Page 1

INSTALLATION INSTRUCTION

CHAMPION® SERIES

SINGLE PACKAGE AIR CONDITIONERS

ELECTRIC/ELECTRIC, AIR-COOLED

Supersedes: 035-16703-000-A-0701

MODELS D1EB018 THRU 060

1-1/2 THRU 5 TON

(10 SEER)

035-16703-001-A-0202

GENERAL

Model D1EB units are factory assembled cooling only air conditioners designed for outdoor installation on a rooftop or a slab.

Field-installedelectricheateraccessories are available to provide

electric heat combined with electric cooling. All units andheaters

are certified by AGA and CGA.

Theunits are completelyassembledon rigid, buteasily removablebaserails. All piping, refrigerantcharge,andelectricalwiringisfactoryinstalledandtested.Theunitsrequireonlyelectric

power and duct connections at the point of installation.

The electric heaters have nickel-chrome resistance wire ele

ments and utilize single point power connection.

INSPECTION

Assoonasaunitisreceived,itshouldbeinspectedforpossible

damage during transit. If damage is evident, the extent of the

damageshould be notedon the carrier'sfreight bill. Aseparate

request for inspection by thecarrier's agentshould bemade in

writing. Refer to Form 50.15-NM for additional information.

Installer should pay particular attention to the words: NOTE, CAUTION and WARNING. Notes are intended to clarify or make

theinstallationeasier.Cautions

and/or equipment damage may result if installation procedure is not handled properly.

aregiventopreventequipmentdamage.Warningsaregiventoalertinstallerthatpersonalinjury

REFERENCE

Additional information on the design, installation, operation

andservice of this equipmentisavailable in the followingreference forms:

• 55.70-N1 -General Installation

• 55.70-N2 -Pre-start & Post-start Check List

• 511.26-N1.1V -Electric Heater Accessory

REPLACEMENT PARTS

•

RefertoReplacementPartsManual for complete listingof

-

replacement parts on this equipment.

All forms referenced in this instruction may be ordered from:

Standard Register

Norman, OK 73069

Toll Free: Tel. 877-318-9675/Fax. 877-379-7920

CAUTION

THIS PRODUCT MUST BE INSTALLED IN STRIC T COMPLIANCE WITH

THE ENCL OSED I NSTAL L ATION INSTRUCTIONS AND ANY APPL I CABL E

LOCAL, STATE , AND NATIONAL CODES I NCLUDING, BUT NOT LIMITE D

TO, BUILDING, ELECTRICAL, AND MECHANICAL CODES.

WARNING

INCORRECT I NSTALLATION MAY CREATE A CONDITION WHERE THE

OPERATION OF THE PRODUCT COULD CAUSE PERSONAL INJURY

OR PROPERTY DAM AGE.

Page 2

035-16703-001-A-0202

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT GENERATION

1 = NEW or Current Design

PRODUCT IDENTIFIER

EB = 10 SEER Cooling Models

LIMITATIONS

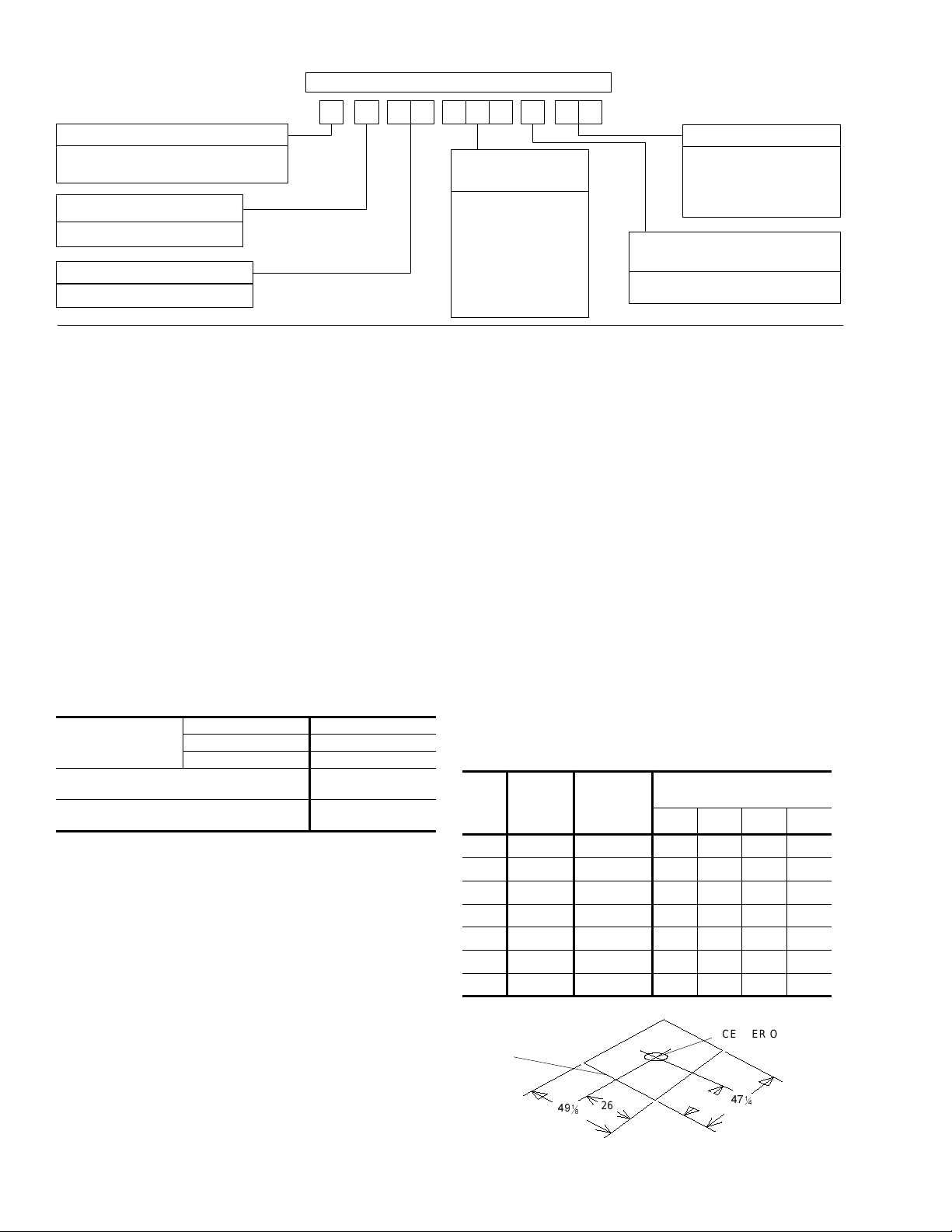

PRODUCT NOMENCLATURE

D

1 E B A

NOMINAL COOLING

CAPACITY(MBH)

018 = 18,000 BTUH

024 = 24,000 BTUH

030 = 30,000 BTUH

036 = 36,000 BTUH

042 = 42,000 BTUH

048 = 48,000 BTUH

060 = 60,000 BTUH

INSTALLATION

20 4 0 6

VOLTAGE CODE

06 = 208/230-1-60

25 = 208/230-3-60

46 = 460-3-60

58 = 575-3-60

FACTORY

INSTALLED ELECTRIC HEAT

A = No Electric Heat Installed

These unitsmust be installed in accordance with the following

national and local safety codes.

1. National Electrical Code ANSI/NFPS No. 70 or Canadian

Electrical Code Part 1, C22.1 (latest editions).

2. Local plumbing and waste water codes and other applica

ble local codes.

Referto Table1 for unitapplicationdata and to Table 5 for electric heat application data.

If components are to be added to a unit to meet local codes, they

aretobeinstalled at the dealer'sand/orthecustomer'sexpense.

Size of unit for proposed installation should be based on heat

loss/heat gain calculations made in accordance with industry

recognized procedures identified by the Air Conditioning Contractors of America.

