S

CO

S

550.37-N1Y (594)

Product Category

®

CAUTION

THE ENCLOSED INSTALLAT I ON INSTRUCTI ONS AND ANY APPL I CABL E

LOCAL, STATE, AND NATIONAL CODES I NCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE WITH

WARNING

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAM AGE.

I NCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

TELLAR ULTRA

SPLIT-SYSTEM COOLING

3 and 5 TONS

NDENSING UNIT

INSTALLATION INSTRUCTION

MODELS H1DS036, H1DS048 and H1DS060

GENERAL

This instruction covers the installation of the following Stellar

ULTRA high efficiency condensin g units.

H1DS036S06

H1DS048S06

H1DS060S06

NOMENCLA T URE

H = Condensing Unit

Product Generation

1 = Design Level

Product Identifier

DS = 16.00 SEER Condensing Unit

Nominal Cooling Capacity

036=36,000 BTUH 048=48,000 BTUH

060=60,000 BTUH

Supersedes: 550.37-N1Y (793)

DS

H 036S061

035-10821

Installer should pay particular attention to the words:NOTE,

CAUTION and WARNING.

NOTES are intended t o cla rif y or make the ins t allat ion easier.

CAUTIONS are given to preve nt equipmen t dama ge.

WARNINGS ar e given to alert the inst aller that personal injury

and/or e quipment damag e may r esult if ins tallatio n proc edures

are not handled properly.

Refrigerant Line Connections

S = Sweat-Connect

Voltage Code

06 = 208/230-1-60

The outdoor condensing unit s are designed to be installed with

corresponding variable speed air handlers and a corresponding coil with sweat connect lines. Each unit is factory charged

with refrigerant sufficient for the s mallest indoor evap orator coil

plus 15 feet of field sup plied vapor and li quid lines. A b alanced

port hard shut-off TXV kit must be used for optimum system

performance.

SAFETY

Use this instruction in conjunction with the instruction for the

appropria te indo or eva porat or coi l, variab le s peed air hand ler and

other acc essor ies. Re ad a ll ins tru ction s be fo re ins ta lling th e uni t.

INSPECTION

As soon as a unit is rece ived, it should be inspec ted for possible

damage during transit. If damage is evident, the extent of the

damage should be not ed on the carrier’s freight bill. A separat e

request for inspec tion by the carrier’ s agent should be made in

writing. See Form 50.15-NM for more info rmat ion.

LIMITATIONS

The unit should be installed in accordance wit h all national and

local safety codes an d the limit ations listed below:

1. Limitations for the indoor unit, coil and appropriate accessories must also be obs erv ed.

2. This unit

handler or furnac e sys tem.

3. The outdoor unit must not be ins talled with any ductwor k in

the air stream. The o ut door fan is t he pro pelle r type and is

not designed to operate against any additional external

stati c pressur e.

4. The unit should not be operated at outdoor temperatures

below 60 °F.

low ambient kit.

operate with an y type of low amb ient kit.

5. Indoor evaporator coil orifice

the installation of a factory s upplied balanc ed port TXV kit.

should not be

The unit is not designed to operate with a

installed with a single speed air

Do not modify the control system to

must be removed prior to

550.37-N1Y

TABLE 1 - PHYSICAL AND ELECT RIC AL DATA

UNIT SUPPLY VOL T AGE 208/230-1-60

NORMAL VOLT AGE RANGE

MI N. C IR C UI T A MPAC I TY 20 25.9 30.5

MAX. OVERCURRENT DEVICE AMPS

COMPRESSOR # 1 AMPS

(Lead Compressor)

COMPRESSOR # 2 AMPS

(Follower Compressor)

CRANKCASE HEATER YES YES YES

FA N MOT OR A MPS

MIN. FIEL D WIRE SIZ E AW G

60°C COPPER CONDUCTORS

MAX. WIRE LENGTH FEET

BASED ON 3% VOLTAGE DROP

FAN DIAMETER INCHES 24 24 24

FAN MOTOR

COIL

LI Q UID LI N E O D 3/8 3/8 3/8

VAPO R L I N E O D 7/8 7/8 7/8

OP E R ATI N G W E I G H T L B S . 277 282 340

1

Utilization range “A” in accordance with ARI standard 110.

