USER’S INFORMATION,

MAINTENANCE AND

SERVICE MANUAL

HIGH EFFICIENCY

TUBULAR HEAT EXCHANGER SERIES

MODELS: PV8*DH/FL8V*DH/FC8V*DH/LL8V*DH/LC8V*DH

(Variable Speed Downflow/Horizontal/Low NOx)

TABLE OF CONTENTS

CONTACT INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

USER’S INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INSTRUCTIONS FOR EXAMINING THE

FURNACE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

HOW YOUR GAS FURNACE WORKS . . . . . . . . . . . . . . . . . . . . . . 3

START-UP AND SHUTDOWN INSTRUCTIONS . . . . . . . . . . . . . . . 3

Read the Instructions Below Before Trying to Start the Furnace . . 3

Operating Instructions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

To Turn Off the Appliance: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FURNACE USER MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . .3

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Removing Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Blower Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SERVICE AND MAINTENANCE MANUAL . . . . . . . . . . . . . . . . . . . . 4

SAFETY SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

FURNACE MAINTENANCE SECTION . . . . . . . . . . . . . . . . . . . . . .4

FURNACE CLEANING SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Burner Removal/Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cleaning the Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

HEATING AIRFLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

ADJUSTMENT OF FAN CONTROL SETTINGS . . . . . . . . . . . . . . . .6

Heating Indoor Fan Off Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Continuous Blower Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Delay Tap Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Humidistat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Hot Surface Ignition System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

FURNACE CONTROL DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . .7

DIAGNOSTIC FAULT CODE STORAGE AND RETRIEVAL . . . . . .8

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

EFFICIENCY

RATING

CERTIFIED

ISO 9001

Certified Quality

Management System

CONTACT INFORMATION

• Go to website at www.york.com click on “contact”, then click on “contact form” and follow the instructions.

• Contact us by mail:

York International

Consumer Relations

5005 York Drive

Norman, OK 73069

The manufacturer recommends that the user read all sections of this manual and keep the manual for future reference.

FIRE OR EXPLOSION HAZARD - Failure to follow safety

warnings exactly could result in serious injury, death, or property damage.

— Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone

(including cell phone) in your building.

• Leave the building immedia te l y.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire department.

— Installation and service must be performed by a quali-

fied installer, service agency or the gas supplier.

SECTION I: USER’S INFORMATION

SAFETY

1. The furnace area must be kept clear and free of combustible materials, gasoline and other flammable vapors and liquids.

2. Insulating materials may be combustible. The furnace must be

kept free and clear of insulating materials. The furnace area must

be examined when installed in an attic or other insulated space or

when insulation is added to be sure that the insulation material has

been kept away from the furnace.

3. The furnace needs air for combustion in order to operate properly

and safely. Do not block or obstruct air openings on the furnace,

air openings to the area where the furnace is installed, or spaces

around the furnace.

4. Follow the instructions exactly as shown on the OPERATING

INSTRUCTION LABEL or the Start-up and Shutdown Instructions

on Page 3 of this manual when lighting the furnace or turning the

furnace off.

5. Should the gas supply fail to shut off or if overheating occurs, shut

off the gas valve to the furnace before shutting off the electrical

supply.

6. Do not use this furnace if any part has been under water. A flooddamaged furnace is extremely dangerous. Attempts to use the furnace can result in fire or explosion. A qualified service agency

should be contacted to inspect the furnace and replace all gas

controls, control system parts, electrical parts that have been wet

or the furnace if deemed necessary.

