Page 1

TECHNICAL GUIDE

MAXA-MI$ER

®

V* Series

Unitized Energy Recovery

Ventilators

ERV Unit with Predator® Packaged Unit

ERV Unit with Sunline® Packaged Unit

Energy recovery COMPONENT rated in

accordance with AHRI/ANSI Standard 1060-2005

and certified to AHRI. Actual performance in

packaged equipment may vary.

®

ERV Unit with Millennium® Packaged Unit

DESCRIPTION

246681-YTG-C-0611

• Reduces cooling load at design temperatures up to 4 tons per

1000 cfm of outside air.

• Reduces heating load up to 2.5 T ons Btuh per 1000 CFM of outside air.

• Dry energy transfer. Moisture in supply (intake) air stream is

transferred to exhaust air stream in a vapor state, eliminating

condensate plumbing from the UERV.

• Attaches directly to the York rooftop units. All mounting equipment is provided.

• Separate fused power supply. (Except Millennium or VR74 or

VR122)

• Filters / mist eliminators are provided on the entering air openings.

• Adjustable support legs are provided.

• Two modes of operation (Pivoting Wheel Models only)

• Recovery mode during normal energy recovery operation.

• True economizer mode when outside sensor calls for

economizer operation (3 - 12.5 ton packaged units

equipped with economizers). U. S. Patent 5,548,970.

• Pivoting wheel models used with packaged unit with economizer. Sequence of operation controlled by economizer controller. (Small Sunline and Predator Only)

• Balancing dampers provided on VR, VH and VU Modules.

(Except Millennium or VR74 and VR122)

• Centrifugal blowers (both intake and exhaust for high static

capability and low sound levels). (Except Millennium, VR74 and

VR122)

• Heavy gauge galvanized steel cabinets corrosion protected with

powder paint process that match York units.

• Fully insulated cabinet.

• AHRI certified internal enthalpy wheel is provided.

• Internal enthalpy wheel made of polymeric material with silica

gel impregnated into the material. The enthalpy wheel has a

five year limited warranty.

• Internal enthalpy wheels are easily cleanable. Large wheels (25

inch diameter and above) are split into easily removable pie

segments. Smaller wheels can be removed from the ERV.

• Continuous operation down to 10 ºF (-12 ºC) without defrost at

indoor relative humidity up to 40%. For temperatures below 10

ºF (-12 ºC), Optional Low Ambient Control Kit is required. Kit

includes temperature sensor to control the ERV before frost

build up can occur on recovery wheel.

®

Note: MAXA-MI$ER

rooftops using 14” high or greater roof curbs.

UERV’s are designed for use with

Note: Predator models ZF/ZH/ZJ/XP* 037-150, with

ERV must use “slab” type economizers and

downflow position.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

ETL Certified per UL 1995 and CSA 22.2

Page 2

TABLE OF CONTENTS

246681-YTG-C-0611

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . 2

YORK UERV MODEL NOMENCLATURE . . . . . . . . . . . 3

APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PRINCIPLE OF OPERATION . . . . . . . . . . . . . . . . . . . . .4

AHRI/ANSI STANDARD 1060-2005 FOR AIR-TO-AIR EN-

ERGY RECOVERY VENTILATION EQUIPMENT . . . . . 4

ENERGY RECOVERY WHEEL . . . . . . . . . . . . . . . . . . . .4

CROSS LEAKAGE IN UERV’S (PURGE SECTORS) . . . 5

OPTIONAL ACCESSORIES - FIELD INSTALLED . . . .5

OPTIONAL ACCESSORIES - FACTORY INSTALLED 6

HOW TO SELECT THE PROPER AIR

CONDITIONING UNIT AND UNITARY ENERGY RECOV-

ERY VENTILATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

LIST OF FIGURES

Fig. # Pg. #

1 UNITIZED ENERGY RECOVERY

VENTILATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 ENERGY RECOVERY WHEEL . . . . . . . . . . . . . . . . . .6

3 “P” SERIES PIVOTING WHEEL FOR UNITS W/ECONO-

MIZERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4 UERV DIMENSIONAL DATA - 036 THROUGH 060 . 20

5 UERV DIMENSIONAL DATA - 037 THROUGH 150 (3 -

12 1/2 TONS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6 UERV DIMENSIONAL DATA - 180 THROUGH 300 (15 -

25 TONS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7 MILLENNIUM UNIT VR074 AND VR122 (25 - 40 TON)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 3

8 STAND ALONE UERV’S FOR SIDE BY SIDE DUCT AR-

RANGEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

9 STAND ALONE UERV’S FOR OVER AND UNDER

DUCT ARRANGEMENTS . . . . . . . . . . . . . . . . . . . . . .26

GUIDE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . 23

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

APPROVALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

OPTIONS 23

SEQUENCE OF OPERATION: . . . . . . . . . . . . . . . . . . 24

UERV TROUBLESHOOTING GUIDE . . . . . . . . . . . . . 25

UERV BELOW 600 CFM WITH STATIONARY WHEEL

(NO ECONOMIZER) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

UERV ABOVE 600 CFM WITH STATIONARY WHEEL

(NO ECONOMIZER) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

UERV ABOVE 600 CFM WITH PIVOTING WHEEL (USED

WITH ECONOMIZER) . . . . . . . . . . . . . . . . . . . . . . . . . . 26

LIST OF TABLES

Tbl. # Pg. #

1 UERV OUTSIDE AIR CFM SELECTION BY CFM . . . . 5

2 PERFORMANCE - 3 THROUGH 12 1/2 TON UNITS . 7

3 PERFORMANCE - 15 THROUGH 25 TON UNITS . . . 8

4 PERFORMANCE - PIVOTING WHEEL MODELS . . . . 9

5 SPECIFICATIONS AND ELECTRICAL DATA - 300

THROUGH 550 CFM ERV’S . . . . . . . . . . . . . . . . . . . 10

6 SPECIFICATIONS AND ELECTRICAL DATA - 600

THROUGH 1700 CFM ERV’S . . . . . . . . . . . . . . . . . . 11

7 SPECIFICATIONS AND ELECTRICAL DATA - 1500

THROUGH 2800 CFM ERV’S . . . . . . . . . . . . . . . . . . 12

8 SPECIFICATIONS AND ELECTRICAL DATA - 2800

THROUGH 3600 CFM ERV’S . . . . . . . . . . . . . . . . . . 13

9 SPECIFICATIONS AND ELECTRICAL DATA - 3400

THROUGH 5600 CFM ERV’S . . . . . . . . . . . . . . . . . . 14

10 SPECIFICATIONS AND ELECTRICAL DATA - 5500

THROUGH 6200 CFM ERV’S . . . . . . . . . . . . . . . . . . 15

11 SPECIFICATIONS AND ELECTRICAL DATA - 6000

THROUGH 13000 CFM UERV’S . . . . . . . . . . . . . . . . 16

12 BLOWER PERFORMANCE CHART - VR074 . . . . . . 20

13 BLOWER PERFORMANCE CHART - VR122 . . . . . . 20

2 Unitary Products Group

Page 3

246681-YTG-C-0611

028 A12 H

Product Category

V = Ventilator

Wheel Type

R = Rooftop Stationary

CFM*

006 = 300 to 550

011 = 600 to 1000

A06 = Small Sunline ZF/ZR/XP036-072

Additional Options

AA = No Options Installed

Duct Type

2= 208/230v-3ph

York UERV Model Nomenclature

H = High Speed**

Product Generation

1 = First Generation

Voltage

4= 460v-3ph

York Rooftop Cabinet

VR

4 A L2 1

O = Stand Alone Over and Under, Stationary

S = Stand Alone Side by Side

P = Rooftop Pivoting (036-060 & 078-150 only)

020 = 1100 to 1700

028 = 2200 to 2800** 1500 to 2200**

036 = 2800 to 3600

046 = 3400 to 4600

062 = 5500 to 6200** 4800 to 5600**

074 = 6000 to 8000

122 = 8000 to 13000

Blower Speed

M = Medium Speed**

V = Variable Speed

L = Constant Volume

5= 575v-3ph

9= 208/320v-1ph

A12 = 50” Predator ZF/ZH/ZR/XP*102-150, ZJ076-150

B12 = 42” Predator ZF/ZR/XP078-090, ZH0037-090, ZJ/ZR076-150

A15 = Large Sunline ZF180

A25 = Large Sunline ZF210-300, ZJ180-300, XP180-240

A40 = Millinnium 25, 30 and 40 Ton Package

A = No Selection on Rooftop Units

L1 = Low Ambient Kit (LAK)*

L2 = LAK & Motorized Outside Air (MOA)*

L3 = LAK, MOA & Stop-Start-Job (SSJ) (not used on P models)*

L4 = LAK, MOA, SSJ & Pressure Sensor (PS) (not used on P)

L5 = LAK & SSJ (not used on P models)*

L6 = LAK, SSJ & PS (not used on P models)

L7 = LAK & PS

L8 = LAK, MOA and PS

M1 = Motorized Outside Air (MOA)*

M2 = MOA, and Stop Start-Jog (SSJ) (not used on P models)*

M3 = MOA, SSJ and Pressure Sensor (PS) (not used on P models)

M4 = MOA and PS

S1 = Stop-Start-Job (SSJ) (not used on P models)*

S2 = SSJ and Pressure Sensor (PS) (not used on P models)

P1 = Pressure Sensor (PS)

* CFM is ERV wheel rating. This may vary depending on unit cabinet pressure drop.

** These CFM ranges are dependant upon blower motor selection.

YORK UERV MODEL NOMENCLATURE

Unitary Products Group 3

Page 4

246681-YTG-C-0611

APPLICATIONS

Unitized Energy Recovery Ventilators (UERV) are used with

the York rooftop packaged units. The internal wheel provides

sensible and latent energy exchange between the entering

and exhaust air streams of a buildin g. Thi s al l ow s a su bstantial amount of the energy, which is normally lost in the

exhaust air stream to be returned into the entering air. Ideal

applications are areas that have cold or hot temperatures, or

areas that have high humidity or very low humidity (recover

exhaust air from buildings that have humidifiers to add

humidity). Application software is available to provide the

energy and dollar savings for all areas of the United States

and Canada.