2

Dual element fuses or HACR circuit breaker.

MODEL H1DS... 036 048 060

1

2

25 35 40

187 to 252

RATE D L OAD 8.3 8.3 10.9

LOCKED ROTOR 48 48 64

RATE D L OAD 9.0 13.5 15.1

LO C KE D RO T O R 48 68 81.0

RATE D L OAD 0.7 0.7 0.7

LO C KE D RO T O R 0.8 0.8 0.8

10 10 8

208V 125 100 100

230V 140 115 110

RATE D H P 1/10 1/10 1/10

NO M I N A L RPM 825 825 825

NO M I N A L CFM 2800 2800 2700

F A CE A R EA SQ . F T. 23.5 23.5 23.5

ROWS DEEP 1 1 2

FI N / I NC H 20 20 16

TO

THERMOSTAT

BLOWER

MOTOR

RELAY

TO POWER

SUPPLY

NEC CLASS 2

WIRING

TO

COIL

NOTE: ALL OUTDOOR WIRING MUST

BE WEATHERPROOF

SEAL OPENING(S) WITH PERMAGUM OR EQUIVALENT

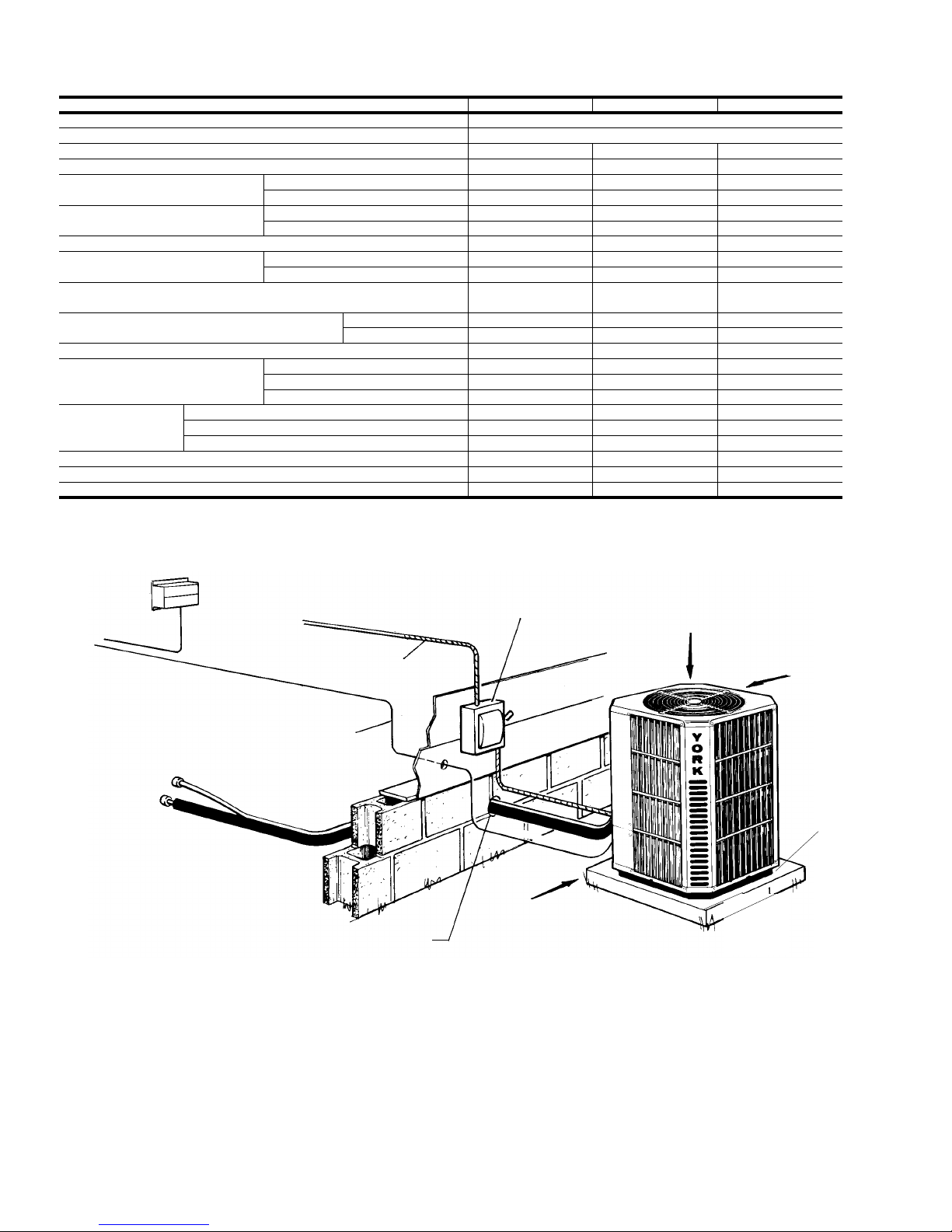

FIGURE 1- TYPICAL INSTALLATION

NEC CLASS 1

WIRING

WEATHERPROOF

DISCONNECT

SWITCH

24" SERVICE

ACCESS CLEARANCE

REQUIRED

48" OVERHEAD

CLEARANCE

REQUIRED

12" REAR AND

SIDES

CLEARANCE

REQUIRED

Sit unit on

rubber

elevator

grommets

to reduce

noise and

allow for

proper

drainage.

2 Central Environmental Systems

550.37-N1Y

LOCA TION

Before startin g th e ins ta llat ion , sele ct and che ck the s uit ability

of the location for both the indoor and outdoor unit . Observe all

limitations and clearan ce re quire ment s.

The outdoor unit must have suf ficient clearance fo r air entrance

to the condens er coil, for air dis charge a nd for s ervic e access.

See Figure 1.

If the unit is to be installed on a hot sun exposed roof or a

black-topped grou nd area, the unit s hould be raised suf ficient ly

above the roof or ground to avoid taking the accumula ted layer

of hot air in to the outdoor u nit.

Provide an adequat e s truc tu ral s uppo rt.

GROUND INSTALLATION

The unit may be installed at ground level on a solid base that

will not shift or settle, causing strain on the refriger ant lines and

possible leaks. Maintain the clearanc es shown in Figure 1 and

install the uni t in a level position. Isolate the base from the

structure to avoid noise or vibration tr ans mi ssion .

Isolate the unit from rain gu tters to avoid any possible wash out

of the foundation.

Normal operating sound levels may be objectionab le if the unit

is placed directly under wi ndows of certa in rooms (bedrooms ,

study, etc.).

ROOF INSTALLATION

When installing units on a roof, the structure must be capable

of supporting the tot al weight of the unit, including a pad, lint els,

rails, etc., which should be used to minimize the transmission

of sound or vibration int o the conditioned space.

