Page 1

®

SUNLINE 2000

SINGLE PACKAGE HEAT PUMPS

INSTALLATION INSTRUCTION

GENERAL

YORK Model BCH units are single package heat pumps

designed for outdoor installation on a rooftop or a slab.

Supplemental electric heaters are available as field-installed

accessories. The units are manufactured under ISO 9002

Quality System Certification.

Units are completely assembled on rigid, permanently

attachedbaserails.Allpiping,refrigerant charge, andelectrical

wiring is factory-installed and tested. The units require only

electricpowerandductconnectionsatthe point of installation.

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

Supersedes: 511.13-N1YI (900)/035-12984-000

MODELS B3CH 048 AND 060

(WORLD 50 HZ)

530.18-N7.1V -Electric Heater Accessory

•

• 530.18-N7.2V -Fuse Block Accessory

Renewal Parts:

•

Refer to Parts Manual for complete listing of replacement

parts on this equipment.

All forms referenced in this instruction may be ordered from:

Standard Register

Toll Free Tel: (405) 691-1126

Toll Free Fax: (405) 799-7746

035-12984-001-A-0204

INSPECTION

Assoonasaunit is received, itshouldbeinspectedforpossible

damage during transit. If damage is evident, the extent of the

damageshould be noted on thecarrier's freight bill. Aseparate

request for inspection by the carrier's agent should be made in

writing. See local distributor for additional information.

APPROVALS

These units are designed and manufactured as follows:

1. For use as a heat pump only unit or a heat pump unit with

supplemental electric heat.

2. For outdoor installation only.

REFERENCE

Additional information on the design, installation, operation

and service of this equipment is available in the following

reference forms:

•

55.70-N1 -General Installation

•

55.70-N2 -Pre-start & Post-start Check List

•

530.18-N1.2V -Economizer Accessory

•

530.18-N1.4V -Fixed Outdoor Air Damper Accessory

•

530.18-N1.6V -Motorized Outdoor Air Damper Accy.

Installershouldpay particular attentionto thewords: NOTE, CAUTIONand WARNING.Notes

installation easier. Cautions

and/or equipment damage may result if installation procedure is not handled properly.

are given to prevent equipment damage. Warnings are given to alert installer that personal injury

TH IS P RO DU CT MU ST BE INS TAL LED IN STR IC T C O M P LIANCE W ITH

THE ENCLOSED INSTALLATION INSTRUCTIONS AND ANY APPLICABLE

LOCAL, STATE, AND NATIONAL CODES INCLUDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

INCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAMAGE.

CAUTION

WARNING

areintended to clarifyor makethe

Page 2

035-12984-001-A-0204

TABLE OF CONTENTS

General

Inspection

Reference

Approvals

Nomenclature

................................................................................

............................................................................

............................................................................

............................................................................

......................................................................

INSTALLATION

Limitations

Location

Condensate Drainage Precaution

Rigging and Handling

Clearances

Ductwork

Filters

Condensate Drain

Service Access

Blower Speed Selection

Disconnect Switch Bracket For Optional Belt-Drive

Compressors

Thermostat

Power and Control Wiring

Electric Heaters...................................................................4

Optional Economizer Rain Hood.........................................6

...........................................................................

...............................................................................

.......................................

..........................................................

..........................................................................

.............................................................................

...................................................................................

...............................................................

....................................................................

......................................................

............

.......................................................................

..........................................................................

...................................................

OPERATION

Cooling System .................................................................12

Preliminary Operation Cooling ..........................................12

Cooling Sequence of Operation ........................................12

Heating Sequence of Operation........................................12

Defrost Sequence of Operation.........................................12

Lockout Control

Checking Supply Airflow

Secure Owner's Approval

.................................................................

....................................................

..................................................

13

13

14

1

1

Normal Maintenance

1

1

2

No. Description Page

1 Unit Application Data

3

3

3

3

3

3

4

4

4

4

2 Air Flow Limitations

3 Physical Data

4 Supply Air Perferformance — BCH048

5 Supply Air Performance — BCH060

6 Motor and Drive Data - Belt-Drive Blower..10

7 Static Resistances

8 Electrical Data — Basic Unit

9 Electrical Data — Heat Pump

10 Belt-Drive Supply Air Motor Pulley Adj.

4

4

4

4

No. Description Page

1 Center of Gravity........................................ 3

2 Recommended Drain Piping...................... 4

3 Typical Field Wiring.................................... 5

4 Economizer Rain Hood Assembly.............. 6

5 Adjusting Enthalpy Setpoint....................... 7

6 Dimensions and Clearances...................... 8 & 9

7 Defrost Initiation Times .............................. 12

8 Ambient Modified Time/Temp. Control....... 12

9 Belt Adjusment

10 Hole Loc. for Press. Drop Readings

11 Press. Drop versus Supply Airflow

MAINTENANCE

.........................................................

TABLES

..................................

....................................

.............................................

......

..........

......................................

......................

....................

.......

FIGURES

...........................................

...........

.............

