Page 1

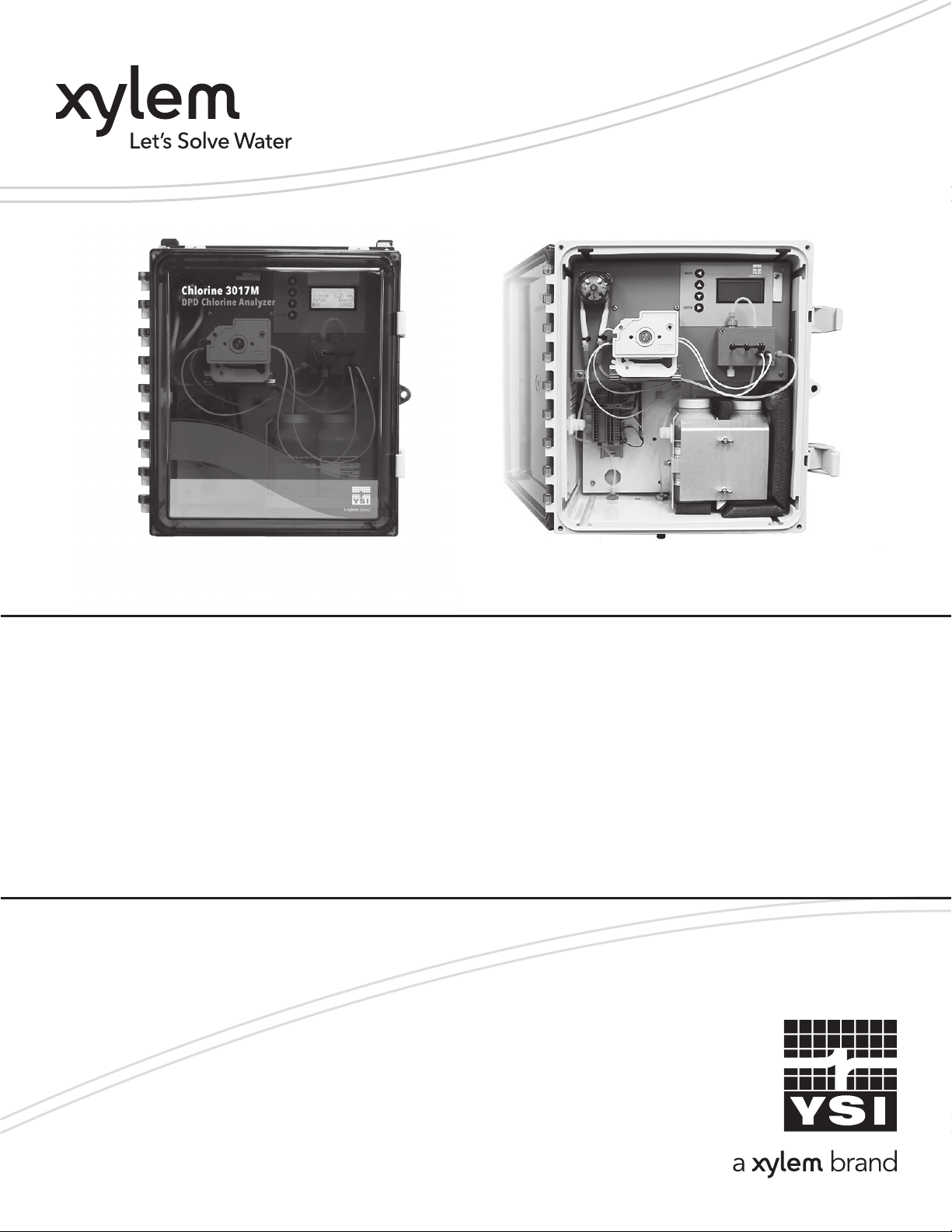

3017M Chlorine Analyzer

DPD CHLORINE ANALYZER

USER MANUAL

332100_Rev A

Page 2

General Information

The information contained in this manual is subject to change without notice.

Effort has been made to make the information in this manual complete, accurate, and current.

The manufacturer shall not be held responsible for errors or omissions in this manual, or for incidental or consequential

damages in connection with the furnishing, performance, or use of this material.

No part of this document may be reproduced, photocopied, or translated to another language without the prior written

consent of YSI.

Consult YSI.com for the most up-to-date version of this manual.

Warranty

YSI warrants each YSI manufactured product against defects in materials and workmanship under normal use

and service for a period of two years. Equipment installed by YSI is warranted from the installation date; all other

equipment is warrantied from the ship date. If purchaser schedules or delays installation more than 90 days after

delivery, then the warranty period starts on the 91st day from date of shipment. This warranty extends only to the

original purchaser. YSI will, at its option, repair or replace equipment that proves to be defective during the warranty

period, provided the equipment is returned to YSI at the expense of the purchaser.

Consumables, expendables, and parts are warranted for 30 days and are not covered under extended warranties or

service contracts.

YSI warrants for a period of one year from the date of delivery: (i) the software, when installed and used with an YSI

recommended hardware configuration, will perform in substantial conformance with the documentation supplied with

the software; and (ii) the physical media on which the software is furnished will be free from defects in materials and

workmanship under normal use.

This warranty shall not apply to defects originating from, but not limited to, the following:

• Improper maintenance or operation by the purchaser;

• Purchaser-supplied accessories or consumables;

• Modification or misuse by the purchaser;

• Operation outside the product’s environmental and electrical specifications;

• Software, interfacing, parts, or supplies not supplied by YSI;

• Improper or inadequate site preparation;

• Purchaser-induced contamination or leaks.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING

BUT NOT LIMITED TO ANY WARRANTY OF MERCHANTABILITY, FITNESS, OR ADEQUACY FOR ANY PARTICULAR

PURPOSE OR USE. YSI SHALL NOT BE LIABLE FOR ANY SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES,

WHETHER IN CONTRACT, TORT, OR OTHERWISE.

Any service requests or questions should be directed to the YSI Customer Support Center at (937) 767-7241.

1

Page 3

Safety Information

Please read this entire manual before unpacking, installing and operating this instrument. Ensure that the protection

provided by the instrument is not impaired. Do not install or use this instrument in any manner other than that specified

in this manual. For operator safety, pay attention to DANGER, WARNING and CAUTION statements throughout the

manual.

Safety Hazard Information

DANGER indicates a potentially or imminently hazardous situation which, if not

avoided, will result in serious injury or death.

WARNING indicates a condition or possible situation that could result in physical

X

injury to the operator.

CAUTION indicates a condition or possible situation that could damage or destroy

the product or the operator’s work.

NOTE: Information that is supplemental to the point in the main text.

Follow warnings and precautions in this manual or on the instrument during operation, service and repair. Failure to

follow these warnings and precautions violates the safety design standards and intended use of the instrument. YSI is

not liable for the operator’s failure to comply with these warnings and precautions.

Precautionary labels

Please read all labels and tags attached to the instrument. Personal injury or damage to the instrument could occur if

not observed.

Electrical equipment marked with this symbol may not be disposed of in the European

public disposal systems after 12 August 2005. In conformity with European local and national

regulations (EU Directive 2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge to the user.

NOTE: For return for recycling, please contact the equipment producer or supplier for

instructions on how to return end-of-life equipment, producer-supplied electrical accessories,

and all auxiliary items for proper disposal.

2

Page 4

TABLE OF CONTENTS

1. General Product Information..........................................4

1.1 Instrument Description...........................................4

1.2 Instrument Specifications.......................................5

1.3 Method of Analysis..................................................6

1.4 Theory of Operation................................................6

2. Installation...........................................................................7

2.1 Unpack the Analyzer................................................7

2.2 Environmental Considerations..............................7

2.3 Analyzer Mounting..................................................7

2.4 Plumbing Connections.........................................10

2.5 Sample Line...........................................................10

2.6 Sample Inlet Device............................................10

2.7 Optional In-Line Filter.........................................13

2.8 Sample Inlet Devices and Systems......................13

2.9 Electrical Connections........................................13

2.9.1 Power Connections.................................13

2.9.2 Wiring the Analyzer.................................14

2.9.3 RS 485.......................................................15

2.9.4 Analog Output (4-20 mA)......................15

2.9.5 Alarm (Relay) Connections.....................15

2.9.6 AC Connections.......................................16

2.9.7 Reagent Preparation................................16

2.10 Pump Tubes..........................................................17

2.10.1 Sample Pump Tube...............................18

2.10.2 Reagent Pump Tubes............................19

3. Analyzer Startup...............................................................20

3.1 Supply the Sample..............................................20

3.2 Supply Power to the Analyzer............................20

3.3 Language Selection............................................21

3.4 Powerup Mode....................................................21

4. Analyzer Operation..........................................................22

4.1 User Interface.......................................................22

4.2 Display...................................................................23

4.3 Touchpad..............................................................23

4.4 Firmware Structure & Operation.......................23

4.5 Unlocking/Locking the Analyzer.......................32

4.6 Method Settings..................................................33

4.7 Setting the 4-20mA Output...............................33

4.8 Setting the Alarm/Timed Event Relays.............33

4.8.1 Setting Alarm Relays with Keypad........33

4.8.2 Setting Alarm Relays w/ MODBUS........34

THIS IS AN INTERACTIVE

ADOBETM PDF DOCUMENT

4.9 Calibration............................................................34

4.9.1 Calibration with Known Standard.........34

4.9.2 Calibration by Comparison....................35

5. Default Configuration & Method Settings..................36

5.1 Method Settings..................................................36

5.1.1 Times.........................................................36

5.1.2 Pumps........................................................37

5.1.3 LEDs..........................................................37

5.2 Setup.....................................................................37

5.2.1 Communications......................................37

5.2.2 4-20 mA Setup.........................................38

5.3 Status......................................................................38

5.4 Linearization.........................................................38

5.5 Maintenance.........................................................38

6. Maintenance......................................................................39

6.1 Regularly Scheduled Maintenance...................39

6.1.1 Reagent Replacement.............................39

6.1.2 Pump & Reagent Tube Replacement....39

6.1.3 Flowcell Cleaning....................................41

6.2 Unscheduled Maintenance................................41

6.2.1 Fuse Replacement...................................41

6.2.2 Linearization.............................................42

6.2.3 Field Linearization Procedure................42

7. Troubleshooting...............................................................45

7.1 Troubleshooting Guide......................................45

7.2 Using Manual Controls & STATUS Screen.......46

7.3 UsingTier 3 Selections & STATUS Screen........47

7.3.1 Main STATUS Screen...............................48

7.3.2 Liquid Level Sensor & Error Levels.......49

7.3.3 Firmware & PCA Revision Levels...........51

8. Parts & Accessories...........................................................52

9. Declaration of Conformity..............................................59

10. Appendix A: MODBUS Manual...................................60

3

Page 5

1. General Product Information

1.1 Instrument Description

DANGER Chemical or biological hazards: If this instrument is used to monitor a treatment process

and/or chemical feed system for which there are regulatory limits and monitoring requirements

related to public health, public safety, food or beverage manufacture or processing, it is the

responsibility of the user of this instrument to know and abide by any applicable regulation and to

have sufficient and appropriate mechanism in place for compliance with applicable regulations in

the event of malfunction of the instrument.

The 3017M Chlorine Analyzer is a microprocessor-controlled process analyzer. It is designed to continuously monitor

an aqueous sample for chlorine content. Either free or total chlorine, in the range of 0 – 5 mg/L can be monitored.

Indicator and buffer solutions are used for the determination of chlorine content. Specific buffer solutions are used for

free or total chlorine.

WARNING Fire hazard: This analyzer is intended to be used for aqueous samples only.

The 3017M Chlorine Analyzer enclosure is rated for IP 66 per IEC 529. The enclosure is dust tight and drip

resistant and is designed for outdoor use. However, a three-sided covering that prevents direct exposure to

sunlight, dripping water, rain, sleet, or snow should be used.

The 3017M Chlorine Analyzer is an on-line photometric analyzer that uses N,N-diethyl-p-phenylene diamine (DPD)

indicator and a buffer to determine chlorine content. The system has two peristaltic pumps that deliver sample and

reagents to the flowcell. The sample pump continually delivers sample to the flowcell. The reagent pump is activated at

a predetermined time to deliver buffer and DPD reagent to the sample stream.

The flowcell consists of a sample inlet, reagent inlets, a static mixer and sample drain. Either a green, blue, or red LED

can be selected to provide the appropriate wavelength of light. Light is transmitted through fiber optic cables through

the flowcell and back to a dual-channel detector. One channel is used for the analysis of the colored complex while the

other channel is used as a reference to monitor the LED source, and thereby, maintain stability

of the system.

The reagents are dispensed from two replaceable bottles. One bottle has a buffer to control the pH; the second bottle

has the DPD reagent that produces a magenta color when chlorine is present in the sample. The degree of color

change is proportional to the amount of chlorine in the sample water. Chlorine concentration is displayed on the front

panel by three-digit LCD readout in mg/L chlorine.

The system accepts commands and sends data over RS-485 using Modbus RTU/ASCII protocols, or through the

touchpad, if the instrument is not operated under Modbus control. A 4-20 mA output is available for connection to

an external datalogger, Programmable Logic Controller (PLC) or Distributive Control System (DCS). Concentration

minimum and maximum values in mg/L chlorine are set by the operator at the analyzer touchpad.

Programmable alarm circuits provide relay closures, both normally open and normally closed, for two selectable

chlorine level set points. Set points can be programmed by the operator anywhere in the overall range. System

warning and system alarm features provide automatic, self-testing diagnostics that detect a number of possible

malfunctions, and provide alarm relay closures indicating a need for operator intervention.

Indicator and buffer reagent containers (500-mL each) are placed in the instrument enclosure. Reagents are

replenished once a month when operating in the 0 – 5 mg/L chlorine range. A clear front cover allows for viewing of

reagent bottles, and other critical components without the need for opening the analyzer enclosure.

