xtreme™

Z-Ultimate

®

Z-Supreme™

1000

2000

3000

4000

5000

8000

D

(Direct thermal)

T

(Thermal transfer)

Z-Endure™

Specialty

Family

Zebra offers a variety of paper and synthetic media,

which will meet the requirements of most applications.

Paper offers an inexpensive way to print in a variety of

general-purpose applications, while synthetic offers more

durable, long-lasting results with resistance to abrasion,

moisture, and chemicals.

Paper Synthetic

• Z-Perform

• Z-Select

• IQ Color

• Specialty

• PolyO

• PolyPro

• Z-Xtreme

• Z-Ultimate

• Z-Supreme

• Z-Endure™

Classifications

Zebra media products are classified by their level of

performance and cost. Specialty products are classified

separately.

1000-5000 8000

The higher the

number, the higher

the performance

Specialty products with some

unique features designed for

specialized applications

Print Technology

Thermal transfer technology uses a ribbon to transfer an

image onto the label material. Direct thermal technology

does not require a ribbon. Instead, a chemically coated

heat-sensitive material produces images as heat is

applied to the surface.

Direct Thermal Thermal Transfer

• Primarily indoor use

• Short to medium-

term lifespan

• Minimal chemical

resistance

Indoor or outdoor usage

Medium to long-term lifespan

Excellent chemical resistance

Ribbon needed

• No ribbon

Unique Feature

The unique feature is a material attribute that differentiates the product. For example, the product can be described

by the color, adhesive, material, or whether it is a tag or receipt.

Unique

Features

Color

Adhesive

Tag/Receipt

Material

Ribbon Formulation

2000 Standard Wax Coated Paper

2100

High-Performance

6000

High-Performance

5319 Performance Wax

5555 Standard Wax/Resin

3200

High-Performance

6100

High-Performance

5586 Premium Wax/Resin

5095

High-Performance

6200

High-Performance

5100 Premium Resin Gloss Synthetics

Image Lock Resin

Wax Coated Paper

Wax Coated Paper

Wax/Resin

Wax/Resin

Resin

Resin

Material

compatibility

Uncoated Paper/

Coated Paper

Coated Paper/

Matte Synthetics

Coated Paper/

Matte Synthetics

Coated Paper/

Matte Synthetics

Coated Paper/

Matte Synthetics

Gloss Paper/

Gloss Synthetics

Gloss Paper/

Gloss Synthetics

Gloss/Matte

Synthetics

Darkness setting Print speed

Low High Low High Low High Low High

Scratch/smear

resistance

Chemical resistance

ADHESIVES

Adhesive Description

Acrylic General-purpose; provides long-term adhesion; resistance to chemicals and UV exposure; works across a wide temperature range

Rubber General-purpose; provides good initial tack; offers adhesion to rough surfaces; not recommended for auto apply

High-Performance Offers higher resistance to chemicals and UV exposure; often has agency approval such as indirect food contact (FDA 175.105), UL/cUL and CSA approval

High-Temp Maintains strong adhesion at high temperatures (over 300º F /149º C)

Cold-Temp Maintains strong adhesion at low temperatures (down to -112º F /-80º C)

All-Temp May be applied to temperatures below freezing (32º F /0º C)

Removable Clean removal from most surfaces without damaging the label or the surface

Ultra-Removable Clean removal from nearly all surfaces, including metal and glass, without damaging the label or the surface

Multi-Removable

High-Tack Acrylic Works well on hard-to-label surfaces and provides good resistance to chemicals and UV exposure

High-Tack Rubber Works very well on hard-to-label surfaces; provides good initial tack

*All adhesives above are permanent unless stated otherwise.

Offers dual functionality; provides permanent long-term adhesion but also allows for clean removal; repositionable to allow for removal, adjustment, and

reapplication

54

Page 4

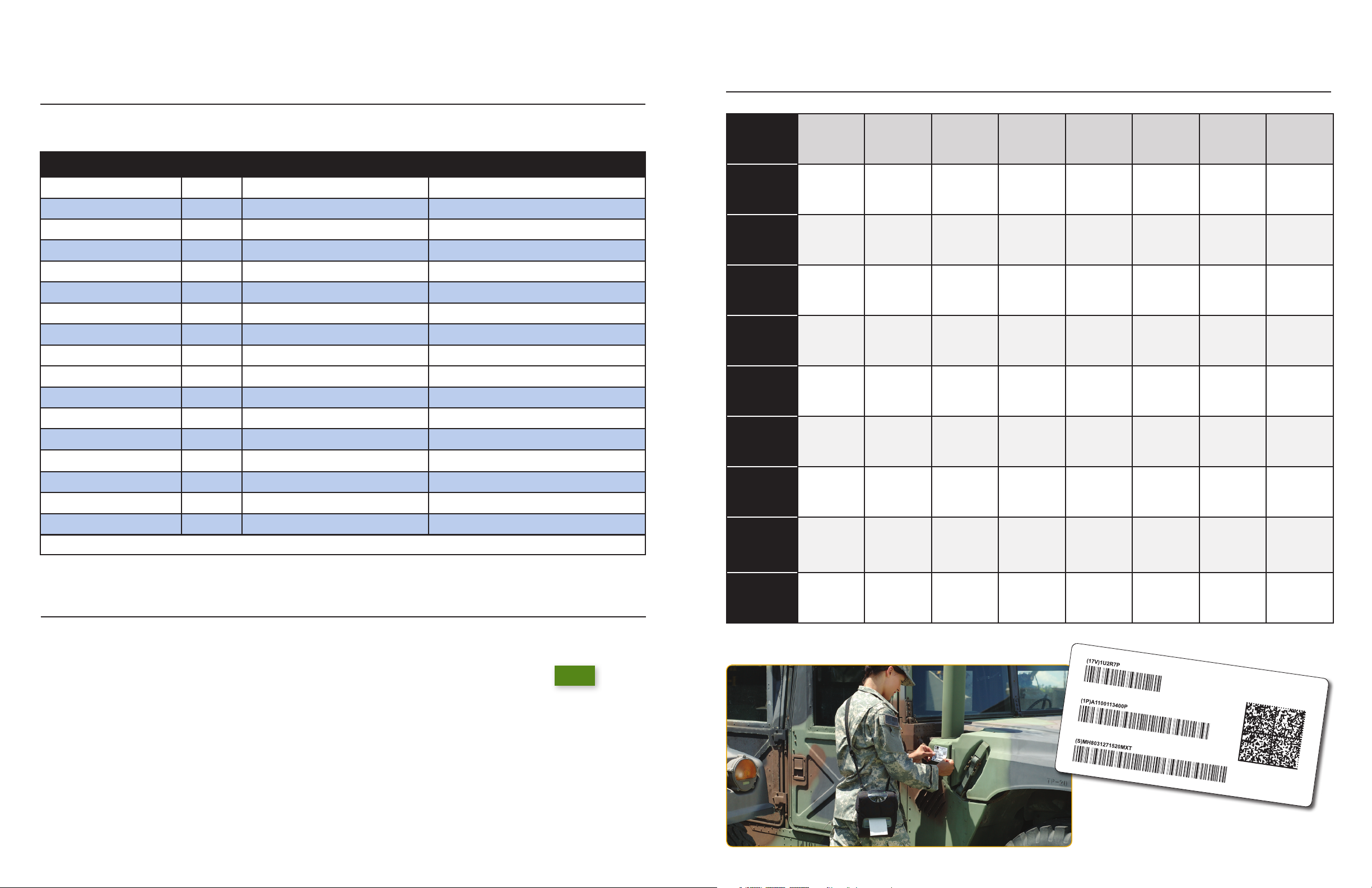

UL/cUL-RECOGNIZED AND CSA-ACCEPTED

LABELING SYSTEM

UID SOLUTION SUPPLIES SELECTOR GUIDE

Zebra offers one of the largest selections of UL/cUL-certified label and ribbon combinations. In addition, all of our

locations are authorized to pre-print the UL mark.

