Page 1

SPLIT-SYSTEM

EVAPORATOR BLOWER

K3EU180

15 NOMINAL TONS

SUNLINE 2000

(WORLD 50 HZ)

550.39-TG5YI (0601)

®

DESCRIPTION

This completely assembled unit includes a well-insulated

cabinet, a DX coil with copper tubes and aluminum fins, an

expansion valve, a distributor, throwaway filters, a centrifugal

blower,ablower motor,an adjustablebeltdrive, ablowermotor

contactorand asmallholding chargeofrefrigerant-22. Theunit

ismanufacturedunderISO9002QualitySystemCertification.

The unit is shipped in the vertical position ready for field

installation. It can be installed for horizontal operation by

reversing the position of the solid bottom panel with the return

air duct flange on the front on the unit.

ACCESSORIES - FIELD INSTALLED

SUPPLYAIR PLENUM - A fully insulated plenum is available

forfree standingunits locatedwithin the conditionedspace. Itis

shipped knocked down for easy field assembly, is finished to

match the exterior of the basic unit, and has double deflection

grilles that can be adjusted to vary the throw, spread and drop

of the supply air.

RETURN AIR GRILLE - An expanded metal grille is available

forfree standingunits locatedwithin the conditionedspace. Itis

finishedtomatchtheexteriorofthebasicunitandisshipped in

one piece for easy installation.

BASE- Abaseisavailableto raisevertical unitsabovethefloor.

Outdoor air may be introduced through the base by cutting an

access opening to accommodate the outdoor air duct

connection. The base is finished to match the exterior of the

basic unit. It may have to be insulated in the field for certain

applications.

THREE-PHASE ELECTRIC HEATERS - Electric heaters are

available in four capacities to provide maximum flexibility. Both

the air conditioning unit and the heater can be selected to

precisely match the cooling and heating requirements of the

conditioned space. These heaters are designed for easy fieldinstallationover thesupplyair opening ofthe unit. Every heater

isfully protectedagainstexcessive currentandtemperature by

fuses and two high limit thermostats.

Units with electric heat require only one power supply for both

the heating elements and the supply air blower motor. The

power wiring can be protected by either dual element/time

delay fuses or an inverse time circuit breaker.

HOTWATERCOIL- Thisdrainable coilhas tworows of13mm (

1

in.) copper tubes, eight aluminum fins per 25mm (1 in.), a

2

casingthat isfinished tomatchthe exteriorof the basicunit, but

nowater control valve.Thecoil slides outof the casing foreasy

fieldinstallation.It shouldbe mountedbetween theunitcoiland

blower section.

STEAMCOIL -The non-freeze coil has onerowof 25mm (1in.)

copper tubes, a 16mm (

(1 in.) tube to distribute the steam evenly across the entire

length of the coil, eight aluminum fins per 25mm (1 in.), a

casing finished to match the exterior of the basic unit, but no

steam control valve. The coil slides out of the casing for easy

field installation and is pitched in the casing to facilitate

condensate drainage. It should be mounted between the unit

coil and blower sections.

SUSPENSION KIT - Suspension kit 1HH0451 is available for

units installed horizontally. The accessory includes two

channel iron supports and the hardware to secure them to the

topoftheunit.Thehangerrodsmustbesuppliedbythefield.

THERMOSTATS - Wall-mounted thermostats and subbases

(24volt) with system and fan switches are available to control

the operation of these split system air conditioners.