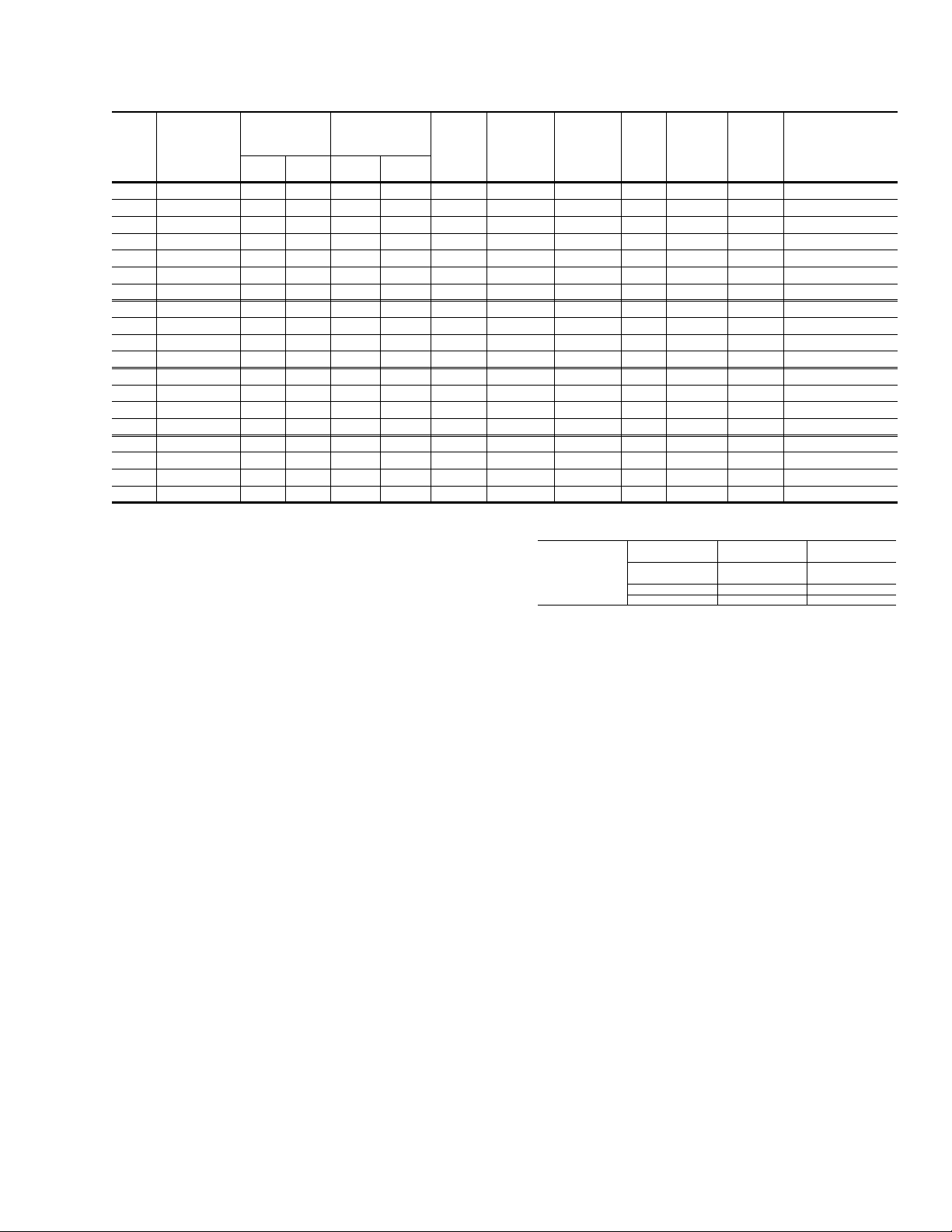

TABLE 1 - UNIT APPLICATION DATA

2

/ Max.

208/230V

Voltage Variation

Min. / Max

Wet Bulb Temperature (°F) of Air on

Evaporator Coil, Min. / Max.

Dry Bulb Temperature (°F) of Air on

Condenser Coil, Min.

1

Rated in accordance with ARI Standard 110, utilization range “A”.

2

A low ambient accessory is available for operation down to 0°F

3

“T1" transformer primary tap must be moved from the 230 volt connection to the 208 volt

connection for low voltage applications of 208 volt and below.

.1

3

460V 414 / 504

575V 518 / 630

187 / 253

57 / 72

45 / 120

3

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Condenser must have an unlimited supply of air. Where a

choiceoflocationispossible,positionunitoneithernorthor

east side of building.

3. For ground level installation, a level pad or slab should be

used.Thethicknessandsizeofthepadorslabusedshould

meet local codes and unit weight. Donot tie the slab to the

building foundation.

4. For roof top installation, be sure the structure will support

the weight of the unit plus any field installed components.

Unitmustbeinstalledonalevelroofcurborappropriatean

gle iron frame providing adequate support under the

compressor/condenser section.

5. Maintain level tolerance of unit to 1/8" maximum.

RIGGING OR HANDLING

-

Care must be exercisedwhen moving the unit. Do not remove

anypackaginguntil the unitisnearthe place ofinstallation.Rig

unit with slings placed under the unit. Spreader bars of sufficient length should be used across the top of the unit.

BEFORE LIFTING A UNIT, MAKE SURE THAT ITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a fork-lift. Slotted openings in the skid are provided for this purpose. Forksmust pass

completely through the base.

RefertoTable2forunitweightsandtoFigure1for approximate

center of gravity.

TABLE 2 - UNITS WEIGHTS

ING

(lbs.)

26

-

CORNER WEIGHTS

(location, lbs.)

“A” “B” “C” “D”

“D”

“B”

CENTER OF GRAVITY

“C”

47

1

4

49

OPERAT

WEIGHT

“A”

1

8

SHIPPING

UNIT

WEIGHT

SIZE

018 318 313 86 76 73 83

024 324 319 88 77 75 85

030 333 328 85 81 82 86

036 338 333 91 80 78 88

042 347 342 94 83 80 91

048 368 363 92 88 92 97

060 376 371 105 100 84 87

FRONT

UNIT

FIG. 1 - CENTER OF GRAVITY

-

(lbs.)

OF

2 Unitary Products Group

Page 3

CLEARANCES

035-16703-001-A-0202

FILTERS

All units require certain clearances for proper operation and

service. Refer to Figure 3 for the clearances required for com

bustion, construction, servicing and proper unit operation.

WARNING:Do not permit overhanging structures or shrubs to

obstruct the condenser air discharge outlet.

DUCT WORK

Theseunitsare adaptable todownflowuse as well asrearsup

ply and return air duct openings. To convert to downflow, use

the following steps:

1. Remove the duct covers found in the bottom return and

supply air duct openings. There are four (4) screws secur

ing each duct cover (save these screws to use later).

2. Installtheductcovers, removed in step one, to the rear sup

ply and return air duct openings. Secure with the four (4)

screws used in step one.

3. Seal the duct covers with silicone caulking.

Downflow units must have an L-shaped supply duct without

any outlets or registers located directly below the supply outlet

of the unit.

Duct work should be designed and sized according to the

methods of the Air Conditioning Contractors of America

(ACCA), as set forth in their Manual D.

A closed return duct system shall be used. This shall not preclude use of economizers or ventilation air intake. Flexible

joints may be used in the supply and return duct work to minimize the transmission of noise.

CAUTION: When fastening duct work to the side duct flanges on

theunit,insertthescrews through the duct flanges only .

DONOTinsertthe screws through the casing.Outdoor

duct work must be insulated and waterproofed.

NOTE: Be sure to note supply and return openings.

Refer to Figure 3 for information concerning rear and bottom

supply and return air duct openings.

Singlephaseunitsareshipped without a filter andis theresponsi

bilityofthe installer to secureafilterin the returnairductwork or

install a Filter/Frame Kit (1FF0114).

A filter rack and a filters are standard on three phase units.

Filters must always be used andmust be kept clean. When fil

ters become dirt laden, insufficient air will be delivered by the

blower,decreasing your units efficiency andincreasingoperat

ing costs and wear-and-tear on the unit and controls.

Filters should be checked monthly especially since this unit

may be used for both heating and cooling.

-

CONDENSATE DRAIN

Acondensatetrap is requiredto beinstalledin thecondensate

drain. The plumbing must conform to local codes. Use a seal

ing compound on male pipe threads. Install the condensate

drain line (

3

“ NPTF) to spill into an open drain.

4

SERVICE ACCESS

Accesstoallserviceablecomponentsis provided by the follow

ing removable panels:

• Blower service access

• Electrical/filter access

• Compressor service access

Refer to Figure 3 for location of these access panelsand minimum clearance.

THERMOSTAT

The room thermostat should be located on an inside wall approximately 56" above the floor where it will not be subject to

drafts, sun exposure or heat from electrical fixtures or appli

ances. Follow manufacturer's instructions enclosed with the

thermostatforgeneral installation procedure.Fouror five color

coded insulated wires (minimum#18 AWG)should be used to

connect thermostat to unit. See Figure 2.

