Page 1

TECHNICAL GUIDE

R-410A

SPLIT-SYSTEM

AIR HANDLERS

MILLENNIUM™

ND360, 480 & 600

30 - 50 Ton

60 Hertz

ND600 AIRHANDLER & M1CZ600 EVAPORATOR SECTION

®

ISO 9001

Certified Quality

Management System

628767-YTG-J-0913

Description

These air handling units are completely assembled units,

including a well-insulated cabinet, a DX cooling coil with copper

tubing, aluminum fins, expansion valve(s), distributor(s), 2”

throwaway filters, a centrifugal blower, a blower motor contactor

and a small holding charge of nitrogen.

Units are shipped in the vertical position ready for field

installation, but can be easily converted to horizontal position.

Page 2

628767-YTG-J-0913

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Air Handling Unit Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Guide Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unit Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cooling and Heating Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Capacity Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Air Handling Unit and Hot Water Coil Accessory Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Air Handling Unit and Steam Coil Accessory Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fan Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Static Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sound Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Weights And Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unit Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Typical Field Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2 Johnson Controls Unitary Products

Page 3

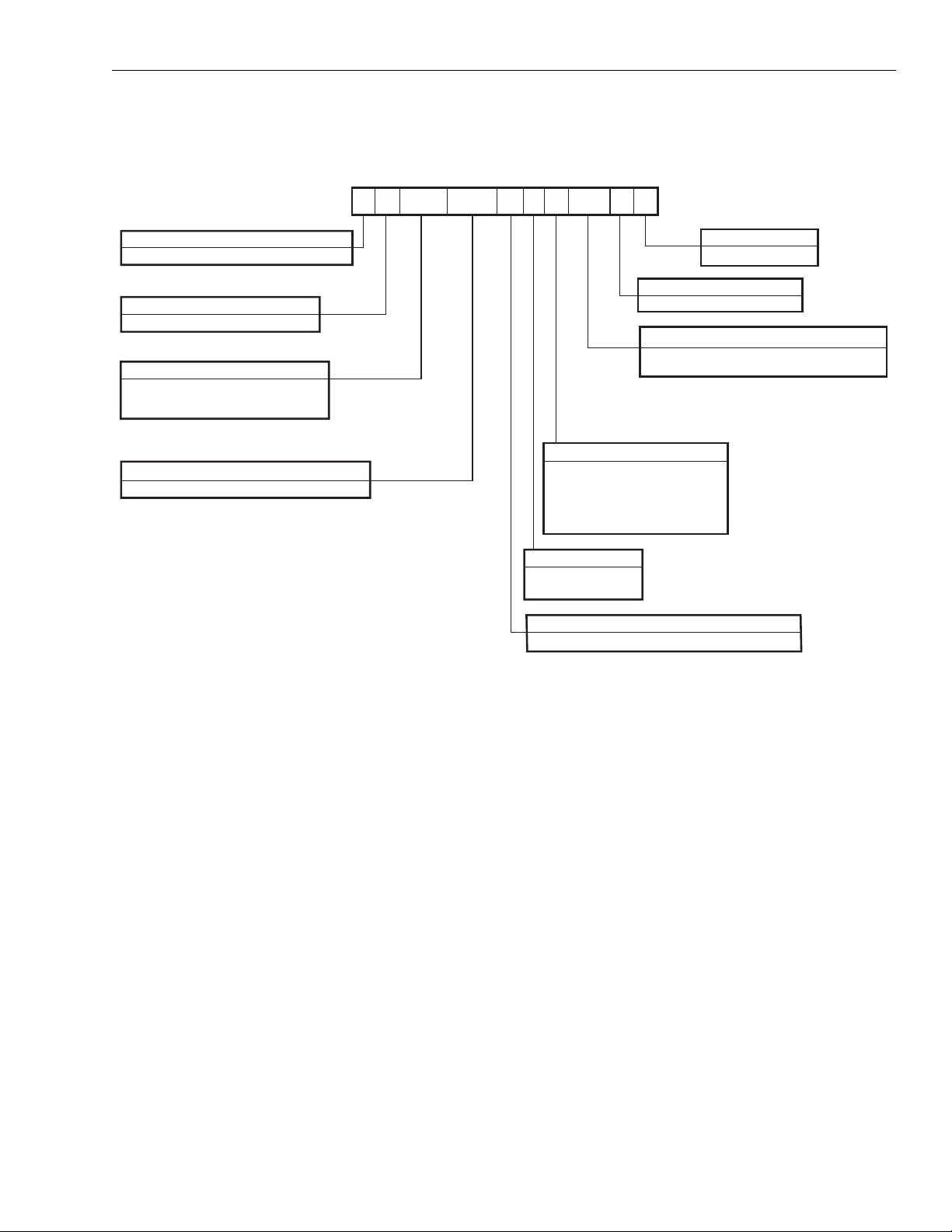

Nomenclature

Product Category

N = Split System, Air Handler, AC R-410A

Product Identifier

D = Standard Efficiency, 4-Pipe (30-50T)

2. Motors, drives, overloads are not shipped with 30-50 ton AH units.

Nominal Cooling Capacity - MBH

360 = 30 Ton

480 = 40 Ton

600 = 50 Ton

C00 = Cooling Only

Product Options

1

AA = No Options Installed

TJ = Technicoat Evap Coil (See Note 1.)

5 = 575-3-60

6 = 208/230/460-3-60

Configured Split Air Handler Model Number Nomenclature

N = None (Motor, Motor Dr. & Motor Overload Kits Req.)

Airflow

2

Product Generation

1 = First Generation

Voltage

Heat Type & Nominal Heat Capacity

N

D

360

C00 N

6

A

AA

1

A

Product Style

A = Style A

1. ND600C00ANAAA1 airhandler does not include

evaporator coil. Customer must order M1CZ600A

Standard Coil or M1CZ600T Technicoat Coil.

Installation Options

A = None

C = YCCS Ctrl CV Cooling/Elec Ht

D = YCCS Ctrl COBP Cooling/Elec Ht

E = YCCS Ctrl CV w/H

2

0

F = YCCS Ctrl COBP w/H

2

0

628767-YTG-J-0913

Johnson Controls Unitary Products 3

Page 4

628767-YTG-J-0913

Air Handling Unit Features and Benefits

Features

These air handlers can be arranged for a variety of air

discharge patterns in either the horizontal or vertical position.

Refer to the unit installation instructions for other application

possibilities.

Benefits

Air handling units are designed with two distinct modules to

provide maximum application flexibility. ND360 and 480

Models are shipped as single packages with the blower

module mounted on top of the coil module. The ND600

Blower Section and the M1CZ600 Evaporator Section are

shipped separately and must be assembled on the job site.

All blower modules can be repositioned in the field to meet a

large number of vertical and horizontal applications.

The blower module includes the blower wheels and room for

a field-mounted motor and drive. All models offer multiple

motor horsepower and drive options to meet both standard

and high static airflow requirements.

The coil module includes direct expansion coils, 2 in.

throwaway filters, liquid line solenoid valves for capacity

reduction, thermal expansion valves, distributors and a

condensate drain pan.

Every air handling coil is pressurized with air and leak tested

under water. After the headers are brazed onto the coil and

the coil is installed in the unit, the coil is pressurized with

nitrogen for pressure testing and additional leak testing. After

the coil is evacuated and dehydrated, it is pressurized with a

holding charge of nitrogen for storage and/or shipping.

These air handlers, combined with condensing units, provide

years of quiet, efficient and dependable operation. These

units are manufactured under ISO 9001 Quality System

Certification.

Unit Installation

Units may be bottom-supported or ceiling-suspended and

can be arranged to meet almost any space or duct

requirements. Each unit is available with a choice of blower

motor horsepower, drive packages and other accessories to

make them suitable for most applications.

Air Handling units are available in four pipe configurations

from 30 to 50 tons. The dual circuit options provide a wide

variety of application and unit match up possibilities.

Blower Motors

unit to meet almost any air delivery requirement. 5 thru 15

HP motors require motor overload protection. All motors

are UL approved, have permanently lubricated ball bearings

and are field-mounted within the insulated cabinet of the units

to minimize the transmission of sound to the surrounding

space.

Contactor and Overload Relays:

with a contactor, an overload relay is required. See Kit details

in Overload Relays Table.

: Different HP motors are available for each

If the Air Handler is shipped

NOTE: All unit models with contactor and overload relays,

the power wiring for blower motor is supplied in the

overload relay kit.

Factory-Mounted Components

Part Load Operation:

(Direct Expansion) coils with pre-piped distributors,

expansion valves and solenoid valves. Field modifications

are not required for part load operations. Capacity reduction

not only provides economical operation, but also maintains

stable temperature and humidity levels in the conditioned

space.

BAS Control:

provides split system integration for YCCS single zone,

change-over bypass and VAV systems.

Easy Service:

every unit. These valves are factory-installed to provide many

years of trouble-free operation. If service is required, it is not

necessary to unbraze any joints. The expansion valves also

include a tee fitting to allow easy installation of hot gas

bypass if required.

Coil Protection:

have factory applied Technicoat coating to provide extended

life to the indoor coil in standard applications and additional

corrosion protection on those applications in sea coast or

corrosive environments.

Accessories

Base Sections (30 and 40 ton):

elevate units above the floor. If desired, a moderate

percentage of outdoor air may be introduced through these

sections by cutting an access opening to accommodate the

outdoor air duct connection. These bases include a durable

finish to match the evaporator blower unit. The base may

have to be insulated for certain applications.

Hot Water Coils:

installation between the blower and the coil modules of both

horizontal and vertical units. Since their casings match the

dimensions and the finish of the basic units, they become an

integral part of the unit after installation. The coils slide out of

their casings for easy installation. Hot water coils have

copper tubes that have been mechanically expanded into

aluminum fins. Both headers are located on the same end of

the coil. Coils are leak-tested at 325 psig under water and

dried before their connections are capped for storage and

shipping.

Steam Coils (30 ton only):

installation between the blower and coil modules of both

horizontal and vertical units. Since the casing matches the

dimensions and the finish of the basic unit, it becomes an

integral part of the unit after installation. The coil slides out of

the casings for easy installation and is pitched in the casings

to facilitate condensate drainage. The coil has copper tubes

that have been mechanically expanded into aluminum fins.

Both headers are located on the same end of the coil. The

coil is leak-tested at 325 psig and dried before the

connections are capped for storage and shipping.

York Commercial Comfort System (YCCS)

These air handlers have multiple DX

Serviceable expansion valves are provided on

The indoor coils of these air handlers can

Base sections can be used to

Drainable water coils are available for field

Steam coils are available for

4 Johnson Controls Unitary Products

Page 5

628767-YTG-J-0913

Guide Specifications

MILLENNIUM™

Split System Air-Cooled Air Handler

Models: NC300 and ND360, 480 and 600

General

Units shall be manufactured by Johnson Controls, Unitary

Products Group in an ISO 9001 certified facility. These

factory-assembled units include a well-insulated cabinet, a

DX cooling coil with copper tubes and aluminum fins,

expansion valve(s), distributor(s), throwaway filters, a

centrifugal blower, a blower motor, an adjustable belt drive, a

blower motor contactor and a small holding charge of

nitrogen. The units are shipped in the vertical position ready

for field installation. The air handler units can be installed for

horizontal operation by reversing the position of the solid

bottom panel with the return air duct flange on the front of the

unit. The products must be tested per AHRI 340/360 and

Underwriter Laboratories U.L. 1995 and carry CSA

certification.

Description

The NC/ND indoor units are completely piped and wired at

the factory and are shipped ready for immediate installation.

Only the interconnecting liquid and suction lines, control

wiring, and the main power wiring are required to complete

the installation. Every coil is dehydrated, evacuated, leak

tested and pressure tested at 450 psig before being

pressurized with a holding charge of nitrogen for shipment

and/or storage.

To eliminate the costly cabinet deterioration problems usually

associated with outdoor equipment, all sheet metal parts are

constructed of commercial grade (G90) galvanized steel.

After fabrication, each part is thoroughly cleaned to remove

any grease or dirt from its surfaces. The parts that will be

exposed to the weather are then coated with a powder paint

to assure a quality finish for many years. This coating system

has passed the 1000-hour, salt spray test per ASTM

Standard B117.

Unit Cabinet

Cabinet shall be constructed of 18 gauge, zinc coated steel,

finished with a powder paint process capable of withstanding

a minimum of 1000 salt spray hours according to ASTM

B117. Cabinet screws shall comply with the ASTM B117 salt

spray test for a minimum of 1000 hours. Panels shall be

removable for easy access to all internal components during

maintenance and service. A filter rack shall be included to

accommodate 1" or 2" filters. Cabinet shall feature a

separate access panel for the controls so that unit airflow

need not be disturbed during servicing. The NC300, ND360480 units are shipped in the vertical position ready for field

installation. The blower module can be repositioned in the

field for maximum flexibility. The ND600 product ships with a

separate M1CZ600A evaporator coil and can be assembled

in the vertical or horizontal position in the field.

Each unit shall have:

a. A steel angle frame to provide the rigid support

required for shipping, rigging and years of dependable

operation.

b. Exterior panels of 18 gauge steel, finished with baked

enamel to provide a long-lasting quality appearance.

c. Removable panels to provide easy access to the

internal components for maintenance and service.

d. A filter rack with 1" or 2" filters.

