York 2000 user manual

®

SUNLINE 2000

SINGLE PACKAGE HEAT PUMPS

INSTALLATION INSTRUCTION

MODELS B*CH 036 AND 048 (STYLE B)

GENERAL

YORK Model BCH units are single package heat pumps

designed for outdoor installation on a rooftop or a slab.

Supplemental electric heate rs are available as field-instal led

accessories.

The units are completely assembled on rigid, permanently

attached base rails. All pipi ng, refrigeran t charge, a nd electrical

wiring is factory-installed and tested. The units require only

electric power and duct co nnecti ons at the po int of i nstall ation.

Supersedes: 511.06-N5Y (1298)

AND MODELS B*CH 060A (STYLE A)

(10 SEER - w/Belt-Drive Option)

(* = 3 or 5)

Replacement Parts:

Refer to Parts M anual for complete li sting of replacem ent

•

part s on this equipment.

All forms referenced in this instruction may be ordered from:

Standard Register

Norman, OK 73069

T oll Free: Tel. 877-318-9675/Fax. 877-379-7920

511.06-N5Y (500)

035-16197

The supplemental electric heaters have nickel-chrome

elements and utilize single point power connection.

INSPECTION

As soon as a unit is received, it should be inspected for possible

damage during transit. If damage is evident, the extent of the

damage should be note d on the carrier’ s fre ight bil l. A se parate

request for inspection by the carrier’s agent should be made in

writing. Refer to Form 50.15-NM for additional information.

REFERENCE

Additional information on the design, installation, operation and

service of this equipment is av ailab le in the f ollo wing ref erence

forms:

55.70-N1 -General Installation

•

55.70-N2 -Pre-start & Post-start Check List

•

530.18-N1.2V -Economiz er Acces so ry

•

530.18-N1.13V -Man. Outdoor Air Damper Accy 0-35%

•

530.18-N1.14V -Man. Outdoor Air Damper Accy 0-100%

•

530.18-N1.12V -Motorized Outdoor Air Damper Accy.

•

530.18-N7.1V -Electric Hea te r Acce ss ory

•

530.18-N7.2V -Fuse Block Accessory

•

Installer shou ld pay particular attent ion to the word s: NOTE, CAUTION and WARNING. Notes are intended to clarify or make

the installation easier. Cautions are given to prevent equipment damage. Warnings are given to alert installer that personal injury

and/or equipmen t da ma ge may result if inst a ll at io n pro ce du r e is not han dl ed properly.

APPROVALS

Design certified by U.L. and C.G.A. as follows:

1. For use as a heat pump only unit or a heat pump unit with

supplemental electric heat.

2. For ou td oo r inst a ll at io n on ly.

3. For in stallation on combustibl e ma te ria l.

LIMITATIONS

CAUTION

THIS PRODUCT MUST BE INSTALLED IN STRICT COMPLIANCE WITH

THE ENCLOSED INSTALLAT I ON I NST RUCTIONS AND ANY APPLI CABL E

LOCAL, STATE, AN D NA TIONAL CODES I NCLUDING, BUT NOT LIMIT E D

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

WARNING

I NCORRECT INSTALLATION MAY CREATE A CONDITION WHERE THE

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAM AGE.

511.06-N5Y

TABLE OF CONTENTS

General................................................................................ 1

Inspection............................................................................. 1

Reference............................................................................. 1

Approvals ............................................................................. 1

Nomenclature....................................................................... 2

INSTALLATION

Limitations............................................................................3

Location ...............................................................................3

Condensate Drainage Precaution.......................................3

Rigging and Handling .......................................................... 3

Clearances...........................................................................3

Ductwork .............................................................................. 3

Filters ................................................................................... 4

Condensate Drain................................................................4

Service Access .................................................................... 4

Blower Speed Selection....................................................... 4

Disconnect Switch Bracket For Optional Belt-Drive ............ 4

Compressors........................................................................ 4

Thermostat...........................................................................4

Power and Control Wiring.................................................... 4

Electric Heaters ................................................................... 5

Optional Economizer Rain Hood.............................. .. .........6

OPERA T ION

Cooling System.................................................................. 12

Preliminary Opera tion Cooling................................. .......... 12

Cooling Sequence of Operation....... .............. .............. ......12

Heating Sequence of Operation................. .. .. .. .............. ...12

Defrost Sequence of Operation......................................... 12

Lockout Control..................................................................13