4

General Product Information

Page 6

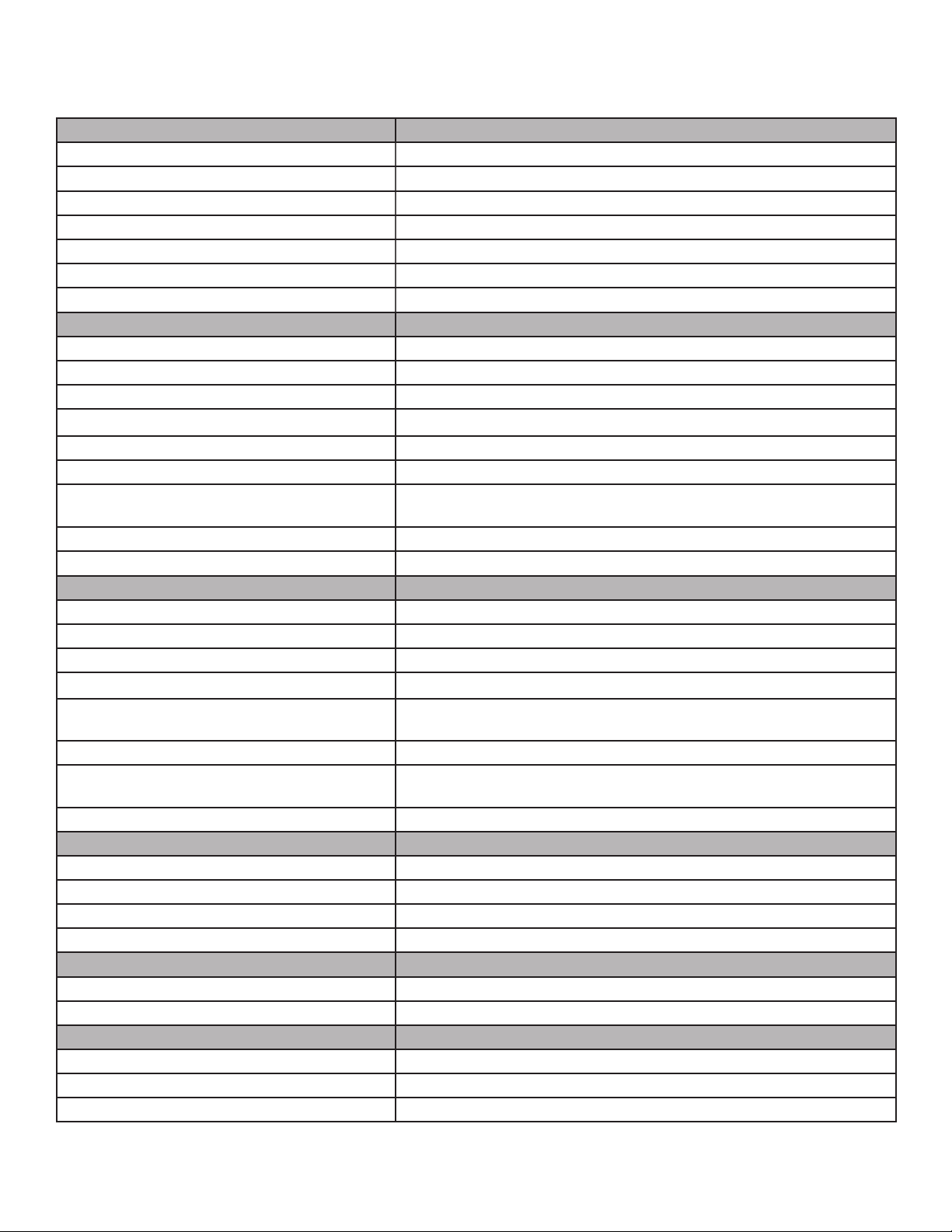

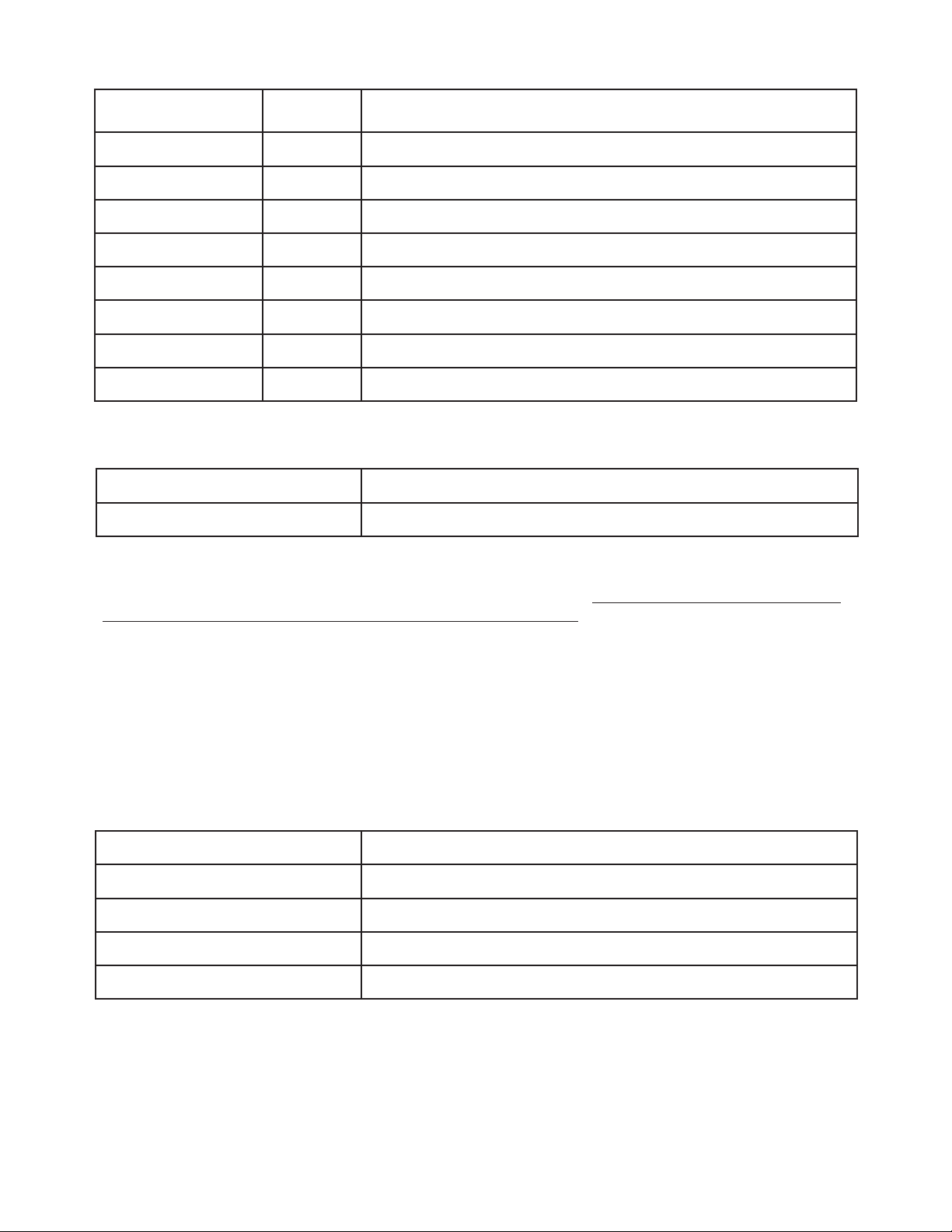

1.2 Instrument Specifications

Performance

Measurement Method N, N-Diethyl-p-phenylenediamine (DPD)

Measurement Range 0-5 mg/L free or total chlorine, reagent dependent

Measurement Interval Programmable; 2.5 to 60 minutes

Accuracy ±0.03 mg/L or ±5%, whichever is greater

Limit of Detection 0.03 mg/L

Calibration Factory calibrated, 1-point if required

Resolution 0.01 mg/L

General

Display 2.8 x 6 cm backlit LCD

Enclosure IP66 (with door latched)

Instrument Dimensions 17.6 x 14.7 x 7.9 inches (44.6 x 37.3 x 18.8 cm)

Mounting 4 mounting struts bolted to back of unit

Instrument Shipping Weight <18 lbs ; 8 kg

Warranty 2 year warranty

Regulatory Compliance US EPA regulations 40 CFR 141.74 and 40 CFR 136.3; Standard method

4500-CL-G; US EPA method 334.0; ISO method 7393-2

Certification CE, cETLus

Language English, French, German, Italian, Spanish

Sample Requirements

Sample Flow Rate to Sample Inlet Device 50 to 1,000 mL/min when using Sample Inlet Device

Inlet pressure 1 to 20 psig with Sample Inlet Device

Sample Temperature Range 41 to 113 °F (5 to 45 °C)

R R

Reagent Sets 330006 - Reagent set for measuring total chlorine

330007 - Reagent set for measuring free chlorine

Reagent Consumption ~30 days per bottle at a 2.5 minute measurement interval

Reagent Storage Life (before hydration) Buffer and indicator: 5 years

DPD powder: 1 year

Reagent Storage Life (after hydration) ~30-40 days

Power & Communication

Power 115-230 VAC , 50-60 Hz, 70VA

Relays Two relays rated at 6A, 30VDC

Analog Output One 4-20 mA configurable output

Digital Output RS-485 Modbus RTU

Optical

Light Source Class 1 LED; wavelength centered at 525 nm

Light Path Length >1 cm

Environmental

Storage Temperature Range 41 to 158 °F (5 to 70 °C)

Operating Temperature Range 41 to 131 °F (5 to 55 °C)

Relative Humidity 90% at 40°C non-condensing

General Product Information

5

Page 7

1.3 Method of Analysis

Free available chlorine (hypochlorous acid and hypochlorite ions) oxidizes the DPD indicator reagent at a pH between

6.3 and 6.6 to form a magenta-colored compound (Würster dye). The intensity of the resulting color is proportional to

the concentration of chlorine in the sample. A buffer solution specifically for free chlorine maintains the proper pH.

Total available chlorine (free chlorine and combined chloramines) is determined by adding potassium iodide to the

reaction. Chloramines in the sample oxidize iodide to iodine, which, along with any free available chlorine, oxidizes

DPD indicator to form the magenta color at a pH of 6.5 – 8.5. A different buffer solution containing potassium iodide

maintains the reaction pH. After the chemical reaction is complete, the optical absorbance at the selected wavelength

is compared to the absorbance measured through the flowcell before the reagents are added. Chlorine concentration

is calculated from the difference in absorbance.

1.4 Theory of Operation

The sample continuously flows through the flowcell. Prior to the addition of reagents, the blank absorbance is

measured. Measurement of the sample blank allows for compensation for any turbidity or natural color in the sample

and provides an automatic zero reference point. Reagents are added after the measurement of the blank sample and

develop the magenta color if chlorine is present in the sample. Absorbance is measured and compared to the blank

reference value.

Peristaltic pumps control the flow of sample and reagents. The sample flows continuously and the reagent pump

delivers a metered amount of buffer and indicator in a 2.5-minute cycle. The cycle operates as follows:

1. The sample is continuously flowing through the flowcell.

2. At a preset time, the absorbance of the blank sample is measured.

3. After the blank absorbance is measured, the indicator and buffer reagents are injected into the flowing stream

of sample.

4. The sample and reagents are allowed to thoroughly mix for the full development of the magenta color. The

measurement of the treated sample is taken to determine the chlorine content.

5. The sample pump increases the flow rate to thoroughly evacuate the flow cell in preparation for the start of the

next cycle.

6

General Product Information

Page 8

2. Installation

DANGER Electrocution and fire hazard. Only qualified personnel should conduct the tasks

described in this section of manual.

WARNING Electrocution hazard. Install a 10A circuit breaker for main power. Identify the circuit

breaker with a label, as a local disconnect for this equipment.

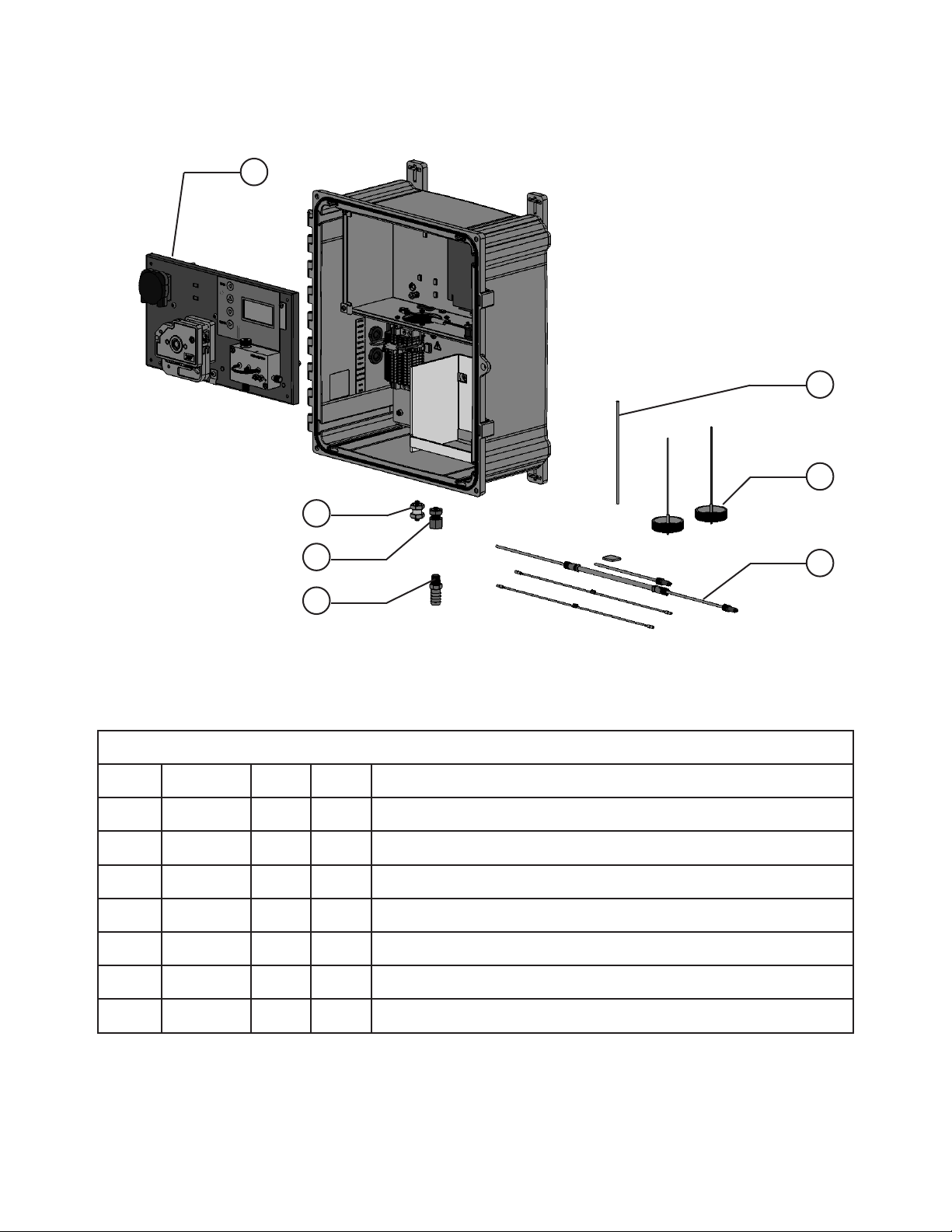

2.1 Unpack the analyzer

Remove the analyzer from the box and inspect it for damage. Verify that all of the parts are contained in the shipment.

