Page 1

S

CO

S

550.37-N1Y (594)

Product Category

®

CAUTION

THE ENCLOSED INSTALLAT I ON INSTRUCTI ONS AND ANY APPL I CABL E

LOCAL, STATE, AND NATIONAL CODES I NCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE WITH

WARNING

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAM AGE.

I NCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

TELLAR ULTRA

SPLIT-SYSTEM COOLING

3 and 5 TONS

NDENSING UNIT

INSTALLATION INSTRUCTION

MODELS H1DS036, H1DS048 and H1DS060

GENERAL

This instruction covers the installation of the following Stellar

ULTRA high efficiency condensin g units.

H1DS036S06

H1DS048S06

H1DS060S06

NOMENCLA T URE

H = Condensing Unit

Product Generation

1 = Design Level

Product Identifier

DS = 16.00 SEER Condensing Unit

Nominal Cooling Capacity

036=36,000 BTUH 048=48,000 BTUH

060=60,000 BTUH

Supersedes: 550.37-N1Y (793)

DS

H 036S061

035-10821

Installer should pay particular attention to the words:NOTE,

CAUTION and WARNING.

NOTES are intended t o cla rif y or make the ins t allat ion easier.

CAUTIONS are given to preve nt equipmen t dama ge.

WARNINGS ar e given to alert the inst aller that personal injury

and/or e quipment damag e may r esult if ins tallatio n proc edures

are not handled properly.

Refrigerant Line Connections

S = Sweat-Connect

Voltage Code

06 = 208/230-1-60

The outdoor condensing unit s are designed to be installed with

corresponding variable speed air handlers and a corresponding coil with sweat connect lines. Each unit is factory charged

with refrigerant sufficient for the s mallest indoor evap orator coil

plus 15 feet of field sup plied vapor and li quid lines. A b alanced

port hard shut-off TXV kit must be used for optimum system

performance.

SAFETY

Use this instruction in conjunction with the instruction for the

appropria te indo or eva porat or coi l, variab le s peed air hand ler and

other acc essor ies. Re ad a ll ins tru ction s be fo re ins ta lling th e uni t.

INSPECTION

As soon as a unit is rece ived, it should be inspec ted for possible

damage during transit. If damage is evident, the extent of the

damage should be not ed on the carrier’s freight bill. A separat e

request for inspec tion by the carrier’ s agent should be made in

writing. See Form 50.15-NM for more info rmat ion.

LIMITATIONS

The unit should be installed in accordance wit h all national and

local safety codes an d the limit ations listed below:

1. Limitations for the indoor unit, coil and appropriate accessories must also be obs erv ed.

2. This unit

handler or furnac e sys tem.

3. The outdoor unit must not be ins talled with any ductwor k in

the air stream. The o ut door fan is t he pro pelle r type and is

not designed to operate against any additional external

stati c pressur e.

4. The unit should not be operated at outdoor temperatures

below 60 °F.

low ambient kit.

operate with an y type of low amb ient kit.

5. Indoor evaporator coil orifice

the installation of a factory s upplied balanc ed port TXV kit.

should not be

The unit is not designed to operate with a

installed with a single speed air

Do not modify the control system to

must be removed prior to

Page 2

550.37-N1Y

TABLE 1 - PHYSICAL AND ELECT RIC AL DATA

UNIT SUPPLY VOL T AGE 208/230-1-60

NORMAL VOLT AGE RANGE

MI N. C IR C UI T A MPAC I TY 20 25.9 30.5

MAX. OVERCURRENT DEVICE AMPS

COMPRESSOR # 1 AMPS

(Lead Compressor)

COMPRESSOR # 2 AMPS

(Follower Compressor)

CRANKCASE HEATER YES YES YES

FA N MOT OR A MPS

MIN. FIEL D WIRE SIZ E AW G

60°C COPPER CONDUCTORS

MAX. WIRE LENGTH FEET

BASED ON 3% VOLTAGE DROP

FAN DIAMETER INCHES 24 24 24

FAN MOTOR

COIL

LI Q UID LI N E O D 3/8 3/8 3/8

VAPO R L I N E O D 7/8 7/8 7/8

OP E R ATI N G W E I G H T L B S . 277 282 340

1

Utilization range “A” in accordance with ARI standard 110.

2

Dual element fuses or HACR circuit breaker.

