York B1HA024A25, B1HA018A25, B1HA024A46, B1HA024A58, B1HA030A06 Installation Instruction

...Page 1

CAUTION

THE ENCLOSED INSTAL L ATI ON INSTRUCT IONS AND ANY APPL ICABLE

LOCAL, STAT E , AND NATIONAL CODES INCL UDING, BUT NOT LIMITED

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE WITH

WARNING

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAM AGE.

I NCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

CHAMPION® SERIES

SINGLE PACKAGE HEAT PUMPS

INSTALLATION INSTRUCTION

GENERAL

Supersedes: 035-16004-000 (0801)

MODELS B1HA018 THRU 060

1.5 THRU 5 TON

(10 SEER)

REFERENCE

035-16004-001-A-0202

YORK Model B1HAunitsarefactoryassembledheatpump s

designed for outdoor installation on a rooftop or a slab. Fieldinstalled electric heater accessories are available to provide

supplemental electric heat combined with electric cooling and

heating.

The units are completely assembled on rigid, removable

base rails. All piping, refrigerant charge, and electrical wiring

is factory installed and tested. The units require only electric

power and duct connections at the point of installation.

The electric heaters have nickel-chrome resistance wire ele

ments and utilize single point power connection.

INSPECTION

As soon as a unit is received, it should be inspected for pos

sible damage during transit. If damage is evident, the extent

of the damage should be noted on the carrier's freight bill. A

separate request for inspection by the carrier's agent should

be made in writing. Refer to Form 50.15-NM for additional in

formation.

Installer should pay particular attention to the words: NOTE, CAUTION and WARNING. Notes are intended to clarify or

make the installation easier.Cautions

sonal injury and/or equipment damage may result if installation procedure is not handled properly.

are given to prevent equipment damage. Warnings are given to alert installer that per

Additional information on the design, installation, operation

andserviceofthis equipmentis availablein thefollowing reference forms:

• 55.70-N1 -General Installation

• 55.70-N2 -Pre-start & Post-start Check List

• 511.26-N1.1V -Electric Heater Accessory

RENEWAL PARTS

•

Referto ReplacementPartsManual forcomplete listingof

-

-

-

replacement parts on this equipment.

All forms referenced in this instruction may be ordered from:

Standard Register

2101 West Techumseh Road

Norman, OK 73069

Toll Free: Tel. 877-318-9675/Fax. 877-379-7920

-

Page 2

035-16004-001-A-0202

PRODUCT NOMENCLATURE

B 1 H A A

PRODUCT CATEGORY

B = Single Package Heat Pumps

(Air Cooled)

20 4 0 6

VOLTAGE CODE

06 = 208/230-1-60

25 = 208/230-3-60

46 = 460-3-60

PRODUCT GENERATION

1 = NEW or Current Design

PRODUCT IDENTIFIER

HA = Heat Pump (10 SEER)

NOMINAL COOLING

CAPACITY(MBH)

018 = 18,000 BTUH 042 = 42,000 BTUH

024 = 24,000 BTUH 048 = 48,000 BTUH

030 = 30,000 BTUH 060 = 60,000 BTUH

036 = 36,000 BTUH

INSTALLED ELECTRIC HEAT

A = No Electric Heat Installed

58 = 575-3-60

FACTORY

INSTALLATION

LIMITATIONS

These units must be installed in accordance with the follow

ing national and local safety codes.

1. National Electrical Code ANSI/NFPS No. 70 or Canadian

Electrical Code Part 1, C22.1 (latest editions).

2. Local plumbing and waste water codes and other applica

ble local codes.

Refer to Table 1 for unit application data and to Table 4 for

electric heat application data.

If components are to be added to a unit to meet local codes,

they are to be installed at the dealer's and/or the customer's expense.

Size of unit for proposed installation should be based on

heat loss/heat gain calculations made in accordance with industry recognized procedures identified by the Air Condition

ing Contractors of America.

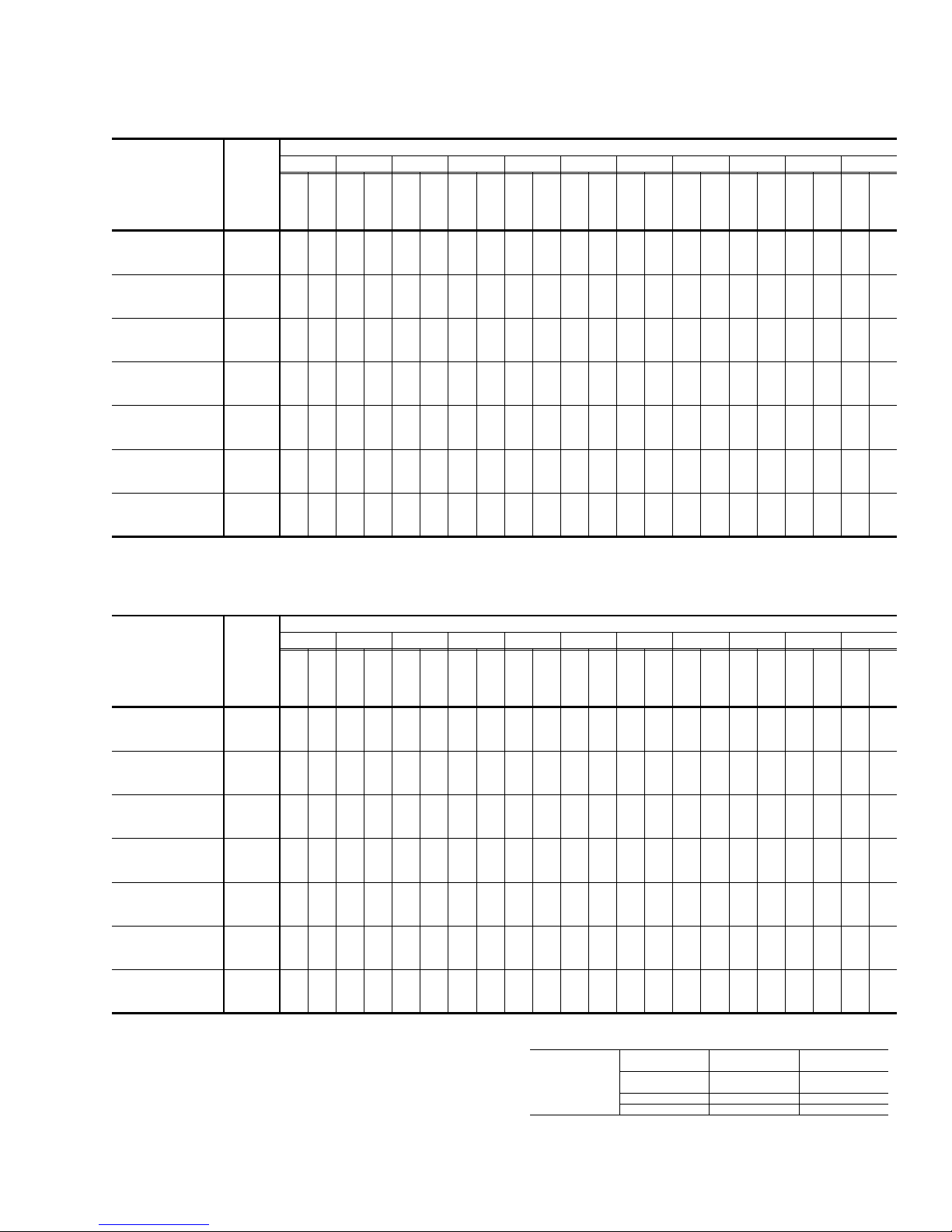

TABLE 1 - UNIT APPLICATION DATA

2

/ Max.

208/230V

Voltage Variation

Min. / Max

Wet Bulb Temperature (°F) of Air on

Evaporator Coil, Min. / Max.

Dry Bulb Temperature (°F) of Air on

Condenser Coil, Min.

1

Rated in accordance with ARI Standard 110, utilization range “A”.

2

A low ambient accessory is available for operation down to 0°F

3

“T1" transformer primary tap must be moved from the 230 volt connection to the 208 volt

connection for low voltage applications of 208 volt and below.

.1

3

460V 414 / 504

575V 518 / 630

187 / 253

57 / 72

45 / 120

-

-

-

3

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Condenser must have an unlimited supply of air. Where a

choiceof locationispossible, positionuniton eithernorthor

east side of building.

3. For ground level installation, a level pad or slab should be

used.The thicknessandsize ofthepad orslabused should

meet local codesand unit weight. Do not tie theslab to the

building foundation.

4. For roof top installation, be sure the structure will support

the weight of the unit plus any field installed components.

2 Unitary Products Group

Unit must be installed on a level roof curb or appropriate

angle iron frame providing adequate support under the

compressor/condenser section.

5. Maintain level tolerance of unit to 1/8" maximum.

RIGGING OR HANDLING

Care must be exercised when moving the unit. Do not re

move any packaging until the unit is near the place of instal

lation. Rig unit with slings placed under the unit. Spreader

bars of sufficient length should be used across the top of the

unit.

BEFORE LIFTING A UNIT, MAKE SURE THAT ITS WEIGHT

IS DISTRIBUTED EQUALLYON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a fork-lift. Slotted

openings in the skid are provided for this purpose. Forks

must pass completely through the base.

Refer to Table 2 for unit weights and to Figure 1 for approxi

mate center of gravity.

TABLE 2 - UNITS WEIGHTS

-

ING

(lbs.)

25

49

OPERAT

WEIGHT

“A”

1

8

SHIPPING

UNIT

WEIGHT

SIZE

018 350 345 103 92 73 82

024 350 345 95 92 80 83

030 360 355 98 94 82 85

036 367 362 100 96 84 87

042 394 389 107 103 90 93

048 445 440 121 117 102 105

060 490 485 133 129 112 116

FRONT

UNIT

(lbs.)

OF

CORNER WEIGHTS

(location, lbs.)

“A” “B” “C” “D”

“D”

“B”

CENTER OF GRAVITY

“C”

22

1

47

4

-

-

FIG. 1 - CENTER OF GRAVITY

-

Page 3

CLEARANCES

All units require certain clearances for proper operation and

service. Refer to Figure 3 for the clearances required for

combustion, construction, servicing and proper unit opera

tion.