Indoor (Evaporator) Fan Assembly

Fan shall be a belt drive assembly and include an adjustable

pitch motor pulley. Job site selected brake horsepower shall

not exceed the motors nameplate horsepower rating plus the

service factor. Units shall be designed to operate within the

service factor. Fan wheel shall be double-inlet type with

forward-curved blades, dynamically balanced to operate

smoothly throughout the entire range of operation. Airflow

design shall be constant air volume. Bearings shall be sealed

and permanently lubricated for longer life and no

maintenance. Blower motors and drive kits are ordered

separately. Power wiring for blower motor is field supplied.

Refrigerant Components

Coils:

a. Evaporator coils shall have aluminum plate fins

mechanically bonded to seamless internally enhanced

copper tubes with all joints brazed.

b. Evaporator coil shall be of the direct expansion, draw

through design.

Refrigerant Circuit and Refrigerant Safety Components:

a. Include factory-mounted distributors, adjustable

thermal expansion valves and solenoid valves for both

capacity reduction and refrigerant pump out on startup.

b. Include factory installed auxiliary side connectors for

the addition of field installed hot ga s byp ass.

c. Shall include filter/strainer to eliminate any foreign

matter.

Controls

Unit controls shall include 208/230/460 or 575 volt

transformer, blower motor contactor and relay, as well as a

low voltage terminal block. Unit wiring shall be color-coded

for easy service and trouble shooting.

Johnson Controls Unitary Products 5

Page 6

628767-YTG-J-0913

The Installer Shall:

Furnish condensing units in accordance with the

performance schedules shown on the plans. Install each unit

as shown on the plans in accordance with the manufacturer's

recommendations and all applicable national and local

codes.

Unit Operating Characteristics

Unit shall be capable of starting and running at 125º F

outdoor temperature, exceeding maximum load criteria AHRI

Standard 360. The compressor, with standard controls, shall

be capable of operation down to 40º F outdoor temperature.

Electrical Requirements

All unit wiring shall enter unit cabinet at a single factory

provided location to minimize cabinet penetrations and avoid

unit field modifications.

Each Unit Shall Include The Following Accessories:

• " Suspension kit

• "Return air grille

• "Hot water coil

•"Steam coil

• "Decorative base

• Metal skid

• "Wood skid

6 Johnson Controls Unitary Products

Page 7

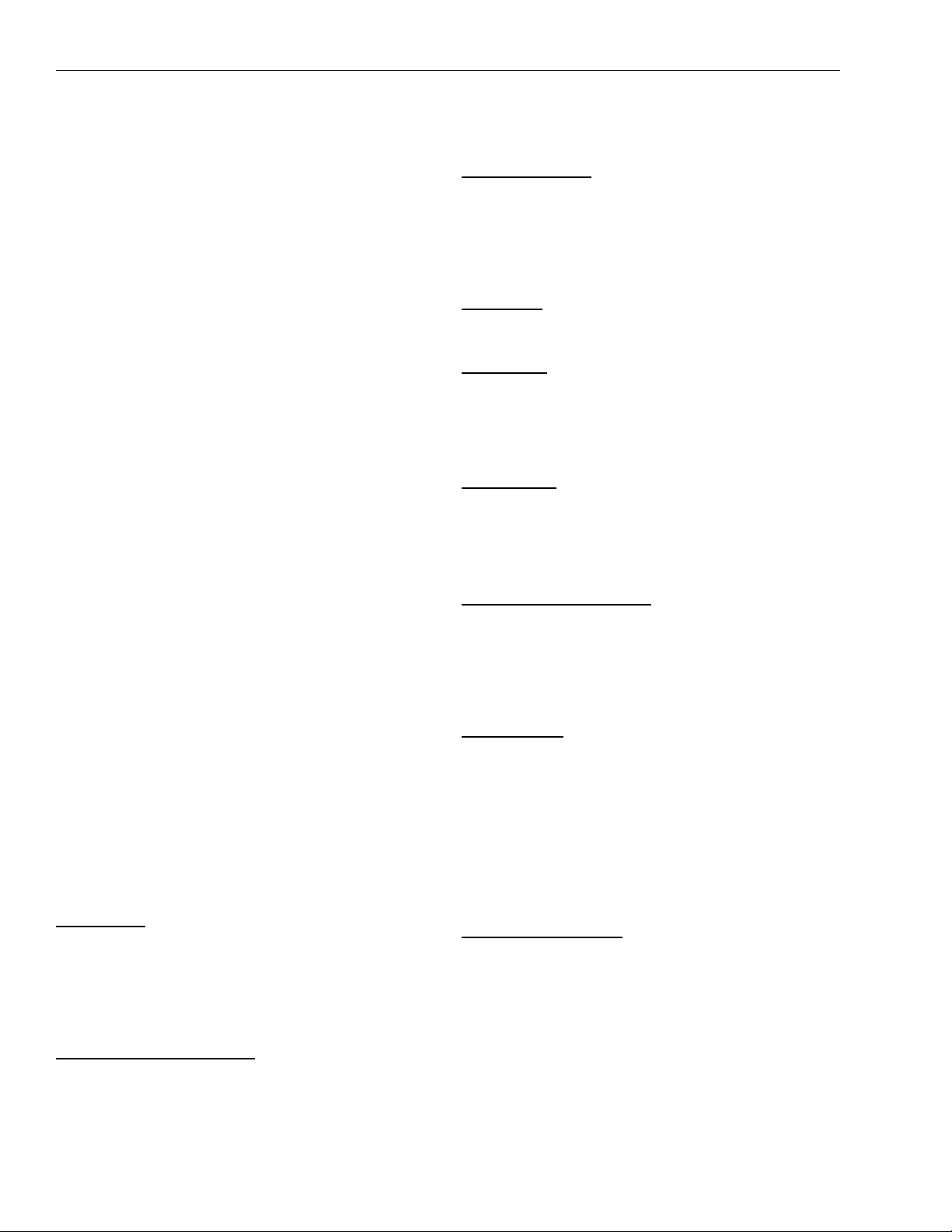

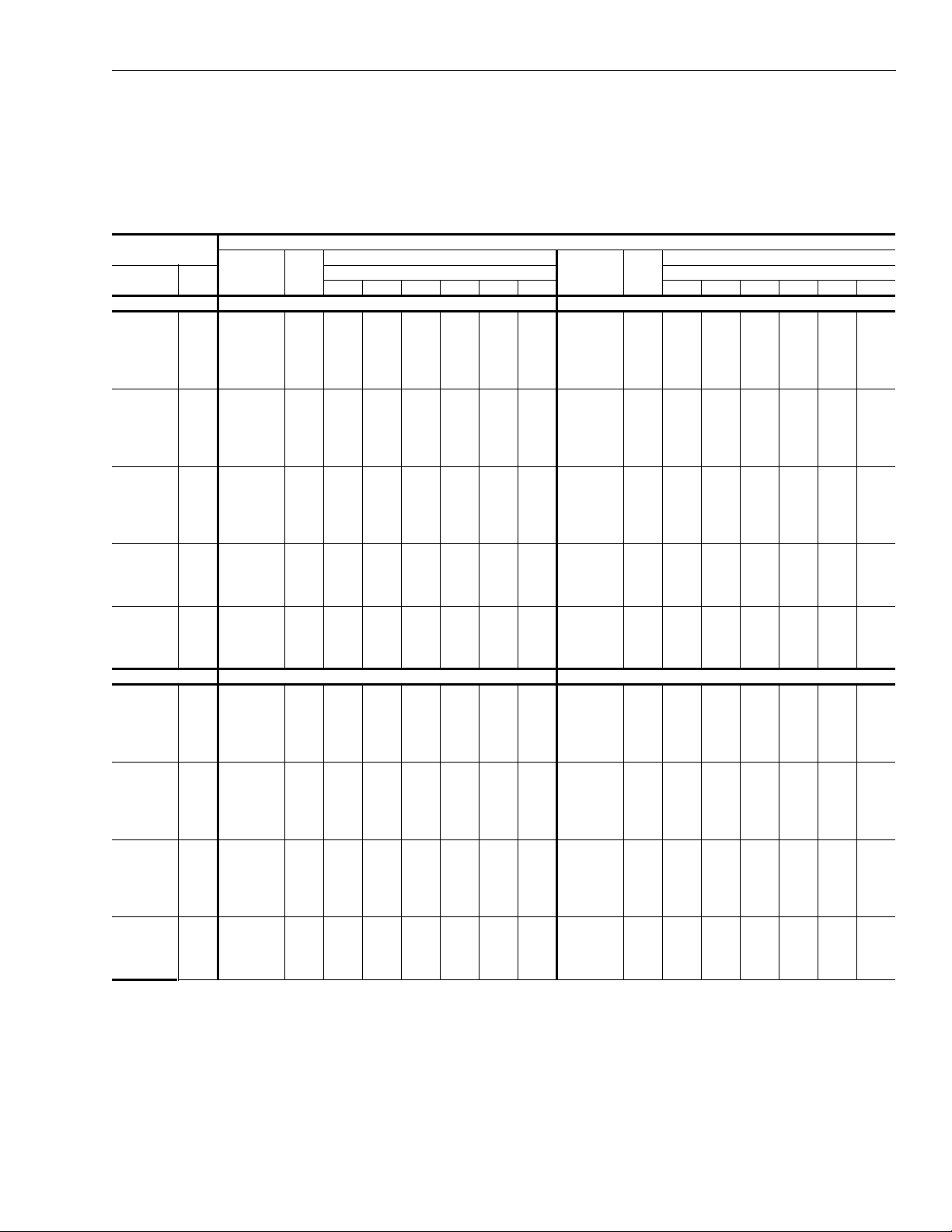

Physical Data

ND360, 480 & 600 Physical Data

Component

Nominal Tonnage 30 40 50

DIMENSIONS (inches)

Length

Width

Height

WEIGHTS

2

(lb)

Unit Shipping

Unit Operating With

5 hp Motor and Drive

7.5 hp Motor and Drive

10 hp Motor and Drive

15 hp Motor and Drive

INDOOR BLOWER

Diameter x Width

Qty.

INDOOR COIL

Face area (Sq. Ft.)

Rows

Fins per inch

Tube diameter

Circuitry Type

Refrigerant Control

SYSTEM DATA

No. Refrigeration Circuits

Suction Line OD (in.)

Liquid Line OD (in.)

FILTERS

Size and Quantity Per Model (In.)

16 x 20 x 2 --- 6 --20 x 20 x 2 --- 3 --20 x 22 x 2 --- --- --16 x 25 x 2 --- --- 6

20 x 25 x 2 10 6 3

25 x 25 x 2 --- --- 6

Face area (Sq. Ft.)

ACCESSORY

HOT WATER COIL DATA

Face area (Sq. Ft.)

Rows

Fins per inch

Tube diameter (Copper) OD (In.)

Connections (Supply and Return) OD (In.)

Weight (lb)

STEAM COIL DATA

Face area (Sq. Ft.)

Rows

Fins per inch

Tube diameter (Copper) (In.)

Connection, (NPTE) (In.)

Inlet

Outlet

Weight (lb)

1

ND600 and M1CZ600A Combined

2

Motor, Motor Drive and Motor Overload Kits must be ordered separately,

The Motor, Motor Drive and Overload Kits are to be field installed.

