Page 1

A

V

A

w

TECHNICAL GUIDE

SPLIT-SYSTEM

IR CONDITIONERS

13 SEER – R-22

MODELS:

H*RD018 THRU 060

(1.5 THRU 5 NOMINAL TONS, 1 PHASE)

H*RD036 THRU 060

(2.5 THRU 5 NOMINAL TONS, 3 PHASE)

O

T

A

R

D

I

E

I

A

F

S

I

T

R

C

E

O

C

M

A

P

I

R

R

-

L

C

E

O

Y

N

R

Y

I

D

R

I

U

A

N

T

T

T

G

I

I

C

A

F

U

N

A

M

CERTIFICATIONAPPLIES ONLY

WHEN THECOMPLETE

O

N

N

U

I

N

G

R

E

C

T

Q

F

N

U

E

I

E

P

M

O

R

T

S

I

N

F

O

I

I

A

C

T

A

0

C

T

R

E

I

S

O

N

1

I

2

S

D

T

R

A

A

N

D

SYSTEM ISLISTED

WITH ARI.

W

I

T

H

LISTED

Due to continuous product improvement, specifications

are subject to change without notice.

isit us on the web at www.york.com

dditional rating information can be found at

ww.ari.org/aridirectory

ISO 9001

Certified Quality

Management System

254892-YTG-C-0606

DESCRIPTION

The 13 SEER Series condensing unit is the outdoor part of a

versatile system of air conditioning. It is designed to be custom-matched with one of UPG’s complete line of evaporator

sections, with each serving a specific function. Matching Air

Handlers are available for upflow, downflow, or horizontal

applications to provide a complete system. Electric Heaters

are available, if required. Add-On coils are available fo r use

with upflow, downflow, or horizontal furnaces and air handlers.

WARRANTY

5-year limited parts warranty.

5-year limited compressor warranty.

FEATURES

• QUALITY CONDENSER COILS - The coil is constructed

of copper tube and aluminum fins.

• PROTECTED COMPRESSOR - The compressor is internally protected against high pressure and temperature.

This is accomplished by the simultaneous operation of

high pressure relief valve and a temperature sensor which

protects the compressor if undesirable operating conditions occur. A liquid line filter-drier further protects the

compressor.

• DURABLE FINISH - The cabinet is made of pre-painted

steel. The pre-treated galvanized steel provides a better

paint to steel bond, which resists corrosion and rust creep.

Special primer formulas and matted-textured finish insure

less fading when exposed to sunlight.

• LOWER INSTALLED COST - Installation time and costs

are reduced by easy power and control wiring connections. Discharge line heat exchanger knockouts are provided, if required. Available in sweat connect models only.

The unit contains enough refrigerant for matching indoor

coils and 15 feet of interconnecting piping. The small base

dimension means less space is required on the ground or

roof.

• TOP DISCHARGE - The warm air from the top mounted

fan is blown up away from the structure and any landscaping. This allows compact location on multi-unit applications.

• LOW OPERATING SOUND LEVEL - The upward air flow

carries the normal operating noise away from the living

area. The rigid top panel effectively isolates any motor

sound. Isolator mounted compressor and the rippled fins

of the condenser coil muffle the normal fan motor and

compressor operating sounds.

• LOW MAINTENANCE - Long life permanently lubricated

motor-bearings need no annual servicing.

• EASY SERVICE ACCESS - Fully exposed refrigerant connections, a single panel covering the electrical controls,

and the molex plug in the control box connecting the condenser fan make for easy servicing of the unit.

• SECURED SERVICE VALVES - Secured re-usable ser-

vice valves are provided on both the liquid and vapor

sweat connections for ease of evacuating and charging.

• U.L. and C.U.L. listed - approved for outdoor application.

Certified in accordance with the Unitary Small Equipment certification program, which is based on ARI Standard 210/240.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

254892-YTG-C-0606

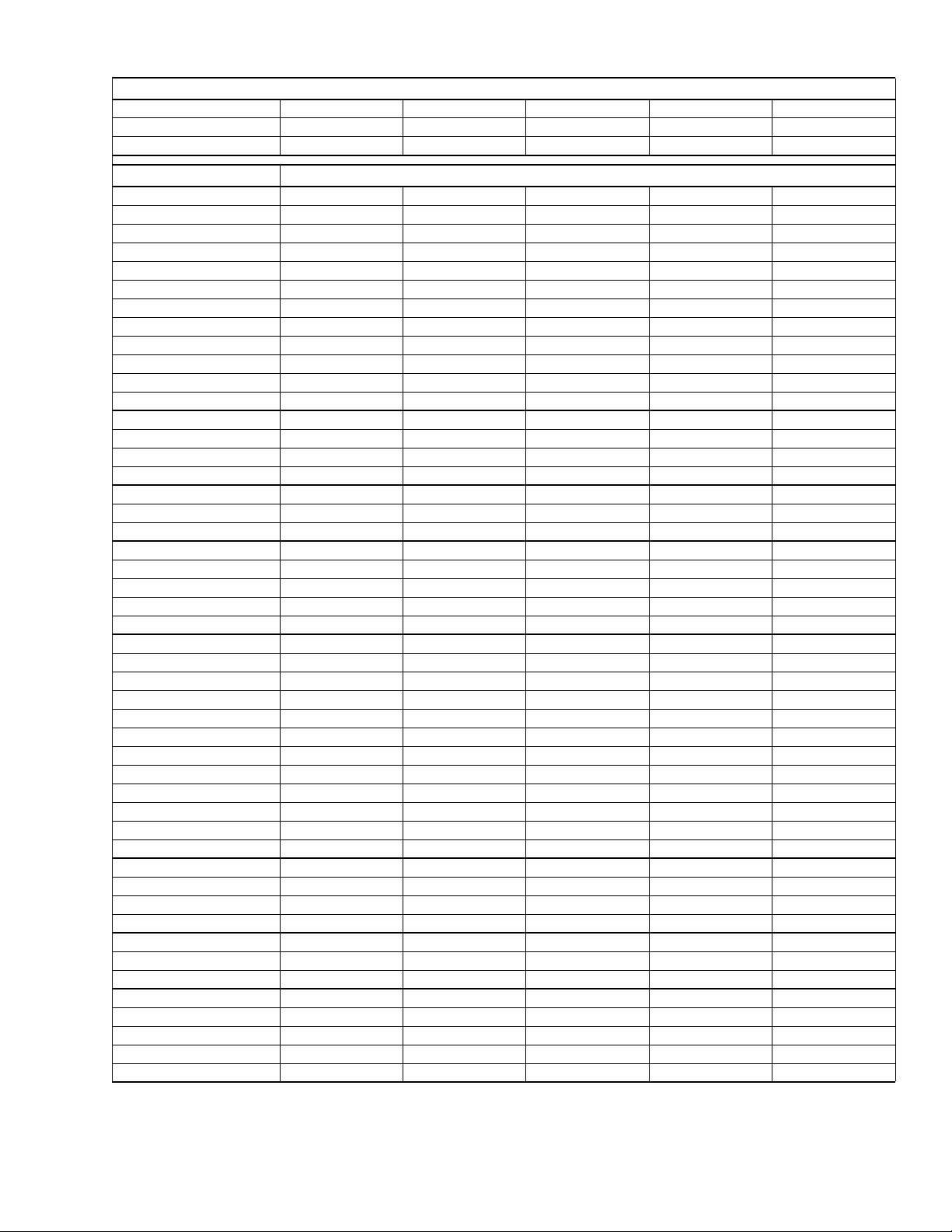

PHYSICAL AND ELECTRICAL DATA - 1 PHASE

MODEL H2RD018S06 H2RD024S06 H2RD030S06 H2RD036S06 H2RD042S06 H2RD048S06 H2RD060S06

Unit Supply Voltage 208-230V, 1φ, 60Hz

Normal Voltage Range

1

Minimum Circuit Ampacity 9.4 11.8 15.1 18.3 18.3 30.3 32.7

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

Compressor Type

Compressor

Amps

4

Rated Load 6.4 9.0 10.7 13.4 13.5 23.0 25.0

Locked Rotor 36 48 61 78 78 115 150

2

3

15 20 25 30 30 50 50

15 15 20 20 20 35 35

Recip Recip Recip Recip Recip

Crankcase Heater No No No No No No No

Fan Motor Amps Rated Load 0.8 0.5 1.5 1.5 1.5 1.5 1.5

Fan Diameter Inches 18 22 22 22 22 24 24

Rated HP 1/8 1/15 1/4 1/4 1/4 1/4 1/4

Fan Motor

Nominal RPM 1075 850 850 850 850 850 850

Nominal CFM 2150 2,200 3100 3150 3550 3550 3600

Face Area Sq. Ft. 11.43 15.72 15.72 15.72 23.60 24.00 27.00

Coil

Rows Deep1111111

Fin / Inches 22 18 22 22 22 22 22

Liquid Line OD (Field Installed) 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Vapor Line OD (Field Installed) 3/4 3/4 3/4 7/8 7/8 7/8 1-1/8

Unit Charge (Lbs. - Oz.)

5

4 - 9 5 - 8 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Charge Per Foot, Oz. 0.68 0.68 0.70 0.70 0.70 0.70 0.76

Operating Weight Lbs. 151 151 183 183 193 215 220

1. Rated in accordance with ARI Standard 110, utilization range “A”.

2. Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3. Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4. All scrolls listed with a superscript “B” are Bristol scrolls. All scrolls listed with a superscript “C” are Copeland scrolls.

5. The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than 15

feet, add or subtract the amount of refrigerant, using the difference in length multiplied by the per foot value.

187 to 252

Scroll

B

Scroll

B

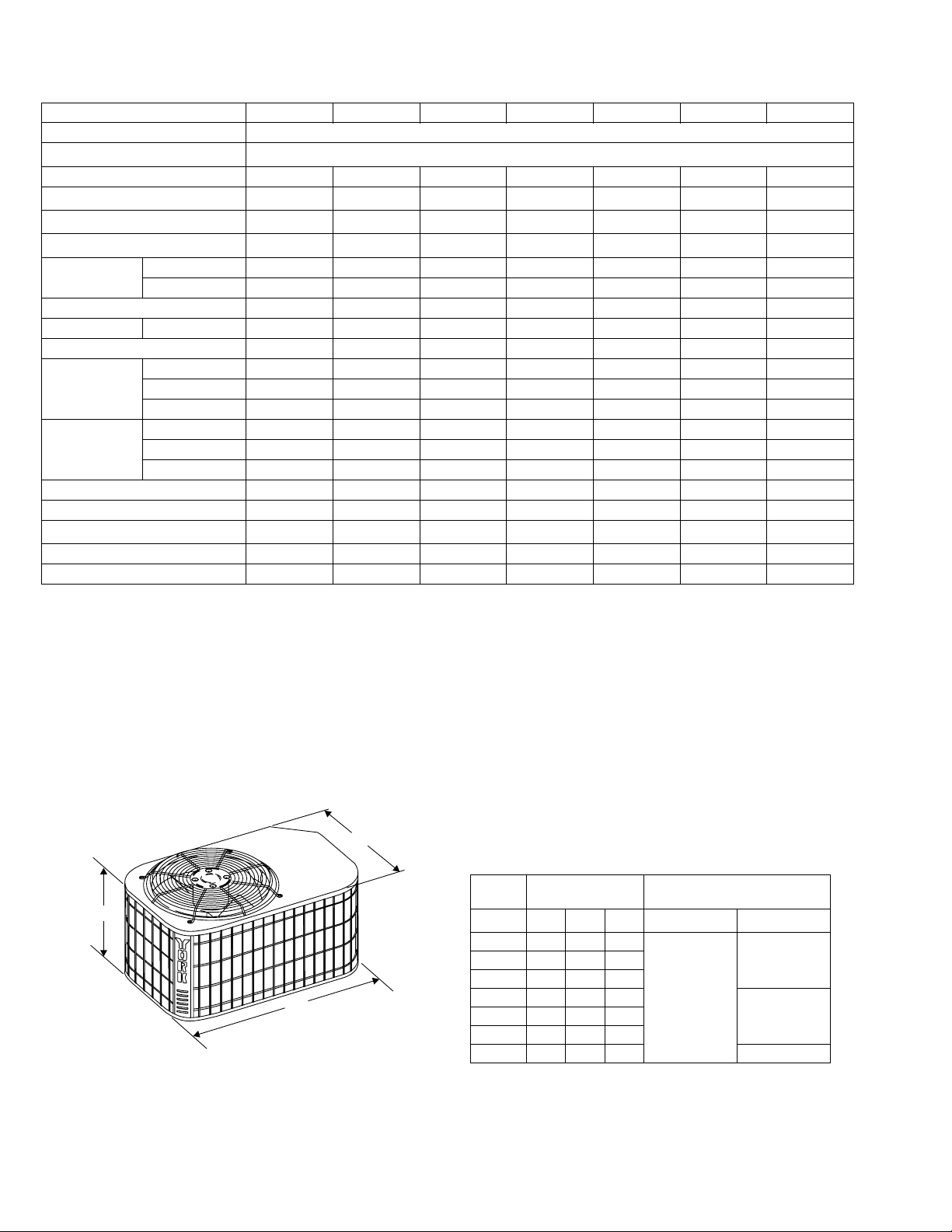

All dimensions are in inches. They are subject to change

without notice. Certified dimensions will be provided upon

C

request.

DIMENSIONS

Unit

Model

A

018 23 35 23

030 27 37 27

B

036 27 37 27

048 34 43 32

060 38 43 32 7/8”*

1. Including Fan Guard.

* Adapter fitting required for 1-1/8” line set.