035-16004-001-A-0202

CAUTION: When fastening duct work to the side duct flanges on

theunit, insertthescrewsthroughtheductflanges only .

DONOT insertthescrews throughthecasing. Outdoor

duct work must be insulated and waterproofed.

-

NOTE: Be sure to note supply and return openings.

WARNING:Donotpermitoverhanging structures or shrubs to

obstruct the condenser air discharge outlet.

DUCT WORK

These units are adaptable to downflow use as well as rear

supply and return air duct openings. To convert to downflow,

use the following steps:

1. Remove the duct covers found in the bottom return and

supply air duct openings. There are four (4) screws secur

ing each duct cover (save these screws to use later).

2. Installtheduct covers,removedin stepone,to therearsup

ply and return air duct openings. Secure with the four (4)

screws used in step one.

3. Seal duct covers with silicone caulk.

Downflow units must have an “L”-shaped supply duct without

any outlets or registers located below the outlet of the unit.

Duct work should be designed and sized according to the

methods of the Air Conditioning Contractors of America

(ACCA), as set forth in their Manual D.

A closed return duct system shall be used. This shall not preclude use of economizers or ventilation air intake. Flexible

joints may be used in the supply and return duct work to minimize the transmission of noise.

Refer to Figure 3 for information concerning rear and bottom

supply and return air duct openings.

FILTERS

Singlephase unitsareshipped withouta filterandistheresponsi

bilityof theinstaller tosecure afilter inthe returnair ductworkor

install a Filter/Frame Kit (1FF0114).

A filter rack and high velocity filters are standard on three

phase units.

-

Filters must always be used and must be kept clean. When

filters become dirt laden, insufficient air will be delivered by

-

the blower, decreasing your units efficiency and increasing

operating costs and wear-and-tear on the unit and controls.

Filters should be checked monthly especially since this unit is

used for both heating and cooling.

CONDENSATE DRAIN

A condensate trap is required to be installed in the condensate drain. The plumbing must conform to local codes. Use a

sealing compound on male pipe threads. Install the condensate drain line (

3

“ NPTF) to spill into an open drain.

4

-

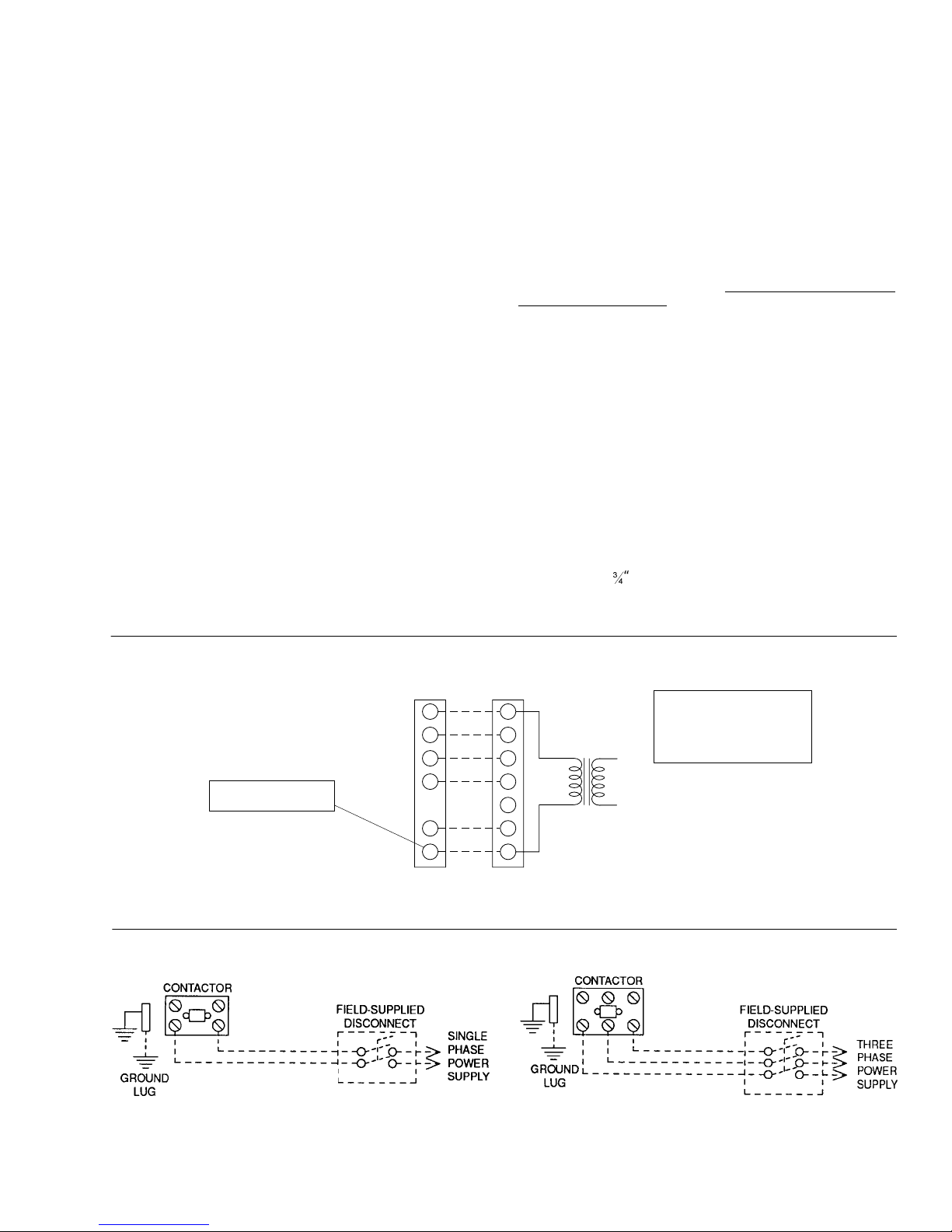

THERMOSTAT

** = Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

PROGRAMMABLE

THERMOSTAT ONLY

* = Only required on units with

supplemental electric heat.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

causeimproperand dangerousoperation.Verifyproperoperationafterservicing.

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON

NECT SWITCH, WIRING &

OVERCURRENT PROTECTION.

-

FIG. 2 - TYPICAL FIELD WIRING DIAGRAM

CONTROL WIRING

UNIT TERMINAL STRIP

R

G

W

O O

C

R

**

G

YY

W2

*

W1

C

POWER WIRING

NOTE:

HEATANTICIPATOR

SHOULD BE SET AT 0.25

AMPS FOR ALL MODELS.

24 VOLTTRANSFORMER

REFER TO ELECTRICAL DATA TA

BLES TO SIZE THE DISCONNECT

SWITCH, WIRING & OVERCUR

RENT PROTECTION.

-

-

Unitary Products Group 3

Page 4

035-16004-001-A-0202

SERVICE ACCESS

Accessto allserviceablecomponents isprovidedby thefollow

ing removable panels:

Blower service access

•

Electrical/Filter access

•

Compressor service access

•

Refer to Figure3 for location of theseaccesspanels and mini

mum clearances.

THERMOSTAT

N.E.C./C.E.C. Voltage tolerances which must be maintained

at the compressor terminals during starting and running con

ditions are indicated on the unit Rating Plate and Table 3.

The wiring entering the cabinet must be provided with me

chanical strain relief.

Afused disconnect switch should be field provided for the unit.

-

If any of the wire supplied with the unit must be replaced, re

placement wire must be of the type shown on the wiring dia

gram.

-

-

-

-

The room thermostat should be located on an inside wall ap

proximately 56" above the floor where it will not be subject to

drafts, sun exposure or heat from electrical fixtures or appli

-

Electrical line must be sized properly to carry the load. Each

unit must be wired with a separate branch circuit fed directly

-

from the meter panel and properly fused.

ances. Follow manufacturer's instructions enclosed with the

thermostat for general installation procedure. Six color coded

insulated wires (minimum #18 AWG) should be used to con

nect thermostat to unit. See Figure 2.

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of the cur

rent N.E.C. ANSI/NFPANo. 70 or C.E.C. and/or local ordi

nances. The unit must be electrically grounded in

-

Refer to Figure 2 for typical field wiring and to the appropriate

-

unit wiring diagram for control circuit and power wiring informa

tion.

COMPRESSORS

-

Units are shipped with compressor mountings factoryadjusted for shipping. Caution: Loosen compressor bolts

half turn before operating unit.

accordance with local codes or, in their absence, with the

.

TABLE 2 - PHYSICAL DATA

BHA

3

1

4

4

3

4

1

4

3

4

1

4

INDOOR

BLOWER

INDOOR

COIL

OUTDOOR

FAN

OUTDOOR

COIL

MODELS

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 9 X 6 10 X 8 10 X 8 10 x 8 11 X 10 11 X 10 11 X 10

FAN MOTOR HP(Three Speed)

ROWS DEEP 2233333

FINS PER INCH 15 13 13 15 15 16 16

FACE AREA(Sq. Ft.) 4.38 4.38 4.38 4.38 4.38 5.62 5.62

PROPELLER DIA. (in.) 22 22 22 22 22 22 22

FAN MOTOR HP

NOM. CFM TOTAL 1,800 1.800 1,800 2,400 2,400 2,800 2,800

ROWS DEEP 1111111

FINS PER INCH 20 20 20 20 20 16 20

FACE AREA(Sq. Ft.) 8.3 11.7 11.7 11.7 11.7 16.4 16.4

018 024 030 036 042 048 060

1

2

1

4

1

2

1

4

1

2

1

4

CHARGE REFRIGERANT22 (lbs./oz.) 4 / 12 5 / 12 7 / 8 5 / 5 5 / 5 9 / 0 10 / 0

FILTER FACE AREA (Sq. Ft. / Qty. / Size) 4.28 / 2 / 14" x 22"

COMPRESSOR HERMETIC Type, (Qty. = 1)

Reciprocating Reciprocating Scroll Scroll Scroll Scroll Scroll

-

1

1

4

TABLE 3 - ADDITIONAL STATIC PRESSURE RESISTANCE

DISCRIPTION

500 600 700 800 900 1,000 1,100 1,200 1,300 1,400 1,500 1,600 1,700 1,800 1,900 2,000

Wet Indoor coil 0.01 0.01 0.01 0.02 0.02 0.03 0.03 0.04 0.04 0.04 0.04 0.04 0.05 0.05 0.06 0.07

Economizer 0.00 0.00 0.00 0.01 0.01 0.01 0.01 0.02 0.03 0.04 0.05 0.06 0.07 0.07 0.08 0.08

Filter/Frame Kit 0.01 0.02 0.02 0.02 0.02 0.02 0.03 0.03 0.03 0.03 0.04 0.05 0.05 0.06 0.06 0.07

Electric Heat 0.02 0.03 0.03 0.03 0.04 0.04 0.05 0.06 0.07 0.08 0.09 0.10 0.01 0.11 0.11 0.12

NOTE: 1. Deduct these resistance values from the available external static pressure shown in the respective Blower Performance Table.