271015-UUM-A-0407

271015-UUM-A-0407

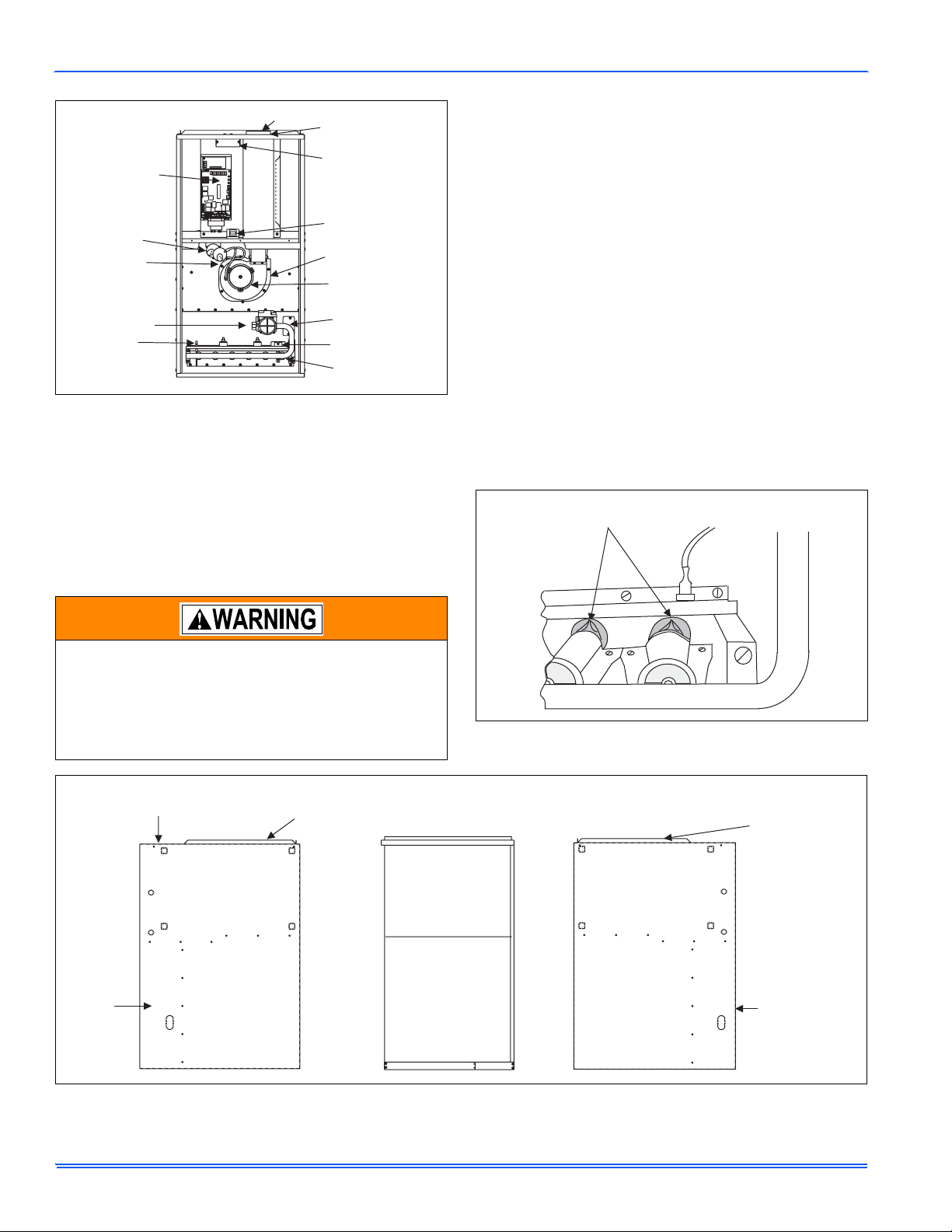

CONTROL

BOARD

PRESUURE

SWITCH

SILICONE

TUBE

GAS VALVE

FLAME

SENSOR

VENT PIPE

FLUE

COLLAR

ELECTRICAL

JUNCTION BOX

SAFETY SHUTOFF

SWITCH

INDUCED DRAFT

ASSEMBLY

INDUCED DRAFT

MOTOR

LIMIT

SWITCH

IGNITOR

MANIFOLD

PIPE

FIGURE 1: Component Locations

7. NEVER. . .Store flammable materials of any kind near your furnace. Gasoline, solvents, and other volatile liquids should be

stored only in approved containers outside your home. These

materials vaporize easily and are extremely dangerous.

8. NEVER. . .Store cleaning materials near your furnace. Materials

such as bleaches, detergents, powdered cleansers, etc., can

cause corrosion of the heat exchangers.