2 Unitary Products Group

Dimensions

(Inches)

1

B C Liquid Vapor

A

Refrigerant Connection

Service Valve Size

3/8”

3/4”024 27 37 27

7/8”042 39 37 27

Page 3

254892-YTG-C-0606

Additional R-22 Charge / Orifice Size for Various Matched Systems - 1 Phase

Outdoor Unit H2RD018S06 H2RD024S06 H2RD030S06 H2RD036S06 H2RD042S06 H2RD048S06 H2RD060S06

Required TXV 1TVM2A1 1TVM2(A,B)1 1TVM2A1 1TVM2A1 1TVM2C1 1TVM2C1 1TVM2C1

Factory R-22 Charge, lbs-oz 4 - 9 6 - 3 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Indoor Coil

FC/MC/PC/UC/UC18A2A 0 ––––––

FC/MC/PC/UC18B2A 0 ––––––

FC/MC/PC/UC24A2A 0 0 –––––

FC/MC/PC/UC24B2A 0 0 –––––

FC/MC/PC/UC30A2A –0 0 ––––

FC/MC/PC/UC30B2A –0 0 ––––

FC/MC/PC/UC36A2A ––0 0 –––

FC/MC/PC/UC36B2A ––0 0 –––

FC/MC/PC/UC36C2A ––0 0 –––

FC/MC/PC/UC42B2C ––––0 ––

FC/MC/PC/UC42C2C ––––0 ––

FC/MC/PC/UC48C2C ––––0 0 –

FC/MC/PC/UC48D2C ––––0 0 –

FC/PC/UC/UC60C2C ––––––0

FC/MC/PC/UC60D2C ––––––0

MC61D2C ––––––0

HC18A2A 0 ––––––

HC30A2A –0 0 ––––

HC36B2A – – 0 0 – – –

HC42C2C ––––0 0 –

HC60C2C –––––0 0

HD24A2A 0 0 –––––

HD36B2A – – 0 0 – – –

HD48C2C ––––0 0 –

HD60D2C –––––0 0

AHP18B2A 0 ––––––

AHP24B2A 0 0 –––––

AHP30B2A –0 0 ––––

AHP36C2A – – 0 0 – – –

AHP42C2C ––––0 ––

AHP/SHP48D2C ––––0 0 –

AHP/SHP60D2C –––0 0 0 0

AV24B2A 0 0 – – – –

AV36C2A – – 0 0 – – –

AV/SV48D2C ––––0 0 –

AV/SV60D2C ––––0 0 0

FC/MC/PC/UC18A3X 0 2B + 1 –––––

FC/MC/PC/UC18B3X 0 2B + 1 –––––

FC/MC/PC/UC24A3X 0 2A + 0 –––––

FC/MC/PC/UC24B3X 0 2A + 0 –––––

FC/MC/PC/UC30A3X –2A + 0 0 ––––

FC/MC/PC/UC30B3X –2A + 0 0 ––––

FC/MC/PC/UC36A3X ––0 0 –––

FC/MC/PC/UC36B3X ––0 0 –––

FC/MC/PC/UC36C3X ––0 0 –––

FC/MC/PC/UC42B3X ––––0 ––

FC/MC/PC/UC42X3X ––––0 ––

FC/MC/PC/UC48C3X ––––0 0 –

FC/MC/PC/UC48D3X ––––0 0 –

FC/PC/UC/UC60C3X ––––––0

FC/MC/PC/UC60D3X ––––––0

MC61D3X ––––––0

For Notes See Page 5.

1,2

TXV KIT3 - Additional Charge, Oz

Unitary Products Group 3

Page 4

254892-YTG-C-0606

Additional R-22 Charge / Orifice Size for Various Matched Systems - 1 Phase (Continued)

Outdoor Unit H2RD018S06 H2RD024S06 H2RD030S06 H2RD036S06 H2RD042S06 H2RD048S06 H2RD060S06

Required TXV 1TVM2A1 1TVM2(A,B)1 1TVM2A1 1TVM2A1 1TVM2C1 1TVM2C1 1TVM2C1

Factory R-22 Charge, lbs-oz 4 - 9 6 - 3 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Indoor Coil

HC18A3X 0 2B + 1 –––––

HC30A3X –2A + 0 0 ––––

HC36B3X – – 0 0 – – –

HC42C3X ––––0 0 –

HC60C3X –––––0 0

HD24A3X 0 2A + 0 –––––

HD36B3X – – 0 0 – – –

HD48C3X ––––0 0 –

HD60D3X –––––0 0

AHP18B3X 0 ––––––

AHP24B3X 0 2A + 0 –––––

AHP30B3X –2A + 0 0 ––––

AHP36C3X – – 0 0 – – –

AHP42C3X ––––0 ––

AHP/SHP48D3X ––––0 0 –

AHP/SHP60D3X –––0 0 0 0

AV24B3X 0 2A + 0 – – – –

AV36C3X – – 0 0 – – –

AV/SV48D3X ––––0 0 –

AV/SV60D3X ––––0 0 0

G2FD024(S,H)14,17 0 2B + 1 –––––

G2FD030(S,H)17 0 2B + 1 –––––

G2FD035(S,H)14 0 2B + 1 –––––

G2FD036(S,H)17 – 2A + 0 0 0 – – –

G2FD036(S,H)21 –––0 –––

G2FD042(S,H)21 –––0 0 ––

G2FD046(S,H)17 –––0 0 ––

G2FD048(S,H)21,24 ––––0 0 –

G2FD060(S,H)24 ––––––0

G2FD061H24 ––––––0

G1HA024H14 0 2B + 1 –––––

G1HA036H14 – 2A + 0 0 ––––

G1HA036H17 – 2A + 0 0 0 – – –

G1HA048H21 –––0 0 0 –

G1HA060H24 –––––0 0

G1HD036 0 2A + 0 0 0 – – –

G1HD048 –––0 –––

G1HD060 ––––0 0 –

G1NA030S17K 0 2B + 1 –––––

G1NA030S21M 0 2B + 1 –––––

G1NA036S17J 0 2A + 0 0 ––––

G1NA036S21C 0 2A + 0 0 ––––

G1NA036S17L – 2A + 0 0 0 – – –

G1NA042S24W –––0 –––

G1NA048S21D – 2A + 0 0 0 – – –

G1NA060S24T ––––0 0 –

G1FA/G1UA030S14 0 2B + 1 –––––

G1FA/G1UA036S14 0 2A + 0 0 ––––

G1FA/G1UA036S17,21 0 2B + 1 –––––

G1FA/G1UA048S17 –––0 0 ––

G1FA/G1UA048S21 –––0 0 ––

G1FA/G1UA060S21,24 ––––––0

F2RP/F2FP024 0 2B + 1 –––––

F2RP/F2FP030 –2A + 0 –––––

F2RP/F2FP036 ––0 ––––

For Notes See Page 5.

1,2

TXV KIT3 - Additional Charge, Oz

4 Unitary Products Group

Page 5

254892-YTG-C-0606

Additional R-22 Charge / Orifice Size for Various Matched Systems - 1 Phase (Continued)

Outdoor Unit H2RD018S06 H2RD024S06 H2RD030S06 H2RD036S06 H2RD042S06 H2RD048S06 H2RD060S06

Required TXV 1TVM2A1 1TVM2(A,B)1 1TVM2A1 1TVM2A1 1TVM2C1 1TVM2C1 1TVM2C1

Factory R-22 Charge, lbs-oz 4 - 9 6 - 3 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Indoor Coil

F2RP/F2FP040 –––0 –––

F2FP048 ––––0 ––

F2FP060 –––––0* –

F2FV060 –––––0 0

G4FA030S14T2A 0 ––––––

G4FA030S14T2B – 1 –––––

G4FA036S14T2A 0 0 0 ––––

G4FA036S17T2A 0 ––––––

G4FA036S21T2A 0 ––––––

G4FA036S21T2B – 1 –––––

G4FA048S17T2A –––0 –––

G4FA048S17T2C – – – 0 – –

G4FA048S21T2A –––0 –––

G4FA048S21T2C ––––0 ––

G4FA060S21T2C ––––––0

G4FA060S24T2C ––––––0

G4FD024H14T2A 0 ––––––

G4FD024H14T2B –1 –––––

G4FD024H17T2A 0 ––––––

G4FD024H17T2B 1 –––––

G4FD030H17T2A 0 ––––––

G4FD035H14T2A 0 ––––––

G4FD036H17T2A – 0 0 0 – – –

G4FD036H21T2A –––0 –––

G4FD042H21T2A –––0 –––

G4FD042H21T2C ––––0 ––

G4FD046H17T2A –––0 –––

G4FD046H17T2C ––––0 ––

G4FD048H21T2A –––––––

G4FD048H21T2C ––––0 0 –

G4FD048H24T2A –––––––

G4FD048H24T2C ––––0 0 –

G4FD060H24T2C ––––––0

G4FD061H24T2C ––––––0

F4FP024H06T2A 0 ––––––

F4FP024H06T2B – 1 –––––

F4FP030H06T2A – 0 –––––

F4FP036H06T2A –––––––

F4FP040H06T2A – – 0 ––––

F4FP042H06T2A –––0 –––

F2FP048H06T2C ––––0 ––

F2FP060H06T2C –––––0* –

F2FV060H06T2C –––––0 0

FOOTNOTES:

PROCEDURES:

1,2

1. Systems matched with furnace or air handlers not equipped with blower-off delays may require blower Time Delay Kit 2FD06700224.

2. PC coils cannot be used in downflow or horizontal applications. FC coils cannot be used in horizontal applications.

3. A TXV kit must be used with these coils to obtain system performance (2A, 2B, and 2C indicate 1TVM series).

* This loose coil match does not achieve 13 SEER.

1. Unit factory char ge listed on the un it nameplate includes refrigerant for the condenser, the smallest evaporator and for 15 feet of interconnecting

line tubing.

2. Verify the TXV and additional charge required for specific evaporator coil in the system using the above table.

3. Additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified in the table above.

4. Permanently mark the unit nameplate with the total system charge. Total System Charge = Base Charge (as shipped) + adder for

evaporator + adder for line set.