-

-

-

-

-

-

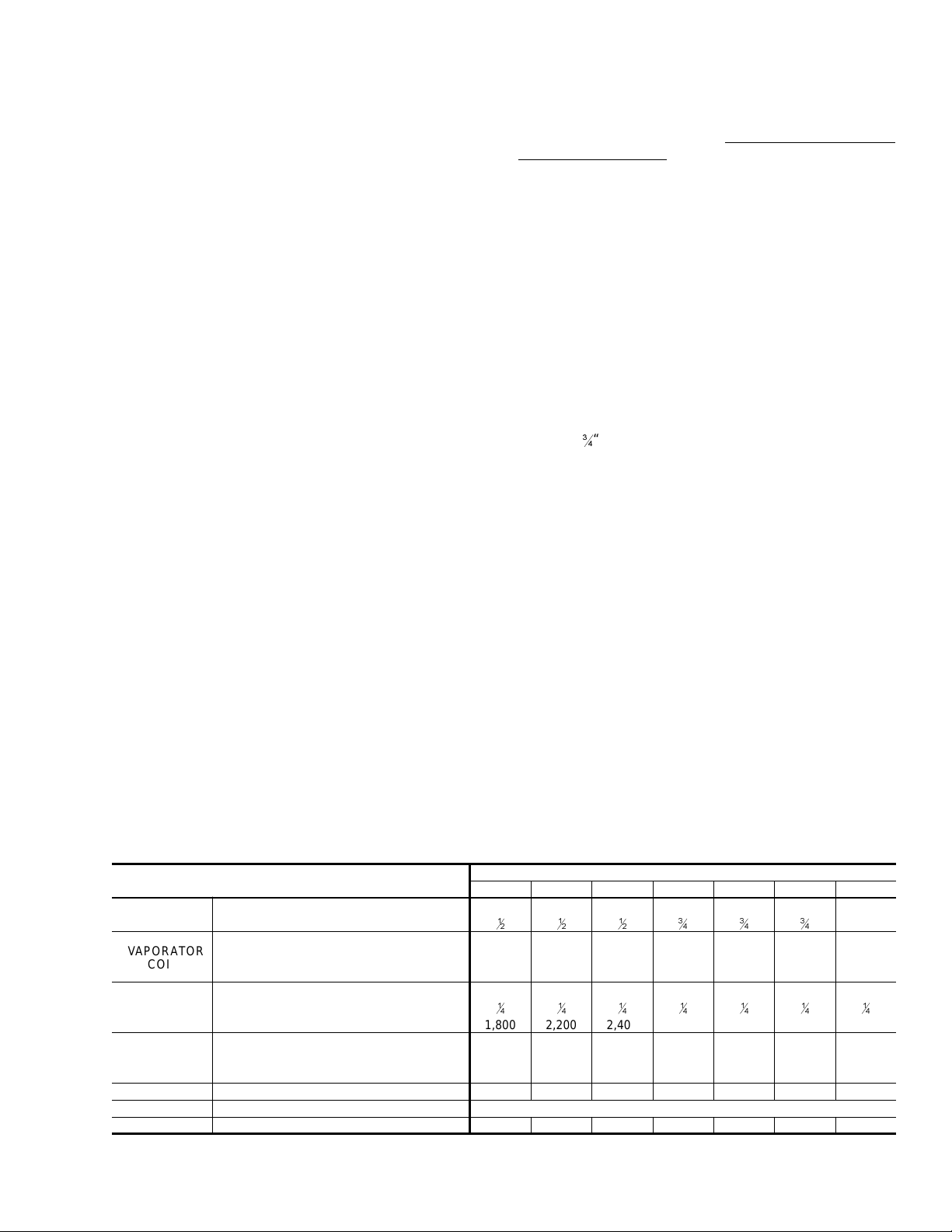

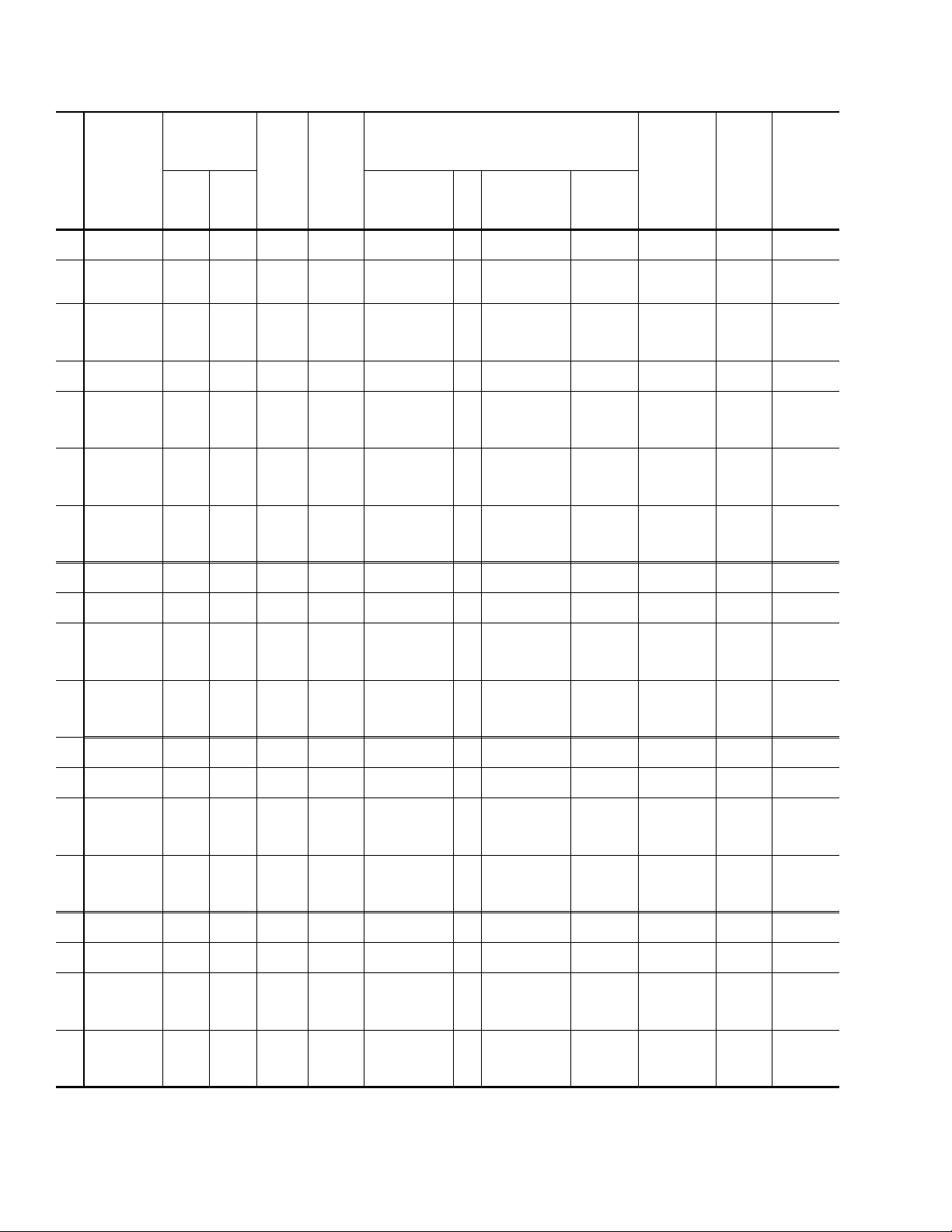

TABLE 3 - PHYSICAL DATA

DEB

3

1

4

4

3

4

1

4

3

4

1

4

1

1

4

EVAPORATOR

BLOWER

EVAPORATOR

COIL

CONDENSER

FAN

CONDENSER

COIL

MODELS

CENTRIFUGAL BLOWER (Dia. x Wd. in.) 9 X 6 10 X 8 10 X 8 10 x 8 11 X 10 11 x 10 11 x 10

FAN MOTOR HP(Three Speed)

ROWS DEEP 2222223

FINS PER INCH 13 15 15 15 15 13 16

FACE AREA(Sq. Ft.) 2.19 2.81 4.38 4.38 4.38 5.62 5.26

PROPELLER DIA. (in.) 22 22 22 22 22 22 22

FAN MOTOR HP

NOM. CFM TOTAL 1,800 2,200 2,400 2,400 2,400 2,800 2,800

ROWS DEEP 1111111

FINS PER INCH 18 16 20 18 16 13 20

FACE AREA(Sq. Ft.) 8.3 8.3 8.3 8.3 11.7 16.4 16.4

018 024 030 036 042 048 060

1

2

1

4

1

2

1

4

1

2

1

4

CHARGE REFRIGERANT 22 (lbs./oz.) 3 / 4 3 / 5 3 / 13 3 / 10 4 / 7 5 / 15 5 / 15

FILTER FACE AREA (Sq. Ft. / Qty. / Size) 2.14 / 2 / 14" x 22"