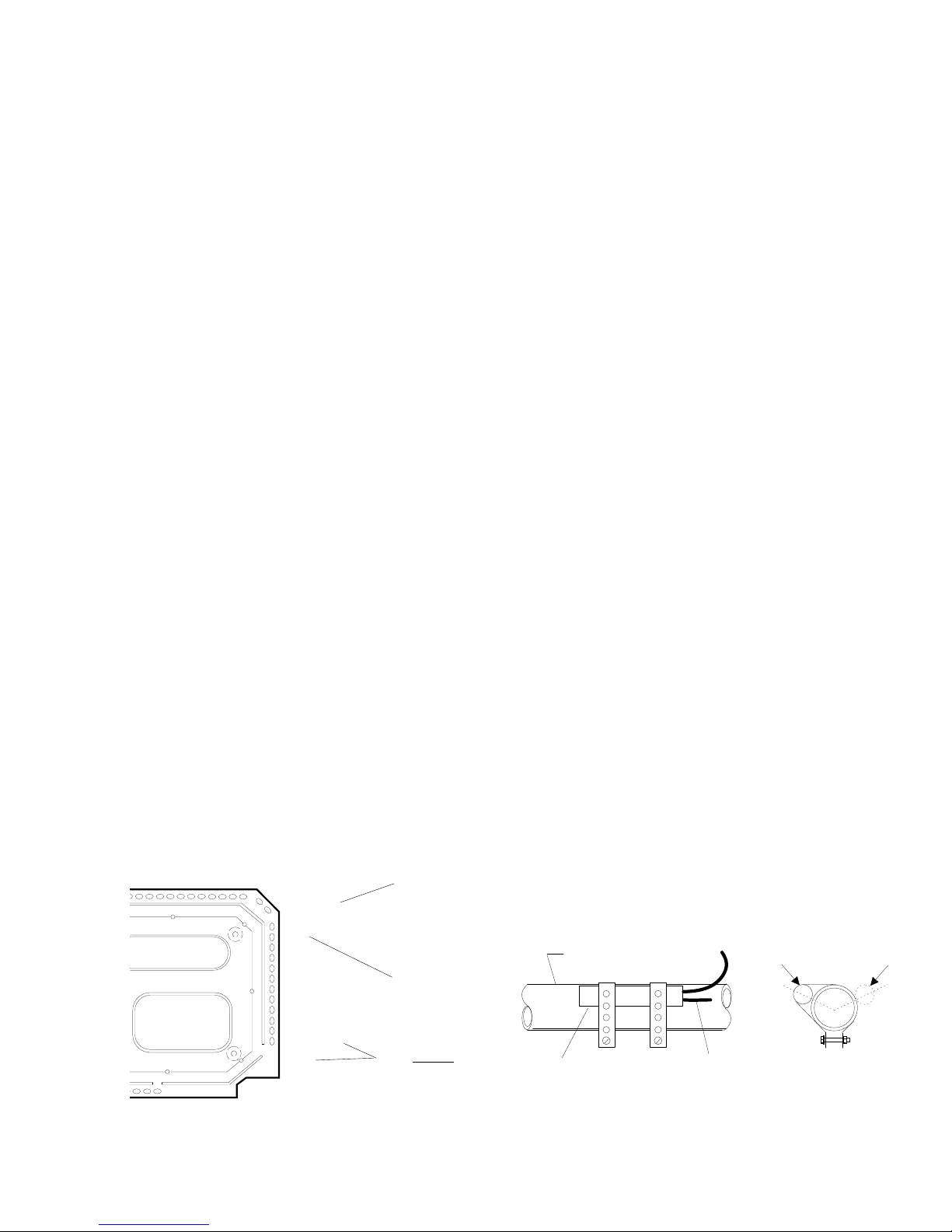

UNIT PLACEMENT

1. Provide a base in the pre-de termined lo cat io n.

2. Remove the shipping carton and inspec t for possible damage.

3. Compressor tie-down bolts should rema in ti ght ene d.

UNIT

BASE

PAN

4. Position t he uni t on the base prov ided .

5. Sit unit on the (4) rub ber elev ating grommets prov ided with

the unit. These sho uld be pos it ion ed as shown in Figure 2

to reduce noise an d allow for prop er drainage.

6. Make a hole(s) in the structure wall large enough to accomodate the insulat ed vapor lin e, the liquid lin e an d the wiring.

TXV INSTALLA TION

This condensing unit requires the installation of a thermal

expansion valve. The TXV controls the superheat of the

refrigerant at the outlet of the evaporator coil, ensuring the

proper refrigerant temperature at the suction of compressor.

Following are the basic steps for installing the TXV. For detail

instruct ions, r efer to the I nstallat ion I nstruc tions accomp anying

the TXV kit.

Install TXV kit as follows:

1. Position the interconnecting refrigerant lines for proper

installation to the outdoor condensing unit and the indoor

evaporator coil, but do not make any connections at this

time.

WARNING:The evaporator coil is under 15 psig pressure .

2. Crack open the liquid lin e fitting of the ind oor coil to relie ve

pressure. This fitting is left handed thread. Turn clockwise

to open.

3. Remove the fit t ing.

4. Using a small diameter wire, remove the orifice from the

other half of the liqu id line fitting .

NOTE: Orifice is not used when the TXV assembly is installed.

5. Reinstall the liquid line fitting hand tight and turn an additional 1/8 turn to seal well.

6. Insert a nd braze t he TXV outlet connec tion to t he liquid line

flare fittin g mount ed on the evaporat or coil.

7. Connect external equalizer t ube to t he vapor line.

8. Position sensing bulb on horizontal portion of vapor line.

Secure using the clamps fur nis hed in th e kit. S ee Fig ure 3.

for positioning of the bulb. Insulate bulb after ins tallation.