TXV KIT3 - Additional Charge, Oz

Unitary Products Group 5

Page 6

254892-YTG-C-0606

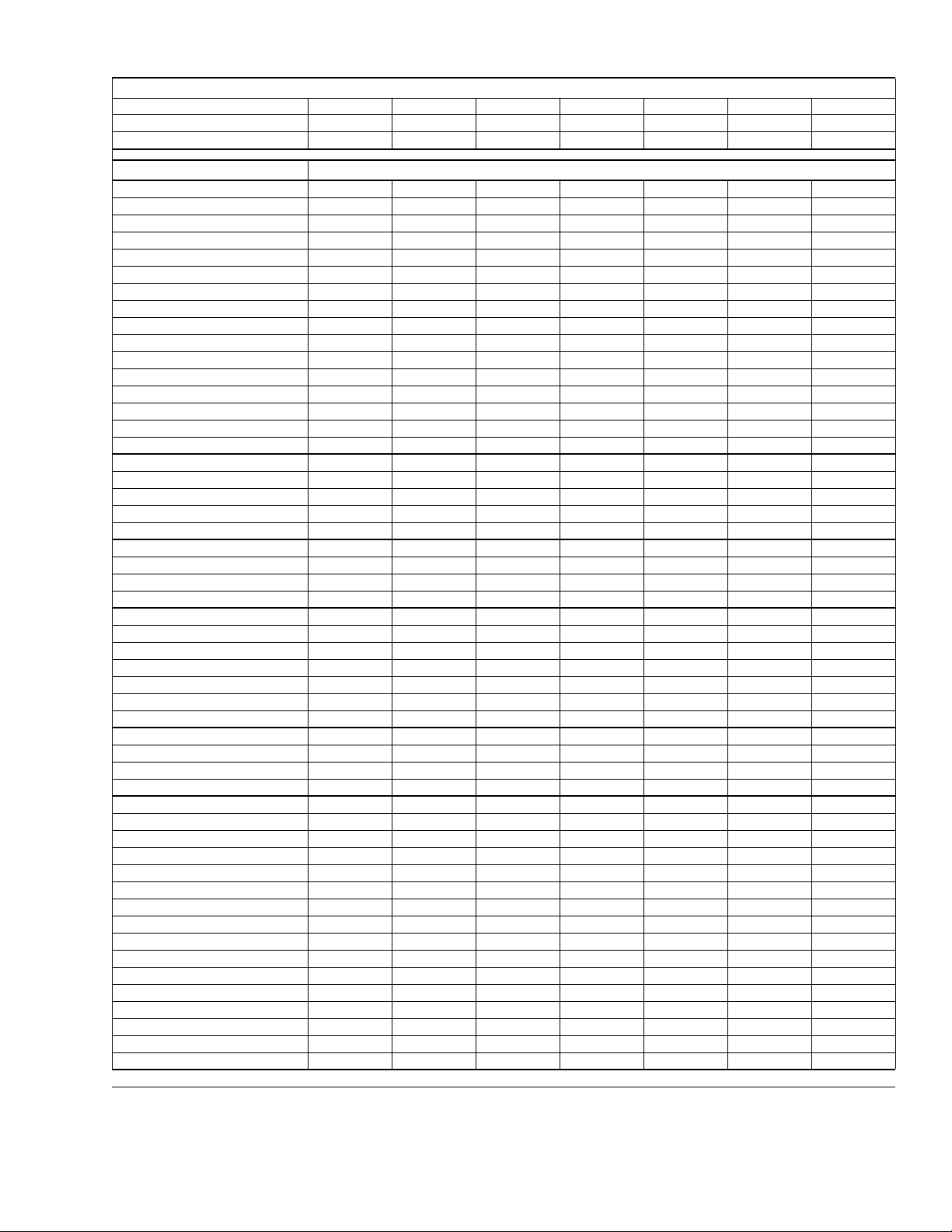

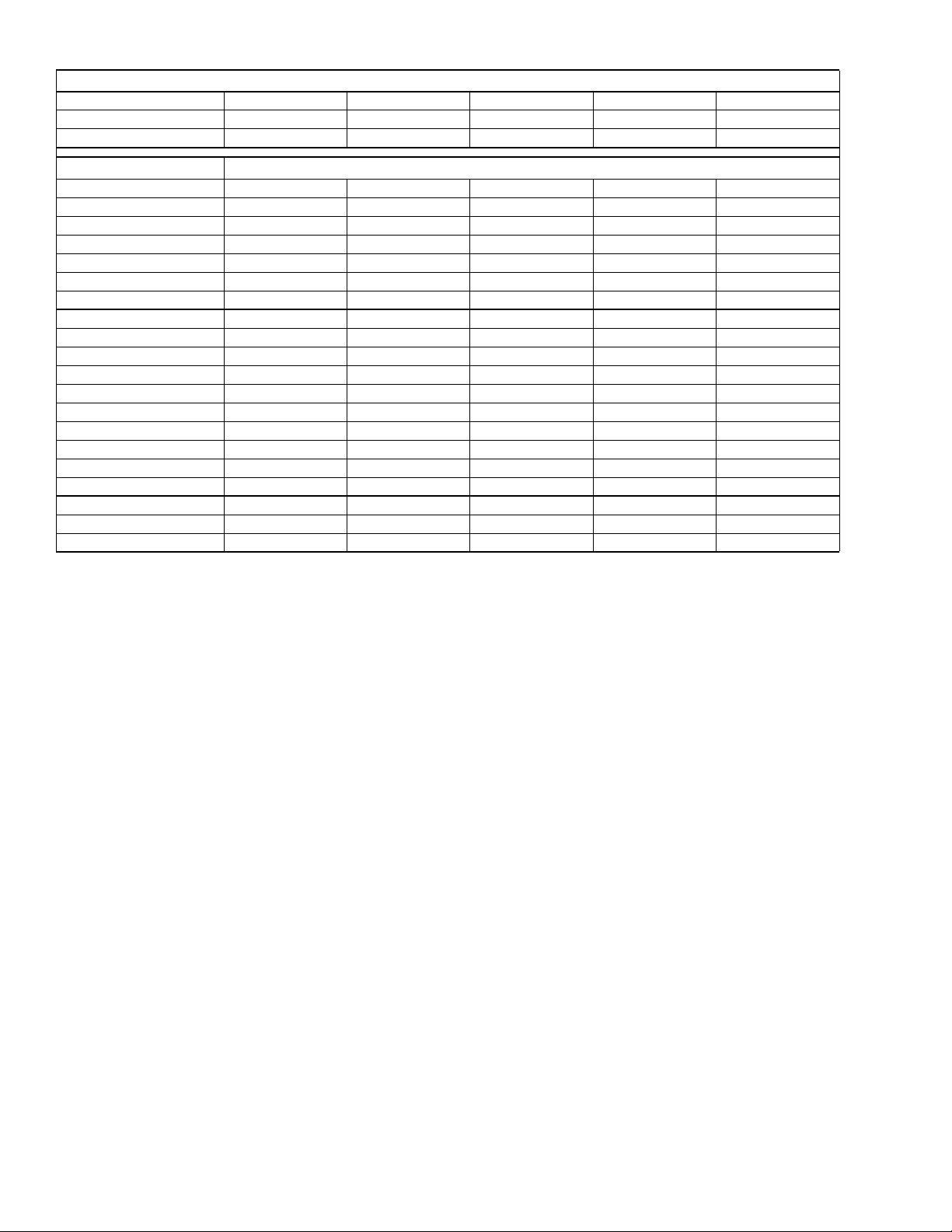

PHYSICAL AND ELECTRICAL DATA - 3 PHASE

MODEL

H1RD

030S25

Unit Supply Voltage 208-230V, 3φ, 60Hz 460V, 3φ, 60Hz

Normal Voltage Range

1

Minimum Circuit Ampacity 14.3 14.3 12.4 21.5 23.1 6.9 9.6 6.9 10.3 11.3

Max. Overcurrent Device Amps

Min. Overcurrent Device Amps

Compressor Type

Compressor Amps

4

Rated Load 10.2 10.2 8.8 16.0 17.3 4.9 13.5 11.8 7.7 8.4

Locked Rotor 72 72 72 115 123 45 45 45 50 70

2

3

Recip Recip Recip ScrollB ScrollB Recip Recip Recip ScrollB ScrollB

Crankcase Heater No No No No No No No No No No

Fan Motor Amps Rated Load 1.5 1.5 1.5 1.5 1.5 0.7 0.7 0.7 0.7 0.7

Fan Diameter Inches 22 22 22 22 24 22 22 22 24 24

Rated HP 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4 1/4

Fan Motor

Nominal RPM 850 850 850 850 850 850 850 850 850 850

Nominal CFM 3100 3150 3550 3550 3600 3100 3150 3550 3550 3600

Face Area Sq. Ft. 15.72 15.72 23.60 24.00 27.00 15.72 15.72 23.60 24.00 27.00

Coil

Rows Deep 1 1 1 1 1 1 1 1 2 2

Fin / Inches 22 22 22 22 22 22 22 22 18 18

Liquid Line Set OD (Field Installed) 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3 /8 3/8 3/8

Vapor Line Set OD (Field Installed) 3/4 7/8 7/8 7/8 1-1/8 3/4 7 /8 7/8 7/8 1-1/8

Unit Charge (Lbs. - Oz.)

5

5 - 13 6 - 0 8 - 13 8 - 6 10 - 2 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Charge Per Foot, Oz. 0.68 0.70 0.70 0.70 0.76 0.68 0.70 0.70 0.70 0.76

Operating Weight Lbs. 208 208 208 215 294 208 208 215 250 294

1. Rated in accordance with ARI Standard 110, utilization range “A”.

2. Dual element fuses or HACR circuit breaker. Maximum allowable overcurrent protection.

3. Dual element fuses or HACR circuit breaker. Minimum recommended overcurrent protection.

4. All scrolls listed with a superscript “B” are Bristol scrolls. All scrolls listed with a superscript “C” are Copeland scrolls.

5. The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than

15 feet, add or subtract the amount of refrigerant, using the difference in length multiplied by the per foot value.

A

B

H1RD

036S25

H1RD

042S25

H1RD

048S25

H1RD

060S25

H1RD

030S46

H1RD

036S46

H1RD

042S46

H1RD

048S46

H1RD

060S46

187 to 252 432 to 504

20 20 20 35 40 15 15 15 15 15

15 15 15 25 25 15 15 15 15 15

All dimensions are in inches. They are subject to change

without notice. Certified dimensions will be provided upon

request.

C

DIMENSIONS

Unit

Model

030 27 37 27

036 27 37 27

048 34 43 32

060 38 43 32 7/8”*

1. Including Fan Guard.

* Adapter fitting required for 1-1/8” line set.

Dimensions

(Inches)

1

B C Liquid Vapor

A

Refrigerant Connection

Service Valve Size

3/8”

3/4”

7/8”042 39 37 27

6 Unitary Products Group

Page 7

254892-YTG-C-0606

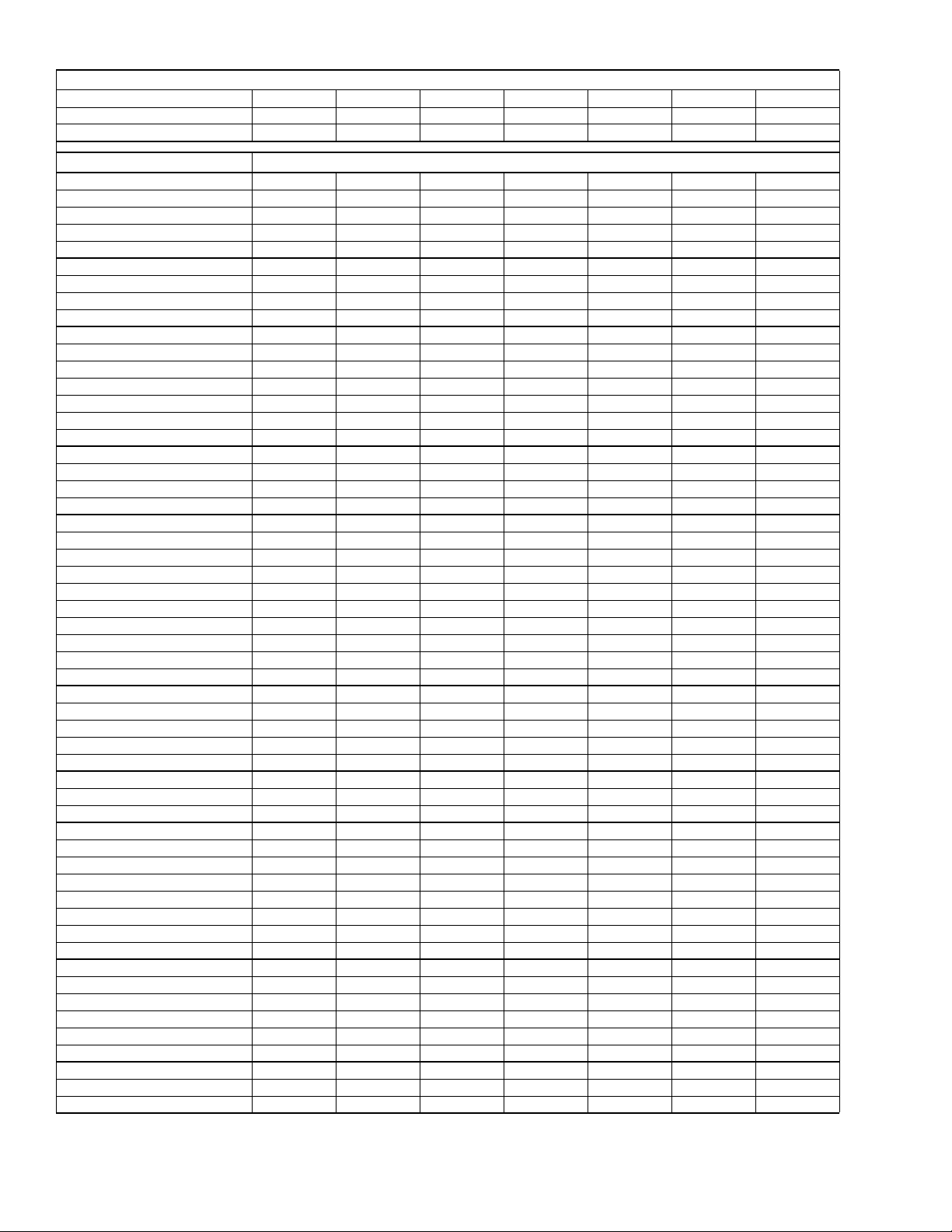

Additional R-22 Charge / Orifice Size for Various Matched Systems - 3 Phase

Outdoor Unit H1RD030S(25,46) H1RD036S(25,46) H1RD042S(25,46) H1RD048S(25,46) H1RD060S(25,46)

Required TXV 1TVM2A1 1TVM2A1 1TVM2C1 1TVM2C1 1TVM2C1

Factory R-22 Charge, lbs-oz 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Indoor Coil

FC/MC/PC/UC30A2A 0 ––––

FC/MC/PC/UC30B2A 0 ––––

FC/MC/PC/UC36A2A 0 0 – – –

FC/MC/PC/UC36B2A 0 0 – – –

FC/MC/PC/UC36C2A 0 0 – – –

FC/MC/PC/UC42B2C – – 0 – –

FC/MC/PC/UC42C2C – – 0 – –

FC/MC/PC/UC48C2C – – 0 0 –

FC/MC/PC/UC48D2C – – 0 0 –

FC/PC/UC/UC60C2C ––––0

FC/MC/PC/UC60D2C ––––0

MC61D2C ––––0

HC30A2A 0 ––––

HC36B2A 0 0 – – –

HC42C2C – – 0 0 –

HC60C2C – – 0 0

HD36B2A 0 0 – –

HD48C2C – – 0 0 –

HD60D2C –––0 0

AHP30B2A 0 ––––

AHP36C2A 0 0 – –

AHP42C2C – – 0 – –

AHP/SHP48D2C – – 0 0 –

AHP/SHP60D2C – 0 0 0 0

FC/MC/PC/UC30A3X 0 ––––

FC/MC/PC/UC30B3X 0 ––––

FC/MC/PC/UC36A3X 0 0 – – –

FC/MC/PC/UC36B3X 0 0 – – –

FC/MC/PC/UC36C3X 0 0 – – –

FC/MC/PC/UC42B3X – – 0 – –

FC/MC/PC/UC43X3X – – 0 – –

FC/MC/PC/UC48C3X – – 0 0 –

FC/MC/PC/UC48D3X – – 0 0 –

FC/PC/UC/UC60C3X ––––0

FC/MC/PC/UC60D3X ––––0

MC61D3X ––––0

HC30A3X 0 ––––

HC36B3X 0 0 – – –

HC42C3X – – 0 0 –

HC60C3X –––0 0

HD36B3X 0 0 – – –

HD48C3X – – 0 0 –

HD60D3X –––0 0

AHP30B3X 0 ––––

AHP36C3X 0 0 – – –

AHP42C3X – – 0 – –

AHP/SHP48D3X – – 0 0 –

AHP/SHP60D3X – 0 0 0 0

For Notes See Page 8.

1

Additional Charge, Oz

Unitary Products Group 7

Page 8

254892-YTG-C-0606

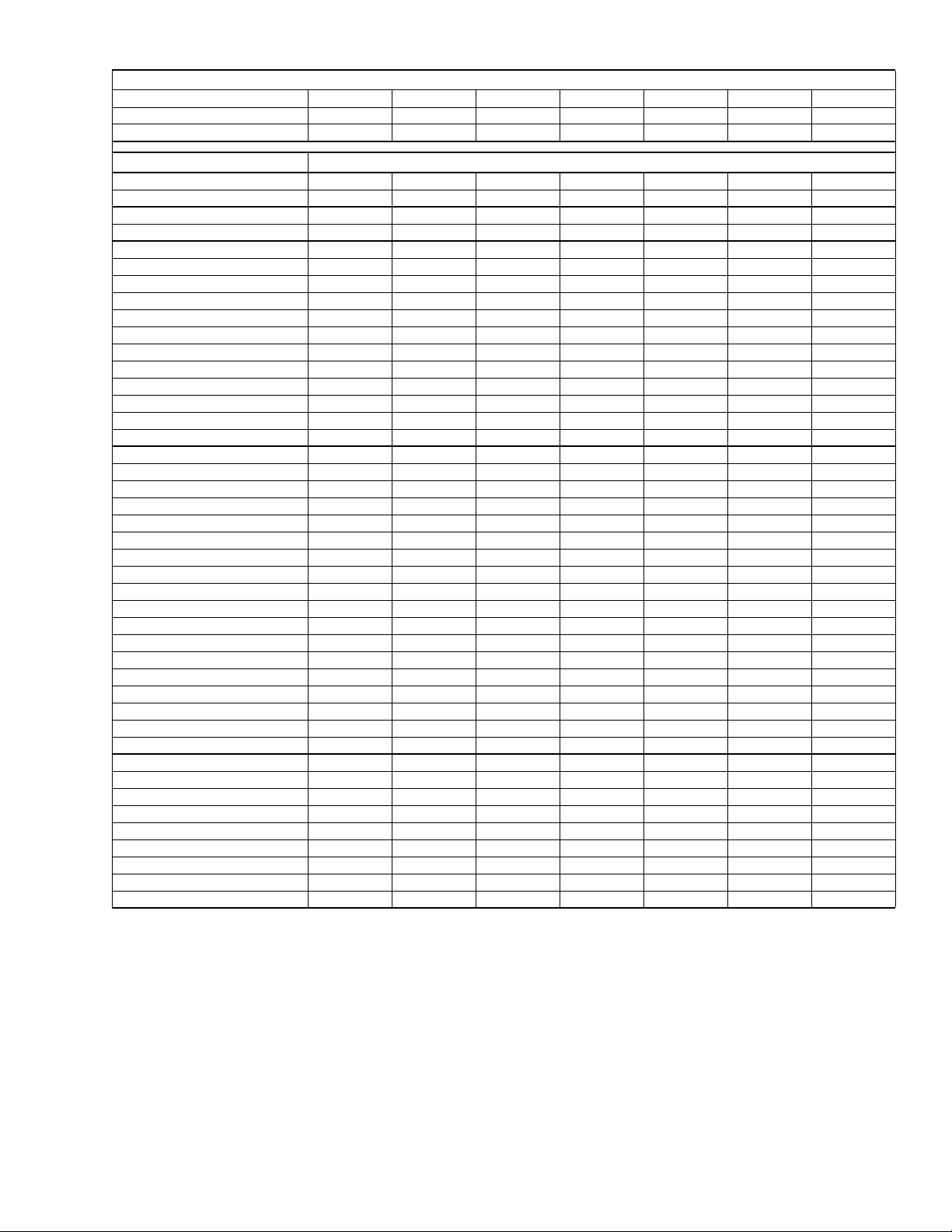

Additional R-22 Charge / Orifice Size for Various Matched Systems - 3 Phase (Continued)

Outdoor Unit H1RD030S(25,46) H1RD036S(25,46) H1RD042S(25,46) H1RD048S(25,46) H1RD060S(25,46)

Required TXV 1TVM2A1 1TVM2A1 1TVM2C1 1TVM2C1 1TVM2C1

Factory R-22 Charge, lbs-oz 5 - 13 6 - 0 8 - 13 8 - 6 10 - 2

Indoor Coil

G4FA036S14T2A 0 ––––

G4FA048S17T2A – 0 – – –

G4FA048S17T2C – – 0 – –

G4FA048S21T2A – 0 – – –

G4FA048S21T2C – – 0 – –

G4FA060S21T2C ––––0

G4FA060S24T2C ––––0

G4FD036H17T2A 0 0 – – –

G4FD036H21T2A – 0 – – –

G4FD042H21T2A – 0 – – –

G4FD042H21T2C – – 0 – –

G4FD046H17T2A – 0 – – –

G4FD046H17T2C – – 0 – –

G4FD048H21T2C – – 0 0 –

G4FD048H24T2C – – 0 0 –

G4FD060H24T2C ––––0

G4FD061H24T2C ––––0

F4FP040H06T2A 0 ––––

F4FP042H06T2A – 0 – – –

F2FP048H06T2C – – 0 – –

FOOTNOTES:

PROCEDURES:

1

1. Systems matched with furnace or air handlers not equipped with blower-off delays may require blower Time Delay Kit 2FD06700224.