9. NEVER. . . Use the area around your furnace as a storage area for

items which could block the normal flow of air. This flow of air is

required for ventilation of the various furnace components.

INSTRUCTIONS FOR EXAMINING THE FURNACE

INSTALLATION

It is the owner’s responsibility to ensure that an annual inspection of the

entire heating portion of the unit is made by a qualified service agency.

Examine the furnace as outlined below in steps “1 - 6” before each

heating season. Use Figure 3 for visual reference.

1. Examine the heat exchanger, vent pipe, combustion air passages,

vent connectors and chimney to be sure they are clear and free of

obstructions.

2. Examine the vent pipe making sure it is firmly in place, that it

slopes slightly upward and is physically sound without holes and

all of the connections are secure.

3. Examine the return-air duct connections to make sure they are

physically sound, sealed to the furnace casing, and the ducts terminate outside the space containing the furnace.

4. Examine the furnace casing making sure the physical support is

sound without sagging, cracks or gaps. Examine the furnace base

making sure it is physically sound without cracks, gaps or sagging

and has a good seal.

5. Examine the furnace casing for obvious signs of deterioration.

6. Examine the burner flames to make sure they are in good adjustment. Refer to the pictorial sketch shown in Figure 2 as a comparison to the actual flame.

BLUE CONE PORTION OF FLAME SHOULD

ENTER HEAT EXCHANGER TUBE

FIRE OR EXPLOSION HAZARD

This furnace is designed and approved for use with Nat-

ural Gas and (LP) Propane Gas ONLY. DO NOT BURN

ANY LIQUID FUEL OR SOLID FUEL IN THIS FURNACE.

Burning any unapproved fuel will result in damage to the

furnace heat exchanger, which could result in Fire, Personal Injury, and/or Property Damage.

3

EXAMINE

RETURN AIR

DUCT

CONNECTION

6

REMOVE

PANEL

TO EXAMINE

BURNER

FLAMES

EXAMINE EXTERNAL

VENT PIPE

4

EXAMINE

FURNACE

CASING

FIGURE 3: Furnace Examination Checkpoints

5

EXAMINE ENTIRE

FURNACE CASING

SHOWN IN ALL

DRAWINGS

1

EXTERNAL HEAT

EXCHANGER

INTERNAL

VENT COMBUSTION

AIR PIPE. MUST

REMOVE PANEL TO

EXAMINE.