14

3

5

7

10

10

10

11

11

13

13

13

13

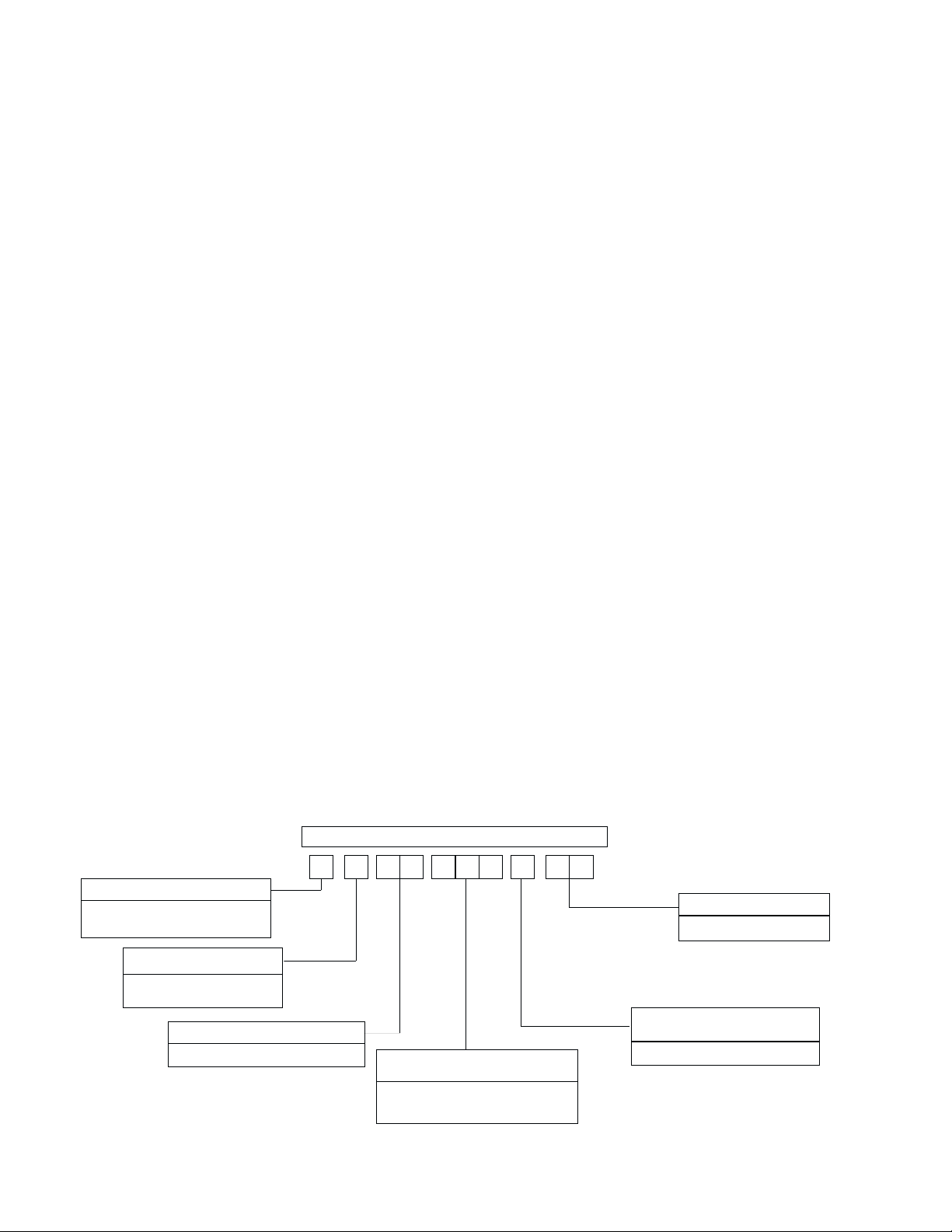

PRODUCT NOMENCLATURE

B 3 C H A

PRODUCT CATEGORY

B = Single Package Heat Pump

(Air Cooled)

PRODUCT GENERATION

3 = Third Generation

PRODUCT IDENTIFIER

CH = Heat Pump

2 Unitary Products Group

NOMINAL COOLING CAPACITY

40 8 5 0

048 = 4 Ton

060 = 5 Ton

VOLTAGE CODE

50 = 380/415-3+N-50

FACTORYINSTALLED HEAT

A = No Supplemental Heat

Page 3

INSTALLATION

LIMITATIONS

These units must be installed in accordance with national and

local or municiple safety codes: Refer to Table 1 for Unit

Application Data.

If components are to be added to a unit to meet local codes, they

TABLE 1 - UNIT APPLICATION DATA

Voltage Variation

Min. / Max.

°C 14 / 22

°F 57 / 72

°C 7 / 49

°F 45 / 120

°C -23

°F -10

Cooling

Heating

Wet Bulb Temperature of Air

on Indoor Coil, Min./Max.

Dry Bulb Temperature of Air

on Outdoor Coil, Min./Max.

Minimum Dry Bulb Temperature

of Air on Outdoor Coil

aretobeinstalledatthedealer'sand / or the customer'sexpense.

342 / 457

035-12984-001-A-0204

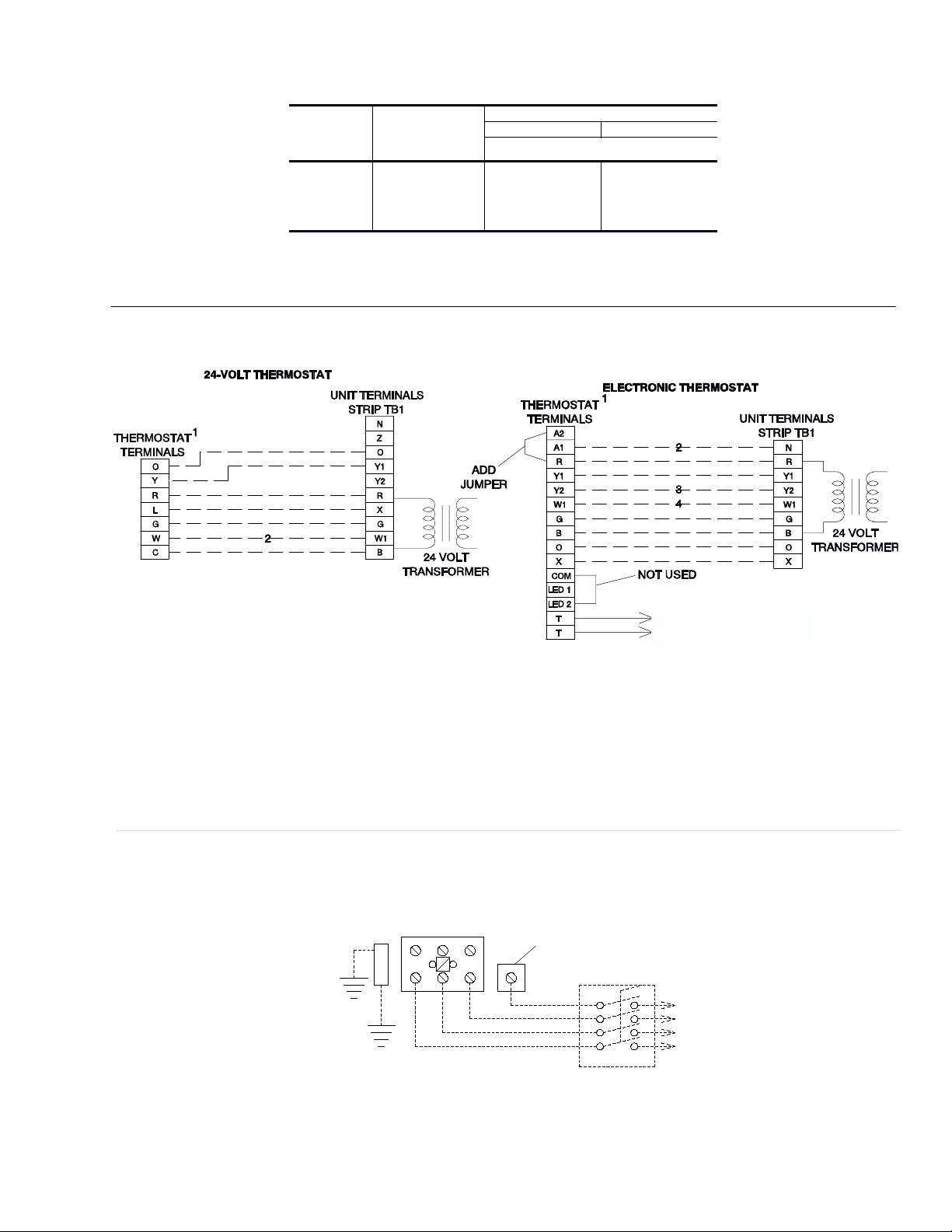

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaginguntil the unitis near the place of installation. Rig the

unit by attaching chain or cable slings to the lifting holes

provided in the base rails. Spreaders, whose length exceeds

the largest dimension across the unit, MUST be used across

the top of the unit.