MODEL H1DS... 036 048 060

1

2

25 35 40

187 to 252

RATE D L OAD 8.3 8.3 10.9

LOCKED ROTOR 48 48 64

RATE D L OAD 9.0 13.5 15.1

LO C KE D RO T O R 48 68 81.0

RATE D L OAD 0.7 0.7 0.7

LO C KE D RO T O R 0.8 0.8 0.8

10 10 8

208V 125 100 100

230V 140 115 110

RATE D H P 1/10 1/10 1/10

NO M I N A L RPM 825 825 825

NO M I N A L CFM 2800 2800 2700

F A CE A R EA SQ . F T. 23.5 23.5 23.5

ROWS DEEP 1 1 2

FI N / I NC H 20 20 16

TO

THERMOSTAT

BLOWER

MOTOR

RELAY

TO POWER

SUPPLY

NEC CLASS 2

WIRING

TO

COIL

NOTE: ALL OUTDOOR WIRING MUST

BE WEATHERPROOF

SEAL OPENING(S) WITH PERMAGUM OR EQUIVALENT

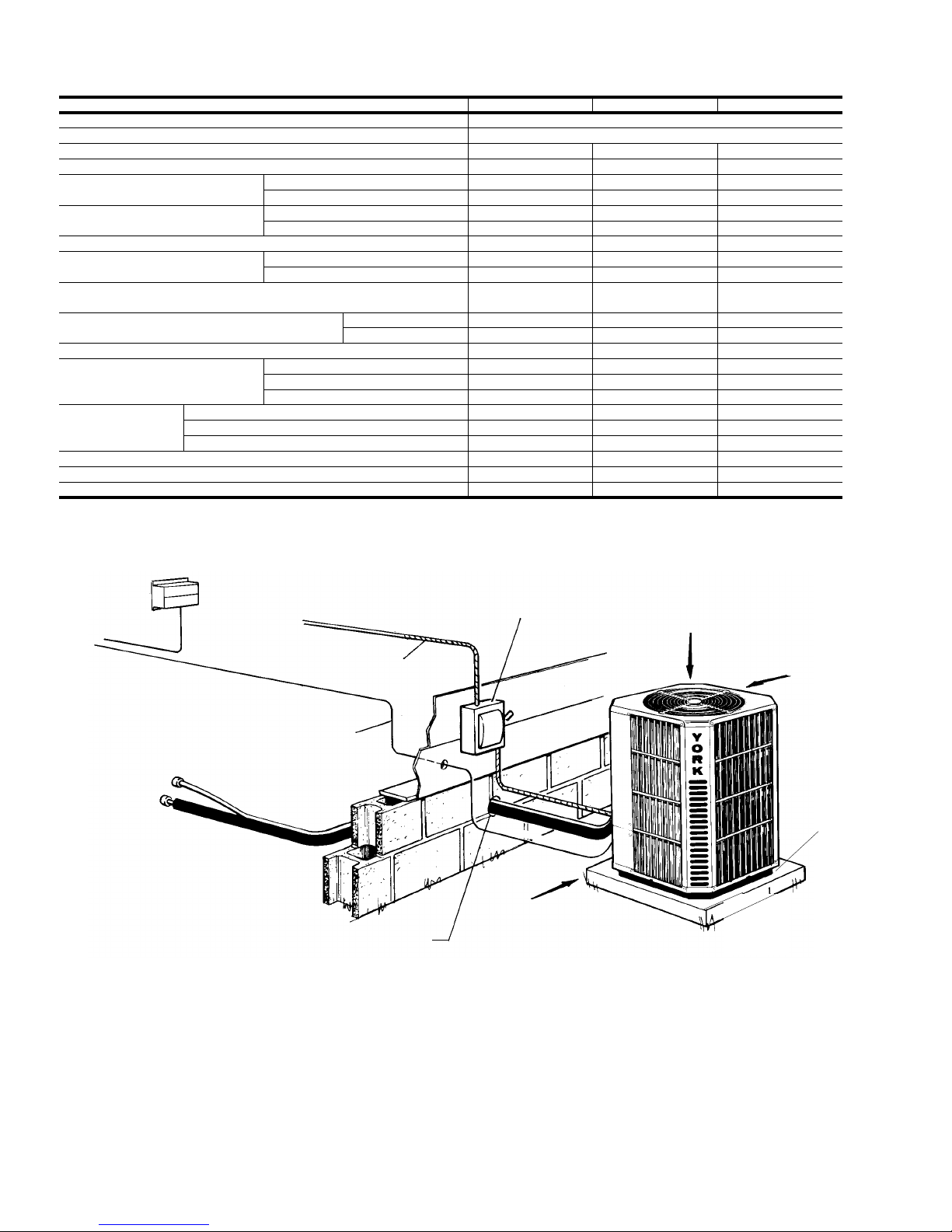

FIGURE 1- TYPICAL INSTALLATION

NEC CLASS 1

WIRING

WEATHERPROOF

DISCONNECT

SWITCH

24" SERVICE

ACCESS CLEARANCE

REQUIRED

48" OVERHEAD

CLEARANCE

REQUIRED

12" REAR AND

SIDES

CLEARANCE

REQUIRED

Sit unit on

rubber

elevator

grommets

to reduce

noise and

allow for

proper

drainage.

2 Central Environmental Systems

Page 3

550.37-N1Y

LOCA TION

Before startin g th e ins ta llat ion , sele ct and che ck the s uit ability

of the location for both the indoor and outdoor unit . Observe all

limitations and clearan ce re quire ment s.

The outdoor unit must have suf ficient clearance fo r air entrance

to the condens er coil, for air dis charge a nd for s ervic e access.

See Figure 1.

If the unit is to be installed on a hot sun exposed roof or a

black-topped grou nd area, the unit s hould be raised suf ficient ly

above the roof or ground to avoid taking the accumula ted layer

of hot air in to the outdoor u nit.

Provide an adequat e s truc tu ral s uppo rt.

GROUND INSTALLATION

The unit may be installed at ground level on a solid base that

will not shift or settle, causing strain on the refriger ant lines and

possible leaks. Maintain the clearanc es shown in Figure 1 and

install the uni t in a level position. Isolate the base from the

structure to avoid noise or vibration tr ans mi ssion .

Isolate the unit from rain gu tters to avoid any possible wash out

of the foundation.

Normal operating sound levels may be objectionab le if the unit

is placed directly under wi ndows of certa in rooms (bedrooms ,

study, etc.).

ROOF INSTALLATION

When installing units on a roof, the structure must be capable

of supporting the tot al weight of the unit, including a pad, lint els,

rails, etc., which should be used to minimize the transmission

of sound or vibration int o the conditioned space.

