Page 1

TECHNICAL GUIDE

GAS-FIRED RESIDENTIAL

SINGLE STAGE MULTI-POSITION

GAS FURNACES

STANDARD & Low NOx MODELS

MODELS: TG8S / TGLS

NATURAL GAS

40 - 130 MBH INPUT

EFFICIENCY

RATING

CERTIFIED

ISO 9001

Certified Quality

Management System

Due to continuous product improvement,

specifications are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional efficiency rating information can

be found at www.gamanet.or g.

363657-YTG-C-0708

DESCRIPTION

These compact units employ induced combustion, reliable

hot surface ignition and high heat transfer aluminized tubular

heat exchangers. The units are factory shipped for installation in upflow or horizontal applications and may be converted for downflow applications.

These furnaces are designed for residential installation in a

basement, closet, alcove, attic, recreation room or garage

and are also ideal for commercial applications. All u nits are

factory assembled, wired and tested to assure safe dependable and economical installation and operation.

These units are Category I listed and may be common vented

with another gas appliance as allowed by the National Fuel

Gas Code.

WARRANTY

20-year limited warranty on the heat exchanger.

10-year heat exchanger warranty on commercial applications.

5-year limited parts warranty.

FEATURES

• Easily applied in upflow, horizontal left or right, or

downflow installation with minimal conversion necessary.

• Compact, easy to install, ideal height 33" tall cabinet.

• Blower-off delay for cooling SEER improvement.

• Easy access to controls to connect power/control wiring.

• Built-in, high level self diagnostics with fault code displays

standard on integrated control module for reliable

operation.

• Low unit amp requirement for easy replacement

application.

• Single wire twinning or staging feature available.

• All models are convertable to use propane (LP) gas.

• Electronic Hot Surface Ignition saves fuel cost with

increased dependability and reliability.

• 100% shut off main gas valve for extra safety.

• 4 speed, direct drive PSC motor.

• 24V, 40 VA control transformer and blower relay supplied

for add-on cooling.

• Hi-tech tubular aluminized steel primary heat exchanger.

• Timed on, adjustable off blower capability for maximum

comfort.

• Blower door safety switch.

• Solid removable bottom panel allows easy conversion.

• Low NOx models have been designed to meet specific

code requirements.

• Airflow leakage less than 1% of total airflow at ductblaster

conditions.

• No knockouts to deal with, making installation easier.

• Movable duct connector flanges for application flexibility.

• Quiet inducer operation.

• Inducer rotates for easy conversion of venting options.

• Fully supported blower assembly for easy access and

removal of blower.

• External air filters used for maximum flexibility in meeting

customers IAQ needs.

• Venting applications - may be installed as a common vent

with other gas-fired appliances or use a masonry chimney.

• 1/4 turn knobs provided for easy door removal.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

