Page 1

8585/8595

VEHICLE-MOUNT

COMPUTERS

(Windows® Embedded Standard 7 &

Windows 7 Professional)

USER GUIDE

Page 2

Page 3

i

8585/8595 VEHICLE-MOUNT COMPUTERS

USER GUIDE

8000240-001

Revision A

July 2015

Page 4

ii 8585/8595 Vehicle-Mount Computer User Guide

Copyright

Zebra and the stylized Zebra head are trademarks of ZIH Corp., registered in many jurisdictions worldwide.

All other trademarks are the property of their respective owners.

© 2015 ZIH Corp and/or its affiliates. All rights reserved.

Disclaimer

Every effort has been made to make this material complete, accurate, and up-to-date. In addition, changes are

periodically incorporated into new editions of the publication.

We reserve the right to make improvements and/or changes in the product(s) and/or the program(s) described

in this document without notice, and shall not be responsible for any damages including, but not limited to,

consequential damages, caused by reliance on the material presented.

Zebra, the Zebra logo, Workabout Pro4 and the names of other products and services provided by Zebra are

trademarks of Zebra.

Windows® and the Windows Logo are trademarks or registered trademarks of Microsoft Corporation in the

United States and/or other countries.

The Bluetooth® word mark and logos are owned by Bluetooth SIG, Inc. and any use of such marks by Zebra is

under license.

All trademarks used herein are the property of their respective owners.

Page 5

Revision History

Changes to the original guide are listed below:

Change Date Description

-001 Rev A 057/2015 Operating system updates.

iii

Page 6

Page 7

TABLE OF CONTENTS

Table of Contents

Overview of the 8585 and 8595 Vehicle-Mount Computers............................................................ vii

Device Models ................................................................................................................................ vii

Scope of Delivery............................................................................................................................ viii

Packaging....................................................................................................................................... viii

Removing the Protective Film from the Display............................................................................. viii

Returning Your Device.................................................................................................................... ix

About the 8585 / 8595 Vehicle-Mount Computer User Manual....................................................... ix

Text Conventions ............................................................................................................................ x

Chapter 1: Approvals and Basic Safety Guidelines

Always Install, Operate, and Maintain the Unit Properly................................................................. 1-1

Safety.............................................................................................................................................. 1-1

Intended Usage............................................................................................................................... 1-1

Initial Operation of the Device......................................................................................................... 1-2

Power Supply.................................................................................................................................. 1-3

External Devices............................................................................................................................. 1-3

Repairs Only .................................................................................................................................. 1-4

CE Marking ..................................................................................................................................... 1-4

RTTE Directive 1999/5/EC.............................................................................................................. 1-4

Special Rule/Restriction ................................................................................................................. 1-5

Regulatory Summary ...................................................................................................................... 1-5

FCC User Information ....................................................................................................................1-5

Declaration of the Federal Communications Commission .................................................. 1-5

Transmission of Radio Frequencies.................................................................................... 1-5

Country Roaming ................................................................................................................1-6

Declaration of Conformity ............................................................................................................... 1-6

Regulatory Information for China.................................................................................................... 1-6

Class A Product Warning ...............................................................................................................1-6

Chinese UM URL .......................................................................................................................... 1-6

Quality Certificate in Chinese when the Factory has ISO 9001 Certification ................................1-7

Page 8

ii 8585/8595 Vehicle-Mount Computer User Guide

Chapter 2: Basic Operation

Removing the Protective Film from the Display.............................................................................. 2-1

Zebra Config: Front Keys, WLAN, Automatic Switch-off................................................................. 2-1

WLAN Settings ............................................................................................................................... 2-2

Radio Performance.........................................................................................................................2-2

Antenna Solutions for Use in Germany..........................................................................................2-3

Laird Connection Manager for WLAN Configuration .....................................................................2-3

Admin Password .................................................................................................................2-4

Protecting the TFT Display from the Memory Effect....................................................................... 2-4

Connectors ..................................................................................................................................... 2-5

Overview of External Connectors...................................................................................................2-5

Adaptor Cables...............................................................................................................................2-5

DC Voltage Supply Connector........................................................................................................2-6

Connecting External Devices.......................................................................................................... 2-7

Powering Up the 8585 .................................................................................................................... 2-7

Powering Down the 8585................................................................................................................ 2-8

Chapter 3: Installing the Computer

Overview......................................................................................................................................... 3-1

Follow and Retain the Mounting Instructions.................................................................................. 3-1

Mechanical Dynamic Loading......................................................................................................... 3-1

Cooling Through the Supply of Fresh Air........................................................................................3-1

Power Supply.................................................................................................................................. 3-2

Vehicle Applications (such as forklifts)............................................................................................ 3-2

Electrical Installation.......................................................................................................................3-2

Wiring Vehicle Power to the 8585/8595 .............................................................................. 3-3

Position of the 8585 in the Vehicle.................................................................................................3-4

Overview of the Assembly Steps....................................................................................................3-4

Cable Cover (splash guard)............................................................................................................ 3-5

Strain Relief .................................................................................................................................... 3-5

Minimum Distance to WLAN Antenna ............................................................................................ 3-5

Antenna Cap and Service USB Interface ....................................................................................... 3-5

Chapter 4: Operation

Touchscreen ................................................................................................................................... 4-1

Construction Type and Resistance.................................................................................................4-1

Operation ........................................................................................................................................4-1

Cleaning..........................................................................................................................................4-2

Touch for MS Windows Embedded Standard 7 .............................................................................4-2

Installation..............................................................

Calibration.......................................................................................................................................4-2

Front Keys and LEDs...................................................................................................................... 4-3

Power Key ......................................................................................................................................4-3

Manual Brightness Control .............................................................................................................4-3

LEDs ...............................................................................................................................................4-3

Special Keys...................................................................................................................................4-4

.....................

........................................ 4-2

Page 9

Table of Contents iii

Shift Key .........................................................................................................................................4-4

Operating States ............................................................................................................................. 4-4

Operating System ........................................................................................................................... 4-4

Pre-installed on Flash.....................................................................................................................4-5

Installing on Flash........................................................................................................................... 4-5

Special Features of the Operating Systems...................................................................................4-5

Serial Port ....................................................................................................................................... 4-5

COM1 as a Power Supply.............................................................................................................. 4-5

Serial Port Printers .........................................................................................................................4-5

Serial Port Bar Code Scanners ......................................................................................................4-5

Tips and Tricks ...............................................................................................................................4-6

Internal Devices .............................................................................................................................. 4-6

Chipset............................................................................................................................................ 4-6

VGA Adaptor ..................................................................................................................................4-6

Onboard Sound Controller .............................................................................................................4-6

Network Adaptor (10/100/1000) .....................................................................................................4-6

Problems with Data Transmission via LAN/Ethernet........................................................... 4-7

Automatic Switch-off....................................................................................................................... 4-7

Modes of Operation.............................................................................................................4-7

Automatic Switch-off Process ............................................................................................. 4-7

Configuration with Zebra Config Program........................................................................... 4-8

Chapter 5: Accessories

Keyboard......................................................................................................................................... 5-1

SMALL Keyboard ........................................................................................................................... 5-1

24-key Keypad................................................................................................................................ 5-1

Scanner Bracket ............................................................................................................................. 5-2

Mouse ............................................................................................................................................. 5-2

USB Stick........................................................................................................................................ 5-2

USB Recovery Stick........................................................................................................................ 5-2

Scanners......................................................................................................................................... 5-2

WLAN Card (PCIe MiniCard).......................................................................................................... 5-3

Microphone (Voice Kit).................................................................................................................... 5-3

Chapter 6: Maintenance and Troubleshooting

Maintenance ................................................................................................................................... 6-1

Cleaning the Housing .....................................................................................................................6-1

Touchscreen Cleaning....................................................................................................................6-1

Troubleshooting ................................................................................