BEFORE LIFTING AUNIT,MAKE SURE THATITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a forklift. Slotted

openings in the base rails are provided for this purpose.

LENGTH OF FORKS MUST BE A MINIMUM OF 1067mm

(42 in.).

Remove the nesting brackets from the four corners on top of

the unit. All screws that are removed when taking these

brackets off must be replaced on the unit.

APPROXINATE

CENTER OF

GRAVITY

BACK

CONDENSER

COIL END

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Outdoor coil must have an unlimited supply of air.

3. For ground level installation, use a level concrete slab with

a minimum thickness of 102mm (4 in.). The length and

widthshould be at least 152mm (6 in.) greater than the unit

base rails. Do not tie slab to the building foundation.

4. Roof structures must be able to support the weight of the unit

and its options and / or accessories. Unit must be installed on

a solid level roof curb or appropriate angle iron frame.

CAUTION: If a unit is to be installed on a roof curb or special frame

other than a YORK roof curb, gasketing must be applied

toallsurfacesthatcomeincontactwith the unit underside.

5. Maintain level tolerance to 13mm (

1

in.) maximum across

2

the entire length or width of the unit.

6. Elevate the unit sufficiently to prevent any blockage of the

airentrances by snowin areas wherethere will besnow ac

cumulation. Check the local weather bureau for the ex

pected snow accumulation in your area.

OUTDOORCOIL CONDENSATEDRAINAGE PRECAUTION

Condensatedrainsfromtheoutdoorcoil during theheatingand

defrost cycles. Normally this condensate may be allowed to

drain directly onto the ground/roof. A gravel bed is

recommended to prevent mud splashing.

WARNING:Theunit should notbe installed in an area wheremud

or ice could cause personal injury. Remember that

condensate drips from the outdoor coil during heat

and defrost cycles and that this condensate freezes

when the temperature of the outdoor air is below 0°C

(32

°

F).

1140

44

502

3

“

19

7

“

8

4

FIG. 1 - CENTER OF GRAVITY

RefertoTable3forunitweightsandtoFigure 1 for approximate

center of gravity.

CLEARANCES

All units require certain clearances for proper operation and

service. Refer to Figure 6 for the clearances required for

combustibleconstruction,servicing,andproperunitoperation.

WARNING:Do not permit overhanging structures or shrubs to

obstruct outdoor air discharge outlet.

DUCTWORK

A closed return duct system shall be used. This does not

preclude use of economizers or outdoor fresh air intake. The

supply and return air duct connections at the unit should be

madewithflexiblejointstominimizethetransmission of noise.

-

Thesupply and return air duct systems should be designed for

theairflowandstatic requirements of thejob.Theyshould NOT

be sized to match the dimensions of the duct connections on

the unit.

CAUTION: When fastening ductwork to the side duct flanges

on the unit, insert the screws through the duct

flanges only. DO NOT insert the screws through

the casing.

Outdoor ductwork must be insulated and water

proofed.

Refer to Figure 6 for information concerning side and bottom

supply and return air duct openings.

FILTERS

Each unit is supplied with 25mm (1 in.) filters . Replacement

1035

40

FRONT

2089

3

“

4

1

“

82

4

51mm (2 in.) filters may be used without modification to the

filter racks. Filters must always be installed ahead of the

evaporator coil and must be kept clean or replaced with same

Unitary Products Group 3

-

Page 4

035-12984-001-A-0204

size and type. Dirty filters reduce the capacity of the unit and

result in frosted coils or safety shutdown. Minimum filter area

and required sizes are shown in Table 3.

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain

linefromthe19mm(

76

3"

51

2"

3

in.)PVCfemaleconnectionon the unit to

4

FIG. 2 - RECOMMENDED DRAIN PIPING

spill into an open drain.

NOTE: The condensate drain line MUST be trapped to pro

vide proper drainage. See Figure 2.

SERVICE ACCESS

Access to all serviceable components is provided by the

following removable panels:

Compressor compartment

•

Heater compartment

•

•

Blower compartment

•

Main control box

•

Filter compartment

•

Motor Access (on units w/belt-drive option)

Refer to Figure 6 for location of these access panels.

BLOWER SPEED SELECTION

Threeblowermotor speeds areavailable on theBCH048 units.

The speed selection is determined by the airflow and ESP

requirements of the applications. BCH060 units have an

adjustable motor pulley to achieve the above conditions.

BCH048 units are shipped with the black wire (labeled #8)

connectedto the high speed tapon the blower motor.If a lower

blower speed is desired, this wire should be moved to the

medium or low speed tap on the motor.

DISCONNECT SWITCH BRACKET FOR UNITS

WITH OPTIONAL BELT-DRIVE BRACKET

A special bracket for mounting a field-supplied disconnect

switch is provided in each BCH060. The bracket is shipped

inside the blower compartment taped to the top of the blower

housing. Install the bracket on the left hand side of the unit as

shownin Figure6. Severalexisting screws at the top of the unit

and one approximately midway down from the top will be used

for mounting the bracket. Screws should be loosened only NOT REMOVED. Mounting holes in the bracket have

elongated keyways allowing easy installation. Re-tighten

screws after bracket is in place to ensure panels will remain

leak tight.

After this unit is installed, back out the compressor bolts until

the sleeve clears the top grommet.

CAUTION: Do Not

loosen compressor mounting bolts.