Product Material Ribbon Recognition

Z-Supreme 2000T White Polyimide 5095, 5100 UL/cUL indoor

Z-Supreme 4000T White Polyimide 5095, 5100 UL/cUL indoor

Z-Ultimate 4000T White Polyester 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Ultimate 4000T Silver Polyester 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Ultimate 4000T Removable Polyester 5095, 5100 UL/cUL indoor

Z-Ultimate 4000T High-Tack Polyester 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Ultimate 3000T White Polyester 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Ultimate 3000T Silver Polyester 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Ultimate 2000T White Polyester 5095, 5100 UL indoor

Z-Xtreme 4000T White Polyester 5319, 3200, 5586, 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Xtreme 4000T Silver Polyester 5319, 3200, 5586, 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Xtreme 4000T High-Tack White Polyester 5319, 3200, 5586, 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Xtreme 4000T High-Tack Silver Polyester 5319, 3200, 5586, 5095, 5100 UL/cUL indoor/outdoor; CSA indoor/outdoor

Z-Xtreme 2000T White Polyester 3200, 5586, 5095 UL/cUL indoor

Media & ribbon

combination

Ribbon type

Material

description

Adhesive types

Minimum

application

temp.

Service temp.

Surface to

be labeled

Z-Ultimate 4000T

White with

5100 Ribbon

Resin Resin Resin Resin Resin Resin Resin Wax-Resin

Gloss Polyester Gloss Polyester Matte Polyester Matte Polyester

Permanent

Acrylic

50° F/10° C 50° F/10° C 50° F/10° C 40° F/4° C 10° F/-12° C 50° F/10° C 50° F/10° C 50° F/10° C

-40° F to 302° F

-40° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

Z-Ultimate 4000T

Silver with 5100

Ribbon

Permanent

Acrylic

-40° F to 302° F

-40° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

Z-Xtreme 5000T

with Image

Lock™ Ribbon

High-Tack

Permanent

Acrylic

-40° F to 302° F

-40° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

8000T Ultra

High-Tack Matte

with 5095 Ribbon

High-Tack

Permanent

Acrylic

-20° F to 302° F

-29° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass,

Rough Surfaces

PolyPro 4000T

with 5095 Ribbon

Matte

Polypropylene

Permanent

Acrylic

-40° F to 250° F

-40° C to 121° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

8000T Image

Lock with Image

Lock Ribbon

Polyolefin

Permanent

Acrylic

-112° F to 248° F

-80° C to 120° C

Corrugate, Paper,

Packaging Films,

Metal, Glass,

Curved Surfaces

Z-Endure™ 4000T

with 5100 Ribbon

Semi-Gloss

Acrylic

Permanent

Acrylic

-40° F to 302° F

-40° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

8000T Piggyback

Clear Matte with

5586 Ribbon

Gloss/Matte

Polyester

Combination

Permanent

Acrylic

-40° F to 302° F

-40° C to 150° C

Corrugate, Paper,

Packaging Films,

Metal, Glass

Z-Xtreme 2000T Silver Polyester 3200, 5586, 5095 UL/cUL indoor

Z-Xtreme 2000T Clear Polyester 3200, 5586, 5095 UL/cUL indoor

8000T Void Matte Polyester 5586, 5095 UL/cUL indoor/outdoor

Many Zebra printing systems are recognized by Underwriters Laboratory (UL/cUL) and accepted by the Canadian Standards Association (CSA) for printing indoor- and outdoor-use labels. These media/ribbon combinations include the above. If your

application requires a UL/cUL-recognized or CSA-accepted labeling system, please consult with your Zebra account executive to determine which printer models can be used with these UL/cUL and CSA label/ribbon combinations.

ENVIRONMENTAL SUSTAINABILITY

Reducing our impact on the environment is important to us all. Many organizations have developed environmental

sustainability plans that include purchasing more environmentally friendly products. In support of these initiatives, Zebra

has added eco-friendly thermal transfer labels to its line of materials. To find these materials, look for:

In addition to offering environmentally-friendly products, our manufacturing plants recycle much of their waste. This

includes the recycling of waste matrix (a by-product of the converting process) plastic banding, stretch film, corrugate,

fiber and plastic cores, plastic card material, office paper and light bulbs.

ECO-

FRIENDLY

Environment

Resistance

Compliant to

MIL PRF

61002A

Indoor

Outdoor up to

3 years

Moisture,

Abrasion, Weak-

to-Moderate

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

3 years

Moisture,

Abrasion,

Weak-toModerate

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

3 years

Moisture,

Abrasion,

Weak-toModerate

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

3 years

Moisture,

Weak-toModerate

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

2 years

Moisture,

Weak-to-Harsh

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

5 years

Moisture,

Abrasion,

Weak-to-Harsh

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

10 years

Moisture,

Abrasion,

Weak-toModerate

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

Indoor

Outdoor up to

3 years

Moisture,

Abrasion,

Weak-to-Harsh

Chemicals

Type II, Grade

A B & C, Style 1,

Composition b

76

Page 5

Labels

Thermal

Transfer

Product Name

Z-Perform™

1000D DT

2000T TT

2000D DT Paper label with an all-temp acrylic adhesive

Z-Select™

4000T TT

4000T All-Temp TT

4000T Removable TT

4000D DT

4000D Removable DT

IQ Color

2000D DT

2000D

Paper Labels

All-Temp

2000D

Removable

2000D

Opaque

Specialty

ZEBRA

EXCLUSIVE

ZEBRA

EXCLUSIVE

ZEBRA

EXCLUSIVE

ZEBRA

EXCLUSIVE

(TT)

Direct

Thermal

(DT)

Bright white, smooth paper facestock that provides the optimal balance between performance and price for industrial applications.

Recommended for indoor use.

Uncoated paper label with a permanent acrylic adhesive;

limited resistance to moisture or abrasion; not recommended for high print speed applications

Paper label with a permanent acrylic adhesive; meets FDA

175.105 indirect food contact requirements

Premium, bright white, ultra-smooth paper facestock specially coated to provide optimal quality. Ideal for high-speed printing applications

where print quality is important. Recommended for indoor use.

Paper label with permanent acrylic adhesive that may be

used across a wide temperature range; meets FDA 175.105

indirect food contact requirements

Paper label with a permanent all-temp acrylic adhesive

that allows the label to be applied to surfaces as cold as

-20° F /-29° C

Paper label with a removable acrylic adhesive for applications requiring clean removability without damaging the

label or the surface; meets FDA 175.105 indirect food

contact requirements

Paper label with a permanent all-temp acrylic adhesive that

allows the label to be applied to surfaces as cold as -20° F /-29° C;

meets FDA 175.105 indirect food contact requirements

Paper label with a removable acrylic adhesive for applications requiring clean removability without damaging the

label or the surface; meets FDA 175.105 indirect food

contact requirements

Bright white, smooth paper facestock that has the ability to print vibrant color on demand in pre-defined zones to be used as a visual cue.

