Page 1

®

SUNLINE 2000

SINGLE PACKAGE HEAT PUMPS

WITH OR WITHOUT SUPPLEMENTAL ELECTRIC HEAT

INSTALLATION INSTRUCTION

208/230/460 V O LT

MODELS ONLY

SAFETY CONSIDERATIONS

Due to system pressure, moving parts and electrical

components, installation and servicing of air conditioning

equipment can be hazardous. Only qualified, trained, service

personnel should install, repair, maintain or service this

equipment.

Observe al l precautions in the li terature, on labels an d tags

accompanying the equipment whenever working on air

conditioning equipment. Be sure to follow all other safety

precautions that apply.

Wear safety glasses and work gloves, and follow all safety

codes. Use a quenching cloth and have a fire extinguisher

avail able for all braz in g op er ations.

GENERAL

YORK Model BCH units are single package heat pumps

designed for outdoo r ins tall at io n on a ro ofto p or a sl ab. These

units can be eq uipped with f actory in stalle d elec tric heat ers f o r

cooling/heating applications .

The units are completely assembled on rigid, permanently

attached base rails. All pipi ng, refrigeran t charge, a nd electrical

wiring is factory installed and tested. The units require electric

power, duct connections and installation of fixed outdoor air

intake damper (units without economizer or motorized damper

option only) at the point of installation.

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

INSPECTION

As soon as a unit is received, it should be inspected for possible

damage during transit. If damage is evident, the extent of the

damage should be note d on the carrier’ s fre ight bil l. A se parate

request for inspection by the carrier’s agent should be made in

writing. Refer to Form 50.15-NM for additional information.

Supersedes: 511.06-N3Y (1294)

MODELS B1CH180 & 240

(8.5 - 8.8 EER)

REFERENCE

Additional information on the design, installation, operation and

service of this equipmen t is av ailab le in the f ollo wing ref eren ce

forms:

55.70-N1 - General Installation

•

55.70-N2 - Pre-start & Post-start Check List

•

44-320-10 - Barometric Relief Damper Accessory

•

Renewal Parts:

Refer to the Renewal Par ts Manual for comple te listing of

•

replacement parts on this equi pm en t.

All forms referenced in this instruction may be ordered from:

Standard Register

Norman, OK 73069

T oll Free: Tel. 877-318-9675/Fax. 877-379-7920

APPROVALS

Design certified by ETL & CGA as follows:

1. For use as a heat pump only unit or a heat pump with or

without supplemental electric heat.

2. For outdoor installatio n on ly.

3. For installation on co mbustible mate rial.

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE

WITH THE ENCLOSED INST ALLA TION INSTR UCTIONS AND ANY

APPLICABLE LOCAL, STATE, AND NATIONAL CODES

INCLUDING, BUT NOT LIMITED TO, BUILDING, ELECTRICAL,

AND MECHANICAL CODES.

INCORRECT INSTALLATION MAY CREATE A CONDITION

WHERE THE OPERATION OF THE PRODUCT COULD CAUSE

PERSONAL INJURY OR PROPERTY DAMAGE

208/230/575 VOLT

MODELS ONLY

CAUTION

WARNING

511.06-N3Y (500)

035-12546-000

Installer should pay particular attention to the words: NOTE, CAUTION and WARNING. Notes are in te nd ed t o cl arify or make

the installa tion ea sier .

and/or equipment damage may result if installation procedure is not handled properly.

Cautions are gi ven t o pre vent equipmen t damage . W arnings are giv en to ale rt installer that personal i njury

Page 2

511.06-N3Y

TABLE OF CONTENTS

General................................................................................ 1

Inspection.............................................................................1

Reference............................................................................. 1

Approvals ............................................................................. 1

Nomenclature.......................................................................2

INSTALLATION

Limitations............................................................................ 3

Location ...............................................................................3

Rigging and Handling .......................................................... 3

Clearances........................................................................... 3

Ductwork .............................................................................. 3

Fixed Outdoor Air Intake Damper........................................ 4

Condensate Drain................................................................4

Compressors........................................................................ 4

Filters ................................................................................... 4

Service Access .................................................................... 4

Thermostat...........................................................................4

Power and Control Wiring.................................................... 4

Optional Electric Heaters......................................... ............ 5

Optional Economizer/Mot. Damper Rain Hood................... 5

Optional Power Exhaust Rain Hood .................................... 7

OPERATION

Cooling System.................................................................. 15

Preliminary Operation Cooling........................................... 15

Cooling Sequence of Op er at io n............... .. .. .. .. ................ ..15

Heating Sequence of Op er at ion ................... .. .. .. .. .............15

Heat Anticipator Setpoints ................................................. 16

Checking Suppl y Air CFM..... .. .. . . .. .. ................ ................ .. .16

Defrost Sequence of Operat ion......................................... 17

Secure Owner’s Approval .................................................. 18

MAINTENANCE

Normal Maintenance ......................................................... 18

TABLES

No. Description Page

1 Unit Applic ation Data .................................. 3

2 Control Wire Sizes ...................................... 5

3 Electric Heat Applica ti on Data.................... 5

4 Physical Data .............................................. 8

5 Four and Six Point Loads............................ 10

6 Supply Air Blower Perf. 15 Ton.................... 12

7 Supply Air Blower Perf. 20 Ton.................... 12

8 Static Resistances ............... ....................... 13

9 Power Exhaust Performance ............. ......... 13

10 Blower Motor and Drive Data...................... 13

11 Electrical Data (Basic Units)....................... 14

12 Electrical Data (Units w/Elec. Heat)............ 14

13 Heat Anticipator Setpoints .......................... 16

FIGURES

No. Description Page

1 Typical Rigging............................................ 3

2 Center of Gra vi ty........... .. .. .. .. .................. .. .. 3

3 Fixed O ut do or Air Dampe r............ .. .. .. ........ 4

4 Recommended Drain Piping....................... 4

5 Typical Field Wiring..................................... 5

6 Adjusting Entha lpy Setpoint.................. .. .... 7

7 Dimensions and Clearances....................... 9

8 Four and Six Point Loads............................ 10

9 Belt Adjus tment ........................................... 16

10 Pressure Drop versus Supply Air CFM...... 16

11 Defrost Initiation Times............................... 17

12 Ambient Modified Time/Temp . Control........ 18

PRODUCT NOMENCLATURE

B 1 C H E C1E

PRODUCT CATEGORY

B = Single Package Heat Pump

(Air Cooled)

PRODUCT GENERATION

1 = 1st Generation

PRODUCT IDENTIFIER

CH = Heat Pump

NOMINAL COOLING

CAPACITY

180 = 15 Tons

240 = 20 Tons

2 Unitary Products Group

FACTORY INSTALLED

0 881 0 2 5

HEAT

A = No Heat

E = Electric

NOMINAL HEATING

CAPACITY

018 = 18 KW

036 = 36 KW

054 = 54 KW

072 = 72 KW

FACTORY INSTALLED

OPTION CODE

EC = Sing. Input Economiz er

DK = Diff. Input Economizer

FD = Sing. Input Economizer

w/Power Exhaust

CF = Diff. Input Economizer

w/Power Exhaust

BG = Motor Outdoor Air

Damper

VOLTAGE CODE

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

Page 3

INSTALLATION

LIMITATIONS

These units must be installed in accordance with the following

national and local safety codes:

In U.S.A.:

1. Nati on al Elec trical Cod e ANSI/ NFPA No. 70.

2. Local electric utility requirements.

In Canada:

1. Current Canadian Electrical Code CSA C22.1.

2. Local electrical code s.

Refer to the Unit Ap plicatio n Data an d to thefor Elec tric Hea t

Application Data table.

If components are to be added to a unit to meet local codes,

they are to be ins talled at the deal er’s and/or the customer’s

expense.

Size of unit for propos ed in st al la tion sh ou ld be ba sed on hea t

loss/heat g ain calcul ation made a ccording to the method s of

the Air Conditioning Contractors of America (ACCA).

TABLE 1

V oltage V ariation,

1

Rated in accordance with ARI Standard 110, utilization range "A".

2

5,000 CFM on 15 ton models with either a 54 or 72 KW heater at 208/230 volts.

LOCATION

Use the following guidelines to sele ct a suitable location for

these units.

