Page 1

TECHNICAL GUIDE

SINGLE PACKAGE

HEAT PUMP/GAS HEAT

14 SEER – R-410A

2 THRU 5 NOMINAL TONS

50 - 125 MBH HEAT INPUT

MODELS: PHG4*24 THRU 60

Due to continuous product improvement, specific ations

are subject to change without notice.

Visit us on the web at

www.upgnet.com and www.york.com

Additional rating information can be found at:

www.ahridirectory.org

WARRANTY SUMMARY*

Extended 10-Years limited parts and compressor warranty

Lifetime gas heat exchanger warranty with registration.

* Extended warranty requires online registration within 90 days of purchase for

replacement or closing for new home purchase. See limited warranty certificate

in User’s Information Manual for details.

®

5127524-YTG-A-0815

DESCRIPTION

These packaged duel fuel cooling/gas heating/heat pumps are

designed for outdoor installation. Only utility and duct

connections are required at the point of installation.

FEATURES

• Operating Efficiency - All PHG4 models provide a minimum

AFUE of 81.0% in gas heating and 14.0 SEER, 11.0 EER

and 8.0 HSPF ratings for heat pump cooling/heating operation. All models meet California Low-Nox requirements of 40

ng/joule emission level for Air Quality Management Districts.

• On Site Flexibility - All model sizes use a compact design

cabinet in one of two footprints. This provides installer flexibility for placing the proper capacity unit on curbs or pads

with the smallest footprint after the internal load has been

determined. Field convertible duct connections from side

shot to down shot allows the installer to have greater flexibility with less inventory.

• Lower Installation Cost - Installation time and costs are

reduced by easy power and control wiring connections. The

small base dimension means less space is required on the

ground or roof. All units are completely wired, charged with

R-410A refrigerant and tested prior to shipment. T est st ations

using a state-of-the-art computerized process system are

used to insure product quality. Refrigerant charge and component part numbers are verified via computers during

assembly. Vital run test statistics such as system pressure,

motor currents, air velocity and temperature, unit vibration,

and gas system safeties are monitored and recorded by the

system to insure unit performance. Equal size side supply

and return duct connections allow easy connecti on of ducts

to match low crawl spaces without transition pieces.

• Utility Connections Made Easy - Gas and electric utility

access provided through the bottom or the side of the unit.

Utility connections can be made quickly and with a mini mum

amount of field labor. A field supplied and field installed electrical disconnect switch must be installed.

• Convertible Airflow Design - The bottom duct openings are

covered when they leave the factory, ready to be used for a

side supply/side return application. If a bottom supply/bottom

return application is desired, simply remove the two panels

from the bottom of the unit and place them in the side supply/

side return duct openings. No panel cutting is required and

no accessory panel is necessary. Convertible airflow design

allows maximum field flexibility and minimum inventory.

• Condensate Pan - A corrosion-resistant, long-lasting, watertight pan is positioned below the indoor coil to collect and

drain all condensate, preventing build-up of stagnant condensate. The condensate pan conforms to ASHRAE 62-89

standards (Ventilation for Acceptable Indoor Air Quality).

• Condensate Drain - The 3/4 inch NPT female connection i s

rigidly mounted to assure proper fit and leak tight seal.

• Durable Finish - The cabinet is made of G90 galvanized

steel with a powder paint coating for appearance and protection. The pre-treated galvanized steel provides a better paintto-steel bond, which resists corrosion and rust creep. Powder

paint finish insures less fading when exposed to sunlight,

and provides superior corrosion resistance (1000 hour salt

spray tested).

Continued on next page.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

5127524-YTG-A-0815

• Full Perimeter Base Rails - The easily removable base rails

provide a solid foundation for the entire unit and protects the

unit during shipment. The rails provide fork lift access from all

sides, and rigging holes are also provided so that an overhead crane can be used to place the units on a roof. On

applications where the unit is placed on a pad, the base will

keep the unit off the pad to deter corrosion. On applications

where height is limited, the base rails may be removed by

removing 2 screws in each corner.

• More Attractive Appearance - A single-piece top cover

containing a top-discharge outdoor fan arrangement requires

less square footage on installation and provides a wider variety of installations. The one-piece design adds greater water

integrity. Rounded corners with water drip edges add to the

attractive appearance.

• Top Discharge - The top-discharge outdoor fan does not

disrupt neighboring areas or dry out vegetation surrounding

the unit. The warm air from the top mounted fan is blown up

and away from the structure and any landscaping. This

allows compact location on multi-unit applications.

• Outdoor Coil Grille - All models utilize a stamped slotted

design which provides superior impact protection against

small objects during transit and after installation.

• Low Operating Sound Level - The upward air flow ca rries

the normal operating noise up and away from the living area.

The rigid top panel effectively isolates noise. Isolator

mounted compressor and the rippled fins of the outdoor coil

muffle the normal fan motor and compressor operating

sounds. The unique formed base pan also aids in sound

attenuation with its structural design. This design strategically places embossments in the pan for optimum strength

and rigidity.

• Fan System - All models operate over a wide range of

design conditions with a standard ECM indoor fan motor.

These units easily match all types of applications and provide greater on-site flexibility to match comfort requirements.

The cooling speed is factory-set and can be field-adjusted to

a alternate speed. The heating speed is factory set to maintain mid point rise at the units heating input, but can be field

adjusted. This allows maximum comfort conditions.

• Simple Control Circuit - A low voltage gas heat printed cir-

cuit board contains a status/diagnostic indicator light. Field

thermostat wiring connects to color coded leads using twist

on wire connectors. Cooling controls use contactor and

relays for simple application and troubleshooting. Mate-nlock plug connectors are used. The electrical control box is

not located in the compressor compartment. The controls are

mounted to allow the separate access panel to be removed

for trouble shooting and maintenance without affecting the

normal system operating pressures. All wiring internal to the

unit is color/number coded.

• Controls - Demand defrost curves are pre-loaded into the

demand defrost control for optimized performance based on

unit capabilities.

• Protected Compressor - The compressor is internally protected against high pressure and temperature. This is

accomplished by the simultaneous operation of high pressure internal relief valve and a temperature sensor which

protect the compressor if undesirable operating conditions

occur.

• Pressure Switches - A high pressure switch is standard in

all units. When abnormal conditions are sensed through the

pressure switch, the unit will lock out preventing any further

operation until reset or problem is corrected.

• Exclusive Coil Design - Grooved copper tubes and

enhanced aluminum fin construction improves heat transfer

for maximum efficiency and durability for long-lasting durability and efficient operation. Indoor coils use tin-coated copper

tubing with aluminum fins for effective heat transfer.

• Heat Exchangers - Gas heat exchangers use corrosionresistant, stainless-steel tubular construction to provide longlife, trouble-free operation. Gas heat exchangers are offered

with lifetime warranties as st

• Post Purge Induced Draft Combustion - Exhausts combustion products from the heat exchanger upon completion

of the heating cycle to prolong the heat exchanger life.

• Spark To Burner Ignition - No pilot assembly required,

which provides more consistent ignition in gas heating mode.

This ignition system is highly reliable, durable and eliminates

nuisance lockouts.

• Multi Port In-shot Burners - No field adjustment is required

to mix the air and gas for natural gas or propane use. These

burners are constructed of high-grade corrosion-resistant,

aluminumized steel.

• Low Maintenance - Long life, permanently lubricated outdoor and indoor fan motor bearings need no annual maintenance, adding greater reliability to the unit. Slide-out blower

assembly can be easily removed for cleaning.

• Easy Service Access - Individual access panels covering

the electrical and gas controls, compressor, and blower section makes servicing easy. Removing this panel will allow

easy removal of the blower assembly for maintenance and

ease of troubleshooting.

• Replacement Parts - The installer requires no special training to replace any of the components of these units and the

number of new components have been reduced to minimize

the inventory of unique parts.

• Loss of Charge Sensor (S1-2LC00024) - Kit provides Loss

of Charge sensor and wiring to provide safe shutdown of

compressor if charge is lost.

• Transition Curb Kits (S1-1TC01*) - Adapter kits to allow

field use of pre-existing installed roof curbs to match PHG4

footprint to Affinity roof curbs, Carrier, Trane, or Goodman

curb footprints. Curb adapters are optional for current generation Carrier replacements but are recommended for previous generation applications. Refer to the PHG4 price pages

for more details.

andard with registration.

2 Johnson Controls Unitary Products

Page 3

5127524-YTG-A-0815

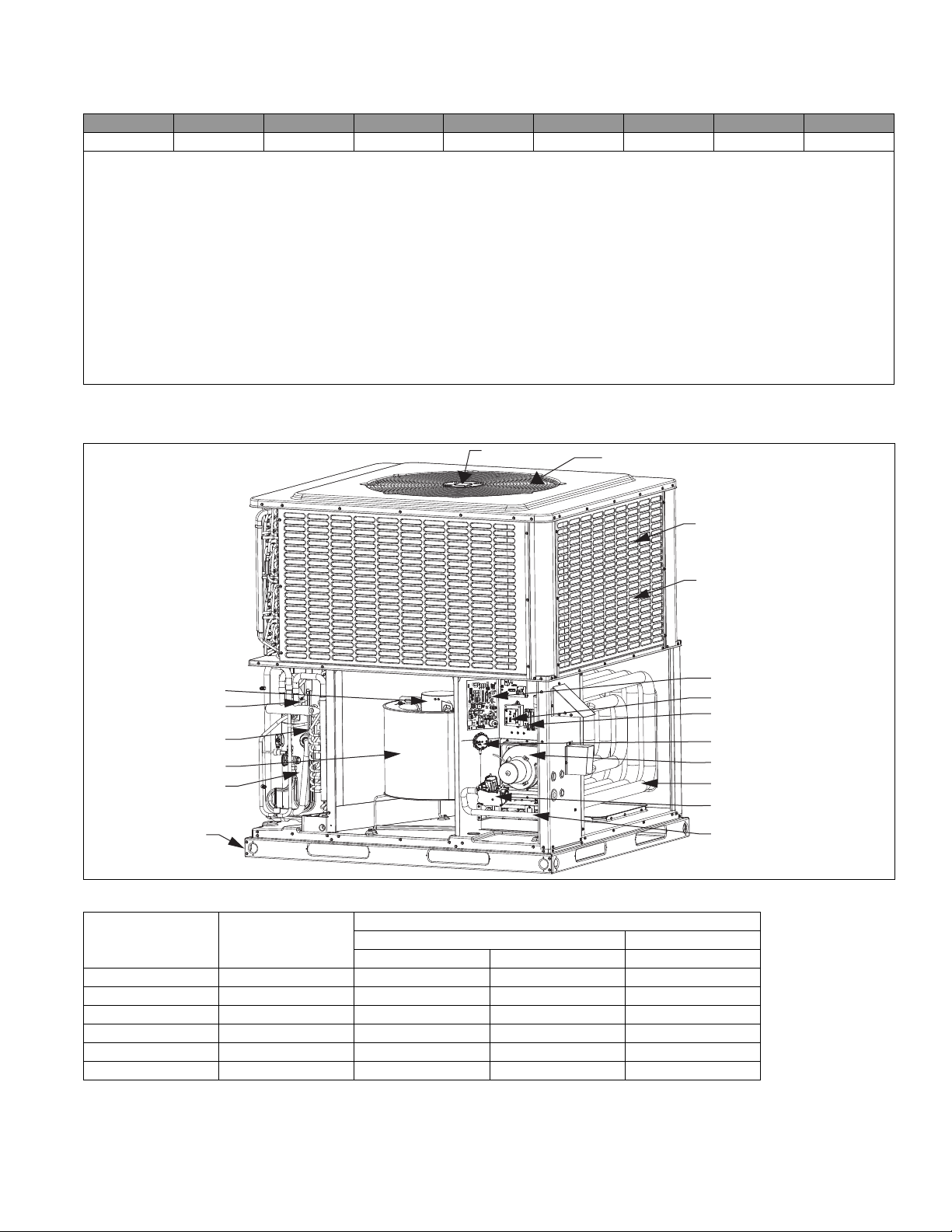

FAN MOTOR

OUTDOOR FAN

COIL GUARD PANEL

OUTDOOR COIL

(Behind Panel)

CONTROL BOARD

TRANSFORMER

HIGH VOLTAGE

CONTACTOR

PRESSURE SWITCH

DRAFT INDUCER BLOWER

GAS VALVE

BURNER

ASSEMBLY

GAS HEAT

EXCHANGER

BLOWER MOTOR

TXV

INDOOR COIL

INDOOR BLOWER

COMPRESSOR

REMOVABLE

BASE RAILS

A0444-001

NOMENCLATURE

PHG 4 A 24 50 2 X 1 A

123456789

1. Model Family

PHG - packaged heat pump with gas heat,

PCG - packaged A/C with gas heat,

PCE - packaged A/C with electric heat,

PHE - packaged heat pump with electric heat

2. Nominal Cooling Efficiency

4 = 14 SEER, 6 = 16 SEER, etc.