Paper label with a permanent acrylic adhesive. Limited

resistance to moisture or abrasion.

Paper label with a permanent all-temp acrylic adhesive.

DT

Limited resistance to moisture or abrasion.

Paper label with a removable acrylic adhesive. Limited

DT

resistance to moisture or abrasion.

Opaque paper label with a high performance, acrylic-based

DT

adhesive. Limited resistance to moisture or abrasion.

White paper labels and tags designed for unique or challenging applications. Recommended for indoor use.

Product Description Applications

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Minimum

Application

Temperature

Indoor, general-purpose labeling; warehouse, distribution,

bakery application, and address labeling

Labeling of packaging material including corrugate, plastic,

and metal; work in process

Packaging and compliance labeling; indoor labeling

applications

Labeling of packaging material including corrugate, plastic,

and metal; product identification, compliance labeling, work

in process

Labeling of packaging material including corrugate, plastic,

and metal; ideal for identifying products in cold storage or

refrigerated warehouses

Product identification; labeling of shelves, bins, or totes

intended for reuse when labels are removed

Labeling of most packaging materials; document tracking;

cold-temp applications; IV bag labeling

General-purpose product and food labeling; removable shelf

labeling

Healthcare for prioritization of lab and pharmacy orders.

Transportation and logistics for sortation and inventory

management. Manufacturing for quality control and work in

process. Retail for shelf and product labeling

Cold temp. applications such as frozen food labeling. Retail

for shelf and product labeling. Healthcare for prioritization of

lab and pharmacy orders.

Transportation and logistics for sortation and inventory

management. Manufacturing for quality control and work in

process. Retail for shelf and product labeling

Applications requiring a “cover-up” label. Transportation

and logistics for sortation and inventory management.

Manufacturing for quality control and work in process.

Retail for shelf and product labeling.

25° F

-4° C

25° F

-4° C

-40° F

-40° C

25° F

-4° C

-20° F

-29° C

40° F

4° C

-20° F

-29° C

40° F

4° C

25° F

-4° C

-20°F

-29°C

40° F

4° C

40°F

4°C

Service

Temperature

-40° F to 140° F

-40° C to 60° C

-65° F to 200° F

-54° C to 93° C

-65° F to 131° F

-54° C to 55° C

-65° F to 200° F

-54° C to 93° C

-65° F to 200° F

-54° C to 93° C

-65° F to 180° F

-54° C to 82° C

-65° F to 140° F

-54° C to 60° C

-65° F to 140° F

-54° C to 60° C

-65° to 120° F

-54° to 40° C

-65°F to 120°F

-54°C to 49°C

-65° to 120° F

-54° to 40° C

-65°F to 120°F

-54°C to 49°C

Surfaces to be Labeled Environment Resistance Suggested Ribbons

Paper

Corrugate

Most Plastics

Packaging Films

Rough Surfaces

Metal and Glass

Moist Surfaces

Curved Surfaces

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • •

nr nr nr

•

• • • • • • • • •

• • • • •

nr nr nr

•

• • • • • • • • •

• • • • • • • • •

• • • • •

nr nr nr

•

• • • • • • • • •

Indoors

Outdoors

nr nr

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr nr

nr nr

nr nr

nr nr

Moisture

•

•

•

•

•

Abrasion

Chemical–Weak

nr nr nr nr

nr nr nr nr

nr nr nr nr

nr nr nr nr

nr nr nr nr

(ie. Alcohol, Bleach)

(ie. Window Cleaner)

Chemical–Moderate

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

(ie. Gasoline, Oil)

Chemical–Harsh

Chemical–Extreme

Standard

(ie. Acetone, Xylene)

N/A N/A

2000,

5319

N/A N/A

2000, 2100,

5319

2000, 2100,

5319

2000, 2100,

5319

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

Application–

Chemicals

Weak and Moderate

Chemicals

and Extreme

High Durability–

Abrasion, Harsh

5555,

3200

5555,

3200

5555,

3200

5555,

3200

8000T High-Tack TT

8000T Super-Tack TT

8000T Multi-Removable TT

8000T Ultra-Removable TT

8000T Opaque TT

8000T Piggyback TT

8000T Semi-Gloss TT

Paper label with a permanent rubber adhesive that provides high

initial tack; meets FDA 175.105 indirect food contact requirements

Paper label with a Hammerlock® permanent rubber

adhesive that provides best initial and long-term adhesion

Paper label with a multi-removable adhesive that offers dual

functionality; provides permanent adhesion to corrugate

surfaces but also allows clean removal from glass surfaces;

repositionable

Paper label with an ultra-removable acrylic adhesive that

provides long-term clean removability

Opaque paper label with a permanent acrylic adhesive;

meets FDA 175.105 indirect food contact requirements

Piggyback paper label with a permanent acrylic adhesive

that allows for removing the label, leaving the liner, and

re-applying the second liner to a final application

Semi-gloss paper label with a permanent rubber adhesive;

meets FDA 175.105 indirect food contact requirements

Labeling of corrugate and recycled corrugate; shipping

labels

Difficult surfaces such as wood and textured substrates

Labeling cartons, totes, and bins; promotional and shelf

labels; allows frequent application and removal of label

Removable shelf or scan pallet labels; removable document

labels

Applications requiring a “cover-up” label; product ID;

chemical containers

Labeling of packaging materials; order picking; work in

process

Product identification; diskette labeling; high-volume

applications

40° F

4° C

30° F

-1° C

25° F

-4° C

20° F

-7° C

20° F

-29° C

25° F

-4° C

25° F

-4° C

-65° F to 160° F

-54° C to 71° C

-65° F to 150° F

-54° C to 66° C

-20° F to 200° F

-29° C to 93° C

-40° F to 160° F

-40° C to 71° C

-65° F to 200° F

-54° C to 93° C

-65° F to 200° F

-54° C to 93° C

-65° F to 160° F

-54° C to 71° C

• • • • • • • • •

• • • • • • • • •

• • • • •

• • • • •

nr

• • •

nr nr nr

•

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

2000,

5319

2000,

5319

2000,

5319

2000,

5319

2000, 5319,

2100

2000,

5319

2000,

5319

5555,

3200

5555,

3200

N/A

5555,

3200

5555,

3200

5555,

3200

3200

98

Page 6

Labels

Product Name

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Product Description Applications

Minimum

Application

Temperature

Service

Temperature

Corrugate

Surfaces to be Labeled Environment Resistance Suggested Ribbons

Paper

Most Plastics

Packaging Films

Rough Surfaces

Metal and Glass

Curved Surfaces

Indoors

Moist Surfaces

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Window Cleaner)

(ie. Gasoline, Oil)

Chemical–Harsh

Chemical–Extreme

Standard

Chemicals

Application–

(ie. Acetone, Xylene)

Weak and Moderate

High Durability–

Extreme Chemicals

Abrasion, Harsh and

Specialty (continued)

8000T High-Gloss TT High-gloss paper label with permanent acrylic adhesive

8000T Lab TT

8000D Lab DT

8000D Near IR DT

8000D IR DT

Paper Labels

8000D High-Temp DT

8000D Linerless

8000D Linerless

Removable

PolyO™

3000T TT

4000T TT

PolyPro™

3000T TT

3000T High-Tack TT

4000T TT

4000T High-Tack TT

Synthetic Labels

4000T Removable TT

4000D DT

4000D Removable DT

Z-Xtreme™

2000T TT

ECO-

FRIENDLY

ECO-

FRIENDLY

BEST

VALUE

White paper labels and tags designed for unique or challenging applications. Recommended for indoor use.