ND360 ND480 ND600

100.1 103.1 105.1

38.1 45.4 53.7

74.6 89.4 99.0

1122 1246 1684

1184 --- --1208 1348 --1224 1364 1742

--- --- 1859

18 X 18 18 X 18 20 x 18

222

25.8 33.3 41.3

444

16 16 16

3/8 3/8 3/8

Interlaced Interlaced Interlaced

TEV TEV TEV

222

1 1/8 1 3/8 2 1/8

7/8 7/8 7/8

34.7 42.6 53.1

21.2 27.2 27.2

222

12 12 8

1/2 1/2 1/2

1 3/8 1 5/8 1 5/8

150 190 190

18.2 --- --1 --- --8 --- --1 --- ---

2 --- ---

1-1/2 --- ---

160 --- ---

Models

628767-YTG-J-0913

1

Johnson Controls Unitary Products 7

Page 8

628767-YTG-J-0913

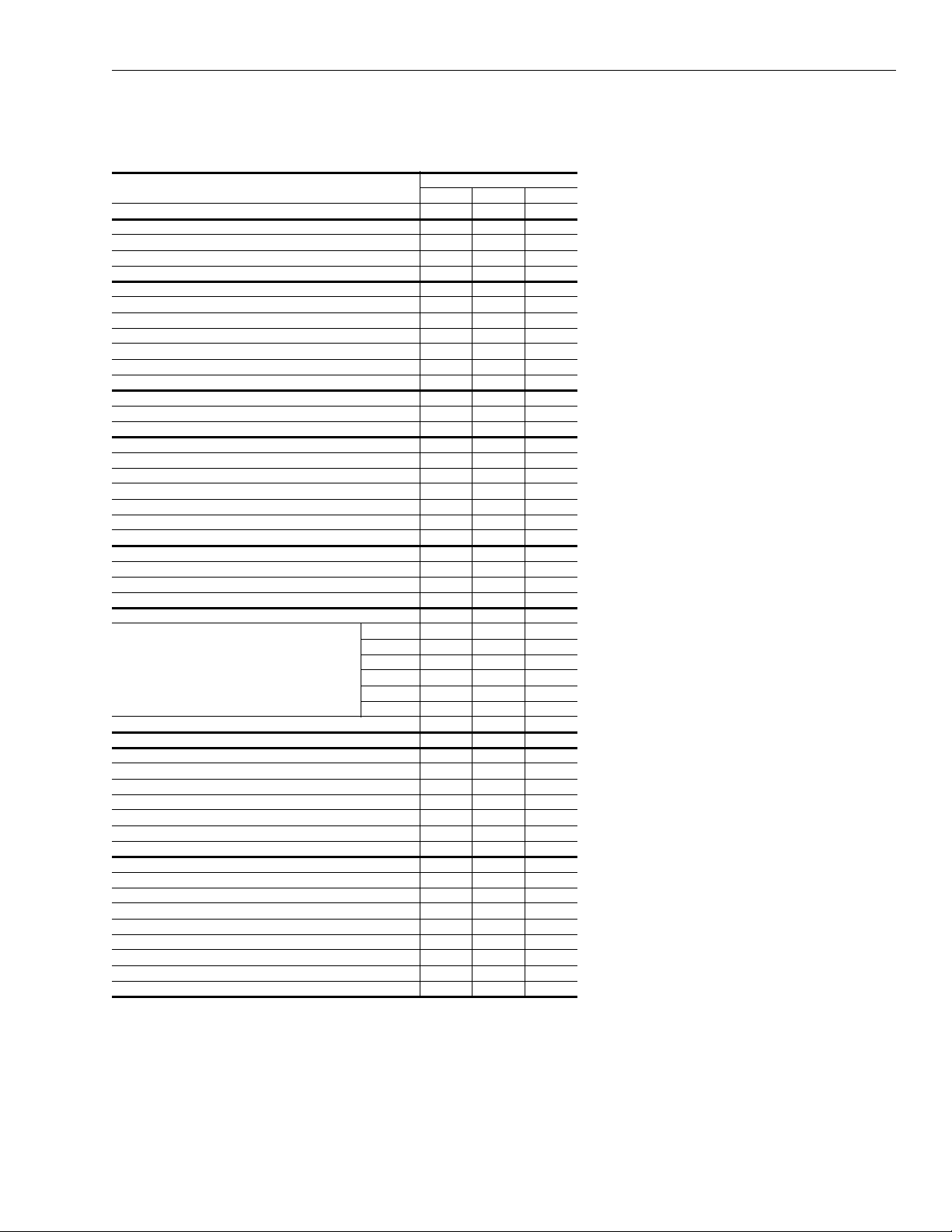

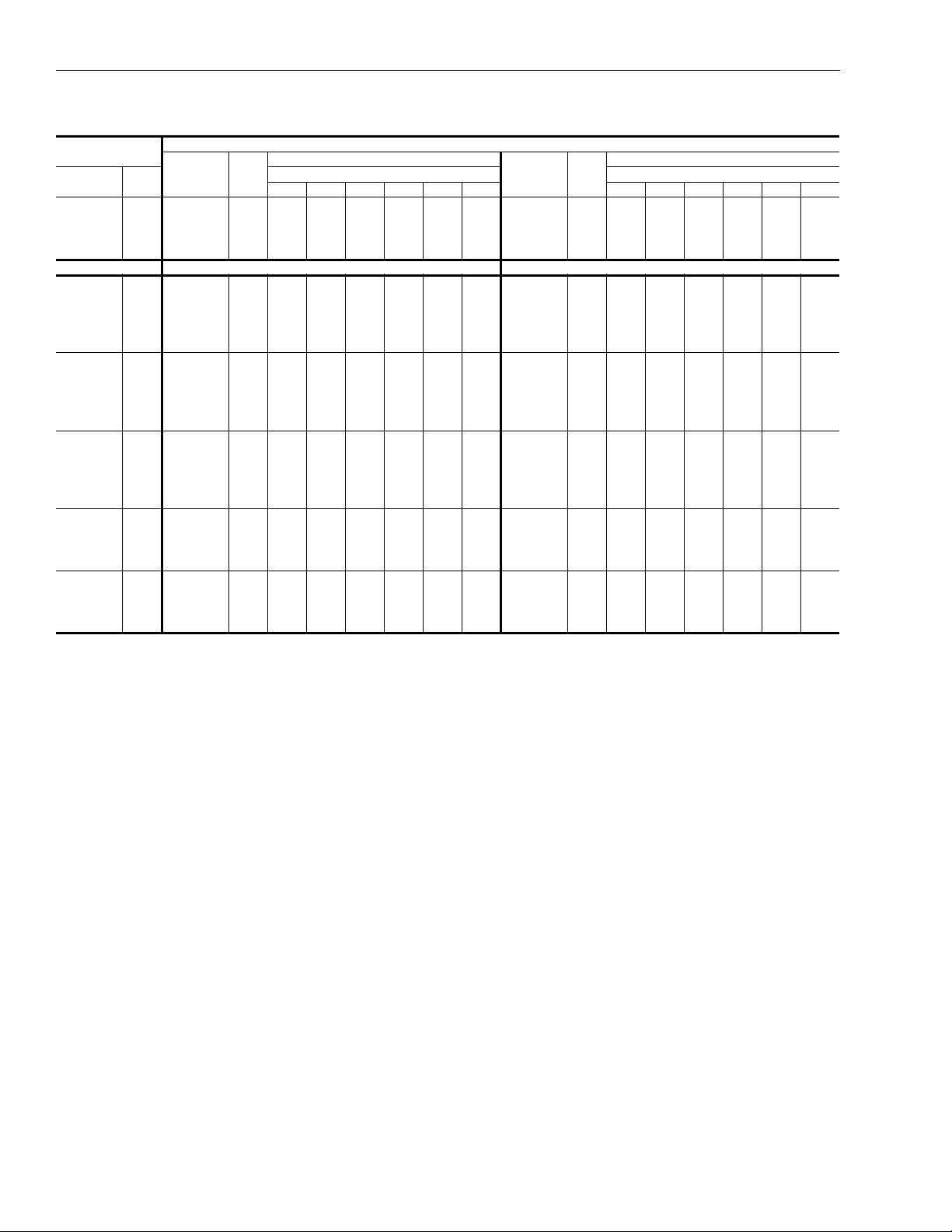

Unit Limitations

Air Handling Unit Limitations

Entering Air Temperature Degrees °F

Model Power Supply Voltage

Voltage Variation Supply Air Range CFM

Min. Max. Min. Max. Min. Max. Min. Max.

208/230-3-60 187 253 10,000 14,000 65/57 95/72 40 77

ND360

460-3-60 414 506 10,000 14,000 65/57 95/72 40 77

575-3-60 540 630 10,000 14,000 65/57 95/72 40 77

208/230-3-60 187 253 12,800 19,200 65/57 95/72 40 77

ND480

460-3-60 414 506 12,800 19,200 65/57 95/72 40 77

575-3-60 540 630 12,800 19,200 65/57 95/72 40 77

208/230-3-60 187 253 16,000 24,000 65/57 95/72 40 77

ND600

460-3-60 414 506 16,000 24,000 65/57 95/72 40 77

575-3-60 540 630 16,000 24,000 65/57 95/72 40 77

1

Heating Min/Max temperatures apply to steam and hot water coils. NOTE: Do not apply steam to hot water coils.

Cooling

DB/WB

Heating DB

1

Cooling and Heating Ratings

Cooling Ratings

Condensing Unit Only

Outdoor

Unit

YD360 333 29.9 11.1 ND360 375 10.0 11.1 12,000

YD480 469 37.4 12.5 ND480 500 10.0 10.8 16,000

YD600 576 50.0 11.5 ND600 620 10.0 10.4 17,500

1

2

3

EER = Energy Efficiency Ratio at full load - the cooling capacity in Btu’s per hour (Btuh) divided by the power input in watts, expressed in Btuh per

watt (Btuh/watt).

EER; condensing unit only ratings based on 45º F SST and 95ºF entering outdoor air temperature.

IEER - A single number cooling part-load efficiency figure that is calculated ba sed on equipment stages and EER at these capacity stages (ANSI/

AHRI STD 340/360 - 2007)

LEGEND

EER = Energy Efficiency Ratio

SST = Saturated Suction Temperature

AHRI = Air Conditioning and Refrigerat ion Institute

IEER = Integrated Energy Efficiency Ratio

Gross Capacity

(MBH)

Tested in accordance with the Unitary Large Equipment certification program, which is based on AHRI Standard 340/360.

Condensing unit only ratings are at 45 F SST and 95 F entering-air temperature.

Deduct 1 MBH when a unit operates at 208 volts.

2

kW EER

Indoor

Unit

Gross Capacity

System Cooling Capacity

3

(MBH)

EER IEER

1

Rated

Airflow

(CFM)

8 Johnson Controls Unitary Products

Page 9

Capacity Performance

Condenser and Air Handling Cooling Capacities

YD360/ND360

Air on

Evaporator Coil

CFM

9000

10500

12000

13500

15000

9000

10500

12000

13500

WB

(°F)

Total

Capacity

(MBh)

77 440.3 26.1 221.9 185.2 148.6 - - - 424.8 28.5 215.2 179.0 142.8 - - 72 411.6 25.5 272.6 235.9 199.2 162.5 - - 396.5 28.0 265.3 229.1 192.9 156.7 - 67 382.9 24.9 323.2 286.6 249.9 213.2 176.5 - 368.3 27.5 315.5 279.3 243.1 206.8 170.6 62 318.5 24.4 318.5 301.8 265.1 228.4 191.8 155.1 311.2 26.9 311.2 300.3 264.1 227.9 191.7 155.5

57 347.4 24.2 347.4 347.4 312.7 276.0 239.3 202.7 335.5 26.8 335.5 335.5 304.9 268.7 232.5 196.3

77 454.2 26.4 247.9 202.9 157.8 - - - 437.9 28.7 236.3 194.0 151.8 - - 72 424.6 25.8 301.8 256.7 211.7 166.6 - - 408.7 28.2 289.6 247.3 205.1 162.8 - 67 394.9 25.2 355.6 310.6 265.5 220.5 175.4 - 379.6 27.7 342.9 300.6 258.4 216.1 173.9 62 328.6 24.6 328.6 320.2 281.7 238.2 191.6 146.6 320.8 27.2 320.8 315.4 280.7 238.5 196.2 154.0

57 358.3 24.4 358.3 358.3 332.3 290.0 242.2 197.1 345.9 27.0 345.9 345.9 324.2 281.9 239.6 197.4

77 468.1 26.7 274.0 220.6 167.1 - - - 451.0 29.0 257.4 209.1 160.8 - - 72 437.5 26.1 331.0 277.6 224.1 170.7 - - 421.0 28.5 313.9 265.5 217.2 168.9 - 67 407.0 25.4 388.0 334.6 281.1 227.7 174.3 - 391.0 27.9 370.3 322.0 273.7 225.4 177.1 62 338.6 24.9 338.6 338.6 298.3 248.0 191.5 138.1 330.4 27.4 330.4 330.4 297.4 249.1 200.8 152.4

57 369.3 24.7 369.3 369.3 351.8 303.9 245.0 191.6 356.2 27.2 356.2 356.2 343.4 295.1 246.7 198.4

72 448.4 26.2 338.1 287.0 235.8 184.6 - - 430.4 28.6 326.0 277.3 228.5 179.8 - 67 417.1 25.5 399.7 346.9 295.7 244.5 193.3 - 399.7 28.0 385.4 336.7 288.0 239.2 190.5 62 347.0 25.0 347.0 347.0 313.7 264.1 211.4 160.2 337.8 27.5 337.8 337.8 312.9 264.2 215.4 166.7

57 378.4 24.8 378.4 378.4 369.7 321.3 267.3 216.1 364.1 27.3 364.1 364.1 357.7 309.0 260.3 211.5

72 459.3 26.3 345.3 296.3 247.4 198.4 - - 439.7 28.7 338.2 289.0 239.9 190.7 - 67 427.2 25.7 411.4 359.3 310.3 261.3 212.3 - 408.4 28.1 400.5 351.4 302.2 253.1 203.9 62 355.5 25.1 355.5 355.5 329.2 280.2 231.2 182.3 345.2 27.6 345.2 345.2 328.4 279.3 230.1 181.0

57 387.6 24.9 387.6 387.6 387.6 338.6 289.6 240.7 372.1 27.4 372.1 372.1 372.1 322.9 273.8 224.7

77 409.2 30.9 208.5 172.7 137.0 - - - 388.6 34.2 199.2 164.5 129.8 - - 72 381.4 30.4 258.1 222.4 186.6 150.9 - - 362.5 33.7 248.3 213.6 178.9 144.2 - 67 353.7 30.0 307.7 272.0 236.2 200.5 164.8 - 336.3 33.2 297.4 262.7 228.0 193.3 158.6 62 303.9 29.5 303.9 298.8 263.1 227.3 191.6 155.8 295.7 32.8 295.7 293.1 262.5 227.8 193.1 158.4