1. Unit is designed for outdoor installation only .

2. Outdoor coils must have an unlimited supply of air. Where

3. For ground level installation, use a level concrete slab with

4. Roof structures must be able to support the weight of the

5. Maintain lev el tole rance t o 1/2" m aximum a cross th e entire

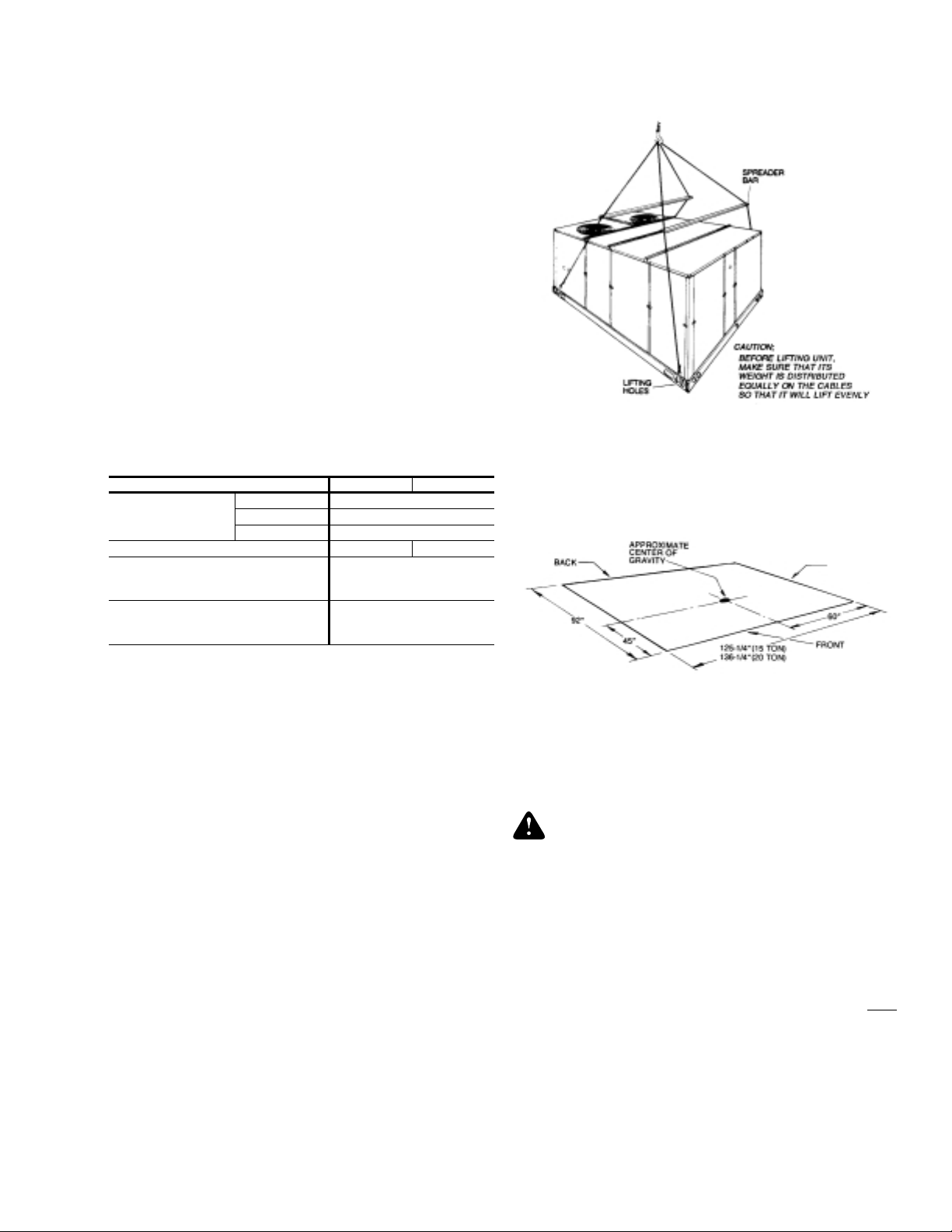

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig the

unit by attaching chain or cable slings to the round lifting holes

provided in t he base rails. Spreaders, wh ose length exceed s

the larger dimension ac ross the unit,

top of the unit. Refer to the Typical Rigging Figure .

- UNIT APPLICATION DATA

Model Size 15 TON 20 T ON

208/230-3-60 187 / 253

Min. / Max.

Supply Air CFM, Min. / Max. 4500

Wet Bulb Temperature (°F)

Dry Bulb Temperature (°F)

1

of Air on Indoor Coil

Min. / Max.

of Air on Outdoor Coil

Min. / Max.

a choice of loca tion is po ssible, positio n the unit on either

north or east side of buildi ng .

a minimum thickness of 4 inches. The length and width

should be at least 6 inches greater than the unit base rail

dimensions. Do not tie slab to the build in g foundation.

unit and its options and/or accessories. Unit must be

installed on a sol id le v el roo f curb or app ropriate angle i ron

frame.

CAUTION: If a unit is to be installed on a roof curb or

special frame other than a YORK roof curb,

gasketing must be applied to a ll surfaces that

come in contact wit h the unit underside.

length or width of the unit.

460-3-60 414 / 506

575-3-60 518 / 630

2

/ 7200 6000 / 9400

57 / 72

45 / 120

be used across t he

MUST

511.06-N3Y

FIG. 1

- TYPICAL RIGGING

Units may also be moved or lifted with a forklift, from the front

or rear only, providing that an accessory skid is used.

LENGTH OF FORKS MUST BE A MINIMUM OF 90".

Refer to the Ph ysical Data t ablef or unit weights a nd to the figure

below for approximate center of gravity.

OUTDOOR

COIL END

FIG. 2

- CENTER OF GRAVITY

CLEARANCES

All units req uire cer tain clearances for prop er operation and

service. Ref er to the Dimensions and Clearances Figure for the

clearances required for combustible construction, servicing,

and proper unit oper at io n.

WARNI NG: Do not permit overhanging structures or shrubs to

obstruct outdoor air di sc ha rge out le t.

DUCTWORK

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors of

America (ACCA).

A closed return duct system shall be used. This shall not

preclude u se of ec onomizers or outd oor fres h air inta ke. The

supply and r eturn air duct connections at t he unit should be

made with flexible joints to minimize transmission of noise.

The supply and return air duct systems should be designed for

the CFM and static requirements of the job. They should

be sized to matc h the dime nsions of the duct connect ions on

the unit.

CAUTION: When fastening ductwork to side duct flanges on

the unit, in sert screws throug h duct flanges only.

DO NOT insert screws through casing.

Outdoor ductwork must be insulated and

waterproofed.

Refer to the Dimensions and Clearances Figure for information

concerning side and bottom supply and return air duct openings.