UNIT PLACEMENT

1. Provide a base in the pre-de termined lo cat io n.

2. Remove the shipping carton and inspec t for possible damage.

3. Compressor tie-down bolts should rema in ti ght ene d.

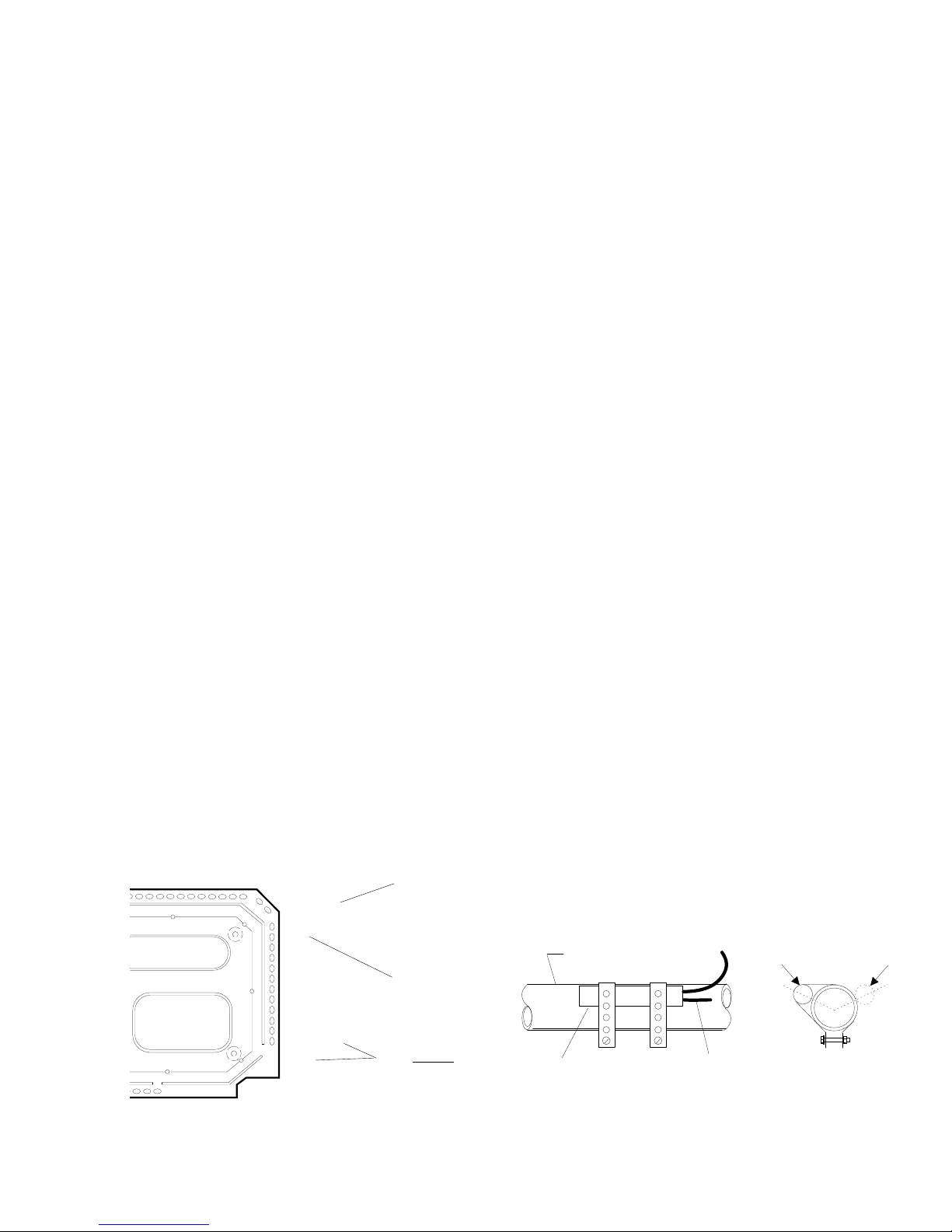

UNIT

BASE

PAN

4. Position t he uni t on the base prov ided .

5. Sit unit on the (4) rub ber elev ating grommets prov ided with

the unit. These sho uld be pos it ion ed as shown in Figure 2

to reduce noise an d allow for prop er drainage.

6. Make a hole(s) in the structure wall large enough to accomodate the insulat ed vapor lin e, the liquid lin e an d the wiring.

TXV INSTALLA TION

This condensing unit requires the installation of a thermal

expansion valve. The TXV controls the superheat of the

refrigerant at the outlet of the evaporator coil, ensuring the

proper refrigerant temperature at the suction of compressor.

Following are the basic steps for installing the TXV. For detail

instruct ions, r efer to the I nstallat ion I nstruc tions accomp anying

the TXV kit.

Install TXV kit as follows:

1. Position the interconnecting refrigerant lines for proper

installation to the outdoor condensing unit and the indoor

evaporator coil, but do not make any connections at this

time.

WARNING:The evaporator coil is under 15 psig pressure .

2. Crack open the liquid lin e fitting of the ind oor coil to relie ve

pressure. This fitting is left handed thread. Turn clockwise

to open.

3. Remove the fit t ing.

4. Using a small diameter wire, remove the orifice from the

other half of the liqu id line fitting .

NOTE: Orifice is not used when the TXV assembly is installed.

5. Reinstall the liquid line fitting hand tight and turn an additional 1/8 turn to seal well.

6. Insert a nd braze t he TXV outlet connec tion to t he liquid line

flare fittin g mount ed on the evaporat or coil.

7. Connect external equalizer t ube to t he vapor line.

8. Position sensing bulb on horizontal portion of vapor line.

Secure using the clamps fur nis hed in th e kit. S ee Fig ure 3.

for positioning of the bulb. Insulate bulb after ins tallation.

FIGURE 2 - POSITIONING GROMMETS

Central Environmental Systems 3

RUBBER

ELEV ATING

GROMMETS

(4)

Note: Do Not block

drainage holes with

grommets.