57 323.6 29.4 323.6 323.6 297.2 261.4 225.7 189.9 309.1 32.7 309.1 309.1 286.3 251.6 216.9 182.2

77 421.5 31.1 224.6 185.1 145.7 - - - 400.6 34.3 223.8 179.3 138.3 - - 72 392.9 30.6 277.4 237.9 198.5 159.0 - - 373.6 33.9 272.7 231.7 190.7 149.6 - 67 364.3 30.2 330.2 290.7 251.2 211.8 172.3 - 346.6 33.4 321.6 284.0 243.0 202.0 160.9 62 313.1 29.7 313.1 310.6 279.8 238.8 200.8 161.3 304.8 33.0 304.8 303.5 279.8 238.0 197.8 156.8

57 333.4 29.6 333.4 333.4 316.1 273.8 237.1 197.6 318.6 32.9 318.6 318.6 305.2 262.8 223.1 182.1

77 433.9 31.3 240.8 197.6 154.4 - - - 412.5 34.5 248.5 194.2 146.9 - - 72 404.4 30.9 296.7 253.5 210.3 167.1 - - 384.7 34.0 297.2 249.8 202.4 155.1 - 67 375.0 30.4 352.7 309.5 266.3 223.0 179.8 - 357.0 33.6 345.8 305.4 258.0 210.7 163.3 62 322.3 29.9 322.3 322.3 296.5 250.2 210.1 166.8 313.9 33.1 313.9 313.9 297.2 248.3 202.4 155.1

57 343.2 29.8 343.2 343.2 334.9 286.2 248.5 205.3 328.1 33.1 328.1 328.1 324.0 273.9 229.3 181.9

72 412.3 31.0 313.9 267.6 221.3 175.1 - - 384.1 34.2 311.6 263.0 214.5 165.9 - 67 382.3 30.5 371.2 326.5 280.2 234.0 187.7 - 356.4 33.8 350.8 319.0 273.4 224.8 176.2 62 328.6 30.0 328.6 328.6 312.1 264.2 219.5 173.3 313.2 33.3 313.2 313.2 303.0 253.7 205.9 157.3

57 349.9 29.9 349.9 349.9 345.7 296.7 253.2 206.9 327.6 33.3 327.6 327.6 325.5 275.5 228.4 179.8

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

628767-YTG-J-0913

Sensible Capacity (MBh)

2

Johnson Controls Unitary Products 9

Page 10

628767-YTG-J-0913

YD360/ND360 (Continued)

Air on

Evaporator Coil

CFM

15000

9000

10500

12000

13500

15000

1

WB

(°F)

72 420.2 31.0 331.0 281.7 232.4 183.1 - - 383.5 34.4 326.1 276.3 226.5 176.7 - 67 389.7 30.6 389.7 343.5 294.2 244.9 195.6 - 355.8 34.0 355.8 332.7 288.7 239.0 189.2 62 334.9 30.1 334.9 334.9 327.6 278.3 229.0 179.7 312.5 33.5 312.5 312.5 308.9 259.1 209.3 159.5

57 356.6 29.9 356.6 356.6 356.6 307.3 257.9 208.6 327.0 33.5 327.0 327.0 327.0 277.2 227.4 177.6

77 368.1 37.4 189.9 156.2 122.6 - - - 347.5 40.7 180.6 148.0 115.4 - - 72 343.5 37.0 238.5 204.8 171.2 137.5 - - 324.5 40.2 228.6 196.0 163.4 130.8 - 67 318.9 36.5 287.0 253.4 219.7 186.1 152.4 - 301.5 39.7 276.7 244.1 211.5 178.9 146.3 62 287.4 36.1 287.4 287.4 262.0 228.3 194.7 161.0 279.1 39.5 279.1 279.1 261.4 228.8 196.2 163.6

57 294.6 36.1 294.6 294.6 275.4 241.8 208.1 174.5 280.1 39.5 280.1 280.1 264.5 231.9 199.3 166.7

77 379.6 37.5 223.1 173.6 131.0 - - - 358.7 40.7 222.3 167.8 123.6 - - 72 354.3 37.1 268.0 225.4 182.9 140.3 - - 335.0 40.3 263.3 219.2 175.1 131.0 - 67 328.9 36.6 313.0 277.3 234.8 192.2 149.6 - 311.2 39.8 304.4 270.6 226.5 182.4 138.3 62 296.4 36.3 296.4 296.4 279.9 237.3 194.7 152.2 288.1 39.5 288.1 288.1 280.0 236.6 191.7 147.6

57 303.9 36.2 303.9 303.9 294.3 251.7 209.1 166.5 289.1 39.6 289.1 289.1 283.4 240.6 195.1 151.0

77 391.2 37.6 256.2 190.9 139.4 - - - 369.9 40.8 264.0 187.5 131.9 - - 72 365.1 37.2 297.6 246.1 194.6 143.1 - - 345.4 40.3 298.0 242.4 186.7 131.1 - 67 338.9 36.7 338.9 301.3 249.8 198.3 146.8 - 320.9 39.9 320.9 297.2 241.6 185.9 130.3 62 305.5 36.4 305.5 305.5 297.8 246.3 194.8 143.3 297.1 39.6 297.1 297.1 297.1 244.4 187.2 131.6

57 313.1 36.4 313.1 313.1 313.1 261.6 210.1 158.6 298.1 39.7 298.1 298.1 298.1 249.3 190.9 135.3

72 355.9 37.5 309.4 258.5 207.6 156.7 - - 327.7 40.8 307.1 253.9 200.8 147.6 - 67 330.4 37.0 330.4 311.6 266.5 215.7 164.8 - 304.5 40.3 304.5 304.2 259.7 206.5 153.3 62 297.8 36.7 297.8 297.8 294.0 243.1 192.2 141.4 282.4 40.0 282.4 282.4 282.4 232.5 178.6 125.4

57 305.2 36.7 305.2 305.2 305.2 254.4 203.5 152.6 282.9 40.1 282.9 282.9 282.9 233.2 178.6 125.5

72 346.7 37.8 321.1 270.9 220.7 170.4 - - 310.0 41.2 310.0 265.5 214.8 164.1 - 67 321.9 37.3 321.9 321.9 283.3 233.0 182.8 - 288.0 40.7 288.0 288.0 277.8 227.1 176.4 62 290.1 37.0 290.1 290.1 290.1 239.9 189.6 139.4 267.7 40.4 267.7 267.7 267.7 220.7 170.0 119.3

57 297.4 37.0 297.4 297.4 297.4 247.1 196.9 146.7 267.8 40.5 267.8 267.8 267.8 217.1 166.4 115.7

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

10 Johnson Controls Unitary Products

Page 11

YD480/ND480

Air on

Evaporator Coil

CFM

12000

14000

16000

18000

20000

12000

14000

16000

18000

20000

WB

(°F)

77 579.6 32.8 292.9 247.9 202.9 - - - 530.5 35.1 268.7 224.3 179.9 - - 72 530.4 31.6 355.0 310.0 265.0 220.0 - - 496.5 34.4 333.0 288.6 244.2 199.8 - 67 481.2 30.3 417.1 372.1 327.1 282.2 237.2 - 462.6 33.7 397.3 352.9 308.5 264.1 219.7 62 451.0 30.3 455.0 418.2 373.2 328.2 283.2 238.2 429.4 33.2 429.4 389.1 344.7 300.3 255.9 211.5

57 448.9 29.6 448.9 448.9 437.7 392.7 347.7 302.7 421.3 33.0 421.3 421.3 395.3 351.0 306.6 262.2

77 600.7 32.8 308.8 259.6 210.4 - - - 556.3 35.3 292.2 242.4 192.5 - - 72 549.4 31.5 372.5 323.3 274.1 224.9 - - 520.6 34.6 361.0 311.2 261.3 211.4 - 67 498.0 30.3 436.1 386.9 337.7 288.5 239.3 - 485.0 34.0 429.8 380.0 330.1 280.2 230.3 62 466.9 30.3 468.9 435.1 385.9 337.8 287.4 238.2 450.2 33.4 450.2 418.7 368.8 318.9 269.0 219.1

57 464.9 29.5 464.9 464.9 453.3 406.6 354.9 305.7 441.7 33.2 441.7 441.7 423.0 373.1 323.2 273.3

77 621.8 32.8 324.8 271.4 217.9 - - - 582.0 35.6 315.8 260.4 205.1 - - 72 568.3 31.5 390.0 336.6 283.1 229.7 - - 544.7 34.9 389.1 333.7 278.4 223.0 - 67 514.9 30.3 455.2 401.7 348.3 294.9 241.4 - 507.4 34.2 462.4 407.0 351.6 296.3 240.9 62 482.8 30.2 482.8 452.0 398.5 347.3 291.7 238.2 471.1 33.6 471.1 448.2 392.9 337.5 282.1 226.7

57 481.0 29.5 481.0 481.0 468.9 420.5 362.1 308.6 462.2 33.5 462.2 462.2 450.6 395.2 339.9 284.5

72 583.2 32.0 421.4 367.3 313.2 259.1 - - 554.4 35.0 419.5 362.4 305.3 248.3 - 67 528.6 30.8 498.7 439.6 385.5 331.4 277.3 - 516.5 34.4 493.9 442.9 385.8 328.7 271.6 62 495.6 30.7 495.6 480.2 440.9 387.9 332.7 278.6 479.4 33.8 479.4 468.0 431.0 373.9 316.8 259.7

57 493.6 30.0 493.6 493.6 487.6 435.9 379.4 325.3 470.4 33.6 470.4 470.4 464.6 407.5 350.4 293.3

72 598.1 32.5 452.8 398.0 343.3 288.5 - - 564.1 35.2 450.0 391.2 332.3 273.5 - 67 542.3 31.3 542.3 477.4 422.6 367.9 313.1 - 525.5 34.5 525.5 478.7 419.9 361.0 302.2 62 508.4 31.2 508.4 508.4 483.2 428.5 373.7 318.9 487.8 33.9 487.8 487.8 469.1 410.3 351.4 292.6

57 506.2 30.5 506.2 506.2 506.2 451.4 396.7 341.9 478.6 33.8 478.6 478.6 478.6 419.8 361.0 302.1

77 481.4 37.4 244.5 200.7 156.9 - - - 462.2 41.8 256.0 212.6 169.1 - - 72 462.7 37.3 311.0 267.2 223.4 179.6 - - 446.3 41.6 315.8 272.4 229.0 185.5 - 67 443.9 37.1 377.5 333.7 289.9 246.1 202.3 - 430.4 41.4 375.6 332.2 288.8 245.4 201.9 62 407.8 36.1 403.8 360.0 316.2 272.4 228.6 184.8 405.5 40.9 403.5 363.1 319.7 276.2 232.8 189.4

57 393.7 36.5 393.7 393.7 353.0 309.2 265.4 221.6 382.2 41.0 382.2 382.2 345.7 302.2 258.8 215.4

77 511.8 37.9 275.6 225.1 174.5 - - - 487.2 42.1 293.1 237.7 185.2 - - 72 491.9 37.7 349.6 299.0 248.5 197.9 - - 470.4 41.8 355.9 303.4 250.8 198.3 - 67 472.0 37.6 423.5 373.0 322.4 271.9 221.3 - 453.7 41.6 418.7 369.0 316.5 264.0 211.5 62 433.6 36.5 431.5 402.2 351.7 300.0 250.6 200.0 427.3 41.1 426.3 402.4 350.3 297.2 245.2 192.7

57 418.5 37.0 418.5 418.5 392.7 339.6 291.6 241.0 402.8 41.2 402.8 402.8 378.9 325.2 273.9 221.4

77 542.2 38.3 306.8 249.5 192.2 - - - 512.1 42.3 330.2 262.8 201.2 - - 72 521.1 38.2 388.2 330.9 273.6 216.3 - - 494.5 42.1 395.9 334.3 272.7 211.1 - 67 500.0 38.1 469.6 412.3 355.0 297.7 240.4 - 476.9 41.8 461.7 405.8 344.2 282.6 221.0 62 459.3 37.0 459.3 444.5 387.2 327.6 272.6 215.3 449.1 41.4 449.1 441.7 380.9 318.2 257.7 196.1

57 443.4 37.4 443.4 443.4 432.3 370.0 317.7 260.4 423.4 41.4 423.4 423.4 412.2 348.1 289.0 227.4

72 525.6 38.1 417.7 357.6 297.5 237.4 - - 497.0 42.1 415.9 352.5 289.0 225.5 - 67 504.3 37.9 489.1 446.1 386.0 325.9 265.9 - 479.3 41.8 471.7 428.5 365.1 301.6 238.1 62 463.3 36.9 463.3 455.9 421.1 359.8 300.9 240.8 451.3 41.4 451.3 447.6 403.8 339.7 276.8 213.4

57 447.2 37.3 447.2 447.2 441.7 379.1 321.5 261.4 425.6 41.4 425.6 425.6 420.0 355.3 293.0 229.6