NOT

Unitary Products Group 3

Page 4

511.06-N3Y

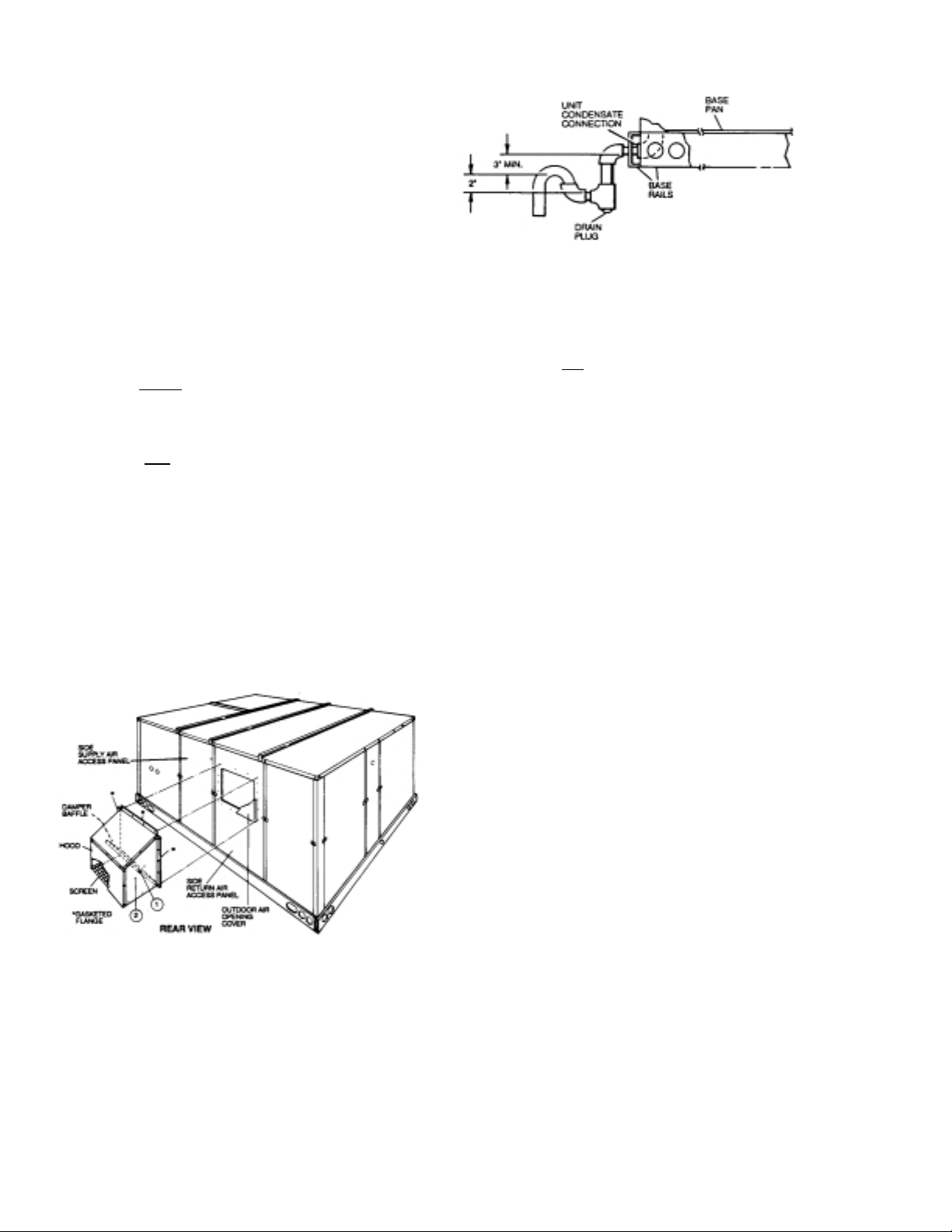

FIXED OUTDOOR AIR INTAKE DAMPER

This damper is shipped inside the return air compartment. It is

completely assembled and ready for installation. A damper

baffle inside the hood is adjustable to provide variable

amounts of outdoor air intake on units that are not provided

with an economizer or a motorized damper option.

Gasketing and mounting screws are provided in a parts bag

attached to the hood assembly. Apply gasketing to the three

flange surfaces on the hood prior to installing the hood. Extend

gasketing 1/4" beyond the top and bottom of the two side

flanges to insure adequate sealing.

FIG. 4 -

RECOMMENDED DRAIN PIPING

Adjusting the damper to the desired air flow may be done before

mounting the hood into position or (after installation) by

removing the front hood panel or the screen on the bottom of

the hood. Damper baffle in po sition 1 will allow appr oximatel y

10% recirculated air f low , pos ition 2 appro ximatel y 15% and, to

allow approximately 25%, remove the damper baffle.

On units with

assembly o v er the o peni ng in the side retu rn air a ccess pane l.

Remove and discard the opening cover and the covering over

the hood moun ti ng h ol es (u se d for ship pi ng) be fore inst al li ng.

Secure with the screws provided.

On units with side return air ap plications, install the damper

assembly on th e return air duc twork as close to the unit as

possible. Cut an opening 16" high by 18" wide in the ductwork

to accommodate the damper. Using the holes in the hood

flanges as a template, drill 9/64" dia. (#26 drill) holes into the

ductwork and secu re with the screws provi de d.

CAUTION: If outdoor air intake will not be required on units

bottom return air appl icat ions , i nstall the d ampe r

with bottom return air applications, the damper

assembly s hould still be moun ted on the side return

air access panel, per the instructions above, to

insure mois ture is not drawn into the unit du ring

operation. The covering over the mounting holes

only need be removed. Do not remove the opening

cover.

COMPRESSORS

Units are ship ped with compres sor mountings facto ry-adjusted

and ready for operation.

CAUTION: Do Not loosen compressor mounting bol ts.

FILTERS

2" filters are supplied wi th each unit. Filters must a lways be

installed ahead of the indoor coil and must be kept clean or

replaced wi th sam e size and typ e. Dirty fi lters will re duce th e

capacity of the unit and will result in frosted coils or safety

shutdown. Minimum filter area and re quired siz es are s hown in

the Physical Data table.

SERVICE ACCESS

Access to all serviceable components is provided by the

follo w in g rem o vable panels:

Compressor compartment

•

Electri c Heat compartment

•

Side Supply & Return Air compartments (Two panels)

•

Blower compartment (Three panels)

•

Main control box

•

Filter compartment

•

Outdoor Air compartment (Two panels)

•

Refer to Dimensions and Clearnaces Fig ure for locati on of

these access panels.

CAUTION: Make sure that all screws and panel latches are

replaced and properly positioned on the unit to

maintain an air-ti gh t se al .

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 56" above the floor where it will not be subject

to drafts, sun exposure or heat from electrical fixtures or

appliances. Follow manufacturer’s instructions enclosed with

thermostat for general installation procedure. Color coded

insulated wires (#18 AWG) should be used to connect

thermostat to unit. Eight conducto rs are requ ire d.

The subbase on the low voltage thermostat includes an

"Emergency H eat" position on the system switch and a pilot

light. In the "Emergency Heat" position, the thermostat will

provide elect ric resist ance he at on ly. Th e com press ors wil l not

run. The pilot light wi ll indi cate th at the switc h is on "E M HT".

FIG. 3

- FIXED OUTDOOR AIR DAMPER

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain line

from the 1" NPT f emale connectio n on the unit to an op en drain.

An alternate drain connection (1" NPT female coupling) is

provided inboard on the same centerline as the exterior

location.

NOTE: The condensate drain operates in a negative pressure

4 Unitary Products Group

in the cabi net. The conden sate drain line MUST be

trapped to provide proper drainage.

Nine conductors are required for this application.

POWER AND CONTR OL WIRING

Field wiring to the unit must conform to provisions of the

National Electrical Code, ANSI / NFPA No. 70 (in U.S.A.),

current Canadian Electric Code (CEC) CSA C22.1 (in Canada)

and/or local ord inances. The unit must be electrically g rounded

in accordance with NEC and C EC (as spec if ied ab ove) and/or

local codes. Voltage tolerances which must be maintained at

the compressor terminals during starting and running

conditions are in di ca ted on the unit Rating Plate.