Paper label with a permanent acrylic adhesive specifically

designed to adhere to small, curved surfaces

Paper label with a permanent acrylic adhesive specifically

designed to adhere to small, curved surfaces

Paper label with a permanent acrylic adhesive; scannable

in both visible and near infrared wavelength; meets FDA

175.105 indirect food contract requirements

Paper label with an all-temp permanent acrylic adhesive;

scannable in visible, near infrared, and infrared ranges;

meets FDA 175.105 indirect food contact requirements

Paper label with high-performance permanent acrylic

adhesive that provides temperature resistance up to

194° F/90° C; offers superior durability under fluorescent

bulbs and partial UV exposure (through window)

Linerless paper label with permanent acrylic adhesive;

DT

eliminates liner waste

Linerless paper label with removable acrylic adhesive;

DT

eliminates liner waste

White, corona-treated polyolefin facestock that provides flexibility for labeling curved or rough surfaces; minimal resistance to scratching

and smearing. Recommended for applications that require up to 6 months outdoors; temperature exposure up to 200° F/93° C.

Highly flexible corona-treated polyolefin label with an alltemp permanent acrylic adhesive that provides high initial

tack designed exclusively for industrial labeling applications

Semi-rigid corona-treated polyolefin label with an all-temp

permanent acrylic adhesive that provides high initial tack

and cold-temperature properties; meets FDA 175.105

indirect food contact requirements

White, matte polypropylene facestock that provides high print quality and resistance to scratching and smearing; offers some flexibility

for labeling curved surfaces. Thermal transfer materials recommended for applications that require up to 1-2 years outdoors; temperature

exposure up to 250° F /121° C.

Polypropylene label with a permanent acrylic adhesive;

meets FDA 175.105 indirect food contact requirements

Polypropylene label with a high-tack permanent

acrylic adhesive

Kimdura® polypropylene label with a permanent acrylic

adhesive; CSA acceptances; meets FDA 175.105 indirect

food contact requirements

Kimdura polypropylene label with a high-tack acrylic

permanent adhesive; meets FDA 175.105 indirect food

contact requirements

Kimdura polypropylene label with a removable acrylic

adhesive; provides good resistance to common industrial

cleaning solutions

Polypropylene label with an all-temp permanent acrylic adhesive that allows label to be applied to surfaces as cold as -40°

F/40° C, meets FDA 175.105 indirect food contact requirements

Polypropylene label with a removable acrylic adhesive;

meets FDA 175.105 indirect food contact requirements

White, matte polyester facestock that provides outstanding print quality and good smear and scratch resistance. Offers excellent resistance

to chemicals. Recommended for applications that require up to 3 years outdoors; temperature exposure up to 300° F/149° C.

Matte polyester label with a permanent acrylic adhesive;

UL/cUL acceptances; provides moderate chemical

resistance; also available in silver and clear

High-gloss retail and consumer goods package labels;

color preprinted labels

In hospitals, laboratories and pharmacies on curved

surfaces, such as vials, test tubes and syringes

In hospitals, laboratories and pharmacies on curved surfaces, such as vials, test tubes and syringes

Shipping applications; indoor, general-purpose labeling;

meets requirements of package delivery industry

Indoor, general-purpose labeling; labeling of most packaging

material; excellent for cold-temperature applications

Hot food labeling such as pizza; coffee; direct store delivery;

archival use and short-term outdoor use -40° F

Indoor, general-purpose labeling; labeling of most packaging

material; excellent for cold-temp applications

Indoor removable general-purpose labeling; labeling of most

packaging material; excellent for cold-temp applications

Chemical drum labeling; product labeling; retail applications;

recyclable shrink wrap applications; labeling harness

configurations

Chemical drum labels; medical and pharmaceutical labeling;

cold-temperature storage

Chemical drum, test tube, or indirect food labeling; capital

asset labeling; labeling small curved or irregularly shaped

products; labeling packages in cold storage

Chemical drum, medical device, or indirect food labeling;

capital asset labeling; labeling small curved or irregularly

shaped products; hard-to-label surfaces

Chemical drum, medical device, or indirect food labeling;

capital asset labeling; labeling small curved or irregularly

shaped products; UID compliance

Chemical drum, medical device, or indirect food labeling;

capital asset labeling; labeling small curved or irregularly

shaped products; hard-to-label surfaces

Removable shelf, bin, furniture, or product labeling

Indoor, general-purpose labeling; houseware goods

labeling; cold storage; provides good resistance to common

industrial cleaning solutions

Indoor, removable, general-purpose labeling; labeling

Tupperware® containers; shelf labeling

UL/cUL compliance product labeling; asset labeling;

serial plate labeling

25° F

-4° C

25° F

-4° C

25° F

-4° C

25° F

-4° C

-20° F

-29° C

-40° C

40° F

4° C

40° F

4° C

25° F

-4° C

10° F

-12° C

45° F

7° C

32° F

0° C

10° F

-12° C

35° F

2° C

45° F

7° C

-40° F

-40° C

10° F

-12° C

50° F

10° C

-65° F to 200° F

-54° C to 93° C

-75° F to 200° F

-59° C to 93° C

-75° F to 120° F

-59° C to 49° C

-40° F to 140° F

-40° C to 60° C

-65° F to 140° F

-54° C to 60° C

-40° F to 194° F

-40° C to 90° C

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-40° F to 200° F

-40° C to 93° C

-40° F to 176° F

-40° C to 80° C

-65° F to 200° F

-54° C to 93° C

-75° F to 200° F

-59° C to 93° C

-40° F to 250° F

-40° C to 121° C

-65° F to 200° F

-54° C to 93° C

0° F to 160° F

-18° C to 71° C

-65° F to 131° F

-54° C to 55° C

-20° F to 120° F

-29° C to 49° C

-40° F to 302° F

-40° C to 150° C

•

nr

• • • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

nr

• • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • • • • • •

• • • • •

nr nr nr

• • • • • • • • • • • • • •

• • • • • • • • • • • • • •

nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr nr

nr nr

nr nr

• • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • •

• • • • • • • • • • • • • • • •

• • • • •

• • • • • • •

• • • • •

• • • • • •

nr nr nr

nr

nr nr nr

nr

• • • • • • •

• • • • • • • •

•

•

nr

• • •

nr

• • •

nr nr nr

nr nr nr

nr nr

5586,

3200

2100, 5319,

5555

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

3200,

5586

5586 5095

3200,

5586

3200,

5586

5555,

3200

5555,

3200

5555,

3200

N/A N/A

N/A N/A

3200,

5586

5095

3200,

5586

5095

5095

5095

5586

5586

5586

5095,

5100

1110

Page 7

Labels

Product Name

Z-Xtreme™ (continued)

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

White, matte polyester facestock that provides outstanding print quality and good smear and scratch resistance. Offers excellent resistance

to chemicals. Recommended for applications that require up to 3 years outdoors; temperature exposure up to 300° F/149° C.

