Zanussi 240206, FCF-10 1-1, FCF101G6, FCF101ENS, 240212 User Manual

...

RANGE

COMPOSITION

A range which combines experience and

innovation; is new in performance, excellent

in quality and economical in use. The ideal

solution for establishments requiring ovens

with high output, compact dimensions,

flexibility of use, high levels of automation,

reduced energy and condiments

consumption, up-to-date design and

maximum reliability.

The range consists of five 10 grid 1/1 GN

models, three electric and two gas, ideal for

all types of traditional oven cooking, roast

meat, cakes, pizzas, fish, vegetables, grilled

food, "au gratin" cooking and the

reconditioning of chilled and frozen food.

240201 + stand

FORCED AIR CONVECTION OVENS

FUNCTIONAL AND

CONSTRUCTION

FEATURES

� The Flow Channel ventilation system

guarantees uniform cooking of food by

optimizing the flow of air and diffusion of heat

throughout the oven chamber, it also means

that it is possible to cook different foods at

the same time without transfer of smell or

flavour.

� External panelling, door, sides and upper

part in 304 AISI stainless steel; the cooking

chamber, grid supports, diffusers, and the fan

walls are in 430 AISI stainless steel; the

double glazed door is made from tempered

glass and gives an excellent view of the

cooking load and a door opening safety

device. The oven chamber has rounded

corners and no joins for ease of cleaning.

� A series of automatic and manual

controls, are supplied as standard, which

allows a lot of oven operations to be

automated without hindering the creativity of

the chef.

� The optimised relationship between

installed power, output and speed of cooking

means that excellent results can be achieved

in terms of economy of use as well as the

production in a short amount of time of a high

FCF-10 1/1

ZANUSSI

P R O F E S S I O N A L

quantity of food and all this with an oven heat

up time of about 6 minutes.