Page 5

511.06-N3Y

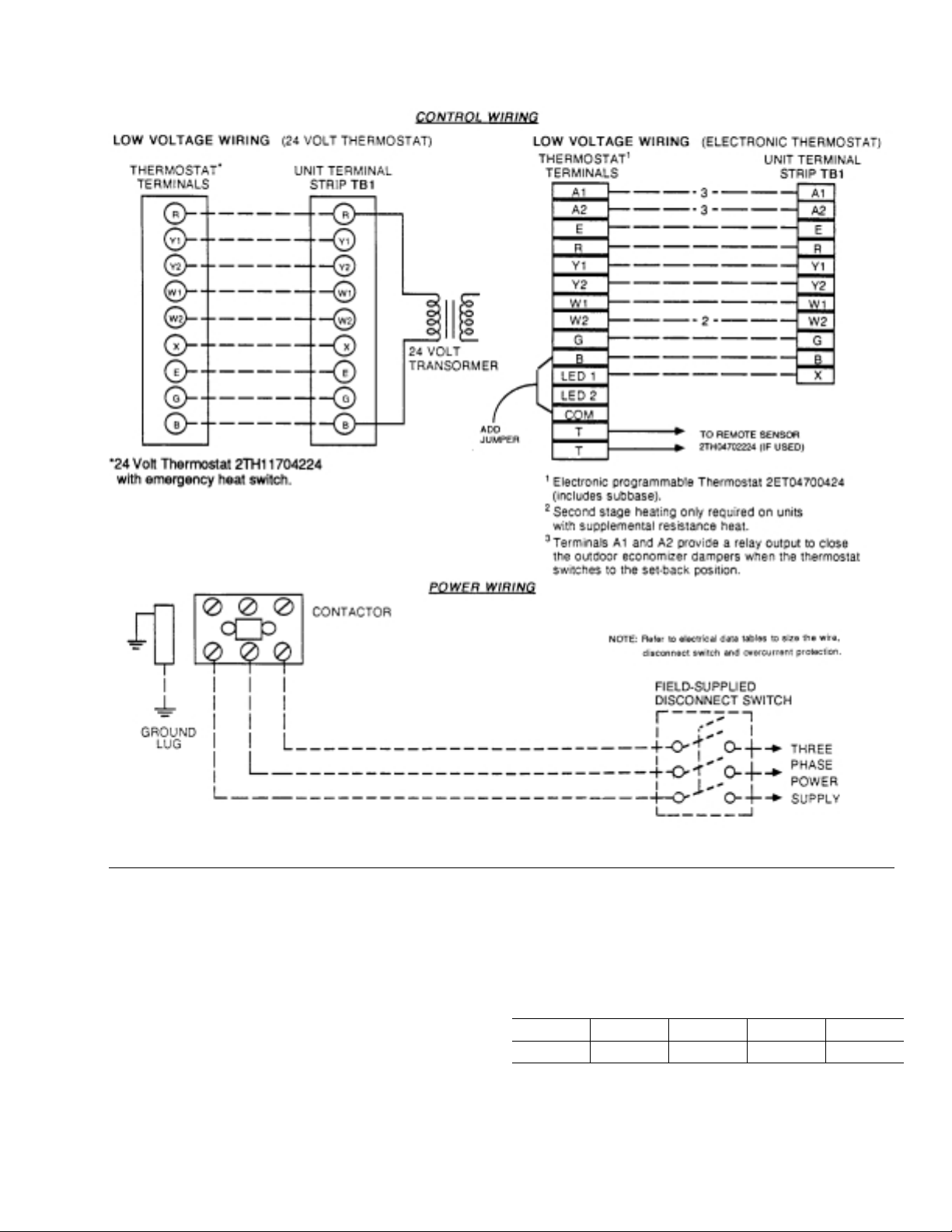

FIG. 5

- TYPICAL FIELD WIRING

The internal wiring harness furnished with this unit is an integral

part of a ETL and CGA design certified unit. Field alteratio n to

comply with electrical codes should not be required.

MUST BE USED so that water or moisture cannot

be drawn into the unit during normal operat ion. The

above waterproofing conditions will also apply

when installing a field-supplied disconnect switch.

A fused disconnect switch should be field provided for the unit.

The switch must be separate from all other circuits. Wire entry

at knockout openings require conduit fittings to comply with

CEC (in Canada), NEC (in U.S.A.) and/or local codes. Refer to

TABLE 2 -

the Dimensions and Clearances Figure for installation location.

If any of the wire supplied with the unit must be replaced,

replacement wire must be of the type shown on the wiring

diagram and the same minimum gauge as the replaced wire.

Electric al line must be sized proper ly to carr y the load . Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

CAUTION: When connecting electrical power and control

wiring to the unit, waterproof type connectors

Unitary Products Group 5

Notes:

1. Solid, Class II copper wire

2. Based on a voltage drop of 1.2 volt s per wir e .

3. Total wire length is from unit to room thermostat, and back to unit

CONTROL WIRE SIZES

Wire Size1 AWG. Gauge

22 20 19 18 16

40 120 150 190 305

Maximum Wire Length

2

Feet

Page 6

511.06-N3Y

Refer to th e Typical Field Wiring Fi gure and to the app ropriate

unit wiring diagram for control circuit and power wiring

information.

all the control sensors are factory mounted as part of the

"Fac to ry install ed " economizer option.

ENTHALPY SET POINT ADJUSTMENT

OPTIONAL ELECTRIC HEATERS

The factory installed heaters are wired for single point power

supply. P ower suppl y need only be brou ght into the s ingle point

terminal block and thermostat w iring to the lo w volta ge terminal

strip located in the upper portion of the unit control box.

These ETL an d CGA a pp roved he ater s ar e loca te d w ithi n th e

central compartment of the unit with the heater elements

extending into the supply air chamber. Refer to the Dimensions

and Clearances Figure for access panel location.

TABLE 3

HEATER SIZE

- ELECTRIC HEAT APPLICATION DATA

NOMINAL

(KW)

18 208/230,460,575 4500 6000

36 208/230,460,575 4500 6000

54

72

VOLT AGE

3 PHASE,

60 HZ

208/230 5000

460, 575 4500

208/230 5000

460, 575 4500

MINIMUM CFM

(UNIT SIZE)

15 TON 20 TON

6000

6000

Fuses are supplied, where required, by the factory. Some KW sizes

require fuses and others do not. Refer to the Electric Heat Application

table for minimum CFM limitations and to the Electrical Data table for

electrical data.

OPTIONAL ECONOMIZER/MOTORIZED DAMPER

RAIN HOOD

The instru ction for the optional econ omizer/motorized damper

rain hood can be found in form 44-320-2. Use these instructions

when field a ssembling an econom izer rain hood onto a un it.

The outdoor and return air damp ers, the damper actuator, the

damper linkage, the outdoor and return air divider baffles, and

Remove the economizer access panel from the unit to check

the following adjustments. Loosen but do not remove the two

panel latches.

CAUTION: Extreme care must be exercised in turning both

the setpoint and minimum position adjusting

screws to prevent twist i ng them off.

1. T he enthalpy set point may now be set by selecting the

desired setpoint shown in the Adj us ti ng En thalpy Setpoi nt

Figure. Adjust as follows:

For a single en thalpy operation, carefully turn the set

•

point adjusting screw to the “A”, “B”, “C” or “D” setting

corresponding t o th e le tt ere d cu rve .

For a dual enthalpy operation, carefully turn the set point

•

adjusting screw fully clockwise past the “D” setting.

2. To check that the damper blades move smoothly without

binding, carefully turn the minimum position adjusting

screw fully cl ockwise and then energize and de -energize

terminals “R” to “G”. With terminals “R” to “G” energized,

turn the minimum position screw counterclockwise until the

desired minimum position has been attained.

3. Replace the economizer access panel. Reposition the two

latches horizontally and retighten the screws.

POWER EXHAUST/BAROMETRIC RELIEF DAMPER

AND RAIN HOOD OPTION

The instructions for the power exhaust/barometric relief

damper and ra in hood can be found in form 44-320-10. The

exhaust fan, all supporting brackets, angles, and the wiring are

factory installed as part of the power exhaust option.

All of the components, including the dampers, hardware, and

mounting inst ructions are shipp ed in a single p ackag e e xternal

from the unit. The hood must be fie ld assem bled and inst alled.

Power exhaust is not available as a field installed option.

6 Unitary Products Group

Page 7

511.06-N3Y

FIG. 6

- ENTHALPY SETPOINT ADJUSTMENT

Unitary Products Group 7

Page 8

511.06-N3Y

TABLE 4

SUPPLY AIR

OUTDOOR

(Two Per Unit)

OUTDOOR

COMPRESSOR

(Qty. Per Unit)

- PHYSICAL DATA

BLOWER

INDOOR

COIL

FANS

COILS

AIR

FIL TERS

CHARGE

MODELS

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 15 x 15 18 x 15

FAN MOTOR HP 5 7.5

ROWS DEEP 4 4

FINS PER INCH 13 13

FACE AREA (Sq. Ft.) 15.5 20.5

PROPELLER DIA. (in.) (Each) 30 30

FAN MOTOR HP (Each) 1 1

NOM. CFM TOTAL (Each) 6500 7200

ROWS DEEP 3 3

FINS PER INCH 15 15

FACE AREA (Sq. Ft.) 36.0 43.3

7-1/2 TON TANDEM 2 10 TON TANDEM - 2

QUANTITY PER UNIT (16" X 20" X 2") - 4

QUANTITY PER UNIT (16" X 25" X 2") - 4

QUANTITY PER UNIT (18" X 24" X 2") 5 TOTAL FACE AREA (sq. ft.) 15.0 20.0

REFRIGERANT 22

(lbs./oz.)

SYSTEM NO. 1 20/8 24/0

SYSTEM NO. 2 22/8 25/0

UNIT SIZE

15 TON 20 TON

OPERATING WEIGHTS (LBS.) 15 TON 20 TON

Basic Unit Heat Pump 2000 2200

Economizer 160

Options

Accessories

Economizer with

Power E xhaust

Motorized Damper 150

18 KW 25

Electric Heat

(Nominal KW)

Roof Curb 175 185

Barometric Damper 45 45

Wood Skid 200 220

36 KW 30

54 KW 35

72 KW 40

245

8 Unitary Products Group

Page 9

RETURN AIR

SUPPLY AIR

OUTDOOR AIR

OUTDOOR AIR

(Economizer)

All dimensions are in inches. They are subject to change without notice. Certified dimensions will be provided upon request.

UTILITIES ENTRY DATA

HOLE

A

B

OPENING

SIZE

USED FOR

(DIA.)

1-1/8" KO

3/4" NPS (Fem.) Bottom

3-5/8" KO

3" NPS (Fem.) Bottom

Control

Wiring

Power

Wiring

511.06-N3Y

Front

Front

DUCT COVERS - Units are shipped with the bottom

duct openings covered. An accessory flange kit is available for connecting side ducts.

For

bottom duct applications:

1. Remov e the side panels from the supply and return

air compartments to gain access to the bottom

supply and return air duct covers.