FIGURE 2 - POSITIONING GROMMETS

Central Environmental Systems 3

RUBBER

ELEV ATING

GROMMETS

(4)

Note: Do Not block

drainage holes with

grommets.

7/8" VAPOR LINE

SENSING

BULB

ROTATE BULB TO KEEP

TAIL AT BOTTOM

10 O'CLOCK

FIGURE 3 - CORRECT BULB LO C ATIONS

OR

END VIEW

2 O'CLOCK

LIQUID

LINE

TAPE

SHEET

METAL

HANGER

INSULA T ED

VAPOR LIN E

TO INDOOR COIL

TO OUTDOOR UNIT

LIQUID LINE

CAP

PVC

CONDUIT

INSULATED

VAPOR LINE

550.37-N1Y

PIPING CONNECTIONS

The outdoor condensing unit may be connected to the indoor

evaporator coil using field supplied refrigerant grade copper

tubing that i s internally clean an d dry . Units should be ins talled

only with the tubing sizes for approved system combinations

as specified in Table 5. The charge g iven is appl icable f or total

tubing lengths up to 15 feet. See Application Data Form 690.01AD1V for installing tubing of longer lengths and elevation

differences.

NOTE: Using a larger than specified line size could result in

oil return problems. Us ing too small a line will result in

loss of capac ity and other p roblems caused by insu fficient refrigerant flow.

Slope horizontal vapor lines at

least 1" every 20 feet toward the outdoor unit to

facilitate pro per oil re tu rn.

