Page 1

INSTALLATION

MANUAL

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SAFET Y C ON S ID E RA T IONS. . . . . . . . . . . . . . . . . . . . . .5

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

REFERENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

APPROVALS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

START-UP (COOLING). . . . . . . . . . . . . . . . . . . . . . . . . .37

NORMAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . .39

®

SINGLE PACKAGE AIR CONDITIONERS AND

SINGLE PACKAGE ELECTRIC UNITS

DM090, 120 and 150

7-1/2 TO 12-1/2 TON

(380V, 3 Phase, 60 HZ)

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . .39

See following pages for a complete Table of Contents.

NOTES, CAUTIONS AND WARNINGS

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. Not es

clarify or make the installation easier. Cautions

to prevent equipment damage. Warnings

installer that personal injury and/or equipment damage

may result if installation procedure is not handled properl y.

are intended to

are given

are given to alert

CAUTION: READ ALL SAFETY GUIDES BEFORE YOU

BEGIN TO INSTALL YOUR UNIT.

SA VE THIS MANUAL

035-17311-002-A-0803

Page 2

TABLE OF CONTENTS

035-17311-002-A-0803

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . .5

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

INSTALLATION SAFETY INFORMATION . . . . . . . . . . . . . 10

PRECEDING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 10

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RIGGING AND HANDLING . . . . . . . . . . . . . . . . . . . . . . . . . 11

CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DUCT COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

COMPRESSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

THERMOSTAT WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

POWER AND CONTROL WIRING . . . . . . . . . . . . . . . . . . . 17

POWER WIRING DETAIL . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OPTIONS/ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . 21

ELECTRIC HEAT ACCESSORIES . . . . . . . . . . . . . . . . . . . . . 21

ELECTRIC HEAT OPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

MOTORIZED OUTDOOR DAMPER . . . . . . . . . . . . . . . . . . . . 21

ECONOMIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

POWER EXHAUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

RAIN HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ECONOMIZER AND POWER EXHAUST SET POINT

ADJUSTMENTS AND INFORMATION . . . . . . . . . . . . . . . 22

MINIMUM POSITION ADJUSTMENT . . . . . . . . . . . . . . . . . . .22

ENTHALPY SET POINT ADJUSTMENT . . . . . . . . . . . . . . . . . 22

POWER EXHAUST DAMPER SET POINT (WITH OR

WITHOUT POWER EXHAUST) . . . . . . . . . . . . . . . . . . . . . . .22

INDOOR AIR QUALITY AQ . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PHASING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

BLOWER ROTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

AIR BALANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CHECKING AIR QUANTITY . . . . . . . . . . . . . . . . . . . . . . . . 31

METHOD ONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

METHOD TWO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SUPPLY AIR DRIVE ADJUSTMENT . . . . . . . . . . . . . . . . . 32

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SEQUENCE OF OPERATIONS OVERVIEW . . . . . . . . . . . 33

COOLING SEQUENCE OF OPERATION . . . . . . . . . . . . . . 34

CONTINUOUS BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

INTERMITTENT BLOWER . . . . . . . . . . . . . . . . . . . . . . . . . . .34

NO OUTDOOR AIR OPTIONS . . . . . . . . . . . . . . . . . . . . . . . .34

ECONOMIZER WITH SINGLE ENTHALPY SENSOR - . . . . .34

ECONOMIZER WITH DUAL ENTHALPY SENSORS - . . . . . .34

ECONOMIZER WITH POWER EXHAUST - . . . . . . . . . . . . . .34

MOTORIZED OUTDOOR AIR DAMPERS - . . . . . . . . . . . . . .34

COOLING OPERATION ERRORS . . . . . . . . . . . . . . . . . . . . .35

HIGH-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . . . .35

LOW-PRESSURE LIMIT SWITCH . . . . . . . . . . . . . . . . . . . . . .35

FREEZESTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

LOW AMBIENT COOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

COMPRESSOR PROTECTION . . . . . . . . . . . . . . . . . . . . . 35

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ELECTRIC HEATING SEQUENCE OF OPERATIONS . . . 36

ELECTRIC HEATING OPERATION ERRORS . . . . . . . . . . 36

TEMPERATURE LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

SAFETY CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

LIMIT SWITCH (LS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

FLASH CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

ELECTRIC HEAT ANTICTPATOR SETPOINTS . . . . . . . . . 36

START-UP (COOLING) . . . . . . . . . . . . . . . . . . . . . . . . . . 37

PRESTART CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . 37

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 37

POST START CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . 37

CHARGING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

NORMAL MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . 39

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

FILTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

OUTDOOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PREDATOR® FLASH CODES . . . . . . . . . . . . . . . . . . . . . . 39

COOLING TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . 41

2 Unitary Products Group

Page 3

035-17311-002-A-0803

LIST OF FIGURES

Fig. # Pg.#

1 UNIT SHIPPING BRACKET . . . . . . . . . . . . . . . . . . . . 10

2 CONDENSER COVERING . . . . . . . . . . . . . . . . . . . . 10

3 COMPRESSOR SECTION . . . . . . . . . . . . . . . . . . . . . 10

4 PREDATOR

®

COMPONENT L OCATION . . . . . . . . . 11

5 UNIT 4 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 UNIT 6 POINT LOAD . . . . . . . . . . . . . . . . . . . . . . . . . 12

7 UNIT CENTER OF GRAVITY . . . . . . . . . . . . . . . . . . . 12

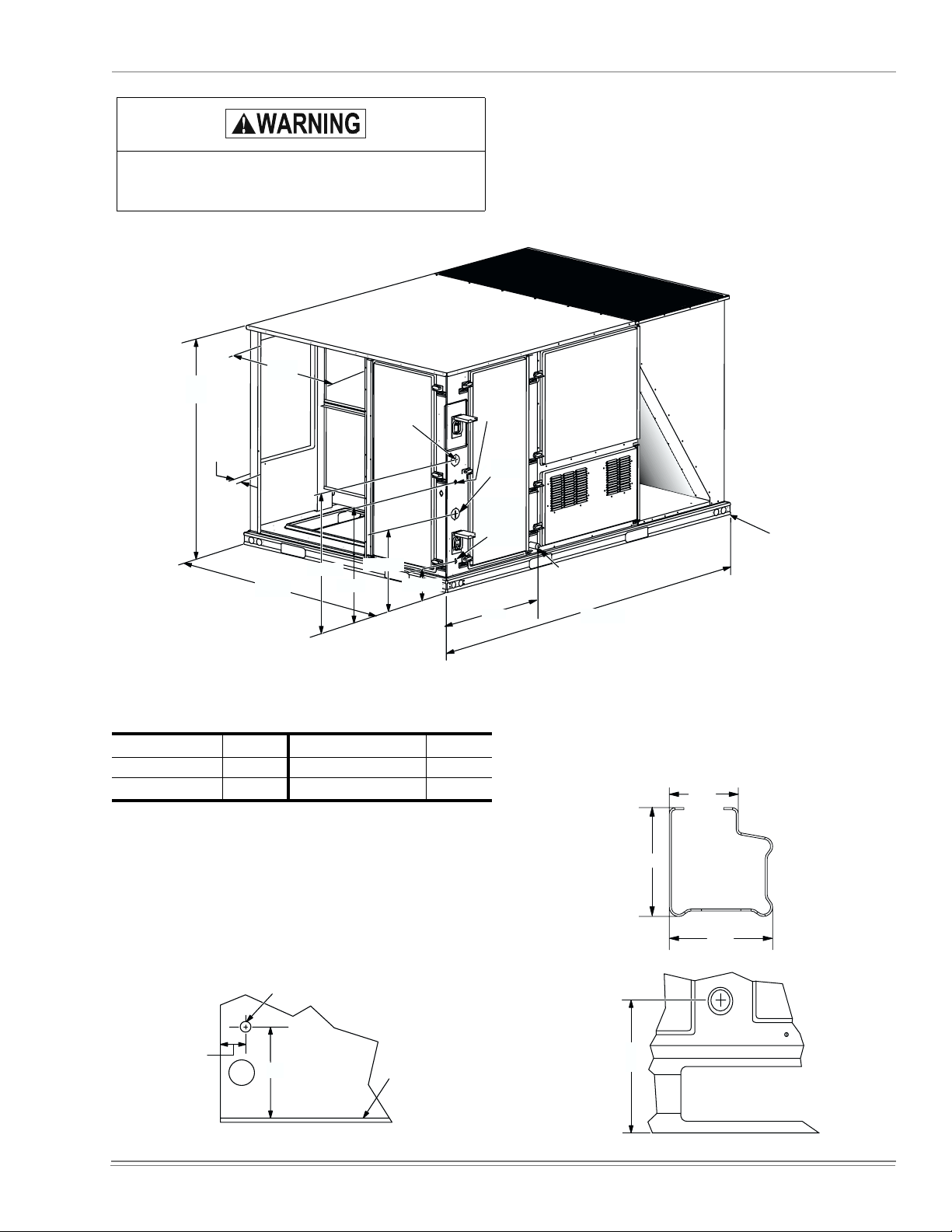

8 UNIT DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9 BOTTOM DUCT OPENINGS (FROM ABOVE) . . . . . 14

10 REAR DUCT DIMENSIONS . . . . . . . . . . . . . . . . . . . . 14

11 PREDATOR

12 SUNLINE™ TO PREDATOR

®

ROOF CURB DIMENSIONS . . . . . . . . 15

®

TRANSITION ROOF

CURBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fig. #

Pg.#

13 SIDE PANELS WITH HOLE PLUGS . . . . . . . . . . . . . 16

14 RETURN DOWNFLOW PLENUM WITH PANEL . . . 16

15 DISCHARGE PANEL IN PLACE . . . . . . . . . . . . . . . . 16

16 CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . 16

17 ELECTRONIC THERMOSTAT FIELD WIRING . . . . 18

18 FIELD WIRING 24 VOLT THERMOSTAT . . . . . . . . . 18

19 FIELD WIRING DISC ONNECT . . . . . . . . . . . . . . . . . 19

20 ENTHALPY SET POINT CHART . . . . . . . . . . . . . . . . 23

21 HONEYWELL ECONOMIZER CONTROL W7212 . . 23

22 BELT ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . 24

23 DRY COIL DELTA P . . . . . . . . . . . . . . . . . . . . . . . . . 32

24 BASIC TROUBLESHOOTING FLOWCHART . . . . . . 40

Unitary Products Group 3

Page 4

LIST OF TABLES

035-17311-002-A-0803

Tbl.# Pg.#

1 UNIT VOLTAGE LIMITATIONS . . . . . . . . . . . . . . . . . 11

2 UNIT TEMPERATURE LIMITATIONS . . . . . . . . . . . . 11

3 UNIT WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 6 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . . 12