7/8" VAPOR LINE

SENSING

BULB

ROTATE BULB TO KEEP

TAIL AT BOTTOM

10 O'CLOCK

FIGURE 3 - CORRECT BULB LO C ATIONS

OR

END VIEW

2 O'CLOCK

Page 4

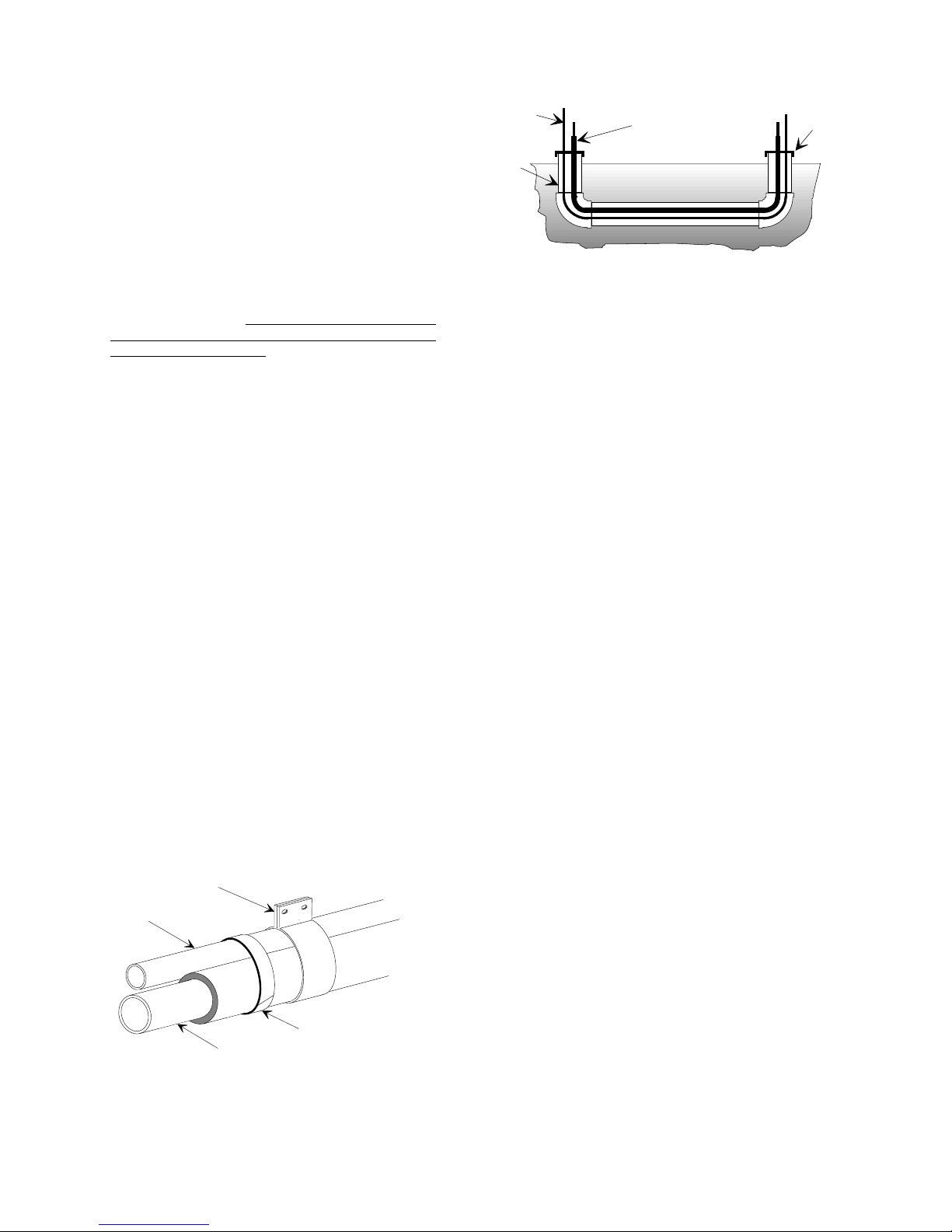

LIQUID

LINE

TAPE

SHEET

METAL

HANGER

INSULA T ED

VAPOR LIN E

TO INDOOR COIL

TO OUTDOOR UNIT

LIQUID LINE

CAP

PVC

CONDUIT

INSULATED

VAPOR LINE

550.37-N1Y

PIPING CONNECTIONS

The outdoor condensing unit may be connected to the indoor

evaporator coil using field supplied refrigerant grade copper

tubing that i s internally clean an d dry . Units should be ins talled

only with the tubing sizes for approved system combinations

as specified in Table 5. The charge g iven is appl icable f or total

tubing lengths up to 15 feet. See Application Data Form 690.01AD1V for installing tubing of longer lengths and elevation

differences.

NOTE: Using a larger than specified line size could result in

oil return problems. Us ing too small a line will result in

loss of capac ity and other p roblems caused by insu fficient refrigerant flow.

Slope horizontal vapor lines at

least 1" every 20 feet toward the outdoor unit to

facilitate pro per oil re tu rn.

PRECAUTIONS DURING LINE INSTALLATI ON

1. Install the lines with as few bends as possible. Care must

be taken not to damage the couplings or kink the tubing.

Use clean hard drawn copper tubing where no appreciable

amount of bending around obstruction is necessary. If soft

copper must be used, care must be taken to avoid sharp

bends which ma y caus e a rest ric tion.

2. The lines should be installed so that they will not obstruct

service acce ss to th e coil, air hand ling s yst em or filt er.

3. Care must also be taken to isolate the refrigerant lines to

minimize noise transmission from the equip ment to the structure.

4. The vapor line must be insulated with a minimum of 1/2"

foam rubber insulation (Arm-A-Flex or equivalent). Liquid

lines that will be exposed to direct sunlight and/or high

temperatures must als o be insulated.

5. Tape and suspend the refrigerant lines as s hown. DO NO T

allow metal-to met al cont ac t. See Figure 4.

6. Use PVC piping as a conduit for all underground installations as shown in Figure 5. Buried lines shoul d be kept as

short as possible to minimize the build up of liquid refrigerant in the vapor line durin g long p eriods of sh utdown.

FIGURE 5 - UNDERGROUND INSTALLATION

7. Pack fiber glass insulation and a sealing material such as

permagum around ref rigerant line s where they penet rate a

wall to reduce vi brat ion and t o retain s ome f lex ibili ty.

8. See Form 690.01-AD1V for additional piping information.

PRECAUTIONS DURING BRAZING OF LINES

All outdoor uni t and evaporat or coil c onnections are c opper-to-

copper and should be brazed with a phosphor ous-copper alloy

material such as Silfos-5 or equivalent. DO NOT use soft

solder.

CAUTION: Dry nitrogen should always be supplied through the

tubing while it is bein g brazed, because the temperature required is high enough t o cause oxidation of t he

copper unless an inert atmosphere is provided. The

flow of dry nitrogen should continue until the joint has

cooled. Always use a pressure regulator and safety

valve to insure tha t only low pressure dry nit rogen is

introduced into the tubing. Only a small flow is necessary to displace air and prevent oxidation.

The outdoor units have re-usable service valves on both the

liquid and vapor connections. The total system refrigerant

charge is retained within the outdoor unit during shipping and

installation. The re-usable service valves are provided to

evacuate and cha rge pe r thi s inst ruc t ion.

Serious service problems can be avoided by taking adequate

precautions to assure an internally clean and dry system.

PRECAUTIONS DURING BRAZING ANGL E VALVE

FIGURE 4 - TUBING HANGER

4 Central Environmental Systems

Precautions should be taken to prevent heat damage to angle

valve by wrapping a wet rag around it as shown in Figure 6.

Also, protect al l painted surfaces and in sulation during brazing.

After brazing - cool joint with wet rag.

WARNING: This is not a backseating v alve. The service access

port has a valve core. Opening or closing valve

does not close serv ice access p ort.

V alve can be opened by removing t he plunger cap (See Figure

7) and fully inserting a hex wrench into the stem and backing

out counter-clockwise until valve stem just touch es retaining ring.

Page 5

FIGURE 6 - HEAT PROTECTION

PLUNGER

CAP

CAUTION: If visual verific ation of the valv e stem reac hing the

retaining ring is impossible, stop backing out the

valve stem when the slightest increase in resistance is felt. Because of the small size and therefore the reduced resistance, back out the liquid

5 turns maximum

valve

retaining ring.

WARNING: If the valve stem is backed out past the retaining

ring, the O’ring can be damaged causing leakage

or system pressure could f orce the valve stem out

of the valve body pos s ibly c ausing p ersonal injur y.

In the event the retaining ring is missing, do not

attemp t t o op e n the valve .

Replace plunger cap f inger tight, then tigh ten an additional 1/12

turn (1/2 hex flat). Cap mus t be replac ed t o pre ven t leaks.

LINE CONNECTION

Connect the refrigerant lines using the fo llowing procedur e:

1. Remove the cap a nd Schrader core from both the liquid and

vapor angle valve serv ice ports at the outd oor unit. Connect

low pressure nitroge n to th e liqui d line serv ic e port .

2. Braze the liquid line to the liquid valve at the outdoor unit.

Be sure to wrap the valve body with a wet rag. Allow the

nitrogen to continue flowing.

3. Carefully remove the rubber plugs from the evaporator

liquid and vapor connectio ns.

to prevent going past the

ANGLE

VALVE

550.37-N1Y

CAUTION: The evaporator is pressuriz ed.

4. Braze the liquid line to the evaporato r liquid connectio n. The

nitrogen sho uld now be flowing throu gh the evaporator co il.

5. Slide the grommet away from the vapor connection at the

coil. Braze the vapor line to the evaporator vapor connection. After the connection has cooled, slide the grommet

back into origina l posit ion.

6. Protect the vapor v alve with a wet rag and braz e the vapor

line connection. The nitrogen flow should be exiting the

system from the vapor service port connection. After this

connection has cooled, remove the nitrogen source from

the liquid fitting servic e port .

7. Evacuate the vapor line, evaporator and the liquid line, to

1000 microns or les s .

8. Leak test all refrigerant piping connect ions including the se rvice port flare caps to be sure they are leak tight. DO NOT

OVERTIGHT EN (between 40 and 60 inch - lbs. maximum ).

NOTE: Do not use the system refrigerant in the outdoor unit

to purge or leak test.

9. Do not re mo ve t he f lare cap s from t he serv ice po rts excep t

when neces sa ry for s erv icing the system.