Product Description Applications

Minimum

Application

Temperature

Service

Temperature

Corrugate

Surfaces to be Labeled Environment Resistance Suggested Ribbons

Paper

Most Plastics

Packaging Films

Rough Surfaces

Metal and Glass

Curved Surfaces

Indoors

Moist Surfaces

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Window Cleaner)

(ie. Gasoline, Oil)

Chemical–Harsh

Chemical–Extreme

Standard

Chemicals

Application–

(ie. Acetone, Xylene)

Weak and Moderate

High Durability–

Extreme Chemicals

Abrasion, Harsh and

2000T Removable TT

4000T TT

4000T High-Tack TT

5000T TT

Z-Ultimate

2000T TT

2000T

Color Stay

3000T TT

4000T TT

4000T High-Tack TT

4000T Removable

®

BEST

VALUE

Synthetic Labels

Z-Supreme™

Matte polyester label with a removable acrylic adhesive;

provides moderate chemical resistance

Matte polyester label with a high-performance acrylic

adhesive; UL/cUL and CSA acceptances; provides

harsh-chemical resistance; also available in silver

Matte polyester label with a high-tack permanent rubber

adhesive; UL/cUL and CSA acceptances; provides

harsh-chemical resistance; also available in silver

Matte polyester label with a permanent acrylic adhesive;

UL/cUL acceptances; provides the most extreme chemical

resistance

White, gloss polyester facestock that provides outstanding print quality and unparalleled smear and scratch resistance. Offers good

resistance to chemicals. Recommended for applications that require up to 3 years outdoors; temperature exposure up to 300° F/150° C.

Polyester gloss label with a permanent acrylic adhesive;

UL acceptance

Gloss polyester label with clear gloss polyester overlaminate and a high-performance permanent acrylic adhesive;

TT

overlaminate protects color floodcoat against color fade in

UV light for up to 2 years

Gloss polyester label with a high-performance permanent

acrylic adhesive; UL/cUL and CSA acceptances; also

available in silver

Gloss polyester label with a high-performance permanent

acrylic adhesive; UL/cUL and CSA acceptances; also available in silver and clear

Gloss polyester label with a high-tack permanent acrylic

adhesive; UL/cUL and CSA acceptances; also available in

silver

Gloss polyester label with a removable acrylic adhesive;

UL/cUL acceptances

White, polyimide facestock designed for high-temperature environments up to 500° F/260° C. Recommended for printed circuit board (PCB) labeling.

Removable shelf or bin labels; provides good resistance to

common industrial cleaning solutions

UL/cUL and CSA compliance product labeling; asset

labeling; automotive labeling, particular around battery use;

medical device labeling; serial plate labeling

UL/cUL and CSA compliance product labeling; medical

device labeling; asset labeling; automotive labeling; serial

plate labeling; hard-to-label surfaces

UL/cUL compliance product labeling, asset labeling, automotive labeling, particularly around battery use; medical

device labeling; serial plate labelings

Product labeling; top-side PCB labeling; asset labeling; automotive labeling; serial plate labeling; fanfolding applications

Application requires color to be durable outdoors for up

to 2 years. Vending machines; utility meters; outdoor/

tools/equipment

UL/cUL and CSA compliance product labeling; top-side PCB

labeling; asset labeling; automotive labeling; serial plate

labeling

UL/cUL and CSA compliance product labeling; top-side PCB

labeling; asset labeling; automotive labeling; serial plate

labeling; UID compliance

UL/cUL and CSA compliance product labeling; asset

labeling; automotive labeling; serial plate labeling;

fanfolding applications; hard-to-label surfaces

UL/cUL compliance product labeling; removable shelf or

scan-pallet labels; labels in contact with moving parts or

friction; fanfolding applications

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

-40° F to 302° F

-40° C to 150° C

-40° F to 300° F

-40° C to 149° C

-40° F to 300° F

-40° C to 149° C

-40° F to 300° F

-40° C to 149° C

-40° F to 302° F

-40° C to 150° C

-40° F to 302° F

-40° C to 150° C

-40° F to 302° F

-40° C to 150° C

-40° F to 302° F

-40° C to 150° C

-40° F to 302° F

-40° C to 150° C

-20° F to 302° F

-29° C to 150° C

• • • • •

nr nr

• • • • • •

• • • • • •

• • • • • •

• • • • •

• • • • •

nr nr nr

nr nr nr

• • • • • •

• • • • • •

• • • • • •

• • • • •

nr nr nr

• • • • • • •

nr

• • • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • • •

• • • • • • •

• • • • • • •

nr

• • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • •

• • • • • • •

nr nr

nr

nr

nr

nr

nr

nr

nr

3200,

5586

3200,

5586

3200,

5586

Image Lock Image Lock

5095 5100

5095 5100

5095 5100

5095 5100

5095 5100

5095 5100

5095,

5100

5095

5095

2000T TT

3000T TT

4000T TT

Z-Endure™

3000T TT

4000T TT

Specialty

8000T Image Lock TT

BEST

VALUE

Long-life acrylic facestock that provides excellent print quality and resistance to scratching and smearing. Recommended for applications

requiring long-term outdoor use; temperature exposure up to 300˚F.

White, synthetic labels designed for unique or challenging applications.

White gloss polyimide label with a high-temp permanent

acrylic adhesive that provides resistance to harsh environments; UL/cUL acceptances; available in 2 mil with paper

or poly liner and 1 mil with paper or poly liner

Matte polyimide label with a high-temp permanent acrylic

adhesive that provides resistance to harsh environments;

not recommended for processes using lead-free solder

Gloss polyimide label with a high-temp permanent acrylic

adhesive that provides resistance to harsh environments;

also available in yellow and blue

White acrylic film with a reflective glass bead coating and

a high-performance permanent acrylic adhesive; excellent

chemical and scratch resistance; provides outdoor durability

of 7 years; also available in yellow, orange and red

White acrylic label with a permanent acrylic adhesive that

offers 10-year outdoor durability.

Polyolefin label with a permanent acrylic adhesive; match with

Image Lock ribbon to produce exceptional print quality; provides excellent chemical resistance; 5-year outdoor durability

Printed circuit board top- and bottom-side applications;

auto-apply applications (poly liner); harsh environments

including lead-free manufacturing processes; high-temp

industrial applications

Printed circuit board top- and bottom-side applications;

harsh environments; high-temp industrial applications

Printed circuit board top- and bottom-side applications

including lead-free manufacturing processes; harsh

environments; high-temp industrial applications

Long-term outdoor safety warning labels; utility pole

labeling; warning/instructional labels for heavy equipment;

durable labels for ABS, aluminum and stainless steel surfaces that will be exposed outdoors for up to 7 years

Vending machines, utility meters, signs, posts; outdoor

tools/equipment that require extended exposure up to 10

years; UID compliance

Chemical drums; laboratory labeling; automotive labeling;

process control of electronic components; serial plate

labeling; UID compliance

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

-40° F to 500° F

-40° C to 260° C

-40° F to 482° F

-40° C to 250° C

-40° F to 500° F

-40° C to 260° C

-40° F to 176° F

-40° C to 80° C

-40° F to 302° F

-40° C to 150° C

-112° F to 248° F

-80° C to 120° C

nr nr nr

nr nr nr

nr nr nr

• • • • • • • • • • • •

• • • • • • • • • • • •

• • • • • • • • • • • •

• • • • • • • • • • • • • • •

• • • • • •

nr

• • • • • • • •

nr

nr

nr

nr

nr

• • • • • • • • • • • • • • • •

5095,

5100

N/A 5100

N/A 5100

5095 5100

5095 5100

N/A Image Lock

5095,

5100

1312

Page 8

Labels

Product Name

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Product Description Applications

Minimum

Application

Temperature

Service

Temperature

Corrugate

Surfaces to be Labeled Environment Resistance Suggested Ribbons

Paper

Most Plastics

Packaging Films

Rough Surfaces

Metal and Glass

Curved Surfaces

Indoors

Moist Surfaces

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Window Cleaner)

