036-21564-003-A-1005

TECHNICAL GUIDE

DESCRIPTION

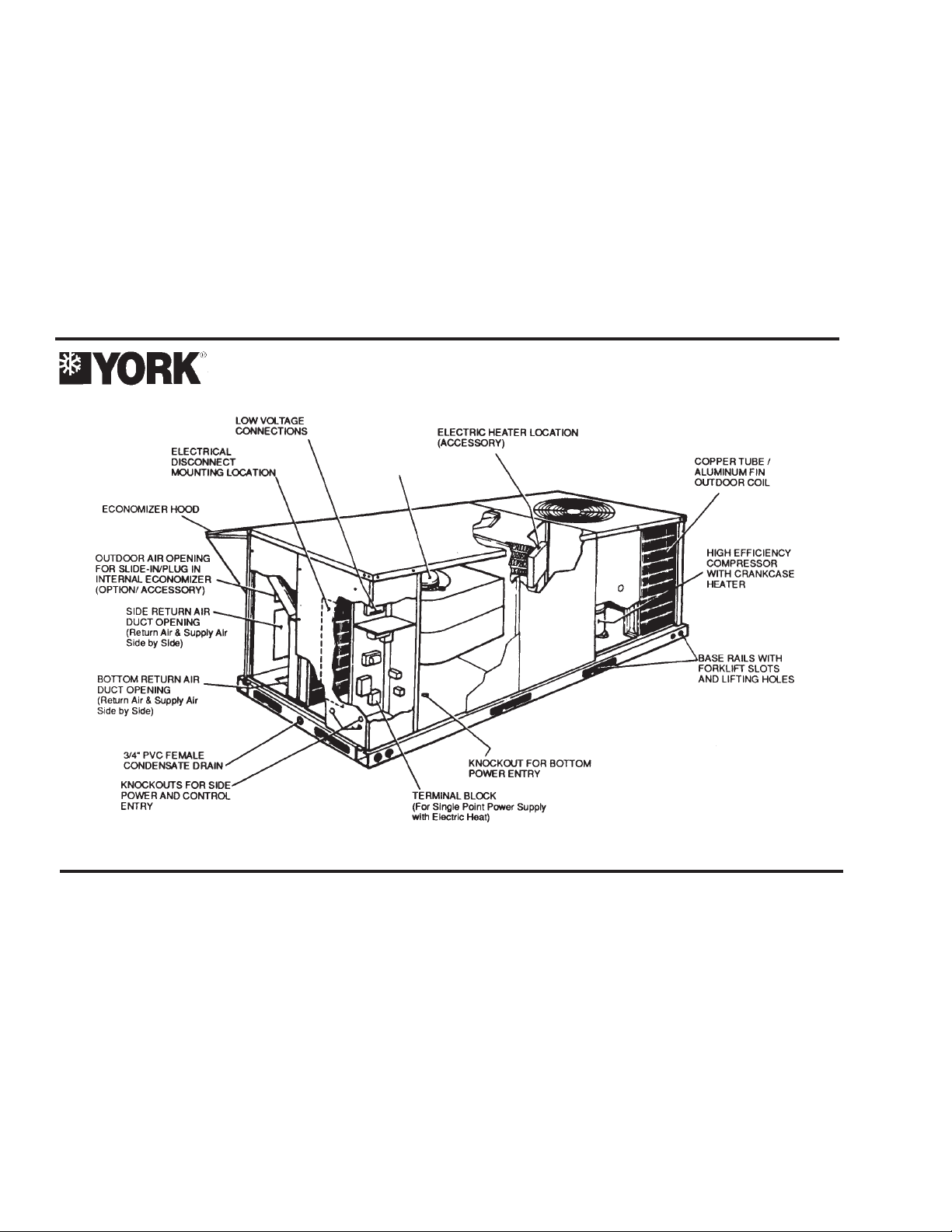

YORK Sunline 2000 Heat Pumps are convertible single

package units with a common cabinet and common roof curb

for the 3, 4 and 5 ton sizes. The units were designed for

residential and light commercial applications. They can easily

be installed on a roof curb, slab, roof jack or frame.

All units are self--contained and assembled on rigid full

perimeter base rails allowing for 3--way fork lift access and

overhead rigging. Every unit is completely charged, wired,

piped and tested at the factory to provide for a quick and easy

field installation.

The units are available with supplemental electric heaters as

field--installed accessories.

Both down and side discharge airflows are available without

having to swap panels. The installer simply removes the duct

covers for the desired configuration. Economizers may be

used on either side or down discharge applications with no

modifications required.

All models include a 1--year limited warranty on the complete

unit. Compressors and electric heater elements each carry an

additional 4--year warranty.

FEATURES

CONTROLS -- These heat pumps utilize a unique time--

temperature defrost circuit which adjusts the time between

defrost cycles based on the outdoor temperature to provide

optimal comfort control and ensure reliable operation. The

ambient--modified, time--temperature defrost control extends the

time below 35°F and shortens the time above 35°F. The nominal

defrost times are field adjustable to 50, 80 and 110 minutes. The

defrost time is initiated and terminated by a liquid line control with

a 10 minute override limit built into the defrost control.

®

SINGLE PACKAGE

AIR-TO-AIR

HEAT PUMPS

B3CH 036, 048 & 060 (208/230, 460V)

B5CH 036 & 060 (575V), B6CH 048

3, 4 AND 5 NOMINAL TONS

(10 SEER)

SUNLINE 2000™

CONVERTIBLE AIRFLOW DESIGN -- Both the side and

bottom duct openings are covered when they leave the factory.

