Page 1

036-21342-002 Rev. E (0505)

c

®

TECHNICAL GUIDE

STEALTH

SPLIT-SYSTEM HEAT PUMP

15 SEER

MODELS: E4TS030 THRU 060

(2.5 THRU 5 NOMINAL TONS)

O

T

A

D

R

E

I

I

A

F

S

I

T

R

C

E

O

C

M

I

N

U

C

E

R

T

A

R

Y

R

A

T

E

Q

I

F

I

C

A

T

I

S

T

A

WITH ARI.

P

L

Y

H

E

I

A

T

N

G

P

U

M

P

R

T

F

N

U

E

I

P

M

O

S

N

O

I

T

C

E

S

I

0

N

O

4

2

D

R

N

A

D

ISO 9001

LISTED

Certified Quality

Management System

R

E

R

U

T

C

A

F

U

N

A

M

CERTIFICATIONAPPLIES ONLY

WHEN THE COMPLETE

SYSTEM IS LISTED

Due to continuous product improvement, specifi

tions are subject to change without notice.

Visit us on the web at www.york.com for the most

up-to-date technical information.

Additional rating information can be found at

www.ariprimenet.org.

DESCRIPTION

The ETS Stealth series heat pump units use Twin Single™

compressor technology to provide cooling efficiencies up to

15.7 SEER and heating efficiencies up to 9.3 HSPF. They are

to be installed with the matching variable speed Enhancer air

handler or Diamond furnace, a corresponding coil and sweat

connect lines. A factory specified balanced port hard shut-off

TXV kit must be used for proper installation and optimum performance.

WARRANTY

5-year limited parts warranty.

10-year limited compressor warranty.

FEATURES

QUALITY CONDENSER COILS - The coil is constructed of

copper tube and hardened aluminum fins for durability and long

lasting efficient operation. The fins on the unit are protected

with a decorative grille.

DURABLE FINISH - Cabinet is made of powder painted steel

over pre-painted primer. The pre-treated flat galvanized steel

provides a better paint to steel bond, which resists corrosion

and rust creep. Special primer formulas and glossy earth tone

finish insure less fading when exposed to sunlight. This finish

has been tested to provide 1/3 greater protection than conventional units.

PROTECTED COMPRESSORS - The Twin Single™ compres-

sor is protected against high pressure. Hard start components

are included to ensure start-up under adverse conditions. All

models have standard crankcase heat for added protection.

OPTIMUM PERFORMANCE - The solid-state electronic controlboard optimizes the compressor staging based on load

requirements, provides a 5-minute anti-short cycle timer, and

simplifies troubleshooting with built in self diagnostics.

LOWER INSTALLED COST - Installation time and costs are

reduced by easy power and control wiring connections. All

units contain enough refrigerant for the smallest matching

indoor coil and 15 feet of interconnecting piping. The small

base dimension means less space is required on the ground or

roof.

EFFECTIVE HUMIDITY CONTROL - The inherent design of

the Stealth system and the staging operation of the Twin Single™ compressor provide effective humidity control at the lowest possible operating cost. An optional dehumidification

control accessory is available to maintain the humidity at a set

desired level.

TOP DISCHARGE - The warm air from the top mounted fan is

blown up away from the structure and any landscaping. This

allows compact location on multi-unit applications.

LOW OPERATING SOUND LEVEL - The upward air flow carries the normal operating noise up away from the living area.

The rigid top panel effectively isolates any motor sound. Isolator mounted compressor and the rippled fins of the condenser

coil muffle the normal fan motor and compressor operating

sounds.

LOW MAINTENANCE - Long life permanently lubricated

motor- bearings need no annual servicing.

EASY SERVICE ACCESS - Fully exposed refrigerant connections and a single panel covering the electrical controls make

servicing easy. Easy access for coil clearing is also provided.

RE-USABLE SERVICE VALVES - Provided on both the liquid

and vapor sweat connections for ease of evacuating and

charging.

FOR DISTRIBUTION USE ONLY - NOT TO BE USED AT POINT OF RETAIL SALE

Page 2

036-21342-002 Rev. E (0505)

SYSTEM OPERATION

This heat pump model is equipped with both YorkGuard V

heat pump control and TS compressor control. The interface

control 6CF board is used to bypass the first stage of heat

when the outdoor temperature falls below certain temperatures. The TS control board is used only to switch between 1

and 2 cylinder operation. The fault codes and pressure switch

on the TS control board are bypassed using the jumpers

between the test and "PS" pins.

1. Anti-short Cycle Timer

The five-minute time delay on YorkGuard V will be used

to prevent the system from short cycling after the thermostat off or power interrupt. This time delay can be

bypassed by temporarily shorting the test terminals on

YorkGuard V for 3 seconds. Since a jumper was factory

installed across the test pins on the TS control board, the

anti-short cycle timer on the TS control board is

bypassed.

2. First Stage Cooling

This heat pump model is equipped with a Twin-Single

compressor. With a call for first stage cooling, the compressor operates one cylinder. The run winding (R) is

connected through the upper left contactor (A) and to the

capacitor and the start winding (S) is connected to line

voltage. The system operates at low discharge pressure

and high suction pressure.

3. Second Stage of Cooling

With a call for second stage cooling, the TS control will

shut the compressor off for two seconds then energize

relays R1 and R2 on the TS control board. This will deenergize (open) the upper left contactor (A) and energize

(close) the lower right contactor (B), connecting the compressor run winding (R) to the line voltage and start

winding (S) to the capacitor. The compressor runs in the

reverse direction with two cylinders compared to the first

stage. The system will operate with two cylinders until

both first and second stage are satisfied. The Y2OUT

signal from the relay board causes the indoor blower to

function at high speed.

If the room thermostat calls for second stage cooling

(Y2) on two consecutive cooling cycles, the next call for

cooling for either first or second stage will energize the

unit in second stage mode. The above mode will be reset

to permit start up on the first stage with only a Y1 call

when the second stage operation cycle runs less than 15

minutes or when 24V to the TS control board is disconnected.

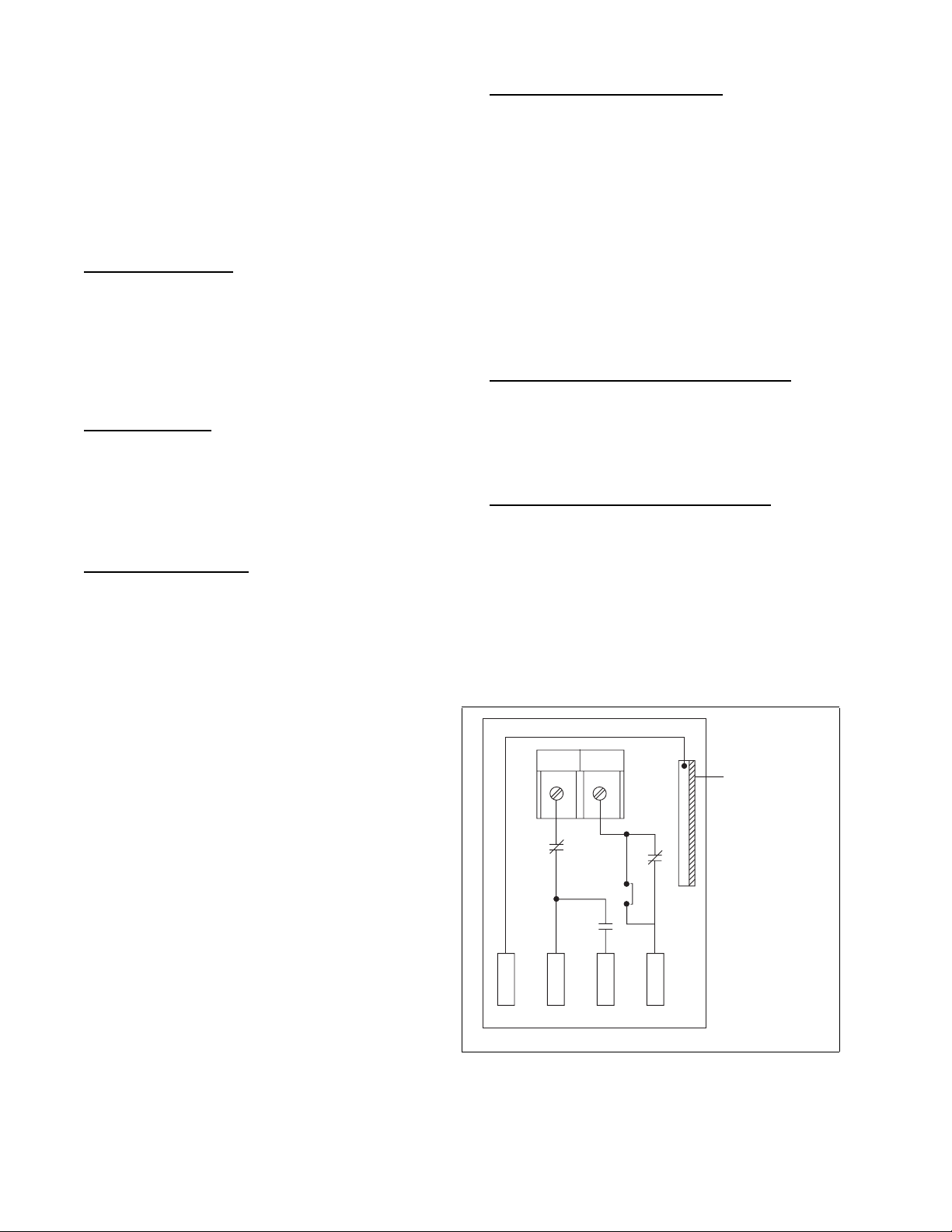

4. 6K Relay on the 6CF Control Board

The 6K relay on the 6CF interface board operates as follows. See Figure 1:

a. If the YorkGuard V defrost control balance point set-

ting is 45°F, the 6K relay will be:

• Energized if liquid temperature goes below 35°F.

• De-energized if the liquid temperature goes above

35°F AND the ambient is greater than 42°F for five

minutes AND the unit is not in defrost.

b. If the YorkGuard V defrost control balance point set-

ting is at anything but 45°F, the 6K relay will be:

• Energized if liquid temperature goes below 45°F.

• De-energized if the liquid temperature goes above

45°F AND the ambient is greater than 55°F AND

the unit is not in defrost.

5. Heating mode with the de-energized 6K relay

The TS compressor operates similar to the first and second stage of cooling modes except there is no O input

from the thermostat, the reversing valve is not energized,

and the system operates in heating heat pump mode.

The YorkGuard V control and the liquid temp erature will

not allow the system to go into the defrost mode.

6. Heating mode with the energized 6K Relay

The energized 6K relay on the interface board (6CF) will

connect Y1 and Y2 and disconnect Y2OUT from the TS

control to the indoor blower if the J1 pin is not in the ON

position. The compressor will operate only in second

stage regardless of the first or second stage call from the

thermostat. The indoor blower will operate in low air

mode. The indoor discharge air temperature should be

about 10°F hotter than a normal heat pump. If highspeed air is preferred, move J1 pin to the ON position at

the interface board (6CF). This will send the Y2OUT signal back to the indoor blower for the high speed air.

Y2

6K

NC

Y2 OUT

6K

NC

J1

6K

NO

24V (R) FROM

YORKGUARD

R

Y2

Y1

Y2 OUT

FIGURE 1 : 6CF Interface Board

2 Unitary Products Group

Page 3

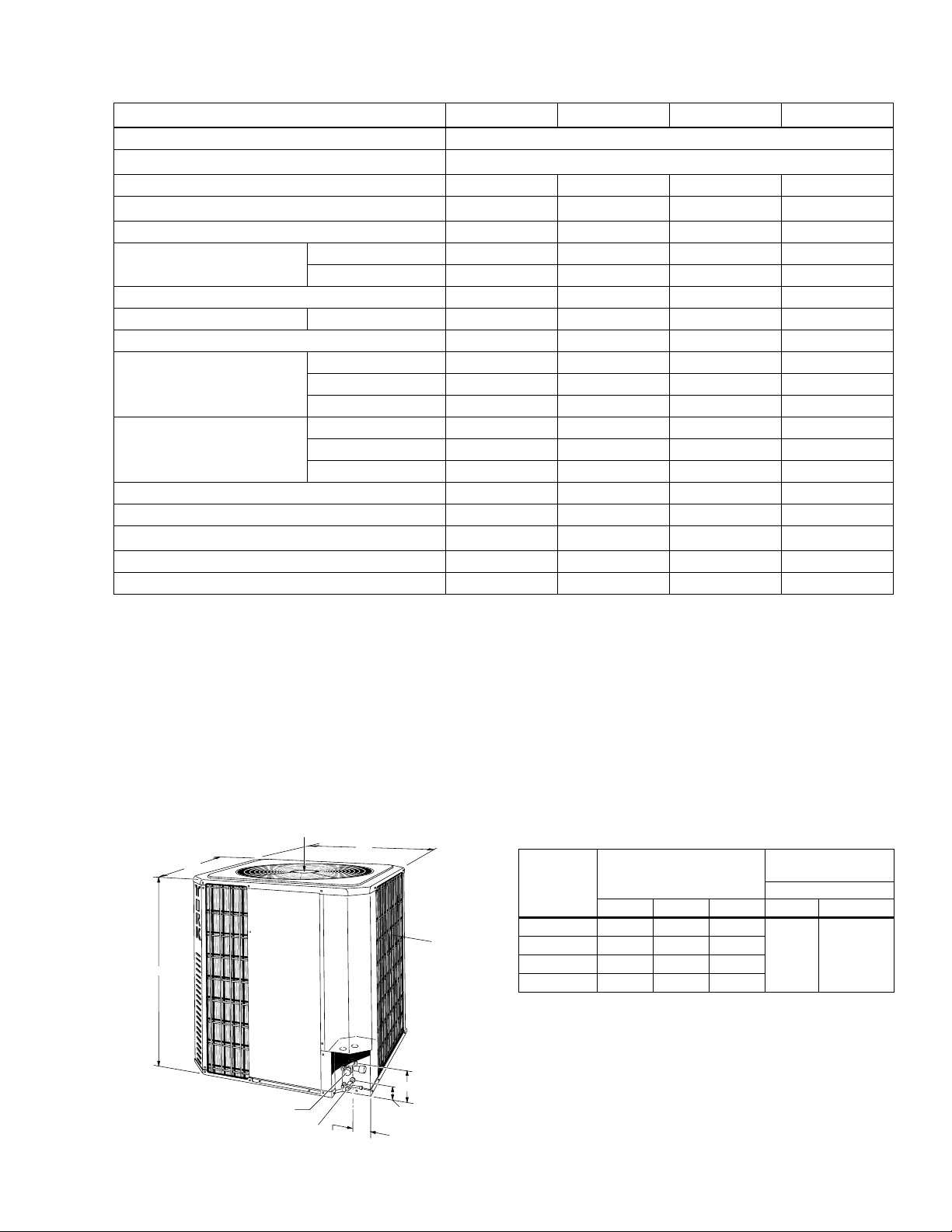

Physical and Electrical Data

036-21342-002 Rev. E (0505)