Checking Supply Air CFM....... .. .............. .. .. .............. .. .. .. ...13

Secure Owner’s Approval .................................................. 14

MAINTENANCE

Normal Maintenance ....... .................................................. 14

TABLES

No. Description Page

1 Unit Application Data................ .. .. .. ............ 3

2 Air Flow Limitati on s..... .. .. .. .. .............. .......... 5

3 Physical Data.............................................. 7

4 Supply Air Perf.

5 Supply Air Perf.

6 Supply Air Perf.

3 & 4 Ton w/Belt-Drive Blower

5 Ton w/Belt-Drive Blower

w/Di rect - D ri ve B l o w e r.......... 10

.. 9

........ 10

7 Static Resistances ...................................... 10

8 Motor and Drive Data - Belt-Drive Blower .. 11

9 Electrical Data w/Direct-Drive Blower......... 11

10 Electrical Data w/Belt-Drive Blower............ 11

11 Belt-Drive Sup pl y Air Moto r Pulley Adj.

......

13

FIGURES

No. Description Page

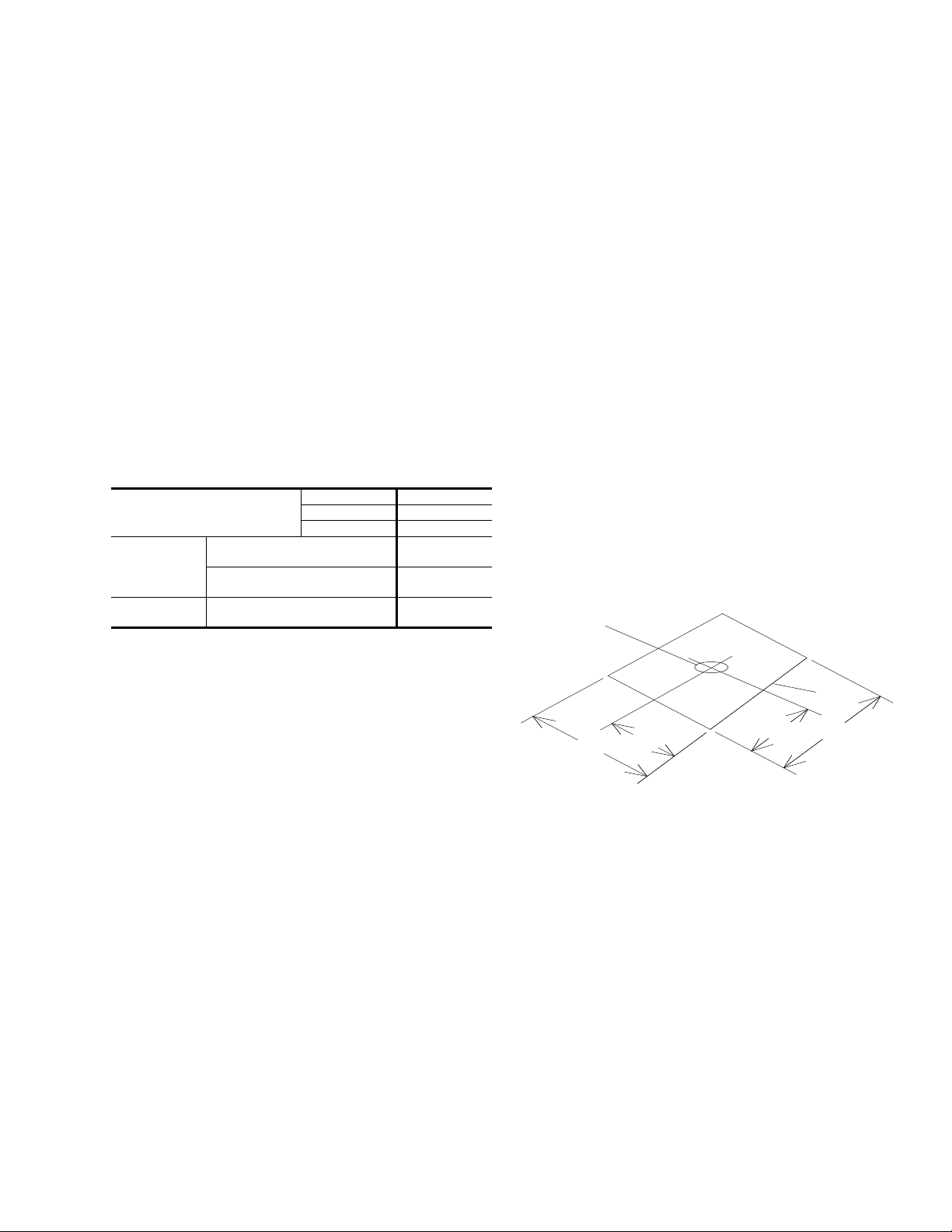

1 Center of Gravity......................................... 3

2 Recommended Drain Piping....................... 4

3 Typical Field Wiring..................................... 5

4 Economizer Rain Hood Assembly.............. 6

5 Adjusting Enthalpy Setpoint........................ 7

6 Dimensions and Clearances....................... 8

7 Defrost Initiati on Times............... ...... ...... .... 12

8 Ambient Modified Time/Temp. Control........ 12

9 Hole Loc. for Press. Drop Readings ........... 13

10 Press. Drop versus Supply Air CFM........... 13

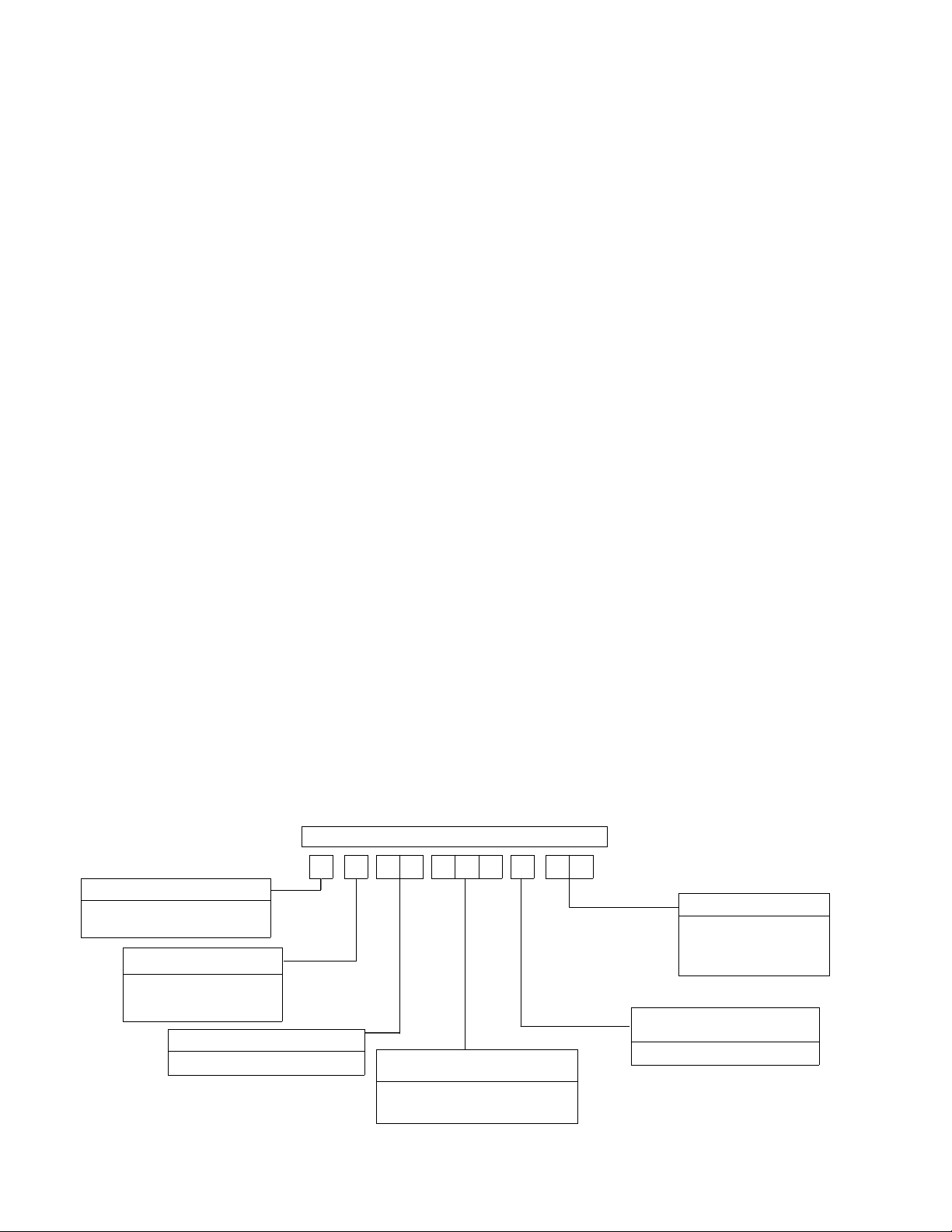

PRODUCT NOMENCLATURE

B 3 C H A

PRODUCT CATEGORY

B = Single Package Heat Pump

(Air Cooled)