FIGURE 2: Burner Flame Drawing

4

EXAMINE

FURNACE

CASING

3

EXAMINE

RETURN AIR

DUCT

CONNECTION

6

REMOVE PANEL

TO EXAMINE

BURNER FLAMES

2 Unitary Products Group

271015-UUM-A-0407

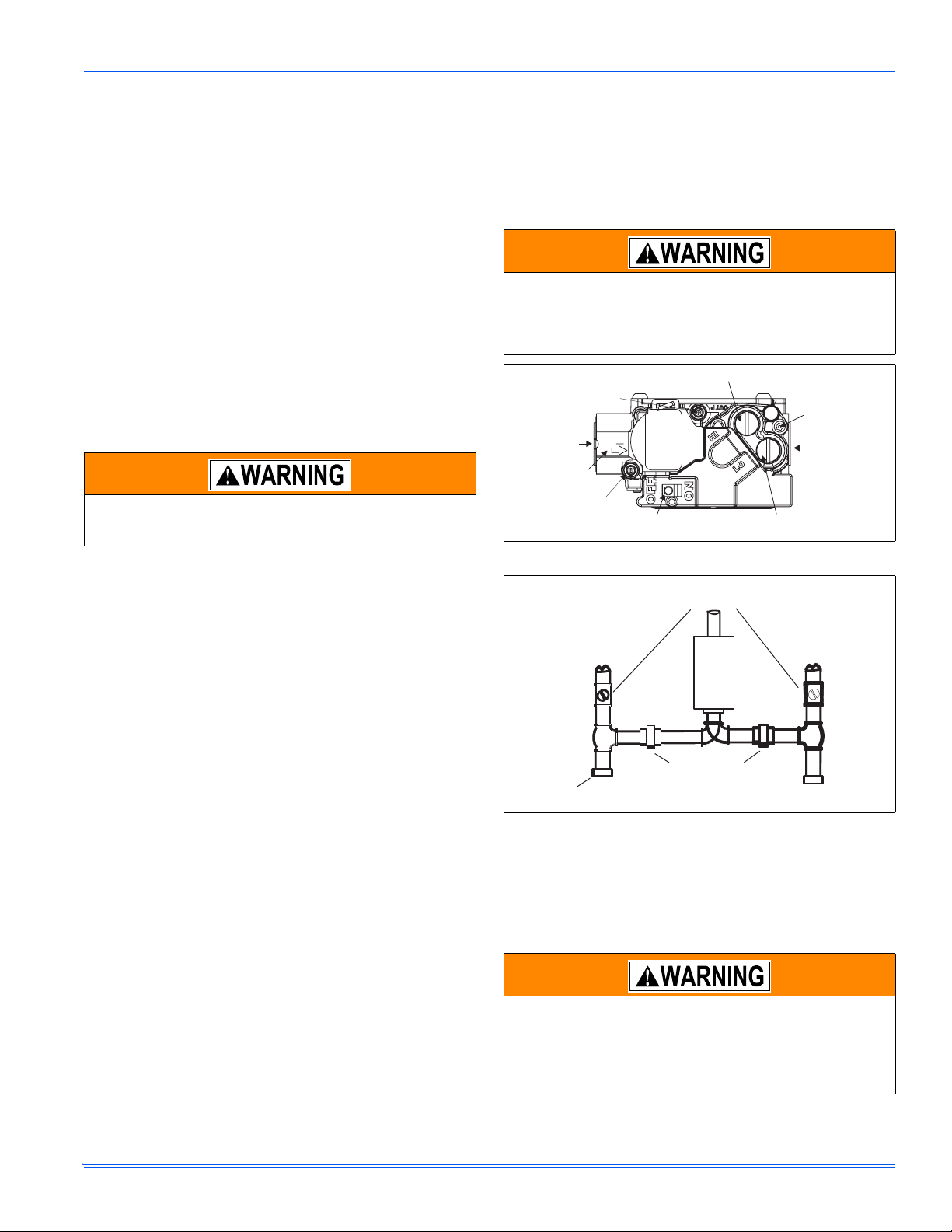

INLET

WRENCH

BOSS

INLET

PRESSURE

PORT

ON OFF

SWITCH

LOW STAGE REGULATOR

ADJUSTMENT

OUTLET

OUTLET

PRESSURE

PORT

VENT

PORT

HIGH STAGE REGULATOR

ADJUSTMENT

HOW YOUR GAS FURNACE WORKS

Your furna ce is a very easy appliance to take for granted. Season after

season, it sits there in your home, keeping you warm and comfortable.

For this reason, you may never have given much thought to the way

your furnace operates. In order to get the safest and most efficient operation from your furnace, you should understand how your furnace does

its job.

When you set your thermostat to provide more heat in your home, you

To Turn Off the Appliance:

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Remove burner access panel.

4. Move gas control switch to the “OFF” position. See Figure 4.

5. Replace burner access panel.

are starting the heating cycle of the furnace. First, the inducer motor

starts to purge the heat exchanger of any remaining gases. Next, the

hot surface ignitor glows and after a warm-up period the gas valve

opens and ignition occurs. A short time later, the blower starts and distributes the warm air throughout the home. When the temperature setting on your thermostat is reached, the gas valve closes, the main

burners are turned off, and the blower continues to run until the remaining warm air in the system is distributed. When the blower stops, the

Should overheating occur, or the gas valve fail to shut off,

turn the external manual gas valve in the gas supply line to

the furnace to the “off” position and let the furnace cool off

before shutting off the electrical power supply. Refer to

Figure 5.

heating cycle has ended.

START-UP AND SHUTDOWN INSTRUCTIONS

Read the Instructions Below Before Trying to Start the

Furnace

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal

injury, and/or loss of life.

A. This appliance does not have a pilot. It is equipped with an ignition

device which automatically lights the burner. Do not try to light the

burner by hand.