� The heating system in the gas models

consist of atmospheric burners; safety is

guaranteed by flame failure device; main

burner ignition by pilot light; piezoelectric

ignition of the pilot light. The heating system

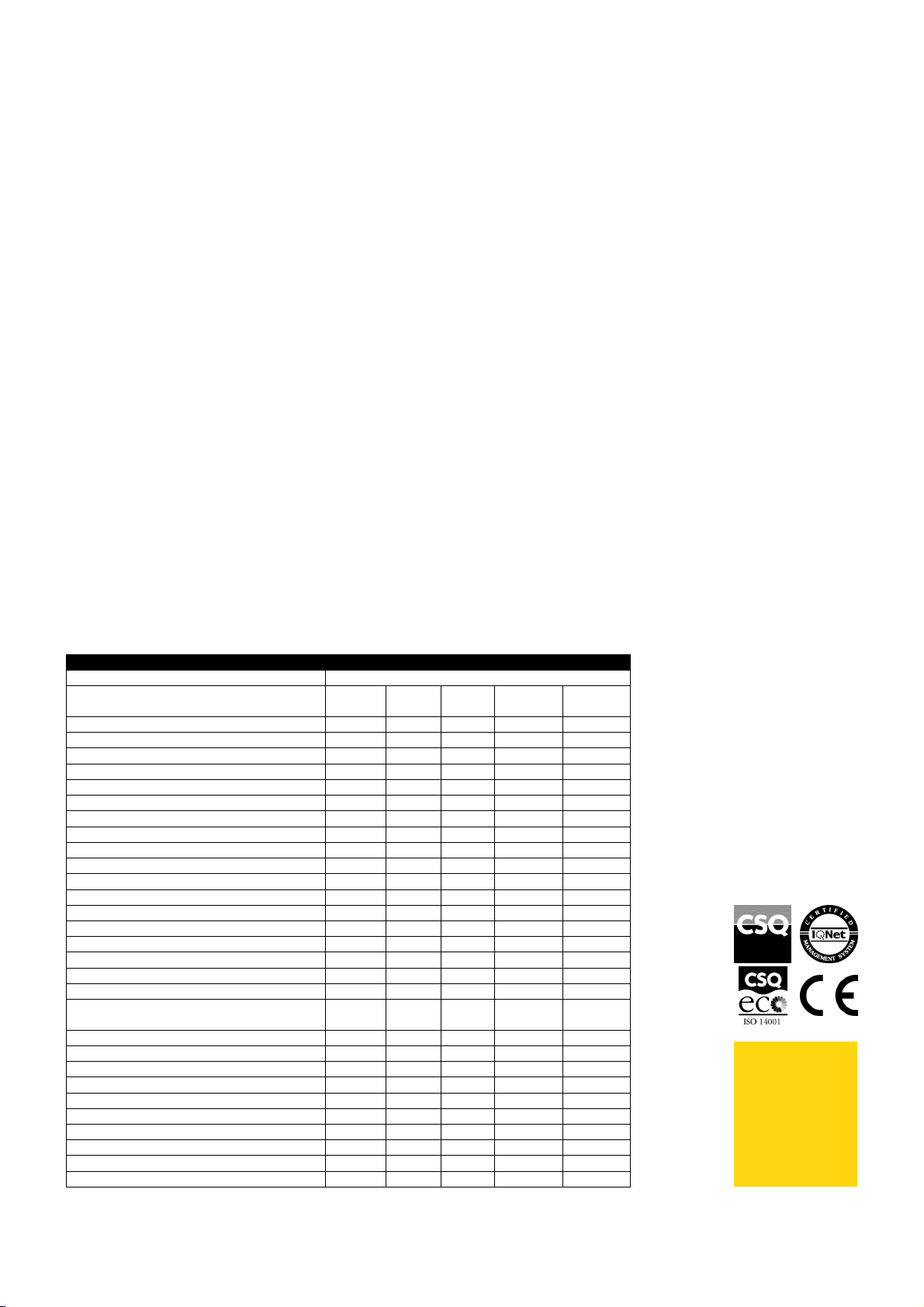

TECHNICAL DATA

CHARACTERISTICS MODELS

FCF101G6

240269

Power supply Gas Gas Electric Electric Electric

Type of grids 1/1

Shelf capacity 10 10 10 10 10

Convection l l l l l

External dimensions - mm

width 890 890 890 890 890

depth 900 900 900 900 900

height 970 970 970 970 970

height adjustment 80 80 80 80 80

Internal dimensions - mm

width 590 590 590 590 590

depth 479 479 503 503 503

height 680 680 680 680 680

Power - kW

gas 18.5 18.5

installed-electric 0.35 0.35 17.3 17.3 17.3

Net weight - kg. 136 136 121.2 121.2 121.2

Supply voltage 220/230 V,

INCLUDED ACCESSORIES

60 MM PITCH SIDE HANGERS

10X1/1 ELE.OVEN

Gastronorm

1N, 60

1 1 1 1 1

in electric models consists of "Incoloy"

armoured elements positioned on the

convector unit.

FCF101G

240201

1/1

Gastronorm

220/230 V,

1N, 50

FCF101E

240206

1/1

Gastronorm

400 V, 3N,50400 V, 3N,60230 V, 3, 50

FCF101ENS

240227

1/1

Gastronorm

FCF101ELN

240212

1/1

Gastronorm

FORCED AIR CONVECTION OVENS

FCF-10 1/1

� Side lighting system using normal bulbs;

press-button door opening and closing

system

� Electromechanical thermostat with an

operating temperature adjustable from 30°C

to 300°C with a visual display to show the

oven is working and the temperature in the

chamber. Timer to set the cooking time,

adjustable up to 120 minutes or for

continuous operation with an acoustic alarm

to show the cycle has finished. At the end of

the set cooking time the heat and the fan are

automatically switched off.

� The humidity level can be set by selecting

one of the 5 levels shown on the control

panel; it functions by injecting water into the

cooking chamber for a few seconds every

minute. Thermometer for controlling the

temperature in the cooking chamber.

� All models comply with the standards

required by the main international approval

bodies and are CE marked.