2. Remove and discard the bottom duct covers. (Duct

openings are closed with sheet metal covers except

when the unit includes a power exhaust option. The

covering consists of a heavy black paper composition.)

3. Replace the side supply and return air compartment

panels.

For

side duct applications;

1. Replace the side panels on the supply and return air

compartments with the accessory flange kit panels.

2. Connect ductwork to the duct flanges on the rear of

the unit.

OUTDOOR SECTION

(ACCESSORY SIDE SUPPLY AND RETURN AIR OPENINGS)

DETAIL "X"

FIG. 7

- DIMENSIONS & CLEARANCES - 15 & 20 TON

INDOOR SECTION

CLEARANCES

Front 36"

Back

Left Side (Filter Access)

Right Side (Cond. Coil) 36"

Below Unit

Above Unit

NOTE: Unit and ductwork are approved for zero clearance to combustible

materials when equipped with electric heat.

1

Units (applicable in U.S . A. only) may be installed on combustib le floors made

from wood or class A, B or C roof covering material.

2

Units must be installed oudo ors. Overhanging structures or shrubs should

not obstruct outdoor air disc h arge outlet.

3

If economizer is factory installed, the assembled hood kit must be removed

prior to final installation. This hood is 54" long.

4

Remove hood kit prior to final installation.

1

2

24" (Less Economizer)

49" (With Economizer)

24" (Less Economizer)

3

36"

(With Economizer)

20"

72" With 36" Maximum

Horizontal Overhang

(For Outdoor Air

Discharge Outlet)

4

Unitary Products Group 9

Page 10

511.06-N3Y

B

A

D

FIG. 8

- FOUR AND SIX POINT LOADS

TABLE 5

- FOUR AND SIX POINT LOADS

UNIT

FRONT

4 POINT LOADS

TOT AL A B C D

C

180 2,190 513 535 583 559

240 2,390 514 538 684 654

NOTE: These weights are with ec on om izer and 36kW electric heat.

UNIT

TOT AL A B C D E F

180 2,190 342 358 373 388 372 357

240 2,390 343 359 407 456 436 389

6 - POINT LOADS (LBS)

A

4 - POINT LOADS (LBS)

E

F

D

C

FRONT

B

6 POINT LOADS

NOTE: These weights are with ec on om izer and 36kW electric heat.

10 Unitary Products Group

Page 11

TABLE 6

511.06-N3Y

- SUPPLY AIR BLOWER PERFORMANCE (1 5 TON)

180 MBH

BLOWER

SPEED,

(RPM)

- BOTTOM DUCT CONNECTIONS

MOTOR

PULLEY

(TURNS

OPEN)*

4500 5250 6000 6750 7200

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

CFM

208 VOLT AND STANDARD DRIVE

850 6.0** 0.9 2.4 2.2 0.7 3.0 2.7 0.5 3.2 2.9 - - - - - 870 5.5 1.0 2.5 2.3 0.8 3.1 2.8 0.6 3.5 3.1 0.2 4.1 3.7 - - 915 4.5 1.1 2.6 2.4 0.9 3.4 3.0 0.7 3.7 3.3 0.3 4.4 3.9 0.2 4.5 4.0

965 3.5 1.2 2.9 2.6 1.0 3.6 3.2 0.8 4.0 3.6 0.5 4.7 4.2 0.4 4.9 4.4

980 3.0 1.3 3.0 2.7 1.1 3.7 3.3 0.9 4.1 3.7 0.6 4.8 4.3 0.5 5.1 4.6

1010 2.0 1.4 3.1 2.8 1.2 3.8 3.4 1.0 4.2 3.8 0.7 5.0 4.5 0.6 5.4 4.8

1040 1.0 1.5 3.2 2.9 1.3 3.9 3.5 1.1 4.5 4.0 0.9 5.2 4.7 0.7 5.7 5.1

208 VOLT AND HIGH SPEED DRIVE ACCESSOR Y

965 6.0 1.2 2.9 2.6 1.0 3.6 3.2 0.8 4.0 3.6 0.5 4.7 4.2 0.4 5.0 4.4

980 5.5 1.3 3.0 2.7 1.1 3.7 3.3 0.9 4.1 3.7 0.6 4.8 4.3 0.5 5.1 4.6

1025 4.5 1.5 3.2 2.9 1.3 3.9 3.5 1.1 4.5 4.0 0.8 5.1 4.6 0.7 5.6 5.0

1065 3.5 1.6 3.4 3.0 1.4 4.0 3.6 1.2 4.7 4.2 1.0 5.5 4.9 - - 1095 3.0 1.7 3.5 3.1 1.5 4.2 3.8 1.3 4.9 4.4 1.2 5.7 5.1 - - 1130 2.0 1.9 3.7 3.3 1.7 4.5 4.0 1.5 5.1 4.6 - - - - - 1170 1.0 2.1 3.9 3.5 2.0 4.7 4.2 1.8 5.5 4.9 - - - - - -

230/460/575 V OLT AND ST ANDARD DRIVE

870 6.0** 1.0 2.4 2.2 0.8 3.1 2.8 0.6 3.5 3.1 0.2 4.1 3.7 - - -

915 5.0 1.1 2.6 2.4 0.9 3.3 3.0 0.7 3.7 3.3 0.3 4.4 3.9 0.2 4.5 4.0

965 4.0 1.2 2.9 2.6 1.0 3.6 3.2 0.8 4.0 3.6 0.5 4.7 4.2 0.4 5.0 4.4

980 3.5 1.3 3.0 2.7 1.1 3.7 3.3 0.9 4.1 3.7 0.6 4.8 4.3 0.5 5.1 4.6

1040 2.0 1.5 3.2 2.9 1.3 3.9 3.5 1.1 4.5 4.0 0.9 5.3 4.7 0.7 5.7 5.1

1065 1.0 1.6 3.3 3.0 1.4 4.0 3.6 1.2 4.7 4.2 1.0 5.5 4.9 - - -

230/460/575 V OLT AND HIGH SPEED DRIVE ACCESSOR Y

980 6.0 1.3 2.9 2.6 1.1 3.7 3.3 0.9 4.1 3.7 0.6 4.8 4.3 0.5 5.1 4.6

1040 4.5 1.5 3.2 2.9 1.3 3.9 3.5 1.1 4.5 4.0 0.9 5.3 4.7 0.7 5.7 5.1

1065 4.0 1.6 3.4 3.0 1.4 4.0 3.6 1.2 4.7 4.2 1.0 5.5 4.9 - - 1095 3.5 1.7 3.5 3.1 1.5 4.2 3.8 1.3 4.9 4.4 1.2 5.7 5.1 - - 1130 2.5 1.9 3.7 3.3 1.7 4.5 4.0 1.5 5.1 4.6 - - - - - 1170 1.5 2.1 3.9 3.5 2.0 4.7 4.2 1.8 5.5 4.9 - - - - - 1190 1.0 2.2 4.0 3.6 2.1 4.8 4.3 2.0 5.7 5.1 - - - - - -

NOTES: 1. Blower performance includes fixed outdoor air, 2" T/A filters, a dry indoor coil and no electric heat.

2. Refer to Page 12 for additional static resistances.

ESP = External Static Pressure available for the supply and return air duct system. All internal unit resistances have been deducted

from the total static pressure of the blower.

* Do

NOT close the pulley below 1 turn open.

** Factory setting.

Unitary Products Group 11

Page 12

511.06-N3Y

TABLE 7

- SUPPLY AIR BLOWER PERFORMANCE (20 TON)

240 MBH

BLOWER

SPEED,

(RPM)

- BOTTOM DUCT CONNECTIONS

MOTOR

PULLEY

(TURNS

OPEN)*

6000 7000 8000 9000 9400

ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW ESP BHP KW

CFM

208 VOLT AND STANDARD DRIVE

870 6.0**0.42.11.80.12.32.0--------900 5.00.83.22.70.53.52.90.23.83.2-----930 4.0 1.1 4.1 3.4 0.9 4.5 3.8 0.6 4.9 4.1 0.1 5.1 4.3 - - 950 3.0 1.3 4.6 3.9 1.1 5.1 4.3 0.8 5.5 4.6 0.4 5.9 5.0 - - 980 2.0 1.6 5.3 4.5 1.4 5.8 4.9 1.2 6.3 5.3 0.7 6.9 5.8 0.2 7.3 6.1