72 530.1 37.9 447.2 384.3 321.4 258.5 - - 499.5 42.1 435.9 370.6 305.3 240.0 - 67 508.6 37.8 508.6 480.0 417.1 354.2 291.3 - 481.7 41.8 481.7 451.2 385.9 320.6 255.2 62 467.2 36.7 467.2 467.2 454.9 392.0 329.2 266.3 453.5 41.3 453.5 453.5 426.7 361.3 296.0 230.7

57 451.0 37.1 451.0 451.0 451.0 388.2 325.3 262.4 427.7 41.4 427.7 427.7 427.7 362.4 297.0 231.7

Total

Capacity

(MBh)

628767-YTG-J-0913

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

95°F 105°F

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

Johnson Controls Unitary Products 11

Page 12

628767-YTG-J-0913

YD480/ND480 (Continued) (Continued)

Air on

Evaporator Coil

CFM

12000

14000

16000

18000

20000

1

WB

(°F)

77 443.0 46.3 267.5 224.4 181.3 - - - 423.8 50.8 278.9 236.2 193.6 - - 72 430.0 46.0 320.6 277.6 234.5 191.5 - - 413.6 50.3 325.5 282.8 240.1 197.4 - 67 416.9 45.6 373.8 330.7 287.7 244.6 201.6 - 403.4 49.8 372.0 329.3 286.6 243.9 201.2 62 403.3 45.7 403.3 366.2 323.1 280.1 237.0 193.9 401.0 50.6 401.0 369.3 326.6 283.9 241.2 198.5

57 370.8 45.5 370.8 370.8 338.3 295.2 252.2 209.1 359.3 50.0 359.3 359.3 331.0 288.3 245.6 202.9

77 462.5 46.3 310.5 250.3 195.8 - - - 437.9 50.5 328.0 262.8 206.4 - - 72 448.9 45.9 362.1 307.7 253.2 198.7 - - 427.4 50.0 368.4 312.0 255.5 199.1 - 67 435.3 45.6 413.8 365.1 310.6 256.1 201.6 - 417.0 49.6 408.9 361.1 304.7 248.2 191.8 62 421.1 45.7 421.1 402.5 348.8 294.4 239.9 185.4 414.8 50.3 414.8 402.6 347.4 291.5 234.5 178.1

57 387.1 45.5 387.1 387.1 365.2 310.8 256.3 201.8 371.4 49.8 371.4 371.4 351.5 296.3 238.6 182.2

77 482.1 46.3 353.6 276.1 210.2 - - - 452.0 50.2 377.0 289.4 219.2 - - 72 467.9 45.9 403.6 337.7 271.9 206.0 - - 441.3 49.8 411.4 341.2 271.0 200.8 - 67 453.7 45.6 453.7 399.4 333.5 267.6 201.7 - 430.6 49.3 430.6 392.9 322.7 252.5 182.3 62 438.8 45.7 438.8 438.8 374.6 308.7 242.8 176.9 428.6 50.1 428.6 428.6 368.2 299.2 227.8 157.7

57 403.5 45.5 403.5 403.5 392.2 326.3 260.4 194.5 383.5 49.5 383.5 383.5 372.1 304.4 231.7 161.5

72 468.4 46.1 414.2 347.3 280.5 213.7 - - 439.8 50.1 412.4 342.2 272.0 201.8 - 67 454.2 45.7 454.2 410.9 344.1 277.3 210.4 - 429.2 49.6 429.2 393.3 323.1 252.9 182.7 62 439.3 45.9 439.3 439.3 386.5 319.6 252.8 186.0 427.4 50.4 427.4 427.4 369.2 299.5 228.8 158.5

57 403.9 45.6 403.9 403.9 398.3 331.4 264.6 197.8 382.3 49.8 382.3 382.3 376.6 307.6 236.2 165.9

72 469.0 46.2 424.7 356.9 289.1 221.4 - - 438.4 50.4 413.5 343.2 273.0 202.8 - 67 454.8 45.9 454.8 422.5 354.7 286.9 219.1 - 427.8 49.9 427.8 393.8 323.5 253.3 183.1 62 439.8 46.0 439.8 439.8 398.4 330.6 262.8 195.0 426.1 50.6 426.1 426.1 370.1 299.9 229.7 159.4

57 404.4 45.8 404.4 404.4 404.4 336.6 268.8 201.0 381.1 50.1 381.1 381.1 381.1 310.8 240.6 170.3

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

12 Johnson Controls Unitary Products

Page 13

YD600/ND600 Air Handler with M1CZ600A Evaporator Section

Air on

Evaporator Coil

CFM

WB

(°F)

15000

17500

20000

21750

23500

15000

17500

20000

21750

23500

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

75°F 85°F

77 778.4 38.3 415.3 359.0 302.7 - - - 739.6 44.5 405.1 348.7 292.3 - - 72 711.3 40.7 471.4 415.1 358.8 302.5 - - 679.6 45.7 463.0 406.7 350.3 293.9 - 67 644.1 43.1 527.5 471.2 415.0 358.7 302.4 - 619.5 46.8 521.0 464.7 408.3 351.9 295.5 62 618.5 41.7 618.5 580.0 523.8 467.5 411.2 354.9 599.2 45.6 599.2 560.7 504.3 447.9 391.6 335.2

57 629.2 40.1 629.2 573.3 517.0 460.7 404.4 348.1 616.4 44.2 616.4 561.2 504.8 448.4 392.1 335.7

77 803.9 38.1 456.4 392.7 329.1 - - - 760.9 44.6 443.3 379.7 316.2 - - 72 734.5 40.5 517.4 453.8 390.2 326.6 - - 699.1 45.7 506.0 442.5 378.9 315.4 - 67 665.2 42.9 578.5 514.9 451.3 387.7 324.1 - 637.4 46.9 568.7 505.2 441.6 378.1 314.6 62 638.8 41.5 638.8 619.6 569.5 508.3 442.3 378.7 616.4 45.7 616.4 597.1 545.5 482.0 418.4 354.9

57 649.9 39.9 649.9 621.9 562.2 501.2 435.0 371.4 634.1 44.3 634.1 606.5 546.1 482.5 419.0 355.5

77 829.3 37.9 497.4 426.5 355.6 - - - 782.2 44.7 481.5 410.8 340.1 - - 72 757.8 40.3 563.4 492.5 421.6 350.7 - - 718.7 45.8 549.0 478.3 407.6 336.9 - 67 686.3 42.7 629.5 558.5 487.6 416.7 345.8 - 655.2 46.9 616.4 545.7 475.0 404.3 333.6 62 659.1 41.2 659.1 659.1 615.2 549.1 473.3 402.4 633.6 45.7 633.6 633.6 586.7 516.0 445.3 374.6

57 670.6 39.7 670.6 670.6 607.4 541.7 465.5 394.6 651.9 44.3 651.9 651.9 587.3 516.6 445.9 375.2

72 784.2 39.9 617.2 540.1 463.0 386.0 - - 737.6 45.5 588.6 512.9 437.2 361.5 - 67 710.3 42.3 681.9 612.8 535.7 458.7 381.6 - 672.4 46.6 653.0 585.3 509.6 433.8 358.1 62 682.2 40.8 682.2 682.2 670.1 595.4 515.9 438.8 650.3 45.4 650.3 650.3 626.8 551.1 475.4 399.7

57 694.3 39.3 694.3 694.3 667.1 592.6 513.0 435.9 669.0 44.0 669.0 669.0 630.0 554.3 478.6 402.9

72 810.6 39.5 671.0 587.7 504.5 421.2 - - 756.4 45.1 628.3 547.5 466.8 386.1 - 67 734.3 41.9 734.3 667.1 583.9 500.6 417.4 - 689.6 46.3 689.6 624.8 544.1 463.4 382.7 62 705.3 40.5 705.3 705.3 725.0 641.7 558.5 475.2 666.9 45.1 666.9 666.9 666.9 586.2 505.5 424.8

57 717.9 38.9 717.9 717.9 726.8 643.6 560.4 477.1 686.1 43.7 686.1 686.1 672.7 592.0 511.3 430.6

95°F 105°F

77 700.8 50.7 394.8 338.4 281.9 - - - 643.6 56.8 367.7 311.4 255.1 - - 72 647.9 50.6 454.7 398.2 341.8 285.3 - - 603.3 56.7 434.4 378.1 321.8 265.5 - 67 595.0 50.4 514.5 458.1 401.6 345.2 288.7 - 563.1 56.6 501.2 444.9 388.6 332.3 276.0 62 579.8 49.5 579.8 541.3 484.9 428.4 371.9 315.5 542.8 55.9 542.8 508.1 451.8 395.5 339.2 282.9

57 603.6 48.3 603.6 549.1 492.7 436.2 379.7 323.3 564.5 55.9 564.5 510.2 453.9 397.6 341.3 285.0

77 717.9 51.1 430.2 366.7 303.3 - - - 663.4 56.8 416.1 342.4 277.3 - - 72 663.7 50.9 494.6 431.1 367.6 304.2 - - 621.9 56.7 480.2 415.1 350.0 284.9 - 67 609.5 50.8 559.0 495.5 432.0 368.6 305.1 - 580.5 56.7 544.4 487.8 422.7 357.5 292.4 62 594.0 49.8 594.0 574.7 521.6 455.7 394.6 331.2 559.6 56.0 559.6 542.3 491.3 425.0 361.0 295.9

57 618.3 48.7 618.3 591.1 530.0 463.9 403.0 339.6 581.9 55.9 581.9 554.8 493.5 427.0 363.2 298.1

77 735.0 51.5 465.6 395.1 324.6 - - - 683.2 56.9 464.5 373.4 299.5 - - 72 679.5 51.3 534.5 464.0 393.5 323.0 - - 640.5 56.8 526.0 452.1 378.1 304.2 - 67 624.1 51.2 603.4 532.9 462.4 391.9 321.5 - 597.9 56.7 587.6 530.7 456.8 382.8 308.9 62 608.1 50.2 608.1 608.1 558.3 483.0 417.3 346.8 576.4 56.0 576.4 576.4 530.7 454.4 382.8 308.9

57 633.1 49.0 633.1 633.1 567.2 491.6 426.3 355.8 599.3 56.0 599.3 599.3 533.0 456.5 385.1 311.1

72 690.9 51.1 560.0 485.7 411.3 337.0 - - 648.5 56.6 546.8 470.5 394.3 318.0 - 67 634.5 50.9 624.1 557.7 483.4 409.0 334.7 - 605.3 56.5 600.2 552.5 476.2 400.0 323.7 62 618.3 49.9 618.3 618.3 583.6 506.8 434.9 360.6 583.5 55.8 583.5 583.5 553.4 476.0 400.9 324.7

57 643.7 48.8 643.7 643.7 593.0 516.0 444.3 369.9 606.8 55.8 606.8 606.8 555.8 478.3 403.3 327.1

72 702.3 50.8 585.6 507.4 429.2 351.0 - - 656.5 56.4 567.5 488.9 410.4 331.9 - 67 644.9 50.7 644.9 582.5 504.3 426.1 347.9 - 612.7 56.3 612.7 574.2 495.7 417.2 338.6 62 628.5 49.7 628.5 628.5 608.9 530.7 452.5 374.3 590.7 55.6 590.7 590.7 576.1 497.5 419.0 340.5

57 654.3 48.5 654.3 654.3 618.7 540.5 462.3 384.1 614.2 55.6 614.2 614.2 578.6 500.0 421.5 343.0

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

628767-YTG-J-0913

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Johnson Controls Unitary Products 13

Page 14

628767-YTG-J-0913

YD600/ND600 Air Handler with M1CZ600A Evaporator Section (Continued)

Air on

Evaporator Coil

CFM

15000

17500

20000

21750

23500

1

WB

(°F)

77 586.4 62.8 340.6 284.5 228.3 - - - 529.2 68.8 313.5 257.5 201.5 - - 72 558.8 62.8 414.2 358.1 301.9 245.8 - - 514.2 68.8 394.0 338.0 282.0 226.0 - 67 531.1 62.7 487.8 431.7 375.5 319.4 263.2 - 499.2 68.9 474.4 418.4 362.5 306.5 250.5 62 505.9 62.3 505.9 475.0 418.8 362.7 306.5 250.4 468.9 68.7 468.9 441.8 385.8 329.8 273.8 217.9

57 525.3 63.4 525.3 471.3 415.2 359.0 302.9 246.7 486.2 70.9 486.2 432.4 376.4 320.4 264.4 208.5

77 608.8 62.6 402.0 318.1 251.3 - - - 554.3 68.3 387.9 293.8 225.3 - - 72 580.2 62.5 465.9 399.1 332.3 265.5 - - 538.4 68.3 451.6 383.1 314.7 246.2 - 67 551.5 62.5 529.8 480.1 413.3 346.5 279.7 - 522.4 68.3 515.2 472.4 404.0 335.5 267.1 62 525.2 62.1 525.2 509.8 461.0 394.2 327.4 260.6 490.9 68.2 490.9 477.3 430.7 363.5 293.8 225.4

57 545.4 63.2 545.4 518.4 457.0 390.2 323.4 256.6 509.0 70.4 509.0 482.1 420.5 353.3 283.6 215.1