COMPRESSOR HERMETIC Type, (Qty. = 1) Recip Recip Recip Recip Recip Scroll Scroll

Unitary Products Group 3

Page 4

035-16703-001-A-0202

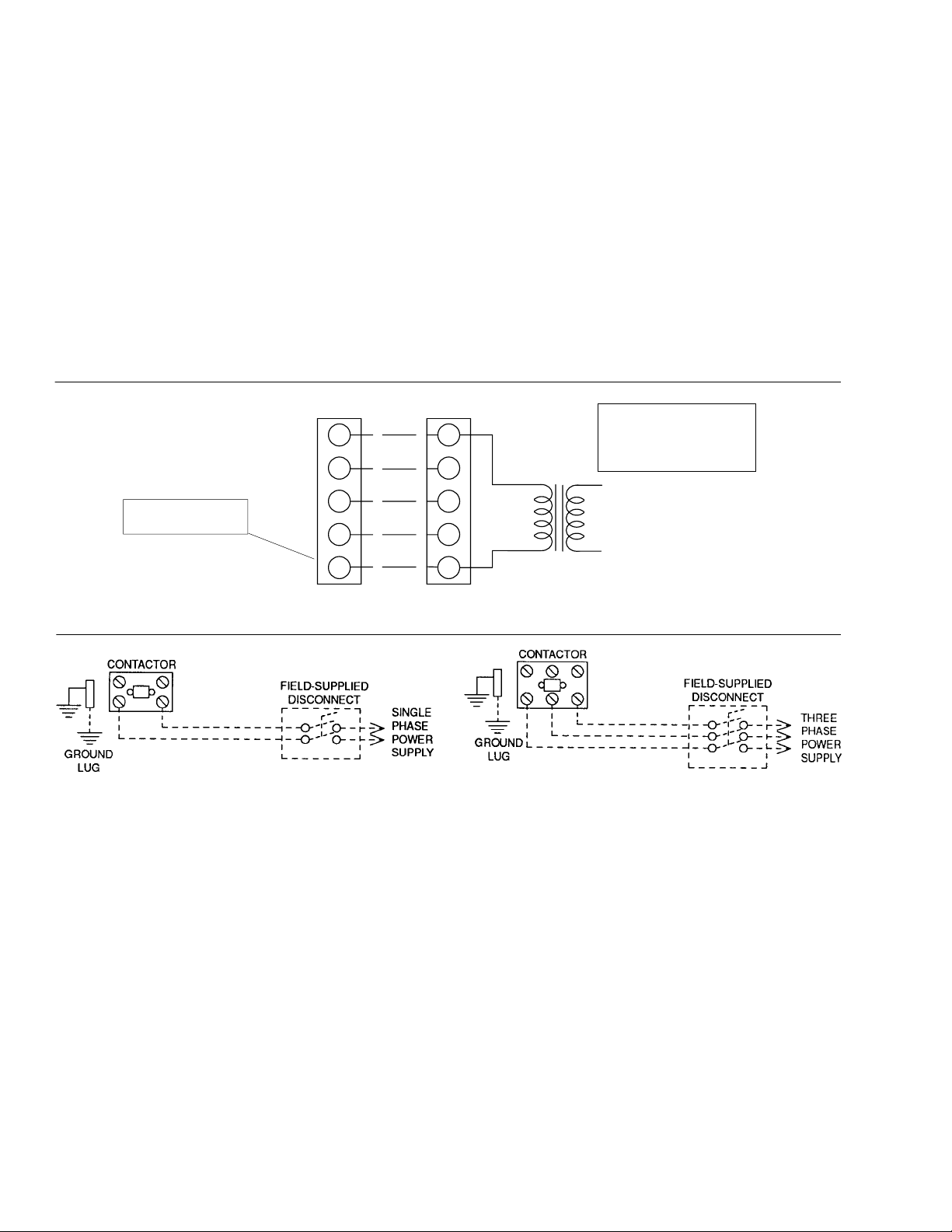

POWER AND CONTROL WIRING

Fieldwiringtotheunitmustconform to provisions of the current

N.E.C. ANSI/NFPANo. 70 or C.E.C. and/or local ordinances.

Theunit must be electricallygroundedin accordance with local

codesor,intheirabsence,withtheN.E.C./C.E.C.Voltagetoler

ances which must be maintained at the compressor terminals

during starting and running conditions areindicated on theunit

Rating Plate and Table 3.

The wiring entering the cabinet must be provided with me

chanical strain relief.

A fused or HACR breaker disconnect switch should be field pro

vided for theunit. If any of thewire suppliedwith the unit must be

replaced,replacement wire mustbe of thetypeshown on thewir

ing diagram.

CONTROL WIRING

** = Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

THERMOSTAT

R

G

UNIT TERMINAL STRIP

**

Electrical line must be sized properly to carry the load. Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

Referto Figure 2for typical fieldwiringand to theappropriate unit

wiring diagram for control circuit and power wiring information.

COMPRESSORS

Unitsare shipped with compressor mountings factory-adjusted

for shipping. CAUTION: Loosen compressor mounting bolts

half turn before operating unit.

-

-

NOTE:

R

G

HEATANTICIPATOR

SHOULD BE SET AT 0.25

AMPS FOR ALL MODELS.

PROGRAMMABLE

THERMOSTAT ONLY

* = Only required on units with

supplemental electric heat.

W

C

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

causeimproperanddangerous operation. Verifyproperoperationafterservicing.

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON

NECT SWITCH, WIRING &

OVERCURRENT PROTECTION.

-

FIG. 2 - TYPICALFIELD WIRING DIAGRAM

YY

*

W

C

POWER WIRING

24 VOLTTRANSFORMER

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON

NECT SWITCH, WIRING &

OVERCURRENT PROTECTION.

-

4 Unitary Products Group

Page 5

TABLE 4 - ELECTRICAL DATA(BASIC UNIT)

035-16703-001-A-0202

MAX.

FUSE

SIZE,

AMPS

2

MAX.

HACR

BREAKER

SIZE,

AMPS

UNIT

POWER

FACTOR

TRANSFORMER

MODEL

DEB

POWER SUP

PLY

VOLTAGE

LIMITATIONS

-

1

COMPRESSOR

MIN. MAX. RLA LRA

COND.

FAN

MOTOR,

FLA

SUPPLY

AIR

BLOWER

MOTOR,

FLA

MINIMUM

CIRCUIT

AMPACITY

018 208/230-1-60 187 253 9.0 48.0 1.1 2.6 14.9 20 20 .96 40

024 208/230-1-60 187 253 11.5 60.0 1.1 2.6 18.1 25 25 .96 40

030 208/230-1-60 187 253 14.7 73.0 1.1 2.6 22.1 30 30 .96 40

036 208/230-1-60 187 253 17.3 94.0 1.1 3.5 26.2 35 35 .96 40

042 208/230-1-60 187 253 20.5 120.0 1.1 3.5 30.2 40 40 .96 40

048 208/230-1-60 187 253 24.4 140.0 1.3 4.0 35.8 45 45 .96 40

060 208/230-1-60 187 253 28.9 165.0 1.3 4.0 44.4 60 60 .96 40

036 208/230-3-60 187 253 10.9 78.0 1.1 3.5 18.2 25 25 .96 75

042 208/230-3-60 187 253 14.1 110.0 1.1 3.5 22.2 30 30 .96 75

048 208/230-3-60 187 253 14.1 105.0 0.7 4.0 22.3 30 30 .96 75

060 208/230-3-60 187 253 16.0 125.0 1.3 7.0 28.3 40 40 .96 75

036 460-3-60 414 504 5.8 40.0 0.6 1.8 9.6 15 15 .96 75

042 460-3-60 414 504 7.1 54.0 0.6 1.8 11.2 15 15 .96 75

048 460-3-60 414 504 7.1 55.0 0.6 2.0 11.5 15 15 .96 75

060 460-3-60 414 504 8.0 67.0 0.7 3.5 14.2 20 20 .96 75

036 575-3-60 518 630 4.5 32.0 0.4 1.5 7.6 15 15 .96 75

042 575-3-60 518 630 5.8 44.0 0.4 1.5 9.1 15 15 .96 75

048 575-3-60 518 630 5.6 44.0 0.6 1.6 9.3 15 15 .96 75

060 575-3-60 518 630 6.4 50.0 0.6 2.8 11.4 15 15 .96 75

1

= Rated in accordance with ARI Standard 110, utilization range “A”.2= Dual element, time delay type.

*= KW listed is for 240 volts, use this table for 208 or 230 volts.

ELECTRIC HEAT

CORRECTION

FACTORS

NOMINAL VOLTAGE VOLTAGE

240

480 460 .92

600 575 .92

208

230

SIZE (VA)

KW CAP. MULTI

PLIER

.75

.92

-

Unitary Products Group 5

Page 6

035-16703-001-A-0202

TABLE 5 - ELECTRICAL DATA (COOLING / ELECTRIC HEAT)

DEB

POWER

SUPPLY

COMPRESSOR

COND.