1015 1.0 1.9 5.9 5.0 1.7 6.5 5.5 1.5 7.0 5.9 1.0 7.7 6.5 0.6 8.2 6.9

208 VOLT AND HIGH SPEED DRIVE ACCESSOR Y

950 6.0 1.3 4.6 3.9 1.1 5.1 4.3 0.8 5.5 4.6 0.4 5.9 5.0 - - -

980 5.0 1.6 5.3 4.5 1.4 5.8 4.9 1.2 6.3 5.3 0.7 6.9 5.8 0.2 7.3 6.1

1010 4.0 1.8 5.8 4.9 1.7 6.3 5.3 1.5 6.9 5.8 1.0 7.5 6.3 0.5 7.9 6.7

1020 3.5 1.9 6.1 5.1 1.8 6.5 5.5 1.6 7.1 6.0 1.1 7.8 6.6 0.6 8.3 7.0

1035 3.0 2.0 6.2 5.2 1.9 6.8 5.7 1.7 7.4 6.2 1.2 8.1 6.8 0.7 8.6 7.3

1050 2.5 2.1 6.4 5.4 2.0 7.0 5.9 1.8 7.6 6.4 1.3 8.3 7.0 - - 1075 2.0 2.3 6.6 5.5 2.1 7.2 6.0 1.9 7.8 6.6 1.5 8.6 7.2 - - 1100 1.0 2.4 6.7 5.6 2.2 7.3 6.1 2.1 7.9 6.7 ------

230/460/575 V OLT AND STANDARD DRIVE

870 6.0**0.42.11.80.12.32.0---------

900 5.00.83.22.70.53.52.90.23.83.2------

930 4.0 1.1 4.1 3.4 0.9 4.5 3.8 0.6 4.9 4.1 0.1 5.1 4.3 - - -

950 3.5 1.3 4.6 3.9 1.1 5.1 4.3 0.8 5.5 4.6 0.4 5.9 5.0 - - -

980 2.5 1.6 5.3 4.5 1.4 5.8 4.9 1.2 6.3 5.3 0.7 6.9 5.8 0.2 7.3 6.1

1015 1.5 1.9 5.9 5.0 1.7 6.5 5.5 1.5 7.0 5.9 1.0 7.7 6.5 0.6 8.2 6.9

1025 1.0 2.0 6.1 5.1 1.8 6.6 5.6 1.6 7.3 6.1 1.1 7.9 6.7 0.7 8.6 7.3

230/460/575 VOLT AND HIGH SPEED DRIVE ACCESSOR Y

950 6.0 1.3 4.6 3.9 1.1 5.1 4.3 0.8 5.5 4.6 0.4 5.9 5.0 - - -

980 5.0 1.6 5.3 4.5 1.4 5.8 4.9 1.2 6.3 5.3 0.7 6.9 5.8 0.2 7.3 6.1

1015 4.0 1.9 5.9 5.0 1.7 6.5 5.5 1.5 7.0 5.9 1.0 7.7 6.5 0.6 8.2 6.9

1035 3.5 2.0 6.2 5.2 1.9 6.8 5.7 1.7 7.4 6.2 1.2 8.1 6.8 0.7 8.6 7.3

1050 3.0 2.1 6.4 5.4 2.0 7.0 5.9 1.8 7.6 6.4 1.3 8.3 7.0 - - 1080 2.0 2.3 6.6 5.5 2.1 7.2 6.0 1.9 7.8 6.6 1.5 8.6 7.2 - - 1100 1.5 2.4 6.7 5.6 2.2 7.3 6.1 2.1 7.9 6.7 -----1120 1.0 2.5 6.8 5.7 2.3 7.4 6.2 2.2 8.1 6.8 ------

NOTES: 1. Blower performance includes fixed outdoor air, 2" T/A filters, a dry indoor coil and no electric heat.

2. Refer to Page 12 for additional static resistances.

ESP = External Static Pressure available for the supply and return air duct system. All internal unit resistances have been deducted

from the total static pressure of the blower.

* Do

NOT close the pulley below 1 turn open.

** Factory setting.

12 Unitary Products Group

Page 13

511.06-N3Y

TABLE 8

TABLE 9

- STATIC RESISTANCES

1

EXTERNAL STATIC PRESSURE DROP

RESISTANCE, IWG

DESCRIPTION

15 TON 20 TON

CFM

4500 6000 7200 6000 8000 9400

WET INDOOR COIL 0.1 0.1 0.1 0.1 0.1 0.1

18 KW 0.1 0.1 0.1 0.1 0.1 0.1

ELECTRIC HEAT OPTIONS

36 KW 0.1 0.2 0.3 0.1 0.2 0.3

54 KW 0.2 0.3 0.4 0.2 0.3 0.4

72 KW 0.2 0.4 0.6 0.2 0.4 0.6

ECONOMIZER OPTION 0.1 0.1 0.1 0.1 0.1 0.1

HORIZONTAL DUCT CONNECTIONS

1

Deduct these resistance values from the available external stati c pressures shown in the respective Blower Performance Table. (See Note 2 f o r exception.)

2

Since the resistance to air flow will be less for horizontal duct connections than for bottom duct connections, add these pressures to the ESP values on the

respective unit’s blower performance table.

2

0.2 0.3 0.5 0.2 0.3 0.5

- POWER EXHAUST PERFORMANCE

MOTOR

SPEED

0.2 0.3 0.4 0.5 0.6

CFM KW CFM KW CFM KW CFM KW CFM KW

HIGH* 5250 0.83 4500 0.85 4200 0.88 3750 0.93 3000 0.99

STATIC RESISTANCE OF RETURN DUCTWORK, IWG

MEDIUM 4900 0.77 3900 0.79 3500 0.82 2900 0.85 - -

LOW 4400 0.72 3700 0.74 3000 0.78 - - - -

Factory Setting

*

Power Exhaust motor is a 3/4 HP, PSC type with sleeve bearings, a 48 frame and inherent protection.

TABLE 10

MODEL

SIZE

15 TON

- BLOWER MOTOR AND DRIVE DATA

1

BLOWER

DRIVE

RANGE

(RPM)

Stan-

850/1065

dard

High

Speed

965/1190 BK80 7.75 7.4 1 BX68 69.8 1

MOTOR

HP FRAME

5 184T 83 1VP56 5.35

ADJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY

EFF.

(%)

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

OUTSIDE

DIA.

(IN.)

BK90 8.75 8.4 1 BX70 71.8 1

4.3-

1-1/8

2

5.3

PITCH

DIA.

(IN.)

BORE

(IN.)

DESIG-

NATION

BELT

(NOTCHED)

PITCH

LENGTH

(IN.)

Access

Stan-

870/1025

20 TON

1

All motors have a nominal speed of 1800 RPM, a 1.15 service factor and a solid base. They can operate to the limit of their service factor because they are located in the moving air, upstream

of any heating device.

2

Do NOT close this pulley below 1 turn open.

High

Speed

950/1120 BK110 10.75 10.4 1-3/16 BX80 81.8 1

Access

7.5 213T 89 1VP68 6.75

dard

5.5-

6.5

2

BK120 11.75 11.4 1-3/16 BX83 84.8 1

1-3/8

QTY.

Unitary Products Group 13

Page 14

511.06-N3Y

TABLE 11

- ELECTRICAL DATA (BASIC UNITS)

COMPRESSORS OUTDOOR FAN

MODEL

POWER

SUPPLY

#1 #2

RLA LRA RLA LRA

MOTORS

(#1 & #2)

HP

EACH

208/230-3-60 28.2 260 28.2 260 1 4.1/4.2 5 14.4/15.4 86.1/87.3 110

B1CH180

460-3-60 14.1 128 14.1 128 1 2.1 5 7.2 43.1 50

575-3-60 11.5 104 11.5 104 1 2.0 5 5.9 35.9 45

208/230-3-60 33.3 300 33.3 300 1 4.1/4.2 7.5 19.4/21.0 102.6/104.4 125

B1CH240

460-3-60 19.2 146 19.2 146 1 2.1 7.5 9.7 57.2 70

575-3-60 12.8 124 12.8 124 1 2.0 7.5 7.8 40.6 50

Although these sizes are based on copper conductors, aluminum wire can be used.

*

Refer to the National Electric Code ( in U.S.A.) or the current Canadian Electrical Code

(in Canada) to determine the proper size.