2. The pressure thru the economizer is greater for 100% outdoor air then for 100% return air. If the resistance of the return air duct system is less then 0.25 IWG, the unit will deliver

less CFM during full economizer operation.

4 Unitary Products Group

RESISTANCE, IWG

CFM

Page 5

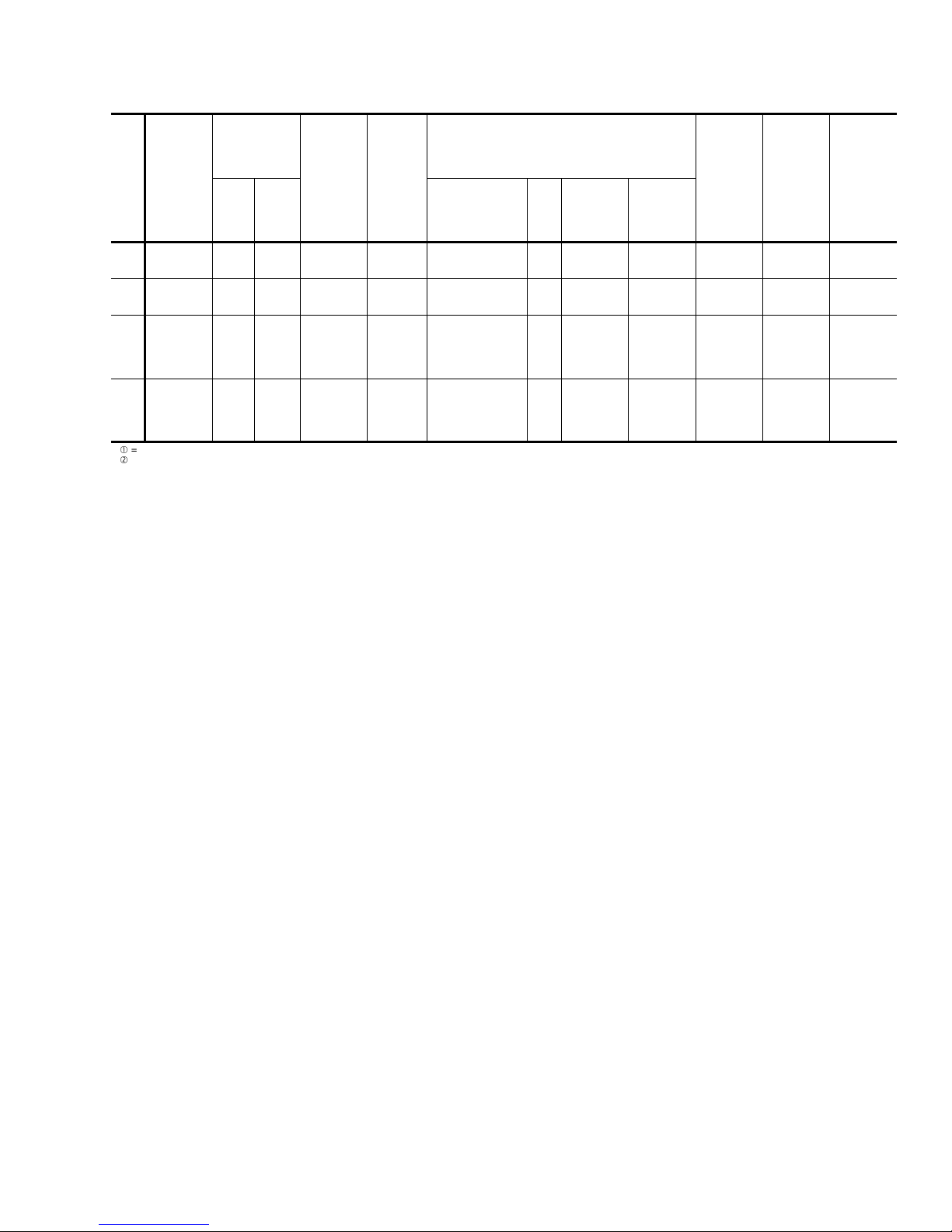

TABLE 4 - SIDE AND BOTTOM SUPPLY AIR BLOWER PERFORMANCE

230/460/575 volts

EXTERNAL STATIC PRESSURE - IWG

MODEL NO.

BHA

MOTOR

SPEED

HI

018

MED

LOW

HI

024

MED

LOW

HI

030

MED

LOW

HI

036

MED

LOW

HI

042

MED

LOW

HI

048

MED

LOW

HI

060

MED

LOW

NOTE: Above data includes allowances for a dry indoor coil and no filters. For additional pressure drops, refer to the “Additional Static Pressure Resistance” table.

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00 1.10

CFM

-

-

-

-

-

900

-

1200

900

-

-

1462

-

-

-

1876

1544

-

2242

-

-

-

-

-

290

390

280

-

526

-

-

-

792

620

-

-

1090

WATTS

1134

1400

1680

1829

1508

2454

2201

-

-

-

-

-

850

-

850

-

-

-

-

-

-

CFM

287

397

267

506

607

772

610

1163

1053

-

-

-

-

-

-

-

-

-

-

-

-

WATTS

1068

1472

1337

1608

1783

1472

2387

2161

-

-

702

-

-

800

-

800

-

-

-

-

-

CFM

220

243

368

243

647

486

584

753

600

1117

1017

-

-

-

-

-

-

-

-

-

-

WATTS

1002

1394

1275

1673

1630

1947

1736

1436

2499

2320

2120

641

760

CFM

-

-

-

-

-

-

-

-

-

-

206

-

-

220

-

367

-

626

467

830

660

882

733

590

1290

1070

980

WATTS

1414

1297

1167

1697

1566

1425

1867

1668

1375

2391

2229

2041

654

536

935

697

936

-

CFM

233

183

338

238

339

617

495

440

740

594

528

857

706

573

1233

1023

927

-

-

-

-

WATTS

1200

1317

1199

1100

1580

1439

1320

1786

1599

1313

2283

2137

1962

668

541

-

867

843

897

-

CFM

401

209

322

183

640

322

688

465

414

706

558

496

832

680

557

1177

977

873

-

-

-

WATTS

1100

1219

1102

1012

1463

1322

1214

1706

1531

1252

2175

2046

1883

652

-

-

-

800

-

800

-

CFM

386

304

620

304

660

435

387

672

522

464

807

653

540

1120

930

820

-

-

-

-

-

WATTS

1116

1339

1182

1050

1637

1434

2067

1950

1797

-

-

-

987

733

-

987

-

-

985

-

-

CFM

507

286

507

533

397

640

476

420

782

622

1080

887

787

-

-

-

-

-

-

-

-

WATTS

1013

1216

1569

1337

1958

1854

1711

CFM

-

-

-

873

867

-

873

-

-

-

-

-

-

1040

035-16004-001-A-0202

493

268

493

507

608

757

591

843

753

-

-

-

-

-

-

-

-

-

-

-

WATTS

1092

1500

1240

1850

1758

1625

CFM

-

-

-

760

-

-

760

-

-

910

-

-

-

-

-

-

-

-

480

-

-

480

-

-

480

-

-

576

-

-

732

560

-

1000

800

720

WATTS

CFM

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

WATTS

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

208 volts

EXTERNAL STATIC PRESSURE - IWG

MODEL NO.

BHA

MOTOR

SPEED

HI

018

MED

LOW

HI

024

MED

LOW

HI

030

MED

LOW

HI

036

MED

LOW

HI

042

MED

LOW

HI

048

MED

LOW

HI

060

MED

LOW

NOTE: Above data includes allowances for a dry indoor coil and no filters. For additional pressure drops, refer to the “Additional Static Pressure Resistance” table.

