Page 1

Required Equipment

• Ion meter or pH/mV meter.

• Wash bottle with distilled or deionized water.

• Several clean beakers.

• 1 mL, 10 mL and 100 mL pipettes.

Required Solutions

• Reference Fill Solution YSI #400378

• 1000 ppm Bromide Standard YSI #400381

• 100 ppm Bromide Standard YSI #400380

• Ionic Strength Adjustor (ISA) YSI #400379

Overview

The YSI 400377 Bromide Ion Selective Electrode is a

combination electrode (includes both reference and sensing

half cells in one body housing) for measuring bromide ion (Br

activity in aqueous samples.

• Technology: Fixed position, solid state sensor

• Size and material:

Body (Epoxy)—12 mm OD x 155mm L

Cap (ABS) —16 mm OD x 57mm L

Cable (Coax type) – 100cm

BNC Connector

• Reference: Double-junction, Ag/AgCl, ceramic pin junction,

refillable, potassium nitrate electrolyte

• Features: long-lasting solid state sensor

• Range: 0.4-79,900 mg/L

• Reproducibility: ±2%

• Slope: -54 to -59 mv/decade @ 25° C typical

• pH range: <12

• Operating Temperature: 0 to 80°C, to 100°C intermitt ent

• Interferences: I

• Applications/Notes: Pool & spa, industrial

-

, Cl-, CN-, NH

-

3

-

)

Electrode Preparation

1. This electrode performs better when the reference

junction is kept wetted during transit and storage.

Unscrew the cap of the storage solution bottle (Soaker

Bottle) and remove the electrode. Caution: Avoid

touching the sensor surface with your fingers.

2. Filling the electrode with electrolyte - the reference

(outer) chamber must be filled with Reference Fill

Solution and remain open during testing:

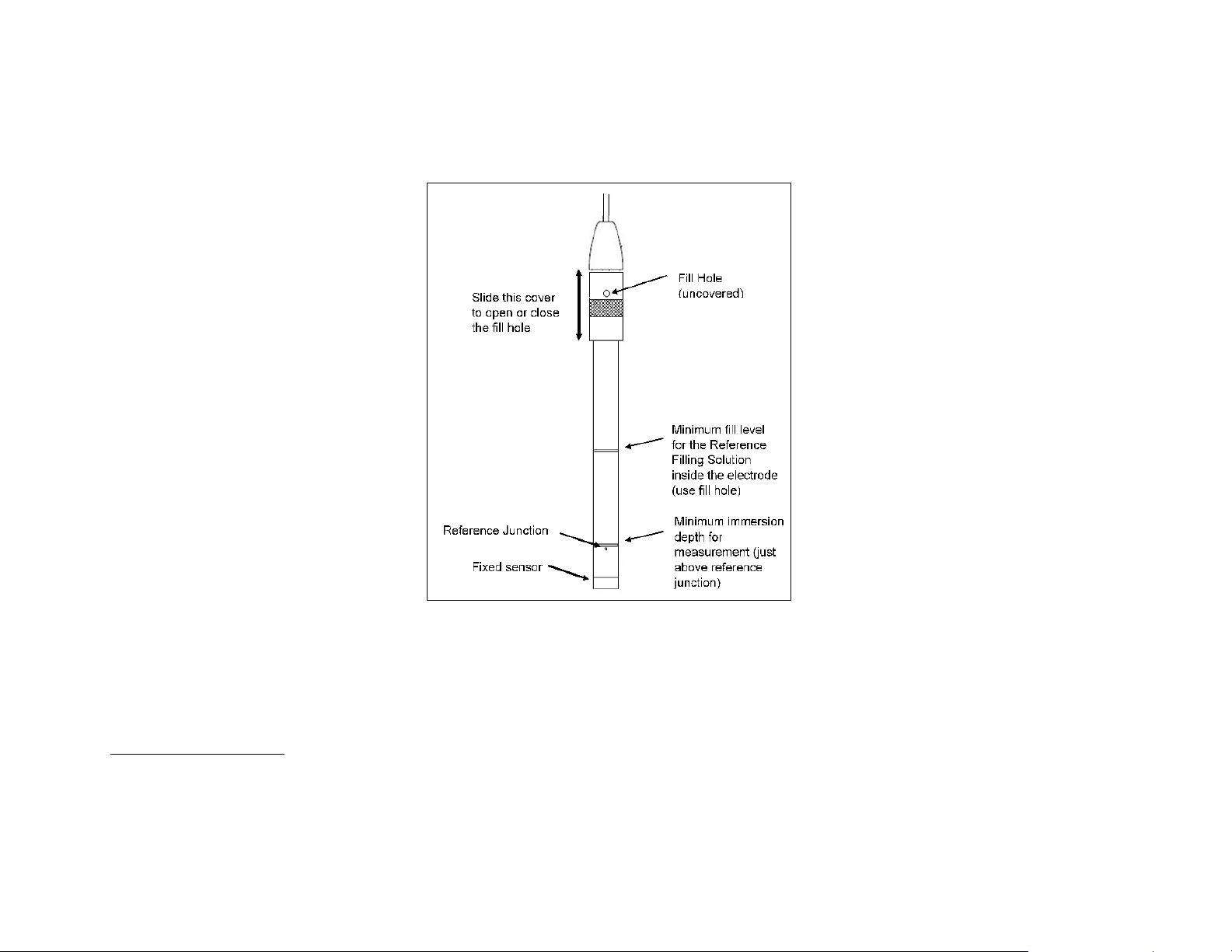

a) Slide the sleeve of the electrode FastFil cap down to

uncover the fill hole. (see fig. 1)

b) Shake the electrode downward like a thermometer to

remove any air bubbles trapped inside.

c) The surface of the Reference Fill Solution in the

reference chamber must be above the inner junction.

This is approximately 3" from the electrode tip.

3. Rinse the electrode with Dl water, blot dry. Do not rub

dry.

4. Soak the electrode in Dl water for 10 minutes, then in a

diluted Bromide Standard Solution for t wo hours prior to

calibration or use.

Electrode Diagram (fig. 1)

Checking Electrode Operation (Slope)

1. Connect the el ectrode to the meter. Place 100 mL Dl water

into a 150 mL beaker. Add 2 mL Bromide ISA to the Dl

water and stir thoroughly.

2. Set the function switch to the mV mode.

3. Rinse the electrode with Dl water, blot dry and place i n the

solution prepared in step 2.

4. Pipet 1 mL of 1000 ppm Bromide Standard into the beaker.

Stir thoroughly, then record the potential (

stable reading is displayed.

5. Pipette 10 mL of the same standard into the s ame beaker.

Stir thoroughly. When a stable reading is dis played, rec ord

the potential (E

6. The difference bet ween the first and the second potential

readings (E

normal range for the slope is -56±4 mV at 25°C.

) in mV.

2

) is defined as the electrode slope. The

2-E1

E

) in mV when a

1

Troubleshooting

If the electrode slope is not within the normal range, the

following procedure may restore the electrode.

1. Soak the electrode in a diluted standard solution for 2

hours before use.

2. Repeat "Checking Elect rode Operation" procedure again.

Note: All standard solutions should be prepared fresh. For

best performance use ISA in all solutions.

Periodically check the Reference Fill Solution level in the

reference chamber of the electrode. The solution level must be

higher than the inner junction which is visible as a white

ceramic pin on the inner body.

If the electrode slope is still outside the normal range after this

procedure, you may need to clean or replace the electrode.

Reading a Sample with the Electrode

Various procedures may be used to determine the

concentration of a sample. The most common is the Direct

Calibration method, which is described below. Contact YSI’s

technical service department for details of other methods.

In Direct Calibration a series of standard solutions of differing

concentrations are used to calibrate the electrode. Then each

sample requires only a single meter reading, which is

compared with the calibration readings t o obtain the sample

concentration. ISA is added to all solutions to ensure the

samples and the standards have the same ionic strength.

Set up:

1. Prepare the electrode as described in "Electrode

Preparation" and "Checking Electrode Operati on" . Connect

the electrode to the meter.

2. Prepare two standard solut ions that differ in concentration

by a factor of ten and bracket the expected sample

concentration range. For example, if your expected sample

concentration is 5 mg/L Bromide, you should use a 1 mg/L

low Standard Solution and a 10 mg/L high Standard

Solution.

