Page 1

FORCED AIR CONVECTION OVENS

Page 2

S

IMPLE APPLIANCES WITH A TRADITION FOR RELIABILITY

FCF OVENS

.

New FCF Ovens: an unbeat

Zanussi has always

served the

ISO 14001

catering sector with the utmost commitment

and dedication. More than 2400 products for

food preparation, cooking, fume extraction and

refrigeration, along with dishwashers and

2

professional

washing machines, testify to our efforts to

provide a wide range of appliances for the

most demanding of requirements. For millions

of users Zanussi has become a byword for

reliability, safety, innovative technology,

ergonomics and energy saving - characteristics

that over the years have formed a relationship

based on trust and cooperation between end

users and a world-leading company. Product

quality and excellent customer relations

backed up by an industrial process certified to

ISO 9001 standards have for years been the

hallmarks of a company for whom no problem

is too big and no customer too small.

Page 3

New products certainly aren’t created by

perfectly into any kitchen, with components

consumption of more than 10%.

chance, and Zanussi designs its products to

meet the real needs of catering professionals

and to ensure the utmost flexibility for any

application.The new range of FCF ovens

(forced air convection ovens) is no exception:

this outstanding line of compact appliances fits

designed for reliability and simplicity of

operation.

FCF ovens combine speed with uniform

cooking, simplicity of use, safety and ease of

cleaning. No less important, they are highly

economical, delivering reductions in gas

FCF ovens bear the CE mark and are designed

to assure speed, simplicity, safety and efficient

operation.

A perfect blend of ingredients from Zanussi,

working alongside today’s catering professional.