TABLE 12

- ELECTRICAL DATA

(UNITS w/SUPPLEMENTAL ELECTRIC HEAT)

HEATER OPTION MINIMUM

MODEL

B1CH

180A25

180A46 460-3-60

180A58 575-3-60

240A25

240A46 460-3-60

240A58 575-3-60

1

Electric Heat CORRECTION FACTORS:

NOMINAL VOLTAGE VOLTAGE KW CAP. MULTIPLIER

208 208 1.00

240 230 0.92

480 460 0.92

600 575 0.92

POWER

SUPPLY

208-3-60

230-3-60

208-3-60

230-3-60

MODEL KW

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

E018

E036

E054

E072

13.5

27.0

40.6

54.1

18.0

36.0

54.0

72.0

18.0

36.0

54.0

72.0

18.0

36.0

54.0

72.0

13.5

27.0

40.6

54.1

18.0

36.0

54.0

72.0

18.0

36.0

54.0

72.0

18.0

36.0

54.0

72.0

1

FLA

EACH

SUPPLY AIR

BLOWER

MOTOR

HP FLA

VOLT AGE

LIMITATIONS**

**

Rated in accordance with ARI Standard 110, utilization rang e "A".

MINIMUM

CIRCUIT

AMPACITY

(AMPS)

POWER SUPPLY

208/230-3-60 187 253

460-3-60 414 506

575-3-60 518 630

MAXIMUM

TIME DELAY

FUSE SIZE

(AMPS)

MIN. MAX.

CIRCUIT

STAGES AMPS

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

1

2

2

2

2

Although these sizes are based on copper conductors, aluminum wire can be used.

Refer to the National Electric code ( in U.S.A.) or the current Canadian Electrical Code

(in Canada) to determin e th e pr op er size.

37.5

75.1

112.6

150.1

43.3

86.6

129.9

173.2

21.7

43.3

65.0

86.6

17.3

34.6

52.0

69.3

37.5

75.1

112.6

150.1

43.3

86.6

129.9

173.2

21.7

43.3

65.0

86.6

17.3

34.6

52.0

69.3

AMPACITY

(AMPS)

133.0

133.0

179.9

179.9

141.4

141.4

195.5

195.5

70.2

70.2

97.3

97.3

57.5

57.5

79.2

79.2

149.5

149.5

196.4

212.7

158.5

158.5

196.4

212.7

84.2

84.2

111.3

111.3

62.3

62.3

83.9

83.9

VOLT AGE

MAXIMUM

TIME DELAY

FUSE SIZE

(AMPS)

150

150

200

200

150

150

200

200

80

80

100

100

60

60

80

80

150

150

200

225

175

175

200

225

90

90

125

125

70

70

90

90

14 Unitary Products Group

Page 15

OPERATION

511.06-N3Y

COOLING SYSTEM

The unit has an air-cooled cooling section and is

factory-charged with Refr igerant-22.

The compresso rs are hermetically sealed, internally sp rung

and base-mounted with rubber-insulated hold-down bolts.

Compressors have inherent (internal) protection. If there is an

abnormal temperature rise in a compressor, the protector will

open to shut down the compressor.

PRELIMINARY OPERATION COOLING

After installation has been completed, energize the crankcase

heaters for at least four hours before operatin g the unit. After

the initial installation, the compressors should be given three

false starts (energized just long enough to make a few

revolutions) with 5-7 minutes delay between each start, before

being put into ful l ti me service.

NOTE: Prior to each cool ing season , the crankcas e heaters

must be energized at le ast 8 hours before system is

put into operation.

COOLING SEQUENCE OF OPERATION

NO OUTDOOR AIR OPTIONS - When the room ther mostat

calls fo r "first-stage" coo ling, the lo w voltag e control circuit f rom

"R" to "G" and "Y1" is completed to energize compressor #1,

outdoor fan motor #1, outdoor fan motor #2 (if the ambient

temperature is abov e 60°F), and the supp ly air b lower motor (if

the fan switch on the room thermostat is set in the "AUTO"

position).

When the thermostat calls for "second-stage" cooling, the low

voltage co ntrol circuit fro m "R" to "Y2" is complete d to energiz e

compressor #2.

After the thermostat is satisfied and opens, all components will

stop simultaneously . The blower motor will continue to operate

if the fan switch on t he room thermostat i s set in the "ON"

position.

The rev ersi ng v a lv e i s ene rgiz ed t hru the " Y1" circu it whe n the

subbase is in the cooling mode.

setpoint, "Y1" energiz es compresso r #1, out door f an motor # 1,

and outdoor fan motor #2 (if the ambient temperature is above

60°F).

When the thermostat calls for "second-stage" cooling, the low

voltage control circuit from "R" to "Y2" is completed. If the

enthalp y of the outdoor ai r is below t he setpoi nt of the e nthalp y

controller (i.e. first stage has energized the economizer), "Y2"

will energize compressor #1. If the outdoor air is above the

setpoint, "Y2" wil l energize compressor #2.

After the thermostat is satisfied and opens, all components will

stop simultaneously . The blower motor will continue to operate

if the fan switch on t he room thermostat i s set in the "ON"

position.

ECONOMIZER WITH DUAL ENTHALPY SENSORS - The

operation with the dual enthalpy sensors is identical to the

single sensor e xcept that a second ent halpy se nsor is mounted

in the retur n air. This return air sensor allows the econ omizer

to choose between outdoor air and return air, whichever has

the lowest enthalpy value, to provide maximum operating

efficiency.

ECONOMIZER (SINGLE OR DUAL) WITH POWER

EXHAUST - Thi s system op erates as specifie d abov e with o ne

addition. The power exhaust motor is energized whenever the

economizer is chosen by the enthalpy sensor for first stage

cooling, "Y1 ". As always, the "R" to "G" connection provides

minimum position but does not provide power exhaust

operation.

MOTORIZED OUTDOOR AIR DAMPERS - This system

operation i s th e sa me a s th e un it s wi th no ou tdoo r ai r op ti on s

with one exception. When the "R" to "G" circuit is complete, the

motorized damper drives open to a position set by the

thumbwheel on the damper motor. When the "R" to "G" circuit

is opened, the damper spring returns fully closed.

HEATING SEQUENCE OF OPERATION

The following sequence of operation is based on using a

standard heat pump two-stage heating/two-stage cooling

thermostat/subbase. Economizer (if supplied) operation is not

allowed in the heatin g mode - however the minimum p ositio n

does operate.

The suction lin e fre ezesta t will cut th e comp res sors ou t when

the suction line temperature drops below 26°F. This is and

automatic reset device.

ECONOMIZER WITH SINGLE ENTHALPY SENSOR - When

the room thermostat calls for "first-stage" cooling, the low

voltage control circuit from "R" to "G" and "Y1" is completed.

The "R" to "G" circuit energizes the blower motor (if the fan

switch on the ro om ther mostat is set in the " AUTO" position)

and drives the economizer dampers from fully closed to their

minimum positi on. If the enthalp y of the ou tdoor air is be low the

setpoint of th e enthalpy cont roller (previous ly determined), "Y1"

energizes the economizer. The dampers will modulate to

maintain a constant supply air temperature as monitored by the

discharge air sensor. If the outdoor air enthalpy is above the

Unitary Products Group 15

FIRST STAGE HEAT

When the thermostat call s for “heat ing”, the low voltag e control

circuit from “R” to “G” and “W1" (wiring sc hematic) is com pleted

to energize the compressors, outdoor fan motors and blower

motor (if subbase is set on auto) simultaneously . If the subbase

has the indoor f an set on ”on " the mo tor will run all of th e tim e.

SECOND STAGE HEAT

If the compressors alone can not satisfy the heating

requirement s, second st age heat wi ll energize a ll the elec tric

heat (if supplied) thru the “W2" circuit.

Page 16

511.06-N3Y

HEAT ANTICIPATOR SETPOINTS

It is important that the an ti ci pator setpoint be correc t. Too high

of a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the

value below the corr ect setp oint will g ive shor ter “ON” cycles

and may result in the lowering of the temperture within the

conditioned space. Refer to the Heat Anticipator Setting Table

for the requi red hea t an ti ci pa to r set ti ng .

TABLE 13

- HEAT ANTICIPATOR SETTING

HEATER

KW

18

36 0.29 0.29

54 0.29 0.58

72 0.58 0.58

18

36 0.29 0.29

54 0.29 0.29

72 0.29 0.29

18

36 0.29 0.29

54 0.29 0.29

72 0.29 0.29

VOLT AGE

208/230-3-60

460-3-60

575-3-60

SETTING, AMPS

TH1 TH2

0.29 -

0.29 -

0.29 -

CHECKING SUPPLY AIR CFM

The RPM of the supply air blower will depend on the required

CFM, the unit options/accessories and the static resistances of

both the supply and the return air duct systems. With this

information, the RPM for the supply air blower and the motor

pulley adjustme nt (turns open) can be de termined from the

Blower Performance Data Tables.

High speed drive accessories (containing a smaller blower

pulley and a shorter belt) are a vailable for application s requiring

the supply air blower to p roduce hi gher CFM ’s and/or higher

static pressures. Use Model 1LD0416 for 15 ton units and

Model 1LD0417 f or 20 ton unit s. Ref er to th e Blower Mot or and

Drive Data table .