.10 .20 .30 .40 .50 .60 .70 .80 .90 1.00 1.10

CFM

-

-

741

-

-

810

-

1080

810

1465

1316

-

1679

1694

1385

2339

1929

-

-

226

-

-

261

351

261

631

473

-

867

690

520

-

1170

940

WATTS

1021

1395

1260

1674

1612

1982

1662

1349

2275

1877

-

-

686

-

-

765

-

766

-

-

-

CFM

212

240

341

240

512

455

614

646

870

673

510

1118

903

-

-

-

-

-

-

-

-

WATTS

1440

1325

1204

1728

1590

1449

1939

1629

1312

2450

2211

1824

-

-

632

961

720

961

-

CFM

198

351

219

331

608

492

438

725

590

526

850

657

500

1213

1067

867

-

-

-

-

-

WATTS

1381

1255

1148

1633

1506

1377

1897

1597

1276

2366

2147

1772

690

577

902

675

902

CFM

-

-

-

-

231

185

321

198

321

581

473

420

697

567

504

830

640

490

1165

1015

830

WATTS

1171

1273

1167

1069

1527

1400

1282

1813

1542

1235

2282

2083

1720

689

659

453

841

627

841

-

CFM

374

210

165

305

215

604

306

656

446

396

666

636

476

800

623

480

1117

963

793

-

-

WATTS

1080

1185

1079

1422

1296

1188

1728

1486

2198

2019

1667

593

487

-

-

751

-

781

-

990

-

CFM

361

188

290

486

280

530

419

372

636

602

447

770

607

1068

912

757

-

-

-

-

-

WATTS

1097

1317

1190

1093

1644

1431

2114

1955

1615

497

-

-

990

720

-

980

-

-

952

911

-

CFM

347

468

274

468

604

392

348

606

470

418

740

590

1020

860

720

-

-

-

-

-

-

WATTS

1004

1205

1063

1559

1336

1989

1854

1586

-

-

-

888

660

-

888

-

-

-

-

-

-

CFM

456

257

456

480

676

428

707

563

993

824

706

-

-

-

-

-

-

-

-

-

-

WATTS

1094

1474

1240

1864

1753

1557

CFM

-

-

-

786

-

-

786

-

-

912

-

-

-

-

-

444

444

456

547

673

537

967

788

691

-

-

-

-

-

-

-

-

-

-

-

-

WATTS

1389

1739

1652

1528

-

-

-

684

-

-

-

-

-

-

-

-

-

-

-

-

-

CFM

432

640

940

752

677

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

WATTS

CFM

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

WATTS

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Unitary Products Group 5

ELECTRIC HEAT

CORRECTION

FACTORS

NOMINAL VOLTAGE VOLTAGE

240

480 460 .92

600 575 .92

208

230

KW CAP. MULTI

PLIER

.75

.92

-

Page 6

035-16004-001-A-0202

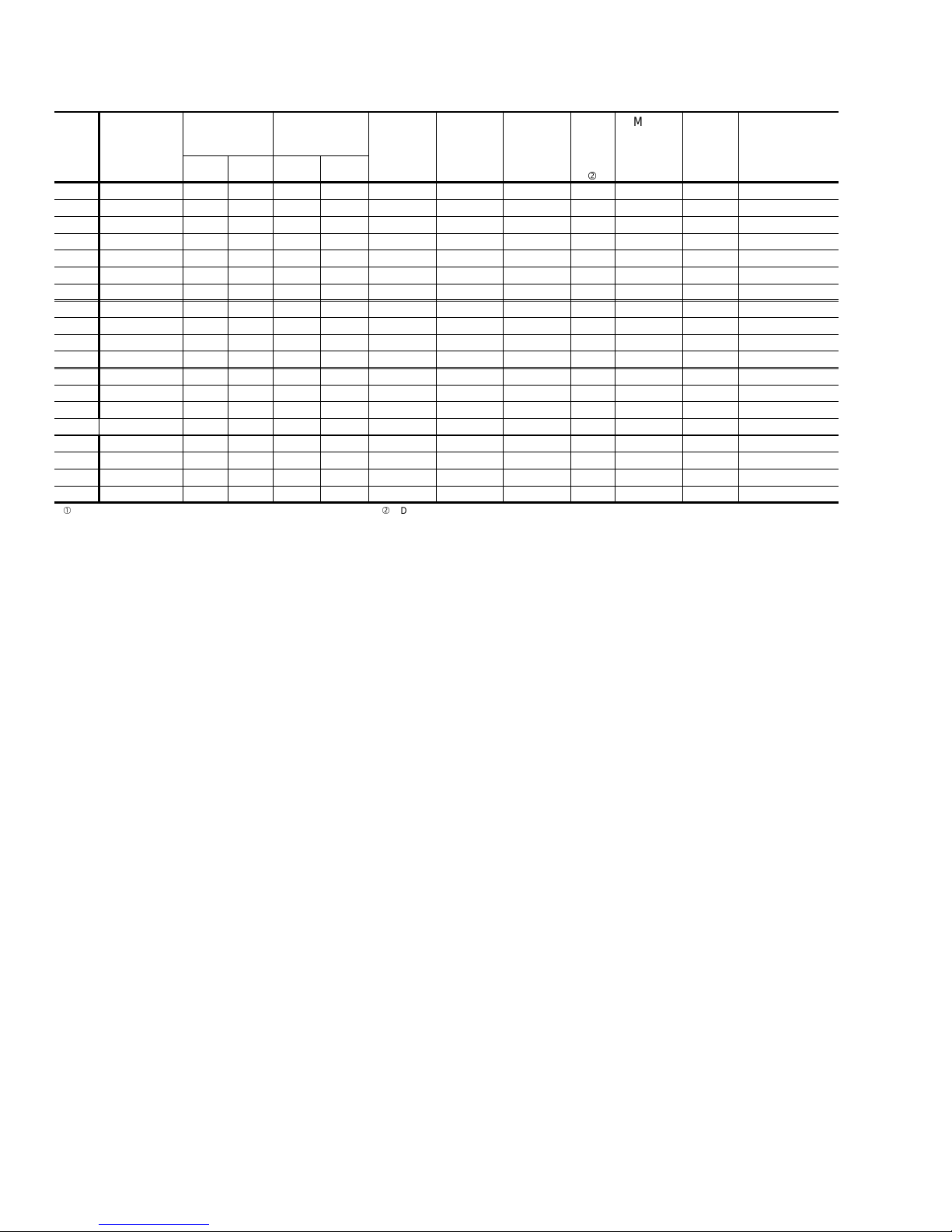

TABLE 5 - ELECTRICAL DATA(HEAT PUMP / ELECTRIC HEAT)

ELECTRIC HEATACCESSORY

STAGE

2NH04500506

2NH0450070612

2NH04500506

2NH04500706

2NH04501006

2NH04500506

2NH04500706

2NH04501006

2NH04501506

2ND04501506 2

2NH04500506

2NH04500706

2NH04501006

2NH04501506

2ND04501506 2

2NH04500506

2NH04500706

2NH04501006

2NH04501506

2ND04501506 2

2NH04501006

2NH04501506

2NH04502006

2NH04502506

2NH04501006

2NH04501506

2NH04502006

2NH04502506

2NH04501025

2NH0450152511

2NH04501025

2NH0450152511

2NH04501025

2NH04501525

2NH04502025

2NH04502525

2NH04501025

2NH04501525

2NH04502025

2NH04502525

2NH04501046

2NH0450154611

2NH04501046

2NH0450154611

2NH04501046

2NH04501546

2NH04502046

2NH04502546

2NH04501046

2NH04501546

2NH04502046

2NH04502546

3.8/5.0 *

5.6/7.5 *

3.8/5.0 *

1

5.6/7.5 *

2

7.5/10.0 *

2

3.8/5.0 *

1

5.6/7.5 *

2

7.5/10.0 *

2

11.3/15.0 *

2

3.8/5.0 18.1/20.8 44.7/48.2 50/50 50/50

3.8/5.0 *

1

5.6/7.5 *

2

7.5/10.0 *

2

11.3/15.0 *

2

3.8/5.0 18.1/20.8 48.8/52.3 60/60 60/60

3.8/5.0 *

1

5.6/7.5 *

2

7.5/10.0 *

2

11.3/15.0 *

2

3.8/5.0 18.1/20.8 52.8/56.3 60/70 60/70

7.5/10.0 *

2

11.3/15.0 *

2

15.0/20.0 *

2

18.8/25.0 *

2

7.5/10.0 *

2

11.3/15.0 *

2

15.0/20.0 *

2

18.8/25.0 *

2

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

1

11.3/15.0 *

1

15.0/20.0 *

2

18.8/25.0 *

2

7.5/10.0 *

1

11.3/15.0 *

1

15.0/20.0 *

2

18.8/25.0 *

2

10.0 **

15.0 **

10.0 **

15.0 **

10.0 **

1

15.0 **

1

20.0 **

2

25.0 **

2

10.0 **

1

15.0 **

1

20.0 **

2

25.0 **

2

KW

TOTAL

AMPS

18.1/20.8

27.1/31.3

18.1/20.8

27.1/31.3

36.1/41.7

18.1/20.8

27.3/31.3

36.1/41.7

54.2/62.5

18.1/20.8

27.1/31.3

36.1/41.7

54.2/62.5

18.1/20.8

27.1/31.3

36.1/41.7

54.2/62.5

36.1/41.7

54.2/62.5

72.2/83.3

90.3/104.2

36.1/41.7

54.2/62.5

72.2/83.3

90.3/104.2

20.8/24.1

31.3/36.1

20.8/24.1

31.3/36.1

20.8/24.1

31.3/36.1

41.7/48.1

52.1/60.1

20.8/24.1

31.3/36.1

41.7/48.1

52.1/60.1

12.8

18.0

12.0

18.0

12.0

18.0

24.1

30.1

12.0

18.0

24.1

30.1

MINIMUM

CIRCUIT

AMPACITY

37.5/41.0

48.8/54.0

40.7/44.2

52.0/57.2

63.3/70.2

44.7/48.2

56.0/61.2

67.3/74.2

89.8/100.3

48.8/52.3

60.1/65.3

71.4/78.3

93.9/104.4

52.8/56.3

64.1/69.3

75.4/82.3

97.9/108.4

81.1/88.1

103.7/114.1

126.3/140.2

148.8/166.2

89.8/96.7

112.3/122.8

134.9/148.8

157.5/174.8

44.3/48.3

57.3/63.3

48.3/57.3

61.3/67.3

49.2/53.2

62.2/68.2

75.3/83.3

88.3/98.3

54.6/58.6

67.6/73.6

80.7/88.7

93.7/103.7

24.6

32.2

26.2

33.8

26.7

34.2

41.7

49.3

29.4

36.9

44.4

51.9

MAX.

FUSE

SIZE,

AMPS

40/45

50/60

45/50

60/60

70/80

50/50

60/70

70/80

90/110

60/60

70/70

80/80

100/110

60/70

70/80

80/90

100/110

90/100

110/125

150/150

150/175

100/110

125/125

150/150

175/175

45/50

60/70

50/60

70/70

50/60

70/70

80/90

90/100

60/60

70/80

90/90

100/110

25

35

30

35

30

35

45

50

30

40

45

60

HACR

BREAKER

100/110

100/110

110/125

150/150

150/175

100/110

125/125

150/150

175/175

100/110

BHA

POWER

SUPPLY

COMPRESSOR

OUTDOOR

FAN

MOTOR

RLA LRA MODEL NO.