If a side supply/side return is desired, you simply remove the

two side duct covers from the outside of the unit and discard

them. If a bottom supply/return is desired, you simply remove

the two bottom duct covers and discard them. No panel cutting

or swapping is required! Convertible airflow design allows

maximum field flexibility and minimum inventory.

FACTORY--INSTALLED OPTIONS -- Economizers can be

installed at the factory. They are shipped installed and wired. The

outdoor air hood needs only to be field assembled and installed.

Adjustable belt--drive blowers are available on most models

from the factory for complete air flow flexibility.

FIELD--INSTALLED ACCESSORIES -- Accessories were

designed for quick and easy installation. The motorized

damper and economizers simply slide in and electrical

connections are made by modular plugs. Electric heaters

mount easily and knockouts are provided in the internal

partitions to connect the elements to the control box single

point kit.

The motorized air damper includes a slid--in/plug--in damper

assembly with a rainhood and filters. The outdoor air dampers

open when the indoor fan motor is energized. The damper is

capable of providing 0% through 100% of outdoor return air

opening.

The manual outdoor damper provides 0% through 35% or 0%

through 100% of return air opening (field adjustable). Designed

for duct mounted side or bottom supply/return applications.

Includes rain hood assembly and filter.

The 14" high roof curb is shipped knocked down. A roof curb

deck is not required because the bottom of the unit is insulated.

COMMON FOOTPRINT/COMMON CABINET -- The 3, 4 and

5 ton units all share the exact same cabinet -- and therefore the

same roof curb. You now have the flexibility of setting one curb

and, after the internal load has been determined, placing the

proper tonnage unit on that curb.

HIGH EFFICIENCY -- All units have a minimum SEER of 10, a

COP of 3.0 (high) and 2.0 (low) and an HSPF as high as 7.3.

These efficiencies exceed all legislated minimum levels and

provide low operating costs.

WIDE RANGE OF INDOOR AIRFLOWS -- All models operate

over a wide range of design conditions with a 3--speed direct-drive fan motor. Belt--drive blowers are also available on all

models.

FULL PERIMETER BASE RAILS -- The permanently

attached base rails provide a solid foundation for the entire unit

and protect the unit during shipment. The rails provide fork lift

access from 3 sides and rigging holes are also provided so that

an overhead crane can be used to place the units on a roof.

FEATURES - CONT'D.

SYSTEM PROTECTION -- Crankcase heaters and internal

compressor protection are standard on all compressors. Every

unit has a liquid line filter--drier, low pressure switch, high

pressure switch and high temperature switch to protect all

system components. A suction line freezestat is supplied on all

three--phase units to protect against loss of charge and coil

frosting due to low economizer outdoor air temperature while

the compressor is running. All units will provide cooling at

ambient temperatures down to 45°F.

UTILITY CONNECTIONS MADE EASY -- Electric utility

knockouts are provided in the unit underside as well as the side

of the unit. A clearly identified location is provided to mount a

SUNLINE 2000™ Heat Pump

DIRECT DRIVE

BLOWER MOTOR

(Belt-Drive Option

also available on some

models)

(Direct Drive Models)

036-21564-003-A-1005

field supplied electrical disconnect switch. Utility connections

can be made quickly and with a minimum amount of field labor.

SIMPLE CONTROL CIRCUIT -- Mate--n--lock plug connectors

are used where line and low voltage wires pass thru internal

bulkheads. This allows for easier troubleshooting and

component replacement. The electrical control box is not

located in the compressor compartment so the access cover

can be removed for troubleshooting without affecting the

normal system operating pressures.

AIR FILTERS -- Units come standard with 1" throwaway filters.

The unit filter racks can accommodate 1" or 2" filters without

any modifications.

TABLE OF CONTENTS

Description

Features

Ratings

Physical Data

Cooling Capacities-3Ton

Cooling Capacities-4Ton

Cooling Capacities-5Ton

Heating Capacities

Supply Air Blower Perf.-3&4Tonw/Belt-Drive

Supply Air Blower Perf.-5Tonw/Belt-Drive

Supply Air Blower Perf. - 3,4&5Tonw/Direct-Drive

Motor and Drive Data

Static Resistances

2 Unitary Products Group

..........................................................................

..............................................................................

................................................................................

.......................................................................

...................................................

...................................................

...................................................

..............................................................

.................

.......................

..........

..........................................................

.............................................................

10

1

Heater / CFM Limitations

1

Field Wiring

3

Electrical Data - Basic Units (Direct-Drive)

3

Elec. Data-Ht. Pump/Elec.Ht. 3 Ton (Direct-Drive)

4

Elec. Data-Ht. Pump/Elec.Ht.4&5Ton(Direct-Drive)

5

Electrical Data - Basic Units (Belt-Drive)

6

Elec. Data-Ht. Pump/Elec.Ht. 3 Ton (Belt-Drive)

7

Elec. Data-Ht. Pump/Elec.Ht.4&5Ton(Belt-Drive)

8

Unit Dimensions

9

Roof Curb Dimensions

9

9

Factory Installed Options / Field-Installed Accessories

.......................................................................

................................................................

Typical Applications

...................................................

......................................................

...........................................................

........................

............

......

...........................

...............

.........

.....