CAUTION: Do not connect manifold gauges unless trouble is

suspected. Approxi mately 3/4 oun ce of refrigeran t

will be lost each time a standard manifold gauge is

connec ted.

10.Release the refrigeran t charge into the s ystem. O pen both

the liquid and vapor valves by removing the plunger cap

and with an allen wrench back out counter-clockwise until

valve stem just touches retaining ring. See Figure 7. Release the refrigera nt charge into the syst em. See "Precautions During B raz ing Angle Valves" on page 4 and 5.

11. If the refrigerant tubing, indoor evaporator coil or outdoor

condensing unit ha s de veloped a leak du ring shipment , or

was, for any other reason, opened to the atmosphere for

more than four (4) minutes, it is necessary to e vacuate the

system down to at least 1000 mic rons to eliminate conta mination and mo istur e in the sy ste m.

If a leak is s uspec ted, lea k test to loc ate the leak . To verif y

the leak, close the valve to the vacuum pump suction to

isolate the pump and h old the system u nder v acuum. If the

micron gauge indicat es a steady and c ont inu ous rise after

a few minutes , it’s an indi cation of a leak . If the guage shows

a rise, then lev els of f aft er a few min ut es an d remains f ai rly

constant, its an indication that the sy stem is leak free, but

still contains moisture and may require further evacuation

if the reading is above 1000 mic rons .

FIGURE 7 - REM OVI NG PLUN GER CA P

Central Environmental Systems 5

WARNING: Never attempt to repair any brazed connections

while the syste m is under pressure. Personal injury

could result.

See "System Start Up" se ction for checkin g and recordin g

system charge.

Page 6

550.37-N1Y

ELECTRICAL CONNECTIONS

GENERAL INFORMATION & GROUNDING

Check the electrical su pply to be sure tha t it meets the values

specified on the unit namepl ate and wirin g label .

Power wiring, contro l (low voltage) wirin g, disconnec t switches

and overcurrent protection to be supp lied by the ins t aller. See

Table 1 for proper sizes. Wire size should be at least equal to

or greater than the s iz e shown in Table 1.

CAUTION: All field wiring must USE COPPER CONDUC-

TORS ONLY and be in accordance with Local,

National Fire, Safety & Electrical Codes. This

unit must be grounded with a separ ate ground

wire in accordance with the above codes.

The complete connection diagram and schematic wiring label

is located on the ins ide surface of the unit elec trical bo x cover.

Field wiring is also shown in Figure 1.

NOTE: The wires for the operatio n of the lead compressor are

solid in color. For differentiation, the wires of the follower compressor are basica lly t he sa me in color, but

striped.

POWER WIRING

1. Install the proper s ize weath erproof disconnect switc h outdoors and within sight of the un it.

THERMOSTAT MOUNTING / WIRING

This condens ing unit must be install ed with the factory re co m-

mended thermostat, 2ET04700224 or any conventional twostage cooling thermostat. The difference between the two

stages of a typical t wo-s ta ge t hermos t at is 2 - 2.5 °F.

The thermostat should be located about 5 ft. above the floor,

where it will be exposed to n ormal roo m air circ ulat ion . Do no t

place it on an outsid e wall or wh ere it is expos ed to the ra dian t

effect from exposed glass or appliances, drafts from outside

doors or supply air grilles.

After the th ermostat is mounted, rout e the 24-vo lt control wiring

(NEC Class 2) from the thermostat to the indoor v arible speed

air handler and outdoor unit. Route the control wirin g into the

grommetted hole in the bottom of control box of the outdoor

unit. Using wire nuts connect to leads provided in unit control

box as per Figure 8.

Interconnecting control wiring must be a minimum of No. 18

AWG color code d insulated wires. If wire lengt hs increase more

than 90 feet, use No. 16 AWG wires, to prevent excessive

voltage drop.

NOTE: T o eliminat e erratic operat ion, seal the hol e in the wall

at the thermostat with permagum or equivalent to

prevent air drafts affecting the anticipators in the

thermostat.

DE-HUMIDIFICA TION CONTROL

2. Run power wiring from the disconne ct swit ch to the unit .

3. Remove the control box cover to gain access to the unit

wiring. Route wires from disconnect through power wiring

opening provide d and into the unit control box a s shown in

Figure 8.

4. Install the proper size time-delay fuses or circuit breaker,

and make the power supply conne ction s.

5. Energize the crank c ase heat er to sa ve time by preheat ing

the compressor oil while the re ma ining instal lat ion is completed.

ACCESSORY WIRING

The electric al acces sories avai lable for thi s unit a re a two s tage

cooling thermostat and an optional De-humidification Control.

Refer to the individual instr uctions packaged with the accessories for installat io n.

A de-humidification control accessory 2HU06700124 may be

required in high humidity areas. This control provides cooling

at a reduced air flow, lowering evaporator temperature and

increasing la te nt cap acity. To install, re fer t o instructions pac kaged with the accessory. Prior to the installation of the de-humidification control, the jumper across the de-humidification

control terminals on the indoor variable speed air handler

terminal board must be removed. See Figure 10. Refer to

Figure 9 for wiring deta ils.

During first or second stage cooling, if the relative humidity in

the space is higher than the desired s et point of the de- humidification cont rol, the var iable speed blower motor will op erate at

a lower speed unti l the de-hu midif ication c ontro l is satis fied. A

40 - 60% relative humidity level is recommended to achieve

optimum comfort.

NOTE: If a de-humidification control is installed, it is recom-

mended that a minimum air flow of 325 cfm/ton be

supplied at all times .

6 Central Environmental Systems

Page 7

FIGURE 8 - TYPICAL FIELD WIRING

FIGURE 9 - T YPICAL FIELD WIRING WIT H

C

ALL FIEL D WIRING TO BE IN ACCORDANCE WITH N ATIONAL ELECTRICA L CODE (NEC) AND/OR LOCAL CODES.

R

Y2

Y1

G

W1

W2

TYPICAL

TWO STAGE

COOLING

THERMOSTAT

MUST BE

USED

INDOOR

VARIABLE SPEED AIR

HANDLER / FURNACE

TERMINAL BOARD

C

R

Y2

Y1

Y

G

W/W1

FOR ELECTRIC HEAT ONLY

W2

BK

X

O

WIRE NUT

BLU

RED

BRN

YEL

BLK

POWER

CONTROL

FACTORY

C

R

Y2

Y1

Y2 OUT

OUTDOOR UNIT

CONTACTOR

T2

T1

M2

L2

L1

(CLASS 1 WIRING)

(CLASS 2 WIRING)

CONTACTOR

T2

T1

M1

L2

L1

POWER WIRING

208/230-1-60

GRD.

SCREW

550.37-N1Y

COOLING

ONLY

C

R

Y2

Y1

G

W1

W2

TYPICAL

TWO STAGE

COOLING

THERMOSTAT

MUST BE

USED

All outdoor wiring must be

weatherproof. Use copper

conductors only .