5

in.) copper tube inside each 25mm

8

Page 2

550.39-TG5YI

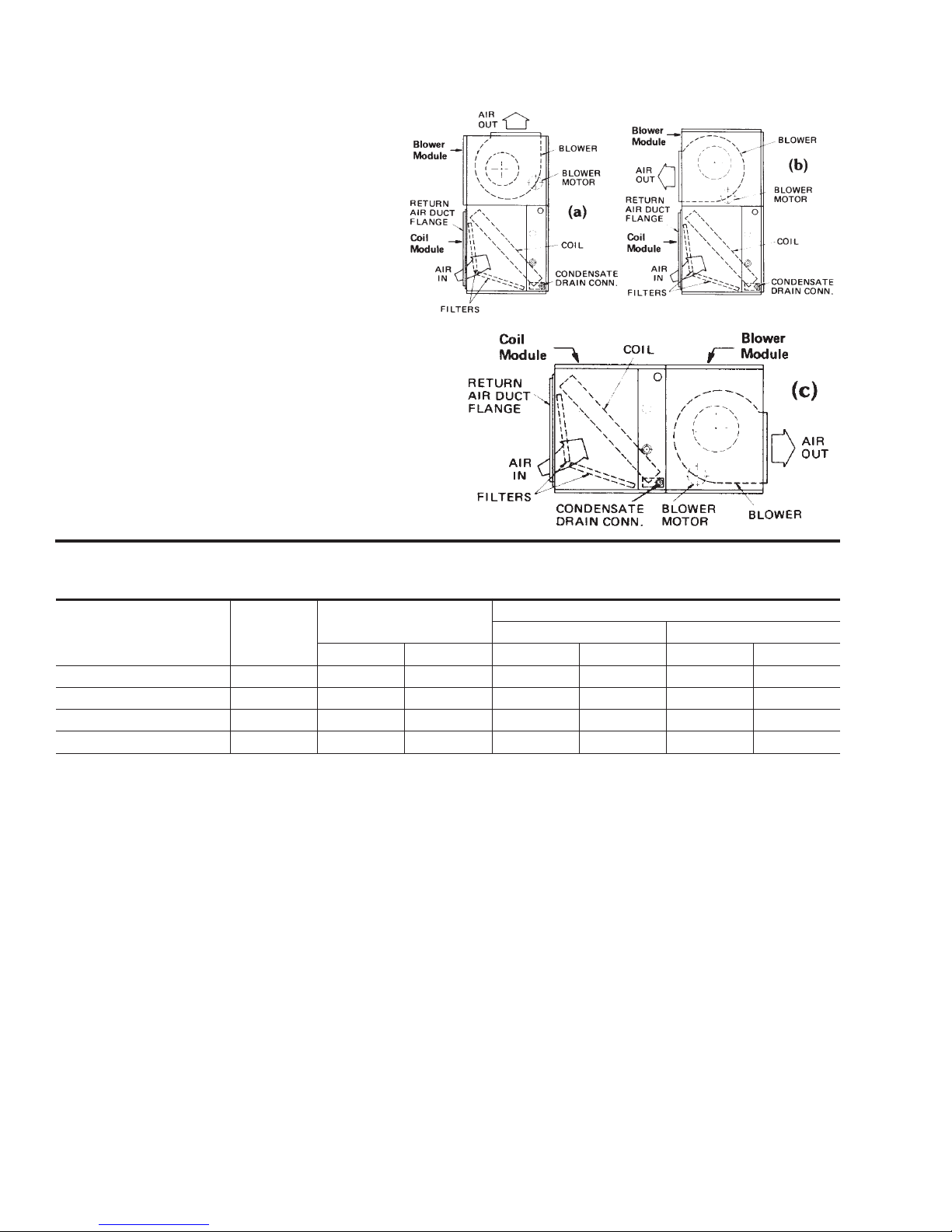

Thisunit has two distinct modules, a blower module

and a coil module. The unit is always shipped in the

vertical position with a vertical air discharge as

shown in illustration (a). The blower module can be

repositionedinthefield asshown inillustration (b)or

(c) for maximum flexibility.

The Supply Air Plenum, Return Air Grille and Base

accessories can be applied on arrangement (a).

The Return Air Grille and Base accessories can be

applied on arrangement (b).

The Supply Air Plenum, Return Air Grille and

Suspension accessories can be applied on

arrangement (c).

HEATING CAPACITY - ELECTRIC HEAT ACCESSORY

Heater Model

2HS04501050 415 7.5 25.6 7.5 25.6 - 2HS04501650 415 12.0 40.9 7.5 25.6 4.5 15.3

2HS04502650 415 19.4 66.5 12.0 40.9 7.5 25.6

2HS04503650 415 26.9 91.9 12.0 40.9 15.0 51.1

1

Capacity ratings do not include the heat generated by the supply air blower motor.

2

For 380 volts, multiply the mbh and kw values by (380/415)2or 0.838.

UL Test

Voltage

Nominal Ratings

kW Mbh kW Mbh kW Mbh

1

Capacity

Per Stage 1 Per Stage 2

1

2 Unitary Products Group

Page 3

550.39-TG5YI

1

STEAM COIL CAPACITY

Steam Coil Model

1NF0452 KEU180

1

These capacities do not include any blower motor heat.

2

Multiply these capacities by the following factors to correct for higher steam pressures

Blower Model

Used On

Steam pressure, kPa/psig 35 / 5 70 / 10 105 / 15 140 / 20 210 / 30

Capacity correction factor 1.06 1.12 1.19 1.25 1.30

,kW @ 14 kPa/Mbh @ 2 psig

m3/s / CFM

2.3 / 4800 298.2 / 1018 268.4 / 916 236.7 / 808 211.5 / 722

2.8 / 6000 329.1 / 1124 297.0 / 1014 265.6 / 907 234.1 / 799

3.4 / 7200 356.4 / 1216 321.8 / 1099 287.9 / 983 254.0 / 867

-12 / 10 -1 / 30 10 / 50 21 / 70

Dry Bulb Temperature of Air Entering Coil, °C/°F

NOTE: Steam rate (kg/hr) = 0.66 x kW

(lb/hr) = 1.025xMbh

CAUTION: Do not operate a motor above its nominal HP rating when a unit is equipped

with a steam coil accessory

1

HOT WATER COIL CAPACITY

Water Coil

Model

1HW0451 KEU180 0.95 / 15

1

These capacities do not include any blower motor heat.