PRODUCT GENERATION

3 = Third Generation

4 = Fourth Generation

5 = Fifth Generation

PRODUCT IDENTIFIER

CH = Heat Pump

2 Unitary Products Group

NOMINAL COOLING CAPACITY

30 6 2 5

036 = 3 Ton

048 = 4 Ton

060 = 5 Ton

VOLTAGE CODE

06 = 208/230-1-60

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

FACTORY INSTALLED HEAT

A = No Supplemental Heat

INSTALLATION

These units must be installed i n accordanc e with the curren t

edition of the following national and local safety codes:

In U.S.A.:

1. National Electrical Code ANSI/NFPA No. 70.

2. Local elec tric ut il ity requirements .

In Canada:

1. Canadian El ectrical Code C22.1

2. Canadian Installation Codes CAN/CGA-B149.1 and .2.

Refer to Table 1 for Unit Applic at ion Data.

If components are to be added to a unit to meet local codes, they

are to be installed at the dealer’s and / or the customer’ s expense .

511.06-N5Y

WARNING: The unit should not be installed in an area where mud

or ice could cause personal injury. Remember that

condensate wil l drip fro m the ou tdoor co il during heat

and defrost cycle s and that this co ndensate will freeze

when the temperat ure of the outdoor air is below 32°F.

RIGGING AND HANDLING

Exercise care when moving the unit. Do not remove any

packaging until the unit is near the place of installation. Rig the

unit by attaching chain or cable slings to the lifting holes

provided in t he base rails. Spreaders, wh ose length exceed s

the larges t dime nsion across the uni t, MUST be used acros s

the top of the unit.

BEFORE LIFTING A UNIT, MAKE SURE THAT ITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Size of unit for propos ed in st al la tion sh ou ld be ba sed on hea t

loss / heat gain calculation made according to the methods of

Air Conditioning Contractors of America (ACCA).

LOCATION

TABLE 1

*Rated in accordance with ARI Standard 110, utilization range "A".

Use the following guidelines to sele ct a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Outdoor coil must have an unlimited supply of air.

3. For ground level installation, a level pad or slab should be

4. Roof structures must be able to support the weight of the unit

- UNIT APPLICATION DATA

V oltage V ariation

Min. / Max.*

Wet Bulb Temperature (°F) of Air

Cooling

Heating

on Indoor Coil, Min. / Max.

Dry Bulb Temperature (°F) of Air

on Outdoor Coil, Min. / Max.

Minimum Dry Bulb T emper ature

(°F) of Air on Outdoor Coil

used. The thickn ess and size of the pa d or slab used should

meet local codes and unit weight. Do not tie the slab to the

building foundation.

and its options and / or accessories. Unit m ust be installed on

a solid level roof curb or appropriate angle iron frame.

208/230V 187 / 253

460V 414 / 506

575V 518 / 630

57 / 72

45 / 120

-10

Units may also be moved or lifted with a forklift. Slotted

openings in the base r ai ls ar e provided for th is purpose .

LENGTH OF FORKS MUST BE A MINIMUM OF 42".

Remove the nesting b rackets from th e four corn ers on to p of

the unit. All screws that are removed when taking these

brackets off must be replaced on the unit.

Refer to T able 3 for unit weights and to Figure 1 for approximate

center of gravity.

CLEARANCES

All units req uire cer tain clearances for prop er operation and

APPROXINATE

CENTER OF

GRAVITY

FRONT

3

⁄

19

7

⁄

44

“

8

FIG. 1

- CENTER OF GRAVITY

3

⁄

“

4

40

service. Refer to Figure 6 for the clearances required for

combustib le construct ion, servicing, an d proper unit op eration.

WARNING:Do not permit overhangin g s tru ct ure s or sh rub s to

obstruct outdoor air di sc ha rge out le t.