B. BEFORE OPERATING; smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

C. Use only your hand to push the gas control switch to the “on” posi-

tion. Never use tools. If the switch will not operate by hand, don’t

try to repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water. Imme-

diately call a qualified service technician to inspect the appliance

and to replace any part of the control system and any gas control,

which has been under water.

Operating Instructions:

1. STOP! Read the safety information above.

2. Set the thermostat to the lowest setting.

3. Turn off all electric power to the appliance.

4. Remove burner access panel.

5. Move gas control switch to the “OFF” position. Do not force. See

Figure 4.

6. Wait five (5) minutes to clear out any gas. If you then smell gas,

STOP! Follow “B” in the safety information above. If you don’t

smell gas, go to next step.

7. Move gas control switch to the “ON” position. Do not force. See

Figure 4.

8. Replace burner access panel.

9. Turn on all electric power to the appliance.

10. Set thermostat to the desired setting. Burner will light, which may

take 30-60 seconds.

11. After three (3) trials for ignition, if the appliance will not operate follow the instructions, “TO TURN OFF THE APPLIANCE” and call

your service technician or gas supplier.

Unitary Products Group 3

FIGURE 4: Gas Valve

EXTERNAL MANUAL

SHUTOFF VALVE

TO GAS

SUPPLY

DRIP

LEG

TO GAS

SUPPLY

GROUNDED JOINT UNION

MAY BE INSTALLED

INSIDE OR OUTSIDE UNIT.

FIGURE 5: Gas Piping

NOTE: The spring-loaded safety cut-off switch, mounted under the

blower deck will automatically cut off the electrical power supply to the

furnace when the blower panel is removed. As a safety precaution, all

electrical power and the gas supply to the furnace should be turned off

before servicing.

FURNACE USER MAINTENANCE

Before proceeding, be sure the area is well ventilated. Turn

the thermostat OFF. If the blower is runni ng, wait until it

stops automatically. Turn OFF the gas and electrical power

supplies to the furnace. Check all metal parts and surfaces

to be sure they have cooled to room temperature before

you begin.

271015-UUM-A-0407

Every time the filters are changed the following items should be visually

inspected:

• Check vent pipe for blockage or leakage.

• Check all components to be sure they are in good condition and

that there are no obvious signs of deterioration.

• Check for dirt or lint on any surfaces or on components. Do not try

to clean any of the surfaces or components. Cleaning of the furnace and its components must be done by a qualified service professional.

If, during the inspection of your furnace, you find any of the following

conditions:

• Excessive amounts of dust and lint on components.

• Damaged or deteriorated components or surfaces.

• Leaks or blockage in the vent pipe passages.

• Water on any surface inside or outside of the furnace.

Do not operate the furnace, call a certified dealer / servicing contractor

to check and / or clean your furnace, or for more information if you have

questions about the operation of your furnace.

If all components appear to be in good operating condition, replace the

front panels. Turn ON the gas and electrical power supplies to the furnace, and set thermostat to the desired temperature.

Air Filters

Dirty filters greatly restrict the flow of air and may cause damage to the

moving parts of the furnace. If the filters become clogged the heat

exchangers and blower motor could overheat resulting in a potentially

dangerous situation.The filters should be checked every 3 months. On

new construction, check the filters every week for the first four weeks

and every three weeks after that, especially if the indoor fan is running

continuously. When replacing the filter(s) you must use filters that are

the same size as those recommended in Table 1. use the following procedure to determine the filter size. Never operate your furnace without a

suitable air filter.

Removing Filters

Externally Mounted Air Filters

Some installations may have the air filter in a rack attached to the casing of the furnace or placed in the return air duct. You can gain access

to the filter by pulling on the door or unscrewing the retaining screw,

then slide the filter(s) out of its channel. Replace throw away filter(s)

with the same size new filter(s). Throw away filter(s) may be replaced

with cleanable filter(s) at this time. Cleanable filter(s) may be cleaned as

described in the manufacturer instructions or as described below and

then re-installed.

To replace the filter after cleaning you must do the following:

1. Slide filter into place.

2. Snap the door on or place the door in position and tighten the

retaining screws, if provided.