If any items are missing or damaged, contact Technical Support, or the local representative.

2.2 Environmental Considerations

The analyzer enclosure is designed for indoor or outdoor installation with an ambient temperature range of 5 – 55 °C

(18 – 131 °F). The enclosure environmental rating is IP 66 with the door closed and latched. For outdoor installation, the

analyzer should be covered by a three-sided cover to protect it from direct sunlight, dripping water, rain, sleet or snow.

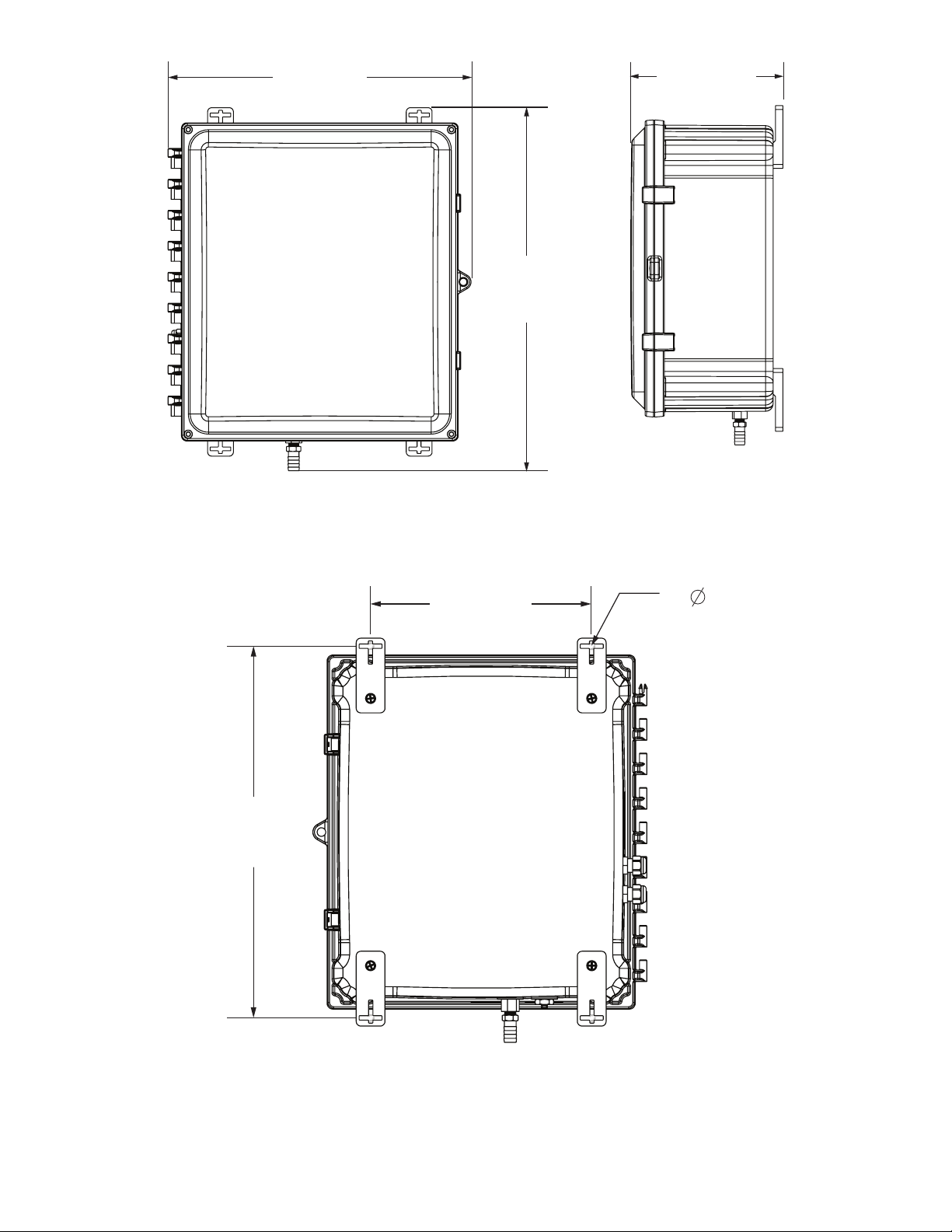

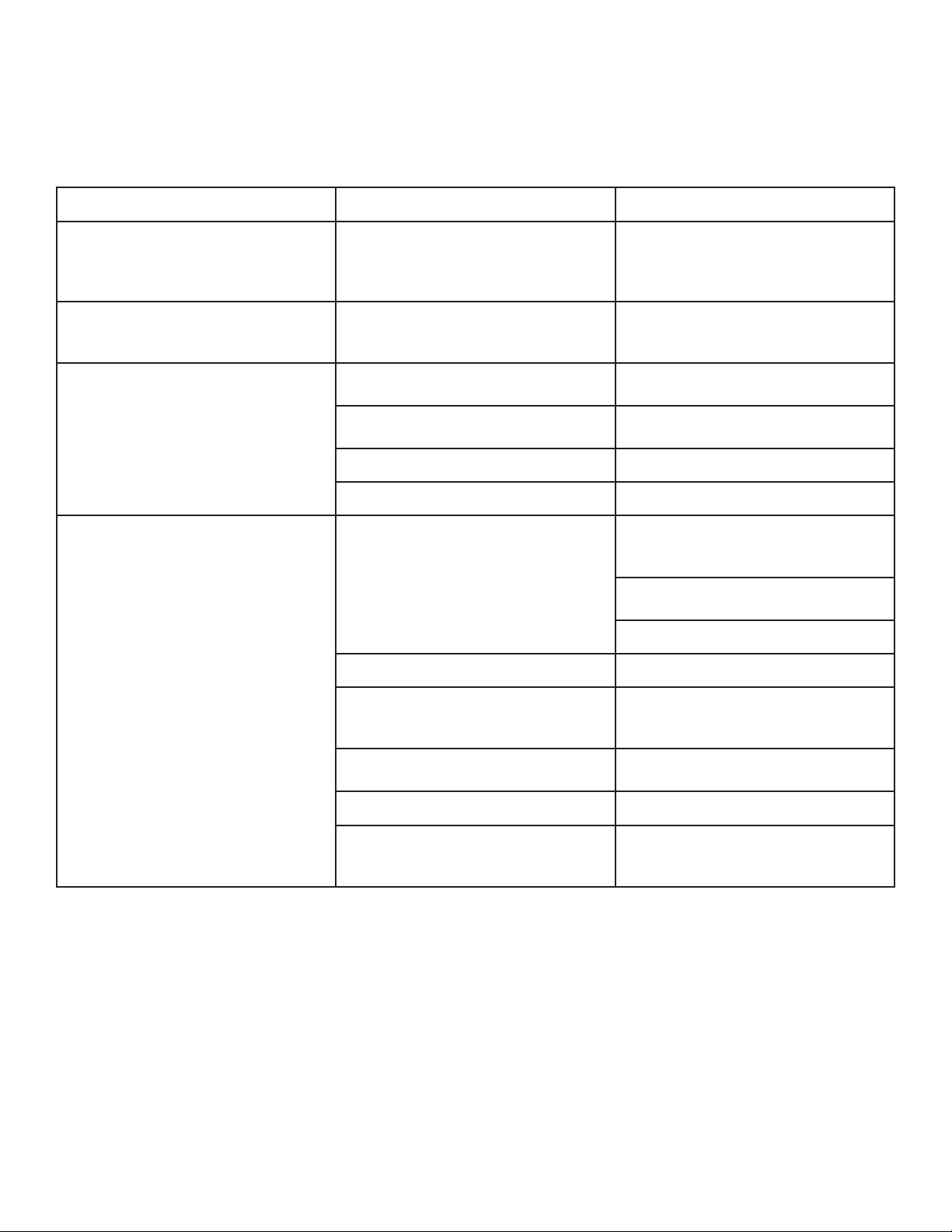

2.3 Analyzer Mounting

The enclosure is designed for wall mounting. Refer to Figures 2.1, 2.2, 2.3 and 2.4 for critical dimensions and other

installation information.

The 3017M has four mounting tabs that must be installed on the enclosure refer to Figure 2.2. These mounting tabs

can be found in a package of mounting hardware that is included with the enclosure. Connect the mounting tabs

to the enclosure using the four (4) #10-32 x 3/8-inch Phillips Drive flat head machine screws found in the mounting

hardware kit.

Use ¼-inch screws, or bolts, depending on mounting location/surface. The analyzer should be mounted at a height

at which it can be safely operated. Mount the analyzer as close as practical to the sampling point to ensure complete

purging of the sample line during each cycle. Leave adequate clearance at the sides and bottom of the analyzer

enclosure for wiring and plumbing connections.

The most common installation approach is the use of Unistrut® frame. Unistrut frame with ¼-inch spring nuts would be

used for mounting the 3017M. The mounting tabs on the 3017M are designed for ¼-inch bolts.

NOTE: The sample pump in the analyzer pulls sample into the flowcell. The maximum distance between the analyzer

and the sample point should not exceed 3.28 ft (1 m).

Installation

7

Page 9

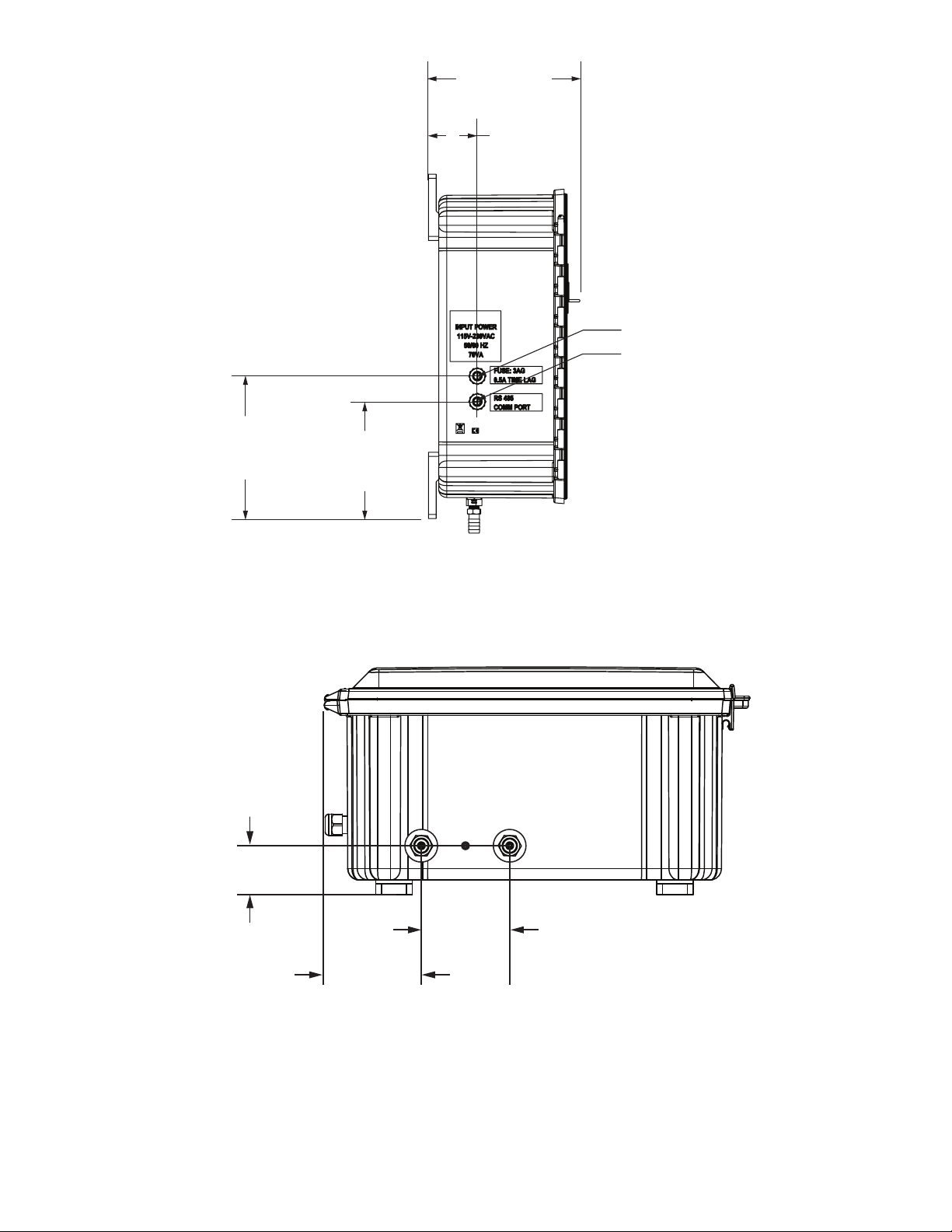

14.674”

(37.27 cm)

7.891”

(20.04 cm)

17.582”

(44.66 cm)

Figure 2.1 3017M overall dimensions

16.172”

(41.08 cm)

9.625”

(24.45 cm)

4X .250” MOUNTING HOLE

(.635 cm)

Figure 2.2 3017M mounting dimensions showing the mounting tabs connected to the enclosure

8

Installation

Page 10

7.361”

(18.70 cm)

2.393”

(6.08 cm)

POWER CONNECTIONS

RELAY/ALARM & NETWORK

CONNECTIONS

7.000”

(17.78 cm)

1.736”

(44.08 cm)

5.745”

(14.59 cm)

Figure 2.3 3017M electrical connections

Installation

2.988”

(75.88 cm)

3.475”

(88.26 cm)

Figure 2.4 3017M plumbing connections

9

Page 11

2.4 Plumbing Connections

NOTE: The waste line contains analysis waste, which include both sample and chemical reagents. The chemicals used

for the analysis are of very low concentrations. Adhere to local codes for the proper disposal of this waste.

Sample inlet and waste connections are made on the bottom of the analyzer. The sample inlet is a quick connect fitting

for a 1/8-inch (3.175-mm) OD tubing. The waste line is a barb fitting for ½-inch (12.7-mm) ID flexible tubing. See Figure

2.4. Connect the 1/8-inch (3.175 mm) OD Teflon® by pushing it into the fitting. A stop will be felt when the tubing is

properly seated in the fitting. Connect the waste line by pushing, and gently twisting, the tubing over the barb on the

fitting. Ensure that the tubing completely covers the barb.

NOTE: No pressure, positive or negative, should be applied to the waste line. Never plug the waste line.

CAUTION Fire hazard. This analyzer is intended for water samples only.

2.5 Sample Line

The selection of a representative sample is important for optimal performance of the analyzer and analytical results.

The sample must be representative of the condition of the entire process. Erratic reading will be realized if the sample

is drawn from a location that is too close to the point of chemical injection, if mixing is incomplete, or if the chemical

reaction is incomplete.