PRINCIPLE OF OPERATION

The UERV enthalpy wheel contains parallel layers of a polymeric material that are impregnated with silica gel (desiccant). The wheel is located in the entering (intake) air and

exhaust air streams of the ventilation equipment. As the

wheel rotates through each air stream, the wheel surface

adsorbs sensible and latent energy. In the heating mode, the

wheel rotates to provide a constant transfer of heat from the

exhaust air stream to the colder intake air stream. During the

cooling season, the process is reversed. On units equipped

with an economizer (3 - 12.5 tons), the wheel pivots out of the

air stream to allow economizer to operate normally for "free

cooling" when outdoor temperature and humidity is acceptable. During economizer operation, the UERV exhaust

blower continues to run, providing power exhaust for the system. The intake blower is de-energized during economizer

operation.

AHRI/ANSI STANDARD 1060-2005 FOR AIR-TO-AIR ENERGY RECOVERY VENTILATION EQUIPMENT

The Air-Conditioning, Heating and Refrigeration Institute

(AHRI) issued Standard 1060-2005 to certify air-to-air energy

recovery ventilators. This standard deals specifically with the

ratings of the Energy Recovery Wheel that is incorporated

into the Energy Recovery Ventilator (ERV). All of the York

ERV's have an AHRI certified energy recovery wheel. The

data shown in the specification charts is the AHRI certified

ratings for the wheel. Actual performance in the ERV may

vary.

Critical Terms for Standard 1060 are as follows:

1. Effectiveness. The measured energy recovery effec-

tiveness not adjusted to account for that portion of the

psychrometric change in the leaving supply air (Station

2) that is the result of leakage of entering exhaust air

(Station 3) rather than exchange of heat or moisture

between the air streams.

2. Net Effectiveness. The measured recovery effective-

ness adjusted to account for that portion of the psychometric change in the leaving supply air (Station 2) that is

the result of leakage of the entering exhaust air (Station

3) rather than exchange of heat or moisture between the

air streams.

3. Exhaust Air Transfer Ratio (EATR). The tracer gas

concentration difference between the leaving supply air

(Station 2) and entering supply (outdoor) air stream (Station 1) divided by the tracer gas concentration in the

entering exhaust (return) air (Station 3) at the 100%

rated air-flow, expressed as a percentage.

4. Outdoor Air Correction Factor (OACF). The entering

supply (outdoor) airflow (Station 1) divided by the measured (gross) leaving supply airflow (Station 2).

ENERGY RECOVERY WHEEL

The heart of the Energy Recovery Ventilator is the Energy

Recovery Wheel (defined by AHRI as a rotary heat

exchanger). The wheel has a patented design of parallel layers of wrapped polymeric material that is impregnated with a

silica gel (desiccant). This unique design makes it the only

truly cleanable wheel on the market today. The small wheels

(30 inch diameter and smaller) are slide out cassettes, and

the larger wheels have pie segments that are removable for

cleaning.

FIGURE 1 - UNITIZED ENERGY RECOVERY

VENTILATOR

4 Unitary Products Group

FIGURE 2 - ENERGY RECOVERY WHEEL

Page 5

246681-YTG-C-0611

CROSS LEAKAGE IN UERV’S (PURGE SECTORS)

to 20% higher to get the desired air intake, and the cost associated with it.

The issue of cross leakage in rotary wheel based UERV's

used in space conditioning applications is often misunderstood. As a result, many systems are installed with purge

sectors and the additional fan capacity required to allow

these sectors to function when in fact they are unnecessary.

A better understanding of the rational for the purge sector,

and its history , allows us to dispense with the purge sector, its

added first cost and continuing cost of operation.

A purge sector minimizes the carry over cross leakage from

the exhaust into the supply (outside air) air stream by shunting a portion of the supply air back into the exhaust air stream

In space conditioning applications, where the ventilation is

operating to maintain acceptable indoor air quality, there are

no contaminants in concentrations large enough to cause

concern. Cross leakage in the UERV system results in a

small amount of the exhaust air, typically less than 5% in balanced airflow, returning to the space. This is not contaminated air, as some would suggest. It is however air that

effectively never left the space. The operation cost of moving

this air is far less than that required for a purge sector. Do not

use the Y ork UER V's in applications that have concentrations

of contaminants.

across the seal separating the exhaust and supply. This is

required in industrial applications where the exhaust carries

contaminants. This typically results in air volume being 15%

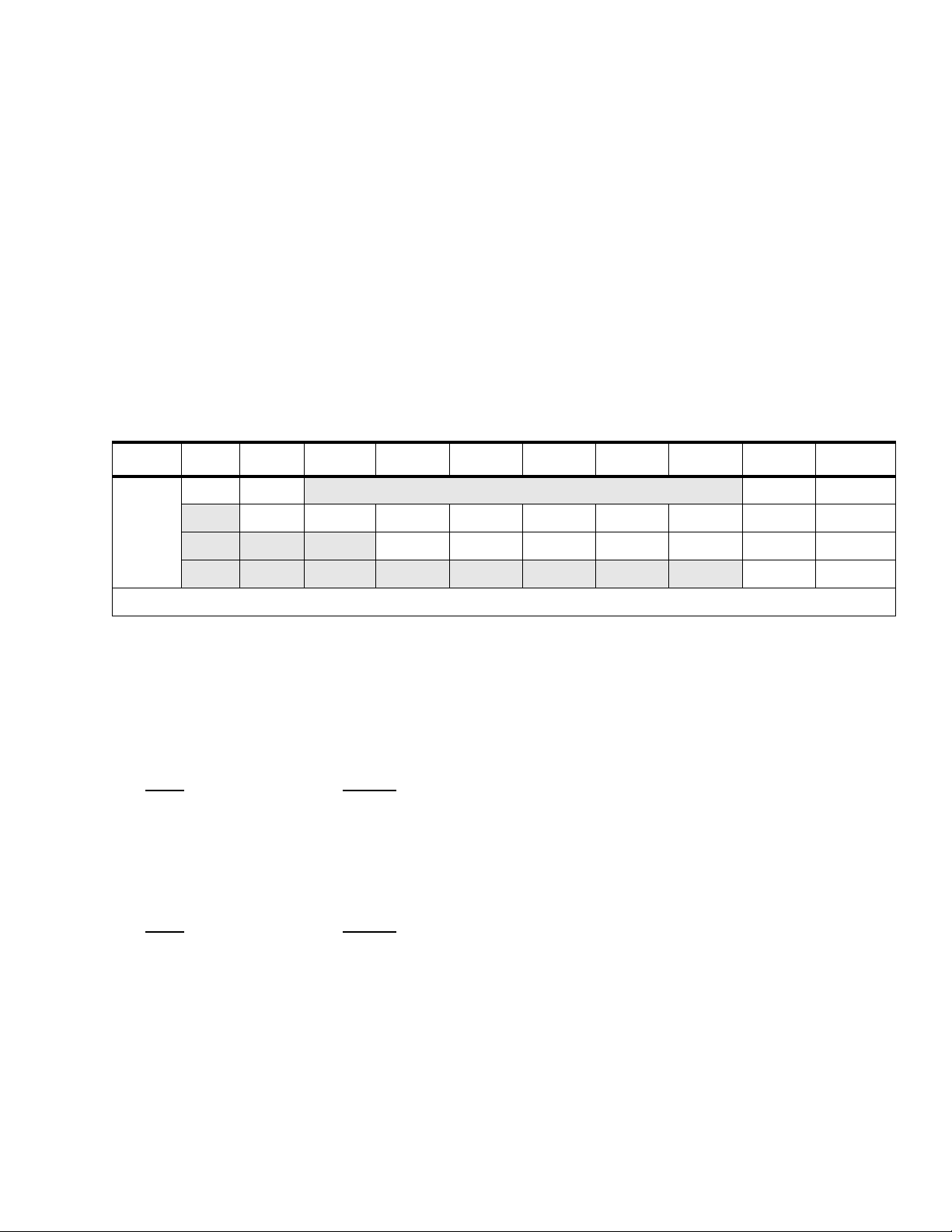

TABLE 1: UERV OUTSIDE AIR CFM SELECTION BY CFM

Unit-Tons 300-550 600-1000 1100-1700 1500-2800 2800-3600 3400-4600 4800-5600 5500-6200 6000-8000 8000-13000

1.5 - 6 1.5 - 6

7.5 - 12.5 7.5 - 12.5 7.5 - 12.5

Rooftop

Stand Alone type ERV’s are available for all tonnage sizes.

15 - 25 15 - 25 15 - 25 15 - 25 15 - 25

Stand Alone ERV’s are available for equipment room applications.

OPTIONAL ACCESSORIES - FIELD INSTALLED

UERV Equipment Support - 8 inch (203 mm) high base for

support of the exhaust and intake end of the UERV. Must be

ordered separately from the UERV.

Equipment Support

Part No.

UERV

VR006 1ES0401

VR/P011 1ES0402

VR/P020 1ES0402

VR/P028 1ES0402

Equipment Support

Part No.

UERV

VR036 1ES0403

VR046 1ES0403

VR062 1ES0404

VR074

VR122

25 - 40 30 - 40

match the specified unit. See specification pages for required

curb. Must be ordered separately from UERV.

Stand Alone Balancing Damper - Balancing dampers are

used with VO and VS models when ERV is connected to the

rooftop unit, not to ductwork on the roof.

Roof Curb - A 14 or 24 inch (355 or 610 mm) roof curb is

required to match supply and exhaust openings of the UERV

with the rooftop units. Y ork provides a full line of roof curbs to

Unitary Products Group 5

Page 6

246681-YTG-C-0611

Ventilator

Wheel Type

CFM = 2800

York Unit Cabinet Size

Blower Speed (H for High, M for Medium)

Voltage

Duct Type (A)

Option Code (see list above)

Generation

V

R

028 A12 H 4 A L3 1

OPTIONAL ACCESSORIES - FACTORY INSTALLED

Low Ambient Control Kit - Prevents frost formation on

energy wheel heat transfer surfaces by terminating the intake

blower operation when discharge air temperature falls below

a field selectable temperature setting. Intake blower operation resumes operation after temperature rises above the

adjustable temperature differential.

Pressure Sensor - Measurement device on the UERV to

determine airflow across the Wheel.

Motorized Intake Air Damper - Damper mounts in the outdoor air intake hood. It opens when the UERV is energized

and closes when de-energized.

Stop-Start-Jog - Function that rotates the Enthalpy Wheel

(non-pivoting models) on a preset timer to prevent contamination of the wheel during economizer operation.

ERV Option Codes (ex.: VR028A12H4AL3 would be an R28

series high speed 460 volt UERV with a Low Ambient kit,

Motorized Outside Air, and Stop-Start-Jog kit.)