10

10

11

11

12

13

13

14

15

17

18

19

036-21564-003-A-1005

RATINGS

CAPACITY RATINGS

ARI RATINGS (SEE NOTE 1) NOMINAL

MODEL

BCH

COOLING

PERFORMANCE

MBH SEER EER MBH COP MBH COP 240V 480V 600V

SOUND

RATING

(SEE NOTE 2)

bels

HSPF

HEATING CAPACITY

47°F17°F

036 39 10.00 9.20 8.6 7.3 39.0 3.0 23.0 2.1 5, 7, 10, 15 & 20 7,10,15 & 20 10, 15 & 20

048 48 10.20 9.25 8.6 6.7 48.0 3.0 26.4 2.0 5, 7, 10, 15 & 20 7,10,15 & 20 10, 15 & 20

060 59 10.00 9.20 8.4 7.0 59.0 3.0 36.0 2.1 5,7,10,15,20 & 30 7,10,15,20 & 30 10,15,20 & 30

NOTE: 1. Certified in accordance with the Unitary Small Equipment certification program, which is based on ARI Standard 210/240.

2. Rated in accordance with ARI Standard 270.

3. Heaters available as accessories - all with single point power supply.

SEER = Seasonal Energy Efficiency Ratio - the total cooling output in BTU's during a normal annual usage period for cooling divided by the total electric power input

in watt-hours during the same period.

EER = Energy Efficiency Ratio-the cooling capacity in BTU's per hour (BTUH) divided by the power input in watts at any given set of rating conditions, expressed in BTUH per watt

(BTUH/watt).

COP = Coefficient of Performance - the total heating capacity provided by the refrigeration system, including circulating fan heat but excluding supplementary

resistance (BTU's per hour) divided by the total electric input (watts) x 3.412.

SOUND POWER RATINGS

Unit

Size

CFM

ESP Blower

Octave Band Centerline Frequency (Hz)

IWG Speed KW 63 125 250 500 1000 2000 4000 8000

038 1200 0.60 LOW 0.60 84 84 74 67 69 62 57 52 74 41

048 1600 0.55 HIGH 0.80 85 85 75 68 70 63 58 53 75 42

060 2000 0.45 HIGH 1.00 86 86 76 69 71 64 59 54 76 43

Sound Power (dB 10

ELECTRIC HEAT CAPACITY

(SEE NOTE 3)

KW

-12

Watts)

SWL

dB(A)

dB(A)

@10ft*

*At a distance of 10 ft from the blower

NOTE: These values have been accessed using a model of sound propagation from a point source into the hemispheric free field. The dBA values provided are to be used for reference only.

Calculation of dBAvalues cover matters of system design and the fan manufacturer has no way of knowingthedetails of each system. This constitutes an exception to any specification or guarantee

requiring a dBA value or sound data in any other form than sound power level ratings.

PHYSICAL DATA

BASIC UNITS

BCH

3

4

1

2

1

1

2

SUPPLY AIR

BLOWER

INDOOR

COIL

OUTDOOR

FAN

OUTDOOR

COIL

AIR

FILTERS

(SEE NOTE)

MODELS

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 12 x 10 12 x 10 12 x 10

FAN MOTOR HP (DIRECT-DRIVE)

FAN MOTOR HP (BELT-DRIVE) 1.5 1.5 1.5

ROWS DEEP 4 3 3

FINS PER INCH 16 15 15

FACE AREA (Sq. Ft.) 4.3 5.1 5.1

PROPELLER DIA. (in.) 22 22 24

FAN MOTOR HP

NOM. CFM TOTAL 4300 4200 4500

ROWS DEEP 1 1 1

FINS PER INCH 20 20 20

FACE AREA (Sq. Ft.) 17.1 17.1 17.1

QUANTITY PER UNIT (15" x 20" x 1") 2 2 2

QUANTITY PER UNIT (14" X 25" X 1") 1 1 1

TOTAL FACE AREA (sq. ft.) 6.6 6.6 6.6

036 048 060

1

2

1

3

CHARGE REFRIGERANT 22 (lbs./oz.) 7/12 9/2 8/4

COMPRESSOR HERMETIC, RECIPROCATING (Qty) 1 1 1

NOTE: Filter racks can accommodate 1" or 2" thick filters.

Unitary Products Group 3

COOLING CAPACITIES - 3 TON (BCH036)

Air On

Indoor

CFM

1750

1500

1400

1200

1050

900

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

2

Sensible Capacity

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 51 3.4 37 32 28 24 19 - - 47 3.7 34 29 25 22 17 - 67 46 3.4 40 40 36 31 26 21 16 44 3.7 38 38 34 29 24 20 15

62 42 3.3 42 42 41 39 34 29 24 38 3.6 38 38 37 35 30 26 21

57 42 3.3 42 42 42 40 35 30 25 37 3.6 37 37 37 35 30 26 22

72 49 3.4 35 30 26 22 18 - - 46 3.7 32 28 24 20 16 - 67 45 3.4 39 37 33 29 24 20 15 42 3.7 36 34 30 27 22 18 14

62 41 3.3 41 41 40 37 32 28 24 37 3.6 37 37 36 33 28 25 21

57 41 3.3 41 41 41 38 34 29 25 36 3.6 36 36 36 33 29 25 21

72 48 3.4 33 29 24 20 16 - - 45 3.7 30 27 22 18 15 - 67 44 3.3 39 36 32 28 23 20 15 41 3.7 36 33 29 26 21 18 13