5 4 POINT LOAD WEIGHT . . . . . . . . . . . . . . . . . . . . . . 12

6 UNIT CLEARANCES . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 CONTROL WIRE SIZES . . . . . . . . . . . . . . . . . . . . . . .17

8 ELECTRICAL DATA - DM090 (7-1/2 TON) WITHOUT

POWER C O N VE N IE N C E O U T L E T . . . . . . . . . . . . . .19

9 ELECTRICAL DATA - DM090 (7-1/2 TON) WITH

POWER C O N VE N IE N C E O U T L E T . . . . . . . . . . . . . .19

10 ELECTRICAL DATA - DM120 (10 TON) WITHOUT

POWER C O N VE N IE N C E O U T L E T . . . . . . . . . . . . . .20

11 ELECTRICAL DATA - DM120 (10 TON) WITH POWER

CONVE NIE N C E OU T L E T . . . . . . . . . . . . . . . . . . . . .20

12 ELECTRICAL DATA - DM150 (12-1/2 TON) WITHOUT

POWER C O N VE N IE N C E O U T L E T . . . . . . . . . . . . . .20

13 ELECTRICAL DATA - DM150 (12-1/2 TON) WITH

POWER C O N VE N IE N C E O U T L E T . . . . . . . . . . . . . .20

14 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

15 MINIMUM SUPPLY AIR CFM . . . . . . . . . . . . . . . . . . . 21

16 SUPPLY AIR LIMITATIONS . . . . . . . . . . . . . . . . . . . . 24

17 7-1/2 TON STANDARD MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 25

18 7-1/2 TON OPTIONAL MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 25

19 10 TON STANDARD MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 26

Tbl.#

20 10 TON OPTIONAL MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 26

21 12-1/2 TON STANDARD MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 27

22 12-1/2 TON OPTIONAL MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 27

23 7-1/2 TON STANDARD MOTOR SIDE SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 28

24 7-1/2 TON OPTIONAL MOTOR SIDE SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 28

25 10 TON STANDARD MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 29

26 10 TON OPTIONAL MOTOR DOWN SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 29

27 12-1/2 TON STANDARD MOTOR SIDE SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 30

28 12-1/2 TON OPTIONAL MOTOR SIDE SHOT

BLOWER PERFORMANCE . . . . . . . . . . . . . . . . . . . 30

29 INDOOR BLOWER SPECIFICATIONS . . . . . . . . . . . 31

30 ADDITIONAL STATIC RESISTANCE . . . . . . . . . . . . 33

31 MOTOR SHEAVE DATUM DIAMETERS . . . . . . . . . . 33

32 ELECTRIC HEAT LIMIT SETTING . . . . . . . . . . . . . . 36

33 ELECTRIC HEAT ANTICIPATOR SETPOINTS . . . . 36

34 7.5 TON STANDARD EFFICIENCY SUPERHEAT

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

35 10 TON STANDARD EFFICIENCY SUPERHEAT

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

36 12.5 TON STANDARD EFFICIENCY SUPERHEAT

CHARGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

37 UNIT CONTROL BOARD FLASH CODES . . . . . . . . 40

Pg.#

4 Unitary Products Group

Page 5

035-17311-002-A-0803

GENERAL

YORK Predator® units are single package air conditioners

designed for outdoor installation on a rooftop or slab and for

non-residential use. These units can be equipped with factory

or field installed electric heaters for heating applications.

These units are completely assembled on rigid, permanently

attached base rails. All piping, refrigerant charge, and electrical wiring is factory installed and tested. The units require

electric power and duct connections. The electric heaters

have nickel-chrome elements and utilize single-point power

connection.

SAFETY CONSIDERATIONS

Due to system pressure, moving parts, and electrical components, installation and servicing of air conditioning equipment

can be hazardous. Only qualified, trained service personnel

should install, repair, or service this equipment. Untrained

personnel can perform basic maintenance functions of cleaning coils and filters and replacing filters.

Observe all precautions in the literature, labels, and tags

accompanyi ng the equipment whenever working on air conditioning equipment. Be sure to follow all other applicable

safety precautions and codes.

REFERENCE

Additional information is available in the following reference

forms:

• General Installation - DM090 - 150, 035-17311-002

• Pre-start & Post-start Check List - 035-18466-000

• Econ om izer Accessory Downflow Factory Installed, 035-18286-000

Downflow Field Inst alled, 035-18285-000

Horizontal Field Installed, 035-18287-000

• Motorized O utdoor Air Damper 035-18283-000

• Manual Outdoor Air Damper (0-100%) 035-18282-000

• Manual Outdoor Air Damper (0-35%) 035-18281-000

• Elect ric Heater Accessory 035-17291-001

• Unit Renewa l Par ts List 035-17288-000

All forms referenced in this instruction may be ordered from:

Stand ard Register

T o ll Free Fax: (877) 379-7920

T o ll Free Phone: (877) 318-9675

APPROVALS

Design certifie d by CSA as fol lows :

Wear safety glasses and work gloves. Use quenching cloth

and have a fire extinguisher available during brazing operations.

INSPECTION

As soon as a unit is received , it should be in spected fo r poss ible damage during transit. If damage is evident, the extent of

the damage should be noted on the carrier’s freight bill. A

separate request for inspection by the carrier’s agent should

be made in writi ng.

This furnace is not to be used for temporary heating

of buildings or structures under construction.

Before performing service or maintenance operations on unit, turn off main power switch to unit. Electrical shock could cause personal injury. Improper

installation, adjustment, alteration, service or maintenance can cause injury or property damage. Refer

to this manual. For assistance or additional information consult a quali fi ed installer, service agency.

1. For use as a cooling only unit, cooling uni t with supplemental elect ri c heat or a forced air furnace.

2. For outdoor installation only.

3. For installation on combustible material and may be

installed dir ectly on combustible flooring or, in the U.S.,

on wood flooring or Class A, Class B or Class C roof covering materials .

This product must be installed in strict compliance

with the enclosed installation instructions and any

applicable local, state, and national codes including,

but not limited to, building, electrical, and mechanical

codes.

Incorrect installation may create a condition where the

operation of the product could cause personal injury

or property damage.

The installer should pay particular attention to the words:

NOTE, CAUTION, and WARNING. NOTES are intended to

clarify or make the installation easier. CAUTIONS are given

to prevent equipment dam age. WARNINGS are given to alert

installer that personal injury and/or equipment damage may

result if inst allation procedure i s not handled properly.

Unitary Products Group 5

Page 6

NOMENCLATURE

6½ - 12½ Ton Predator Model Number Nomenclature

035-17311-002-A-0803

D M C00

Product Category

D = Air Cond., Single Package

Product Identifier

M = R-22 Standard Efficiency

Nominal Cooling Capacity - MBH

090 = 7-½ Ton

120 = 10 Ton

150 = 12-½ Ton

Heat Type & Nominal Heat Capacity

C00 = Cooling Only. Suitable for field installed electric heat

Electric Heat Options

E09 = 9 kW Electric Heat

E18 = 18 kW Electric Heat

E24 = 24 kW Electric Heat

E36 = 36 kW Electric Heat

E54 = 54 kW Electric Heat

Voltage

3 = 380-3-60

AA 3090

A3A

Product Generation

3 = Third Generation

Installation Options

A = No Options Installed

B = Option 1

C = Option 2

D = Options 1 & 2

E = Option 3

F = Option 4

G = Options 1 & 3

H = Options 1 & 4

J = Options 1, 2 & 3

K = Options 1, 2 & 4

L = Options 1, 3 & 4

M = Options 1, 2, 3 & 4

N = Options 2 & 3

P = Options 2 & 4

Q = Options 2, 3 & 4

R = Options 3 & 4

S = Option 5

T = Options 1 & 5

U = Options 1, 3 & 5

V = Options 1, 4 & 5

W = Options 1, 3, 4 & 5

X = Options 3 & 5

Y = Options 4 & 5

Z = Options 3, 4 & 5

Additional Options

(See Next Page)

Options

1 = Disconnect

2 = Non-Pwr’d Conv Outlet

3 = Smoke Detector S. A.

4 = Smoke Detector R. A.

5 = Pwr’d Conv Outlet

Airflow

A = Standard Motor

B = Standard Motor/Economizer/Barometric Relief (Downflow only)

C = Standard Motor/Economizer/Power Exhaust (Downflow only)

D = Standard Motor/Motorized Damper (Downflow only)

E = Standard Motor/Horizontal Economizer (No Barometric Relief or Power Exhaust)

F = Standard Motor/Slab Economizer/Power Exhaust (Downflow only)

G = Standard Motor/Slab Economizer/Barometric Relief (Downflow only)

L = Standard Motor/BAS Ready Econ (NoBASController)/Barometric Relief w/2" Pleated Filters (Downflow only)

M = Standard Motor/BAS Ready Econ (NoBASController)/Power Exhaust w/2" Pleated Filters (Downflow only)

N = High Static Motor

P = High Static Motor/Economizer/Barometric Relief (Downflow only)

Q = High Static Motor/Economizer/Power Exhaust (Downflow only)

R = High Static Motor/Motorized Damper (Downflow only)

S = High Static Motor/Horizontal Economizer (No Barometric Relief or Power Exhaust)

T = High Static Motor/Slab Economizer/Power Exhaust (Downflow only)

U =High Static Motor/Slab Economizer/Barometric Relief (Downflow only)

Y = High Static Motor/BAS Ready Econ (NoBASController)/Barometric Relief w/2" Pleated Filters (Downflow only)

Z = High Static Motor/BAS Ready Econ (NoBASController)/Power Exhaust w/2" Pleated Filters (Downflow only)

6 Unitary Products Group

Page 7

035-17311-002-A-0803

NOMENCLA TURE, ADDITO NAL OPTIONS:

AA None

AB Phase Monitor

AC Coil Guard

AD Dirty Filter Switch

AE Phase Monitor & Coil Guard

AF Phase Monitor & Dirty Filter Switch

AG Coil Guard & Dirty Filter Switch

AH Phase Monitor, Coil Guard, & Dirty Filter Switch

CA CPC Controller with Dirty Filter Switch & Air Proving Switch

CB CPC Controller, DFS, APS & Phase Monitor

CC CPC Controller, DFS, APS & Coil Guard

CD CPC Controller, DFS, APS, Phase Monitor , & Coil Guard

CE CPC Controller, DFS, APS & Tech nico at Cond. Coil

CF CPC Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monitor

CG CPC Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard

CH CPC Controller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard

CJ CPC Controller, DFS, APS & Te ch nico at Evap. Coil

CK CPC Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor

CL CPC Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard

CM CPC Controller, DFS, APS, Technico at Evap. Coil, Phase Monitor, & Coil Guard

CN CPC Controller, DFS, APS & Technicoat Evap. & Cond Coils

CP CPC Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Phase Monitor

CQ CPC Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

CR CPC Controller, DFS, APS, Technicoat Cond Coils, Phase Monitor, & 2” Pleated Filters