1

“

⁄

82

4

“

4

CAUTION: If a unit is to be installed on a roof curb or special frame

DUCTWORK

other than a YORK roof curb , gasketing must be applied to

all surfaces that come in contact with the unit underside.

Ductwork should be designed and sized according to the

methods in Manual Q of the Air Conditioning Contractors of

5. Maintain le v el tole rance t o 1/2" m aximum a cross th e entire

America (ACCA).

length or width of the unit.

A closed return duct system shall be used. This shall not

6. Elevate the unit sufficiently to prevent any blockage of the

air entrances by snow in areas where there will be snow

accumulation . Check the local weathe r bureau for the ex-

preclude u se of ec onomizers or outd oor fres h air inta ke. The

supply and r eturn air duct connections at t he unit should be

made with flexible j oint s to m inimiz e th e tr ansm issi on o f no ise .

pected snow accumulation in your area.

The supply and return air duct systems should be designed for

OUTDOOR COIL CONDENSA TE DRAI NAG E PRECA UTION

Condensate will drain from the outdoor coil during the heating

and defrost cycles. Normally this condensate may be allowed

to drain directly onto the ground/roof. A gravel bed is

recommended to prevent mud splashing.

Unitary Products Group 3

the CFM and static requirements of the job. They should NOT

be sized to matc h the dime nsions of the duct connect ions on

the unit.

CAUTION: When fastening duc twor k to the side duct fl ange s

on the unit, insert the screws through the duct

flanges only. DO N OT insert the sc rews through t he

511.06-N5Y

casing.

Outdoor ductw ork must be insulated and waterproofed.

Refer to Figure 6 for infor mation concerning side and bottom

supply and return air duct openings.

FILTERS

1" filters are supplied with each unit. 2" replacement filters may

be used with no modification to the filter racks. Filters must

always be installe d ahead of the evaporator c oil and must be

kept clean or rep laced wit h same siz e and type . Dirty filte rs will

reduce the capacity of the unit and will result in frosted coils or

safety shutdown. Minimum filter area an d required sizes are

shown in T able 3.

Figure 6. Several existing screws at the top of the unit and one

approximately midway down from the top will be used for

mounting the bracket. Screws should be lo os ened onl y - NOT

REMOVED. Mounting holes in the bracket have elongated

keyways allowing easy installation. Re-tighten screws after

bracke t is in pl ac e to ens ure pan el s wil l rem ai n le ak t ight.

COMPRESSORS

On some units the co mpressor is mounted on spr ings which

have been tightened down for shipment only.

After this un it is in stalle d, back out the compre ssor bo lts unti l

the sleeve clears the top g r om me t.

CAUTION: Do Not loosen compressor mounting bolts.

CONDENSATE DRAIN

Plumbing must conform to local codes. Use a sealing

compound on male pipe threads. Install a condensate drain line

from the 3/4" PVC f emale conn ection on the un it to spill into an

open drain.

NOTE: The condensate drain line MUST be trapped to provide

proper drainage. See Figure 2.

SERVICE ACCESS

FIG. 2

- RECOMMENDED DRAIN PIPING

Access to all serviceable components is provided by the

follo w in g rem o vable pane ls :

Compressor compartment

•

Heater compartment

•

Blower compartment

•

Main control box

•

Filter compartment

•

Motor Access (on units w /b el t-d rive option)

•

Refer to Figure 6 for locati on of th es e ac ce ss pan el s .

BLOWER SPEED SELECTION

Three blower motor speeds are available on the di rect-drive

units. The speed selection for the direct-drive units is

determined by the CFM and ESP requirements of the

applications. Al l units with belt-drive optio n have an a dj us ta ble

motor pulley to achieve the above conditions.

All direct-drive units are shipped with the black wire (labeled

#8) connected to the high speed tap on the blower motor. If a

lower blo wer speed is desire d, this wire shou ld be mov ed to the

medium or low speed tap on the motor.

DISCONNECT SWITCH BRACKET FOR UNITS

WITH OPTIONAL BELT-DRIVE BRACKET

A special bracket for mounting a field-supplied disconnect

switch is provided in each unit ordered with an optional

belt-drive supp ly air blower. The bracket is shipped inside the

blower compartment taped to the top of the blower housing.