62 40 3.3 40 39 38 34 30 26 22 36 3.6 36 35 34 30 27 23 19

57 40 3.3 40 40 39 35 31 27 23 36 3.5 36 36 35 31 27 24 20

72 47 3.4 31 27 24 20 16 - - 44 3.7 29 25 22 18 14 - 67 41 3.3 36 32 29 25 22 18 14 39 3.6 34 30 27 23 20 17 13

62 38 3.3 38 37 36 32 29 25 21 35 3.6 35 34 33 29 26 23 19

57 37 3.3 37 37 36 33 30 26 22 35 3.5 35 35 34 31 28 24 20

72 45 3.3 28 25 22 19 16 - - 42 3.6 26 23 20 17 14 - 67 41 3.3 34 30 27 24 20 17 14 38 3.6 31 27 25 22 18 15 12

62 36 3.3 36 35 33 30 27 24 21 34 3.5 34 33 31 28 25 22 19

57 36 3.3 36 36 34 31 28 25 22 33 3.5 33 33 31 28 25 22 20

72 45 3.3 26 24 20 17 15 - - 40 3.6 23 21 17 15 13 - 67 39 3.3 31 28 25 22 19 17 14 35 3.6 27 25 22 19 17 15 12

62 35 3.2 35 34 32 29 25 23 20 32 3.5 32 30 28 25 22 20 17

57 35 3.2 35 35 32 30 26 24 21 31 3.5 31 31 28 26 23 21 18

85 °F95°F

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

036-21564-003-A-1005

2

Sensible Capacity

1

, MBH

Air On

Indoor

CFM

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

105 °F115°F

2

Sensible Capacity

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

2

Sensible Capacity

1

, MBH

72 44 4.0 31 27 24 20 16 - - 42 4.2 30 26 23 19 15 - -

1750

67 40 4.0 34 34 31 26 22 18 13 36 4.1 31 31 28 24 20 16 12

62 35 3.9 35 35 34 32 28 24 20 34 4.1 34 34 33 31 27 23 19

57 35 3.9 35 35 35 33 29 25 20 33 4.1 33 33 33 31 27 23 19

72 43 4.0 30 26 22 19 15 - - 41 4.2 29 25 21 18 15 - -

1500

67 38 4.0 32 31 27 24 20 16 12 35 4.1 30 28 25 22 18 15 11

62 34 3.9 34 34 33 30 26 23 19 33 4.1 33 33 32 29 25 22 19

57 34 3.9 34 34 34 31 28 24 20 32 4.1 32 32 32 29 26 22 19

72 42 4.0 28 25 21 17 14 - - 39 4.2 26 23 19 16 13 - -

1400

67 37 4.0 32 30 26 23 19 16 12 34 4.1 30 27 24 21 17 15 11

62 33 3.9 33 32 31 28 24 21 18 32 4.1 32 31 30 27 24 20 17

57 32 3.8 32 32 31 28 24 21 18 32 4.0 32 32 31 28 24 21 18

72 41 4.0 27 23 20 17 13 - - 37 4.2 24 21 18 15 12 - -

1200

67 35 3.9 30 27 24 21 18 15 11 32 4.1 28 24 22 19 17 14 10

62 32 3.9 32 31 30 26 24 21 17 30 4.1 30 29 28 25 22 19 16

57 31 3.8 31 31 31 27 25 21 18 29 4.0 29 29 29 25 23 20 17

72 40 3.9 24 22 19 16 14 - - 35 4.1 21 19 17 14 12 - -

1050

67 34 3.9 28 24 22 19 16 14 11 31 4.0 25 22 20 18 15 12 10

62 30 3.8 30 29 27 25 22 20 17 29 4.0 29 28 26 24 21 19 16

57 30 3.8 30 30 28 25 23 20 18 28 4.0 28 28 26 24 21 19 17

72 38 3.9 21 20 16 14 12 - - 34 4.1 19 18 15 12 11 - 67 32 3.9 25 22 20 18 15 13 11 29 4.0 23 20 18 16 14 12 10

900

62 29 3.8 29 27 25 23 20 18 16 27 4.0 27 25 24 21 18 17 15

1

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance Table, multiply this value by

3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2

These ratings include the compressor and the outdoor fan motors but not the supply air blower motor. The total outdoor fan motor power input is 0.35 KW.

Refer to the Blower Performance Table for the KW of the supply air blower motor.

57 29 3.8 29 29 26 24 21 19 17 26 4.0 26 26 23 22 19 17 15

NOMINAL RATING

ALL SENSIBLE CAPACITY

4 Unitary Products Group

036-21564-003-A-1005

COOLING CAPACITIES - 4 TON (BCH048)

Air On

Indoor

CFM

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

2

85 °F95°F

Sensible Capacity

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 56 4.1 42 36 31 26 - - - 53 4.5 40 35 29 24 - - 67 53 4.0 48 47 41 36 30 25 - 51 4.4 46 45 41 35 30 24 -

2000

62 49 4.0 49 49 48 44 38 33 28 46 4.3 46 46 45 41 35 30 24

57 49 3.9 49 49 49 44 38 33 28 46 4.3 46 46 46 41 35 30 24

72 55 4.0 40 35 30 25 - - - 53 4.4 38 33 28 23 - - 67 52 4.0 47 44 39 34 29 24 - 51 4.4 44 44 39 34 29 24 -

1800

62 48 3.9 48 48 47 43 38 33 28 47 4.3 47 47 45 40 36 31 26

57 48 3.9 48 48 48 43 38 33 28 45 4.2 45 45 45 40 35 30 25

72 53 4.0 37 33 28 24 - - - 52 4.4 36 32 27 23 - - 67 51 4.0 46 42 37 33 28 24 - 50 4.3 44 43 38 34 29 25 -