CV CPC Controller, DFS, APS, & 2” Pleated Filters

CX CPC Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, Coil Guard

HA Hon ey w e ll Exc e l 10 C on troller with Dirty Fil ter Sw it ch & Air Pr ov in g Swit ch

HB Honeywe ll Excel 10 Controller, DFS, APS & Phase Monitor

HC Honeywell Excel 10 Controller, DFS, APS & Coil Guard

HD Honeywell Excel 10 Controller, DFS, APS, Phase Monitor, & Coil Guard

HE Honeywe ll Excel 10 Controller, DFS, APS & Technicoat Cond. Coil

HF Honeywell Excel 10 Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monito r

HG Honeywell Excel 10 Controller, DFS, APS, Techn icoa t Cond. Coi l, & Coil Guard

HH Honeywell Excel 10 Controller, DFS, APS, Technicoat Con d. Coil, Phas e Monit or, & Coil Guard

HJ Honeywe ll Excel 10 Contro ller, DFS, APS & Technicoat Evap. Coil

HK Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor

HL Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard

HM Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. Coil, Phase Monitor, & Coil Guard

Unitary Products Group 7

Page 8

HN H oneyw ell Exce l 10 Controller, DFS, APS & Technicoat Evap. & Cond Coils

HP Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Phase Monitor

HQ Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

HR Honeywell Excel 10 Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, & Coil Guard

JA Johnson UNT Controller with Dirty Filter Switch & Air Proving Switch

JB Johnson UNT Controller, DFS, APS & Phase Monitor

JC Johnson UNT Controller, DFS, APS & Coil Guard

JD Johnson UNT Controller, DFS, APS, Phase Monitor, & Coil Guard

JE Johnson UNT Controller, DFS, APS & Technico at Cond. Coil

JF Johnson UNT Contro ller, DFS, APS, Technicoat Cond. Coi l, & Phase Mon itor

JG Johnson UNT Controller, DFS, APS, Technicoat Con d. Coil, & Coil Guard

JH Johns on UNT Contro ller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard

JJ Johnson UNT Controller, DFS, APS & Technicoat Evap. Coil

JK Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, & Phase Monitor

JL Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, & Coil Guard

JM Johnson UNT Controller, DFS, APS, Technicoat Evap. Coil, Phase Monitor, & Coil Guard

JN Johnson UNT Controlle r, DFS, APS & Technicoat Evap. & Cond Coils

JP Johnson UNT Controller, DFS, APS, T echnicoat Evap. & Cond Coils, & Phase Monitor

JQ Johnson UNT Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

JR Johnson UNT Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, & Coil Guard

NA Novar ETC-3 Controller with Dirty Filter Switch & Air Proving Switch

NB Novar ETC-3 Controller, DFS, APS & Phase Monitor

NC Novar ETC-3 Controller, DFS, APS & Coil Guard

ND Novar ETC-3 Controller, DFS, APS, Phase Monitor, & Coil Guard

NE Novar ETC-3 Controller, DFS, APS & Technicoat Cond. Coil

NF Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, & Phase Monitor

NG Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, & Coil Guard

NH Novar ETC-3 Controller, DFS, APS, Technicoat Cond. Coil, Phase Monitor, & Coil Guard

NJ Novar ETC-3 Controller, DFS, APS & Technicoat Evap. Coil

NK Novar ETC-3 Cont rol ler, DFS, APS, Technicoa t Evap. Coil, & Phase M onito r

NL Novar ETC-3 Controlle r, DFS, APS, Technicoat Evap. Coi l, & Coil Guard

NM Novar ETC-3 Controller, DFS, APS, Technicoat Evap. Coi l, Phase Mo nitor, & Coil Guard

NN Novar ETC-3 Controller, DFS, APS & Technicoat Evap. & Cond Coils

NP Novar ETC-3 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Phase Monitor

NQ Novar ETC-3 Controller, DFS, APS, Technicoat Evap. & Cond Coils, & Coil Guard

NR Novar ETC-3 Controller, DFS, APS, Technicoat Evap. & Cond Coils, Phase Monitor, & Coil Guard

TA Technicoat Condenser Coil

TB Technicoat Condenser C oil & Phase Monitor

TC Technicoat Condenser Coil & Coil Guard

TD Technicoat Condenser Coil & Dirty Filter Switch

035-17311-002-A-0803

8 Unitary Products Group

Page 9

035-17311-002-A-0803

TE Technicoat Condenser Coil, Phase Monitor, & Coil Guard

TF Technicoat Condenser Coil, Phase Monitor, & Dirty Filter Switch

TG T echnicoat Condenser Coil, Coil Guard , & Dirty Filter Swit ch

TH Technicoat Condenser Coil, Phase Monitor, Coil Guard, & Dirty Filter Switch

TJ Technicoat Evaporator Coil

TK Technicoat Evaporator Coil & Phase Monitor

TL Technicoat Evaporator Coil & Coil Guard

TM Technicoat Evaporator Coil & Dirty Filter Switch

TN Technicoat Evaporator Coil, Phase Monitor, & Coil Guard

TP Technicoat Evaporator Coil, Phase Monitor, & Dirty Filter Switch

TQ Technicoat Evaporator Coil, Coil Guard, & Dirty Filter Switch

TR Technicoat Evaporator Coil, Phase Monitor, Coil Guard, & Dirty Filter Switch

TS Technicoat Evaporator & Condenser Coils

TT Technicoa t Evaporator & Condenser Coils & Phase Monitor

TU Technicoat Evaporator & Condenser Coils & Coil Guard

TV Technicoat Evaporator & Condenser Coils & Dirty Filter Switch

TW Technicoat Evaporator & Condenser Coils, Phase Monitor, & Coil Guard

TX Technicoat Evaporator & Co ndenser Coils, Phas e Monitor, & Dirty Filter Switch

TY Technicoat Evaporator & Co ndenser Coils, Coil Guard, & Dirty Filter Switch

TZ Technicoat Evaporat or & Conden ser Coils, Phase Moni tor, C oil Guar d, & Dirty Filter Switch

Unitary Products Group 9

Page 10

035-17311-002-A-0803

INSTALLATION

INSTALLATION SAFETY INFORMATION

Read these instructions before continuing this appliance

installation. This is an outdoor combination heating and cooling unit. The installer must assure that these instructions are

made available to the consumer and with instructions to

retain them for future reference.

1. Install this furnace only in a location and posi ti on as

specified on Page 11 of these instructions.

2. This equipment is not to be used for tempor ary heating

of building s or st ructures under construction.

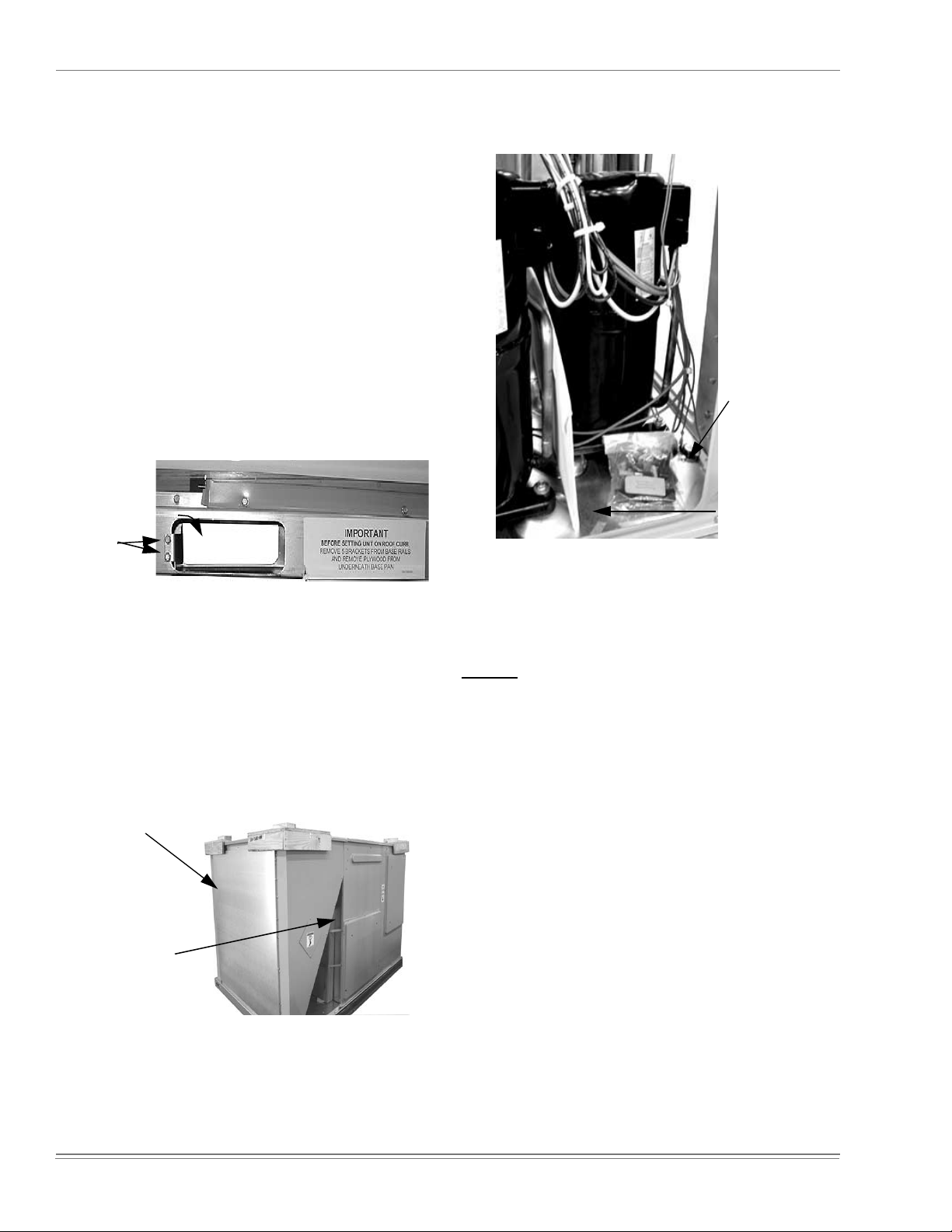

PRECEDING INSTALLATION

1. Remove the two screws holdi ng the bra ckets in the f ront,

rear and compressor side fork-lift slots.

Bracket

Screws

Turn down

Toolless

Doorknobs

Installation

Instruction

Packet

FIGURE 3 - COMPRESSOR SECTION

FIGURE 1 - UNIT SHIPPING BRACKET

2. Turn each bracket toward the ground and the protective

plywood cov e rin g w ill d ro p to the gr ound.