MOTOR

RLA LRA MODEL NO.

FAN

FLA

SUPPLY

AIR

BLOWER

MOTOR,

FLA

MODEL

018 208/230-1-60 9.0 48.0 1.1 2.6

024 208/230-1-60 11.2 60.0 1.1 2.6

030 208/230-1-60 12.0 73.0 1.1 2.6

036 208/230-1-60 17.3 94.0 1.1 3.5

042 208/230-1-60 20.5 120.0 1.1 3.5

048 208/230-1-60 24.4 140.0 1.3 4.0

060 208/230-1-60 28.9 165.0 1.3 7.0

036 208/230-3-60 10.9 78.0 1.1 3.5

042 208/230-3-60 14.1 110.0 1.1 3.5

048 208/230-3-60 14.1 105.0 0.7 4.0

060 208/230-3-60 16.0 125.0 1.3 7.0

036 460-3-60 5.8 40.0 0.6 1.8

042 460-3-60 7.1 54.0 0.6 1.8

048 460-3-60 7.1 55.0 0.6 2.0

060 460-3-60 8.0 67.0 0.7 3.5

036 575-3-60 4.5 32.0 0.4 1.5

042 575-3-60 5.8 44.0 0.4 1.5

048 575-3-60 5.6 44.0 0.6 1.6

060 575-3-60 6.4 50.0 0.6 2.8

1

= Dual element, time delay type. * = KW listed is for 240 volts, use table on previous page for 208 or 230 volts.

2

= Standard circuit breakers may be used in Canada and on applications ** = KW listed is for 480 volts, use table on previous page for 460 volts.

over 60 amps where the heaters are separately fused. *** = KW listed is for 600 volts, use table on previous page for 575 volts.

ELECTRIC HEATACCESSORY

STAGE

2NH04500506

2NH0450070612

2NH04500506

2NH04500706

2NH04501006

2NH04500506

2NH04500706

2NH04501006

2NH04501506

1

2

2

1

2

2

2

2NH04501006

2NH0450150622

2NH04500506

2NH04500706

2NH04501006

2NH04501506

2NH04501006

2NH04501506

2NH04502006

2NH04502506

2NH04501006

2NH04501506

2NH04502006

2NH04502506

1

2

2

2

2

2

2

2

2

2

2

2

2NH04501025

2NH0450152511

2NH04501025

2NH0450152511

2NH04501025

2NH04501525

2NH04502025

2NH04502525

2NH04501025

2NH04501525

2NH04502025

2NH04502525

1

1

2

2

1

1

2

2

2NH04501046

2NH0450154611

2NH04501046

2NH0450154611

2NH04501046

2NH04501546

2NH04502046

2NH04502546

2NH04501046

2NH04501546

2NH04502046

2NH04502546

1

1

2

2

1

1

2

2

2NH04501058

2NH0450155811

2NH04501058

2NH0450155811

2NH04501058

2NH04501558

2NH04502058

2NH04502558

2NH04501058

2NH04501558

2NH04502058

2NH04502558

1

1

2

2

1

1

2

2

KW

3.8/5.0 *

5.6/7.5 *

3.8/5.0 *

5.6/7.5 *

7.5/10.0 *

3.8/5.0 *

5.6/7.5 *

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

11.3/15.0 *

3.8/5.0 *

5.6/7.5 *

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

11.3/15.0 *

15.0/20.0 *

18.8/25.0 *

7.5/10.0 *

11.3/15.0 *

15.0/20.0 *

18.8/25.0 *

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

11.3/15.0 *

7.5/10.0 *

11.3/15.0 *

15.0/20.0 *

18.8/25.0 *

7.5/10.0 *

11.3/15.0 *

15.0/20.0 *

18.8/25.0 *

10.0 **

15.0 **

10.0 **

15.0 **

10.0 **

15.0 **

20.0 **

25.0 **

10.0 **

15.0 **

20.0 **

25.0 **

10.0 ***

15.0 ***

10.0 ***

15.0 ***

10.0 ***

15.0 ***

20.0 ***

25.0 ***

10.0 ***

15.0 ***

20.0 ***

25.0 ***

TOTAL

AMPS

18.1/20.8

27.1/31.3

18.1/20.8

27.1/31.3

36.1/41.7

18.1/20.8

27.3/31.3

36.1/41.7

54.2/62.5

36.1/41.7

54.2/62.5

18.1/20.8

27.1/31.3

36.1/41.7

54.2/62.5

36.1/41.7

54.2/62.5

72.2/83.3

90.3/104.2

36.1/41.7

54.2/62.5

72.2/83.3

90.3/104.2

20.8/24.1

31.3/36.1

20.8/24.1

31.3/36.1

20.8/24.1

31.3/36.1

41.7/48.1

52.1/60.1

20.8/24.1

31.3/36.1

41.7/48.1

52.1/60.1

12.0

18.0

12.0

18.0

12.0

18.0

24.1

30.1

12.0

18.0

24.1

30.1

9.6

14.4

9.6

14.4

9.6

14.4

19.2

24.1

9.6

14.4

19.2

24.1

MINIMUM

CIRCUIT

AMPACITY

25.8/29.3

37.1/42.3

25.8/29.3

37.1/42.3

48.4/55.3

25.8/29.3

37.1/42.3

48.4/55.3

71.0/81.4

49.5/56.5

72.1/82.5

30.2/30.4

38.2/43.4

49.5/56.5

72.1/82.5

50.1/57.1

72.1/83.1

95.3/109.2

117.8/135.2

53.9/60.8

76.5/86.9

99.0/112.9

121.6/139.0

30.4/34.4

43.5/49.5

30.4/34.4

43.5/49.5

31.1/35.1

44.1/50.1

57.1/65.1

70.2/80.2

34.8/38.8

47.8/53.9

60.9/68.9

73.9/83.9

17.3

24.8

17.3

24.8

17.5

25.1

32.6

40.1

19.4

26.9

34.4

42.0

13.9

19.9

13.9

19.9

14.0

20.0

26.1

32.1

15.5

21.5

27.6

33.6

MAX.

FUSE

SIZE,

AMPS

30/30

40/45

30/30

40/45

50/60

30/30

40/45

50/60

80/90

50/60

80/90

40/40

50/50

50/60

80/90

60/60

80/90

100/110

125/150

70/70

80/90

100/125

125/150

35/35

45/50

35/35

45/50

35/40

45/60

60/70

80/90

40/40

50/60

70/70

80/90

20

25

20

25

20

30

35

45

20

30

35

45

15

20

15

20

15

25

30

35

20

25

30

35

1

BREAKER

100/110

125/150

100/125

125/150

MAX.

HACR

SIZE

30/30

40/45

30/30

40/45

50/60

30/30

40/45

50/60

80/90

50/60

80/90

40/40

50/50

50/60

80/90

60/60

80/90

70/70

80/90

35/35

45/50

35/35

45/50

35/40

45/60

60/70

80/90

40/40

50/60

70/70

80/90

2

20

25

20

25

20

30

35

45

20

30

35

45

15

20

15

20

15

25

30

35

20

25

30

35

6 Unitary Products Group

Page 7

Checking Supply Air CFM

To check the supplyair CFMaftertheinitialbalancinghas been

completed:

1.Remove the two ¼ inch dot plugs in the duct panel.

035-16703-001-A-0202

adrycoil,the compressors should be deactivated while thetest

is being run.

4.Knowingthe pressuredrop across adry coil, theactual CFM

throughthe unit canbedetermined from thecurvein Coil Delta

P vs. Supply Air CFM figure.

2.Insert at least 8 inches of ¼ inch tubing into each of these

holes for sufficient penetration into the airflow on both sides of

the indoor coil.

3.Using an inclined manometer, determine the pressure drop

acrossthedryevaporatorcoil.Sincethemoistureonanevapo

ratorcoilmayvarygreatly,measuring the pressure drop across

awetcoilunderfieldconditions would be inaccurate. Toensure

D1NA Coil Delta P vs Airflow

0.9

0.8

0.7

0.6

0.5

0.4

ID Coil Delta P

0.3

D1NA018

WARNING!Failuretoproperlyadjustthetotalsystemairquan

tity can result in extensive system damage.

Afterreadingshave been obtained, remove thetubes andrein

stall the two ¼ inch plugs removed in Step 1.

NOTE: De-energize the compressors before taking any test

measurements to ensure a dry indoor coil.

