Page 1

English

Important Safety Information

These warnings are provided in the interest of safety. You must read them carefully before installing or using

the appliance.

Installation

It is mandatory that all operations required for the

installation are carried out by a qualified or competent

person, in accordance with existing rules and

regulations.

It is dangerous to alter the specification in any way.

Should you connect any electrical tool to a plug near

this cooking appliance, ensure that electric cables are

not in contact with it and keep them far enough from

the heated parts of this appliance.

If the appliance is out of order, disconnect it from the

electric supply.

Disconnect the appliance from the electrical supply,

before carrying out any cleaning or manteinance work.

Ensure a good ventilation around the appliance. A

poor air supply could cause lack of oxygen.

Ensure that the gas supply complies with the gas type

stated on the identification label, placed near the gas

supply pipe.

Using a gas cooking appliance will produce heat

and moisture in the room which it has been

installed in. Ensure a continuous air supply,

keeping the air vents in good conditions or

installing a cooker hood with discharge tube.

In case of intensive or long time use of the

appliance, make the ventilation more efficient,

by opening a window or increasing the electric

exhaust fan power.

Once you removed all packaging from the appliance,

ensure that it is not damaged and the electric cable is

in perfect conditions. Otherwise, contact your dealer

before proceeding with the installation.

The manufacturer disclaims any responsability

should all the safety measures not be carried out.

Child Safety

Service Centre

Under no circumstances should you attempt to repair

the appliance yourself. Repairs carried out by

unexperienced persons may cause injury or serious

malfunctioning. Refer to your local Service Centre.

Always insist on genuine spare parts.

Environmental Information

After installation, please dispose of the packaging with

due regard to safety and the environment.

When disposing of an old appliance, make it unusable,

by cutting off the cable.

It is most important that this instruction book

is be retained with the appliance for future

reference. Should the appliance be sold or

transferred, always ensure that the book is left

with the appliance in order that the new

owner can get to know the functions of the

appliance and the relevant warnings.

Guide to Use the instructions

The following symbols will be found in the text to guide

you throughout the Instructions:

Safety Instructions

Step by step instructions for an operation

F

Hints and Tips

Environmental information

This appliance has been designed to be operated by

adults and children under supervision. Young children

must not be allowed to tamper with the controls or play

near or with the appliance.

Accessible parts of this appliance may become hot

when it is in use. Children should be kept away until

it has cooled.

During use

This appliance has been designed for cooking edible

foodstuff and to be used for domestic non-professional

purposes only. It must not be used for any other

purpose.

For hygiene and safety reasons, this appliance should

be kept clean at all times. A build-up of fats or other

foodstuff could result in a fire.

Ensure that all control knobs are in the OFF position

when not in use.

30

This appliance complies with the following

E.E.C. Directives:

- 73/23 - 90/683 (Low Voltage Directive);

- 89/336

- 90/396 (Gas Appliances)

- 93/68 (General Directives)

and subsequent modifications.

MANUFACTURER: ELECTROLUX ZANUSSI S.p.A.

These instructions are only for the countries

stated by the symbol printed on the front cover

of this instruction book.

(Electromagnetical Compatibility Directive);

Viale Bologna, 298

47100 FORLÌ (Italy)

Page 2

Contents

For the User For the Installer

Important Safety Information 30

Operation 31

Cleaning and Maintenance 32

Operation

Hob burners control knobs

The hob burners control knobs are situated on the hob

front panel. The symbols on the knobs mean that :

l there is no gas supply

there is maximum gas supply

there is minimum gas supply

Technical Data 33

Installation 33

Electrical Connection 34

Adaptation to different types of gas 35

Building In 36

Possibilities for insertion 37

Lighting the burners

For easier lighting, proceed before putting a

pan on the pan support.

To light a burner:

F

l Depress the relevant switch marked with a small

spark. Then, push the relevant knob down and turn it

anti-clockwise until it reaches the "maximum"

position.Check the flame is regular and adjust it as

required.

l If you cannot light the flame even after several

attempts, check the "cap" (Fig. 1 lett. A) and the

"crown" (Fig. 1 lett. B) are in the correct position.

l To put the flame out, turn the knob to the symbol l.

Always turn the flame down or put it out before

taking the pans off the burner.

Using the hob correctly

To ensure maximum burner efficiency, it is strongly

recommended that you use only pots and pans with a

bottom fitting the size of the burner used, so that flame

will not spread beyond the bottom of the vessel (see the

table beside).

It is also advisable, as soon as a liquid starts boiling, to

turn down the flame so that it will barely keep the liquid

simmering.

Use only pans or pots with flat bottom.