3. Make sure the door is secure to the end of the filter rack.

TABLE 1:

Filter Sizes

Cabinet Size Top Return (in) Top Return (cm)

A (2) 14 x 20 (2) 35.6 x 50.8

B (2) 14 x 20 (2) 35.6 x 50.8

C (2) 14 x 20 (2) 35.6 x 50.8

How to Clean your Filter

High-velocity filters may be cleaned with a vacuum cleaner or washed

with a garden hose. Be sure to shake off excess water and allow filter to

completely dry before re-installing the filter.

Blower Care

Even with good filters properly in place, blower wheels and motors will

become dust laden after long months of operation. The entire blower

assembly should be inspected annually. If the motor and wheel are

heavily coated with dust, they can be brushed and cleaned with a vacuum cleaner. If the blower cannot be properly cleaned without removing

it from the furnace, then this service must be performed by a qualified

service agency.

Make sure you DO NOT move the clip on weight on the

indoor fan wheel when cleaning the wheel. This weight is

used to balance the wheel. Moving the weight will cause

the fan wheel to vibrate.

Motor Lubrication

The motors in these furnaces are permanently lubricated, and do not

require periodic oiling.

SECTION II: SERVICE AND MAINTENANCE

MANUAL

SAFETY SECTION

The following safety rules must be followed when servicing the

furnace.

ELECTRIC SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in

dangerous operation, serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

serious injury, and death or property damage.

• Before servicing, disconnect all electrical power to the furnace.

• When servicing controls, label all wires prior to disconnecting. Reconnect wires correctly.

• Verify proper operation after servicing.

FURNACE MAINTENANCE SECTION

The furnace should be cleaned and adjusted by a certified dealer or

qualified service contractor once a year or before the start of every

heating season. The following items must be cleaned and serviced or

replaced if there are signs of deterioration.

1. The vent terminal screen (if applicable).

2. The furnace vent and combustion air intake passageways. Should

it be necessary to service the vent/air intake system, the manufacturer recommends this service be conducted by a qualified service

agency. The operation of this appliance requires the reassembly

and resealing of the vent/air intake system.

3. The furnace burners, ignitor and flame sensor.

4 Unitary Products Group

271015-UUM-A-0407

FURNACE CLEANING SECTION

NOTE: The cleaning operations listed below must be performed only by

a qualified service agency.

Burner Removal/Cleaning

The main burners should be checked periodically for dirt accumulation.

If cleaning is required, follow this procedure:

1. Turn off the electrical power to the unit.

2. Turn off the gas supply at the external manual shut-off valve and

loosen the ground union joint.

3. Remove the upper access panel and remove the burner box

cover.

4. Disconnect wires from flame sensor, rollout switch and HSI igniter.

Remove igniter carefully, as it is easily broken.

5. Remove the screws that hold the burner box assembly to the vest

panel and remove the assembly.

6. Remove burners from the burner assembly.

7. Burners may be cleaned by rinsing in hot water.

8. Reassemble the burners in the reverse order.

Cleaning the Heat Exchanger

Lower Heat Exchanger Access

1. Turn off the electrical power to the unit and turn off gas supply at

the shutoff valve.

2. Remove the blower and burner compartment access doors. Disconnect the gas supply piping at the union to permit removal of the

entire burner and gas control assembly from the vestibule panel.

Use the wrench boss on the gas valve when removing or installing

this piping. See Figure 4.

3. Unplug the igniter from the wire harness. Disconnect sensor and

rollout switch wires located on top of the air shield. Identify and

note the location of all leads for ease of reinstallation. Also disconnect the wires at the side rollout switches (upflow only) and the

gas valve wires.

4. Remove the screws holding the burner assembly to the vestibule

panel and remove this assembly. Handle the assembly carefully

since it contains the igniter, which is fragile and easily broken. T he

lower portion of the heat exchanger will now be exposed. To clean

the burner assembly, use a vacuum cleaner, or remove the burners as outlined in burner cleaning, and clean in hot water.