MODEL

E4TS030 E4TS036 E4TS048 E4TS060

UNIT SUPPLY VOLTAGE 208/230-1-60

NORMAL VOLTAGE RANGE

1

187 to 252

MIN. CIRCUIT AMPACITY 14.8 18.3 28.0 34.4

MAX. OVERCURRENT DEVICE AMPS

2

25 30 50 60

COMPRESSOR TYPE T27B264CBCA T27B355CBCA T29A464BBCA T29A544BBCA

COMPRESSOR AMPS

RATED LOAD 11.3 14.1 21.2 26.3

LOCKED ROTOR 65 84 130 142

CRANKCASE HEATER YES YES YES YES

FAN MOTOR AMPS RATED LOAD .7 .7 1.5 1.5

FAN DIAMETER INCHES 24 24 24 24

RATED HP 1/10 1/10 1/4 1/4

FAN MOTOR

NOMINAL RPM 825 825 825 850

NOMINAL CFM 2650 2650 3200 3200

FACE AREA SQ. FT.20.020.020.020.0

COIL

ROWS DEEP1122

FIN / INCH 16 16 13 13

LIQUID LINE OD 3/8 3/8 3/8 3/8

VAPOR LINE OD 7/8 7/8 7/8 7/8

UNIT CHARGE, (LBS - OZ)

3

9 - 9 10 - 1 12 - 1 13 - 1

CHARGE PER FOOT, OZ .70 .70 .70 .70

OPERATING WEIGHT LBS. 242 242 310 310

1. Rated in accordance with ARI Standard 110, utilizaton range “A”.

2. Dual element fuses or HACR circuit breaker.

3. The Unit Charge is correct for the outdoor unit, matched indoor coil and 15 feet of refrigerant tubing. For tubing lengths other than

15 feet, add or subtract the amount of refrigerant calculated, using the difference in length multiplied by the per foot value.

48" OVERHEAD

CLEARANCE

B

A

VAPOR

CONNECTION

LIQUID CONNECTION

3-1/8

C

AIR IN

4 SIDES

5-1/2

2-3/8

All dimensions are in inches. They are subject to change without

notice. Certified dimensions will be provided upon request.

UNIT

MODEL

E4TS

030

036

048

060

DIMENSIONS

ABC

31-7/8 35 35

31-7/8 35 35

31-7/8 35 35

37-7/8 35 35

REFRIGERANT

CONNECTION

LINE SIZE

LIQUID VAPOR

3/8

Unitary Products Group 3

7/8

Page 4

036-21342-002 Rev. E (0505)

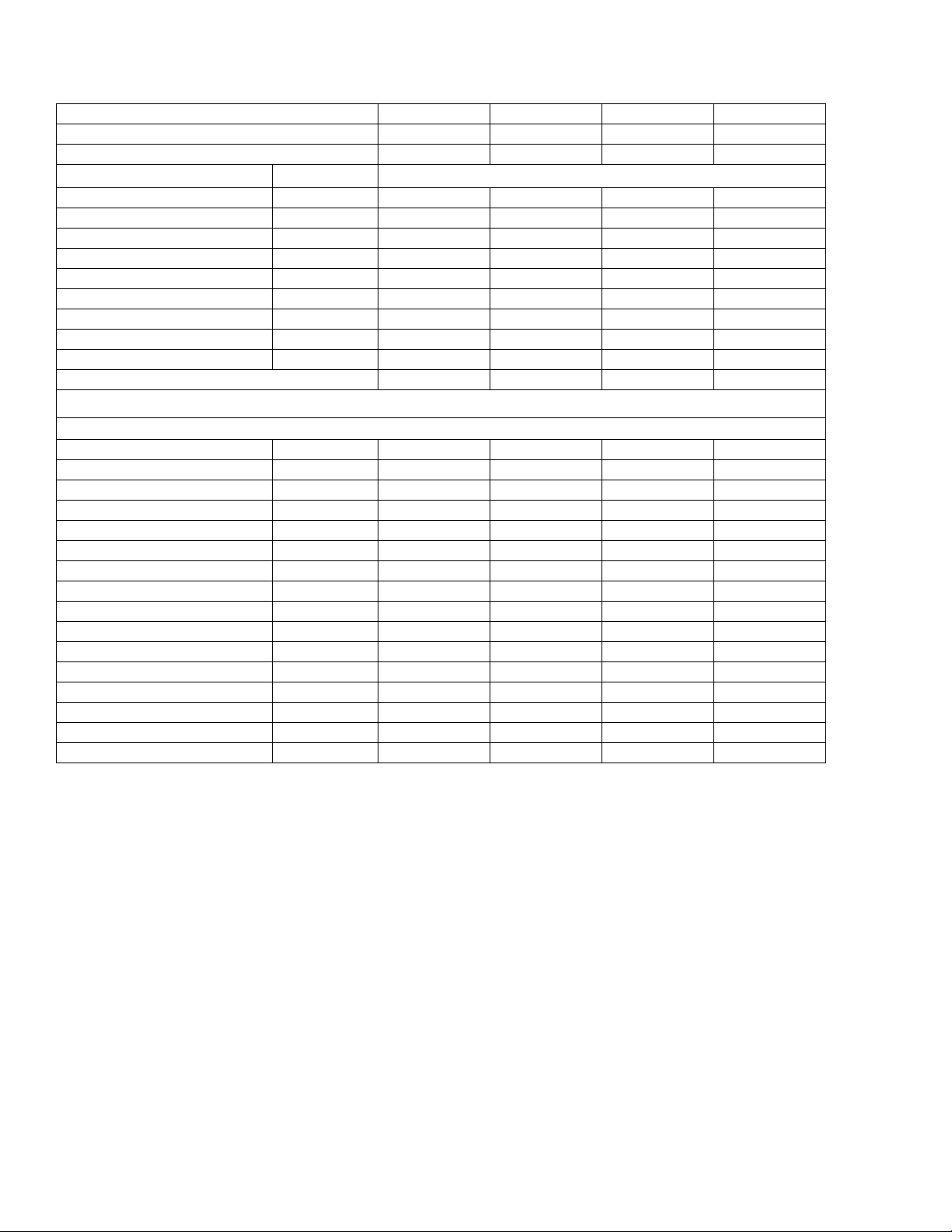

Additional R-22 Charge / Orifice Size for Various Matched Systems

OUTDOOR UNIT E4TS030 E4TS036 E4TS048 E4TS060

UNIT ORIFICE(S)** ————

FACTORY CHARGE, LBS. - OZ. 9 - 9 10 - 1 12 - 1 13 - 1

1

INDOOR COIL

G1FA/G1UA048S17,21 78 701 + 0 702 + 0 — —

G1FA/G1UA060S21,24 84 — 702 + 10 703 + 0 703 + 0

G1FA060S21,24T 84 — — 703 + 0 703 + 0

G2FD046(S,H)17 78 701 + 0 702 + 0 — —

G2FD042(S,H)21 78 701 + 0 — — —

G2FD048(S,H)21, 24 84 701 + 6 702 + 0 — —

G2FD060(S,H)24 90 — 702 + 10 703 + 0 703 + 0

G2FD060H24T 90 — — 703 + 0 703 + 0

G2FD061H24 90 — — 703 + 8 703 + 4

REFRIGERANT LINE ADDER OZ. / FT. .70 .70 .70 .70

COIL ORIFICE

REQUIRED SYSTEM EXPANSION DEVICE + ADDITIONAL CHARGE, OZ.

Airflow

VARIABLE SPEED INDOOR

N1VSB12 Hi/Low CFM 1050/630 — — —

N1VSC16 Hi/Low CFM 1065/650 1185/770 — —

N1VSD20 Hi/Low CFM — 1200/780 1605/1040 1860/1200

P1XDB12V075 Hi/Low CFM 1040/580 1220/690 — —

P1XUB12V055 Hi/Low CFM 1020/570 1200/660 — —

P1DUB16V080 Hi/Low CFM 1050/540 1200/650 — —

P1XUC16V075 Hi/Low CFM 1000/550 1200/650 1605/880 —

P1DUC20V080 Hi/Low CFM — 1220/660 1620/900 1870/1030

P1DUC20V096 Hi/Low CFM — 1200/650 1610/900 1850/1080

P1XUC20V095 Hi/Low CFM — 1200/630 1590/850 1880/1000

P1XUD20V112 Hi/Low CFM — 1260/720 1620/920 1800/990

P1XDD20V112 Hi/Low CFM — 1200/690 1610/850 1870/1010

F(2,3)FV060 Hi/Low CFM — — 1600/1040 1875/1200

Hi CFM — 1000 1200 1600 1900

Max Low CFM — 850 1000 1350 1600

Recommended Low CFM — 600 750 900 1050

1. Unit factory charge listed on the unit namep late includes refrigerant for the condensor, the smallest evaporator and for 15 feet of

interconnecting line tubing.

2. Verify the TXV kit and the additional charge required for the specific evaporator coil in the system using the table above.

3. Add additional charge for the amount of interconne cting line tubing greater than 15 feet at the rate specified in the table above.

4. Permanently mark the unit nameplate with the total system charge.

5. Total System Charge = Base charge (as shipped) + adder for evaporator + adder for line set.

4 Unitary Products Group

Page 5

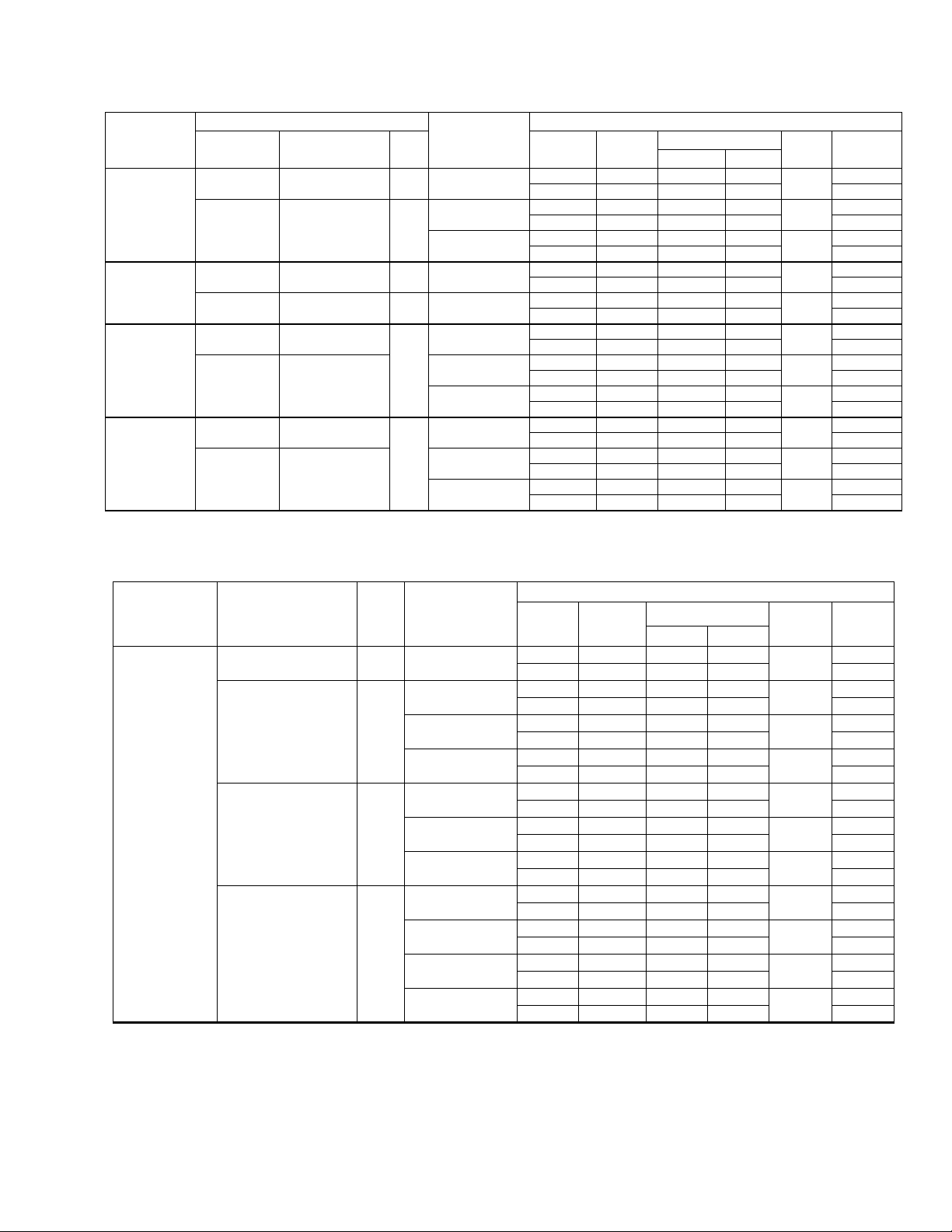

COOLING CAPACITY - Variable Speed Air Handler

UNIT

MODEL

E4TS030

E4TS036

E4TS048

E4TS060

1. G2FD coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Single phase units require single phase 2HK heaters.

N1VS AIR HANDLER

MODEL

N1VSB12 5,7.5,10,15,18 17 G2FD046S17

N1VSC16 5,7.5,10,15,20 21

N1VSC16 5,7.5,10,15,20 21 G2FD048S21

N1VSD20 7.5,10,15,20,25,30 24 G2FD048S24

F(2,3)FV060 10,15,20,25

N1VSD20 7.5,10,15,20,25,30

F(2,3)FV060 10,15,20,25

N1VSD20 7.5,10,15,20,25,30

ELECTRIC

HEA T KW

2

COIL MODEL

W

G2FD042S21

G2FD048S21

G2FD060S24

24

G2FD061H24

G2FD060S24

24

G2FD061H24

–

–

1

STAGE

(# CYL)

RATED

CFM

1 630 15200 12200

2 1050 29000 21400 12.0

1 650 15000 12000

2 1065 28600 21000 11.9

1 650 15800 12600

2 1065 30000 22000 12.1

1 770 21400 15400

2 1185 36000 25600 11.6

1 780 21600 15600

2 1200 36400 26000 11.8

1 1040 26800 21800

2 1600 48000 35600 11.4

1 1040 26800 21800

2 1605 48000 35600 11.4

1 1040 27400 22200

2 1605 49000 36400 11.6

1 1220 27800 23400

2 1875 55500 40500 10.4

1 1200 27800 23400

2 1860 55500 40500 10.4

1 1200 29000 24000

2 1860 57000 41500 10.6

TOTAL SENS.