3. Cabinet Size

A = small 35 x 51, B = large 45 x 51

4. Nominal Air Conditioning Cooling Capacity BTUx1000

24 = 24,000 BTU, etc.

5. Gas Heating Input BTU/Hr x 1000

050 = 50,000 BTU/Hr. input, blank = electric heat

6. Voltage-Phase-Frequency

2 = 208/230-1-60, 3=208/230-3-60, 4 = 460-3-60

7. NOx Approval

X = low-NOx, blank = not low-Nox

8. Generation Level

1 = first generation

9. Revision Level

A = original release, B = second release

Examples:

PHG4B421002X1A is a dual fuel, 14 SEER, 3-1/2 ton, large cabinet, single-stage heat, 100,000 BTU gas heat, 230 volt, single phase, low-NOx

model (first generation, first release)

COMPONENT LOCATION

Unit Limitations

Unit Limitations

Model Unit Voltage

Applied Voltage Outdoor DB Temp

Min Max Max (°F)

PHG4A24 208/230-1-60 187 252 125

PHG4A30 208/230-1-60 187 252 125

PHG4B36 208/230-1-60 187 252 125

PHG4B42 208/230-1-60 187 252 125

PHG4B48 208/230-1-60 187 252 125

PHG4B60 208/230-1-60 187 252 125

Johnson Controls Unitary Products 3

Page 4

5127524-YTG-A-0815

ACCESSORIES

• Propane Conversion Kit (S1-1NP0702, S1-1NP0701) - Kit

includes burner orifices, gas valve conversion and installation instructions necessary to field convert uni t from natural

gas to propane.

• Economizer for Downflow Applications

(S1-2EE04708424, S1-2EE04708524) - Modulating integrated economizer provides simultaneous operation

between the mechanical cooling and economizer operation.

Independent blade design insures proper control and less

than 1% leak rate. Includes hood and mesh bird screen filter

integrated into the hood, dry bulb sensor and relief damper.

Separate field accessories of single enthalpy and dual

enthalpy are also available.

• Economizer for Horizontal Applications

(S1-2EE04708624, S1-2EE04708724) - Modulating integrated economizer provides simultaneous operation

between the mechanical cooling and economizer operation.

Independent blade design insures proper control and less

than 1% leak rate. Includes hood and mesh bird screen filter

integrated into the hood, dry bulb sensor and relief damper.

Separate field accessories of single enthalpy and dual

enthalpy are also available.

• Single/Dual Enthalpy Sensor (S1-2EC04700624) - Sensor

replaces dry bulb sensor standard in economizer kit. Provides improved economizer operation by sensing the dry

bulb temperature from outdoors plus the enthalpy content of

the outdoor air.

• CO2 Sensor Kit (S1-2AQ04700824) - Sensor kit detects

CO2 levels automatically and overrides the economizer

when CO2 levels rise above the preset limits.

• Outdoor Temperature Sensor Kit

(S1-2EC04700724S1-2EC04700724v) - Additional outdoor

air temperature sensor kit used with economizers.

• Filter/Frame Kit (Single Phase Only)

(S1-1FF0602, S1-1FF0601) - Kit contains the necessary

hardware to field install return air filters into the base unit.

The filter rack is suitable for either 1" or 2" filters. (filters not

supplied) This kit is available for single phase horizontal or

vertical duct applications.

• Motorized Fresh Air Damper

(S1-2MD04705224, S1-2MD04705124) - Designed for duct

mounted side supply/return and unit mounted down supply/

return applications. Damper capable of providing 0% through

50% of outdoor air (field supplied). Closes on power loss,

includes hood and screen assembly.

• Rectangle to Round (Horizontal) Adapter

(S1-1AK0110, S1-1AK0111) - Kit includes one supply and

one return air rectangle to round duct adapter. Adapters are

preformed and designed to fit over current horizontal duct

openings on the base unit. Transition is from rectangle to 12"

round for the 1AK0110 kit and from rectangle to 14" round for

the 1AK0111 kit.

• Rectangle to Round (Downflow) Adap ter

(S1-1AK0108, S1-1AK0109) - Kit includes one supply and

one return air rectangle to round duct adapter. Adapters are

preformed and designed to fit into current downflow duct

openings on the roof curb. Transition is from rectangle to 16"

round for the 1AK0108 kit and from rectangle to 18" round for

the 1AK0109 kit.

• Roof Curbs (S1-1RC0503, S1-1RC0501) - NRCA approved

curbs provide proper fit to base unit for rooftop installations.

Curbs are designed to be assembled through hi nge pins in

each corner. Kit also provides seal strip to assure an air tight

seal. These are 8 inch high roof curbs.

• Roof Curbs (S1-1RC0504, S1-1RC0502) - NRCA approved

curbs provide proper fit to base unit for rooftop installations.

Curbs are designed to be assembled through hi nge pins in

each corner. Kit also provides seal strip to assure an air tight

seal. These are 14 inch high roof curbs.

• Manual Outdoor Damper

(S1-1FA0502, S1-1FA0501) - Provides 0% through 50% outdoor air capability (field adjustable). Designed for duct

mounted side supply/return applications. Includes hood and

screen assembly.

• Wall Thermostat - The units are designed to operate with

standard, 24-volt electronic and electro-mechanical thermostats. All units can operate with single stage heat/single

ge cool thermostats - with or without the economizer.

a

st

• Low Ambient Kit (S1-2LA04700824) - Kit provides necessary hardware to convert unit to operate in cooling cycle

down to 0º F. Standard unit operation 45º F.

• Base Rail Hole Cover Kit (S1-1HC0101) - Kit provides necessary hardware to close off openings in base rails to block

off openings, i.e. prevent animal entrance.

4 Johnson Controls Unitary Products

Page 5

5127524-YTG-A-0815

GUIDE SPECIFICATIONS

GENERAL

Units shall be manufactured by Unitary Products in an ISO

9001 certified facility. Package units give you the flexibility and

choices you need in today’s market. These packaged cooling/

heating air conditioners are designed for outdoor installation.

Only utility and duct connections are required at the point of

installation. The single-stage gas fired heaters have stainless

steel tubular heat exchangers and spark to burner ignition.

They are available in natural gas with field conversion to

propane.

DESCRIPTION

Units shall be factory-assembled, single packaged, Heat

Pumps with Electric Cooling/Gas Heating units, designed for

outdoor installation. They shall have built in, equal size, field

convertible duct connections for supply/return or horizontal

supply/return. The units shall be factory wired, piped, charged

with R-410A Refrigerant and factory tested prior to shipment. All

unit wiring shall be both numbered and color coded. All models

shall be rated in accordance with DOE and AHRI test

procedures for both heating and cooling operation. Units shall

be CSA listed and classified to ANSI Z21.47/CAN/ CSA 2.3

standards and UL 1995/CAN/CSA No. 236-M90 standards.

• Operating Efficiency - All Heat Pump models shall be rated

at 14.0 SEER, 11.0 EER, and 8.0 HSPF for heat pump cooling and heating operation. All models shall be rated at 81.0%

AFUE for gas heating operation.

• Low Operating Sound Level - The upward air flow carries

the normal operating noise up and away from the living area.

The rigid top panel effectively isolates noise. Isolator

mounted compressor and the rippled fins of the outdoor coil

muffle the normal fan motor and compressor operating

sounds. The unique formed base pan also aids in sound

attenuation with its structural design. Sound ratings as tested

under AHRI test procedures shall be less than 77 dbA for all

models.

UNIT CABINET

Unit cabinet shall be a single piece design, with drip e dges and

no-seam corners to provide optimum water integrity. Unit shall

have a rigidly mounted outdoor coil guard to provide protection

from objects and personnel after installation. Indoor blower

section shall be insulated with foil-faced or foam insulation,

fastened to prevent insulation from entering the air stream.

Cabinet panels shall be separate, easily removable for

servicing and maintenance. Unit shall be built on a formed,

design base pan, with embossments at critical points to add

strength and rigidity and to aid in minimizing sound. Full

perimeter base rails shall be provided to assure reliable transit

of equipment, overhead rigging, for truck access and proper

sealing on roof curb applications. Base rails shall be easily

removable, when required to lower unit height. Filters shall be

field installed and field provided and be accessi ble through a

removable access door, sealed airtight. Units vertical discharge

and return duct configuration shall be designed to fit between

standard 24” O.C. beams without modification to building

structure, duct work and base unit. Condensate pan shall be

internally sloped and conform to ASHRAE 62-89 self-draining

standards, with 3/4” NPT female ridged mount connection.

• Durable Finish - The cabinet shall be is made of G90 galvanized steel with a powder paint coating for appearance and

protection. The pre-treated galvanized steel shall provide a

better paint-to-steel bond, which resists corrosion and rust

creep. Powder paint finish shall provide superior corrosion

resistance (1000 hour salt spray tested).

• On Site Flexibility - All model sizes shall use a compact

design cabinet in one of two footprints. This provides installer

flexibility for placing the proper capacity unit on curbs or pads

with the smallest footprint after the internal load has been

determined. Field convertible duct connections from side

shot to down shot allows the installer to have greater flexibility with less inventory.

• Attractive Appearance - A single-piece top cover containing

a top-discharge outdoor fan arrangement shall be used

which requires less square footage on installation and provides a wider variety of installations. The one-piece design

adds greater water integrity. Rounded corners with water drip

edges add to the attractive appearance and prevent wate r

penetration.

• Convertible Airflow Design - The bottom duct openings are

covered when they leave the factory, ready to be used for a

side supply/side return application. If a bottom supply/bottom

return application is desired, simply remove the two panels

from the bottom of the unit and place them in the side supply/

side return duct openings. No panel cutting is required and

no accessory panel is necessary. Convertible airflow design

allows maximum field flexibility and minimum inventory.

• Utility Connections Made Easy - Electric utility access shall

be provided through the bottom or the side of the unit. Utility

connections should be made quickly and with a minimum

amount of field labor. A field supplied and field installed electrical disconnect switch must be installed.

• Easy Service Access - Individual access panels are provided in access to all major components - compressors,

indoor coils, blower, controls/gas heating section, filters, etc.

that makes servicing easy. Removing these panels allow

easy removal of the components such as the blower assembly for maintenance and ease of troubleshooting.

• Top Discharge - The top-discharge outdoor fan does not

disrupt neighboring areas or dry out vegetation surrounding

the unit. The warm air from the top mounted fan is blown up

and away from the structure and any landscaping.

• Outdoor Coil Grille - All models utilize a stamped slotted

design which provides superior impact protection against

small objects during transit and after installation.

Indoor Blower Assembly - Fan shall be direct drive design.