Install sample line taps into the side or center of larger process pipes to minimize the chance of ingestion of sediment

or air bubbles. A tap projecting into the center of a pipe is an ideal configuration. Opaque tubing is recommended if

the tubing is exposed to sunlight in order to prevent algae growth.

2.6 Sample Inlet Device

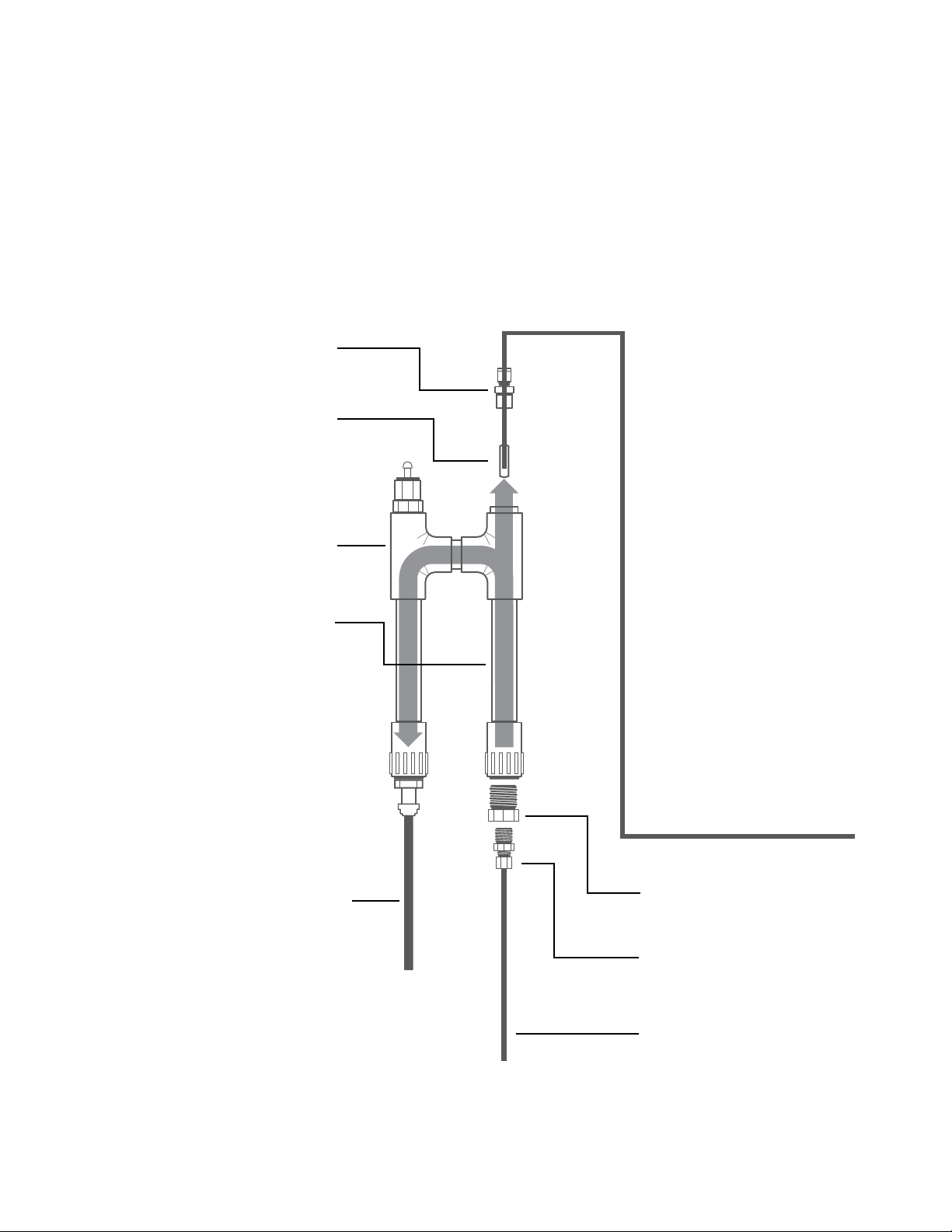

The Sample Inlet Device, part number 327114, is shown in Figure 2.5. It is a simple, easy-to-use device that serves as

the interface between the sample tap and the 3017M. It consists of inlet and outlet ports, a 60-micron filter for filtration

of fine particles, if necessary, and a 20-psig pressure relief valve. The Sample Inlet Device is rated for line pressure in

the range of 1 – 20 psig (0.069 to 1.38 bar). It may be necessary to install an in-line pressure regulator, or shut-off valve

upstream of the Sample Inlet Device.

These instructions cover the plumbing connections for the Sample Inlet Device, part number 327114. See Figure 2.5.

Other sampling schemes can be used with the 3017M. The critical point is that the sample inlet line from the 3017M is

always immersed in sample that is representative of the process that is being monitored.

The instrument is designed to require very little head pressure to operate. If the Sample Inlet Device is being used the

pressure range is 1 psi (0.069 bar) to 20 psi (1.38 bar). The maximum allowable fluid temperature is 50°C (122°F).

Opaque tubing is recommended if the tubing is exposed to sunlight in order to prevent algae growth. Note that the

sample inlet and outlet connectors are compatible with ¼-inch (6.35-mm) O.D. flexible tubing. The outlet port of the

Sample Inlet Device has a pressure relief valve that will open if the sample pressure through the device exceeds 20-psi

(1.38 bar).

The 1/8-inch (3.175-mm) sample inlet line from the analyzer to the Sample Inlet Device will be connected to sample

inlet side of the Sample Inlet Device through a bored-through, Swagelok® fitting with a Teflon® ferrule.

10

Installation

Page 12

The analyzer has a separate drain for the flow from the sample and reagent pumps onboard the analyzer. The drain

tubing is ½-inch (12.7-mm) flexible tubing.

NOTE: The analyzer drain must be open to the atmosphere. No pressure, positive or negative, must be applied to the

drain tube.

NOTE: The waste from the drain connection of the instrument contains reagents diluted with large quantities of water.

Route the drain line from the analyzer to the appropriate point in accordance with local codes or regulations.

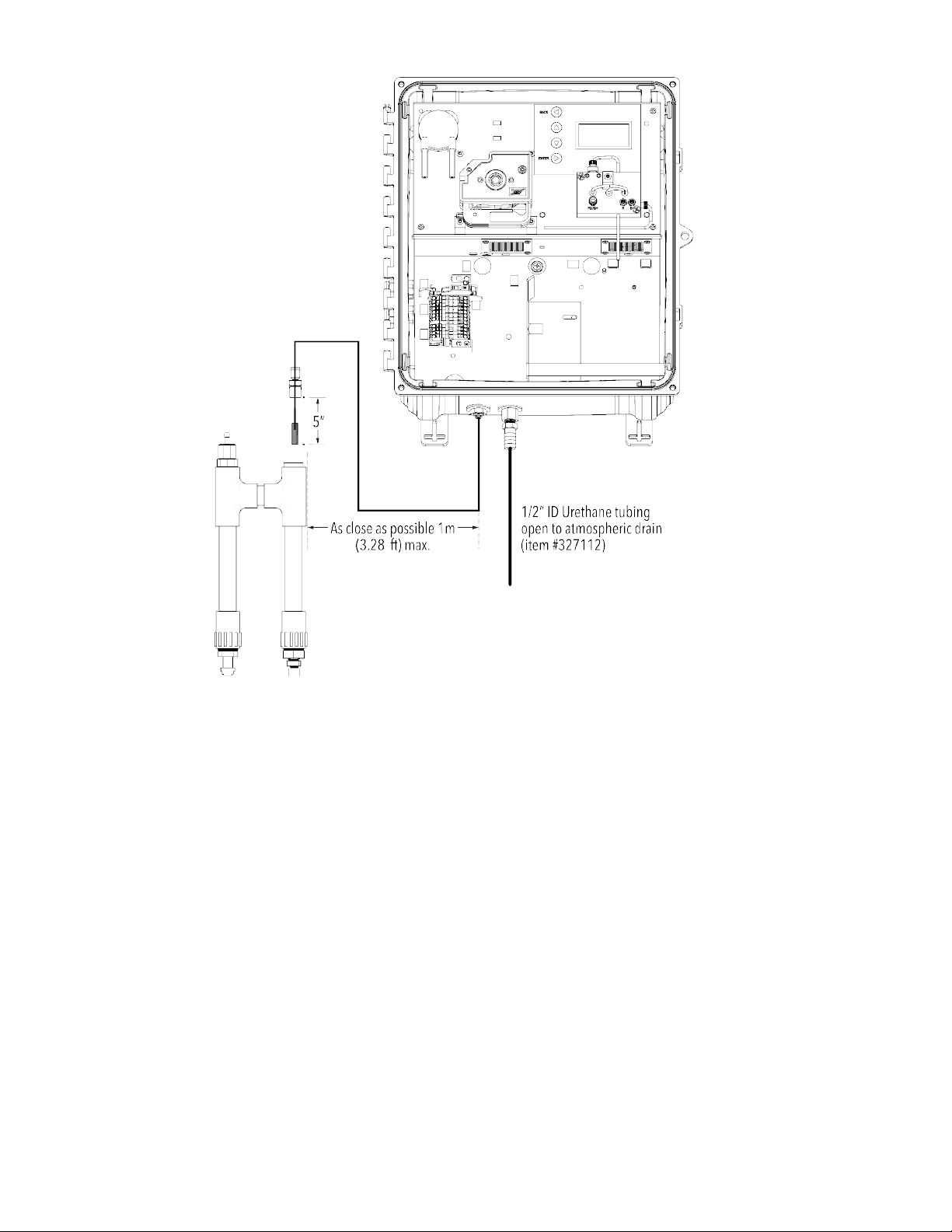

The ideal location for the Sample Inlet Device is below the 3017M and as close as practical to the 1/8-inch (3.175 mm)

quick connect fitting at the bottom of the analyzer. The installation location of the Sample Inlet Device should not

exceed 3.28 ft. (1 m) from the analyzer. See Figure 2.6.

1/4” NPT to 1/8” TUBE

BRASS FITTING

POLY FILTER 60U

SAMPLE INLET

DEVICE ASSEMBLY

INSERT POLY FILTER ON END

OF 1/8” TUBE TO MIDDLE OF

CLEAR INLET TUBE

1/2” ID URETHANE

TUBING TO DRAIN

1/8” X 1X16” ID

TEFLON TUBING

1/2” TO 1/4” PVC

REDUCING BUSHING

1/4” TO 1/4” TUBE

BRASS FITTING

Installation

1/4” POLY TUBING FROM

FLOW PRESSURE REGULATED

SAMPLE STREAM TAP

Figure 2.5 Sample Inlet Device (part #327114)

11

Page 13

Figure 2.6 Recommended position of the Sample Inlet Device with 3017M

The Sample Inlet Device is supplied with quick connect fittings for ¼-inch (6.35-mm) OD tubing. Other fittings may be

substituted depending on the application, but these are not supplied with the device.

Secure the Sample Inlet Device to the wall, panel, or other structure. Push the ¼-inch OD tubing into the inlet fitting.

A stop will be felt when the tubing is properly seated in the fitting. Repeat this process for the outlet fitting. Route the

outlet tubing to an atmospheric drain, or sump.

Remove the 1/8-inch NPT to 1/8-inch Tube fitting at the top of the Sample Inlet Device. This fitting has Teflon® twopiece ferrule. Take care not to lose it, or over-tighten. It can be reused numerous times if not over-tightened.

Insert the sample pick-up line into the fitting and attach the 60 micron filter to the end of the sample line. Secure the

fitting to the Sample Inlet Device. Position the sample pick-up line/filter at approximately mid-way in the Sample Inlet

Device. Gently tighten (do not overtighten) the 1/8-inch nut on the fitting.

Apply sample to the system and check for leaks. Ensure that the sample from the outlet of the Sample Inlet Device is

flowing freely to the drain.

12

Installation

Page 14

2.7 Optional In-Line Filter

In some applications, the addition of first-stage filtration may be necessary before the Sample Inlet Device. A 40-mesh

strainer is available, but not included with the analyzer.

The 40-mesh strainer may be installed at any point in the sample line prior to the inlet of the Sample Inlet Device.

However, a position in close proximity to the inlet of the Sample Inlet Device is recommended to prevent the build-up

of contamination in the sample line after the strainer.

2.8 Optional Sample Inlet Devices

and Systems

The 3017M Chlorine Analyzer is not absolutely dependent upon a pressurized stream of water. For instance, a sample

may be placed in a container and the sample inlet tube submerged in it. As long as the sample inlet tube shown in

Figure 2.6 is submersed in a representative sample, the Sample Pump on the instrument will draw the sample into the

instrument. Therefore, any number of different sample devices can be used on the 3017M.

The sample inlet tube may be inserted into a flowing stream of water. As long as the recommended distances from

the instrument to the sample point are followed and the sample tube is always fully submersed in water, and steps are

taken to prevent clogging, the Sample Pump should draw water into the analyzer.