L1 - Low Ambient Kit (LAK) *

L2 - LAK & Motorized. Outside Air (MOA) *

L3 - LAK, MOA, & Stop-Start-Jog (SSJ) *

L4 - LAK, MOA, SSJ, & Pressure Sensor (PS)

L5 - LAK and SSJ *

L6 - LAK, SSJ, and PS

L7 - LAK and PS

L8 - LAK, MOA, and PS

M1 - Motorized Outside Air (MOA) *

M2 - MOA and Stop-S tart-Jog (SSJ) *

M3 - MOA, SSJ, and Pressure Sensor (PS)

M4 - MOA and PS

S1 - Stop-Start-Jog (SSJ) *

S2 - SSJ and Pressure Sensor (PS)

P1 - Pressure Sensor (PS)

NOTE: * denotes only options available for VR074 & VR122.

HOW TO SELECT THE PROPER AIR CONDITIONING UNIT AND UNITARY ENERGY RECOVERY VENTILATOR

1. Determine the air conditioning load requirements with

the required amount of outside air without an UERV.

2. Select the proper UERV for the outside air CFM require-

ments and calculate the tonnage reduction through the

York UERV software program.

3. Select the air conditioning unit required by reducing the

load determined in step 1 by the reduction in step 2.

(Example: If the load in Step 1 was 10 tons, and the

reduction in Step 2 was 2.5 tons, select a 7.5 ton unit.)

4. Select the proper UERV based on the select unit. The

York part numbering scheme is as follows:

6 Unitary Products Group

Page 7

246681-YTG-C-0611

TABLE 2: PERFORMANCE - 3 THROUGH 12 1/2 TON UNITS

“R” Series Stationary Wheel for Units without Economizers

York

Packaged Unit

Model No.

Small Sunline

ZF036-060

ZR036-060

XP036-060

(42”)

Short Predator

ZH037-090

ZF078-090

ZJ037-061

ZR037-090

(50”)

Tall Predator

ZF102-150

ZH102-150

ZJ078-150

XP102-150

ZR102-150

Unit

Size

(Tons)

3 - 6

3 - 7.5

6 - 12.5

ERV CFM

Range

300-550 VR006A06H

600-1000 VR011A06H

300-550 VR006B06H

600-1000 VR011B12H

11 00-1700 VR020B12H

600-1000 VR011A12H

11 00-1700 VR020A12H

1500-2200 VR028A12M

2200-2800 VR028A12H

Matching ERV

Model

V oltage &

Phase

110v-1ph 1

208/230v-1ph 9

208/240v-3ph 2

460v-3ph 4

208/230v-1ph 9

208/230v-3ph 2

460v-3ph 4

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

Voltage

Code

Nominal AHRI Data (Total

CFM

500 65% 64%

900 73% 72%

500 65% 64%460v-3ph 4

900 73% 72%460v-3ph 4

1600 65% 64%460v-3ph 4

900 73% 72%460v-3ph 4

1600 65% 64%460v-3ph 4

1950 71% 70%460v-3ph 4

2600 65% 63%460v-3ph 4

Net Effectiveness

Heating Cooling

Note 1: Complete York ERV model number includes the electrical information. Example ZF 060

needing 500 CFM outside of air at 230 volts/3 phase. Model would be a VR006A06H2AAA1.

Unitary Products Group 7

Page 8

246681-YTG-C-0611

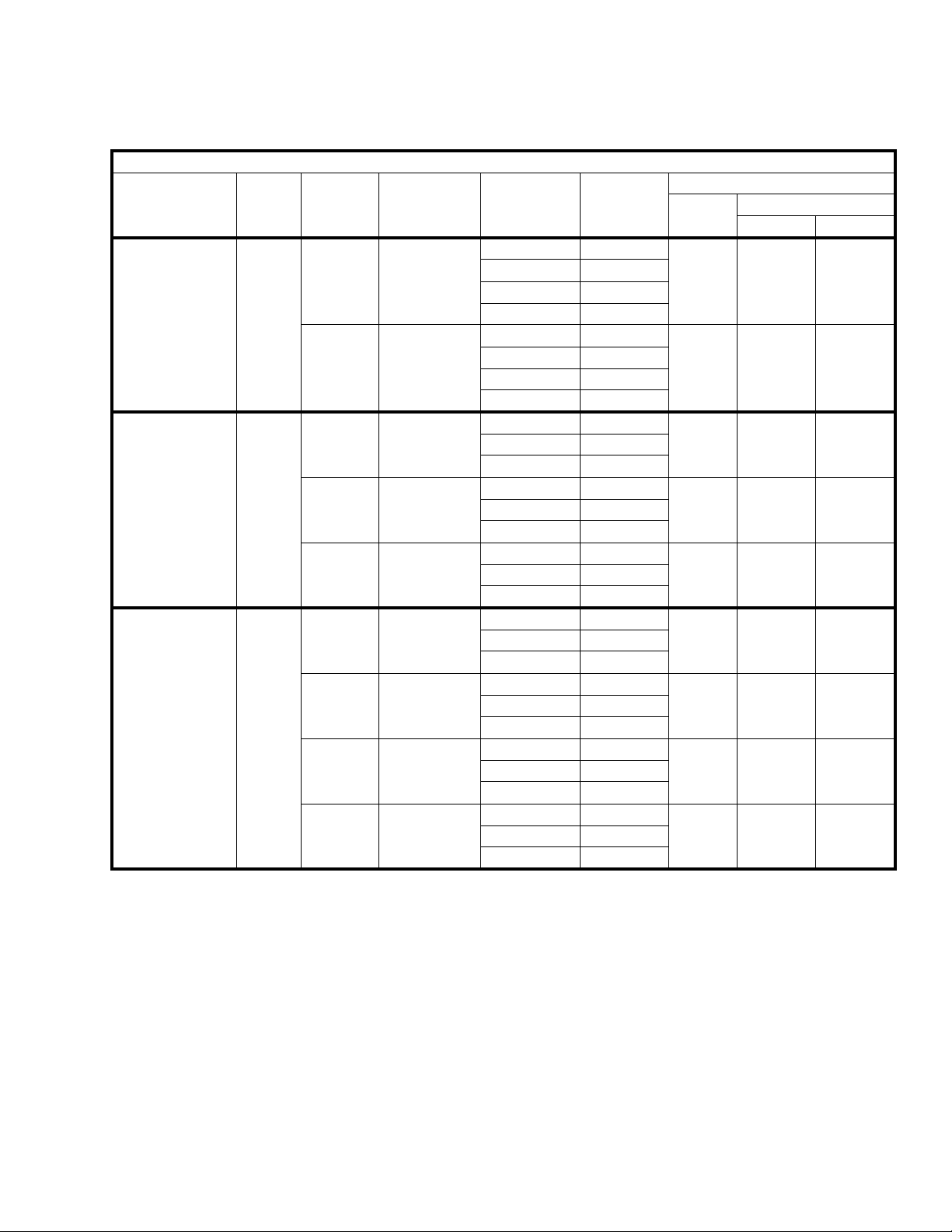

TABLE 3: PERFORMANCE - 15 THROUGH 25 TON UNITS

Use this table to determine ventilation and size requirements. Table shows York packaged units and matching ERV model,

Air Flow Range, and AHRI rated Net Effectiveness at 100% of rated CFM.

“R” Series Stationary Wheel for Units without Economizers

York

Packaged Unit

Model No.

Large Sunline

ZF180

ZJ180

ZR180

XP180

Large Sunline

ZJ210-300

ZR240-300

ZF210-300

XP240

Millennium

Z32

Z33

Z34

Note 1: Complete York ERV model number includes the electrical information. Example: ZJ180 needing 2800 CFM

outside of air at 230 volts/3 phase. Model would be a VR028A15H2AAA1.

Note 2: For VR074 and VR122 units used with an economizer must have the Start-Stop-Jog (SSJ) option.

Unit

Size

(Tons)