Blower wheel shall be double-inlet type with forward-curved

blades, dynamically balanced to operate smoothly throughout

the entire range of operation. Airflow design shall be constant

air volume. Bearings shall be sealed and permanently

lubricated for longer life and no maintenance. Fan assembly

shall be a slide-out design for easy removal and cleaning.

Indoor blower motors shall be equipped with a standard high

efficiency brushless DC motor (constant torque) also known as

a standard ECM motor.

Johnson Controls Unitary Products 5

Page 6

5127524-YTG-A-0815

Outdoor Fan Assembly - The outdoor fan shall be of the

direct-driven propeller type, discharge air vertically, have

aluminum blades riveted to corrosion resistant steel spider

bracket and shall be statically balanced for smooth operation.

The outdoor fan motor shall be totally enclosed with

permanently lubricated bearings and internally protected

against overload conditions.

REFRIGERANT COMPONENTS

• Protected Compressor - The compressor shall be a fully

hermetic type, direct drive compressor, that is internally protected against high pressure and temperature. This is

accomplished by the simultaneous operation of high pressure internal relief valve and a temperature sensor which

protect the compressor if undesirable operating conditions

occur. The hermetic motor shall be suction gas cooled and

have a voltage range of +/- 10% of the unit nameplate voltage. Compressors shall have internal isolation and sound

muffling to minimize vibration and noise, and be externally

isolated on a dedicated, independent mounting.

• Indoor Coils - Indoor coils shall be of the direct expansion,

draw through design and have aluminum plate fins mechanically bonded to seamless internally enhanced tin-coated

copper tubes with all joints brazed.

• Condensate Pan - A corrosion-resistant, long-lasting, watertight pan is positioned below the indoor coil to collect and

drain all condensate, preventing build-up of stagnant condensate. The condensate pan conforms to ASHRAE 62-89

standards (Ventilation for Acceptable Indoor Air Quality).

• Condensate Drain - The 3/4 inch NPT female connection is

rigidly mounted to assure proper fit and leak tight seal.

• Outdoor Coils - Outdoor coils shall have aluminum plate fins

mechanically bonded to seamless internally enhanced co pper tubes with all joints brazed, and be a draw through

design.

Refrigerant Circuit and Refrigerant Safety Components

shall include: Thermal expansion devices (TXV's) shall be

factory mounted and provided, Filter/strainer to eliminate any

foreign matter, reversing valves to control refrigerant flow.

GAS HEATING SECTION

Heat exchanger and exhaust system shall be constructed of

corrosion-resistant materials and shall be designed with

induced draft combustion with post purge logic and redundant

main gas valve. The heat exchanger shall be of the tubular

type, constructed of stainless steel for corrosion resistance and

allowing minimum mixed air entering temperature of 40 °F.

Burners shall be of the in-shot type, constructed of

aluminumized steel. All gas piping shall enter the unit cabinet at

a single location through either the side or bottom, without any

field modifications. An integrated control board shall provide

timed control of indoor fan functioning and burner ignition.

Heating section shall be provided with the following minimum

protection:

a. Primary high-temperature limit switch.

b. Induced draft pressure switch.

c. Flame roll out switch(s) (manual reset).

d. Flame proving controls.

All gas heat models will meet California requirement for

emissions of less than 40 nanograms per Joule (California

requirement on single phase models only).

CONTROLS

• Simple Control Circuit - Field thermostat wiring connects to

color coded leads using twist on wire connections. Cooli ng

controls use contactor and relays for simple application and

troubleshooting. Mate-n-lock plug connectors are used.

Heating controls consist of direct spark ignition control and

demand defrost heat pump control. The electrical control box

is not located in the compressor compartment. The controls

are mounted to allow the separate access panel to be

removed for trouble shooting and maintenance without

affecting the normal system operating pressures. All wiring

internal to the unit is color/number coded.

• Pressure Switches - A high pressure switch is standard in

all units. When abnormal conditions are sensed through the

pressure switch, the unit will lock out preventing any further

operation until reset or problem is corrected.

• Factory Testing - Installation time and costs are reduced by

easy power and control wiring connections. All units are

completely wired, charged with R-410A and tested prior to

shipment. Test stations using a state-of-the-art computerized

process system shall be used to insure product quality.

Refrigerant charge and component part numbers are verified

via computer bar code scans during assembly. Vital run test

statistics such as system pressure, motor currents, air velocity and temperature, unit vibration, and gas system safeties

are monitored and recorded by the system to insure unit performance. This data could be provided by serial number

tracking if requested.

Spark To Burner Ignition - No pilot assembly required, wh ich

provides more consistent ignition in gas heating mode. This

ignition is highly reliable, durable and eliminates nuisance

lockouts.

6 Johnson Controls Unitary Products

Page 7

5127524-YTG-A-0815

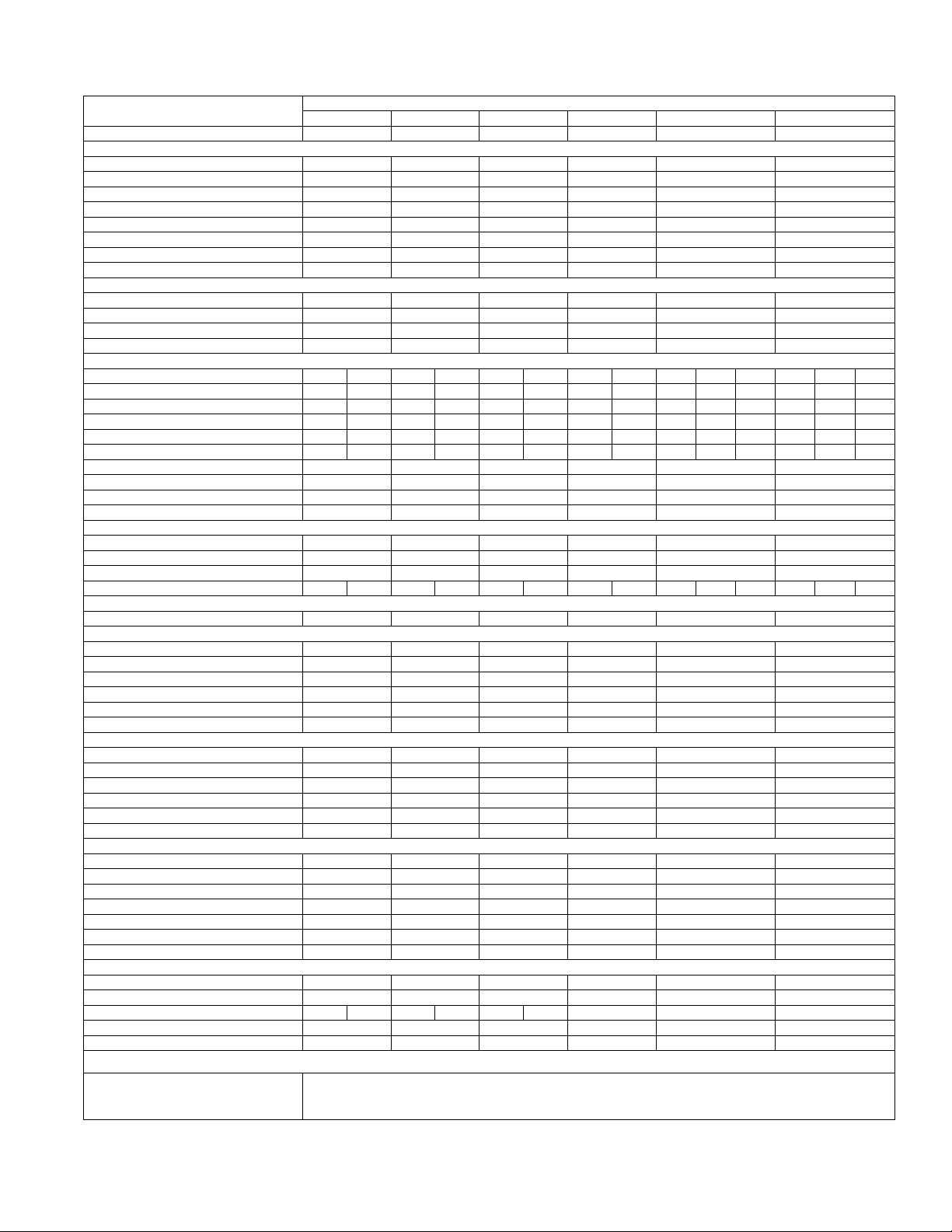

Physical Data

COMPONENT

NOMINAL TONNAGE 2.0 2.5 3.0 3.5 4.0 5.0

AHRI Cooling Performance

Gross Capacity @ AHRI A point (MBH) 23.5 29.4 36.0 41.1 47.0 58.1

AHRI net capacity (MBH) 23.1 29.0 35.5 40.7 45.5 57.5

EER 11.0 11.0 11.0 11.0 11.0 11.0

SEER 14.0 14.0 14.0 14.0 14.0 14.0

Nominal CFM 800 1000 1200 1400 1600 2000

System power (KW) 1.8 2.1 2.8 3.2 3.6 4.7

Refrigerant type R410A R410A R410A R410A R410A R410A

Refrigerant charge (lb-oz) 8-8 9-8 11-13 13-0 12-13 16-10

AHRI Heat Pump Heating Performance

47 Capacity Rating (MBH) 21.9 27.0 33.5 38.1 44.1 55.9

System Power (kW/COP) 1.8 2.1 2.6 2.9 3.5 4.3

17 F Capacity Rating (MBH) 11.3 14.5 19.0 22.0 25.4 31.7

HSPF (BTU/Watts-hr.) 8.0 8.0 8.0 8.0 8.0 8.0

AHRI Gas Heat Performance

Heating model 50 75 50 75 65 100 65 100 65 100 125 65 100 125

Heat input (K Btu) 50.0 75.0 50.0 75.0 65.0 100.0 65.0 100.0 65.0 100.0 125.0 65.0 100.0 125.0

Heat output (K Btu) 40 60 40 60 52 80 52 80 52 80 100 52 80 100

AFUE % 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0 81.0

No. burners 2 3 2 3 2 3 2 3 2 3 4 2 3 4

No. stages 1 1 1 1 1 1 1 1 1 1 1 1 1 1

Temperature Rise Range (°F) 40-70 40-70 40-70 40-70 40-70 40-70

Max. Static Pressure w.c. 0.5 0.5 0.5 0.5 0.5 0.5

Max. Outlet Air Temp. (°F) 180 180 180 180 180 180

Gas piping connection (in.) 1/2 1/2 1/2 1/2 1/2 1/2

Dimensions (inches)

Length 51-1/4 51-1/4 51-1/4 51-1/4 51-1/4 51-1/4

Width 35-3/4 35-3/4 45-3/4 45-3/4 45-3/4 45-3/4

Height 47 49 49 49 53 55

Operating WT. (lbs.) 394 404 449 453 498 505 532 534 551 559 564 577 581 588

Compressors

Type Scroll Scroll Scroll Scroll Scroll Scroll

Outdoor Coil Data

Face area (Sq. Ft.) 15.3 17.2 19.8 19.8 24.1 26.3

Rows 2 2 2 2 2 2

Fins per inch 22 22 22 22 22 22

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Interlaced Interlaced Interlaced Interlaced Interlaced Interlaced

Refrigerant Control TXV TXV TXV TXV TXV TXV

Indoor Coil Data

Face area (Sq. Ft.) 3.4 3.4 3.4 4.4 4.4 4.4

Rows 3 3 3 3 3 4

Fins per inch 16 16 16 16 16 16

Tube diameter 3/8 3/8 3/8 3/8 3/8 3/8

Circuitry Type Interlaced Interlaced Interlaced Interlaced Interlaced Interlaced

Refrigerant control TXV TXV TXV TXV TXV TXV

Outdoor Fan Data

Fan diameter (Inch) 24 24 26 26 26 26

Type Prop Prop Prop Prop Prop Prop

Drive type Direct Direct Direct Direct Direct Direct

No. speeds 1 1 1 1 1 1

Motor HP each 1/10 1/8 1/3 1/3 1/3 1/3

RPM 850 850 850 850 850 850

Nominal total CFM 2400 2400 3200 3200 3200 3200

Direct Drive Indoor Fan Data

Fan Size (Inch) 11 x 8 11 x 8 11 x 10 11 x 10 11 x 10 11 x 10

Type Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal Centrifugal

Motor HP each 1/3 1/2 1/3 1/2 1/2 3/4 3/4 3/4 1

RPM 1200 Max 1200 Max 1200 Max 1200 Max 1200 Max 1200 Max

Frame size 48 48 48 48 48 48

Filters

Quantity - Size

PHG4A24 PHG4A30 PHG4B36 PHG4B42 PHG4B48 PHG4B60

Field-supplied external filters must be sized so as not to exceed 300 fpm air velocity through disposable

filters. For internal filter use, a filter rack kit is available. Consult the instructions supplied with that kit for

replacement filter sizes. Filter sizes: A=20x20, B=20x30.