Install the bracket on the left hand side of the unit as shown in

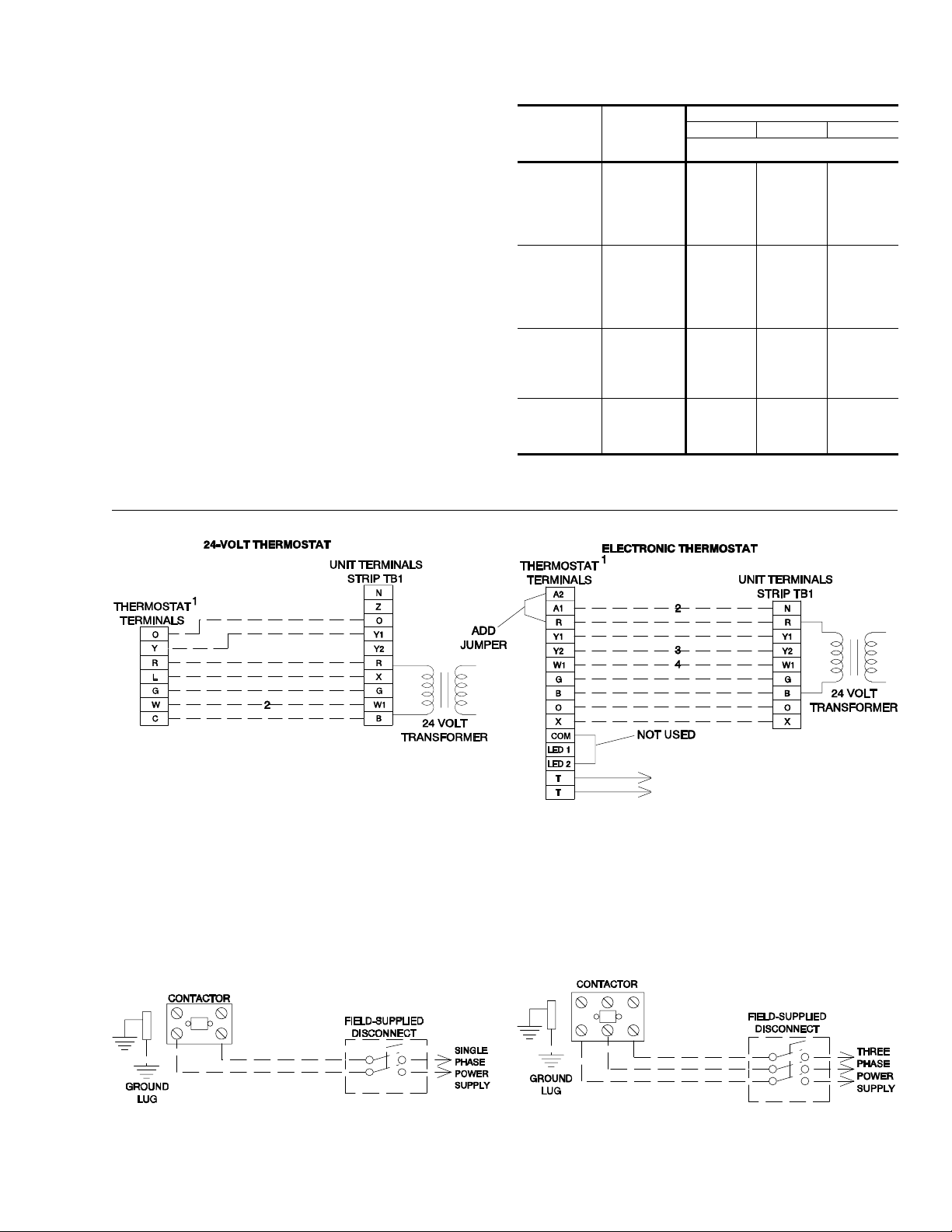

THERMOSTAT

The room thermostat should be located on an inside wall

approximately 56" above the floor where it will not be subject

to drafts, sun exposure, or heat from electrical fixtures or

appliances. Follow manufacturer’s instructions enclosed with

thermostat for general installation procedure. Color coded

insulated wires (#18 AWG) should be used to connect

thermostat to unit. See Figure 3 for w iring det ai ls.

NOTE: On units with econ omizer, remove jumper "J1" from

termin als 8 and 10 on plug connector J3/P 7 on the

relay board in the unit control box. Refer to the unit

wiring labels located on the inside of the control box

access panel.

An "Emergency Heat" position is provided with the thermostat.

In the "Emergency Heat" position, the thermostat will allow

electric resistance heat only. The compressor will be locked

out. A pilot light on the thermostat will indicate that the switch

is on "EM HT".