Carefully supervise cookings with fats or oil,

since these types of foodstuff can result in a

fire, if over-heated.

Fig. 1

Fig. 2

Table of minimum and maximum diameters of pots

which can be placed on the burners

Burner minimum maximum

Big (rapid) 180 mm. 260 mm.

Medium (semirapid) 120 mm. 220 mm.

Small (Auxiliary) 80 mm. 160 mm.

FO 0204

A - Burner cap

B - Burner crown

C - Ignition candle

diameter diameter

31

Page 3

Cleaning and Maintenance

Disconnect the appliance from the electrical

supply, before carrying out any cleaning or

manteinance work.

General cleaning

- Wash the enamelled components with warm soapy

water. Never use abrasive cleaners

- Frequently wash the "caps" and the "crowns" with

hot soapy water, carefully taking away any built-up of

food.

- Carefully wash the stainless steel components with

water, then wipe them dry with a soft cloth.

- The pan supports are dishwasher proof. If the marks

are particularly difficult to remove, use common non-

abrasive cleaners or specific products.

- Never use steel wool pads or acids.

Fig. 3

Electric ignition

In models provided with electric ignition, this feature is

obtained through a ceramic "candle" and a metal

electrode (fig. 1 lett. C). Keep these components well

clean, to avoid difficult lighting, and check that the burner

crown holes (lett. B) are not obstructed.

FO 2110

Periodic maintenance

Periodically ask your local Service Centre to check the

conditions of the gas supply pipe and the pressure

adjuster, if fitted.

To ensure the good operation of the hob and its safety

features, it is necessary that the taps are periodically

lubricated.

l The periodic lubrication of the taps must be

carried out by qualified personnel, which you

must refer to also in case of malfunctioning.

32

Page 4

Technical Data

Gas Burners Rating

Rapid Burner (big) 3 kW (G20) - 2,8 kW (G30-31)

Auxiliary Burner (small) 1 kW

Semirapid Burner (medium) 2 kW

Category II 2E+3+

Appliance class 3

Installation

l The side walls of the unit in which the hob is

going to be installed, must not exceed the height

of the working top.

l Avoid installing the appliance in the proximity of

inflammable materials (e.g. curtains, tea towels

etc.).

l The following instructions about installation and

maintenance must be carried out by qualified

personnel in compliance with the regulation in

force. The regulation to be applied for this type

of installation is NBN D 5I.003 : "Installations

functioning with combustible gas lighter than

air".

l The appliance must be electrically disconnected

before all interventions. If any electric supply to

the appliance is required to carry out the work,

ensure all the necessary precautions are followed.

Gas connection

Setting Natural Gas G20/G25 - 20/25 mbar

Gas connection G 1/2"

Electric Supply 230 V 50 Hz

Hob recess dimensions

Length 550 mm.

Width 470 mm.

IMPORTANT - To ensure a correct operation, a saving

of energy and the long-life of the appliance, the voltage

pressure of the appliance must correspond to the

recommended values.