1600

62 47 3.9 47 47 46 41 37 32 28 45 4.2 45 45 44 40 36 31 27

57 47 3.9 47 47 47 42 38 33 29 44 4.1 44 44 44 40 36 31 27

72 52 4.0 34 30 26 22 - - - 49 4.3 33 29 25 21 - - 67 49 3.9 42 38 34 30 26 22 - 47 4.2 42 38 34 30 26 22 -

1400

62 46 3.8 46 45 42 38 34 30 26 43 4.1 43 42 40 36 32 28 24

57 45 3.8 45 45 43 39 35 31 27 42 4.1 42 42 40 36 32 28 24

72 50 3.9 31 27 24 20 - - - 47 4.2 29 25 22 18 - - 67 47 3.9 38 35 31 28 24 21 - 45 4.2 37 34 30 27 23 20 -

1200

62 44 3.8 44 42 39 35 32 28 25 40 4.1 40 39 36 32 29 25 22

57 44 3.7 44 43 39 36 32 29 25 40 4.0 40 39 36 32 29 25 22

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

2

Sensible Capacity

1

, MBH

Air On

Indoor

CFM

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

105 °F115°F

Sensible Capacity

2

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

2

Sensible Capacity

1

, MBH

72 51 4.9 40 35 29 24 - - - 49 5.2 39 34 29 23 - - 67 46 4.7 42 42 39 34 28 23 - 41 5.0 40 40 37 32 26 21 -

2000

62 43 4.6 43 43 42 37 32 27 21 40 4.9 40 40 39 34 29 23 18

57 43 4.6 43 43 43 38 32 28 22 40 4.8 40 40 40 34 30 24 19

72 50 4.8 38 33 28 23 - - - 47 5.1 37 32 27 22 - - 67 45 4.7 41 41 37 32 27 22 - 40 4.9 37 36 35 30 25 20 -

1800

62 42 4.6 42 42 41 37 32 27 22 39 4.8 39 39 37 34 29 24 19

57 42 4.5 42 42 42 37 33 27 23 38 4.7 38 38 38 33 30 25 20

72 49 4.8 35 31 26 22 - - - 46 5.1 34 29 25 20 - - 67 44 4.6 40 40 35 31 26 22 - 39 4.9 36 36 32 28 23 19 -

1600

62 41 4.5 41 41 40 35 32 27 23 37 4.7 37 37 36 33 28 24 19

57 41 4.4 41 41 41 36 32 28 23 37 4.7 37 37 37 34 28 25 20

72 47 4.7 32 28 24 20 - - - 44 5.0 31 27 23 19 - - 67 42 4.5 38 36 32 28 24 20 - 37 4.8 36 34 30 26 21 17 -

1400

62 39 4.4 39 38 37 33 28 25 20 36 4.7 36 35 34 30 26 22 18

57 39 4.4 39 39 37 33 29 25 21 36 4.6 36 36 34 31 26 23 19

72 44 4.6 28 25 21 18 - - - 42 4.9 28 24 21 17 - - 67 40 4.5 36 32 29 25 22 18 - 36 4.7 34 31 27 24 20 17 -

1200

62 38 4.4 38 36 34 29 27 22 20 35 4.6 35 34 30 28 24 20 17

1

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance Table, multiply this value by

3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2

These ratings include the compressor and the outdoor fan motors but not the supply air blower motor. The total outdoor fan motor power input is 0.35 KW.

Refer to the Blower Performance Table for the KW of the supply air blower motor.

57 37 4.3 37 37 34 30 27 23 20 35 4.6 35 35 31 29 24 21 18

NOMINAL RATING

ALL SENSIBLE CAPACITY

Unitary Products Group 5

COOLING CAPACITIES - 5 TON (BCH060)

Air On

Indoor

CFM

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

2

85 °F95°F

Sensible Capacity

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

72 68 5.7 51 44 38 31 - - - 67 6.0 51 45 38 31 - - 67 65 5.6 58 56 50 43 37 30 - 64 5.9 56 56 50 43 37 30 -

2500

62 61 5.6 61 61 59 53 46 39 33 59 5.9 59 59 57 50 44 38 31

57 60 5.5 60 60 59 53 47 40 33 58 5.8 58 58 57 51 44 39 32

72 67 5.6 48 42 36 30 - - - 66 5.9 48 42 36 30 - - 67 64 5.6 57 54 48 42 36 30 - 63 5.9 55 54 48 42 35 29 -

2250

62 60 5.5 60 60 57 51 45 39 33 57 5.8 57 57 55 50 44 38 32

57 59 5.5 59 59 58 52 46 40 34 57 5.8 57 57 56 50 45 39 33

72 66 5.6 45 40 34 29 - - - 65 5.9 45 40 34 29 - - 67 63 5.5 56 51 45 40 35 29 - 61 5.9 55 51 45 40 34 29 -

2000

62 59 5.4 59 59 55 50 44 39 33 56 5.8 56 56 54 49 44 38 33

57 58 5.4 58 58 57 52 46 41 36 56 5.7 56 56 55 50 44 39 34

72 64 5.5 42 37 32 27 - - - 62 5.9 43 38 33 28 - - 67 61 5.5 52 47 42 37 33 28 - 59 5.8 53 48 44 39 34 29 -

1750

62 57 5.4 57 56 51 46 41 37 32 54 5.7 54 54 52 48 43 38 33

57 57 5.4 57 57 53 48 44 39 34 54 5.7 54 54 53 49 43 39 34

72 62 5.5 38 34 30 25 - - - 60 5.8 41 36 32 28 - - 67 59 5.5 48 43 39 35 31 26 - 57 5.8 51 46 42 38 34 29 -

1500

62 55 5.4 55 52 47 43 39 35 30 52 5.7 52 52 50 46 42 38 34

57 55 5.3 55 54 49 45 41 37 32 52 5.6 52 52 51 47 42 39 35

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

036-21564-003-A-1005

2

Sensible Capacity

1

, MBH

Air On

Indoor

CFM

Coil

WB

°F

Tota l

Cap.