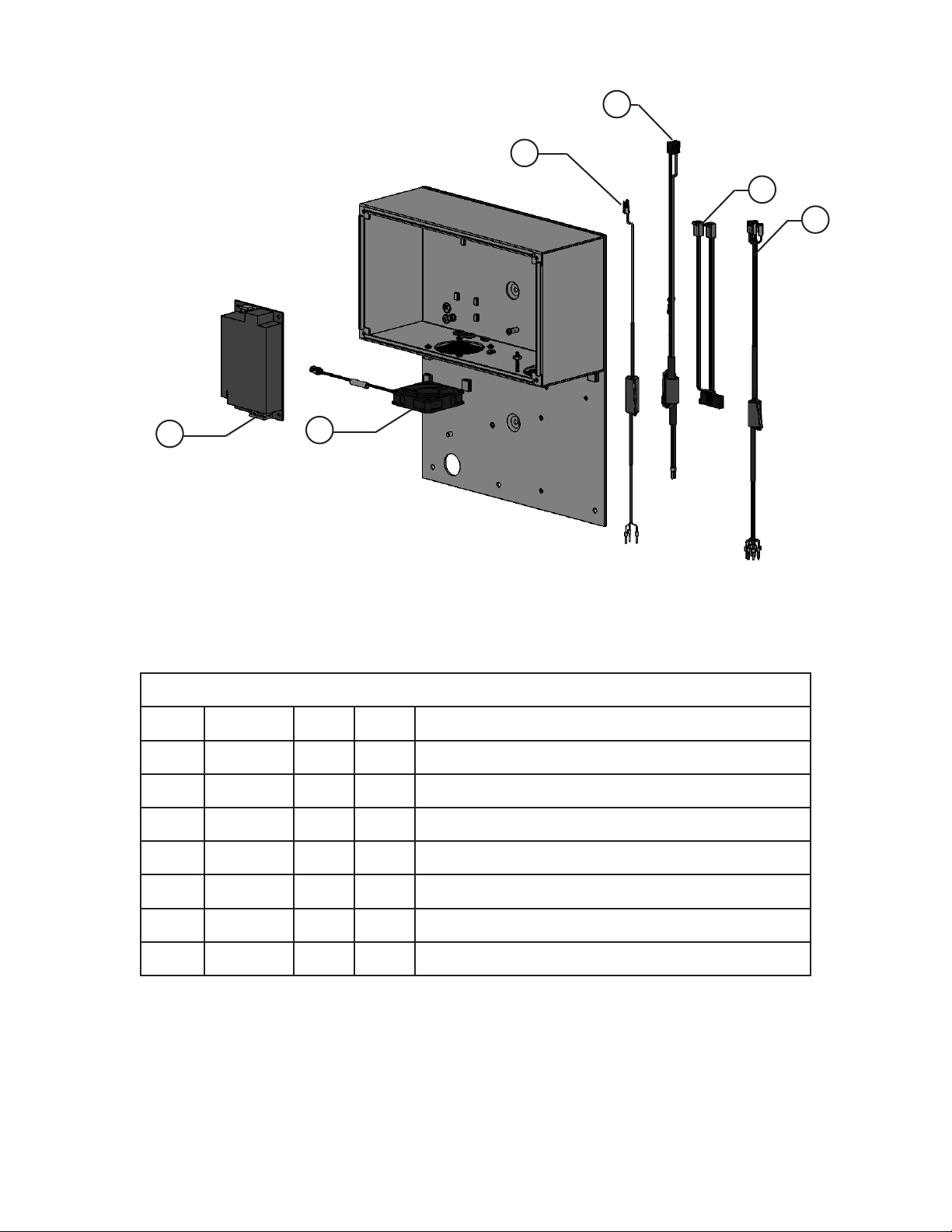

2.9 Electrical Connections

The cable glands on the left-hand-side of the analyzer will accept cable diameters from 0.23 in (5.8 mm) to 0.53 in

(13.5 mm). All terminals are designed to accept wires in the range of 14-28 AWG. All wires should be stripped to a

length of 1/4- inch (6.35 mm). Wire ferrules have been found to be particularly useful with the terminal block in the

analyzer.

The power and RS 485/4-20 mA connections are made through the cable glands that are supplied with the analyzer.

The power and RS 48/4-20 mA cable glands can be found on the left-hand-side of the analyzer. See Figure 2.3.

If alternate cable glands are desired, use sealing-type conduit fittings to maintain IEC 529 IP 66 rating. Alternatively,

hard conduit and conduit seals may be used for power and RS 485/4-20 mA connections.

2.9.1 Power Connections

DANGER Electrocution hazard. Only qualified personnel should conduct the tasks described in this

section of the manual. Connect equipment in accordance with national, state and local electrical

codes. When working inside of the enclosure power should be disconnected prior

to entry.

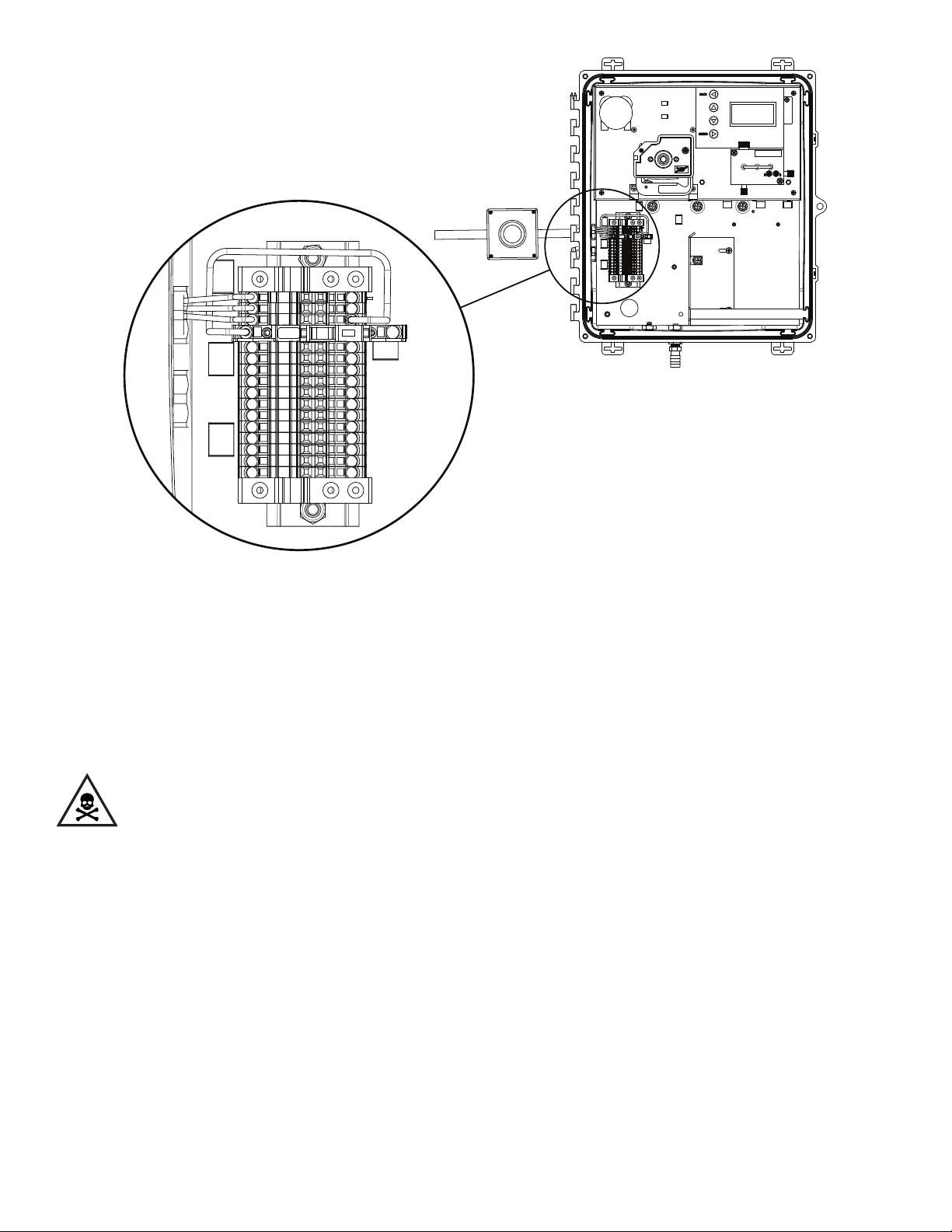

Power, signal, relay and alarm connections are made at the terminal block inside the enclosure on the left-hand-side

of the analyzer. For industrial applications, the national electrical codes of most countries may require that AC service

be hard-wired and contained in rigid conduit systems. The 3017M has been designed to conform to that requirement.

Refer to Figure 2.3.

Additionally, electrical and instrumentation standards require a local means of removing power from a device. The

3017M does not have a power on/off switch. However, a fusible link on the terminal block can be used to

remove power from the analyzer. An external means of removing power from the analyzer may be necessary.

Installation

13

Page 15

External

Power Switch

(optional)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Figure 2.7 3017M showing terminal block and external power switch

In applications where power cords are allowed by local electrical code and power surges and transients are not a

concern, a power cord with three 18 gauge wires can be used. The cable gland on the left-hand-side of the analyzer is

compatible with most, standard power AC power cords.

2.9.2 Wiring the Analyzer

DANGER Electrocution hazard. Ensure that the power cord is not connected to outlet, or other

power source.

NOTE: The 3017M can accept either 115 VAC or 230 VAC. There is no voltage selector switch.

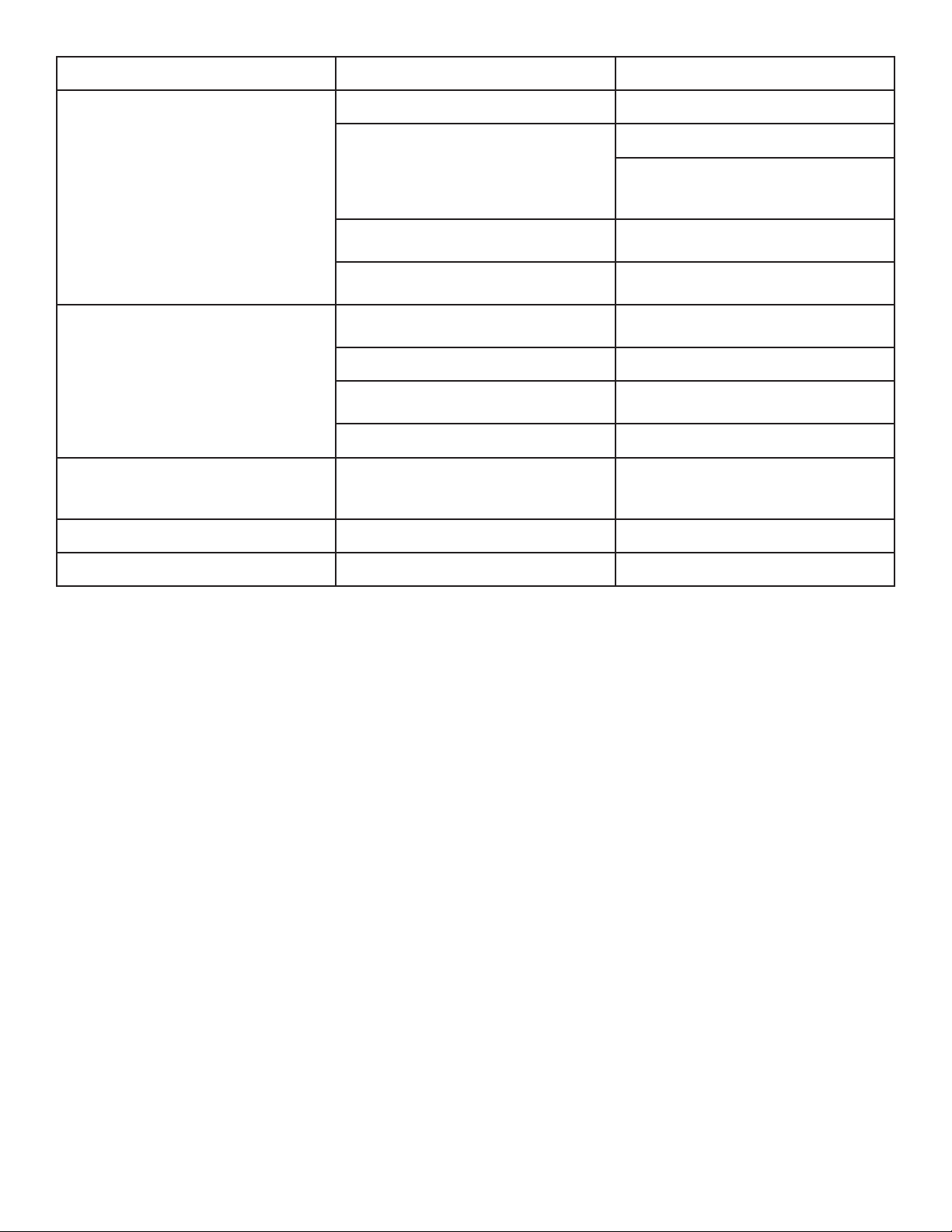

The 3017M uses WAGO® connectors for power, signal, and alarm connections. See Figure 2.8 and Tables 1 and 2. The

individual connector blades are opened by inserting the tip of a narrow, flat-blade screwdriver into the square opening

of the connector. Insert the screwdriver tip until it bottoms-out in the connector. Insert the stripped wire and remove

the screwdriver. Gently pull on the wire to ensure that the blades of the connector have secured

the wire.

14

Installation

Page 16

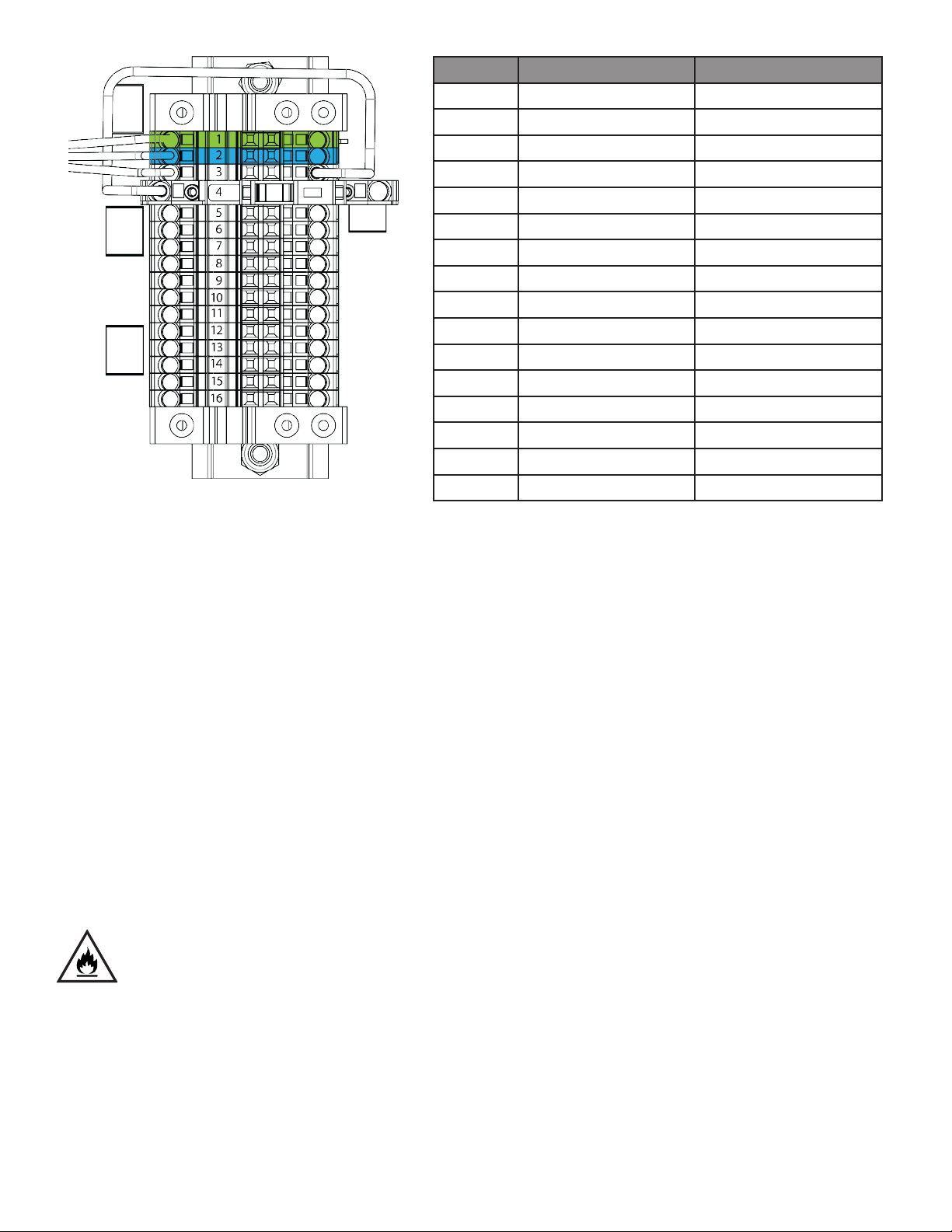

Position Connection/Purpose Wire Color

1 AC Earth Green/Green Yellow

2 AC Neutral (Line 2) White/Blue

3 AC Line (Line 1) Black/Brown

4 Fusible Link (0.5A) Brown

5 RS 485-A White

6 RS 485-B Grey

7 RS 485 RTN Purple

8 4-20 mA (+) Blue

9 4-20 mA (-) Green

10 ALARM 1 (NC) Yellow

11 ALARM 1 (COM) Orange

12 ALARM 1 (NO) Red

13 ALARM 2 (NC) Brown

14 ALARM 2 (COM) Black

15 ALARM 2 (NO) Pink

16 SPARE

Figure 2.8 3017M terminal block

Table 1 Position and purpose for each

wire on the 3017M terminal block

2.9.3 RS 485

The RS-485 full-duplex (3-wire) digital interface operates with differential levels that are not susceptible to electrical

interferences. This is why cable lengths up to 3,000 ft. can be implemented. The last device on each bus may require

terminating with a 120 ohm resistor to eliminate signal reflection on the line. Do not run RS-485 cables in the same

conduit as mains power. Reference Appendix A: MODBUS Manual.