Page 2

NOTE: Temperature compensation is not typical of ISE

measurements - for best performance, try to ensure that

the standards are within 5 to 10°C of the sample.

Measurement:

If using a meter with direct concentration reading capability

(see the meter instructi on manual for s pecific i nf ormati on):

1. Place 100 mL of the low standard into a 150 mL beaker.

Add 2 mL of ISA. Stir thoroughly.

2. Rinse electrode with Dl water, blot dry and place in the

beaker. Wait for a stable reading, and then adjust the

meter to display the value of the standard. Refer to the

meter's instruction manual for the meter adjustment

procedure.

3. Measure 100 mL of the high standard into a second 150

mL beaker. Add 2 mL of ISA and stir.

4. Rinse electrode with Dl water, blot dry and place in the

second beaker. Wait for a stable readi ng, and then adjust

the meter to display the value of the second standard.

5. Pipette 100 mL of s ample into a 150 m L beak er. Add 2 mL

of ISA. Stir thoroughly.

6. Rinse electrode with Dl water, blot dry and place in the

sample beaker. Wait for a stable readi ng and the sample

concentration will be displayed on the meter.

7. Determine the sample concentration usi ng the calibration

curve prepared in Step 6 above.

Electrode Storage

Short Term (over night or the weekend):

Rinse the electrode thoroughly with Dl water and place the tip

in a diluted standard solution between measurements. Slide

the FastFil sleeve to close the fill hole.

Refill the reference before putting the electrode back into

service.

Long Term:

Refill the electrode with Reference Filling S olution and close

the fill hole. Put the soaker bottl e (storage bottle) on the end of

the electrode with a wetted sponge to keep the reference from

drying out.

Follow procedures in "Electrode Preparation" and "Checking

Electrode Operation" before using the electrode again.

Electrode Cleaning

Cleaning should only be attempted if troubleshooting methods

fail. The solid state sensor can be buffed with a light cloth or

polishing strip if it shows signs of oxidation or precipitate

formation. It can also be rinsed vigorously under warm water

to remove debris. Soaking for 10-15 minutes in DI water might

be useful in extracting other contaminants.

Recondition the electrode by soaking in a low standard

solution immediately after any cleaning method.

Warranty Statement

The YSI TruLine Bromide ISE is warranted for twelve (12)

month from date of purchase by the end user agains t defects

in materials and workmanship. Within the warranty period, YSI

will repair or replace, at it s sole discretion, free of charge, any

product that YSI determines to be covered by this warranty.

To exercise this warranty, call your local YSI representative, or

contact YSI Customer Service in Yell ow Springs, Ohio at +1

937 767-7241, 800-897-4151, info@ysi.com or visit ysi.com

(Support tab). Send the product and proof of purchase,

transportation prepaid, to the Authorized Service Center

selected by YSI. Repair or replacement will be made and the

product returned, transportation prepaid. Repaired or replaced

products are warranted for the balanc e of t he original warranty

period, or at least 90 days from date of repair or replacement.

LIMITATION OF WARRANTY

This Warranty does not apply to any YSI product damage or

failure caused by:

1) failure to install, operate or use the product in

accordance with YSI's written instructions;

2) abuse or misuse of the product;

3) failure to maintain the product in accordance with YSI's

written instructions or standard industry procedure;

4) any improper repairs to the product;

5) use by you of defective or improper components or parts

in servicing or repairing the product;

6) modification of the product in any way not expressly

authorized by YSI.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR P URPOSE. YSI's LIAB ILITY UNDER

THIS WARRANTY IS LIMITED TO REPAIR OR

REPLACEMENT OF THE PRODUCT, AND THIS SHALL BE

YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY

DEFECTIVE PRODUCT COVERED BY THIS WARRANTY.

IN NO EVENT SHALL YSI BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CO NSEQUENTIAL DAMAGES

RESULTING FROM ANY DEFECTIVE PRODUCT COVERED

BY THIS WARRANTY.

1725 Brannum Lane

Yellow Springs, OH

Tel: +1 937-767-7241

DOCUMENT ID: 400377MAN AUG2014C

YSI

800-765-4974

info@ysi.com

ysi.com

Loading...

Loading...