Zanussi ZT 1082 User Manual

WASHING MACHINE

ZT 102

ZT 1082

INSTRUCTION BOOKLET

124978193

CONTENTS

2

Important information .................Page 3

Installation .....................Page 4

n Unpacking ......................Page 4

n Positioning ......................Page 4

n Water inlet ......................Page 4

n Water drainage ....................Page 5

n Levelling ......................Page 6

n In the interest of the environment ................Page 6

n Electrical connection ...................Page 7

n Building-in ......................Page 8-9

Description of the appliance ...............Page 10

Technical specifications ................Page 10

Getting to know your machine ..............Page 11

n Control panel .....................Page 11

n Washing hints .....................Page 12

n Use of detergent and additives ................Page 13

n Programmes for cotton and linen ................Page 14

n Programmes for synthetics, delicates and wool ............Page 15

n Wash care symbols ...................Page 16

Using your machine ..................Page 17

n Washing 4.5 kg of white cotton at 95°C ..............Page 17

n Washing 2 kg of synthetic fabrics at 50°C .............Page 18

Maintenance and cleaning ...............Page 19

n Descaling, after each wash, external cleaning ............Page 19

n Cleaning the dispenser drawer, cleaning the drawer recess, the water inlet filters . . Page 19

n Cleaning the filter ....................Page 20

n The dangers of freezing ..................Page 20

Servicing ......................Page 21-22

Zanussi guarantee conditions ..............Page 23

Important

Your machine is fitted with a balance control device, which ensures the machine is stable during the

spin. If the wash load appears not to have been spun sufficiently at the end of the wash cycle, because it

is not evenly distributed in the drum, the balance control device may have operated. It will therefore be

necessary to redistribute the wash load manually and select a spin programme. For more detailed

information see the section headed "Servicing".

IMPORTANT INFORMATION

3

It is most important that this instruction book

should be retained with the appliance for future

reference. Should the appliance be sold or

transferred to another owner, or should you

move house and leave the appliance, always

ensure that the book is supplied with the

appliance in order that the new owner can get

to know the functioning of the appliance and

the relevant warnings.

These warnings have been provided in the

interest of safety. You MUST read them carefully

before installing or using the appliance.

Istallation

n

This appliance is heavy. Care should be taken

when moving it.

n

All packing and transit bolts must be removed

before use. Serious damage can occur to the

product and to property if this is not adhered to.

See relevant section in instructions.

n

Any plumbing work required to install this

appliance should be carried out by a qualified

plumber or competent person.

n

Any electrical work required to install this

appliance should be carried out by a qualified

electrician or competent person.

n

Care must be taken to ensure that the appliance

does not stand on the electrical supply cable.

n

If the machine is situated on a carpeted floor,

please adjust the feet in order to allow air to

circulate freely.

Use

n

Always unplug the appliance and turn off the

water after use.

n

Do not overload the appliance. See relevant

section in instruction book.

n

Only wash fabrics which are designed to be

machine washed. If in doubt, consult the care

label on the clothes.

n

Before washing, ensure that all pockets are

empty and buttons and zips are fastened. Avoid

washing frayed or torn articles and treat stains

such as paint, ink, rust, and grass before

washing. Underwired bras must NOT be

machine washed.

n

Any objects such as coins, safety pins, nails,

screws, stones or any other hard, sharp material

can cause extensive damage and must not be

placed into the machine.

n

Garments which have been in contact with

volatile petroleum products should not be

machine washed. If volatile cleaning fluids are

used, care should be taken to ensure that the

fluid is removed from the garment before placing

in the machine.

n

Wash small items such as socks, laces,

washable belts etc in a washing bag or pillow

case as it is possible for such items to slip down

between the tub and the inner drum.

n

Only use the advised quantities of fabric

softener. Damage to the fabric can ensue if you

over-fill. Refer to the manufacturer’s

recommendations of quantities.

n

As some duvets and eiderdowns should be

washed in large commercial machines because

of their bulk, please check with the manufacturer

of the item before washing in a domestic

machine.

n

Leave the porthole door slightly ajar between

washes to preserve the door seal.

Service/Repair

n

Under no circumstances should you attempt to

repair the machine yourself. Repairs carried out

by inexperienced persons may cause injury or

serious malfunctioning. Contact your local

Zanussi Service Centre. Always insist on

genuine Zanussi spare parts.