15

17.5 - 25

25-40

ERV CFM

Range

1500-2200 VR028A25H

2200-2800 VR028A25H

2800-3600 VR036A15H

3400-4600 VR046A15H

4800-5600 VR062A25M

5500-6200 VR062A25H

2200-2800 VR028A25H

2800-3600 VR036A25H

3400-4600 VR046A25H

4800-5600 VR062A25M

5500-6200 VR062A25H

6000-8000 VR074A40*

8000-13000 VR122A40*

Matching ERV

Model

Voltage &

Phase

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 4

575v-3ph 2

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

Voltage

Code

Nominal AHRI Data (Total

CFM

1950 71% 70%460v-3ph 4

2600 65% 63%460v-3ph 4

3100 65% 63%460v-3ph 4

3900 65% 63%460v-3ph 4

4125 71% 70%460v-3ph 4

5500 65% 63%460v-3ph 4

2600 65% 63%460v-3ph 4

3100 65% 63%460v-3ph 4

3900 65% 63%460v-3ph 4

4125 71% 70%460v-3ph 4

5500 65% 63%460v-3ph 5

6600 65% 63%460v-3ph 4

10800 65% 63%460v-3ph 4

Net Effectiveness

Heating Cooling

8 Unitary Products Group

Page 9

246681-YTG-C-0611

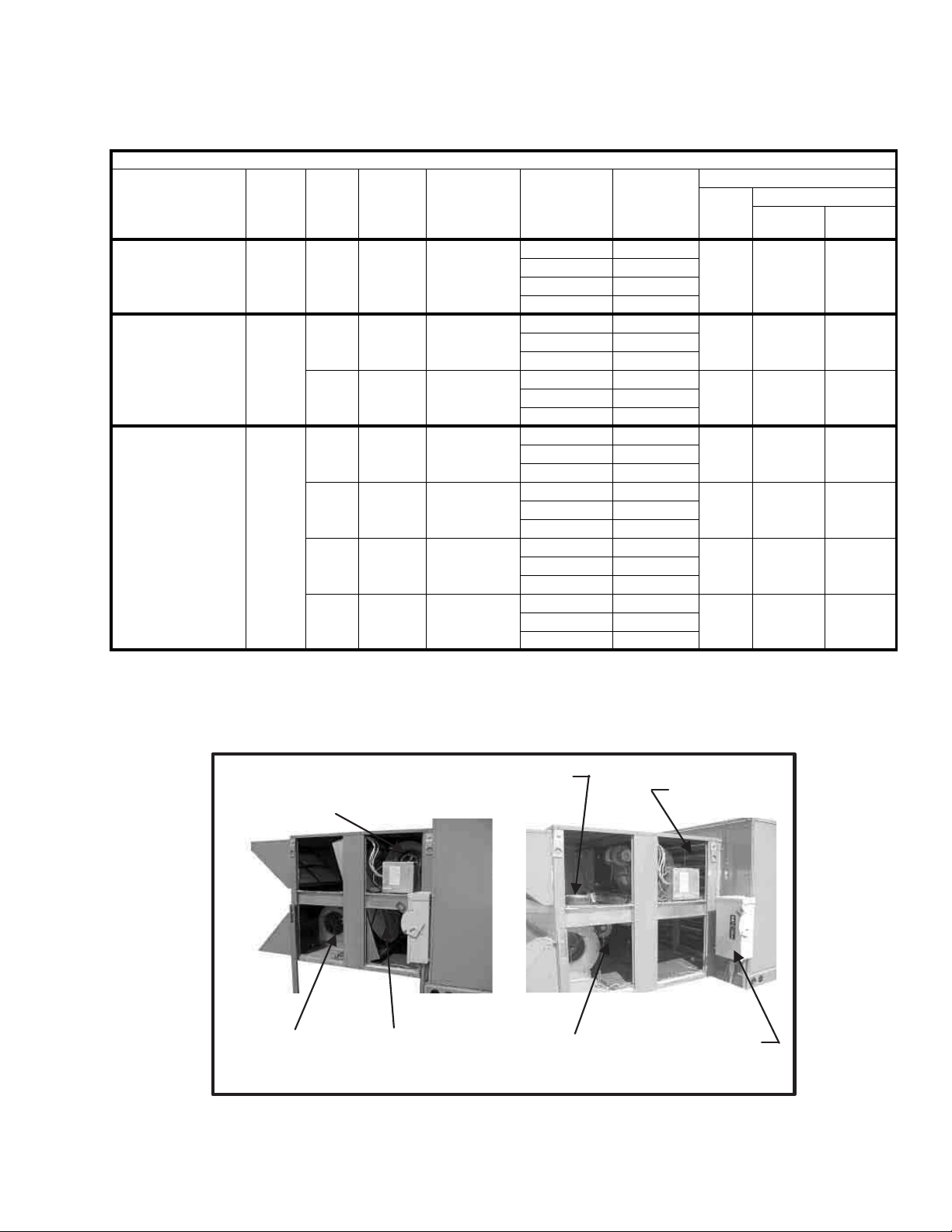

Enthalpy Wheel

(with removable pie

segments)

Air Blower

(

)

e

Air Blower

(energized)

Air Blower

Fresh Air Damper

(opens during economizer

operation)

local code approval

)

Enthalpy Wheel

Discharge Air Stream

TABLE 4: PERFORMANCE - PIVOTING WHEEL MODELS

“P” Series Pivoting Wheel for Units with Economizers

York

Packaged Unit

Model No.

Small Sunline

ZF036-060

ZR036-060

XP036-060

Short Predator (42”)

ZH037-090

ZF078-090

ZJ037-061

ZR037-090

XP078-090

Tall Predator (50”)

ZF102-150

ZH102-150

ZJ078-150

XP102-150

ZR102-150

Note 1: Complete York ERV model number includes the electrical information. Example ZF 060

Unit

Size

(Tons)

3 - 6

ERV

CFM

Range

600-

1000

600-

1000

7.5 - 8.5

1100-

1700

600-

1000

1100-

6.5 -

12.5

1700

1500-

2200

2200-

2800

needing 800 CFM outside of air at 230 volts/3 phase. Model would be a VP011A06H2AAA1.

2: Predator models ZF/ZH/ZJ/XP* 037-150, with ERV must use “slab” type economizers and downflow

position.

Max.

CFM

Power

Exhaust

Matching

ERV

Model

1900 VP011A06H

1900 VP011B12H

3000 VP020B12H

1900 VP011A12H

3000 VP020A12H

3450 VP028A12M

4200 VP028A12H

Voltage &

Phase

Voltage

Code

208/230v-1ph 9

208/240v-3ph 2

460v-3ph 4

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

208/230v-3ph 2

575v-3ph 5

Nominal AHRI Data (T otal

Net Effectiveness

CFM

Heating Cooling

900 73% 72%

900 73% 72%460v-3ph 4

1600 65% 64%460v-3ph 4

900 73% 72%460v-3ph 4

1600 65% 64%460v-3ph 4

1950 71% 70%460v-3ph 4

2600 65% 63%460v-3ph 4

Pivoted out of Intake and

Outsid

Exhaust

energized

Exhaust

Unit & UERV Disconnect

(provided correct wire size used

for both units and

FIGURE 3 - “P” SERIES PIVOTING WHEEL FOR UNITS W/ECONOMIZERS

Unitary Products Group 9

Page 10

TABLE 5: SPECIFICATIONS AND ELECTRICAL DATA - 300 THROUGH 550 CFM ERV’S

VS006 - S/S Stand Alone Stationary

Model Numbers

Line Voltage - 60hz 115v-1ph 208/230v/460-1ph 208/230v/460-3ph

Motor - hp / type 0.25 / PSC

Wheel Size (dia x width) - in 5.5 x 6.3

Fresh Air

Blower

Exhaust Air

Blower

Wheel

Electrical

Data

Total

Electrical

Wheel

Data

Enthalpy

Wheel AHRI

Rating Data

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total

Total

Effectiveness

Net

Effectiveness

Curb A/C Unit Curb Height - in 14

Weights

Note: 1: A st epdown transformer is provided to stepdown high voltage primary to 115 volt secondary.

Motor Speed - rpm 1780

Motor Speed(s) 2

Bearing Type Sleeve

Full Load Amps 3.8

Service Factor 1.1

Motor - hp 0.25 / PSC

Wheel Size (dia x width) - in 5.5 x 6.3

Motor Speed - rpm 1780

Motor Speed(s) 2

Bearing Type Sleeve

Full Load Amps-Stationary 3.8

Service Factor 1.1

Potential Volts 115

Motor Speed (RPM)/Wheel (RPM) 1050/68

Full Load Amps 0.7

MCA 8.7

OCPD 10

Wheel Depth 2

Wheel Diameter 19.3

Construction / Media Type One Piece / Polymeric

Nominal Airflow CFM 500 @ .6

EATR - -0.50 H

EATR - 0.00 H

EATR - +0.50 H

OACF - -0.50 H

OACF - 0.00 H

OACF - +0.50 H

O9.90%

2

O0.20%

2

O0.00%

2

O1.02%

2

O1.33

2

O1.59%

2

100% Airflow Heating 68% 60% 65%

75% Airflow Heating 73% 65% 70%

100% Airflow Cooling 68% 60% 64%

75% Airflow Cooling 73% 65% 69%

100% Airflow Heating 68% 60% 65%

75% Airflow Heating 73% 65% 70%

100% Airflow Cooling 68% 60% 64%

75% Airflow Cooling 73% 65% 69%

Shipping Weight - lbs. 198

Net Weight - lbs. 155

VR006 - Rooftop Stationary

VO006 - O/U Stand Alone Stationary

246681-YTG-C-0611

10 Unitary Products Group

Page 11

246681-YTG-C-0611

TABLE 6: SPECIFICATIONS AND ELECTRICAL DATA - 600 THROUGH 1700 CFM ERV’S

VR011 - Rooftop Stationary

Model Numbers

VP011 - Rooftop Pivoting

VO011 - O/U Stand Alone

VS011 - S/S Stand Alone

Line Voltage - 60hz 208/ 230v-1ph 208/ 230v-3ph 460v- 1ph 460v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp / type .5 / PSC 1.0 / Belt

Wheel Size (dia x width) - in 10 x 6 AT 9 x 9

Fresh Air

Blower

Exhaust

Blower

Wheel

Electrical

Electrical

Wheel

Enthalpy

Wheel

Rating

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

Effec-

Effec-

Weights

Motor Speed - rpm 1120 / 960 / 850 1725

Motor Speed(s) 3 Adjustable Sheave

Bearing Type Sleeve Ball

Full Load Amps 3.4 3.8 1.9 1.4

Service Factor 1 1.15

Motor - hp Stationary .5 / PSC 1.0 / Belt

Motor - hp Pivoting .5 / PSC 1.5 / Belt

Wheel Size (dia x width) - in 10 x 6 AT 9 x 9

Motor Speed - rpm 1120 / 960 / 850 1725

Air

Motor Speed(s) 3 Adjustable Sheave

Bearing Type Sleeve Ball

Full Load Amps-Stationary 3.4 3.4 1.5 1.5 3.8 1.9 1.4

Full Load Amps-Pivoting 3.4 3.4 1.5 1.5 5.6 2.8 2.0

Service Factor 1 1.15

Potential Volts 208 / 230 208 / 230

Motor Speed (RPM)/Wheel

(RPM)

Data

Full Load Amps 0.3 0.3

MCA - Stationary 8.25 8.25 4.4 4.4 8.85 4.58 3.45

OCPD - Stationary 10 10 6 6 12 6 5

Total

MCA - Pivoting 8.25 8.25 4.4 4.4 11.1 5.7 4.2

OCPD - Pivoting 10 10 6 6 15 8 6

Wheel Depth - in 3 3

Diameter - in 25.3 30.346

Data

Construction / Media Type Segmented / Polymeric Segmented / Polymeric

Nominal Airflow CFM 900 @ 1.0 1600 @ .95

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

AHRI

OACF - -1.00 H

Data

OACF - 0.00 H

OACF - +1.00 H

100% Airflow Heating 76% 68% 73% 68% 61% 65%

Total

75% Airflow Heating 81% 73% 78% 72% 67% 71%

tive-

100% Airflow Cooling 76% 68% 72% 68% 61% 64%

ness

75% Airflow Cooling 81% 73% 76% 72% 67% 70%

100% Airflow Heating 76% 68% 73% 68% 61% 65%

Net

75% Airflow Heating 81% 73% 78% 72% 67% 71%

tive-

100% Airflow Cooling 76% 68% 72% 68% 61% 64%

ness

75% Airflow Cooling 81% 73% 76% 72% 67% 70%

Curb A/C Unit Curb Height - in 14 on A06 24

Shipping Weight - lbs. 318 425

Net Weight - lbs. 245 345

Note: 1. Pivoting electrical data applies to VP models only.