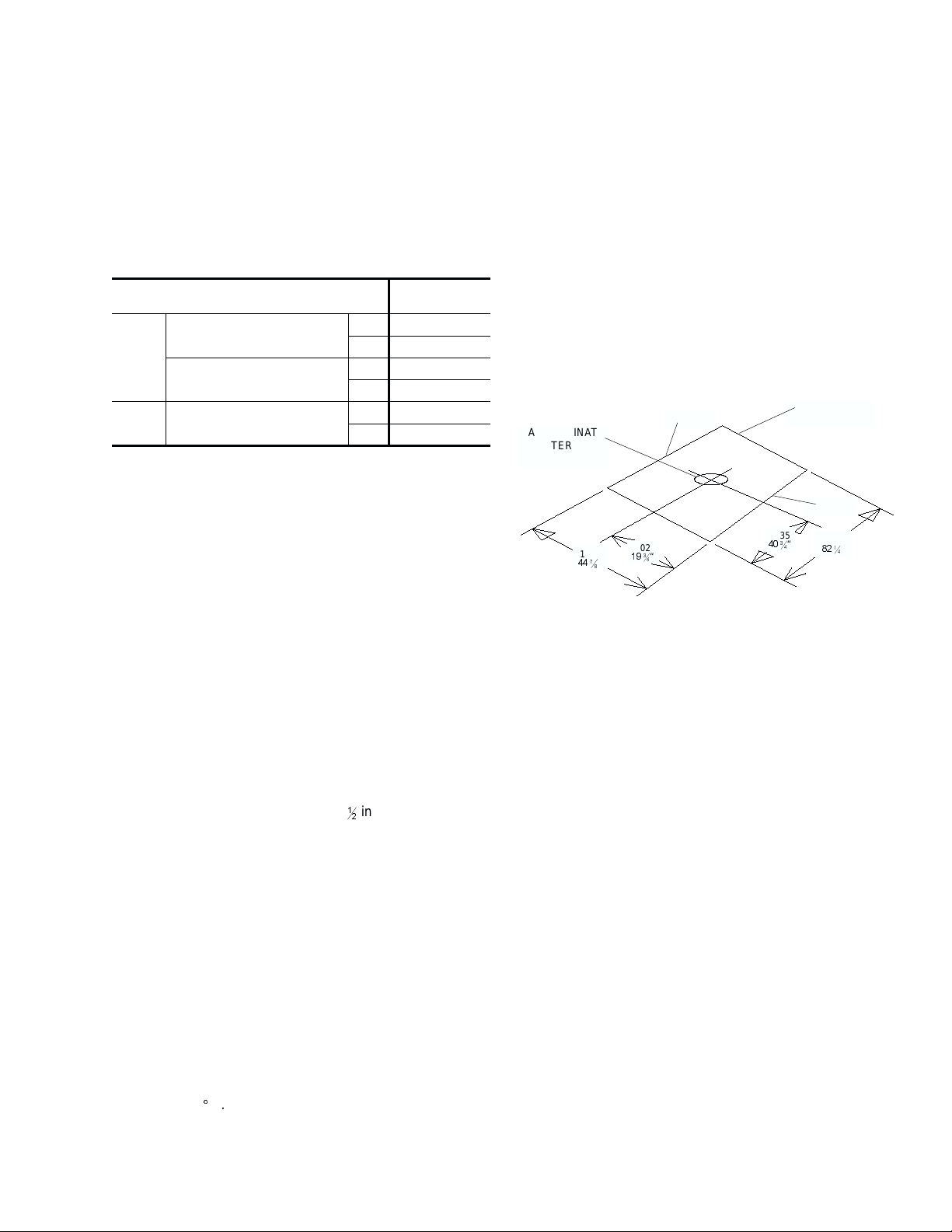

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 1422mm (56 in.) above the floor where it is not

subjected to drafts, sun exposure, or heat from electrical

fixtures or appliances. Follow manufacturer's instructions

enclosed with thermostat for general installation procedure.

Color coded insulated wires (#18 AWG) should be used to

connect thermostat to unit. See Figure 3 for wiring details.

NOTE: On units with economizer, remove jumper “J1" from

An “Emergency Heat” position is provided with the

thermostat.In the “Emergency Heat” position, the thermostat

allowselectricresistanceheatonly.The compressorislocked

out. Apilot light on the thermostat indicates that the switch is

-

on “EM HT”.

terminals 8 and 10 on plug connector J3/P7 on the re

layboardin the unitcontrolbox. Refer totheunitwiring

labels located on the inside of the control box access

panel.

POWER AND CONTROL WIRING

Voltagetolerances which must be maintained at the compressor

terminals during starting and running conditions are indicated on

the unit Rating Plate and Table 1.

The wiring harness furnished with this unit is an integral partof

the unit. Field alteration to comply with electrical codes should

not be required.

A disconnect switch should be field provided for the unit. The

switch must be separate from all other circuits. Refer to Figure

6forinstallationlocation.If any of thewiresuppliedwith the unit

mustbe replaced, replacement wire must be of the typeshown

on the wiring diagram.

Electrical lines must be sized properly to carry the load. USE

COPPERCONDUCTORSONLY.Eachunit must bewired with

a separate branch circuit fed directly from the meter panel and

properly protected.

CAUTION: When connecting electrical power and control wir

Refer to Figure 3 for typical field wiring and to the appropriate

unit wiring diagram for control circuit and power wiring

information. Refer to Tables 8 and 9 for electrical data.

ing to the unit, waterproof type connectors MUST

BE USED so that water or moisture cannot be

drawn into the unit during normal operation. The

above waterproofing conditions also apply when

installing a field-supplied disconnect switch.

ELECTRIC HEATERS

Supplemental electric heaters may be ordered as a fieldinstalled accessory. Refer to Form 530.18-N7.1V for

installation instruction. These approved heaters are located

within the central compartment of the unit (see Figure 6 for

access panel) with the heating elements extending into the

supply air chamber.

-

-

COMPRESSORS

On some units the compressor is mounted on springs which

have been tightened down for shipment only.

4 Unitary Products Group

Fuses are supplied, where required, by the factory. Some kW

sizes require fuses and others do not. Refer to the electric

Page 5

TABLE 2 - AIR FLOW LIMITATIONS

NOMINAL

HEATER

SIZE

KW

7

10

15

20

30

VOLTAGE

380/415-3+N-50

CONTROL WIRING

UNIT MODEL SIZE, NOMINAL TONS

MINIMUM SUPPLYAIR CFM

1,300

1,300

1,300

1,300

45

1,600

1,600

1,600

1,600

–

1,600

035-12984-001-A-0204

1 Typical 24-volt thermostat with subbase

-2ET03700424 for manual changeover.

2

Only required on units with supplemental electric heat.

Note: The thermostat terminals shown

above are typical. Check thermostat

and unit wiring diagrams for correct

wiring connections.

POWER WIRING

CONTACTOR

TO REMOTE SENSOR

2ET04701324 IF USED

1 Typical Electronic programmable thermostat 2ET04701124 with subbase for

either manual or automatic changeover.

2

Only required on units with economizer. Remove jumper L2 from terminals

4 and 9 on jumper plug P7. The outdoor air intake dampers will return to their

fully closed position when the thermostat switches to the “unoccupied” mode.

3

Second stage cooling may be used on units with economizer. Remove jumper

J1 from terminals 8 and 10 on jumper plug connector P7.

4

Only required on units with supplemental electric heat.

NEUTRAL

TERMINAL

BLOCK

FIELD-SUPPLIED

DISCONNECT

GROUND

LUG

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION.

FIG. 3 - TYPICAL FIELD WIRING

Unitary Products Group 5

Page 6

035-12984-001-A-0204

heater accessory installation instruction for the heater

electrical data.

The minimum air flow limitations across these heaters are

listed in Table 2.

OPTIONAL ECONOMIZER RAIN HOOD

The following procedure should be used when assembling an

economizer rain hood onto a unit. Refer to Figure 4. The

outdoor and return air dampers, damper actuator, the linkage

and all the controls are factory mounted as part of the

economizer option.

All of the hood components, including the filters, the gasketing

and the hardware for assembling are located above the top

filter racks within the filter section. The outdoor air sensor is in

thebagofpartslocatedatthebottomofthe return air section.