General Safety

n

It is dangerous to alter the specifications or

attempt to modify this product in any way.

n

This appliance is designed to be operated by

adults. Children should not be allowed to tamper

with the controls or play with the product.

n

Pets and children have been known to climb into

washing machines. Please check your drum

before use.

n

The glass door becomes very hot during the

washing cycle. Keep children away from the

vicinity of the appliance whilst it is in operation.

Environment protection

n The materials used on this appliance marked

with the symbol are recyclable.

This means that they can be recycled by

disposing of them properly in appropriate

collection containers.

n

When disposing of your old washing machine,

the electric cable must be cut off and the door

catch must be made unusable.

INSTALLATION

4

Unpacking

Before starting the machine up, the packing must

be removed as follows.

You are advised to keep all the packaging for reuse in case the machine is to be transported again.

Using a spanner unscrew and remove the rear right

bolt. Lay the machine gently on its back, making

sure that the hoses are not squashed.

Remove the polystyrene base and take off the

bottom panel by unscrewing the central screw.

Carefully slide out the right polythene bag.

Repeat the operation for the left and central

polythene bags.

Re-fit the bottom panel using the 4 screws supplied

with the door hinges (in the plastic bag) and the

previously removed screw.

P0453

P0016

P0015

P0457

P0255

Set the machine upright and remove the two

remaining bolts from the back.

Pull out the three plastic spacers from the holes

into which the bolts were fitted.

Plug the open holes with the plugs which you can

find at the back of the appliance.

Positioning

Install the machine on a flat hard floor.

Make sure that air circulation around the machine is

not impeded by carpets, rugs etc. Check that the

machine does not touch the wall or other kitchen

units.

Never place cardboard, wood or similar materials

under the machine to compensate for any

unevenness in the floor.

Your new washing machine has been designed to

be permanently plumbed in to your home’s water

supply and drainage system. However, if this is not

possible, it may be connected to suitable existing

taps with the drain hose discharging into a sink.

The appliance has two inlet hoses, hot and cold,

with female 3/4” BSP thread connectors. If this

connection is not compatible with the plumbing of

the existing installation, a variety of connectors are

available from good hardware stores and plumbers

merchants to suit most domestic plumbing. Any

alteration to your existing plumbing must be carried

out by a competent person, or qualified plumber.

Water inlet

The inlets on the back of the appliance are colour

coded, blue for cold and red for hot.

Before connecting the hoses be sure to fit the mesh

filters supplied as per diagram.

P0003

P0020

P0256

5

If only a cold water supply is available, connect the

two hoses to a cold water outlet by means of a «Y»

connection piece.

Installation should comply with local water authority

and building regulations’ requirements.

The appliance must be given a separate cold water

supply and not be connected to a mixer tap, a

single outlet water heater or a booster pump. A

minimum water pressure of 0.48 bar is required for

safe operation of the appliance.

If you cannot make the cold water connection direct

from the rising mains, you may be able to operate

the appliance from your cold water storage system.

There should be a minimum distance of 5.02m

(16

1

/

2

ft) between the appliance’s inlet and the

bottom of the water storage tank.

There will be sufficient pressure for the hot water

supply, providing there is a minimun height of 2.74

metres (9 ft) between the bottom of the cold water

storage tank and the bottom of the hot water

cylinder.

Set the hoses correctly by loosening the ring nuts.

After positioning the inlet hoses, be sure to tighten

the ring nuts again to prevent leaks.

Water drainage

This appliance is designed to be permanently

plumbed into your home's water supply and

drainage system.

The appliance drain hose should hook into a

standpipe, the hook in the drain hose is formed

using the plastic “U-Piece” supplied.