MODELS

Johnson Controls Unitary Products 7

Page 8

5127524-YTG-A-0815

COOLING PERFORMANCE DATA

PACKAGED UNIT MODEL NO. PHG4A24

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 600 800 1000

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 24.9 28.3 28.3 31.8 34.8 28.3 30.6 31.0 34.5 36.9 31.6 32.8 33.8 37.1 39.0

S.C. 23.5 19.9 18.0 17.8 15.0 26.5 23.4 20.7 20.2 16.1 29.5 26.8 23.4 22.6 17.1

K.W. 0.98 0.98 0.98 0.98 0.97 1.03 1.03 1.03 1.03 1.02 1.08 1.08 1.08 1.08 1.07

T.C. 24.2 26.9 26.9 30.0 33.1 27.2 29.0 29.2 32.3 35.2 30.2 31.2 31.4 34.6 37.3

S.C. 22.5 19.2 17.0 16.9 14.1 25.3 22.6 19.6 19.4 15.4 28.1 26.0 22.2 22.0 16.8

K.W. 1.10 1.09 1.08 1.09 1.08 1.15 1.15 1.14 1.14 1.14 1.20 1.20 1.19 1.19 1.19

T.C. 23.4 25.4 25.5 28.2 31.5 26.1 27.5 27.3 30.1 33.6 28.8 29.5 29.1 32.0 35.6

S.C. 21.5 18.5 16.1 16.0 13.2 24.2 21.9 18.5 18.7 14.8 26.8 25.2 21.0 21.4 16.4

K.W. 1.21 1.21 1.19 1.20 1.20 1.27 1.26 1.25 1.25 1.25 1.32 1.31 1.31 1.31 1.31

T.C. 22.3 23.5 23.7 26.4 29.5 24.7 25.3 25.2 28.2 31.4 27.1 27.0 26.7 29.9 33.3

S.C. 20.4 17.7 15.2 15.1 12.4 22.8 20.7 17.4 17.6 14.0 25.1 23.7 19.6 20.2 15.5

K.W. 1.36 1.35 1.34 1.35 1.35 1.41 1.41 1.40 1.40 1.40 1.47 1.46 1.45 1.45 1.45

T.C. 21.2 21.7 21.9 24.6 27.5 23.4 23.1 23.1 26.2 29.2 25.5 24.5 24.4 27.8 30.9

S.C. 19.4 16.8 14.4 14.3 11.6 21.4 19.5 16.3 16.6 13.1 23.4 22.1 18.2 18.9 14.7

K.W. 1.51 1.50 1.49 1.50 1.50 1.56 1.55 1.54 1.55 1.55 1.61 1.60 1.59 1.60 1.60

T.C. 19.3 19.5 19.7 22.5 24.7 20.9 20.8 20.6 23.5 26.2 22.5 22.1 21.6 24.4 27.7

S.C. 17.8 15.9 13.2 13.4 10.5 19.4 18.2 15.2 15.5 11.9 21.0 20.4 17.1 17.6 13.3

K.W. 1.71 1.71 1.70 1.71 1.71 1.76 1.76 1.75 1.76 1.76 1.82 1.81 1.81 1.81 1.81

T.C. 17.4 17.4 17.5 20.5 22.1 18.6 18.6 18.2 20.8 23.3 19.7 19.8 18.9 21.2 24.6

S.C. 16.2 15.1 12.2 12.5 9.5 17.5 16.9 14.1 14.4 10.7 18.7 18.8 16.1 16.2 11.9

K.W. 1.91 1.91 1.90 1.91 1.91 1.96 1.96 1.96 1.96 1.96 2.01 2.02 2.01 2.01 2.01

T.C. 15.6 15.3 15.4 18.4 19.4 16.2 16.4 15.8 18.2 20.4 16.8 17.5 16.2 18.0 21.5

S.C. 14.7 14.3 11.1 11.6 8.5 15.5 15.7 13.0 13.2 9.5 16.4 17.1 15.0 14.9 10.5

K.W. 2.11 2.12 2.11 2.11 2.11 2.16 2.17 2.16 2.16 2.16 2.21 2.22 2.22 2.21 2.21

COOLING PERFORMANCE DATA

PACKAGED UNIT MODEL NO. PHG4A30

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 800 1000 1200

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 30.3 33.5 33.8 37.2 42.9 32.8 35.3 35.8 39.4 45.4 35.3 37.2 37.8 41.6 47.9

S.C. 29.3 26.1 22.5 22.6 18.8 32.2 28.9 24.8 24.4 20.1 35.1 31.7 27.1 26.2 21.5

K.W. 1.50 1.50 1.50 1.50 1.51 1.50 1.50 1.50 1.50 1.51 1.50 1.50 1.51 1.51 1.51

T.C. 29.0 31.7 31.8 35.6 39.8 31.2 33.5 33.7 37.6 42.7 33.4 35.4 35.5 39.6 45.5

S.C. 28.3 25.3 21.5 21.7 17.4 30.7 28.3 23.8 23.9 19.1 33.2 31.4 26.1 26.1 20.9

K.W. 1.66 1.66 1.66 1.67 1.67 1.66 1.66 1.66 1.67 1.67 1.66 1.66 1.67 1.67 1.68

T.C. 27.6 29.9 29.9 34.0 36.8 29.6 31.7 31.5 35.8 40.0 31.5 33.6 33.2 37.6 43.2

S.C. 27.3 24.5 20.5 20.7 16.0 29.3 27.8 22.8 23.4 18.1 31.3 31.1 25.2 26.1 20.3

K.W. 1.82 1.83 1.82 1.84 1.84 1.82 1.83 1.82 1.84 1.84 1.83 1.83 1.83 1.84 1.85

T.C. 25.6 28.1 27.5 31.6 35.0 27.4 29.5 28.9 33.1 37.4 29.1 30.9 30.3 34.7 39.8

S.C. 25.4 23.3 19.5 19.8 15.3 27.1 26.4 21.8 22.3 17.2 28.9 29.5 24.2 24.8 19.1

K.W. 2.02 2.03 2.02 2.04 2.04 2.03 2.03 2.03 2.04 2.05 2.03 2.03 2.03 2.04 2.05

T.C. 23.6 26.4 25.2 29.2 33.2 25.2 27.3 26.3 30.5 34.8 26.7 28.1 27.4 31.8 36.5

S.C. 23.4 22.1 18.6 18.9 14.7 25.0 25.0 20.8 21.2 16.3 26.5 27.9 23.1 23.5 17.9

K.W. 2.23 2.23 2.23 2.24 2.25 2.23 2.23 2.23 2.24 2.25 2.24 2.24 2.23 2.24 2.25

T.C. 21.1 22.9 22.1 26.0 29.6 22.6 23.8 22.8 27.1 30.8 24.0 24.6 23.6 28.2 32.1

S.C. 21.0 20.1 16.7 17.3 13.4 22.4 22.2 18.7 19.4 14.7 23.8 24.4 20.7 21.5 16.0

K.W. 2.52 2.51 2.51 2.53 2.54 2.52 2.52 2.51 2.53 2.54 2.53 2.53 2.51 2.53 2.54

T.C. 18.7 19.6 19.0 22.8 26.1 20.0 20.4 19.4 23.7 27.0 21.3 21.1 19.9 24.6 27.9

S.C. 18.6 18.1 14.9 15.7 12.2 19.9 19.5 16.6 17.6 13.2 21.2 21.0 18.4 19.6 14.2

K.W. 2.80 2.79 2.79 2.80 2.81 2.80 2.80 2.79 2.80 2.81 2.81 2.80 2.79 2.80 2.81

T.C. 16.3 16.2 16.0 19.7 22.6 17.5 16.9 16.1 20.4 23.1 18.7 17.7 16.1 21.1 23.6

S.C. 16.2 16.1 13.1 14.2 10.9 17.4 16.8 14.6 15.9 11.6 18.6 17.5 16.0 17.6 12.3

K.W. 3.08 3.07 3.07 3.08 3.09 3.08 3.07 3.07 3.08 3.09 3.09 3.08 3.07 3.08 3.09

8 Johnson Controls Unitary Products

Page 9

COOLING PERFORMANCE DA TA

PACKAGED UNIT MODEL NO. PHG4B36

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 1000 1200 1400

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 40.4 43.9 43.9 47.3 46.7 43.3 45.1 45.4 47.7 47.3 46.2 46.2 46.8 48.2 47.8

S.C. 40.0 34.9 30.5 29.3 22.4 42.9 40.4 32.6 31.2 23.3 45.9 45.9 34.6 33.0 24.3

K.W. 1.97 1.98 1.98 1.98 1.98 2.06 2.07 2.07 2.07 2.07 2.16 2.16 2.16 2.16 2.16

T.C. 37.9 41.2 41.4 45.1 47.2 40.4 42.4 42.6 46.0 47.8 42.8 43.7 43.8 46.9 48.5

S.C. 37.9 33.7 29.1 28.4 22.3 40.4 38.1 32.7 30.6 23.5 42.8 42.5 36.4 32.7 24.7

K.W. 2.17 2.18 2.17 2.18 2.18 2.26 2.27 2.27 2.28 2.28 2.36 2.36 2.37 2.37 2.37

T.C. 35.4 38.5 38.9 42.8 47.6 37.5 39.8 39.8 44.2 48.4 39.5 41.1 40.7 45.7 49.1

S.C. 35.4 32.5 27.6 27.4 22.1 37.5 35.7 32.9 29.9 23.7 39.5 39.0 38.2 32.5 25.2

K.W. 2.36 2.39 2.36 2.39 2.39 2.46 2.48 2.47 2.48 2.48 2.56 2.57 2.58 2.58 2.58

T.C. 33.1 35.4 35.8 39.7 44.4 34.7 36.5 36.6 40.7 45.2 36.4 37.5 37.4 41.6 46.0

S.C. 33.1 30.8 26.1 25.9 20.7 34.7 34.0 30.0 28.2 22.3 36.4 37.1 33.9 30.6 23.9

K.W. 2.63 2.65 2.63 2.65 2.65 2.72 2.74 2.73 2.74 2.74 2.81 2.83 2.83 2.83 2.83

T.C. 30.7 32.2 32.7 36.6 41.1 32.0 33.1 33.4 37.1 42.1 33.4 33.9 34.1 37.6 43.0

S.C. 30.7 29.1 24.6 24.3 19.4 32.0 32.2 27.1 26.5 21.0 33.4 33.9 29.6 28.7 22.6

K.W. 2.89 2.91 2.89 2.91 2.91 2.98 3.00 2.98 3.00 3.00 3.07 3.09 3.08 3.09 3.09

T.C. 27.8 28.4 28.7 32.2 36.6 28.8 29.1 29.0 32.3 37.1 29.8 29.7 29.3 32.5 37.5

S.C. 27.8 26.7 22.7 22.5 17.6 28.8 28.8 24.6 24.6 19.0 29.8 29.7 26.5 26.8 20.5

K.W. 3.26 3.28 3.27 3.28 3.28 3.35 3.37 3.36 3.37 3.37 3.44 3.46 3.45 3.46 3.46

T.C. 25.1 24.8 24.9 27.9 32.3 25.7 25.2 24.7 27.7 32.2 26.4 25.6 24.5 27.4 32.1

S.C. 25.1 24.3 20.9 20.7 15.8 25.7 25.2 22.2 22.8 17.1 26.4 25.6 23.6 24.9 18.5

K.W. 3.63 3.64 3.63 3.63 3.64 3.72 3.73 3.73 3.72 3.73 3.81 3.82 3.82 3.81 3.82

T.C. 22.3 21.1 21.1 23.7 27.9 22.6 21.3 20.5 23.0 27.3 22.9 21.5 19.8 22.4 26.8

S.C. 22.3 21.1 19.0 18.9 14.1 22.6 21.3 19.8 21.0 15.3 22.9 21.5 19.8 22.4 16.4

K.W. 3.99 4.00 4.00 3.99 4.00 4.08 4.09 4.09 4.08 4.09 4.17 4.18 4.18 4.17 4.18

COOLING PERFORMANCE DA TA

PACKAGED UNIT MODEL NO. PHG4B42

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 1200 1400 1600

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 45.8 50.4 50.3 53.3 55.3 47.6 51.3 51.2 54.1 56.6 49.5 52.3 52.1 54.9 57.9