� Main switch/Cooking mode selector which

can be used to set: ON/OFF, convection

without humidification and convection with

humidification (choice of 5 different humidity

levels). Rapid cooling of the oven by air with

the door open. The oven is designed to be

fitted with a probe which is available as an

accessory.

� Presence of a thermometer for a quick

check of the temperature inside the cooking

chamber.

� Gas models are supplied for use with

natural gas, with LPG conversion jets

supplied as standard.

* In accordance with CE regulations for gas

models belonging to Class B11 (power over 14

kW), it is necessary to install a chimney (if

installed under a hood) or chimney and draft

diverter if the waste gases are vented directly

outside.

OPTIONAL ACCESSORIES

ACCESSORIES MODELS

FCF101G6

240269

1 GRID GN1/1 FOR 8 WHOLE CHICKENS(1.2KG) 922266 922266 922266 922266 922266

1/1GN DRAIN PAN GUIDE KIT 921713 921713 921713 921713 921713

2 GRIDS GN 1/1 FOR CHICKENS (8 PER GRID) 922036 922036 922036 922036 922036

60 MM PITCH SIDE HANGERS 10X1/1 ELE.OVEN 922121 922121 922121

60 MM PITCH SIDE HANGERS 10X1/1 GAS OVEN 922122 922122

80 MM PITCH SIDE HANGERS 10X1/1 ELE.OVEN 922115 922115 922115

80 MM PITCH SIDE HANGERS 10X1/1 GAS 0VEN 922116 922116

AUTOMATIC WATER SOFTENER FOR OVENS 921305 921305 921305 921305 921305

BASE FOR 10X1/1GN OVEN ON CASTORS 922114 922114 922114 922114 922114

BASE FOR OVEN 10X1/1 922102 922102 922102 922102 922102

CUPBOARD STAND 10X1/1 FOR OVEN 922109 922109 922109 922109 922109

EXTERNAL SIDE SPRAY UNIT 922171 922171 922171 922171 922171

FAT FILTER FOR GAS OVENS 10&20X1/1-2/1 921700 921700

FAT FILTER FOR OVENS 10X1/1-2/1 922178 922178 922178

FEET FOR OVENS 6&10 GN1/1-10 GN2/1 922127 922127 922127 922127 922127

FLUE CONDENSER FOR GAS OVENS 10X1/1-2/1 921701 921701

FRYING GRIDDLE GN 1/1 FOR OVENS 922215 922215 922215 922215 922215

HOT BASE CUPB. F.10GN1/1 OVEN ON CASTORS 922023 922023 922023 922023 922023

HOTCUPBOARD STAND 10X1/1

CONVECT.STEAMER

KIT TO CONVERT TO 10X1/1 SLIDE-IN RACK 922201 922201 922201 922201 922201

PAIR OF 1/1 GN AISI 304 S/S GRIDS 921101 921101 921101 921101 921101

PAIR OF 1/2 GN PAN SUPPORT SHELVES 921106 921106 921106 921106 921106

PROBE FOR OVENS 6-10X1/1 921702 921702 921702 921702 921702

RESIN SANITIZER FOR WATER SOFTENER 921306 921306 921306 921306 921306

RETRACTABLE HOSE REEL SPRAY UNIT 922170 922170 922170 922170 922170

SHELF GUIDES FOR 10X1/1-OVEN BASE 922106 922106 922106 922106 922106

THERMAL JACKET FOR SLIDE-IN RACK 10X1/1 922150 922150 922150 922150 922150

TROLLEY FOR 10XGN1/1 ROLL IN RACK 922130 922130 922130 922130 922130

WATER FILTER FOR OVENS 0.8 L/MIN. 922186 922186 922186 922186 922186

BCAC1 2009-06-25 The Company reserves the right to alter technical specifications without prior notice.

922112 922112 922112 922112 922112

FCF101G

240201

FCF101E

240206

FCF101ENS

240227

FCF101ELN

240212

ZANUSSI

P R O F E S S I O N A L

www.zanussiprofessional.com

Loading...

Loading...