NOTE: Water Temperature Drop, °C =

CAUTION: Do NOT operate a motor above its nominal HP rating when a unit is equipped with a hot water coil accessory.

Blower Model

Used On

°F =

l/s / GPM m

kW

16 71./x

ls

Mbh

2

x

GPM

, kW/Mbh

3

/s / CFM

2.3 / 4800 135.5 / 463 175.1 / 598 215.8 / 737 257.4 / 879 294.1 / 1004

2.8 / 6000 150.0 / 512 195.0 / 666 240.3 / 820 285.9 / 976 326.6 / 1115

3.4 / 7200 162.4 / 554 210.8 / 720 260.4 / 889 309.8 / 1058 354.3 / 1210

Entering Water Temperature Minus Entering Air Temperature, °C/°F

21 / 70 32 / 90 43 / 110 54 / 130 66 / 150

2

CAPACITY CORRECTION VS

PRESSURE DROP VS L/S / GPM

l/s / GPM 0.63 / 10 / 1.26 / 20 1.90 / 30

1HW0450

1HW0451

Meters (H2O) = 45,942 x kPa

Feet (H2O) = 2031 x psi

Unitary Products Group 3

Pressure Drop,

kPa / psig/

l/s / GPM 0.95 / 15 1.90 / 30 2.83 / 45

Pressure Drop,

kPa / psig

0.7 / 0.10 2.2 / 0.32 4.7 / 0.67

1.2 / 0.17 4.0 / 0.58 8.5 / 1.22

L/S / GPM

1HW0450

1HW0451

l/s / GPM 1.26 / 20 1.90 / 30

Capacity

Correction

GPM 1.90 / 30 2.83 / 45

Capacity

Correction

1.12 1.15

1.11 1.15

Page 4

550.39-TG5YI

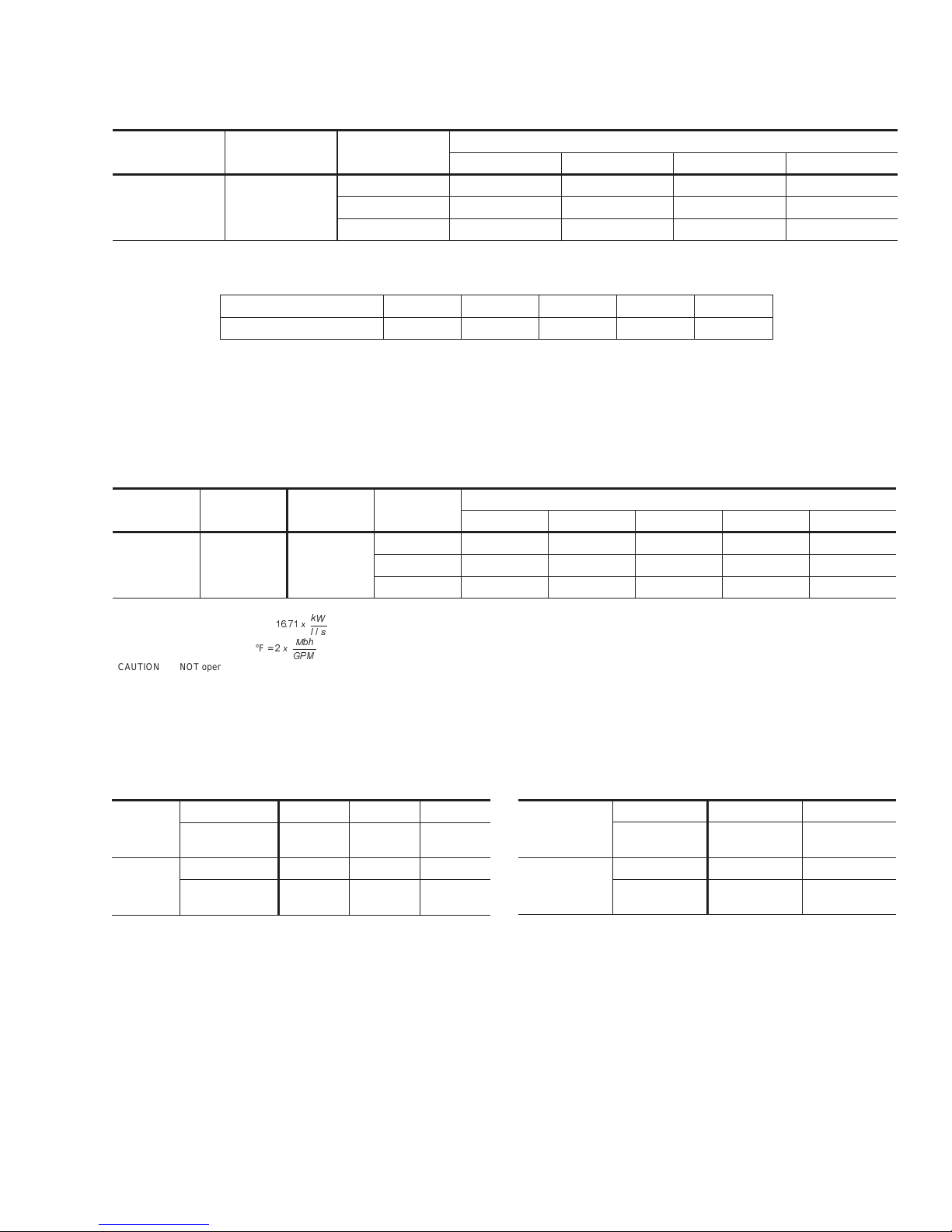

SUPPLY AIR BLOWER PERFORMANCE

1

2

OUTPUT

2

- (m3/s)

(kW)

1

- (CFM)

OUTPUT

(BHP)

INPUT

(kW)

INPUT

(KW)

ESP

(Pa)

ESP

(IWG)

AIRFLOW

2

OUTPUT

(kW)

AIRFLOW

2

OUTPUT

(BHP

)

INPUT

(kW)

INPUT

(kW)

ESP

(Pa)

ESP

(IWG)

2

2

OUTPUT

(kW)

OUTPUT

(BHP

)

INPUT

(kW)

INPUT

(kW)

ESP

(Pa)

ESP

(IWG)

2

2