(ie. Gasoline, Oil)

Chemical–Harsh

Chemical–Extreme

Standard

Application–

ate Chemicals

(ie. Acetone, Xylene)

Weak and Moder-

Chemicals

High Durabil-

ity–Abrasion,

Harsh and Extreme

Specialty (continued)

8000T Low-Temp Matte TT

8000T CryoCool™ TT

8000T Low-Temp Gloss TT

8000T Primary Blood Bag TT

8000T Blood Bag TT

8000T Jewelry TT

8000D Jewelry DT

Z-Slip DT

8000D Shelf Label DT

8000T GHS

Laminate

8000T Ultra High-Tack

Matte

Synthetic Labels

8000T RetroScan TT

8000T ESD Gloss TT

8000T Piggyback Clear

Matte

8000T Void Gloss TT

8000T Void Matte Silver TT

8000T Checkerboard

Gloss Silver

8000T GHS

Polyester

8000T GHS

Vinyl

NEW

ITEM

NEW

ITEM

NEW

ITEM

White, synthetic labels designed for unique or challenging applications.

Matte polyolefin label with a cold-temp permanent acrylic

adhesive that offers -112° F /-80° C performance for

low-temperature use; provides resistance to repeated

freeze and thaw cycles

Polypropylene label with a cold-temp permanent acrylic

adhesive that offers extremely low-temperature

performance down to -320° F /196° C

Gloss polypropylene label with a cold-temp permanent

acrylic adhesive that offers -112° F /-80° C performance for

low-temperature use; provides outdoor durability for

1-2 years; available in white

Polypropylene label with an all-temp acrylic adhesive;

compliant with FDA 175.105

Polypropylene label with a permanent acrylic adhesive Secondary blood bag labeling. Should not be applied

Polypropylene label with a permanent acrylic adhesive;

provides high print quality and smudge resistance;

available in custom colors

Polypropylene label with a permanent acrylic adhesive;

UV shield provides resistance to ultraviolet light; available

in custom colors

Direct thermal paper tag combined with a clear

polypropylene label featuring a permanent acrylic adhesive

Matte polypropylene label with an all-temp acrylic adhesive.

Features a varnish that protects the image, allowing the 8000D

Shelf Talker Clear to be placed over it and removed cleanly

Thermal transfer white polypropylene label with a clear gloss

polyester overlaminate and permanent acrylic adhesive.

TT

Overlaminate provides added durability for pre-printed red

diamonds against abrasion and chemicals. BS 5609 Section 2

and 3 certified when paired with 5095 resin ribbon.

Matte polyester label with a high-tack permanent acrylic

TT

adhesive for difficult-to-label surfaces

Silver gloss retro-flective polyester label with a permanent

acrylic adhesive designed specifically for long-range scanning

Gloss polyester electrostatic dissipative label with a

high-temp permanent acrylic adhesive; meets ESD S11.11

Surface Resistance Test requirements

Piggyback matte polyester label with a permanent

TT

acrylic adhesive that can be over-laminated with a clear

polyester liner

White gloss polyester label with a tamper-proof adhesive

that leaves a “void” pattern when label is removed

Matte polyester label with a tamper-proof adhesive that

leaves a “void” pattern when label is removed; UL acceptances

Silver gloss polyester label with a tamper-proof adhesive

TT

that leaves a checkerboard pattern when label is removed;

maintains tamper evidence feature up to 176° F /80° C

Thermal transfer white matte polyester label with a permanent

acrylic adhesive. Provides excellent chemical resistance.

TT

Adhesive system designed to bond well to painted steel, fiber

and plastic drums. BS 5609 Section 2 and 3 certified when

paired with 5095 resin ribbon and Red Resin ribbon.

Thermal transfer matte white vinyl label with a permanent

acrylic adhesive. Offers exceptional flexibility for curved

surfaces and excellent chemical resistance. Adhesive system

TT

designed to bond well to painted steel, fiber and plastic drums.

BS 5609 Section 2 and 3 certified when paired with 5095 resin

ribbon and Red Resin ribbon.

Cold-temperature applications down to -112° F/-80° C; cold

storage; virology labeling, genetics labeling, DNA

sequencing; labeling vials, test tubes, ampules

Cryogenic applications involving a deep freezing process;

medical labs, hospitals

Cold-temperature applications down to -112° F/ -80° C;

cold storage; virology labeling, genetics labeling, DNA

sequencing; steam sterilization

Primary blood bag labeling; IV bag labeling

directly to blood bag

Ideal for jewelry and ring labels; safe to use in jewelry

steamers and cleaners

Ideal for jewelry and ring labels; safe to use in jewelry

cleaners

Packing slip, invoice and compliance labeling

Shelf label that withstands refrigeration and freezing

Chemical drum labeling; GHS applications with pre-printed

color, specifically those requiring BS 5609 Section 2 and 3

compliance

Asset and machinery tracking; labeling textured surfaces,

plastic, painted or bare metal and wood; UID compliance

Indoor warehouse bin/shelf/location labels for long-range

scanning

Applications requiring resistance to electrostatic discharge;

circuit boards, disk drives, and other sensitive electronic

components

Asset management labeling; chemical containers;

automotive labeling; UID compliance

Serial number plates; warranty/authenticity label; tamperevident security labels; capital asset labeling

Serial number plates; warranty/authenticity label; tamperevident security labels; capital asset labeling

Security and product authentication applications such as

cellular phones

Chemical drum labeling; GHS applications, specifically those

requiring BS 5609 Section 2 and 3 compliance

Chemical drum labeling; GHS applications, specifically those

requiring BS 5609 Section 2 and 3 compliance

50° F

10° C

-20° F

-29° C

50° F

10° C

-20° F

-29° C

45° F

7° C

45° F

7° C

-10° F

-23° C

23° F

-5° C

-20° F

-29° C

45° F

7° C

50° F

10° C

45° F

7° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

50° F

10° C

10° F

-12° C

10° F

-12° C

-112° F to 200° F

-80° C to 93° C

-320° F to 190° F

-196° C to 88° C

-112° F to 200° F

-80° C to 93° C

-65° F to 200° F

-54° C to 93° C

-40° F to 250° F

-40° C to 120° C

-40° F to 250° F

-40° C to 121° C

-40° F to 120° F

-40° C to 49° C

-20° F to 131° F

-29° C to 55° C

-40° F to 150° F

-40° C to 66° C

-65°F to 200°F

-54°C to 93°C

-20° F to 302° F

-29° C to 150° C

-40° F to 300° F

-40° C to 149° C

-40° F to 302° F

-40° C to 150° C

-40° F to 302° F

-40° C to 150° C

-40° F to 158° F

-40° C to 70° C

-40° F to 104° F

-40° C to 40° C

-40° F to 176° F

-40° C to 80° C

-40°F to 302°F

-40°C to 150°C

-40°F to 176°F

-40°C to 80°C

• • • • • • • • • • • • • • •

• • • • • • • • • • • • • • •

• • • • • • • • • • • • • • •

• • • • • • • • • • • • • • •

• •

• •

• •

nr nr

nr nr

nr nr

• • • • • • • • • • •

• • • • • • • • • • •

• • • • •

nr

• • • •

nr

nr

nr

nr

nr

nr

nr nr

• • • • • • • • • • • • • • • •

• • • • • • • • •

nr

• • •

• • • • • • • • • • • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

nr nr

nr nr

nr nr

• • • •

• • • •

• • • •

nr

• • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • •

nr

• • • • • • • •

• • • • • • • • • • • • • • •

• • • • • • • • • • • • • • •

nr nr nr

nr

nr

nr

nr

nr

nr

nr

nr

nr

5555 3200

5095 5095

5095 5095

5555,

3200

5555,

3200

3200,

5586

N/A N/A

N/A N/A

N/A N/A

5095 5095

5555,

3200

5095 5095

5095 5100

2000, 2100,

5319

5095 5100

5555,

3200

5095 5100

5095

&

Red Resin

5095

&

Red Resin

5586

5586

5095

5586

3200

5586

5095

&

Red Resin

5095

&

Red Resin

1514

Page 9

Labels

Product Name

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Product Description Applications