3. Remove the condenser coil external protective covering

prior to operati on.

4. Remove the toolless doorknobs and instruction packet

prior to installation.

Condenser

Coil External

Protective

Covering

Barometric

Relief Hood in

Shipping Location (if included)

FIGURE 2 - CONDENSER COVERING

LIMITATIONS

These units must be installed in accordance with the following:

In U.S.A.

1. National Electrical Code, ANSI/NFPA No. 70 - Latest

2. Local building codes, and

3. Local plumbing and waste water codes, and

4. Other applicable local codes.

Refer to Tables 1 & 2 for unit appli cation data.

If components are to be added to a unit to meet local codes,

they are to be installed at the dealer’s and/or customer’s

expense.

Size of unit for propos ed installation should be based on heat

loss/heat gain calculation made according to the methods of

Air Conditioning Contractors of America (ACCA).

:

Edition

10 Unitary Products Group

Page 11

035-17311-002-A-0803

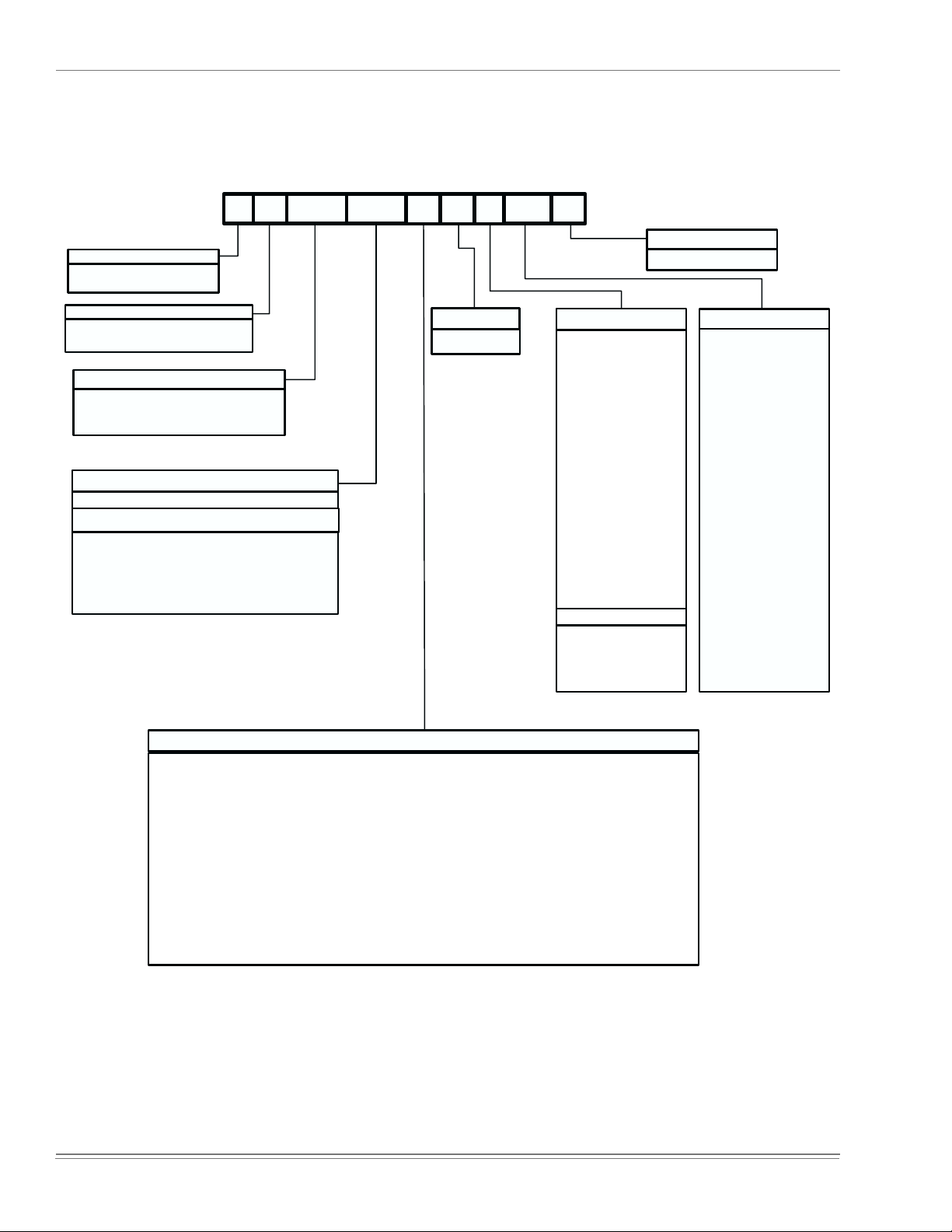

Terminal block for

hi-voltage connection

Simplicity™ Control board

w/screw connector

for T-stat wiring and

network connection

Disconnect location

(optional disconnect switch)

Filter access (2” throw-away)

Filter drier (solid

core)

Second model nameplate inside hinged

access panel

Dual stage

cooling for

max. com fort

Compressor #2

access (highefficiency compressor with

crankcase heater

Base rails w/forklift slots (3 sides)

and lifting holes)

Tool-less door

latch

Side entry power

and control wiring

knockouts

FIGURE 4 - PREDATOR® COMPONENT LOCATION

TABLE 1: UNIT VOLTAGE LIMITATIONS

Power Rating Minimum Maximum

380 350 418

TABLE 2: UNIT TEMPERATURE LIMITATIONS

Temperature Min. Max.

Wet Bulb T emperature (°F) of A i r on

Evaporator Coil

Dry Bulb Temperature (°F) of A ir o n

Condenser Coil

*.

A low ambient accessory is available for operation

57 72

*

0

125

down to - 20°F.

LOCATION

Use the following guidelines to select a suitable location for

these units:

1. Unit is designed for outdoor installation only.

2. Condenser coils must have an unlimited supply of air.

Where a choice of location is possible, positi on the unit

on either north or east side of building.

3. Suitable for mounting on roof curb.

Condenser

section

Belt-drive

blower motor

Slideout motor

& blower

assembly for

easy access

adjustment &

service

Compressor #1 access (highefficiency compressor w/

crankcase heater))

Slide-out drain pan

with steel 3/4” FPT

Roof curbs in eight- and fourteen-inch

heights. Roof curbs for transitioning from

York Sunline™ footprint to the DM

Series footprint are also available

(field-installed accessory)

connection

4. For ground level install ation, use a level concret e slab

with a minimum thickness of 4 inches. The length and

width should be at least 6 inches greater than the unit

base rails. Do not tie slab to the building foundation.

5. Roof structures must be able t o supp ort the weight of the

unit and its options/accessories. Unit must be installed

on a solid, level roof curb or appropriate angle iron

frame.

6. Maintain level tolerance to 1/2” across the entire width

and length of unit.

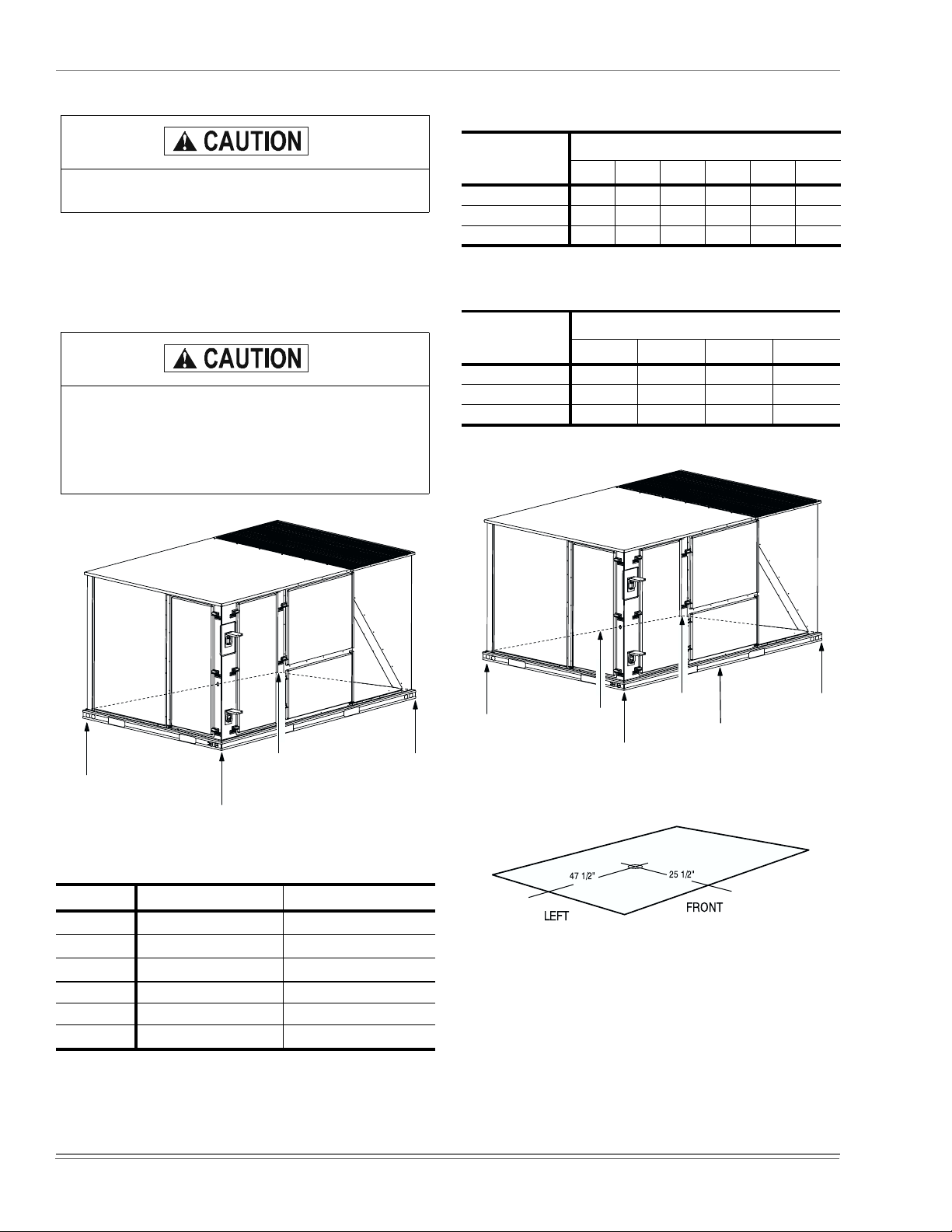

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig

the unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreader bars, whose length

exceeds the largest dimension across the unit, MUST be

used across the top of the unit.

If a unit is to be installed on a roof curb other than a

YORK roof curb, gasketing must be applied to all

surfaces that come in contact with the unit underside.

Unitary Products Group 11

Page 12

Before lifting, make sure the unit weight is distributed equall y on the riggin g cables so it wil l lift evenly.