OUTPUT

(kW)

OUTPUT

(BHP)

SUPPLY AIR BLOWER PERFORMANCE

BLOWER

SPEED

RPM

ESP

(Pa)

2

OUTPUT

2.26 m

INPUT

(kW)

3

/s 2.55 m3/s 2.83 m3/s 3.11 m3/s 3.40 m3/s

(kW)

ESP

(Pa)

600 114 1.07 1.34 74 1.25 1.56 27 1.46 1.80 - - - - - 615 136 1.15 1.43 99 1.33 1.64 55 1.55 1.90 3 1.08 2.20 - - 700 208 1.36 1.68 174 1.58 1.94 134 1.81 2.22 89 2.06 2.54 30 2.32 2.82

800 312 1.77 2.17 285 2.01 2.47 248 2.26 2.74 206 2.51 3.05 154 2.79 900 422 2.20 2.68 404 2.46 2.99 311 2.73 - - - - - - -

SUPPLY AIR BLOWER PERFORMANCE

BLOW

ER

SPEED

RPM

ESP

(IWG)

2

OUTPUT

(BHP)

INPUT

(kW)

ESP

(IWG)

4800 CFM 5400 CFM 6000 CFM 6600 CFM 7200 CFM

600 0.46 1.44 1.34 0.30 1.68 1.56 0.11 1.96 1.80 - - - - - 615 0.55 1.54 1.43 0.40 1.79 1.64 0.22 2.08 1.90 0.01 2.41 2.20 - - 700 0.84 1.83 1.68 0.70 2.12 1.94 0.54 2.43 2.22 0.36 2.77 2.54 0.12 3.12 2.82

800 1.26 2.38 2.17 1.15 2.70 2.47 1.00 3.03 2.74 0.83 3.37 3.05 0.62 3.75 900 1.70 2.95 2.68 1.63 3.30 2.99 1.52 3.67 - - - - - - -

1

Unit resistance is based on a wet evaporator coil and clean filters.

2

Available static pressure in Pa (IWG) to overcome the resistance of the duct system and any accessories added to the unit.

INPUT

(kW)

INPUT

(kW

NOTE:Motors canbe selectedtooperate intothe servicefactorbecause theyare locatedinthe movingair stream,upstreamof any

heating device.

LEGEND:

RPM range for standard factorymounted drive components.

Exceeds the output limitation of the standard

factory-mounted blower motor.