363657-YTG-C-0708

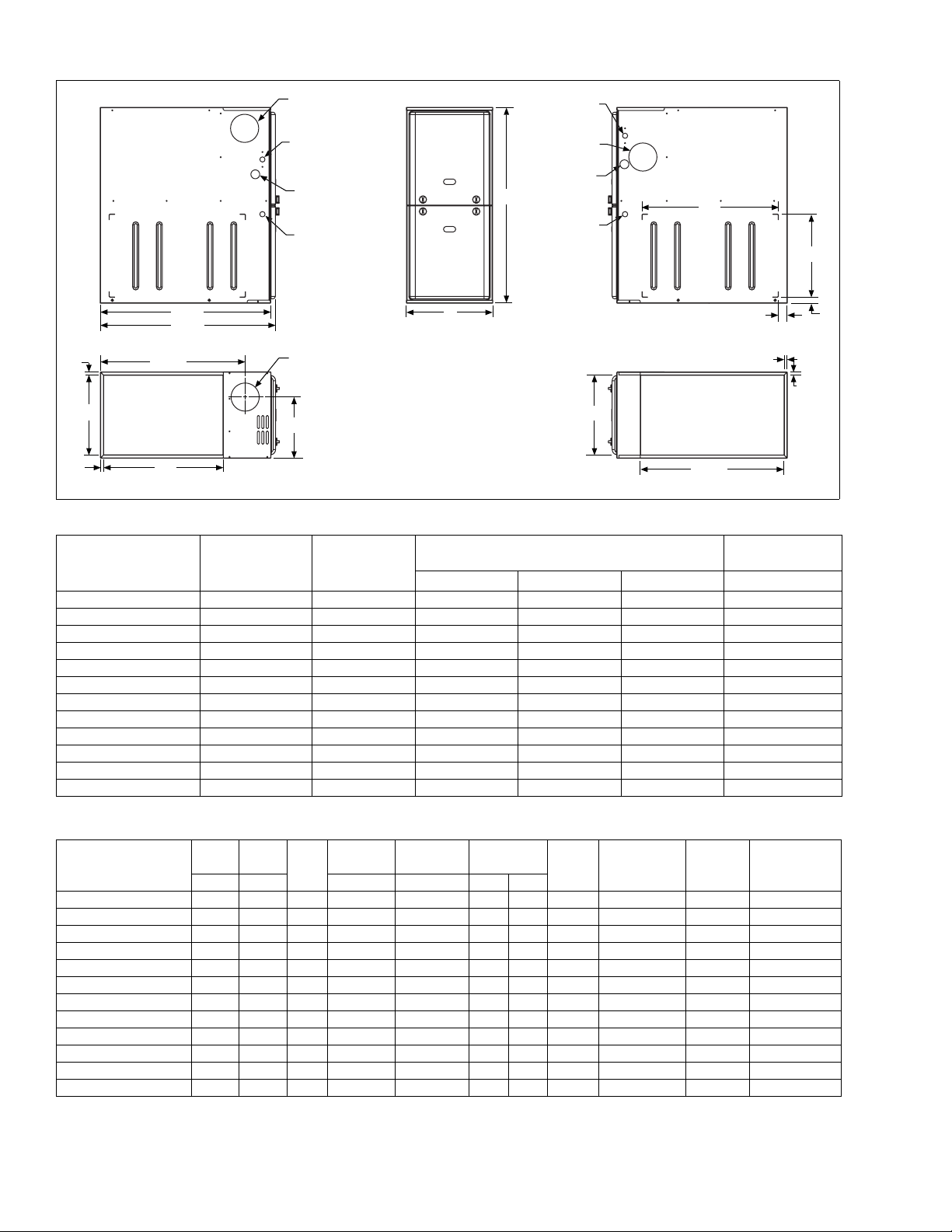

RIGHT SIDE

23”

1.5”

.5”

24.25”

RETURN END

.5”

.5”

LEFT SIDE

28.5”

29.5”

24.38”

B

20”

Vent Connection

Outlet

Electrical

Entry

Gas Pipe

Entry

Thermostat

Wiring

4” Diameter

Vent Connection

Outlet

C

FRONT

A

33”

Electrical

Entry

Vent

Connection

Outlet

Gas Pipe

Entry

Thermostat

Wiring

B

SUPPLY END

Cabinet and Duct Dimensions

Models

Nominal

CFM (m

3

/min)

Cabinet

Size

Cabinet Dimensions (Inches)

ABCLbs

TG(8,L)S040A08MP11 800 A 14 1/2 13 3/8 10.3 89

TG(8,L)S060A10MP11 1000 A 14 1/2 13 3/8 10.3 91

TG(8,L)S060A12MP11 1200 A 14 1/2 13 3/8 10.3 94

TG(8,L)S080B12MP11 1200 B 17 1/2 16 3/8 11.8 103

TG(8,L)S080C16MP11 1600 C 21 19 7/8 13.6 114

TG(8,L)S080C22MP11 2200 C 21 19 7/8 13.6 119

TG(8,L)S100B12MP11 1200 B 17 1/2 16 3/8 11.8 108

TG(8,L)S100C16MP11 1600 C 21 19 7/8 13.6 118

TG(8,L)S100C20MP11 2000 C 21 19 7/8 13.6 122

TG(8,L)S120C16MP11 1600 C 21 19 7/8 15.8 123

TG(8,L)S120C20MP11 2000 C 21 19 7/8 15.8 129

TG(8,L)S130D20MP11 2000 D 24 1/2 23 3/8 17.5 135

Approximate

Operating Weights

14”

1”

.5”

Ratings & Physical / Electrical Data

Models

Input Output

AFUE

Air Temp.