1. With filter section access panel removed, take out hood

components, filters and sensor described above. Remove

and discard outdoor air opening cover on back unit (Upper

right hand corner).

2. Remove the 13mm (

panel (located to the right side of the outdoor air opening).

Insert the two loose wires from inside the unit, into the

13mm (

1

in.) bushing provided. Insert wires and bushing

2

into knockout. Snap bushing into place.

3. Mount the outdoor air sensor to the rear panel, just below

the knockout described in Step 2. Secure with two selfdrilling screws at dimples (B) provided in the panel.

NOTE: Sensor must be positioned so that the sensing ports

are at the top (louvers pointing downward) and terminal connections to the right.

4. Connectthe two wires, indicated in Step2, to the sensor as

follows:

•

Wire #73 to terminal (+)

•

Wire #74 to terminal (S)

5. Assemble the LH and RH side plates to the top cover (2

screws each side) to form the hood. Apply gasketing to the

1

in.) knockout (A) in the units rear

2

flangesurface on each side plate.Extend gasketing 6mm (

1

in.) beyond top and bottom of each flange to insure ade

4

quatecorner sealing. Securethis assembly tothe unit back

panel(upper right hand corner). First,remove screw(C) on

unit top cover. Then slip flange of hood cover in under

flange of unit top cover, replace screw (C), engaging hole

(E)in hood flange and tighten. Attach the two sideplates to

theunit panel by usingtwo self-drillingscrews for eachside

plate at dimples (D) provided in the panel.

6. Position fillpiece at bottom of hood, between the two side

plates but do not secure at this time. (Slotted openings

MUSTbedownwardfor drainage). Afterfillpieceisproperly

positioned, note where contactis made with the unit panel.

Remove fillpiece and apply gasket material to this area to

provide a seal. Reposition fillpiece and secure with 2

screws.

7. Install the two filters into the hood assembly, sliding down

along retainers on side plates, into fillpiece at bottom of

hood.

NOTE: Install filters so that “Air Flow” arrows point toward the

unit.

8. Install filter cover over the end of the hood with one screw

(center of hood), securing filters into position.

CAUTION: When proceeding with steps 9 and 10, extreme

care must be exercised while turning both the set

point and minimum position adjusting screws to

prevent twisting them off.

9. The enthalpy set point for the dampers may now be set by

selectingthe desired set-pointfrom graph inFigure 5. Fora

singleenthalpy economizer,carefully turn the set-point adjusting screw to the “A”, “B”, “C” or “D” setting corresponding to the lettered curve. For a dual enthalpy economizer,

carefully turn the set-point adjusting screw fully clockwise

past the “D” setting.

10.To check that the damper blades move smoothly without

binding, carefully turn the minimum position adjusting

-

GASKETED

FLANGE

L. H. SIDE

PLATE

FILTER

COVER

FILTERS

HOOD

COVER

FILLPIECE

OUTDOOR AIR

OPENING COVER

D

E

D

GASKETED

FLANGE

R. H.

SIDE

PLATE

C

D

A

B

D

SIDE DUCT

APPLICATION SHOWN

OUTDOOR AIR

SENSOR

GASKET

FILTER SECTION

ACCESS PANEL

FIG. 4 - ECONOMIZER RAIN HOOD ASSEMBLY (OPTION)

6 Unitary Products Group

Page 7

035-12984-001-A-0204

FIG. 5 - ENTHALPY SET POINT ADJUSTMENT

TABLE 3 - PHYSICAL DATA

MODELS

CENTRIFUGAL BLOWER (Dia. x

SUPPLYAIR

BLOWER

INDOOR

COIL

OUTDOOR

FAN

OUTDOOR

COIL

AIR

FILTERS

(SEE NOTE)

CHARGE REFRIGERANT 22 (kg / lbs./oz.) 4.2 / 9.2 3.7 / 8/4

NOTE: Filter racks are adapted for 1" or 2" thick filters.

Unitary Products Group 7

Wd.,mm/in.)

FAN MOTOR HP(Direct-Drive Units)

FAN MOTOR HP(Belt-Drive Units)

ROWS DEEP

FINS PER 25mm (1 inch)

FACE AREA(m

PROPELLER DIA. (mm/in.)

FAN MOTOR kW/HP

NOM. CFM TOTAL

ROWS DEEP

FINS PER 25mm (1 inch)

FACE AREA(m

QUANTITY PER UNIT (14" x 20" x 1")

QUANTITY PER UNIT (14" X 25" X 1")

TOTAL FACE AREA (m

2

2

/ft2)

/ft2)

2

/ ft2.)

305 x254

12 x 10

0.47 / 5.1

610 / 24

0.37 / 0.5

BCH

048 060

305 x 254

0.75

NA

3

15

4,200

1

20

17.1

2

1

6.3

12 x 10

0.47 / 5.1

610 / 24

0.37 / 0.5

4,500

NA

1.5

3

15

1

20

17.1

2

1

6.3

Basic Unit

Electric Heat

(Nominal Kw)

Economizer

Motorized Outdoor Air

Damper

Barometric Relief/Fixed

Outdoor Air Intake Damper

Roof Mounting Curb

Belt-Drive Blower

WEIGHTS (kg/lbs)

048 270 / 595

060 281 / 620

OPTIONS / ACCESSORIES

5 - 7 kW 8.2 / 18

10 - 15 kW 10.4 / 23

20 - 30 kW 12.7 / 28

22.7 / 50

21.8 / 48

4.5 / 10

41.7 / 92

2.3 / 5

Page 8

035-12984-001-A-0204

(Direct-Drive Units)

829

32-5/8"

2090

82-1/4"

OUTDOOR COIL

RETURN AIR

137

5-3/8

1140

44-7/8"

200

7-7/8"

445

17-1/2"

213

8-3/8"

171

6-3/4"

206

8-1/8"

165

6-1/2"

292

11-1/2"

445

17-1/2"

UTILITIES ENTRY DATA

HOLE

A 5mm (7/8") *

B 51mm (2") *

*Knockouts in the bottom of the unit can be located by the slice

in the insulation.

**Do not remove the 2" knockout ring.

KNOCKOUT

SIZE

(DIA.)

64

2-1/2

SUPPLYAIR

OUTDOOR AIR

OUTDOOR AIR

(Economizer)

All dimensions are in millimeters and

inches.They are subject to change without

notice. Certified dimensions will be provided upon request.

USED FOR

Control Wiring

(Side or Bottom)**

Power Wiring

(Side or Bottom)

Front 610mm (24")

Back

Left Side (Filter Access)

Right Side (OD Coil) 610mm (24")

Below Unit

Above Unit

NOTE:

Units and ductwork are approved for zero clearance to combustible materials when

equipped with electric heaters.

1

Units may be installed on combustible floors made from wood or class A, B or C

roof covering material.