Data Transmission via LAN/Ethernet.............................................................................................6-1

Images for AMD Devices are not Compatible with Intel Devices .................................................. 6-2

8585/8595 AMD: Switch Off/Restart .............................................................................................6-2

Common Mistakes in Usage .......................................................................................................... 6-2

Intel Images are not Compatible with AMD Devices...................................................................... 6-2

Power Supply .................................................................................................................................6-2

Powering Up/Down......................................................................................................................... 6-2

.............................................. 6-1

Page 10

iv 8585/8595 Vehicle-Mount Computer User Guide

Cable Cover....................................................................................................................................6-2

Mounting/Installation.......................................................................................................................6-2

Mobile Application on Vehicles....................................................................................................... 6-3

Using the Touchscreen ...................................................................................................................6-3

Cleaning the Touchscreen..............................................................................................................6-3

Disposal .......................................................................................................................................... 6-3

Chapter 7: Device Description and Technical Specifications

General ........................................................................................................................................... 7-1

Device Models ................................................................................................................................ 7-2

Abbreviations Used for Devices and Accessories .......................................................................... 7-2

Device/Type identification ............................................................................................................... 7-2

Device Type Plate...........................................................................................................................7-2

Technical specifications .................................................................................................................. 7-3

Mechanical (8585/8595).................................................................................................................7-3

8585/8595 AMD: CPU, Cache, RAM (Motherboard) .......................................................... 7-3

Operating System (Optional) for 8585/8595 AMD .........................................................................7-4

Serial Port .......................................................................................................................................7-4

USB-connection, Service USB.......................................................................................................7-4

Touchscreen Interface ....................................................................................................................7-4

8585/8595 AMD: Network Interface ...............................................................................................7-4

Power Supply..................................................................................................................................7-5

Power Supply Fuses ......................................................................................................................7-5

Ambient Conditions .......................................................................................................................7-6

Dimensions 8585/10 ....................................................................................................................... 7-6

Front View....................................................................................................................................... 7-6

Side View........................................................................................................................................ 7-8

Top View .........................................................................................................................................7-9

VESA Drill Holes.............................................................................................................................7-10

Approvals........................................................................................................................................ 7-10

Appendix A: Zebra Config Program

Basic Safety Guidelines.................................................................................................................. A-1

Overview of Functions .................................................................................................................... A-1

Installation....................................................................................................................................... A-3

System Requirements............................................................................................................... A-3

Pre-installed on Zebra Computers............................................................................................ A-3

Subsequent Installation............................................................................................................. A-3

Automatic Installation of Software Keyboard .........................

Files .......................................................................................................................................... A-3

Starting the Program................................................................................................................. A-4

Password Check .................................................................................................................A-4

Accessing Config with WES 7............................................................................................. A-4

FBWF Advice at the Start of the Program........................................................................... A-4

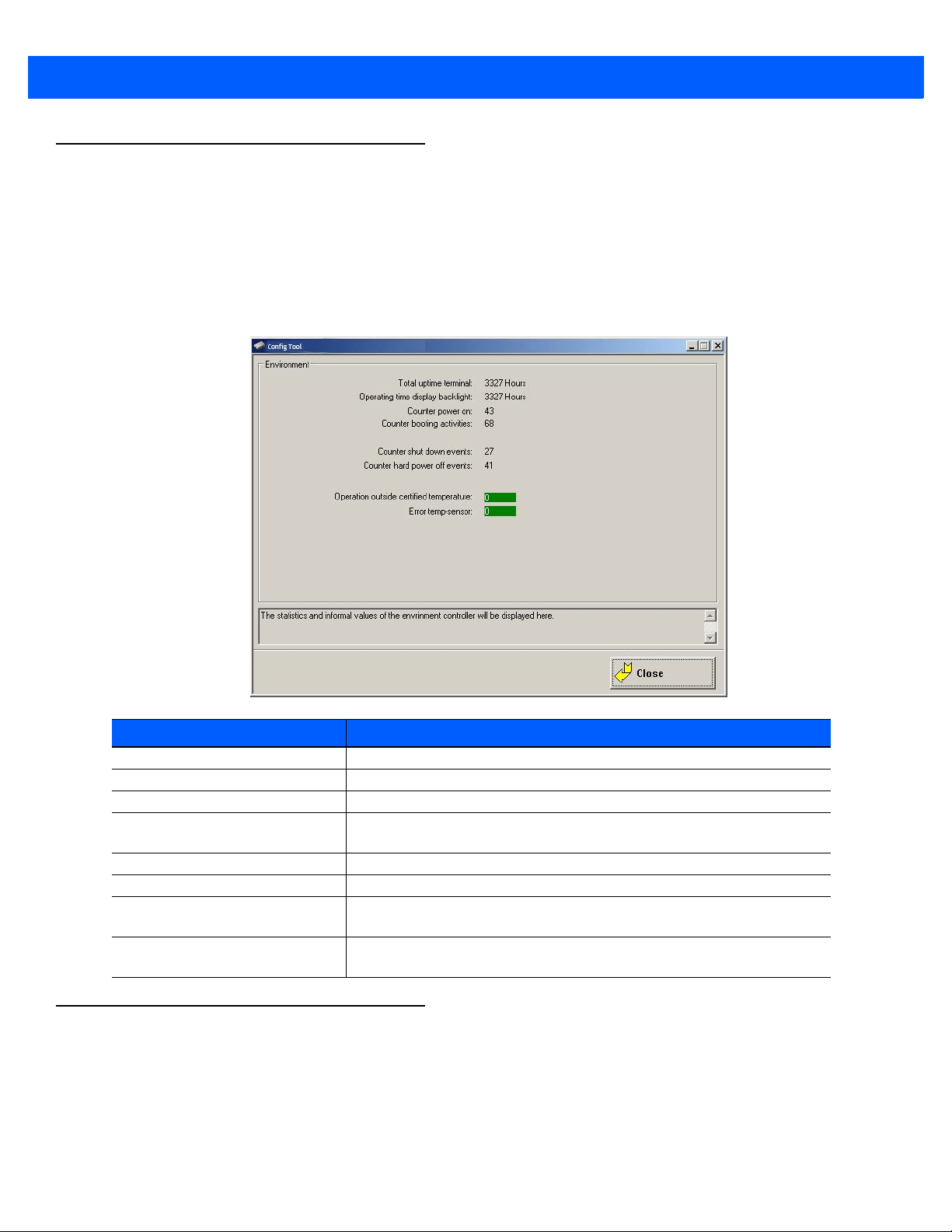

Hardware Monitor ........................................................................................................................... A-5

Environment.................................................................................................................................... A-6

......................