Upper Heat Exchanger Access

1. Perform steps 1-4 above.

2. Disconnect vent piping from the vent motor assembly at the top

panel on the furnace (upflow only). On downflow models, the vent

pipe is attached to the vent motor outlet. Remove this screw

before proceeding.

3. Unplug the vent motor wires and ground wire. Remove the pressure switch tubing at the tap on the vent motor housing.

NOTE: It is recommended that replacement gaskets be available

before removing vent motor.

4. Remove six mounting screws that hold the vent motor to the

restrictor plate. The surface is gasketed and gasket can be reused

if it is carefully removed. It is necessary to remove this assembly to

gain access to the restrictor plate mounting holes. The assembly

may be vacuumed if cleaning is necessary. If any vent assembly

parts are damaged, replace with an entire new assembly (except

for gaskets).

5. Remove the perimeter screws attaching the restrictor plate assembly to the vestibule panel. The surface is also gasketed. The

assembly, including the flue baffle plate (rear) may be vacuumed

or cleaned with hot water if necessary.

6. The upper portion of the heat exchanger is now accessible. With a

long flexible wire brush, clean inside each tube at both the top and

bottom. The brush must pass around the rear heat exchanger

tubes. Vacuum loose scale and dirt from each tube.

7. Clean - Replace all components in reverse order. Re-gasket all

surfaces which required a gasket. Reconnect all wiring. Reattach

vent pipe and gas supply lines before restoring service to furnace.

Restore electrical power, check gas supply piping for leaks, and

then verify furnace operation.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing.

SEQUENCE OF OPERATION

The following describes the sequence of operation of the furnace. Refer

to Figure 1 for component location.

1. Call for 1st stage only

• On a call for 1st stage heat, the thermostat closes a circuit

between R and W1.

• The Microprocessor in the Furnace Control runs a ‘Self Check’.

• The Control checks the Primary Limit, Auxiliary Limit, and Roll-

out Switches for closed contacts.

• The Control checks that the Low Fire Pressure Switch (1LP) is

open.

• The Inducer Motor is energized on high speed, closing the con-

tacts of 1LP.

• The Control checks that 1LP is closed.

• The Igniter is energized for 17 seconds.

• The Gas Valve is energized on 1st Stage (Low Fire).

• Flame Rectification is recognized within 7 seconds.

• The Inducer is switched to low speed.

• 30 seconds after flame is proven, the ‘Heat Low’ relay is ener-

gized providing 120 Volts AC to the Blower Motor.

• At the same time, the EAC and Hum relays are energized, pro-

viding 120 Volts AC to the EAC Hot and Hum terminals.

2. Call for 2nd Stage after 1st Stage is operating

• A call for 2nd Stage can be made by a 2-Stage thermostat, or by

the W2 delay timer on the furnace control.

• The Inducer Motor is shifted to high speed by the control, closing

the contacts of 2LP (The High Fire Pressure Switch.).

• The Control checks that 2LP is closed.

• The Gas Valve is energized on 2nd Stage (High Fire).

• The Control simultaneously de-energizes the Heat Low relay

and energizes the Heat High relay, providing 120 Volts AC to a

different speed of the Blower Motor.

3. 2nd Stage is satisfied, 1st Stage still calling.

• If a Single Stage Thermostat is used, the Furnace will stay on

High Fire until the thermostat is satisfied.

• When the circuit between R and W2 is opened, the Control

switches the Inducer Motor to low speed, causing the contacts of

2LP to open.

• When 2LP opens, 2nd Stage of the Gas Valve is de-energized.

• 30 seconds later, the Control switches the Blower from Heat

High to Heat Low.

4. 1st Stage Satisfied

• The Thermostat opens the circuit between R and W1

• Immediately the Gas Valve is de-energized and Flame Rectifica-

tion is lost.

• The Inducer Motor is de-energized after a 15 second Post Purge

and the Hum terminal is de-energized.

• The ‘Fan Off Delay’ circuit is initiated. The Delay time can be

field set at 60, 90, 120, or 180 seconds. It comes from the factory set at 60 seconds.

• The Heat Low terminal is de-energized; stopping the Blower and

the EAC terminal is de-energized.

Unitary Products Group 5

Loading...

Loading...