MBH

1

Power

Input

KW

105 °F115°F

2

Sensible Capacity

Entering Dry Bulb, °F Entering Dry Bulb, °F

86 83 80 77 74 71 68 86 83 80 77 74 71 68

Temperature of Air on Outdoor Coil

1

, MBH

Tota l

Cap.

MBH

1

Power

Input

KW

2

Sensible Capacity

1

, MBH

72 64 6.0 51 44 38 31 - - - 60 6.9 50 43 37 30 - - 67 59 5.9 51 51 49 42 36 29 - 54 6.6 54 53 47 41 34 27 -

2500

62 54 5.9 54 54 51 46 40 33 26 49 6.5 49 49 48 42 35 28 22

57 54 5.8 54 54 52 46 41 33 26 49 6.5 49 49 49 43 35 28 23

72 63 5.9 48 42 36 30 - - - 60 6.8 47 41 35 29 - - 67 58 5.9 51 51 46 40 34 28 - 54 6.6 47 47 45 39 32 26 -

2250

62 53 5.8 53 53 52 46 40 34 28 49 6.5 49 49 47 42 36 30 24

57 53 5.8 53 53 52 46 41 35 27 49 6.4 49 49 48 43 37 31 25

72 62 5.9 45 39 34 28 - - - 59 6.8 44 38 33 27 - - 67 57 5.9 51 49 44 38 33 27 - 53 6.5 45 45 42 36 31 26 -

2000

62 52 5.8 52 52 51 46 40 35 30 48 6.4 48 48 46 42 36 31 25

57 52 5.7 52 52 51 46 40 36 31 47 6.4 47 47 46 43 36 32 25

72 60 5.9 41 37 32 27 - - - 56 6.7 40 35 30 25 - - 67 55 5.8 48 46 41 36 31 26 - 51 6.5 43 43 38 33 29 24 -

1750

62 50 5.7 50 50 48 43 39 34 29 46 6.4 46 46 43 38 33 28 24

57 50 5.7 50 50 48 43 39 34 30 45 6.3 45 45 43 38 33 28 25

72 57 5.8 38 34 30 25 - - - 53 6.6 36 31 27 23 - - 67 53 5.8 47 43 38 34 30 26 - 48 6.4 41 39 35 30 26 22 -

1500

62 48 5.7 48 48 45 41 37 32 28 44 6.3 44 44 39 35 30 26 22

1

These capacities are gross ratings. For net capacity, determine the KW of the supply air blower motor from the Blower Performance Table, multiply this value by

3.415 MBH / KW to determine the motor heat, and deduct this heat from the gross capacity of the unit.

2

These ratings include the compressor and the outdoor fan motors but not the supply air blower motor. The total outdoor fan motor power input is 0.35 KW.

Refer to the Blower Performance Table for the KW of the supply air blower motor.