036-21342-002 Rev. E (0505)

COOLING

NET MBH

SEER EER

15.5

15.4

15.7

15.0

15.2

15.0

15.0

15.2

14.5

14.5

14.7

13.7

13.6

13.9

13.3

13.6

13.6

13.6

13.8

13.2

13.2

13.4

COOLING CAPACITY - Variable Speed Furnace

UNIT

MODEL

E4TS030

For notes see Page 7.

VARIABLE SPEED

FURNACE MODEL

P1XDB12V 17 G2FD046S17

P1XUB12V 17

P1DUB16V 17

P1XUC16V 21

WCOIL MODEL

G2FD046S17

G1UA048S17

G1FA048S17

G2FD046S17

G1UA048S17

G1FA048S17

G2FD042S21

G1UA048S21

G1FA048S21

G2FD048S21

COOLING

STAGE

(# CYL)

RATED

CFM

1 580 13800 10400

2 1040 28200 20800 11.6

1 570 13800 10400

2 1020 28000 20600 11.6

1 570 13800 10400

2 1020 28000 20600 11.6

1 570 13800 10400

2 1020 28000 20600 11.6

1 540 13600 10200

2 1050 28200 20800 11.7

1 540 13600 10200

2 1050 28200 20800 11.7

1 540 13600 10200

2 1050 28200 20800 11.7

1 600 13600 10400

2 1100 28000 20600 11.4

1 600 13800 10600

2 1100 28800 21400 11.6

1 600 13800 10600

2 1100 28800 21400 11.6

1 600 14200 10800

2 1100 29000 21400 11.8

NET MBH

TOTAL SENS.

1

SEER2EER

15.0

15.0

15.0

15.0

15.0

15.0

15.0

14.8

15.2

15.2

15.3

3

13.3

13.3

13.3

13.3

13.4

13.4

13.4

13.2

13.6

13.6

13.7

Unitary Products Group 5

Page 6

036-21342-002 Rev. E (0505)

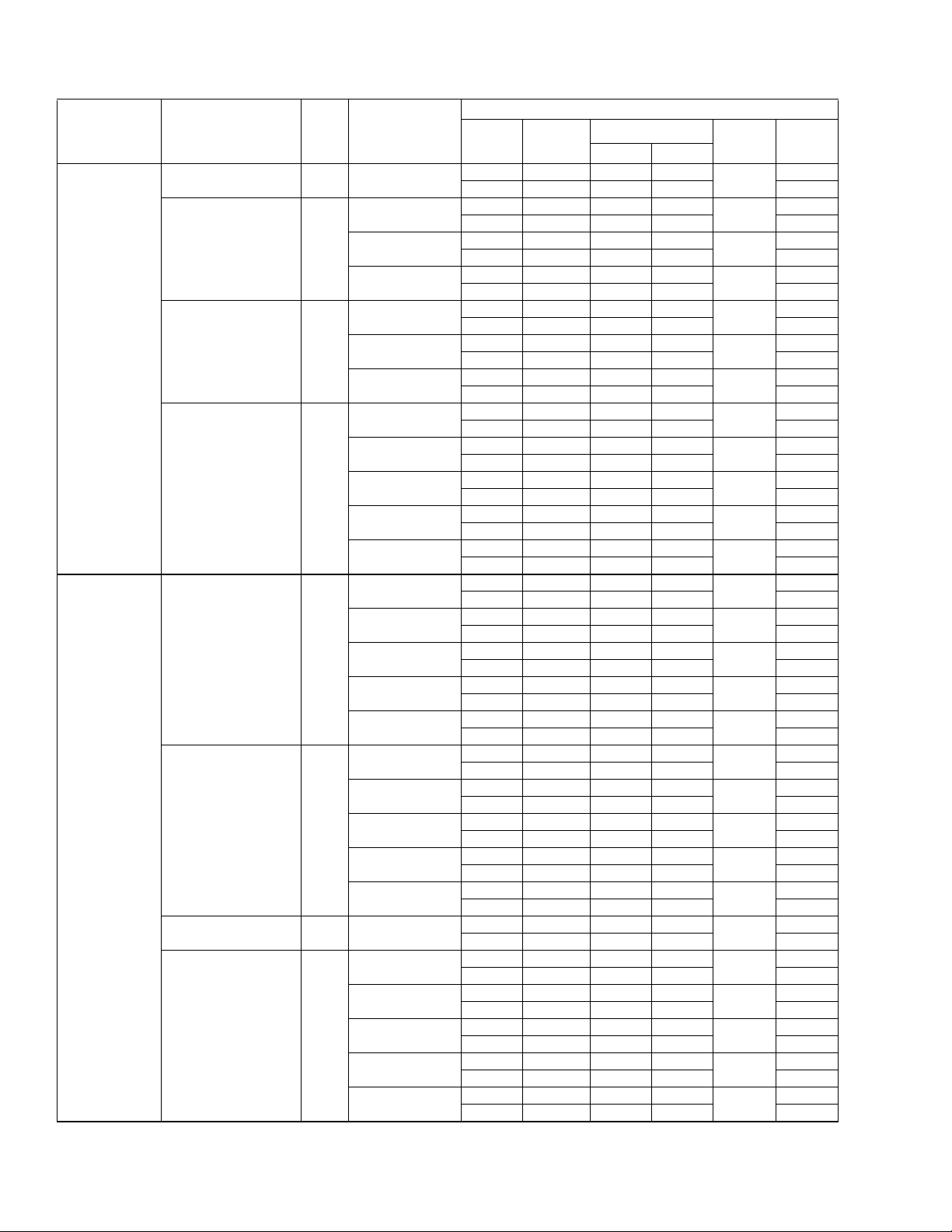

COOLING CAPACITY - Variable Speed Furnace (Continued)

UNIT

MODEL

E4TS036

E4TS036

For notes see Page 7.

VARIABLE SPEED

FURNACE MODEL

P1XDB12V 17 G2FD046S17

P1XUB12V 17

P1DUB16V 17

P1XUC16V 21

P1DUC20V 21

P1XUC20V 21

P1XDD20V 24 G2FD048S24

P1XUD20V 24

WCOIL MODEL

G2FD046S17

G1UA048S17

G1FA048S17

G2FD046S17

G1UA048S17

G1FA048S17

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S24

G1FA048S24

G2FD048S24

G1UA060S24

G1FA060S24

STAGE

(# CYL)

COOLING

RATED

CFM

1 690 20000 15200

2 1220 35600 25800 10.8

1 660 19800 15000

2 1200 35400 25600 11.0

1 660 19800 15000

2 1200 35400 25600 11.0

1 660 19800 15000

2 1200 35400 25600 11.0

1 650 20000 15000

2 1200 35600 25600 11.0

1 650 20000 15000

2 1200 35600 25600 11.0

1 650 20000 15000

2 1200 35600 25600 11.0

1 640 20200 15200

2 1200 35800 25800 11.1

1 640 20200 15200

2 1200 35800 25800 11.1

1 640 20400 15400

2 1200 36000 26000 11.1

1 640 21000 15800

2 1200 37000 26600 11.3

1 640 21000 15800

2 1200 37000 26600 11.3

1 640 20200 15200

2 1200 35800 25800 11.2

1 640 20200 15200

2 1200 35800 25800 11.2

1 640 20400 15400

2 1200 36000 26000 11.3

1 640 21000 15800

2 1200 37000 26600 11.4

1 640 21000 15800

2 1200 37000 26600 11.4

1 625 20000 15000

2 1200 35600 25600 11.0

1 625 20000 15000

2 1200 35600 25600 11.0

1 625 20200 15200

2 1200 35800 25800 11.2

1 625 20800 15600

2 1200 36800 26400 11.3

1 625 20800 15600

2 1200 36800 26400 11.3

1 690 20400 16200

2 1200 36000 27400 11.3

1 715 20600 16000

2 1260 36200 27200 11.2

1 715 20600 16000

2 1260 36200 27200 11.2

1 715 20800 16200

2 1260 36400 27400 11.4

1 715 21400 16600

2 1260 37400 28000 11.6

1 715 21400 16600

2 1260 37400 28000 11.6

NET MBH

TOTAL SENS.

1

SEER2EER

14.0

14.0

14.0

14.0

14.0

14.0

14.0

14.0

14.0

14.0

14.4

14.4

14.1

14.1

14.3

14.6

14.6

14.0

14.0

14.2

14.5

14.5

14.5

14.2

14.2

14.5

14.8

14.8

12.4

12.5

12.5

12.5

12.6

12.6

12.6

12.5

12.5

12.6

13.0

13.0

12.5

12.5

12.8

13.1

13.1

12.6

12.6

12.7

13.0

13.0

12.9

12.8

12.8

13.0

13.3

13.3

3

6 Unitary Products Group

Page 7

036-21342-002 Rev. E (0505)

COOLING CAPACITY - Variable Speed Furnace (Continued)

UNIT

MODEL

E4TS048

E4TS048 P1XUD20V 24

E4TS060

1. Cooling MBH based on 80° F entering air temperature, 50% RH and rated airflow.

2. SEER (Seasonal Energy Efficiency Ratio) equals the total cooling output in BTU’s during a normal annual usage period for cooling divided by the total electric power input in watt-hours during the same period. Normal annual usage is a combination of both

one and two cylinder operating periods.

3. EER (Energy Efficiency Ratio) equals the total cooling output in BTU’s at 95° F outdoor ambient divided by the total electric power

in watt-hours at those conditions.

VARIABLE SPEED

FURNACE MODEL

P1XUC16V 21

P1DUC20V 21

P1XUC20V 21

P1XDD20V 24

P1XDD20V 24

P1XUD20V 24

WCOIL MODEL

G1UA060S21

G1UA060S21

G1UA060S21

G1FA060S21

G1UA060S21

G1FA060S21

G2FD060S24

G2FD061H24

G1UA060S24

G1FA060S24

G2FD060S24

G2FD061H24

G2FD060S24

G2FD061H24

G1UA060S24

G1FA060S24

G2FD060S24

G2FD061H24

STAGE

(# CYL)

RATED

CFM

1 880 23800 17600

2 1600 47000 33800 10.8

1 880 23800 17600

2 1600 47000 33800 10.8

1 900 24200 18000

2 1610 47500 34200 10.9

1 900 24200 18000

2 1610 47500 34200 10.9

1 850 23600 17400

2 1590 47000 33800 10.8

1 850 23600 17400

2 1590 47000 33800 10.8

1 880 24400 18400

2 1580 47500 34200 11.0

1 880 24800 18800

2 1580 48500 34800 11.2

1 915 24800 18800

2 1620 48000 34600 11.0

1 915 24800 18800

2 1620 48000 34600 11.0

1 915 24800 18800

2 1620 48000 34600 11.0

1 915 25200 19200

2 1620 49000 35200 11.3

1 1000 27000 20400

2 1800 55000 39600 10.0

1 1000 28000 20800

2 1800 56000 40000 10.2

1 990 27000 20400

2 1800 55500 40000 10.2

1 990 27000 20400

2 1800 55500 40000 10.2

1 990 27000 20400

2 1800 55500 40000 10.2

1 990 28000 20800

2 1800 56500 40500 10.4

COOLING

NET MBH

1

TOTAL SENS.