77 631.3 62.4 463.4 351.8 274.3 - - - 579.4 67.8 462.4 330.1 249.2 - - 72 601.5 62.3 517.6 440.2 362.7 285.3 - - 562.6 67.8 509.2 428.3 347.3 266.4 - 67 571.8 62.3 571.8 528.6 451.2 373.7 296.3 - 545.7 67.8 545.7 526.4 445.5 364.6 283.7 62 544.6 61.9 544.6 544.6 503.2 425.8 348.3 270.9 512.8 67.7 512.8 512.8 475.7 397.1 313.8 232.9

57 565.5 63.0 565.5 565.5 498.8 421.4 343.9 266.5 531.8 69.9 531.8 531.8 464.6 386.2 302.7 221.8

72 606.1 62.2 533.5 455.3 377.2 299.0 - - 563.8 67.7 520.2 440.2 360.1 280.0 - 67 576.2 62.1 576.2 547.3 469.1 390.9 312.8 - 547.0 67.7 547.0 542.0 462.0 381.9 301.8 62 548.7 61.7 548.7 548.7 523.2 445.1 366.9 288.8 514.0 67.6 514.0 514.0 493.1 414.2 332.9 252.9

57 569.8 62.8 569.8 569.8 518.7 440.5 362.3 284.2 532.9 69.8 532.9 532.9 481.5 402.7 321.4 241.3

72 610.7 62.0 549.4 470.5 391.6 312.7 - - 565.0 67.6 531.3 452.0 372.8 293.6 - 67 580.5 61.9 580.5 565.9 487.1 408.2 329.3 - 548.3 67.6 548.3 548.3 478.4 399.2 320.0 62 552.9 61.5 552.9 552.9 543.3 464.4 385.5 306.6 515.1 67.5 515.1 515.1 510.5 431.2 352.0 272.8

57 574.2 62.6 574.2 574.2 538.5 459.6 380.8 301.9 534.1 69.7 534.1 534.1 498.4 419.2 340.0 260.8

These capacities are gross ratings. For net capacity, deduct supply air blower motor, MBh. Example: Refer to the appropriate Blower

Total

Capacity

(MBh)

Total

1

Input

2

(kW)

Sensible Capacity (MBh)

Return Dry Bulb (°F) Return Dry Bulb (°F)

90 85 80 75 70 65 90 85 80 75 70 65

115°F 125°F

Performance Table for the BHP of the supply air blower motor, MBh = 3.415 x kW and kW = BHP x 0.746

efficiency.

2

These ratings include the condenser fan motors and the compressor motors but not the supply air blower motor.

Temperature of Air on Condenser Coil

Total

Capacity

(MBh)

Total

1

Input

(kW)

Sensible Capacity (MBh)

2

nameplate rated motor

14 Johnson Controls Unitary Products

Page 15

Air Handling Unit and Hot Water Coil Accessory Heating Capacity

628767-YTG-J-0913

ND360 / 1HW0406, ND480 & ND600 / 1HW0407

UNIT

MODEL

ND360 1HW0406 50

ND480

ND600 75

1

NOTE: Temperature Water Drop (ºF) = (2 X MBH) / GPM.

HOT WATER

COIL MODEL

1HW0407

These capacities do not include any blower motor heat.

GPM CFM

8,000 236 304 372 440 508

10,000 265 341 416 492 568

12,000 291 374 457 540 623

14,000 315 405 495 585 675

12,800 348 447 547 646 746

75

16,000 389 500 611 722 833

19,200 425 547 668 790 911

16,000 389 500 611 722 833

20,000 436 561 686 810 935

24,000 473 610 746 882 1,019

1

ENTERING WATER TEMPERATURE MINUS ENTRY AIR TEMPERATURE °F.

70 90 110 130 150

Hot Water Coil Capacity Correction And Pressure Drop Vs GPM1

HOT WATER COIL MODEL GPM

25 0.4 0.79

1HW0406

1HW0407

1

For pressure drop in feet (water), multiply these values by 2.31.

50 1.0 1.00

75 1.8 1.04

100 3.4 1.07

50 1.0 0.95

75 1.5 1.00

100 2.4 1.03

125 3.5 1.05

PRESSURE DROP

CAPACITY (MBH)

PSI

CAPACITY CORRECTION

FACTOR

Johnson Controls Unitary Products 15

Page 16

628767-YTG-J-0913

Air Handling Unit and Steam Coil Accessory Heating Capacity

ND360 / 1NF0454

1

UNIT

MODEL

ND360 1NF0454

1

These capacities do not include any blower motor heat.

STEAM COIL

MODEL

CFM DRY BULB TEMPERATURE OF AIR ENTERING COIL (°F)

8,000 535 483 432 380

10,000 592 535 478 422

12,000 642 580 518 456

14,000 687 621 555 489

CAPACITY (MBH) @ 2 PSIG

10 30 50 70

Steam Coil Capacity Correction Factors For High Steam Pressure

STEAM PRESSURE (PSIG) 5101520 25

CAPACITY CORRECTION FACTOR 1.05 1.12 1.19 1.25 1.30

NOTE: Steam Rate = (lbs/Hr.) = 1.025 x MBH

16 Johnson Controls Unitary Products

Page 17

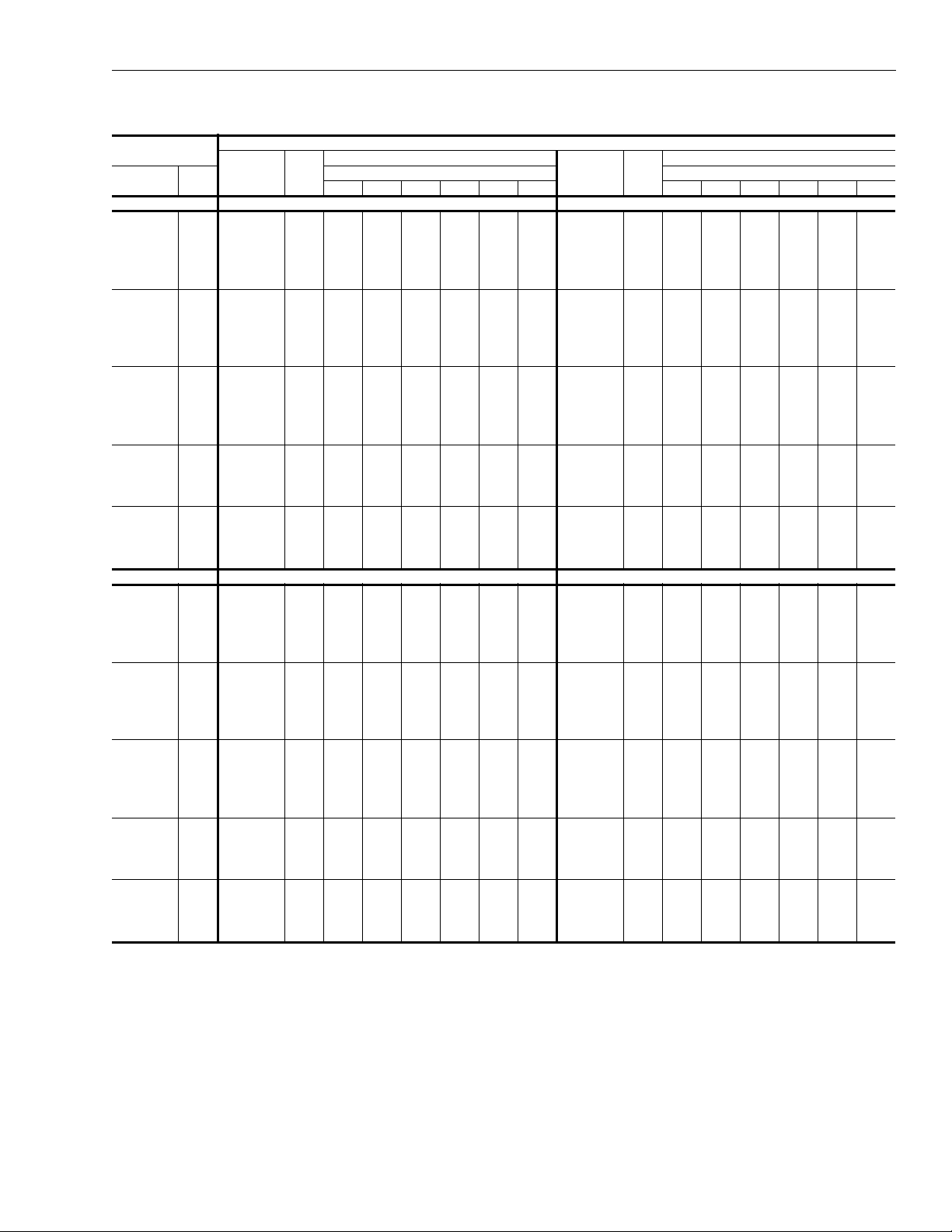

628767-YTG-J-0913

Fan Performance

ND360, 480 & 600 Fan Performance

ND360 Fan Performance Data - 30 Ton

CFM

RPM

600 0.20 3.1 2.9 0.02 3.6 3.4 - - - - - - - - 635 0.31 3.3 3.1 0.13 3.8 3.5 - - - - - - - - 700 0.54 3.7 3.5 0.38 4.2 3.9 0.20 4.8 4.5 0.03 5.3 5.0 - - 775 0.85 4.4 4.1 0.70 4.8 4.5 0.54 5.3 5.0 0.39 5.8 5.5 0.20 6.4 6.0

800 0.97 4.7 4.4 0.82 5.1 4.8 0.66 5.6 5.2 0.52 6.1 5.7 0.35 6.7 6.3

875 1.34 5.6 5.2 1.19 6.0 5.7 1.04 6.6 6.2 0.93 7.1 6.6 0.77 7.7 7.2

900 1.47 5.9 5.5 1.33 6.4 6.0 1.17 7.0 6.5 1.07 7.5 7.0 0.90 8.2 7.6

940 1.70 6.5 6.1 1.55 7.0 6.6 1.40 7.7 7.2 1.31 8.3 7.8 1.09 9.0 8.4

ND480 Fan Performance Data - 40 Ton

RPM

600 0.84 6.0 5.2 0.63 7.2 6.2 0.40 8.4 7.2 0.13 9.7 8.4

660 1.19 7.3 6.3 1.00 8.5 7.3 0.78 9.8 8.5 0.50 11.2 9.7

700 1.42 8.2 7.1 1.25 9.4 8.1 1.03 10.7 9.2 - - 760 1.78 9.5 8.2 1.63 10.8 9.3 - - - - - 800 2.02 10.4 9.0 1.89 11.8 10.2 - - - - - -

10,000 11,000 12,000 13,000 14,000

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

CFM

12,800 14,400 16,000 17,600

SP BHP kW SP BHP kW SP BHP kW SP BHP kW

ND600 Fan Performance Data - 50 Ton

CFM

RPM

600 0.82 6.0 5.2 0.59 7.2 6.2 0.35 8.4 7.2 0.08 9.7 8.4 - - 660 1.17 7.3 6.3 0.96 8.5 7.3 0.73 9.8 8.5 0.45 11.2 9.7 0.14 12.7 11.0

700 1.40 8.2 7.1 1.21 9.4 8.1 0.98 10.7 9.2 0.70 12.2 10.5 0.40 13.7 11.8

760 1.76 9.5 8.2 1.59 10.8 9.3 1.38 12.3 10.6 1.11 13.8 11.9 0.81 15.6 13.5

800 2.00 10.4 9.0 1.85 11.8 10.2 1.64 13.3 11.5 1.38 14.9 12.9 1.09 16.9 14.6

900 2.60 12.8 11.0 2.49 14.5 12.5 2.35 16.0 13.8 - - - - - 930 2.78 13.5 11.6 2.68 15.3 13.2 - - - - - - - - -

16,000 18,000 20,000 22,000 24,000

SP BHP kW SP BHP kW SP BHP kW SP BHP kW SP BHP kW

Johnson Controls Unitary Products 17

Page 18

628767-YTG-J-0913

ND360, 480 & 600 Drive Kit Data

ADJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY BELTS

PITCH DIA.

(IN.)

BORE

(IN.)

PITCH DIA.

(IN.)

BORE

(IN.)

QTY.

PITCH

LENGTH

(IN.)