............................. A-3

Page 11

Table of Contents v

Information on 8585 .................................................................................................................. A-6

Automatic Switch-off Configuration Dialog......................................................................................A-6

Settings ..................................................................................................................................... A-8

Switch-On ................................................................................................................................. A-9

Switch-Off.................................................................................................................................. A-10

Front Panel ..................................................................................................................................... A-10

Configuration Dialog ................................................................................................................ A-10

Assigning Front Panel Keys...................................................................................................... A-11

Deleting Front Panel Key Assignment ...................................................................................... A-11

Starting an External Program with the Front Panel Keys.......................................................... A-11

Common System Settings .............................................................................................................. A-11

Windows Embedded Standard 7 and Windows 7 Professional ................................................ A-12

Automatic Windows Logon.................................................................................................. A-12

Logon with Software Keyboard ........................................................................................... A-12

Common.............................................................................................................................. A-13

Remote Desktop Logon with SW-Keyboard........................................................................ A-13

Keyboard / Front Key Locking............................................................................................. A-14

WES 7....................................................................................................................................... A-14

Automatic Windows Logon.................................................................................................. A-14

Software Keyboard..............................................................................................................A-15

Keyboard / Front Key Locking............................................................................................. A-15

Network Settings............................................................................................................................. A-16

Common ................................................................................................................................... A-16

Computer name ..................................................................................................................A-16

Network Adapter ................................................................................................................. A-16

Automatic Computer Renaming................................................................................................ A-17

Network Startup .............................................................................................................................. A-17

Autostart Programs ................................................................................................................... A-18

IP Address for Startup Check.................................................................................................... A-18

WLAN.............................................................................................................................................. A-19

Information on the WLAN Status Window................................................................................. A-19

Signal Strength and Quality ...................................................................................................... A-20

Basic Legend for Signal Strength.............................................................................................. A-20

WLAN Status Window Settings Dialog...................................................................................... A-21

Window Settings ................................................................................................................. A-21

Connect Program................................................................................................................A-22

Extended Settings............................................................................................................... A-22

WLAN Status Window and Radio Cards................................................................................... A-22

rite WLAN L

W

Information in the WLAN Log File ....................................................................................... A-23

Software Activation ......................................................................................................................... A-24

Activate Automatic Switch-off.................................................................................................... A-24

Activate Software Keyboard...................................................................................................... A-24

Enhanced Write Filter ..................................................................................................................... A-25

Set Boot Command (BootCmd) ................................................................................................ A-26

File Based Write Filter..................................................................................................................... A-26

The FBWF Menus: Current and Target Status of the Installation.............................................. A-26

FBWF Configuration ................................................................................................................. A-27

Current Configuration..........................................................................................................A-27

Exceptions for Write Protection........................................................................................... A-28

Modified Files in the Cache................................................................................................. A-28

og File................................................................................................................. A-23

Page 12

vi 8585/8595 Vehicle-Mount Computer User Guide

Settings........................................................................................................................................... A-31

Command Lines Parameter IMPORT (only for administrators) ................................................ A-33

Info Header of an Export File.................................................................................................... A-33

Index............................................................................................................ I

Page 13

ABOUT THIS GUIDE

ABOUT THIS GUIDE

Overview of the 8585 and 8595 Vehicle-Mount Computers

The 8585 and 8595 Vehicle-Mount Computers are multi-function industry computers designed for stationary

and mobile use. Detailed information is listed in Chapter 7: Device Description and Technical Specifications.

Due to its rugged design (aluminium housing), this vehicle-mounted computer provides effective protection

against mechanical, electrical and chemical influences and extreme ambient temperatures.

In this manual, we strive to provide all the information required for using your 8585. However, because this is a

versatile product that can be used in many different scenarios, we cannot guarantee that the information

contained in this manual will cover every single aspect.

Should you require further information or if you have questions or issues needing clarification, please contact

your nearest agent or representative.

Device Models

This manual applies to the following models of this Vehicle-Mount Computer:

• The 8585 with 10.4" display.

• The 8595 with 12.1" display.

NOTE The Model 8585 Vehicle-Mount Computer is used as an example throughout the manual, but all

features are also applicable to the Model 8595.

Page 14

Figure 1

The 8585 Vehicle-Mount Computer

Scope of Delivery

The delivery includes at least the following:

• 8585 or 8595.

• Cable cover.

• The assembly kit.

• Ignition or Screen Blanking power cable.

• Optionally ordered accessories.

• Quick Start Guide - English and Chinese

Please verify the delivery contents immediately on receipt.

Packaging

The packaging material has been selected to optimally protect your device while simultaneously

offering the best possible ecological compatibility. We therefore kindly request that you store the

original packaging material or ensure it is used for another suitable purpose such as transporting the unit or returning shipment.

Caution:

Property

Damage

If you repack the device, please ensure that the cling wrap in the cardboard fr ame is

positioned towards the front of the device so that it can provide the proper protection.

Removing the Protective Film from the Display

The front display of the 8585 is protected during transport by a transparent film. This film should

remain on the front display during assembly to avoid damage to the front display surface.

Only remove the film once all of the assembly work has been completed.

Page 15

Returning Your Device

Due care was exercised when putting together the contents of your delivery and dispatching your device.

Nevertheless, if you still have cause for complaint, please contact your representative.

Should you need to return the device, please use the original packaging.

About the 8585 / 8595 Vehicle-Mount Computer User Manual

This manual has been designed to make using the 8585 and 8595 Vehicle-Mount Computers as simple as

possible and provide expert assistance if problems should occur. The manual generally refers to the 8585

model.

The manual contains important information on using the device safely, properly and efficiently. Adhering to this

information helps to avoid dangers, reduces repair costs and breakdown times, and increases the reliability

and lifespan of the device.

We will not assume responsibility for any damage caused by the improper use of the 8585 or 8595 and/or

disregard of the instructions in this manual.

For Qualified Personnel

About This Guide ix

This manual was written for qualified personnel. The information is intended exclusively to complement the

expertise of qualified personnel, not to replace it.

Keep this Manual

Please keep this manual in a safe place. It should always be at hand near the described device.