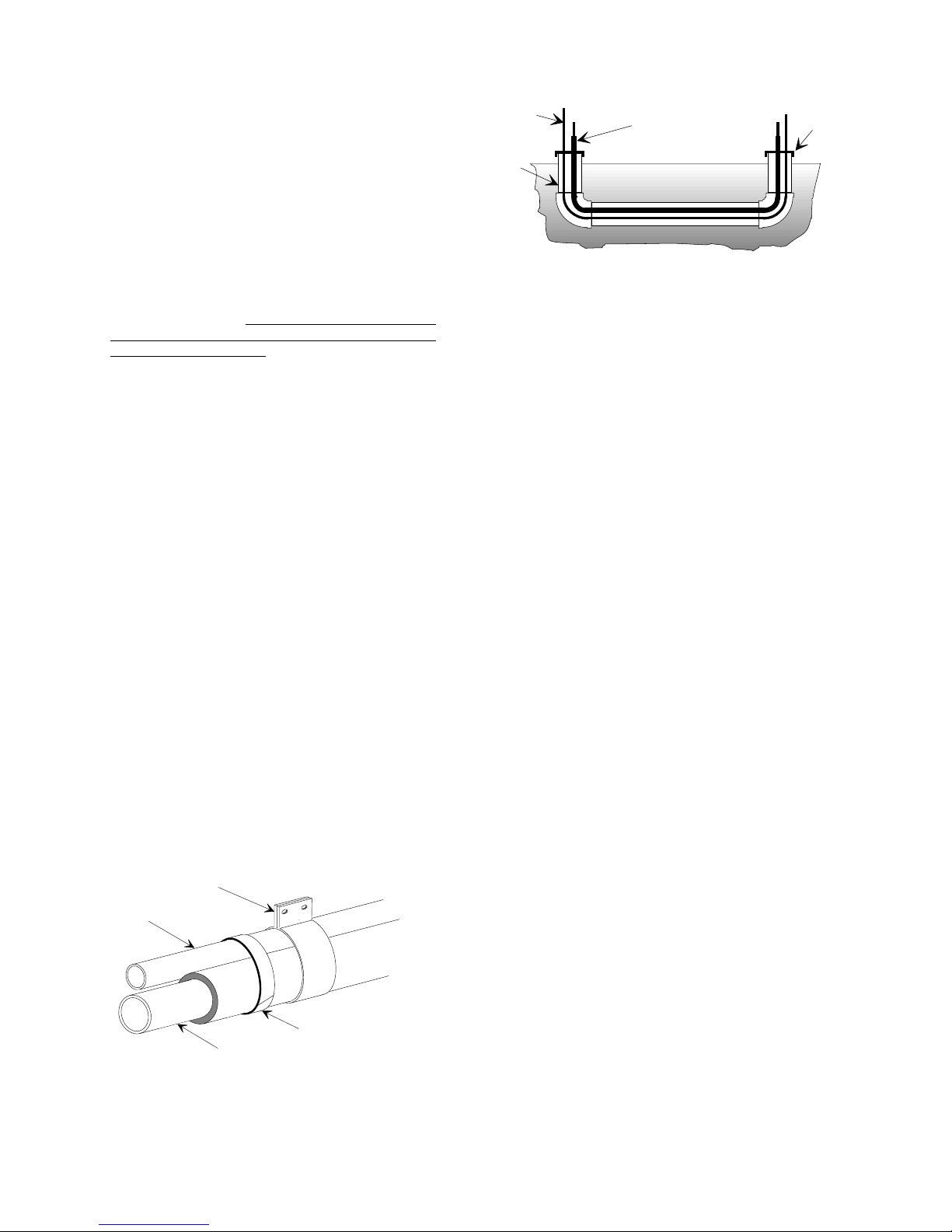

PRECAUTIONS DURING LINE INSTALLATI ON

1. Install the lines with as few bends as possible. Care must

be taken not to damage the couplings or kink the tubing.

Use clean hard drawn copper tubing where no appreciable

amount of bending around obstruction is necessary. If soft

copper must be used, care must be taken to avoid sharp

bends which ma y caus e a rest ric tion.

2. The lines should be installed so that they will not obstruct

service acce ss to th e coil, air hand ling s yst em or filt er.

3. Care must also be taken to isolate the refrigerant lines to

minimize noise transmission from the equip ment to the structure.

4. The vapor line must be insulated with a minimum of 1/2"

foam rubber insulation (Arm-A-Flex or equivalent). Liquid

lines that will be exposed to direct sunlight and/or high

temperatures must als o be insulated.

5. Tape and suspend the refrigerant lines as s hown. DO NO T

allow metal-to met al cont ac t. See Figure 4.

6. Use PVC piping as a conduit for all underground installations as shown in Figure 5. Buried lines shoul d be kept as

short as possible to minimize the build up of liquid refrigerant in the vapor line durin g long p eriods of sh utdown.

FIGURE 5 - UNDERGROUND INSTALLATION

7. Pack fiber glass insulation and a sealing material such as

permagum around ref rigerant line s where they penet rate a

wall to reduce vi brat ion and t o retain s ome f lex ibili ty.

8. See Form 690.01-AD1V for additional piping information.

PRECAUTIONS DURING BRAZING OF LINES

All outdoor uni t and evaporat or coil c onnections are c opper-to-

copper and should be brazed with a phosphor ous-copper alloy