FLA

SUPPLY

AIR

BLOWER

MOTOR,

FLA

MODEL

018 208/230-1-60 9.0 48.0 1.1 2.6

024 208/230-1-60 11.2 60.0 1.1 2.6

14.7 73.0 1.1 2.6

030 208/230-1-60

14.7 73.0 1.1 2.6

0.0 0.0 0.0 0.0 7.5/10.0 36.1/41.7 45.1/52.1 50/60 50/60

17.3 94.0 1.1 3.5

036 208/230-1-60

17.3 94.0 1.1 3.5

0.0 0.0 0.0 0.0 7.5/10.0 36.1/41.7 45.1/52.1 50/60 50/60

20.5 120.0 1.1 3.5

042 208/230-1-60

20.5 120.0 1.1 3.5

0.0 0.0 0.0 0.0 7.5/10.0 36.1/41.7 45.1/52.1 50/60 50/60

048 208/230-1-60 24.4 140.0 1.5 4.0

060 208/230-1-60 28.9 165.0 1.5 7.0

036 208/230-3-60 10.9 78.0 1.1 3.5

042 208/230-3-60 14.1 110.0 1.1 3.5

048 208/230-3-60 14.1 105.0 1.5 4.0

060 208/230-3-60 16.0 125.0 1.5 7.0

036 460-3-60 5.8 40.0 0.6 1.8

042 460-3-60 7.1 54.0 0.6 1.8

048 460-3-60 7.1 55.0 0.8 2.0

060 460-3-60 8.0 67.0 0.8 3.5

= Dual element, time delay type. * = KW listed is for 240 volts, use table at top of page for 208 or 230 volts.

= Standard circuit breakers may be used in Canada and on applications ** = KW listed is for 480 volts, use table at top of page for 460 volts.

over 60 amps where the heaters are separately fused. *** = KW listed is for 600 volts, use table at top of page for 575 volts.

MAX.

SIZE

40/45

50/60

45/50

60/60

70/80

50/50

60/70

70/80

90/110

60/60

70/70

80/80

60/70

70/80

80/90

90/100

45/50

60/70

50/60

70/70

50/60

70/70

80/90

90/100

60/60

70/80

90/90

25

35

30

35

30

35

45

50

30

40

45

60

6 Unitary Products Group

Page 7

TABLE 5 - ELECTRICAL DATA(HEAT PUMP / ELECTRIC HEAT) (Continued)

035-16004-001-A-0202

COMPRES

BHA

POWER

SUPPLY

RLA LRA MODEL NO.

MODEL

036 575-3-60 4.5 32.0 0.4 1.5

042 575-3-60 5.8 44.0 0.4 1.5

048 575-3-60 5.6 44.0 0.6 1.6

060 575-3-60 6.4 50.0 0.6 2.8

= Dual element, time delay type. * = KW listed is for 240 volts, use table at top of page for 208 or 230 volts.

= Standard circuit breakers may be used in Canada and on applications ** = KW listed is for 480 volts, use table at top of page for 460 volts.

over 60 amps where the heaters are separately fused. *** = KW listed is for 600 volts, use table at top of page for 575 volts.

SOR

OUT

DOOR

FAN

MOTOR

FLA

-

SUPPLY

AIR

BLOWE

R

MOTOR,

FLA

ELECTRIC HEATACCESSORY

STAGE

2NH04501058

2NH0450155811

2NH04501058

2NH0450155811

2NH04501058

2NH04501558

2NH04502058

2NH04502558

2NH04501058

2NH04501558

2NH04502058

2NH04502558

1

1

2

2

1

1

2

2

KW

10.0 ***

15.0 ***

10.0 ***

15.0 ***

10.0 ***

15.0 ***

20.0 ***

25.0 ***

10.0 ***

15.0 ***

20.0 ***

25.0 ***

TOTAL

AMPS

9.6

14.4

9.6

14.4

9.6

14.4

19.2

24.1

9.6

14.4

19.2

24.1

MINIMUM

CIRCUIT

AMPAC

ITY

19.6

25.6

21.1

27.2

21.3

27.3

33.3

39.3

23.4

29.5

35.5

41.5

-

MAX.

FUSE

SIZE,

AMPS

20

30

25

30

25

30

35

40

25

30

40

45

HACR

BREAKER

MAX.

SIZE

20

30

25

30

25

30

35

40

25

30

40

45

Unitary Products Group 7

Page 8

035-16004-001-A-0202

TABLE 6 - ELECTRICAL DATA(BASIC UNIT)

MAX.

FUSE

SIZE,

AMPS

MAX.

HACR

BREAKER

SIZE,

AMPS

UNIT

POWER

FACTOR

TRANSFORMER

MODEL

BHA

POWER SUP

PLY

VOLTAGE

LIMITATIONSCOMPRESSOR

MIN. MAX. RLA LRA

OUTDOOR

FAN

MOTOR,

FLA

SUPPLY

AIR

BLOWER

MOTOR,

FLA

MINIMUM

CIRCUIT

AMPACITY

018 208/230-1-60 187 253 9.0 48.0 1.1 2.6 14.9 20 20 .96 40

024 208/230-1-60 187 253 11.2 60.0 1.1 2.6 17.7 25 25 .96 40

030 208/230-1-60 187 253 12.0 73.0 1.1 2.6 18.7 25 25 .96 40

036 208/230-1-60 187 253 17.3 94.0 1.1 3.5 26.2 35 35 .96 40

042 208/230-1-60 187 253 20.5 120.0 1.1 3.5 30.2 40 40 .96 40

048 208/230-1-60 187 253 24.4 140.0 1.5 4.0 36.0 50 50 .96 40

060 208/230-1-60 187 253 28.9 165.0 1.5 7.0 44.6 60 60 .96 40

036 208/230-3-60 187 253 10.9 78.0 1.1 3.5 18.2 25 25 .96 75

042 208/230-3-60 187 253 14.1 110.0 1.1 3.5 22.2 30 30 .96 75

048 208/230-3-60 187 253 14.1 105.0 1.5 4.0 23.1 30 30 .96 75

060 208/230-3-60 187 253 16.0 125.0 1.5 7.0 28.5 40 40 .96 75

036 460-3-60 414 504 5.8 40.0 0.6 1.8 9.6 15 15 .96 75

042 460-3-60 414 504 7.1 54.0 0.6 1.8 11.2 15 15 .96 75

048 460-3-60 414 504 7.1 55.0 0.8 2.0 11.7 15 15 .96 75

060 460-3-60 414 504 8.0 67.0 0.8 3.5 14.3 20 20 .96 75

036 575-3-60 518 630 4.5 32.0 0.4 1.5 7.6 15 15 .96 75

042 575-3-60 518 630 5.8 44.0 0.4 1.5 9.1 15 15 .96 75

048 575-3-60 518 630 5.6 44.0 0.6 1.6 9.3 15 15 .96 75

060 575-3-60 518 630 6.4 50.0 0.6 2.8 11.4 15 15 .96 75

= Rated in accordance with ARI Standard 110, utilization range “A”.

= Dual element, time delay type.

SIZE (VA)

8 Unitary Products Group

Page 9

Checking Supply Air CFM

To check the supply air CFM after the initial balancing has

been completed:

1.Remove the two ¼ inch dot plugs in the duct panel.

035-16004-001-A-0202

curate. To ensure a dry coil, the compressors should be de

activated while the test is being run.

4.Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curve in

Coil Delta P vs. Supply Air CFM figure.

-

2.Insert at least 8 inches of ¼ inch tubing into each of these

holes for sufficient penetration into the airflow on both sides

of the indoor coil.

3.Using an inclined manometer, determine the pressure drop

across the dry evaporator coil. Since the moisture on an

evaporator coil may vary greatly, measuring the pressure

drop across a wet coil under field conditions would be inac

0.4

0.35

0.3

0.25

0.2

DeltaStatic(IWG)

0.15

0.1

B1HA024 B1HA030-36B1HA018

-

B1HA Coil Delta

WARNING! Failure to properly adjust the total system air

quantity can result in extensive system damage.

After readings have been obtained, remove the tubes and

reinstall the two ¼ inch plugs removed in Step 1.

NOTE: De-energize the compressors before taking any test

measurements to ensure a dry indoor coil.

B1HA048-60

B1HA042

B1HA018

B1HA024

B1HA042

B1HA030-36

B1HA048-60

Linear (B1HA018)

Linear (B1HA024)

Linear (B1HA030-36)

Linear (B1HA042)

Linear (B1HA048-60)

0.05

0

0 500 1000 1500 2000 2500

Airflow (CFM)

Unitary Products Group 9

Page 10

035-16004-001-A-0202

TABLE 7 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 600 CFM (B1HA018)

OUTDOOR

TEMPERATURE,

°F

65 9.2 14.5 19.7 25.0 30.2 35.5 40.8 40.3 39.7 39.2 38.7

70 9.6 14.2 18.8 23.4 28.0 32.5 37.1 37.3 37.5 37.7 37.9

75 10.1 14.0 17.9 21.8 25.7 29.5 33.4 34.3 35.2 36.1 37.0

80 10.5 13.7 17.0 20.2 23.4 26.6 29.8 31.4 33.0 34.6 36.2

85 11.0 13.5 16.0 18.5 21.1 23.6 26.1 28.4 30.7 33.0 35.4

90 11.4 13.3 15.1 16.9 18.8 20.6 22.4 25.5 28.5 31.5 34.5

95 11.9 13.0 14.2 15.3 16.5 17.6 18.8 22.5 26.2 30.0 33.7

100 9.0 10.3 11.7 13.1 14.4 15.8 17.1 20.1 23.0 26.0 28.9

105 6.0 7.6 9.2 10.8 12.4 14.0 15.5 17.7 19.8 22.0 24.1

110 - - 6.7 8.5 10.3 12.1 13.9 15.3 16.6 18.0 19.3

115 - - - 6.3 8.3 10.3 12.3 12.9 13.4 14.0 14.5

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 8 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 600 CFM (B1HA018)

INDOOR DB

TEMPERATURE,

°F

55 9.7 10.2 10.9 12.1 14.2 17.6 23.3 32.8

70 - - - 3.0 5.1 8.5 14.2 23.7

80 -----4.19.819.3

-100 102030405060

OUTDOOR TEMPERATURE, °F

10 Unitary Products Group

Page 11

TABLE 9 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 800 CFM (B1HA024)

035-16004-001-A-0202

OUTDOOR

TEMPERATURE,

°F

65 17.0 18.2 19.4 20.5 21.7 22.8 24.0 27.0 30.0 33.0 36.0

70 14.3 15.5 16.7 17.8 19.0 20.1 21.3 24.6 27.9 31.1 34.4

75 11.6 12.8 13.9 15.1 16.3 17.4 18.6 22.2 25.7 29.3 32.9

80 8.9 10.1 11.2 12.4 13.6 14.7 15.9 19.7 23.6 27.5 31.4

85 6.2 7.4 8.5 9.7 10.9 12.0 13.2 17.3 21.5 25.7 29.9

90 - - 5.8 7.0 8.2 9.3 10.5 14.5 19.4 23.9 28.3

95 ----5.56.67.812.5 17.3 22.1 26.8

100 -----5.46.310.4 14.6 18.7 22.9

105 -------8.311.815.4 19.0

110 -------6.29.112.1 15.0

115 --------6.48.811.1

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 10 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 800 CFM (B1HA024)