WARNING! Before transporting, assembling, and starting the computer, please read this manual

carefully and follow all the requirements in Chapter 1: Approvals and Basic Safety

Guidelines, as well as the safety guidelines in the individual chapters.

Chapter : About This Guide. provides a basic overview of the 8585/8595 user guide.

Chapter 1: Approvals and Basic Safety Guidelines. describes the safety practices required for the opera-

tion of the 8585 and 8595.

Chapter 2: Basic Operation. describes the steps required to get the 8585 ready for operation, device fea-

tures, connectors, power, and WLAN.

Chapter 3: Installing the Computer. describes the instructions for safely and effectively mounting the

computer.

Chapter 4: Operation. describes the touchscreen, keys, operating system, ports, and internal devices.

Chapter 5: Accessories. describes the peripherals and accessories available for your computer.

Chapter 6: Maintenance and Troubleshooting. describes the care of the 8585, steps to investigate prob-

lems, and common usage mistakes.

Chapter 7: Device Description and Technical Specifications. lists the specifications for the 8585 and 8595

computers.

Appendix A: Zebra Config Program. describes the detailed configuration information for the Zebra Config

program.

Page 16

x 8585/8595 Vehicle-Mount Computer User Guide

Text Conventions

NOTE Notes highlight additional helpful information.

WARNING! This symbol indicates hazards that pose a risk to life and limb (such as

contacting the power supply), as detailed below.

IMPORTANT These statements provide particularly important instructions or addi-

tional information that is critical to the operation of the equipment.

Caution:

Property

Damage

This statement warns you of any dangers or hazards that could potentially cause damage to

the computer or system (such as malfunctions, data loss, equipment damage, e tc.).

WARNING! Mild injury is possible.

WARNING! There is a possible risk of death / serious injury.

WARNING! There is an immediate risk of death / serious injury.

Page 17

CHAPTER 1 APPROVALS AND BASIC

SAFETY GUIDELINES

APPROVALS AND BASIC SAFETY GUIDELINES 1

Always Install, Operate, and Maintain the Unit Properly

The 8585 was designed and built according to modern technology and accepted safety regulations. However,

the operation of the 8585 can endanger personnel or third parties and cause damage to the device and other

material assets, when for example the device is:

• Installed incorrectly or improperly.

• Operated by untrained or uninstructed personnel.

• Improperly operated and maintained.

• Not used as intended.

The operator commitments in regards to safety (accident prevention regulations, work protection) are to

be followed.

Safety

In order to prevent injury and damage, please read and observe the following safety guidelines prior to

assembly and commissioning. The manufacturer assumes no liability for any and all damages that can be

attributed to non-compliance with these guidelines.

Intended Usage

The 8585 is a multifunction terminal for stationary and mobile use in commercial applications (for example

logistics, storage, manufacturing). Different or extraordinary usage is not permitted.

For resulting damage, the user/operator of the 8585 is solely responsible.

This also applies to any changes you make to the device.

Compliance with the contents of the safety guidelines is particularly important for the proper use of this device.

Page 18

1 - 2 8585/8595 Vehicle-Mount Computer User Guide

Initial Operation of the Device

Area of Application: Not for use in life-support systems or critical safety systems

The device is not designed for use in life-support systems or critical safety systems where system malfunction

can lead to the direct or indirect endangerment of human life. The operator shall take full responsibility for

using the device in these situations.

The device cannot be used in combination with safety functions for machines and equipment which have to

conform to the requirements of EN 954-1.

Installation/Initial Operation

Installation of the 8585 on a vehicle must be performed in accordance with Chapter 3: Installing the Computer.

Specifically, special attention must be paid to the various electrical potentials of the vehicle. Some vehicles

have a chassis that is connected to one of the battery supply lines (DC+ or DC-), while most electrically-driven

forklift vehicles have floating chassis, connected to neither DC+ or DC-. Refer to Vehicle Applications (such as

forklifts) on page 3-2 for required wiring of vehicle power and fusing for the 8585.

Risk of injury during transit or installation

The unit could fall during transit or installation and cause injury. Always ensure that there are two persons

available when installing or removing the device.

Choice of Location: Observe the Protection Class

The ambient conditions at the point of installation must comply with the device's protection class.

Supply of Fresh Air: Avoid overheating the unit

The 8585 is based on a passive cooling concept. As a result, the waste heat which is produced inside the

device is emitted over the surface of the housing. For this system to function properly, sufficient fresh air circulation is required. Never install the system in a closed environment where the cooling air is unable to dissipate

accumulated heat to the outside.

If the 8585 is not able to draw in fresh cooling air, this may cause overheating and severe damage to the unit.

The maximum allowed ambient temperature for the system needs to be taken into account for the concrete

application area.

Install an easily accessible disconnecting device

The device is not supplied with a disconnector (switch) that can be accessed externally. The power supply

connector is therefore used as a disconnector. Therefore it needs to be easily accessible.

If it is necessary to establish a fixed connection, an easily accessible disconnecting device (e.g. a switch such

as a circuit breaker) should be installed close to the device. Ensure that the power cable is laid so that it is

mechanically protected.

Laying Power Supply Cables: Observe the local installation regulations

The power supply cables must be laid in accordance with the applicable local installation regulations.

Ensure that no persons are injured in case the mounting bracket breaks

The 8585 may in no case be installed in such a way that persons can be injured during a breaking of the

mounting bracket (e.g. fatigue break).

If the device is mounted in a place where people can be injured if the bracket should break, appropriate safety

measures must be put in place (e.g. install a security cable in addition to the device bracket).

Page 19

Radio Performance: Do not exceed the maximum permissible transmitting power

Do not exceed the maximum permissible transmitting power which is specified by each separate country. 8585

users must verify this themselves.

Power Supply

The mains power cord shall comply with the national safety regulations of the country where the equipment is

to be used.

Operation in an Emergency: Immediately disconnect the device from the power supply

In case of emergency (such as damage to the power cable, or housing, or ingress of liquid or other foreign

bodies), the device must be disconnected immediately from the power supply. Contact technical support staff

at once.

Protection of the power supplies

If, after replacement, the fuse fed by the internal power supply blows again, the device must be sent in for

servicing immediately.

Danger of electrocution when cleaning/servicing the device

Approvals and Basic Safety Guidelines 1 - 3

In order to avoid electrocution always disconnect the 8585 from the power supply before cleaning or servicing

the device.

When charging the vehicle battery please note:

While charging the vehicle battery the 8585 has to be either disconnected from the battery or it has to be deter-

mined that the maximum allowed input voltage of the 8585 is not exceeded.

Do not switch on devices with damaged cables or plugs

Do not use the 8585 when a cable or plug is damaged. Have the damaged parts replaced immediately!

Do not connect or disconnect any cables during storms

Cables must never be connected or disconnected during an electrical storm.