O 9.30% 7.80%

2

O 0.70% 0.40%

2

O 0.00% 0.00%

2

O 0.97% 0.97%

2

O 1.19% 1.16%

2

O 1.34% 1.29%

2

1050/56 1050/46

VR020 - Rooftop Stationary

VP020 - Rooftop Pivoting

VO020 - O/U Stand Alone

VS020 - S/S Stand Alone

Unitary Products Group 11

Page 12

TABLE 7: SPECIFICATIONS AND ELECTRICAL DATA - 150 0 THROUGH 2800 CFM ERV’S

246681-YTG-C-0611

Model Numbers

* VP028 - Rooftop Pivoting

VS028 - S/S Stand Alone

VO028 - O/U Stand Alone

Line Voltage - 60hz 208/230v-3ph 460v-3ph 575v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp / type 1.5 / Belt 2 / Belt

Wheel Size (dia x width) - in 10 x 10 10 x 10

* VR028 - Rooftop Stationary

Fresh Air

Blower

Exhaust

Blower

Wheel

Electrical

Data

Total

Electrical

Wheel

Data

Enthalpy

Wheel

AHRI

Rating

Data

Total

Effective-

ness

Effective-

ness

Curb A/C Unit Curb Height - in 24 on A12, 14 on A15 & A25 24 on A12, 14 on A15 & A25

Weights

Note: Pivo ting electrical data applies to VP models only.

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps 5.6 2.8 2 7.0 3.5 2.4

Service Factor 1.15 1.15

Motor - hp Stationary 1.5 / Belt 2 / Belt

Motor - hp Pivoting 3 / Belt Wheel Size (dia x width) - in 10 x 10 10 x 10

Motor Speed - rpm 1725 1725

Air

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps-Stationary 5.6 2.8 2 7.0 3.5 2.4

Full Load Amps-Pivoting 9 4.4 3.6 - - Service Factor 1.15 1.15

Motor - hp (1 phase) 0.17 0.17

Potential Volts 200-208 / 230 200-208 / 230

Motor Speed (RPM)/Wheel (RPM) 825/58 825/58

Full Load Amps 0.6 0.6

MCA - Stationary 13.2 6.9 5.1 16.4 8.5 6

OCPD - Stationary 20 10 7 20 10 7

MCA - Pivoting 17.5 8.9 7.1 - - OCPD - Pivoting 25 12 10 - - Wheel Depth x Diameter - in 3 x 37.759 3 x 37.759

Construction / Media Type Segmented Pies / Polymeric Segmented Pies / Polymeric

Nominal Airflow CFM 2600 @ .95 2600 @ .95

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

OACF - -1.00 H

OACF - 0.00 H

OACF - +1.00 H

O 6.10% 6.10%

2

O 0.40% 0.40%

2

O 0.00% 0.00%

2

O 0.99% 0.99%

2

O 1.13% 1.13%

2

O 1.23% 1.23%

2

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

100% Airflow Heating 68% 60% 65% 68% 60% 65%

75% Airflow Heating 74% 67% 71% 74% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 74% 67% 70% 74% 67% 70%

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Net

75% Airflow Heating 74% 67% 71% 74% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 74% 67% 70% 74% 67% 70%

Shipping Weight - lbs. 470 470

Net Weight - lbs. 395 395

* Electric data is for (A12) ZH/ZF/ZJ 078-150 and XP 078-150 only.

** Electric da ta is for (A15 and A25) ZH/ZF/ZJ 180-300 and XP 180 and 240 only.

12 Unitary Products Group

Page 13

246681-YTG-C-0611

TABLE 8: SPECIFICATIONS AND ELECTRICAL DATA - 2800 THROUGH 3600 CFM ERV’S

Model Numbers

VR036 - Rooftop Stationary

VS036 - S/S Stand Alone

VO036 - O/U Stand Alone

Line Voltage - 60hz 208/230v-3ph 460v-3ph 575v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp / type 2 / Belt 2 / Belt

Wheel Size (dia x width) - in 12 x 9 12 x 9

Fresh Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps 7.0 3.5 3.2 7.0 3.5 2.4

Service Factor 1.15 1.15

Motor - hp Stationary 3 / Belt 2 / Belt

Wheel Size (dia x width) - in 12 x 9 12 x 9

Exhaust Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps-Stationary 7.0 3.5 3.2 7.0 3.5 2.4

Service Factor 1.15 1.15

Motor - hp (1 phase) 0.50 0.50

Wheel

Electrical

Data

Potential Volts 200-208 / 230 200-208 / 230

Motor Speed (RPM)/Wheel

(RPM)

1725/64 1725/64

Full Load Amps 1.2 1.2

Total

Electrical

Wheel

Data

MCA - Stationary 16.4 8.6 6.6 16.4 8.6 6.6

OCPD - Stationary 25 12 9 25 12 9

Wheel Depth x Diameter - in 3 x 41.825 3 x 41.825

Construction / Media Type Segmented Pies / Polymeric Segmented Pies / Polymeric

Nominal Airflow CFM 3100 @ .9 3100 @ .9

O 4.90% 4.90%

2

O 1.30% 1.30%

2

O 0.30% 0.30%

2

O 0.99% 0.99%

2

O 1.07% 1.07%

2

O 1.12% 1.12%

2

Enthalpy

Wheel AHRI

Rating Data

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

OACF - -1.00 H

OACF - 0.00 H

OACF - +1.00 H

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Total

Effective-

ness

75% Airflow Heating 74% 67% 71% 74% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 74% 67% 70% 74% 67% 70%

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Net

Effective-

ness

75% Airflow Heating 74% 67% 71% 74% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 74% 67% 70% 74% 67% 70%

Curb A/C Unit Curb Height - in 24 24

Weights

Shipping Weight - lbs. 571 571

Net Weight - lbs. 475 475

Unitary Products Group 13

Page 14

TABLE 9: SPECIFICATIONS AND ELECTRICAL DATA - 340 0 THROUGH 5600 CFM ERV’S

246681-YTG-C-0611

Model Numbers VS046 - S/S Stand Alone

VR046 - Rooftop Stationary

VO046 - O/U Stand Alone

Line Voltage - 60hz 208/230v-3ph 460v-3ph 575v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp / type 5 / Belt 3 / Belt

Wheel Size (dia x width) - in 12 x 12 12 x 12

Fresh Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps 12.8 6.4 5.1 9.4 4.3 3.4

Service Factor 1.15 1.15

Motor - hp Stationary 5 / Belt 3 / Belt

Wheel Size (dia x width) - in 12 x 12 12 x 12

Exhaust Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps-Stationary 12.8 6.4 5.1 9 4.4 3.6

Service Factor 1.15 1.15

Motor - hp (1 phase) 0.5 0.5

Wheel

Electrical

Data

Potential Volts 200-208 / 230 200-208 / 230

Motor Speed (RPM)/Wheel

(RPM)

1075/57 1075/57

Full Load Amps 1.2 1.2

Total

Electrical

Wheel

Data

MCA - Stationary 30 15.6 12 22 11 9.1

OCPD - Stationary 40 25 15 30 15 12

Wheel Depth x Diameter - in 3 x 46.776 3 x 46.776

Construction / Media Type Segmented Pies / Polymeric Segmented Pies / Polymeric

Nominal Airflow CFM 3900 @ .95 3900 @ .95

O 4.40% 4.40%

2

O 1.10% 1.10%

2

O 0.20% 0.20%

2

O 0.99% 0.99%

2

O 1.06% 1.06%

2

O 1.11% 1.11%

2

Enthalpy

Wheel AHRI

Rating Data

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

OACF - -1.00 H

OACF - 0.00 H

OACF - +1.00 H

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Total

Effective-

ness

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Net

Effective-

ness

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

Curb A/C Unit Curb Height - in 24 24

Weights

Shipping Weight - lbs. 920 920

Net Weight - lbs. 805 805

14 Unitary Products Group

Page 15

246681-YTG-C-0611

TABLE 10: SPECIFICATIONS AND ELECTRICAL DATA - 5500 THROUGH 6200 CFM ERV’S

Model Numbers

VR062 - Rooftop Stationary

VO062 - O/U Stand Alone

VS062 - S/S Stand Alone

Line Voltage - 60hz 208/230v-3ph 460v-3ph 575v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp / type 5 / Belt 5 / Belt

Wheel Size (dia x width) - in 12 x 12 12 x 12

Fresh Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps 15 7.4 5.8 15 7 5.8

Service Factor 1.15 1.15

Motor - hp Stationary 5 / Belt 5 / Belt

Wheel Size (dia x width) - in 12 x 12 12 x 12

Exhaust Air

Blower

Motor Speed - rpm 1725 1725

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps-Stationary 14.8 7 5.1 14.8 7 5.1

Service Factor 1.15 1.15

Motor - hp (1 phase) 0.5 0.5

Wheel

Electrical

Data

Potential Volts 200-208 / 230 200-208 / 230

Motor Speed (RPM)/Wheel

(RPM)

1075/54 1075/54

Full Load Amps 1.2 2.7

Total

Electrical

Wheel

Data

MCA - Stationary 34.8 17.5 13.6 34.8 17.5 13.6

OCPD - Stationary 40 25 20 40 25 20

Wheel Depth x Diameter - in 3 x 52.026 3 x 52.026

Construction / Media Type Segmented Pies / Polymeric Segmented Pies / Polymeric

Nominal Airflow CFM 5500 @ .95 5500 @ .95

O 4.00% 4.00%

2

O 1.00% 1.00%

2

O 0.20% 0.20%

2

O 0.99% 0.99%

2

O 1.06% 1.06%

2

O 1.10% 1.10%

2

Enthalpy

Wheel AHRI

Rating Data

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

OACF - -1.00 H

OACF - 0.00 H

OACF - +1.00 H

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Total

Effective-

ness

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

100% Airflow Heating 68% 60% 65% 68% 60% 65%

Net

Effective-

ness

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

Curb A/C Unit Curb Height - in 24 24

Weights

Shipping Weight - lbs. 1250 1250

Net Weight - lbs. 1075 1075

Unitary Products Group 15

Page 16

246681-YTG-C-0611

TABLE 11: SPECIFICATIONS AND ELECTRICAL DATA - 6000 THROUGH 13000 CFM UERV’S

UERV Series VR074 VR122

Line Voltage - 60hz 208/230v-3ph 460v-3ph 575v-3ph 208/230v-3ph 460v-3ph 575v-3ph