SEER2EER

14.0

14.0

14.0

14.0

14.0

14.0

14.0

14.4

14.2

14.2

14.2

14.5

13.7

14.0

13.8

13.8

13.8

14.0

3

12.6

12.6

12.6

12.6

12.6

12.6

12.5

12.7

12.7

12.7

12.7

12.9

12.6

12.8

12.5

12.5

12.5

12.8

Unitary Products Group 7

Page 8

036-21342-002 Rev. E (0505)

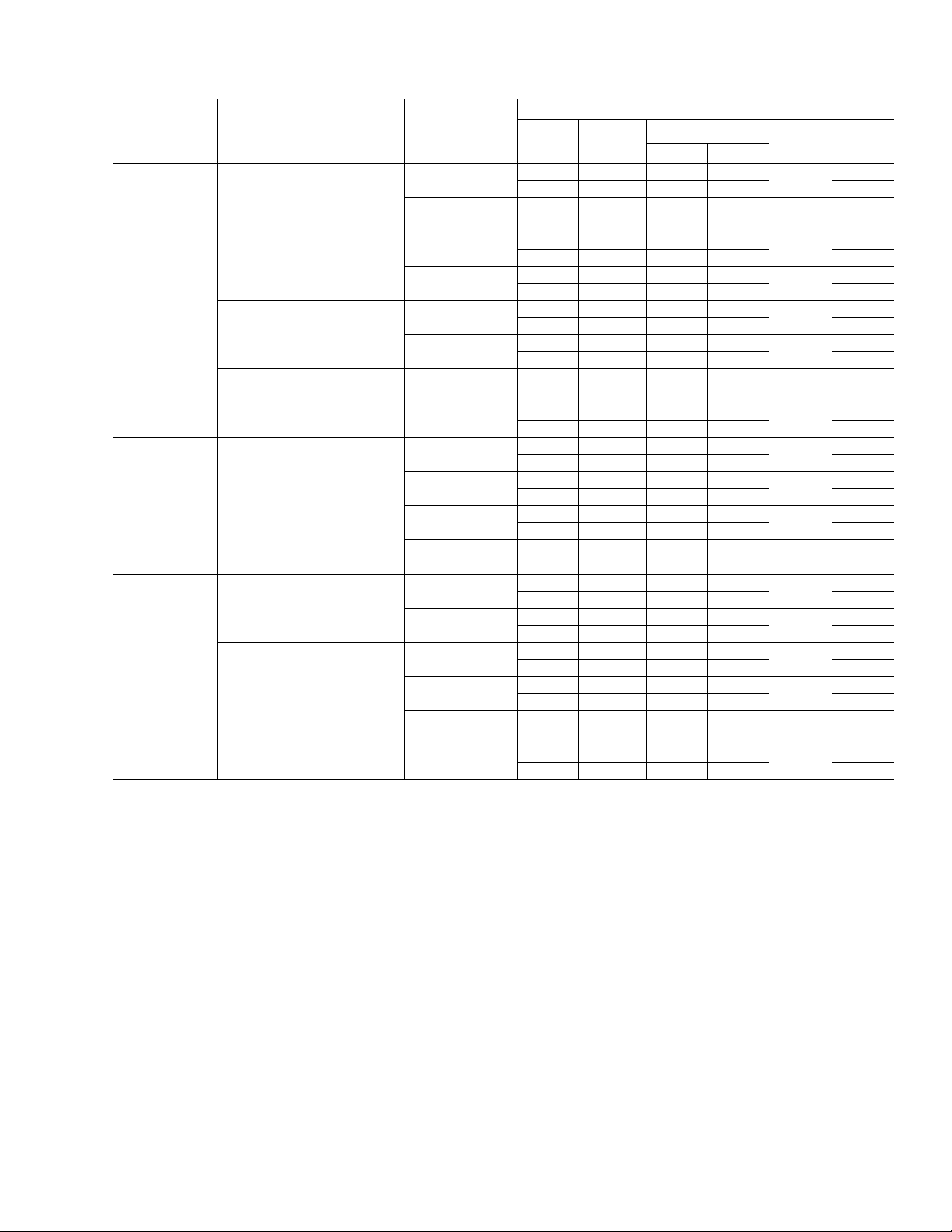

HEATING CAPACITY - Variable Speed Air Handler

UNIT

MODEL

E4TS030

E4TS036

E4TS048

E4TS060

1. G2FD coils available with a factory installed horizontal drain pan. See price pages for specific model number.

2. Single phase units require single phase 2HK heaters.

N1VS AIR HANDLER

MODEL

N1VSB12 5,7.5,10,15,18 17 G2FD046S17

N1VSC16 5,7.5,10,15,20 21

N1VSC16 5,7.5,10,15,20 21 G2FD048S21

N1VSD20 7.5,10,15,20,25,30 24 G2FD048S24

F(2,3)FV060 10,15,20,25

N1VSD20 7.5,10,15,20,25,30

F(2,3)FV060 10,15,20,25

N1VSD20 7.5,10,15,20,25,30

ELECTRIC

HEAT KW

2

COIL MODEL

W

G2FD042S21

G2FD048S21

24

G2FD060S24

G2FD061H24

24

G2FD060S24

G2FD061H24

–

–

1

STAGE

(# CYL)

RATED

CFM

1 630 13400 – – 3.80

2 630 24600 14400 8.7 3.48

2 1050 26400 15400 9.0 3.60

1 650 13200 – – 3.80

2 650 24200 14200 8.7 3.46

2 1065 26000 15200 9.0 3.58

1 650 13800 – – 3.88

2 650 24800 14800 8.9 3.52

2 1065 27000 16000 9.2 3.64

1 770 19600 – – 3.78

2 770 31600 19000 8.7 3.52

2 1185 35000 20800 9.2 3.54

1 780 20000 – – 3.86

2 780 32000 19200 8.8 3.62

2 1200 35600 21200 9.3 3.74

1 1040 23800 – – 3.66

2 1040 43500 24800 8.2 3.50

2 1600 47000 26400 8.5 3.58

1 1040 23800 – – 3.66

2 1040 43500 24800 8.2 3.50

2 1605 47000 26400 8.5 3.58

1 1040 24200 – 3.72

2 1040 44500 25600 8.4 3.58

2 1605 48000 27000 8.7 3.66

1 1220 25800 – – 3.58

2 1220 51000 26400 8.1 3.32

2 1875 54000 28600 8.5 3.44

1 1200 25800 – – 3.58

2 1200 51000 26400 8.1 3.32

2 1860 54000 28600 8.5 3.44

1 1200 26600 – – 3.64

2 1200 50500 26800 8.3 3.38

2 1860 55000 29200 8.7 3.50

HEATING

47 OD 17 OD

NET MBH

HSPF COP@ 47

8 Unitary Products Group

Page 9

HEATING CAPACITY - Variable Speed Furnace

UNIT

MODEL

E4TS030

E4TS036

For notes see Page 12.

VARIABLE SPEED

FURNACE MODEL

P1XDB12V075 17 G2FD046S17

P1XUB12V055 17

P1DUB16V080 17

P1XUC16V075 21

P1XDB12V075 17 G2FD046S17

P1XUB12V055

WCOIL MODEL

G2FD046S17

G1UA048S17

G1FA048S17

G2FD046S17

G1UA048S17

G1FA048S17

G2FD042S21

G1UA048S21

G1FA048S21

G2FD048S21

17 G2FD046S17

G1UA048S17

G1FA048S17

036-21342-002 Rev. E (0505)

HEATING

STAGE

(# CYL)

RATED

CFM

1 580 12800 - - 3.58

2 580 24000 14000 8.3 3.38

2 1040 26200 15200 8.6 3.56

1 570 12800 - - 3.58

2 570 23800 13800 8.3 3.34

2 1020 26000 15000 8.6 3.52

1 570 12800 - - 3.58

2 570 23800 13800 8.3 3.34

2 1020 26000 15000 8.6 3.52

1 570 12800 - - 3.58

2 570 23800 13800 8.3 3.34

2 1020 26000 15000 8.6 3.52

1 540 12400 - - 3.54

2 540 24200 14200 8.3 3.39

2 1050 26400 15400 8.6 3.58

1 540 12400 - - 3.54

2 540 24200 14200 8.3 3.39

2 1050 26400 15400 8.6 3.58

1 540 12400 - - 3.54

2 540 24200 14200 8.3 3.39

2 1050 26400 15400 8.6 3.58

1 600 13000 - - 3.70

2 600 24800 14600 8.4 3.46

2 1100 27000 15800 8.7 3.64

1 600 13200 - - 3.72

2 600 25200 15000 8.5 3.50

2 1100 27400 16400 8.8 3.68

1 600 13200 - - 3.72

2 600 25200 15000 8.5 3.50

2 1100 27400 16400 8.8 3.68

1 600 13400 - - 3.76

2 600 25400 15200 8.6 3.50

2 1100 27600 16600 8.9 3.68

1 690 17400 - - 3.56

2 690 31000 18400 7.9 3.26

2 1220 34600 20600 8.3 3.52

1 660 17200 - - 3.54

2 660 31000 18400 8.0 3.30

2 1200 34600 20600 8.4 3.56

1 660 17400 - - 3.58

2 660 31400 18400 8.0 3.32

2 1200 35000 20800 8.4 3.58

1 660 17400 - - 3.58

2 660 31400 18600 8.0 3.32

2 1200 35000 20800 8.4 3.58

NET MBH

47 OD 17 OD

1,2

HSPF3COP4 @ 47 F

Unitary Products Group 9

Page 10

036-21342-002 Rev. E (0505)

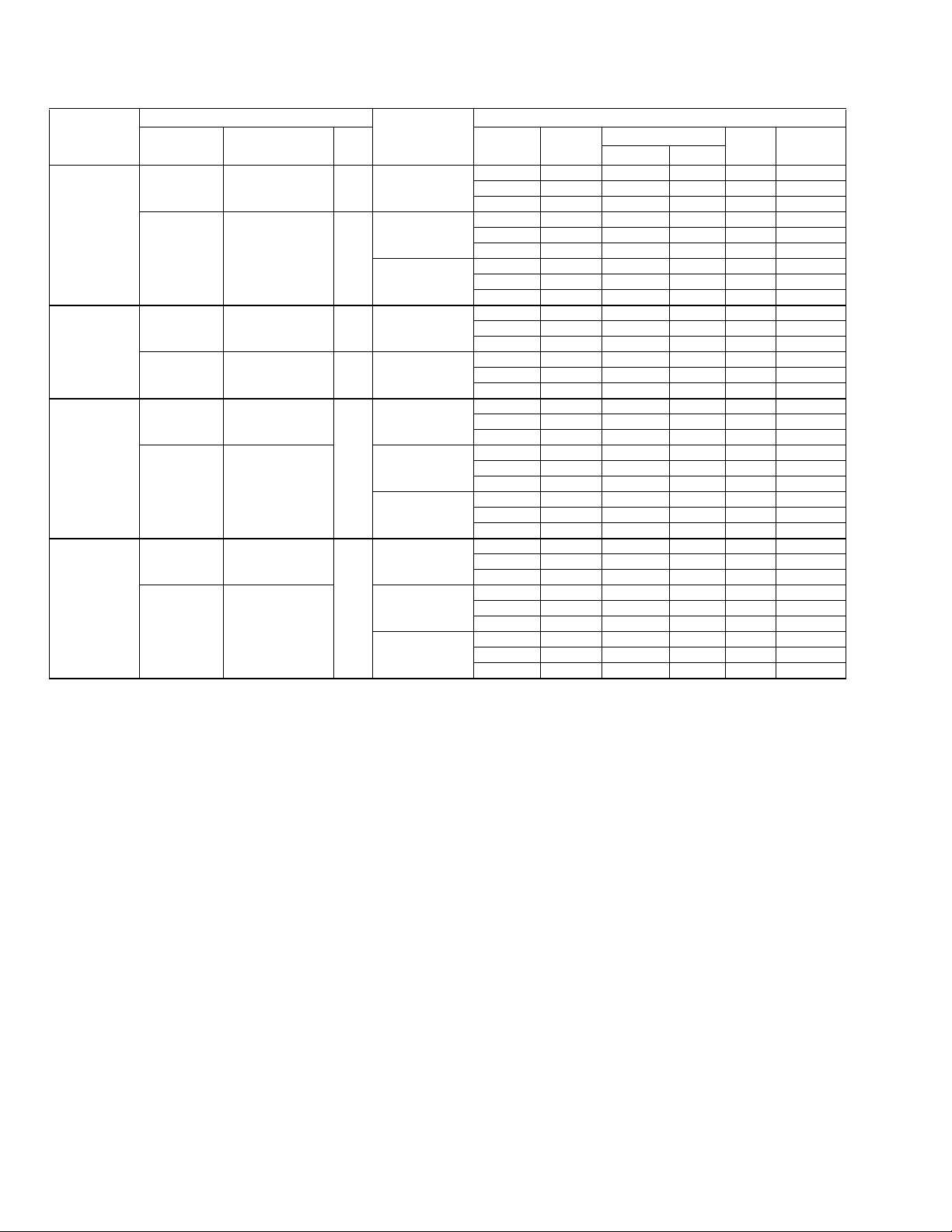

HEATING CAPACITY - Variable Speed Furnace (Continued)

UNIT

MODEL

E4TS036

For notes see Page 12.

VARIABLE SPEED

FURNACE MODEL

P1DUB16V080 17

P1XUC16V075 21

P1DUC20V080 21

P1DUC20V096 21

WCOIL MODEL

G2FD046S17

G1UA048S17

G1FA048S17

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

STAGE

(# CYL)

HEATING

RATED

CFM

1 650 17000 - - 3.54

2 650 31000 18400 8.0 3.30

2 1200 34600 20600 8.4 3.56

1 650 17200 - - 3.58

2 650 31400 18600 8.0 3.32

2 1200 35000 20800 8.4 3.58

1 650 17200 - - 3.58

2 650 31400 18600 8.0 3.32

2 1200 35000 20800 8.4 3.58

1 640 17000 - - 3.54

2 640 31600 18800 8.0 3.36

2 1200 35200 21000 8.4 3.62

1 640 17000 - - 3.54

2 640 31600 18800 8.0 3.36

2 1200 35200 21000 8.4 3.62

1 640 17200 - - 3.56

2 640 32000 19000 8.1 3.40

2 1200 35600 21200 8.5 3.66

1 640 17600 - - 3.60

2 640 32400 19400 8.4 3.48

2 1200 36000 21600 8.7 3.74

1 640 17600 - - 3.60

2 640 32400 19400 8.4 3.48

2 1200 36000 21600 8.7 3.74

1 650 17200 - - 3.52

2 650 32400 19000 8.1 3.44

2 1220 36000 21200 8.5 3.70

1 650 17200 - - 3.52

2 650 32400 19000 8.1 3.44

2 1220 36000 21200 8.5 3.70

1 650 17400 - - 3.54

2 650 32600 19400 8.2 3.48

2 1220 36200 21600 8.6 3.74

1 650 18000 - - 3.60

2 650 33000 19800 8.5 3.52

2 1220 36600 22000 8.8 3.78

1 650 18000 - - 3.60

2 650 33000 19800 8.5 3.52

2 1220 36600 22000 8.8 3.78

1 640 17000 - - 3.54

2 640 31800 18800 8.0 3.36

2 1200 35400 21000 8.4 3.62

1 640 17000 - - 3.54

2 640 31800 18800 8.0 3.36

2 1200 35400 21000 8.4 3.62

1 640 17200 - - 3.56

2 640 32000 19000 8.1 3.40

2 1200 35600 21200 8.5 3.66

1 640 17600 - - 3.60

2 640 32600 19400 8.4 3.48

2 1200 36200 21600 8.7 3.74

1 640 17600 - - 3.60

2 640 32600 19400 8.4 3.48

2 1200 36200 21600 8.7 3.74

NET MBH

47 OD 17 OD

1,2

HSPF3COP4 @ 47 F

10 Unitary Products Group

Page 11

HEATING CAPACITY - Variable Speed Furnace (Continued)

UNIT

MODEL

E4TS036

E4TS048

For notes see Page 12.