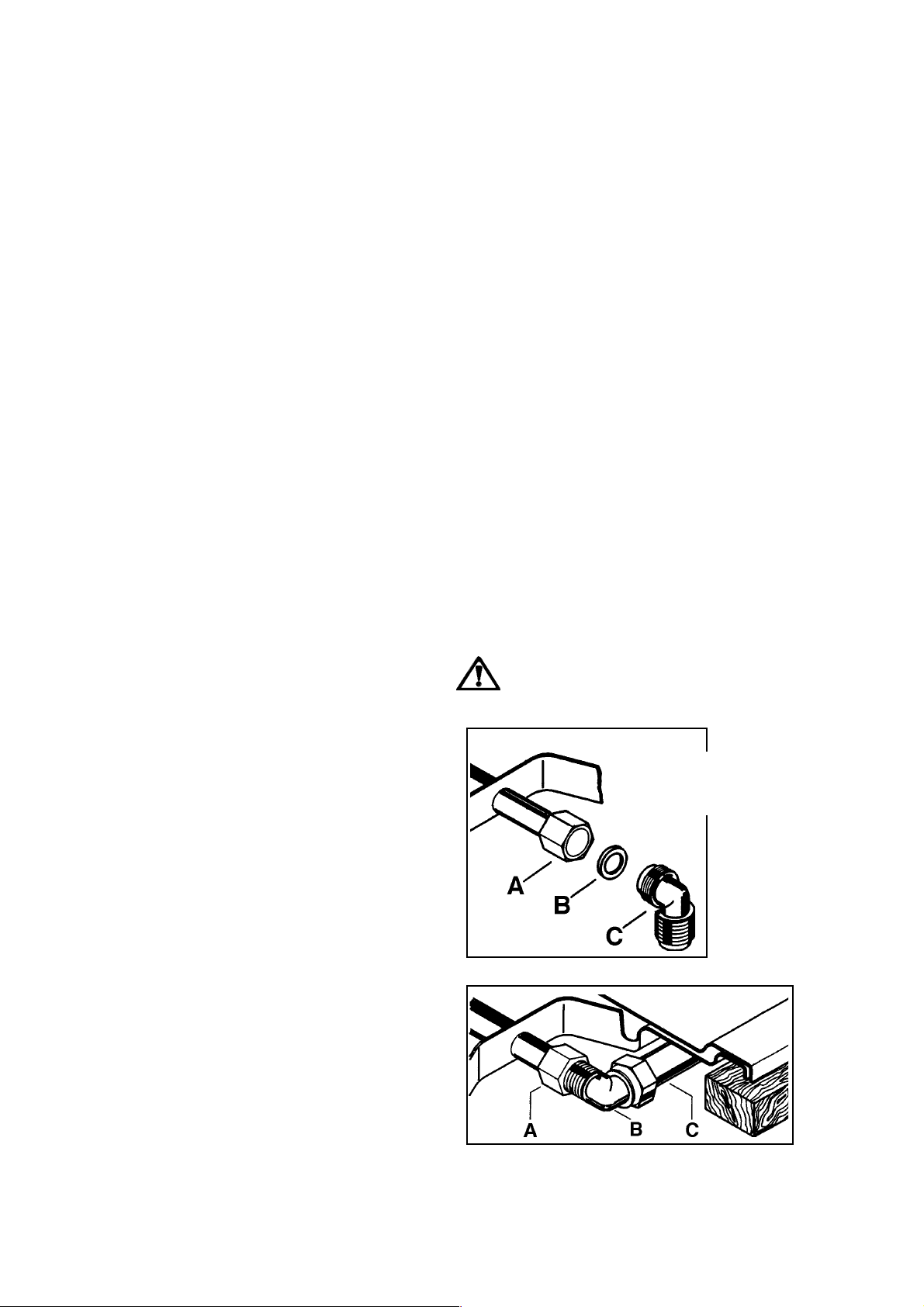

The adjustable connection is fixed to the comprehensive

ramp by means of a threaded nut GJ 1/2". Interpose the

sealing between the components as shown in fig. 4.

Screw the parts without forcing, adjust the connection in

the required direction and tighten everything.

The adjustable connection allows the feeding pipe to be

situated in the site purposefully allocated on the side of

the protection box of the hob itself (Fig. 5). This connection

allows the overall dimensions of the hob plus the fedding

pipe to be contained into a depth of 30 mm.

IMPORTANT - When the final connection has been

made, it is essential that a thorough leak test is

carried out on the hob and installation. Use some

soapy water, never a flame.

It is indispensible that the connection to the gas mains

are carried out by means of an AGB tap. Choose fixed

connections or use a flexible pipe in AGB (stainless

steel).

If using flexible metallic pipes, be careful they do not

come in contact with mobile parts or they are not

squeezed. Use the same attention when the hob is

combinated with an oven.

This hob can be operated by Slochteren gas (G25) with

a nominal pressure of 25 mbar or by natural gas with

nominal pressure of 20 mbar. No regulation is required for

use by these two types of gas.

Before fitting the appliance ensure that the installation

has the correct voltage for the appliance. At full capacity,

the drop in pressure must not exceed 5%. Such a drop in

pressure is caused by the following parameters:

- maximum capacity of meter;

- diameter and lenght of the tube in front and behind the

meter;

- section of transit of variuos tubes positioned on the

circuit;

- diameter of eventual connections.

A) Ramp with ending nut

B) Seal

C) Adjustable connection

FO 2365

FO 0265

A) Ramp ending with nut

B) Adjustable connection

C) Rigid or flexible metallic gas pipe

Fig. 4

Fig. 5

33

Page 5

Electrical Connection

The appliance is designed to be connected to 230 V

monophase electricity supply.

The connection must be carried out in compliance with

the laws and regulations in force.

Before the appliance is connected:

1) check that the main fuse and the domestic installation

can support the load (see the rating label);

2) check that the power supply is properly earthed in

compliance with the current rules;

3) check the socket or the double pole switch used for

the electrical connection can be easily reached with

the appliance built in the forniture unit.

The appliance is supplied with a connection cable. This

has to be provided with a proper plug, able to support the

load marked on the identification plate. The plug has to be

fitted in a proper socket.