Motor - hp (2) 5 / Belt (2) 7.5 / Belt

Wheel Size (dia x width) - in (2) 12 x 12 (2) 15 x 15

Motor Speed - rpm 1725 1725

Exhaust Air

Blower

Wheel

Electrical

Data

Total

Electrical

Wheel

Data

Enthalpy

Wheel

Airflow Data

Thermal Ratings @ 0” Pressure Diff. Sensible Latent Total Sensible Latent Total

Total

Effective-

ness

Net

Effective-

ness

Curb A/C Unit Curb Height - in 14 14

Weights

Motor Speed(s) Adjustable Sheave Adjustable Sheave

Bearing Type Ball Ball

Full Load Amps 14.8 7 5 22.4 9.7 7.8

OCPD 20 9 7 30 15 10

Service Factor 1.15 1.15

Motor - hp (3 phase) 0.25 0.25 0.25 0.25 0.25 0.25

Motor Speed (RPM)/Wheel

(RPM)

850/49 850/51

Full Load Amps 2.5 1.2 0.95 2.5 1.2 0.95

OCPD 322322

MCA 34.9 16.6 12.7 52 22.6 19

OCPD 50 20 15 70 30 25

Wheel Depth x Diameter - in 3 x 58 3 x 74

Construction / Media Type Segmented Pies / Polymeric Segmented Pies / Polymeric

Nominal Airflow CFM 6600 @ .95 10800 @ .95

EATR - -1.00 H

EATR - 0.00 H

EATR - +1.00 H

OACF - -1.00 H

OACF - 0.00 H

OACF - +1.00 H

O 4.60% 3.40%

2

O 1.90% 1.20%

2

O 0.90% 0.40%

2

O 0.99% 0.99%

2

O 1.05% 1.04%

2

O 1.09% 1.07%

2

100% Airflow Heating 68% 60% 65% 68% 60% 65%

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

100% Airflow Heating 68% 60% 65% 68% 60% 65%

75% Airflow Heating 73% 67% 71% 73% 67% 71%

100% Airflow Cooling 68% 60% 63% 68% 60% 63%

75% Airflow Cooling 73% 67% 70% 73% 67% 70%

Shipping Weight - lbs. 2800 3000

Net Weight - lbs. 2600 2800

16 Unitary Products Group

Page 17

246681-YTG-C-0611

ERV Model York Size A B C D CFM

(1238)

(203)

300-550036-072

24.75

(629)

37.9 6

(964)

8

(203)

ZF036-060

ZR036-060

24.63

(624)

600-1000036-072

(816)

(851)

C

A

Enthalpy Wheel

Intake Air Blower

VR006A06H

VR011A06H

48.75

(1238)

8

(203)

600-1000036-072

32.13

(816)

33.5

(851)

VP011A06H

-1RC0434

XP036-060

Small Sunline

Model Number York Size A B C D CFM

20.32

(516)

11

(279)

32.13

(816)

33.5

(851)

44.75

(1137)

60.38

(1533)

600-1000

1100-1700

14" High Curbs Required on "VR011" & "VP011" - 1RC0471

078-102

078-102

090-150

24" High Curbs Required on "VR028" & "VP028" - 1RC0476

(946)

24" High Curbs Required on "VR020" & "VP020" - 1RC0476

(953)

090-150

C

D

A

B

Optional Equipment

Support

Exhaust Blower

Outdoor Air

Intake Blower

Enthalpy Wheel

VR011B12H

VP011B12H

VR020B12H

VP020B12H

VR011A12H

VP011A12H

VR020A12H

VP020A12H

43.56

(1106)

42.63

(1083)

1500-2200090-150

42.63

(1083)

(1631)

18.32

(466)

090-150 2200-2800

43.56

(1106)

(1631)

18.32

(466)

VR028A12M

VP028A12M

VR028A12H

VP028A12H

20.32

(516)

11

(279)

32.13

(816)

33.5

(851)

44.75

(1137)

60.38

(1533)

600-1000

1100-1700

37.25

(946)

37.5

(953)

ZH037, 049, 061, 078, 090, 102, 120, 150

ZF078, 090, 102, 120, 150

Predator

ZR037, 049, 061, 078, 090, 102, 120, 150

XP078, 090, 102, 120, 150

14" High Curbs Required on "VR06" - 1RC0471

300-550037-061

24.75

(629)

37.9

(9

8

(203)

24.63

(624)

VR006B12H

14" High Curbs Required -

D

B

Exhaust Blower

32.13

FIGURE 4 - UERV DIMENSIONAL DATA - 036 THROUGH 060

FIGURE 5 - UERV DIMENSIONAL DATA - 037 THROUGH 150 (3 - 12 1/2 TONS)

Unitary Products Group 17

37.25

37.5

33.5

48.75

8

Page 18

Model Number Unit Size A B C D CFM

1500-2200

180-300

180

180-300

180

180-300

180

180-300

180

180-300

24" High Curbs Required on "VR036" - 1RC0477 or 1RC0478

14" Roofcurbs Required on "VR028" - 1RC0436 - 437

52.68

(1338)

57.38

(1457)

ZF180, 210, 240, 300

ZR240, 300

ZJ180, 210, 240, 300

XP180, 240

46.68

(1186)

57.38

(1457)

60.00

(1524)

30.50

(775)

2800-3600

24" High Curbs Required on "VR062" - 1RC0477 or 1RC0478

3400-4600

4800-5600

5500-6200

58.88

(1496)

57.38

(1457)

57.38

(1457)

22.50

(572)

2200-2800

52.13

(1327)

24" High Curbs Required on "VR046" - 1RC0477 or 1RC0478

180

42.63

(1083)

D

A

Exhaust

Blower

Outdoor Air Intake

Blower

Enthalpy

Wheel

C

VR028A15M

VR028A15H

VR028A25M

VR036A15H

VR036A25H

VR046A15H

VR046A25H

VR062A15M

VR062A25M

VR062A15H

VR062A25H

58.88

(1496)

43.56

(1106)

60.00

(1524)

60.00

(1524)

60.00

(1524)

30.50

(775)

30.50

(775)

30.50

(775)

NOTE: Refer to Unit Price Pages for exact unit, ERV and curb matchup.

Large Sunline

246681-YTG-C-0611

B

FIGURE 6 - UERV DIMENSIONAL DATA - 180 THROUGH 300 (15 - 25 TONS)

18 Unitary Products Group

Page 19

246681-YTG-C-0611

74.75

24.59

61.23

82.13

20.92

Millennium

Z32

Z33

Z34

Model Number CFM Description

VR074A40L 6000 - 8000 Constant Volume

VR074A40V 6000 - 8000 Variable Air Volume

VR122A40L 8000 - 13000 Constant Volume

VR122A40V 8000 - 13000 Variable Air Volume

- Designed to meet Millennium unit specifications

- 14’ High Curbs Required

- Rooftop unit blower exceeds the capacity of the ERV Exhaust Blowers

- See blower performance charts for airflow at various external static pressures.

FIGURE 7 - MILLENNIUM UNIT VR074 AND VR122 (25 - 40 TON)

Unitary Products Group 19

Page 20

TABLE 12: BLOWER PERFORMANCE CHART - VR074

RPM Range

Low 910-1320 Standard Unit

High 1325-1565 Optional Kit (01-KIT-RH58)

RPM Range

Low 775-1000 St andard Unit

Med 1000-1200 Optional Kit (01-KIT-RM74)

High 1175-1375 Optional Kit (01-KIT-RH74)

Exhaust

Blower RPM for VR074, (2) 5HP, Barometric Hood

00.511.52

6000 910 1060 1200 1300 1400

6500 955 1095 1225 1360 1430

CFM

7000

7500

1000 1130 1260 1380 1475

1040 1170 1290 1400 1500

8000 1080 1200 1315 1425 1530

Notes:

1. Drive losses included in the above table

2. Performance can vary depending on ambient conditions

3. Blower RPMs are for reference only

TABLE 13: BLOWER PERFORMANCE CHART - VR122

Exhaust

Blower RPM for VR122, 7.5HP, Barometric Hood

00.511.52

8000

9000

CFM

10000

11000

12000 970 1070 1165 1250 1355

13000 1015 1110 1200

Notes:

1. Drive losses included in the above table

2. Performance can vary depending on ambient conditions

3. Blower RPMs are for reference only

775 900 1030 1125 1200

825 945 1055 1150 1240

875 985 1090 1190 1280

925 1030 1125 1215 1310

246681-YTG-C-0611

External Static Pressure (in water)

External Static Pressure (in water)

1280 1360

20 Unitary Products Group

Page 21

246681-YTG-C-0611

UERV with Rooftop for Maximum Outside Air UERV with Horizontal Ductwork

(balancing damper field supplied)(optional balancing damper can be provided with UERV)

Balancing Damper

(field supplied)

uctwork Field

Supplied

1. Stand Alone design allows higher levels of out door air to be introduced into the a/c unit.

2. Static test ports provided to verify intake and

exhaust CFM.

3. Balancing damper is field provided when UERV

is connected to ductwork. System will not

operate properly without balancing damper.

4. Roof curbs are available for the UERV's.

5. CFM at 0.0 external static pressure.

Series Model Number

VS006 1RC0480

VS011

VS020

VS028

VS036

VS046

VS062

300-550 23.25 x 32.5 34.69 24.75 24.63 8.00 20.00 2.32 2.00 0.75 8.00

600-1000 30.25 x 43 44.25 32.13 33.50 12.00 27.00 3.25 5.00 1.56 17.00

1100-1700

35.5 x 52.75

54.38 37.25 37.50 12.00 30.00 1.63 4.00 4.06 20.32

1500-2800

41 x 49.5

52.25 42.62 43.56 14.00 32.00 1.63 4.00 4.75 22.50

2800-3600

41.81 x 55.75

46.69 6.00

3400-4600

47.81 x 55.75

52.69 6.66

4800-6200

54 x 55.75

58.88 8.21

EF I

Dimensional Data

Features and Notes

UERV Roof Curbs

Series

CFM Range Curb Size G HCD

6.03

10.32

30.5060 57.37 16.5 39.5

AB

C

A

E

B

D

VS006

VS011

VS020

VS028

VS036

VS046

VS062

1RC0481

1RC0482

1RC0483

1RC0485

1RC0486

1RC0484

9.00

13.41

D

UERV Data

UERV

F

FIGURE 8 - STAND ALONE UERV’S FOR SIDE BY SIDE DUCT ARRANGEMENTS

Unitary Products Group 21

G

D

H

Page 22

1. Stand Alone design allows higher levels of out-

door air to be intr oduced into the a/c unit.

2. Static test ports provided to verify intake and

exhaust CFM.