Note the f ol lowing:

1. The supply air CFM mus t be wi thin t he l imitat ions sho wn in

Unit Application Data table.

2. Pulleys can be adjusted in half turn increments.

3. The tension on the belt shou ld be adjust ed as show n in the

Belt Adjustment Figu re .

Start the supply air blower motor. Adjust the resistances in both

the supply an d the retur n air duct system s to balan ce the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other tha n the equipment installe r.

T o check the supply air CFM after the initial balancing has been

completed:

1. Remove the two 5/16 " dot plugs fro m the blo wer motor a nd

the filter access panels shown in the Dimensions and

Clearances Figure.

2. Insert at least 8" of 1/4 inch tubing into each of these h oles

for sufficient pene tration into the air flow on both side s of

the indoor coil.

NOTE: The tubes must be inserted and held in a position

perpendicular to the air flow so that velocity pressure will not affect the static pressu re readings.

FIG.9 -

BELT ADJUSTMENT

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit and clean 2" filters, can be

determined from the curve in the figure below.

WARNING: Failure to properly adjust the total system air

quantity can result in extensive blower damage.

After readings have been obtained, remove the tubes and

reinstall the two 5/16" dot plugs that were removed in Step 1.

NOTE: DE-ENERGIZE THE COMPRESSORS BEFORE TAKING

ANY TEST MEASUREMENTS TO ASSURE A DRY INDOOR

COIL.

BELT DRIVE BLOWER

All units have belt drive single-speed blower motors. The

variable pitch pu lley on the blower motor can be adjust ed to

obtain the desired supply air CFM.

3. Using an inclined manometer, determine the pressure drop

across a d ry indoor c oil. Since the mo isture on an indoor

coil may vary greatly, measuring the pressure drop across

a wet coil under field condi tions would be inac curate. To

assure a dry coil, the compres sors who uld be d e-act iv ated

while the test i s being run.

16 Unitary Products Group

FIG. 10 -

PRESSURE DROP ACROSS A DRY INDOOR

COIL VS SUPPLY AIR CFM

Page 17

DEFROST SEQUENCE OF OPERATION

511.06-N3Y

LOCKOUT CONTROL

These heat pumps have a unique “ambient modified”

time-temperature def rost c ontrol that a utomat icall y adju sts to

changes in the outdoor temperature. The defrost control will

shorten the defrost initiation time periods above 35°F and will

extend the defrost initiation time periods below 35°F. T he

control is factory set to defrost at 110 minutes (T3), but it can

be field adju sted to defro st at 80 minutes (T2) or 50 minute s

(T1) in areas w ith high humidity.

The curve in the Deforst Initation Times Figure sho ws how defrost

initiation times are automatically compensated for changes in

outdoor temperature.

EXAMPLE: If t he timer is factory set on pin T-3 (110 minutes at

35°F outdoor) an d t he ou td oor te mp erat ur e cl im bs to 45°, the

time initiatio n cy cle will decrease to every 100 minutes.

If the outdoor temperature drops to 10°F where ice is less likely

to form, the 110 minute interval will extend to every 150

minutes.

Two r equir ements must be m et before a d efrost c ycle can be

initiated.

1. The defrost time cycle must be com pl et e .

2.

The liquid line temperature must be less than 28°F.

Defrost will terminate when the liquid line sensor reaches 55°F

or after 10 mi nut es. I f bo th or jus t on e ci r cu it def r os ts, el ec tr i c

heat is energized.

The defrost time cycle will restart 10 minutes after the start of

the defrost cycle even though the liquid sensor terminated

defrost after 3 minutes.

During troubleshooting, the defrost time can be reduced to 20

seconds by sh orting out the SW1 tes t pegs on the module . The

pegs are 1 /2" long, 3/ 16" apar t and are m ounted on a whit e

base.

Any one of four conditions will put the system into a lock-out

condition durin g th e he at ing or cooling mode:

1.

The discharge line temperature reaches 255°F (215°F

reset) or,

2. The discharge pressure reaches 398 PSIG (310 PSIG

reset) or,

3.

The suction line fr ee z e stat equals 26°F (38°F reset) or ,

4. The low-pressure cut-out equals 7 PSIG (22 PSIG reset).

A lock-out will energize the emergency heat light on the

thermostat and the red LED ligh t on the unit relay board. T urning

the thermostat switch to “Off” then back to “On”, will reset the

system.

NOTICE T O O WNER:

If a lockout occurs, ch eck for the following pr oblems before

calling a serviceman:

1. Dirty filters.

2. Snow accumulation.

3. Lea f or de bris blockage.

After eliminating the problem, attempt to restart the system as

follows:

turn the system swi tch on the thermostat to its “OFF” position

•

for 10 seconds.

turn it back to its origina l position.

•

If the unit doesn’ t st art, call a serviceman .

NOTE: Models with an anti-recycle accessory will have a

5-minute delay before starting.

FIG. 11 -

Unitary Products Group 17

DEFROST INITIATION TIMES

Page 18

511.06-N3Y

T3 - 110 MINUTE SETTING

(Factory Set Point)

SHORTING PEGS TO

OVERRIDE TIMER

FOR SERVICE

MOVABLE JUMPER

WIRE TO CHANGE

DEFROST TI MER

T2 - 80 MINUTE SETTING

T1 - 50 MINUTE SETTING

FIG. 12

- AMBIENT MODIFIED TIME/TEMPERATURE CONTROL

SECURE OW NER’S APPROVAL

: When the system is functioning properly, secure the owner’s approval. Show him the

location of all disconnect switches and the thermostat. Teach him how to start and stop the unit and how to adjust temperature

settings within the limitations of the system.

MAINTENANCE

NORMAL MAINTENANCE

CAUTION: Prior to any of the following maintena nce proc e-

dures, shut off all electric power to the unit to

prev en t pe rso na l injury.

FILTERS - Inspect once a month. Replace disposable or clean

permanent type as necessary. DO NOT replace permanent

type with disposable. The dimensional size of the replacement

filter must be the same as the replaced filter.

MOTORS

Outdoor f an mo tors are p ermanently l ubricated and requ ire no

maintenance.

Indoor Blower Motor and Drive - The indoor blower motor

features ball bea rings that do not req uire pe riodi c lubr icati on.

Periodic lubrication of the motor and bearings can extend the

life of com po ne nt s but is optional.

CAUTION: Damage can oc cur if the b earin gs are overlub ri-

cated. Use grease sparingly.

WARNI NG: Perform all ma intenance oper ations on the b lower

motor with electric power disconnected from the

unit. Do not attempt to lubricate bearings with the

unit in operation.

On an annual basis, check the motor for accumulations

of dust, etc. that may block the cooling slots in the motor

shell. Check for loose, damaged or misaligned drive

components. Check that al l mounti ng bol ts ar e tight. Replace

defective parts as required.

If desired, every three years remove both pipe plugs at each

end shell and cl ean out an y hardened grease or f oreign ma tter .

Replace one plug on each end with a clean grease fi tting. Using

a low pressure grease gun, pu mp grease (C hevron SRI-2 or

equivalent) into the bearing cavity until new grease shows at

the open port. Do not over lubricate. Run the motor for ten

minutes unti l e xcess grea se is pu rged from the ca vity. Repla ce

the plugs.

On 20 ton onl y, units ar e suppli ed with blower sha ft beari ngs

that do not require maintenance but may be relubricated if

desired. Every thr ee years, usin g a l ow pres sur e gre ase gun ,

pump grease into the bear ing grease fitti ng until grease j ust

begins to show at the seals. Do not over lubr icate. Use any

lithium base gr ease recommende d for ball bearing service.

OUTDOOR COIL - Dirt should not be allowed to accumulate

on the outdoor coil surface or other par ts in the air circuit.

Cleaning sh ould be as often a s nec es sar y to kee p coi l cle an.

Use a brush, vacuum cleaner attachment, or other suitable

means. If water is used to clean coil, be sure electric power to

the unit is shut off prior to cleaning.

NOTE: Exercise care when cleaning the coil so that the coil

fins are not damage d.

Do not permit the hot outdoor air discharge to be

obstructed by overhanging structures of shrubs.

18 Unitary Products Group

Page 19

511.06-N3Y

Unitary Products Group 19

Page 20

5005 York Drive, Norman, OK 73069

Subject to change without notice. Printed in U.S.A

Copyright by York International Corporation 2000. All Rights Reserved.

Code: SBY

511.06-N3Y

Loading...

Loading...