Minimum

Application

Temperature

Service

Temperature

Corrugate

Surfaces to be Labeled Environment Resistance Suggested Ribbons

Paper

Most Plastics

Packaging Films

Rough Surfaces

Metal and Glass

Curved Surfaces

Indoors

Moist Surfaces

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Window Cleaner)

(ie. Gasoline, Oil)

Chemical–Harsh

Chemical–Extreme

Standard

Application–

ate Chemicals

(ie. Acetone, Xylene)

Weak and Moder-

Chemicals

High Durabil-

ity–Abrasion,

Harsh and Extreme

Specialty (continued)

8000T Z-Destruct™ TT

8000T Vinyl Clear TT

8000T Vinyl Outlast TT

Synthetic Labels

8000T Cling TT Gloss static cling vinyl label

Tags

Product Name

Z-Perform

1000T Tag TT Uncoated paper tag available in 7.5 and 9.5 mil thickness

1000D Tag DT Uncoated paper tag available in 5.3 mil thickness

Z-Select

Paper Tags

4000T Tag TT Paper tag available in 5.0, 7.0, and 9.0 mil thickness

4000D Tag DT Paper tag available in 5.3 and 7.5 mil thickness General-purpose ticketing; shop floor tracking tickets; retail hang tag N/A

PolyPro

4000T Tag TT Polypropylene tag available in 7.0 and 8.5 mil thickness

Z-Ultimate

4000T Tag TT Gloss polyester laminated tag available in 8 mil thickness

White, synthetic labels designed for unique or challenging applications.

Vinyl label with a permanent acrylic adhesive that

destructs when label is removed

Clear matte vinyl label with a permanent acrylic adhesive

that is highly flexible

White semi-gloss vinyl label with a permanent acrylic adhesive; offers excellent flexibility for curved surfaces; provides

outdoor durability of 5 years and excellent UV resistance

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Bright white, smooth paper facestock that provides the optimal balance between performance and price for industrial applications.

Recommended for indoor use.

Premium, bright white, ultra-smooth paper facestock specially coated to provide optimal quality. Ideal for high-speed printing applications

where print quality is important. Recommended for indoor use.

White, matte polypropylene facestock that provides high print quality and resistance to scratching and smearing; offers some flexibility

for labeling curved surfaces. Thermal transfer materials recommended for applications that require up to 1-2 years outdoors; temperature

exposure up to 250° F.

White, gloss polyester facestock that provides outstanding print quality and unparalleled smear and scratch resistance. Offers good

resistance to chemicals. Recommended for applications that require up to 3 years outdoors; temperature exposure up to 300° F.

Product Description Applications

Serialized data and warranty labels; applications requiring

destructible solution; ideal for high-value electronics

Wrap around wire labeling; wrap around vial or tube

labeling

Vial or tube labeling; warranty labeling; safety warning

labels; outdoor piping requiring outdoor durability of up to

5 years

Oil change, preventive maintenance and service.

Temporary parking stickers.

General-purpose ticketing; retail hang tags; inventory and shop floor

tracking tickets

General-purpose ticketing; retail hang tags; inventory and shop floor

tracking tickets

General-purpose ticketing; retail hang tags; inventory control and

shop floor tracking tickets

Outdoor, general purpose tagging; wire marking, visitor passes,

bin tags, pallets

Tags requiring high environmental resistance; outdoor storage tags;

water immersed tags, steel tags; high-quality hang tags

50° F

10° C

50° F

10° C

50° F

10° C

32° F

0° C

-60° F to 250° F

-51° C to 121° C

-40° F to 176° F

-40° C to 80° C

-40° F to 170° F

-40° C to 77° C

-40° F to 200° F

-40° C to 93° C

Minimum

Application

Temperature

N/A

N/A

N/A

N/A

N/A

• • • • • • • • • • • • • • •

• • • • • • • • • • • • • •

• • • • • • • • • • • • • •

• • • • • •

Environment Resistance Suggested Ribbons

Service

Temperature

-50° F to 200° F

-46° C to 93° C

-40° F to 140° F

-40° C to 60° C

-40° F to 200° F

-40° C to 93° C

-40° F to 140° F

-40° C to 60° C

-40° F to 200° F

-40° C to 93° C

-40° F to 200° F

-40° C to 93° C

Indoors

•

•

•

•

• • • • • • • •

• • • • • • •

nr nr

Outdoors

nr nr

nr nr

nr

nr

• • •

• • •

• • •

Moisture

Abrasion

• •

• •

nr

Chemical–Weak

(ie. Window Cleaner)

(ie. Alcohol, Bleach)

Chemical–Moderate

nr nr nr

nr nr nr

nr nr nr

nr nr nr

• • • •

Chemical–Harsh

nr nr

nr nr

(ie. Gasoline, Oil)

Chemical–Extreme

nr

nr

(ie. Acetone, Xylene)

3200,

5555,

3200 (white),

5319 (clear)

Standard

Application–

Weak and Moder-

2000,

5319

N/A N/A

2000, 2100,

5319

N/A N/A

3200, 5586 5095

5095 5100

5586

3200

5555 5095

ate Chemicals

5095

5586,

5095

N/A

High Durability–

Abrasion, Harsh and

N/A

5555,

3200

Extreme Chemicals

Specialty

8000T Light-Weight Tag TT

Synthetic Tags

8000T Tuff Tag TT

8000T Ultra-Tuff Tag TT

8000T Nylon Tag TT

White, synthetic tags designed for unique or challenging applications.

Tyvek® olefin tag that provides tear resistance and durability;

lightweight; available in 8.0 mil thickness

V-Max® polyolefin tag that provides tear strength and outdoor use up

to 1-2 years; available in 7.0 mil thickness

Valéron® polyethylene tag that provides the highest tear resistance

and durability; available in 7.5 and 9.5 mil thickness

Woven nylon tag that may be sewn into clothing; provides

outstanding print quality; available in 5.7 mil thickness

Sewn-in tags, lawn tags, garment tags; seat belts; greenhouse and

nursery tags; staple-on tags; outdoor storage

Nursery tags; lumber tags; outdoor storage tags

Nursery tags; lumber tags; construction applications;

outdoor storage tags

Seat belt tagging; care tag applications N/A

N/A

N/A

N/A

-40° F to 200° F

-40° C to 93° C

-70° F to 200° F

-57° C to 93° C

-70° F to 200° F

-57 C to 93° C

-40° F to 302° F

-40° C to 150° C

• • • • • •

• • • • • •

nr nr

nr nr

• • • • • • •

• • • • • • •

nr

nr

2000,

5319

5555,

3200

5555,

3200

N/A Nylon Ribbon

3200

5586

5586

1716

Page 10

Receipts

Product Name

Z-Perform

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Bright white, smooth paper facestock that provides the optimal balance between performance and price for industrial applications.