If connecting the appliance directly to the electric system,

it is necessary that you install a double pole switch

between the appliance and the electricity supply, with a

minimum gap of 3 mm. between the switch contacts and

of a type suitable for the required load in compliance with

the current rules.

The connection cable has to be placed in order that, in

each part, it cannot reach a temperature 90 °C higher than

the room temperature.

The brown coloured phase cable (fitted in the terminal

block contact marked with "L") must always be connected

to the network phase.

Replacement of the voltage

cable

In case the connection cable needs to be replaced, only

cable type H05V2V2-F T90 must be used. The cable

section must be suitable to the voltage and the working

temperature.

The yellow/green earth wire must be approximately 2

cm. longer than the phase wires (Fig. 6).

Phase

FO 0480

Neutral

wire

Ground (yellow - green)

Fig. 6

34

Page 6

Adaptation to different types of gas

Injectors replacement

Remove the pan supports.

Remove the burner's caps and crowns.

With a socket spanner 7 unscrew and remove the

injectors (Fig. 7), and replace them with the ones

required for the type of gas in use (see table 2).

Reassemble the parts, following the same procedure

backwards.

Replace the rating label (placed near the gas supply

pipe) with the relevant one for the new type of gas

supply. You can find this label in the package of the

injectors supplied with the appliance.

Should the feeding gas pressure be different or variable

compared with the required pressure, an appropriate

pressure adjuster must be fitted on the gas supply pipe,

in compliance with the rules in force.

Fig. 7

FO 0392

Adjustment of minimum level

To adjust the minimum level of the burners, proceed as

follows:

Light the burner.

Turn the knob on the minimum position.

Remove the knob.

Bypass screw

With a thin screwdriver, adjust the by-pass screw (see

Fig. 8). If changing from natural gas to LPG, completely

tighten clockwise the screw, until a small regular

flame is obtained.

Table 1 : By-pass diameters

Finally check the flame does not go out when quickly

turning the knob from the maximum position to the

minimum position.

This procedure can easily be carried out, anyhow the hob

has been positioned or built in the working top.

Burner Ø By-pass

Auxiliary 28

Semi-rapid 32

Rapid 40

Table 2 : injectors

BURNER NORMAL REDUCED NORMAL

POWER POWER POWER

Fig. 8

in 1/100

of mm.

kW kW NATURAL GAS LPG

G20 - 20 mbar 28-30/37 mbar

inj. 1/100 m3/h inj. 1/100 g/h - G30 g/h - G31

Auxiliary (small) 1 0,33 70 0,095 50 72 71

Semi-rapid (medium) 2 0,45 96 0,190 71 145 143

Natural gas :

Rapid (big) 3 0,65 119 0,286 86 203 200

LPG : 2,8

35

Page 7

Building In

A = Auxiliary burner

SR = Semirapid burner

R = Rapid Burner

These hobs can be inserted in a built-in kitchen unit

whose depth is between 550 and 600 mm. The hobs

dimensions are shown in Fig. 9.

SR

SR

500

Installation and assembly

These hobs can be installed in a kitchen unit with an

opening for insertion whose dimensions are shown in

Fig. 10.

Carry out the building in of the hob as follows:

F

put the relevant sealings, supplied with the hob, on the

edges of the cut out, taking care that the sealings

meet without overlapping;

place the hob in the cut out, taking care of its centring;

fix the hob with the relevant screws (Fig. 11). The

traction of the screws is able to trace the sealing, any

excess of which can then be easily removed.

The edge of the hob forms a double labyrinth seal which

provides a total guarantee against infiltration of liquids.

FO 2096

FO 2098

470

R

55 min.

30

A

580

Fig. 9

550

Fig. 10

36

FO 0199

a) sealing

a

Fig. 11

Page 8

470

30

591

380

140

Possibilities for insertion

Kitchen unit with door

Proper arrangements must be taken in designing

the forniture unit, in order to avoid any contact

with the bottom of the hob which can be heated

when it is operated. The recommended solution

is shown in Fig. 12.

The panel fitted under the hob should be easily

removable to allow an easy access if a technical

assistance intervention is needed.

Kitchen unit with oven

The hob recess dimensions must comply the

indication given in Figs. 13 and 16 and must be

provided with brackets to allow a continuous

supply of air.

To avoid overhating, the building in should be

carried out as shown in Figs. 14 and 15.

The hob's electric connection and the oven's one

must be carried out separately, both for safety

reasons and to allow the oven to be easily taken

off the unit.

Hanging forniture units or hoods must be placed

at 650 mm. minimum from the hob (Fig. 17).

Fig. 12

30

60

a

20 min

b

FO 1013

FO 0947

a) Removable panel

b) Space possibly useful for connections

Fig. 14

Fig. 15

Fig. 13

Fig. 16

550 min.