VARIABLE SPEED

FURNACE MODEL

P1XUC20V095 21

P1XDD20V112 G2FD048S24

P1XUD20V112 24

P1XUC16V075 21

P1DUC20V080 21

P1DUC20V096 21

P1XUC20V095 21

WCOIL MODEL

G1UA048S21

G1FA048S21

G2FD048S21

G1UA060S21

G1FA060S21

G1UA048S24

G1FA048S24

G2FD048S24

G1UA060S24

G1FA060S24

G1UA060S21

G1FA060S21

G1UA060S21

G1FA060S21

G1UA060S21

G1FA060S21

G1UA060S21

G1FA060S21

STAGE

(# CYL)

036-21342-002 Rev. E (0505)

HEATING

RATED

CFM

1 625 16600 - - 3.48

2 625 31800 18800 7.9 3.34

2 1200 35400 21000 8.3 3.60

1 625 16600 - - 3.48

2 625 31800 18800 7.9 3.34

2 1200 35400 21000 8.3 3.60

1 625 16800 - - 3.52

2 625 32000 19000 8.0 3.38

2 1200 35600 21200 8.4 3.64

1 625 17200 - - 3.58

2 625 32600 19400 8.3 3.44

2 1200 36200 21600 8.6 3.70

1 625 17200 - - 3.58

2 625 32600 19400 8.3 3.44

2 1200 36200 21600 8.6 3.70

1 690 18000 - - 3.56

2 690 32000 19000 8.4 3.54

2 1200 35600 21200 8.7 3.80

1 715 18000 - - 3.52

2 715 32600 19600 8.3 3.54

2 1260 36200 21800 8.7 3.80

1 715 18000 - - 3.52

2 715 32600 19600 8.3 3.54

2 1260 36200 21800 8.7 3.80

1 715 18200 - - 3.56

2 715 32800 19800 8.4 3.56

2 1260 36400 22000 8.8 3.82

1 715 18800 - - 3.64

2 715 33400 20200 8.7 3.64

2 1260 37000 22400 9.0 3.90

1 715 18800 - - 3.64

2 715 33400 20200 8.7 3.64

2 1260 37000 22400 9.0 3.90

1 880 20800 - - 3.24

2 880 43500 24200 7.7 3.36

2 1600 47000 26200 8.0 3.54

1 880 20800 - - 3.24

2 880 43500 24200 7.7 3.36

2 1600 47000 26200 8.0 3.54

1 890 21000 - - 3.28

2 890 43500 24400 7.8 3.44

2 1620 47000 26400 8.1 3.62

1 890 21000 - - 3.28

2 890 43500 24400 7.8 3.44

2 1620 47000 26400 8.1 3.62

1 900 21400 - - 3.32

2 900 43500 24200 7.8 3.42

2 1610 47000 26200 8.1 3.60

1 900 21400 - - 3.32

2 900 43500 24200 7.8 3.42

2 1610 47000 26200 8.1 3.60

1 850 20200 - - 3.20

2 850 43000 23800 7.6 3.36

2 1590 46500 25800 7.9 3.54

1 850 20200 - - 3.20

2 850 43000 23800 7.6 3.36

2 1590 46500 25800 7.9 3.54

NET MBH

47 OD 17 OD

1,2

HSPF3COP4 @ 47 F

Unitary Products Group 11

Page 12

036-21342-002 Rev. E (0505)

HEATING CAPACITY - Variable Speed Furnace (Continued)

UNIT

MODEL

E4TS048

E4TS060

1. Heating MBH based on ARI standards of 70° DB entering indoor air, 72% RH outdoor air with 25 feet of interconnecting piping and

no supplemental electric heat operation.

2. Integrated heating capacities include the effect of defrost cycles in the temperature range where they occur.

3. HSPF (Heating Seasonal Performance Factor) is the total heating output during a normal annual usage period for heating divided

by the total electric power input during the same period.

4. COP equals MBH output divided by (total KW input x 3.412).

ACCESSORIES

Refer to Price Manual for specific model numbers.

TXV Kit - Factory specified and required for proper unit per-

formance.

E4TS030 = 1TV0701

E4TS036 = 1TV0702

VARIABLE SPEED

FURNACE MODEL

P1XDD20V112

P1XUD20V112 24

P1XDD20V112

P1XUD20V112 24

WCOIL MODEL

G2FD060S24

G2FD061H24

G1UA060S24

G1FA060S24

G2FD060S24

G2FD061H24

G2FD060S24

G2FD061H24

G1UA060S24

G1FA060S24

G2FD060S24

G2FD061H24

STAGE

(# CYL)

RATED

CFM

1 880 21400 - - 3.30

2 880 43000 23800 7.7 3.34

2 1580 46500 25800 8.0 3.52

1 880 22000 - - 3.38

2 880 44000 24400 7.9 3.42

2 1580 47500 26400 8.2 3.60

1 915 22200 - - 3.34

2 915 44000 25000 7.8 3.36

2 1620 47500 27000 8.1 3.54

1 915 22200 - - 3.34

2 915 44000 25000 7.8 3.36

2 1620 47500 27000 8.1 3.54

1 915 22200 - - 3.34

2 915 44000 25000 7.8 3.36

2 1620 47500 27000 8.1 3.54

1 915 22600 - - 3.40

2 915 45000 25600 8.0 3.44

2 1620 48500 27600 8.3 3.62

1 1000 23400 - - 3.38

2 1000 49500 26000 7.5 3.28

2 1800 54000 28400 7.9 3.46

1 1000 23400 - - 3.48

2 1000 50500 26600 7.9 3.35

2 1800 55000 29000 8.2 3.52

1 990 23200 - - 3.34

2 990 49500 26000 7.6 3.34

2 1800 54000 28400 8.0 3.52

1 990 23200 - - 3.34

2 990 49500 26000 7.6 3.34

2 1800 54000 28400 8.0 3.52

1 990 23200 - - 3.34

2 990 49500 26000 7.6 3.34

2 1800 54000 28400 8.0 3.52

1 990 23200 - - 3.42

2 990 50500 26600 8.0 3.40

2 1800 55000 29000 8.3 3.58

Dehumidification Control - Model 2HU06700124 available

for use in areas where a higher level of humidity control is

required.

Fossil Fuel Relay (Model 2FF02700101) - Required for use

with all furnace applications.

SOUND RATINGS*

E4TS048 = 1TV0703

E4TS060 = 1TV0703

UNIT MODEL

Room Thermostat - Matching 2-Stage cooling thermostats

are available to provide features required for any installation.

See list below:

2ET03700624 - Honeywell Programmable

2ET03700524 - Honeywell Non-Programmable

2EP32U70124 - White Rodgers Programmable

030 72 73

036 75 78

048 77 79

060 79 81

* Rated in accordance with ARI 270-95 Standards.

HEATING

NET MBH

47 OD 17 OD

1,2

HSPF3COP4 @ 47 F

SOUND RATINGS

(dba)

1 CYLINDER 2 CYLINDER

12 Unitary Products Group

Page 13

COOLING PERFORMANCE DATA

E4TS030S06A WITH N1VSC1606 / G2FD048S21 - HIGH CFM 2-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

105

115

125

ID CFM 980 1065 1210

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 35.72 32.39 29.01 29.01 27.74 36.45 33.78 30.89 30.89 28.07 37.18 35.17 32.78 32.78 28.39

S.C. 16.87 21.50 26.90 21.61 26.84 17.73 23.46 29.75 24.46 27.62 18.59 25.42 32.61 27.31 28.39

K.W. 2.13 2.11 2.07 2.07 2.00 2.19 2.19 2.12 2.12 2.01 2.26 2.26 2.17 2.17 2.01

T.C. 33.76 30.76 27.81 27.81 27.15 34.33 31.89 29.38 29.38 28.08 34.89 33.02 30.96 30.96 29.01

S.C. 16.34 21.18 26.05 20.76 25.72 17.09 22.72 28.08 22.84 27.37 17.84 24.26 30.10 24.91 29.01

K.W. 2.32 2.27 2.21 2.21 2.17 2.38 2.34 2.27 2.27 2.21 2.44 2.40 2.33 2.33 2.24

T.C. 31.81 29.13 26.61 26.61 25.99 32.20 30.00 27.87 27.87 27.06 32.60 30.87 29.14 29.14 28.13

S.C. 15.81 20.86 25.21 19.91 24.61 16.46 22.22 27.01 21.72 26.37 17.10 23.59 28.82 23.53 28.13

K.W. 2.51 2.43 2.36 2.36 2.32 2.56 2.49 2.42 2.42 2.38 2.61 2.55 2.48 2.48 2.43

T.C. 29.85 27.50 25.40 25.40 24.27 30.08 28.11 26.37 26.37 25.00 30.31 28.71 27.33 27.33 25.73

S.C. 15.28 20.53 24.36 19.06 23.49 15.82 21.61 25.64 20.35 24.61 16.36 22.68 26.93 21.64 25.73

K.W. 2.70 2.59 2.51 2.51 2.45 2.74 2.64 2.57 2.57 2.51 2.78 2.69 2.63 2.63 2.57

T.C. 27.96 25.92 24.24 24.24 23.58 28.02 26.27 24.90 24.90 24.03 28.09 26.62 25.56 25.56 24.47

S.C. 14.77 20.22 23.53 18.24 22.41 15.20 21.00 24.31 19.02 23.44 15.63 21.79 25.09 19.80 24.47

K.W. 2.88 2.75 2.65 2.65 2.60 2.92 2.79 2.72 2.72 2.68 2.95 2.83 2.78 2.78 2.76

T.C. 26.06 24.33 23.07 23.07 22.40 25.96 24.43 23.43 23.43 22.90 25.86 24.53 23.80 23.80 23.41

S.C. 14.25 19.90 22.71 17.41 21.32 14.58 20.40 22.98 17.69 22.37 14.91 20.90 23.26 17.97 23.41

K.W. 3.06 2.90 2.79 2.79 2.77 3.09 2.94 2.86 2.86 2.85 3.12 2.97 2.93 2.93 2.92

036-21342-002 Rev. E (0505)

E4TS030S06A WITH N1VSC1606 / G2FD048S21 - LOW CFM 1-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

ID CFM 650 720 770

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 19.20 18.62 17.94 17.94 17.75 19.55 18.71 18.06 18.06 17.86 19.90 18.81 18.17 18.17 17.98

S.C. 9.57 13.15 15.71 10.79 17.10 9.85 13.55 15.58 10.66 17.54 10.13 13.95 15.46 10.54 17.98

K.W. 0.99 0.98 0.97 0.97 0.95 1.01 0.99 0.98 0.98 0.96 1.02 1.01 0.99 0.99 0.98

T.C. 18.20 17.39 16.87 16.87 16.60 18.52 17.52 16.99 16.99 16.72 18.83 17.65 17.12 17.12 16.84

S.C. 9.28 12.73 14.29 9.38 16.13 9.59 12.98 14.46 9.54 16.49 9.90 13.22 14.62 9.71 16.84

K.W. 1.07 1.06 1.05 1.05 1.03 1.09 1.07 1.06 1.06 1.05 1.10 1.08 1.07 1.07 1.06

T.C. 17.20 16.16 15.80 15.80 15.45 17.48 16.32 15.93 15.93 15.71 17.75 16.48 16.06 16.06 15.97

S.C. 9.00 12.32 12.88 7.96 15.16 9.34 12.41 13.33 8.42 15.57 9.68 12.49 13.79 8.87 15.97

K.W. 1.16 1.15 1.14 1.14 1.12 1.18 1.17 1.15 1.15 1.14 1.20 1.19 1.17 1.17 1.15

Multipliers for determining the performance with other indoor sections.

HIGH CFM LOW CFM

Air Handler Coil

N1VSB12 G2FD046S17 0.97 0.96 0.97

N1VSC16 G2FD042S21 0.95 0.94 0.97

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.94 0.94 0.98

P1XUB12V G2FD046S17 0.93 0.93 0.97

P1XUB12V G1UA048S17 0.93 0.93 0.97

P1XUB12V G1FA048S17 0.93 0.93 0.97

P1DUB16V G2FD046S17 0.94 0.94 0.97

P1DUB16V G1UA048S17 0.94 0.94 0.97

P1DUB16V G1FA048S17 0.94 0.94 0.97

P1DUC16V G2FD042S21 0.93 0.93 0.99

P1DUC16V G1UA048S21 0.96 0.96 1.00

P1DUC16V G1FA048S21 0.96 0.96 1.00

P1DUC16V G2FD048S21 0.97 0.96 0.99

Coil

T.C. S.C. KW

T.C. S.C. KW

Air Handler Coil

N1VSB12 G2FD046S17 0.94 0.99 0.96

N1VSC16 G2FD042S21 0.93 0.97 0.96

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.85 0.84 0.90

P1XUB12V G2FD046S17 0.85 0.84 0.90

P1XUB12V G1UA048S17 0.85 0.84 0.90

P1XUB12V G1FA048S17 0.85 0.84 0.90

P1DUB16V G2FD046S17 0.84 0.83 0.88

P1DUB16V G1UA048S17 0.84 0.83 0.88

P1DUB16V G1FA048S17 0.84 0.83 0.88

P1DUC16V G2FD042S21 0.84 0.84 0.90

P1DUC16V G1UA048S21 0.85 0.84 0.88

P1DUC16V G1FA048S21 0.85 0.86 0.88

P1DUC16V G2FD048S21 0.88 0.88 0.90

Coil

T.C. S.C. KW

T.C. S.C. KW

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Unitary Products Group 13

Page 14

036-21342-002 Rev. E (0505)

COOLING PERFORMANCE DATA

E4TS036S06A WITH N1VSC1606 / G2FD048S21 - HIGH CFM 2-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

105

115

125

ID CFM 1000 1185 1350

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 42.71 39.07 35.00 35.00 33.88 43.34 40.24 36.13 36.13 36.54 43.97 41.41 37.26 37.26 39.19