3

Page 4

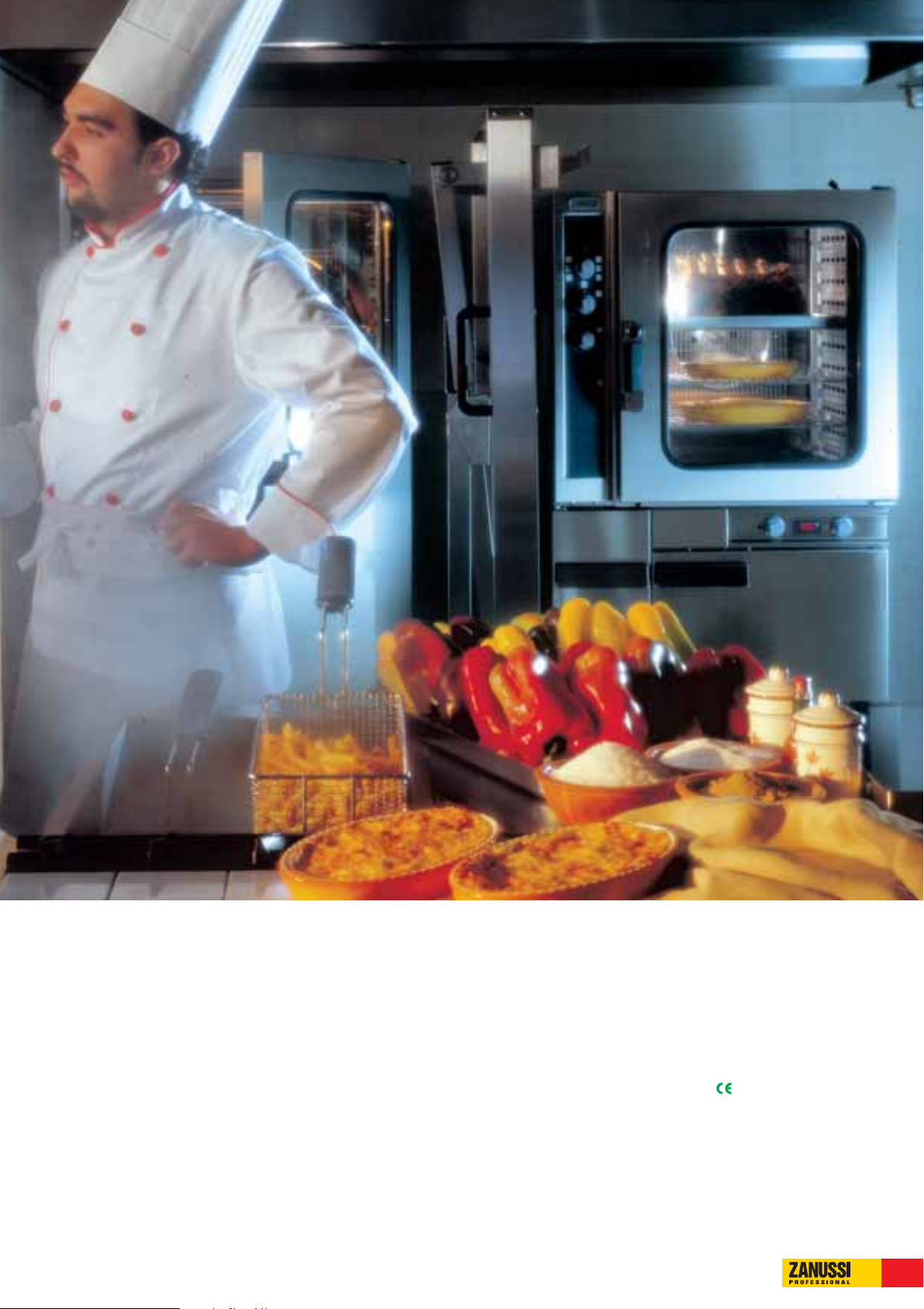

Cooking with forced hot air is the rapid

and reliable answer

to daily cooking requirements.

Zanussi forced air convection

ovens: perfect for cooking au

gratin, grilling or roasting.

The modern catering sector demands

appliances that offer savings in terms of

time, energy and capital investment along

with the versatility to tackle any working

requirement.The new range of Zanussi

FCF ovens has been developed to meet

precisely these needs with cutting-edge

technology that delivers high-level

performance. With new heating unit

technology, Zanussi FCF ovens reach

cooking temperature in just half the time

of conventional appliances, while the

fan-driven airflow ensures extra-quick

cooking. An unprecedented maximum

temperature of 300°C and the Flow

Channel heat optimisation system

ensure extremely uniform temperature

distribution on the surface of the trays

on the various oven loading levels.With

such advanced technology, the results

could hardly fail to be outstanding.

Speed and simplicity of operation

combined with uniform cooking make

Zanussi FCF ovens ideal for meat,

cakes and a wide range of different

bread and confectionery products.

A further important feature is the

humidifier that prevents the food

from drying out while it cooks.