1. Unit factory charg e listed on the unit nameplate includes refr igerant for the condenser, the smallest evaporator and for 15 feet of inter-

connecting

line tubing.

2. Verify the TXV and additional charge required for specific evaporator coil in the system using the above table.

3. Additional charge for the amount of interconnecting line tubing greater than 15 feet at the rate specified in the table above.

4. Permanently mark the unit nameplate with the total system charge. Total System Charge = Base Charge (as shipped) + adder for

evaporator + adder for line set.

Additional Charge, Oz

8 Unitary Products Group

Page 9

COOLING CAPACITY - With Air Handler Coils

UNIT

MODEL

H2RD018S06

H2RD024S06

H2RD030S06

H1RD030S(25,46)

H2RD036S06

H1RD036S(25,46)

H2RD042S06

H1RD042S(25,46)

H2RD048S06

H1RD048S(25,46)

H2RD060S06

H1RD060S(25,46)

H2RD018S06

H2RD024S06

H2RD030S06

H2RD036S06

H2RD042S06

H2RD048S06

H2RD060S06

For Notes See Page 10.

MODEL

MA08B 2,5,8 17 FC/MC18B 600 17.5 11.7 13.00 11.00

MA08B 2,5,8 17 G*FD024H17 600 17.5 11.7 13.00 11.00

MA08B 2,5,8 17 FC/MC24B 800 23.0 16.6 13.00 11.00

MA08B 2,5,8 17 G*FD024H17 800 23.0 16.6 13.00 11.00

MA12B 5,8,10 17 FC/MC30B 1000 29.6 21.0 13.00 11.00

MA12B 5,8,10 17 FC/MC36B 1000 29.6 21.3 13.00 11.00

MA12B 5,8,10 17 G*FD036H17 1000 29.6 21.3 13.00 11.00

MA12B 10 17 FC/MC30B 1000 29.0 20.9 13.00 11.00

MA12B 10 17 FC/MC36B 1000 29.0 20.9 13.00 11.00

MA12B 10 17 G*FD036H17 1000 29.0 20.9 13.00 11.00

MA12B 5,8,10 17 FC/MC36B 1200 34.8 25.4 13.00 11.00

MA12B 5,8,10 17 G*FD036H17 1200 34.8 25.4 13.00 11.00

MA12B 10 17 FC/MC36B 1200 34.5 25.2 13.00 11.00

MA12B 10 17 G*FD036H17 1200 34.5 25.2 13.00 11.00

MA16C 5,8,10,15,18 21 FC/MC42C 1400 40.5 29.6 13.00 11.00

MA16C 5,8,10,15,18 21 FC/MC48C 1400 41.0 30.2 13.00 11.00

MA14D 5,8,10,15,18 24 FC/MC48D 1400 41.0 30.2 13.00 11.00

MA16C 5,8,10,15,18 21 G*FD042H21 1400 40.5 29.6 13.00 11.00

MA16C 5,8,10,15,18 21 G*FD048H21 1400 41.0 30.2 13.00 11.00

MA14D 5,8,10,15,18 24 G*FD048H24 1400 41.0 30.2 13.00 11.00

MA16C 10,15,18 21 FC/MC42C 1400 39.5 29.6 13.00 11.00

MA16C 10,15,18 21 FC/MC48C 1400 40.0 30.2 13.00 11.00

MA14D 10,15,18 24 FC/MC48D 1400 40.0 30.2 13.00 11.00

MA16C 10,15,18 21 G*FD042H21 1400 39.5 29.6 13.00 11.00

MA16C 10,15,18 21 G*FD048H21 1400 40.0 30.2 13.00 11.00

MA14D 10,15,18 24 G*FD048H24 1400 40.0 30.2 13.00 11.00

MA16C 5,8,10,15,18 21 FC/MC48C 1600 47.0 35.7 13.00 11.00

MA16C 5,8,10,15,18 21 G*FD048H21 1600 47.0 35.7 13.00 11.00

MA20D 8,10,15,20,25 24 FC/MC48D 1600 47.0 35.1 13.00 11.00

MA20D 8,10,15,20,25 24 G*FD048H24 1600 47.0 35.1 13.00 11.00

MA16C 10,15,18 21 FC/MC48C 1600 46.0 34.4 13.00 11.00

MA16C 10,15,18 21 G*FD048H21 1600 46.0 34.4 13.00 11.00

MA20D 10,15,18,20 24 FC/MC48D 1600 46.0 34.4 13.00 11.00

MA20D 10,15,18,20 24 G*FD048H24 1600 46.0 34.4 13.00 11.00

MA20D 5,8,10,15,20,25 24 FC/MC60D 1600 55.0 39.6 13.00 11.00

MA20D 5,8,10,15,20,25 24 G*FD060H24 1600 55.0 39.6 13.00 11.00

MA20D 5,8,10,15,20,25 24 G*FD061H24 1800 55.5 40.0 13.00 11.00

MA20D 5,8,10,15,20,25 24 MC61D 1800 55.5 40.0 13.00 11.00

MA20D 10,15,18,20 24 FC/MC60D 1600 54.5 39.3 13.00 11.00

MA20D 10,15,18,20 24 G*FD060H24 1600 55.0 39.3 13.00 11.00

MA20D 10,15,18,20 24 G*FD061H24 1800 54.5 39.3 13.00 11.00

MA20D 10,15,18,20 24 MC61D 1800 55.0 39.3 13.00 11.00

MV12B 5,8,10,15 17 FC/MC18B 600 17.7 11.7 14.00 11.50

MV12B 5,8,10,15 17 FC/MC24B 600 18.0 11.8 14.00 11.50

MV12B 5,8,10,15 17 FC/MC24B 800 23.4 16.5 14.00 11.50

MV12B 5,8,10,15 17 FC/MC30B 800 23.4 16.6 14.00 11.50

MV12B 5,8,10,15 17 FC/MC30B 1000 30.0 21.0 14.00 11.50

MV12B 5,8,10,15 17 FC/MC36B 1000 30.0 21.2 14.00 11.50

MV16C 5,8,10,15,18,20 21 FC/MC36C 1000 30.0 21.2 14.00 11.50

MV12B 5,8,10,15 17 FC/MC36B 1200 35.0 25.0 13.50 11.00

MV16C 5,8,10,15,18,20 21 FC/MC36C 1200 35.2 25.2 14.00 11.50

MV16C 5,8,10,15,18,20 21 FC/MC42C 1400 40.5 29.1 13.75 11.00

MV16C 5,8,10,15,18,20 21 FC/MC48C 1400 41.5 29.7 14.00 11.50

MV20D 8,10,15,18,20,25 24 FC/MC48D 1400 41.5 29.8 14.00 11.50

MV16C 5,8,10,15,18,20 21 FC/MC48C 1600 47.0 34.7 13.50 11.00

MV20D 8,10,15,18,20,25 24 FC/MC48D 1600 47.0 34.6 13.50 11.00

MV20D 8,10,15,18,20,25 24 FC/MC60D 1800 54.0 38.6 13.00 11.00

MV20D 8,10,15,18,20,25 24 MC61D 1800 55.5 39.1 13.25 11.00

AIR HANDLER

ELECTRIC

HEAT KW

1 PH 13 SEER AC WITH MV - VARIABLE SPEED

2

1 & 3 PH 13 SEER AC WITH MA

W

COIL MODEL

1

RATED

CFM

254892-YTG-C-0606

COOLING

NET MBH

TOTAL SENS.

SEER EER

Unitary Products Group 9

Page 10

254892-YTG-C-0606

COOLING CAPACITY - With Air Handler Coils (Continued)

UNIT

MODEL

MODEL

AIR HANDLER

ELECTRIC

HEAT KW

1

COIL MODEL

2

W

RATED

CFM

1 PH 13 SEER AC WITH AV / SV - VARIABLE SPEED

H2RD018S06 AV24 2,5,8,10,15 17 – 600 18.0 11.7 14.00 11.50

H2RD024S06 AV24 2,5,8,10,15 17 – 800 23.2 16.5 14.00 11.50

H2RD030S06 AV36 5,8,10,15,18 21 – 1000 30.0 21.2 14.00 11.50

H2RD036S06

AV36 5,8,10,15,18 21 – 1200 35.2 25.0 14.00 11.50

AV/SV48 5,8,10,15,18,20,25 24 – 1200 35.8 25.0 13.75 11.00

H2RD042S06 AV/SV48 5,8,10,15,18,20,25 24 – 1400 40.5 29.1 14.00 11.50

H2RD048S06 AV/SV48 5,8,10,15,18,20,25 24 – 1600 47.0 34.7 13.50 11.00

H2RD060S06 AV/SV60 5,8,10,15,18,20,25 24 – 1800 55.0 39.1 13.15 11.00

1 & 3 PH 13 SEER AC WITH AHP / F*FP / F*FV

AHP18 2,5,8 17 – 650 17.7 12.3 13.00 11.00

H2RD018S06

AHP24 2,5,8,10 17 – 655 17.9 12.5 13.50 11.00

F*FP024 5,8,10 17 – 650 17.5 12.2 13.00 11.00

AHP24 2,5,8,10 17 – 830 23.0 16.8 13.00 11.00

H2RD024S06

AHP30 5,8,10 17 – 795 23.6 17.0 13.00 11.00

F*FP024 5,8,10 17 – 800 23.0 16.8 13.00 11.00

F*FP030 5,8,10,15 17 – 800 23.0 16.8 13.00 11.00

AHP30 5,8,10 17 – 1015 30.0 21.9 13.00 11.00

H2RD030S06

AHP36 5,8,10,15,18 17 – 1040 30.0 22.6 13.50 11.00

F*FP036 5,8,10,15,19 21 – 1000 29.6 21.3 13.00 11.00

AHP30 5,8,10 17 – 1015 29.7 21.7 13.00 11.00

H1RD030S(25,46)

AHP36 5,8,10,15,18 17 – 1040 29.7 22.4 13.50 11.00

F4FP036 5,8,10,15,19 21 – 1000 29.3 21.1 13.00 11.00

AHP36 5,8,10,15,18 17 – 1235 35.0 27.2 13.50 11.00

H2RD036S06

AHP42 5,8,10,15,18 21 – 1255 35.0 27.5 13.50 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1200 36.0 26.7 14.00 11.50

F*FP040 5,8,10,15 21 – 1200 34.8 25.4 13.00 11.00

AHP36 5,8,10,15,18 17 – 1235 34.7 27.0 13.50 11.00

H1RD036S(25,46)

AHP42 5,8,10,15,18 21 – 1255 34.7 27.3 13.50 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1200 35.7 26.5 14.00 11.50

F*FP040 5,8,10,15 24 – 1200 34.5 25.2 13.00 11.00

AHP42 5,8,10,15,18 21 – 1485 41.0 31.0 13.00 11.00

H2RD042S06

AHP/SHP48 5,8,10,15,20 24 – 1400 42.0 30.7 13.50 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1400 40.5 33.2 14.00 11.50

F*FP048 5,8,10,15 24 – 1400 41.0 31.0 13.00 11.00

AHP42 5,8,10,15,18 21 – 1485 40.0 30.3 13.00 11.00

H1RD042S(25,46)

AHP/SHP48 5,8,10,15,20 24 – 1400 41.0 30.0 13.50 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1400 39.5 32.5 14.00 11.50

F4FP048 5,8,10,15 24 – 1400 40.0 30.3 13.00 11.00

F*FV060 5,8,10,15,20,25 24 – 1600 47.5 36.9 13.50 11.00

H2RD048S06

AHP/SHP48 5,8,10,15,20 24 – 1675 47.0 36.8 13.00 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1600 47.0 36.2 13.75 11.00

H1RD048S(25,46)

H2RD060S06

AHP/SHP48 5,8,10,15,20 24 – 1675 46.0 36.1 13.00 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1600 46.0 35.5 13.75 11.00

F*FV060 5,8,10,15,20,25 24 – 1850 55.0 40.3 13.20 11.00

AHP/SHP60 5,8,10,15,20,25 24 – 1850 55.0 40.3 13.00 11.00

H1RD060S(25,46) AHP/SHP60 5,8,10,15,20,25 24 – 1850 54.0 39.6 13.00 11.00

Rated in accordance with DOE test procedures (Federal Register 12-27-79 and 3-18-88) and ARI Standards 210.

Cooling MBH based on 80°F entering air temperature, 50% RH, and rated air flow.

EER (Energy Efficiency Ratio) is the total cooling output in BTU’s at 95°F outdoor ambient divided by the total electric power in watt-hours at those conditions.

SEER (Seasonal Energy Efficiency Ratio) is the total cooling output in BTU’s during a norma l annual usage period for cooling divided by the total electric power

input in watt-hours during the same period.

1. G2FD coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Single phase units require single phase 2HK heaters.

— = Not applicable.

COOLING

NET MBH

TOTAL SENS.

SEER EER

10 Unitary Products Group

Page 11

COOLING CAPACITY - Upflow, Downflow & Horizontal Furnaces and Coils

UNIT MODEL

H2RD018S06

H2RD024S06

H2RD030S06

H1RD030S(25,46)

H2RD036S06

H1RD036S(25,46)

For Notes See Page12.

FURNACE**

CFM RANGE

(MIN.-MAX.)