3. Balancing damper field supplied.

eries

odel No

1RC0480

1RC0481

1RC0482

1RC0483

1RC0484

1RC0485

1RC0486

UERV

Series

CFM Range

Curb Size

JxK)

ABCDEFGH I

300-550 23.25 x 32.5 34.83 24.75 24.63 8.00 20.00 2.00 2.25 2.32 8.00

30.25 x 43 44.75 32.13 33.50 12.00 27.00

Features and Notes

4. Roof curbs are available for the UERV's.

600-1000

UERV with Horizontal Ductwork

UERV Roof Curbs

Dimensional DataUERV Data

2.60 5.00 2.56 11.00

18.3239.50 8.00 3.59

18.32

2800-3600

41.81 x 55.75

4.00 5.3152.25 42.63 43.56 14.00

20.3252.38 37.25 37.50 12.00 30.00 4.50 4.00 3.63

8.19

57.37 16.50

32.00 4.75

8.19

39.50 8.19

57.37 16.5060.00

54 x 55.75 60.00 58.88

60.00 52.69

46.69

1100-1700

1500-2800

3400-4600 47.81 x 55.75

41 x 49.5

35.5 x 52.75

18.32

8.00 9.68 18.32

8.00 6.59

4800-6200 57.37 16.50 39.50

Ductwork Field

Supplied

A

F

D

E

B

C

B

A

J

K

VO006

VO011

VO020

VO028

VO036

VO046

VO062

5. CFM is based on 0 external static pressure.

VO006

VO011

VO020

VO028

VO036

VO046

VO062

S

M

246681-YTG-C-0611

D

C

14

H

(

FIGURE 9 - STAND ALONE UERV’S FOR OVER AND UNDER DUCT ARRANGEMENTS

22 Unitary Products Group

Page 23

246681-YTG-C-0611

GUIDE SPECIFICATIONS

Prepared for the guidance of architects, consulting engineers, and mechanical contractors.

GENERAL

Furnish and install _____________ mechanical cooling system, complete with a Unitized Energy Recovery Ventilator

(UERV).

APPROVALS

The Unitized Energy Recovery Ventilator will contain an

energy recovery component rated in accordance with AHRI/

ANSI Standard 1060-2005 with ratings certified by AHRI.

Cabinet

UERV shall be designed to attach directly to the a/c (rooftop,

upflow, horizontal) unit. It shall be G90 galvanized material

with a powdered enamel paint finish electrostatically bonded

to the metal. Cabinet panels where conditioned air is handled

shall be fully insulated to prevent sweating and minimize

sound. Openings shall be provided for power connections.

Lifting devices will be provided for rigging. Test ports shall be

provided so airflow can be measured across the energy

recovery wheel.

Intake Air Blower (direct drive)

UERV shall contain a centrifugal blower. All UERV's will be

equipped with direct drive PSC blower motors. The motor will

be multiple speed and will be individually controlled. Airflow

will also be adjustable by means of a damper on the intake air

opening. Blowers and motors will be removable through

means of a connecting plug for ease of servicing.

Intake Air Blower (belt drive)

UERV shall contain a centrifugal blower. It shall have ball

bearings and adjustable belt drive. Motor mount base shall

permit ease of motor changeover and belt tension adjustment. On pivoting wheel models, supply blower will be deenergized during economizer operation. (Except for VR074

and VR122.)

Exhaust Air Blower (direct drive)

UERV shall contain a centrifugal blower. All UERV's will be

equipped with direct drive PSC blower motors. The motor will

be multiple speed and shall be individually controlled. Blowers and motors will be removable through means of a connecting plug for ease of servicing. On pivoting wheel models,

blower shall be sized to provide power exhaust during economizer operation.

Exhaust Air Blower (belt drive)

sized to provide power exhaust during economizer operation.

Where single blowers cannot provide adequate exhaust, two

blowers will be utilized. One blower is energized during

energy recovery mode, and both blowers are energized during economizer mode.

Energy Recovery Wheel

The energy recovery device shall be a rotary heat exchanger

per AHRI Standard 1060 description. The device will be an

enthalpy wheel coated with a silica gel desiccant by a patented process without the use of binders or adhesives which

may plug the desiccant aperture. The substrate shall be a

lightweight polymer. Desiccant shall not dissolve or deliquesce in the presence of water or high humidity. The wheel

shall be easily cleanable with standard coil cleaning solution.

On UERV's Series 20 and less, the wheel will easily be

removable from the cabinet for cleaning. On UERV's Series

20 and above, the wheel will be provided with removable segments for cleaning and maintenance. All diameter and perimeter seals shall be provided. The energy recovery cassette

shall be Underwriters Laboratories Recognized Component

for electrical and fire safety.

Balancing Dampers

Balancing dampers will be provided for all VR UERV’s. These

dampers will be mounted inside the rooftop air conditioning

unit to adjust for the amount of exhaust air on packaged units.

On pivoting wheel models, the unit econ o mi z er becomes the

balancing damper. Upflow and horizontal ERVs' will have the

balancing damper provided in the ERV. Optional on VO and

VS UERV’s when connected to rooftop units. (Except for

VR074 and VR122.)

Barometric Relief Dampers

Barometric relief dampers will be provided in the exhaust air

hood to prevent air infiltration when the UERV is de-energized.

ERV Support

All UERV's will be provided with support legs attached to the

cabinet to support the intake and exhaust end of the ERV

unit. Horizontal ERV's will be provided with support brackets

for hanging.

Filters

All units shall be provided with mist eliminator type filters in

the intake air hood.

Power Connection

The UERV shall be provided with a single point power connection for high voltage.

UERV shall contain a centrifugal blower. It shall have ball

bearings and adjustable belt drive. Motor mount base shall

permit ease of motor changeover and belt tension adjustment. On pivoting wheel models, exhaust blowers shall be

Unitary Products Group 23

OPTIONS

Optional UERV Equipment Support

Page 24

246681-YTG-C-0611

Furnish and install the optional equipment support for the

intake and exhaust end of the unit.

Optional Roof Curb

Furnish and install the optional roof mounting frame to maintain proper height above the roof.

Optional Low Ambient Kit

Furnish and install the optional low ambient kit to prevent

frost formation on the energy recovery wheel.

Optional Motorized Intake Air Damper

Furnish and install the optional motorized intake air damper.

Optional Stop-Start-Jog

On units without economizers furnish and install the optional

stop-start-jog controls.

SEQUENCE OF OPERATION:

Fixed Models - Normal Operation

1. The space thermostat sends a signal to the RTU for cooling, heating or fan only operation.

2. The ERV is activated simultaneously with the supply

blower of the RTU. The intake blower, the exhaust

blower, and the wheel rotation motor of the ERV are activated. These motors will remain energized as long as

the supply blower on the RTU is energized. The RTU is

in standard (non-economizer) mode.

3. If the optional motorized fresh air damper in the outside air intake of the ERV is present, it opens and the ERV is energized.

4. If the optional low ambient kit is present, and the temperature leaving the exhaust side of the wheel drops below

the field adjusted set point on the temperature sensor of

the low ambient kit, the optional motorized fresh air

damper will close and the intake blower will de-energize.

The exhaust air blower and wheel rotation motor will continue to operate. When the temperature sensor has a

sixteen-degree rise, the wheel is defrosted and the

optional motorized damper will open and the fresh air

blower will reactivate.

2. The ERV is activated with the supply blower of the RTU.

The intake blower, the exhaust blower, and the wheel

rotation motor of the ERV are activated. These motors

will remain energized as long as the supply blower on

the RTU is energized and the RTU is in standard (noneconomizer) mode.

3. If the optional motorized fresh air damper in the outside air intake of the ERV is present, it opens and the ERV is energized.

4. If the optional low ambient kit is present, and the temperature leaving the exhaust side of the wheel drops below

the field adjusted set point on the temperature sensor of

the low ambient kit, the optional motorized fresh air

damper will close and the intake blower will de-energize.

The exhaust air blower and wheel rotation motor will continue to operate. When the temperature sensor has a

sixteen-degree rise, the wheel is defrosted and the

optional motorized damper will open and the fresh air

blower will reactivate.

Pivoting Models - Economizer Operation

1. The space thermostat sends a signal to the RTU for cooling operation.

2. The outdoor air sensor for the RTU senses the outdoor

air and determines it is appropriate for economizer operation.

3. As the economizer outside air dampers open, the ERV economizer end switch is activated sending a signal to the ERV that the system is in the economizer mode.

4. The intake blower, the exhaust blower and the wheel rotation motor all deactivate for up to two minutes. The optional motorized fresh air damper (if present) also closes.

5. The ERV enthalpy wheel pivots out of the air stream and the bypass dampers along each side of the intake blower open.

6. After a time delay to allow the wheel to pivot out of the

airstream and the bypass dampers to open, the optional

motorized fresh air damper opens to allow for full economizer operation, and the exhaust blower is reactivated to

provide power exhaust for the system.

Pivoting Models - Normal Operation

1. The space thermostat sends a signal to the RTU for cooling, heating or fan only operation.

24 Unitary Products Group

Page 25

246681-YTG-C-0611

UERV TROUBLESHOOTING GUIDE

UERV BELOW 600 CFM WITH ST A TIONARY WHEEL (NO ECONOMIZER)

UERV will not operate.

1. Quick check items. a. Verify S51 door switch is closed. The switch must be

in the closed position to power the A130 circuit

board.

b. Verify the A130 circuit board switch SW1 Power is in

the “on” position.

c. Verify 24 volts to A130 circuit board terminals TB1

“G” and “C” if in the cooling mode, or “W” and “C” if

in the heating mode. The terminals must be powered to allow any blower relays / contactors to operate.

2. Verify high voltage power to UERV. a. Verify 110 volts for UERV to L1 and L2 on TB2 on

the A130 board.

b. Verify the F1 fuse is good. Replace any bad fuses.

c. Verify that the T28 step down transformer on 208,

230, and 460 volt units have the voltage correctly

applied to the correct transformer terminals.

UERV has power, but the enthalpy wheel does not spin.

1. Check wheel belt is in place and tight.

2. Verify the A130 circuit board switch SW1 Power is in the "on" position.

3. Verify the A130 circuit board terminals Wheel "1" and "2" are outputting 110 volts to B28 wheel motor through J/ P150 plug assembly.

4. Verify B28 wheel motor C23 capacitor is good. Replace the capacitor if it is bad.

5. If the optional Stop, Start, Jog (SSJ) feature is installed, verify that the temperature setpoint on the SSJ does not have the wheel stopped.