Units may be moved or lifted with a forklift. Slotted openings

in the base rails are prov ided for this purpose.

035-17311-002-A-0803

TABLE 4: 6 POINT LOAD WEIGHT

Model

Location (lbs.)

ABCDEF

DM090

158 142 128 187 207 230

DM120 168 151 136 198 219 244

DM150 180 161 145 212 235 262

*.

Weights inc lude largest ga s he at op tion.

*

LENGTH OF FORKS MUST BE A MINIMUM OF 60

INCHES.

All panels must be secured in place when the unit is

lifted.

The condenser coils should be protected from rigging cable damage with plywood or other suitable

material.

L E F T

A

F R O N T

CB

TABLE 5: 4 POINT LOAD WEIGHT

Model

ABCD

DM090

230 197 287 336

DM120 245 209 305 357

DM150 262 224 327 382

*.

Weights inc lude largest ga s he at op tion.

L E F T

A

B

Location (lbs.)

C

E

F

FIGURE 6 - U NIT 6 POI N T LOAD

*

F R O N T

D

D

FIGURE 5 - UNIT 4 POINT LOAD

TABLE 3: UNIT WEIGHTS

Model

DM090 1056 1051

DM120

DM150 1200 1195

Econ. 85 84

w/ PE 150 148

Elec. Heat

*.

†.

Shipping Weight

2

Weights include largest gas heat option.

54kW heater.

*

1121 1116

49 49

Operating Weight

(lb.)

†

(lb.)

FIGURE 7 - UNIT CENTER OF GRAVITY

CLEARANCES

All units require particular clearances for proper operation

and service. Installer must make provisions for adequate

ventilation ai r in accordance with appli cable provisions of the

local building codes. Refer to Table 6 for clearances required

for combustible construction, servicing, and proper unit operation.

47 1/2"

LEFT

12 Unitary Products Group

25 1/2"

FRONT

Page 13

035-17311-002-A-0803

A

Do not permit overhanging structures or shrubs to

obstruct condenser air discharge outlet, combustion

air inlet or vent outlets.

3 0 - 1 1 / 3 2

5 0 - 3 / 4

P o w e r

E n t r y

Ø 2 - 1 / 2

C o n t r o l

E n t r y

Ø 7 / 8

4 - 1 / 4

3 0 - 3 / 1 6

5 9

L E F T

2 4 - 3 / 1 6

FIGURE 8 - UNIT DIMENSIONS

TABLE 6: UNIT CLEARANCES

*

Top

Front

†

Rear

*.

Units must be installed outdoors. Overhanging structure or shrubs should not obstr uct condenser air discharg e ou tlet.

†.

T o remove the slide-out drain pan, a rear clearance of

sixty in ches is required. If space is unavailable, the

drain pan can be removed through the fr ont by sepa rating the corner wall.

‡.

Units ma y be i nst al le d on com bu st ib le fl oo rs ma de f rom

wood or cl ass A, B or C roof covering materials.

DETAIL A

72” Right 12”

36”

36”

G a s P i p e I n l e t

Bottom

Left

1 7 - 3 / 1 6

‡

6 - 3 / 1 6

36”

0”

P o w e r

E n t r y

Ø 2 - 1 / 2

C o n v e n i e n c e

P o w e r

O u t l e t

E n t r y

Ø 7 / 8

2 7

F o r D r a i n

D i m e n s i o n s

S e e D e t a i l B

8 9

F R O N T

F o r B a s e r a i l

D i m e n s i o n s

S e e D e t a i l

NOTE: A one-inch clearance must be provided between

any combustible material and the supply ductwork

for a distance of 3 feet from the unit.

DETAIL B

3 - 3 / 4

2 - 3 / 8

3 - 9 / 1 6

DETAIL C

5 - 1 / 4

1 7 - 1 3 / 1 6

V i e w o f W a l l A c r o s s f r o m C o i l

B a s e

P a n

5 - 3 / 8

Unitary Products Group 13

Page 14

035-17311-002-A-0803

6

.

32-11/16

6-13/16

6-13/16

Return

Air

18

27-1/2

Bottom

Condensate

Entry

FRONT

63-1/2

21-3/16

19-3/16

17-3/16

LEFT

7-1/8

14-

23/32

16-3/8

18-1/16

19-5/8

FIGURE 9 - BOTTOM DUCT OPENINGS (FROM ABOVE)

Supply

Air

21

Bottom

Power, Control

Convenience

Outlet Wiring

Entries

and

24

6-13/16

Bottom Gas

Supply Entry

12-15/1

1 8 - 1 / 4

5 - 5 / 3 2

FIGURE 10 - REAR DUCT DIMENSIONS

2 8 - 1 / 4

S u p p l y

A i r

D o t P l u g s

R e t u r n

A i r

1 8 - 1 / 4

P a t c h P l a t e

F o r S l i d e - O u t

D r a i n P a n

2 - 3 1 / 3 2

3 1 - 1 1 / 1 6

2 8 - 1 / 4

1 8 - 1 / 1 6

14 Unitary Products Group

Page 15

035-17311-002-A-0803

DUCTWORK

Ductwork should be designed and sized according to the

methods in Manual D of the Air Conditioning Contractors of

America (ACCA) or as recommended by any other recognized authority such as ASHRAE or SMACNA.

A closed return duct system should be used. This will n ot

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

made wit h fl exib le joints to minim iz e noi s e.

The supply and return air duct systems should be designed

for the CFM and static press ure requi rement s of the job. They

should NOT be sized to match the dimensions of the duct

connections on t he unit.

Refer to 9 for bottom air duct openings. Refer to Figure 10 for

rear air duct openings.

8 0 - 5 / 8

2 0

2 0

6

DUCT COVERS

Units are shipped with the side duct openings covered and a

covering over the bottom of the unit. For bottom duct application, no duct cover changes are necessary. For side duct

application, remove the side duct covers and install over the

bottom duct openings. The panels removed from the side

duct connecti ons are designed to be reused by securing each

panel to its respective downflow opening. But keep in mind

that the supply panel is installed with the painted surface UP,

facing the heat exchanger, while the return panel is installed

with the painted surface DOWN, facing the downflow duct

opening. The supply panel is secured with the bracket

(already in place from the facto ry) and two screws. I t’s a snug

fit for the panel when sliding it between the heat exchanger

and unit bottom, but there is room. The return panel is

secured with four screws .

R I G H T

I N S U L A T E D D E C K U N D E R

C O N D E N S E R S E C T I O N

S U P P L Y

2 T Y P .

3 0

5 0 - 1 / 2

R E T U R N

FIGURE 11 - PREDATOR® ROOF CURB DIMENSIONS

5 0 - 1 / 2

7 6 - 5 / 8

F R O N T

3 0 - 1 / 2

R E T U R N

9 4

2 T Y P

8 o r 1 4

I N S U L A T E D D E C K U N D E R

C O M P R E S S O R S E C T I O N

F R O N T

2 3

4

S U P P L Y

5 9 - 1 / 4

6 4 - 1 / 4

8 0 - 5 / 8

1 0

R I G H T

2 6

FIGURE 12 - SUNLINE™ TO PREDATOR® TRANSITION ROOF CURBS

Unitary Products Group 15

Page 16

When fastening ductwork to side duct flanges on

unit, insert screws through duct flanges only. DO

NOT insert screws through casing. Outdoor ductwork must be insulated and water-proofed.

FIGURE 13 - SIDE PANELS WITH HOLE PLUGS

Note orientation. Panel is “insulation” side up.

035-17311-002-A-0803

CONDENSATE DRAIN

The side condensate drain is reversible and maybe re-oriented to the rear of the cabinet to facilitate condensate piping. A condensate drain connection is available through the

base pan for piping inside the roof curb. Trap the connection

per Figure 16. The trap and drain lines should be protected

from freezing.

Plumbing must conform to local codes. Use a sealing compound on male pipe threads. Install condensate drain line

from the 3/4 inch NPT female connection on the unit to an

open drain.

O P T I O N A L C O I L

G U A R D

3 " M i n i m u m

FIGURE 14 - RETURN DOWNFLOW PLENUM WITH

PANEL

FIGURE 16 - CONDENSATE DRAIN

COMPRESSORS

The comp ress ors are moun te d on e las tom er in sula tor s. T he

mounting bolt s have been fully tightened fo r shi pping.

Do not loosen the compressor mounting bolts.

FILTERS

Two-inch filters are supplied with each unit. One-inch filters

may be used with no modification to the filter racks. Filters

must always be installed ahead of evaporator coil and must

be kept clean or replaced with same size and type. Dirty filters reduce the capacity of the unit and result in frosted coils

or safety shutdown. All units use four (4) 20”x25”x2” filters.

The unit should not be operated without filters properly

installed.

Make sure that panel latches are properly positioned

FIGURE 15 - DISCHARGE PANEL IN PLACE

on the unit to maintain an airtight seal.

16 Unitary Products Group

Page 17

035-17311-002-A-0803

THERMOSTAT WIRING

The thermostat should be located on an inside wall approximately 56 inches above the floor where it will not be subject

to drafts, sun exposure or heat from electrical fixtures or

appliances. Follow the manufacturer's instructions enclosed

with thermostat for general installation procedure. Seven (7)

color-coded, insulated wires should be used to connect the

thermostat to the unit. Refer to Table 7 for control wire sizing

and maximum length.

TABLE 7: CONTROL WIRE SIZES

Wire Size

18 AWG

*.

From the unit to the thermostat and back to the unit.

Maximu m L en gt h

150 Feet

*

POWER AND CONTROL WIRING

Field wiring to the unit, fuses, and disconnects must conform

to provisions of National Electrical Code (NEC), ANSI/NFPA

No. 70 – Latest Edition (in U.S.A.), current Canadian Electrical Code C221, and/or local ordinances. The unit must be

electrically grounded in accordance with NEC and CEC as

specified above and/or local codes.

Voltage tolerances which must be maintained at the compressor terminals during starting and running conditions are

indicated on the unit Rating Plate and Table 1.

The internal wiring harnesses furnished with this unit are an

integral part of the design certified unit. Field alteration to

comply with electrical codes should not be required. If any of

the wire supplied wi th the unit must be replaced, replacement

wire must be of the type shown on th e wiring diagram and the

same minimum gauge as the replaced wire.

A disconnect must be utilized for these units. Factory

installed disconnects are available. If installing a disconnect

(field supplied or York International

refer to Figure 4 for the recommended mounting location.

supplied accessory),

Avoid damage to internal components if drilling

holes for disconnect mounting.

NOTE: Since not all local codes allow the m ounting of a dis-

connect on the unit, please confirm compliance with

local code before mounting a disconnect on the unit.