material such as Silfos-5 or equivalent. DO NOT use soft

solder.

CAUTION: Dry nitrogen should always be supplied through the

tubing while it is bein g brazed, because the temperature required is high enough t o cause oxidation of t he

copper unless an inert atmosphere is provided. The

flow of dry nitrogen should continue until the joint has

cooled. Always use a pressure regulator and safety

valve to insure tha t only low pressure dry nit rogen is

introduced into the tubing. Only a small flow is necessary to displace air and prevent oxidation.

The outdoor units have re-usable service valves on both the

liquid and vapor connections. The total system refrigerant

charge is retained within the outdoor unit during shipping and

installation. The re-usable service valves are provided to

evacuate and cha rge pe r thi s inst ruc t ion.

Serious service problems can be avoided by taking adequate

precautions to assure an internally clean and dry system.

PRECAUTIONS DURING BRAZING ANGL E VALVE

FIGURE 4 - TUBING HANGER

4 Central Environmental Systems

Precautions should be taken to prevent heat damage to angle

valve by wrapping a wet rag around it as shown in Figure 6.

Also, protect al l painted surfaces and in sulation during brazing.

After brazing - cool joint with wet rag.

WARNING: This is not a backseating v alve. The service access

port has a valve core. Opening or closing valve

does not close serv ice access p ort.

V alve can be opened by removing t he plunger cap (See Figure

7) and fully inserting a hex wrench into the stem and backing

out counter-clockwise until valve stem just touch es retaining ring.

Loading...

Loading...