Rise

MBH MBH °F °F HP Amps

TG(8,L)S040A08MP11 40 32 80.0 25-55 155 1/5 2.1 9 x 8 10 4.5 14

TG(8,L)S060A10MP11 60 48 80.0 25-55 155 1/3 3.8 9 x 8 10 6.0 14

TG(8,L)S060A12MP11 60 48 80.0 30-60 160 1/3 4.8 11 x 8 10 7.0 14

TG(8,L)S080B12MP11 80 64 80.0 35-65 165 1/3 4.8 11 x 8 10 7.5 14

TG(8,L)S080C16MP11 80 64 80.0 25-55 155 1/2 7.5 11 x 10 15 10.0 14

TG(8,L)S080C22MP11 80 64 80.0 25-55 155 1 14.5 11 x 11 20 16.0 12

TG(8,L)S100B12MP11 100 80 80.0 40-70 170 1/3 4.8 9 x 8 10 7.5 14

TG(8,L)S100C16MP11 100 80 80.0 35-65 165 1/2 7.5 11 x 10 15 10.0 14

TG(8,L)S100C20MP11 100 80 80.0 25-55 155 1 14.5 11 x 11 20 17.0 12

TG(8,L)S120C16MP11 120 96 80.0 40-70 170 1/2 7.5 11 x 10 15 10.0 14

TG(8,L)S120C20MP11 120 96 80.0 30-60 160 1 14.5 11 x 11 20 17.0 12

TG(8,L)S130D20MP11 130 104 80.0 35-65 165 1 14.5 11 x 11 20 17.0 12

Nominal external static pressure is 0.50” w.c. at f urnace outlet ahead of cooling coils.

Annual Fuel Utilization Efficiency (AFUE) numbers are determined in accordance with DOE Test procedures.

Wire size and over current protection must comply with the National Electrical Code (NFPA-70-latest edition) and all local codes.

Max. Outlet

Air Temp

Blower

Blower

Size

Max

Over-Current

Protect

Total Unit

Amps

Min. wire Size

(awg) @ 75 ft

one way

2 Johnson Controls Unitary Products

Page 3

363657-YTG-C-0708

HORIZONTAL SIDEWALL VENTING

For applications where vertical venting is not possible, the

only approved method of horizontal venting is the use of an

auxiliary power vent. Auxilary power venters must be

approved by CSA, UL, or other recognized safety agencies.

Follow all application and installation details provided by the

manufacturer of the power vent.

FILTER PERFORMANCE

The airflow capacity data published in the “Blower Performance” table listed above represents blower performance

WITHOUT filters.

All applications of these furnaces require the use of field

installed air filters. All filter media and mounting hardware or

provisions must be field installed external to the furnace cabinet. DO NOT attempt to install any filters inside the furnace.

NOTE: Single side return above 1800 CFM is app roved as

long as the filter velocity does not exceed filter manufacturer’s recommendation and a transition is used to allow use

on a 20x25 filter.

Recommended Filter Sizes

CFM

800 A 16 x 25 14 x 25

1000 A 16 x 25 14 x 25

1200 A 16 x 25 14 x 25

1200 B 16 x 25 16 x 25

1600 B 16 x 25 16 x 25

1600 C 16 x 25 20 x 25

2000 C (2) 16 x 25 20 x 25

2200 C (2) 16 x 25 20 x 25

2000 D (2) 16 x 25 22 x 25

NOTES:

1. Air velocity through throwaway type filters may not exceed 300

feet per minute (91.4 m/min). All velocities over this require the

use of high velocity filters.

2. Do not exceed 1800 CFM using a single side return and a 16x25

filter. For CFM greater t han 1800, you may use two si de returns or

one side and the bottom or one return with a transition to allow

use of a 20x25 filter.

Cabinet

Size

Side

(in)

Bottom

(in)

Unit Clearances to Combustibles (All dimensions in inches, and all surfaces identified with the unit in an upflow

configuration)

Application Top Front Rear

Upflow 1 6 0 0 3 6 Combustible Yes Yes Yes No

Upflow B-Vent 1 3 0 0 0 1 Combustible Yes Yes Yes No

Downflow 1 6 0 0 3 6

Downflow B-Vent 1 3 0 0 0 1

Horizontal 1 6 0 0 3 6 Combustible No Yes Yes

Horizontal B-Vent 1 3 0 0 0 1 Combustible No Yes Yes

1. Special floor base or air conditioning coil required for use on combusti ble floor.

2. Line contact only permitted between lines formed by the intersecti on of the rear p anel and sid e pane l (top in horizont al po sition ) of the f urnace ja cket and bui lding joists, studs or framing.