4 Unitary Products Group

Page 5

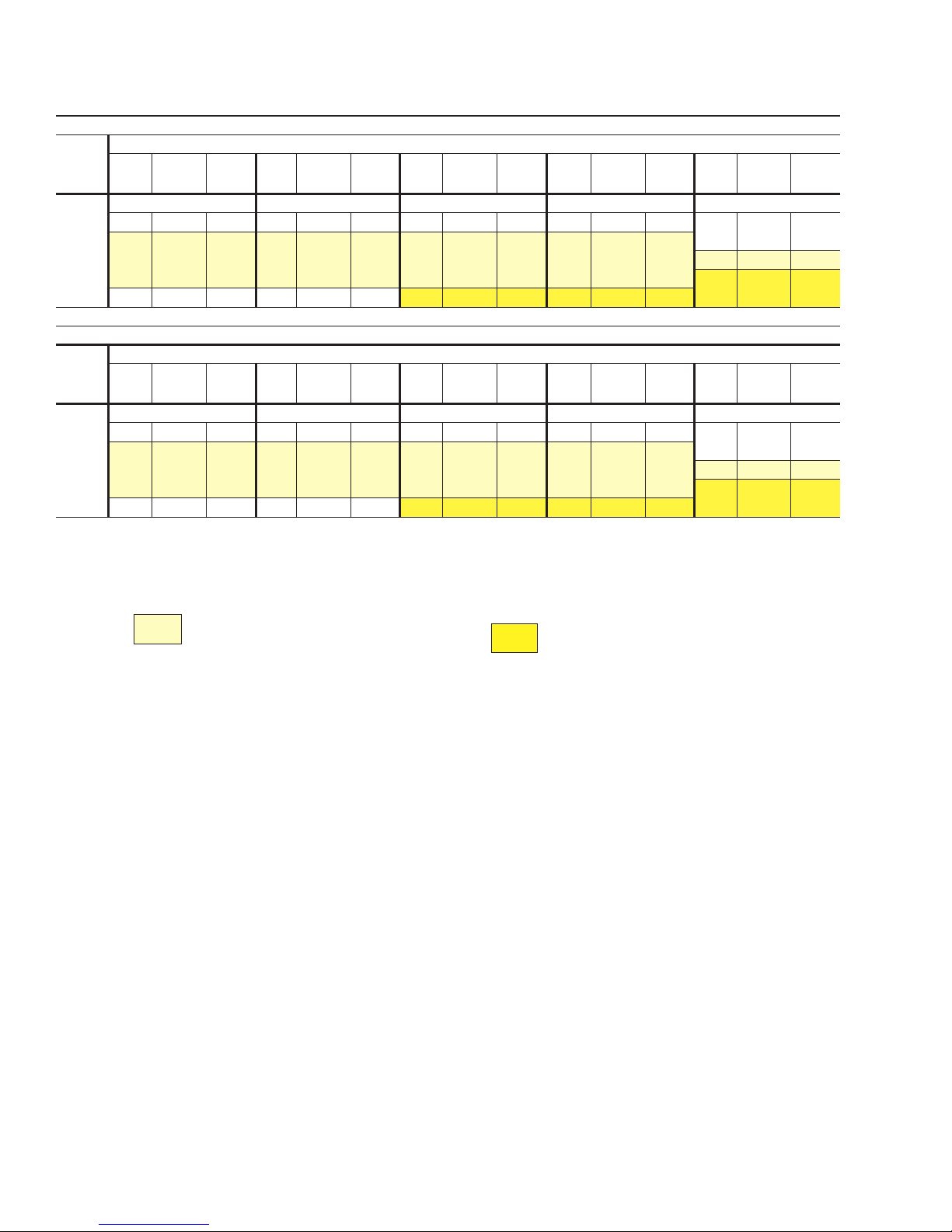

STATIC RESISTANCES FOR UNIT ACCESSORIES

Static resistance, pascal

Unit Model Accessory

Electric Heat

KEU180

Static resistances, IWG

Unit Model Accessory

KEU180

Supply Air Plenum 8 10 12 15 18

Return Air Grille 10 12 15 18 20

Hot Water Coil 45 55 64 74 84

Steam Coil 37 45 55 64 74

Electric Heat

Supply Air Plenum 0.03 0.04 0.05 0.06 0.07

Return Air Grille 0.04 0.05 0.06 0.07 0.08

Hot Water Coil 0.18 0.22 0.26 0.03 0.34

Steam Coil 0.15 0.18 0.22 0.26 0.30

10 kW 10 12 15 20 25

16 kW 18 21 27 35 42

26 kW 32 40 50 60 72

36 kW 50 60 72 87 106

10 kW 0.04 0.05 0.06 0.08 0.10

16kW 0.07 0.09 0.11 0.14 0.17

26 kW 0.13 0.16 0.20 0.24 0.29

36 kW 0.20 0.24 0.29 0.35 0.42

2.26 2.55 2.83 3.11 3.40

4800 5400 6000 6600 7200

3

m

CFM

550.39-TG5YI

/s

Unitary Products Group 5

Page 6

550.39-TG5YI

3

/S

SUPPLY AIR PLENUM PERFORMANCE DATA,

M

Angle of Deflection

Model

KEU

Spread

(Meters)