D1NA048-60D1NA042D1NA024

D1NA036

-

-

D1NA024-30

D1NA036

D1NA042

D1NA048-60

D1NA018

Linear (D1NA024-30)

Linear (D1NA036)

Linear (D1NA042)

Linear (D1NA048-60)

Linear (D1NA018)

0.2

0.1

0

400 600 800 1000 1200 1400 1600 1800 2000 2200

Airflow (CFM)

Unitary Products Group 7

Page 8

035-16703-001-A-0202

TABLE 6 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB018

OUTDOOR

TEMPERATURE

(F)

65 17.8 19.8 21.8 23.9 25.9 27.9 29.9 31.1 32.3 33.6 34.8

70 12.2 14.9 17.5 20.2 22.8 25.4 28.1 29.3 30.6 31.9 33.1

75 6.6 9.9 13.2 16.4 19.7 23.0 26.3 27.6 28.9 30.2 31.5

85 - - - 9.0 13.6 18.1 22.6 24.0 25.4 26.8 28.3

90 - - - 8.0 12.0 16.0 19.9 21.7 23.4 25.1 26.8

95 - - - 6.9 10.4 13.8 17.3 19.3 21.3 23.3 25.3

100 - - - 5.3 8.0 10.6 13.3 16.0 18.7 21.4 24.1

105 ----5.57.49.212.7 16.1 19.5 22.9

110 ------5.29.313.4 17.6 21.7

115 -------6.010.8 15.7 20.5

TABLE 7 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB024

OUTDOOR

TEMPERATURE

(F)

65 13.5 15.0 16.5 18.0 19.6 21.1 22.6 23.9 25.3 26.6 27.9

70 10.1 11.8 13.5 15.2 16.9 18.6 20.3 21.9 23.4 25.0 26.5

75 6.7 8.6 10.5 12.4 14.3 16.2 18.1 19.8 21.6 23.4 25.2

80 - 5.4 7.5 9.6 11.6 13.7 15.8 17.8 19.8 21.8 23.8

85 - - - 6.7 9.0 11.2 13.5 15.7 17.9 20.2 22.4

90 - - - 6.3 8.3 10.3 12.3 14.5 16.7 19.0 21.2

95 - - - 6.0 7.6 9.3 11.0 13.3 15.5 17.8 20.0

100 - - - 5.3 6.6 7.8 9.1 11.1 13.1 15.0 17.0

105 ----5.56.47.28.910.6 12.3 14.0

110 ------5.36.78.29.611.0

115 --------5.76.88.0

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 600 CFM/TON

INDOOR WB TEMPERATURE (F)

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 800 CFM/TON

INDOOR WB TEMPERATURE (F)

55 57 59 61 63 65 67 69 71 73 75

TABLE 8 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB030

OUTDOOR

TEMPERATURE

(F)

65 21.6 22.5 23.4 24.3 25.3 26.2 27.1 27.5 28.0 28.4 28.8

70 18.0 19.3 20.5 21.7 23.0 24.2 25.4 26.0 26.6 27.1 27.7

75 14.5 16.0 17.6 19.1 20.7 22.2 23.8 24.5 25.2 25.9 26.6

80 11.0 12.8 14.7 16.5 18.4 20.3 22.1 23.0 23.8 24.7 25.5

85 7.4 9.6 11.8 14.0 16.1 18.3 20.5 21.5 22.4 23.4 24.4

90 - 5.6 7.9 10.3 12.6 15.0 17.3 18.8 20.3 21.9 23.4

95 - - - 6.6 9.1 11.6 14.1 16.2 18.3 20.3 22.4

100 - - - 5.4 7.2 9.1 10.9 13.5 16.1 18.7 21.3

105 ----5.36.67.810.9 14.0 17.1 20.3

110 -------8.311.915.5 19.2

115 -------5.79.814.0 18.1

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 1,000 CFM/TON

INDOOR WB TEMPERATURE (F)

TABLE 9 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB036

OUTDOOR

TEMPERATURE

(F)

65 11.5 13.4 15.4 17.4 19.4 21.4 23.4 24.6 25.9 27.1 28.4

70 9.3 11.4 13.4 15.5 17.6 19.6 21.7 23.3 24.9 26.4 28.0

75 7.1 9.3 11.4 13.6 15.8 17.9 20.1 22.0 23.9 25.7 27.6

80 - 7.2 9.4 11.7 13.9 16.2 18.4 20.6 22.8 25.1 27.3

85 - 5.1 7.5 9.8 12.1 14.5 16.8 19.3 21.8 24.4 26.9

90 - 5.5 7.4 9.2 11.0 12.8 14.6 17.6 20.6 23.6 26.5

95 - 5.9 7.3 8.6 9.9 11.2 12.5 15.9 19.3 22.8 26.2

100 - 5.5 6.6 7.8 9.0 10.2 11.4 15.0 18.5 22.1 25.6

105 - - 6.0 7.1 8.2 9.3 10.3 14.0 17.7 21.4 25.1

110 - - 5.4 6.4 7.3 8.3 9.2 13.1 16.9 20.7 24.5

115 - - - 5.7 6.5 7.3 8.1 12.1 16.1 20.0 24.0

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 1,200 CFM/TON

INDOOR WB TEMPERATURE (F)

8 Unitary Products Group

Page 9

TABLE 10 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB042

OUTDOOR

TEMPERATURE

(F)

65 20.3 21.9 23.5 25.0 26.6 28.1 29.7 30.6 31.6 32.6 33.6

70 16.7 18.5 20.3 22.1 23.9 25.7 27.5 28.6 29.7 30.8 32.0

75 13.0 15.1 17.1 19.2 21.2 23.2 25.3 26.6 27.8 29.1 30.4

80 9.4 11.7 13.9 16.2 18.5 20.8 23.1 24.5 25.9 27.3 28.7

85 5.7 8.2 10.8 13.3 15.8 18.4 20.9 22.5 24.0 25.6 27.1

90 - 6.5 9.1 11.7 14.2 16.8 19.4 21.0 22.6 24.1 25.7

95 - - 7.4 10.0 12.7 15.3 17.9 19.5 21.1 22.7 24.3

100 - - 5.8 7.9 10.0 12.0 14.1 16.3 18.4 20.6 22.8

105 - - - 5.8 7.3 8.7 10.2 13.0 15.8 18.6 21.4

110 -----5.56.49.813.2 16.5 19.9

115 -------6.510.5 14.5 18.5

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 1,400 CFM/TON

INDOOR WB TEMPERATURE (F)

TABLE 11 - SUPERHEAT CHARGING TABLE FOR MODELD1EB048

OUTDOOR

TEMPERATURE

(F)

65 13.5 15.4 17.3 19.1 21.0 22.8 24.7 26.1 27.6 29.0 30.5

70 10.7 12.7 14.7 16.8 18.8 20.9 22.9 24.7 26.5 28.2 30.0

75 7.8 10.0 12.2 14.5 16.7 18.9 21.2 23.3 25.4 27.5 29.6

80 - 7.3 9.7 12.1 14.5 17.0 19.4 21.8 24.2 26.7 29.1

85 - - 7.2 9.8 12.4 15.0 17.6 20.4 23.1 25.9 28.6

90 - - 6.1 7.7 9.4 11.0 12.7 16.6 20.5 24.4 28.3

95 - - - 5.7 6.3 7.0 7.7 12.7 17.8 22.8 27.9

100 - - - 5.3 5.9 6.5 7.1 11.1 15.1 19.1 23.0

105 ----5.56.06.69.512.4 15.3 18.2

110 ----5.05.56.07.89.711.613.4

115 ------5.46.27.07.88.6

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 1,600 CFM/TON

INDOOR WB TEMPERATURE (F)

035-16703-001-A-0202

TABLE 12 - SUPERHEAT CHARGING TABLE FOR MODEL D1EB060

OUTDOOR

TEMPERATURE

(F)

65 25.3 25.8 26.3 26.8 27.3 27.8 28.3 28.7 29.1 29.6 30.0

70 22.2 23.0 23.7 24.4 25.1 25.9 26.6 27.4 28.2 28.9 29.7

75 19.2 20.1 21.1 22.1 23.0 24.0 24.9 26.1 27.2 28.3 29.4

80 16.1 17.3 18.5 19.7 20.9 22.1 23.3 24.7 26.2 27.7 29.1

85 13.1 14.5 15.9 17.3 18.8 20.2 21.6 23.4 25.2 27.0 28.9

90 10.3 11.7 13.1 14.5 15.9 17.3 18.6 21.1 23.5 25.9 28.3

95 7.6 8.9 10.3 11.6 13.0 14.3 15.7 18.7 21.8 24.8 27.8

100 6.6 7.7 8.9 10.1 11.3 12.5 13.6 16.7 19.7 22.7 25.8

105 5.6 6.6 7.6 8.6 9.6 10.6 11.6 14.6 17.6 20.7 23.7

110 - 5.4 6.2 7.0 7.9 8.7 9.5 12.5 15.6 18.6 21.6

115 - - - 5.5 6.2 6.8 7.5 10.5 13.5 16.5 19.5

55 57 59 61 63 65 67 69 71 73 75

SUPERHEATATCOMPRESSOR SUCTION (F), AIRFLOW = 2,000 CFM/TON

INDOOR WB TEMPERATURE (F)

Unitary Products Group 9

Page 10

035-16703-001-A-0202

HIGH VOLTAGE CONN.