6. If all of the above are operational, the wheel motor is bad. Replace it with new motor.

3. Verify B26 wheel motor C25 capacitor is good. Replace the capacitor if it is bad.

4. If all of the above are operational, the exhaust motor is bad. Replace it with new motor.

UERV has power, but the fresh air blower does not

operate.

1. Verify the A130 circuit board switch SW1 Power is in the "on" position.

2. Verify the A130 circuit board terminals Fresh "1” and "3" if in high speed operation, or "1” and "2" if in low speed operation are outputting 110 volt s to B27 fresh air blower motor though J/P148 plug assembly.

3. On units equipped with the optional low ambient control,

verify that the A130 circuit board TB3 terminals marked

"low ambient" are closed. The low ambient control will

stop the fresh air motor operation and close the optional

outside air damper if it senses conditions for frost on the

UERV wheel. The "low ambient" terminals can be

jumped together to verify if the low ambient control has

the fresh air blower stopped.

4. Verify B27 wheel motor C26 capacitor is good. Replace the capacitor if it is bad.

5. If all of the above are operational, the fresh air motor is bad. Replace it with new motor.

UERV has power, but the optional motorized fresh air

damper does not open.

1. Verify 24 volts to A130 circuit board terminals TB1 "G" and "C" if in the cooling mode, or "W" and "C" if in the heating mode.

2. Verify the A130 circuit board switch SW1 Power is in the "on" position.

3. Verify 24 volts to B30 motorized outdoor air motor through J/P160 plug assembly.

4. If all of the above are operational, replace the outdoor air damper motor.

UERV ABOVE 600 CFM WITH ST ATIONARY WHEEL (NO ECONOMIZER)

UERV has power, but the exhaust blower does not

operate.

1. Verify the A130 circuit board switch SW1 Power is in the "on" position.

2. Verify the A130 circuit board terminals Exhaust "1” and "3” if in high speed operation, or "1” and "2" if in low speed operation are outputting 110 volts to B26 exhaust blower motor though J/P151 plug assembly.

Unitary Products Group 25

UERV will not operate.

1. Quick check items. a. Verify S51 door switch is closed. The switch must be

in the closed position to power the A130 circuit

board.

Page 26

246681-YTG-C-0611

b. Verify 24 volts to A130 circuit board terminals

XFORMER "+" and "-". The terminals must be powered to allow blower contactors to operate.

c. Verify 24 volts to A130 circuit board terminals TB 37

numbers "1" and "3". T erminal "1" is the hot and "3"

is the common side of the power source fr om activa tion power source (a/c unit, energy management

control, etc.). Typically, "1" would be from the blower

contactor on an a/c unit.

2. Verify high voltage power to UERV. a. Check for correct voltage for UERV to L1 and L2 on

1-phase units.

b. Check for correct voltage for UERV to L1, L2, and

L3 on 3-phase units.

c. Verify the F29 fuses are good. Replace any bad

fuses.

d. Verify that the T27 transformer has the UERV volt-

age correctly applied to the correct transformer terminals.

UERV has power, but the enthalpy wheel does not spin.

1. Check wheel belt is in place and tight.

2. Verify the A130 circuit board terminals Exhaust "A" (hot)

and "B" (common) are outputting 24 volts to K163 contactor terminal "A" and "B" and that the contacts are

closed.

3. Verify power to B28 wheel motor.

4. Verify B28 wheel motor C23 capacitor is good. Replace the capacitor if it is bad. (Except VR074 to VR122)

5. If the optional Stop, Start, Jog (SSJ) feature is installed, verify that the timer on the SSJ does not have the wheel stopped.

6. If all of the above are operational, the wheel motor is bad. Replace it with new motor.

UERV has power, but the exhaust blower does not

operate.

1. Check that the blower belt is in place and tight on belt drive models. If it is loose, tighten it. If it is broken replace it.

2. Verify the A130 circuit board terminals Exhaust "A" (hot)

and "B" (common) are outputting 24 volts to K163 contactor terminal "A" and "B", and that the contacts are

closed.

3. Verify power to B26 exhaust blower motor.

4. On direct drive models, verify B26 wheel motor C25 capacitor is good. Replace if necessary.

5. If all of the above are operational, the exhaust motor is bad. Replace it with new motor.

UERV has power, but the fresh air blower does not

operate.

1. Check that the blower belt is in place and tight on belt

drive models. Tighten it if it is loose. Replace it if it is broken.

2. Verify the A130 circuit board terminals Fresh "A" (hot)

and "B" (common) are outputting 24 volts to K164 contactor terminal "A" and "B", and that the contacts are

closed.

3. Verify power to B27 fresh air blower motor though J/ P148 plug assembly.

4. On direct drive models, verify B27 wheel motor C26 capacitor is good. Replace if necessary.

5. On units equipped with the optional low ambient control,

verify that the circuit on the A130 circuit board terminal

"5" and "6" is closed. The low ambient control will stop

the fresh air motor operation and close the optional outside air damper if it senses frost on the UERV wheel.

Terminal "5" and "6" can be jumped to gether to verify if

the low ambient control has the fresh air blower stopped.

6. If all of the above are operational, the fresh air motor is bad. Replace it with new motor.

UERV has power, but the optional motorized fresh air

damper does not open.

1. Verify 24 volts to the A130 circuit board terminals XFORMER "+" and "-".

2. Verify 24 volts to A130 circuit board terminals TB 37

numbers "1" and "3". T erminal "1" is the hot and "3" is the

common side of the power source from activation power

source (a/c unit, energy management control, etc.). Typically, "1" would be from the blower contactor on an a/c

unit.

3. Verify 24 volts to B30 motorized outdoor air motor through J/P160 plug assembly.

4. If all of the above are operational, replace the outdoor air damper motor.

UERV ABOVE 600 CFM WITH PIVOTING WHEEL (USED WITH ECONOMIZER)

UERV will not operate.

1. Quick check items. a. Verify S51 door switch is closed. The switch must be

in the closed position to power the A130 circuit

board.

26 Unitary Products Group

Page 27

246681-YTG-C-0611

b. Verify 24 volts to A130 circuit board terminals

XFORMER "+" and "-". The terminals must be powered to allow any blower relays / contactors to operate.

c. Verify 24 volts to A130 circuit board terminals TB 37

numbers "1" and "3". T erminal "1" is the hot and "3"

is the common side of the power source fr om activa tion power source (a/c unit, energy management

control, etc.). Typically, "1" would be from the blower

contactor on an a/c unit.

2. Verify high voltage power to UERV. a. Check correct voltage for UERV to L1 and, L2 on 1-

phase units.

b. Check for correct voltage to L1, L2, and L3 on 3-

phase units.

c. Verify the F29 fuses are good. Replace any bad

fuses.

d. Verify that the T27 transformer has the UERV volt-

age correctly applied to the correct transformer terminals.

UERV has power, but the enthalpy wheel does not spin.

1. Check wheel belt is in place and tight.

2. Verify the A130 circuit board terminals Exhaust 1 "A" (hot) and "B" (common) are outputting 24 volts to K163 contactor terminal "A" and "B" and that the contacts are closed.

3. Verify power to B28 wheel motor through J/P150 plug assembly.

a. If there is no power on the T1 leg of the motor (pivot-

ing models only) verify that the S110 switch located

inside the B29 damper motor is in the closed position.

4. Verify B28 wheel motor C23 capacitor is good. Replace the capacitor if it is bad.

5. If all of the above are operational, the wheel motor is bad. Replace it with new motor.

UERV has power, but the exhaust blower does not

operate.

1. Check that the blower belt is in place and tight. If it is loose, tighten it. If it is broken replace it.

4. On direct drive models, verify B26 wheel motor C25 capacitor is good. Replace if necessary.

5. If all of the above are operational, the exhaust motor is bad. Replace it with new motor.

UERV has power, but the fresh air blower does not

operate.

1. Energy Recovery Mode of operation. a. Check that the blower belt is in place and tight on

belt drive models. Tighten it if it is loose. Replace it if

it is broken.

b. Verify the A130 circuit board terminals Fresh "A"

(hot) and "B" (common) are outputting 24 volts to

K164 contactor terminal "A" and "B", and that the

contacts are closed.

c. Verify power to B27 fresh air blower motor though J/

P148 plug assembly.

d. On units equipped with the optional low ambient

control, verify that the circuit on the A130 circuit

board terminal "5" and "6" is made. The low ambient

control will stop the fresh air motor operation and

close the optional outside air damper if it senses

frost on the UERV wheel. Terminal "5" and "6" can

be jumped together to verify if the low ambient control has the fresh air blower stopped.

e. On direct drive models, verify B27 wheel motor C26

capacitor is good. Replace if necessary.

f. If all of the above are operational, the fresh air motor

is bad. Replace it with new motor.

2. Economizer Mode of operation. a. The fresh air blower is not operational in the econo-

mizer mode.

UERV has power, but the wheel does not rotate out of

airstream during economizer operation.

1. Check the linkage from the B29 damper motor to the UERV wheel.

2. Verify shipping retainers are removed.

3. Verify the S122 economizer end switch is closed. The switch is located on the damper and closes when the damper moves from minimum position to the economizer position (field adjustable).

2. Verify the A130 circuit board terminals Exhaust 1 "A" (hot) and "B" (common) are outputting 24 volts to K163 contactor terminal "A" and "B", and that the contacts are closed.

3. Verify power to B26 exhaust blower motor though J/P151 plug assembly.

Unitary Products Group 27

4. Verify the B29 damper motor has 24 volts to terminals "B" and "T1" through J/P160 plug assembly

5. If all of the above are operational, replace the damper motor.

Page 28

UERV has power, but the optional motorized fresh air

damper does not open.

1. Verify 24 volts to the A130 circuit board terminals XFORMER "+" and "-".

2. Verify 24 volts to A130 circuit board terminals TB 37

numbers "1" and "3". Terminal "1" is the "hot" and "3" is

the "common" side of the power source from activation

power source (a/c unit, energy management control,

etc.). Typically, "1" would be from the blower contactor

on an a/c unit.

3. Verify 24 volts to B30 motorized outdoor air motor through J/P160 plug assembly.

4. If all of the above are operational, replace the outdoor air damper motor.

Subject to change without notice. Printed in U.S.A. 246681-YTG-C-0611

Copyright © August 26, 2011 by Johnson Controls, Inc. All rights reserved. Supersedes: 246681-YTG-B-0607

Johnson Controls Unitary Products

5005 York Drive

Norman, OK 73069

Loading...

Loading...