INDOOR

VARIABLE SPEED AIR

HANDLER / FURN ACE

TERMINAL BOARD

C

R

Y2

Y1

Y

G

W/W1

W2

BK

X

O

DE-HUMIDIFICATION

CONTROL CONNECTION

(JUMPER MUST BE REMOVED)

POWER

CONTROL

FACTORY

CONTROL

WIRING

OUTDOOR UNIT

WIRE NUT

BLU

RED

BRN

YEL

BLK

FOR ELECTRIC HEAT ONLY

C

R

Y2

Y1

Y2 OUT

CONTACTOR

T2

T1

M2

L2

L1

(CLASS 1 WIRING)

(CLASS 2 WIRING)

CONTACTOR

T2

T1

M1

L2

L1

POWER WIRING

208/230-1-60

GRD.

SCREW

POWER

WIRING

COOLING

WITH

DE-HUMIDIFICATION

CONTROL

DE-HUMIDIFICATION CONTROL

Central Environmental Systems 7

Page 8

DELAY

PROFILE T AP

COOL TAP

ELECTRIC

HEA T TAP

ADJ TAP

ELECTRIC HEAT OR TRANSFORMER WIRING

HARNESS CONNECTS HERE

550.37-N1Y

TABLE 2 - RECOMMENDED SPEED TAP SELECTION

INDOOR

V A RIABLE

SPEED

AIR

HANDLER

N1VSD14

N2VSD20

SCREW

TERMINAL

BOARD

INDOOR

EVAP.

COIL

G/HC036

G/HC042

G/HC048

G/HC060

NOTE: For ARI testing requirements, adjust the delay profile in "Test Mode". Refer to Installation Instructions for N1VS variable speed

air handlers for additional details if necessary.

NA = N ot Applicable.

COOL

TAP

Jumper

at "B"

Jumper

at "A"

Jumper

at "A"

H*DS036 H*DS048 H*DS060

ADJ

TAP

NO

Jumper

NO

Jumper

Jumper

at "C"

DELAY

PROFILE

Jumper

at "C"

Jumper

at "C"

Jumper

at "C"

CONDENSING UNITS

COOL

TAP

NA NA NA NA NA NA

Jumper

at "B"

Jumper

at "C"

ADJ

TAP

NO

Jumper

NO

Jumper

DELAY

PROFILE

Jumper

at "C"

Jumper

at "C"

COOL

TAP

NA NA NA

Jumper

at "B"

ADJ

TAP

Jumper

at "C"

BLOWER MOTOR

INTERFACE HARNESS

CONNECTS HERE

JUMPER IN STORED POSITIO N

(Vertically on RH side, pins "A" and "B")

DELAY

PROFILE

Jumper

at "C"

DE-HUMIDIFI

CATION

CONTROL

ACCESSORY

JUMPER

HEAT PUMP JUMPER

FIGURE 10 - N1VS/N2VS Connector Board

SPEED TAP SELECTION FOR VARIABLE SPEED

AIR HANDLERS

The variable speed air handler motor’s speed tappings must

be adjusted from the factory settings for the required outdoor

condensing unit as shown in Table 2. A typical v ariable speed

air handler (N1VS/N2V S) connector board co nfiguration sho wing the various speed taps is shown in Figure 10. Refer to

variable speed air handl er installation inst ructions for additional

details, regarding the C FM for the c orre sponding speed taps.

JUMPER IN "A" CF M

(Horizontally jumper two "A" pins)

By selecting the speed taps shown in Table 2, the air handler

will deliver the rated CFM when both (lead and follower)

compressors are running, and the air handler motor will operate at a lower speed automatically when only the lead compressor is running. The variable speed motor used in this air

handler is programmed to automatically adjust to the lower

speed when there is a call for first stage (Y1) cooling from the

two stage cooling ther mo stat .

8 Central Environmental Systems

Page 9

LIQUID

PRESSURE

(PSIG) @

SERVICE

PORT

Required Subcooling Temp. ° F

LIQUID

PRESSURE

(PSIG) @

SERVICE

PORT

Required Subcooling Temp. ° F

5 10 12 15 20 5 10 12 15 20

Liquid Line Temperature ° F Liquid Line Temperature ° F

139 73 68 66 63 58 264 116 111 109 106 101

146 76 71 69 66 61 271 117 112 110 107 102

153 79 73 71 68 63 276 120 115 113 110 105

161 82 77 75 72 67 285 122 117 115 112 107

166 85 90 88 85 80 301 126 121 119 116 111

179 89 84 82 79 74 309 127 122 120 117 112

187 92 87 85 82 77 317 130 125 123 120 115

196 95 90 88 85 80 325 132 127 125 122 117

202 97 92 90 87 82 333 134 129 127 124 119

208 99 94 92 89 84 342 136 131 129 126 121

220 103 98 96 93 88 350 138 133 131 128 123

229 106 101 99 96 91 359 140 135 133 130 125

236 108 103 101 98 93 368 142 137 135 132 127

246 111 106 104 101 96 377 144 139 137 134 129

256 114 109 107 104 99 386 146 141 139 136 131

TABLE 4 - SUB-COOLING CHART

550.37-N1Y

SYSTEM START-UP

ENERGIZE CRANKCASE HEATER

This unit is equipped with crank ca se heat ers for both th e lead

and follower compressors. The operation of the crankcase

heater is monito red by means of the con tro l board .

CAUTION: An attempt to start the compressor without at least

8 hours of crankcase heat will damage the compressor.

A warning label with an adhesive back is supplied in the unit

installation in struction p acket. This label shoul d be attac hed to

the field su pplied disconnec t switch where it will be easily seen.

See below .

IMPORTANT

IF POWER HAS BEEN OFF FOR 8 HOURS OR LONGER,

DISCONNECT SWITCH MUST BE TURNED ON 8 HOURS

BEFORE THERMOS TAT IS SE T TO “HEAT”,"COOL" OR

“AUTO”

035-03095.

In order to energize the crankcas e heater:

- Set indoor two stage cooling ther mo stat to "OFF" pos ition .

- Close the line power disconne ct to the unit .

CHECKING SYSTEM CHARGE

The factory charge in the outdoor unit is listed in the Table 5 as

well as unit nameplat e and inclu des enough charge for th e unit

and the corresponding indoor evaporator coil. This unit includes suffic ient charge for 15 feet of line set s. T ab le 6 lists the

refrigerant line ch arges for addi ti onal le ngt hs .

CAUTION:

REFRIGERANT CHARGING SHOULD ONLY BE

CARRIED OUT BY A QUALIFIED AIR CONDITIONING CONTRACTOR.

In order to check whether the unit has the required charge in

the system, follow t he proc edur e des cri bed be l ow.