31

1

LOW VOLTAGE CONN.

7

“ DIA. KNOCKOUT

8

SIDE SUPPLY

AIR OPENING

SIDE RETURN

AIR OPENING

LOW VOLTAGE CONN.

7

“ DIA. KNOCKOUT

8

HIGH VOLTAGE CONN.

7

" DIA. KNOCKOUT

8

" DIA. KNOCKOUT

32

(OVERALL)

FRONT

COMPRESSOR

SERVICE ACCESS

COMPARTMENTPANEL

DIMENSION

“A”

1

33

2

1

41

2

3

2

“A”

8

(OVERALL)

UNIT SIZE

018 - 042

048 - 060

REFRIGERANT

CONNECTIONS

ELECTRICAL/FILTER

SERVICE ACCESS

COMPARTMENTPANEL

1

17

1

49

8

28

4

22

4

1

4

FRONT

1

2

2

3

3

4

1

1

1

4

2

1

1

17

HIGH VOLTAGE

CONN.

1

KNOCKOUT

4

2

31

7

“ x

“ DIA.

32

8

1

28

4

1

22

4

UNIT CONDENSATE

CONNECTION

(TRAP REQUIRED)

1

47

4

(OVERALL)

3

“ NPTI

4

All dimensions are in inches. They are

subject to change without notice. Certified

HIGH VOLTAGE CONN.

23

" DIA. KNOCKOUT

1

64

dimensions will be provided upon request.

1

43

1

2

40

2

3

26

4

CLEARANCES

(Minimum)

Front 12"

Back 0"

Left Side (Filter Access) 24"

Right Side 24"

Below Unit

Above Unit

1

2

0"

36" (For Condenser

CONDENSATE

3

DRAIN

“ NPTI

4

Air Discharge)

22

6

BOTTOM SUPPLY

AIR OPENING

1

14

2

1

2

OUTDOOR

COIL

3

2

8

3

1

4

15

15

9

28

16

1

3

2

3

1

4

1

Units may be installed on combustible floors made from wood or class A,

B or C roof covering material.

2

Units must be installed outdoors. Overhanging structures or shrubs

should not obstruct outdoor air discharge outlet.

SIDE SUPPLY

AIR OPENING

3

28

8

1

14

2

15

3

1

4

BACK

3

3

8

SIDE RETURN

AIR OPENING

1

14

2

1

3

2

4

BOTTOM RETURN

AIR OPENING

FIG. 3 - DIMENSIONS AND CLEARANCES

10 Unitary Products Group

Page 11

Cooling

035-16703-001-A-0202

SEQUENCE OF OPERATION

Heating

The following sequences of operation are based on using a

standard single-stage cooling thermostat.

WITH POWER TO UNIT AND THERMOSTAT IN COOLING

MODE.

1. If the fan switch on the thermostat is in the “ON” position,

the 24 volts at “G” will energize the “K1" relay on the fan

control board, close the ”K1" relay contacts, and energize

the indoor blower motor. If the fan switch is in the “AUTO”

position,the blower will operateonlywhen there isacall for

cooling by the thermostat.

2. Ona call forcooling, the thermostatwillsend 24 voltsto“Y”

on the fan control board. The 24 volt signal will energize

contactor“M1", andpower will be supplied to the compres

sor and outdoor fan motor.If the fan switch on the thermo

statison the ”AUTO"position, thethermostatwillalso send

a 24 volt signal to “G” on the fan control board and the in

door blower will operate as indicated in step 1.

3. When the demand for cooling has been satisfied, the “M1"

contactorwillbede-energized when the 24 volt”Y"signalis

removed. If the fan switch on the thermostat is energized

when the 24 volt “Y” signal is removed. If the fan switch on

thethermostat is inthe “ON” position,theindoor blower will

continuetorun.Ifthefanswitchisinthe“AUTO”position,the24volt“G”signalwill be removed, and after a

60 second delay, the “K1" relay will open and deenergize the indoor blower motor,

WITH POWER TO UNIT AND THERMOSTAT IN HEATING

MODE.

1. If the fan switch on the thermostat is in the “ON” position,

the24 volts at “G”will energize the “K1"relay contacts, and

energize the indoor blower motor. If the fan switch on the

thermostat is in the ”AUTO" position, the blower will oper

ateonlywhenthere is a call for heating bythethermostat.

2. On a call for heating, the thermostat will send 24 volts to

“W1"on the fancontrol board. The24volts signal willener

gize relay ”K2" on the fan control board, and the first stage

of electric heat will be energized.

3. Whenthe heatingdemand is satisfied,the electric heatwill

-

-

be de-energized when the 24 volt “W1" and ”W2" signals

are removed. If the fan switch on the thermostat is in the

“ON” position, the indoor blower will continue to run. If the

-

fanswitchis in the “AUTO”position, the“K1" relaywillopen

andde-energizetheindoorblowermotor after the appropri

ate time delay.

Please refer to Table 13 and 14 for more information.

-

-

-

TABLE 13 - THERMOSTAT SIGNALS (SINGLE PHASE UNITS)

STATE

SIGNAL

ON FAN INSTANT ON

“G”

OFF FAN INSTANTOFF

FAN INSTANT ON

ON

“G”

“Y”

“G”

“W1"

“G”

“W1"

”W2"

COMPRESSOR AND OUTDOOR FAN INSTANT ON

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

OFF

FAN 60 SECOND DELAY OFF

FAN INSTANT ON

ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 1 ELEC. HEAT INSTANT OFF

OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

ON

HEATER BANK 2 ELEC. HEAT 10 SECOND DELAY ON

HEATER BANK 3 ELEC. HEAT 20 SECOND DELAY ON

HEATER BANK 1 ELEC. HEAT INSTANT OFF

HEATER BANK 2 ELEC. HEAT

OFF

HEATER BANK 3 ELEC. HEAT 1 SECOND DELAY ON

FAN

6

1

SECOND DELAYOFF

2

BOARD FUNCTION

1

SECOND DELAYON

2

“W1"

”W2"

“W1"

”W2"

STATE

SIGNAL

ON

OFF

ON

OFF

ON

OFF

BOARD FUNCTION

FAN INSTANT ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 1 ELEC. HEAT INSTANT OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

HEATER BANK 1 ELEC. HEAT

HEATER BANK 2 ELEC. HEAT INSTANT ON

HEATER BANK 1 ELEC. HEAT

HEATER BANK 2 ELEC. HEAT INSTANT OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

HEATER BANK 1 ELEC. HEAT INSTANT ON

HEATER BANK 2 ELEC. HEAT 10 SECOND DELAY ON

HEATER BANK 3 ELEC. HEAT 20 SECOND DELAY ON

STAGE 1 ELEC. HEAT INSTANT OFF

HEATER BANK 2 ELEC. HEAT

HEATER BANK 3 ELEC. HEAT 1 SECOND DELAY ON

1

FAN

SECOND DELAYOFF

6

2

1

SEC. DELAYOFF

2

1

SEC. DELAYOFF

2

1

SECOND DELAYON

2

Unitary Products Group 11

Page 12

035-16703-001-A-0202

TABLE 14 - THERMOSTAT SIGNALS (THREE PHASE UNITS)

STATE

SIGNAL

ON FAN INSTANT ON

“G”

OFF FAN INSTANTOFF

FAN INSTANT ON

ON

“G”

“Y”

“G”

“W1"

“G”

“W1"

”W2"

COMPRESSOR AND OUTDOOR FAN INSTANT ON

COMPRESSOR AND OUTDOOR FAN INSTANT OFF

OFF

FAN 60 SECOND DELAY OFF

FAN INSTANT ON

ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT OFF

OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT OFF

OFF

FAN

BOARD FUNCTION

1

SECOND DELAYOFF

6

2

“W1"

”W2"

“W1"

”W2"

SIGNAL

ON

OFF

ON

OFF

ON

OFF

STATE

FAN INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT OFF

FAN 5 SECOND DELAY OFF

FAN INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT ON

HEATER BANK 1, 2 AND 3 ELEC. HEAT INSTANT OFF

1

FAN

SECOND DELAYOFF

6

2

BOARD FUNCTION

SECUREOWNER'S APPROVAL:When the systemisfunctioningproperly,securetheowner's approval. Showhimthe

location of all disconnect switches and the thermostat. Teach him how to start and stop the unit and how to adjust temperature

settings within the limitations of the system.