S.C. 21.26 25.43 31.63 26.34 32.81 21.75 27.35 33.71 28.25 36.00 22.25 29.27 35.79 30.17 39.19

K.W. 2.61 2.58 2.47 2.47 2.46 2.73 2.68 2.58 2.58 2.55 2.85 2.79 2.69 2.69 2.64

T.C. 40.45 37.03 33.34 33.34 32.20 40.99 38.12 34.47 34.47 34.69 41.53 39.21 35.60 35.60 37.17

S.C. 20.15 24.74 30.32 25.03 31.29 20.83 26.61 32.25 26.76 34.23 21.51 28.48 34.18 28.48 37.17

K.W. 2.84 2.79 2.67 2.67 2.65 2.96 2.89 2.79 2.79 2.73 3.08 3.00 2.90 2.90 2.82

T.C. 38.19 34.99 31.68 31.68 30.51 38.64 36.00 32.81 32.81 32.83 39.09 37.01 33.93 33.93 35.15

S.C. 19.04 24.05 29.02 23.72 29.77 19.90 25.61 30.79 25.26 32.46 20.76 27.68 32.56 26.80 35.15

K.W. 3.08 2.99 2.87 2.87 2.85 3.20 3.10 2.99 2.99 2.93 3.31 3.21 3.12 3.12 3.01

T.C. 35.93 32.95 30.02 30.02 28.83 36.29 33.88 31.15 31.15 30.98 36.65 34.81 32.27 32.27 33.13

S.C. 17.93 23.36 27.71 22.42 28.26 18.97 25.12 29.33 23.77 30.70 20.02 26.89 30.94 25.11 33.13

K.W. 3.32 3.20 3.07 3.07 3.05 3.43 3.31 3.20 3.20 3.15 3.54 3.42 3.33 3.33 3.24

T.C. 33.74 30.98 28.42 28.42 27.19 34.01 31.83 29.53 29.53 29.18 34.29 32.67 30.65 30.65 31.18

S.C. 16.85 22.69 26.44 21.15 26.79 18.07 24.40 27.91 22.31 28.98 19.30 26.12 29.38 23.48 31.18

K.W. 3.55 3.40 3.26 3.26 3.24 3.66 3.51 3.40 3.40 3.36 3.77 3.62 3.54 3.54 3.47

T.C. 31.54 29.00 26.81 26.81 25.56 31.73 29.77 27.92 27.92 27.39 31.92 30.54 29.04 29.04 29.22

S.C. 15.77 22.02 25.17 19.88 25.31 17.18 23.68 26.49 20.86 27.26 18.58 25.34 27.81 21.84 29.22

K.W. 3.78 3.60 3.45 3.45 3.42 3.88 3.71 3.60 3.60 3.55 3.99 3.82 3.75 3.75 3.68

Multipliers for determining the performance with other indoor sections.

HIGH CFM

Air Handler Coil

N1VSD20 G2FD048S24 1.01 1.02 1.00

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.99 1.01 1.06

P1XUB12V G2FD046S17 0.98 1.00 1.04

P1XUB12V G1UA048S17 0.98 1.00 1.04

P1XUB12V G1FA048S17 0.98 1.00 1.04

P1DUB16V G2FD046S17 0.99 1.00 1.04

P1DUB16V G1UA048S17 0.99 1.00 1.04

P1DUB16V G1FA048S17 0.99 1.00 1.04

P1DUC16V G1UA048S21 0.99 1.01 1.04

P1DUC16V G1FA048S21 0.99 1.01 1.04

P1DUC16V G2FD048S21 1.00 1.02 1.05

P1DUC16V G1UA060S21 1.03 1.04 1.06

P1DUC16V G1FA060S21 1.03 1.04 1.06

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Coil

T.C. S.C. KW

T.C. S.C. KW

Variable Speed

Furnace

P1DUC20V G1UA048S21 0.99 1.01 1.03

P1DUC20V G1FA048S21 0.99 1.01 1.03

P1DUC20V G2FD048S21 1.00 1.02 1.03

P1DUC20V G1UA060S21 1.03 1.04 1.05

P1DUC20V G1FA060S21 1.03 1.04 1.05

P1XUC20V G1UA048S21 0.99 1.00 1.04

P1XUC20V G1FA048S21 0.99 1.00 1.04

P1XUC20V G2FD048S21 0.99 1.01 1.03

P1XUC20V G1UA060S21 1.02 1.03 1.05

P1XUC20V G1FA060S21 1.02 1.03 1.05

P1XDD20V G2FD048S24 1.00 1.07 1.03

P1XUD20V G1UA048S24 1.01 1.06 1.04

P1XUD20V G1FA048S24 1.01 1.06 1.04

P1XUD20V G2FD048S24 1.01 1.07 1.03

P1XUD20V G1UA060S24 1.04 1.09 1.04

P1XUD20V G1FA060S24 1.04 1.09 1.04

Coil

T.C. S.C. KW

14 Unitary Products Group

Page 15

COOLING PERFORMANCE DATA

E4TS036S06A WITH N1VSC1606 / G2FD048S21 - LOW CFM 1-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

ID CFM 680 770 860

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 25.53 22.96 21.67 21.67 19.33 25.89 23.72 22.21 22.21 20.25 26.24 24.48 22.74 22.74 21.17

S.C. 12.14 15.13 18.09 14.65 19.09 12.67 16.04 19.20 15.76 20.13 13.20 16.95 20.32 16.87 21.17

K.W. 1.35 1.35 1.33 1.33 1.33 1.37 1.37 1.36 1.36 1.34 1.39 1.38 1.38 1.38 1.35

T.C. 24.11 21.94 20.57 20.57 18.91 24.68 22.56 21.14 21.14 19.62 25.25 23.19 21.72 21.72 20.34

S.C. 11.53 14.70 17.83 14.38 18.63 12.20 15.80 18.30 14.82 19.48 12.87 16.91 18.78 15.26 20.34

K.W. 1.48 1.47 1.45 1.45 1.44 1.50 1.49 1.47 1.47 1.46 1.53 1.51 1.50 1.50 1.47

T.C. 22.70 20.91 19.46 19.46 18.49 23.47 21.40 20.08 20.08 19.00 24.25 21.89 20.70 20.70 19.51

S.C. 10.93 14.27 17.56 14.12 18.17 11.73 15.40 17.40 13.89 18.84 12.54 16.87 17.24 13.66 19.51

K.W. 1.62 1.58 1.56 1.56 1.56 1.64 1.61 1.59 1.59 1.58 1.66 1.63 1.61 1.61 1.60

Multipliers for determining the performance with other indoor sections.

LOW CFM

036-21342-002 Rev. E (0505)

Air Handler Coil

N1VSD20 G2FD048S24 1.01 1.01 0.99

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.93 0.99 1.00

P1XUB12V G2FD046S17 0.93 0.97 0.98

P1XUB12V G1UA048S17 0.93 0.97 0.98

P1XUB12V G1FA048S17 0.93 0.97 0.98

P1DUB16V G2FD046S17 0.93 0.97 0.99

P1DUB16V G1UA048S17 0.93 0.97 0.99

P1DUB16V G1FA048S17 0.93 0.97 0.99

P1DUC16V G1UA048S21 0.94 0.99 1.00

P1DUC16V G1FA048S21 0.94 0.99 1.00

P1DUC16V G2FD048S21 0.95 1.00 1.01

P1DUC16V G1UA060S21 0.98 1.03 1.00

P1DUC16V G1FA060S21 0.98 1.03 1.00

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Coil

T.C. S.C. KW

T.C. S.C. KW

Variable Speed

Furnace

P1DUC20V G1UA048S21 0.94 0.99 1.00

P1DUC20V G1FA048S21 0.94 0.99 1.00

P1DUC20V G2FD048S21 0.95 1.00 0.99

P1DUC20V G1UA060S21 0.98 1.03 1.00

P1DUC20V G1FA060S21 0.98 1.03 1.00

P1XUC20V G1UA048S21 0.93 0.97 0.99

P1XUC20V G1FA048S21 0.93 0.97 0.99

P1XUC20V G2FD048S21 0.94 0.99 0.99

P1XUC20V G1UA060S21 0.97 1.01 0.99

P1XUC20V G1FA060S21 0.97 1.01 0.99

P1XDD20V G2FD048S24 0.95 1.05 0.98

P1XUD20V G1UA048S24 0.96 1.04 1.00

P1XUD20V G1FA048S24 0.96 1.04 1.00

P1XUD20V G2FD048S24 0.97 1.05 0.99

P1XUD20V G1UA060S24 1.00 1.08 1.00

P1XUD20V G1FA060S24 1.00 1.08 1.00

Coil

T.C. S.C. KW

Unitary Products Group 15

Page 16

036-21342-002 Rev. E (0505)

COOLING PERFORMANCE DATA

E4TS048S06A WITH N1VSD2006 / G2FD060S24 - HIGH CFM 2-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

105

115

125

E4TS048S06A WITH N1VSD2006 / G2FD060S24 - LOW CFM 1-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

ID CFM 1420 1600 1750

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 56.47 53.15 46.83 46.83 39.34 56.73 53.18 47.38 47.38 40.76 56.99 53.21 47.93 47.93 42.18

S.C. 28.32 36.17 42.10 34.23 38.85 29.16 37.77 43.94 36.08 40.51 30.01 39.37 45.77 37.93 42.18

K.W. 3.61 3.49 3.34 3.34 3.30 3.79 3.66 3.48 3.48 3.36 3.97 3.82 3.62 3.62 3.41

T.C. 53.54 50.52 44.60 44.60 38.36 53.57 50.59 45.30 45.30 39.65 53.61 50.66 46.00 46.00 40.94

S.C. 27.19 35.23 41.03 33.16 37.86 27.99 36.86 42.50 34.61 39.40 28.79 38.50 43.97 36.06 40.94

K.W. 3.91 3.77 3.59 3.59 3.54 4.09 3.94 3.74 3.74 3.60 4.28 4.10 3.89 3.89 3.66

T.C. 50.60 47.89 42.38 42.38 37.29 50.42 48.00 43.22 43.22 38.48 50.24 48.11 44.07 44.07 39.66

S.C. 26.05 34.28 39.96 32.09 36.87 26.81 35.60 41.06 33.14 38.27 27.56 37.63 42.17 34.18 39.66

K.W. 4.21 4.04 3.84 3.84 3.81 4.39 4.21 3.99 3.99 3.87 4.58 4.38 4.15 4.15 3.94

T.C. 47.67 45.26 40.15 40.15 35.74 47.26 45.41 41.14 41.14 37.04 46.86 45.56 42.13 42.13 38.34

S.C. 24.92 33.33 38.89 31.02 35.52 25.63 35.04 39.63 31.66 36.93 26.34 36.76 40.36 32.30 38.34

K.W. 4.50 4.32 4.08 4.08 4.04 4.69 4.49 4.25 4.25 4.16 4.88 4.66 4.42 4.42 4.29

T.C. 44.83 42.71 37.99 37.99 34.19 44.20 42.90 39.13 39.13 35.62 43.58 43.09 40.26 40.26 37.04

S.C. 23.83 32.41 37.85 29.98 34.03 24.49 34.16 38.23 30.23 35.53 25.15 35.91 38.61 30.48 37.04

K.W. 4.79 4.59 4.33 4.33 4.26 4.98 4.76 4.50 4.50 4.38 5.18 4.93 4.68 4.68 4.49

T.C. 41.98 40.16 35.83 35.83 32.61 41.14 40.39 37.11 37.11 34.54 40.30 40.62 38.38 38.38 36.46

S.C. 22.73 31.50 36.81 28.94 32.58 23.34 33.28 36.84 28.80 34.52 23.96 35.06 36.86 28.66 36.46

K.W. 5.08 4.86 4.57 4.57 4.48 5.27 5.03 4.75 4.75 4.64 5.47 5.20 4.93 4.93 4.80

ID CFM 850 1040 1140

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 28.53 27.17 25.56 25.56 24.29 30.53 28.62 26.71 26.71 24.96 32.53 30.07 27.86 27.86 25.63

S.C. 13.88 20.03 22.49 18.01 23.48 15.36 21.33 23.53 18.80 24.56 16.84 22.62 24.57 19.60 25.63

K.W. 1.67 1.62 1.57 1.57 1.51 1.67 1.63 1.60 1.60 1.56 1.66 1.64 1.62 1.62 1.60

T.C. 28.30 26.99 25.39 25.39 24.12 29.30 27.71 25.97 25.97 25.28 30.30 28.44 26.54 26.54 26.43

S.C. 14.72 21.03 23.45 18.97 23.45 15.46 21.68 23.72 18.98 24.94 16.20 22.33 23.99 19.00 26.43

K.W. 1.84 1.79 1.74 1.74 1.69 1.84 1.80 1.76 1.76 1.71 1.84 1.81 1.77 1.77 1.74

T.C. 28.06 26.80 25.22 25.22 25.01 28.06 26.80 25.22 25.22 24.11 28.06 26.80 25.22 25.22 23.20

S.C. 15.56 22.03 24.42 19.93 24.67 15.56 21.80 23.92 19.17 23.94 15.56 22.03 23.42 18.40 23.20

K.W. 2.01 1.97 1.91 1.91 1.85 2.01 1.97 1.91 1.91 1.86 2.01 1.97 1.91 1.91 1.87

Multipliers for determining the performance with other indoor sections.