WARNING:DO NOT VENT REFRIGERANT TO THE ATMOS-

PHERE. IT IS NECESSARY TO RECOVER THE

REFRIGERANT DURING ANY REPAIR OR INST ALLATION OF THE SYSTEM.

1. Set room thermostat at desired temperature. The thermostat may be energized at first (Y1) stage or second (Y2)

stage. If only the first stage (Y1) is energiz ed, only the lead

compressor will be in operat ion. Both the compress ors will

be in operation if the second stage of thermostat (Y2) is

energized.

Set room therm ostat at "COOL" position and fan switch at

"AUTO" or "FAN" position. There is a five minute delay

when the "system control board" is powered for the first

time. Refer to "System Functions" for more information

about time delays.

2. Operate the unit for a minimum of 15-20 minutes before

checki n g th e ch a rg e .

3. Ve rif y the de sire d indo or air han dler ai r flo w (CFM).

4. The system charge should be varified with only the lead

compressor running, however it can be also checked with

both the compressors running at t he same time at the rat ed

indoor air handle r air flow. However, it is required to es tablish the subcoolin g level at any one condition i.e. either with

the lead compressor running or when both (the lead and

follower) compressors are running.Recommended subcooling temperat ure is listed in Table 3.

TABLE 3 - RECOMMENDED SUBCO OLING

RECOMMENDED SUBCOOLING °F

MODEL

H1DS036 10 18

H1DS048 10 18

H1DS060 10 18

*Lead compressor is designated / labeled as the # 1 compressor. Follower compressor is the # 2 compressor.

LEAD

COMPRESSOR

ONLY

LEAD + FOLLOWER*

(BOTH)

COMPR. RUNNING

Central Environmental Systems 9

Page 10

550.37-N1Y

5. Measure li quid ref rige rant p res su re a t th e service valve by

attaching an accurate pressure gauge to the service port

and record the pressure.

NOTE: When only the lead compressor is running, the

suction pressure will be higher than a standard

single speed system, or a dual compressor system with both compressors running. This is a

normal operation for a dual compressor system

operating with a large indoor coil at part load

capacities.

6. Refer to the Table 3 to find the recommended subcooling

temperature.

7. Refer to Table 4 to deter mine the proper l iquid line temperature at the point where the "Required Subc ooling Temperature" and "Measured Liquid Pressure"(from step 5)

intersect. Record t he requ ired li quid li ne t emperat ur e.

8. Measure the liquid line temperature by attaching an accurate electro nic thermomete r or a thermistor at the liquid line

near the cond ens ing un it.

9. If the liquid line temperatu re is higher th an the valu e determined in step 7, add refrigerant charge carefully until the

recommended subcooling temperature is obtained at the

correspondi ng liqu id line pres sure.

CAUTION: DO NOT OVERCHARGE THE SYSTEM,

THIS COULD LEAD TO DAMAGE TO THE

COMPRESS ORS.

It is suggested to maintain the recommended subcooling

levels indica ted in Table 4, wit hin ±2 °F . Too low a subc ooling or too high a subc ooling will re sult in poo r performan ce

of the air condit ion ing unit.

NOTE: If liquid line temperature is lower, remove and

recover the refrige rant charge unt il the reco mmended subcooling temperat ure is obt aine d.

EXAMPLE:

Given an H1DS036 with only the lead compressor operating

on first stage.

1. Liquid pressure at t he service valve = 179 lbs.

2. Recommended subc ool ing t empera tu re f rom Table 3.

= 10 °F

3. Required liquid line temperat ure from Table 4 = 84 °F

If the measured liquid line temperature at the liquid line near

the condens ing un it = 89 °F, then the actual level of subc ooling

based on Table 4 = 5° F

Therefore, add charge to reach required liquid line temperature given in Step 3, thereby, reaching the recommended

subcooling lev el in St ep 2 abov e.

If the measured liquid line temperature at the liquid line near

the condensing uni t = 79 °F, then the actual level of subc ooling

based on Table 4 = 15 °F.

Therefore, remove and re cover charge t o reach required li quid

line temperature given in Step 3, thereb y , reaching the recommended subcooling level in Step 2.

Once the charge is established when the lead compressor is

running, it is not neces sary to establish the ch arge once again

when both compressors are running. However it is recommended to energize the second compressor to verify system

performance.

TABLE 6 - REFRIGERANT LINE CHARGES

UNIT

SIZE

036, 048, 060 3/8 7/8 0.70

LIQUID LINE OD

VAPOR

LINE OD

R22 CHARGE

OZ / FT

TABLE 5 - CHARGE ADD STANDARD COILS

APPROVED SYSTEM COMBINATIONS

(Outdoor Unit / Variable Speed Air Handler & Coil)

H1DS036

N1VSD14

N2VSD20

H1DS048 N2VSD20

H1DS060 N2VSD20 G3HC / G1FC060 14 - 6 +0

10 Central Environmental Systems

G3HC / G1FC036

G3HC / G1FC042 +0

G3HC / G1FC048 +0

G3HC / G1FC060 +14

G3HC / G1FC048

G3HC / G1FC060 +14

CONDENSING UNIT

FACTORY CHARGE

LBS. - OZ.

9 - 9

9 - 9

INDOOR COIL

ADJUSTMENT

CHARGE, OZ.

+0

+0

Page 11

550.37-N1Y

RECORDING TOTAL SYSTEM CHARGE

The factory charge in the outdoor unit is listed in Table 5 and

includes enough charge for the unit, matched evaporator and

15 feet of lines. In stallations over 15 feet lo ng and some indoor

coil matches may require some addition al charge. Table 6 lists

the refrigeran t line charges .

The “TOTAL SYSTEM CHARGE” must be permanently

stamped on the unit dat a plat e.

Total system charge is determined as follows:

1. Determine t he c onde nsi ng unit c harge from Table 5.

2. Determine indo or coil adjustment charge fro m Table 5.

3. Calculat e the additional ch arge for line lengths greater than

15 feet using Table 6 factors.

4. Total system charge = Item 1 + Item 2 + Item 3.

5. Permanently stamp the unit da ta plate with the total amount

of refrigerant in the system.

SYSTEMS FUNCTIO NS

The dual compress or Stellar UL TRA air con ditioner has un ique

system functions as described below.

erations. See Table 7, which provides a list of LED functions

and definitio ns.

Power Supply

The five minute control board time delay is energized by means

of 24V power supply from th e transformer installed in the indoor

variable speed air handler. As soon as the control board

receives power, it warms up for five minutes before it starts

operating. The control boar d also has a 3A fuse which protects

the control board f rom sh ort circuit ing.

Five Minute Time Delay (Control Board)

Every time the con trol board is po wered afte r a power interruption, it will delay the operation f or fiv e minute s . Th e LED ligh t

on the control board wil l blink "ON" for 1 second and "OFF" f or

4 seconds, indicating a warm up period for the control board.