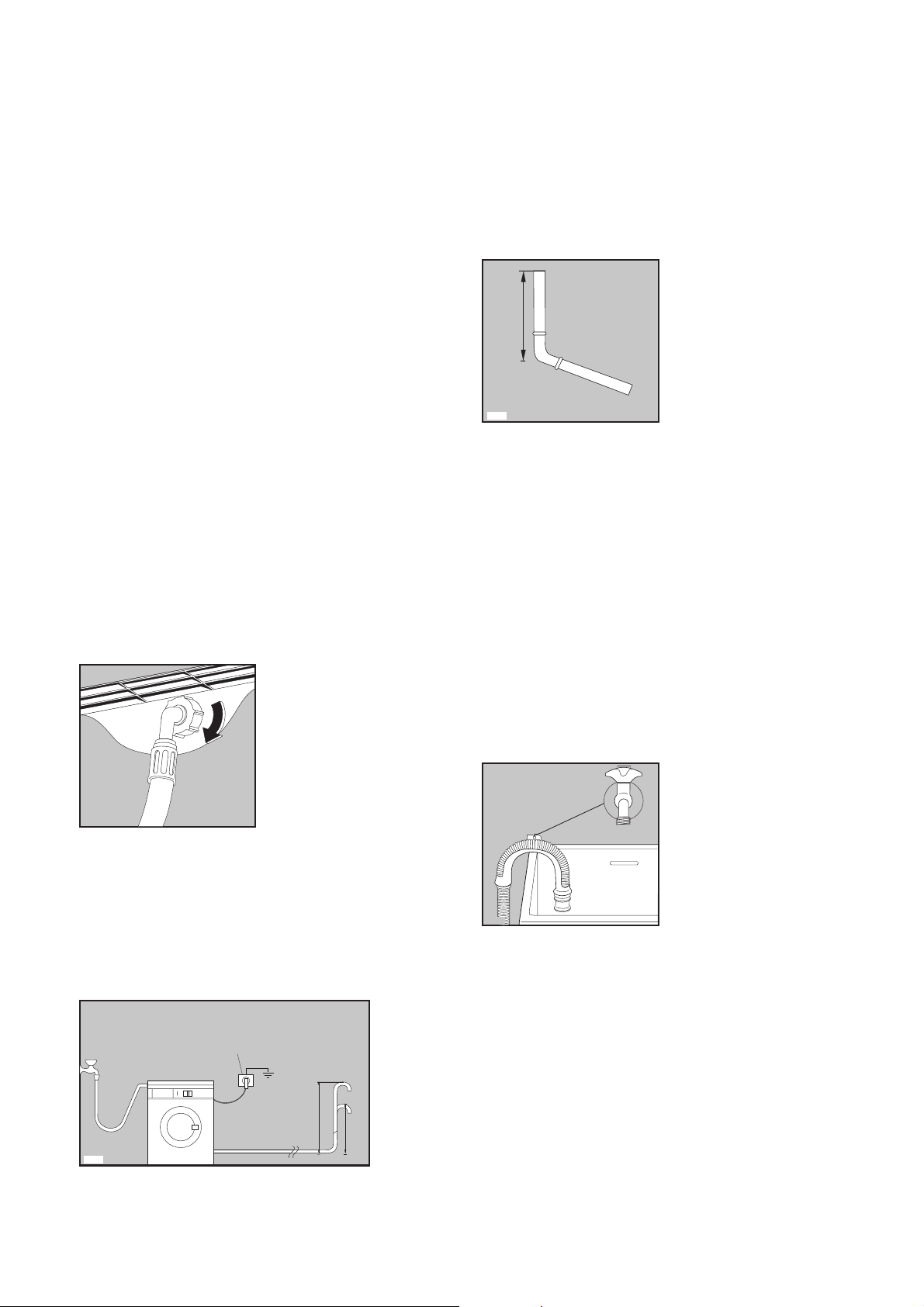

P1039

3 pin

Max. 90 cm.(35.4")

Min.60 cm.

(23.6")

P0021

The standpipe should have an internal diameter of

approximately 38mm (see diagram) thus ensuring

there is an air break between the drain hose and

standpipe.

When discharging into a standpipe ensure that the

top of the curve in the hose end is no more than

90cm (35.4'') and no less than 60cm (23.6'') above

floor level. The upright standpipe should have a

minimum length of 30cm (12'') from the bottom of

the elbow to the top of the pipe (see diagram).

Make sure that it is designed in such a way, that the

end of the drain hose cannot be covered with water.

The drain hose may be extended to a maximum of

4 metres. An additional drain hose and joining

piece is available from your local Service Force

Centre.

The joining piece must have an internal diameter of

18mm.

If you intend the drain hose to empty into a sink,

make sure that the sink is empty and the plug hole

is not blocked. Use the plastic “U-Piece” supplied.

Important

Before connecting up the machine to new pipework

or to pipework that has not been used for some

time, run off a reasonable amount of water to flush

out any debris that may have collected in the pipes.

P0022

P1040

Min. 30 cm.(12")

38 mm.(1/ ") diameter

standpipe

1

2

6

Levelling

Level the washing machine by raising or lowering

the feet. The feet may be tight to adjust as they

incorporate a self locking nut, but the machine

MUST be level.