HIGH CFM LOW CFM

Air Handler Coil

N1VSD20 G1FD061S24 1.02 1.02 1.00

F(2,3)FV060 1.00 1.00 1.00

Variable Speed

Furnace

P1DUC16V G1UA060S21 0.98 0.95 1.03

P1DUC16V G1FA060S21 0.98 0.95 1.03

P1DUC20V G1UA060S21 0.99 0.96 1.04

P1DUC20V G1FA060S21 0.99 0.96 1.04

P1XUC20V G1UA060S21 0.98 0.95 1.03

P1XUC20V G1FA060S21 0.98 0.95 1.03

P1XDD20V G2FD060S24 0.99 0.96 1.03

P1XDD20V G2FD061H24 1.01 0.98 1.03

P1XUD20V G1UA060S24 1.00 0.97 1.04

P1XUD20V G1FA060S24 1.00 0.97 1.04

P1XUD20V G2FD060S24 1.00 0.97 1.04

P1XUD20V G2FD061H24 1.02 0.99 1.03

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Coil

T.C. S.C. KW

T.C. S.C. KW

Air Handler Coil

N1VSD20 G1FD061S24 1.02 1.02 1.01

F(2,3)FV060 1.00 1.00 1.00

Variable Speed

Furnace

P1DUC16V G1UA060S21 0.89 0.81 0.96

P1DUC16V G1FA060S21 0.89 0.81 0.96

P1DUC20V G1UA060S21 0.90 0.83 0.97

P1DUC20V G1FA060S21 0.90 0.83 0.97

P1XUC20V G1UA060S21 0.88 0.80 0.95

P1XUC20V G1FA060S21 0.88 0.80 0.95

P1XDD20V G2FD060S24 0.91 0.84 0.99

P1XDD20V G2FD061H24 0.93 0.86 0.99

P1XUD20V G1UA060S24 0.93 0.86 0.99

P1XUD20V G1FA060S24 0.93 0.86 0.99

P1XUD20V G2FD060S24 0.93 0.86 0.99

P1XUD20V G2FD061H24 0.94 0.86 0.99

Coil

T.C. S.C. KW

T.C. S.C. KW

16 Unitary Products Group

Page 17

COOLING PERFORMANCE DATA

E4TS060S06A WITH N1VSD2006 / G2FD061S24 - HIGH CFM 2-CYLINDER OPERATION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

105

115

125

E4TS060S06A WITH N1VSD2006 / G2FD061S24 - LOW CFM 1-CYLINDER OPERA TION

CONDENSER

ENTERING AIR

TEMPERATURE

75

85

95

ID CFM 1540 1860 2075

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 65.80 61.90 55.01 55.01 53.57 65.60 63.40 57.21 57.21 56.10 65.40 64.90 59.41 59.41 58.62

S.C. 32.90 42.32 49.80 40.94 51.43 33.42 44.11 51.70 42.35 55.02 33.94 45.90 53.60 43.76 58.62

K.W. 4.53 4.43 4.30 4.30 4.20 4.76 4.66 4.50 4.50 4.43 4.99 4.89 4.69 4.69 4.65

T.C. 62.52 58.95 52.76 52.76 51.36 62.48 60.20 54.76 54.76 53.68 62.44 61.45 56.75 56.75 56.00

S.C. 31.56 41.12 48.61 39.75 49.31 32.21 43.00 50.40 41.02 52.66 32.86 44.88 52.18 42.28 56.00

K.W. 4.95 4.77 4.58 4.58 4.49 5.15 4.99 4.78 4.78 4.72 5.35 5.21 4.99 4.99 4.94

T.C. 59.25 56.00 50.51 50.51 49.15 59.36 57.00 52.31 52.31 51.27 59.48 58.00 54.10 54.10 53.39

S.C. 30.22 39.93 47.42 38.57 47.19 31.01 41.50 49.09 39.69 50.29 31.79 43.87 50.76 40.81 53.39

K.W. 5.30 5.10 4.85 4.85 4.78 5.51 5.38 5.07 5.07 5.00 5.72 5.52 5.28 5.28 5.22

T.C. 55.97 53.05 48.27 48.27 46.94 56.25 53.80 49.85 49.85 48.86 56.52 54.55 51.44 51.44 50.77

S.C. 28.89 38.73 46.23 37.38 44.68 29.80 40.79 47.79 38.35 47.73 30.71 42.85 49.34 39.33 50.77

K.W. 5.66 5.44 5.13 5.13 5.07 5.87 5.64 5.35 5.35 5.30 6.09 5.84 5.58 5.58 5.53

T.C. 52.79 50.19 46.09 46.09 44.80 53.22 50.70 47.47 47.47 46.52 53.64 51.21 48.86 48.86 48.23

S.C. 27.59 37.57 45.08 36.22 42.43 28.63 39.72 46.52 37.06 45.33 29.67 41.86 47.96 37.90 48.23

K.W. 6.06 5.76 5.40 5.40 5.35 6.25 5.96 5.63 5.63 5.58 6.44 6.15 5.86 5.86 5.81

T.C. 49.61 47.33 43.91 43.91 42.66 50.19 47.59 45.10 45.10 44.17 50.77 47.86 46.28 46.28 45.69

S.C. 26.29 36.41 43.93 35.07 40.19 27.46 38.64 45.25 35.77 42.94 28.63 40.87 46.58 36.46 45.69

K.W. 6.43 6.09 5.66 5.66 5.64 6.62 6.27 5.91 5.91 5.86 6.80 6.46 6.15 6.15 6.08

ID CFM 1000 1200 1350

ID DB (°F) 80 80 80 75 80 80 80 80 75 80 80 80 80 75 80

ID WB (°F) 72 67 62 62 57 72 67 62 62 57 72 67 62 62 57

T.C. 32.55 29.26 27.63 27.63 24.63 34.33 31.48 29.47 29.47 26.89 36.12 33.70 31.31 31.31 29.15

S.C. 17.01 21.12 25.18 18.13 23.65 18.49 23.34 28.06 20.26 26.40 19.97 25.56 30.93 22.39 29.15

K.W. 1.63 1.64 1.61 1.61 1.61 1.73 1.72 1.71 1.71 1.69 1.82 1.81 1.81 1.81 1.77

T.C. 30.74 27.96 26.21 26.21 24.10 32.75 29.94 28.06 28.06 26.05 34.76 31.92 29.90 29.90 28.00

S.C. 16.16 20.52 24.82 17.77 23.14 17.81 23.01 26.70 18.87 25.57 19.47 25.50 28.59 19.98 28.00

K.W. 1.85 1.83 1.81 1.81 1.79 1.95 1.93 1.91 1.91 1.89 2.05 2.03 2.02 2.02 1.98

T.C. 28.93 26.66 24.80 24.80 23.57 31.16 29.00 26.65 26.65 25.21 33.39 30.13 28.49 28.49 26.85

S.C. 15.31 19.92 24.45 17.40 22.63 17.14 24.00 25.35 17.48 24.74 18.96 25.44 26.25 17.56 26.85

K.W. 2.07 2.03 2.00 2.00 1.98 2.18 2.16 2.12 2.12 2.09 2.28 2.25 2.23 2.23 2.19

036-21342-002 Rev. E (0505)

Multipliers for determining the performance with other indoor sections.

HIGH CFM LOW CFM

Air Handler Coil

N1VSD20 G1FD060S24 0.97 0.98 0.99

F(2,3)FV060 0.97 0.98 0.99

Variable Speed

Furnace

P1XDD20V G2FD060S24 0.96 0.95 1.02

P1XDD20V G2FD061H24 0.98 0.96 1.02

P1XUD20V G1UA060S24 0.97 0.96 1.01

P1XUD20V G1FA060S24 0.97 0.96 1.01

P1XUD20V G2FD060S24 0.97 0.96 1.01

P1XUD20V G2FD061H24 0.99 0.98 1.01

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Coil

T.C. S.C. KW

T.C. S.C. KW

Air Handler Coil

N1VSD20 G1FD060S24 0.96 0.98 0.98

F(2,3)FV060 0.96 0.98 0.98

Variable Speed

Furnace

P1XDD20V G2FD060S24 0.93 0.85 0.99

P1XDD20V G2FD061H24 0.97 0.87 1.01

P1XUD20V G1UA060S24 0.93 0.85 1.00

P1XUD20V G1FA060S24 0.93 0.85 1.00

P1XUD20V G2FD060S24 0.93 0.85 1.00

P1XUD20V G2FD061H24 0.97 0.87 1.01

Coil

T.C. S.C. KW

T.C. S.C. KW

Unitary Products Group 17

Page 18

036-21342-002 Rev. E (0505)

HEATING PERFORMANCE DATA

E4TS030S06A WITH N1VSC1606 / G2FD048S21 - HIGH CFM 2-CYLINDER OPERATION

ID CFM 980 1065 1210

OD DB ID DB (°F)

60 35.86 2.17 36.10 2.19 36.34 2.20

60

47

35

17

7

-3

70 33.48 2.30 33.93 2.31 34.39 2.32

80 31.09 2.43 31.77 2.44 32.44 2.45

60 28.88 2.04 29.01 2.07 29.14 2.09

70 26.78 2.14 27.00 2.17 27.22 2.19

80 24.68 2.24 24.99 2.26 25.29 2.29

60 22.40 1.90 22.79 1.92 23.17 1.94

70 20.57 1.98 20.94 2.00 21.31 2.02

80 18.73 2.05 19.10 2.08 19.46 2.10

60 16.95 1.71 17.09 1.74 17.22 1.78

70 15.20 1.77 15.40 1.84 15.60 1.83

80 13.46 1.83 13.71 1.94 13.97 1.88

60 12.23 1.50 12.34 1.52 12.45 1.54

70 11.24 1.57 11.39 1.60 11.53 1.61

80 10.24 1.64 10.43 1.68 10.62 1.68

60 7.92 1.37 7.99 1.39 8.06 1.41

70 7.28 1.43 7.37 1.46 7.47 1.47

80 6.63 1.49 6.75 1.53 6.87 1.53

MBTUH

1,2

KW

MBTUH

1,2

KW

E4TS030S06A WITH N1VSC1606 / G2FD048S21 - LOW CFM 1-CYLINDER OPERATION

ID CFM 650 720 770

OD DB ID DB (°F)

60 20.36 1.08 20.52 1.09 20.67 1.09

60

47

35

For notes see Page 11.

70 18.50 1.16 18.66 1.17 18.81 1.17

80 16.64 1.24 16.79 1.25 16.95 1.25

60 16.02 1.05 16.15 1.06 16.28 1.08

70 14.90 1.12 15.00 1.13 15.10 1.14

80 13.77 1.19 13.85 1.20 13.93 1.20

60 12.60 1.02 12.71 1.04 12.82 1.07

70 12.00 1.08 12.07 1.10 12.13 1.12

80 11.40 1.13 11.42 1.15 11.45 1.16

MBTUH

1,2

KW

MBTUH

1,2

KW

Multipliers for determining the performance with other indoor sections.

2-CYLINDER OPERATION 1-CYLINDER OPERATION

Air Handler Coil

N1VSB12 G2FD046S17 0.98 0.99 0.91 0.96

N1VSC16 G2FD042S21 0.96 0.98 0.90 0.95

HIGH CFM LOW CFM

MBTUH KW MBTUH KW

Air Handler Coil

N1VSB12 G2FD046S17 0.89 0.91

N1VSC16 G2FD042S21 0.88 0.90

1,2

MBTUH

1,2

MBTUH

LOW CFM

MBTUH KW

KW

KW

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.97 1.00 0.89 0.94

P1XUB12V G2FD046S17 0.96 1.00 0.88 0.95

P1XUB12V G1UA048S17 0.96 1.00 0.88 0.95

P1XUB12V G1FA048S17 0.96 1.00 0.88 0.95

P1DUB16V G2FD046S17 0.98 1.00 0.90 0.95

P1DUB16V G1UA048S17 0.98 1.00 0.90 0.95

P1DUB16V G1FA048S17 0.98 1.00 0.90 0.95

P1DUC16V G2FD042S21 1.00 1.00 0.92 0.95

P1DUC16V G1UA048S21 1.01 1.01 0.93 0.96

P1DUC16V GFA048S21 1.01 1.01 0.93 0.96

P1DUC16V G2FD048S21 1.02 1.02 0.94 0.97

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

18 Unitary Products Group

Coil

MBTUH KW MBTUH KW

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.85 0.93

P1XUB12V G2FD046S17 0.85 0.93

P1XUB12V G1UA048S17 0.85 0.93

P1XUB12V G1FA048S17 0.85 0.93

P1DUB16V G2FD046S17 0.83 0.91

P1DUB16V G1UA048S17 0.83 0.91

P1DUB16V G1FA048S17 0.83 0.91

P1DUC16V G2FD042S21 0.87 0.91

P1DUC16V G1U A048S21 0.88 0.92

P1DUC16V GFA048S21 0.88 0.92

P1DUC16V G2FD048S21 0.89 0.92

Coil

MBTUH KW

Page 19

HEATING PERFORMANCE DATA

E4TS036S06A WITH N1VSC1606 / G2FD048S21 - HIGH CFM 2-CYLINDER OPERATION

ID CFM 1000 1185 1350

OD DB ID DB (°F)

60 42.57 2.80 43.13 2.81 43.69 2.82

60

47

35

17

7

-3

For notes see Page 11.

70 40.33 2.98 40.99 2.99 41.65 3.00

80 38.08 3.17 38.85 3.17 39.61 3.18

60 38.00 2.63 38.09 2.64 38.18 2.66

70 35.19 2.77 35.60 2.79 36.01 2.81

80 32.38 2.91 33.11 2.94 33.83 2.96

60 30.23 2.37 30.03 2.40 29.82 2.44

70 27.59 2.48 27.79 2.52 27.99 2.57

80 24.96 2.59 25.56 2.64 26.16 2.69

60 22.29 2.14 22.47 2.20 22.64 2.25

70 20.61 2.22 21.20 2.27 21.79 2.32

80 18.93 2.29 19.93 2.34 20.94 2.39

60 17.34 1.92 17.41 1.95 17.48 1.97

70 16.08 2.02 16.34 2.05 16.60 2.07

80 14.83 2.12 15.27 2.14 15.71 2.17

60 12.18 1.76 12.23 1.79 12.28 1.81

70 11.30 1.85 11.48 1.88 11.66 1.90

80 10.42 1.94 10.73 1.97 11.04 1.99

MBTUH

1,2

KW

MBTUH

1,2

KW

Multipliers for determining the performance with other indoor sections.