Left

Side

Right

Side

Flue

Floor/

Bottom

1

1

1

1

Closet Alcove Attic

Yes Yes Yes No

Yes Yes Yes No

Line

Contact

Yes

Yes

2

2

Johnson Controls Unitary Products 3

Page 4

363657-YTG-C-0708

ACCESSORIES

PROPANE (LP) CONVERSION KIT -

1NP0347 - All Models except 130,000 BTU input

1NP0501 - 130,000 BTU input only

This accessory conversion kit may be used to convert natural

gas units for propane (LP) operation.

SIDE RETURN FILTER RACKS -

1SR0200 - All Models

1SR0302 - All Models

1SF0101 - All Models

BOTTOM RETURN FILTER RACKS -

1BR0514 or 1BR0614 - For 14-1/2” cabinets

1BR0517 or 1BR0617 - For 17-1/2” cabinets

1BR0521 or 1BR0621 - For 21” cabinets

1BR0524 or 1BR0624 - For 24-1/2” cabinets

1BR05xx series are galvanized steel filter racks. 1BR06xx

are pre-painted steel filter racks to match the appearance of

the furnace cabinet.

COMBUSTIBLE FLOOR BASE KIT -

For installation of these furnaces in downflow applications

directly onto combustible flooring material, These kits are

required to prevent potential overheating situations. These

kits are also required in any applications where the furnace in

installed in a downflow configuration without an evaporator

coil, where the combustible floor base kit provides access for

combustible airflow.

1CB0514 - For 14-1/2” cabinets

1CB0517 - For 17-1/2” cabinets

1CB0521 - For 21” cabinets

1CB0524 - For 24-1/2” cabinets

EAC TRANSITION KITS -

For installation of EAC accessories with these furnaces to

provide easy transition of return airflow through the EAC to

get the proper sealing and reduced airflow leakage.

1TK1001 - For all models using side return

1 TK1014 - For 14-1/2” cabinets using bottom return

1 TK1017 - For 17-1/2” cabinets using bottom return

1 TK1021 - For 21” cabinets using bottom return

1 TK1024 - For 24-1/2” cabinets using bottom return

MASONRY CHIMNEY KITS -

1CK0603

1CK0604

For installations where these furnaces are vented using

existing or new lined masonry chimneys.

HIGH ALTITUDE PRESSURE SWITCHES -

For installation where the altitude is less than 8,000 feet it is

not required that the pressure switch be changed. For altitudes above 8,000 feet, see kits below.

1PS3301

1PS3302

ROOM THERMOSTATS - A wide selection of compatible

thermosets are available to provide optimum performance

and features for any installation.

1H/1C, manual change-over electronic non-programmable

thermostat.

1H/1C, auto/manual changeover, electronic programmable,

deluxe 7-day, thermostat.

1H/1C, auto/manual changeover, electronic programmable.

* For the most current accessory information, refer to the

price book or consult factory.

4 Johnson Controls Unitary Products

Page 5

Blower Performance CFM - Any Position (without filter) - Bottom Return

Bottom Airflow Data (SCFM)