Electrical line must be sized properly to carry the load. USE

COPPER CONDUCTORS ONLY. Each unit must be wired

with a separate branch circuit fed directly from the meter

panel and properl y fused.

Refer to Figures 17, 18 and 19 for typical field wiring and to

the appropriate unit wiring diagram mounted inside control

doors for control ci rcuit and power wiring infor ma ti on.

When connecting electrical power and control wiring

to the unit, water-proof connectors must be used so

that water or moisture cannot be drawn into the unit

during normal operation. The above water-proofing

conditions will also apply when installing a field supplied disconnect switch.

POWER WIRING DETAIL

Units are factory wired for the voltage shown on the unit

nameplate. Refer to Electrical Data Tables 8 through 13 size

power wiring, fuses, and disconnect switch.

Power wiring is brought into the unit through the side of the

unit or the basep an inside the curb.

Unitary Products Group 17

Page 18

035-17311-002-A-0803

2

T H E R M O S T A T

T E R M I N A L S

R C

R H

Y 1

Y 2

W 1

W 2

G

C

X 1

X 3

X 4

A 1

A 2

T

T

1

E l e c t r o n i c p r o g r a m m a b l e T h e r m o s t a t 2 E T 0 7 7 0 0 1 0 0 2 4 ( i n c l u d e s s u b b a s e ) .

T e r m i n a l s A 1 a n d A 2 p r o v i d e a r e l a y o u t p u t t o c l o s e t h e o u t d o o r

e c o n o m i z e r d a m p e r s w h e n t h e t h e r m o s t a t s w i t c h e s t o t h e s e t - b a c k p o s i t i o n .

1

T O R E M O T E S E N S O R

2 E T 0 4 7 0 1 3 2 4 I F U S E D

2

FIGURE 17 - ELECTRONIC THERMOSTAT FIELD WIRING

U N I T T E R M I N A L S

S T R I P T B 1

R

Y 1

Y 2

W 1

W 2

G

C

X

O C C

2 4 V o l t

T r a n s f o r m e r

T - S T A T

W 1

W 2

Y 1

G

Y 2

C

R H

R C

W 1

W 2

Y 1

O C C

M I N P O S

Y 2

S D

FIGURE 18 - FIELD WIRING 24 VOLT THERMOSTAT

G

R E M O T E

U N I T C O N T R O L

B O A R D

X

R

C

18 Unitary Products Group

Page 19

035-17311-002-A-0803

Y

RLALR

AFLA

1.5 2 1.5 2 1.5 2 1.5 2 1.5 2

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

None -- -- 20.7 21.7 22.9 23.9 25 25 25 30

2TP04520950 5.6 8.5 20.7 21.7 22.9 23.9 25 25 25 30

2TP04521850 11.3 17.2 25.3 26.6 28.1 29.3 30 30 30 30

2TP04522450 15 22.8 32.4 33.6 35.1 36.4 35 35 40 40

2TP04523650 21.3 32.4 44.3 45.6 47.1 48.3 45 50 50 50

* Maximum HACR breaker of the same AMP size is applicable.

0.0

Max

Fuse*

Size

(Amps)

Max Fuse*

Size

w/Power

Exhaust

3.1 4.1 2.2

ActualKWHeater

Amps

Min.

Circuit

Ampacity

(Amps)

380

7.1 54.0 0.8

MCA

w/Power

Exhaust

(Amps)

Pwr

Exh

Motor

Pwr

Conv

Outlet

Electric Heater

Model No.

FLA FLA

Voltage

Compressors

OD Fan

Motors

Supply

Blower

Motor FLA

AFLA

T E R M I N A L B L O C K T B 1

G R O U N D

L U G

F A C T O R Y O R F I E L D

S U P P L I E D D I S C O N N E C T

T H R E E

P H A S E

P O W E R

S U P P L

FIGURE 19 - FIELD WIRING DISCONNECT

TABLE 8: ELECTRICAL DATA - DM090 (7-1/2 TON) WITHOUT POWER CONVENIENCE OUTLET

TABLE 9: ELECTRICAL DATA - DM090 (7-1/2 TON) WITH POWER CONVENIENCE OUTLE T

Voltage

Unitary Products Group 19

Compressors

RLALR

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

380

7.1 54.0 0.8

Maximum HACR breaker of the same AMP size is applicable.

*

OD Fan

Motors

Motor FLA

Supply

Blower

1.5 2 1.5 2 1.5 2 1.5 2 1.5 2

3.1 4.1 2.2 6.3

Motor

Pwr

Pwr

Exh

Conv

Outlet

FLA FLA

Electric Heater

Model No.

None -- -- 27 28 29.2 30.2 30 35 35 35

2TP04520950 5.6 8.5 27 28 29.2 30.2 30 35 35 35

2TP04521850 11.3 17.2 33.2 34.5 36 37.2 35 35 40 40

2TP04522450 15 22.8 40.2 41.5 43 44.2 45 45 45 45

2TP04523650 21.3 32.4 52.2 53.5 55 56.2 60 60 60 60

Actual

KW

Heater

Amps

Min.

Circuit

Ampacity

(Amps)

MCA

w/Power

Exhaust

(Amps)

Fuse*

(Amps)

Max

Size

Max Fuse*

Size

w/Power

Exhaust

Page 20

035-17311-002-A-0803

AFLA

AFLA

AFLA

A

TABL E 10: ELECTRICAL DATA - DM120 (10 TON) WI THOUT POWER CONVENIENCE OUTLET

Voltage

Compressors

RLALR

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

11.5 75.0 1.6

380

* Maximum HACR breaker of the same AMP size is applicable.

OD Fan

Motors

Supply

Blower Motor

FLA

2 3 2323232 3

4.1 5.3 2.2

Pwr

Exh

Motor

FLA FLA

Pwr

Conv

Outlet

0.0

Min. Circuit

Electric Heater

Model No.

None -- -- 33.2 34.4 35.4 36.6 40 45 45 45

2TP04521850 11.3 17.2 33.2 34.4 35.4 36.6 40 45 45 45

2TP04522450 15 22.8 33.6 35.1 36.4 37.9 40 45 45 45

2TP04523650 21.3 32.4 45.6 47.1 48.3 49.8 50 50 50 50

2TP04525450 33.8 51.4 69.3 70.8 72.1 73.6 70 80 80 80

ActualKWHeater

Amps

Ampacity

(Amps)

MCA

w/Power

Exhaust

(Amps)

Fuse*

(Amps)

TABL E 11: ELECTRICAL DATA - DM120 (10 TON) WITH POWER CONVENIENCE OUTLET

Voltage

Compressors

RLALR

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

11.5 75.0 1.6 4.1 5.3 2.2 6.3

380

*

Maximum HACR breaker of the same AMP size is applicable.

OD Fan

Motors

Supply

Blower Motor

FLA

2 3 2323232 3

Pwr

Exh

Conv

Motor

Outlet

FLA FLA

Heater

Amps

Min. Circuit

Ampacity

(Amps)

Pwr

Electric Heater

Model No.

None -- -- 39.5 40.7 41.7 42.9 50 50 50 50

2TP04521850 11.3 17.2 39.5 40.7 41.7 42.9 50 50 50 50

2TP04522450 15 22.8 41.5 43 44.2 45.7 50 50 50 50

2TP04523650 21.3 32.4 53.5 55 56.2 57.7 60 60 60 60

2TP04525450 33.8 51.4 77.2 78.7 79.9 81.4 80 80 80 90

Actual

KW

MCA

w/Power

Exhaust

(Amps)

Fuse*

(Amps)

Max

Size

Max

Size

Max Fuse*

Size

w/Power

Exhaust

Max Fuse*

Size

w/Power

Exhaust

TABLE 12: ELECTRICAL DATA - DM150 (12-1/2 TON) WITHOUT POWER CONVENIENCE OUTLET

Voltage

Compressors

RLALR

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

380

9.6 79.0 1.6

* Maximum HACR breaker of the same AMP size is applicable.

OD Fan

Motors

Supply

Blower

Motor FLA

3 5 3535353 5

5.3 8.1 2.2

Pwr

Exh

Conv

Outlet

Motor

FLA FLA

Pwr

Min.

Electric Heater

Model No.

None -- -- 30.1 32.9 32.3 35.1 35 40 40 40

2TP04521850 11.3 17.2 30.1 32.9 32.3 35.1 35 40 40 40

0.0

2TP04522450 15 22.8 35.1 38.6 37.9 41.4 40 40 40 45

2TP04523650 21.3 32.4 47.1 50.6 49.8 53.3 50 60 50 60

2TP04525450 33.8 51.4 70.8 74.3 73.6 77.1 80 80 80 80

ActualKWHeater

Amps

Circuit

Ampacity

(Amps)

MCA

w/Power

Exhaust

(Amps)

Max

Fuse*

Size

(Amps)

TABL E 13: ELECTRICAL DATA - DM150 (12-1/2 TON) WI TH POWER CONVENIENCE OUTLET

Voltage

380

*

Compressors

RLALRAFL

ea. ea. ea. HP HP HP HP HP HP HP HP HP HP

9.6 79.0 1.6 5.3 8.1 2.2 6.3

Maximum HACR breaker of the same AMP size is applicable.

OD Fan

Motors

Supply

Blower Motor

FLA

3 5 35353535

Pwr

Exh

Conv

Motor

Outlet

FLA FLA

Pwr

Electric Heater

Model No.

None -- -- 36.4 39.2 38.6 41.4 45 45 45 50

2TP04521850 11.3 17.2 36.4 39.5 38.7 42.2 45 45 45 50

2TP04522450 15 22.8 43 46.5 45.7 49.2 45 50 50 50

2TP04523650 21.3 32.4 55 58.5 57.7 61.2 60 60 60 70

2TP04525450 33.8 51.4 78.7 82.2 81.4 84.9 80 90 90 90

Actual

KW

Heater

Amps

Min. Circuit

Ampacity

(Amps)

MCA

w/Power

Exhaust

(Amps)

Max

Fuse*

Size

(Amps)

Max Fuse*

Size

w/Power

Exhaust

Max Fuse*

Size

w/Power

Exhaust

20 Unitary Products Group

Page 21

035-17311-002-A-0803

TABLE 14: PHYSICAL DATA

Evaporator

Blower

Evaporator

Coil

Condenser

Fan

(2 per Unit)

Condenser

Coil

(2 per unit)

Refrigerant

Charge

Compressors

Air Filters

DM

DM

DM

DM

DM

Component

Models

090 120 150

Blower, Centrifuga l (Dia. X Wd. in.) 15 x 15 15 x 15 15 x 15

Motor, Stan dard (HP) 1-1/2 2 3

Motor, Optional (HP) 2 3 5

Rows 2 2 3

Fins per Inch 15 15 15

Height (in.) 32 40 40

2

Face Area (ft.