450

750

600

1000

800

1200

800

1200

1000

1400

1000

1400

W

14,17 FC/MC/PC/UC18 600 17.5 11.7 13.00 11.00

14,17 FC/MC/PC/UC24 600 17.7 11.9 13.00 11.00

14 G*FA030S14 600 17.7 11.9 13.00 11.00

14,17 G*FD024H14,17 600 17.5 11.7 13.00 11.00

17 G*FD030H17 600 17.5 11.7 13.00 11.00

14 G*FD035H14 600 17.5 11.7 13.00 11.00

14 HC24 600 17.5 11.7 13.00 11.00

– HD24 600 18.0 12.1 13.00 11.00

14,17 FC/MC/PC/UC24 800 23.0 16.6 13.00 11.00

14,17 FC/MC/PC/UC30 800 23.0 16.6 13.00 11.00

17,21 G*FA030S14 800 23.0 16.6 13.00 11.00

14 G*FA036S17 800 23.0 16.6 13.00 11.00

14,17 G*FD024H14,17 800 23.0 16.6 13.00 11.00

17 G*FD030H17 800 23.0 16.6 13.00 11.00

14 G*FD035H14 800 23.0 16.6 13.00 11.00

17 G*FD036H17 800 23.4 16.9 13.00 11.00

14 HC30 800 23.4 16.9 13.00 11.00

– HD24 800 23.4 17.2 13.00 11.00

14,17 FC/MC/PC/UC30 1000 29.6 21.0 13.00 11.00

14,17,21 FC/MC/PC/UC36 1000 29.6 21.3 13.00 11.00

14 G*FA036S14 1000 29.6 21.0 13.00 11.00

17 G*FD036H17 1000 29.6 21.3 13.00 11.00

21 G*FD036H21 1000 29.6 21.3 13.00 11.00

14 HC30 1000 29.6 21.6 13.00 11.00

17 HC36 1000 30.0 21.9 13.00 11.00

- HD36 1000 30.0 22.0 13.50 11.00

14,17 FC/MC/PC/UC30 1000 29.0 20.9 13.00 11.00

14,17,21 FC/MC/PC/UC36 1000 29.0 20.9 13.00 11.00

14 G*FA030S14 1000 29.0 20.9 13.00 11.00

17 G*FD036H17 1000 29.0 20.9 13.00 11.00

21 G*FD036H21 1000 29.0 20.9 13.00 11.00

14 HC30 1000 29.0 20.9 13.00 11.00

17 HC36 1000 29.0 20.9 13.00 11.00

- HD36 1000 29.0 20.9 13.50 11.00

14,17,21 FC/MC/PC/UC36 1200 34.8 25.4 13.00 11.00

17 G*FA042S17 1200 34.8 25.4 13.00 11.00

17 G*FD036H17 1200 34.8 25.4 13.00 11.00

21 G*FD036H21 1200 34.8 25.4 13.00 11.00

21 G*FD042H21 1200 35.0 25.4 13.00 11.00

17 G*FD046H17 1200 34.8 25.4 13.00 11.00

17 HC36 1200 35.0 25.6 13.00 11.00

– HD36 1200 36.0 26.6 13.00 11.00

14,17,21 FC/MC/PC/UC36 1200 34.5 25.2 13.00 11.00

17 G*FA042S17 1200 34.5 25.2 13.00 11.00

17 G*FD036H17 1200 34.5 25.2 13.00 11.00

21 G*FD036H21 1200 34.5 25.2 13.00 11.00

21 G*FD042H21 1200 34.7 25.2 13.00 11.00

17 G*FD046H17 1200 34.5 25.2 13.00 11.00

17 HC36 1200 34.7 25.4 13.00 11.00

– HD36 1200 35.7 26.4 13.00 11.00

COIL

MODEL

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

254892-YTG-C-0606

1

SEER

EER

Unitary Products Group 11

Page 12

254892-YTG-C-0606

COOLING CAPACITY - Upflow, Downflow & Horizontal Furnaces and Coils (Continued)

FURNACE**

UNIT MODEL

H2RD042S06

H1RD042S(25,46)

H2RD048S06

H1RD048S(25,46)

H2RD060S06

H1RD060S(25,46)

1. Requires a 2FD06700224 Blower Time Delay unless a standard furnace is equipped with one.

** Refer to Quick Selection Chart for specific furnace match-up.

CFM RANGE

(MIN.-MAX.)

1200

1600

1200

1600

1400

1800

1400

1800

1600

2000

1600

2000

W

17,21 FC/MC/PC/UC42 1400 40.5 29.6 13.00 11.00

21,24 FC/MC/PC/UC48 1400 41.0 30.2 13.00 11.00

17 G*FA042S17 1400 40.5 29.6 13.00 11.00

21 G*FA048S21 1400 41.0 29.6 13.00 11.00

21 G*FD042H21 1400 40.5 29.6 13.00 11.00

17 G*FD046H17 1400 40.5 29.6 13.00 11.00

21,24 G*FD048H21,24 1400 41.0 30.2 13.00 11.00

21 HC48 1400 41.0 29.9 13.00 11.00

– HD48 1400 41.5 29.5 13.00 11.00

17,21 FC/MC/PC/UC42 1400 39.5 28.9 13.00 11.00

21,24 FC/MC/PC/UC48 1400 40.0 29.5 13.00 11.00

17 G*FA042S17 1400 39.5 28.9 13.00 11.00

21 G*FA048S21 1400 40.0 28.9 13.00 11.00

21 G*FD042H21 1400 39.5 28.9 13.00 11.00

17 G*FD046H17 1400 39.5 28.9 13.00 11.00

21,24 G*FD048H21,24 1400 40.0 29.5 13.00 11.00

21 HC48 1400 40.0 29.2 13.00 11.00

- HD48 1400 40.5 28.8 13.00 11.00

21,24 FC/MC/PC/UC48 1600 47.0 35.1 13.00 11.00

21,24 G*FD048H21,24 1600 47.0 35.1 13.00 11.00

21 HC48 1600 46.5 35.0 13.00 11.00

– HD48 1600 47.0 34.8 13.00 11.00

21,24 FC/MC/PC/UC48 1600 46.0 34.4 13.00 11.00

21,24 G*FA048S21 1600 46.0 34.4 13.00 11.00

21,24 G*FD048H21,24 1600 46.0 34.4 13.00 11.00

21 HC48 1600 45.5 34.3 13.00 11.00

– HD48 1600 46.0 34.1 13.00 11.00

21,24 FC/MC/PC/UC60 1800 55.0 39.6 13.00 11.00

21,24 G*FA060S21,24 1800 55.0 39.6 13.00 11.00

24 G*FD060H24 1800 55.0 39.6 13.00 11.00

24 G*FD061H24 1800 55.5 39.6 13.00 11.00

24 MC61 1800 55.5 40.0 13.00 11.00

24 HC60 1800 55.0 39.6 13.00 11.00

– HD60 1800 55.0 39.9 13.00 11.00

21,24 FC/MC/PC/UC60 1800 54.5 39.3 13.00 11.00

21,24 G*FA060S21,24 1800 54.5 39.3 13.00 11.00

24 G*FD060H24 1800 54.5 39.3 13.00 11.00

24 G*FD061H24 1800 54.5 39.3 13.00 11.00

24 MC61 1800 55.0 39.7 13.00 11.00

24 HC60 1800 54.5 39.3 13.00 11.00

– HD60 1800 54.5 39.6 13.00 11.00

COIL

MODEL

RATED

CFM

TOTAL SENS.

COOLING

NET MBH

SEER

1

EER

12 Unitary Products Group

Page 13

COOLING CAPACITY - With Variable Speed Furnaces

UNIT MODEL

H2RD018S06

H2RD024S06

H2RD030S06

For Notes See Page15.

VARIABLE SPEED

FURNACE MODEL

1 PH 13 SEER AC WITH VARIABLE SPEED FURNACES

PV8*A12 FC/MC/PC18A 14 600 17.8 11.9 14.00 11.50

PV9*A12 FC/MC/PC18A 14 600 17.8 11.8 14.00 11.50

P(C,V)9*B12 FC/MC/PC18B 17 600 17.8 11.8 14.00 11.50

PV8*A12 FC/MC/PC24A 14 600 18.0 12.1 14.00 11.50

PV9*A12 FC/MC/PC24A 14 600 18.0 12.0 14.00 11.50

P(C,V)9*B12 FC/MC/PC24B 17 600 18.0 12.0 14.00 11.50

PV8*A12 HC24 14 600 17.8 11.9 14.00 11.50

PV9*A12 HC24 14 600 17.8 11.8 14.00 11.50

PV8*A12 HD24 – 600 18.0 12.2 14.00 11.50

PV9*A12 HD24 – 600 18.0 12.2 14.00 11.50

PV8*A12 FC/MC/PC24A 14 800 23.2 16.7 14.00 11.50

PV8*B16 FC/MC/PC24B 17 800 23.4 16.8 14.00 11.50

PV9*A12 FC/MC/PC24A 14 800 23.2 16.7 14.00 11.50

P(C,V)9*B12 FC/MC/PC24B 17 800 23.2 16.7 14.00 11.50

PV8*A12 FC/MC/PC30A 14 800 23.2 16.8 14.00 11.50

PV8*B16 FC/MC/PC30B 17 800 23.4 16.8 14.00 11.50

PV9*A12 FC/MC/PC30A 14 800 23.2 16.8 14.00 11.50

P(C,V)9*B12 FC/MC/PC30B 17 800 23.2 16.8 14.00 11.50

PV8*A12 HC30 14 800 23.6 17.1 14.00 11.50

PV9*A12 HC30 14 800 23.6 17.0 14.00 11.50

PV8*A12 HD24 – 800 23.8 17.3 14.00 11.50

PV9*A12 HD24 – 800 23.8 17.3 14.00 11.50

PV8*A12 FC/MC/PC30A 14 1000 30.0 21.1 13.50 11.00

PV8*B16 FC/MC/PC30B 17 1000 30.0 21.4 14.00 11.50

PV9*A12 FC/MC/PC30A 14 1000 29.8 21.1 13.50 11.00

P(C,V)9*B12 FC/MC/PC30B 17 1000 30.0 21.1 13.50 11.00

PV8*A12 FC/MC/PC36A 14 1000 30.0 21.5 13.50 11.00

PV8*B16 FC/MC/PC36B 17 1000 30.0 21.6 14.00 11.50

PV8*C16 FC/MC/PC36C 21 1000 30.0 21.6 14.00 11.50

PV8*C20 FC/MC/PC36C 21 1000 30.0 21.6 14.00 11.50

PV9*A12 FC/MC/PC36A 14 1000 30.0 21.5 13.50 11.00

P(C,V)9*B12 FC/MC/PC36B 17 1000 30.0 21.5 13.75 11.00

P(C,V)9*C16 FC/MC/PC36C 21 1000 30.0 21.5 14.00 11.50

P(C,V)9*C20 FC/MC/PC36C 21 1000 30.0 21.5 14.00 11.50

PV8*A12 HC30 14 1000 30.0 21.7 14.00 11.50

PV9*A12 HC30 14 1000 30.0 21.7 14.00 11.50

PV8*B16 HC36 17 1000 30.0 22.1 14.00 11.50

P(C,V)9*B12 HC36 17 1000 30.0 22.0 14.00 11.50

PV8*A12 HD36 – 1000 30.0 22.1 14.00 11.50

PV8*B16 HD36 – 1000 30.0 22.2 14.00 11.50

PV8*C16 HD36 – 1000 30.0 22.3 14.00 11.50

PV8*C20 HD36 – 1000 30.0 22.3 14.00 11.50

PV9*A12 HD36 – 1000 30.0 22.1 14.00 11.50

P(C,V)9*B12 HD36 – 1000 30.0 22.2 14.00 11.50

P(C,V)9*C16 HD36 – 1000 30.0 22.2 14.00 11.50

P(C,V)9*C20 HD36 – 1000 30.0 22.2 14.00 11.50

COIL

MODEL

1

254892-YTG-C-0606

COOLING

W

RATED

CFM

NET MBH

TOTAL SENS.

2

SEER EER

Unitary Products Group 13

Page 14

254892-YTG-C-0606

COOLING CAP ACITY - With Variable Speed Furnaces (Continued)

COOLING

NET MBH

2

SEER EER

UNIT MODEL

H2RD036S06

H2RD042S06

For Notes See Page15.

VARIABLE SPEED

FURNACE MODEL

1 PH 13 SEER AC WITH VARIABLE SPEED FURNACES

PV8*A12 FC/MC/PC36A 14 1200 35.0 25.4 13.00 11.00

PV8*B16 FC/MC/PC36B 17 1200 35.2 25.6 13.75 11.00

PV8*C16 FC/MC/PC36C 21 1200 35.2 25.6 14.00 11.50

PV8*C20 FC/MC/PC36C 21 1200 35.2 25.6 14.00 11.50

PV9*A12 FC/MC/PC36A 14 1200 34.8 25.4 13.00 11.00

P(C,V)9*B12 FC/MC/PC36B 17 1200 35.0 25.5 13.25 11.00

P(C,V)9*C16 FC/MC/PC36C 21 1200 35.2 25.6 13.75 11.00

P(C,V)9*C20 FC/MC/PC36C 21 1200 35.2 25.6 14.00 11.50

PV8*B16 G1FA048S17 17 1200 34.6 25.1 13.00 11.00

PV8*B16 G2FD036(S,H)17 17 1200 34.6 25.1 13.00 11.00

P(C,V)9*B12 G2FD036(S,H)17 17 1200 34.6 25.1 13.00 11.00

PV8*C16 G2FD036(S,H)21 21 1200 34.6 25.1 13.00 11.00

PV8*C20 G2FD036(S,H)21 21 1200 34.6 25.1 13.00 11.00

P(C,V)9*C16 G2FD036(S,H)21 21 1200 34.6 25.1 13.00 11.00

P(C,V)9*C20 G2FD036(S,H)21 21 1200 34.6 25.1 13.00 11.00

PV8*B16 G2FD046(S,H)17 17 1200 34.6 25.1 13.00 11.00

PV8*B16 HC36 17 1200 36.0 26.6 14.00 11.50

P(C,V)9*B12 HC36 17 1200 36.0 26.5 13.75 11.00

PV8*A12 HD36 – 1200 36.0 26.7 13.50 11.00

PV8*B16 HD36 – 1200 36.0 26.8 14.00 11.50

PV8*C16 HD36 – 1200 36.0 26.8 14.00 11.50

PV8*C20 HD36 – 1200 36.0 26.8 14.00 11.50

PV9*A12 HD36 – 1200 36.0 26.7 13.50 11.00

P(C,V)9*B12 HD36 – 1200 36.0 26.7 14.00 11.50

P(C,V)9*C16 HD36 – 1200 36.0 26.8 14.00 11.50

P(C,V)9*C20 HD36 – 1200 36.0 26.8 14.00 11.50

PV8*B16 FC/MC/PC42B 17 1400 40.5 29.7 13.50 11.00

PV8*C16 FC/MC/PC42C 21 1400 40.5 29.7 13.50 11.00

PV8*C20 FC/MC/PC42C 21 1400 40.5 29.7 13.50 11.00

PV8*C16 FC/MC/PC48C 21 1400 41.5 30.1 13.75 11.00

PV8*C20 FC/MC/PC48C 21 1400 41.5 30.1 14.00 11.50

P(C,V)9*C16 FC/MC/PC48C 21 1400 41.5 30.1 13.50 11.00

P(C,V)9*C20 FC/MC/PC48C 21 1400 41.5 30.1 13.75 11.00

P(C,V)9*D20 FC/MC/PC48D 24 1400 41.5 30.1 13.50 11.00

PV8*C16 HC48 21 1400 41.0 30.0 13.50 11.00

PV8*C20 HC48 21 1400 41.5 30.1 13.75 11.00

P(C,V)9*C16 HC48 21 1400 41.0 30.0 13.50 11.00

P(C,V)9*C20 HC48 21 1400 41.0 30.1 13.75 11.00

PV8*C16 HD48 – 1400 42.0 30.6 14.00 11.50

PV8*C20 HD48 – 1400 42.0 30.6 14.00 11.50

P(C,V)9*C16 HD48 – 1400 42.0 30.5 13.75 11.00

P(C,V)9*C20 HD48 – 1400 42.0 30.6 14.00 11.50

P(C,V)9*D20 HD48 – 1400 42.0 30.5 14.00 11.50

COIL

MODEL

1

W

RATED

CFM

TOTAL SENS.