Models Speed

High 966 923 874 804 717 566 386 121 NA NA

TG(8,L)S040A08MP11

Medium High 813 782 743 687 605 464 280 118 NA NA

Medium Low 745 706 667 619 545 413 205 NA NA NA

Low 684 655 614 565 489 342 171 NA NA NA

High 1292 1230 1160 1088 1004 891 760 476 129 129

TG(8,L)S060A10MP11

Medium High 1203 1157 1105 1035 942 846 728 485 133 129

Medium Low 1043 1010 962 905 823 705 491 305 124 123

Low 869 845 811 772 708 579 438 178 145 125

High 1358 1341 1319 1303 1275 1238 1190 1130 1062 943

TG(8,L)S060A12MP11

Medium High 1097 1083 1075 1064 1042 1024 997 962 906 821

Medium Low 935 928 920 899 872 840 809 771 731 659

Low 800 779 763 736 711 687 657 622 584 529

High 1329 1307 1285 1247 1195 1143 1091 1027 927 806

TG(8,L)S080B12MP11

Medium High 994 1004 1008 984 970 941 893 839 773 669

Medium Low 786 790 782 781 761 743 726 685 630 540

Low 655 654 647 629 620 594 560 524 469 399

High 1881 1822 1783 1696 1602 1539 1465 1394 1267 1130

TG(8,L)S080C16MP11

Medium High 1553 1535 1492 1456 1408 1343 1279 1226 1113 1014

Medium Low 1312 1286 1288 1260 1205 1143 1091 1029 966 841

Low 1169 1166 1128 1098 1069 1032 987 909 835 747

High 2811 2725 2638 2540 2448 2339 2224 2111 1974 1831

TG(8,L)S080C22MP11

Medium High 2234 2233 2147 2092 2042 1974 1907 1820 1705 1575

Medium Low 1722 1716 1690 1681 1603 1553 1489 1426 1335 1241

Low 1396 1375 1348 1325 1263 1200 1150 1120 1052 965

High 1314 1318 1292 1265 1223 1177 1119 1051 971 890

TG(8,L)S100B12MP11

Medium High 1010 1004 1003 995 992 956 914 857 798 721

Medium Low 812 805 796 786 777 754 727 685 626 560

Low 661 659 644 623 614 605 568 532 482 399

High 2069 2014 1956 1885 1820 1748 1668 1577 1468 1362

TG(8,L)S100C16MP11

Medium High 1662 1656 1639 1608 1586 1544 1491 1421 1338 1204

Medium 1368 1371 1377 1376 1367 1334 1295 1250 1188 1104

Low 1016 1014 1018 1030 1012 996 975 944 898 852

High 2893 2774 2687 2589 2478 2376 2255 2120 1978 1824

TG(8,L)S100C20MP11

Medium High 2272 2243 2204 2169 2086 2018 1940 1842 1743 1602

Medium Low 1765 1752 1737 1718 1674 1619 1561 1493 1437 1312

Low 1425 1380 1409 1378 1307 1274 1226 1180 1113 1025

High 1752 1724 1702 1664 1600 1542 1454 1372 1264 1119

TG(8,L)S120C16MP11

Medium High 1469 1449 1453 1420 1382 1344 1269 1197 1118 1022

Medium Low 1248 1235 1226 1207 1179 1133 1077 992 922 841

Low 1076 1076 1046 1025 1002 968 927 869 784 707

High 2701 2620 2533 2429 2338 2227 2112 1993 1861 1706

TG(8,L)S120C20MP11

Medium High 2125 2083 2046 1994 1955 1901 1857 1737 1621 1497

Medium Low 1664 1664 1647 1619 1580 1555 1468 1392 1332 1226

Low 1358 1339 1330 1318 1286 1235 1185 1141 1060 938

High 2823 2714 2613 2507 2399 2282 2170 2042 1908 1761

TG(8,L)S130D20MP11

Medium High 2242 2188 2154 2102 2045 1970 1887 1792 1673 1537

Medium Low 1805 1791 1738 1725 1675 1623 1567 1487 1394 1256

Low 1425 1427 1403 1335 1324 1280 1236 1176 1103 996

NOTES:

1. Airflow expressed in standard cubic feet per minute (CFM).

2. Motor voltage at 115 V.

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Ext. Static Pr es su r e ( in . H2 O )

363657-YTG-C-0708

Johnson Controls Unitary Products 5

Page 6

Blower Performance CFM - Any Position (without filter) - Left Side Return

Left Side Airflow Data (SCFM)