1

3

Horizontal

Louvers

0° 18°

Drop

(Meters)

Vertical Louvers

2

4

1

22

° Spread

2

Throw

3

(Meters)

Min Max Min Max

Face

3

m

/s

Velocity

(MPM)

Sound

Power

dB (10)

12 Watts

Vertical Louvers

0° Spread

Throw

(Meters)

3

Min Max Min Max

1

Spread

(Meters)3

Horizontal

Louvers

0° 18°

Drop

(Meters)

Vertical Louvers

2

45° Spread

Throw

(Meters)3

Min Max Min Max

4

Spread

(Meters)

1

3

2.26 268 26 25.5 40.1 9.7 14.6 7.0 3.6 18.5 28.9 11.6 17.0 6.4 3.3 14.0 22.0 22.2 34.0 3.6 1.8

2.55 304 28 28.9 45.3 10.9 16.4 7.3 3.6 20.7 32.5 12.8 19.2 6.7 3.3 15.8 24.6 24.6 37.7 3.6 1.8

180

2.83 337 30 32.2 50.1 11.9 18.0 7.6 4.0 23.1 36.2 14.0 21.0 7.0 3.6 17.3 27.0 27.4 42.0 4.0 2.1

3.11 371 33 35.3 55.3 13.1 20.0 7.9 4.0 25.5 40.0 15.2 23.1 7.0 3.6 19.2 29.8 30.1 46.2 4.0 2.1

3.40 404 36 38.3 60.5 14.0 21.3 8.2 4.3 28.0 43.5 16.7 25.2 7.3 3.6 20.7 32.5 33.1 50.5 4.3 2.1

1

Adusting the vertical louvers will vary the throw, the spread and the drop.

2

Adjusting the horizontal louvers will only vary the drop.

3

The velocity of the air will be 125 ft./min. at the minimum distance and 80 ft./min. at the maximum distance.

4

The velocity of the conditioned air at the bottom of the drop will be 50 ft./min. Drafts will occur if the drop extends into the

occupied level of the conditioned space.

Horizontal

Louvers

0° 18°

Drop

(Meters)4

2

SUPPLY AIR PLENUM PERFORMANCE DATA, CFM

Angle of Deflection

Model

KEU

CFM

Face

Velocity

(FPM)

Sound

Power

dB (10)

12 Watts

Vertical Louvers

0° Spread

Throw

3

(Feet)

Min Max Min Max

Spread

(Feet)

1

3

Horizontal

Louvers

0° 18°

Drop

4

(Feet)

Vertical Louvers

2

22

Throw

(Feet)

1

° Spread

2

3

Min Max Min Max

4800 880 26 84 132 32 48 23 12 61 95 38 56 21 11 46 72 73 112 12 6

5400 1000 28 95 149 36 54 24 12 68 107 42 63 22 11 52 81 81 124 12 6

180

6000 1110 30 106 165 39 59 25 13 76 119 46 69 23 12 57 89 90 138 13 7

6600 1220 33 116 182 43 65 26 13 84 131 50 76 23 12 63 98 99 152 13 7

7200 1330 36 126 199 46 70 27 14 92 143 55 83 24 12 68 107 109 166 14 7

1

Adusting the vertical louvers will vary the throw, the spread and the drop.

2

Adjusting the horizontal louvers will only vary the drop.

3

The velocity of the air will be 125 ft/min. at the minimum distance and 80 ft/min. at the maximum distance.

4

The velocity of the conditioned air at the bottom of the drop will be 50 ft./min. Drafts will occur if the drop extends into the

occupied level of the conditioned space.

Spread

(Feet)3

1

Horizontal

Louvers

0° 18°

Drop

4

(Feet)

Vertical Louvers

2

45° Spread

Throw

3

(Feet)

Min Max Min Max

1

Spread

(Feet)3

Horizontal

Louvers

0° 18°

Drop

(Feet)4

2

BLOWER MOTOR AND DRIVE DATA

Motor

(kW/HP)

Blower

Range

(RPM)

2.2 / 3 615/800

6 Unitary Products Group

Adjustable Motor Pulley Fixed Blower Pulley Belt

Pitch Dia

(mm/in.)

86 - 112/

3.4 - 4.4

Bore

(mm/in.)

22.2 /

Pitch Dia.

(mm/in.)

7

203 / 8.0 25 / 1 A54 1405 / 55.3

8

Bore

(mm/in/)

Designation

Pitch Lg.

(mm/in.)