2

Units must be installed outdoors. Overhanging structures or shrubs should not

obstruct outdoor air discharge outlet.

1

2

25mm (12") (Less Economizer)

914mm (36") (With Economizer)

610mm (24") (Less Economizer)

914mm (36") (With Economizer)

0mm (0")

1829mm (72") (For Outdoor Air

Discharge)

FIGURE 6 - DIMENSIONS & CLEARANCES

8 Unitary Products Group

Page 9

437

1

17

REAR VIEW

SIDE SUPPLYAND RETURN AIR

DUCT OPENINGS

035-12984-001-A-0204

DUCT COVERS - Units are shipped with all air duct

openings covered.

For side

duct applications;

1.Remove and discard the supply and return air duct

covers.

2.Connect ductwork to duct flanges on the rear of the

292

1

11

2

unit.

For bottom

“

1. Remove the side supply air duct cover to gain ac

duct applications;

-

cess

to the bottom supply air knockout panel.

76

3"

2. Remove and discard the bottom knockout panel.

3. Replace the side duct cover.

4

117

292

11

5

“

2

165

6

437

1

“

2

1

“

17

2

200

7

“

7

8

4. With filter section access panel removed from the

1

“

2

unit, remove and discard the bottom return air

knockout panel.

“

8

REAR VIEW

DETAIL “A”

UNIT WITH ECONOMIZER RAINHOOD

698

27

1

2

41

5

“

1

8

3

“ CONDEN-

4

SATE

638

1

“

27

2

267

1

“

19

2

DRAIN CONN.

(Must be trapped)

502

3

19

4

1140

7

“

44

8

“

L.H. END VIEW

260

1

“

10

A

89

4

1

3

2

111

3

“

4

8

210

8

DETAIL “B”

REAR VIEW

416

3

“

16

8

117

5

“

4

8

454

7

“

17

8

184

7

1

“

4

260

1

“

10

4

1340

44

B

7

“

8

L.H. END VIEW

UNIT WITH FIXED OUTDOOR AIR / BAROMETRIC RELIEF RAINHOOD

FIGURE 6 - DIMENSIONS & CLEARANCES (continued)

Unitary Products Group 9

“

1

4

Page 10

035-12984-001-A-0204

TABLE 4 - SUPPLY AIR PERFORMANCE - BCH048

380 / 415 VOLTS - SIDE DUCT APPLICATIONS

MODEL

048

MODEL

048

*INCLUDES ALLOWANCES FOR A WET INDOOR COIL AND 1" FILTERS. REFER TO THE STATIC RESISTANCES TABLE FOR RESISTANCE VALUES ON APPLICATIONS OTHER

THAN HEATPUMP UNITS WITH SIDE DUCT AIRFLOWS.

MOTOR

SPEED

HI

MED

LOW

MOTOR

SPEED

HI

MED

LOW

3

/s Watts m3/s Watts m3/s Watts m3/s Watts m3/s Watts m3/s Watts m3/s Watts m3/s Watts m3/s Watts

m

-

-

-

-

0.85

0.77

910

810

0.84

0.76

880

780

0.94

0.82

0.75

0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

CFM Watts CFM Watts CFM Watts CFM Watts CFM Watts CFM Watts CFM Watts CFM Watts CFM Watts

-

-

-

1810

1635

910

810

1780

1610

880

780

2000

1740

1580

Available External Static Pressure - Pa*

1010

0.92

975

0.90

945

850

760

0.80

0.73

825

740

0.79

0.73

800

730

0.87

0.76

0.71

Available External Static Pressure - IWG*

1010

1950

975

1905

945

850

760

1700

1555

825

740

1665

1540

800

730

1840

1620

1510

910

775

715

910

775

715

0.83

0.74

0.69

1770

1560

1460

825

740

690

825

740

690

0.78

0.70

0.66

1660

1480

1400

825

700

660

825

700

660

0.72

0.66

0.61

1530

1390

1300

TABLE 5 - SUPPLY BLOWER PERFORMANCE - BCH060

MODEL

AIR FLOW

3

m

/s / CFM

223 / 0.90 248 / 1.00 273 / 1.10 298 / 1.20 322 / 1.30 347 / 1.40 372 / 1.50

RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts RPM Watts

1.18 / 2500 --------------

1.13 / 2400 1193 1665 ------------

1.08 / 2300 1170 1580 1202 1620 ----------

1.04 / 2200 1148 1480 1180 1530 ----------

0.99 / 2100 1121 1385 1155 1425 1190 1475 --------

0.94 / 2000 1100 1285 1133 1340 1169 1385 1205 1445 ------

060

0.90 / 1900 1079 1180 1110 1240 1143 1280 1178 1330 1222 1375 ----

0.85 / 1800 1058 1060 1090 1135 1122 1190 1158 1240 1196 1295 ----

0.80 / 1700 1035 960 1071 1030 1103 1100 1134 1140 1164 1175 1197 1205 - -

0.75 / 1600 1020 900 1056 965 1088 1035 1118 1065 1145 1105 1170 1130 1198 1150

0.71 / 1500 1004 860 1038 880 1070 925 1101 980 1130 1045 1158 1075 1184 1110

*INCLUDES ALLOWANCES FOR A WET INDOOR COIL AND 1" FILTERS. REFER TO THE STATIC RESISTANCES TABLE FOR RESISTANCE VALUES ON APPLICATIONS OTHER

THAN

HEATPUMP UNITS WITH SIDE DUCT AIRFLOWS.

Available External Static Pressure -Pa/ IWG*

775

660

615

775

660

615

TABLE 6 - MOTOR AND DRIVE DATA - Belt-Drive Blower

MOTOR*

FRAME

SIZE

SERVICE

FACTOR

MODEL

BLOWER

RANGE

(RPM)

kW/HP RPM

BCH060 850 - 1180 0.75/1.0 1450 56 1.15

*All motors have solid bases and are inherently protected. These motors can be selected to operate into their service factor because they are located in the moving air, upstream of any

heating device.

ADJUSTABLE

MOTOR PULLEY

PITCH

DIA.

mm (in.)

BORE

mm (in.)

71 - 97

(2.8 - 3.8)

22 127 (5.0) 25 (1) 947 (37.3) A36

FIXED

BLOWER PULLEY

PITCH

DIA.

mm (in.)

BORE

mm (in.)

PITCH

LENGTH

(mm in.)

BELT

DESIG-

NATION

TABLE 7 - STATIC RESISTANCES*

EXTERNAL STATIC PRESSURE DROP

RESISTANCE, Pa/IWG

3

DESCRIPTION

Economizer/Motorized Damper

Electric Heaters

1

Bottom Duct Connections

1Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2

The pressure thru the economizer is greater for 100% outdoor air than for 100% return air. If the resistance of the return air duct system is less than 0.25 IWG, the unit will deliver less CFM

during full economizer operation.