S.C. 45.8 40.4 34.5 33.0 25.6 47.6 42.5 36.2 34.4 26.5 49.5 44.6 37.9 35.9 27.4

K.W. 2.26 2.27 2.28 2.28 2.28 2.37 2.37 2.37 2.38 2.38 2.47 2.47 2.46 2.47 2.47

T.C. 43.1 47.4 47.8 52.0 55.3 44.8 48.6 48.7 52.9 56.2 46.4 49.8 49.7 53.9 57.0

S.C. 43.1 39.3 33.5 32.9 25.6 44.8 42.1 35.8 34.9 26.7 46.4 45.0 38.0 36.9 27.8

K.W. 2.49 2.50 2.51 2.51 2.52 2.60 2.60 2.60 2.61 2.62 2.70 2.69 2.69 2.71 2.71

T.C. 40.3 44.4 45.3 50.7 55.4 41.9 45.8 46.3 51.8 55.8 43.4 47.3 47.3 52.9 56.2

S.C. 40.3 38.2 32.6 32.7 25.5 41.9 41.8 35.3 35.3 26.8 43.4 45.4 38.1 37.9 28.2

K.W. 2.72 2.73 2.73 2.74 2.76 2.82 2.82 2.82 2.85 2.86 2.93 2.92 2.92 2.95 2.95

T.C. 37.1 40.6 41.2 46.5 51.5 38.5 41.6 41.9 47.2 52.2 39.9 42.7 42.6 47.9 52.9

S.C. 37.1 36.1 30.4 30.7 24.0 38.5 39.1 33.0 33.0 25.4 39.9 42.0 35.5 35.4 26.7

K.W. 3.02 3.02 3.03 3.04 3.05 3.12 3.12 3.12 3.14 3.15 3.22 3.22 3.22 3.24 3.25

T.C. 34.0 36.8 37.2 42.4 47.6 35.2 37.5 37.6 42.7 48.6 36.5 38.1 38.0 43.0 49.7

S.C. 34.0 34.1 28.3 28.7 22.5 35.2 36.4 30.6 30.8 23.9 36.5 38.1 32.9 32.9 25.3

K.W. 3.31 3.31 3.33 3.35 3.35 3.41 3.41 3.42 3.44 3.45 3.51 3.51 3.51 3.53 3.55

T.C. 30.8 32.1 32.0 37.2 42.4 32.0 33.1 32.1 37.1 42.8 33.3 34.1 32.2 36.9 43.2

S.C. 30.8 30.4 26.1 26.6 20.4 32.0 32.5 27.5 28.5 21.7 33.3 34.1 29.0 30.4 23.1

K.W. 3.73 3.73 3.74 3.76 3.76 3.83 3.83 3.83 3.85 3.86 3.93 3.93 3.92 3.95 3.96

T.C. 27.7 27.5 27.0 32.2 37.4 28.9 28.8 26.8 31.6 37.1 30.1 30.1 26.6 31.0 36.9

S.C. 27.7 26.9 24.0 24.7 18.4 28.9 28.7 24.5 26.3 19.7 30.1 30.1 25.1 28.0 20.9

K.W. 4.13 4.14 4.14 4.16 4.17 4.23 4.24 4.23 4.25 4.26 4.33 4.34 4.32 4.35 4.36

T.C. 24.6 23.0 21.9 27.1 32.3 25.8 24.6 21.5 26.1 31.5 27.0 26.2 21.0 25.1 30.6

S.C. 24.6 23.0 21.8 22.7 16.5 25.8 24.6 21.5 24.1 17.6 27.0 26.2 21.0 25.1 18.7

K.W. 4.53 4.54 4.53 4.56 4.58 4.63 4.64 4.63 4.65 4.66 4.73 4.74 4.72 4.75 4.75

5127524-YTG-A-0815

Johnson Controls Unitary Products 9

Page 10

5127524-YTG-A-0815

COOLING PERFORMANCE DATA

PACKAGED UNIT MODEL NO. PHG4B48

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 1400 1600 1800

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 48.0 51.3 52.4 56.5 64.4 50.6 53.7 54.5 60.0 66.5 53.1 56.1 56.7 63.6 68.5

S.C. 48.0 44.1 37.9 40.8 33.6 50.6 47.6 40.5 42.6 35.0 53.1 51.0 43.2 44.3 36.4

K.W. 2.63 2.64 2.63 2.66 2.70 2.77 2.77 2.77 2.80 2.82 2.91 2.90 2.90 2.93 2.95

T.C. 45.0 48.1 48.9 54.0 60.8 47.3 50.1 50.9 56.8 62.7 49.7 52.0 53.0 59.5 64.7

S.C. 45.0 41.5 35.6 37.5 31.0 47.3 44.8 38.1 39.6 32.6 49.7 48.0 40.6 41.7 34.2

K.W. 2.90 2.92 2.90 2.94 2.96 3.03 3.05 3.03 3.07 3.09 3.17 3.17 3.16 3.21 3.22

T.C. 42.0 44.9 45.4 51.6 57.2 44.1 46.4 47.3 53.5 59.0 46.2 47.9 49.3 55.4 60.8

S.C. 42.0 38.9 33.3 34.2 28.4 44.1 41.9 35.7 36.6 30.1 46.2 45.0 38.0 39.0 31.9

K.W. 3.16 3.21 3.16 3.22 3.22 3.30 3.32 3.30 3.35 3.35 3.43 3.44 3.43 3.48 3.49

T.C. 39.3 41.4 41.9 48.2 53.7 41.1 42.8 43.5 49.9 55.3 42.9 44.1 45.2 51.7 56.8

S.C. 39.3 36.4 31.0 32.0 26.1 41.1 39.4 33.2 34.3 27.7 42.9 42.4 35.5 36.6 29.4

K.W. 3.53 3.56 3.52 3.57 3.58 3.66 3.68 3.65 3.70 3.72 3.79 3.81 3.79 3.84 3.85

T.C. 36.6 37.9 38.5 44.8 50.1 38.1 39.1 39.7 46.4 51.5 39.7 40.4 41.0 48.0 52.9

S.C. 36.6 34.0 28.6 29.8 23.8 38.1 36.9 30.8 32.0 25.3 39.7 39.8 33.0 34.2 26.9

K.W. 3.91 3.91 3.87 3.93 3.95 4.03 4.04 4.01 4.06 4.08 4.16 4.17 4.15 4.19 4.20

T.C. 33.2 34.2 34.7 41.0 46.0 34.4 35.4 35.9 42.2 47.3 35.7 36.5 37.0 43.4 48.6

S.C. 33.2 32.3 26.9 27.7 21.9 34.4 34.8 28.9 29.7 23.4 35.7 36.5 31.0 31.7 24.9

K.W. 4.40 4.40 4.38 4.43 4.44 4.53 4.53 4.51 4.56 4.57 4.66 4.66 4.64 4.69 4.70

T.C. 29.9 30.7 31.1 37.3 42.1 30.8 31.7 32.1 38.1 43.3 31.8 32.8 33.1 38.9 44.4

S.C. 29.9 30.6 25.2 25.6 20.1 30.8 31.7 27.1 27.5 21.5 31.8 32.8 29.0 29.4 22.9

K.W. 4.89 4.89 4.87 4.91 4.92 5.02 5.01 5.00 5.04 5.05 5.15 5.14 5.12 5.17 5.18

T.C. 26.5 27.1 27.5 33.6 38.2 27.2 28.1 28.3 34.0 39.2 27.9 29.0 29.1 34.4 40.3

S.C. 26.5 27.1 23.5 23.6 18.3 27.2 28.1 25.2 25.3 19.7 27.9 29.0 27.0 27.1 21.0

K.W. 5.37 5.37 5.36 5.39 5.40 5.50 5.49 5.48 5.52 5.53 5.64 5.62 5.60 5.65 5.66

COOLING PERFORMANCE DATA

PACKAGED UNIT MODEL NO. PHG4B60

CONDENSER

ENTERING AIR

TEMPERATURE

55 / 45

65 / 55

75 / 63

85 / 69

95 / 75

105 / 83

115 / 89

125 / 95

ID CFM 1600 1400 1200

IDDB 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

IDWB 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 61.5 74.6 68.4 68.6 81.4 65.3 74.6 70.4 70.6 80.6 69.1 74.7 72.3 72.6 79.7