Any necessary adjustment can be made with a

spanner. Accurate levelling prevents vibration, noise

and displacement of the machine during operation.

Some vibration is inevitable, especially if mounted

on a wooden floor.

Sprung wooden floors are particularly susceptible

to vibration. For advice, consult a builder. If

possible, always place the machine on a solid floor.

Special conditions

If the floor is carpeted with a deep-pile carpet or

covered with crumbly or soft material, insert a rigid

support base under the feet to prevent noise,

vibration or displacement. The base should

protrude a few centimetres beyond the edges of the

machine.

Warning

The machine should NOT be placed

on deep pile carpeting.

Note

Please ensure that when the appliance is installed

it is easily accessible for the engineer in the event

of a breakdown.

All plumbing and electrical work required to install

this appliance must be carried out by competent

persons or qualified plumbers or electricians.

P0850

In the interest of the environment

Washing machines and dishwashers should be

connected to the FOUL drainage system, the water

will then be taken to a sewage works for treatment

before being discharged safely into a river.

It is essential that these appliances are not

connected to the surface water drainage system as

this water is discharged directly into a river or

stream and may cause pollution.

If you require any further advice please contact

your local authority drainage department.

SHOWER

BATH

SINK TOILET

BIDET

WASHING

MACHINE

DISHWASHER

RAINWATER

'RUN-OFF'

SURFACE WATER

DRAINS & SEWERS

UNTREATED

DISCHARGE

RIVER

FOUL DRAIN

FOUL SEWERS

SEWAGE

TREATMENT

WORKS

RIVER

P0987

TREATED

DISCHARGE

7

Electrical connection

Any electrical work required to install this appliance

should be carried out by a qualified electrician or

competent person.