57 48 5.6 48 48 45 41 38 32 28 43 6.2 43 43 40 36 30 26 23

NOMINAL RATING

ALL SENSIBLE CAPACITY

6 Unitary Products Group

036-21564-003-A-1005

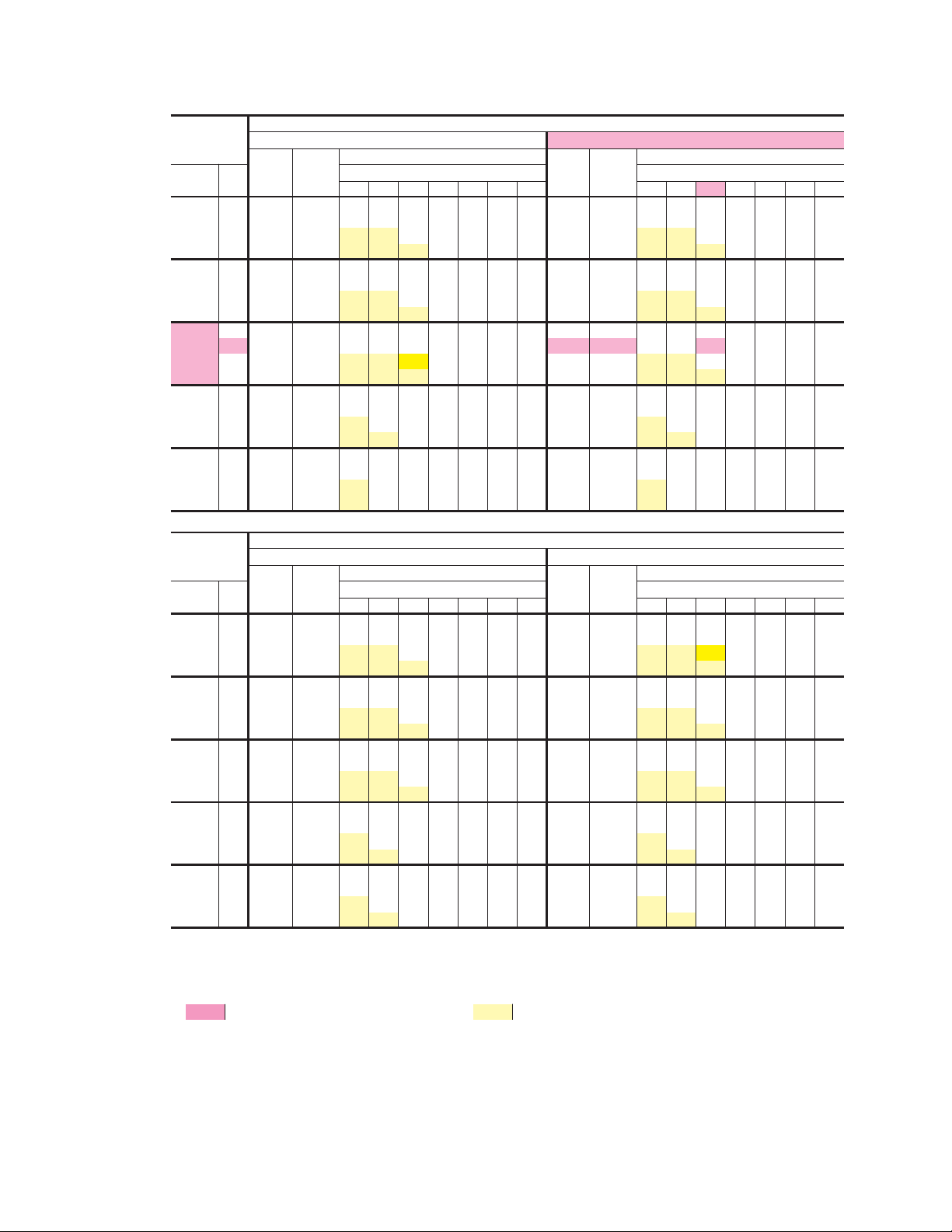

HEATING CAPACITIES

CFM

1750

1400

1200

1050

2000

1600

1200

2500

2000

1500

RET. AIR CAP

°F

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

55

70

80

&KW-100 102030405060

MBH 13.1 16.4 23.5 29.1 30.2 41.7 47.0 48.2

KW 2.9 3.0 3.2 3.3 3.5 3.7 3.8 3.9

MBH 11.9 15.0 21.5 26.7 27.7 38.2 43.1 44.1

KW 3.0 3.1 3.4 3.4 3.6 3.8 3.9 4.1

MBH 10.9 13.6 19.6 24.3 25.2 34.8 39.3 40.2

KW 3.1 3.2 3.4 3.5 3.8 3.9 4.1 4.2

MBH 12.4 15.5 22.5 27.7 28.7 39.6 44.7 45.8

KW 2.7 2.9 3.0 3.1 3.3 3.5 3.6 3.7

MBH 11.4 14.1 20.3 25.2 26.1 36.1 40.7 41.6

KW 2.9 3.0 3.2 3.3 3.5 3.7 3.8 3.9

MBH 10.4 13.1 18.0 23.2 24.2 33.3 37.6 38.5

KW 3.0 3.1 3.2 3.4 3.6 3.8 3.9 4.0

MBH 11.8 14.8 21.3 26.5 27.5 37.8 42.7 43.7

KW 2.7 2.8 3.0 3.1 3.3 3.4 3.5 3.6

MBH 10.8 13.5 19.4 24.0 24.9 34.4 38.8 39.7

KW 2.9 3.0 3.1 3.3 3.4 3.6 3.7 3.8

MBH 9.9 12.4 17.8 22.0 22.9 31.5 35.6 36.5

KW 2.9 3.1 3.2 3.4 3.5 3.7 3.8 3.9

MBH 11.2 14.1 20.3 25.2 26.1 35.9 40.6 41.6

KW 2.6 2.7 2.9 3.0 3.3 3.3 3.5 3.5

MBH 10.2 12.8 18.5 22.8 23.6 32.7 36.9 37.8

KW 2.8 2.9 3.0 3.2 3.3 3.5 3.6 3.7

MBH 9.3 11.7 16.7 20.7 21.5 29.8 33.6 34.4

KW 2.8 3.0 3.1 3.3 3.4 3.6 3.7 3.8

MBH 12.3 17.3 22.5 28.2 36.3 44.5 53.8 61.6

KW 3.4 3.5 3.6 3.6 3.8 4.0 4.6 5.2

MBH 11.8 16.6 21.6 27.1 34.9 42.8 51.7 59.2

KW 3.5 3.6 3.8 3.8 4.0 4.2 4.8 5.4

MBH 10.9 15.3 19.9 24.9 32.1 39.4 47.6 54.5

KW 3.6 3.7 4.0 4.0 4.1 4.4 5.0 5.7

MBH 12.1 17.0 22.0 27.7 34.5 42.3 51.2 58.6

KW 3.3 3.4 3.5 3.6 3.6 3.8 4.4 5.0

MBH 11.6 16.3 21.2 26.6 33.2 40.7 49.2 56.3

KW 3.4 3.5 3.6 3.7 3.8 4.0 4.6 5.2

MBH 10.7 15.0 19.5 24.5 30.5 37.4 45.3 51.8

KW 3.5 3.6 3.8 3.9 4.0 4.2 4.8 5.4

MBH 10.9 15.3 19.9 24.9 31.7 38.9 47.0 53.8

KW 3.1 3.2 3.3 3.4 3.5 3.7 4.2 4.8

MBH 10.5 14.7 19.1 24.0 30.5 37.4 45.2 51.7

KW 3.2 3.3 3.4 3.5 3.6 3.8 4.4 5.0

MBH 9.6 13.5 17.6 22.0 28.1 34.4 41.6 47.6

KW 3.3 3.4 3.5 3.6 3.8 4.0 4.6 5.2

MBH 18.2 24.7 31.1 38.4 45.6 55.4 64.7 75.6

KW 5.0 5.1 5.2 5.3 5.3 5.6 5.9 6.5

MBH 17.5 23.7 29.9 37.0 43.9 53.3 62.2 72.7

KW 5.2 5.3 5.4 5.5 5.6 5.9 6.2 6.8

MBH 16.1 21.8 27.5 34.0 40.4 49.0 57.2 66.9

KW 5.4 5.6 5.7 5.8 5.9 6.0 6.5 7.2

MBH 18.0 24.4 30.8 38.1 45.0 54.7 63.9 74.7

KW 4.7 4.8 4.9 5.0 5.3 5.5 5.8 6.4

MBH 17.3 23.5 29.6 36.6 43.3 52.6 61.4 71.8

KW 4.9 5.0 5.1 5.2 5.5 5.8 6.1 6.7

MBH 15.9 21.6 27.2 33.7 39.8 48.4 56.5 66.1

KW 5.1 5.3 5.4 5.5 5.8 6.1 6.4 7.0

MBH 16.2 22.0 27.8 34.3 41.4 50.2 58.7 68.6

KW 4.5 4.6 4.7 4.8 5.0 5.3 5.5 6.1

MBH 15.6 21.2 26.7 33.0 39.8 48.3 56.4 66.0

KW 4.7 4.8 4.9 5.0 5.2 5.5 5.8 6.4

MBH 14.4 19.5 24.6 30.4 36.6 44.5 51.9 60.7

KW 4.9 5.0 5.1 5.2 5.5 5.8 6.1 6.7

BCH036

OUTDOOR AIR TEMPERATURE, °F (72% RH)