Models Speed

0.10.20.30.40.50.60.70.80.91.0

High 994 971 942 899 829 725 419 120 NA NA

TG(8,L)S040A08MP11

Medium High 824 804 777 739 675 489 350 361 NA NA

Medium Low 757 733 694 659 575 444 399 NA NA NA

Low 707 684 641 604 495 397 282 NA NA NA

High 1371 1323 1251 1169 1086 971 843 521 NA NA

TG(8,L)S060A10MP11

Medium High 1249 1207 1158 1098 1018 921 669 503 NA NA

Medium Low 1059 1026 997 949 889 793 582 420 NA NA

Low 854 836 809 775 717 576 464 216 NA NA

High 1406 1401 1394 1379 1338 1304 1261 1202 1135 1040

TG(8,L)S060A12MP11

Medium High 1129 1126 1107 1094 1076 1047 1010 966 921 843

Medium Low 970 947 933 916 890 863 827 789 741 668

Low 834 809 797 768 740 710 677 634 586 534

High 1274 1285 1255 1239 1207 1158 1111 1049 979 830

TG(8,L)S080B12MP11

Medium High 975 974 968 960 948 923 879 823 756 672

Medium Low 777 771 772 762 752 734 695 651 604 529

Low 647 634 623 610 602 588 552 506 457 381

High 1825 1781 1746 1695 1641 1587 1521 1429 1330 1184

TG(8,L)S080C16MP11

Medium High 1516 1493 1482 1464 1442 1411 1343 1275 1192 1035

Medium 1294 1297 1271 1238 1187 1120 1083 1028 979 851

Low 1126 1115 1095 1049 1027 996 957 929 840 742

High 2972 2863 2769 2671 2571 2465 2352 2227 2095 1950

TG(8,L)S080C22MP11

Medium High 2173 2146 2103 2082 2036 1966 1904 1827 1738 1621

Medium Low 1670 1667 1647 1618 1585 1549 1492 1408 1350 1238

Low 1371 1339 1317 1284 1259 1199 1147 1085 1024 928

High 1258 1278 1283 1259 1240 1204 1149 1073 1015 897

TG(8,L)S100B12MP11

Medium High 986 995 1011 1003 962 935 913 861 808 738

Medium Low 793 786 786 783 780 750 733 702 627 567

Low 667 653 640 629 604 583 558 519 469 427

High 2009 1994 1933 1893 1836 1763 1691 1606 1508 1389

TG(8,L)S100C16MP11

Medium High 1523 1506 1521 1490 1466 1435 1393 1326 1241 1119

Medium Low 1230 1249 1245 1230 1218 1195 1161 1120 1039 949

Low 1126 1115 1095 1049 1027 996 957 929 840 742

High 2964 2886 2794 2707 2623 2522 2415 2281 2149 2012

TG(8,L)S100C20MP11

Medium High 2192 2178 2150 2109 2098 2007 1956 1888 1795 1671

Medium Low 1699 1695 1706 1632 1612 1568 1519 1460 1392 1293

Low 1361 1356 1337 1304 1267 1243 1191 1149 1077 994

High 1789 1774 1738 1702 1665 1608 1514 1431 1343 1205

TG(8,L)S120C16MP11

Medium High 1451 1445 1431 1413 1394 1362 1312 1235 1149 1037

Medium 1202 1210 1266 1252 1226 1191 1082 1028 950 852

Low 1063 1050 1033 1010 1007 982 941 889 845 778

High 2828 2768 2699 2612 2524 2423 2308 2219 2118 1982

TG(8,L)S120C20MP11

Medium High 2085 2073 2042 2029 1967 1896 1893 1816 1717 1635

Medium Low 1620 1631 1636 1593 1567 1557 1520 1476 1407 1263

Low 1322 1311 1302 1271 1241 1201 1162 1101 1042 979

High 2958 2862 2758 2662 2553 2447 2328 2203 2056 1893

TG(8,L)S130D20MP11

Medium High 2191 2182 2157 2092 2085 1997 1932 1844 1741 1608

Medium Low 1737 1738 1713 1691 1675 1590 1531 1467 1389 1276

Low 1404 1394 1380 1355 1327 1276 1220 1163 1095 1013

NOTES:

1. Airflow expressed in standard cubic feet per minute (CFM).

2. Return air is through side opposite motor (left side) .

3. Motor voltage at 115 V.

4. Airflow through across motor side (right side) may be slightly less than the data shown above.

Ext. Static Pressure (in. H2O)

Subject to change without notice. Printed in U.S.A. 363657-YTG-C-0708

Copyright © 2008 by Johnson Controls, Inc. All rights reserved. Supersedes: 363657-YTG-B-0608

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

Loading...

Loading...