FO 0938

Fig. 17

50 cm

360 cm

2

2

FO 0939

120 cm

180 cm

2

2

FO 0198

560 min.

650 mm

FO 2099

37

Page 9

GUARANTEE - SPARE PARTS (only for BENELUX)

When calling for repairs during the period of guarantee

ofthe appliance, the original invoice or receipt must be

shown or sent together with the appliance to be repaired.

General conditions of guarantee

1 The manufacturer guarantees the appliance indicated

on the relative invoice for a period of one year from the

date of purchase. In case of a fault during this period

if caused bya defect in materials and/or construction,

the client is entitled to repair free of charge.

1a Concerning vacuum cleaners for domestic use, the

total periodof guarantee is two years. Accessories

are subject to a direct usage, consequently these

articles are excluded from the guarantee.

2 The manufacturer guarantees technical assistance

and repairsfor one year. Spare parts fitted during

repair are also covered by a one year guarantee from

the date of repair. In case of fault during this period,

as a direct result of the repair work carried out or

caused by the new parts fitted on such occasion, the

client is entitled to repair free of charge. The execution

of repairs does not prolong the total period of guarantee

covering the appliance.

3 Technical Assistance at domicile will be provided

only for large apparatus which are difficult to transport

such as: washing machines, spin-driers,

dishwashers,refrigerators, freezers (vertical or

horizontal), ovens, cookers and built-in appliances.

3a The above-mentioned conditions are also valid for

refrigerators for caravens on condition that they are

situated within the national boundaries and are

accessible by roads open to traffic. Furthermore, at

the time of the intervention the appliance and its

owner, or the person so authorized, must be present

at the place agreed upon for the intervention.

4 If, in the opinion of the manufacturer, the appliance

as described in point 3 must be transported to a

Technical Assistance laboratory, the transportation

will be carried out as established by the manufacturer,

at his expense and under his responsibility.

5 All appliances not mentioned under points 3 and 3a,

includingappliances having the same functional

characteristics but whose transport is easy, must be

sent to the Technical Assistance or taken to them.

Throughout the period of guarantee the cost of return

transportation will be taken care by the manufacturer.

6 If during the period of guarantee a disfunction occurs

due to a defect which cannot be repaired, the

appliance will be replaced free of charge.

Extension of the guarantee

7 For motorcompressors of refrigerators/ freezers

(excluding the starting device and thermal interrupter)

a decreasing guarantee of 20% per year for a period

of five years from the date of purchase of the

appliance indicated on the relative invoice with repairs

free of charge throughout the entire period under

guarantee. On completion of the total period of

guarantee the cost of travel, workmanship and

eventual spare parts will be at the expense of the

client.

Exclusion from guarantee

8 The free execution of work for the repair and/ or

substitution as set out above will not apply if:

- The purchase invoice or receipt indicating the date of

purchase and the identification of the appliance

cannot be presented or was not sent with the

appliance to be repaired;

- The appliance is used for purposes other than those

of the domestic nature for which it was made;

- The appliance was not installed, handled or used in

conformity with the indications in the instruction

manual or in the modalities for use;

- The appliance has been repaired or modified

incorrectly by unqualified personnel.

8a If the appliance has been built-in, underinserted,

suspendedor installed in such a way that the time

required to move it and put it back in position

exceeds thirty minutes in total, the extra expenditures

occurred will be billed to the owner of the appliance.

8b ln case of deterioration due to an irregular installation

carried out in agreement with the owner of the

appliance, the manufacturer and the technical

assistance decline all responsibility.

8c Damage such as scratches, knocks or breakage of

movable or dismountable units which were not notified

to the manufacturer at the time of delivery are not

covered by the guarantee.

Important notice

This appliance has been made to be safe. Inadequate

repairs can nonetheless compromise this safety. To

avoid such problems and to prevent any eventual damage

we advise you to have repairs carried out exclusively by

qualified personnel.We advise you to have repairs or

maintenance carried out by the retailer or the local

Electrolux Service and

to request only original

spare parts.

Belgium

Bergensesteenweg 719 / B - 1520 Halle (Lembeek)

Repairing to customer's house:

Tel.: 02-3630444

Fax.: 02-3630400

Spare parts:

Tel.: 02-3630555

Fax.: 02-3630500

Luxembourg

7, Rue de Bitbourg / L-1273 Luxembourg-Hamm

Customer care:

Tel.: 42 43 11

Fax: 42 43 13 60

38

Page 10

Page 11

35673-3302 11/01

Grafiche MDM - Forlì

Loading...

Loading...