2.9.4 Analog Output (4-20 mA)

The 4-20 mA output is driven by a 12 VDC power source or may be driven by an external power source by changing

the jumper position on the Main Control PCA. The 4-20 mA output will drive loads from 0 to 600 Ohms. Transformer

isolation is provided on the analyzer. Do not run 4-20 mA cables in the same conduit as mains power.

2.9.5 Alarm (Relay) Connections

CAUTION Fire hazard. Current to the relay contacts must be limited to 6A resistive. A method to

remove power from the relays locally must be available in case of an emergency or for servicing

the analyzer.

The analyzer has two potential-free, single pole-double throw Alarm Relays. The relays are rated at 30 V, 6A. The Alarm

connections are labeled Normally Open (NO), Normally Closed (NC) and Common (C). The alarm is configured failsafe; the normal condition is with power applied to the analyzer and in a non-alarm condition.

Installation

15

Page 17

2.9.6 AC Connections (if applicable)

Connect the unpowered, AC power wires to the terminal block as follows:

1. If using a power cord, strip the outer sheath back 4 inches. Strip each individual wire back 1/4 inch (6.35 mm).

If using individual wires, strip each wire back 1/4 inch.

2. Remove the nut from the cable gland and route the power cord through the nut and cable gland into the

enclosure.

3. Pull the power cord back so that the end of the sheath aligns with the inside edge of the cable gland in the

enclosure. This ensures that the nut will tighten on the sheath and seal the connection.

4. Connect the three wires to the proper connector using the information in Table 1, Table 2 and Figure 2.8.

Regional Wire Color Earth Ground Line 1 (Hot) Line 2 (Neutral)

North America Green Black White

IEC Green with yellow tracer Brown Blue

Table 2 Main Power Terminal Wiring

2.9.7 Reagent Preparation

The 3017M requires two reagents; a buffer solution and an indicator solution that contains the DPD powder. These

reagents must be mixed and installed in the analyzer enclosure. The buffer and indicator solutions are mixed in 500-mL

bottles that can be found in either: KIT-FREE CHLORINE, part number 330007, or KIT-TOTAL CHLORINE, part number

330006. Each kit will contain the items below. The containers in the respective kits are clearly marked. The buffer and

indicator bottles are installed on the right-hand side of the analyzer enclosure with the BUFFER in the farthest, righthand position closes to the right side of the enclosure.

1. Diphenylenediamine (DPD) reagent in a small amber glass bottle

2. The 500 mL buffer reagent pre-charged with dry powder and a fill line

3. The 500 mL indicator reagent pre-charged with dry powder and a fill line

4. Instructions for use

NOTE: 1 liter of deionized water (not included) is needed to prepare the reagents. If deionized water is not available,

then use water that is known to be chlorine free. If necessary, test this water with a handheld meter, or other laboratory

test to verify that the water is free of chlorine.

CAUTION The DPD powder must be mixed in the indicator container.

16

Installation

Page 18

Preparing the reagents

1. First prepare the buffer by adding approximately half of the required DI water to the buffer bottle, capping the

bottle, and shaking vigorously until the dry powder inside has completely dissolved.

2. Once solids are no longer visible, carefully fill the bottle to the fill line, recap it, and mix it again by shaking

vigorously for approximately 1 minute. Then let stand until the bubbles clear. The buffer is ready for use.

WARNING Indicator reagent is corrosive. handle with care.

3. Carefully add approximately 1/3 of the required water to the indicator reagent bottle, cap the bottle securely,

and mix it by shaking for approximately 1 to 2 minutes. It is likely there will still be solid material in the bottle.

Add a second one-third of the required water and mix again for 1 to 2 minutes. There should be little-to-no

solid material left in the bottle. If necessary, mix for an additional 1 to 2 minutes, or until all solid material is

in the solution.

4. Transfer the contents of the DPD (brown glass) bottle into the indicator reagent bottle, minimizing the amount

of material left in the brown bottle. Cap securely and shake the indicator bottle, at which time the color should

begin to darken slightly.

5. Carefully add the final amount of water to reach the fill line of the indicator reagent bottle, cap securely and

mix again, then let stand until bubbles clear. The indicator reagent is ready for use.

6. After mixing, the reagents have a shelf life of 30 days at room temperature and 90 days refrigerated at 77° F

(25° C).

Installing the reagents

1. Replace the plain bottle cap with the buffer reagent bottle cap (with siphon tube and barbed fitting) and

place the prepared, colorless buffer in the right bottle bay of the 3017M.

2. Replace the plain bottle cap with the indicator reagent bottle cap (with siphon tube and barbed fitting) and

place the prepared, slightly-colored indicator in the left bottle bay of the 3017M.

3. Carefully connect the pump tubing from the rear reagent pump cassette to the barb on the indicator reagent

bottle and do the same for the front cassette tube with the buffer bottle.

4. Replace the bottle retaining plate to secure the bottles.

2.10 Pump Tubes

WARNING Pinch Point Hazard – While pumps are running it may be possible to become entangled

in them while they rotate. Operators should not attempt to replace tubing while the pumps are in

operation.

WARNING Leak Hazard – A leak detector is advised to be installed into the analyzer to ensure any

leaks will be noticed before causing damage to the analyzer. All barbed connections should utilize

cable ties in order to protect from disconnection.

Installation

17

Page 19

2.10.1 Sample Pump Tube

The analyzer is shipped with the sample pump tube and the reagent pump tubes in place. However, the sample pump

tube must be installed on the sample pump rollers.

1. Refer to Figure 2.9.

2. Remove the cover from the sample pump by placing your finger under the bottom of the cover and gently

pulling outward. Take care to not allow the pump roller to fall out of the assembly.

3. A small package of silicone lubricant, part #331121, will be located on top of the rollers. This will be used to

lubricate the sample pump tube before assembly.

4. Locate the package of silicone lubricant and cut a small opening across one corner of the package.

5. Apply a thin layer of the silicone lubricant to the section of the tube that will mount on the roller in the pump.

A small bead of approximately 3-mm in diameter should be sufficient. Spread the lubricant along the section

of the tube that will contact the pump tube rollers. Do not apply the lubricant in excess. There is sufficient

lubricant in the startup kit for multiple pump tube installations. Remove any excess.

6. Hold the pump tube over the roller, and gently push the roller onto the drive shaft of the pump motor. Your

fingers should be all that is necessary to insert the sample pump tube onto the rollers of the pump. Do not use

any type of sharp tool to position the tube. Damage may result.

7. Position the tube so that it connects so that the barb fitting connections on each end are as even as possible.

Adjust the tube by gently moving back and forth on the rollers.

8. Install the cover.

18

Figure 2.9 Installation of the sample pump tube

Installation

Page 20

2.10.2 Reagent Pump Tubes

1. The reagent pump tubes are installed in the proper position in the reagent pump. They were connected to

the flowcell at the factory. During the preparation of the reagents, the other ends of the pump tubes were

connected to their respective reagents..

2. Tension the platens by pushing down on the tensioners. The tensioners will make an audible “click”. Typically,

three “clicks” is sufficient tension on the pump tube. Do not overtighten as this may result in premature failure

of the tubes.

3. See Figure 2.10.

4. Installation complete.

Installation

Figure 2.10 Complete reagent tube installation and platen tube tensioning

19

Page 21

3. Analyzer Startup

3.1 Supply the Sample

NOTE: Double-check all fittings to ensure security before applying pressure to the Sample Inlet Device (if used).

Start the sample flowing through the device to which the sample line from the analyzer is attached, or inserted. If this is

the Sample Inlet Device, part #327114, adjust the pressure/flow so that liquid is flowing through the device. Nominally,

the flow rate will be in the range of 500 – 1,000 ml/min.

It is not absolutely necessary to have process sample available to start the instrument. If process sample is not

available, the sample line from the analyzer may be inserted into a container of water. Fill a container with water that

contains some known level of chlorine. This could be checked prior to startup with a handheld meter. Position the

container in a convenient location under, or near, the analyzer and insert the sample line into the container.

3.2 Supply Power to the Analyzer

Ensure that the fusible link on the terminal block is open. If an external power switch is installed, close it at this time.

Once power is available, close the fusible link. The instrument will proceed to the analyzer self-check and come to the

STARTUP mode as shown below. See Figure 3.1.

The analyzer will be in a LOCKED state. This means that the user will only have access to the commands in Tier 1 of the

firmware. For more information on these commands, and the procedure to UNLOCK the analyzer, refer to Section 4.7.

BACK

ENTER

Chlorine 3017M

Chlorine 0.00 mg/L

STATUS: STARTUP

STATUS: STARTUP

Figure 3.1 3017M STARTUP screen

20

Analyzer Startup

Page 22

3.3 Language Selection

English is the default language. Spanish, French, German and Italian are available. If one of these languages is desired,

take the following steps.

From the touchpad, select MENU > SETUP > LANGUAGE. Use the UP/DOWN arrows to select the language of your

choice. Use the BACK arrow to exit from this menu. All of the text should now be in the language of your choice.

3.4 POWERUP Mode

The default POWERUP mode is STARTUP. The POWERUP MODE is user-selectable; refer to Section 4.5. Every time the

power is cycled on the analyzer, the STARTUP sequence will occur. There are other options for the POWERUP MODE.

These are: STANDBY and SHUTDOWN.

In STANDBY, when power is applied, the analyzer will come to the STANDBY mode. The sample and reagent pumps

will occasionally rotate to prevent the tubes from taking a set due to prolonged periods of idleness.

In SHUTDOWN, when power is applied, the analyzer will come to the SHUTDOWN mode. Power will remain ON;

however, the sample and reagent pumps will not periodically turn.

The STARTUP state consists of the following sequence of events. Each event, or state, will be displayed on the screen.

• PRIME: The sample and reagent pumps will turn at a high speed to prime the lines with liquid.

• RINSE: The reagent pump will stop, and the sample pump will continue to turn and rinse the flowcell with sample.

• RUN: The sample pump will return to the speed for normal operation.

• SET AUTOGAIN: The zero point, sample without reagent, is determined.

• INJECT REAGENT: The reagent pump will start and run for the predetermined amount of time.

• INTEGRATE: The analyzer measures the absorption of light that corresponds to the concentration of the sample

flowing through the flowcell.

• CALCULATE VALUE: The concentration of the sample is calculated against the calibration curve stored on

the analyzer.

• DISPLAY VALUE: The concentration of the sample is displayed on the screen.

Observe the outlet of the flowcell. As liquid start to fill the tubes, air will be displaced in the tubes. Since there should

be chlorine in the sample, the waste from the flowcell will turn a magenta color during the PRIME state.

Two, or three, cycles may be necessary to obtain a stable reading. If bubbles persist after several cycles, ensure all

tubes are submersed in liquid, and check all fittings for tightness. The analyzer will continue to measure the sample in

the normal operation until a new command is entered, such as, STANDBY. STANDBY state is the preferred state if the

analyzer is not actively monitoring a sample stream.

If normal operation is not desired at this point in time, select: MENU > STANDBY and place the instrument in the

STANDBY mode.

After the analyzer is set up to run, the cover should be secured using the 8-32 screws that are included with the

mounting hardware in order to prevent unauthorized access to the analyzer by untrained personnel.