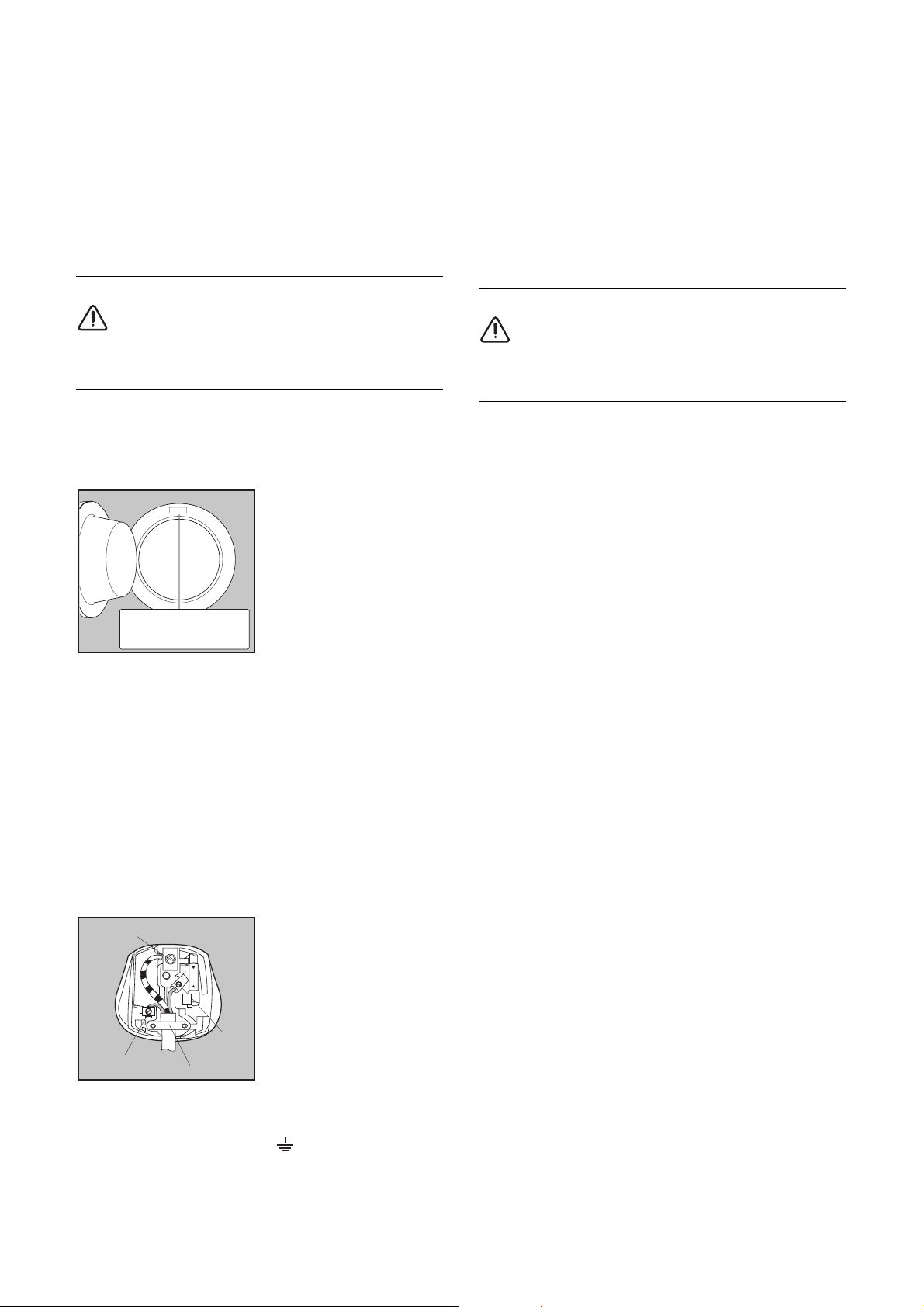

WARNING: THIS APPLIANCE MUST BE

EARTHED.

The manufacturer declines any liability

should this safety measure not be

observed.

Before switching on, make sure the electricity

supply voltage is the same as that indicated on the

appliance’s rating plate. The rating plate is located

at the top of the rim of the open door.

The appliance is supplied with a 13amp plug fitted.

In the event of having to change the fuse in the

plug supplied, a 13amp ASTA approved (BS1362)

fuse must be used.

Should the plug need to be replaced for any

reason, proceed as described below.

The wires in the mains lead are coloured in

accordance with the following code:

Green and Yellow - Earth

Blue - Neutral

Brown - Live

The wire coloured green and yellow must be

connected to the terminal marked with the letter

«E» or by the earth symbol or coloured green

and yellow.

The wire coloured blue must be connected to the

terminal «N» or coloured black.

GREEN & YELLOW

BROWN

CORD CLAMP

BLUE

13A

P1041

E

N

L

Mod. ..........

Prod. No. ...........

Ser. No. .........

Mod.

..........

Ser.

P0042

The wire coloured brown must be connected to the

terminal marked «L» or coloured red.

Upon completion there must be no cut, or stray

strands of wire present and the cord clamp must

be secure over the outer sheath.

WARNING:

A cut off plug inserted into a 13 amp

socket is a serious safety (shock) hazard.

Ensure that the cut off plug is disposed of

safely.

Should the appliance power supply cable

neeed to be replaced, this should be carried

out by our Service Force Centre.

Permanent connection

In the case of permanent connection it is

necessary that you install a double pole switch

between the appliance and the electricity supply

(mains), with a minimum gap of 3mm between the

switch contacts and of a type suitable for the

required load in compliance with the current

electrical regulations.

The switch must not break the yellow and green

earth cable at any point.