DESIGNATION

UNIT MODEL

ND360

ND480

ND600

DRIVE KIT

MODEL

NUMBER

1LD0415 636 - 795 4.0 - 5.0 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0407 668 - 827 4.2 - 5.2 1 3/8 11.0 1 3/16 2 63.3 A62

1LD0408 827 - 986 5.3 - 6.3 1 3/8 11.0 1 3/16 2 59.7 A59

1LD0409 607 - 776 4.3 - 5.5 1 3/8 12.4 1 3/16 2 85.1 B84

1LD0410 776 - 917 5.4 - 6.6 1 3/8 12.4 1 3/16 2 86.8 B85

1LD0411 692 - 833 4.8 - 6.0 1 3/8 12.4 1 3/16 2 78.6 B78

1LD0412 762 - 931 5.4 - 6.6 1 5/8 12.4 1 3/16 2 76.8 B75

BLOWER

RPM

RANGE

ND360, 480 & 600 Motor Kit Data

UNIT MODEL HP MOTOR KIT MODEL NUMBER FRAME SIZE

2LP04605133

2LP04605158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04607133

2LP04607158 575

2LP04610133

2LP04610158 575

2LP04610133

2LP04610158 575

2LP04615133

2LP04615158 575

184

213

215

213

215

215

254

ND360

ND480

ND600

5.0

7.5

10

7.5

10

10

15

VOLTAGE

(3PH-60-HZ)

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

208/230/460

ND 360, 480 & 600 Overload Relay Kit

VOLTAGE 208/230V 460V 575V

MOTOR HP OVERLOAD KIT

5 2MP04708500 2MP04708300 2MP04708300

7.5 2MP04708700 2MP04708400 2MP04708300

10 2MP04708900 2MP04708500 2MP04708400

15 2MP04709000 2MP04708700 2MP04708500

ND 360, 480 & 600 Overload Setting

VOLTAGE 208/230V 460V 575V

MOTOR HP

5 14/13 6.5 5

7.5 21/20 9.5 7.5

10 26/25 13 10

15 38/36 18 15

1

Motors with Service Factor of 1.15 or Greater: Adjust overload relay dial to the

motor nameplate Full Load Amps (FLA).

2

Motors with Service Factor Less Than 1.15: Adjust overload relay dial based on the

OVERLOAD SETTING (Full Load Amps)

formula: Motor nameplate FLA x 0.90 = relay setting

18 Johnson Controls Unitary Products

12

Page 19

Static Resistance

Static Resistance

Model CFM Hot Water Coil Steam Coil

ND360

ND480

ND600

Sound Performance

628767-YTG-J-0913

10000 0.08 0.11

11000 0.09 0.14

12000 0.10 0.17

13000 0.12 0.20

14000 0.14 0.23

12800 0.11 -

14400 0.13 -

16000 0.15 -

17600 0.17 -

19200 0.20 -

16000 0.15 -

18000 0.18 -

20000 0.21 -

22000 0.24 -

24000 0.28 -

Indoor Sound Power Levels

Model

(Tons)

ND360

(30)

ND480

(40)

ND600

(50)

1

These values have been accessed using a model of sound propagation from a point source into the hemispheric/free field. The dBA

CFM

12000 0.75 755 5.66 86 84 84 82 81 81 77 74 69

16000 0.80 800 8.9 92 90 90 88 90 86 84 81 76

2

20000 1.13 700 10.7 88 87 87 85 86 82 80 78 73

ESP

(IWG)

Blower

RPM BHP

Sound Rating

dB (A)

1

Sound Power, dB (10

Octave Band Center line Frequency (Hz)

63 125 250 500 1000 2000 4000 8000

values provided are to be used for reference only. Calculation of dBA values cover matters of system design and the fan manufacture

has no way of knowing the details of each system. This constitutes an exception to any specification or guarantee requiring a dBA

value of sound data in any other form than sound power level ratings.

2

ND600 Combined with M1CZ600 Evaporator Section

-12

) Watts

Johnson Controls Unitary Products 19

Page 20

628767-YTG-J-0913

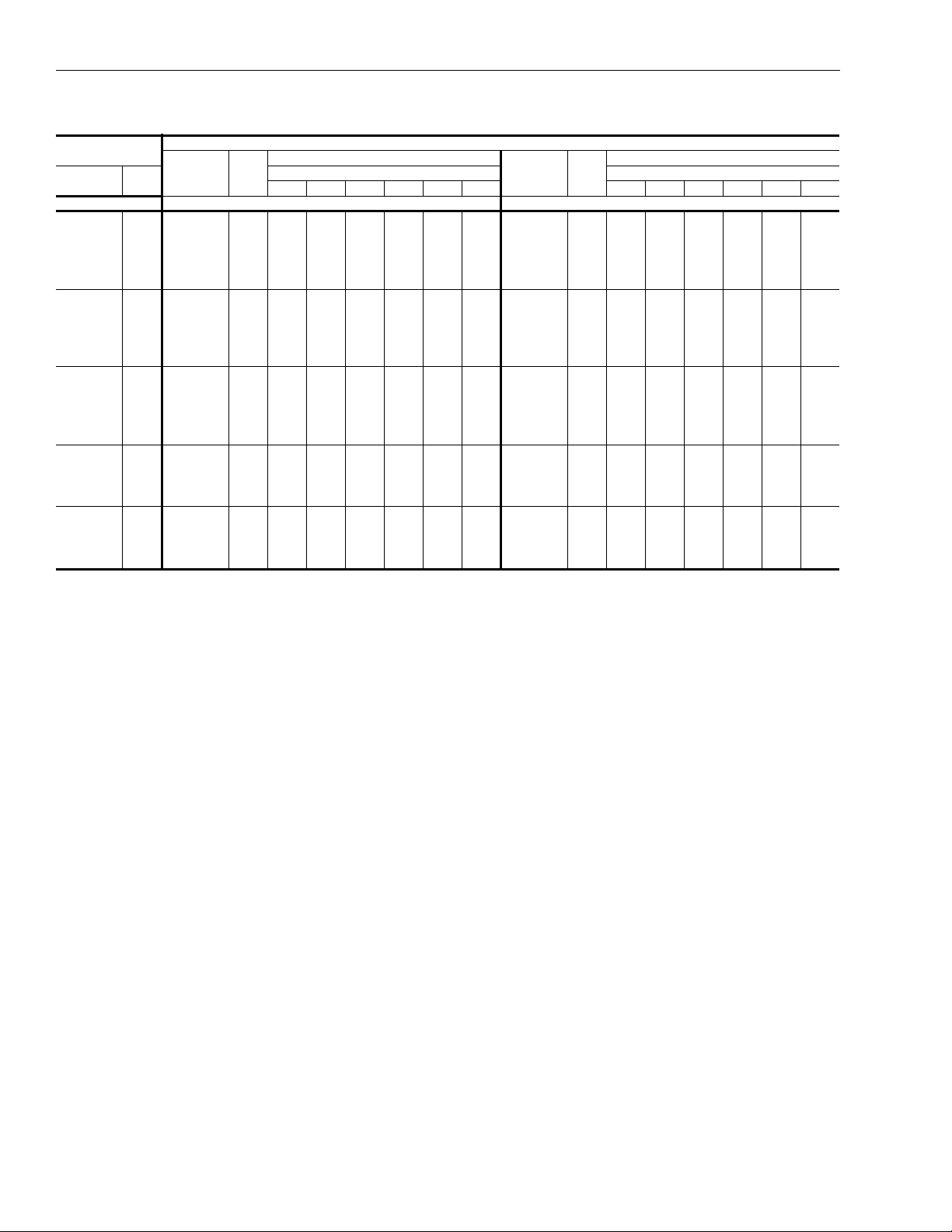

Electrical Data

Electrical Data

MAX.

FUSE

SIZE

(Amps)

UNIT

MODEL

ND360

ND480

ND600

HP FLA

5.0

7.5

10

7.5

10

10

15

VOLTAGE

(3PH-60HZ)

16.7 208 21 35

15.2 230 19 30

7.6 460 10 15

6.1 575 8 15

24.2 208 30 50

22 230 28 45

11 460 14 20

9 575 11 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

24.2 208 30 50

22 230 28 45

11 460 14 20

9 575 11 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

30.8 208 39 60

28 230 35 60

14 460 18 30

11 575 14 20

46.2 208 58 100

42 230 53 90

21 460 26 45

17 575 21 35

MIN

CIRCUIT

AMPACITY

20 Johnson Controls Unitary Products

Page 21

Typical Wiring Diagrams

Air Handling Units

Typical ND360, 480 & 600 Indoor Unit Wiring Diagram (Contactor)

628767-YTG-J-0913

Johnson Controls Unitary Products 21

Page 22

628767-YTG-J-0913

D (E) (D) C D (E) (D) C

(F) (C) (F) (C)

A (A) (B) B A (A) (B) B

Vertical

Horizontal

X

Y

CG

X

Y

CG

MOTOR

MOTOR

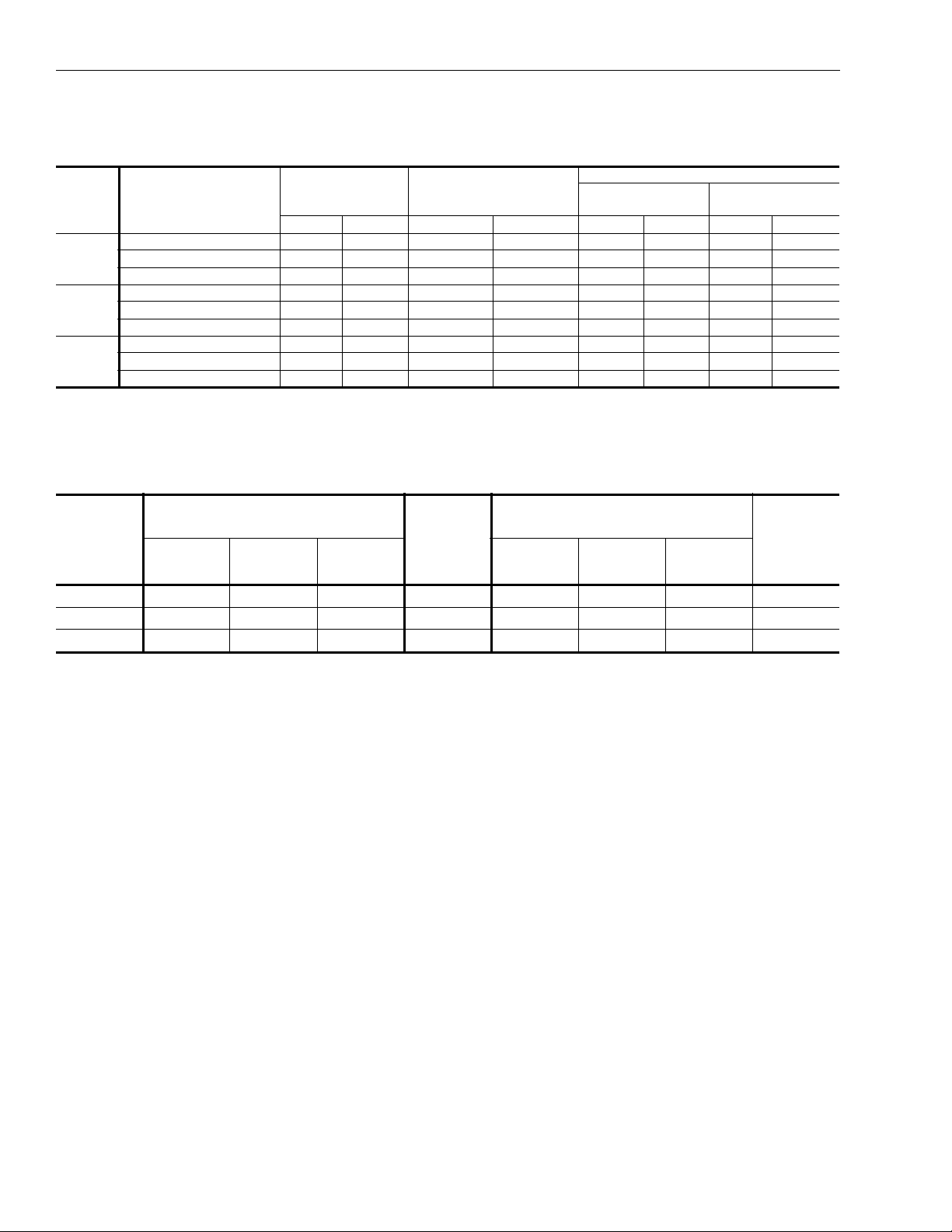

Weights And Dimensions

Corner Weights & Center of Gravity ND360, 480 & 600 Unit

Evaporator

Model Drive HP

Section

Cabinet

Wt (lb)

Vertical Airflow

5.0 567 490 110 1122 1184 20.1 44.3 297 363 288 236 200 244 215 191 157 176

ND360

ND480

ND600

M1CZ600 ~ ~ ~ ~ 979 ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

7.5 567 490 134 1122 1208 20.3 44.0 301 376 295 236 202 252 222 197 158 178

10 567 490 150 1122 1224 20.5 43.8 304 385 299 236 203 257 226 201 159 179

7.5 654 527 141 1246 1348 24.6 45.1 334 424 330 260 223 283 249 221 174 196

10 654 527 157 1246 1364 24.8 44.9 336 434 334 259 224 288 254 226 175 197

10 ~ 645 155 705 1742

15 ~ 645 272 705 1859

Horizontal Airflow

5.0 567 490 110.2 1122 1184 36.4 44.3 332 328 260 264 224 221 195 173 175 197

ND360

ND480

ND600

M1CZ600 ~ ~ ~ ~ 979 ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

1

7.5 567 490 134 1122 1208 36.5 44.0 339 338 265 266 227 226 199 177 178 200

10 567 490 150 1122 1224 36.6 43.8 345 344 268 268 230 230 202 180 180 203

7.5 654 527 140.7 1246 1348 43.1 45.1 387 371 288 301 258 248 218 194 202 228

10 654 527 156.9 1246 1364 43.2 44.9 392 378 291 303 261 251 221 196 204 230

10 908.5 645 154.9 705 1742

15 908.5 645 271.7 705 1859

Operating weight includes ND600 Air Handler and M1CZ600 Evaporator Coil Combined.