Propeller Dia. (in., each) 24 24 24

Motor (HP, each) 1/3 3/4 3/4

CFM, Nominal (each) 3400 4400 4400

Rows (each) 1 1 2

Fins per Inch 20 20 20

Height (in. each) 28 44 44

Face Area (ft.

System 1 (lb./o z. ) 4/12 6/12 10/12

System 2 (lb./oz.) 4/6 6/12 9/8

Quantity 222

Size (Wd. x Ht. x Thickness in.) 25x20x2 25x20x2 25x20x2

Number Per Unit 4 4 4

each)

2

each)

Type Recip Recip Recip

10.6 13.2 13.2

9.2 14.5 14.5

OPTIONS/ACCESSORIES

ELECTRIC HEAT ACCESSORIES

Electric heaters are available as field installed accessories.

Refer to electric heat instructions for installation. These heaters mount in the he at compartment with the heating elements

extending into the supply air chamber. All electric heaters are

fused and intended for use with single point power supply.

ELECTRIC HEAT OPTION

The factory-installed heaters are wired for single point power

supply. Power supply need only be brought into the single

point termin al bl ock.

These CSA approved heaters are located within the central

compartment of the unit with the heater elements extending

into the supply air chamber.

Fuses are suppli ed, where required, by the factory . Some kW

sizes require fuses and other do not. Refer to Table 15 for

minimum CFM lim itations and to Tables 8 t hrough 13 for el ectrical data.

TABLE 15: MINIMUM SUPPLY AIR CFM

Heater Unit Model Size, Nominal Tons

kW Voltage

9

18 2250 3000 3750

24 2250 3000 3750

36 2250 3000 3750

54 N/A 3000 3750

380

MOTORIZED OUTDOOR DAMPER

The Motorized Outdoor Damper can be a factory installed

option or a field installed accessory. If factory installed, refer

to the instructions included with the outdoor air hood to complete the assembly. Field installed Motorized Outdoor

Damper accessories include complete instructions for installation.

7.5 10 12.5

Minimum Supply Air CFM

2250 N/A N/A

Unitary Products Group 21

Page 22

035-17311-002-A-0803

ECONOMIZER

The Economizer can be a factory installed option or a field

installed accessory. If factory installed, refer to the instructions included with the outdoor air hood to complete the

assembly. Field installed Economizer accessories include

complete instructions for installation.

There are two Economizer options:

1. Down Flow application with barometric relief hood

standard.

2. Horizontal Flo w application that requires the purchase of

a barometric relief hood.

POWER EXHAUST

The Power Exhaust can be a factory installed option or a field

installed accessory. If factory installed, refer to the instructions included with the outdoor air hood to complete the

assembly. Field installed Power Exhaust accessories include

complete instructions for installation.

The Power Exhaust factory installed option is for Down Flow

application only.

There are two field in stalled Power Exhaust accessories:

1. Down Flow application.

2. Horizontal Flo w application that requires the purchase of

a barometric relief hood.

RAIN HOOD

All of the hood components, including the filters, the gasketing and the hardware for assembling, are packaged and

located between the condenser coil section and the main unit

cabinet, if the unit has factory installed options. If field

installed accessories are being installed all parts necessary

for the installation comes in the accessory .

ON position and then OFF or energize and de-energize

termi na ls “R ” to “G”.

• With the thermostat set to the indoor fan ON position or

terminals “R” to “G” ener gized, turn the Minimum Position Adjusting scr ew (l ocated on the damper control

module) counterclockwise until the desired mini m um

damper position has been attained.

ENTHALPY SET POINT ADJUSTMENT

The enthalpy set point may now be set by selecting the

desired set point shown in the Enthalpy Set Point Adjustment

Figure 20. Adjust as follows:

• For a single enthalpy operation carefully turn the set

point adjusting screw (found on the damper control mod ule) to the "A", "B", "C" or "D" setting corresponding to

the lettered curve of the Enthalpy Set Point Adjustment

Figure 20.

• For a dual enthal py operati on, car efull y turn the set point

adjusting screw fully clockwise past the "D" setting.

POWER EXHAUST DAMPER SET POINT (WITH OR WITHOUT POWER EXHAUST)

• With no power exhaust option, adjust the Exhaust Air

Adjustment Screw fully clockwise. This will allow 2nd

stage cooling to operate.

• With power exh aust option, each buildi ng pressurization

requirement will be different. The point at which the

power exhaust comes on is dete rmined by the economizer damper position (Percent Open). The Exhaust Air

Adjustment Screw should be set at the Percent Open of

the economizer damper at which the power exhaust is

needed. It can be set from 0 to 100% dampe r open.

INDOOR AIR QUALITY AQ

ECONOMIZER AND POWER EXHAUST SET POINT

ADJUSTMENTS AND INFORMATION

Remove the top rear access panel from the unit. Locate the

economizer control module, where the following adjustments

will be made.

Indoor Air Quality (indoor sensor input): Terminal AQ accepts

a +2 to +10 Vdc signal with respect to the (AQ1) terminal.

When the signal is below it's set point, the act uator is allowed

to modulate normally in accordance with the enthalpy and

mixed air sensor inputs. When the AQ signal exceeds it's set

point setting and there is no call for free cooling, the actuator

is proportionat ely modulated from the 2 to 10 Vdc signal, with

2 Vdc corresponding to full closed and 10 Vdc corresponding

to full open. When there is no call for free coolin g, the damper

position is limited by the IAQ Max damper position setting.

Extreme care must be exercised in turning all set

point, maximum and minimum damper positioning

adjustment screws to prevent twisting them off.

When the signal exceeds it's set point (Demand Control Ven-

tilation Set Point) setting and there is a call for free cooling,

the actuator modulates from the minimum position to the full

open position based on the highest call from either the mixed

MINIMUM POSITION ADJUSTMENT

• Check that the damper blades move smoothly wi thout

binding; care fully turn the Minimum Position Adjust

screw (found on the damper control module) fully clockwise and then set the t hermostat indoor fan switch t o the

air sensor input or the AQ voltage input.

• Optional CO

• Optional CO

Space Sensor Kit Part # 2AQ04700324

2

Sensor Kit Part # 2AQ04700424

2

Replace the top rear access panel on the unit.

22 Unitary Products Group

Page 23

035-17311-002-A-0803

CONTROL

CURVE

A

B

C

D

CONTROL POINT

APPROX.

0

F (0C)

AT 50% RH

73 (23)

70 (21)

67 (19)

63 (17)

45

(7)

40

(4)

35

(2)

50

(10)

110

100

95

85

55

(13)

60

(16)

90

(29)

(32)

80

(27)

75

(24)

70

(21)

65

(18)

A

(35)

(38)

105

(41)

(43)

B

C

D

40

35

(2)

(4)45(7)

APPROXIMATE DRY BULB TEMPERATURE - 0F (0C)

FIGURE 20 - ENTHALPY SET POINT CHART

Exhaust Air

Adjustment

Screw

Exhaust Air LED

Damper Min.

Position

Screw

Indoor Air Quality

Max. Adjustment

Screw

Indoor Air Quality

LED

Indoor Air Quality

Min. Adjustment

Screw

Free Cooling LED

Economizer Enthalpy

Set Point Adjustment

Screw

SO+ SO

50

(10)55(13)

N

N1

P1

P

T1

T

AQ1 AQ

SR

SR+

65

70

60

(21)

(16)

(18)

EXH

Set

EXH

Min

Pos

IAQ

Max

IAQ

IAQ

Min

Free

Cool

BC

A

D

C

D

75

(24)80(27)

A

B

95

105

85

(29)

90

(32)

100

(38)

(35)

TR TR1

24

Vac

HOT

(41)

24

Vac

COM

110

(43)

+

1

3

EF EF1

2

5

4

FIGURE 21 - HONEYWELL ECONOMIZER CONTROL W7212

Unitary Products Group 23

Page 24

PHASING

Predator® units are properly phased at the factory. Check for

proper compressor rotation. If the blower or compressors

rotate in the wrong direction at st art-up, the electr ical connection to the unit is misphased. Change the phasing of the Field

Line Connection at the factory or field supplied disconnect to obtain proper rotation. (Scroll compressors operate in

only one direction. If the scroll is drawing low amperage, has

similar suction and discharge pressures, or producing a high

noise level, the scroll is misphased.)

Scroll compressors require proper rotation to operate correctly. Units are properly phased at the factory. Do not change the internal wiring to make the

blower condenser fans, or compressor rotate correctly.

035-17311-002-A-0803

A

C*

* NEVER LOOSEN

A

B

SPAN LENGTH

DEFL. FORCE

A

BLOWER ROTATION

Check for proper supply air blower rotation. If the blower is

rotating backwards, the line voltage at the unit point of power

connection is misphased (See ‘PHASING’).

TABLE 16: SUPPLY AIR LIMITATIONS

Unit Size Minimum Maximum

090

120 3000 5000

150 3750 6250

2250 3750

BELT TENSION

The tension on the belt should be adjusted as shown in

Figure 22.

FIGURE 22 - BELT ADJUSTMENT

Procedure for adjusting belt tension:

1. Loosen six nuts (top and bottom) A.

2. Adjust by turning (B).

3. Ne ver loosen nuts (C).

4. Use belt tension checker to apply a perpendicular

force to one belt at the mid point of the span as

shown. Deflection distance of 4mm (5/32”) is

obtained.

To determine the deflection distance from normal

position, use a straight edge from sheave to sheave

as reference line. The recommended deflection

force is as fo llo w s :

Tension new belts at the max. deflection force recommended for the belt section. Check the belt tension at least two times during the first 24 hours of

operation. Any retensioning should fall between the

min. and max. deflection force values.

5. After adjusting retighten nuts (A).

24 Unitary Products Group

Page 25

035-17311-002-A-0803

††

W

†

BHP CFM

††

W

TABLE 17: 7-1/2 TON STANDARD MOTOR DOWN SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.2

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - 3715 1573 1.69 3634 1434 1.54 3431 1265 1.36 3218 901 0.97 3024 976 1.05

††

W

BHP CFM

††

W

BHP CFM

0.4 3650 1657 1.78 3510 1490 1.60 3320 1313 1.41 3079 1145 1.23 2832 810 0.87 2586 860 0.92

0.6 3334 1522 1.63 3146 1351 1.45 2910 1169 1.25 2621 1005 1.08 2307 706 0.76 - - -

0.8 2903 1352 1.45 2622 1167 1.25 2404 1013 1.09 2054 858 0.92 - - - - - -

1.0 2356 1159 1.24 - - - - - - - - - - - - - - -

*.

Blowe r performance for gas heat includes maximum number of heat tubes available for each tonnage.

†.

Blowe r performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have been

deducted from the total static pressure of the blower.