8

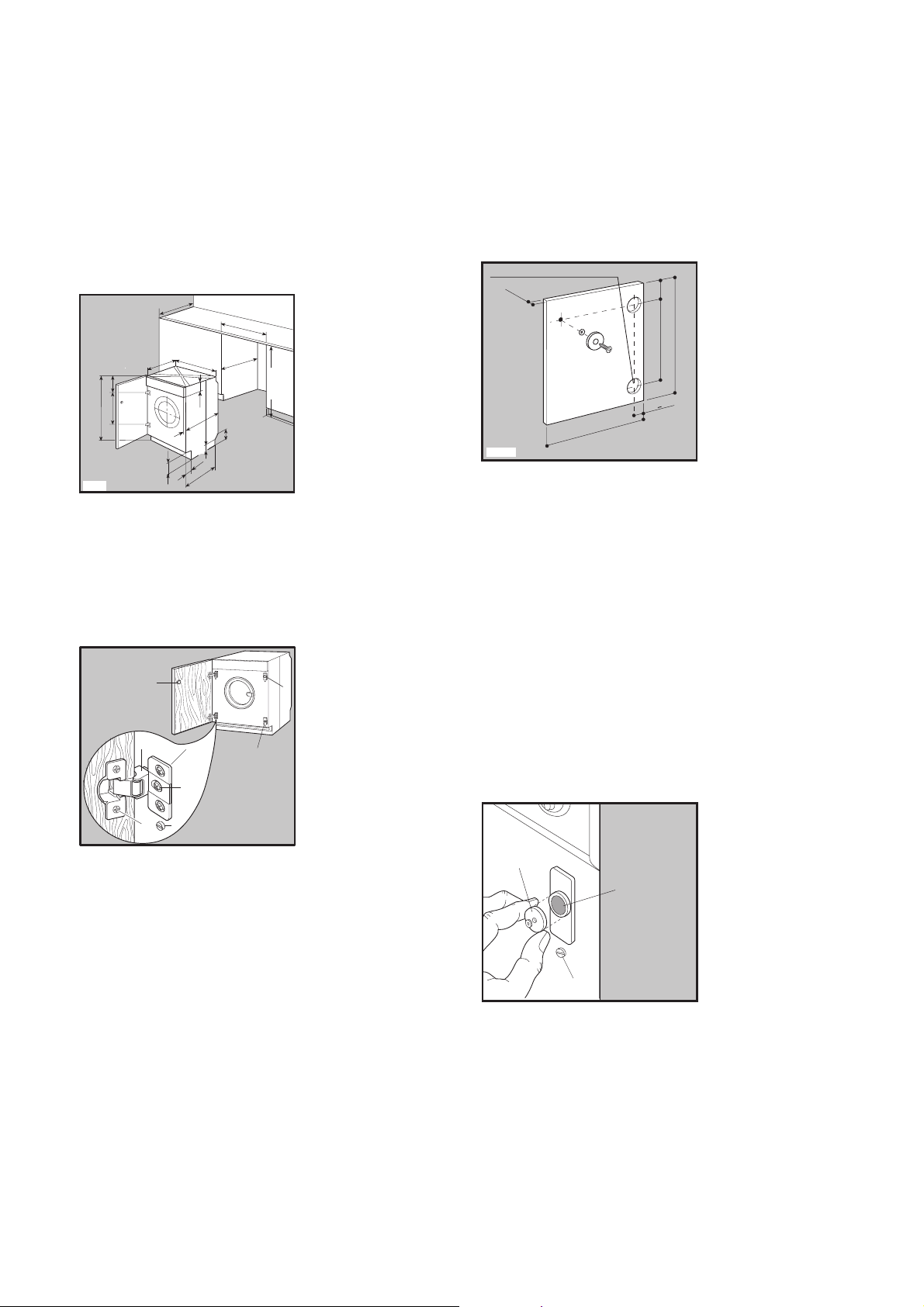

Building-in

This appliance has been designed to be built into

the kitchen furniture.

The recess should have the dimensions shown in

picture A.

Preparation and assembly of the door

The machine is originally pre-arranged for the

assembly of a door opening from right to left.

In this case it is sufficient to screw in the hinges (1)

and the counter-magnet (6) provided with the

appliance, at the right level (Fig. B).

a) Door

The dimensions of the door should be:

- width 595-598 mm

- thickness 16-22 mm

The height (C-Fig. C) depends on the height of the

adjacent furniture's base.

b) Hinges

To mount the hinges it is necessary to drill two

holes (dia. 35 mm, depth 12.5-14 mm depending

on the depth of door furniture) on the inner side of

the door. The distance between the holes hobs

fixing centres must be 416 mm.

The distance (B) from upper edge of the door to

the centre of the hole depends on the adjacent

furniture's dimensions.

4

1

2

3

6

1

2

3

P0982

7

8

B

5

P0965

820 min

570 min.

600

596

416

176,5

818

541

195

490

160

120

90

8

515

165

A

600

The required dimensions are given in the picture C.

The hinges will be fixed to the door by means of

screws for wood (2-Fig. B) supplied with the

appliance.

c) Mounting the door

Fix the hinges (1) to the machine by means of the

M5x8 screws (3-Fig. B). The hinges can be

adjusted to compensate for possible uneven

thickness of the door.

To align the door perfectly it is necessary to loosen

the screw (3-Fig. B), adjust the door and tighten

the screw again.

d) Counter-magnet (6)

The appliance is pre-arranged for a magnetic

closure of the door. To enable a correct operation

of this device, it is necessary to screw the countermagnet (6) (steel disk + rubber ring) into the inner

side of the door.

Its position must correspond to the magnet (4) on

the appliance (see picture D).

P0984

6

4

8

D

35 Ø 12.5-14 depth

16-22

B

C

22+1,5

595-598

416

P0422S

C

Loading...

Loading...