14 Unitary Products Group

Page 15

COOLING CAP ACITY - With Variable Speed Furnaces (Continued)

UNIT MODEL

H2RD048S06

H2RD060S06

1. MC coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Variable speed furnaces have B.O.D (Blower on Delay) standard.

VARIABLE SPEED

FURNACE MODEL

1 PH 13 SEER AC WITH VARIABLE SPEED FURNACES

PV8*C16 FC/MC/PC48C 21 1500 46.5 34.2 13.00 11.00

PV8*C20 FC/MC/PC48C 21 1600 47.0 35.2 13.00 11.00

P(C,V)9*C16 FC/MC/PC48C 21 1600 47.0 35.2 13.00 11.00

P(C,V)9*C20 FC/MC/PC48C 21 1600 47.0 35.2 13.00 11.00

P(C,V)9*D20 FC/MC/PC48D 24 1600 47.0 35.2 13.25 11.00

PV8*C16 HC48 21 1500 46.5 33.9 13.00 11.00

PV8*C20 HC48 21 1600 47.0 35.0 13.00 11.00

P(C,V)9*C16 HC48 21 1600 46.5 35.0 13.00 11.00

P(C,V)9*C20 HC48 21 1600 46.5 35.0 13.00 11.00

PV8*C16 HD48 – 1500 47.0 34.6 13.25 11.00

PV8*C20 HD48 – 1600 47.0 35.8 13.50 11.00

P(C,V)9*C16 HD48 – 1600 47.0 35.7 13.00 11.00

P(C,V)9*C20 HD48 – 1600 47.0 35.7 13.25 11.00

P(C,V)9*D20 HD48 – 1600 47.0 35.8 13.50 11.00

PV8*C20 FC/PC60C 21 1730 54.0 38.9 13.00 11.00

P(C,V)9*C20 FC/PC60C 21 1620 54.5 37.9 13.00 11.00

P(C,V)9*D20 FC/MC/PC60D 24 1620 54.5 37.9 13.25 11.00

PV8*C20 MC61 24 1730 55.0 39.3 13.00 11.00

P(C,V)9*C20 MC61 24 1620 54.0 38.0 13.00 11.00

P(C,V)9*D20 MC61 24 1620 55.0 38.1 13.25 11.00

PV8*C20 HC60 24 1730 54.0 38.9 13.00 11.00

P(C,V)9*D20 HC60 24 1620 54.5 37.9 13.25 11.00

PV8*C20 HD60 – 1730 55.0 39.1 13.00 11.00

P(C,V)9*C20 HD60 – 1620 54.5 38.0 13.00 11.00

P(C,V)9*D20 HD60 – 1620 54.0 38.1 13.25 11.00

COIL

MODEL

1

W

RATED

CFM

NET MBH

TOTAL SENS.

2

254892-YTG-C-0606

COOLING

SEER EER

Unitary Products Group 15

Page 16

254892-YTG-C-0606

ACCESSORIES

Refer to Price Manual for specific model numbers.

HARD START KIT - Provides increased starting torque for

areas with low voltage.

COMPRESSOR BLANKET - Designed to further reduce the

normal compressor operating sound. Refer to price pages for

specific match-ups.

OFF CYCLE TIMER DELAY - Provides a 5-minute off cycle

to prevent rapid recycling of the compressor.

ROOM THERMOSTATS - A wide selection of compatible

thermosets are available to provide optimum performance

and features for any installation.

1H/1C, manual change-over electronic non-programmable

thermostat.

TYPICAL INSTALLATION

MINIMUM 24” SERVICE ACCESS

60” OVERHEAD

CLEARANCE

10” CLEARANCE

COIL AREA

CLEARANCE ON ONE SIDE

1H/1C, auto/manual changeover, electronic programmable,

deluxe 7-day, thermostat.

1H/1C, auto/manual changeover, electronic programmable.

* For the most current accessory information, refer to the

price book or consult factory.

SOUND POWER RATINGS*

UNIT MODEL (dBA)

018 75

024 74

030 75

036 75

042 76

048 76

060 76

* Rated in accordance with ARI 270-95 Standards.

WEATHERPROOF

DISCONNECT

SWITCH

THERMOSTAT

TO FURNACE OR

AIR HANDLER

TERMINAL BLOCK

NEC CLASS 1 WIRING

NEC CLASS 2 WIRING

TO INDOOR COIL

NOTE: ALL OUTDOOR WIRING

MUST BE WEATHERPROOF.

TYPICAL FIELD WIRING - 1 Phase Application

ALL FIELD WIRING TO BE IN ACCORDANCE WITH ELECTRIC CODE (NEC) AND/OR LOCAL CODES

GND.

LUG

POWER WIRING

208/230-1-60

CONTACTOR

TERMINALS

COIL

CONDENSING UNIT

ALL OUTDOOR WIRING MUST BE WEATHERPROOF. USE COPPER CONDUCTORS ONLY.

24 VOLT CONTROL WIRING

MINIMUM 18 GA. WIRE

(NEC CLASS 2)

SEAL OPENING(S) WITH

PERMAGUM OR EQUIVALENT

CONTROL ACCESS PANEL

POWER WIRING

CONTROL WIRING

FACTORY WIRING

FURNACE OR AIR HANDLER TERMINAL BLOCK

CYRGW

*

TERMINAL W IS ONLY

REQUIRED ON SYSTEMS

WITH HEAT.

R

Y

ROOM THERMOSTAT

*

GW

16 Unitary Products Group

Page 17

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD018S06

INDOOR COIL MODEL NO. FC/MC/PC/UC18

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA08B MC18B 1.00 1.00 1.00

MA08B MC24B 1.01 1.02 1.01

MA08B G*FD024H17 1.00 1.00 1.00

MA08B G*FD030H17 1.01 1.02 1.01

AHP18 – 1.01 1.05 1.01

AHP24 – 1.02 1.07 1.02

F*FP024 – 1.00 1.04 1.00

MV12B FC/MC18B 1.01 1.00 0.97

MV12B FC/MC24B 1.03 1.01 0.98

AV24 – 1.03 1.01 0.98

– FC/MC/PC/UC24 1.01 1.02 1.01

– HC24 1.00 1.00 1.00

– HD24 1.03 1.03 1.03

– G*FA030S14 1.00 1.00 1.00

– G*FA036S14 1.01 1.02 1.01

– G*FA036S17,21 1.00 1.00 1.00

– G*FD024H14,17 1.00 1.00 1.00

– G*FD030H17 1.00 1.00 1.00

– G*FD035H14 1.00 1.00 1.00

IDCFM 450 600 750

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 15.4 17.8 18.0 21.0 22.6 17.3 18.9 18.8 21.1 22.6 19.2 19.9 19.5 21.2 22.7

S.C. 15.1 13.5 11.8 12.2 9.6 17.0 15.8 13.2 13.3 10.0 18.9 18.2 14.5 14.4 10.5

KW 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

T.C. 14.6 16.8 16.8 19.4 21.2 16.3 17.6 17.4 19.6 21.3 17.9 18.4 18.0 19.8 21.4

S.C. 14.4 13.0 11.1 11.5 9.1 16.0 15.1 12.5 12.6 9.5 17.6 17.2 13.8 13.6 10.0

KW 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1 1.1

T.C. 13.9 15.8 15.5 17.9 19.9 15.3 16.4 16.0 18.1 19.9 16.6 17.0 16.6 18.3 20.0

S.C. 13.7 12.5 10.5 10.7 8.6 15.0 14.3 11.7 11.8 9.0 16.4 16.1 13.0 12.9 9.4

KW 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2

T.C. 13.2 14.7 14.2 16.4 18.5 14.3 15.1 14.7 17.5 18.6 15.3 15.5 15.1 16.8 18.7

S.C. 13.0 12.0 9.8 9.9 8.1 14.1 13.6 11.0 11.7 8.5 15.1 15.1 12.3 12.1 8.9

KW 1.2 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3 1.3

T.C. 12.3 13.5 13.1 15.2 17.1 13.2 13.9 13.4 15.3 17.1 14.1 14.2 13.8 15.4 17.1

S.C. 12.1 11.5 9.3 9.5 7.5 13.0 12.7 10.5 10.5 8.0 13.9 13.9 11.7 11.6 8.4

KW 1.3 1.3 1.3 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4 1.4

T.C. 11.4 12.3 12.0 14.0 15.7 12.1 12.7 12.2 14.0 15.6 12.8 13.0 12.5 13.9 15.5

S.C. 11.2 11.0 8.8 9.1 7.0 11.9 11.9 10.0 10.1 7.4 12.6 12.7 11.2 11.1 7.8

KW 1.4 1.4 1.4 1.4 1.5 1.4 1.4 1.4 1.5 1.5 1.5 1.5 1.4 1.5 1.5

T.C. 10.5 11.1 10.9 12.8 14.3 11.0 11.4 11.0 12.6 14.1 11.6 11.7 11.2 12.5 13.9

S.C. 10.3 10.5 8.4 8.6 6.5 10.9 11.1 9.5 9.6 6.9 11.4 11.6 10.7 10.6 7.3

KW 1.5 1.5 1.5 1.5 1.6 1.5 1.5 1.5 1.5 1.6 1.6 1.6 1.5 1.6 1.6

Variable Speed

Furnace

PV8*A12 FC/MC/PC18A 1.02 1.02 0.97

PV9*A12 FC/MC/PC18A 1.02 1.01 0.97

P(C,V)9*B12 FC/MC/PC18B 1.02 1.01 0.97

PV8*A12 FC/MC/PC24A 1.03 1.03 0.98

PV9*A12 FC/MC/PC24A 1.03 1.03 0.98

P(C,V)9*B12 FC/MC/PC24B 1.03 1.03 0.98

PV8*A12 HC24 1.02 1.02 0.97

PV9*A12 HC24 1.02 1.01 0.97

PV8*A12 HD24 1.03 1.04 0.98

PV9*A12 HD24 1.03 1.04 0.98

Coil T.C. S.C. KW

Unitary Products Group 17

Page 18

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD024S06

INDOOR COIL MODEL NO. FC/MC/PC/UC24

CONDENSING

ENTERING AIR

TEMPERATURE

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA08B MC24B 1.00 1.00 1.00

MA08B MC30B 1.00 1.00 1.00

MA08B G*FD024H17 1.00 1.00 1.00

MA08B G*FD030H17 1.00 1.00 1.00

AHP24 – 1.02 1.01 1.00

AHP30 – 1.02 1.02 1.03

F*FP024 – 1.02 1.01 1.00

F*FP030 – 1.02 1.01 1.00

MV12B FC/MC24B 1.02 0.99 0.97

MV12B FC/MC30B 1.02 0.99 0.97

AV24 – 1.02 0.99 0.97

– FC/MC/PC/UC30 1.00 1.00 1.00

– HC30 1.02 1.02 1.02

– HD24 1.03 1.04 1.02

– G*FA030S14 1.00 1.00 1.00

– G*FA036S14 1.00 1.00 1.00

– G*FA036S17,21 1.00 1.00 1.00

– G*FD024H14,17 1.00 1.00 1.00

– G*FD030H17 1.00 1.00 1.00

– G*FD035H14 1.00 1.00 1.00

– G*FD036H17 1.00 1.00 1.00

IDCFM 600 800 1000

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 21.8 23.8 23.8 25.7 28.3 24.1 25.1 25.1 26.8 29.8 21.8 26.5 26.5 28.0 31.3

S.C. 21.8 19.5 15.2 16.6 13.6 24.1 23.0 17.6 19.1 15.6 20.4 26.4 19.9 21.6 17.5

KW 1.60 1.62 1.62 1.65 1.67 1.70 1.71 1.71 1.73 1.75 1.60 1.79 1.79 1.81 1.84

T.C. 20.4 21.9 21.9 24.2 26.4 21.4 23.6 23.6 25.3 27.7 22.5 25.3 25.3 26.3 29.0

S.C. 20.4 18.6 14.2 16.1 13.0 21.4 21.8 16.4 18.7 14.9 22.1 25.0 18.5 21.3 16.8

KW 1.71 1.72 1.72 1.77 1.79 1.77 1.82 1.82 1.85 1.88 1.83 1.91 1.91 1.94 1.97

T.C. 19.0 20.0 20.0 22.7 24.5 21.6 22.1 22.1 23.8 25.7 23.2 24.1 24.1 24.7 26.8

S.C. 18.7 17.6 13.3 15.5 12.3 21.2 20.6 15.2 16.6 14.2 23.2 23.6 17.1 21.0 16.0

KW 1.81 1.82 1.82 1.88 1.92 1.93 1.93 1.93 1.98 2.01 2.05 2.04 2.04 2.06 2.11

T.C. 17.6 18.1 18.1 21.2 22.6 20.8 20.5 20.5 22.1 23.6 23.9 22.9 22.9 23.1 24.6

S.C. 17.6 16.7 12.3 15.0 11.7 20.3 19.4 14.0 17.8 13.5 23.9 22.2 15.7 20.7 15.3

KW 1.92 1.92 1.92 2.00 2.04 2.09 2.04 2.04 2.09 2.14 2.27 2.16 2.16 2.19 2.25

T.C. 19.3 17.0 17.0 19.3 21.1 20.3 18.8 18.8 20.2 22.0 21.2 20.7 20.7 21.1 22.9

S.C. 19.316.011.714.211.220.318.212.816.813.121.220.514.019.414.9

KW 2.10 2.01 2.01 2.10 2.16 2.21 2.14 2.14 2.20 2.26 2.32 2.28 2.28 2.30 2.37

T.C. 15.4 15.8 15.8 17.4 19.6 17.0 17.2 17.2 18.3 20.4 18.5 18.5 18.5 19.2 21.2

S.C. 15.4 15.4 11.1 13.5 10.7 17.0 17.1 11.7 15.8 12.7 18.5 18.5 12.2 18.0 14.6

KW 2.09 2.09 2.09 2.19 2.28 2.24 2.24 2.24 2.30 2.39 2.37 2.39 2.39 2.41 2.49

Variable Speed

Furnace

PV8*A12 FC/MC/PC24A 1.01 1.01 0.96

PV9*A12 FC/MC/PC/24A 1.01 1.01 0.97

PV8*B16 FC/MC/PC/24B 1.01 1.01 0.96

P(C,V)9*B12 FC/MC/PC24B 1.01 1.01 0.96

PV8*A12 FC/MC/PC30A 1.01 1.01 0.96

PV9*A12 FC/MC/PC30A 1.01 1.01 0.97

PV8*B16 FC/MC/PC30B 1.01 1.01 0.96

P(C,V)9*B12 FC/MC/PC30B 1.01 1.01 0.96

PV8*A12 HC30 1.02 1.03 0.98

PV9*A12 HC30 1.02 1.02 0.98

PV8*A12 HD24 1.04 1.04 0.99

PV9*A12 HD24 1.04 1.04 0.99

Coil T.C. S.C. KW

18 Unitary Products Group

Page 19

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD030S06 , H1RD030S(25,46) **