External Devices

The use of additional wiring and other peripheral devices, which are not recommended or sold by the manufac-

turer can result in fire, electrocution or personal injury.

If a power supply is used, only use the power supply recommended by the manufacturer.

Before connecting or disconnecting peripheral devices (exception: USB devices), the 8585 must be discon-

nected from the power supply! Otherwise, this could seriously damage both the 8585 and the

connected devices!

Make sure that external peripheral devices with their own power supply are switched on at the same time or

after you start the 8585.

If this is not possible, please ensure that the 8585 is adequately protected from power leakage caused by an

external device.

Ensure that the power and grounding of any external peripheral devices to be connected to the 8585 are

consistent with the power and grounding of the 8585.

Page 20

1 - 4 8585/8595 Vehicle-Mount Computer User Guide

Malti

[Maltese]:

Dan l-apparat huwa konformi mal-?ti?iet essenzjali u lprovedimenti l-o?ra rileva nt i tad - Dir et t iv a 1999 /5/EC.

Magyar

[Hungarian]:

Ez a készülék teljesíti az alapvető követelményeket és más

1999/5/EK irányelvben meghatározott vonatkozó

rendelkezéseket.

Norsk

Norwegian]:

Dette utstyret er i samsvar med de grunnlegg e n de kr a v og

andre relevante bestemmelser i EU-direktiv 1999/5/EF.

Polski

[Polish]:

Urządzenie jest zgodne z ogólnymi wymaganiami oraz

szczególnymi warunkami określonymi Dyrektywą UE:

1999/5/EC.

Português

[Portuguese]:

Este equipamento está em conformidade com os requisitos

essenciais e outras provisões relevantes da Directiva

1999/5/EC.

Slovensko

[Slovenian]:

Ta naprava je skladna z bistvenimi zahtevami in ostalimi

relevantnimi pogoji Direktive 1999/5/EC.

Slovensky

[Slovak]:

Toto zariadenie je v zhode so základnými požiadavk ami a inými

príslušnými nariadeniami direktív: 1999/5/E C.

Suomi

[Finnish]:

Tämä laite täyttää direktiivin 1999/5/EY olennaiset vaatimukset

ja on siinä asetettujen muiden laitetta koskevien määräysten

mukainen.

Svenska

[Swedish]:

Denna utrustning är i överensstämmelse med de väsentliga

kraven och andra relev anta bestämmelser i Direktiv

1999/5/EC.

Repairs Only

Never carry out repairs on the device yourself. Always contact technical support and send in your unit for repair

if necessary. Refer to the following web site for further details:

www.zebra.com/support

On the back of the 8585 you will find the device's type plate which has important information about the device

which you must quote for technical service. It provides important information about the configuration and

manufacture of the device in abbreviated form.

Always provide technicians with the full model name and serial number.

CE Marking

Remark for CE class B products: Class B products may be used in residential environment but with the

condition that the end user is informed about the possible consequence with a warning information in the

user manual:

RTTE Directive 1999/5/EC

WARNING! This is a class B device. This equipment may cause interference in a resi-

dential installation. In this case the user is encouraged to perform

appropriate measures to correct the interference.

With regard to the RTTE Directive 1999/5/EC the statements in the declaration of conformity for the

8585 apply.

Page 21

Special Rule/Restriction

For the 8585 with WLAN 802.11a/b/g/n, the following restrictions apply:

• WLAN 5 GHz band: 5.15 GHz – 5.35 GHz may only be used indoors.

• WLAN operation outdoors in France is only permitted in the 2454 – 2483.5 MHz range at

max. 10 mW EIRP.

Regulatory Summary

FCC User Information

Declaration of the Federal Communications Commission

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules and meets all requirements of the Canadian Interference-Causing Equipment

Standard ICES-003 for digital apparatus. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

Approvals and Basic Safety Guidelines 1 - 5

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/T.V. technician for help.

Zebra is not responsible for any radio television interference caused by unauthorized modifications of this

equipment or the substitution or attachment of connecting cables and equipment other than those specified by

Zebra. The correction of interference caused by such unauthorized modification, substitution or attachment will

be the responsibility of the user. The use of shielded I/O cables is required when connecting this equipment to

any and all optional peripheral or host devices. Failure to do so may violate FCC and ICES rules.

WARNING! FCC warning: Any change or modification which is not expressly approved

in the corresponding pages can lead to the withdrawal of the operating

license for this device.

In order to comply with the FCC requirements regarding radio frequency

exposure from vehicle-mounted transmission devices the antenna has to be

kept at least 20 cm away from people.

Transmission of Radio Frequencies

Use care in airplanes or in clinical/medical areas

Some devices in hospitals and airplanes are not protected from radio frequency energy. Consequently, do not

use the 8585 in airplanes or hospitals without prior authorization. Here use of the 8585 is only permitted if

authorization is obtained.

Page 22

1 - 6 8585/8595 Vehicle-Mount Computer User Guide

Caution with pacemakers

Do not use the 8585 near pacemakers. The 8585 can affect the function of medically implanted devices such

as pacemakers and create interference. Do not place the 8585 near such devices.

Keep a minimum distance of 20 cm between such a device and the 8585 in order to reduce the risk

of interference.

If you have reason to assume that interference has occurred, then turn the 8585 off and consult a heart expert.

Country Roaming

This device incorporates the International Roaming feature (IEEE802.11d) which will ensure the product operates on the correct channels for the particular country of use.

Declaration of Conformity

Declaration of Conformity (DoC) is available at: http://www.zebra.com/doc

Regulatory Information for China

Class A Product Warning

Chinese Warning Statement for Class A ITE

Warning

This device is Class A. The device may generate radio interference at home. The user may need to take realistic action at the interference.

警告

此为 A 级产品,在生活环境中,该产品可能会造成无形电干扰。在这种情况下,可能需要用户对干扰采取切实

可行的措施。

Chinese UM URL

China

通过访问以下网址可下载当地语言支持的产品说明书

http://www.zebra.com/CN-ZH/Pages/Contact_Us#support_tab

Local language translations are available at the following website:

http://www.zebra.com/CN-ZH/Pages/Contact_Us#support_tab

Page 23

Approvals and Basic Safety Guidelines 1 - 7

Quality Certificate in Chinese when the Factory has ISO 9001 Certification

合格证 Quality Certificate

Page 24

Page 25

CHAPTER 2 BASIC OPERATION

BASIC OPERATION 2

Removing the Protective Film from the Display

WARNING! Before operating the unit for the first time, carefully read Chapter 1: Approvals and

Basic Safety Guidelines.

NOTE Configure the computer before fastening it to machines or vehicles. Software configuration for

the WLAN, shutdown automation, etc. is significantly simpler and more convenient on the

desktop.

The front display of the 8585 is protected during transport by a transparent film. This film should remain on the

front display during assembly to avoid damage to the front display surface.

Only remove the film once all of the assembly work has been completed.