Furthermore, the humidifier not

FACING PAGE

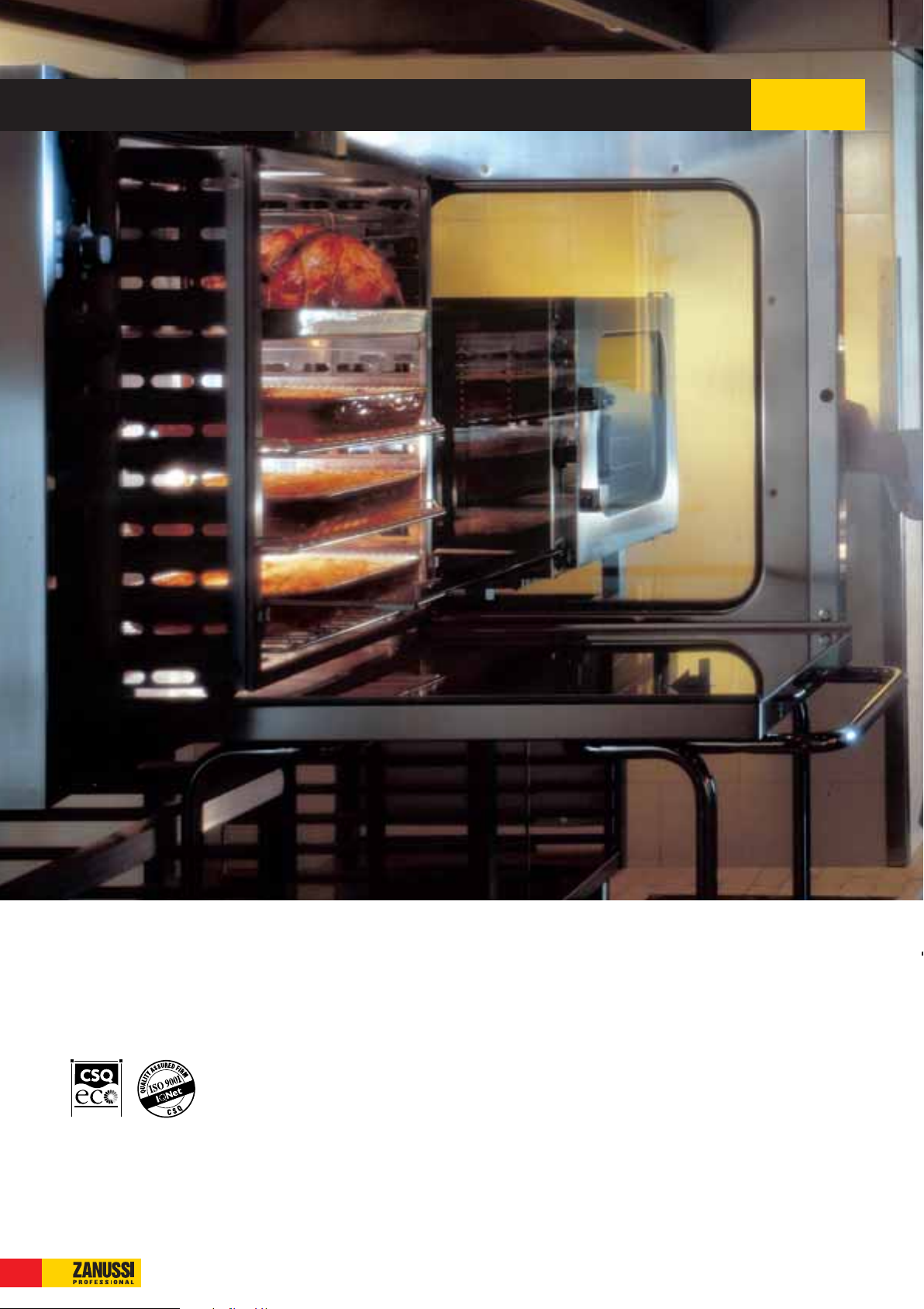

The ventilation system optimises airflow inside

the oven chamber, assuring extremely uniform

temperature distribution regardless of how much

food is being cooked.

only keeps meat moist and tender but

also dramatically reduces weight loss.

Every model in the new range has

low operating costs.

The improved combustion system

provides a reduction in gas consumption

of more than 10%, while the construction

technology promotes ease of cleaning

and hence maximum hygiene.

The new Zanussi FCF ovens: extremely

safe and easy to use with a rigorous

cooking process control system and

rugged, durable construction materials.

4

Page 5

FCF OVENS

A

HIGHT TEMPERATURE AT THE EART OF A SIMPLE AND RELIABLE SYSTEM

5

Page 6

The traditional kitchen in

Like all Zanussi Professional ovens, the

FCF series have oven chambers designed

for crosswise insertion of

the GN 1/1 trays.

The wider and shallower

shape of the cooking

chambers makes for easy

use and assures better heat

diffusion and greater

visibility. All corners inside

the oven chamber are

rounded and without joins.

The grid supports can be

removed without the need

of tools to facilitate

thorough cleaning of the

oven chamber.

10

1/1

ABOVE

The FCF 10 1/1 oven can accommodate 10 1/1 GN

grids (not provided).

Available in both gas and electric versions.

6

Page 7

1/1

6

20

1/1

LEFT

The FCF 6 1/1 oven can accommodate

6 1/1 GN grids (not provided).

Available in both gas and electric

versions

ALONGSIDE

The FCF 20 1/1 oven can accommodate

20 1/1 GN grids (not provided).

Available in both gas and electric

versions.

10

2/1

20

2/1

LEFT

The FCF 10 2/1 oven can accommodate

10 2/1 GN grids or 20 1/1 GN grids

(not provided).

Available in both gas and electric

versions.