1, 2

5 - 15 KW 10 / 0.04 12 / 0.05 15 / 0.06 17 / 0.07 20 / 0.08 25 / 0.10 30 / 0.12 35 / 0.14 40 / 0.16

20 - 30 KW 15 / 0.06 17 / 0.07 20 / 0.08 22 / 0.09 27 / 0.11 32 / 0.13 37 / 0.15 42 / 0.17 50 / 0.20

1

0.47/1000 0.57/1200 0.66/1400 0.75/1600 0.85/1800 0.94/2000 1.04/2200 1.13/2400 1.232600

17 / 0.07 20 / 0.08 22 / 0.09 27 / 0.11 32 / 0.13 37 / 0.15 42 / 0.17 50 / 0.20 57 / 0.23

15 / 0.06 17 / 0.07 20 / 0.08 22 / 0.09 25 / 0.10 27 / 0.11 30 / 0.12 35 / 0.14 40 / 0.16

10 Unitary Products Group

m

/s/CFM

Page 11

035-12984-001-A-0204

TABLE 8 - ELECTRICAL DATA - Basic Unit

SUPPLY

AIR

BLOWER

MOTOR,

FLA

TOTAL

UNIT

AMPACITY,

AMPS

MODEL

BCH

POWER SUPPLY

VOLTAGE

LIMITATIONS

COMPRESSOR OUTDOOR

MIN. MAX. RLA LRA

FAN

MOTOR,

FLA

048 380/415-3+N-50 342 457 9.6 66 1.8 4.0 18.3 25 25 10 (6MM

060 380/415-3+N-50 342 457 10.0 75 1.8 2.6 16.9 25 25 10 (6MM

NOTES: 1. Dual element, time delay type.

2. Based on 75°C copper conductors.

MAX.

FUSE

SIZE,

(SEE NOTE 1)

AMPS

MAX.

HACR

BREAKER

SIZE,

AMPS

(SEE NOTE 2)

MIN.

WIRE

SIZE,

AWG

2

)

2

)

TABLE 9 - ELECTRICAL DATA

HEATER

MODEL

BCH

POWER

SUPPLY

048 380/415-3+N-50

060 380/415-3+N-50

ACCESSORY

MODEL

NUMBER

2CE04510746*

2CE04511046*

2CE04511546*

2CE04512046*

2CE04510746*

2CE04511046*

2CE04511546*

2CE04512046*

2CE04513046*

- Heat Pump with Supplemental Electric Heat

SUPPLY

AIR

BLOWE

R

MOTOR

FLA

4.0

2.6

ELECTRIC HEATERS

KW STAGES

4.3 / 5.1

6.3 / 7.5

8.5 /

10.2

12 / 14.6

4.3 / 5.1

6.3 / 7.5

8.5 /

10.2

12 / 14.6

18 / 22

1

1

1

2

1

1

1

2

2

TOTAL

AMPS

7.1

10.5

14.1

20.3

7.1

10.5

14.1

20.3

30.0

TOTAL

UNIT

AMPACITY

AMPS

26.5

30.3

34.5

41.1

25.7

30.0

34.6

42.2

54.3

MAX.

FUSE

SIZE,

(SEE NOTE 1)

AMPS

30

35

40

45

30

35

40

45

60

MAX.

HACR

BREAKER

SIZE,

AMPS

30

35

40

45

30

35

40

45

60

MIN.

WIRE

SIZE,

AWG

(SEE NOTE 2)

10 (6mm

8 (10mm

8 (10mm

8 (10mm

10 (6mm

8 (10mm

8 (10mm

8 (10mm

6 (16mm

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

Unitary Products Group 11

Page 12

035-12984-001-A-0204

OPERATION

screw fully clockwise and then energize and de-energize

terminals “R” to “G”. With terminals “R” to “G” energized,

turnthe minimumposition screwcounterclockwise until the

desired minimum position has been attained.

11.Replace the filter section access panel.

COOLING SYSTEM

The unit has an air-cooled condenser and is factory-charged

with Refrigerant-22.

250

200

150

100

T3 - 110 Minute Setting (Factory Set Point)

T2 - 80 Minute Setting

The compressor is hermetically sealed, internally sprung,

mounted on spring isolators and inherently (internally)

protected. If there is an abnormal temperature rise in the

compressor,theprotectoropens to shut downthecompressor.

PRELIMINARY OPERATION COOLING

After the installation has been completed, the crankcase

heaterofthecompressor must beenergizedforat least 4hours

before starting the unit. After this initial warm-up, the

compressor should be given three false starts (energized just

long enough to make a few revolutions) with a 5 minute delay

between each start before being put into full time service.

NOTE: Prior to each cooling season, the crankcase heater

mustbe energizedat least 10 hours before the system

is put into operation.

COOLING SEQUENCE OF OPERATION

When the thermostat calls for cooling, the compressor and the

outdoor fan motor will be energized through terminal “Y1" and

the supply air blower motor will be energized through terminal

”G" (if the fan switch on the subbase is set in the “AUTO”

position). The supply air blower motor will run continuously if

the fan switch is set in the “ON” position.

The reversing valve is energized thru the “O” circuit when the

subbase is in the cooling mode.

HEATING SEQUENCE OF OPERATION

The following sequence of operation is based on using a

standardYORK heatpumpthermostatwithtwoheatingstages.

FIRST STAGE HEAT

When the thermostat callsfor heating, the compressor and the

outdoor fan motor will be energized through terminal “Y1" and

the supply air blower motor will be energized through terminal

”G" (if the fan switch on the subbase is set in the “AUTO”

position). The supply air blower motor will run continuously if

the fan switch is set in the “ON” position.

50

T1 - 50 Minute Setting

0

TIME BETWEEN DEFROST CYCLES, MINUTES

-10

20

10

0

OUTDOOR AMBIENT, DEG. F

40

30

50

FIG. 7 - DEFROST INITIATION TIMES

adjusted to defrost at 80 minutes (T2) or 50 minutes (T1) in

areas with high humidity.

The curve in Figure 7 shows how defrost initiation times are

automatically compensated for changes in outdoor

temperature.

EXAMPLE: If the time is factory set on pin T-3 (110 minutes at

2°C(35°F)outdoor)and the outdoortemperatureclimbsto 7°C

(45°F), the time initiation cycle decreases to 100 minutes.

If the outdoor temperature drops to -12°C (10°F) where ice is

less likely to form, the 110 minute interval increases to 150

minutes.

Two requirements must be met before a defrost cycle can be

initiated.

1. The defrost time cycle must be complete.

2. The liquid line temperature must be less than -2°C (28°F).

Defrost terminates when the liquid line sensor reaches 13°C

(55°F) or after 10 minutes.

The defrost time cycle restarts 10 minutes after the start of the

defrost cycle even though the liquid sensor terminated defrost

after 3 minutes.

T2 - 80 MINUTE SETTING

T3 - 110 MINUTE SETTING

(Factory Set Point)

T1 - 50 MINUTE SETTING

60

SECOND STAGE HEAT

If compressor operation can not satisfy the heating

requirements, second stage heat will energize supplemental

electric heat (if supplied) thru the “W1" circuit.