**.

“Tur ns Open” refers to the setting of the variable pitch motor sheave, where “0 Turns Open” is fully closed.

††.

W = Watts

††

W

†

BHP CFM

††

W

TABLE 18: 7-1/2 TON OPTIONAL MOTOR DOWN SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.2

0.4

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - - - - - - - - - - 3992 1904 2.04 3798 1679 1.80

- - - - - - - - - 3930 2017 2.16 3734 1786 1.92 3486 1552 1.66

††

W

BHP CFM

††

W

BHP CFM

0.6 - - - - - - 3947 2176 2.33 3670 1895 2.03 3394 1641 1.76 3084 1401 1.50

0.8

- - - 4138 2384 2.56 3623 2009 2.15 3323 1742 1.87 2971 1477 1.58 2591 1236 1.33

1.0 4126 2430 2.61 3643 2145 2.30 3224 1820 1.95 2889 1569 1.68 2466 1306 1.40 - - -

3613 2238 2.40 3143 1921 2.06 2748 1621 1.74 2369 1385 1.49 - - - - - -

1.2

1.4 3099 2039 2.19 2636 1714 1.84 2195 1424 1.53 - - - - - - - - -

258618331.97---------------

1.6

*.

Blowe r performance for gas heat includes maximum number of heat tubes available for each tonnage.

†.

Blowe r performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have been

deducted from the total static pressure of the blower.

**.

“Tur ns Open” refers to the setting of the variable pitch motor sheave, where “0 Turns Open” is fully closed.

††.

W = Watts

BHP

BHP

Unitary Products Group 25

Page 26

035-17311-002-A-0803

TABLE 19: 10 TON STANDARD MOTOR DOWN SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.2

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - - - - - - - 3896 1639 1.76 3688 1453 1.56 3447 1268 1.36

††

W

BHP CFM

††

W

BHP CFM

†

††

W

BHP CFM

††

W

0.4 4040 2076 2.23 4005 1934 2.07 3790 1698 1.82 3569 1508 1.62 3333 1330 1.43 3057 1147 1.23

0.6 3890 2006 2.15 3697 1790 1.92 3427 1550 1.66 3152 1356 1.45 - - - - - -

0.8 3620 1882 2.02 3324 1629 1.75 2972 1380 1.48 - - - - - - - - -

1.0 3227 1708 1.83 - - - - - - - - - - - - - - -

*.

Blower performance for gas h eat includes maximum number of heat tubes available for each to nnage.

†.

Blower performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have be en

deduct ed from the total static pressure of the blower.

**.

“Turns Open” refe rs to the setti ng of the varia bl e pit ch mot or sh eave , whe r e “0 Turns Open” is fu lly close d .

††.

W = Watts

TABLE 20: 10 TON OPTIONAL MOTOR DOWN SHOT BLOWER PERFORMANCE*

TURNS OPEN

‡

ESP

CFM

4965 3485 3.74 4875 3150 3.38 4613 2739 2.94 4322 2374 2.55 4156 2106 2.26 3907 1860 1.99

0.4

012345

††

W

BHP CFM

††

W

BHP CFM

††

W

BHP CFM

**

††

BHP CFM

W

†

††

W

BHP CFM

††

W

0.6 4876 3416 3.66 4651 2997 3.21 4359 2582 2.77 4038 2220 2.38 3860 1966 2.11 3590 1724 1.85

4713 3291 3.53 4387 2823 3.03 4077 2417 2.59 3719 2059 2.21 3541 1827 1.96 3242 1584 1.70

0.8

1.0 4476 3116 3.34 4084 2632 2.82 3768 2245 2.41 3365 1892 2.03 3197 1691 1.81 - - -

4165 2898 3.11 3741 2427 2.60 3432 2070 2.22 - - - - - - - - -

1.2

1.4 3779 2646 2.84 3359 2212 2.37 3069 1895 2.03 - - - - - - - - -

3319 2372 2.54 - - - - - - - - - - - - - - -

1.6

*.

Blower performance for gas h eat includes maximum number of heat tubes available for each to nnage.

†.

Blower performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have be en

deduct ed from the total static pressure of the blower.

**.

“Turns Open” refe rs to the setti ng of the varia bl e pit ch mot or sh eave , whe r e “0 Turns Open” is fu lly close d .

††.

W = Watts

BHP

BHP

26 Unitary Products Group

Page 27

035-17311-002-A-0803

††

W

†

BHP CFM

††

BHP

W

TABLE 21: 12-1/2 TON STANDARD MOTOR DOWN SHOT BLOWER PERFORMANCE*

TURNS OPEN

‡

ESP

CFM

0.4

5078 3630 3.89 4809 3103 3.33 4594 3053 3.27 4360 2478 2.66 4090 2093 2.24 3812 1798 1.93

012345

††

W

BHP CFM

††

W

BHP CFM

††

W

BHP CFM

**

††

BHP CFM

W

0.6 4865 3456 3.71 4584 2961 3.17 4349 2912 3.12 4106 2318 2.49 3814 1964 2.11 - - -

0.8 4642 3284 3.52 4356 2828 3.03 4089 2776 2.98 3840 2137 2.29 - - - - - -

1.0 4408 3114 3.34 4124 2705 2.90 3815 2647 2.84 - - - - - - - - -

1.2 4164 2947 3.16 3889 2592 2.78 - - - - - - - - - - - -

1.4 391027872.99---------------

*.

Blowe r performance for gas heat includes maximum number of heat tubes available for each tonnage.

†.

Blowe r performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have been

deducted from the total static pressure of the blower.

**.

“Tur ns Open” refers to the setting of the variable pitch motor sheave, where “0 Turns Open” is fully closed.

††.

W = Watts

††

W

†

BHP CFM

††

BHP

W

TABLE 22: 12-1/2 TON OPTIONAL MOTOR DOWN SHOT BLOWER PERFORMANCE*

TURNS OPEN

‡

ESP

CFM

5994 5400 5.79 5565 4369 4.69 5488 4169 4.47 5264 3599 3.86 4990 3085 3.31 4738 2812 3.02

0.4

012345

††

W

BHP CFM

††

W

BHP CFM

††

W

BHP CFM

**

††

BHP CFM

W

0.6 5824 5216 5.59 5368 4186 4.49 5289 3991 4.28 5049 3437 3.69 4763 2937 3.15 4491 2655 2.85

5641 5022 5.39 5170 4012 4.30 5076 3807 4.08 4822 3272 3.51 4528 2790 2.99 4235 2497 2.68

0.8

1.0 5444 4819 5.17 4971 3846 4.12 4847 3618 3.88 4584 3103 3.33 4286 2644 2.83 3969 2340 2.51

5233 4609 4.94 4771 3687 3.95 4604 3426 3.67 4335 2933 3.15 4035 2499 2.68 - - -

1.2

1.4 5009 4394 4.71 4571 3537 3.79 4346 3233 3.47 4074 2762 2.96 3777 2356 2.53 - - -

4771 4174 4.48 4370 3395 3.64 4074 3040 3.26 3802 2590 2.78 - - - - - -

1.6

1.8 4520 3951 4.24 4169 3262 3.50 3786 2850 3.06 - - - - - - - - -

4255 3728 4.00 3966 3137 3.36 - - - - - - - - - - - -

2.0

2.2 3976 3505 3.76 3763 3020 3.24 - - - - - - - - - - - -

*.

Blowe r performance for gas heat includes maximum number of heat tubes available for each tonnage.

†.

Blowe r performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have been

deducted from the total static pressure of the blower.

**.

“Tur ns Open” refers to the setting of the variable pitch motor sheave, where “0 Turns Open” is fully closed.

††.

W = Watts

Unitary Products Group 27

Page 28

035-17311-002-A-0803

TABLE 23: 7-1/2 TON STANDARD MOTOR SIDE SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.4

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - - - - 3736 1476 1.58 3487 1284 1.38 3231 1109 1.19 3001 970 1.04

††

W

BHP CFM

††

W

BHP CFM

†

††

W

BHP CFM

††

BHP

W

0.6 - - - 3572 1514 1.62 3389 1339 1.44 3094 1151 1.23 2764 972 1.04 2446 824 0.88

0.8 3422 1558 1.67 3179 1364 1.46 2889 1164 1.25 2554 985 1.06 - - - - - -

1.0 2891 1347 1.44 2372 1088 1.17 2050 922 0.99 - - - - - - - - -

1.2 2017 1051 1.13 - - - - - - - - - - - - - - -

*.

Blower performance for gas h eat includes maximum number of heat tubes available for each to nnage.

†.

Blower performance includes two-inch throwaway filters.

‡.

ESP (External Static Pressure) given is that available for the supply and return air duct system. All internal resistances have been

deduct ed from the total static pressure of the blower.

**.

“Turns Open” refe rs to the setti ng of the varia bl e pit ch mot or sh eave , whe r e “0 Turns Open” is fu lly close d .

††.

W = Watts

TABLE 24: 7-1/2 TON OPTIONAL MOTOR SIDE SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.4

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - - - - - - - - - - - - - 3910 1726 1.85

††

W

BHP CFM

††

W

BHP CFM

†

††

W

BHP CFM

††

BHP

W

0.6 - - - - - - - - - - - - 3857 1842 1.98 3597 1430 1.53

0.8

- - - - - - - - - 3804 1957 2.10 3503 1689 1.81 3172 1430 1.53

1.0 - - - - - - 3774 2088 2.24 3406 1778 1.91 3032 1497 1.61 2248 1143 1.23

1.2

- - - - - - 3327 1866 2.00 2926 1578 1.69 2160 1217 1.31 - - -

1.4 - - - 3270 1971 2.11 2537 1544 1.66 2043 1296 1.39 - - - - - -

3196 2077 2.23 2460 1651 1.77 - - - - - - - - - - - -

1.6

1.8 242617681.90---------------

*.

Blower performance for gas h eat includes maximum number of heat tubes available for each to nnage.

†.

Blower performance includes two-inch throwaway filters.

‡.

ESP (Exte rna l S t a tic P res sur e ) giv en is that av ai la ble f or the su pp ly a nd ret u rn ai r duct sys t em. Al l int er nal r es is tan ce s ha ve be en

deduct ed from the total static pressure of the blower.

**.

“Turns Open” refe rs to the setti ng of the varia bl e pit ch mot or sh eave , whe r e “0 Turns Open” is fu lly close d .

††.

W = Watts

28 Unitary Products Group

Page 29

035-17311-002-A-0803

TABLE 25: 10 TON STANDARD MOTOR DOWN SHOT BLOWER PERFORMANCE*

**

††

BHP CFM

W

ESP

0.2

TURNS OPEN

‡

CFM

012345

††

BHP CFM

W

- - - - - - - - - 3896 1639 1.76 3688 1453 1.56 3447 1268 1.36

††

W

BHP CFM

††