ALONGSIDE

The FCF 20 2/1 oven can accommodate

20 2/1 GN grids or 40 1/1 GN grids

(not provided).

Available in both gas and electric

versions.

7

Page 8

FCF ovens: simple and

FCF OVENS have simple and ergonomic

control panels, with knobs that are easy

to operate and simple to set.

In short, these ovens combine advanced

technology with ease of operation.

The control panels on electric and gas

models incorporate the following features:

- Main switch / “cooking mode”

selector which can be used to set:

- convection cooking without humidification

- convection cooking with humidification,

with a choice of five different humidity levels

- rapid oven chamber cooling

- Thermostat: with temperature settings

from 30 °C to 300 °C

- Timer: with cooking times from 0 to 120

minutes and a continuous operation position

- Probe (accessory): with temperature

settings from 0 to 99 °C.

For gas models only:

- pilot burner ignition:

--

electric igniter, with single-action valve

for models 10 1/1, 10 2/1, 20 1/1 and 20 2/1

- piezoelectric igniter for model 6 1/1

ABOVE

Electric oven control panel

LEFT

Cooking with probe, which allows the food core

temperature to be controlled with precision

(essential for large joints of meat).

8

Page 9

FCF oven control panel functions

Heating with

low-level humidification

for stewed vegetables (peas,

peppers, etc.).

Heating with

medium/low-level

humidification

for vegetables au gratin,

roast meat and fish, soufflés

and timbales, etc.

Heating with mediumlevel humidification

for all types of roast meat

and fish (small pieces).

Heating with

medium/high-level

humidification

for all types of red meat

(large pieces).

ABOVE

Gas oven control panel

Heating with high-level

humidification

for all types of white meat

(large pieces), for bread

products and for regenerating

up pre-cooked food.

Ventilation without

heating

for rapid cooling of the oven

chamber after cooking.

Heating without

humidification

for crisp cooking, browning,

au gratin and grilling.

Cooking with probe

to measure the food core

temperature for extra precise,

calibrated cooking.

9

Page 10

Even the smallest details of FCF ovens have

been designed to ensure ease of

operation and cleaning. In particular

the oven chamber has rounded

corners with no sharp edges or joins,

making it extremely easy to clean.

All tray supports are easy

to remove and the large oven door

has rounded seals without recesses

which could trap dirt. A quick

cleaning procedure is all it takes at

the end of the day to ensure total

hygiene: a 5th level humidification

cycle (with valve closed), a quick

spray of detergent and then a rinse

with the spray arm to finish. Keeping

your oven clean is now a quick and

simple operation.

.Simple to use, hygien

ABOVE

The entire range of Zanussi FCF ovens features a

side lighting system that makes it easy to keep a

check on the cooking process.

RIGHT

The FCF ovens have extremely simple and safe

door opening/closing systems.

Models 6 1/1, 10 1/1 and 10 2/1 have

a press-button system.

Models 20 1/1 and 20 2/1 use a rotating handle

(see photo right).

RIGHT

Oven chamber dehumidification valve

(for electric models only).

10

Page 11

LEFT

Control knob for selecting humidification

level.

LEFT

The humidification device can be used for

selecting the desired level of humidity,

to preserve the natural moisture of food

and for regenerating pre-cooked food.

LEFT

The rapid cooling system reduces the

temperature in the oven quickly and

allows you to move on to the next cooking

cycle without having to wait too long

for the oven to cool down.

ALONGSIDE

The tray racks are mounted on pins for

ease of removal, making them extremely

simple to clean.

11

Page 12

FCF ovens are backed up by a wide range

of top-quality accessories. Developed to

meet the special needs that arise in the

kitchen, these accessories can be

selected to create a customised oven

with the ideal working configuration.

ALONGSIDE

The heated cupboard base is available for

models 10 1/1 and 10 2/1.

It has tray racks and

a removable panel for installation of the

retractable spray arm.

A solution for an

RIGHT

The retracting spray arm makes it even simpler

to clean your oven.

Available for models 6 1/1,

10 1/1 and 10 2/1.

RIGHT

The gas models are designed to include

a flue condenser in countries where

its use is mandatory.