2-CYLINDER OPERATION

Air Handler Coil

N1VSB12 G2FD046S17 0.98 1.04 0.89 0.94

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.97 1.03 0.87 0.96

P1XUB12V G2FD046S17 0.97 1.02 0.87 0.95

P1XUB12V G1UA048S17 0.98 1.03 0.88 0.95

P1XUB12V G1FA048S17 0.98 1.03 0.88 0.95

P1DUB16V G2FD046S17 0.97 1.02 0.87 0.95

P1DUB16V G1UA048S17 0.98 1.03 0.88 0.95

P1DUB16V G1FA048S17 0.98 1.03 0.88 0.95

P1DUC16V G1UA048S21 0.99 1.02 0.89 0.95

P1DUC16V G1FA048S21 0.99 1.02 0.89 0.95

P1DUC16V G2FD048S21 1.00 1.02 0.90 0.95

P1DUC16V G1UA060S21 1.01 1.01 0.91 0.94

P1DUC16V G1FA060S21 1.01 1.01 0.91 0.94

Coil

HIGH CFM LOW CFM

MBTUH KW MBTUH KW

MBTUH KW MBTUH KW

Variable Speed

Furnace

P1DUC20V G1U A048S21 0.99 1.03 0.89 0.95

P1DUC20V G1FA048S21 0.99 1.03 0.89 0.95

P1DUC20V G2FD048S21 1.00 1.02 0.90 0.95

P1DUC20V G1U A060S21 1.02 1.02 0.92 0.95

P1DUC20V G1FA060S21 1.02 1.02 0.92 0.95

P1XUC20V G1UA048S21 0.99 1.03 0.89 0.96

P1XUC20V G1FA048S21 0.99 1.03 0.89 0.96

P1XUC20V G2FD048S21 1.00 1.03 0.90 0.95

P1XUC20V G1UA060S21 1.02 1.03 0.92 0.96

P1XUC20V G1FA060S21 1.02 1.03 0.92 0.96

P1XDD20V G2FD048S24 1.00 0.98 0.90 0.91

P1XUD20V G1UA048S24 1.02 1.00 0.92 0.93

P1XUD20V G1FA048S24 1.02 1.00 0.92 0.93

P1XUD20V G2FD048S24 1.02 1.00 0.92 0.93

P1XUD20V G1UA060S24 1.04 1.00 0.94 0.93

P1XUD20V G1FA060S24 1.04 1.00 0.94 0.93

Coil

036-21342-002 Rev. E (0505)

MBTUH

1,2

KW

HIGH CFM LOW CFM

MBTUH KW MBTUH KW

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Unitary Products Group 19

Page 20

036-21342-002 Rev. E (0505)

HEATING PERFORMANCE DATA

E4TS036S06A WITH N1VSC1606 / G2FD048S21 - LOW CFM 1-CYLINDER OPERATION

ID CFM 670 770 860

OD DB ID DB (°F)

60 24.27 1.49 24.88 1.50 25.48 1.51

60

47

35

For notes see Page 11.

70 22.72 1.59 23.42 1.61 24.13 1.62

80 21.16 1.70 21.96 1.71 22.77 1.73

60 21.43 1.42 21.73 1.43 22.04 1.44

70 19.73 1.51 20.00 1.52 20.42 1.53

80 18.03 1.59 18.42 1.61 18.81 1.62

60 18.92 1.36 18.99 1.36 19.06 1.37

70 17.14 1.42 17.22 1.44 17.30 1.45

80 15.35 1.49 15.45 1.51 15.54 1.52

MBTUH

1,2

KW

MBTUH

1,2

KW

Multipliers for determining the performance with other indoor sections.

1-CYLINDER OPERATION

MBTUH

1,2

KW

Air Handler Coil

LOW CFM

MBTUH KW

N1VSB12 G2FD046S17 0.98 1.00

Variable Speed

Furnace

P1XDB12V G2FD046S17 0.87 0.94

P1XUB12V G2FD046S17 0.86 0.94

P1XUB12V G1UA048S17 0.87 0.94

P1XUB12V G1FA048S17 0.87 0.94

P1DUB16V G2FD046S17 0.85 0.93

P1DUB16V G1UA048S17 0.86 0.93

P1DUB16V G1FA048S17 0.86 0.93

P1DUC16V G1UA048S21 0.85 0.93

P1DUC16V G1FA048S21 0.85 0.93

P1DUC16V G2FD048S21 0.86 0.93

P1DUC16V G1UA060S21 0.88 0.94

P1DUC16V G1FA060S21 0.88 0.94

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Coil

MBTUH KW

Variable Speed

Furnace

P1DUC20V G1UA048S21 0.85 0.93

P1DUC20V G1FA048S21 0.85 0.93

P1DUC20V G2FD048S21 0.86 0.93

P1DUC20V G1UA060S21 0.88 0.94

P1DUC20V G1FA060S21 0.88 0.94

P1XUC20V G1UA048S21 0.83 0.92

P1XUC20V G1FA048S21 0.83 0.92

P1XUC20V G2FD048S21 0.84 0.92

P1XUC20V G1UA060S21 0.86 0.93

P1XUC20V G1FA060S21 0.86 0.93

P1XDD20V G2FD048S24 0.90 0.98

P1XUD20V G1UA048S24 0.90 0.99

P1XUD20V G1FA048S24 0.90 0.99

P1XUD20V G2FD048S24 0.91 0.99

P1XUD20V G1UA060S24 0.94 1.00

P1XUD20V G1FA060S24 0.94 1.00

Coil

LOW CFM

MBTUH KW

20 Unitary Products Group

Page 21

HEATING PERFORMANCE DATA

E4TS048S06A WITH N1VSD2006 / G2FD060S24 - HIGH CFM 2-CYLINDER OPERATION

ID CFM 1420 1600 1750

OD DB ID DB (°F)

60 58.57 4.00 59.37 4.01 60.17 4.02

60

47

35

17

7

-3

70 55.72 4.22 56.47 4.24 57.21 4.26

80 52.87 4.44 53.56 4.47 54.26 4.50

60 48.43 3.61 49.54 3.66 50.65 3.72

70 46.01 3.79 47.00 3.85 47.99 3.91

80 43.60 3.96 44.46 4.03 45.32 4.10

60 39.06 3.24 39.49 3.31 39.92 3.37

70 36.62 3.38 37.06 3.46 37.51 3.55

80 34.17 3.52 34.63 3.62 35.09 3.72

60 28.62 2.97 28.81 3.06 29.00 3.15

70 26.00 3.05 26.40 3.16 26.80 3.27

80 23.38 3.13 23.99 3.26 24.60 3.39

60 21.24 2.68 21.53 2.72 21.82 2.77

70 19.89 2.79 20.21 2.85 20.52 2.91

80 18.55 2.91 18.88 2.98 19.22 3.05

60 14.73 2.48 14.93 2.53 15.13 2.57

70 13.79 2.58 14.01 2.64 14.22 2.70

80 12.86 2.69 13.09 2.76 13.32 2.82

MBTUH

1,2

KW

MBTUH

1,2

KW

E4TS048S06A WITH N1VSD2006 / G2FD060S24 - LOW CFM 1-CYLINDER OPERATION

ID CFM 850 1040 1140

OD DB ID DB (°F)

60 29.44 1.89 30.37 1.88 31.31 1.87

60

47

35

For notes see Page 11.

70 27.16 2.00 28.00 2.00 28.83 2.00

80 24.88 2.12 25.62 2.12 26.36 2.13

60 25.88 1.80 26.28 1.81 26.68 1.81

70 23.31 1.90 23.80 1.91 24.29 1.91

80 20.73 1.99 21.32 2.00 21.90 2.01

60 22.75 1.72 22.75 1.74 22.75 1.76

70 20.01 1.80 20.24 1.82 20.47 1.83

80 17.27 1.87 17.73 1.89 18.20 1.90

MBTUH

1,2

KW

MBTUH

1,2

KW

Multipliers for determining the performance with other indoor sections.

2-CYLINDER OPERA T ION 1-CYLINDER OPERATION

Air Handler Coil

N1VSD20 G1FD061S24 1.02 1.00 0.95 0.95

F(2,3)FV060 1.00 1.00 0.93 0.95

HIGH CFM LOW CFM

MBTUH KW MBTUH KW

Air Handler Coil

N1VSD20 G1FD061S24 1.02 1.00

F(2,3)FV060 1.00 1.00

036-21342-002 Rev. E (0505)

MBTUH

MBTUH

1,2

1,2

KW

KW

LOW CFM

MBTUH KW

Variable Speed

Furnace

P1DUC16V G1UA060S21 1.00 1.01 0.93 0.96

P1DUC16V G1FA060S21 1.00 1.01 0.93 0.96

P1DUC20V G1UA060S21 1.00 0.99 0.93 0.94

P1DUC20V G1FA060S21 1.00 0.99 0.93 0.94

P1XUC20V G1UA060S21 0.99 1.00 0.91 0.95

P1XUC20V G1FA060S21 0.99 1.00 0.91 0.95

P1XDD20V G2FD060S24 0.99 1.01 0.91 0.95

P1XDD20V G2FD061H24 1.01 1.01 0.94 0.95

P1XUD20V G1UA060S24 1.01 1.02 0.94 0.97

P1XUD20V G1FA060S24 1.01 1.02 0.94 0.97

P1XUD20V G2FD060S24 1.01 1.02 0.94 0.97

P1XUD20V G2FD061H24 1.03 1.02 0.96 0.97

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

Unitary Products Group 21

Coil

MBTUH KW MBTUH KW

Variable Speed

Furnace

P1DUC16V G1U A060S21 0.87 0.99

P1DUC16V G1FA060S21 0.87 0.99

P1DUC20V G1U A060S21 0.90 0.99

P1DUC20V G1FA060S21 0.90 0.99

P1XUC20V G1UA060S21 0.85 0.97

P1XUC20V G1FA060S21 0.85 0.97

P1XDD20V G2FD060S24 0.90 1.00

P1XDD20V G2FD061H24 0.92 1.00

P1XUD20V G1UA060S24 0.93 1.02

P1XUD20V G1FA060S24 0.93 1.02

P1XUD20V G2FD060S24 0.93 1.02

P1XUD20V G2FD061H24 0.95 1.02

Coil

MBTUH KW

Page 22

036-21342-002 Rev. E (0505)

HEATING PERFORMANCE DATA

E4TS060S06A WITH N1VSD2006 / G2FD061S21 - HIGH CFM 2-CYLINDER OPERATION

ID CFM 1540 1860 2075

OD DB ID DB (°F)

60 65.76 4.68 66.22 4.71 66.68 4.74

60

47

35

17

7

-3

70 63.45 4.98 64.33 5.02 65.20 5.07

80 61.15 5.27 62.43 5.33 63.72 5.40

60 56.89 4.31 57.80 4.39 58.70 4.47

70 54.00 4.51 55.00 4.61 56.00 4.70

80 51.10 4.71 52.20 4.82 53.30 4.93

60 46.70 3.92 47.54 4.04 48.37 4.16

70 43.54 4.04 44.43 4.17 45.31 4.30

80 40.38 4.17 41.32 4.30 42.25 4.44

60 29.71 3.45 30.61 3.58 31.51 3.70

70 28.44 3.50 29.20 3.68 29.96 3.86

80 27.16 3.55 27.79 3.79 28.41 4.02

60 21.86 2.75 22.24 2.81 22.63 2.87

70 20.78 2.86 21.19 2.94 21.60 3.02

80 19.70 2.96 20.14 3.06 20.57 3.16

60 13.59 2.44 13.84 2.50 14.08 2.56

70 12.92 2.53 13.18 2.61 13.44 2.68

80 12.25 2.62 12.53 2.72 12.80 2.81

MBTUH

1,2

KW

MBTUH

1,2

KW

E4TS060S06A WITH N1VSD2006 / G2FD061S21 - LOW CFM 1-CYLINDER OPERATION

ID CFM 1000 1200 1350

OD DB ID DB (°F)

60 36.04 2.14 36.57 2.14 37.10 2.13

60

47

35

For notes see Page 11.

70 33.56 2.28 34.11 2.28 34.65 2.28

80 31.08 2.42 31.64 2.42 32.20 2.42

60 26.89 2.03 28.43 2.03 29.97 2.04

70 25.57 2.13 26.60 2.14 27.63 2.15

80 24.26 2.24 24.77 2.25 25.28 2.26

60 17.25 1.86 19.73 1.88 22.20 1.89

70 17.10 1.93 18.56 1.95 20.02 1.97

80 16.94 2.00 17.39 2.02 17.84 2.04

MBTUH

1,2

KW

MBTUH

1,2

KW

Multipliers for determining the performance with other indoor sections.

2-CYLINDER OPERATION 1-CYLINDER OPERATION

MBTUH

MBTUH

1,2

1,2

KW

KW

Air Handler Coil

N1VSD20 G1FD060S24 0.98 1.00 0.93 0.98

F(2,3)FV060 0.98 1.00 0.93 0.98

Variable Speed

Furnace

P1XDD20V112 G2FD060S24 0.98 0.99 0.90 0.94

P1XDD20V112 G2FD061H24 1.00 0.99 0.92 0.95

P1XUD20V112 G1UA060S24 0.98 0.98 0.90 0.93

P1XUD20V112 G1FA060S24 0.98 0.98 0.90 0.93

P1XUD20V112 G2FD060S24 0.98 0.98 0.90 0.93

P1XUD20V112 G2FD061H24 1.00 0.98 0.92 0.93

NOTE: KW RATING IS FOR OUTDOOR AND INDOOR UNITS.

22 Unitary Products Group

Coil

HIGH CFM LOW CFM

MBTUH KW MBTUH KW

MBTUH KW MBTUH KW

Air Handler Coil

N1VSD20 G1FD060S24 0.89 0.91

F(2,3)FV060 0.88 0.90

Variable Speed

Furnace

P1XDD20V112 G2FD060S24 0.88 0.95

P1XDD20V112 G2FD061H24 0.88 0.92

P1XUD20V112 G1UA060S24 0.87 0.95

P1XUD20V112 G1FA060S24 0.87 0.95

P1XUD20V112 G2FD060S24 0.87 0.95

P1XUD20V112 G2FD061H24 0.87 0.93

Coil

LOW CFM

MBTUH KW

MBTUH KW

Page 23

MATCHING INDOOR COMPONENTS

G1UA

UPFLOW

AIR HANDLERS - FOR NON-FURNACE APPLICATIONS

036-21342-002 Rev. E (0505)

G2FD*

MULTI-POSITION

(UPFLOW, HORIZONTAL

AND DOWNFLOW)

G1FA

FULL CASED

N1VS

MODULAR BLOWER

(UPFLOW, HORIZONTAL

AND DOWNFLOW)

G2FD

COIL

F2FV

FAN COIL UNITS

(UPFLOW, HORIZONTAL)

Unitary Products Group 23

Page 24

NOTES

Subject to change without notice. Printed in U.S.A. 036-21342-002 Rev. E (0505)

Copyright © by York International Corp. 2005. All rights reserved. Supersedes: 036-21342-002 Rev. D (1104)

Unitary 5005 Norman

Product York OK

Group Drive 73069

Loading...

Loading...