Page 7

PHYSICAL DATA - UNITS AND ACCESSORIES

550.39-TG5YI

Description

Unit Model

KEU180

Rows Deep & Rows High 3 x 32

Finned Length - mm/inches 1372 / 54

Evaporator Coil

Face Area - square meters/square feet 1.15 / 12.4

Tube OD - mm /inches 9.5 / 3/8

Fins per 25mm (1 in.) 13

Centrifugal Blower

(Forward Curve)

1

Motor

Filters

(Throwaway)

Wheel Dia. x Width - mm (inches)

Nominal HP Rating 3

Quantity per unit

508mm x 508mm x 25mm

20" x 20" x 1"

Face area - square meters/square feet 1.55 / 16.7

475 x 475

(18 x 18)

Distributor One per unit 7-4-13

Basic Unit 390 / 177

Accessories

Supply Plenum 51.7 / 114

Return Air Grille 9.1 / 20

Operating Weight

kg/lbs

Hot Water Coil 49.9 / 110

Steam Coil 51.3 / 113

Base 45.4 / 100

10 kW 37.6 / 83

Electric Heater

16 kW 29.9 / 66

26 kW 32.2 / 71

36 kW 33.5 / 74

1

Tube OD, mm/inches

/ 12.7 (copper)

2

Rows Deep 2

Hot Water Coil

Fins per 25mm (1 in.) 8 (aluminum)

Face Area, square meters/square feet 0.63 / 6.8

Connections (supply & return) 25mm (1") NPTE

Outer Tube OD, mm/inches 25 / 1 (brass)

Rows Deep 1

Steam Coil

Fins per 25mm (1 in.) 8 (aluminum)

Face Area, square meters/square feet 0.94 / 10.1

Connection

Inlet 38mm (1

Outlet 38mm (1

% Nickel 59.2

Electric Heater

Heater Elements

% Chromium 16.0

Watt Density, watts/sq. in. 59.0

Face Area, square meters/square feet 0.28 / 3.0

Shipping Volume - cubic meters/cubic feet/ (Basic Unit) 2.5 / 88

1

Refer to Blower Motor and Drive Data table for additional motor and drive data.

2

Refer to the unit Installation Instruction 550.39-N5YI for the distributed weight of the evaporator blower unit.

6

1

“) NPTE

2

1

“) NPTE

2

Unitary Products Group 7

Page 8

550.39-TG5YI

UNIT DIMENSIONS

-

ACCESSORIES

All dimensions are in millimeters and inches. They are sub

ject to change without notice. Certified dimensions will be

provided upon request.

•ELECTRIC HEATER

Add 381mm (15 in.) to Unit Height when using 10, 16, 26 or 36kW Heater

•SUPPLYAIR PLENUM

Add 686mm (27 in.) to Unit Height when used

•BASE

Add 610mm (24 in.) to Unit Height when used

MINIMUM CLEARANCES (mm/in.)

Side with RETURN AIR opening - 610 / 24

Side with SUPPLYAIR opening - 610 / 24

Side with PIPING CONNECTIONS - 1549 / 61

Side opposite PIPING CONNECTIONS - 660 / 26

Bottom -

1 Overall dimension of the unit will vary if an electric heater, a supply air plenum or a base is used.

2

This dimension is required for removal of the DX coil. Only 660mm (26 in.) is required for normal

4

1

2

3

servicing.

3

If the DX coil has to be removed, this dimension is required to loosen screws that secure the coil to

the unit frame. This dimension will also be required for blower motor access if the piping

connections are made on the opposite side of the unit.

4

Allow enough clearance to trap the condensate drain line.

8 Unitary Products Group

Page 9

ACCESSORY DIMENSIONS

STEAM COIL

REFER TO THE UNIT DRAWING FOR

DUCT FLANGE DIMENSIONS.

550.39-TG5YI

38mm

1

(1

) NPTE

2

CONN'S.

Coil

Model

Unit

Model

1NF0452* KEU180

Steam coil Dimensions, mm (inches)

ABCDEF

1543

(60

819

3

)

(32

4

152

1

)

(6)76(3)89(3

4

445

1

)

(17

2

* Installs between the unit coil section and the blower section.

Coil Model

Unit

Model

1HW0452* KEU180

Water Coil Dimensions, mm (inches)

ABCDEFG

819

154

(60

3

)

(32

4

1

)

4

152

(6)58(2

5

32

)84(3

5

)98(3

16

27

32

1

)

2

51mm

(2")

25mm

(1") NPTE

CONN'S.

170

11

)

(6

)

16

502"

WITH ELECTRIC HEAT- Remove the 66mm (2

7

in.) knockouts from the rear panel of the plenum. Remove the 43.7mm (1

(

8

out and one of the

12.7mm (

Route the power wiring conduit through the 64mm (2

field-supplied fitting on the electric heat accessory. Connect the power wiring to the fuse

block in the heater control box.

Route the control wires through the 22.2mm (

minals on block 4TB. Secure them with the 12.7mm (

Accessory

Model

7

“ (22.2mm) knockouts from the top panel of the basic unit. Install a

8

1

in.) squeeze connector in both of the 22.2mm (

2

Unit Model

1SP0452 KEU180

1

in.) knockout and one of the 22.2mm

2

7

in.) openings.