S.C. 61.5 46.4 47.0 55.3 37.3 65.3 49.2 50.6 60.0 38.1 69.1 52.1 54.2 64.6 38.9

K.W. 3.37 3.44 3.40 3.41 3.45 3.54 3.59 3.56 3.57 3.61 3.72 3.74 3.72 3.73 3.76

T.C. 58.9 66.6 64.2 67.4 77.8 62.3 64.4 65.8 69.2 78.2 65.6 62.1 67.4 71.1 78.5

S.C. 58.9 48.4 45.0 49.0 36.9 62.3 48.6 48.5 53.0 37.8 65.6 48.7 52.0 57.1 38.8

K.W. 3.69 3.75 3.74 3.77 3.82 3.87 4.06 3.90 3.93 3.98 4.05 4.37 4.06 4.10 4.14

T.C. 56.3 58.7 60.0 66.2 74.3 59.2 54.1 61.2 67.8 75.8 62.1 49.5 62.5 69.5 77.3

S.C. 56.3 50.4 42.9 42.6 36.5 59.2 47.9 46.4 46.1 37.6 62.1 45.4 49.8 49.5 38.7

K.W. 4.01 4.06 4.09 4.14 4.18 4.20 4.53 4.25 4.30 4.35 4.39 5.01 4.41 4.47 4.52

T.C. 52.5 54.1 55.0 61.5 69.1 55.1 52.4 56.2 62.7 70.5 57.8 50.6 57.4 63.9 72.0

S.C. 52.5 47.9 40.8 40.5 33.4 55.1 48.3 44.1 43.8 34.8 57.8 48.6 47.3 47.1 36.2

K.W. 4.49 4.53 4.54 4.60 4.64 4.67 4.85 4.70 4.76 4.81 4.85 5.17 4.87 4.93 4.97

T.C. 48.6 49.5 50.0 56.7 63.8 51.1 50.6 51.2 57.5 65.3 53.5 51.7 52.4 58.3 66.7

S.C. 48.6 45.4 38.8 38.4 30.2 51.1 48.6 41.8 41.6 32.0 53.5 51.7 44.8 44.8 33.8

K.W. 4.97 5.01 4.99 5.05 5.10 5.14 5.17 5.15 5.22 5.26 5.31 5.33 5.32 5.39 5.42

T.C. 44.5 44.3 44.1 50.1 57.4 46.5 45.1 44.7 50.2 58.2 48.6 46.0 45.4 50.3 59.1

S.C. 44.5 41.6 35.9 36.5 27.7 46.5 43.9 38.2 39.0 29.4 48.6 46.0 40.4 41.4 31.1

K.W. 5.66 5.68 5.66 5.71 5.75 5.83 5.84 5.82 5.88 5.91 5.99 6.00 5.99 6.04 6.07

T.C. 40.5 39.2 38.4 43.6 51.1 42.1 39.9 38.5 43.0 51.4 43.8 40.5 38.6 42.5 51.7

S.C. 40.5 37.9 33.2 34.6 25.2 42.1 39.3 34.7 36.4 26.9 43.8 40.5 36.2 38.1 28.5

K.W. 6.33 6.34 6.31 6.35 6.39 6.49 6.50 6.47 6.52 6.55 6.66 6.66 6.63 6.68 6.71

T.C. 36.5 34.1 32.7 37.1 44.9 37.7 34.6 32.3 35.9 44.6 39.0 35.0 31.8 34.8 44.3

S.C. 36.5 34.1 30.4 32.8 22.8 37.7 34.6 31.2 33.8 24.4 39.0 35.0 31.8 34.8 25.9

K.W. 7.00 6.99 6.97 6.99 7.02 7.16 7.15 7.12 7.16 7.18 7.32 7.31 7.28 7.32 7.34

10 Johnson Controls Unitary Products

Page 11

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4A24

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

MBH COP KW MB H COP KW MBH COP KW

28.1 4.56 1.80 29.3 5.06 1.69 30.5 5.63 1.58

26.7 3.92 1.99 27.8 4.34 1.87 29.0 4.82 1.76

25.3 3.39 2.18 26.4 3.75 2.05 27.5 4.16 1.93

23.4 4.00 1.71 24.1 4.31 1.63 24.9 4.66 1.56

22.3 3.42 1.91 23.0 3.70 1.82 23.7 4.00 1.73

21.3 2.96 2.10 21.9 3.20 2.00 22.5 3.46 1.90

20.7 3.61 1.67 21.4 3.87 1.61 22.0 4.16 1.54

19.8 3.09 1.87 20.4 3.32 1.79 21.0 3.58 1.71

18.8 2.66 2.06 19.4 2.87 1.97 20.0 3.10 1.88

17.1 3.08 1.62 17.6 3.28 1.57 18.2 3.48 1.53

16.7 2.69 1.80 17.0 2.83 1.75 17.3 2.98 1.69

16.2 2.38 1.99 16.3 2.47 1.93 16.4 2.57 1.86

13.6 2.57 1.54 13.9 2.65 1.52 14.1 2.75 1.50

12.7 2.14 1.73 12.9 2.22 1.69 13.1 2.31 1.66

11.8 1.80 1.91 12.0 1.87 1.87 12.2 1.95 1.82

12.2 2.36 1.51 12.1 2.37 1.49 12.1 2.38 1.48

11.4 1.97 1.68 11.3 1.99 1.66 11.3 2.01 1.63

10.5 1.65 1.86 10.4 1.67 1.82 10.4 1.70 1.79

5127524-YTG-A-0815

ID CFM

600 800 1000

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4A30

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

60

70

80

MBH COP KW MB H COP KW MBH COP KW

34.6 4.82 2.10 35.6 5.05 2.06 36.6 5.29 2.02

33.3 4.19 2.32 34.2 4.40 2.27 35.0 4.62 2.22

32.0 3.67 2.55 32.8 3.86 2.48 33.5 4.05 2.41

29.1 4.13 2.06 29.6 4.27 2.03 30.1 4.41 1.99

27.7 3.55 2.27 28.2 3.68 2.23 28.7 3.81 2.20

26.2 3.07 2.49 26.7 3.19 2.44 27.2 3.31 2.40

25.5 3.69 2.02 26.1 3.82 2.00 26.7 3.95 1.97

24.3 3.15 2.25 24.8 3.27 2.21 25.3 3.39 2.18

23.0 2.71 2.48 23.5 2.82 2.43 23.9 2.93 2.38

21.2 3.17 1.95 21.4 3.22 1.94 21.6 3.26 1.93

20.3 2.74 2.16 20.5 2.78 2.14 20.7 2.83 2.13

19.3 2.38 2.37 19.5 2.42 2.35 19.7 2.47 2.32

16.3 2.55 1.86 16.1 2.51 1.87 15.9 2.47 1.88

14.3 2.00 2.10 14.5 2.03 2.08 14.5 2.06 2.06

12.4 1.55 2.33 12.8 1.63 2.29 13.2 1.71 2.24

13.7 2.20 1.81 13.6 2.16 1.84 13.6 2.13 1.86

12.7 1.84 2.01 12.5 1.81 2.03 12.4 1.77 2.04

11.7 1.54 2.21 11.4 1.51 2.21 11.2 1.47 2.22

ID CFM

800 1000 1200

Johnson Controls Unitary Products 11

Page 12

5127524-YTG-A-0815

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4B36

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60 41.6 4.67 2.60 42.7 4.87 2.56 43.8 5.08 2.52

70 39.9 4.08 2.86 40.9 4.25 2.81 41.9 4.42 2.77

80 38.2 3.58 3.11 39.1 3.73 3.06 40.0 3.88 3.01

60 35.3 4.14 2.49 35.8 4.23 2.47 36.3 4.33 2.45

70 33.8 3.59 2.75 34.2 3.67 2.72 34.7 3.76 2.69

80 32.3 3.13 3.01 32.7 3.21 2.97 33.0 3.29 2.93

60 31.5 3.76 2.45 32.0 3.83 2.44 32.4 3.90 2.42

70 30.1 3.26 2.70 30.5 3.33 2.68 31.0 3.40 2.66

80 28.7 2.84 2.95 29.1 2.91 2.92 29.5 2.97 2.90

60 26.8 3.29 2.38 27.0 3.31 2.38 27.2 3.33 2.39

70 25.3 2.82 2.62 25.6 2.85 2.62 25.8 2.88 2.62

80 23.9 2.43 2.87 24.1 2.47 2.86 24.4 2.50 2.84

60 20.1 2.54 2.31 20.3 2.54 2.33 20.4 2.54 2.35

70 18.7 2.16 2.52 18.4 2.11 2.54 18.0 2.06 2.56

80 17.3 1.84 2.74 16.5 1.75 2.76 15.7 1.65 2.77

60 17.6 2.28 2.25 17.6 2.26 2.28 17.7 2.23 2.31

70 16.1 1.90 2.48 16.3 1.89 2.50 16.4 1.89 2.52

80 14.7 1.59 2.70 14.9 1.59 2.72 15.0 1.60 2.74

MBH COP KW MBH COP KW MBH COP KW

ID CFM

1000 1200 1400

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4B42

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60 48.14.383.2149.14.363.2950.14.333.38

70 46.03.843.5046.93.833.5847.83.823.65

80 43.93.383.7944.73.383.8645.43.383.92

60 40.13.833.0640.73.753.1641.23.683.27

70 38.03.323.3438.53.273.4439.03.223.54

80 35.92.893.6336.32.863.7136.82.833.80

60 35.33.413.0235.73.313.1536.13.223.27

70 33.22.903.3533.42.823.4633.62.753.57

80 31.12.473.6731.12.413.7731.12.353.87

60 25.52.522.9527.92.653.0830.32.763.20

70 25.82.323.2426.42.303.3627.02.273.47

80 26.12.163.5325.02.003.6423.81.863.74

60 21.62.192.8722.02.133.0222.52.083.16

70 20.01.863.1419.81.763.2819.61.683.41

80 18.41.573.4117.51.453.5316.71.333.65

60 17.61.802.8517.01.653.0116.41.513.16

70 16.71.583.0916.01.443.2415.31.313.38

80 15.81.393.3214.91.263.4614.11.143.60

MBH COP KW MBH COP KW MBH COP KW

ID CFM

1200 1400 1600

12 Johnson Controls Unitary Products

Page 13

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4B48

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60 56.5 4.87 3.39 57.8 4.95 3.41 59.0 5.03 3.43

70 54.9 4.29 3.74 56.0 4.37 3.74 57.0 4.46 3.74

80 53.3 3.80 4.09 54.2 3.89 4.07 55.1 3.98 4.05

60 48.4 4.33 3.27 49.2 4.37 3.29 49.9 4.42 3.30

70 46.7 3.77 3.62 47.4 3.82 3.62 48.1 3.87 3.63

80 45.0 3.32 3.97 45.6 3.36 3.96 46.2 3.41 3.95

60 43.3 3.94 3.21 43.8 3.96 3.23 44.3 3.98 3.25

70 40.5 3.36 3.52 41.7 3.44 3.55 42.9 3.51 3.57

80 37.8 2.88 3.84 39.7 3.00 3.86 41.5 3.12 3.89

60 37.5 3.50 3.13 37.0 3.40 3.18 36.6 3.31 3.23

70 35.2 2.93 3.51 34.7 2.88 3.52 34.2 2.83 3.53

80 32.9 2.47 3.88 32.3 2.45 3.86 31.8 2.42 3.84

60 28.4 2.71 3.06 28.2 2.66 3.09 28.0 2.61 3.13

70 27.2 2.33 3.41 27.0 2.30 3.43 26.9 2.27 3.46

80 26.0 2.02 3.76 25.9 2.00 3.77 25.8 1.99 3.79

60 25.8 2.53 2.98 25.5 2.43 3.05 25.1 2.34 3.12

70 24.1 2.13 3.30 24.0 2.09 3.36 24.0 2.05 3.41

80 22.4 1.80 3.62 22.6 1.80 3.66 22.9 1.81 3.70

MBH COP KW MB H COP KW MBH COP KW

5127524-YTG-A-0815

ID CFM

1400 1600 1800

HEATING PERFORMANCE DATA

PACKAGED UNIT MODEL NO PHG4B60

AIR TEMP.

ENTERING

OUTDOOR UNIT

60

47

40

30

17

10

AIR TEMP.

ENTERING

INDOOR COIL

60 70.2 4.50 4.55 71.2 4.54 4.59 72.2 4.57 4.61

70 67.6 3.94 5.01 68.4 3.98 5.03 69.1 4.02 5.03

80 65.0 3.48 5.46 65.5 3.51 5.46 66.1 3.56 5.44

60 58.4 3.98 4.28 58.7 3.93 4.36 59.0 3.88 4.44

70 56.3 3.46 4.76 56.5 3.44 4.80 56.8 3.42 4.86

80 54.1 3.03 5.23 54.3 3.03 5.25 54.6 3.03 5.26

60 52.5 3.69 4.17 52.8 3.61 4.28 53.0 3.54 4.38

70 49.8 3.15 4.63 50.4 3.13 4.71 51.1 3.13 4.78

80 47.0 2.70 5.09 48.1 2.73 5.13 49.1 2.77 5.17

60 38.2 2.87 3.89 38.2 2.77 4.03 38.2 2.68 4.15

70 39.5 2.63 4.38 37.9 2.49 4.46 36.3 2.35 4.51

80 40.9 2.45 4.88 37.7 2.25 4.88 34.4 2.06 4.88

60 29.5 2.33 3.71 32.5 2.41 3.94 35.4 2.48 4.17

70 27.6 1.92 4.19 30.5 2.04 4.36 33.4 2.16 4.53

80 25.6 1.59 4.69 28.5 1.74 4.78 31.5 1.88 4.88

60 30.1 2.31 3.79 29.9 2.21 3.96 29.8 2.12 4.11

70 28.4 1.98 4.19 28.2 1.90 4.32 28.0 1.83 4.46

80 26.8 1.71 4.57 26.5 1.65 4.69 26.2 1.59 4.82

MBH COP KW MB H COP KW MBH COP KW

ID CFM

1600 1800 2000

Johnson Controls Unitary Products 13

Page 14

5127524-YTG-A-0815

HIGH VOLTAGE

CONNECTION 7/8”

HIGH VOLTAGE

CONNECTION 1-3/32”

COMPRESSOR

ACCESS PANEL

CONDENSATE

DRAIN

BLOWER

ACCESS

PANEL

CONTROL ACCESS

PANEL

LOW VOLTAGE CONNECTION

GAS SUPPLY

EXHAUST HOOD

COMBUSTION AIR INTAKE

HEAT EXCHANGER ACCESS PANEL

B

A

C

A0296-001

COIL GUARD

DIMENSIONS

Unit Dimensions

Model

ABC

PHG4A24 51-1/4 35-3/4 47

PHG4A30 51-1/4 35-3/4 49

PHG4B36 51-1/4 45-3/4 49

PHG4B42 51-1/4 45-3/4 49

PHG4B48 51-1/4 45-3/4 53

PHG4B60 51-1/4 45-3/4 55

Dimensions

Unit Clearances1

2

Direction Distance (in.) Direction Distance (in.)