Analyzer Startup

21

Page 23

4. Analyzer Operation

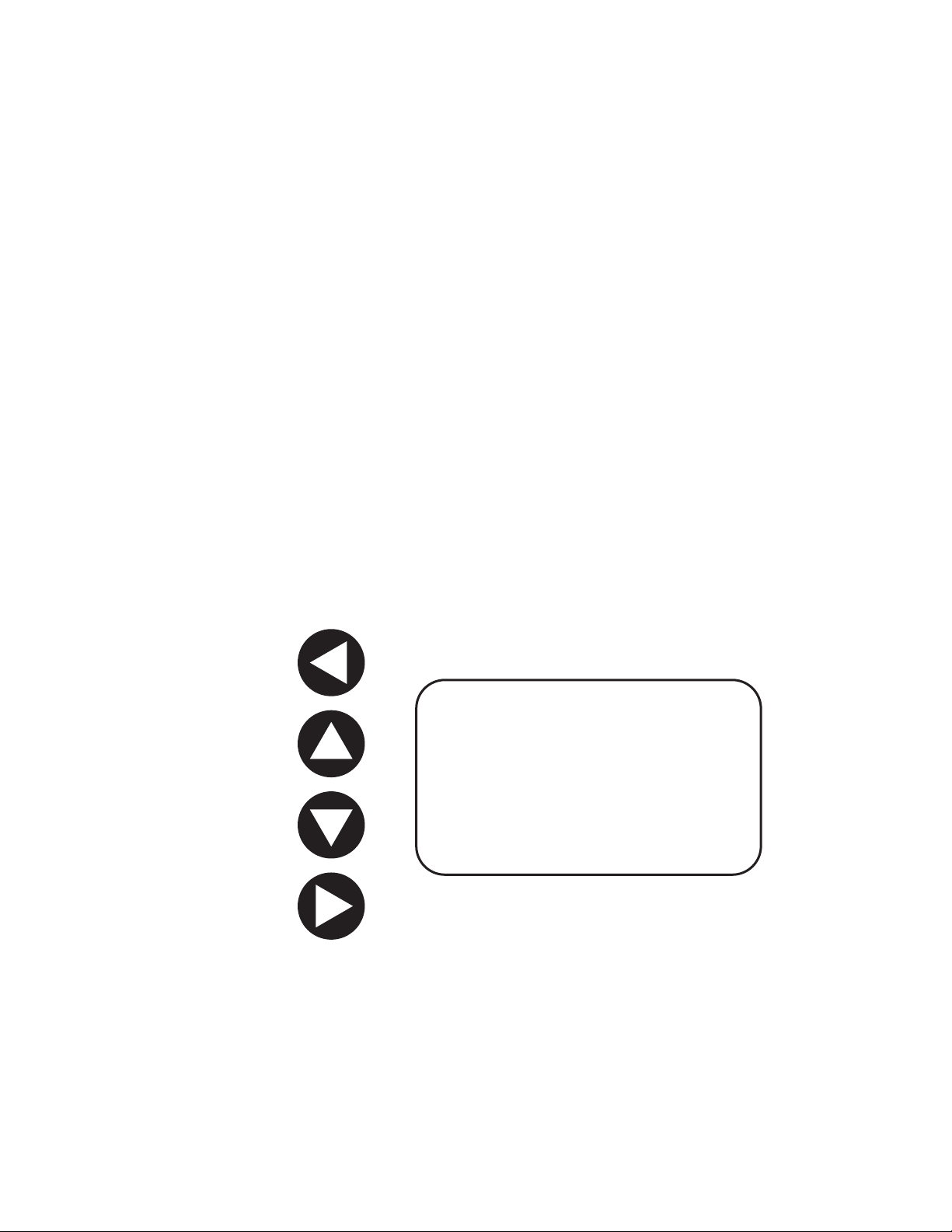

4.1 User Interface

NOTE: Double-check all fittings to ensure security before applying pressure to the Sample Inlet Device (if used).

Start the sample flowing through the device to which the sample line from the analyzer is attached, or inserted. If this

is the Sample Inlet Device, part number 327114, adjust the pressure/flow so that liquid is flowing through the device.

Nominally, the flow rate will be in the range of 500 – 1,000 ml/min.

It is not absolutely necessary to have process sample available to start the instrument. If process sample is not

available, the sample line from the analyzer may be inserted into a container of water. Fill a container with water that

contains some known level of chlorine. This could be checked prior to startup with a handheld meter. Position the

container in a convenient location under, or near, the analyzer and insert the sample line into the container.

2

1

BACK

3

4

5

ENTER

Figure 4.1 3017M HOME Screen

As noted in Section 3, the analyzer is typically left in the STANDBY mode unless (1) it is actively monitoring chlorine

level in the sample stream, or (2) some other function has been purposely chosen from the list of available functions.

See Figure 4.1.

1 Display Screen:

Display area for chlorine concentration, status, and menu information.

Chlorine 3017M

Chlorine 0.00 mg/L

STATUS: STANDBY

MENU

LOCKED

7

6

Back Arrow:

2

setting from another section of the firmware is changed, pressing the BACK button will save that setting.

3 Up Arrow:

4 Down Arrow:

Enter Arrow:

5

menu option.

Menu Line:

6

UNLOCKED status.

7 Status Line:

22

The BACK button is used to step back out of a given Tier and ultimately to the HOME screen. If a

Used to scroll through menu options or edit parameters/settings.

Used to scroll through menu options or edit parameters/settings.

Accepts an edited value but does not save it, moves deeper into the menu structure, or accepts a

Allows access to commands within each Tier of the firmware. Displays local mode and LOCKED and

Provides real-time status of the analyzer during normal and manual operation.

Table 1 Analyzer keypad and display list functions

Analyzer Operation

Page 24

4.2 Display

The unit has a four-line display and the firmware can be navigated by use of the directional keypad at the left of the

display. Figure 4.1 shows the HOME screen and Table 1 lists the function of each key and area of the display. This

is the desired screen during normal operation. The upper row is used for reporting chlorine levels. The next row

indicates the status of the analyzer and the bottom row is divided into two parts. MENU provides access to the

next Tier of commands.

4.3 Touchpad

The touchpad has four buttons that are used to navigate through the various tiers of firmware commands and other

selections. UP/DOWN buttons move through the possible selections within each tier. A blinking cursor will appear to

indicate which command, or selection, is available when the ENTER button is pushed. The BACK button is used to step

back out of a given Tier and ultimately to the HOME screen. The HOME screen is shown in Figure 4.1.

4.4 Description of Firmware Structure

and Operation

The firmware on the 3017M has a tier structure with tier 1 as the upper-most level. Commands in tier 1 are routinely

used in the operation of the analyzer. Settings in tier 2, and higher tiers, are used to configure the analyzer. Refer to the

tables below for a brief description of each command or setting. Refer to the appropriate section of this manual for

default settings, and procedures for making changes to other settings.

Navigating the firmware is done by use of the four directional arrow keys. Generally, up and down navigate the menus,

right confirms a selection, and left exits a menu.

Tier 1 Selections

MENU is the area of the firmware where method parameters and hardware settings are adjusted. Pressing MENU, when

the cursor is present on MENU, moves to the next Tier of commands.

SHUTDOWN is the command that will stop the motion of the peristaltic pumps and prepare the analyzer for storage

or shipping.

STANDBY is the command that will place the analyzer in a best-practice offline mode that maintains the peristaltic pump

tubing by infrequent rotation of the sample and reagent pump motors.

STARTUP is the command that adjusts gains and applies a fresh calibration, primes the sample and reagent lines, rinses

the system, and begins to RUN samples. It is most useful when first powering up the unit or after recalibration.

PRIME is the command that turns both the sample pump and reagent pump at a higher-than-normal rate of speed to

prime the sample pathway and clear bubbles.

RUN is the command that starts the analyzer collecting data automatically using current method parameters.

CALIBRATE is the command state that allows the analyzer to be calibrated in the field using a secondary standard.

RINSE is the command state that flushes sample from the unit in preparation for storage or shipment, or for any

purpose when it is necessary to flush the flowcell with sample.

Analyzer Operation

23

Page 25

Tier 2 Selections - MENU

METHOD is the area of the menu that allows for method parameters to be adjusted. Default method settings are ideal for

almost all applications.

SETUP is the area of the menu where communications details and other non-method parameters are set.

STATUS is the command that displays current analyzer status in several areas.

LINEARIZATION is the area of the menu where the unit calibration and linearization commands and parameters are

located.

MAINTENANCE is the area of the menu where the maintenance commands are located. This is also where you will access

ENGINEERING ACCESS to unlock the analyzer.

Tier 2 Selections - LINEARIZATION

CALIBRATION STANDARD sets the nominal concentration of the calibration standard in parts-per-million (mg/L) chlorine.

CALIBRATION GAIN is the gain used for field calibrations, if needed; editing is not recommended.

LINEARIZATION A-COEF is for informational use and troubleshooting; not altered in normal use.

LINEARIZATION B-COEF is for informational use and troubleshooting; not altered in normal use.

LINEARIZATION C-COEF is for informational use and troubleshooting; not altered in normal use.

LINEARIZATION STANDARD LO is the low calibration standard used for linearization.

LINEARIZATION STANDARD MED is the medium standard used for linearization.

LINEARIZATION STANDARD HI is the high standard used for linearization.

LINEARIZATION TASK opens a list of four tasks that allow for field linearization by capturing the absorbance of the

LO, MED, and HI standards and linearizing with those values. Not recommended for normal use.

24

Analyzer Operation

Page 26

Tier 2 Selections - MAINTENANCE

CLEAR ALARMS & TIMER clears any alarms that are present. This includes the reagent lifetime alarm.

ENGINEERING ACCESS unlocks the analyzer for modification from the keypad. The user must scroll up/down till the

passcode = 19. To lock the unit to prevent modification the passcode must be set to any number other than “19”. When

the system is locked, the only functions allowed to be modified from the keypad are RUN MODE and CLEAR ALARMS &

TIMER.

ALARMS - When the system is locked a notification on the home page indicates “LOCKED”. The system is LOCKED on

power-up.

SET REAGENT LIFETIME - Enter the time at which an alarm will be displayed that indicates the lifetime of the reagents has

expired. The minimum time is 20 days. The maximum time is 99 days.

TOGGLE SAMPLE PUMP is a command that toggles the state of the sample pump from off to on or vice versa.

TOGGLE REAGENT PUMP is a command that toggles the state of the reagent pump from off to on or vice versa.

TOGGLE ALARM1 is a command that toggles the state of relay 1 from off to on or vice versa.

TOGGLE ALARM2 is a command that toggles the state of relay 1 from off to on or vice versa.

TOGGLE THERMAL DRIVE is a command that toggles the state of the thermoelectric cooler device between ON and

OFF. The external heat sink fan is not affected.

Tier 3 Selections - STATUS: For troubleshooting (no adjustments)

Refrnc VDC - The instantaneous voltage seen at the A/D convertor from the reference channel.

Sample VDC - The instantaneous voltage seen at the A/D convertor from the sample channel.

Ref - The gain setting for the reference channel. (1) is the lowest setting and (8) is the highest setting. The number to the

right of the gain setting can be used to monitor the gain change.

Sam - The gain setting for the sample channel. (1) is the lowest setting and (8) is the highest setting. The number to the

right of the Gain Setting and can be used to monitor the gain change.

L - The low linearization sample and its absorbance.

H - The high linearization sample and its absorbance

M - The medium linearization sample and its absorbance

C - The calibration sample and its absorbance

Liquid Lvl Sensor - The liquid level sensor status: 1 is tripped, 0 is not tripped

Analyzer Operation

25

Page 27

Tier 3 Selections - STATUS: For troubleshooting (no adjustments), cont’d

Error - The error status: 1 is showing an error flag, 0 is not showing an error flag

Firmware - The two-letter code is the firmware revision, ex. DZ.

PCA - The PCA revision level.

Compiled - The compile date of the firmware.

Tier 3 Selections - METHOD

TIMES is the section of the method where the durations of the various analysis method states are set.

PUMPS is the section of the method where the pump speeds are set.

RELAYS - Configure Alarm/Relays 1 and 2.

LEDS is the section of the method where the power of the light source is set.

METHOD SAVE RESTORE is the area of the firmware where update method parameters are saved and re-loaded.

Default parameters for the 3017M mode can be selected.

Tier 3 Selections - TIMES (See graphic in Figure 4.2 for more clarity.)

RUN TIME is the total cycle time for the chlorine analysis.

INJ TIME sets the time that the reagent pumps turn to inject buffer and indicator reagent during a RUN.

INTEGRATE START sets the time when the detector response begins to be integrated for calculation of peak area.

INTEGRATE STOP sets the time when the detector response is no longer integrated for calculation of peak area.

STBY RUN TIME sets the running time for the reagent pump when the analyzer is in the STANDBY mode. The sample

pump will automatically run for (1) minute after the reagent pump stops.

STBY WAIT TIME sets the interval between pump maintenance turns while the analyzer is in STANDBY mode. See

Figure 4.3 for more clarity. The waiting time is set at a fixed 30 minutes, and the running time is typically set at 8

seconds.

RINSE TIME - This is the time that the sample pump will run during the STARTUP sequence. The RINSE occurs after

PRIME during the STARTUP sequence.

PRIME TIME - This is the length of time that the sample and reagent pumps will run during the STARTUP sequence.

26

Analyzer Operation

Page 28

Figure 4.2 A depiction of the state timing for the chlorine measurement

Tier 3 Selections - TIMES (See graphic in Figure 5.2 for more clarity.)

Figure 4.3 A depiction of the sample and reagent pump activity during the STANDBY state

Analyzer Operation

27

Page 29

Tier 3 Selections - PUMPS

SAMPLE FLO RUN sets the percentage of maximum flow that the sample pump will turn during the RUN state.

SAMPLE FLO PRI sets the percentage of maximum flow that the sample pump will turn during the PRIME state.

SAMPLE FLO STBY sets the percentage of maximum flow that the sample pump will turn during the STANDBY state.

SAMPLE FLO RINSE sets the percentage of maximum flow that the sample pump will turn during the RINSE state.

REAG FLO RUN sets the percentage of maximum flow that the reagent pump will turn during the RUN state.

REAG FLO PRI sets the percentage of maximum flow that the reagent pump will turn during the PRIME state.

REAG FLO STBY sets the percentage of maximum flow that the reagent pump will turn during the STANDBY state.

REAG FLO RINSE sets the percentage of maximum flow that the reagent pump will turn during the RINSE state.

Tier 3 Selections - RELAYS

RELAY 1 TYPE - The following entries are available: (0) operates as a timed relay with setpoints entered in RELAY 1 TIME

ON and OFF; (1) alarms when chlorine level is below setpoint that is set in RELAY 1 SETPOINT; (2) alarms when chlorine

level is above setpoint that is set in RELAY 1 SETPOINT, and (3) operates as a system alarm when an ERROR flag is set (see

MODBUS map).

RELAY 1 SETPOINT - Chlorine concentration level for either low chlorine level, RELAY 1 MODE (1), or high chlorine level

RELAY 1 MODE (2).

RELAY 1 ON TIME - The time in the analysis cycle at which RELAY 1 will close when RELAY 1 MODE (0) is set in RELAY 1

MODE.

RELAY 1 OFF TIME - The time in the analysis cycle at which the RELAY 1 will open when RELAY 1 MODE (0) is set in RELAY

1 MODE.

RELAY 2 MODE - The following entries are available: (0) operates as a timed relay with setpoints entered in RELAY 2

TIME ON and OFF; (1) alarms when chlorine level is below setpoint that is set in RELAY 2 SETPOINT; (2) alarms when

chlorine level is above setpoint that is set in RELAY 2 SETPOINT, and (3) operates when an ERROR flag is set (see

MODBUS map).

RELAY 2 SETPOINT - Chlorine concentration level for either low chlorine level, RELAY 2 MODE (1), or high chlorine

level RELAY 2 MODE (2).

RELAY 2 ON TIME - The time in the analysis cycle at which the RELAY 2 will close when RELAY MODE (0) is set in

RELAY 2 MODE.