INDOOR DB

TEMPERATURE,

°F

55 12.6 13.0 13.5 14.2 15.4 17.2 19.9 24.2

70 ----3.35.17.912.1

80 ------4.99.1

-100 102030405060

HEATING SUPERHEAT AT COMPRESSOR SUCTION, °F

TABLE 11 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 1,000 CFM (B1HA030)

OUTDOOR

TEMPERATURE,

°F

65 17.0 20.0 22.9 25.9 28.9 31.8 34.8 39.0 43.1 47.3 51.5

70 14.3 16.9 19.5 22.2 24.8 27.5 30.1 34.2 38.2 42.3 46.4

75 11.5 13.9 16.2 18.5 20.8 23.1 25.4 29.4 33.4 37.3 41.3

80 8.8 10.8 12.8 14.8 16.7 18.7 20.7 24.6 28.5 32.3 36.2

85 6.1 7.7 9.4 11.0 12.7 14.4 16.0 19.8 23.6 27.4 31.1

90 - - 6.0 7.3 8.7 10.0 11.3 15.0 18.7 22.4 26.1

95 -----5.66.610.2 13.8 17.4 21.0

100 ------5.27.910.7 13.4 16.2

105 -------5.67.69.511.4

110 ---------5.66.7

115 -----------

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 12 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 1,000 CFM (B1HA030)

INDOOR DB

TEMPERATURE,

°F

55 15.3 15.6 16.0 16.8 17.9 19.6 22.2 26.2

70 ----3.24.97.511.5

80 ------4.58.5

-100 102030405060

OUTDOOR TEMPERATURE, °F

Unitary Products Group 11

Page 12

035-16004-001-A-0202

TABLE 13 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 1,200 CFM (B1HA036)

OUTDOOR

TEMPERATURE,

°F

65 12.8 16.1 19.3 22.5 25.8 29.0 32.2 35.0 37.7 40.4 43.1

70 11.4 14.3 17.2 20.1 22.9 25.8 28.7 31.6 34.4 37.3 40.1

75 9.9 12.5 15.0 17.6 20.1 22.7 25.2 28.2 31.1 34.1 37.1

80 8.5 10.7 12.9 15.1 17.3 19.5 21.7 24.8 27.9 31.0 34.0

85 7.0 8.9 10.8 12.6 14.5 16.3 18.2 21.4 24.6 27.8 31.0

90 5.6 7.1 8.6 10.1 11.7 13.2 14.7 18.0 21.3 24.7 28.0

95 - 5.3 6.5 7.7 8.8 10.0 11.2 14.6 18.1 21.5 25.0

100 - - 5.1 6.0 6.9 7.8 8.7 11.7 14.7 17.7 20.7

105 -----5.66.28.711.313.9 16.4

110 -------5.87.910.0 12.2

115 ---------6.27.9

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 14 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 1,200 CFM (B1HA036)

INDOOR DB

TEMPERATURE,

°F

55 9.7 10.1 10.7 11.8 13.7 17.0 22.6 32.2

70 ----4.67.813.4 23.0

80 ------7.316.9

-100 102030405060

HEATING SUPERHEAT AT COMPRESSOR SUCTION, °F

TABLE 15 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 1,400 CFM (B1HA042)

OUTDOOR

TEMPERATURE,

°F

65 34.0 34.2 34.4 34.6 34.8 35.0 35.2 36.2 37.3 38.4 39.4

70 31.1 31.5 31.9 32.2 32.6 33.0 33.4 34.8 36.3 37.7 39.2

75 28.3 28.8 29.4 29.9 30.5 31.0 31.6 33.4 35.3 37.1 39.0

80 25.4 26.1 26.9 27.6 28.3 29.1 29.8 32.0 34.3 36.5 38.7

85 22.6 23.5 24.4 25.3 26.2 27.1 28.0 30.6 33.2 35.9 38.5

90 19.7 20.8 21.9 23.0 24.0 25.1 26.2 29.2 32.2 35.2 38.3

95 16.9 18.1 19.4 20.6 21.9 23.2 24.4 27.8 31.2 34.6 38.0

100 14.5 15.6 16.6 17.7 18.7 19.7 20.8 24.4 27.9 31.5 35.1

105 12.2 13.1 13.9 14.7 15.5 16.3 17.1 20.9 24.6 28.4 32.1

110 9.9 10.5 11.1 11.7 12.3 12.9 13.5 17.4 21.3 25.3 29.2

115 7.6 8.0 8.4 8.8 9.1 9.5 9.9 14.0 18.1 22.1 26.2

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 16 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 1,400 CFM (B1HA042)

INDOOR DB

TEMPERATURE,

°F

55 5.1 5.5 6.2 7.4 9.6 13.5 20.3 32.4

70 ----5.08.915.7 27.8

80 -----5.412.2 24.3

-100 102030405060

OUTDOOR TEMPERATURE, °F

12 Unitary Products Group

Page 13

TABLE 17 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 1,600 CFM (B1HA048)

035-16004-001-A-0202

OUTDOOR

TEMPERATURE,

°F

65 11.4 12.4 13.5 14.6 15.7 16.8 17.9 19.3 20.7 22.1 23.5

70 10.3 11.2 12.2 13.1 14.0 14.9 15.9 17.4 18.9 20.4 21.9

75 9.3 10.0 10.8 11.6 12.3 13.1 13.9 15.4 17.0 18.6 20.2

80 8.2 8.8 9.4 10.0 10.6 11.2 11.8 13.5 15.2 16.9 18.5

85 7.2 7.7 8.1 8.5 9.0 9.4 9.8 11.6 13.4 15.1 16.9

90 6.5 7.0 7.4 7.9 8.3 8.8 9.2 10.6 12.0 13.4 14.8

95 5.9 6.3 6.8 7.2 7.7 8.1 8.6 9.6 10.6 11.6 12.6

100 - 5.5 6.1 6.6 7.2 7.8 8.4 9.3 10.3 11.3 12.3

105 - - 5.4 6.1 6.8 7.5 8.2 9.1 10.1 11.0 11.9

110 - - - 5.5 6.3 7.2 8.0 8.9 9.8 10.7 11.6

115 ----5.96.97.88.79.510.4 11.2

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 18 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 1,600 CFM (B1HA048)

INDOOR DB

TEMPERATURE,

°F

55 8.3 8.4 8.6 9.0 10.1 12.4 17.4 28.6

70 -----4.29.220.4

80 ------5.716.9

-100 102030405060

HEATING SUPERHEAT AT COMPRESSOR SUCTION, °F

TABLE 19 - COOLING SUPERHEAT AT COMPRESSOR SUCTION, AIRFLOW = 2,000 CFM (B1HA060)

OUTDOOR

TEMPERATURE,

°F

65 26.7 27.6 28.5 29.4 30.3 31.2 32.1 33.0 33.9 34.8 35.7

70 21.9 23.0 24.1 25.2 26.3 27.4 28.5 30.0 31.4 32.8 34.3

75 17.0 18.3 19.7 21.0 22.3 23.7 25.0 27.0 28.9 30.9 32.9

80 12.2 13.7 15.3 16.8 18.4 19.9 21.5 24.0 26.5 29.0 31.4

85 7.3 9.1 10.8 12.6 14.4 16.2 17.9 20.9 24.0 27.0 30.0

90 7.2 8.3 9.4 10.6 11.7 12.8 13.9 17.3 20.6 23.9 27.2

95 7.0 7.5 8.0 8.5 9.0 9.5 9.9 13.6 17.2 20.8 24.4

100 7.2 7.6 8.0 8.3 8.7 9.1 9.5 12.4 15.3 18.2 21.1

105 7.4 7.7 7.9 8.2 8.5 8.7 9.0 11.2 13.4 15.6 17.8

110 7.6 7.8 7.9 8.1 8.2 8.4 8.5 10.0 11.5 13.0 14.4

115 7.8 7.8 7.9 7.9 8.0 8.0 8.1 8.8 9.6 10.3 11.1

55 57 59 61 63 65 67 69 71 73 75

INDOOR WB TEMPERATURE, °F

TABLE 20 - HEATING SUPERHEAT ATCOMPRESSOR SUCTION, AIRFLOW = 2,000 CFM (B1HA060)

INDOOR DB

TEMPERATURE,

°F

55 5.5 5.7 6.2 6.8 8.0 9.9 13.1 18.6

70 -----4.88.013.4

80 ------5.611.0

-100 102030405060

OUTDOOR TEMPERATURE, °F

Unitary Products Group 13

Page 14

035-16004-001-A-0202

HIGH VOLTAGE CONN.

31

1

LOW VOLTAGE CONN.

7

“ DIA. KNOCKOUT

8

SIDE SUPPLY

AIR OPENING

SIDE RETURN

AIR OPENING

LOW VOLTAGE

CONN.

7

“ DIA. KNOCK

8

-

HIGH VOLTAGE CONN.

7

" DIA. KNOCKOUT

8

" DIA. KNOCKOUT

32

(OVERALL)

FRONT

COMPRESSOR

SERVICE ACCESS

COMPARTMENTPANEL

DIMENSION

“A”

1

33

2

1

41

2

3

2

“A”

8

(OVERALL)

UNIT SIZE

018 - 042

048 - 060

REFRIGERANT

CONNECTIONS

ELECTRICAL/FILTER

SERVICE ACCESS

COMPARTMENTPANEL

1

17

1

49

8

28

4

22

FRONT

4

1

4

3

3

4

1

2

2

1

1

1

4

1

1

17

HIGH VOLTAGE

CONN.

1

KNOCKOUT

4

2

2

31

7

“ x

“ DIA.

32

8

1

28

4

1

22

4

UNIT CONDENSATE

CONNECTION

(TRAP REQUIRED)

1

47

4

(OVERALL)

3

“ NPTI

4

All dimensions are in inches. They are

subject to change without notice. Certified

HIGH VOLTAGE CONN.