Top

3

36 Power Entry (Right Side) 36

Side Opposite Ducts 36 Left Side 24

Duct Panel 0 Bottom

1. A 1" clearance must be provided between any co mbustible material and the supply air duct work.

2. The products of combustion must not be allowed to accumulate within a confined space and recirculate.

3. Units must be installed outdoors. Over hanging structure or shrubs should not obstruct condenser air discharge outlet.

4. Units may be installed on combustible materials made from wood or cla ss A, B or C roof covering materials only if factory

base rails are left in place as shipped.

4

1

14 Johnson Controls Unitary Products

Page 15

Indoor Blower Specifications

5127524-YTG-A-0815

Model

HP RPM EFF. SF Frame

Motor

PHG4A24 1/2 Variable 0.8 1.0 48

PHG4A30 1/2 Variable 0.8 1.0 48

PHG4B36 1/2 Variable 0.8 1.0 48

PHG4B42 3/4 Variable 0.8 1.0 48

PHG4B48 3/4 Variable 0.8 1.0 48

PHG4B60 1 Variable 0.8 1.0 48

Sound Performance - Dual Fuel Cooling Sound Power Levels

Model

(Tons)

PHG4A24

PHG4A30

PHG4B36

PHG4B42

PHG4B48

PHG4B60

1. Rated in accordance with AHRI Standard 270.

Sound Rating

dB (A)

72.4 61 .8 60.5 63.1 62.5 57.1 51.8 44.0

68.7 58 .3 58.8 56.6 57.3 54.0 48.4 43.0

73.2 61 .8 63.2 60.5 64.4 58.9 53.4 45.9

73.6 62 .4 59.0 61.5 64.9 60.3 55.8 50.6

74.0 62 .0 62.0 60.9 64.7 60.1 56.6 49.2

74.1 65 .9 61.8 60.8 63.5 58.7 55.5 48.3

1

125 250 500 1000 2000 4000 8000

Octave Band Centerline Frequency (Hz)

Sound Performance - Dual Fuel Heating Sound Power Levels

Model

(Tons)

PHG4A24

PHG4A30

PHG4B36

PHG4B42

PHG4B48

PHG4B60

1. Rated in accordance with AHRI Standard 270.

Sound Rating

dB (A)

70.3 64.7 59.2 59.8 58.1 54.3 49.2 43.2

69.0 57.5 58.0 58.0 63.8 53.2 47.6 49.7

72.8 60.1 62.5 60.4 64.5 58.8 53.0 46.0

73.6 62.4 58.3 61.5 65.7 59.7 54.4 47.9

74.6 66.0 63.3 61.1 64.6 60.2 56.4 48.9

73.7 61.6 59.4 60.5 63.6 58.7 55.1 51.4

1

125 250 500 1000 2000 4000 8000

Octave Band Centerline Frequency (Hz)

Electrical Data

OD Fan

Motor

Model Voltage

Compressor

RLA LRA MCC FLA FLA

24050 208/230-1-60 10.0 62.0 16.0 0.7 2.6 15.8 25

24075 208/230-1-60 10.0 62.0 16.0 0.7 3.8 17.0 25

30050 208/230-1-60 14.0 73.0 22.0 0.6 2.6 20.7 30

30075 208/230-1-60 14.0 73.0 22.0 0.6 3.8 21.9 35

36065 208/230-1-60 17.0 79.0 26.0 1.7 3.8 26.8 40

36100 208/230-1-60 17.0 79.0 26.0 1.7 5.4 28.4 45

42065, 42100 208/230-1-60 18.0 112.0 28.0 1.7 5.4 29.6 45

48065, 48100, 48125 208/230-1-60 22.0 117.0 34.0 1.7 5.4 34.6 50

60065, 60100, 60125 208/230-1-60 24.0 144.0 38.0 1.7 7.0 38.7 60

1. Minimum Circuit Ampacity.

2. Maximum Over Current Protection per standard UL 1995.

3. Fuse or HACR circuit breaker size field installed.

Supply

Blower Motor

MCA

(Amps)

1

Max Fuse2/

3

Breaker

Size

(Amps)

Johnson Controls Unitary Products 15

Page 16

5127524-YTG-A-0815

X

CENTER OF

GRAVITY

FRONT

OF UNIT

Y

"D"

"C"

"B"

"A"

A0295-001-TG

COMPRESSOR

WEIGHTS & DIMENSIONS

Weights and Dimensions

Model Weight (lbs.) Center of Gravity 4 Point Load Location (lbs.)

ShippingOperatingXYABCD

24050 399 394 28 15 131 101 86 76

24075 409 404 28 15 135 103 86 80

30050 454 449 28 15 155 108 96 90

30075 458 453 28 15 161 102 90 100

36065 503 498 29 14 176 122 104 96

36100 510 505 29 14 178 123 109 95

42065 537 532 29 14 190 132 112 98

42100 539 534 29 14 191 133 109 101

48065 556 551 28 14 199 137 106 109

48100 564 559 28 14 194 141 117 107

48125 569 564 29 14 193 146 126 99

60065 582 577 29 14 199 151 127 100

60100 586 581 28 14 201 152 123 105

60125 593 588 27 15 202 151 125 110

16 Johnson Controls Unitary Products

Page 17

AIRFLOW PERFORMANCE

Airflow - Side Duct Application

Model Motor Speed

Low (1) 732 667 624 567

Low/Medium (2) 818 771 723 674

24050

24075

30050

30075

36065

36100

42065

42100

48065

48100

Continued on next page.

Medium (3) 823 774 721 676

Medium/High (4) 994 948 906 865

High (5) 1148 1108 1071 1035

Low (1) 887 847 802 750

Low/Medium (2) 978 941 898 850

Medium (3) 1171 1114 1074 1039

Medium/High (4) 1349 1297 1265 1224

High (5) 1487 1462 1392 1331

Low (1) 700 657 599 554

Low/Medium (2) 906 868 825 779

Medium (3) 992 951 911 868

Medium/High (4) 1075 1032 1000 958

High (5) 1136 1089 1053 1018

Low (1) 1076 1020 984 943

Low/Medium (2) 1102 1048 1010 974

Medium (3) 1191 1140 1112 1076

Medium/High (4) 1201 1225 1187 1151

High (5) 1370 1329 1283 1271

Low (1) 1225 1174 1131 1090

Low/Medium (2) 1259 1209 1166 1126

Medium (3) 1314 1271 1229 1186

Medium/High (4) 1348 1306 1259 1222

High (5) 1506 1471 1403 1389

Low (1) 1342 1302 1260 1217

Low/Medium (2) 1425 1368 1332 1293

Medium (3) 1554 1503 1465 1423

Medium/High (4) 1658 1599 1588 1530

High (5) 1743 1697 1650 1604

Low (1) 1315 1266 1229 1194

Low/Medium (2) 1436 1382 1342 1304

Medium (3) 1458 1406 1365 1327

Medium/High (4) 1573 1523 1484 1445

High (5) 1743 1697 1650 1604

Low (1) 1436 1382 1342 1304

Low/Medium (2) 1544 1492 1455 1416

Medium (3) 1573 1523 1484 1445

Medium/High (4) 1681 1640 1599 1557

High (5) 1743 1697 1650 1604

Low (1) 1046 1009 980 946

Low/Medium (2) 1295 1250 1213 1172

Medium (3) 1620 1564 1517 1466

Medium/High (4) 1798 1722 1669 1620

High (5) 2146 2085 2025 1960

Low (1) 1620 1564 1517 1466

Low/Medium (2) 1694 1630 1580 1530

Medium (3) 1798 1722 1669 1620

Medium/High (4) 1835 1758 1703 1653

High (5) 2146 2085 2025 1960

5127524-YTG-A-0815

External Static Pressure (Inches WC)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

SCFM SCFM SCFM SCFM

SCFM SCFM SCFM SCFM

517 470 415 369

628 579 530 482

631 583 533 505

823 778 739 700

996 960 925 901

705 664 613 563

803 759 713 667

993 949 906 864

1185 1146 1107 1063

1318 1281 1241 1201

512 461 411 365

735 692 650 608

826 787 747 712

918 874 837 800

978 941 903 869

903 859 819 779

934 890 850 810

1038 1000 958 919

1118 1080 1041 1002

1209 1176 1143 1109

1046 993 941 888

1084 1032 980 928

1144 1097 1049 998

1179 1133 1086 1036

1345 1305 1262 1216

1178 1134 1082 1034

1251 1208 1163 1113

1386 1346 1302 1257

1495 1454 1414 1373

1557 1511 1463 1418

1156 1117 1080 1036

1262 1220 1179 1131

1286 1244 1203 1155

1408 1367 1327 1279

1557 1511 1463 1418

1262 1220 1179 1131

1376 1336 1294 1248

1408 1367 1327 1279

1517 1478 1436 1393

1557 1511 1463 1418

915 878 844 779

1133 1087 1045 964

1418 1360 1308 1206

1572 1527 1480 1413

1872 1862 1798 1735

1418 1360 1308 1206

1482 1430 1380 1292

1572 1527 1480 1413

1604 1558 1511 1442

1872 1862 1798 1735

Johnson Controls Unitary Products 17

Page 18

5127524-YTG-A-0815

Airflow - Side Duct Application (Continued)

External Static Pressure (Inches WC)

Model Motor Speed

Low (1) 1620 1564 1517 1466

Low/Medium (2) 1798 1722 1669 1620

48125

Medium (3) 1922 1863 1804 1754

Medium/High (4) 2001 1952 1890 1839

High (5) 2146 2085 2025 1960

Low (1) 1073 1043 1009 988

Low/Medium (2) 1329 1292 1250 1223

60065

Medium (3) 2054 1998 1934 1890

Medium/High (4) 2195 2144 2098 2049

High (5) 2445 2388 2306 2293

Low (1) 1730 1682 1628 1592

Low/Medium (2) 1858 1807 1749 1710

60100

Medium (3) 2054 1998 1934 1890

Medium/High (4) 2195 2144 2098 2049

High (5) 2445 2388 2306 2293

Low (1) 2063 2008 1943 1899

Low/Medium (2) 2130 2084 2032 1983

60125

Medium (3) 2195 2144 2098 2049

Medium/High (4) 2275 2252 2169 2154

High (5) 2445 2388 2306 2293

1. Airflow tested with dry coil conditions, without air filters, at 230 volts

2. Applications above 0.8" w.c. external static pressure are not recommended.

3. Brushless DC high efficiency standard ECM blower motor used for all indoor blower assemblies.

4. Minimal variations in airflow performance data results from operating at 208 volts. Data above may be used in those cases.