8

1

in.) opening and connect it to the

2

7

in.) openings and connect them to the ter

8

1

in.) squeeze connectors.

2

23

32

in.) knock

ABCDEFGHKL

1543

(60

787

3

)

(31)

4

686

(27)

(

KNOCKOUT FOR POWER

AND

CONTROL WIRING

WITHOUT ELECTRIC HEAT - Remove both 22.2mm (

of the plenum and both 22.2mm (

-

stall a 12.7mm (

unit openings. Install a 12.7mm (

Connect the power wiring conduit to the fitting on the plenum. Route the power wiring

through the conduit, one of the squeeze connectors on the unit, and the field-supplied

squeeze connector on the blower motor contactor.

Route the control wires through the remaining plenum and unit openings aand connect

-

them to the terminals on block 4TB. Secure them with the 12.7mm (

tors.

1

in.) squeeze connector in one of the plenum openings and both of the

2

7

in.) knockouts from the top panel of the basic unit. In

8

1

in.) conduit fitting in the other opening of the plenum.

2

7

in.) knockouts from the rear panel

8

Plenum Dimensions, mm (inches)

1695

(66

3

505

)

(19

4

156

7

)

8

1

(6

8

25

)

(1)

64

1

(2

)

2

(2

(3

1

in.) squeeze connec

2

495

1

(19

)

2

-

-

44

3

(1

)

4

Unitary Products Group 9

Page 10

550.39-TG5YI

ACCESSORY DIMENSIONS

ELECTRIC HEATER

19

3

(

)

4

ACCESS OPENING FOR

POWER SUPPLYWIRING

10kW THRU 36kW - Add 32mm (1

43.7mm (1

the knockout ring and add a 38mm (1

50mm (1

23

in.) hole for wire sizes up through #1 AWG Remove

32

31

in.) hole for wire sizes up through #0 AWG.

32

1

in.) conduit fitting to the

4

1

in.) conduit fitting to the

2

WIRING HARNESS

LOCATION

This opening in the bottom of the

heater control box is used for the

wiring harness that connects the

heateraccessory to thebasic unit.It

is provided with a squeeze

connector for securing the the

wiring harness. Its location

corresponds to the location of the

43.7mm (1

23

in.) knockout in the

32

top panel of the basic unit.

COOLING ONLY UNITS

ELECTRICAL DATA

Blower Motor

kW/HP

2.2 / 3 380/415-3-50 5.2 37.0 10 122 (400)

* Dual element, time delay fuses.

Power Supply FLA LRA

13

1

(

)

2

Accessory

Model

2HS04501050

2HS04501650

2HS04502650

2HS04503650

Nom

. kW

10

16

26

36

Heater Dimensions, mm (inches)

ABCDEFGHKLM

692

(27

641

362

1

1

)

(25

)

4

(14

4

25

1

)

(1)

4

13

102

(4)

140

1

(

)

(5

2

Maximum

Fuse Size* Amps

1

2

25

1

)38(1

)

(1)

2

Wire Length* * m (Ft.)

565

1

(22

)

4

Maximum

489

(19

1

)

4

UNITS WITH ELECTRIC HEAT

Heater Nominal Heat Volt Heat FLA Motor FLA Ampacity

10 kW 7.5 415 10.4 5.2 19.5 20 12 AWG 45.6 (150)

16 kW 12.0 415 16.6 5.2 27.3 30 10 AWG 53.2 (175)

26 kW 19.4 415 27.0 5.2 40.3 45 8 AWG 53.2 (175)

36 kW 26.9 415 37.4 5.2 53.3 60 6 AWG 68.4 (225)

* Dual element, time delay fuses.

** Based on three 60° C, 14 AWG, insulated copper conductors in steel conduit and a 3% voltage drop.

10 Unitary Products Group

Maximum

Fuze Size,

Amps*

Wire Size

(Copper Con

ductor)

Maximum

-

Wire Length,

m (Ft.)**

Page 11

FIELD WIRING

Cooling only

550.39-TG5YI

TERMINALS ON

1-STAGE COOLING

THERMOSTAT

2TH13700424

CONTROL WIRING

Units with steam or hot water coil AC-

TERMINALSONBLOCK3TBOF

THE BLOWER UNIT

Units with electric heat accessory

Unitary Products Group 11

Page 12

Subject to change without notice. Printed in U.S.A

Copyright by York International Corporation 2001. All Rights Reserved.

Unitary

Products

Group

5005

York

Drive

Supersedes: 550.39-TG5Y(0501)

550.39-TG5Y (0601)

Norman

OK

73069

Loading...

Loading...