12

Page 13

LEFT

The ambient cupboard base for models 10 1/1

and 10 2/1 is fitted with tray racks and a practical

drawer. It also has a compartment for the

installation of an automatic water softener.

LEFT

Trolley with slide-in rack available for

electric or gas model 20 2/1.

ALONGSIDE

Trolley with slide-in rack available for gas

or electric models 10 1/1 and 10 2/1.

13

Page 14

Specifications and feat

FCF 6 1/1 OVENS

FCF 6 1 G:

gas 6 1/1 GN grids

860 x d.746 x h.701

FCF 6 1 E:

electric 6 1/1 GN grids

860 x d.746 x h.633

FCF 10 1/1 OVENS

FCF 10 1 G:

gas 10 1/1 GN grids

890 x d.900 x h.970

FCF 10 1 E:

electric 10 1/1 GN grids

890 x d.900 x h.970

FCF 10 2/1 OVENS

FCF 10 2 G:

gas 10 2/1 GN grids

890 x d.1215 x h.970

FCF 10 2 E:

electric 10 2/1 GN grids

890 x d.1215 x h.970

FCF 20 1/1 OVENS

FCF 20 1 G:

gas 20 1/1 GN grids

890 x d.900 x h.1800

FCF 20 1 E:

electric 20 1/1 GN grids

890 x d.900 x h.1750

14

Page 15

FCF 20 2/1 OVENS

ACCESSORIES

BASES HANDLING SYSTEM OTHER

FCF 20 2 G:

gas 20 2/1 GN grids

890 x d.1215 x h.1800

FCF 20 2 E:

electric 20 2/1 GN grids

890 x d.1215 x h.1750

Base for 6 1/1 oven

Base for 10 1/1 oven

Base for 10 2/1 oven

Tray racks for 6 1/1 - 10 1/1 10 2/1 oven base

Cupboard base for 10 1/1

oven

Cupboard base for 10 2/1

oven

Heated cupboard base for

10 1/1 oven

Heated cupboard base for

10 2/1 oven

Feet kit for 10 1/1 and 10 2/1

ovens

Trolley for 10 1/1 - 10 2/1

slide-in rack

Trolley for 20 1/1 slide-in rack

Trolley for 20 2/1 slide-in rack

Tray racks with 80 mm spacing

for 10 1/1 electric oven

Tray racks with 80 mm spacing

for 10 1/1 gas oven

Tray racks with 80 mm spacing

for 10 2/1 oven

Tray racks with 60 mm spacing

for 10 1/1 electric oven

(provided)

Tray racks with 60 mm spacing

for 10 1/1 gas oven (provided)

Tray racks with 60 mm spacing

for 10 2/1 oven (provided)

10 1/1 sliding tray holder kit

10 2/1 sliding tray holder kit

20 1/1 slide-in rack with

80 mm spacing

20 2/1 slide-in rack with

80 mm spacing

20 1/1 slide-in rack with

60 mm spacing (provided)

20 2/1 slide-in rack with

60 mm spacing (provided)

Base for 20 1/1 slide-in rack

Base for 20 2/1 slide-in rack

Retractable spray arm

External spray arm

Support for confectionery tray

Flat aluminium confectionery

tray

2 AISI 304 stainless steel

1/1 GN grids

2 AISI 304 stainless steel

2/1 GN grids

2 grids for 1/2 GN tray

supports

Fat filter for 6 1/1 oven

Fat filter for 10 1/1 - 10 2/1

electric ovens

Fat filter for 10 1/1 - 10 2/1

gas ovens

Automatic water softener for

ovens

Resin sanitiser for water

softener

Water filter for ovens without

boiler

Flue condenser / draft diverter

for 10 1/1 - 10 2/1 gas ovens

Probe kit for 6 1/1 - 10 1/1

ovens

Probe kit for 10 2/1 ovens

Probe kit for 20 1/1 - 20 2/1

ovens

Insulating cover for 10 1/1

slide-in rack

Insulating cover for 10 2/1

slide-in rack

Insulating cover for 20 1/1

slide-in rack

Insulating cover for 20 2/1

slide-in rack

15

Page 16

Loading...

Loading...