DEFROST SEQUENCE OF OPERATION

The BCH has a unique “ambient modified” time-temperature

SHORTING PEGS TO

OVERRIDE TIMER

FOR SERVICE

MOVABLE JUMPER

WIRE TO CHANGE

DEFROST TIMER

defrost control that automatically adjusts to changes in the

outdoor temperature. The defrost control will shorten the

defrostinitiation time periodsabove 2°C (35°F)and will extend

thedefrost initiation timeperiods below 2°C(35°F). The control

is factory set to defrost at 110 minutes (T3), but it can be field

FIG. 8 - AMBIENT MODIFIED TIME/TEMPERATURE

CONTROL

12 Unitary Products Group

Page 13

035-12984-001-A-0204

During troubleshooting, the defrost time can be reduced to 20

secondsby shortingout theSW1 testpegs onthe module. The

pegs are 13mm (

1

in.) long, 1mm (

2

3

in.) apart and are

16

mounted on a white base. See Figure 8.

LOCKOUT CONTROL

Any one of four conditions will put the system into a lock-out

condition during the heating or cooling mode:

1.

The discharge line temperature reaches 124°C (255°F)

(102°C [215°F] reset) or,

2. The discharge pressure reaches 2770 kPa (398 PSIG)

(2158 kPa [310 PSIG] reset) or,

3.

The suction line freezestat equals -3°C (26°F) (3°C [38°F]

reset) or,

4. Thelow-pressure cut-outequals 49 kPa (7 PSIG) (153 kPa

[22 PSIG] reset).

A lock-outl energizes the emergency heat light on the

thermostat and the red LED light on the unit relay board.

Turning the thermostat switch to “Off” then back to “On”, will

reset the system.

NOTICE TO OWNER:

If a lockout occurs, check for the following problems before

calling a serviceman:

1. Dirty filters.

2. Snow accumulation.

3. Leaf or debris blockage.

After eliminating the problem, attempt to restartthe system as

follows:

turn the system switch on the thermostat to its “OFF”

•

position for 10 seconds.

•

turn it back to its original position.

If the unit doesn't start, call a serviceman.

NOTE: Models with an anti-recycle accessory will have a 5-

minute delay before starting.

FIG. 9 - BELTADJUSTMENT

obtain the desired supply airflow. Refer to Table 6 for blower

motor drive data. The tension on the belts should be adjusted

as shown in Figure 9.

Startthe supply airblower motor.Adjust the resistancesin both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply airflow after the initial balancing has been

completed:

CHECKING SUPPLY AIRFLOW

419

The speed of the supply air blower will depend on the required

airflow, the unit accessories and the static resistances of both

1

“

16

2

the supply and the return air duct systems. With this

information, the speed for the supply air blower can be

TABLE 10 - BELT-DRIVE SUPPLY AIR

MOTOR PULLEY ADJUSTMENT

TURNS

OPEN*

5

4

3

2

1

0

*Pulley can be adjusted in half-turn increments.

determined from the blower performance and static resistance

data on Tables 4, 5 and 7.

Knowing the required blower RPM and the blower motor kW

(HP), the speed setting for the supply air motor can be

determined.

The setting (turns open) for the optional belt-drive supply air

pulley can be determined from Table 10.

OPTIONAL BELT-DRIVE BLOWER

Allunits with belt-driveblowers havesingle speed motors. The

variable pitch pulley on the blower motor can be adjusted to

Unitary Products Group 13

BLOWER DRIVE RANGE (RPM)

060

850

916

982

1048

1114

1180

DAMPER

ASSEMBLY

FILTERS

DUCT FLANGES

(Back of Unit)

L.H. END VIEW

(Filter Access End)

FIG. 10 - HOLE LOCATIONS (PRESS. DROPREADING)

1. Drill two 8mm (

Figure 10.

2. Insertat least203mm (8in.) of6mm (

of these holes for sufficient penetration into the air flow on

both sides of the indoor coil.

NOTE: The tubes must be inserted and held in a position per

pendiculartotheairflowso that velocity pressuredoes

not affect the static pressure readings.

5

in.) holes in the side panels as shown in

16

435

1

“

17

8

5

“ HOLES

16

INDOOR

COIL

FRONT OF UNIT

1

in.)tubing intoeach

4

533

21"

-

Page 14

035-12984-001-A-0204

3. Usingan inclinedmanometer,determine the pressuredrop

across a dry indoor coil. Since the moisture on an indoor

coilmayvarygreatly,measuringthe pressure drop acrossa

wet coil under field conditions would be inaccurate. To

ensurea dry coil, the compressorsshould be de-energized

while the test is being run.

4. Knowing the pressure drop across a dry coil, the actual airflow

throughtheunitcanbedeterminedfrom the curve inFigure11.

WARNING:Failureto properlyadjust thetotal system air quan

Afterreadings have been obtained, remove the tubes and seal

the drilled holes in the side panels. 8mm (

029-13880) are available through normal parts ordering

tity can result in poor system performance.

5

in.) dot plugs (P/N

16

-

procedures.

NOTE: DE-ENERGIZE THE COMPRESSORS BEFORE

TAKINGANY TEST MEASUREMENTS TO ENSURE

A DRY INDOOR COIL.

SECURE OWNER'S APPROVAL:When the system is functioning properly,secure the owner's approval. Show him the location

of all disconnect switches and the thermostat. Teachhim how to start and stop the unit and how to adjust temperature settings

within the limitations of the system.

MAINTENANCE

NORMAL MAINTENANCE

CAUTION: Prior to any of the following maintenance proce-

dures, shut off all power to the unit to prevent personal injury.

FILTERS- Inspect once a month. Replace disposable or clean

permanent type as necessary. DO NOT replace permanent

type with disposable.

MOTORS-Indoor fan andoutdoor fan motorsare permanently

lubricated and require no maintenance.

OUTDOORCOIL- Dirtshouldnot be allowedtoaccumulate on

theoutdoorcoilsurface or other partsintheaircircuit. Cleaning

should be as often as necessary to keep coil clean. Use a

brush, vacuum cleaner attachment, or other suitable means. If

water is used to clean coil, be sure power to the unit is shut off

prior to cleaning.

NOTE: Exercise care when cleaning the coil so that the coil

fins are not damaged.

Do not permit the outdoor air discharge to be ob

structed by overhanging structures of shrubs.

-

14 Unitary Products Group

Page 15

035-12984-001-A-0204

Unitary Products Group 15

Page 16

Unitary Products Group

5005 York Drive, Norman, Ok 73069

Subject to change without notice. Printed in U.S.A.

Copyright by York International Corporation 2004. All Rights Reserved.

Supersedes: 511.13-N1YI (900) / 035-12984-000

035-12984-001-A-0204

Loading...

Loading...