BCH048

BCH060

Unitary Products Group 7

036-21564-003-A-1005

SUPPLY AIR BLOWER PERFORMANCE - BCH036 & 048 with Belt-Drive

BCH036 - SIDE DUCT APPLICATIONS (230/460/575 VOLTS)

MODEL

BCH

036

AIR FLOW

CFM

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 1125 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 1100

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 ----818665858740898820940890980950

1500 ------842695882755922835962895

1400 ------833650867705904765942820

1300 --------858665893725932785

1200 --------847640880680916730

0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

Available External Static Pressure - IWG*

MODEL

NOTE: FOR 208 VOLTS, MULTIPLY VALUES BY 0.95.

*INCLUDES ALLOWANCES FOR A WET INDOOR COIL AND 1" FILTERS. REFER TO THE STATIC RESISTANCES TABLE FOR RESISTANCE VALUES ON APPLICATIONS OTHER

THAN HEAT PUMP UNITS WITH SIDE DUCT AIRFLOWS.

BCH

036

AIR FLOW

CFM

2000 1103 1270 -----------1900 1085 1210 -----------1800 1064 1145 1102 1180 ---------1700 1040 1075 1081 1115 1121 1140 -------1600 1020 1005 1060 1050 1100 1085 -------1500 1003 945 1044 995 1086 1035 -------1400 982 880 1024 920 1067 965 1107 1000 -----1300 970 835 1010 870 1053 920 1099 960 -----1200 953 780 992 815 1034 855 1080 905 ------

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

Available External Static Pressure - IWG*

BCH048 - SIDE DUCT APPLICATIONS (230/460/575 VOLTS)

MODEL

BCH

048

AIR FLOW

CFM

2000 843 860 880 925 919 1005 956 1065 993 1145 1030 1195 1067 1235

1900 817 775 854 850 893 920 930 995 970 1065 1008 1125 1046 1170

1800 790 700 828 760 867 840 906 905 944 980 985 1040 1025 1100

1700 - - 802 670 840 745 881 815 920 900 961 970 1001 1030

1600 ----818665858740898820940890980950

1500 ------842695882755922835962895

1400 ------833650867705904765942820

1300 --------858665893725932785

1200 --------847640880680916730

0.20 0.30 0.40 0.50 0.60 0.70 0.80

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

Available External Static Pressure - IWG*

MODEL

BCH

NOTE: FOR 208 VOLTS, MULTIPLY VALUES BY 0.95.

*INCLUDES ALLOWANCES FOR A WET INDOOR COIL AND 1" FILTERS. REFER TO THE STATIC RESISTANCES TABLE FOR RESISTANCE VALUES ON APPLICATIONS OTHER

THAN HEAT PUMP UNITS WITH SIDE DUCT AIRFLOWS.

8 Unitary Products Group

048

AIR FLOW

CFM

2000 1103 1270 -----------1900 1085 1210 -----------1800 1064 1145 1102 1180 ---------1700 1040 1075 1081 1115 1121 1140 -------1600 1020 1005 1060 1050 1100 1085 -------1500 1003 945 1044 995 1086 1035 -------1400 982 880 1024 920 1067 965 1107 1000 -----1300 970 835 1010 870 1053 920 1099 960 -----1200 953 780 992 815 1034 855 1080 905 ------

0.90 1.00 1.10 1.20 1.30 1.40 1.50

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

Available External Static Pressure - IWG*

Loading...

Loading...