Blower

Section

Cabinet

Wt (lb)

Drive

Section

Cabinet

Wt (lb)

Weight

(lbs.)

Ship

ping

Center of

Gravity

Opera

CG XCG Y A B C D ABCDEF

ting

1

31.4 46.1 393 570 461 318 267 387 341 303 209 235

1

32.4 45.0 408 639 496 318 272 426 376 333 213 240

1

52.1 46.1 446 517 418 361 303 351 309 275 237 267

1

52.5 45.0 480 567 440 373 320 378 333 296 250 282

4 Point Load Location

(lbs.)

6 Point Load Location

(lbs.)

22 Johnson Controls Unitary Products

Page 23

628767-YTG-J-0913

57.7

Ø0.88 KO

ELECTRIC HEAT

CONNECTION

15.9

4X Ø0.88 KO

CONTROLS

CONNECTION

3.0

9.1

5.3

22.0

62.4

22.0

22.5

5.3

2.6

19.0

SUPPLY

AIR

SUPPLY

AIR

100.1

95.6

2.4

33.2

37.3

36.7

Ø0.88 LIQUID

CONNECTION

SYSTEM 2

Ø1.125 SUCTION

CONNECTION

SYSTEM 1

Ø0.88 DRAIN

CONNECTION

Ø1.125 SUCTION

CONNECTION

SYSTEM 2

38.1

3.4

4.1

5.1

6.1

3.6

5.5

23.6

5.9

74.7

0.63

Ø0.88 LIQUID

CONNECTION

SYSTEM 1

RETURN

AIR

RETURN

AIR

TOP

FRONT SIDE

Unit Dimensions ND360

Johnson Controls Unitary Products 23

Page 24

628767-YTG-J-0913

73.3

74.0

SUPPLY

AIR

RETURN

AIR

HORIZONTAL CONFIGURATION

Unit Dimensions ND360 (Continued)

24 Johnson Controls Unitary Products

Page 25

TOP

4X Ø0.88 KO

CONTROLS

CONNECTION

3.0

5.5

5.3

22.0

60.5

22.0

20.6

5.3

2.6

19.0

SUPPLY

AIR

SUPPLY

AIR

44.0

44.7

40.5

2.4

98.5

103.1

0.63

89.4

10.1

23.1

7.9

7.6

3.5

3.2

4.3

4.5

7.1

45.4

Ø0.88 LIQUID

CONNECTION

SYSTEM 1

Ø0.88 LIQUID

CONNECTION

SYSTEM 2

Ø1.375 SUCTION

CONNECTION

SYSTEM 1

Ø0.88 DRAIN

CONNECTION

Ø1.375 SUCTION

CONNECTION

SYSTEM 2

RETURN

AIR

RETURN

AIR

105.1

628767-YTG-J-0913

FRONT SIDE

Unit Dimensions ND480

Johnson Controls Unitary Products 25

Page 26

628767-YTG-J-0913

88.2

88.8

RETURN

AIR

SUPPLY

AIR

HORIZONTAL CONFIGURATION

Unit Dimensions ND480 (Continued)

26 Johnson Controls Unitary Products

Page 27

628767-YTG-J-0913

103.1

23.061.7

23.018.5

2.6

24.9

6.1

4.6

6.1

7.8

9.1

Ø0.88 KO

CONTROLS

CONNECTION

Ø1.13 KO

CONTROLS

CONNECTION

Ø1.38 KO

CONTROLS

CONNECTION

DETIAL A

SCALE 0.375

(2X TYP)

SEE DETAIL A

SUPPLY

AIR

SUPPLY

AIR

45.5

45.4

44.0

SUPPLY

AIR

SUPPLY

AIR

TOP

FRONT SIDE

Unit Dimensions ND600

Johnson Controls Unitary Products 27

Page 28

628767-YTG-J-0913

53.7

54.4

49.5

2.4

2.3

53.7

98.5

103.1

105.1

RETURN

AIR

RETURN

AIR

Ø0.88 LIQUID

CONNECTION

SYSTEM 2

Ø0.88 LIQUID

CONNECTION

SYSTEM 1

Ø.88 DRAIN

CONNECTION

Ø2.13 SUCTION

CONNECTION

SYSTEM 2

Ø2.13 SUCTION

CONNECTION

SYSTEM 1

3.2

6.7

7.6

3.4

7.3

13.3

27.6

10.2

TOP

FRONT SIDE

Unit Dimensions M1CZ600 Evaporator Section

28 Johnson Controls Unitary Products

Page 29

VERTICAL CONFIGURATION

53.7

54.4

45.5

99.0

97.8

103.1

105.1

SUPPLY

AIR

SUPPLY

AIR

RETURN

AIR

RETURN

AIR

98.4

97.2

SUPPLY

AIR

RETURN

AIR

NAMEPLATE

FRONT SIDE

628767-YTG-J-0913

HORIZONTAL CONFIGURATION

Unit Dimensions ND600 Air Handler & M1CZ600 Evaporator Coil

Johnson Controls Unitary Products 29

Page 30

628767-YTG-J-0913

Unit Connection Sizes

Model ND360 ND480 ND600 M1CZ600A

Dimensions (inches)

Length 100.1 103.1 103.1 103.1

Width

Height

System Data

No. Refrigeration Circuits 2 2 2

Suction Line OD (in.) 1 1/8 1 3/8 - 2 1/8

Liquid Line OD (in.) 7/8 7/8 - 7/8

Power Wiring Knockout 7/8 7/8 1 3/8 -

Control Wiring Knockout 7/8 7/8 7/8 -

Drain Line 7/8 7/8 - 7/8

Blower Outlet

Number 222 -

Width 19.0 19.0 24.9 -

Length 22.0 22.0 23.0 -

Return Air Inlet

Width 33.2 40.5 - 49.5

Length 95.6 98.5 - 98.5

38.1 45.4 45.5 53.7

74.7 89.4 45.4 54.4

Minimum Clearances

Top with Supply Air Opening

1

Front with Return Air Opening 24”

Right Side with access for Piping, Power & Control

Wiring Connections

Left Side 24”

3

Rear

4

Bottom

1

This dimension will vary if a supply air plenum or a base is

used.

2

This dimension is required for normal installation and service.

3

Although no clearance is required for service and operation,

2

some clearance may be required for routing the power and

control wiring.

4

Allow enough clearance to trap the condensate drain line.

24”

24”

N/A

N/A

Dimensions Hot Water Coil

Dimensions Hot Water Coil

COIL

MODEL

UNIT

MODEL

ABCDEF

1HW0406 ND360 100-1/8 37-7/8 6-3/4 3-7/8 1-3/8 1-3/8

1HW0407

ND480

ND600

103-1/8 45-1/4 6-1/2 4 1-5/8 1-5/8

30 Johnson Controls Unitary Products

DIMENSIONS

Page 31

628767-YTG-J-0913

Dimensions Steam Coil

Dimensions Steam Coil

COIL

MODEL

1NF0454 ND360 100-1/8 37-7/8 4-3/8 18-3/8 1-1/2 2 2-1/2

1

Coils are field-installed between the evaporator coil and the blower section of the unit.

1

UNIT

MODEL

DIMENSIONS

ABCDEFG

Dimensions Base Section

Dimensions Base Sections

BASE

MODEL

1BS0406 ND360 100-1/8 37-7/8

1BS0407 ND480 103-1/8 45-1/4

1

Ventilation air can be brought into the unit through the

base section providing the base section is fully insulated in the field.

UNIT

MODEL

1

DIMENSIONS

AB

Johnson Controls Unitary Products 31

Page 32

628767-YTG-J-0913

AX

3

1-1/2

EVAP . COIL

SECTION

BLOWER

SECTION

U

3 O

U

HEATIN G COIL

2

SUSPENSION

ANGLES

1

BLOWER

SECTION

EVAP.

COIL

SECTION

CX

1

2

3

3

4

4

VERTICAL UNIT SUPPORTED

FROM BELOW

F

A

B

E

D

B

A

E

AX

BX

BX

BX

BX

HORIZONTAL

UNIT SUSPENDED

FROM ABOVE

The same channels can be used in either position. When used to

support a vertical unit, these channels should be cut to match the

bottom dimension of the evaporator section.

The suspension channels have two sets of mounting holes to

accommodate horizontal units with or without a heating coil. On

a horizontal unit without a heating coil, the suspension channels

will extend 3” beyond both ends of the unit.

The same channels can be used to support a horizontal, floormounted unit from below.

After these bottom channels are cut per Note 1, a new hole will have

to be drilled at the cut end if the unit is to be mounted on isolators.

C

D

C

F

Unit Mounting

ND360, 480 & 600

The ND Series evaporator units may be suspended from

joists with isolation type hangers or hooks. Suspension

accessories 1HH0403 (ND360), 1HH0404 (ND480) and

1HH0405 (ND600 Air Handler with M1CZ600 Evaporator

Section) may be ordered separately. All Suspension

accessories include three suspension channels and

ND360 & 480 Mounting Detail

hardware. The channels extend across the evaporator

section, the heating section (if included) and the blower

section. Each channel is to be bolted to both sections as

shown in Weight Distribution with Suspension Application

Figures. Refer to the Unit Mounting Dimensions Table for

mounting details and Corner Weights Tables for unit weight

distribution.

ND480/ND360 Weight Distribution With Suspension Application

32 Johnson Controls Unitary Products

Page 33

NOTE: The following illustration shows how the channels

E

D

AX

C

BX

BX

B

A

F

should be secured to the unit using the hardware

provided with the suspension accessory.

(2) 9/16 HOLES FOR 1/2

HANGER RODS

SUSPENSION

CHANNEL

628767-YTG-J-0913

5/16 NUT,

FLATWASHER

3/8 NUT (USED

AS SPACER)

SIDE

PANEL

3

ND360/ND480 Details For Secu r ing Suspension Channels

LOCKWASHER,

FLATWASHER

UNIT PANEL

5/16 BOLT,

FLAT-WASHER

UNIT ANGLE

5/16 NUT,

ND600 & M1CZ600 Weight Distribution With Suspension Application

Johnson Controls Unitary Products 33

Page 34

628767-YTG-J-0913

CENTER CHANNEL (Location “1”)

CENTER CHANNEL (Location “2”)

ND600 Mounting Detail

When arranged horizontally, the ND600 air handler and

M1CZ600 evaporator coil can be suspended from joists with

hanger rods using a suspension accessory.

The suspension channels require no drilling o r cutting. Each

channel has enough holes in its bottom flange for:

1. Four bolted connections to the evaporator coil section. (Only two are used on the outside supports)

2. One bolted connection to the heating coil section.

3. Four bolted connections to the blower section. (Only two are used on the outside supports)

See Figure details for securing suspension chan nels.

When the heating section is not included, each channel will

extend 3" beyond the front and the rear of the unit. Bolt holes

in the bottom flange of each channel will still align with the

holes provided in the top framework of the evaporator section

and the blower section.

For both outside channels and for the Point 1 locations on the

center channel, the bolted connections are to be made where

the top sheet metal panels are attached to the unit

framework. The ¼” screws and cage nuts must be removed

and may be discarded. For the Point 2 locations on the center

channel, the bolted connections are to be made through the

knockouts in the top sheet metal panels. 5/16” cage nuts are

provided in the unit framework under these knockout

locations. Note that these cage nuts are part of the basic unit.

They are not supplied with the suspension accessory.

.

ND600 & M1CZ600 Details For Securing Suspension Channels

34 Johnson Controls Unitary Products

Page 35

Unit Mounting Dimensions

628767-YTG-J-0913

UNIT

ND360

ND480

ND600

DIMENSIONS, INCHES

AX BX CX

69-1/4 49-1/16 26-5/8

84 50-9/16 34

87 51-1/2 ~

Johnson Controls Unitary Products 35

Page 36

628767-YTG-J-0913

Typical Field Wiring Diagrams

Typical Field Wiring Diagram ND360/480 Evaporator Units, ND600 Air Handler and M1CZ600A Evaporator Coil when

Matched with YD360/480/600 Condenser

NOTE: On non ND evaporator models, isolation relays must be installed to avoid overloading on 75VA transformers on the

condensing unit.

Typical ND360/480 & M1CZ600A Liquid Line Solenoid

36 Johnson Controls Unitary Products

Page 37

Standard Terminal Block on NC300, ND360/480

and ND600 with M1CZ600A models. On non

NC/ND models isolation relays must be installed to

avoid overloading on 75 VA transformer on

condensing unit.

Non NC/ND units may not include any or all of

the components required to wire the unit. Use

the diagram as general reference only.

Primary side of transformer

connect to line side of power

supply.

Primary side of transformer

connect to line side of power

supply.

628767-YTG-J-0913

Ty pical Liquid Line Solenoid Wiring

Johnson Controls Unitary Products 37

Page 38

Subject to change without notice. Printed in U.S.A. 628767-YTG-J-0913

Copyright © 2014 by Johnson Controls, Inc. All rights reserved. Supersedes: 628767-YTG-I-0113

York International Corporation

5005 York Drive

Norman, OK 73069

Loading...

Loading...