Zebra Config: Front Keys, WLAN, Automatic Switch-off

The Zebra Config program can be found on your 8585. Use it for settings such as the following:

• Configuring the front keys of the 8585.

• Setting up the WLAN status display.

• Turning the 8585 on and off together with the vehicle ignition (automatic switch-off).

NOTE To configure units with AMD installed, Config Tool Version3.1.1.0 or higher is required.

Page 26

Figure 2-1

NOTE You can find detailed configuration information in Appendix A: Zebra Config

Zebra Config Program Menu

Program.

WLAN Settings

The settings and access data form must be defined for radio networks like WLAN depending on

the optional equipment and intended use of the 8585.

WARNING! Please pay attention to all basic safety guidelines for WLAN, especially

Radio Performance

WARNING! Do not exceed the maximum permissible transmitting power which is

Please keep in mind the configuration for the transmitting power:

• Wireless card (programmed driver capacity).

• Connecting cables.

• Antenna gain.

RTTE Directive 1999/5/EC on page 1-4 and FCC User Information on

page 1-5.

specified by each separate country. 8585 users must verify this

themselves.

Page 27

Basic Operation 2 - 3

Help table for the correct setting:

Antenna Solutions for Use in Germany

The integrated antenna solutions are based on the prevailing IEEE 802.11 standard. This standard allows wireless data transfer at rates from 1 Mbps to 54 Mbps using the 2.4 GHz and 5 GHz frequency band (300 Mbps if

using IEEE 802.11n).

WARNING! In Germany according to regulations published in the gazette 89/2003 of the RegTP

(regulating body for telecommunications and mail), now: “Bundesnetzagentur” Federal network agency for electricity, gas, telecommunications, post and railway the maximum permissible transmitting power, EIRP (equivalent isotropically radiated power), in the 2.4 GHz frequency band is set at 20 dBm.

The transmitting power of the integrated Zebra antenna (Zebra 3 dBi) must be set to

50 mW (17 dBm) so that the EIRP limit value is adhered to when using the antenna.

Example configuration of the transmission power using the Laird Connection Manager program:

Figure 2-2

Configuring the antenna transmitting power with Laird (example)

Laird Connection Manager for WLAN Configuration

The Laird Connection Manager is used to set up the WLAN configuration for the 8585.

WARNING! WLAN configurations may only be modified by qualified IT technical staff.

Launch this connection manager with a double tap on the Laird Connection Manager icon on the desktop:

Page 28

2 - 4 8585/8595 Vehicle-Mount Computer User Guide

Figure 2-3

Laird Connection Manager Icon

Admin Password

In order to make adjustments in Laird, it is necessary to enter a password.

1. To do so, click the Admin Login tab. An input field appears for the password.

Figure 2-4

Laird Connection Manager Admin Password input

The standard password is: SUMMIT (must be entered in capital letters!) You can find details about the configuration parameters in the Laird Connection Manager user guide at:

http://www.lairdtech.com/brandworld/library/User%20Guide%20-%20Laird%20Connection%20Manager.pdf

Protecting the TFT Display from the Memory Effect

The TFT display of the 8585 has to be protected from the burning in of a motionless image. An image that has

remained motionless for too long can cause irreversible damage to the display. With TFT displays there no

cathode rays burning in an after-image as in old TV sets or monitors, but TFT displays still have a memory

effect. This is because with a still image the liquid crystal molecules align themselves in a certain way and

become inert if they are not moved. Like burning in the effect is irreversible, but can be avoided by regularly

turning off the display or by using a screen saver with changing content.

Define in the power management centre of the utilized operating system that the displays of the 8585 should

be turned off when no user input occurs.

A motionless image can stay on the display for a maximum of 12 hours. After more than 12 hours there is the

risk of the memory effect.

Page 29

Connectors

Overview of External Connectors

Basic Operation 2 - 5

Figure 2-5

Figure 2-6

Connectors overview

External connectors detailed view (example 24/48 VDC)

Adaptor Cables

Two types of adaptor cables are available for use with the 8585/8595. An extension power cable

(PN 13985–301) is available as an accessory. The power extension cable is connected to the vehicle on one

side and the adaptor cable on the other side. All cables can be used with every voltage. Zebra offers an ignition

and a screen blanking (display-off) adaptor cable. The external wire of the adapter cable must be connected to

the ground lug of the terminal and to the vehicle chassis.

NOTE Refer to Wiring Vehicle Power to the 8585/8595 on page 3-3 for details about ignition and screen

blanking installation instructions.

If you require Pre-Regulator or UPS installation instructions, please contact Zebra personnel for

assistance.

The ignition adaptor cable is connected to the power input of the 8585/8595 only; the screen blanking cable

must be connected to the power input and COM1. If you require both the screen blanking and the ignition

options, you will need to contact Zebra personnel for assistance.

Page 30

2 - 6 8585/8595 Vehicle-Mount Computer User Guide

Ignition Adaptor Cable Screen Blanking Adaptor Cable

PN 1616302-001 PN 1616303-001

Figure 2-7

Adaptor Cable Options

DC Voltage Supply Connector

Version: Phoenix Combicon, 3-pin.

Figure 2-8

Explanation:

Ignition on means that a control signal has to be routed to this connection (e.g., ignition of a vehicle), that

matches the supply voltage level and is able to supply at least 1 W to the 8585.

The signal reference is DC–.

External view of the DC power supply connector

Page 31

Connecting External Devices

The 8585 must be disconnected from the power supply:

• Before external devices (e.g., scanner, keyboard) are connected or disconnected, and

• Before the 8585 can be connected to a network.

All connections and interfaces on the 8585 are located on the underside of the unit.

Ensure that the power and grounding of any external peripheral devices to be connected to the 8585 are

consistent with the power and grounding of the 8585.

Basic Operation 2 - 7

Caution:

Property

Damage

Make sure that external peripheral devices with their own power supply are switched on at th e same

time as the 8585 or after you star t the 8585. If this is not possible, please ensure that the 8585 is adequately protected from power leakage caused by an external device.

Only power up the 8585 when all devices have been connected and the 8585 has been closed correctly

(remember the cable cover!). Otherwise, you may damage the 8585.

Powering Up the 8585

Only power up the 8585 after connecting all of the devices.

The 8585 is powered up by connecting it to an appropriate power supply and then, depending on the version of

the device, either using the [Power] key or the ignition signal.

You have to hold the [Power] key down for a short time.

Caution:

Property

Damage

Make sure there is a suitable disconnecting device such as a power switch or circuit breaker in the

power supply circuit.

Page 32

2 - 8 8585/8595 Vehicle-Mount Computer User Guide

Power key

Figure 2-9

8585 Power key

Powering Down the 8585

Always shut down the 8585 as follows:

1. Power down the device using the ignition input or the [Power] key.

2. Remove the cable cover.

3. Disconnect the device from the DC supply voltage (pull the plug).

Page 33

CHAPTER 3 INSTALLING THE COMPUTER

INSTALLING THE COMPUTER 3

Overview

The 8585 can be installed in a variety of ways:

• It can be positioned horizontally on a desk or mounted on a steering wheel and vehicle console.