INDOOR COIL MODEL NO. FC/MC/PC/UC30

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

** For three-phase, decrease T.C. by 0.6 and S.C. by 0.3.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

IDCFM 800 1000 1200

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 27.0 31.8 30.1 33.7 35.6 29.0 33.4 31.3 35.1 36.7 31.1 35.0 32.6 36.5 37.7

S.C. 26.9 24.7 20.6 21.2 16.0 29.0 27.7 22.9 23.4 17.7 31.1 30.7 25.2 25.6 19.5

KW 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8 1.8

T.C. 25.9 30.3 28.7 32.1 33.6 27.9 31.9 29.9 33.4 34.5 29.8 33.5 31.1 34.7 35.4

S.C. 25.9 24.2 20.0 20.5 15.6 27.8 27.0 22.3 22.7 17.2 29.8 29.8 24.5 24.9 18.8

KW 1.9 1.9 1.9 2.0 2.0 1.9 1.9 1.9 2.0 2.0 2.0 1.9 2.0 2.0 2.0

T.C. 24.9 28.8 27.2 30.4 31.7 26.7 30.4 28.4 31.7 32.4 28.6 32.0 29.6 32.9 33.1

S.C. 24.9 23.7 19.5 19.7 15.2 26.7 26.3 21.7 21.9 16.7 28.5 28.9 23.9 24.1 18.1

KW 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.1 2.2 2.1 2.1 2.1 2.1 2.2

T.C. 23.8 27.4 25.8 28.7 29.7 25.6 28.9 26.9 30.0 30.2 27.3 30.5 28.1 31.2 30.7

S.C. 23.8 23.2 18.9 18.9 14.8 25.5 25.6 21.1 21.2 16.2 27.3 28.1 23.3 23.4 17.5

KW 2.2 2.2 2.2 2.3 2.3 2.2 2.2 2.2 2.3 2.3 2.3 2.3 2.2 2.3 2.3

T.C. 22.8 25.9 24.3 27.1 27.8 24.4 27.5 25.3 28.2 28.2 26.0 29.1 26.4 29.3 28.5

S.C. 22.7 22.4 18.3 18.3 14.1 24.3 24.5 20.4 20.5 15.4 25.9 26.5 22.6 22.6 16.6

KW 2.4 2.4 2.4 2.4 2.5 2.4 2.4 2.4 2.4 2.5 2.4 2.4 2.4 2.5 2.5

T.C. 21.8 24.5 22.8 25.5 25.9 23.2 26.1 23.7 26.5 26.1 24.7 27.8 24.7 27.4 26.4

S.C. 21.7 21.6 17.6 17.7 13.5 23.2 23.3 19.7 19.8 14.6 24.7 25.0 21.8 21.9 15.8

KW 2.5 2.5 2.5 2.6 2.6 2.6 2.5 2.5 2.6 2.7 2.6 2.6 2.5 2.6 2.7

T.C. 20.8 23.0 21.3 23.9 24.0 22.1 24.8 22.2 24.7 24.1 23.4 26.5 23.0 25.6 24.3

S.C. 20.6 20.9 17.0 17.1 12.8 22.0 22.2 19.0 19.1 13.9 23.4 23.5 21.1 21.1 15.1

KW 2.7 2.7 2.6 2.7 2.8 2.7 2.7 2.7 2.7 2.8 2.8 2.7 2.7 2.8 2.8

Air Handler Coil T.C. S.C. KW

MA12B MC30B 1.00 1.00 1.00

MA12B MC36B 1.00 1.01 1.00

MA12B G*FD036H17 1.00 1.01 1.00

AHP30 – 1.01 1.04 1.01

AHP36 – 1.01 1.08 1.01

F*FP036 – 1.00 1.01 1.00

MV12B* FC/MC30B 1.01 1.00 0.97

MV12B* FC/MC36B 1.01 1.01 0.97

MV16C* FC/MC36C 1.01 1.01 0.97

AV36* – 1.01 1.01 0.97

– FC/MC/PC/UC36 1.00 1.01 1.00

– HC30 1.00 1.03 1.00

– HC36 1.01 1.04 1.01

– HD36 1.01 1.05 1.01

– G*FA036S14 1.00 1.00 1.00

– G*FD036H17 1.00 1.00 1.00

– G*FD036H21 1.00 1.00 1.00

* = Single-phase outdoor units only.

Variable Speed

Furnace

PV8*A12 FC/MC/PC30A 1.01 1.00 1.01

PV9*A12 FC/MC/PC30A 1.01 1.02 0.97

PV8*B16 FC/MC/PC30B 1.01 1.00 1.01

P(C,V)9*B12 FC/MC/PC30B 1.01 1.00 1.01

PV8*A12 FC/MC/PC36A 1.01 1.02 1.01

PV9*A12 FC/MC/PC36A 1.01 1.03 0.97

PV8*B16 FC/MC/PC36B 1.01 1.03 0.97

P(C,V)9*B12 FC/MC/PC36B 1.01 1.03 0.97

PV8*C16 FC/MC/PC36C 1.01 1.02 1.01

PV8*C20 FC/MC/PC36C 1.01 1.02 1.01

P(C,V)9*C16 FC/MC/PC36C 1.01 1.02 0.97

P(C,V)9*C20 FC/MC/PC36C 1.01 1.02 0.97

PV8*A12 HC30 1.01 1.03 0.97

PV9*A12 HC30 1.01 1.03 0.97

PV8*B16 HC36 1.01 1.05 0.97

P(C,V)9*B12 HC36 1.01 1.05 0.97

PV8*A12 HD36 1.01 1.05 0.97

PV8*B16 HD36 1.01 1.06 0.97

PV8*C16 HD36 1.01 1.06 0.97

PV8*C20 HD36 1.01 1.06 0.97

PV9*A12 HD36 1.01 1.05 0.97

P(C,V)9*B12 HD36 1.01 1.06 0.97

P(C,V)9*C16 HD36 1.01 1.06 0.97

P(C,V)9*C20 HD36 1.01 1.06 0.97

* = Single-phase outdoor units only.

Coil T.C. S.C. KW

Unitary Products Group 19

Page 20

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD036S06 , H1RD036S(25,46) **

INDOOR COIL MODEL NO. FC/MC/PC/UC36

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

** For three-phase, decrease T.C. by 0.3 and S.C. by 0.2.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA12B FC/MC36B 1.00 1.00 1.00

MA12B G*FD036H17 1.00 1.00 1.00

AHP36 – 1.01 1.07 1.01

AHP42 – 1.01 1.08 1.01

AHP/SHP60 – 1.03 1.05 0.99

F*FP040 – 1.00 1.00 1.00

MV12B* FC/MC36B 1.01 0.98 1.01

MV16C* FC/MC36C 1.01 0.99 0.97

AV36* – 1.01 0.99 0.97

AV/SV48* – 1.03 0.99 1.00

– HC36 1.01 1.01 1.01

– HD36 1.03 1.05 1.03

– G*FA048S17 1.00 1.00 1.00

– G*FA048S21 1.00 1.00 1.00

– G*FD036H17 1.00 1.00 1.00

– G*FD036H21 1.00 1.00 1.00

– G*FD042H21 1.03 1.05 1.03

– G*FD046H17 1.00 1.00 1.00

* = Single-phase outdoor units only.

IDCFM 1000 1200 1400

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 35.0 35.7 34.7 38.9 40.5 37.2 37.2 35.8 40.0 41.4 39.3 38.8 36.9 41.1 42.3

S.C. 32.1 30.0 25.0 25.8 19.7 33.8 32.8 27.5 28.1 21.3 35.6 35.7 29.9 30.4 22.9

KW 2.0 2.0 2.0 2.0 2.1 2.0 2.0 2.0 2.0 2.1 2.0 2.0 2.0 2.0 2.1

T.C. 33.3 34.2 33.1 37.0 38.7 35.6 35.9 34.3 38.1 39.5 38.0 37.6 35.4 39.1 40.4

S.C. 30.5 29.0 24.3 24.9 19.2 32.3 31.7 26.7 27.2 20.7 34.2 34.4 29.1 29.5 22.3

KW 2.2 2.2 2.2 2.2 2.3 2.2 2.2 2.2 2.2 2.3 2.2 2.2 2.2 2.2 2.3

T.C. 31.6 32.6 31.6 35.1 36.8 34.1 34.5 32.8 36.1 37.7 36.6 36.3 34.0 37.1 38.5

S.C. 28.8 28.0 23.5 24.0 18.6 30.8 30.6 25.9 26.4 20.2 32.9 33.2 28.4 28.7 21.8

KW 2.3 2.4 2.4 2.4 2.5 2.4 2.4 2.4 2.4 2.5 2.4 2.4 2.4 2.4 2.5

T.C. 29.9 31.1 30.0 33.2 35.0 32.5 33.1 31.3 34.8 35.8 35.2 35.1 32.5 35.1 36.6

S.C. 27.2 27.0 22.7 23.1 18.0 29.3 29.5 25.2 25.4 19.6 31.5 31.9 27.6 27.9 21.2

KW 2.5 2.5 2.5 2.6 2.7 2.5 2.6 2.6 2.6 2.7 2.6 2.6 2.6 2.6 2.7

T.C. 28.8 29.5 28.1 31.1 32.6 31.0 31.3 29.2 32.0 33.3 33.3 33.2 30.3 33.0 34.0

S.C. 26.1 25.9 21.7 22.2 17.3 27.9 28.0 24.0 24.5 18.8 29.7 30.1 26.3 26.9 20.4

KW 2.7 2.7 2.7 2.8 2.9 2.7 2.8 2.7 2.8 2.9 2.8 2.8 2.8 2.8 2.9

T.C. 27.7 27.9 26.3 29.1 30.4 29.6 29.6 27.2 30.0 30.9 31.5 31.3 28.2 30.9 31.4

S.C. 25.0 24.9 20.7 21.3 16.6 26.5 26.6 22.9 23.6 18.1 28.0 28.4 25.0 25.9 19.6

KW 2.9 2.9 2.9 3.0 3.1 2.9 2.9 2.9 3.0 3.1 3.0 3.0 2.9 3.0 3.1

T.C. 26.6 26.3 24.4 27.0 28.1 28.2 27.9 25.3 27.9 28.4 29.7 29.5 26.1 28.8 28.8

S.C. 24.0 23.8 19.8 20.4 15.9 25.1 25.3 21.7 22.7 17.3 26.2 26.7 23.7 25.0 18.8

KW 3.1 3.1 3.0 3.1 3.3 3.1 3.1 3.1 3.2 3.3 3.2 3.2 3.1 3.2 3.3

Variable Speed

Furnace *

PV8*A12 FC/MC/PC36A 1.01 1.00 1.01

PV9*A12 FC/MC/PC36A 1.00 1.00 1.00

PV8*B16 FC/MC/PC36B 1.01 1.01 1.01

P(C,V)9*B12 FC/MC/PC36B 1.01 1.00 1.01

PV8*C16 FC/MC/PC36C 1.01 1.01 0.97

PV8*C20 FC/MC/PC36C 1.01 1.01 0.97

P(C,V)9*C16 FC/MC/PC36C 1.01 1.01 1.01

P(C,V)9*C20 FC/MC/PC36C 1.01 1.01 0.97

PV8*B16 HC36 1.03 1.05 0.99

P(C,V)9*B12 HC36 1.03 1.04 1.03

PV8*A12 HD36 1.03 1.05 1.03

PV8*B16 HD36 1.03 1.06 0.99

PV8*C16 HD36 1.03 1.06 0.99

PV8*C20 HD36 1.03 1.06 0.99

PV9*A12 HD36 1.03 1.05 1.03

P(C,V)9*B12 HD36 1.03 1.05 0.99

P(C,V)9*C16 HD36 1.03 1.06 0.99

P(C,V)9*C20 HD36 1.03 1.06 0.99

* = Single-phase outdoor units only.

Coil T.C. S.C. KW

20 Unitary Products Group

Page 21

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD042S06 , H1RD042S(25,46) **

INDOOR COIL MODEL NO. FC/MC/PC/UC42

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

** For three-phase, decrease T.C. by 1.0 and S.C. by 0.7.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA12C MC42C 1.00 1.00 1.00

MA14D MC42D 1.00 1.00 1.00

MA12C MC48C 1.01 1.02 1.01

MA14D MC48D 1.01 1.02 1.01

MA12C G*FD042H21 1.00 1.00 1.00

MA12C G*FD048H21 1.01 1.02 1.01

AHP42 – 1.01 1.05 1.01

AHP/SHP48 – 1.04 1.04 1.04

AHP/SHP60 – 1.00 1.12 0.96

F*FP048 – 1.01 1.05 1.01

MV16C* FC/MC42C 1.00 0.98 1.00

MV16C* FC/MC48C 1.02 1.00 0.98

MV20D* FC/MC48D 1.02 1.01 0.98

AV/SV48* – 1.00 0.98 1.00

– FC/MC/PC/UC48 1.01 1.02 1.01

– HC48 1.01 1.01 1.01

– HD48 1.02 1.00 1.02

– G*FA048S17 1.00 1.00 1.00

– G*FA048S21 1.01 1.02 1.01

– G*FD042H21 1.00 1.00 1.00

– G*FD046H17 1.00 1.00 1.00

– G*FD048H21,24 1.01 1.02 1.01

* = Single-phase outdoor units only.