MAINTENANCE

NORMAL MAINTENANCE

WARNING:Prior to any of the following maintenance proce-

dures, shut off all power to the unit, to avoid personal injury.

Periodic maintenance consists of changing or cleaning filters

and general cleaning of the outdoor coil.

OUTDOORCOIL-Dirtshouldnotbe allowed to accumulateon

theoutdoorcoilsurfaceor other partsin the air circuit. Cleaning

should be as often as necessary to keep the coil clean. Use a

brush, vacuum cleaner attachment, or other suitable means. If

waterisused to clean thecoil,besurethat the power totheunit

is shut off prior to cleaning.

FILTERS-Inspect once a month.ReplaceDisposableorclean

Permanent Type as necessary. DO NOT replace Permanent

Type with Disposable.

MOTORS- Indoor and outdoor fanmotors are permanently lu

bricated and require no maintenance.

CAUTION: Exercise care when cleaning the coil so that the

coil fins are not damaged.

Donotpermitthehotcondenserairdischargetobe

-

obstructed by overhanging structures or shrubs.

12 Unitary Products Group

Page 13

POWER SUPPLY

208/230-1-60

USE COPPER

CONDUCTORS ONLY

SECONDARY POWER SUPPLY

FOR DUAL POINT ELEC HEAT

208/230-1-60

USE COPPER

CONDUCTORS ONLY

(HTR5)

(HTR4)

(HTR3)

(HTR2)

(M1)

705/PR

708/PR

716/PR

713/PR

710/PR

F6

F4

F2

(K6)

(K4)

(K5)

(K3)

(M1)

714/BK

706/BK

711/BK

703/BK

709/BK

F1

F3

F5

DUAL POINT ELECTRIC HEAT (SEE NOTE 9)

DETAIL A

FOR DUAL POINT

ELECTRIC HEAT

POWER SUPPLY

SEE DETAIL A

FOR DEFROST

CONTROL

031-09104-000A

SEE DETAIL C

FOR DUAL POINT

ELECTRIC HEAT

POWER SUPPLY

SEE DETAIL A

SEE

DETAIL

"B"

035-16703-001-A-0202

DEFROST

CONTROL

031-01268-000B

SECONDARY POWER SUPPLY

FOR DUAL POINT ELEC HEAT

208/230-1-60

USE COPPER

CONDUCTORS ONLY

POWER SUPPLY

208/230-1-60

USE COPPER

709/BK

703/BK

711/BK

706/BK

714/BK

CONDUCTORS ONLY

(M1)

(K3)

(K5)

(K4)

(K6)

(M1)

(HTR2)

(HTR3)

(HTR4)

(HTR5)

F1

F3

F5

DETAIL A

DUAL POINT ELECTRIC HEAT (SEE NOTE 9)

710/PR

705/PR

713/PR

708/PR

716/PR

OPTIONAL CCH

S / P CONFIGURATION

CCH

BLK

L1

BLK

T1

F2

F4

F6

D / P CONFIGURATION

CCH

BLK

BLK

M1 - 2

2

T2

L

L1

L2

DETAIL C

M1

DS

BLU

222/Y

BLU

M

DFST

STAT

COMPR

RELAY

R

C

DETAIL B

FIG. 4 - TYPICALWIRING DIAGRAM (208/230-1-60 POWER SUPPLY)

Unitary Products Group 13

Page 14

035-16703-001-A-0202

DETAIL A

M1

222/Y

COMPR

RELAY

M

FOR DEFROST

CONTROL

031-09104-000A

SEE DETAIL A

DEFROST

CONTROL

031-01268-000B

DS

BLU

DFST

BLU

STAT

R

C

FIG. 5 - TYPICALWIRING DIAGRAM (230-3-60 POWER SUPPLY)

14 Unitary Products Group

Page 15

035-16703-001-A-0202

BLU

221/B R

DS

RVS

BLU

220/O

ELEM ENTARY DIAG RAM

GND

USE CO PPER

LU G

CONDUCTORS

ONLY

POW ER SUPPLY W /

ELEC HEAT 460-3-60

O R 57 5 -3 -6 0

(SEE D ET A)

IO F A N

MOTOR

BRN

1

PRP

223/B R

FOR DEFROST

CONTROL

031-09104-000A

SEE D ETAIL B

203/B R

FS

803

/B K

(SEE D ET A)

(SEE D ET A)

RC3

M3

DS

222/Y

M1

804

/B K

HP

219/B K

SEE N OTE 7

RVS

120/Y

SEE N OTE 6

BLU

LP

802

/B K

203/B R

130/P R

220/O

221/B R

201/B R

BLU

805

/B L

213/R

202/Y

R

C

M

RV

C

L3

A

DFST

STAT

COM PR

RELAY

PRESS

SW ITCH

K3

L1

L2

813/B R

B

814/Y

COND FAN

DEFROST

CONTROL

031-01268-000B

T'STAT

DEF

DEF

POW ER SUPPLY W /OUT

ELEC HEAT 460-3-60

O R 57 5 -3 -6 0

709/R

711/P R

710/O

T1

BLK

703/R

706/P R

707/0

717/R

713/P R

719/0

224/R

X

R

C

218/Y

Y

215/O

O

217/G Y

W

216/W

W1

P3

M2-1

CCH

205/R

207/B R

2

3

4

S3

F24

M1-1

L1

M1-2

L2

M1-3

L3

110

/O

L1

BLK

K3-1

74

K3-2

8

5

K3-3

9

6

K4-1

74

K4-2

712/B L

5

8

K4-3

96

213/R

M2

L2

L1

L1

L2

L21

H1

L1

L1

RYG

T1

114/B K

T2

T3

704/B K

HTR

2

705/B L

708/Y

718/B K

HTR

5

720/Y

208/P R

K1

209\R

K2

K2

CONTROL LOGIC

W2

126/Y

M3-1

L1

105/B L

HTR

1

HTR

4

FAN CONTROL

BOARD

K1

W1

121/B K

123/B L

HTR

CB

206/B R

L2

T1

RC2

HTR

3

6

T

LH

FL

H4

H3

H2

OC

L1

COM PR

3

L3

BLK

00 FA N

MOTOR

BRN

1

PRP

M1

R

DFST

STAT

C

M

COM PR

RELAY

DETAIL B

109/B K

C

T1

212

/R

24V

S2

P2

1

809/O

2

808/B R

3

4

5

810/B L

6

TB1

O

R

G

H

TH2

Y

W

X

B

LS

K4

ON

FAN

AUTO

TH1/TC 1

TC1

TH1

EM H T (RED )

108

/P R

480 O R 600

214/B R

204/B R

SEE N OTE 8

811/0

ROOM THERMOSTAT

COOL

ANT

OFF

HEAT

EM H T

TH2 AN T

8D

7E

11D , 14D , 15D

21D , 24D

4 D , 5 D , 6 D

FIG. 6 - TYPICALWIRING DIAGRAM (460-3-60 & 575-3-60 POWER SUPPLY)

Unitary Products Group 15

Page 16

035-16703-001-A-0202

TYPICAL WIRING DIAGRAM LEGEND

CB

F7 F8 F9

HTR 4 ELECTRIC HEATER (OPT. ACCSSRY: 15, 20, & 25 KW ELEC HEAT)

HTR 5 ELECTRIC HEATER (OPT. ACCSSRY: 20 & 25 KW ELEC HEAT)

HTR 6 ELECTRIC HEATER (OPT. ACCSSRY: 20 & 25 KW ELEC HEAT)

K7 RELAY LIMIT TRIP, 24 VDC COIL

M2 CONTACTOR, ELECTRIC HEAT, 230V COIL

M3 CONTACTOR, ELECTRIC HEAT, 230V COIL

PTCR START ASSIST (OPTIONAL DEVICE)

S4/P4

S3/P3

TB2 TERMINAL BLOCK ECM MOTOR "SPEED" CONNECTIONS

CIRCUIT BREAKER 24V, 3 AMP

, 20, & 25

, 20, & 25

20 & 25

ALL KW ELEC HEAT)

20 & 25 KW ELEC HEAT)

SOCKET/PLUG CONNECTION ON ID FAN MOTOR,24V

SOCKET/PLUG CONNECTION ON ID FAN MOTOR, 230V

, 20, & 25

TYPICAL WIRING DIAGRAM NOTES

16 Unitary Products Group

Page 17

Unitary Products Group

5005 York Drive, Norman Oklahoma 73069

Subject to change without notice. Printed in U.S.A.

Copyright by York International Corporation 2001. All Rights Reserved.

Supersedes 035-16703-000-A-0701

035-16703-001-A-0202

Loading...

Loading...