5. Heating applications tested at 0.50" w.c. esp, and cooling applications tested at 0.30" w.c.esp per standards.

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

SCFM SCFM SCFM SCFM

SCFM SCFM SCFM SCFM

1418 1360 1308 1206

1572 1527 1480 1413

1724 1658 1612 1559

1820 1742 1696 1651

1872 1862 1798 1735

963 941 917 892

1192 1165 1136 1105

1843 1801 1757 1710

2003 1955 1883 1868

2235 2178 2129 2077

1552 1517 1479 1439

1667 1629 1589 1546

1843 1801 1757 1710

2003 1955 1883 1868

2235 2178 2129 2077

1851 1809 1763 1717

1927 1951 1860 1815

2003 1955 1883 1868

2112 2065 1989 1976

2235 2178 2129 2077

Airflow - Bottom Duct Application

Model Motor Speed

Low (1) 754 710 665 611

Low/Medium (2) 867 815 773 720

24050

24075

30050

30075

Continued on next page.

Medium (3) 951 908 868 828

Medium/High (4) 1024 982 942 902

High (5) 1204 1159 1121 1085

Low (1) 899 869 827 782

Low/Medium (2) 1033 960 924 879

Medium (3) 1186 1133 1095 1056

Medium/High (4) 1357 1322 1284 1248

High (5) 1480 1439 1404 1367

Low (1) 726 676 622 575

Low/Medium (2) 928 886 841 795

Medium (3) 1021 983 942 900

Medium/High (4) 1109 1071 1029 995

High (5) 1170 1134 1096 1061

Low (1) 1076 1042 1009 969

Low/Medium (2) 1104 1063 1025 987

Medium (3) 1205 1170 1136 1098

Medium/High (4) 1285 1251 1213 1179

High (5) 1406 1375 1341 1306

External Static Pressure (Inches WC)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

SCFM SCFM SCFM SCFM

SCFM SCFM SCFM SCFM

560 491 445 391

677 622 559 505

781 735 686 631

861 817 775 721

1051 1013 975 938

734 685 630 575

834 787 735 685

1016 975 935 891

1211 1174 1127 1087

1369 1299 1264 1226

520 467 410 376

745 706 658 607

855 811 770 729

949 908 864 826

1020 978 938 899

930 890 849 808

947 908 869 830

1060 1025 985 943

1141 1104 1065 1027

1271 1236 1198 1163

18 Johnson Controls Unitary Products

Page 19

5127524-YTG-A-0815

Airflow - Bottom Duct Application (Continued)

External Static Pressure (Inches WC)

Model Motor Speed

Low (1) 1231 1186 1146 1103

Low/Medium (2) 1270 1225 1189 1140

36065

Medium (3) 1317 1286 1245 1198

Medium/High (4) 1358 1317 1275 1238

High (5) 1517 1475 1447 1400

Low (1) 1340 1299 1264 1224

Low/Medium (2) 1409 1368 1334 1291

36100

Medium (3) 1527 1492 1470 1419

Medium/High (4) 1663 1585 1594 1601

High (5) 1711 1677 1643 1600

Low (1) 1332 1295 1263 1222

Low/Medium (2) 1457 1419 1376 1340

42065

Medium (3) 1451 1412 1371 1339

Medium/High (4) 1568 1524 1491 1464

High (5) 1711 1677 1643 1600

Low (1) 1455 1414 1379 1335

Low/Medium (2) 1566 1532 1492 1455

42100

Medium (3) 1565 1530 1491 1458

Medium/High (4) 1675 1641 1606 1578

High (5) 1711 1677 1643 1600

Low (1) 1032 999 970 938

Low/Medium (2) 1272 1236 1204 1165

48065

Medium (3) 1611 1574 1518 1494

Medium/High (4) 1892 1777 1771 1701

High (5) 2131 2058 1998 1949

Low (1) 1598 1548 1502 1454

Low/Medium (2) 1663 1612 1568 1522

48100

Medium (3) 1789 1733 1670 1650

Medium/High (4) 1931 1814 1808 1736

High (5) 2131 2058 1998 1949

Low (1) 1598 1548 1502 1454

Low/Medium (2) 1766 1703 1656 1611

48125

Medium (3) 1912 1875 1805 1787

Medium/High (4) 2105 2014 2006 1931

High (5) 2131 2058 1998 1949

Low (1) 1026 999 989 950

Low/Medium (2) 1263 1230 1192 1165

60065

Medium (3) 1987 1933 1861 1817

Medium/High (4) 2114 2050 2047 1974

High (5) 2369 2308 2249 2183

Low (1) 1655 1612 1596 1531

Low/Medium (2) 1766 1720 1667 1629

60100

Medium (3) 1987 1933 1861 1817

Medium/High (4) 2114 2050 2047 1974

High (5) 2369 2308 2249 2183

Low (1) 1973 1924 1905 1826

Low/Medium (2) 2024 1983 1937 1889

60125

Medium (3) 2123 2075 2019 1970

Medium/High (4) 2191 2154 2117 2075

High (5) 2369 2308 2249 2183

1. Airflow tested with dry coil conditions, without air filters, at 230 volt s

2. Applications above 0.8" w.c. external static pressure are not recommended.

3. Brushless DC high efficiency standard ECM blower motor used for all indoor blower assemblies.

4. Minimal variations in airflow performance data results from operating at 208 volts. Data above may be used in those cases.

5. Heating applications tested at 0.50" w.c. esp, and cooling applications tested at 0.30" w.c.esp per standards.

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

SCFM SCFM SCFM SCFM

SCFM SCFM SCFM SCFM

1069 1030 977 912

1098 1046 1008 960

1151 1110 1064 1024

1197 1148 1105 1057

1357 1318 1275 1232

1182 1182 1097 1049

1253 1201 1173 1128

1385 1343 1299 1250

1521 1480 1440 1400

1560 1503 1466 1425

1185 1148 1110 1063

1299 1253 1215 1160

1296 1257 1211 1165

1425 1383 1345 1296

1560 1503 1466 1425

1294 1254 1212 1160

1416 1372 1333 1280

1419 1381 1336 1290

1535 1495 1455 1412

1560 1503 1466 1425

910 879 843 808

1129 1081 1037 968

1439 1405 1357 1266

1639 1617 1565 1489

1892 1840 1788 1728

1410 1362 1307 1251

1476 1422 1370 1297

1596 1578 1535 1483

1673 1650 1597 1519

1892 1840 1788 1728

1410 1362 1307 1251

1566 1518 1469 1419

1750 1713 1672 1636

1898 1845 1793 1739

1892 1840 1788 1728

907 907 886 862

1167 1101 1099 1071

1820 1715 1725 1651

1899 1889 1920 1866

2126 2088 2034 1990

1461 1462 1429 1391

1632 1539 1537 1498

1820 1715 1725 1651

1899 1889 1920 1866

2126 2088 2034 1990

1743 1744 1703 1660

1886 1843 1799 1759

1978 1862 1849 1804

2002 1995 2028 1974

2126 2088 2034 1990

Johnson Controls Unitary Products 19

Page 20

5127524-YTG-A-0815

D

16

C

A

B

A

A0298-001

SUPPLY

AIR DUCT

RETURN

AIR DUCT

F

E

$

%

$

$

6833/<

$,5'8&7

5(7851

$,5'8&7

Additional Static Resistance

Size (Tons) CFM Wet Indoor Coil Economizer1Filter/Frame Kit

24 (2.0)

30 (2.5)

36 (3.0)

42 (3.5)

48 (4.0)

60 (5.0)

500 0.01 0.00 0.01

600 0.01 0.00 0.02

700 0.01 0.00 0.04

800 0.02 0.01 0.06

900 0.03 0.01 0.08

1000 0.04 0.01 0.10

1100 0.05 0.01 0.13

1200 0.06 0.02 0.16

700 0.01 0.00 0.04

800 0.02 0.01 0.06

900 0.03 0.01 0.08

1000 0.04 0.01 0.10

1100 0.05 0.01 0.13

1200 0.06 0.02 0.16

1300 0.07 0.03 0.17

700 0.01 0.00 0.04

800 0.02 0.01 0.06

900 0.03 0.01 0.08

1000 0.04 0.01 0.10

1100 0.05 0.01 0.13

1200 0.06 0.02 0.16

1300 0.07 0.03 0.17

1400 0.08 0.04 0.18

1100 0.02 0.02 0.04

1200 0.03 0.02 0.04

1300 0.04 0.02 0.05

1400 0.05 0.03 0.05

1500 0.06 0.04 0.06

1600 0.07 0.04 0.07

1700 0.07 0.04 0.08

1800 0.08 0.04 0.09

1900 0.09 0.05 0.10

2000 0.09 0.05 0.11

1100 0.02 0.02 0.04

1200 0.03 0.02 0.04

1300 0.04 0.02 0.05

1400 0.05 0.03 0.05

1500 0.06 0.04 0.06

1600 0.07 0.04 0.07

1700 0.07 0.04 0.08

1800 0.08 0.04 0.09

1900 0.09 0.05 0.10

2000 0.09 0.05 0.11

1100 0.02 0.02 0.04

1200 0.03 0.02 0.04

1300 0.04 0.02 0.05

1400 0.05 0.03 0.05

1500 0.06 0.04 0.06

1600 0.07 0.04 0.07

1700 0.07 0.04 0.08

1800 0.08 0.04 0.09

1900 0.09 0.05 0.10

2000 0.09 0.05 0.11

1. The pressure drop through the economizer is greater for 100% outdoor air

than for 100% return air. If the resist ance of the return air duct is less than

0.25 IWG, the unit will deliver less CFM during full economizer operation.

Filter pressure drop based on standard filter media tested at velocities not to

exceed 300 ft/min.

BOTTOM DUCT DIMENSIONS (Inches)

Model ABCDEF

24, 30 10 21.5 5 4.5 47.5 32

36, 42, 48, 60 14 13.5 5 3.5 47.5 42

REAR DUCT DIMENSIONS (Inches)

Model A B

24, 30 9.6 22

36, 42, 48, 60 13.6 14

20 Johnson Controls Unitary Products

Page 21

UNIT TYPICAL DUCT APPLICATIONS

ROOF CURB

INSTALLATION

REAR DUCT

ROOF CURB

INSTALLATION

BOTTOM DUCT

SLAB ON

GROUND

INSTALLATION

A0324-001

A0325-001

SUPPLY

AIR DUCT

TO POWER SUPPLY

RETURN

AIR DUCT

FIELD-SUPPLIED

DISCONNECT

SWITCH

CONTROL WIRING TO

INDOOR THERMOSTAT

TO GAS

SUPPLY LINE

MANUAL GAS

SHUTOFF VAVLE

CONDENSATE

DRAIN

5127524-YTG-A-0815

UNIT TYPICAL SLAB ON GROUND INSTALLATION (Gas model shown)

Johnson Controls Unitary Products 21

Page 22

UNIT TYPICAL ROOF CURB INSTALLATION (Gas model shown)

SUPPLY

AIR DUCT

TO POWER SUPPLY

RETURN

AIR DUCT

FIELD-SUPPLIED

DISCONNECT

SWITCH

CONTROL WIRING TO

INDOOR THERMOSTAT

TO GAS

SUPPLY LINE

MANUAL GAS

SHUTOFF VAVLE

ROOF CURB

ROOF

CONDENSATE

DRAIN

A0326-001

A0435-001

RETURN AIR

DUCT

SUPPLY AIR

DUCT

EXTERNAL STATIC PRESSURE SETUP

To measure external static pressure:

• Measure the supply air static pressure

• Record this positive number

Subject to change without notice. Published in U.S.A. 5127524-YTG-A-0815

Copyright © 2015 by Johnson Controls, Inc. All rights reserved. Supersedes: Nothing

York International Corp.

5005 York Drive

• Measure the return air static pressure

• Record this negative number

• Treat the negative number as a positive and add the two numbers

together

• This is total system static

Norman, OK 73069

Loading...

Loading...