This will prevent the un it from short cyc ling.

Five Second Time Delay

A five second time delay is energized every time the board

receives a control signal Y1 or Y2 from the thermostat. This

prevents cycling of the unit and unnecessary operation of the

unit as a result of thermostat jigglin g.

One Minute Inter Stage Time Delay

COOLING OPERATION

The condensing unit utilize s a two stage cooling indoor thermostat. Depending on the cooling load requirements, the compressors are energized in sequence by means of the two stage

thermostat.

With a call for first stage cooling (Y1), the out door fan and the

lead compressor are energized. Simultaneously, the variable

speed indoor blower motor is also energized and the blower

delivers the corresponding airflow adequate for the first stage

cooling load.

With a call for second stage cooling (Y2), the follower compressor is also energized. Simultaneously, the variable speed

blower now delivers the rated CFM in order to satisfy the

cooling demand. The follower compressor is energized only

when cooling demand is not met by the lead compressor

running alone. Once t he second stage building load is satisfied,

the unit will operate with only the lead compressor, until first

stage indoor c ooling the rmostat is sati sfied, o r if t here is a call

for second stage c oolin g oper ation.

SYSTEM CONTROL BOARD OPERATIONS

The Stellar ULTRA air conditioner utilizes a control board to

control as well as monitor the operatio n of the two stage cooling

system. The following is an overview of the functions of the

control board.

Control Board LED Fun ctio ns

The control board used t o contro l and mon itor the op erat ion of

the two stage cooling sys tem has a LED mounted on the board,

which provides signals (Fault Codes) for several system op-

Anytime the unit receives a call for second stage cooling

operation (Y2) from t he thermostat, when the lead compressor

is operating, there is a one minute time delay before the

follower compressor will start. The outdoor fan motor and the

lead compressor continue to run during this inter-stage time

delay.

Five Minute Time Delay (Co m pr es so r 1 an d 2)

A five mi nute t ime delay p revents the system from short cyc ling

after a thermostat of f cyc le or po we r int errup ti on.

There is a five minute time delay for both, the lead and the

follower compres sor after a the rmostat of f cycle. These delay s

are incorporated to prevent the short cycling of the unit. However , during t he fi ve minute de lay on the follower c ompres sor,

the lead compressor and the outdoor fan will continue to run,

together with the indoor variable speed air handler, if the call

for cooling still exists.

For servicing or during ins tallation of the condensing unit, t he time

delay may be overridden by momentarily jumpering the test

terminal and "R" terminal on the board if necessa ry . However ,

the jumper must be removed during no r mal opera ti on.

Pressure Switches

High and low pressure switches are installed and wired in

series. They p rovide addtional protection for the system if any

abnormal operating conditions occur. If the control board

senses a tripping of the high or low pressure switch, the control

will provide a five minute delay before the system starts operating again. The LED will blink rapidly indic ating that there is a

Central Environmental Systems 11

Page 12

550.37-N1Y

TABLE 7 - LED FUNCTIONS

LED DISPLAY DEFINITION

LED LIGHT "ON" (No Flashing) Normal Operation

FLASH (1 Second) PAUSE (4 Seconds) Control Board Warm-up Operation

FLASH (1 Second) PAUSE (1 Second) High or Low Pressure Switch Trip

RAPID FLASHES High or Low Pressure Switch Lockout

LED LIGHT "OFF" No Power Supply or Board Failure

system error. The LED will blink "ON" for 1 sec ond an d "O FF"

for 1 second during the opening of either h igh o r low pre ssure

switches. If four t rips occur within 30 minut es, the control b oard

logic will lock out the outdoor unit, preventing operation. The

unit can be operated again by resetting the indoor two stage

cooling thermost at once the loc kou t cond it ion is reso lv ed.

Crankcase Heater Operation

The control board will energize the cra nkcase heater during the

condensing unit "OFF" cy cle.

Condensin g Unit Fan Ope r atio n

The control board will ene rgize the condensing unit fan a nytime

the compressor is operati ng. The outdoor fan will remain energized during the "One Minute Inter-Stage Time Delay". However , the fan will not remain energized, if either , the High or Lo w

pressure switch es trip.

INSTRUCTING THE OWNER

Assist owner with processing warr ant y ca rds . Revi ew Owne rs

Guide and provide a copy for the owner guidance on proper

operation and main tenanc e. Inst ruct the o wner or the o perator

how to start, stop and adjust temperature setti ng.

1. The outdoor fan should be running, with warm air being

discharged from t he top of the unit .

2. The indoor blower (furnace or air handler) will be operat ing,

discharging cool air from the ducts.

3. The vapor line at the outdoor unit will feel cool to the touch.

4. The liquid line at the outdoo r unit will feel warm to the to uch.

If unit is not operating p roperly , check the follo wing items bef ore

calling a servic eman :

1. Indoor section for dir ty filt er.

2. Outdoor sect io n for leaf or debr is block ag e.

Eliminate problem, turn off the thermostat for 10 seconds and

attempt start. Wait 5 minutes. If system does not start, call

service technician.

MAINTENANCE

1. Dirt should not be allowed to accumulate on the outdoor

coils or other parts in the air circuit. Clean as often as

necessary to keep the unit clean. Use a brush, vacuum

cleaner attac hment , or ot her suit able mea ns.

When applicable, instruct the owner that the compressor is

equipped with a crankcase heater to prevent the migration of

refrigerant to the compressor during the “OFF” cycle. The

heater is energized only when the uni t is not running. If the main

switch is disconnected for long periods of shut down, do not

attempt to start the unit 8 hours after the switch has been

connected. This will allow suf ficient time for all liquid refrigerant

to be driven out of the compressor .

The installer should also instruct the owner on proper operation and maintena nc e of all other s ystem compo nents.

INDICATIONS OF PROPER OPERATION

Cooling operation is the same as any conventional air conditioning unit.

The following checks may be made to determine if the system

is operating properly:

2. The outdo or fan moto r is permanently lubricated and does

not require periodic oiling.

3. If the coil needs to be cleaned, it should be washed with

Calgon CalClean (mix one part CalClean to seven parts

water). Allow solution to remain on coil for 30 minutes

before rinsing with clean water. Solution should not be

permitted to come in contact with painted surfaces.

4. Refer to th e furnac e or air han dler ins truc tio ns f or filt er and

blower motor maintena nc e.

5. The evaporator coil drain pan should be inspected and

cleaned regula rly to prevent odors and assure proper drainage.

WHEN THE SYSTEM IS FUNCTIONING PROPERLY AND

THE OWNER HAS BEEN FULLY INSTRUCTED, SECURE

THE OWNER’S APPROV AL.

P.O. Box 1592, York, Pennsylvania USA 17405-1592

Subject to change wi thout notice. Printed in U.S.A

Copyright by York International Corporation 1994. All Rights Reserved.

Loading...

Loading...