• Wall mounts are also available for mounting the unit on machines and operating panels.

• Roof mounting is also possible, for example under the vehicle roof.

Depending on the vibration resistance and pivoting demands, mounting brackets, clamp foots or RAM mount

elements can also be used to attach the device. Please contact your Zebra sales office to find out more about

the whole range of installation options on offer.

WARNING! The unit could fall during transit or installation/mounting and cause injury. Always

ensure that there are two people available when installing or removing the device.

Follow and Retain the Mounting Instructions

Please follow the mounting instructions included with assembly kit when installing your 8585. Please make

sure that you retain the instructions.

Pay careful attention to Chapter 1: Approvals and Basic Safety Guidelines.

Mechanical Dynamic Loading

Since the 8585 is a weighted structure, it is invariable that the unit will be subject to mechanical dynamic

effects. Therefore optimizing the mounting is necessary.

Cooling Through the Supply of Fresh Air

The 8585 employs a passive cooling concept whereby the waste heat generated inside the device is emitted

from the surface of the housing. For this system to function properly, sufficient fresh air circulation is required.

Page 34

Never install the system in a closed environment where the cooling air is unable to dissipate

accumulated heat to the outside.

Caution:

Property

Damage

If the 8585 does not have access to fresh cooling air, it may result in overheating and

severe damage to the unit. The maximum permissible ambient temperature for the entire

system needs to be taken into account for the concrete application area.

Power Supply

The 8585 is equipped with a galvanically separated, integrated DC power supply.

Power is connected to the underside of the unit using a Phoenix Contact plug. There is no

power switch.

Caution:

Property

Damage

The 8585 must only be connected to a SELV circuit.*Ensure that there is a suitable disconnecting device such as a power switch or circuit breaker in the power supply circuit.

Ensure that the disconnecting device isolates all supply voltage lines.The DC+ connecting cable must be protected by a fuse (30 AT max.). The ignition connecting cable must

be protected by a fuse of the following type: 5x20 mm T 125 mA L / 250 V , for example, a

Wickmann 195-125 mA / 250 V.

* The SELV circuit is a secondary circuit that is designed and protected so that its voltages will

not exceed a safe value both when operating correctly or if a single error occurs.

WARNING! Use the connecting cables supplied by Zebra to connect the 8585 to the

power supply.

Make sure that the connecting cables are laid without kinks and are

protected.

Vehicle Applications (such as forklifts)

Electrical Installation

Pay special attention to the various electrical potentials when installing the unit on a vehicle

(such as a forklift).

In the 8585, the logic ground and the shield ground are firmly linked.

The “logic ground” is the earth line (GND) for all of the internal electrical components, such as

the display and the CPU.

The cable shielding and the housing are connected to the “shield ground”.

Page 35

Installing the Computer 3 - 3

Ground bolt

Caution:

Property

Damage

Figure 3-1

WARNING! PAY CLOSE ATTENTION TO THE FOLLOWING WARNINGS!

Some forklifts have a chassis that is connected to DC+. Therefore, the 8585

chassis is also connected to DC+. However, if you use peripheral devices that

supply DC– to the 8585 via an interconnector (such as a DC– serial port), this will

cause a short circuit. This will inevitably lead to malfunctions or even a total

system failure.

Always attach the ring tongue on the white supply voltage cable to the ground

bolt situated on the connector bay.

Most electrically-driven forklift vehicles have floating chassis, connected to

neither DC+ or DC-. However, electrical faults can cause the battery + or - to be

connected to the chassis via low resistance paths. All connected peripherals

must be completely isolated.

Position of the ground bolt

WARNING! Individual vehicle requirements and any installed supplementary electronic systems

on the vehicles must be reviewed to ensure 8585/8595 grounding is compatible follow vehicle manufacturers recommendations.

• The other end of the white supply voltage cable should be connected to the vehicle's chassis.

• Make sure that the 8585's connecting cable is attached as close to the battery as possible. Connecting the

8585 to large electrical loads, such as converters for the forklift motor may result in random restarts, malfunctions and/or irreparable damage to the device.

• If you want to connect devices fed by other power sources to the 8585, such as printers and so on, be sure

to power up the peripheral devices at the same time or after the 8585. Otherwise, you may encounter

start-up problems, malfunctions or even irreparable damage to the device.

Wiring Vehicle Power to the 8585/8595

WARNING! Applying a voltage above the input voltage rating or reversing polarity may result in

permanent damage to the 8585/8595 and will void the product warranty.

A 1.8 meter (6 ft.) extension power cable (PN 13985–301) is available which should be used to wire the

8585/8595 to the truck battery. This cable needs to be ordered separately. This cable should be wired to a

filtered, fused (maximum 10A) accessory supply on the vehicle. On negative chassis vehicles, the positive lead

Page 36

3 - 4 8585/8595 Vehicle-Mount Computer User Guide

should be fused. On positive chassis vehicles, the negative lead should be fused. On floating chassis vehicles,

the positive and negative leads must be fused. Any additional wiring (minimum 18 gauge), connectors or

disconnects used should be rated for at least 90 VDC, 10 A.

When connecting PN 13985-301, ensure that the screen blanking wires (clearly labelled) and the power wires

(red/black leads) are reliably secured away from each other, or are separated with reliably secured certified

insulation. Minimum 2.8 mm distance, or 0.4mm distance through insulation is required for the separation.

The red lead of the power cable attaches to the positive vehicle supply. The black lead connects to the negative supply – this should be connected to a proper terminal block and not to the vehicle body. The external wire

of the power adapter cable is connected to the ground lug of the 8585/8595 terminal connector bay and to the

vehicle chassis.

You have the option of connecting power before or after the key switch. The 8585/8595 should not be shut off

by simply removing the power. If it is wired after the key switch, the operator must shut down the 8585/8595

using the Windows shutdown procedure before turning off the vehicle. If it is wired before the key switch, then

to avoid excessive drain on the vehicle battery, either the operator should shut it down when the vehicle is to be

left off for an extended period, or the ignition cable shutdown wire should be connected and the 8585/8595

configured to shutdown automatically.

If an unfused power source must be used, a fuse assembly (PN 19440-300) and diode/choke assembly

(PN 30723-301A) must be added to the extension power cable (the fuse, diode/choke and instructions are

supplied with the cable). Use only a 10A slow blow UL approved fuse in the fuse assembly. The fuse assembly

must be located as close as practical to the DC supply, and shall connect to either the positive, or negative side

of the DC supply, depending on the chassis grounding scheme. For floating chassis vehicles, an additional 10

A slow blow UL approved fuse (fuse assembly PN 19440-300) should be installed on both power supply lines.