23

" DIA. KNOCKOUT

1

64

dimensions will be provided upon request.

1

43

1

2

40

2

3

26

4

CLEARANCES

(Minimum)

Front 12"

Back 0"

Left Side (Filter Access) 24"

Right Side 24"

Below Unit 0"

Above Unit

36" (For Condenser

CONDENSATE

3

DRAIN

“ NPTI

4

Air Discharge)

1

22

6

OUTDOOR

BOTTOM SUPPLY

AIR OPENING

1

14

2

2

COIL

3

2

8

3

1

4

15

15

9

28

16

1

3

2

3

1

4

Units may be installed on combustible floors made from wood or class A,

B or C roof covering material.

Units must be installed outdoors. Overhanging structures or shrubs

should not obstruct outdoor air discharge outlet.

1

SIDE SUPPLY

AIR OPENING

3

28

8

1

14

2

15

3

4

BACK

3

3

8

SIDE RETURN

AIR OPENING

1

14

2

1

3

2

4

BOTTOM RETURN

AIR OPENING

FIG. 3 - DIMENSIONS AND CLEARANCES

14 Unitary Products Group

Page 15

SEQUENCE OF OPERATION

Anti-short Cycle Timer

Thisunit hasan anti-shortcycle timerbuilt into thedefrost con

trol.This timer willnot permitthe compressorto startwithin five

minutesafter thecompletion ofthe lastcycle orpower interrup

tion. To bypass the anti-short cycle feature, short the “TEST”

pins together for 2 seconds.

The following sequences of operation are based on using a

standard single-stage heat pump thermostat.

Cooling Operation

WITH POWER TO UNIT AND THERMOSTAT IN COOLING

MODE.

1. If the fan switch on the thermostat is in the “ON” position,

the 24 volts at “G” will energize the “K1" relay on the fan

control board, close the ”K1" relay contacts, and energize

the indoorblower motor.If the fanswitch on the thermostat

isinthe “AUTO”position, theblower willoperate only when

there is a call for cooling by the thermostat.

2. Ona call forcooling, thethermostat willsend 24 voltsto “Y”

and “O” on the fan control board. After the anti-short cycle

period is complete,The 24 volt signal will energize contac

tor “M1", and the reversing valve solenoid. Power will be

supplied tothe compressor andoutdoor fan motor,and the

reversing valve willswitch to the cooling position. Ifthe fan

switch onthe thermostat is onthe ”AUTO" position,the fan

control will energize the indoor blower.

3. When the demand for cooling has been satisfied, the 24

volt“Y” signalis removedand the“M1" contactorwill bedeenergized. Ifthe fan switchon thethermostatis inthe ”ON"

position, the indoor blower will continue to run. If the fan

switchisinthe“AUTO”position, the“K1"relaywill openand

de-energize the indoorblower motor after a 60 second delay,

Heating Operation

WITH POWER TO UNIT AND THERMOSTAT IN HEATING

MODE.

035-16004-001-A-0202

-

-

statisin the“ON”position, theindoorblowerwill continueto

run.Ifthe fanswitchis inthe“AUTO”position, the“K1"relay

willopen andde-energize theindoor blowermotor afterthe

appropriate time delay.

Please refer to Tables 7 and 8 for more information.

Defrost Operation

The minimum time between defrosts can be field selected at

30, 60 or 90 minutes. The default time is 90 minutes if the

jumper is not installed.

Defrostwill initiatewhen thedefrost sensor,locatedon theout

doorcoil, sensesatemperature below31°F andwhen thetime

since the last defrost is greater than the selected time on the

defrost control. The defrost cycle terminates when either the

defrost sensor reaches 55°F or the unit has been in defrost

mode for 10 minutes. If the room thermostatopens during de

frost,the unitwillresume operationindefrost whenthe thermo

stat re-closes.

During the defrost mode, the defrost control will provide a 24

-

volt signal from terminal “W1/66" to the fan control terminal

”W1".This signalwillenergize electricheatstage1,if theunitis

so equipped.

For troubleshooting purposes, thedefrost cycle canbe manu

ally initiated by shorting the “TEST” pins together for 5 sec

onds.Defrostwill terminatenormallyduring the“TEST”mode.

Heat Pump Safety Switch Operation

If the unit is equipped with the field installed upgrade safety

package, the refrigeration system will be protected against

high or low refrigerant pressure and low indoor coil temperature.If anyof thesethreesafety switchesopens, theunit willbe

shutoff forthe 5minute anti-shortcycle time.Oncethishasexpired, asix hour elapsedrun timer begins.If a secondopening

of a safety switch occurs during this six hour period, the compressor will be locked out.

-

-

-

-

-

1. If the fan switch on the thermostat is in the “ON” position,

the 24 volts at “G” will energize the “K1" relay on the fan

control board, close the ”K1" relay contacts, and energize

the indoorblower motor.If the fanswitch on the thermostat

isinthe “AUTO”position, theblower willoperate only when

there is a call for heating by the thermostat.

2. Ona callfor heating,the thermostatwill send24 voltsto “Y”

on thefan control board. Afterthe anti-short cycle periodis

complete, the 24 volts signal will energize contactor coil

“M1"and powerwill besupplied tothe compressorand out

door fanmotor. Thereversing valve willremain in theheat

ing position. If the fan switch on the thermostat is in the

”AUTO" position, the fan control will energize the indoor

blower.

3. For units equipped with supplementary electric heat, if the

heat pump cannot meet the demand, the thermostat “W”

willsend24 voltsto “W2"on thefancontrol board.This sig

nal will also be sent through the defrost control terminals

”W" and “W1/66" andbackto the fan control ”W1". This 24

volt signal will energize all stages of electric heat.

4. When theheating demand issatisfied, the electricheatwill

bede-energized when the 24 volt “W”signal is removed,

and the “M1" contactor will be de-energized when the 24

volt ”Y" signal is removed. If the fan switch on the thermo

Resetting the lockout function is accomplished by;

1. Removing power from the control's thermostat 1st stage

(Y)inputfor atimenot toexceed5seconds (ON-OFF-ON).

2. Removing power from “R” for more than 2 seconds.

3. Shortingthe“TEST” pinstogetherfor morethan2seconds.

Electric Heat Limit Switch Operation

-

-

Thelimit switchresponds toover temperatureconditions inthe

airduct. Opening ofthe deviceresults indropping powerto the

relays. Thecontrollogic will also respond byturning off the re

lays. After four limit cycle trips the unit goes into a 1 hour soft

lockout period. If during this period the control “sees” another

limitcycle, theunit willgo intoa hardlockout condition.Once in

a hard lockout state, the fan is locked on and the heaters are

-

disabled. Only a power cycle will clear the state.

During the soft lockout period, the fan responds to thermostat

input but the heaters are enabled. This is to sense a failed

heater relay. The limit cyclecount is reset at the startof a heat

request. If the limit remains open for period of 80 seconds or

more, the control is immediately put intoahard lockout condi

tion. Only a power cycle will clear this state.

-

SECURE OWNER'S APPROVAL: When the system is functioning properly, secure the owner's approval. Show him

the location of all disconnect switches and the thermostat. Teach him how to start and stop the unit and how to adjust tem

perature settings within the limitations of the system.

-

-

-

Unitary Products Group 15

Page 16

035-16004-001-A-0202

TABLE 21 - THERMOSTATSIGNALS (SINGLE PHASE UNITS)

SIGNAL STATE BOARD FUNCTION

“G”

“G” & “Y” & “O”

“G” & “Y”

“G” & “W”

“G” & “Y” & “W”

“W”

ON FAN INSTANT ON

OFF FAN INSTANT OFF

FAN INSTANT ON

ON

COMPRESSOR AND OUTDOOR FAN INSTANT ON (AFTER ANTI-SHORT CYCLE DELAY)

REVERSING VALVE ENERGIZED

SYSTEM OPERATES IN COOLING

OFF

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

ON

COMPRESSOR AND OUTDOOR FAN INSTANT ON (AFTER ANTI-SHORT CYCLE DELAY)

SYSTEM OPERATES IN HEATING

OFF

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 2 ELEC. HEAT 10 SEC. DELAY ON

HEATER BANK 3 ELEC. HEAT 20 SEC. DELAY ON

HEATER BANK 3 ELEC. HEAT INSTANT OFF

OFF

HEATER BANK 2 ELEC. HEAT

HEATER BANK 1 ELEC. HEAT 1 SEC. DELAY OFF

FAN 10 SEC. DELAY OFF

FAN INSTANT ON

COMPRESSOR AND OUTDOOR FAN INSTANT ON

ON

SYSTEM OPERATES IN HEATING

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 2 ELEC. HEAT 10 SEC. DELAY ON

HEATER BANK 3 ELEC. HEAT 20 SEC. DELAY ON

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

HEATER BANK 3 ELEC. HEAT INSTANT OFF

OFF

HEATER BANK 2 ELEC. HEAT

HEATER BANK 1 ELEC. HEAT 1 SEC. DELAY OFF

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 2 ELEC. HEAT 10 SEC. DELAY ON

HEATER BANK 3 ELEC. HEAT 20 SEC. DELAY ON

HEATER BANK 3 ELEC. HEAT INSTANT OFF

OFF

HEATER BANK 2 ELEC. HEAT

HEATER BANK 1 ELEC. HEAT 1 SEC. DELAY OFF

FAN 10 SEC. DELAY OFF

1

SEC. DELAYOFF

2

1

SEC. DELAYOFF

2

1

SEC. DELAYOFF

2

16 Unitary Products Group

Page 17

TABLE 22 - THERMOSTATSIGNALS (THREE PHASE UNITS)

SIGNAL STATE BOARD FUNCTION

“G”

“G” & “Y” & “O”

“G” & “Y”

“G” & “W”

“G” & “Y” & “W”

“W”

ON FAN INSTANT ON

OFF FAN INSTANT OFF

FAN INSTANT ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

COMPRESSOR AND OUTDOOR FAN INSTANT ON (AFTER ANTI-SHORT CYCLE DELAY)

REVERSING VALVE ENERGIZED

SYSTEM OPERATES IN COOLING

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

COMPRESSOR AND OUTDOOR FAN INSTANT ON (AFTER ANTI-SHORT CYCLE DELAY)