IDCFM 1200 1400 1600

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 39.6 44.0 42.6 46.7 50.0 41.5 45.0 43.4 47.6 50.4 43.4 46.0 44.3 48.5 50.8

S.C. 39.3 37.3 30.7 31.1 23.6 41.0 39.7 33.1 33.3 24.7 42.7 42.2 35.5 35.5 25.7

KW 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3

T.C. 38.0 41.8 40.3 44.4 47.2 40.0 42.9 41.1 45.2 47.7 41.9 43.9 41.9 46.0 48.1

S.C. 37.6 36.1 29.8 30.0 22.7 39.3 38.5 32.0 32.2 23.8 40.9 40.8 34.2 34.4 24.8

KW 2.5 2.5 2.5 2.5 2.6 2.5 2.5 2.5 2.5 2.6 2.5 2.5 2.5 2.5 2.6

T.C. 36.4 39.6 38.0 42.1 44.4 38.4 40.7 38.7 42.8 44.9 40.4 41.9 39.4 43.4 45.4

S.C. 36.0 34.9 28.8 28.9 21.8 37.6 37.2 30.9 31.1 22.9 39.2 39.5 33.0 33.4 24.0

KW 2.7 2.7 2.7 2.7 2.8 2.7 2.7 2.7 2.7 2.8 2.7 2.7 2.7 2.8 2.8

T.C. 34.7 37.4 35.7 39.8 41.6 36.9 38.6 36.3 40.5 42.2 39.0 39.8 36.9 40.9 42.8

S.C. 34.3 33.8 27.8 27.8 20.8 35.9 36.0 29.8 29.6 22.0 37.4 38.2 31.7 32.3 23.1

KW 2.9 2.9 2.9 3.0 3.1 2.9 2.9 2.9 3.0 3.1 2.9 2.9 2.9 3.0 3.1

T.C. 33.3 35.6 33.5 37.4 39.0 35.2 36.7 34.1 37.9 39.4 37.2 37.7 34.7 38.4 39.8

S.C. 32.1 32.6 26.9 26.9 19.8 33.8 34.5 28.8 29.0 21.0 35.6 36.3 30.8 31.2 22.2

KW 3.1 3.1 3.1 3.2 3.3 3.1 3.1 3.1 3.2 3.3 3.2 3.2 3.1 3.2 3.3

T.C. 31.9 33.8 31.4 35.1 36.4 33.6 34.7 31.9 35.6 36.6 35.4 35.7 32.5 36.0 36.8

S.C. 31.4 31.5 26.0 26.0 18.9 32.6 33.0 27.9 28.0 20.1 33.8 34.5 29.8 30.1 21.3

KW 3.3 3.3 3.3 3.4 3.5 3.4 3.4 3.3 3.4 3.5 3.4 3.4 3.4 3.4 3.6

T.C. 30.5 32.0 29.2 32.8 33.9 32.1 32.8 29.8 33.2 33.9 33.6 33.7 30.3 33.6 33.9

S.C. 30.0 30.4 25.2 25.1 17.9 31.0 31.5 27.0 27.0 19.1 32.1 32.6 28.8 28.9 20.4

KW 3.5 3.5 3.5 3.6 3.8 3.6 3.6 3.5 3.6 3.8 3.6 3.6 3.6 3.7 3.8

Variable Speed

Furnace

PV8*B16 FC/MC/PC42B 1.00 1.00 1.00

PV8*C16 FC/MC/PC42C 1.00 1.00 1.00

PV8*C20 FC/MC/PC42C 1.00 1.00 1.00

PV8*C16 FC/MC/PC48C 1.02 1.02 1.02

PV8*C20 FC/MC/PC48C 1.02 1.02 0.98

P(C,V)9*C16 FC/MC/PC48C 1.02 1.02 1.02

P(C,V)9*C20 FC/MC/PC48C 1.02 1.02 1.02

P(C,V)9*D20 FC/MC/PC48D 1.02 1.02 1.02

PV8*C16 HC48 1.01 1.01 1.01

PV8*C20 HC48 1.02 1.02 1.02

P(C,V)9*C16 HC48 1.01 1.01 1.01

P(C,V)9*C20 HC48 1.01 1.02 1.01

PV8*C16 HD48 1.04 1.03 0.99

PV8*C20 HD48 1.04 1.03 0.99

P(C,V)9*C16 HD48 1.04 1.03 1.04

P(C,V)9*C20 HD48 1.04 1.03 0.99

P(C,V)9*D20 HD48 1.04 1.03 0.99

* = Single-phase outdoor units only.

Coil T.C. S.C. KW

Unitary Products Group 21

Page 22

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD048S06, H1RD048S(25,46) **

INDOOR COIL MODEL NO. FC/MC/PC/UC48

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

** For three-phase, decrease T.C. by 1.0 and S.C. by 0.7.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA12C MC48C 1.01 1.02 1.01

MA20D MC48D 1.00 1.00 1.00

MA12C G*FD048H21 1.01 1.02 1.01

MA20D G*FD048H24 1.00 1.00 1.00

AHP/SHP48 – 1.00 1.05 1.00

F*FV060* – 1.01 1.05 1.01

AHP/SHP60 – 1.01 1.03 1.01

MV16C* FC/MC48C 1.00 0.99 1.00

MV20D* FC/MC48D 1.00 0.99 1.00

AV/SV48* – 1.00 0.99 1.00

– HC48 0.99 1.00 0.99

– HD48 1.00 0.99 1.00

– G*FD048H21,24 1.00 1.00 1.00

* = Single-phase outdoor units only.

IDCFM 1400 1600 1800

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 45.9 49.0 47.2 51.9 54.5 48.7 50.8 48.2 52.9 54.7 51.5 52.5 49.2 53.9 54.9

S.C. 44.2 41.8 34.6 34.7 27.5 45.8 44.4 36.9 36.9 28.2 47.5 47.0 39.2 39.0 29.0

KW 2.6 2.6 2.6 2.7 2.7 2.6 2.6 2.6 2.7 2.7 2.6 2.6 2.6 2.7 2.7

T.C. 44.6 47.5 45.7 50.3 52.8 47.4 48.9 46.5 51.0 53.0 50.1 50.4 47.4 51.7 53.2

S.C. 42.9 41.2 34.0 34.2 26.9 44.5 43.7 36.2 36.3 28.0 46.1 46.1 38.5 38.4 29.0

KW 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0 3.0

T.C. 43.3 45.9 44.1 48.7 51.1 46.0 47.1 44.9 49.1 51.3 48.8 48.2 45.6 49.6 51.6

S.C. 41.6 40.6 33.4 33.7 26.4 43.1 42.9 35.6 35.7 27.7 44.6 45.2 37.7 37.8 28.9

KW 3.3 3.3 3.3 3.4 3.4 3.3 3.3 3.3 3.4 3.4 3.3 3.3 3.3 3.4 3.4

T.C. 42.0 44.4 42.6 47.1 49.3 44.7 45.2 43.2 47.0 49.7 47.4 46.1 43.8 47.5 50.0

S.C. 40.4 39.9 32.8 33.1 25.9 41.8 42.1 34.9 35.1 27.4 43.1 44.3 37.0 37.2 28.9

KW 3.7 3.7 3.6 3.7 3.7 3.7 3.7 3.7 3.7 3.7 3.7 3.7 3.7 3.7 3.7

T.C. 40.5 42.5 40.5 44.7 46.4 43.1 43.5 41.1 44.8 46.7 45.6 44.4 41.7 45.0 47.0

S.C. 38.7 38.5 31.8 32.2 24.9 40.0 40.4 33.9 34.2 26.4 41.4 42.3 36.0 36.3 27.8

KW 4.2 4.2 4.1 4.2 4.2 4.2 4.2 4.2 4.2 4.2 4.2 4.2 4.2 4.2 4.2

T.C. 39.1 40.7 38.4 42.3 43.5 41.5 41.7 39.0 42.5 43.8 43.9 42.8 39.7 42.6 44.1

S.C. 37.2 37.2 30.8 31.2 24.0 38.4 38.7 32.9 33.3 25.4 39.6 40.3 35.0 35.4 26.8

KW 4.7 4.6 4.6 4.7 4.7 4.7 4.7 4.6 4.7 4.7 4.7 4.7 4.6 4.7 4.7

T.C. 37.7 38.8 36.3 40.0 40.7 39.9 40.0 37.0 40.1 40.9 42.1 41.2 37.6 40.3 41.2

S.C. 35.6 35.8 29.9 30.3 23.1 36.7 37.0 32.0 32.4 24.4 37.9 38.3 34.0 34.5 25.8

KW 5.2 5.1 5.1 5.2 5.2 5.2 5.1 5.1 5.2 5.2 5.2 5.2 5.1 5.2 5.2

Variable Speed

Furnace *

PV8*C16 FC/MC/PC48C 0.99 0.97 0.99

PV8*C20 FC/MC/PC48C 1.00 1.00 1.00

P(C,V)9*C16 FC/MC/PC48C 1.00 1.00 1.00

P(C,V)9*C20 FC/MC/PC48C 1.00 1.00 1.00

P(C,V)9*D20 FC/MC/PC48D 1.00 1.00 1.00

PV8*C16 HC48 0.99 0.97 0.99

PV8*C20 HC48 1.00 1.00 1.00

P(C,V)9*C16 HC48 0.99 1.00 0.99

P(C,V)9*C20 HC48 0.99 1.00 0.99

PV8*C16 HD48 1.01 0.99 1.01

PV8*C20 HD48 1.01 1.02 1.01

P(C,V)9*C16 HD48 1.01 1.02 1.01

P(C,V)9*C20 HD48 1.01 1.02 1.01

P(C,V)9*D20 HD48 1.01 1.02 1.01

* = Single-phase outdoor units only.

Coil T.C. S.C. KW

22 Unitary Products Group

Page 23

254892-YTG-C-0606

COOLING PERFORMANCE DATA

AIR CONDITIONER MODEL NO. H2RD060S06, H1RD060S(25,46)**

INDOOR COIL MODEL NO. FC/MC/PC/UC60

CONDENSING

ENTERING AIR

TEMPERATURE

65

75

85

95

105

115

125

NOTE: ALL CAPACITIES INCLUDE INDOOR FAN HEAT AT 1250 BTUH/1000 CFM.

** For three-phase, decrease T.C. by 0.5 and S.C. by 0.3.

Multipliers for determining the performance with other indoor sections.

NOTE: For dry bulb temperatures different than those listed (between 73-87 F), sensible capacity increases by 1060 BTUH per 1000 CFM per degree above the

listed temperature and decreases by 1060 BTUH per 1000 CFM per degree below the listed temperature.

Air Handler Coil T.C. S.C. KW

MA20D MC60D 1.00 1.00 1.00

MA20D MC61D 1.01 1.01 1.01

MA20D G*FD060H24 1.00 1.00 1.00

MA20D G*FD061H24 1.01 1.01 1.01

AHP/SHP60 – 1.00 1.02 1.00

F*FV060* – 1.00 1.02 1.00

MV20D* FC/MC60D 0.98 0.97 0.98

MV20D* MC61D 1.01 0.99 1.01

AV/SV60* – 1.00 1.02 1.00

– MC61 1.01 1.01 1.01

– HC60 1.00 1.00 1.00

– HD60 1.00 1.01 1.00

– G*FA060S21,24 1.00 1.00 1.00

– G*FD060H24 1.00 1.00 1.00

– G*FD061H24 1.01 1.01 1.01

MA20D MC60D 1.00 1.00 1.00

* = Single-phase outdoor units only.

IDCFM 1650 1900 2150

ID DB (°F) 80 80 75 80 80 80 80 75 80 80 80 80 75 80 80

ID WB (°F) 57 62 62 67 72 57 62 62 67 72 57 62 62 67 72

T.C. 57.2 57.4 54.0 59.6 59.1 58.9 59.1 55.2 60.4 61.1 60.6 60.8 56.3 61.2 63.1

S.C. 52.1 48.7 39.6 38.8 28.1 54.1 51.9 42.7 42.0 31.1 56.1 55.2 45.7 45.3 34.1

KW 3.0 3.1 3.1 3.1 3.1 3.0 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1 3.1

T.C. 54.9 55.1 51.6 57.2 57.0 56.9 56.8 52.7 58.1 58.2 59.0 58.5 53.8 59.0 59.5

S.C. 50.0 47.4 38.6 38.0 27.7 52.1 50.5 41.6 41.1 30.0 54.2 53.6 44.7 44.2 32.3

KW 3.5 3.5 3.5 3.6 3.6 3.5 3.5 3.5 3.6 3.6 3.5 3.5 3.5 3.6 3.6

T.C. 52.6 52.9 49.3 54.8 54.8 54.9 54.5 50.3 55.8 55.4 57.3 56.1 51.2 56.9 55.9

S.C. 48.0 46.1 37.6 37.3 27.3 50.1 49.0 40.6 40.2 28.8 52.3 52.0 43.6 43.2 30.4

KW 4.0 4.0 4.0 4.0 4.1 4.0 4.0 4.0 4.0 4.1 4.0 4.0 4.0 4.0 4.1

T.C. 50.2 50.7 46.9 52.4 52.7 52.9 52.2 47.8 55.0 52.5 55.6 53.7 48.7 54.7 52.3

S.C. 45.9 44.8 36.5 36.5 26.9 48.1 47.6 39.5 39.6 27.7 50.4 50.4 42.5 42.1 28.5

KW 4.4 4.4 4.4 4.4 4.6 4.5 4.4 4.4 4.5 4.6 4.5 4.4 4.4 4.5 4.6

T.C. 48.3 48.2 44.9 49.9 49.4 50.5 49.9 45.3 50.8 49.2 52.8 51.6 45.6 51.6 49.0

S.C. 43.9 43.2 35.6 35.4 25.7 46.0 45.6 38.4 38.1 26.8 48.0 47.9 41.1 40.8 28.0

KW 5.1 5.0 5.1 5.1 5.2 5.1 5.1 5.1 5.1 5.2 5.1 5.1 5.1 5.1 5.2

T.C. 46.4 45.9 43.0 47.5 46.1 48.2 47.7 42.8 48.1 46.0 50.0 49.6 42.5 48.6 45.9

S.C. 42.0 41.7 34.7 34.4 24.6 43.9 43.6 37.2 37.0 26.0 45.7 45.5 39.8 39.5 27.5

KW 5.7 5.7 5.7 5.7 5.8 5.7 5.7 5.7 5.7 5.8 5.7 5.7 5.7 5.7 5.8

T.C. 44.5 43.5 41.1 45.1 42.9 45.8 45.5 40.3 45.3 42.8 47.2 47.6 39.5 45.6 42.7

S.C. 40.1 40.2 33.7 33.4 23.5 41.8 41.6 36.1 35.8 25.2 43.4 43.1 38.4 38.3 26.9

KW 6.3 6.3 6.3 6.3 6.4 6.3 6.3 6.3 6.3 6.5 6.3 6.4 6.3 6.3 6.5

Variable Speed

Furnace*

P(C,V)9*D20 FC/MC/PC60D 0.99 0.96 0.99

PV8*C20 FC/PC60C 0.98 0.98 0.98

P(C,V)9*C20 FC/PC60C 0.99 0.96 0.99

PV8*C20 HC60 0.98 0.98 0.98

P(C,V)9*D20 HC60 0.99 0.96 0.99

PV8*C20 HD60 1.00 0.99 1.00

P(C,V)9*C20 HD60 0.99 0.96 0.99

P(C,V)9*D20 HD60 0.98 0.96 0.98

PV8*C20 MC61D 1.00 0.99 1.00

P(C,V)9*C20 MC61D 0.98 0.96 0.98

P(C,V)9*D20 MC61D 1.00 0.96 1.00

* = Single-phase outdoor units only.

Coil T.C. S.C. KW

Unitary Products Group 23

Page 24

K

NOTES

Subject to change without notice. Printed in U.S.A. 254892-YTG-C-0606

Copyright © by York International Corp. 2006. All rights reserved. Supersedes: 254892 / 036-21339-002 Rev. B (0206)

Unitary 5005 Norman

Products York O

Group Drive 73069

Loading...

Loading...