RELAY 2 OFF TIME - The time in the analysis cycle at which the RELAY 1 will open when RELAY MODE (0) is set in

RELAY 2 MODE.

28

Analyzer Operation

Page 30

Tier 3 Selections - LEDS

GREEN LED POWER % sets the percentage of maximum power that the green LED will be driven.

BLUE LED POWER % sets the percentage of maximum power that the blue LED will be driven.

RED LED POWER % sets the percentage of maximum power that the red LED will be driven.

Tier 3 Selections - METHOD SAVE RESTORE

SAVE CURRENT METHOD saves updates to method parameters to be applied as the current method.

RESTORE SAVED METHOD restores method parameters to the existing saved method. There is only one active method

on the analyzer at a time

RESTORE DEFAULT 3017M METHOD restores the method parameters to the factory defaults for operation of the

instrument as a municipal chlorine analyzer and erases the previous method.

Tier 3 Selections - SETUP

COMMUNICATIONS is the area of setup that sets whether the analyzer is set for MODBUS or LOCAL control, sets the

Modbus address and baud rate and toggles between ASCII Modbus and Modbus RTU.

4-20 SETUP is the area of setup that sets the DAC counts for the 4 and 20 mA levels, sets the concentration limits for the

output of the 4-20 mA signal, and allows for a test of the output current.

A/D GAIN is the area of setup that allows the reference and sample gain at the analog-to-digital converter to be set, as

well as an instant autogain to be determined and applied.

LANGUAGE Choose between English, Spanish, French, Italian and German for all text.

POWERUP MODE This selection allows the choice of STARTUP, STANDBY or SHUTDOWN as the default condition upon

the application of power to the analyzer.

DISPLAY MODE Choose between the following for display of the results; PPM 2 significant figures, mg/L 2 significant

figures or PPM 3 significant figures.

LINEARIZATION MODE Choose between either a linear or 2nd order curve fitting routine for the linearization of the

instrument.

Analyzer Operation

29

Page 31

Tier 3 Selections - COMMUNICATIONS

BAUD RATE sets the baud rate that the analyzer will use for communications.

MODBUS ADDRESS sets the Modbus address of the analyzer for use in Modbus communication.

ASCII/RTU MODE toggles from ASCII communications to RTU and back. The current setting is indicated.

MODBUS LOCKOUT chooses between MODBUS IS AVAILABLE or UNDER LOCAL CONTROL. This “Modbus Lockout”

function restricts the Modbus host from modifying any registers. The host is still able to read all registers. If the host tries

to access a write function, the analyzer will issue a “BUSY” Modbus exception. The status of the lockout may be read as

ALARM4 bit 15 as well as the display of “LocalMode” on the LCD home screen.

Tier 3 Selections - 4-20 SETUP

DAC Counts for 4mA sets the DAC counts that correspond to a 4-mA signal.

DAC Counts for 20mA sets the DAC counts that correspond to a 20-mA signal.

4 MA EQUIVALENCE sets the mg/L equivalence for the 4mA signal. For example, if 4 mA= 1.00 mg/L, the sample

concentration will be 1 mg/L when the 4-20 mA system is delivering 4 mA.

20 MA EQUIVALENCE sets the mg/L equivalence for the 20 mA signal. For example, if 20 mA is set to 5 mg/L, the

sample concentration will be 5 mg/L when the 4-20 mA system is delivering 20 mA.

MID-RANGE TEST is a command that outputs a fixed current at half of full scale for troubleshooting purposes. For

example, if the 4 mA-mg/L value is set to 0 mg/L and the 20 mA value is set to 5 mg/L, pressing this control will force

the display, Modbus output and 4-20 mA signal all to 2.5 mg/L.

Tier 3 Selections - A/D GAIN

A/D GAIN CH0 The analog-to-digital (A/D) converter has a variable gain amplifier stage at the input. The gain ranges

from 1X to 128X by powers of 2. A/D GAIN CH0 is the amount of amplification applied to channel 0, the sample

photometric detector.

A/D GAIN CH1 The analog-to-digital (A/D) converter has a variable gain amplifier stage at the input. The gain ranges

from 1X to 128X by powers of 2. A/D GAIN CH1 is the amount of amplification applied to channel 1, the reference

photometric detector.

USE A/D AUTOGAIN Since the photometric detection process measures the decrease in light through the photocell

as the target analyte is being measured, it is advantageous to have the photocell at close to a full-scale reading when

no analyte is present for the greatest sensitivity. The USE A/D AUTOGAIN setting automatically sets the gain on the

photocells to ensure maximum gain within the range of the amplifiers. 1 = ON; 0 = OFF. It is recommended that this

setting always be ON.

INSTANT A/D AUTOGAIN This task runs the auto gain routine. If USE A/D AUTOGAIN is on, this routine is run at

analyzer startup.

30

Analyzer Operation

Page 32

Tier 3 Selections - LANGUAGE

ENGLISH All text in English.

SPANISH All text in Spanish.

FRENCH All text in French.

GERMAN All text in German.

ITALIAN All text in Italian.

Tier 3 Selections - POWERUP MODE

SHUTDOWN Upon application of power, the analyzer will proceed to the SHUTDOWN mode.

STANDBY Upon application of power, the analyzer will proceed to the STANDBY mode.

STARTUP Upon application of power, the analyzer will proceed to the STARTUP mode and begin to analyze the sample

stream, or sample, to which the sample line is connected.

Tier 3 Selections - SELECT DISPLAY MODE

ppm 2 Decimals Displays the result as parts-per-million (ppm) with two significant figures after the decimal point.

mg/L 2 Decimals Displays the result as milligrams per Liter (mg/L) with two significant figures after the decimal point.

ppm 3 Decimals Displays the result as parts-per-million (ppm) with three significant figures after the decimal point.

Tier 3 Selections - LINEARIZATION MODE

LINEAR Applies a linear curve fit to the calibration regardless of mode of operation. The default setting for 3017M is

2-ORDER.

POLY-2 Applies a 2nd Order curve fit to the calibration regardless of mode of operation. The default setting for 3017M is

POLY-2 (2-ORDER).

Analyzer Operation

31

Page 33

Tier 3 Selections - LINEARIZATION

LINEARIZATION TASK Locks the absorbance readings for the determination of the LOW, MED, and HI coefficients for

either a linear or 2nd order curve fit. Once the absorbance readings are determined, depressing RELINEARIZE will lock

these absorbance readings and determine coefficients.

Tier 3 Selections - LINEARIZATION TASK

LOCK LO - This task captures the absorbance for the low linearization standard for use later in linear or 2nd order

curve fitting.

LOCK MED - This task captures the absorbance for the medium linearization standard for use later in linear or 2nd order

curve fitting.

LOCK HI - This task captures the absorbance for the high linearization standard for use later in linear or 2nd order

curve fitting.

RELINEARIZE - This task determines the linearization coefficients based on data previously captured using the above

three commands for either a linear or 2nd order curve fit, and locks those coefficients.

4.5 Unlocking/Locking the Analyzer

Adjustment to the following analyzer settings in Sections 4.6, 4.7 and 4.8 requires unlocking the analyzer.

ENGINEERING ACCESS unlocks the analyzer for modification of settings from the keypad. When the system is locked,

the only functions that can be accessed from the keypad are Tier 1 options.

ENGINEERING ACCESS is a Tier 2 option. Navigate by selecting MENU > MAINTENANCE > ENGINEERING ACCESS.

Use the UP/DOWN buttons to enter the Passcode: 19. Use the BACK button to save and exit from this level. The display

should appear as shown in Figure 4.4.

After all of the settings have been modified, navigate back to ENGINEERING ACCESS. Use the UP/DOWN buttons to

enter any value for the Passcode other than 19. Use the BACK button to save and exit from this level.

2

BACK

3

Chlorine 3017M

Chlorine 0.00 mg/L

4

STATUS: SHUTDOWN

MENU

5

ENTER

32

Figure 4.4 3017M display showing analyzer in unlocked condition

Analyzer Operation

Page 34

4.6 Method Settings

Section 5 provides a detailed description of the default method settings in the 3017M firmware. The 3017M is tested

and shipped with default settings for the various states. These default settings are appropriate for most applications.

However, if a setting is changed, this changed must be saved to the new method. Select: MENU > METHOD >

METHOD SAVE RESTORE > SAVE CURRENT METHOD. If this step is not taken, the changes to the method will be lost

at the next power cycle.

NOTE: If for any reason, you are unsure as to what may have, or have not, been changed and you wish to start the

process over from the default settings, select: MENU > METHOD > METHOD SAVE RESTORE > DEFAULT

METHOD 3017.

4.7 Setting the 4-20 mA Output

Navigate as follows: MENU > SETUP > 4-20 SETUP. The analyzer has a default, full-scale output of 5.00 mg/L. If another

full-scale range is desired, set that value prior to adjusting the 4-20 mA output. Select: 20 mA Cl Equivalence and

change the full-scale output if necessary using the UP/DOWN buttons on the keypad.

Depress the BACK button and select: DAC Counts for 4 mA. The analyzer will output 4 mA. Read the output with a

properly calibrated voltmeter at the analyzer, datalogger, or other remote device or location. If the analyzer signal is

being connected to some other device that may be a considerable distance from the analyzer, then the signal output

should be measured at that location. Using the UP/DOWN buttons, adjust the 4 mA output until the reading is within

specification.

Depress the BACK button and select: DAC Counts for 20 mA. The analyzer will output 20 mA. Read the output with a

properly calibrated voltmeter at the analyzer, datalogger, or other remote device or location. If the analyzer signal is

being connected to some other device that may be a considerable distance from the analyzer, then the signal output

should be measured at that location. Using the UP/DOWN buttons, adjust the 20 mA output until the reading is within

specification.

Depress the BACK button then the DOWN button and navigate to mid-range test. The analyzer will output 12 mA. It

will be necessary to save these settings in the method. Save the method settings. Save the method settings: MENU >

METHOD > METHOD SAVE RESTORE > SAVE CURRENT METHOD.

4.8 Setting the Alarm/Timed Event Relays

4.8.1 Setting the Alarm Relays with Keypad

The analyzer has two potential-free relays (Relay 1 and Relay 2). The relay settings are accessed through MENU >

METHOD > RELAYS. The relays may be assigned to one of the functions below. Only one function can be assigned

to each relay. The relays are rated for 30 VDC, 6A. They are not designed for high voltage, or alternating current

applications.

• Low Concentration: The alarm is triggered if the chlorine concentration is less than or equal to the setpoint. The

setpoint has a range of 0.00 to 5.00 mg/L.

• High Concentration: The alarm is triggered if the chlorine concentration is greater than or equal to the setpoint.

The setpoint has a range of 0.00 to 5.00 mg/L.

• Timed Event: Operates as a timed relay. The relay can be activated during the time between RUN start and

approximately 10 seconds before reagent injection. The relay can be deactivated during the time between RUN

start and approximately 10 seconds before reagent injection.

Analyzer Operation

33

Page 35

Perform the following steps to assign a function to Relay 1 or Relay 2.

1. Select: MENU > METHOD > RELAYS

2. Select: RELAY 1 MODE

The MODE selection determines how the relay will operate. The choices are as follows:

1. (0): Operates as a timed relay with setpoints entered in RELAY 1 TIME ON and OFF.

2. (1): Alarms when the chlorine concentration is below, or equal to, the setpoint that is set in RELAY 1 SETPOINT.

3. (2): Alarms when the chlorine concentration is higher, or equal to, the setpoint that is set in RELAY 1 SETPOINT.

4. (3): Operates as a system alarm when an error flag is set.

Save the method settings: MENU > METHOD > METHOD SAVE RESTORE > SAVE CURRENT METHOD.

When the relays are configured as concentration/error alarms, the relay is activated when the condition occurs. Either

relay may be activated on high chlorine, low chlorine, or error flag. Alarm relays can be used to control chemical feeds

as ON/OFF control, by using them as a high or low alarm set point through an auxiliary device such as Programmable

Logic Controller (PLC).

4.8.2 Setting the Alarm Relays through MODBUS

The items available for viewing under status are covered in Section 5 and will not be covered in detail in this section.

However, the information provided under STATUS is very important if troubleshooting is necessary.

1. The alarm is set through Modbus. The alarm type is register 16: 0=off, 1=low alarm, 2=high alarm, & 3+ error

alarm. The alarm set point is a floating variable assigned to registers 17 & 18

2. If the alarm type is set to 1, then the alarm will go off if the Cl concentration is below the set point. If the alarm type

is set to 2, then the alarm will go off if the Cl concentration is above the set point.

3. If the alarm is set to 0, then the alarm output acts like a time relay according to TimeValve1On (Modbus 33) and

TimeValve1Off (Modbus 34).

When the relays are configured as concentration/error alarms, the relay is activated when the condition occurs. Either

relay may be activated on high chlorine, low chlorine, or error flag. Alarm relays can be used to control chemical feeds

as ON/OFF control, by using them as a high or low alarm set point through an auxiliary device such as a Programmable

Logic Controller (PLC).

4.9 Calibration

The 3017M Chlorine Analyzer is factory calibrated. The instrument does not require calibration unless it is specified by

your regulatory agency or standard operating procedure. Follow the instructions in Section 4.9 for calibration of the

analyzer.

4.9.1 Calibration with a Known Standard

CAUTION Chemical exposure hazard: Always review the Safety Data Sheets (SDS) that accompanies

any chemical to familiarize yourself with proper handling precautions, emergency procedures, and waste

disposal. Protective eye wear is recommended when handling any chemical.

1. Place the analyzer in the STANDBY mode.

2. Prepare a zero chlorine solution by placing 1 liter of normal water on a heated stirring plate and heat for 24 hours,

while stirring, at just under 100 °C. It is not necessary to boil the water. Otherwise, obtain 1 liter of chlorine-free,

demineralized water.

34

Analyzer Operation

Page 36

3. Using the water from step 1, prepare a chlorine standard solution with a value of 3 to 5 mg/L. Determine the value

of the standard to the nearest 0.01 mg/L using a EPA approved reference method.

4. Select: MENU > LINEARIZATION > CALIBRATION STANDARD. Enter the value of the calibration standard that was

determined in Step 3. Use the BACK button to exit back to the HOME screen.

5. Remove the 1/8-inch sample line from the bottom of the analyzer that is connected to the Sample Inlet Device, and

connect the piece of 1/8-inch tubing that can be found with the instrument.

6. Place the line in the standard and from the keypad select: RINSE. Rinse the sample pump tube and flowcell for 2

minutes.

7. Select: STANDBY and allow the sample pump to come to a complete stop.

8. Select: STARTUP. The analyzer will enter the normal STARTUP cycle, and proceed to normal RUN state. Allow the

analyzer to run on this standard for approximately 5 cycles, or 10 minutes.