SYSTEM OPERATES IN HEATING

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

HEATER BANK 1, 2 & 3 ELEC. HEAT INSTANT ON

HEATER BANK 4, 5 & 6 ELEC. HEAT 10 SEC. DELAY ON

HEATER BANK 4, 5 & 6 ELEC. HEAT INSTANT OFF

HEATER BANK 1, 2 & 3 ELEC. HEAT

FAN 10 SEC. DELAY OFF

FAN INSTANT ON

COMPRESSOR AND OUTDOOR FAN INSTANT ON

SYSTEM OPERATES IN HEATING

HEATER BANK 1, 2 & 3 ELEC. HEAT INSTANT ON

HEATER BANK 4, 5 & 6 ELEC. HEAT 10 SEC. DELAY ON

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

HEATER BANK 4, 5 & 6 ELEC. HEAT INSTANT OFF

HEATER BANK 1, 2 & 3 ELEC. HEAT

FAN 60 SEC. DELAY OFF

FAN INSTANT ON

HEATER BANK 1, 2 & 3 ELEC. HEAT INSTANT ON

HEATER BANK 4, 5 & 6 ELEC. HEAT 10 SEC. DELAY ON

HEATER BANK 4, 5 & 6 ELEC. HEAT INSTANT OFF

HEATER BANK 1, 2 & 3 ELEC. HEAT

FAN 10 SEC. DELAY OFF

1

SEC. DELAYOFF

2

1

SEC. DELAYOFF

2

1

SEC. DELAYOFF

2

035-16004-001-A-0202

MAINTENANCE

NORMAL MAINTENANCE

WARNING:Prior to any of the following maintenance proce

dures, shut off all power to the unit, to avoid per

sonal injury.

Periodic maintenance consists of changing or cleaning filters

and general cleaning of the outdoor coil.

FILTERS - Inspect once a month. Replace Disposable or

clean Permanent Type as necessary. DO NOT replace Per

manent Type with Disposable.

MOTORS - Indoor and outdoor fan motors are permanently

lubricated and require no maintenance.

Unitary Products Group 17

-

OUTDOOR COIL - Dirt should not be allowed to accumulate

-

on the outdoor coil surface or other parts in the air circuit.

Cleaning should be as often as necessary to keep the coil

clean. Use a brush, vacuum cleaner attachment, or other

suitable means. If water is used to clean the coil, be sure

that the power to the unit is shut off prior to cleaning.

CAUTION: Exercise care when cleaning the coil so that the

-

coil fins are not damaged.

Donotpermitthehotcondenser airdischargeto be

obstructed by overhanging structures or shrubs.

Page 18

035-16004-001-A-0202

POWER SUPPLY

208/230-1-60

USE COPPER

CONDUCTORS ONLY

SECONDARY POWER SUPPLY

FOR DUAL POINT ELEC HEAT

208/230-1-60

USE COPPER

CONDUCTORS ONLY

(HTR5)

(HTR4)

(HTR3)

(HTR2)

(M1)

705/PR

708/PR

716/PR

713/PR

710/PR

F6

F4

F2

(K6)

(K4)

(K5)

(K3)

(M1)

714/BK

706/BK

711/BK

703/BK

709/BK

F1

F3

F5

DUAL POINT ELECTRIC HEAT (SEE NOTE 9)

DETAIL A

FOR DUAL POINT

ELECTRIC HEAT

POWER SUPPLY

SEE DETAIL A

FOR DEFROST

CONTROL

031-09104-000A

SEE DETAIL C

FOR DUAL POINT

ELECTRIC HEAT

POWER SUPPLY

SEE DETAIL A

SEE

DETAIL

"B"

DEFROST

CONTROL

031-01268-000B

SECONDARY POWER SUPPLY

FOR DUAL POINT ELEC HEAT

208/230-1-60

USE COPPER

CONDUCTORS ONLY

POWER SUPPLY

208/230-1-60

USE COPPER

709/BK

703/BK

711/BK

706/BK

714/BK

CONDUCTORS ONLY

(M1)

(K3)

(K5)

(K4)

(K6)

(M1)

(HTR2)

(HTR3)

(HTR4)

(HTR5)

F1

F3

F5

DETAIL A

DUAL POINT ELECTRIC HEAT (SEE NOTE 9)

710/PR

705/PR

713/PR

708/PR

716/PR

OPTIONAL CCH

S / P CONFIGURATION

CCH

BLK

L1

BLK

T1

F4

F6

D / P CONFIGURATION

CCH

BLK

BLK

M1-2

2

T2

L

L1

L2

F2

DETAIL C

M1

BLU

DS

222/Y

DFST

STAT

BLU

M

COMPR

RELAY

R

C

DETAIL B

FIG. 4 - TYPICAL WIRING DIAGRAM (208/230-1-60 POWER SUPPLY)

18 Unitary Products Group

Page 19

035-16004-001-A-0202

DETAIL A

COMPR

RELAY

222/Y

M1

M

FOR DEFROST

CONTROL

031-09104-000A

SEE DETAIL A

DEFROST

CONTROL

031-01268-000B

DS

BLU

DFST

STAT

BLU

R

C

FIG. 5 - TYPICAL WIRING DIAGRAM (230-3-60 POWER SUPPLY)

Unitary Products Group 19

Page 20

035-16004-001-A-0202

BLU

221/B R

DS

RVS

BLU

220/O

ELEM ENTARY DIAGRAM

GND

USE COPPER

LU G

CONDUCTORS

ONLY

POW ER SUPPLY W /

ELEC HEAT 460-3-60

O R 5 75 -3 -6 0

(SEE DET A)

IO F A N

MOTOR

BRN

1

PRP

223/B R

FOR DEFROST

CONTROL

031-09104-000A

SEE D ETAIL B

203/B R

FS

803

/B K

(SEE DET A)

(SEE DET A)

RC3

M3

DS

222/Y

M1

804

/B K

HP

219/B K

SEE N OTE 7

RVS

SEE N OTE 6

BLU

LP

802

/B K

203/B R

120/Y

130/P R

201/B R

BLU

805

/B L

220/O

221/B R

213/R

202/Y

R

C

M

RV

C

L3

A

DFST

STAT

COM PR

RELAY

PRESS

SW ITCH

K3

L1

L2

813/B R

B

814/Y

COND FAN

DEFROST

CONTROL

031-01268-000B

T'STAT

DEF

DEF

POW ER SUPPLY W /OU T

ELEC HEAT 460-3-60

O R 5 75 -3 -6 0

709/R

711/P R

710/O

T1

BLK

703/R

706/P R

707/0

717/R

713/P R

719/0

224/R

X

R

C

218/Y

Y

215/O

O

217/G Y

W

216/W

W1

P3

M2-1

CCH

205/R

207/B R

2

3

4

S3

F24

110

/O

M1-1

L1

M1-2

L2

M1-3

L3

L1

BLK

K3-1

704/B K

74

K3-2

705/B L

8

5

K3-3

708/Y

9

6

K4-1

718/B K

74

K4-2

712/B L

5

8

K4-3

720/Y

96

213/R

M2

208/P R

L2

L1

L1

L2

L21

H1

L1

L1

RYG

T1

114/B K

T2

T3

L1

105/B L

HTR

1

HTR

2

HTR

4

HTR

5

K1

209\R

K2

K2

CONTROL LOGIC

W2

W1

121/B K

123/B L

L2

126/Y

M3-1

T1

RC2

HTR

3

HTR

6

CB

206/B R

FAN CO NTROL

BOARD

P2

T

LH

FL

H4

H3

H2

K1

OC

L3

L1

COM PR

3

S2

1

2

3

4

5

6

TB1

BLK

BRN

PRP

212

/R

809/O

808/B R

810/B L

R

G

H

Y

X

C

T1

24V

O

TH2

W

B

00 F AN

MOTOR

1

109/B K

TH1/TC 1

TC1

TH1

EM HT (RED )

LS

K4

FAN

AUTO

ON

ANT

108

/P R

480 O R 600

214/B R

204/B R

SEE N OTE 8

811/0

M1

ROOM THERMOSTAT

COOL

OFF

HEAT

EM HT

TH2 A NT

DETAIL B

8D

7E

11D , 14D , 15D

21D , 24D

4 D , 5 D , 6 D

M

R

DFST

STAT

C

COM PR

RELAY

FIG. 6 - TYPICAL WIRING DIAGRAM (460-3-60 & 575-3-60 POWER SUPPLY)

20 Unitary Products Group

Page 21

TYPICAL WIRING DIAGRAM LEGEND (See page 16, 17 and 18)

035-16004-001-A-0202

CB

F7 F8 F9

HTR 4 ELECTRIC HEATER (OPT. ACCSSRY: 15, 20, & 25 KW ELEC HEAT)

HTR 5 ELECTRIC HEATER (OPT. ACCSSRY: 20 & 25 KW ELEC HEAT)

HTR 6 ELECTRIC HEATER (OPT. ACCSSRY: 20 & 25 KW ELEC HEAT)

K7 RELAY LIMIT TRIP, 24 VDC COIL

M2 CONTACTOR, ELECTRIC HEAT, 230V COIL

M3 CONTACTOR, ELECTRIC HEAT, 230V COIL

PTCR START ASSIST (OPTIONAL DEVICE)

S4/P4

S3/P3

TB2 TERMINAL BLOCK ECM MOTOR "SPEED" CONNECTIONS

CIRCUIT BREAKER 24V, 3 AMP

, 20, & 25

, 20, & 25

20 & 25

ALL KW ELEC HEAT)

20 & 25 KW ELEC HEAT)

SOCKET/PLUG CONNECTION ON ID FAN MOTOR,24V

SOCKET/PLUG CONNECTION ON ID FAN MOTOR, 230V

, 20, & 25

TYPICAL WIRING DIAGRAM NOTES (See page 16, 17 and 18)

Unitary Products Group 21

Page 22

035-16004-001-A-0202

22 Unitary Products Group

Page 23

035-16004-001-A-0202

Unitary Products Group 23

Page 24

035-16004-001-A-0202

Unitary Products Group

5005 York Drive, Norman, Oklahoma 73069

Subject to change without notice. Printed in U.S.A.

Copyright by York International Corporation 2000. All Rights Reserved.

Supersedes: 035-16004-000-0801

035-16004-001-A-0202

Loading...

Loading...