POWER AND CONTR OL WIRING

Field wiring to the unit must conform to provisions of the National

Electrical Code (NEC) ANSI/NFPA No. 70 (in U.S.A.), current

Canadian Electrical Code (CEC) C22.1 (in Canada) and/or local

ordinances. The unit must be electrically grounded in accordance

with the NEC and CEC (as specified above) and/or local codes.

V oltage tolerances which m ust be maintained at the compressor

terminals during starting and running conditions are indicated on

the unit Rating Plate and T ab le 1.

The wiri ng har n ess fu rni shed w ith t his un it is an int egral part

of a UL and C.G.A. design certified unit. Field alteration to

comply with electrical codes should not be required.

A disconnect switch should be field provided for the unit. The

switch must be separate from all other circuits. Refer to Figure

6 for installation location. If any of the wire supplied with the unit

must be replaced, replacement wire must be of the type shown

on the wiring diagram.

Electrical lines must be sized properly to carry the load. USE

COPPER CONDUCTORS ONLY. Each unit must be wired with

a separate branch circuit fed directly from the meter panel and

properly protected.

CAUTI ON: When connecting electrical power an d contro l wi r-

ing to the unit, waterproof type connectors MUST

BE USED so that water or moisture cannot be

drawn into the unit during normal operation. The

above waterproofing conditions will also apply

when install ing a field-sup plied disconnect switch.

Refer to Figure 3 for typical field wiring and to the appropriate

unit wiring diagram for control circuit and power wiring

information. Refer to Tables 9 and 10 for electrical data.

4 Unitary Products Group

ELECTRIC HEATERS

Supplemental electric heaters may be ordered as a

field-installed accessory. Refer to Form 530.18-N7.1V for

installation instruction . The se UL and C .G. A. appro ve d heaters

are located within the central compartment of the unit (see

Figure 6 for ac cess panel) wi th the heati ng elements e xtendi ng

into the supply air chamber.

Fuses are supp li ed , whe re r eq ui red , by the factory. Some KW

sizes require fuses and others do not. Refer to the electric

heater accessory installation instruction for the heater electrical

data.

The minimum air flow limitations across these heaters are listed

in Table 2.

TABLE 2

NOMINAL

- AIR FLOW LIMITATIONS

HEATER

SIZE

VOLT AGE

UNIT MODEL SIZE, NOMINAL TONS

1

KW

1,100

1,100

1,200

1,200

1,300

10

15

20

5

7

208 /

230-1-60

30

1,100

1,100

1,200

1,200

1,300

10

15

20

5

7

208 /

230-3-60

30

10

15

20

7

460-3-60

1,100

1,200

1,200

1,300

30

10

15

20

575-3-60

1,200

1,200

1,300

30

1208/230 and 46 0 v olt heaters are UL appro v ed .

208/230 and 575 volt h eaters are CGA approved.

2

CGA minimum is 1,40 0 C FM .

511.06-N5Y

345

MINIMUM SUPPLY AIR CFM

1,300

1,300

1,300

1,300

2

–

1,300

–

1,300

1,300

1,300

1,300

2

1,300

–

–

1,300

1,300

1,300

1,300

–

–

1,300

1,300

1,400

–

–

1,600

1,600

1,600

1,600

2

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,600

1,800

1

24-volt thermostat with subbase;

-2TH11704024 for manual changeover.

-2TH11704124 for automatic changeover.

2

Only required on units with supplemental electric heat.

CONTROL WIRING

1

Electronic progammable thermostat 2ET04700324 with subbase for either

manual or automatic changeover.

2

Only required on units with economizer. Remove jumper L2 from terminals

4 and 9 on jumper plug P7. The outdoor air intake dampers will return to their

fully closed position when the thermostat switches to the “unoccupied” mode.

3

Second stage cooling may be used on units with economizer. Remove jumper

J1 from terminals 8 and 10 on jumper plug connector P7.

4

Only required on units with supplemental electric heat.

POWER WIRING

TO REMOTE SENSOR

2TH04702224 IF USED

REFER TO ELECTRICAL DATA

T ABLES TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION.

FIG. 3

- TYPICAL FIELD WIRING

REFER TO ELECTRICAL DATA

T ABLES TO SIZE THE DISCONNECT

SWITCH, THE WIRING AND THE

OVERCURRENT PROTECTION.

Unitary Products Group 5

Loading...

Loading...