Recommended for indoor use.

Product Description Applications

Thickness

(Mil)

Service

Temperature

Archivability Topcoated Sensitivity

Environment Resistance Suggested Ribbons

Indoors

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Gasoline, Oil)

Chemical–Harsh

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Window Cleaner)

Standard

Chemicals

Application–

Chemical–Extreme

(ie. Acetone, Xylene)

Weak and Moderate

High Durability–

Extreme Chemicals

Abrasion, Harsh and

Paper Receipts

Receipts

Synthetic

Wristbands

Product Name

1000D Receipt DT Premium receipt paper that offers excellent quality at a low cost

Z-Select

4000D Receipt DT

4000T Receipt TT Receipt paper available in 3.0 mil thickness Staple-on tickets; plastic bag inserts; packing lists

Specialty

8000D High-Temp Receipt DT

PolyPro

4000D Receipt DT Polypropylene receipt paper that is waterproof and tearproof

Premium, bright white, ultra-smooth paper facestock specially coated to provide optimal quality. Ideal for high-speed printing

applications where print quality is important. Recommended for indoor use.

Receipt paper featuring a topcoat that allows for exceptional

long-life durability and resistance

White receipt paper designed for unique or challenging applications. Recommended for indoor use.

Receipt paper that provides temperature resistance up to

194° F/90° C; offers superior durability under fluorescent bulbs

and partial UV exposure (through a window)

White, matte polypropylene facestock that provides high print quality and resistance to scratching and smearing.

Performance Characteristics: •Recommended •Test In Your Application nr Not Recommended

Thermal

Transfer

(TT)

Direct

Thermal

(DT)

Product Description Applications Closure Type

General purpose mobile workforce applications including route

accounting and field service

Mobile workforce applications including route accounting

and field service

Mobile workforce applications that will be exposed to high

temperature including e-citation

Mobile workforce applications, such as e-citation, that will be

exposed to moisture and require a durable receipt

2.4 or 3.5

3.2

3.0

3.2

3.8

* The thermal image will remain legible for the archival life provided the image is fully developed on the recommended thermal printer and the document is stored with compatible materials under proper storage conditions

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-40° F to 200° F

-40° C to 93° C

-40° F to 194° F

-40° C to 90° C

-40° F to 140° F

-40° C to 60° C

10 years* No

25 years* Yes High

10 years* Yes N/A

20 years* Yes N/A

10 years* Yes High

2.4 mil–Medium

3.5 mil–High

•

•

•

nr nr

nr

• • •

nr

• • •

nr nr nr nr

•

• • • • •

• • • • •

nr nr nr

nr nr nr

nr nr nr

nr nr nr

N/A N/A

N/A N/A

2000, 2100,

5319

N/A N/A

N/A N/A

5555,

3200

Environment Resistance Suggested Ribbons

Service

Temperature

Indoors

Outdoors

Moisture

Abrasion

Chemical–Weak

(ie. Window Cleaner)

(ie. Alcohol, Bleach)

Chemical–Moderate

(ie. Gasoline, Oil)

Chemical–Harsh

Standard

Chemicals

Application–

Chemical–Extreme

(ie. Acetone, Xylene)

Weak and Moderate

High Durability–

Extreme Chemicals

Abrasion, Harsh and

®

Z-Band

UltraSoft DT

Comfort DT

Direct DT

QuickClip™ DT

Soft Infant DT

4000 TT

Synthetic Wristbands

Fun DT

Splash DT

Synthetic wristbands uniquely configured for optimal use in Zebra tabletop and desktop printers. Each material provides durability and

security enhancements including security slits, void features, or clip closures.

Soft, flexible polypropylene and vinyl wristband with an adhesive tab

for securement and a silver antimicrobial coating; tamper-evident;

MR-Safe; Scannable up to 14 days

Light-weight, flexible polypropylene wristband with an adhesive tab

for securement and a silver antimicrobial coating; tamper-evident;

color-coding options; latex-free; MR-Safe; Scannable up to 7 days

Polypropylene wristband with an adhesive tab for securement;

tamper-evident slits, color-coding options; latex free; MR-safe;

Scannable up to 14 days

Polypropylene wristband with secure clip closure; color clips

available; latex free; MR-safe; Scannable up to 14 days

Polypropylene wristband with a soft nylon lining delicate enough for

fragile skin. Features an adhesive closure; latex free; MR-safe

Thermal transfer, white, gloss polyester wristband with a permanent

acrylic adhesive; latex free; Scannable up to 14 days

Polypropylene wristband with an adhesive tab for securement. For

one-day use and minimal water exposure in the recreation market

Polypropylene wristband with an adhesive tab for securement. For

multi-day use and excessive water exposure in the recreation market

Patient identification in healthcare facilities Adhesive

Patient identification in healthcare facilities Adhesive

Patient identification in healthcare facilities Adhesive

Patient identification in healthcare facilities Clip

Patient identification in healthcare facilities of infants with

sensitive skin

Patient identification in healthcare facilities Adhesive

Guest identification, tracking and access control. Cashless point

of sale for food and merchandise. Ideal for carnivals/amusement

parks, fairs/festivals, theme parks, zoos/aquariums, sporting events,

concerts and nightclubs

Guest identification, tracking and access control. Cashless point of

sale for food and merchandise. Ideal for water parks, resorts and

cruise lines.

Adhesive

Adhesive

Adhesive

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

-20° F to 300° F

-29° C to 149° C

-40° F to 140° F

-40° C to 60° C

-40° F to 140° F

-40° C to 60° C

• • • • • •

• • • • • •

• • • • • •

• • • • • •

• • • • • •

nr nr

nr nr

nr nr

nr nr

nr nr

• • • • • • •

• • • • • •

• • • • • •

nr nr

nr nr

nr

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

5095 5100

N/A N/A

N/A N/A

1918

Page 11

©2013 ZIH Corp. All product names and numbers are Zebra trademarks, ZipShip is a Zebra service mark, and Zebra, the Zebra head graphic, Z-Band, and Z-Ultimate are registered trademarks of ZIH Corp. All rights

reserved. Hammerlock is a registered trademark of Avery Dennison Corporation. Valéron and V-Max are registered trademarks of Illinois Tool Works Inc. Tyvek is a registered trademark of E.I. du Pont de Nemours and

Company. Tupperware is a registered trademark of Dart Industries Inc. Kimdura is a registered trademark of Kimberly-Clark Corporation. All other trademarks are the property of their respective owners.

Corporate Headquarters Asia-Pacific Headquarters EMEA Headquarters Latin America Headquarters

+1 800 423 0442 +65 6858 0722 +44 (0)1628 556000 +1 847 955 2283

E-mail: inquiry4@zebra.com E-mail: apacchannelmarketing@zebra.com E-mail: mseurope@zebra.com E-mail: inquiry4@zebra.com

Other Locations

USA: California, Georgia, Illinois, Rhode Island, Texas, Wisconsin Europe: France, Germany, Italy, the Netherlands, Poland, Spain, Sweden, Turkey,

United Kingdom Asia Pacific: Australia, China, Hong Kong, India, Japan, Malaysia, South Korea, Singapore, Thailand Latin America: Brazil, Florida

www.zebra.com

(LA Headquarters in USA), Mexico Africa/Middle East: Dubai, South Africa

P1021760 (7/14)

Loading...

Loading...