To safely wire power to the 8585/8595, review these guidelines and follow the instructions that apply to your

needs:

• When connecting the cable (PN 13985-301) to the screen blanking cable (PN 1616303-001), the wire pair

on the 13985-301 labelled “screen blanking” connect to the screen blanking control device, which must

provide an isolated relay closure across the pair.

• When connecting the cable (PN 13985-301) to the ignition cable (PN 1616302-001), the wire pair labelled

“screen blanking” on the 13985-301 has a different function; the red wire must connect to a DC+ voltage

source switched on by the ignition, while the black wire may connect to DC- or be taped off.

• Note that only the ignition function is supported by the UPS (models PS1110/PS1120), not the

screen blanking. If both screen blanking and ignition are to be used on the same 8585/8595, contact Zebra

for details.

Position of the 8585 in the Vehicle

In the vehicle, the driver's field of view must be kept free.

If a keyboard and scanner are installed on the 8585, please plan sufficient space.

No part of the 8585 system may project beyond the vehicle.

Overview of the Assembly Steps

Before fastening the 8585 to the vehicle:

• The shutdown automation must be configured.

• The forklift must be prepared (connection to ignition, correct voltage, etc.).

We recommend the following installation sequence:

1. Fasten the bracket to the vehicle.

Page 37

2. Install 8585 to the bracket.

Cable Cover (splash guard)

Installing the Computer 3 - 5

Caution:

Property

Damage

For safety reasons, the supplied cable cover for the external ports must be installed prior to using

the 8585.

Protection class

In order to comply with the certified protection class, please use the assembly kit included with the 8585.

Please observe the installation instructions included with this assembly kit.

Strain Relief

After the 8585 and bracket are fastened:

• Prepare the strain relief.

• Install the cables loosely on the strain relief rail.

• As far as possible, route cables leading to or away from the unit next to one another without crossing.

Completing:

• Fasten the cables to the strain relief rail.

• Be sure that the cables are fastened precisely at the positions at which the cable openings in the cable

cover are located.

Minimum Distance to WLAN Antenna

WARNING! In order to avoid exceeding the limits determined by the FCC for exposure to radio

waves, you (and other people in your vicinity) should maintain a minimum distance

of 20 cm from the antenna integrated into the computer.

Please note this when mounting Zebra industry computers with WLAN antennas.

Antenna Cap and Service USB Interface

Under the antenna cap (protective cap) of the 8585, there is a Service USB interface.

Page 38

3 - 6 8585/8595 Vehicle-Mount Computer User Guide

Antenna cap

and Service USB interface

Do not pull the antenna connection cable too far out of the unit, catch it, or cut it.

Figure 3-2

To access this Service USB interface, you need to remove the antenna cap from the unit.

Caution:

Property

Damage

Antenna cap 8585

Incorrect or improper removal and fastening of the antenna cap can impair the function of the entire

8585 system. These actions, or if the 8585 is operated with the antenna cap/service USB inter face open

for a longer period of time than required for service tasks, will invalidate any warranty provided by

Zebra.The service USB interface may only be used for maintenance purposes, e.g. to load software

updates. The antenna cap/service USB interface may only remain open for the duration of the service

work. It may only be opened and closed by qualified technical personnel.

No objects or fluids may be introduced into the 8585 while the antenna cap and the USB interface

are open.

Only when the antenna cap/service USB interface is properly closed again may operation be resumed;

protection class is then ensured again.

Figure 3-3

Service USB under the antenna cap

Unfasten antenna cap from unit and refasten it:

1. Unscrew the two screws from the antenna cap with an Allen key (size 3 mm).

2. Lift the antenna cap carefully to avoid pulling on the antenna connection cables (max. 2 to 3 cm).

Page 39

Installing the Computer 3 - 7

3. Holding the antenna cap, making sure that no pulling tension is exerted on the antenna

connection cables.

4. The Service USB interface is now accessible.

WARNING! One end of the antenna connection cables is attached to the antenna cap, the other

end to the internal WLAN unit of the 8585. The cables must not be pulled out of the

8585 too far and become detached from the WLAN unit! This might damage the

WLAN unit or other components of the device.

5. Place the antenna cap back onto the 8585.

WARNING! Take care not to trap the antenna connection cables when doing this.

The antenna cap seal must not be damaged; it must be seated correctly in

the groove.

6. Reinsert and tighten the two screws of the antenna cap (1 Nm torque).

Page 40

Page 41

CHAPTER 4 OPERATION

OPERATION 4

Touchscreen

The 8585 is equipped with a resistive touchscreen.

Caution:

Property

Damage

Keep the panel surface clean.

Prevent any kind of adhesive from being applied to the surface.

Avoid high voltage and/or static charge.

Touchscreens may not be operated with ball-point pens or writing utensils, tools of any kind (e.g. screwdrivers) or with sharp objects (knives, scalpels, etc).

Touch the panel with your finger or stylus only to ensure normal operation. Any sharp-edged or hard

objects are prohibited.

Operate the panel in a stable environment. Abrupt variation on temperature and humidity may cause

malfunction of the panel.

Avoid applying excessive activation force or sudden impact on the panel surface.

Construction Type and Resistance

• 5-wire touch sensor using analog-resistive touch technology.

• Construction: Film-Glass (FG).

• Hardness of surface: 3H (ASTM D3363).

• Resistance: 35 million actuations.

Operation

Operation of the resistive touchscreen is recommended with:

• Clean, dry fingers.

• Clean, dry, soft gloves.

• Suitable touch stylus (plastic or wood, rounded tip).

Page 42

Cleaning

Use neutral detergent or isopropyl alcohol on a clean soft cloth to clean the panel surface.

Prevent using any kind of chemical solvent, acidic or alkali solution.

Touch for MS Windows Embedded Standard 7

Installation

The touch drivers to be used can be found on the Flash medium under Util/atouch/<verNR>.

1. Open the corresponding folder and run Setup.exe.

2. On the Welcome dialog click Next.

3. In the Software Lice nse Agreement window select: I accept all of the terms of the above

License Agreement and then click Next.

4. On the Select Controller dialog choose serial (RS/232) and click Next.

5. On the Serial Configuration dialog choose COM2 and 9600 Baud and click Next.

6. Deselect the option on the Configuration Complete dialog and close by clicking Finish.

7. Two Files Needed windows will appear querying the path to the tsufiltr.sys file (see

Figure 4-1 Files Needed touch installation dialog).

8. Select Browse to navigate to the installation folder indicated above, then choose the

Serial folder and click OK.

Figure 4-1

9. Confirm the final message Setup is now complete by clicking OK.

The computer does not need to be restarted.

Calibration

The touchscreen must be calibrated so that it functions correctly.

1. Start the touch configuration tool under Start/Programs/Hampshire TSHARC Control Panel.

2. Select the Calibration tab and click the Touch field.